Page 1

EPSON TERM NAL PRINTER

S~hs.

800+

SERVICE MANUAL

EPSON

Page 2

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever without

SEIKO EPSON’S express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made toensure theaccuracyof thecontentsof this manual. However, should

any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for any errors in this

manual or the consequence thereof.

Epson and Epson ESC/P are registered trademark of Seiko Epson Corporation.

General Notice: Other product names used herein are for identication purposes only and maybe

trademarks of their respective campanies.

@Copyright 1994 by SEIKO EPSON CORPORATION Nagano, Japan

-i-

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2)

damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/

maintenance procedures.

1.

2.

3.

Signals a precaution which, if ignored, could result in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

1.

CERTIFIED REPAIR TECHNICIAN.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLT-

2.

AGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO

NOT CONNECT IT TO THE POWER SOURCE.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM

3.

THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4.

IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

5.

BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

ICS

OR OTHER

- ii -

Page 4

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair

of

Stylus 800+.

The instructions and procedures included herein are intended for the experience repair technician, and

attention should be given to the precautions on the preceding page. The chapters are organized as

follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview, lists specifications, and illustrates the

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENT

Includes a step-by-step guide for adjustment.

main components of the printer.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives

required to service the equipment.

APPENDIX

“Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice,

-

iv -

Page 5

Revision

Rev.

A

REVISION SHEET

issue

Dste

April 20, 1994

Revisbn

Page

Ist issue

“v-

4. .

‘+,-

-’

c)

Page 6

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATING PRINCIPLES

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

DISASSEMBLY AND ASSEMBLY

ADJUSTMENT

TROUBLESHOOTING

MAINTENANCE

-

vi -

Page 7

Chapter 1 General Description

Table of Contents

1.1 FEATURES

1.2 SPECIFICATIONS

1.2.1

1.2.2

1.2.3

1.2.4 Ink Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . “ .. ....0.. s “ 0..

1.2.5 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Reliability. . . . . . . . . . . . . . . . . . . . . . . . . . . . “ . . . s Q “ “ .0. . s .- “ - “ “ “ 1-10

1.2.8 SafetyApprovals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.9 Physical Specifications . . . . . . . . . . . . . . . .. .. .. .. ... ... .”.

1.3 INTERFACE SPECIFICATIONS

1.4 PRINTER OPERATIONS

1.4.1 Control Panel.... . . . . . . . . . . . . . . . .. ... ...

1.4.2 Panel Operation atPowerOn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3 Default Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -” .. 0.-. “

1.4.4

1.4.5 ErrorConditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..”...-””

Printing Specifications. . . . . . . . . . . . . . . . . . .

Paper Handling Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial InkCharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.’.

. . . . . . . . . . . “ s -----

. ““.... 1-9

.“.””.. 1-9

.O-”.””-”.= 1-10

-”s”- 1-10

..”.-OS --.oo.mS”m” 1-13

1-1

1-3

1-3

1-5

“

.

1-6

1-8

1-11

1-13

1-14

1-14

. 1-15

1-15

1.5 MAIN COMPONENTS

1.5.1

1.5.2 Power Supply Unit

1.5.3

Main Control Board

Printer Mechanism (M-4811). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(C134

(C106 PSB-B/PSE-B

MAIN Board). . . . . . . . . . . . . . . . . . . . . . . .

Board). . . . . . . . . . . . . . . . . .

1-16

1-16

1-17’

1-17

List of Figures

Figure 1-1. View of the Stylus 800+. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure l-2. Nozzle Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-3. Printable Area - Cut Sheet (Built-in Sheet Feeder). . . . . . . . . . . . .

Figure 1-4. Printable Area - Cut Sheet / Envelope (Manual Insertion Slot) . . . . 1-7

Figure 1-5. Adjust Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . “ .-. . “ . .

Figure 1-6. Temperature / Humidity Range. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-7. Data Transmission Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-8. Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-9.

Figure 1-10.

Figure 1-11. Printer Mechanism (M-4811). . . . . . . . . . . . . . . . . . . . . . . . . . . .

C134

MAIN Board Component Layout . . . . . . . . . . . . . . . . . . . . .

C106 PSB-B/PSE-B

Board Component Layout . . . . . . . . . . . . .

.

. . . . . .

1-1

1-13

1-16

1-17

1-17

1-1

1-3

1-7

1-8

1-9

I

Rev.

A

l-i

Page 8

Table 1-1. Consumable forthe Stylus

800+.

. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table l-2. Feature Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table l-3. Print SpeedandPrintable Columns . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-4. Character Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-5. Adjust Lever Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Table l-6. Requirements for Operation andStorage . . . . . . . . . . . . . . . . . . . . . 1-9

Table l-7. Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table l-8. Signal

andConnector PinAssignments . . . . . . . . . . . . . . . . . . . . . 1-11

Table l-9. Default Setting Item. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Table 1-10. Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

@

-.

.:

;:. ,

‘

l-ii

Rev.

@

A

Page 9

Stylus

tUW+

service Manual

General Description

1.1 FEATURES

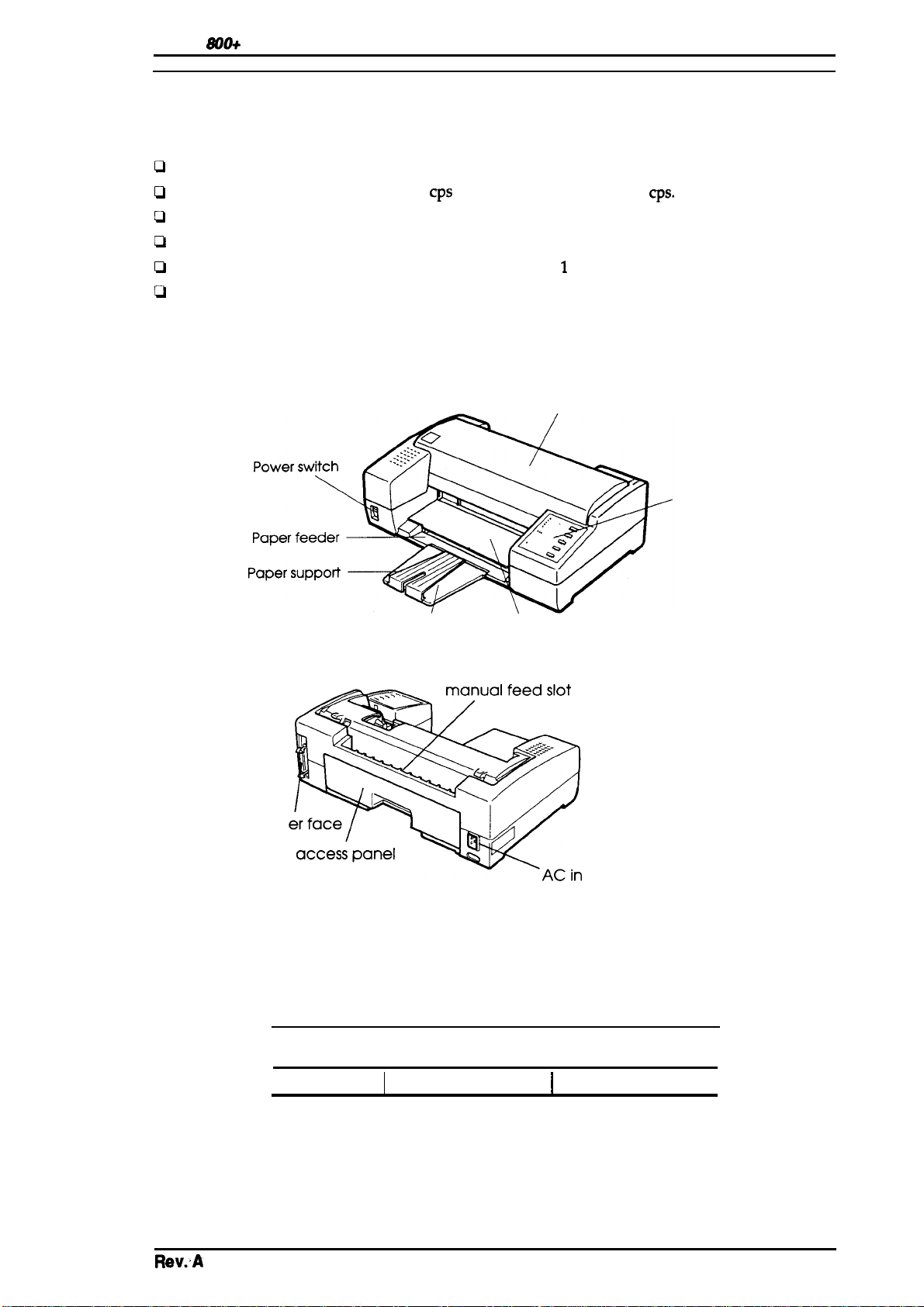

The Stylus 800+ is a serial inkjet printer that uses a newly developed inkjet technology to produce

superb quality output with high-speed printing. The major features of this printer are:

~

High print quality from a MACH (Multi-Layer ACtuator Head) inkjet technology.

