Page 1

Chapter 4

Adjustment

4.1 Over View.................................................................................................................1

4.1.1 Adjustment Required ................................................................................................................ 2

4.1.2 Adjustment Tools....................................................................................................................... 3

4.2 Adjustment...............................................................................................................4

4.2.1 Platen Gap (PG) Adjustment .................................................................................................... 4

4.2.2 Input of Customer Data............................................................................................................. 7

4.2.3 Ink Charge.................................................................................................................................. 8

4.2.4 Write to the Head Voltage Value............................................................................................. 10

4.2.5 Head Angular Adjustment....................................................................................................... 13

4.2.6 BK.-Linear Adjustment............................................................................................................ 16

4.2.7 Head GAP Timing Adjustment................................................................................................18

4.2.8 Bi-d adjustment ....................................................................................................................... 22

Page 2

Adjustment

4.1 Overview

This section describes adjustment required when the printer is reassembled after repair. Read the

instructions headed under “CAUTION” before starting adjustment.

CAUTION

;

Always perform adjustment using the program specified for each unit.

;

Ink cartridge used for this printer is one-time-cartridge. If the same c artridge is r einstalled, bubbles

are formed in the printhead, which might cause dot missing. Therefore always install a new

cartridge after removing the used one for repair.

;

The ink consumption counter is reset when the cartridge is replaced during the ink cartridge

change sequence. Therefore be sure not to replace the ink cartridge without putting the printer in

the ink cartridge change mode.

;

Use 720 dpi exclusive paper when printing the adjustment pattern.

;

Perform the each adjustment by using exclusive adjustment program.

Rev. A

4-1

Page 3

EPSON Stylus

2

&RORU

800

4.1.1 Adjustment Required

This section gives inf orm ation on the adjustm ent required af ter disass embling and r eassem bling. Be sure

to perform the specif ied adjustment whenever you remove or replace the part for repair. Table 4- 1 lists

the required adjustments for several units and corresponding adjust items, which must be accomplished in

the order instructed in Table 4-1.

Table 4- 1. Required Adjustment

Replaced Unit/Part Adjustment Item and the Corresponding Menu

Printer Mechanism

C202 MAIN Board

Printhead

After disassembling and

reassembling the CR unit

Top frame

CR motor

Ink drain pad 1. EEPROM reset (Refer Chapter 6)

Note) * The adjusting program doesn’t run without inputting the customer data.

1. Customer data writing operation * :Input of Customer data

2. Initial ink charge :Ink charge

3. Head VH voltage input :Write to the Head voltage value

4. Head gap adjustment :Head GAP timing adjustment

5. Bi-d adjustment :Bi-d adjustment

1. Customer data writing operation * :Input of Customer data

2. Head VH voltage input :Write to the Head voltage value

3. Head gap adjustment :Head GAP timing adjustment

4. Bi-d adjustment :Bi-d adjustment

5. Ink drain pad replacement (Refer to Chapter 6 Maintenance.)

Note) Whenever C202MAIN board is replaced with a new one, all stored

data of EEPROM is lost. This means that the ink consumption

counter is lost. Therefore, whenever C202MAIN Board is replaced,

the printer must be equipped with a new ink cartridge. Above listed

adjustment items must be executed after replacing the ink cartridge

with a new one.

1. Customer data writing operation * :Input of Customer data

2. Initial ink charge :Ink charge

3. Head VH voltage adjustment :Write to the Head voltage value

4. Head angular adjustment :Head angular adjustment

5. Black/color head vertical adjustment:BK.-M Linear adjustment

6. Head gap adjustment :Head GAP timing adjustment

7. Bi-d adjustment :Bi-d adjustment

1. Platen gap adjustment

2. Customer data writing operation * :Input of Customer data

3. Head angular adjustment :Head angular adjustment

4. Black/color head vertical adjustment:BK.-M Linear adjustment

5. Head gap adjustment :Head GAP timing adjustment

6. Bi-d adjustment :Bi-d adjustment

1. Platen gap adjustment

2. Customer data writing operation * :Input of Customer data

3. Bi-d adjustment :Bi-d adjustment

1. Customer data writing operation * :Input of Customer data

2. Bi-d adjustment :Bi-d adjustment

4-

Rev. A

Page 4

Adjustment

3

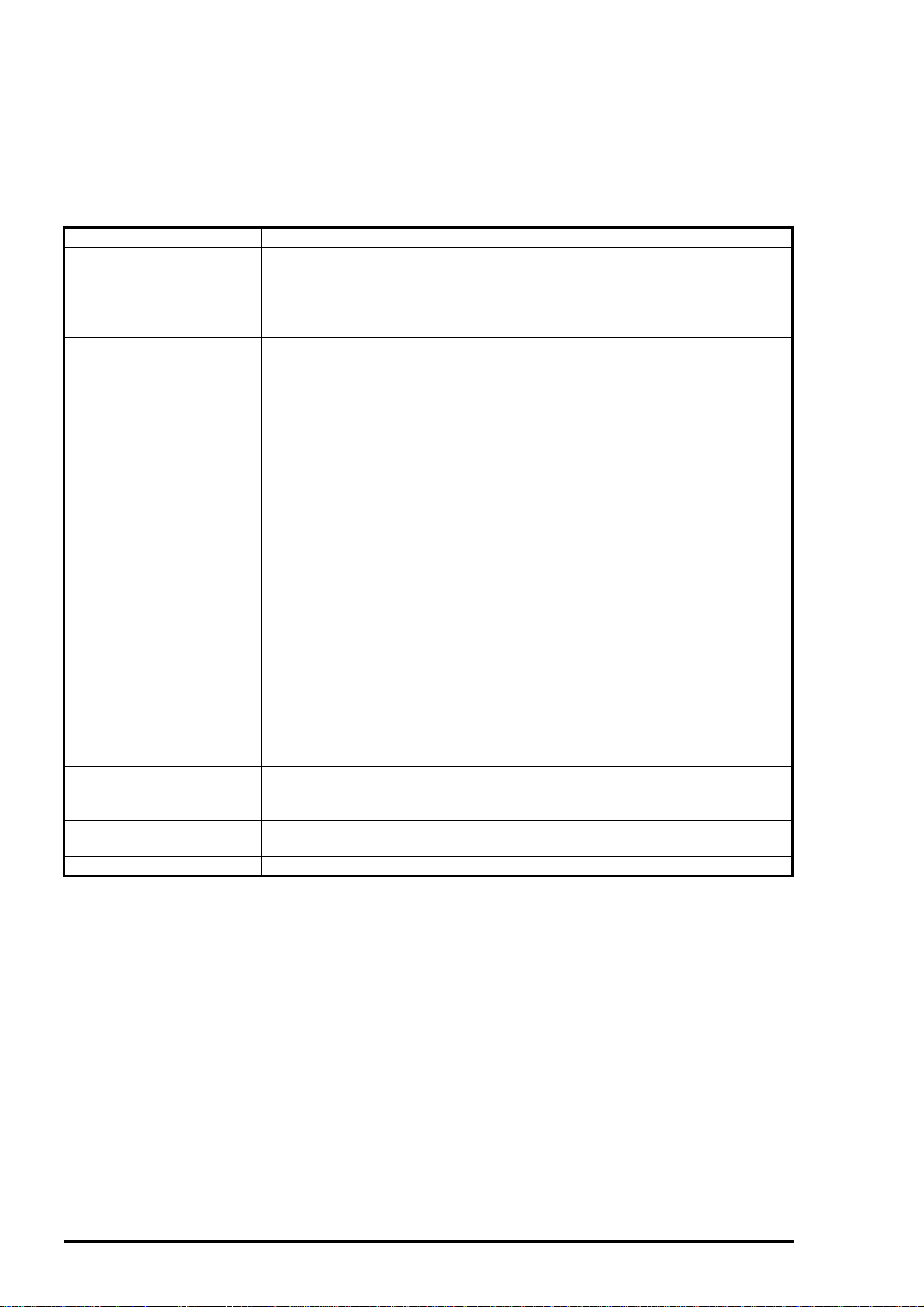

4.1.2 Adjustment Tools

Table 4-2 shows the tools necessary to adjust this printer and the menus to be adjusted.

