Page 1

Chapter 2

Operating Principles

2.1 Overview................................................................................................................2-1

2.2 Printer Mechanism Operating Principles ...........................................................2-1

2.2.1 General Description ...............................................................................................................2-1

2.2.2 Printing Mechanism ...............................................................................................................2-2

2.2.2.1 Printing Process ........................................................................................................2-3

2.2.2.2 Printing Methods........................................................................................................2-3

2.2.3 Carriage (CR) Mechanism...................................................................................................... 2-4

2.2.4 Paper Feed Mechanism..........................................................................................................2-5

2.2.5 Platen Gap (PG) Adjust Mechanism ..................................................................................... 2-6

2.2.6 CR Lock Mechanism ..............................................................................................................2-6

2.2.7 ASF Mechanism...................................................................................................................... 2-7

2.2.8 Ink System...............................................................................................................................2-9

2.2.8.1 Pump Mechanism.................................................................................................... 2-10

2.2.8.2 Capping Mechanism................................................................................................ 2-12

2.3 Electrical Circuit Operation Principles.............................................................2-13

2.3.1 C202 PSB/PSE board............................................................................................................ 2-13

2.3.2 C202 MAIN Control Board....................................................................................................2-15

2.3.2.1 Printhead Driver Circuit ........................................................................................... 2-16

2.3.2.2 Reset Circuits..........................................................................................................2-18

2.3.2.3 Motor Driver Circuits................................................................................................ 2-19

2.3.2.4 Sensor Circuits........................................................................................................2-20

2.4 Ink System Management....................................................................................2-21

2.4.1 Ink System Operations.........................................................................................................2-21

2.4.2 Timers and Counters............................................................................................................2-22

2.4.3 Ink System Sequence...........................................................................................................2-23

Page 2

Operating Principles

2.1 Overview

This chapter provides information on the printer mechanism, electrical circuit, and ink system. The

operating principles for each mechanism in the printer mechanism is described individually. The

description for the electrical circuit is divided into 2 parts; C202 PSB/PSE board and C202 MAIN board.

2.2 Printer Mechanism Operating Principles

2.2.1 General Description

This printer is m ainly composed of the printing m echanism , paper feed m echanism , car riage m echanism ,

pump mechanism, and ASF mechanism. There are 3 motors, carriage motor (CR motor), paper feed

motor, (PF motor) and pump motor. Table 2-1 shows each motor and corresponding units and assem blies

driven.

Table 2-1. Motor and Unit/Assembly Driven

Motor Unit/Assembly driven

PF motor PF roller assembly, CR lock lever

CR motor CR unit, Capping unit

Pump motor Pump unit, Capping unit, Wiper, ASF unit

When the PF Motor rotates clockwise, the torque is us ed to drive PF Roller assembly and release CR

Lock Lever, while the torque is used to set the CR Lock Lever when the PF Motor rotates

counterclockwise.

The CR motor transmit the torque via Timing Belt to shift the CR unit in the both right and lef t direc tions in

parallel with the Platen. The torque from the Pump Motor, switched by the disengage mechanism, is

transmitted to the ASF and the Pump m otor. The figure below shows the structure bloc k of the printer

mechanism .

CR Motor

Pump Motor

PF Motor

Carriage Mechanism

Slider Mechanism

Disengage Mechanism

Figure 2-1. Printer Mechanism Block Diagram

Print Mechanism

Black

Pump Mechanism

ASF Mechanism

Paper Feed Mechanism

CR Lock Mechanism

Color

Rev. A

2-1

Page 3

EPSON Stylus

2

&2/25

800

2.2.2 Printing Mechanism

The printing method used for this printer is O n-demand ink jet s ystem, same as for other EPSON ink jet

printers. This printer, however, uses newly designed MACH Head, which ensures a high level of printing

quality at a higher speed. This printer is equipped with separate printheads of the same type; one for black

and one for each of the three colors (magenta, cyan, and yellow). Quick penetration, the type of black and

color ink, is also im proved for this pr inter, which enables the users to have the printing im age in the high

quality on the normal paper.

Printhead

The black and color printheads for this printer use the newly designed MACH Head (E-CHIPS Head).

The structure of the printhead is the same as for previous CHIPS Head except for the nozzle

configuration. The Black Head for this printer has 128 nozzles (32 nozzles for each of 4 rows ) which

is as twice as many as previous EPSON ink jet printers , and the Color Head has 192 nozzles (32

nozzles for each of 6 rows) which is 3 times as many as previous EPSON ink jet printer s. Theref ore

printing quality as well as the speed for this printer is higher than ever. The nozzle structure for this

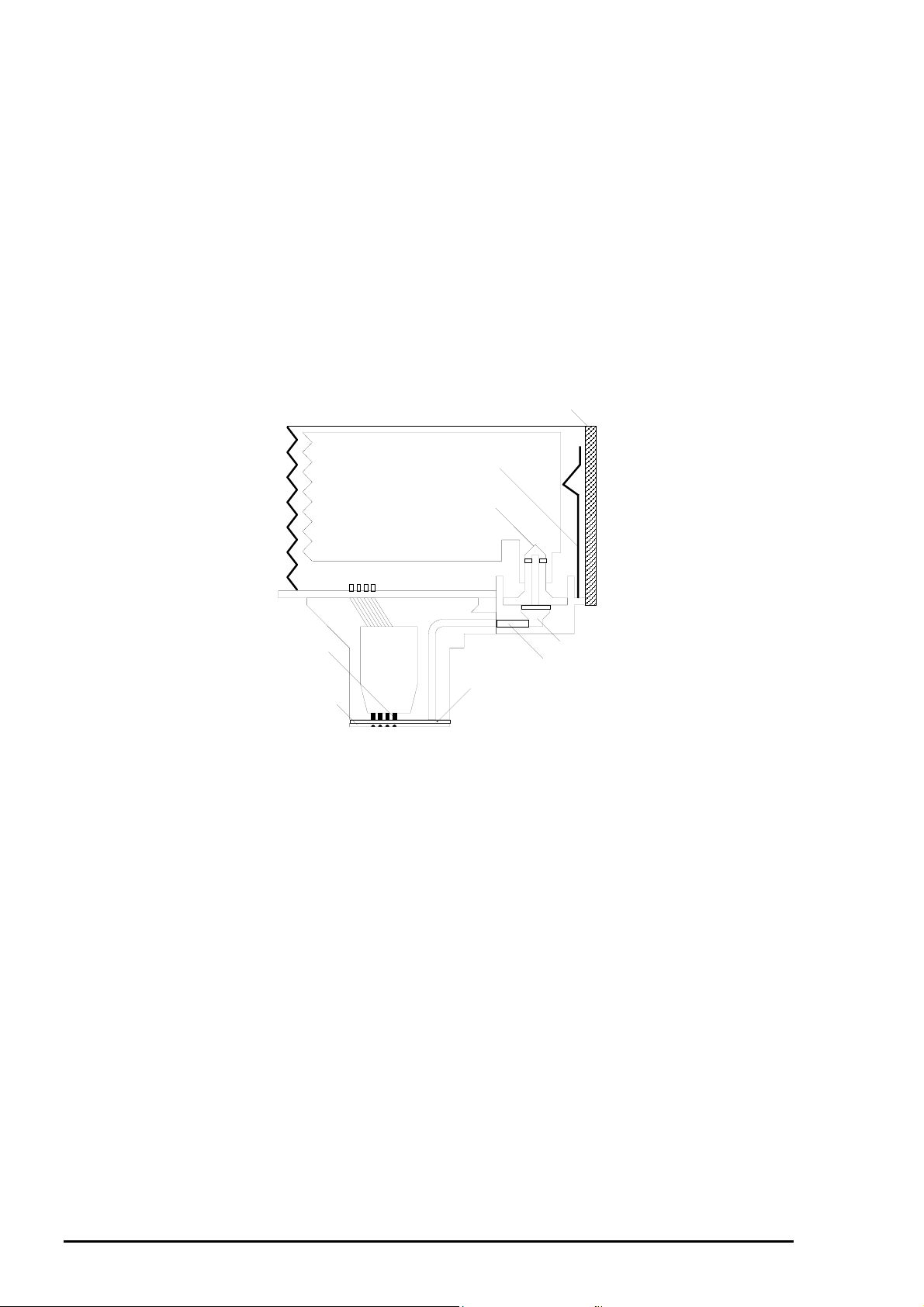

printhead is shown in the figure below.

Printhead Driver Board

Ink Cartridge Sensor Lever

Cartridge Needle

(Ink Cartridge)

PZT

Cavity

Nozzle Plate

Filter

Ink Tube

Figure 2-2. Printhead Structure

PZT

PZT is an abbreviation of the Piezo Electric Element. Print signal from C202 MAIN board is sent

through the driver board on the Printhead unit and to the PZT. Then, the PZT pushes the top cavity

which has ink stored, and makes the ink discharge from each nozzle located on the nozzle plate.

Cavity Set

Ink which is absorbed from ink cartridge goes through the filter and will be stored temporarily in

this tank, which is called “cavity” unit driven by PZT.

Nozzle Plate

The board with nozzle holes on the Printhead surface is called Nozzle Plate.

Filter

When the ink cartridge is installed, if any dirt or dust around the cartridge needles are absorbed

into the head inside, there is a great possibility of causing nozzle clog and disturbance of ink flow

and finally causing alignment failure and dot-missing. In order to prevent this, filter is set at

cartridge needle below and ink is once filtered here.

2-

Rev. A

Page 4

Operating Principles

3

2.2.2.1 Printing Process

Steps bellow describes how the on-demand ink jet system ejects the ink from each nozzle in the

printhead.