D

Fast printing of LQcharacters at 165

D

Compact design saves precious work space.

D

Built-in auto sheet feeder with a capacity for a

D

Equipped with4 scalable fonts, 5 bitmap LQ fonts, and

Cl

9 character tables for the standard version

15 character tables for the NLSP (National Langauage Support) version.

The figure below shows a view of the printer.

cps

and draft characters at 250

maximum of 100 cut sheets (either A4 or letter).

1

draft font, standard.

Printer cover

cps.

parallel

control panel

Paper separator Paper feeder cover

int

let

Figure 1-1. View of the Stylus 800+

Rev.A

Table 1-1. Consumable for the Stylus 800+

Part No.

I

S020025

Description

I

Ink cartridge

I

I

Black ink cartridge

Type

I

I

1-1

Page 10

Gomrd

oescf@knl

wh18ao&

Su’v&ohhud

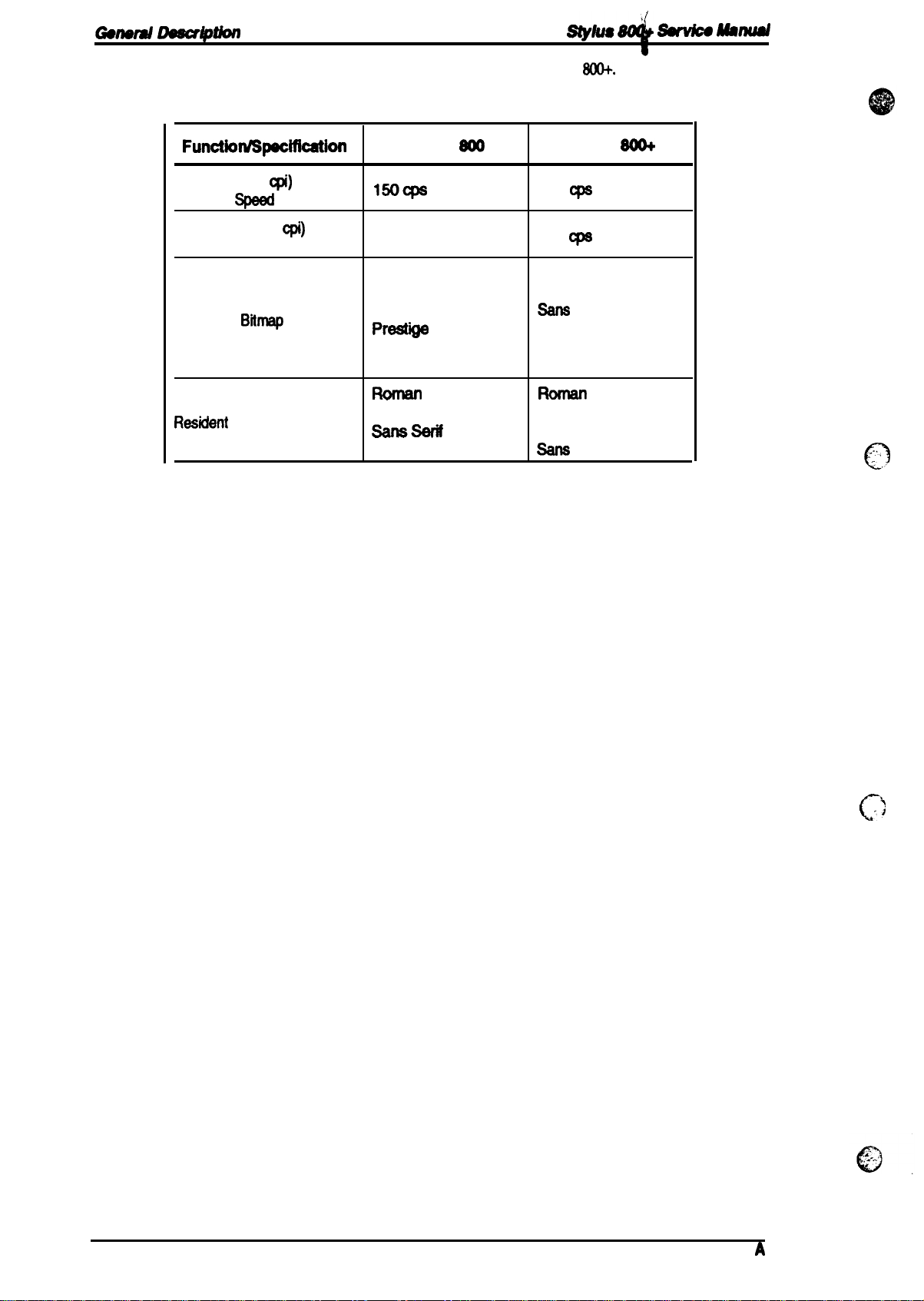

Table

1-2

shows the differences

Function/SpecWation

LQ Fonts (10

Printing

Draft Fonts (10

Printing Speed

Resident

Rasident

cpi)

Spaed

Bitrnsp

Scalable Fonts

in features for the Stylus 800 and Stylus

Table 1-2. Feature Comparison

cpi)

Fonts

stylus

150CPS

cannot printing

Roman ‘

sane serif

Courier

Prest”*

script

Roman T

~=

Saris Serif H

Soo

165

250

Draft

Roman

Ssns

Courier

Prestige

script

Roman T

Saris serif

sane

W+.

stylus

Cps

Cpe

Serif

Serif H

SO&

..,,’,

n

<,,.

1-2

Rev.

..1

c’

A

Page 11

Stylus

800+

service Manual

1.2 SPECIFICATIONS

This section provides detailed statistics for this printer.

1.2.1 Printing Specifications

GenwW

Description

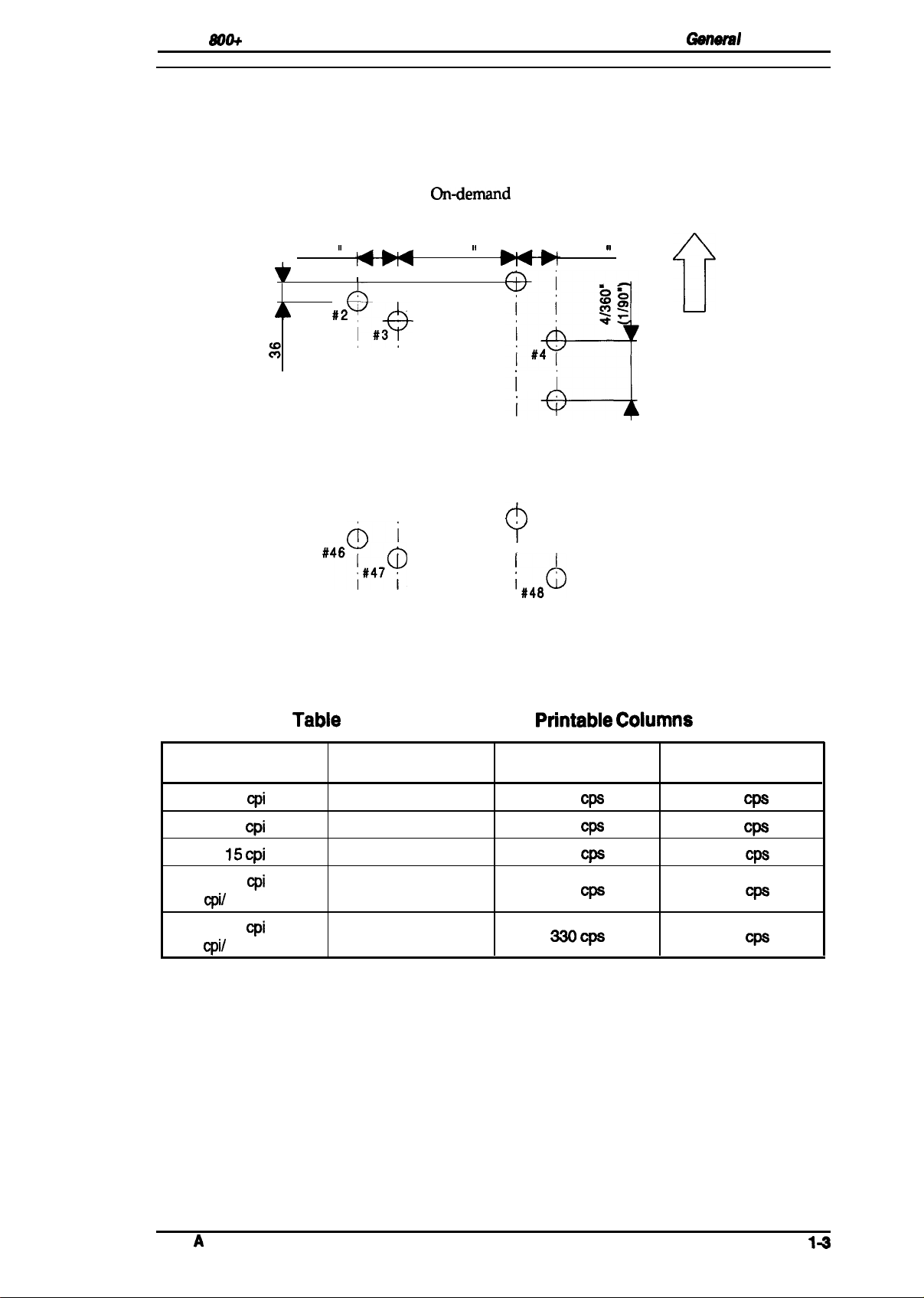

Print system: Ondernand

Nozzle configuration:

17/360

‘o

%

II

#2y

A

I

I #3

,+

48 nozzles (12 nozzles

1,

60/360

,

#1

i i

I

i

‘d

i i

ii

ii

ii

hi

#45 ‘

9

#’$6Y#47~

I

Figure 1-2. Nozzle Configuration

inkjet system

x

4 staggered columns)

,,

12/3

~

‘O=a

60

i

~$

i’

i #4 i

i’

i’

i i

i

I

i

i,48d)

0

Paper feed

direction

Print direction:

Print speed and printable columns:

Character Pitch

10

cpi

12

cpi

15 cpi

17

cpi

(10

cpi/

condensed)

20

cpi

(12

cpi/

condensed)

Tabie

1-3. Print Speed and

Printable Columns Print Speed (LQ)

80

96

120

137

160

Bidirectional printing with logical seeking control

See table below.