Table 4- 2. Adjustment Tools

Tools for adjusting Item to be adjusted

Program disk for adjustment

y DOS system

y GWBASIC

y Adjustment program

(Version J70C00E)

Thickness gauge (1.1 mm) Platen gap adjustment

The program disk for adjustment consis ts of the total of 40 files such as DOS system, GW BASIC.EXE,

and adjusting programs. The adjusting menus in the program are as shown below:

Customer data writing operation

Initial ink charge (Ink charge)

Head voltage adjustment

Head angular adjustment

Black/color head vertical adjustment

Head gap adjustment

Bi-d adjustment

Main menu

Input of Customer data

Adjustment/Print inspection

Change of center value

Input of comment

Change of date

Change of time

End

Select Menu :?_

Sub menu

Ink charge

Write to the Head voltage value

All adjustment

Head angular adjustment

BK.-M Linear adjustment

Head GAP timing adjustment

Bi-d adjustment

Print inspection

Ink discharge

Customer data change/End

Select Menu :?_

Print inspection sub menu

Input M/C No. : ?_

Black voltage value :

Color voltage value :

GOS paper print test

S.F. paper print test

O.Q.A print test

Cleaning

Return to the MENU

Letter paper print test

Select Menu :?_

Figure 4-1. Adjustment Program Menu

Select the item in the light gray shaded box to perform necessary adjustment. You can proceed to the sub

menu thorough the item in the dark gray shaded box in the bold line. Selecting “All adjustment” in the

sub menu enables you to perform the following adjus tments consec utively; “ Head angular adjustment”,

“BK.-M Linear adjustment” and “Head G AP adjustment/Bi-d adjustment” T his sec tion, however, only

refers to the individual adjustment methods.

CAUTION

During adjustment, values such as Customer data, head voltage value, head gap adjustment

;

value, and Bi-d adjustment value are written into the EEPROM at the specified timing as follows;

Customer data : At performing “Print Inspection”.

Head voltage value : When the “Return” key is pressed after entering the

values during “Write to the Head voltage value”

menu . The data is then transferred to the printer.

Bi-d/ Head gap adjustment value: At performing “Print Inspection”.

Rev. A

4-

Page 5

EPSON Stylus

4

&RORU

800

4.2 Adjustment

This section provides detailed information on how to perform the adjustments listed below and the notice

headed under “CAUTION”.

Platen gap adjustment

Customer data writing operation

Initial ink charge

Head voltage data writing operation

Head angular adjustment

BK-M Liner adjustment

Head gap adjustment

Bi-d adjustment

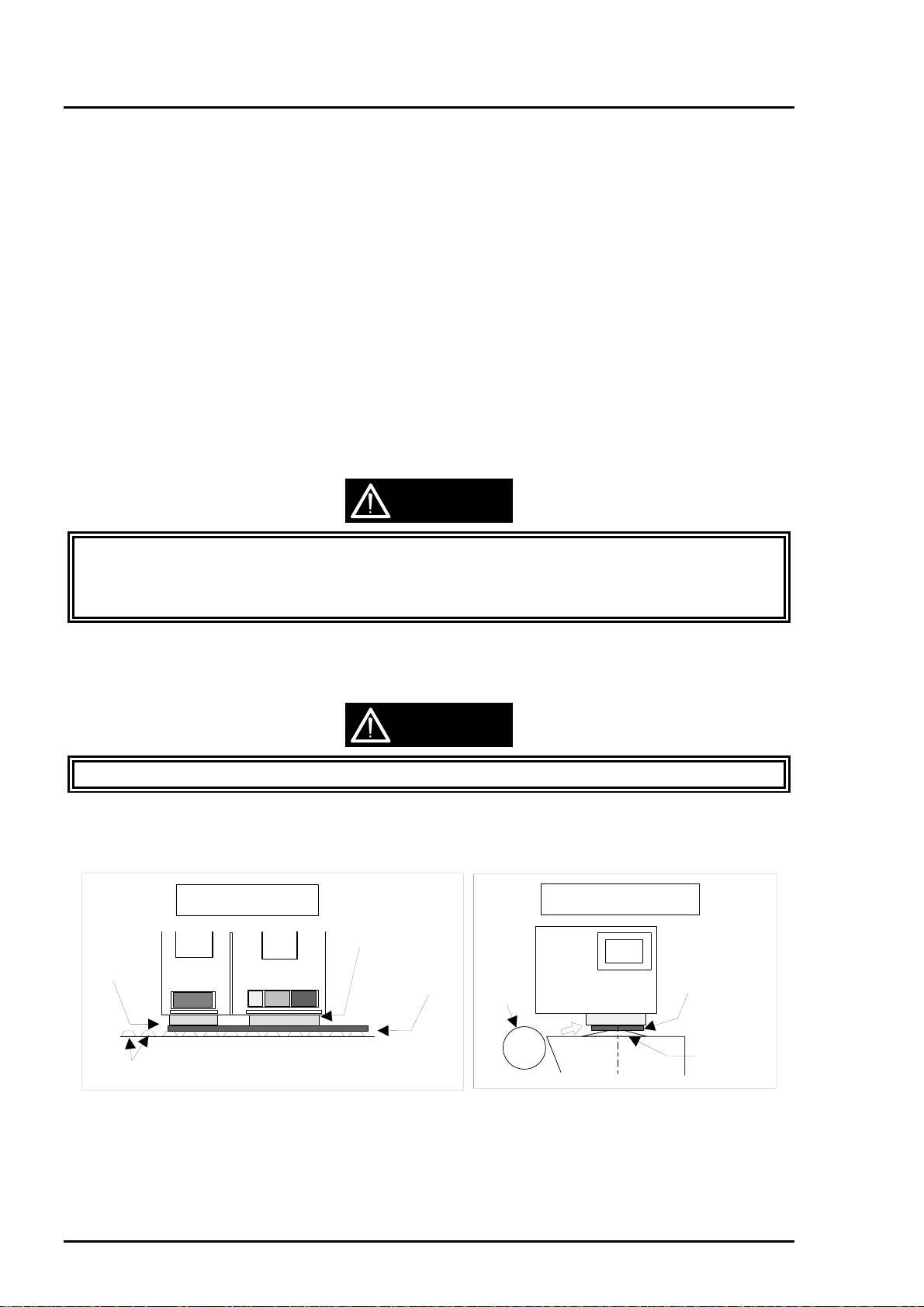

4.2.1 Platen Gap (PG) Adjustment

This adjustment is performed to obtain the appropriate gap between the head nozzle surface and the

platen, and is necessary when the parallelism adjust bushing has been set off the position during

disassembling and ass embling.

which is adjusted by inserting the thickness gauge between the head nozzle surface and platen then

turning the both left and right parallelism adjust bushings. This section describes how to adjust the PG gap

in the correct order along with cautions.