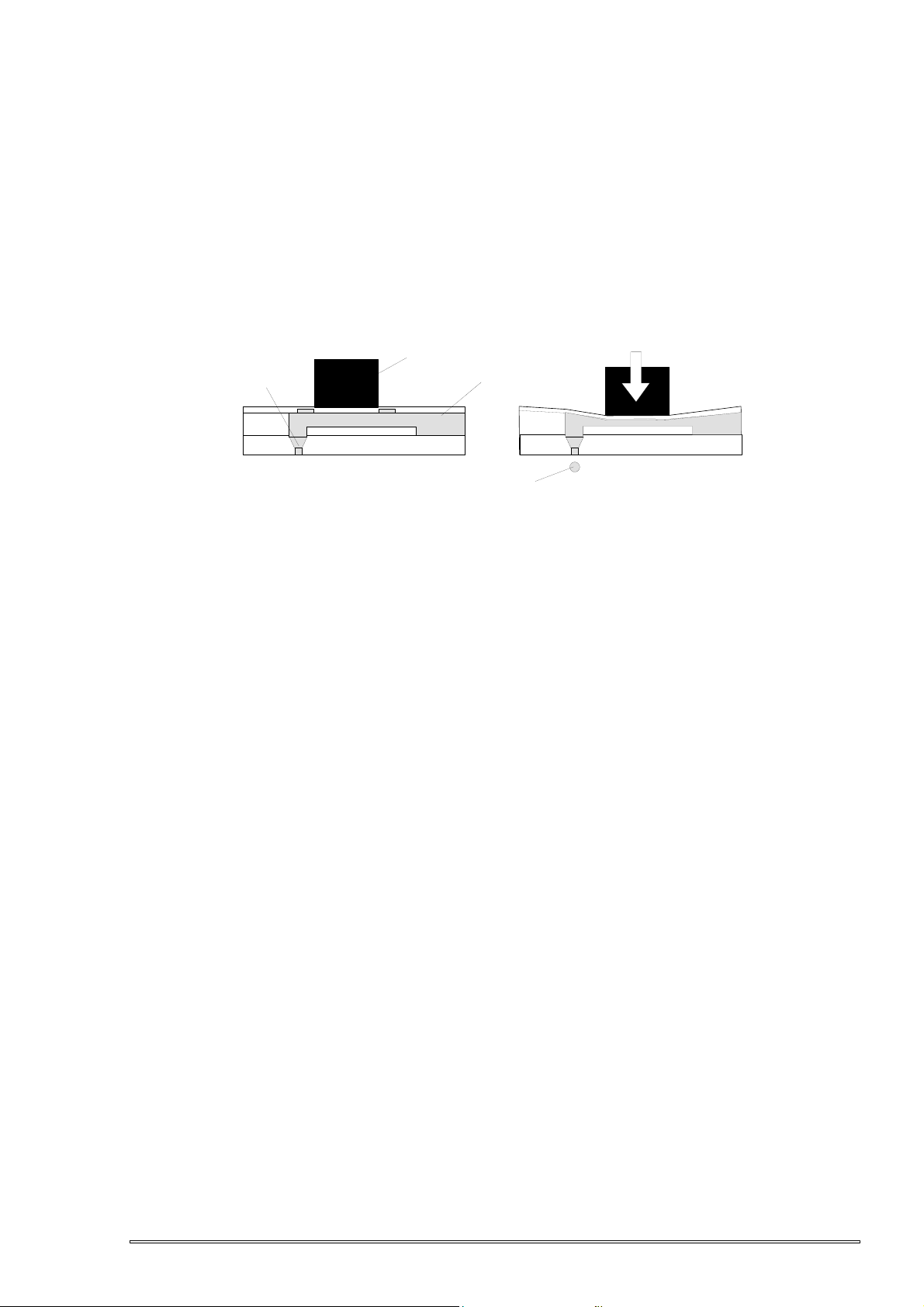

<

Step 1>Normal state

When the print signal is not output, PZT also dose not move in the waiting state (normal state).

<

Step 2>Ejecting state

When the print signal is output from the C202 MAIN board, Nozzle selector IC mounted on the head driver

board latches the data once by 1-byte unit. Appropriate PZT latched by nozzle selector is pushed in to the

cavity by applying common voltage from the C202 MAIN board. By this operation, ink that is stored in the

cavity pops out from nozzles.

Nozzle

Normal State

Piezo

Cavity

Ejected ink

Ejecting State

Figure 2-3. Print Process

During the ink charging or cleaning operation, the ink left in the cavity is vacuumed out by the Pump

mechanism via Capping unit, then is ejected to the waste ink tank . The cavity is refilled with ink from the

Ink Cartridge during the printing or other operations. The viscosity of the ink tends to change according to

the temperatures around the heads, and the change in vis cosity results in the low printing quality. This is,

however, avoided by attaching the thermistor directly to the driver circuit board. It is used to determ ine the

proper drive pulse automatically according to the detected temperature.

2.2.2.2 Printing Methods

This printer has 3 kinds of diff erent dot to com pos e the print im age; Norm al dot, Double f iring Norm al dot,

and Micro dot. Each dot is selected to control printing depending on the conditions s uch as the paper type

and the print resolution set through the printer driver.

Normal dot / Double Firing Normal dot printing mode

Normal dot/Double firing Normal dot printing modes are available for the both black and color

printings. Normal dot printing mode is designed to form single dot with 2 head drive pulses. With this

mode, the dot diameter is expanded to solve the white banding problem which occurs during solid

printing at 360 dpi. This printer is, however, designed to use less ink than other printers do to perform

printing at 1440 dpi, the maximum solution on the horizontal line. Therefore the Double firing Normal

dot and Normal dot used for this printer is considered equivalent to the Normal dot mode and Micro

dot mode used for previous ink jet printers respectively. Double firing Normal dot mode is normally

selected for printing at 360 dpi, and the Normal dot mode is used for printing in 720 X 360 dpi or 720

dpi X 720 dpi, depending on the paper type.

EPSON Micro dot printing

Both black and color printings can be performed in the Micro dot printing mode. In the Normal dot

printing, one dot is formed with 2 pulses. On the other hand, EPSON micro dot printing mode forms

one dot with single pulse using less ink. As mentioned above, the Micro dot printing for this printer is

controlled to use less ink to create images at 1440 dpi, the maximum solution on the horizontal line.

This mode is used for printing at 720 dpi or 1440 dpi by controlling the firing duty of the ink.

Micro Weave Printing

This function is developed to enhance quality in graphic image by eliminating white banding which

occurs on each line. This printer is equipped with a new micro weave printing mode and is controlled

to form a horizontal line using 2 different types of nozzle. With this mode, the printer can prevents

color inks from mixing with each other before drying and can provide clearer colors in the output. The

Micro Weave printing can be selected through the printer driver.

Rev. A

2-

Page 5

EPSON Stylus

4

&2/25

800

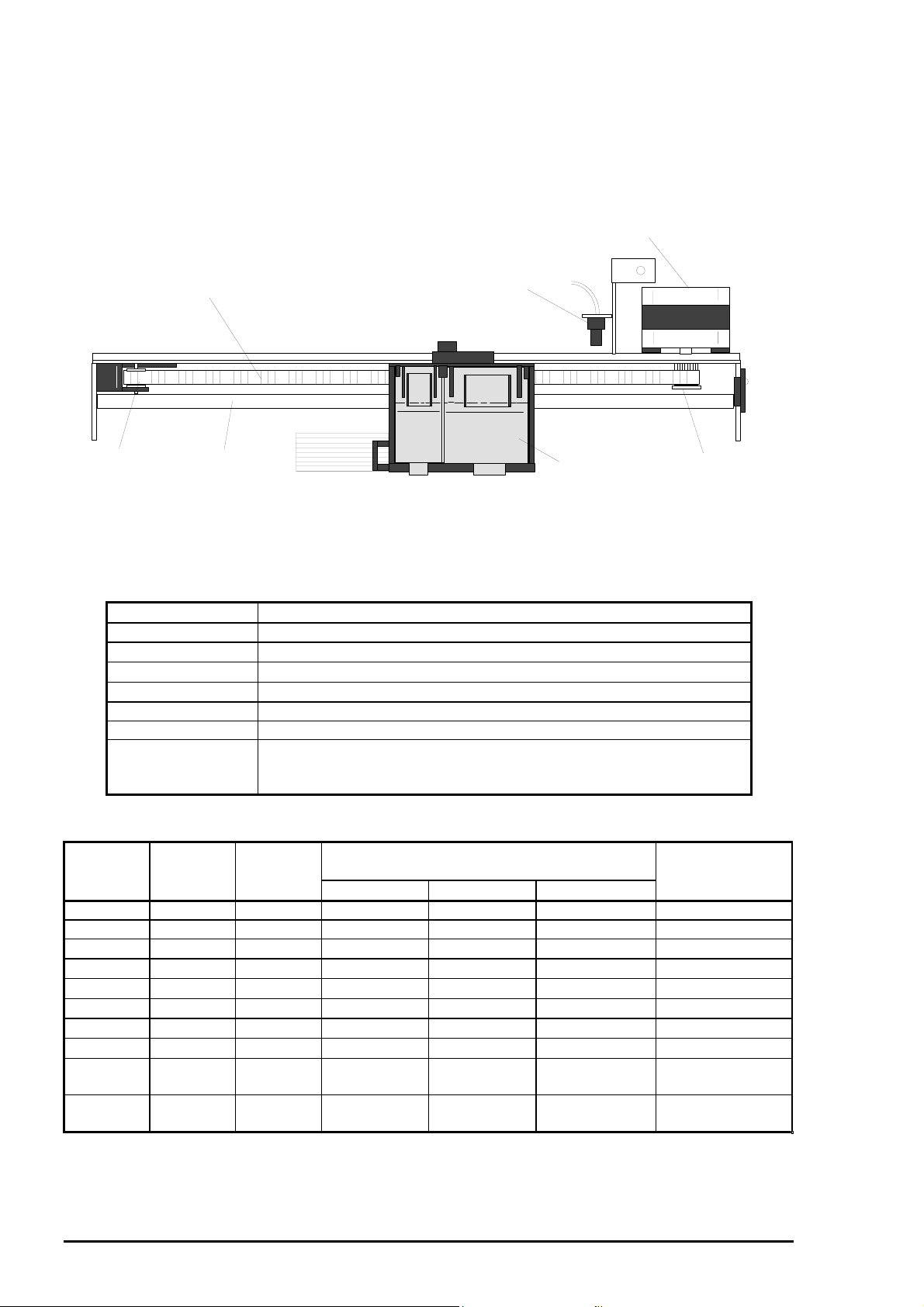

2.2.3 Carriage (CR) Mechanism

The CR mechanism is composed of the CR motor, Timing Belt, CR Guide Shaft, Top Frame, and Home

Position (HP) sensor. The torque from the CR motor is transmitted to the CR unit via the Timing Belt to

move the CR unit along the CR Guide Shaft both right and left, depending on the direction in which the CR

motor rotates. W hen the CR unit returns to the HP position, it is detected by the HP sensor mounted on

the right end of the Top Frame, and the information is fed back to the IC2 gate array (E05B33CB). Figure

2-4 illustrates the CR mechanism conception.