Printabie Coiumns

Print Speed (Draft)

165

CPS

198

C@

246

@s

283

Cpe

330cps

250

300

375

429

500

Cps

Cps

Cps

Cps

Cps

Rev.

A

14

Page 12

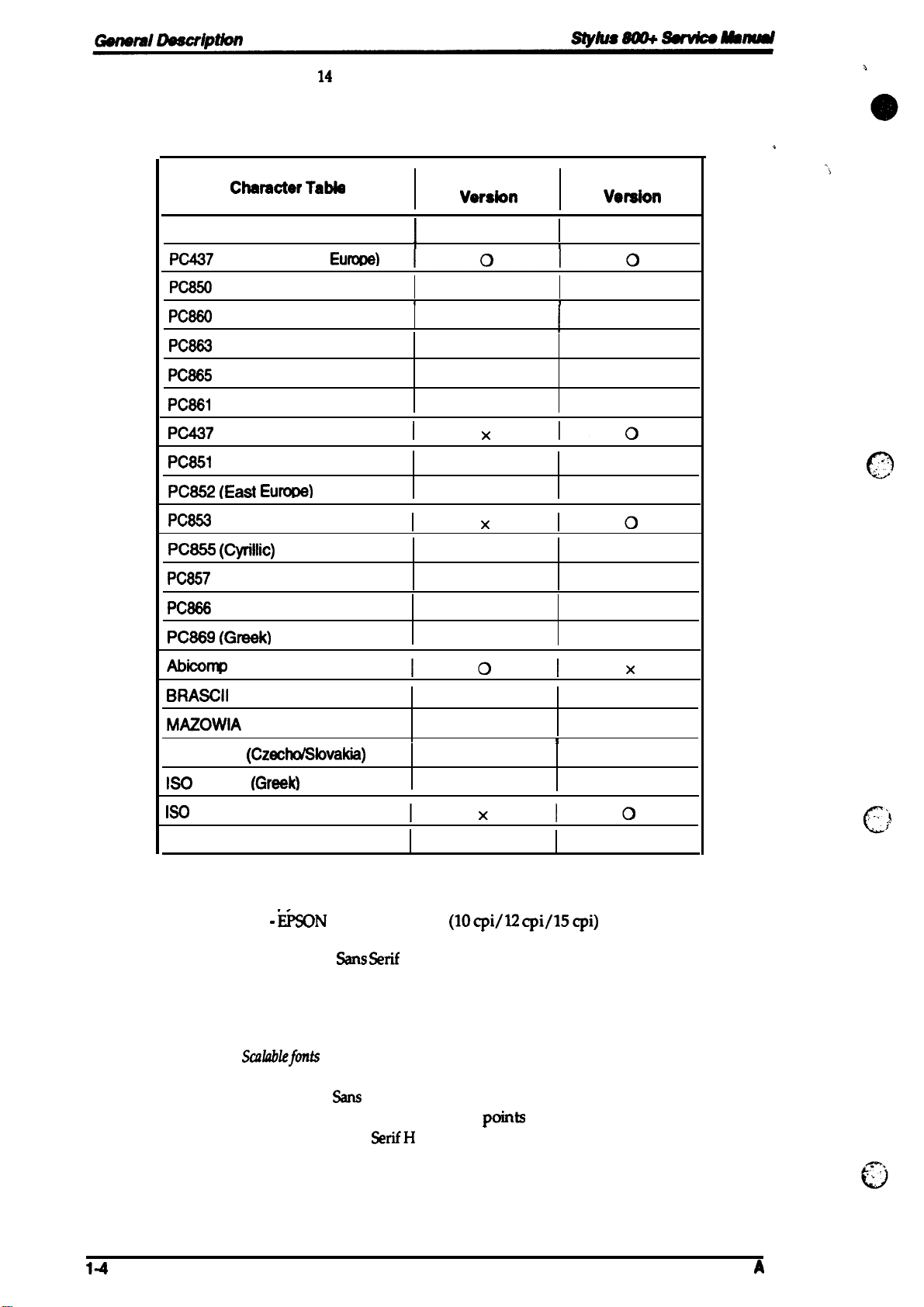

Character sets:

Character tables:

Legal and

See the table below.

14

international character sets.

Chamcter Table

Italic

PC437

{lJ.S./Standard

PC850

(Multilingual)

PC880

(Portuguese)

PC883

(Canadian-French)

PC885

(Nordic)

PC881

(Iceland)

PC437

Greek

PC851

(Greek)

PC852 (East Eurme)

PC853

(Turkish)

PC855 (Cyrillic)

PC857

(Turkish)

Table 1-4. Character Tables

standard

Veraion

o

o

o

1

I

I

Eumtw)

I

1010

1

o

o

o x

Ixlo

x

x

Ixlo

x

x

*

NLSP

Vewaion

0

0

x

x

x

o

o

o

o

Fonts:

PC888

(Russian)

PC889 (Greek)

Abicornp

BRASCII

MAZOWIA

Code

ISO

8859-7

ISO

Latin IT (Turkish)

Bulgaria

(Poland)

MJK

(Czecho/Sbvakia)

(Greek)

(Bulgaria)

o supported

Bitmap fonts —

-

- EPSON Roman

- EPSON

-

- EPSON Prestige

- EPSON Script

Scdiablefmts

-

- EPSON %s Serif

- EPSON Roman T

- EPSON Saris

x Not supported

ii50N

EPSON

Draft

%llS %if

Courier

—

EPSON Roman

SerifH

x

x

Iolx

o

x

x

x

I

Ixlo

x

(lOcpi/12

(10/12/15/proportional)

(10/12/15/proportional)

(10/12/15)

(10/12/15)

(10/12/15)

8-32 points (units= 2 points)

8-32 points (units= 2 points)

8-32

8-32 points (units= 2 points)

cpi/15cpi)

points

(units= 2 points)

o

o

x

o

o

o

o

I

14

Rev.

A

Page 13

Stylus

S00+

Print mode:

Servke

A4snusl

For

bitrnapfonts

—

General Description

Selection and mixture of the following modes are allowed.

- Print quality (LQ)

- Character pitch (10/12/15

- Condensed (not available with

- Double width

- Emphasized

- Italic

- Double underline

- Strike through

cpi

or proportional)

15

cpi

character pitch)

- Double height

- Double strike

- Underline

-

OverScore

- Shadow / outline

For scalable fonts —

-

Emphasized

- Italic

- Double underline

-

Strike through

- Double strike

- Underline

-

OverScore

- Shadow / outline

Control codes:

Input buffer

Esc/P2

32KB or 8KB (selected using the default setting labeled “Mixed text/

graphics mode”)

1.2.2 Paper Handling Specification

Feeding system:

Feeding pitch:

Paper path:

Feeding speed:

Friction feed from the built-in sheet feeder or manual insertion slot.

Note: The

following operations are

1. Reverse feeding

or 16 mm (0.63 inches) from the

2. Reverse feeding beyond 7.9mm

1,6

or l&in& feed or

Prow

Built-in sheet feeder (front entry)

Manual insertion slot (top-rear entry)

87 rns (at

1/6-inch feed

pitch)

w“thin

3mm (O.

ammable

nota//owed.

12inches) ftvm

Mtom

(0.3inches).

in

1A60-inch

the top edge

edge of the paper.

minimum increments.

Rev. A

1-5

Page 14

General

Deecriptbn

1.2.3 Paper Specifications

Usable paper:

Slykls m

~Mmud

cut sheet

Envelope

With the built-in

size:

skt

feeder —

For European/Paafic version:

A4(WXL :210 mm(83”)x

297mm(11.T’))

For U.S. version:

Letter (W x L: 216 mm (85”) x279 mm (11.0”))

‘IhiClmess:

weight

Quality:

0.06564Bond paper,

o.14mrn(o.oo26

90g/m2 (18 -

Ph&Ompier

- 0.0055”)

241b.