The standard value for the platen gap w ith this printer is 1.1 mm

,

CAUTION

Never touch the thickness gauge with your bare hand.

;

;

Make sure there is no oil, foreign object, and rust on the thickness gauge.

;

Check if your thickness gauge is not warped by checking it with the flat surface or new gauge.

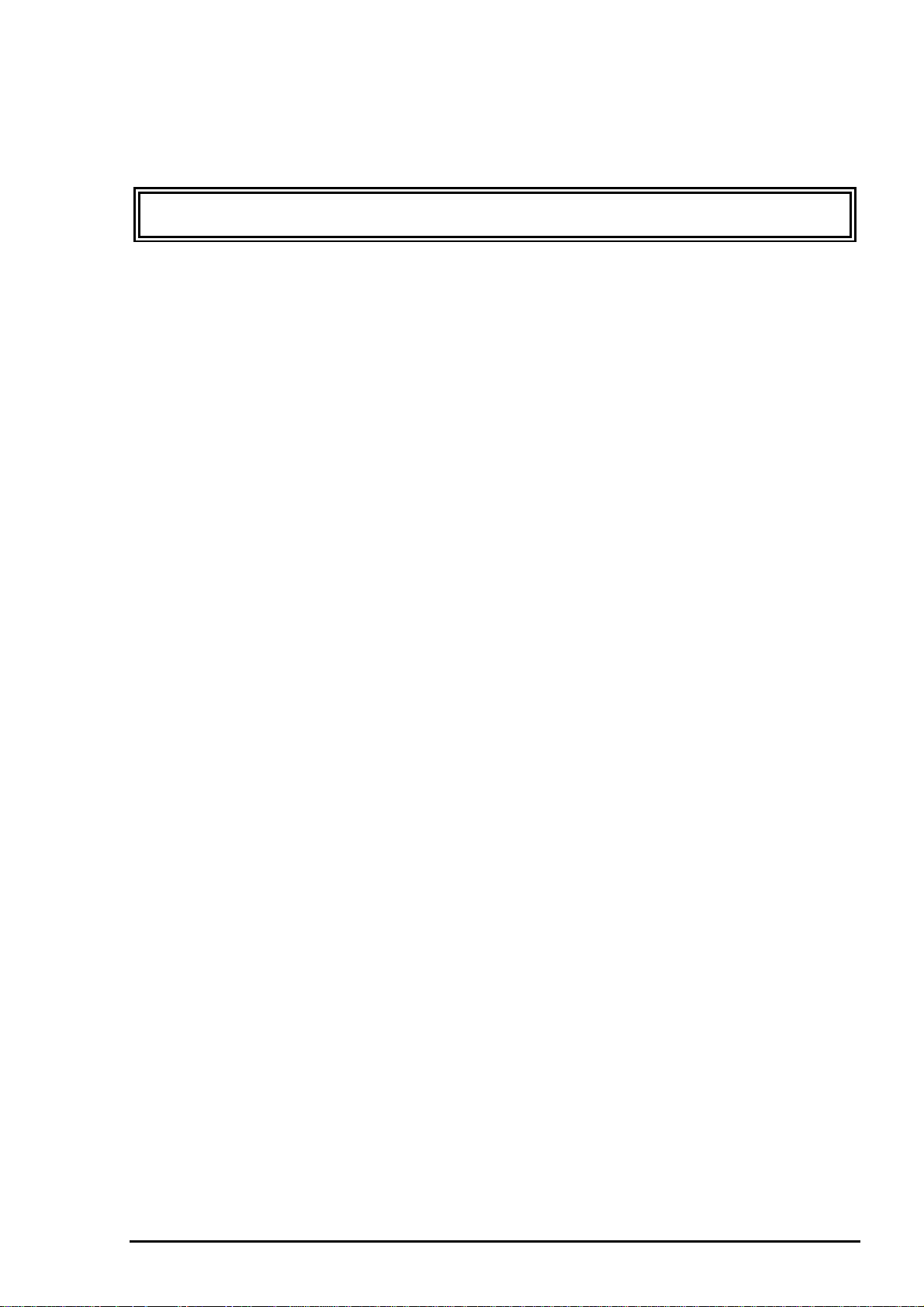

1. Set the PG lever to “+” (wide) position and shift the CR unit left. Then place the thickness gauge by

sliding it from the rear (PF roller side) into the front. In this time, don’t contact the thickness gauge to

the PF roller surface.

CAUTION

Be sure to level the thickness gauge when placing it onto the diamond cut rib on the platen plate.

;

2. Set the PG lever to “0” (narrow) position and shift the CR unit from left to right or vice versa by

holding the upper side of the timing belt.

Printer Mechanism

Viewed from the Left Side

Thickness Gauge

Black Head

Printer Mechanism

Viewed from the Front

Color Head

Thickness Gauge

PF Roller

Platen

Diamond Rib

Figure 4-2. Thickness Gauge Setting

4-

Diamond Rib

Rev. A

Page 6

Adjustment

5

g

3. Turn the left parallelism adjust bushing to the rear (narrower) step by step toward the left parallelism

adjust bushing set position, where the thickness gauge starts shif ting together with the CR unit. Then

shift the lever one step back to the front (wider) from the adjusted position.

Left Parallelsm Adjust Bushing

Rear side (Close)

Push to the rear

Viewed from the Left Frame Side

Figure 4-3. Left Parallelism Bushin

4. Hold the upper side of the timing belt and slide it to move the CR unit from right to left or vise versa to

confirm that the thickness gauge set on the platen does not move.

5. Return the PG lever toward “+” (wide) direction to remove the thick ness gauge, and slide the CR unit

right. Then place the thickness gauge by sliding it from the rear (PF roller side) into the f ront. During

this operation, don’t contact the PF roller surface with the thickness gauge.

6. Set the PG lever to the ”0” (narrower) position and shift the CR unit from left to right or vice vers a by

holding the upper side of the timing belt.

7. Turn the right parallelism adjust bushing to the rear step by step to the right parallelism adjust

bushing set position where the thickness gauge starts moving together with the CR unit. Then shift

the lever one step back to the front (wider) from the adjusted position.

8. Hold the upper side of the timing belt and slide it to move the CR to conf irm that the thick nes s gauge

set on the platen does not move.

Front side (Open)

Pull forward

Right Parallelism Adjust Bushing

Front side (Open)

Pull forward

Viewed from the Right Frame Side

Figure 4-4. Right Parallelism Bushing

9. Repeat the steps from 1 to 4 at the left end to confirm that the gap is correctly adjusted.

10. If the correct adjustment is confirmed, fix the left and right parallelism adjust bushings with the

screws (CBS, 3X6).

Rear side (Close)

Push to the rear

CAUTION

When fastening the screws, be careful not to dislocate bushings from the adjusted position

;

;

The tightening torque for the screws (CBS, 3X6) is 4.5 kg ~ 5.5 kg-cm.

Rev. A

4-

Page 7

EPSON Stylus

6

&RORU

800

CAUTION

;

After performing the PG gap adjustment, make sure that the “Cleaner Head” and head nose are in

contact with each other by the proper portion by following the instruction below.

11. Set the “PG Lever” to the “+” (wide) position.

12. Release the “CR Lock Lever” by turning it forward using the tweezers, and shif t the CR unit f rom the

CR home position to the right end of the “Front Paper Guide“. Then set the “Head Cleaner” to the

wiping/rubbing position by turning the larger gear of the “Pump Motor Reduction Gear” in counter

clock wise direction (forward).