The CR motor, which drives the CR mechanism, is a 4-phases/200-pole/HB type stepping motor and is

CR Motor

HP Sensor

CR Unit

CR Motor Pinion Gear

Sub Pulley

Timing Belt

CR Guide Shaft

Figure 2-4. Carriage Mechanism

controlled by the constant current bipolar control system. The current control signal for eac h phase and

phase control signal output from the IC2 gate array E05B33CB are converted into the CR m otor control

signal by the IC13 bipolar driver UDN2917EB to control the CR motor. Refer to Table 2-2 and Table 2-3

which show the CR specification and the drive frequency.

Table 2-2. CR Motor Specification

Item Description

Motor type 4-phases / 200-pole / HB type stepping motor

Drive voltage

Coil resistance

Inductance

42 VDC ± 5%

7.8 Ω ± 10% (at 25° C per 1 phase)

14 mH ± 20% (1 KHz, 1 Vrms)

Drive frequency 240 ~ 4080 Hz

Excitation mode Bipolar drive

Minimum step 1/120 inch / pulse (2-2 phase drive), 1/240 inch / pulse (1-2 phase

drive)

1-480 inch / pulse (W1-2 phase drive)

Table 2-3. CR Motor Drive Terms

Mode CR speed

(CPS)

Drive

frequency

Drive system and acceleration/deceleration

step

Acceleration/

De celeration

(Hz) A*2:1, D*3:2 A:2, D:2 Constant pulse*

Fast skip 340 4080 64 (W1-2) 164 (2-2) (2-2) 180

DRAFT 266.7 3200 88 (W1-2) 86 (2-2) (2-2) 108

LQ 200 2400 432 (W1-2)

TEXT LQ 200 2400 240 (W1-2)

SLQ 100 1200 432 (W1-2)

Capping 90 1080 64 (W1-2)

wiping 2 80 960 64 (W1-2)

Wiping 40 480 16 (W1-2)

Capping

20 240 8 (W1-2)

(W1-2) 108

(W1-2) 60

(W1-2) 108

(W1-2) 16

(W1-2) 16

(W1-2) 4

(W1-2) 2

(open)

Constant

20 240

(W1-2)

value

Note) *1: Step : reduced to 2-2 phase

*2: Acceleration

*3: Deceleration

2-

1

Rev. A

Page 6

Operating Principles

5

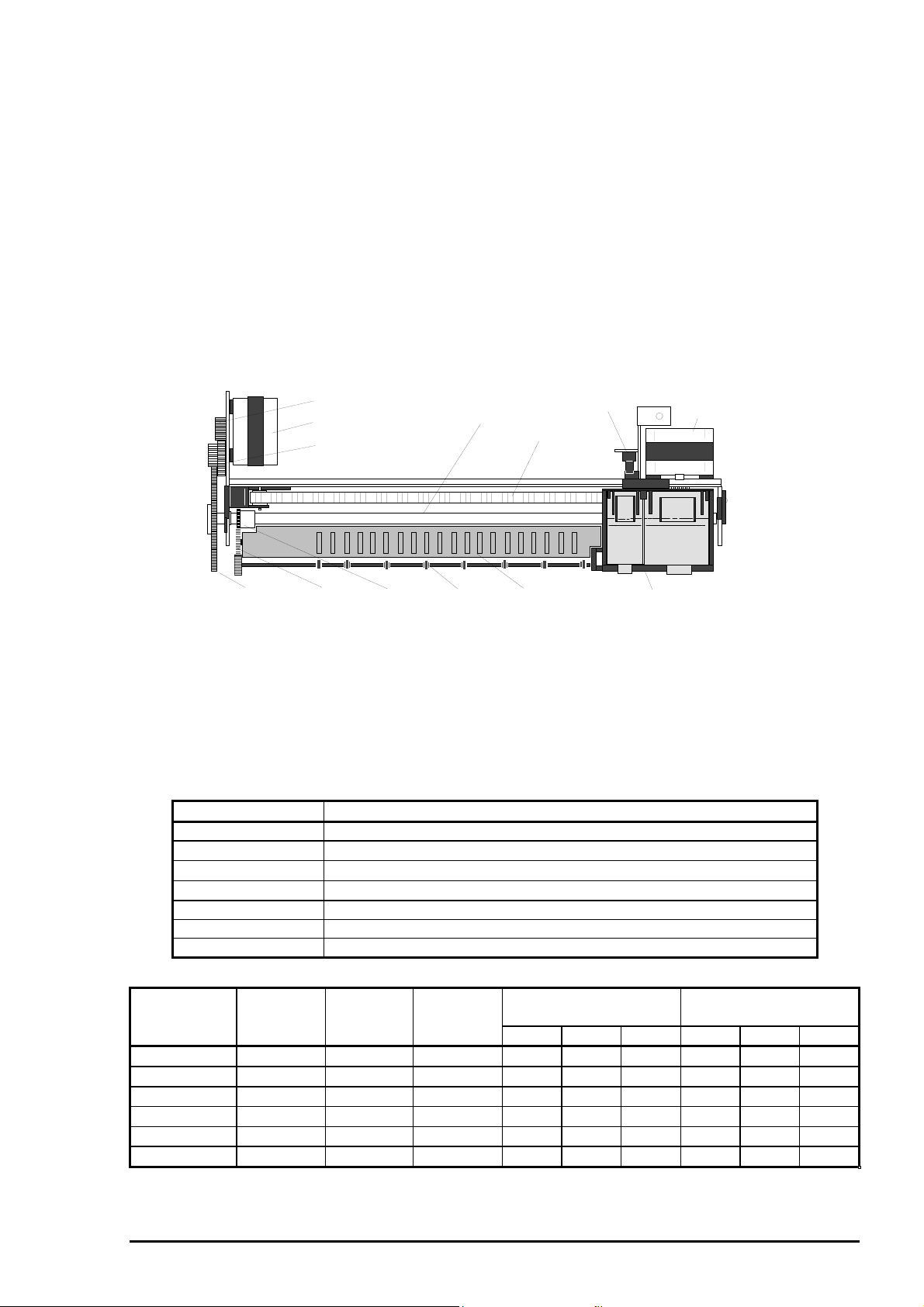

2.2.4 Paper Feed Mechanism

This printer is equipped with the PF motor which is used to feed paper only to improve f eeding s peed. The

drive from the Pump motor is used to load paper at the ASF and the drive from the PF roller is

independently used to feed paper only. The paper f eed mec hanism is classif ied to 2 parts; the paper f eed

part having the PF roller for the main assembly, and the paper eject part having the Paper eject roller for

the main assembly. The PF roller is coated with the powdery material, which is used to improve the paper

feed accuracy. The PF motor located at the rear left part of the printer mechanism tr ansmits the torque via

the Combination gear (14, 31.5) and Gear (70) to the PF roller assembly to feed paper loaded.

The torque is then transm itted from the Gear (17) on the Paper feed roller assem bly to the Paper eject

roller via the Gear (19) to eject paper. The torque is transmitted in the following order:

Paper feed part

1) PF motor pinion gear → 2) Combination gear 14, 31.5 → 3) Gear 70 → 4) PF roller assembly

Paper Eject part

1) PF motor pinion gear → 2) Combination gear 14, 31.5 → 3) Gear 70 → 4) Gear 17 (PF roller

assembly) → 5) Gear 19 (Front paper guide assembly ) → 6) Paper eject roller assembly (Front paper

eject assembly)

Gear 70

PF Motor Pinion Gear

PF Motor

Combination Gears 14, 31.5

Gear 19

Gear 17

Paper Eject

Roller

PF Roller Assembly

Paper Guide Assembly

(Front)

HP Sensor

Timing Belt

CR Motor

CR Unit

Figure 2-5. Paper Feed Mechanism

This printer uses a 4-phases/96-pole/HB type pulse motor which is controlled by the bipolar constant

voltage system for the PF motor. The current control signal for each phase and phase control signal

output from the IC2 gate array E05B33CB are converted into the PF motor control signal by the IC16

bipolar driver UDN2917EB to control the PF motor. Since the power switch of this printer is wired to the

secondary circuitry, the voltage remains the constant level until the loaded paper is ejected after the printer

power is turned off. Table 2-4 and Table 2-5 show the PF motor specification and PF motor drive

frequency, respectively.

Table 2-4. PF Motor Specification

Item Description

Motor type 4-phases / 96-pole / HB type pulse motor

Drive voltage

Coil resistance

Inductance

42 VDC ± 5% (The voltage applied to the driver)

7.8 Ω ± 10% (at 25° C per 1 phase)

14 mH ± 20% (1 KHz, 1 Vrms)

Drive frequency 400 ~ 4320 Hz

Excitation mode Bipolar drive

Minimum step 1/120 inch / pulse (2-2 phase drive)

Table 2-5. PF Motor Drive Terms

Mode

Feeding

speed-

Drive

Frequency

Pulse

interval-

Acceleration step

for each phase

Deceleration step

for each phase

(inch/s) (Hz) (us) W1-2 2-2 1-2 W1-2 2-2 1-2

Normal feed 5 3600 278

Fast feed 6 4320 231

Slow feed 2.5 1800 556

At loading 3 22160 463

Micro adjust 1 1.25 900 1111 2

Micro adjust 2 0.55 400 2500

50

60

20

30

2

50

60

20

30

Note) Drive frequency and pulse interval are reduced to 2-2 phase.