/ 55- 78

paper

With manual insertion —

Width:

Length:

Thickness:

weight

182-216 mm (7.2 - 8.5”)

257- 297mm(lo.1 - 11.7”)

O.(M5-

0.11

52-

90g/m2

rnm(O.0026-

(14 -

0.0043”)

241b

/ 45-

78kg)

Quality: Bond paper, Photocopier paper

#6

(w

X

L :

166

Size:

#lI)(wx

Thickness:

0.16-052

Note: Variatbnsrnpaperthkkness

mm (6%”) X %? mm

L

:240

mm(9k”) X

mm(O.0063

- 0.020”)

W”thi.

104mm(41Z$”))

theprintaMearea mustbe

0.25mm (0.CMW~ orless.

weight:

Quality:

45- 90g/m2 (12Bond paper, Air mail

241b.)

kg)

(354”))

Notes

1. Envekpesare usable only Mthmanualinsertion feed.

2.

Ptintingon envelcpeskguamnte edonlyatmxmal

and humidity.

3. lnsertenve@esinto

themanualinsertion slotsidewaya.

temperature

14

Rev.

A

Page 15

Stylus &MO+ Service Manual

General Description

Printable area:

Cut sheet (with built-in sheet feeder)

B

(Left margin) ,

Figure 1-3. Printable Area — Cut Sheet

c

—

t--

(Right margin) ,

Printable area

(Built-in Sheet Feeder)

—

-4

A

(Top margin)

D

(Bottom margin)

-1

-+

Notes:

Cut Sheet / envelopes (with the manual insertion slot)

B

(Left margin)

D

Printable area

c

~Right

margin)

Figure 1-4. Printable Area — Cut Sheet/

(Manual Insertion Slot)

A: The minimum top margin= 3 mm (O. 12”)

B: The minimum Ieflmargin = 3 mm

C: The minimum right margin is

A4 size= 3.0 mm (O.

Letter size =

Manual insertion =3 mm (O.

Manual insertion = ‘Paper

D: The minimum bottom

9.0

12”)

mm

(0.38~

matgin

(0.12”)

127

(Paper widths A4 (210 mm))

w“dth”

207 mm

= 13 mm (0.51”)

—

s

t-

A

J

(Top margin)

D

(Bottom margin)

EnveIoW

(8.3”)

(Paper width 2 A4 (210 mm))

Rev.

A

1-7

Page 16

-nerd

Description

stylus

8m+

~

Mstnd

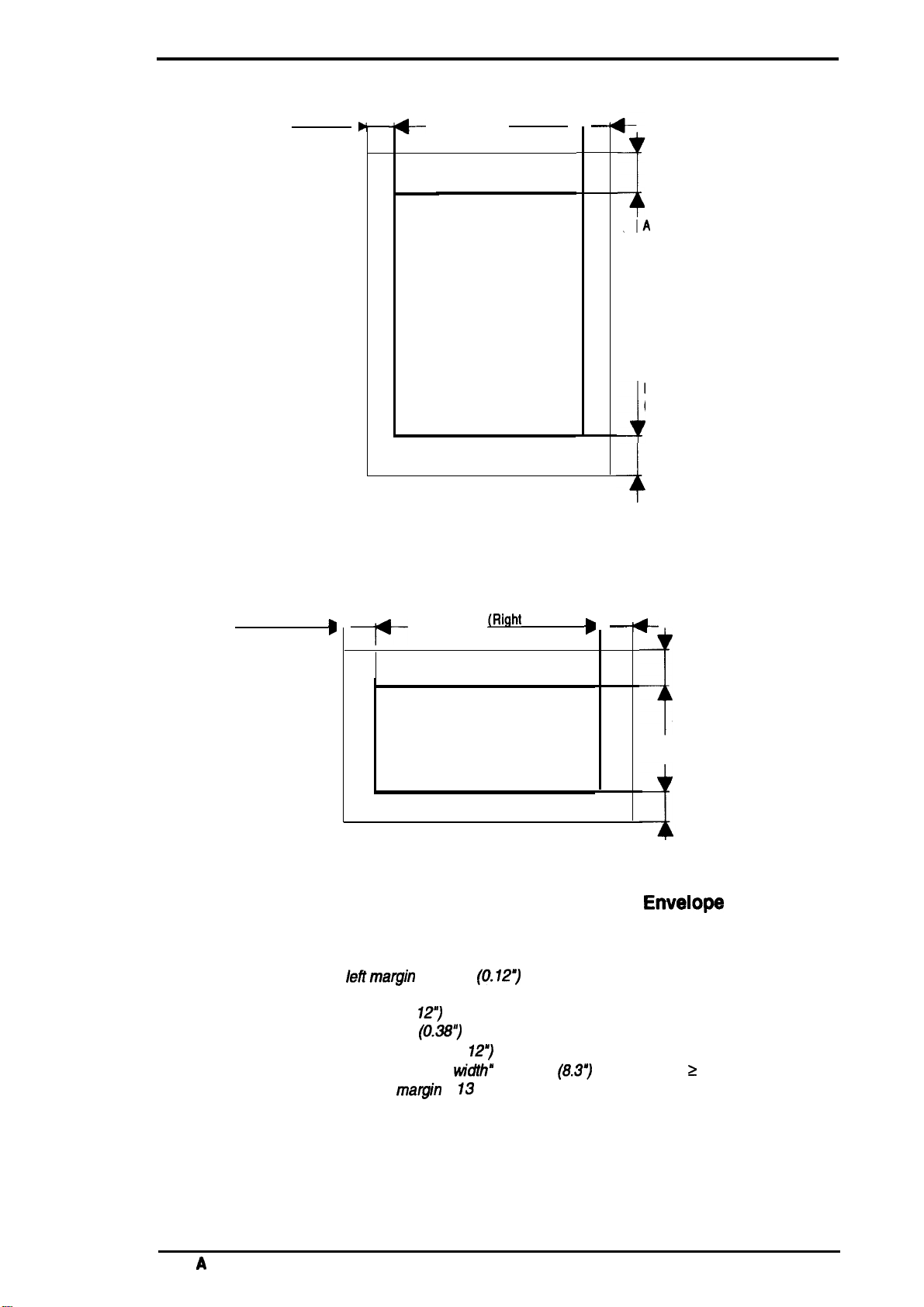

Adjust lever settings:

Lever Position

Plain paper, bond paper

The adjust lever,

position for the paper thickness, as shown below.

attadwd

to the carriage

Table 1-5. Adjust Lever Settings

Paper Type

Left

Right

Cut Sheets

Envelopes

\

\

(Ox

:

:

.

,

, ,

,

,

. . . . . . ------

unit

must be set to proper

Papsr

Thkknsss

0.065-0.11

nun

(0.0026- 0.0056”)

0.16- 0.52

(0.0063-

mm

0.020”)

Envelopes

/

,,

,,

In

0

4

1.2.4 Ink Cartridge

Type:

Ink color:

Print capacity:

Ink

capacity:

Life:

Temperature conditions:

Dimensions:

Figure 1-5. Adjust

Exclusive cartridge

Black

0.7

million characters (LQ)

29.0 +o.5/-l.occ

The effective life from the

2years (total time

6

Storage —

Transport —

Note: Ink freezes in

Width

Depth 54.5 mm (215”)

Height 38.5

months(afterunpacking)

If

requires

(2P

C(77 9).

28.5mm(l.12”)

(SOXXX25)

inpackageandafterunpacking)

-30- m c (-22 - 104°

(Up to 1 month at

-30-

WC (-22 -

(Up to 1 month at 40° C (104° P) or 120 hours at

(140’ P’))

the rnk

sewal

hours to unfreeze at mom temperature

mm(l.52”)

Imer

rndicated

cartridge if kept below-C (26.6°

production date is:

F)

W

C

(14W P))

140”

F)

6(T’

9.

C

‘:”.

c

\

Page 17

Stylus 800+

1.2.5

service Manual

Environmental Conditions

Table 1-6. Requirements for Operation and Storage

Ganwd

Description

Description

Temperature

Humidity

Resistance to shock

Resistance to vibration

Note:

*7

= Operating conditions must be h this range shown h the

*2=

When the pnnteris in the shipping container.

*3= Without condensation.

Humidity

(%RH)

80%

ss~o

*o’Y.

Operating

10- 35° C (50 - 95° F)*

20- 80% RH “1’”

3

1 G, within 1 ms

0.15 G, 10-55 Hz

l

-20- 50° c (-4 - 122°

5- 85% RH ‘2”3

2 G, within 2 ms ● 2

0.50 G, 10-55 Hz ● 2

figure

Print assured range

Storage

Mow.

F)

● 2

10”

c

(5o”

F) (80” F) (95” F) (“F)

Figure 1-6. Temperature/ Humidity Range

1.2.6 Electrical Specifications

Table 1-7. Electrical Specifications

Item

Rated voltage

Input voltage range

Rated frequency range

Input frequency range

Rated current

Power consumption

Insulation resistance

(applying 500

120 V Version

103.5- 132 V 198-264 V

49.5 -60.5 Hz 49.5 -60.5 Hz

Approx.