CAUTION

Make sure that the “Change Cam” is set to the pump drive side during this operation. (Refer to

;

Figure 2-10 and 3-66 for the cam position.)

;

Stop turning the “Pump Reduction Gear” when you feel any resistance while turning the gear.

13. Slide the CR unit from left to right or vice versa by holding the upper side of the “Timing Belt” (or top

edge of the CR unit). Then check if the “Head Cleaner” and color head nose (metallic fram e part of

the head) come in contact with each other by 5 mm or more.

Carriage

Head Nose

Head Cleaner

Figure 4-5. Contact Area of the Color Head and Head Cleaner

Contact Area :

0.5 mm or more

CAUTION

When sliding the “Head Cleaner” to the metallic frame part of the head, be careful not to slide into

;

the head surface beyond the metal frame.

;

Check the “Cleaner Head” from the front left of the printer whether the contac t portion of the color

head and head cleaner is appropriate.

14. If you confirm the proper contact, return the large gear of the “Pum p Reduction Gears” in clock wise

direction to position the cleaner head under the “Sub Cable Holder” securely. If the portion is not

correct, check the positions for the “Head Cleaner” and “Pump Unit”, and replace the parts if

necessary.

15. Return the “CR unit” to the home position manually and set the “PG Lever” bac k to the “0” (narrow)

position.

4-

Rev. A

Page 8

Adjustment

7

4.2.2 Input of Customer Data

This operation is required when the C202 MAIN board is replaced. The program for this adjustment is

used to write the Customer data (set for each destination) into the EEPROM on the ASP C202 MAIN

board. If this program is not properly operated, it might caus e failure in reading CG data and installing

various types of utility using Bi-directional interface. The procedure for this operation is described below.

Customer data writing is programmed to be performed ahead of other adjustments. Therefore you

;

cannot proceed to any other adjustments without executing this operation first.

1. Set this program to FFD on your PC and turn the PC on.

2. The program automatically sets up and the following menu appears on the screen.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

> 12-03-1996

****

3. Enter “1” for

4. Press

“ENTER”

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

Select Menu ?_

“Select menu :?”

key, and the menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

to select “

.....................

........................

..........................

..........................

Figure 4-6. Main Menu

Input of Customer data

.....................

........................

..........................

..........................

..............

................

..............

................

1

2

3

4

5

6

9

> 12-03-1996

****

1

2

3

4

5

6

9

” in the menu.

Select Menu : 1

Input the customer data

Memory-SW data (4col data) : ?

Figure 4-7. Input of Customer Data

5. Enter the 4-column code which corresponds to the destination for

and press

6. After performing necessary adjustments , store the setting values in the EEPROM on the C202 MAIN

board by selecting and performing

“ENTER”

key. The customer codes for each destination is listed below:

0000 : EAI, EAI (Latin)

0101 : EDG (NLSP) EDG (NLSP)

0001 : Europe Standard (EDG, EFS, EIS, EIB, EUL)

“Print Inspection”

in the sub menu.

Rev. A

“Memory-SW data (4 col data)”

4-

Page 9

EPSON Stylus

8

&RORU

800

4.2.3 Ink Charge

You must perform this operation after installing the “ASP Pr inthead” or ” ASP Printer Mec hanism ” in which

new “Printheads” are installed. “ASP Printheads” or “Printheads” installed in the “ASP Printer Mechanism ”

has shipping liquid filled in the cavity, and this operation is required to eject the liquid to r eplace it with the

ink. Therefore be sure to perform the initial ink charge operation whenever you replace the printhead,

since the lack of this oper ation might cause dot miss ing. The procedure and notes for this operation are

described below.

CAUTION

Avoid unnecessary initial ink charge operation, which consumes considerable amount of ink

;

(about one fifth of the ink cartridge capacity is consumed by this operation).

;

Do not turn the printer off before this program is completed. Otherwise, the ink dose not filled

enough in the cavity of the “Printhead”. in case of the power was turned off while this operation, do

this operation again by using this program.

;

This initial charge program is difference with the initial charge sequence which is carried out

automatically on the first power on time. This program carry out to chage the almost same value of

the ink which is used on the first power on initial charge sequence.

1. Set this program to FFD on your PC and turn the PC on.

2. The program automatically sets up and the following menu appears on the screen.

Stylus COLOR 800 J70C00E

> 12-03-1996

****

1

2

3

4

5

6

9

> 12-03-1996

****

1

2

3

4

5

6

9

” in the menu.

3. Enter “1” for

4. Press

“ENTER”

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

Select Menu ?_

“Select menu : ?”

key, and the menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

to select “

.....................

........................

..........................

..........................

Figure 4-8. Main Menu

Input of Customer data

.....................

........................

..........................

..........................

..............

................

..............

................

Select Menu : 1

Input the customer data

Memory-SW data (4col data) : ?

Figure 4-9. Input of Customer Data

4-

Rev. A

Page 10

Adjustment

9

5. Enter the the 4-column code which corresponds to the destination for “Memory-SW data (4 col

data)” and press “ENTER” key. (See the code list on Page 4-6.)

6. Enter “2” for “Select menu : ?” to select “Adjustment/Print inspection” in the menu.

7. Press “ENTER” key, and the sub menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer Data <

> 12-03-1996

****

Ink charge

Write to the Head voltage value

All adjustment

Head angular adjustment

BK.-M Linear adjustment

Head GAP timming adjustment

Bi-d adjustment

Print inspection

Ink discharge

Customer data change/End

Select Menu ?_

BI-D (center value 0,0)

Gap Timming (center value 0,0)

Figure 4-10. “Adjustment/Inspection” Sub Menu

8. Enter “0” for “Select menu : ?” to select “Ink charge” in the menu.

9. Press “ENTER” key, and the menu returns to the sub menu and the Initial ink charge sequence

starts. The Power LED on the control panel is blinking during this operation.

10. If you don’t proceed to the next adjustment, enter “9” for “Select menu : ?” to select “Customer

data change/End” in the current menu, and the menu returns to the main menu.

..............................

.......

..........................

.............

.............

.......

.....................

......................

........................

...........

0

1

2

3

4

5

6

7

8

9

11. Enter “9” for “Select menu : ?” then press “ENTER” to exit the program.

Rev. A

4-

Page 11

EPSON Stylus

0

&RORU

800

4.2.4 Write to the Head Voltage Value

This operation is required after installing the “ASP C202 MAIN board”, “ASP Printhead”, or “ASP Pr inter

Mechanism” in which new printheads are already installed. This operation is necessary to correct the head

drive pulse which differs from printhead to printhead depending on the piezoelectric elements

manufactured unevenly. This program allows you to write individual head voltage value into the EEPROM

on the C202 MAIN board. A failure in executing this program will result in inferior pr inting. The pr ocedure

for this operation is described below.

CAUTION

Take a note of the 5 columns head VH voltage value which is stamped on the left side of the

;

printhead before installing the new printhead.

;

“ASP Printer Mechanism” is equipped with the printhead. Do not forget to note the head VH

voltage value for the equipped printheads. The 5 columns head VH voltage value is stanpped on

label which is pasted on the printer mechanism package.

1. Set this program to FFD on your PC and turn the PC on.

2. The program automatically sets up and the following menu appears on the screen.

3. Enter “1” for

4. Press

“ENTER”

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

Select Menu ?_

“Select menu : ?”

key, and the menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

to select “

.....................