Rev. A

2-

Page 7

EPSON Stylus

6

&2/25

800

2.2.5 Platen Gap (PG) Adjust Mechanism

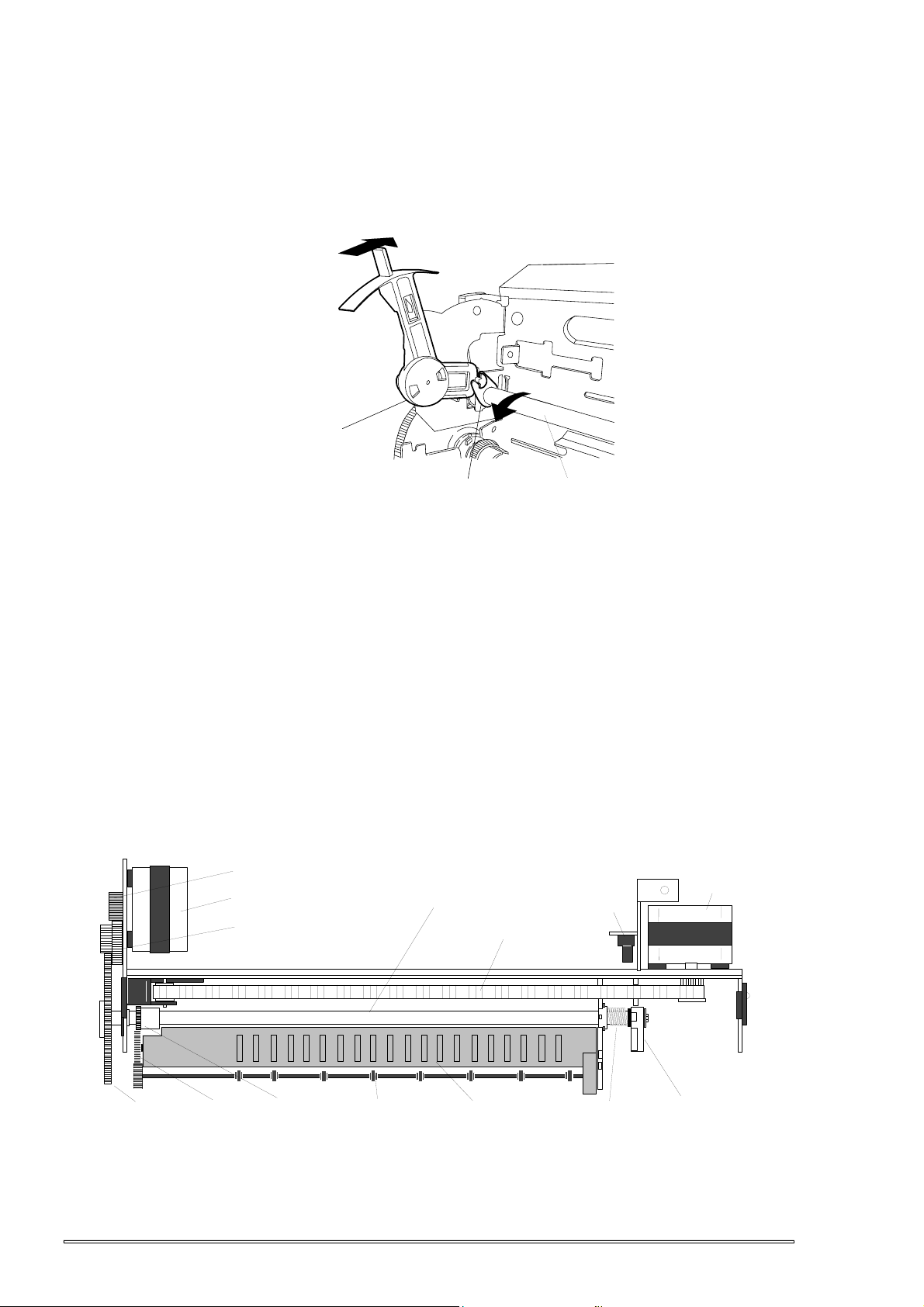

The PG adjust mec hanism, located at the lef t of the printer m echanism , consists of the PG lever, PF sub

lever, right/left parallelism adjust bushings, and CR guide shaft. PG adjust mechanism is equipped to keep

the proper platen gap according to the paper thickness to prevent ink from having friction. The PG lever

joins to the CR guide shaft which has an eccentr icity via PG sub lever, and switching the lever from “0” to

“+” rotates the CR shaft and the platen gap changes from narrow to wide. Figure 2-6 show the PG adjus t

mechanism .

PG Lever Position +

PG Lever Position 0

PG Lever

PG Sub Lever

CR Guide Shaft

Figure 2-6. PG Adjust Mechanism

2.2.6 CR Lock Mechanism

The CR lock lever, locate at the right side of the printer mechanis m, is composed of the PF motor, PF

roller assembly, Stopper lever (CR lock lever) and so on. When there is no paper loaded and no data

stored, CR lock m echanism fixes the CR unit to the c apping position. This operation is accom plished by

rotating the PF motor clock wise with the specified steps to set the stopper lever at the r ight end of the PF

roller to the left of the CR unit. The stopper lever is then r elease fr om the set position when the PF m otor

rotates counterclockwise with the specified steps. The drive from the PF motor is transmitted in the

following order;

1) PF motor pinion gear 2) Combination gear 14, 31.5 3) Gear 70

4) PF roller assembly 5) Stopper lever

The figure below shows the CR lock mechanism.

PF Motor Pinion Gear

PF Motor

Combination Gears

14, 31.5

PF Roller Assembly

Timing Belt

HP Sensor

CR Motor

Gear 70

Gear 19

Gear 17

Paper Eject

Roller

Paper Guide

(Front)

Compression Spring

5.85

Stopper Lever

Figure 2-7. CR Lock Mechanism

2-

Rev. A

Page 8

Operating Principles

7

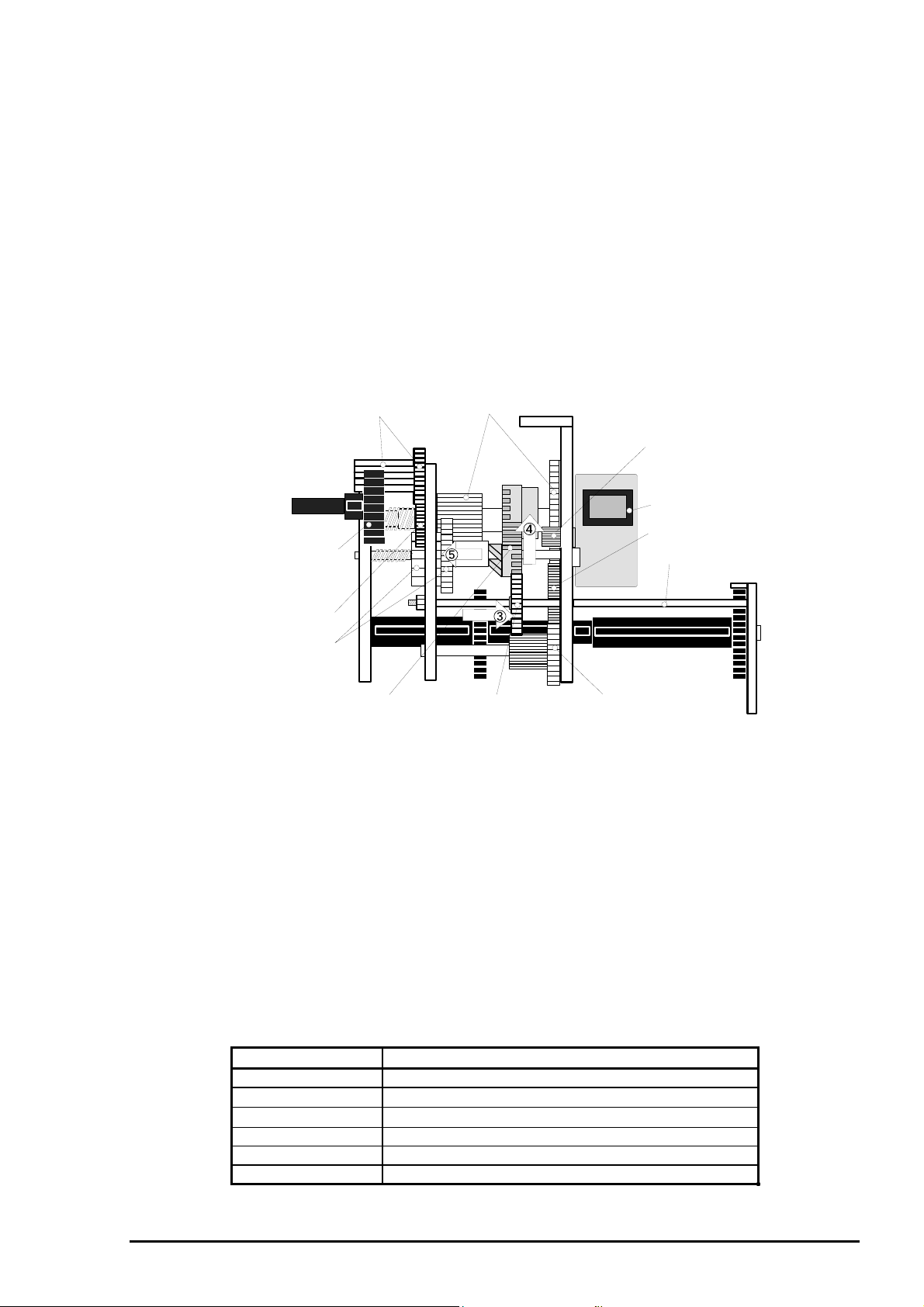

2.2.7 ASF Mechanism

ASF mechanism, which consists of the Pum p motor, slider mechanism , disengage mechanism , and ASF

unit, loads paper into the paper feed mechanism. When the CR unit returns to the home position, it

pushes the slider in the slider m echanism to the right and the Gear (16) in the slider m echanism then

comes to engage with the Change cam in the dis engage mechanism. W ith this m otion, the Pump m otor

rotates with the specified steps in the counter c lock wise, which switches the Change c am to the ASF unit

side, then the torque from the Pum p motor is transmitted to the ASF unit. The pr ocess in which the drive

from the pump unit is switched to the ASF unit side is described below. Figure 2-8 illustrates the process

for the switching operation.