(self-test with 10

10

line and chassis)

27” C

c

“c

35”

220-240 V Version

120

VAC

220-240

VAC

50-60 Hz 50-60 Hz

0.5 A

13 W

cpi

LQ (self-test with 10

characters)

MQ,

minimum 10

VDC

between AC

(applying 500

0.3 A

Approx.

13 W

characters)

MQ,

minimum

VDC

between AC

line and chassis)

cpi

LQ

Dielectric strength

Rev.

A

1000

VAC rms

1200

-1 minute or

VAC rms

-1 second

(between AC line and chassis)

1500

(beween

VAC rms

‘c ‘ine

and

-1 minute

Chasis)

14

Page 18

Gsnsrd Dssaiption

1.2.7 Reliability

stylus 8@+

ssfwicsmm4d

MTBF:

Printhead life:

Total print volume:

1.2.8 Safety

Safety

Radio frequency interference (lWI):

1.2.9

Size(Wx DX H):

Weight

standards:

Physicai

4000 power on hours

1 billion dots per nozzle

75000 pages (with A4 or letter-size paper)

Approvais

US. version:

European version:

US. version:

European version:

Specifications

435 X 264 X 154 mm (17.1 x 10.4x

Approximately 4.8

(POH)

at a duty cycle of 10’Yo

UL1950 with D3

CSA22.2 m

EN 60950

IEC 950

FCC

Vfg.

EN 55022

ka

excluding the ink cartridge

m

(SEMKO, DEMKO, NEMKO, SETI)

part

15, subpart B,

243

(VDE

0878 part 3, part 30)

(CISPR Pub.22) ClaSS

6.1 inches)

ChSS

B

B

-iii.”

c)

1-1o

Rev.

A

Page 19

Stylus

800+

service

Manual

General Dasoription

1.3 INTERFACE SPECIFICATIONS

The Stylus 800+ is equipped with an 8-bit parallel interface, standard.

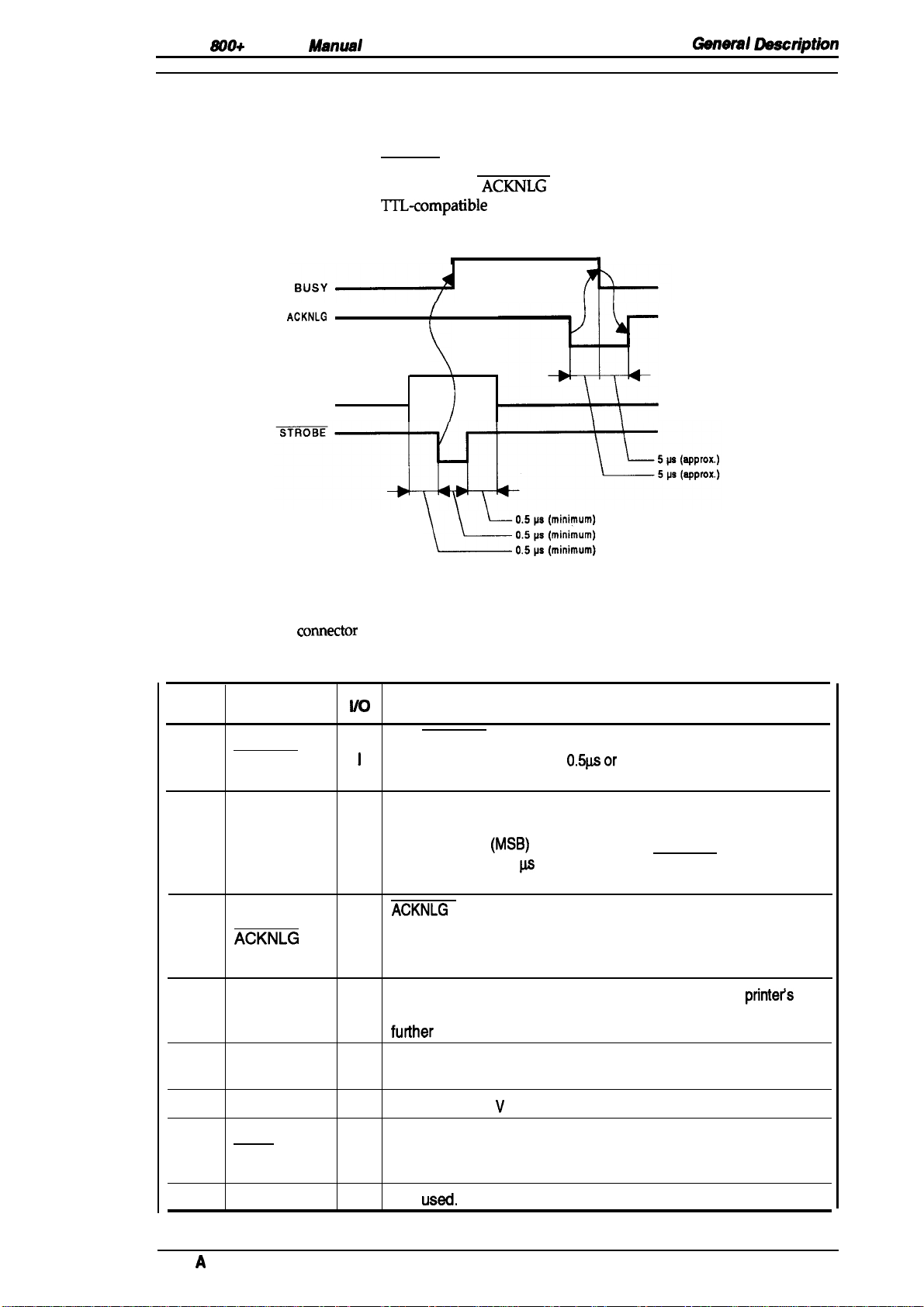

Data format:

Synchronization:

Handshaking:

Signal level:

Adaptable connector:

Data transmission timing:

ACKNLG

DATA

Figure 1-7. Data Transmission Timing

8 bit parallel

STROBE pulse synchronization

By BUSY and

TI’L-compatible

36-pin 57-30364) (Amphenol) or equivalent

See Figure 1-7.

ACKNLG

h

signals

level

i

[

)

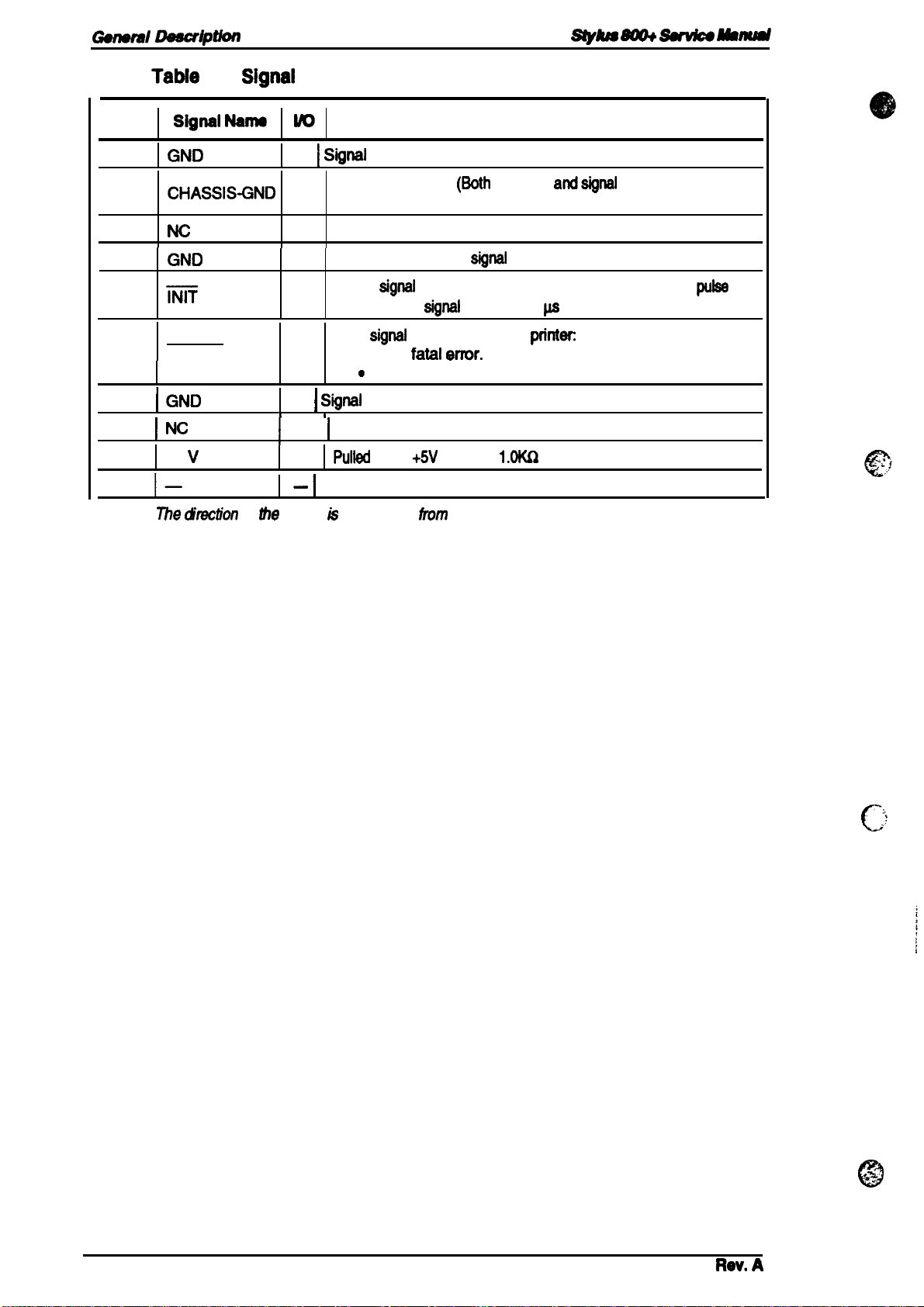

Table 1-8 shows the

comector

Table 1-8. Signal and Connector Pin Assignments

Pin No. Signal Name

STROBE

1

2-9

10

11

12

DATA 1-8

ACKNLG

BUSY

PE

pin assignments and signal functions of the 8-bit parallel interface.