........................

..........................

..........................

Figure 4-1 1. Main Menu

Input of customer data

.....................

........................

..........................

..........................

..............

................

..............

................

> 12-03-1996

****

1

2

3

4

5

6

9

> 12-03-1996

****

1

2

3

4

5

6

9

” in the menu.

Select Menu : 1

Input the customer data

Memory-SW data (4col data) : ?

-

4-1

Rev. A

Page 12

Adjustment

5. Enter the 4-column code which corres ponds to the destination for “Memory-SW data (4 col data)”

and press “ENTER” key. (See the code list on Page 4-6.)

6. Enter “2” for “Select menu : ?” to select “Adjustment/Print inspection” in the menu.

7. Press “ENTER” key, and the sub menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer Data <

> 12-03-1996

****

Ink charge

Write to the Head voltage value

All adjustment

Head angular adjustment

BK.-M Linear adjustment

Head GAP timming adjustment

Bi-d adjustment

Print inspection

Ink discharge

Customer data change/End

Select Menu ?_

BI-D (center value 0,0)

Gap Timming (center value 0,0)

Figure 4-13. “Adjustment/Inspection” Sub Menu

8. Enter “1” for “Select menu : ?” to select “Write to the Head voltage value” in the menu.

9. Press “ENTER” key, and the following appears.

<<<< Write the HEAD Voltage value>>>>

Black Head voltage

Black voltage value (5chr. ID data (ex.18A09)) :

..............................

.......

..........................

.............

.............

.......

.....................

......................

........................

...........

0

1

2

3

4

5

6

7

8

9

----Voltate value---------------------Black voltate value :

Color voltage value

“Write to the Head Voltage Value”

10. Input the correct head voltage with 5 colums and check if the head voltage value was input on the

confirmation m enu which is shown on the screen. If correc t, press “ENTER” key. If incorrect, press

“SPACE” key and replace the incorrect value with the correct one.

Rev. A

:

Figure 4-14.

4-1 1

Page 13

EPSON Stylus

2

&RORU

800

<<<<Write the Head Voltage value>>>

Black Head voltage

Black Head voltage value (5chr. ID data (ex.18A09)):24B16

Color Head voltage voltage

Color Head voltage value (5chr. ID data (ex. 18A09)): 14B14

OK? <Space> to retry <Return> to write the value & return to the MENU

------Voltage value------------------Black voltage :

Color voltage :

Figure 4-15. Write to the Head Voltage Value (2)

11. After inputting the correct values, the head voltage values are s tored in the EEPROM on the C202

MAIN board by pressing the “ENTER” key, and the sub menu appears.

12. If ther e is no more adjustment to be perf ormed, enter “9” for “Select menu : ?” to select “Customer

data change/End” in the sub menu, then press “ENTER” k ey, and the menu r eturns to the main

menu.

13. Enter “9” for “Select menu : ?”, then press the “ENTER” key to exit the program.

4-1

Rev. A

Page 14

Adjustment

3

4.2.5 Head Angular Adjustment

This adjustment must be operated when replacing the printhead or dis as sembling and assem bling the CR

unit in order to attach the printheads at the proper angular on the level. This adj ustment , perf ormed on

physical basis, is accomplis hed by moving the head angular adjustm ent lever ass embled to the f ront s ide

of the CR unit. You can identify and adjust the slant according to the result on the test pattern output

during the adjusting program. Therefore there is no value to be written into the EEPROM on the C202

MAIN board. The adjustment procedure is as follows;

1. Set this program to FFD on your PC and turn the PC on.

2. The program automatically sets up and the following menu appears on the screen.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

> 12-03-1996

****

3. Enter “1” for

4. Press

“ENTER”

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

Select Menu ?_

“Select menu : ?”

key, and the menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

to select “

.....................

........................

..........................

..........................

Figure 4-16. Main Menu

.....................

........................

..........................

..........................

1

..............

................

Input of customer data

..............

................

2

3

4

5

6

9

> 12-03-1996

****

1

2

3

4

5

6

9

” in the menu.

Select Menu : 1

Input the customer data

Memory-SW data (4col data) : ?

Figure 4-17. Input of Customer Data

5. Enter the suitable 4 columns data for

Regarding the suitable 4 columns data, refer the page 4-6.

6. Enter “2” for

Rev. A

“Select menu : ?”

“Memory-SW data (4 col data)”

to select

and press

“Adjustment/Print inspection”

“ENTER”

in the menu.

key.

4-1

Page 15

EPSON Stylus

4

7. Press “ENTER” key, and the menu below appears.

&RORU

800

Stylus COLOR 800 J70C00E

Customer : Standard Customer Data <

> 12-03-1996

****

Ink charge

Write to the Head voltage value

All adjustment

Head angular adjustment

BK.-M Linear adjustment

Head GAP timming adjustment

Bi-d adjustment

Print inspection

Ink discharge

Customer data change/End

Select Menu ?_

BI-D (center value 0,0)

Gap Timming (center value 0,0)

Figure 4-18. “Adjustment/Inspection” Sub Menu

8. Enter “3” for “Select menu : ?” to select “Head angular adjustment” in the menu, then press

“ENTER” key.

9. Enter a dummy number in 3 digits such as “000” or “111” for “MC No.”, and the head angular

adjustment pattern is printed out.

..............................

.......

..........................

.............

.............

.......

.....................

......................

........................

...........

0

1

2

3

4

5

6

7

8

9

CAUTION

When the MC number is entered, the head angular adjustment pattern is printed and the following

;

message appears on the screen;

“Space“ key to print again (“Return” to the MENU) (“0” key to cleaning/ “E” key to

escape to the error)

If you identify missing dots on the pattern, you can enter “0” to reprint the adjustment pattern after

performing the head cleaning. The black and color head cleaning is executed either individually or

together, which you can select. This cleaning is same as CL2 cleaning.