Disengage mechanism switch process

1) CR shifts to the home position.

2) Slider shifts to the right end. (Slider mechanism)

3) The Gear (16) is engaged to the Change cam in the disengage mechanism. (Slider mechanism)

4) The Change Cam is switched to the ASF side. (Disengage mechanism)

5) The Combination Gear (14.4, 21.6) shifts to the left.

The figure below shows movement of above mentioned process 3) to 5).

Combination Gear

12, 20.8

Combination Gears

12, 26

Pump Motor

Pinion Gear

Pump Motor

Gear 11.5

Gear 27.2

Gear 16.8

Combination Gears

14.4, 21.6

Cam

Gear 16

(Slider Mechanism)

Combination Gears

12, 15

Slider Shaft

Figure 2-8. ASF Mechanism

Transmission process of the Pump motor’s torque

1) Pump motor pinion gear2) Combination gear 12, 26 3) Combination gear 14.4, 21.6

4) Gear 16.8 5) Combination gear 12, 20.8 6) Gear 27.2 (ASF unit)

7) LD roller shaft (ASF unit)

Note) This order has no relevance to the order in the figure above.

The ASF home position is sensed by the detection wheel attached to the right end of the LD roller shaft

and ASF HP sensor, and the detected condition is fed back to the IC2 E05B33CB. The ASF motor is

controlled based on the home position which is detected by the ASF HP sensor. A 4-phase/48 -pole PM

type pulse motor is used for the pump motor which is controlled by the constant current bipolar drive. T he

current control signal for each phase and phase control signal output from the IC2 gate array E05B33CB

are converted into the pump motor control s ignal by the IC6 bipolar driver UDN2917EB to control the PF

motor. Table 2-6 and Table 2-7 show the pump motor specification and pump motor drive frequency,

respectively.

Table 2-6. Pump Motor Specification

Item Description

Motor type 4-phases / 48-pole / PM type pulse motor

Drive voltage

Coil resistance

42 VDC ± 5% (The voltage applied to the driver)

9.3 Ω ± 10% (at 25° C per 1 phase)

Drive frequency 272 ~ 654 Hz

Excitation mode Bipolar drive

Minimum step 1/218 inch / pulse (2-2 phase drive)

Rev. A

2-

Page 9

EPSON Stylus

8

&2/25

800

Table 2-7. Pump Motor Drive Terms

Mode Frequency Pulse Feeding Acceleration step Deceleration step

interval speed W1-phase 1-2 phase W1-phase 1-2 phase

Paper back feed 436 2294 2 inch/S 5

5

ASF multiple feeding prevention mechanism

The paper loading assembly in the ASF is composed of the D-cut paper loading roller, C-cut cam,

paper feed back lever, and pinch roller. The C-cut cam and the D-cut roller have synchronous

movement staying on the same shaft. When they rotate counter clock wise (viewed from the right), the

paper feed back lever, moving in accordance with the notch portion of the C-cut cam, pushes the

dislocated paper back up to the standby position. Dislocation means the situation in which multiple

paper including the paper to be loaded at the next rotation slip off the standby position and fall into the

paper path.

D-Shape Paper

Loading Roller

Paper Feed Back Lever

C-Cut Cam

Pintch Roller

Hopper

Hopper Spring

Pad Spring

Figure 2-9. ASF multiple feeding prevention mechanism

ASF multiple feeding prevention mechanism operating principles

[Step1] : When the Load/ Eject switch is pressed or printing order is input from the PC, PF

motor rotates counterclockwise and makes the C-cut Cam rotates in the same

direction.

[Step2] : The Paper feed back lever clutched to the C-cut cam rises with the counter clock wise

rotation to catch the slipped paper. Along with this motion, the pad is pushed

backward and the Pinch roller and the D-cut paper loading roller become to no

friction condition.

[Step3] : When the dislocated paper is pushed back up to the standby position by the Paper

feed back lever, the counter wise rotation of the Pump motor releases the Release

hopper lever and the C-cut paper feed roller begins to load the paper.

[Step4] : When the ASF finishes to feed the paper to the specified position, the flat part of the

C-cut paper loading roller turns around to the paper path side, where the C-cut paper

loading roller loses contact with the paper and the Pinch roller supports the paper

instead. The paper Pinch roller continues to support the paper until the paper is

completely ejected from the ASF with the rotation of the PF roller. The Paper feed

back lever ,during this movement, is in the stand by position, as illustrated in the

above left figure.

2-

Rev. A

Page 10

Operating Principles

9

2.2.8 Ink System

The ink system for this printer is composed of the following and performs absorbing and ejecting ink,

cleaning the printhead surface, and capping the printheads.

Ink cartridge

Pump mechanism

Wiping mechanism

Capping mechanism

Waste ink drain pads

This section describes the operational principles of the pump mechanism and capping mechanism.

The figure below shows the structure of the ink system.

Pump

Motor

Combination Gear

12, 26

Combination Gear

14.4, 21.8

Cleaner Head

Black Ink Cartridge

Capping Mechanism

Color Ink Cartridge

Air Valve

Wiping Mechanism

Pump 1

Clutch

Pump Mechanism

Waste Ink Drain Pads

Pump Drive

Shaft

Gear 21.6

Pump 2

Pump Reduction

Shaft

Figure 2-10. Ink System

Rev. A

2-

Page 11

EPSON Stylus

0

&2/25

800

2.2.8.1 Pump Mechanism

The functions of the Pump m echanism, which is composed of the Pump motor, Slider mechanism, and

Disengage mechanism , are Absorbing black /color ink f rom the capping unit, f alse absorption, and setting

and resetting of the wiper. When the CR returns to the CR hom e pos ition, it pushes the s lider in the Slider

mechanism to the right end. That movement engages the Gear 16 in the slider mechanism with the

Change Cam in the Disengage mechanism. Then the Change Cam switches to the Pump mechanism

side when the Pump motor rotates c lock wise with the specified steps, and the drive from the Pump motor

is transmitted to the Pump mechanism. The torque is transmitted to the Pump side via the Disengage

mechanism in the following order:

1. Disengage mechanism switch process

2. CR shifts to the home position.

3. Slider shifts the right end. (Slider mechanism)

4. The Gear 16 is engaged to the Change Cam. (Slider mechanism)

5. The Change Cam switches to the pump side. (Disengage mechanism)

6. The Combination Gear 14.4, 21.6 shifts to the right. (Disengage mechanism)

The following figure shows how the gears are engaged.

Combination Gears

12, 20.8

Gear 27.2

Gear 16.8

Combination Gears

14.4, 21.6

Cam

Gear 16

(Slider Mechanism)

Combination Gears

12, 26

Pump Motor Pinion Gear

Pump Motor

Gear 11.5

Slider Shaft

Pump Drive Shaft

Combination Gears

12, 15

Pump Reduction Gear

Gear 21.6

Pump Unit

Figure 2-11. Pump Mechanism

Transmission process of the Pump motor’s torque

1) Pump motor pinion gear 2) Combination gear 12, 26 3) Combination gear 14.4, 21.6

4) Pump drive shaft 5) Gear 21.6 6) Pump reduction shaft

7) Pump unit

Note) This order is irrelevant to the order indicated with arrows in the figure above.

2-1

Rev. A

Page 12

Operating Principles

The pump unit switches its function depending on the direction in which the pump motor rotates, as show

in Table 2-8;

Table 2-8. Pump Motor Rotation and Function

Motor rotation direction Function

Clock wise direction

(Forward)

Counter clock wise direction

(Reverse)

Color ink absorption, Color ink false absorption,

Color ink Micro absorbing, Resetting the wiper

Black ink absorption, Black ink false absorption,

Black ink Micro absorbing, Setting the wiper

Note) The directions for the rotation are described when the motor is viewed from the pinion gear

side.

Pump Motor

(Clock Wise Direction)

Color Capping

Black Capping

Color Pump Side

Color Ink Absorbed

Color Capping

Color Pump Side

No Color Ink Absorbed

Waste Ink

Drain Pads

Waste Ink

Drain Pads

Black Pump Side Black Pump Side

No Black Ink Absorbed

Pump Motor

(Counter Clock Wise Direction)

Black Capping

Black Pump Side

Black Ink Absorbed

Wiper

Wiper Reset

Black Pump Side

Wiper Set

Figure 2-12. Pump Mechanism

The pump motor for this printer also drives the ASF m echanism. See Table 2-6 for its specification. The

drive terms for the pump motor in the pump mode is as shown in Table 2-9.

Table 2-9. Pump Motor Drive Terms in the Pump Mode

Absorption Mode Frequency Pulse

interval

W1-2

phase

High speed 1350 741

Normal speed 675 1481

Low speed 281 3559 0

At disengage 141 7092 0

Rev. A

Acceleration step Deceleration step

2-2

phase

30

1-2

phase

W1-2

phase

18

0

0

2-2

phase

30

1-2

phase

18

2-11

Page 13

EPSON Stylus

2

&2/25

800

2.2.8.2 Capping Mechanism

The capping mechanism caps the printheads with the cap holder to prevent the ink around the nozzles

from increasing viscosity while the printer is in stand-by status or the printer power is off. Is has 2 separ ate

holders; one for the color inks and the other for the black ink. W hen the CR shif ts fr om the hom e position

to the right end of the CR (Motion 1 in Figure 2-13), they move up into the c apping position (Motion 2 in

Figure 2-13) to cap the printheads. Moreover, by shifting the CR unit to the right end of the CR shaft, the

air valve is shut out completely (Motion 3 in Figure 2-13).