I/o

The STROBE pulse is used to read data from the host computer.

1

The pulse width must be

and data is latched with rising edge of this signal.

DATA 1-8 are parallel data bits. When one of these signals is

HIGH, the data bit is 1; when LOW, the data bit is O. The most

significant bit

I

maintained for 0.5

edge.

ACKNLG

approximately 10 p.s. This signal goes LOW on completion of

o

data reception to indicate the printer is ready to receive further

data.

The BUSY signal informs the host computer of the

o

status. When this signal is HIGH, the printer cannot accept

futiher

data.

This signal indicates whether paper is available in the printer or

o

not. A HIGH level indicates no paper.

(MSB)

p.s

is the acknowledge pulse, with a width of

Description

0.5p.sor

is DATA 8. The signal state must be

on either side of STROBE signal’s active

more. Normally, it is HIGH,

printet’s

13

14

15

Rev.

SLCT

AFXT

NC

A

o

Pulled up to +5 V through a 1.OK S2 resistor in the printer.

If this signal is set to LOW, the printer automatically performs

I

one line feed upon receipt of a CR (carriage return) code. The

status of this signal is checked only at power on and initialization

—

Not

USed.

1-11

Page 20

Garleml

Descdption

Styhm

m

Sutdc9 Msmd

Pin No.

16

17

18

19-30

31

32

33

34

35

36

Note:

Tabie

1-8.

I

Signai Narno

I GND

CHASSIS-GND

Nc

GND

m

ERROR

I GND

I

NC

+5

v

l—

Z5e

&ection of

Signai

and Connector Pin Assignments (Continued)

I

I

W

— I

Signai

Chassis ground.

—

connected in the printer.)

—

Not used.

—

Twisted-pair return

if this

i

width of this

This

o

—

I

Signai

1 1

—

I

!

tie

signal h as viewed

Not used.

—

Puited

,

—

I

Not used

ground.

signai

go& LOW, the printer is initialized. The

signat

goes LOW if the

● has a

.

runs

fatai wmr.

out

ground.

up to

+5V

(reserved).

Description

(i30th

chassis

signai

ground.

signai

must be 50 @ or more.

printec

of paper.

through

tkom

the

1.OKQ

printer.

resistor in the

andsignai

ground are

pulse

printer.

c

%,

@

‘,

;’

.

1-12

Rav. A

Page 21

Stylus

&WO+

Sarvke Manual

General Dsscrlptkm

1.4 PRINTER OPERATIONS

This section describes the basic operations of the printer.

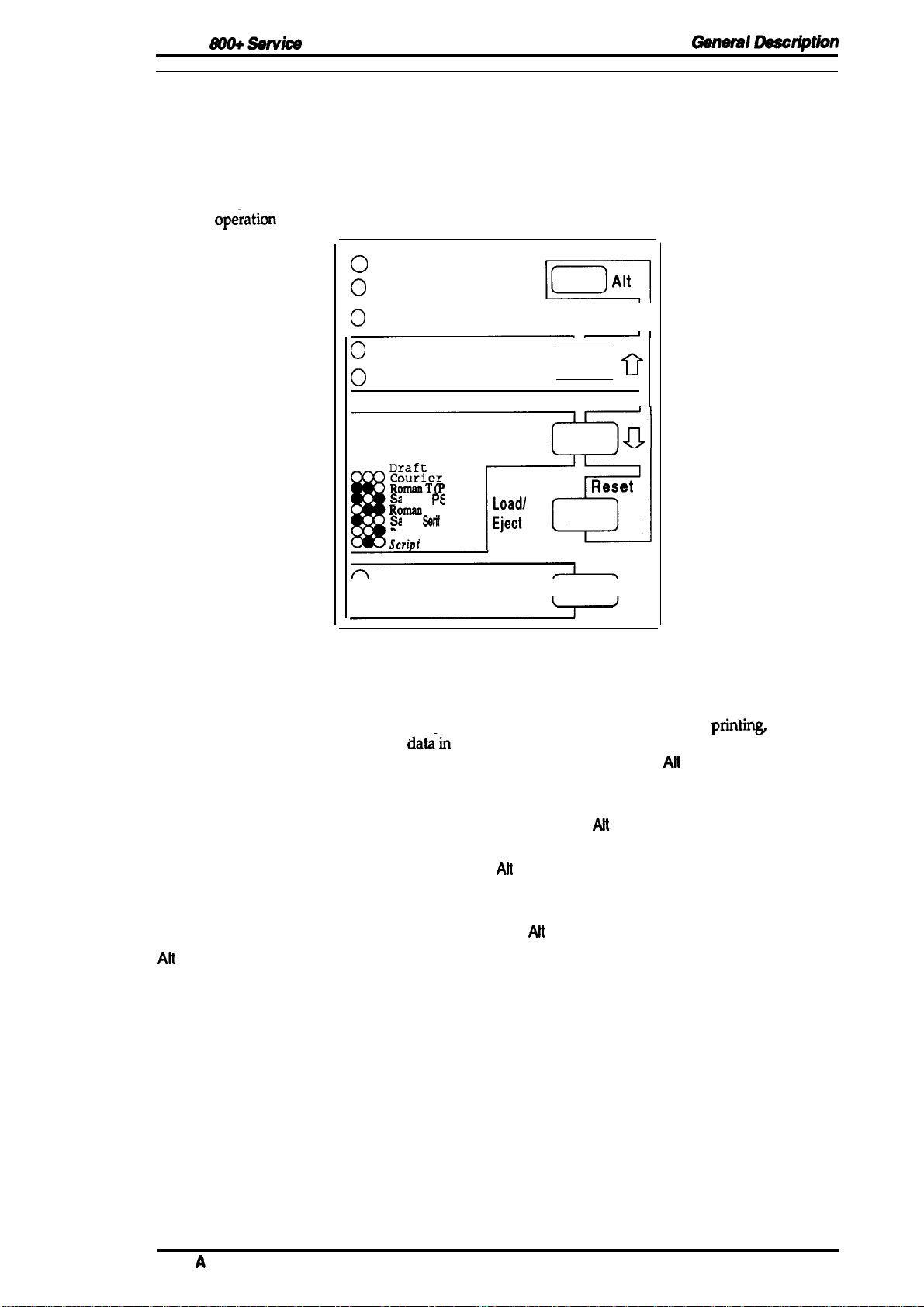

1.4.1 Control Panel

The control panel for this printer contains five non-lock type push buttons and nine LED indicators

for easy

ope;ation

of the various printer functions.

O

Data

O

Paper Out

0

Ink Out

O

Economy

O

Condensed

E=El

II

[:: 1

0

Buttons

Pause

Economy/Condensed

Font

Load/Eject

Alt

000

m

Draft

ourier

omarIT

S)

ii..

San:

#’

s H ( S)

D,..,,

lwum

Saris

B--

B

“ Pause

Sarif

Prestige

scriDt

‘on’

I.oadl

Eject

m

FIUl

Reset

II

Figure 1-8. Control Panel

Switches printer status between printing and no

print

datz-in

the input buffer.

When you hold down this button and the

for 2 seconds, the printer initiates printhead cleaning.

Selects economy or condensed printing alternately. Also works as a

reverse micro feed button, if the

Selects one of the available fonts. Also works as a forward micro

feed button, if the

When you press this button, the printer either loads new paper into

the printer or ejects paper currently in the paper path. Also works

as a reset button, if the Ah button has been pressed.

This button alternates functions of certain buttons. When you hold

down this button in pause mode for 3 seconds, the printer moves

the carriage to the ink cartridge installation/replacement position.

Ait

button has been pressed.

Alt

button has been pressed.

Alt

printin~

button in pause mode

if there is

Indicators

Pause

Data

Paper Out

Ink Out

Economy/Condensed

Font

Rev.