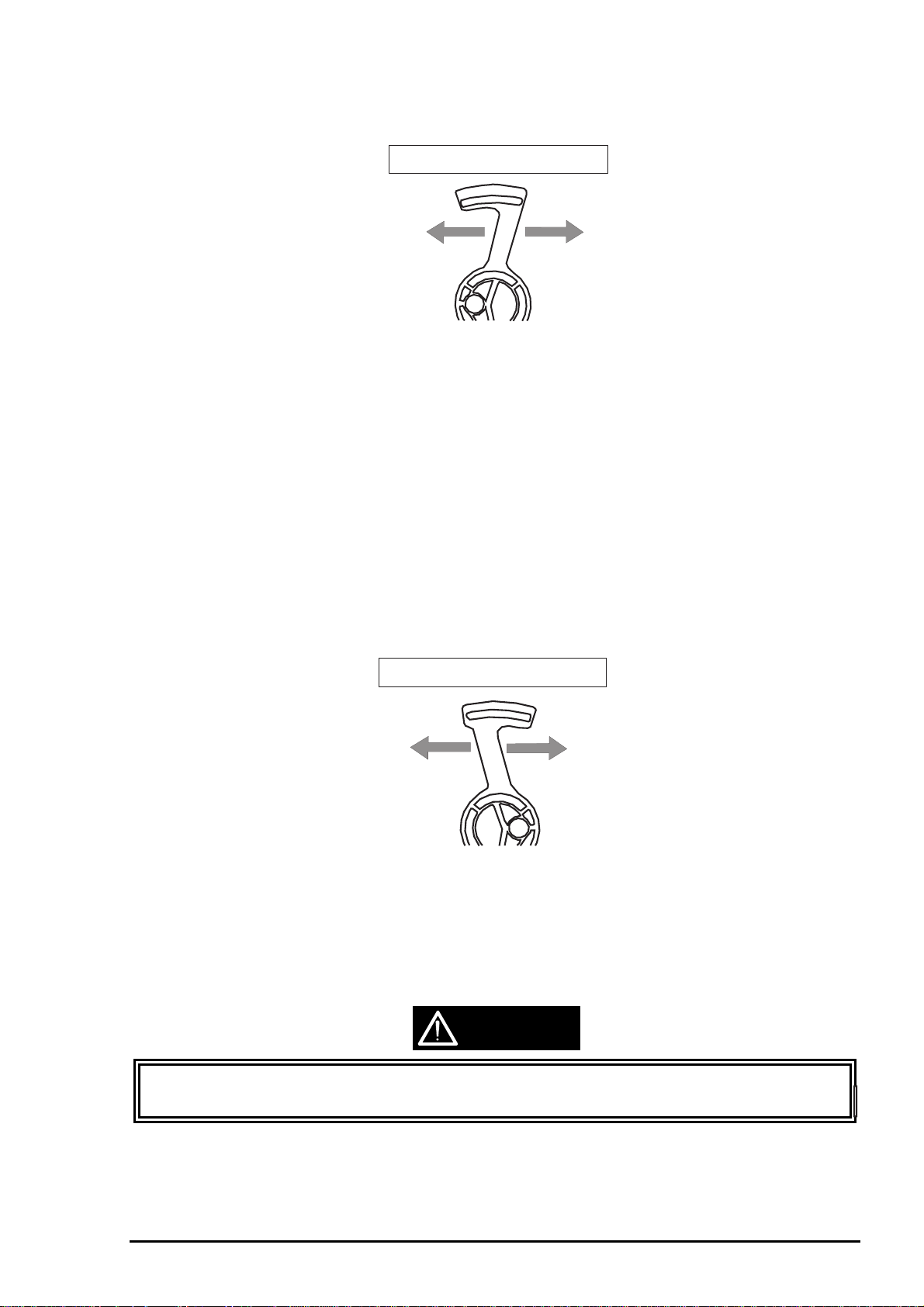

10. Look at the output to chec k if the lines are printed at the regular interval. Figure below shows how to

move the head angular adjust lever to adjust different misalignment patterns for each head.

Black Printing Color Printing

Move the lever

right.

Correct pattern

Move the lever

left.

Move the lever

right.

Correct pattern

Move the lever

left.

Head Angular Adjustment Lever

Figure 4-19. Use of the Head Angular Adjust Lever

4-1

Rev. A

Page 16

Adjustment

5

CAUTION

;

Slant changes with a unit of 0.02 mm by moving the head angular adjustment lever one step.

11. Af ter adjus ting the angular adj ustment lever by looking the adjustment pattern s heet, pres s “SPACE”

key to print another adjustment pattern sheet.

12. If the lines in the new adjustment patterns are aligned at the r egular interval, press “ENTER” key,

and the sub menu appears on the screen.

13. If you don’t proceed to the next adjustment, enter “9” for “Select menu : ?” to select “Customer

data change/End” in the menu, then press “ENTER” key to return to the main menu.

14. Enter “9” for “Select menu : ?” then press “ENTER” key to exit the program.

Rev. A

4-1

Page 17

EPSON Stylus

6

&RORU

800

4.2.6 BK.-Linear Adjustment

BK.-M Linear adjustment is required when replacing the printhead or disassem bling and assembling the

CR unit, and is performed to adjust the vertical position of the color head by using the black head for the

basis. This adjustment, which depends on the physical operation, is accomplished by moving the head

vertical adjust lever assembled to the right side of the CR unit. By running this program, the head vertical

adjustment pattern is printed to identif y the misalignment caused by the vertical gap between the Black

Head and Color Head. According to the printed pattern, adjust the gap by moving the head vertical

adjustment lever. Therefore this adjustment has no value to be written into the EEPROM on the C202

MAIN board. The adjustment procedure is as follows;

1. Set this program to FFD on your PC and turn the PC on.

2. The program automatically sets up and the following menu appears on the screen.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

> 12-03-1996

****

3. Enter “1” for

4. Press

“ENTER”

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

Select Menu ?_

“Select menu : ?”

key, and the menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

to select

.....................

........................

..........................

..........................

Figure 4-20. Main Menu

“Input of Customer data”

.....................

........................

..........................

..........................

..............

................

..............

................

1

2

3

4

5

6

9

> 12-03-1996

****

1

2

3

4

5

6

9

in the menu.

Select Menu : 1

Input the customer data

Memory-SW data (4col data) : ?

Figure 4-21. Input of Customer Data

5. Enter the 4-column code which corres ponds to the destination for

and press

6. Enter “2” for

4-1

“ENTER”

“Select menu : ?”

key. (See the code list in Page 4-6.)

to select

“Adjustment/Print inspection”

“Memory-SW data (4 col data)”

in the menu.

Rev. A

Page 18

7

7. Press “ENTER” key, and the sub menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer Data <

> 12-03-1996

****

Adjustment

Ink charge

Write to the Head voltage value

All adjustment

Head angular adjustment

BK.-M Linear adjustment

Head GAP timming adjustment

Bi-d adjustment

Print inspection

Ink discharge

Customer data change/End

Select Menu ?_

BI-D (center value 0,0)

Gap Timming (center value 0,0)