The air valve is released and shut to alternate the f alse absorption m ode and absorption m ode. (Ref er to

Section 2.4 for the details.) Since this printer has the Power supply board on the secondary electrical

circuit, capping operation is com pletely carried out with the constant voltage if the printer power is turned

off during the capping operation. The figure below shows the Capping mechanism.

To the Drain Pads

Black Ink Cartridge

Cap 1

Figure 2-13. Capping Mechanism

2

Cap 2

Color Ink Cartridge

2

2

1

3

Air Valve

Air Tubes

2-1

Rev. A

Page 14

Operating Principles

3

2.3 Electrical Circuit Operation Principles

This printer consists of the following circuit boards:

C202 MAIN board

C202 PSB/PSE board

C202 Panel board

In addition to the circuit boards above, the printhead driver circ uit is directly attached to each of the black

and color heads in the CR unit. This section describes the operational principle of the C202 PSB/PSE

board and C202 MAIN board. Table 2-10 shows the input voltages and applications.

Printer Mechanism

CR Motor

PF Motor

Pump Motor

Color Head

Driver Circuit

Sensors

Black Head

Driver Circuit

C202 PSB/PSE Board

+42 VDC

+5 VDC

C202 PNL Board

C202 MAIN Control Board

Figure 2-14. Electrical Circuit Block Diagram

2.3.1 C202 PSB/PSE board

The electrical circuit of this printer uses RCC (Riging Choke Converter) which outputs 2 different types of

the VDC necessary to operate the printer.

Table 2-10. DC Voltage Distribution

VDC Application

+42 V Motors

Printhead common voltage

+5 V C202 MAIN control board (logic)

C202 panel board

Sensors

(HP sensor, ASF HP sensor , PE sensor)

The power switch of this printer is in the secondary circuit that allows the PSB/PSE board to continue to

supply voltage for the power and logic lines for a minimum of 20 sec onds until the printhead r eturns to the

capping position even if the printer is turned off during printing. This extra tim e prevents ink leak age and

dried printhead caused by the printhead being left uncapped. The AC voltage from the AC inlet is first

input to the filter circuit for higher harmonics absorption and is then input to the rectification and smoothing

circuit, converting into DC voltage. This DC voltage is then input to the switching circuit. Along with this

switching operation by FET on the primary side, +42 voltage is generated and stabilized on the sec ondary

side, which is then converted into the stable +5 VDC by the chopping regulator IC.

Figure 2-15 shows the block diagram of the electrical circuit.

Rev. A

2-1

Page 15

EPSON Stylus

4

&2/25

800

Primary Circuit Secondary Circuit

Full Wave

Rectifier Circuit

Filter Circuit

AC Input

Smoothing

Circuit

Switching

Circuit

Photo

Coupler

Photo

Coupler

Smoothing

Circuit

+5V Switching Regulator

+5V Constant Voltage Control Circuit

+5V Over Current Protection Circuit

+42V Constant Current

Control Circuit

+5V Over Voltage

Protecion Circuit

+42V Over Voltage

Protection Circuit

+42V Over Current

Protection Circuit

Power Off Delay Circuit

+42V

+5V

Power Switch

Figure 2-15. VDC Circuit Block Diagram

The operating principles of various protection circuit and controller c irc uit in the f igure above ar e desc r ibed

below.

+5 VDC line over voltage protection circuit

The output voltage level of +5 V is monitored by a Zener diode (AD53) on the secondary circuit. If the

voltage level exceeds 9 V, the switching FET Q1 goes Off in the following order, and no induced

electromotive is generated and production of +5 VDC and +42 VDC stops as the result.

Zener diode (ZD53) detects voltage which exceeds +9 V at +5 V line.

Transistor Q81 goes On.

Photo coupler PC1 goes On.

FET Q31 goes On and the gate current for the switching FET Q1 is cut off.

Switching FET Q1 goes Off.

+5 VDC line constant voltage control circuit

Voltage at the +5 VDC line is monitored by the regulator IC51. Abnormal voltage at the +5 VDC line is

detected and the information is fed back to the +5 V conparator in the IC, then +5 VDC is controlled or

cut off.

+5 VDC line over voltage protection circuit

The output level of the +42 VDC line is monitored by the 2 Zener diodes ZD52 and ZD87. When the

output level of the +42 VDC line exceeds +48 V, the Switching FET Q1 goes Off in the following

sequence.

Zener diodes (ZD52, ZD87) detect the voltage over 48 V at the +42 V line.

Transistor Q81 goes On.

Photo coupler PC1 goes On.

FET Q31 goes On and the gate current for the switching FET Q1 is cut off.

Switching FET Q1 goes Off.

+42 VDC line constant voltage control circuit

Voltage at the +42 VDC line is monitored by the Zener diodes ZD51 and ZD81 to ZD86. When the

voltage at the +42 VDC line exceeds, the Switching FET Q1 is controlled in the following sequence.

Zener diodes (ZD52 and ZD81 to ZD86) detect the voltage over 38V at the +42 VDC line.

Transistor Q81 goes On.

Photo coupler PC1 goes On.

The transistors Q3 and Q2 go off and gate current for the switching FET Q1 is cut off.

Switching FET Q1 goes Off.

When the voltage level drops under +38 V, the photo coupler PC1 and transistors Q3 and

Q2 go Off and the swathing FET Q1 goes back On.

+42 VDC line overcurrent protection circuit

The output current is monitored by the transistors Q81 and Q82. When the output current is

abnormally low , the information is fed back to the primary circuit via the photo coupler PC1 to stop the

switching operation.

2-1

Rev. A

Page 16

Operating Principles

5

2.3.2 C202 MAIN Control Board

C202 MAIN control board consists of the following:

Logic circuits for PROM, DRAM, CPU, ASIC and EEPROM

Motor control and driver circuits for CR motor, PF motor, and pump motor

Head control/ driver circuit for the black and color heads

Other circuits for the I/F (Parallel I/F, Mac serial. Type B I/F), sensors, RTC timers, and reset

Figure 2-16 shows the circuit block diagram for the main control board.

C202 MAIN Control Board

C202 PNL Board

IC3

P-ROM (4M)

IC1

CPU

IC7

CG-ROM

(16M)

Ink Cartridge

(Black)

Black Ink

Driver Circuit

Ink Cartridge

(Color)

Color Head

Driver Circuit

IC5

DRAM (4M)

Common

Driver

Common

Driver

IC2

Gate Array

C202 PSB/PSE

Board

+42 V

+5 V

IC11

EEPROM

IC20

Timer IC

IC16

PF Motor

Driver

IC13

CR Motor

Driver

IC6

Pump Motor

Driver

IC15

Mac Serial I/F

Tranceiver IC

IC9

5V line

Reset IC

IC8

+42V line

Reset IC

Data Bus

CR Unit

Address Bus

HP

Sensor

PE

Sensor

Figure 2-16. C202 MAIN Board Block Diagram

Table 2-11 shows the allocated functions for the CPU and the gate array.

Table 2-11. Allocated Functions for the CPU and the Gate Array

IC Location Function

Sets the current value for each motor.

Outputs the driving trigger pulse for each motor.

Outputs the driving trigger pulse for each head

Outputs the system clock.

CPU IC1

Inputs the resistance value for the thermistor .

Inputs the On/Off signal of installation status for

each cartridge.

Transfers received data from I/F to DRAM

Controls interruption signals

Controls the motor drivers.

Controls printing data for each head.

Controls data from I/F and transfers it to the CPU.

Gate Array IC2

Outputs head driver control pulses.

Counts dot numbers used for printing.

Controls voltages for EEPROM, control panel,

timers, and heads.

HP

Sensor

IC12

Parallel I/F IC

Type B I/F

Rev. A

2-1

Page 17

EPSON Stylus

&2/25

800

2.3.2.1 Printhead Driver Circuit

The printhead driver circuits, which are separately built in for the blac k and color heads, consist of the

common drivers (black head:IC17, color head:IC18) on the C202 MAIN board and nozzle selec tors ( Black

head:IR2C72C, Color head: IR2C73C) on the head driver boards. Each common driver produces

trapezoidal pulses according to the signals sent fr om the IC2 gate array, and transfer them to the nozzle

selector on the head driver board. Printing data is converted into serial data at the gate ar ray and is then

transferred to the nozzle selector on the head driver board to select the nozzles to be activated. The PZT

common lines are selectively driven simultaneously based on the driver waveform produced at the

common driver to activate the nozzles selected by the printing data.

+42V

C202 MAIN Board

+5V

Black Printhead Driver Board

Gate Array

IC 2

E05B33CB

BCHG 68

BKC 61

BND1 67

BND2 66

BMD1 63

BMD2 62

SBDATA 75

SCLK 79

BHCLK 87

BHLAT 86

BBHDATA 89

BAHDATA 90

VHPR 82

CCHG 74

CKC 69

CND1 73

CND2 72

CMD1 71

CMD2 70

SCDATA 76

CHCLK 95

CHLAT 94

YHDATA 99

MHDATA 98

CHDATA 97

IC 17

HBD2813C

Common Driver

(Black Head)

IC 17

HBD2813C

Common Driver

(Color Head)

CN9

CN10

Common

Signal

Common

Signal

VDD

CCLK

CLAT

VH

CSI2

IR2C72C

Nozzle

Selector

VDD (+5V)

BCLK

BLAT

BSI2

BSI1

VH

IR2C72C

Nozzle

Selector

VDD (+5V)

CCLK

CLAT

CSI3

CSI1

VH

IR2C73C

Nozzle

Selector

Black Head

Drive Waveform

Color Head

Drive Waveform

Color Printhead Driver Board

Figure 2-17. Printhead Driver Circuit Block Diagram

Common driver circuit for the black head

The common driver IC17 HBD2813C produces trapezoidal waveforms by combining the 6 different

signals BCHG, BND1, BND2, BMD1, BMD2 and BKC output from the IC2 E05B33CB gate array using

VM voltage as the basis. There are 7 particular types of trapezoidal waveforms produced for the

normal dot mode, Micro dot mode and so on, and each form varies depending on the width of the

combined signals. The rising form is determined by the BCHG and BKC regardless of the printing

mode. The falling form is determined by the 2 different pairs of signals; BND1 and BND2 in the normal

dot mode, and by BMD1 and BMD2 in the micro dot mode. The VH voltage adjusting values stored in

the EEPROM, which is unique to each head and, is read into the gate array, and then transferred in 8bit serial data via CBDATA signal to be set in the common driver. With this procedure, the internal

resistance is determined and the driver waveform is adjusted as the result.