A

Lights when the printer is in pause mode.

Lights when there is print data in the input buffer.

Lights when the printer is out of paper. Blinks if a paper jam occurs.

Lights when the printer detects an ink end in the ink cartridge.

Blinks when the ink level becomes low.

This LED shows the currently selected mode.

Indicates the currently selected font.

1-13

Page 22

Gen9m/ Lkscd@n

1.4.2 Panel Operation at Power On

SiJdu88m+

~

Wnual

You can turn on the following functions

panel.

Self-test mode:

Hex dump mode:

monstration mode:

De

Smudge prevention mode:

Other functions that can be activated from the control panel at power on, such as the default setting

mode and the initial ink charge mode, are described in the sections that follow.

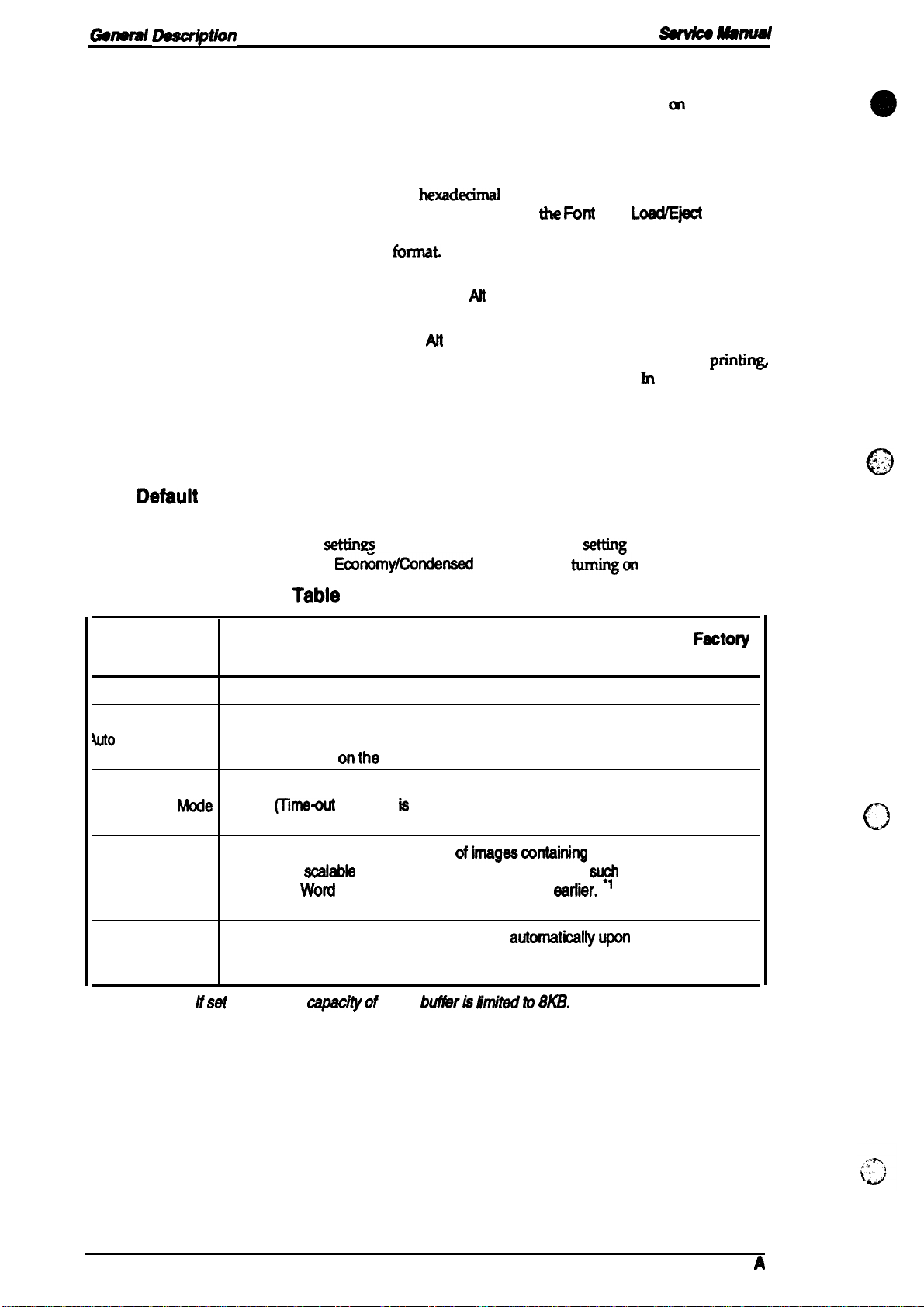

1.4.3

The printer lets you set and save some default settings that it will start with after every

initialization. You can define the

setting mode by holding down the

Defauit

Setting

Start self-test printing by turning the printer on while holding down

the Font button (LQ self-test) or

Start the built-m

printer on while holding down

Once this mode is selected, the printer pMts all received data m

hexadecimal

Start printing of a demonstration page by turning on the printer

while holding down the Ah button.

Enter smudge prevention mode by turning on the printer while

holding down the AH and Font buttons.

If the paper has a tendency to smudge during high duty

you can prevent smudges using this feature. Jn this mode, the

printer waits a few

settings

Ecofimy/Condensed

at

power on by holding down buttons cm the control

LoadEject

hexadwirnal

hrnat.

seconds after printing a line to line feed.

in the table below in default

data dump print mode by turning the

(he Font

button while

button (Draft self-test).

and

LOWE~

setting

mode. Start default

tuming-6n

the printer.

buttons.

printins

,..

..”’,

,,..

0

Tabie

1-9. Default Setting ttem

Menu

Contents

Character Table Selects the character table

ON: Print direction is selected automatically for optimal print

4uto

Print Direction

Network l/F

Mixed Text/

Graphics Mode

Auto Line Feed receipt of the CR code.

Note:

●

Mcde

1 =

OFF: For normal use.

ON: Line feed operation is performed

OFF: No line feed operation with CR code.

/fset

to ON, the

quality (alignment).

OFF: Depends

ON: For netvvorkenvironments, such as LocalTalk.

(Thne+xh

ON: For

ON: To ensure proper printing

and

MS

onthe

printing ie disabled.)

normal environments. (Time-out printing is enabled.)

ecalable

Wotd

capcityof

fonts using certain applications,

or WordPerfect version 5.1 or

Description

ESC U command.

input

bufferh finu’tedto 8KB.

ofimagescontaining

automsticaltyupon

graphics

~lh

eartier.

as

Fectoty

Setting

ON

OFF

c)

OFF

OFF

1-14

Rev.