Figure 4-22. “Adjustment/Inspection” Sub Menu

8. Enter “4” for “Select menu : ?” to select “BK.-M Linear adjustment” in the menu.

9. Press “ENTER” key, and the printer prints the adjustment pattern in black and magenta ink.

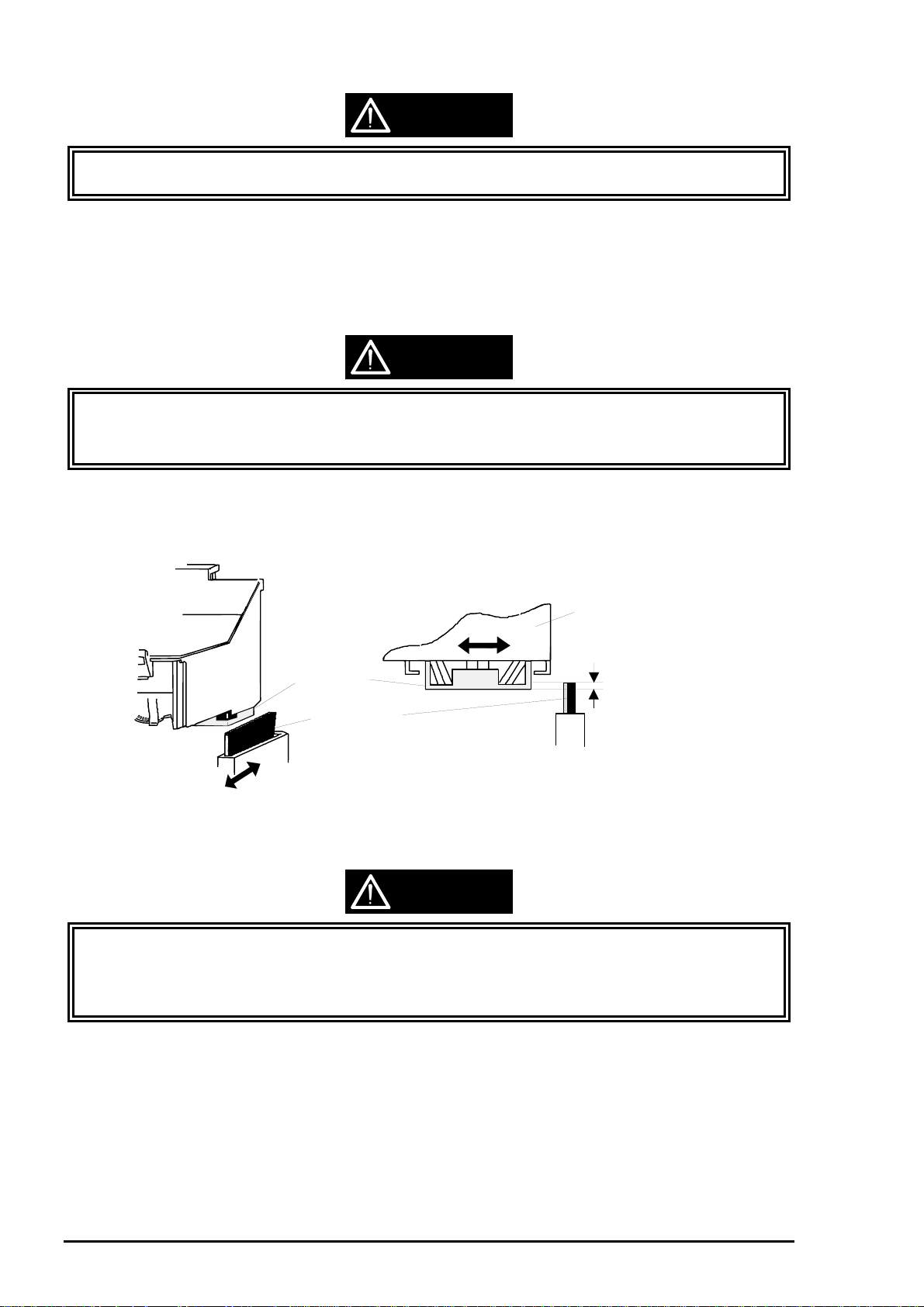

10. Look at the output to check if the lines f or black and magenta ar e mos t closely aligned. Figure below

shows how to move the head vertical adjust lever to adjust different misalignment patterns.

Black Col or Bl ack

Black Col or Bl ack

..............................

.......

..........................

.............

.............

.......

.....................

......................

........................

...........

0

1

2

3

4

5

6

7

8

9

Paper feed

direction

Move the Lever forward

Move the Lever backward

Figure 4-23. Use of the Head Vertical Adjust Lever

Paper feed

direction

Head Vertical Adjustment

Lever

CAUTION

Slant changes with a unit of 0.02 mm by moving the head angular adjust lever one step.

;

11. After adjust the head vertical adjustment lever by looking the adjustment pattern sheet, press

“SPACE” key to print adjustment pattern sheet agin.

12. If the new adjustment patterns is aligned within the specific ation, press “ENTER” key, and the sub

menu appears on the screen.

13. If ther e is no adjus tm ent to be perfor m ed, enter “9” for “Select menu : ?” to select “Customer data

change/End” in the menu, then press “ENTER” key to return to the main menu.

14. Enter “9” for “Select menu : ?” then press “ENTER” key to exit the program.

Rev. A

4-1

Page 19

EPSON Stylus

8

&RORU

800

4.2.7 Head GAP Timing Adjustment

Head GAP Timing Adjustment is requir ed when the C202 MAIN board or the Printhead is replaced (or

disassembling and assem bling the CR unit) to correct the vertic al misalignment c aused by different print

timings between black and color ink s. This adjustment, s ame as f or the Bi-d adjustment, is perf ormed by

entering the adjusting value. Therefore the adjus ting values are s tored in the EEPRO M on the C202 MAIN

board. The adjusting procedure is described below.

1. Set this program to FFD on your PC and turn the PC on.

2. The program automatically sets up and the following menu appears on the screen.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

> 12-03-1996

****

3. Enter “1” for

4. Press

“ENTER”

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

Select Menu ?_

“Select menu : ?”

key, and the menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

to select

.....................

........................

..........................

..........................

Figure 4-24. Main Menu

“Input of Customer data”

.....................

........................

..........................

..........................

..............

................

..............

................

1

2

3

4

5

6

9

> 12-03-1996

****

1

2

3

4

5

6

9

in the menu.

Select Menu : 1

Input the customer data

Memory-SW data (4col data) : ?

Figure 4-25. Input of Customer Data

5. Enter the 4-column code which corres ponds to the destination for

and press

6. Enter “2” for

4-1

“ENTER”

“Select menu : ?”

key. (See the code list in Page 4-6.)

to select

“Adjustment/Print inspection”

“Memory-SW data (4 col data)”

in the menu.

Rev. A

Page 20

7. Press “ENTER” key, and the sub menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer Data <

> 12-03-1996

****

Adjustment

Ink charge

Write to the Head voltage value

All adjustment

Head angular adjustment

BK.-M Linear adjustment

Head GAP timming adjustment

Bi-d adjustment

Print inspection

Ink discharge

Customer data change/End

Select Menu ?_

BI-D (center value 0,0)

Gap Timming (center value 0,0)

Figure 4-26. “Adjustment/Inspection” Sub Menu

8. Enter “5” for “Select menu : ?” to select “Head GAP timing adjustment” in the menu.

9. Press “ENTER” key, the menu below appears, along with 6 adjustment patterns (3 for 200 cps and 3

for 100 cps) printed in black and magenta.

Monitor display

Adjustment area (-30 to 30)

200 CPS : ?_

..............................

.......

..........................

.............

.............

.......

.....................

......................

........................

...........

0

1

2

3

4

5

6

7

8

9

200 cps : -2

200 dps : 0

200 cps : 2

100 cps : -2

100 cps : 0

200 cps : 2

Adjustment pattern

Figure 4-27. Head Gap Adjustment Patterns

Rev. A

4-19

Page 21

EPSON Stylus

0

&RORU

800

10. Look at the output to check if the lines f or black and color are m ost closely aligned. If not, input the

proper value to adjust the misalignment according to the result, as shown in the figure below.

Black

Color

Black

Value to Enter:

Minus

Direction in which

the paper is fed

Value to Enter:

Black

Color

Black

Plus

Figure 4-28. Adjusting Value Determination

CAUTION

The printed vertical line shift about 0.07mm by inputting “4” on 200 cps adjustment mode and “2”

;

on 100cps adjustment mode.

11. If the value input is incorrect, enter the correct value after pressing the “SPACE” key and press

“ENTER” key to set the values, then the menu returns to the sub menu.

12. Enter “7” for “Select menu : ?” and press “ENTER” key to proceed to “Print Inspection” in the sub

menu in order to check how the set values affect to the outcome. The menu appears is as follows;

Input M/C No. : ?

M/C No. :

Black voltage value :

Color voltage value :

Figure 4-29.

Setting Menu (1) for Print Inspection

Input M/C No. : ?

Black voltage value : 24B16

Color voltate value : 14B14

OK? ('Return' to NEXT) :

M/C No. :

Black voltage value :

Color voltage value :

Figure 4-30.

Setting Menu (2) for Print Inspection

4-2

Rev. A

Page 22

Adjustment

g

13. Follow the menu by entering a dummy M/C No. in 3 digits and black/color head voltages

corresponding the installed printheads, then press “ENTER” key, and the menu below appears.