2-16

Head Drive Waveform

LAT

NCHG

BCHG

BND1

BND2

BMD1

BMD2

BKC

Figure 2-18. Waveform Producing Process for Black Nozzle

Rev. A

Page 18

Operating Principles

7

Black head nozzle selector circuit

The printing data is input from the data input ports D0 to D15 of the IC2 E05B33CB gate array to the

gate array to be converted into serial data and output to the nozzle selector from the BBHDATA and

BHADATA ports. The data is then separated to 2 sides through the port BBHDATA and BHADATA

which are allocated with 2 lines of black nozzles; the lines #1, #3 and #2, #4 respectively. The smallernumbered nozzle on each line receives data faster. Data is transferred from IC2 gate array to Nozzle

selector IC IR 2C72C at 64 bit / 2.5 MHz synchronizing with the BHCLK (Clock signal) and BHLAT

(latch signal). On/Off status of each nozzle in the nozzle selector is determined based on the data

transferred.

Common driver circuit for the color head

The circuit structure for the color head is basically the same as for the black head. The common driver

IC18 HBD2813C produces trapezoidal waveforms by combining the 6 different signals CCHG, CND1,

CND2, CMD1, CMD2 and CKC output from the IC2 E05B33CB gate array. There are 7 particular

types of trapezoidal waveforms produced for normal dot mode, Micro dot mode and so on, and each

form varies depending on the width of the combined signals. The rising form is determined by the

CCHG and CKC regardless of the printing mode. The falling form is determined by the 2 different pairs

of signals; CND1 and CND2 in the normal dot mode, and CMD1 and CMD2 in micro dot mode. The

VH voltage adjusting value stored in the EEPROM, which is unique to each head is read into the gate

array, and then transferred in 8-bit serial data via SBDATA signal to be set in the common driver. With

this procedure, the internal resistance is determined and the driver waveform is adjusted as the result.

Head Drive Waveform

LAT

NCHG

CCHG

CND1

CND2

CMD1

CMD2

CKC

Figure 2-19 Waveform Producing Process for Color Nozzles

Color head nozzle selector circuit

The printing data is input from the data input port D0 to D15 of the IC2 E05B33CB gate array to the

gate array to be converted into serial data, and output to the nozzle selector from the YHDATA,

MHDATA , and CHDATA ports according to the color. The data is then allocated to the corresponding

nozzle lines, alternating 2 lines; from #1 to #2. Data is transferred from IC2 gate array to Nozzle

selector IC IR 2C72C at 64 bit / 2.5 MHz synchronizing with the BHCLK (Clock signal) and CHLAT

(latch signal). On/Off status of each nozzle in the nozzle selector is determined based on the data

transferred.

Rev. A

2-1

Page 19

EPSON Stylus

8

&2/25

800

2.3.2.2 Reset Circuits

The C202 MAIN board contains two reset circuits; for logic line (+5 V) and power line (+42 V). The

voltages for +5 V and +42 V in each reset circuit are monitored to prevent printer m alfunction caused by

abnormal voltage levels. W hen an abnormal condition is detected, a reset signal is sent to the CPU to

reset the CPU and the gate array. The function of the reset circuit is described below.

Reset circuit for the +5 V line

The +5 V reset circuit monitors voltage level for the +5 V line at the port 3 VCC of IC9 PST592D, and

outputs a reset signal from the port 1 VOUT to the CPU gate array when it detects an abnormal

voltage level. The IC9 is energized under the conditions below.

When the printer is turned On, a reset signal is output for 100ms after the +5 V line voltage level

rises to 4.2 V.

During printing operation, when the 5 V line voltage level drops under 4.2 V, a reset signal is output.

The reset signal does not go off until 100 ms passed after the +5 V line voltage level recovers to 4.2

V, as described above.

Reset IC for +5V line

IC1

CPU

RES

IC9

81

VOUT 1

MRES 2

VCC 3

GND 4

+5V

R29 1K

27 MRES

23 RESET

+5V

IC2

Gate array

Figure 2-20. Reset Circuit for the +5 VDC line

Reset circuit for the +42 V line

The +42 V reset circuit monitors voltage level of 42 V at the port 3 VCC of IC8 M51955D, and feeds

back the information on the Power On/Off status to the CPU according to the detected voltage. When

the +42 V line drops under +33.2 V, IC8 detects the Power Off status and outputs an reset signal from

the port 6 to the CPU port 82 NMI via OR circuit of the IC19. When the voltage level recovers to 32.2

V, the port 6 of the IC8 stops outputting the signal, which is detected at the port 78 of the CPU.

NC8 8

VCC 7

OUT 6

NC5 5

+5V

IC19

1

4

2

TC7S32F

R78

10K

82 NMI

78 P21

IC1

CPU

27 MRES

IC2

81RES

23 RESET

Gate Array

LED4

113

R11

120K

1%

R12

4.65K

1%

+42V

C15

0.1U

Reset IC for +42V line

1 NC1

2 IN

IC8

3 NC3

4 GND

+5V

Figure 2-21 Reset Circuit for the +42 VDC line

2-1

Rev. A

Page 20

Operating Principles

9

2.3.2.3 Motor Driver Circuits

This printer is equipped with the 3 motors ; CR motor, PF motor, and pump motor. Since they are all driven

by the UDN2917EB, they use the same control system.

CR motor driver circuit

The phase control signal for the CR motor is converted into the UDN2917EB Micro-step bipolar driver

system at the IC2 gate array, then output from the port 55 to the port 43 and 26 of the IC13

UDN2917EB. IC13 determines the phase mode according to the signal sent. The current control

signal is also produced in IC2 gate array and output from the port from 51 to 54 to the port 1, 2, 23 and

24 of the IC13 UDN2917EB.

PF motor driver circuit

The motor driver circuit for the PF motor is the same as for the CR motor.

Pump motor driver circuit

The motor driver circuit for the Pump motor is the same as for the CR motor.

198

CRTRG

IC2

Gate Array

Data Bus

IC1

CPU

CRA0

CRA1

CRB0

CRB1

CRAPH

CRBPH

DA1

51

52

53

54

55

56

112

2

I10

1

I11

23

I20

24

I21

43

PH1

26

PH2

UDN2917EB

44

VREF1

25

VREF2

IC13

Figure 2-22. CR Motor Driver Circuit

6

A

3

A

18

B

21

B

1 CR A

3 CR-A

2 CR B

4 CR-B

CR Motor

Rev. A

2-1

Page 21

EPSON Stylus

0

&2/25

800

2.3.2.4 Sensor Circuits

The sensors equipped with this printer are as follows:

3 photo diode sensors :HP sensor, ASF HP sensor, PE sensor

2 mechanism switch sensors :Black and White cartridge sensors

1 thermistor for the color head

HP sensor

HP sensor, which is mounted to the upper right end of the top frame, determines the CR home

position. When the CR returns to the home position, the detector plate attached to the back of the CR

unit cuts in between the sensor terminals, and a High signal is output to the CPU. Low signal is then

output to the CPU when the CR leaves the home position.

ASF HP Sensor

This sensor is mounted to the left end of the ASF to detect the ASF home position. While the printer is

in standby status after the printer power is on, the ASF is controlled to be located in the ASF home

position, which means the ASF is ready to load paper. ASF HP position is detected by the ASF HP

sensor and the ASF detector wheel attached to the left end of the LD roller. The ASF HP detector

wheel has a small portion cutout and when the cutout comes into the position between the photo diode

terminals, the ASF home position is detected. Under this condition, Low signal is output to the CPU.

Therefore when the cutout goes out of the home position, the ASF detector wheel cuts in between the

photo diode terminals and High signal is output.

PE sensor

PE sensor, which is mounted onto the bottom right end of the Top frame in the printer mechanism,

detects paper end condition. The paper end condition is detected when the detector plate on the PE

sensor lever cuts in between the photo diode terminals and a High signal is output to the CPU. When

the paper was loaded, it pushes up the PE sensor lever. With this motion, the detector plate, along

with the PE sensor lever, is upheld so that it does not fall in between the diode terminals, and a High

signal is output to the CPU.

Ink cartridge sensor

Ink cartridge sensor which is built into each printhead determines if the black/color ink cartridge is

installed. If the cartridge is installed, the sensor plate is pressed down and it connects 2 terminals on

the printhead driver board, and then Low signal is output to the CPU. With no cartridge installed, the

sensor plate loses contact with the terminals on the printhead driver board, and High signal is output to

the CPU.

Printhead thermistor

Printhead thermistors are directly attached to each black and color printhead driver board. This printer,

however, only refers to the signal from the thermistor on the color head. The thermistor monitors the

temperatures around the printhead and feeds back the information to the analog port 105 of the CPU.

This information allows the printer to control the discharge voltage of the head drive pulse according

the ink viscosity.

+5V

Head Thermistor

Black Ink Cartridge

Sensor

Color Ink Cartridge

Sensor

105

106

107

AN0

P41

P42

IC1

CPU

Data Bus

IC2

Gate Array

SWA0

SWC0

SWC1

59

60

57

+5V

+5V

+5V

HP Sensor

+5V

ASF HP Sensor

+5V

PE Sensor

Figure 2-23. Sensor Circuit

2-2

Rev. A

Page 22

Operating Principles

2.4 Ink System Management

This section explains how the ink system is controlled to protect the printheads and the ink supply system

to ensure high-quality output. This printer has several ink system control sequences which var y depending

on the combinations of the basic ink system operations. T he pr inter s elec ts the most suitable sequence by

referring to the various printer information such as values for the timers and counters stored in the

EEPROM, flag and numbers of sensor signals. This section describes the basic ink operations, timers

counters and ink sequences.

2.4.1 Ink System Operations

The basic ink system operations are as described below.

Rubbing

This operation is to rub the printhead surface against the felt part of the head cleaner (left half of the

blade) in the pump unit by shifting the CR from left to right. The printer operates this to eliminate ink

and dust adhered to the printhead surface to regain normal ink ejection state and ensure firm capping

operation. A little amount of ink is absorbed to the nozzle surface before Rubbing operation to let the

adhered objects come off easily.

Wiping

During this operation, the CR moves from right to left to rub the printheads against the rubber part of

the head cleaner (right half of the blade) in the pump unit. The printer performs this operation prior to

ink absorption by eliminating the ink and dust adhered on the printheads to regain normal ink ejection

state and ensure firm capping operation.

Ink Absorbing operation

This operation is to absorb ink from the ink cavities by rotating the pump for the both black and color

heads with the specified steps while the head surfaces are capped and the air valve is closed. The

printer performs this operation to eliminate the ink which has increased viscosity and bubbles around

the nozzles.

False Absorbing operation

This operation removes ink remaining inside the caps by rotating the black and color pumps with the

specified steps while the head surfaces are capped and the air valve is opened. This operation is

accomplished to remove ink from the nozzle plate by vacuuming and ejecting the ink remained after

the Ink absorbing operation and Flushing operations.

Micro Absorbing

This operation absorbs ink from the ink cavity by rotating the black and color pumps with the specified

steps while the head surfaces are capped and the air valve is opened. The purpose of this sensitive

operation is to eliminate bubbles formed in the ink cavities during the Ink absorbing operation.

Flushing operation

This operation is to eject the specified amount of ink from the head when the CR goes into the false

absorbing position. This is performed to avoid increase in ink viscosity. There are 3 types of Flushing

operations, as listed below;

Table 2-12. Flushing Specification

Numbers of shots Driver waveform

Power flushing 4000 shots + 2V, Maximum 36V f or the correc t voltage of the

normal dot

Periodical flushing 36 shots Waveform for the normal dot

Cleaning flushing 1400 shots Waveform for the normal dot

Micro Vibration

Micro Vibration is performed to prevent ink from increasing viscosity. It adds the micro vibration to the

ink inside the cavity by applying driver voltage and pulse which vibrate the piezo elements. The printer

only performs this operation while the CR motor is accelerating to move the CR for printing operation.

Rev. A

2-21

Page 23

EPSON Stylus

2

&2/25

800

2.4.2 Timers and Counters

This printer is equipped with numbers of timer counters, s oft counters and flag. Their values, which are

mostly stored in the EEPROM, are the basis for selecting the ink sequence to be performed.

CL Timer

CL Timer manages auto cleaning. It remains active while the printer power is off and is reset when the

cleaning sequence is executed.

Accumulated Printing Timer

This timer accumulates the period of time spent for printing. The value of this timer is not cleared after

the printer is powered off. This timer is activated when the cap is removed and pauses the job when

the printer goes into the waiting status. The value of this counter is reset when the Ink Absorbing

operation is executed.

Power Off Timer

This timer monitors how long the printer power is off.

Ink Counter RB, Ry

This counter monitors the amount of ink used in the cap during the Flushing operation. The value is

stored after the printer power is turned off. When the value exceeds the specified value, the printer

performs the False Absorbing operation and then resets the counter.

CL2 Counter KKb, Kky

The printer uses the value on this counter for the basis of determining the manual cleaning sequence

order operated thorough the control panel. A cleaning is usually performed in the order of CL1, CL1’,

and CL2. This printer, however, doesn’t necessarily follow this order depending on the numbers of

pages printed after the latest cleaning sequence was performed.

(Set individually for the black and color inks.)

(Set individually for the black and color inks.)

(Set individually for the black and color inks.)

(Set individually for the black and color inks.)

Protect Counter A

This counter monitors the total amount of ink drained into the wast ink drain pads. When the value

exceeds the specified value (counter value:49000), the maintenance error occurs. This counter is

reset by performing the EEPROM reset operation.

Ink Consumption Counter Cb, Cy, Cm, Cc

(Set individually for the black and color inks.)

Each counter counts the amount of ink consumed thorough out the printing, cleaning, and Flushing

operations after the ink cartridge is installed. The printer or the EPW indicates the Ink low and Ink end

status according to the value on this counter. Even though the printer is turned off before a cleaning

sequence compoletes, the printer regards the job as a full cleaning and adds the specified value of the

cleaning to the consumption counter. This counter is reset when the cartridge is removed only in the

Cartridge replacement operation mode which is selected by the Panel Operation.

Table 2-13. Ink Consumption Counter

Black ink cartridge Color ink cartridge

Ink low counter

Ink end counter

37.6×10

41.6×10

7

7

17.2×10

19.2×10

7

7

2-2

Rev. A

Page 24

Operating Principles

3

2.4.3 Ink System Sequence

The ink system sequences operated in this printer are combinations of the basic ink system operations

described in Section 2.4.1. The printer selects the most suitable ink sequence according to the information

provided by the various counters, timers, and flags . T he major ink system sequences are des c ribed in this

section.

Manual Cleaning

Manual cleaning is performed by pressing the cleaning button on the control panel. The cleaning

mode is to be used is selected from following 5 modes according to the CL2 Counter value for KKB,

Kky (cleaning selecting counter) and number of the pages printed after the latest cleaning.

CL1 (Normal cleaning mode) : Wiping, Ink Absorbing, Micro Absorbing, False Absorbing.

CL1’(Powerful cleaning mode) : Wiping, Ink Absorbing, Micro Absorbing, False Absorbing.

The composed operations are same as for CL1, except the

amount of consumed ink.

CL2 (Powerful cleaning mode) : Wiping, Rubbing Ink Absorbing, Micro Absorbing,

False Absorbing.

Every operation except for Rubbing is the same as for CL1’.

However, the amount of the consumed ink is larger than CL1’

CL3 (False cleaning mode) : Wiping, Micro Absorbing, False Absorbing.

The amount of consumed Ink is very little since Ink Absorbing

is not operated.

One time CL : Wiping, Ink Absorbing, Micro Absorbing, False Absorbing.

The composed operations are same as for CL1, except the

amount of consumed ink. This cleaning mode consumes the

largest amount of ink.

CL2 counter is used to determine the cleaning mode to be performed when the forcible cleaning is

repeated. The counter is reset if the printer is turned off. The printer normally follows the order

CL1 → CL1’→ CL2, which, however, can vary depending on the conditions, as described below;

CL3 is selected if no image is printed after the latest cleaning.

CL1 is selected if 5 pages or less is printed after the latest cleaning.

CL1, CL1’ or CL2 is selected according to the CL2 Counter value for Kkb, Kky under the

following conditions;

5 pages or more is printed after the latest cleaning, and the current ink cartridge is a

replacement of the old one which was removed according to the Ink End-Low error

indication.

One time CL is performed under the following condition;

5 pages or more are printed after the latest cleaning, and the current cartridge is a

replacement of the old one which was removed without the Ink End-Low error indication.

Timer Cleaning

This cleaning is performed automatically based on the value for the CL Timer counter while the printer

power is On. This sequence, having 4 separate modes (Timer CL1, Timer CL2, Timer CL3, and Timer

CL4) for each black and color ink, differs from the manual cleaning modes in the basic ink system

operation sequence. It doesn’t contain Ink Absorbing but Wiping and Micro Absorbing operations.

Therefore the consumed ink amount is a little compared with the manual cleaning.

Power ON Sequence

During this sequence, the printer performs the following:

Refers to Protect Counter A.

Resets CL2 Counter Kkb, Kky.

Checks if the ink cartridges are installed.

Checks consumed ink amount.

Performs necessary cleaning based on the conditions such as Initial charging, HP status,

Power Off Timer, and CL timers.

Resets Power off timer.

Rev. A

2-2

Page 25

EPSON Stylus

4

Cartridge Replacement Sequence

The printer determines which ink cartridge (black or color) needs replacing in Cartridge replacement

CL sequence according to the conditions such as cartridge installation, Ink Low and Ink End. Cartridge

replacement CL sequence consists of Wiping, Ink Absorbing, Micro Absorbing, and False Absorbing,

and consumes less ink than that of the manual cleaning sequence. If the Initial charge flag is not

detected during this operation since the printer is new, the printer enters Initial ink charge sequence

instead. During Cartridge replacement sequence, One-time flag is reset or set in the EEPROM

according to the consumed ink amount for the removed cartridge (If 50% was used or not.). This flag

indicates whether the cartridge was removed because of the Ink End status or by accident. The printer

stores this information in the EEPROM to refer when selecting the manual cleaning mode to be

carried out. In case that the ink cartridge was removed from the CR unit with the condition that less

than 50% ink was consumed, the one-time flag is set in the EEPROM and one-time cleaning is carried

out at the first manual cleaning operation after completion of Cartridge replacement Sequence.

Initial Charge Sequence

The printer performs Wiping, Rubbing, Ink absorbing, Micro absorbing, and False absorbing during

Initial charge sequence. This sequence is performed according to the Initial charge flag status. This

sequence, which consumes a large amount of ink (about 20 % of total ink amount), requires

approximately 7 minutes to execute, and CL timers for each color, Accumulated printing timer, Initial

ink charge flag, and One-time flag are reset with the completion of this sequence.

&2/25

800

2-2

Rev. A

Loading...

Loading...