14. If the value input is incorrect, press “SPACE” and enter the correct value. If the input values are

Stylus COLOR 800 J70C00E

Customer : Sstandard cistpmer DATA <

> 12-03-0996

****

GOS paper print test

S.F. paper print test

O.Q.A. print test

Cleaning

Return to the MENU

Letter paper print test

Select Menu ?_

MC/No. : 000

Black voltage value : 24B16

Color voltage value : 14B14

correct, proceed to the menu shown below by pressing the “ENTER” key.

15. Enter “2” for “Select menu : ?” to select “S.F. paper print test” in the menu, then press “ENTER”

key, and the printer outputs the result of the head gap timing adjustment , along with the results of

other adjustments.

16. Look at the output to check if the lines are most closely aligned. If not, enter “9” for “Select menu :

?” to select “Return to the MENU”, then press “ENT ER” key to return to the sub menu.

.................................

Settin

.......................

........................

...........................

........................

.......................

Figure 4-31.

Menu (3) for Print Inspection

1

2

5

0

9

7

17. Repeat the steps fr om 8 to 16 until the output is satisfac tory, then enter “9” for “Select menu : ?” in

the menu indicated in Figure 4-31 and press “ENTER” key to return to the sub menu.

18. If ther e is no adjus tm ent to be perfor m ed, enter “9” for “Select menu : ?” to select “Customer data

change/End” in the menu, then press “ENTER”.

19. Enter “9” for “Select menu : ?” to exit the program.

Rev. A

4-21

Page 23

EPSON Stylus

2

&RORU

800

4.2.8 Bi-d adjustment

Bi-d adjustment is required when the printer is under the following conditions; the printer m echanism is

replaced, the C202 MAIN board is replaced, the CR unit is disass embled and assembled, top f rame is

replaced, and the CR motor is disassembled. This program enables you to align the vertical line by

adjusting the print timing in the Bi-directional black printing mode. The adjustment value is stored in the

EEPROM on the C202 MAIN board. The adjusting procedure is described below.

1. Set this program to FFD on your PC and turn the PC on.

2. The program automatically sets up and the following menu appears on the screen.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

> 12-03-1996

****

3. Enter “1” for

4. Press

“ENTER”

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

Select Menu ?_

“Select menu : ?”

key, and the menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer DATA <

Input Customer data

Adjustment/Print inspection

Changing of center value

Input of comment

Change of date

Change of time

END

to select

.....................

........................

..........................

..........................

Figure 4-32. Main Menu

“Input of Customer data”

.....................

........................

..........................

..........................

..............

................

..............

................

1

2

3

4

5

6

9

> 12-03-1996

****

1

2

3

4

5

6

9

in the menu.

Select Menu : 1

Input the customer data

Memory-SW data (4col data) : ?

Figure 4-33. Input of Customer Data

5. Enter the 4-column code which corres ponds to the destination for

and press

6. Enter “2” for

4-2

“ENTER”

“Select menu : ?”

key. (See the code list in Page 4-6.)

to select

“Adjustment/Print inspection”

“Memory-SW data (4 col data)”

in the menu.

Rev. A

Page 24

3

7. Press “ENTER” key, and the sub menu below appears.

Stylus COLOR 800 J70C00E

Customer : Standard Customer Data <

> 12-03-1996

****

Adjustment

Ink charge

Write to the Head voltage value

All adjustment

Head angular adjustment

BK.-M Linear adjustment

Head GAP timming adjustment

Bi-d adjustment

Print inspection

Ink discharge

Customer data change/End

Select Menu ?_

BI-D (center value 0,0)

Gap Timming (center value 0,0)

Figure 4-34. “Adjustment/Inspection” Sub Menu

8. Enter “6” for “Select menu : ?” to select “Bi-d adjustment” in the menu.

9. Press “ENTER” key, and the menu below appears, along with 6 adjustment patterns, 3 for 267 cps

and 3 for 200 cps, are printed in black as shown in Figure 4-35.

Monitor display

Adjustment area (-30 to 30)

267 CPS : ?_

..............................

.......

..........................

.............

.............

.......

.....................

......................

........................

...........

0

1

2

3

4

5

6

7

8

9

267 cps Bi-D : -4

267 cps Bi-D : 0

267 cps Bi-D : 4

200 cps Bi-D : -2

200 cps Bi-D : 0

200 cps Bi-D : 2

Figure 4-35. Bi-d Adjustment Patterns

Rev. A

4-2

Page 25

EPSON Stylus

&RORU

800

10. Look at the output to check if the lines are most closely aligned. If not, adjust the misalignment

referring to the output result, as shown in the figure below.

Direction in which

the paper is fed

Value to Enter:

Minus

Value to Enter:

Plus

Figure 4-36. Adjusting Value Determination

CAUTION

As you change the value with a unit of 4 for 267cps or 2 for 200 cps, the slant moves

;

approximately 0.07 mm or 0.035 mm, respectively.

;

The printed vertical line shift about 0.07mm by inputting “4” on 267cps adjustment mode . On the

200cps adjustment mode, by inputting “2” , the printed vertical line shift about 0.035mm..

11. If the value input is incorrect, enter the correct value after pressing the “SPACE” key and press

“ENTER” key to set the values, then the menu returns to the sub menu.

12. Enter “7” for “Select menu : ?” then press “ENTER” key to proceed to the “Print Inspection” in the

sub menu, in order to check how the set values affec t to the outcome. The following appears on the

screen.

Input M/C No. : ?

M/C No. :

Black voltage value :

Color voltage value :

Figure 4-37.

Setting Menu (1) for Print Inspection

13. Follow the menu by entering a dummy M/C No. in 3 digits, black voltage, and color voltage

corresponding the installed printheads, then press “ENTER” key, and the following menu appears.

Input M/C No. : ?

Black voltage value : 24B16

Color voltate value : 14B14

OK? ('Return' to NEXT) :

M/C No. :

Black voltage value :

Color voltage value :

Figure 4-38.

SettingMenu(2)forPrintInspection

4-24

Rev. A

Page 26

Adjustment

5

14. If the value input is incorrect, press “SPACE” and enter the correct value. If the input values are

correct, press the “ENTER” key to proceed to the menu shown below.

Stylus COLOR 800 J70C00E

Customer : Sstandard cistpmer DATA < > 12-03-0996

GOS paper print test

S.F. paper print test

O.Q.A. print test

Cleaning

Return to the MENU

Letter paper print test

Select Menu ?_

MC/No. : 000

Black voltage value : 24B16

Color voltage value : 14B14

Figure 4-39 Setting Menu (3) for Print Inspection

.................................

.......................

........................

...........................

........................

.......................

****

1

2

5

0

9

7

15. Enter “2” for “Select menu : ?” to select “S.F. paper print test” in the menu, then press “ENTER”

key, and the printer outputs the result of the Bi-d adjustment, along with the results of other

adjustments.

16. Look at the output to check if the alignment is satisfactor y. If not, enter “9” for “ Select menu : ?” to

select “Return to the MENU”, then press “ENTER” key.

17. Repeat the steps 8 to 16 until the output is satisfactor y, then enter “9” for “Select menu : ?” in the

menu shown in Figure 4-39 and press “ENTER” key to return to the sub menu.

18. If there is no more adjustments to be performed, enter “9” for “Select menu : ?” to select

“Customer data change/End” in the menu, then press “ENTER”.

19. Enter “9” for “Select menu : ?” to exit the program.

Rev. A

4-2

Loading...

Loading...