A

Page 23

Stylus

800+ Setvica

Manual

General Daacription

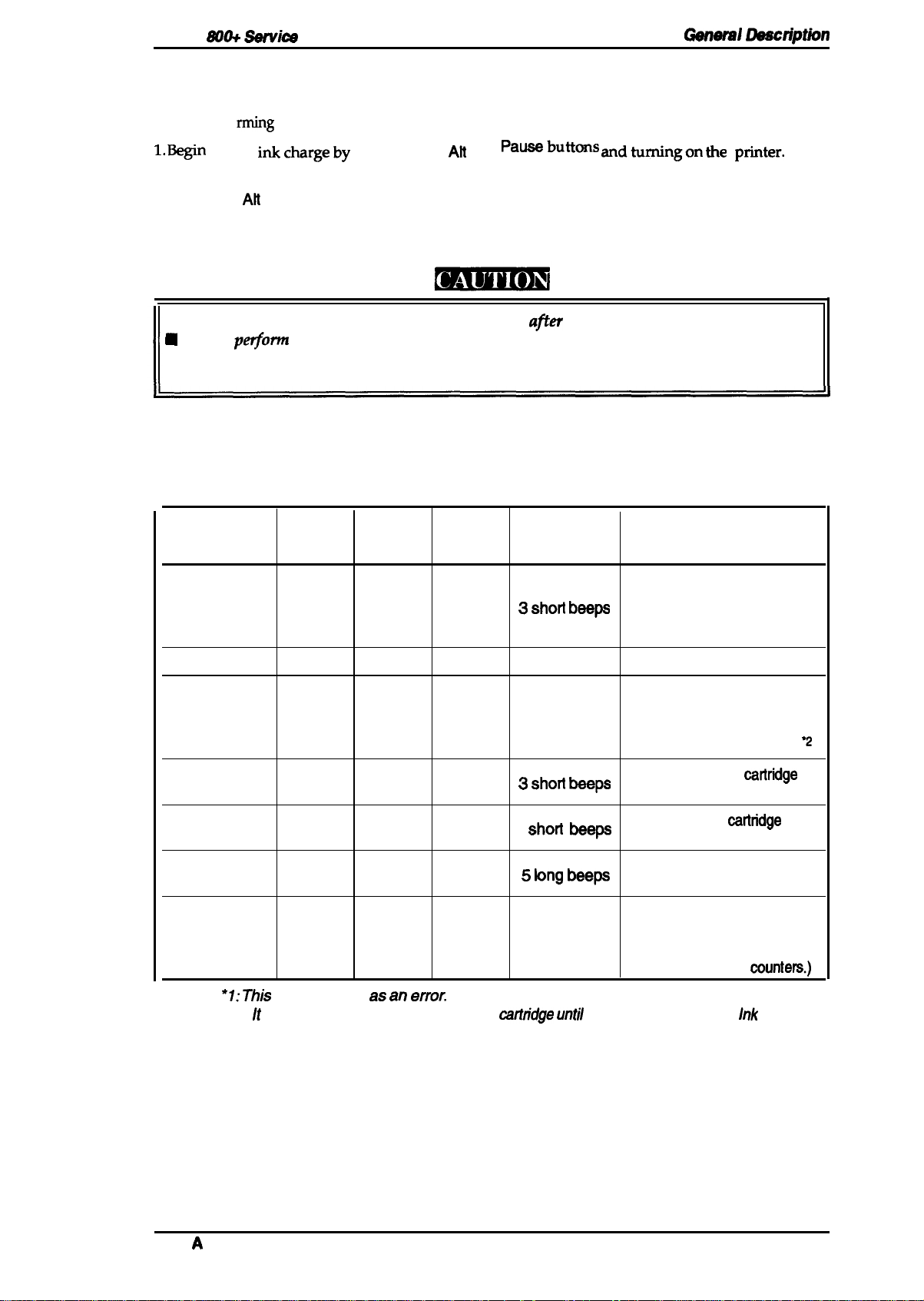

1.4.4 Initial Ink Charge

When the printer is setup for the first time, the printer’s entire ink supply path must be filled with

rming

ink by perfo

the initial ink charge operation, as described below.

1. Be@

2.

3. Press the

The Pause

initial

inkchargeby

Install the ink cartridge.

Alt

button.

LED blinks while the initial ink charge operation is in progress, and when it completes,

pressing the

Alt

and

Pa~butions andtirningon the

pfiter.

the printer automatically becomes ready.

■

The ink cartridge

N

Do not

perjorm

must be

installed immediately

afler

unpacking the package.

the initial ink charge operation more than twice on the same printer.

Otherwise, the operation consumes too much ink in the cartridge and shortens the life of

the waste ink tank.

1.4.5 Error Conditions

The printer detects various errors and indicates them with the LED indicators and the buzzer.

Table 1-8. Error Codes

Error

Paper end

Paper

LED

ON

Ink End

LED LED

OFF

Pause

OFF

Buzzer Recovery

Load paper and press the

~ ~hon ~wp

following buttons:

1. Pause

2. Load/Eject

Paper jam

Ink low ● 1

Ink end

No ink cartridge

Carriage error

Waste ink tank

over-flow

Notes:

“1: This

●

2: It is not

error.

BLINKS

OFF

OFF

OFF

OFF

OFF

is not treated as an

OFF OFF

BLINKS

ON

ON

OFF OFF

ON

error.

necessary to replace the ink

3 short beeps Same as above.

—

OFF

OFF

No beeps

a Shoti ~ps

3

‘hod be~

~ ~ng beep

BLINKS 3 short beeps

caflndge until

the printer detects the

Press Pause and replace

the ink cartridge with a new

one. Then, press Pause

again to resume printing.

Replace the ink

catlridge

V

and press Pause.

Install the ink

cattridge

and

press Pause.

Tum the printer off and back

on again.

Service maintenance

required. (Replace the waste

ink absorbing material and

reset the protect

munters.)

Ink

End

Rev.

A

1-15

Page 24

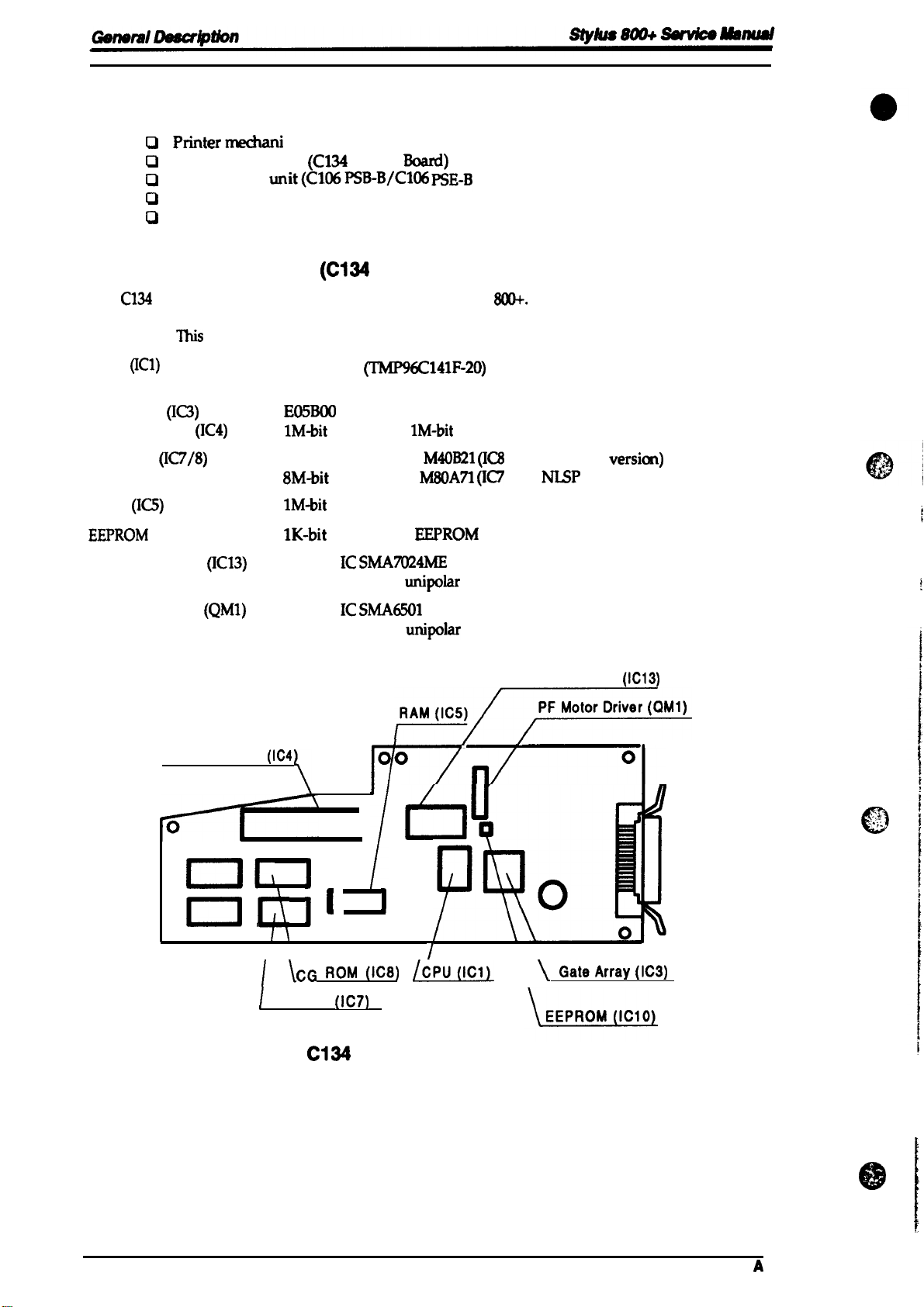

1.5 MAIN COMPONENTS

The main

1.5.1 Main Control Board

The

the host computer and processing received print data, as well as control of the whole printer

mechanism.

CPU

Gate array

Program ROM

CG ROM

RAM

EEPROM

CR motor driver

components

o

PMtermechanl

Cl

Main control board

0

Power supply unit(C106PSB-B/C106

0

Control panel

0

Housing

of this printer are:

“sm (M-4611)

(C134

(C134

C134

MAIN

(ICl)

(n)

(IC1O) IK-bit

board is the main

This

board consists of the following components

(IC3)

(IC4)

(IC7/8)

(IC13)

Constant current

controller of the Stylus

16-bit CPU

19.6608 MHz operating clock

E05BO0

IM-bit

EPROM or

4M-bit mask ROM

8M-bit

mask ROM

IM-bit

PSRAM

(64x 16 bit)

Hybrid IC

MAIN Baud)

PSE-B

MAIN Board)

~141F-20)

IM-bit

M40B21 (IC8

M80A71 (IC7

EEPROM

SMA7024ME

unipolar

Board)

800+.

It takes charge of interfacing with

mask ROM

/ for standard

/ for

drive

NISP

versicm)

version)

PF motor driver

Program ROM

ml,

n

o

(QM1)

Hybrid IC

Constant voltage

(IC4

I), I t

I

\

CG

H

~

CG ROM

Figure 1-9.

SMA6501

unipolar

Fr~

I

\

I

drive

CR Motor Driver

/

1

I

‘

[

0

/

ROM (Ica)

(IC7)

C134

MAiN Board Component Layout

(!W!_@L

\\

\

\

@teArray(lc3)

(IC13)

.,.

..>s

-.;:.

o

1-16

Rev.

A

Page 25

Stylus

S00+ Sarvica

Manual

General Daacription

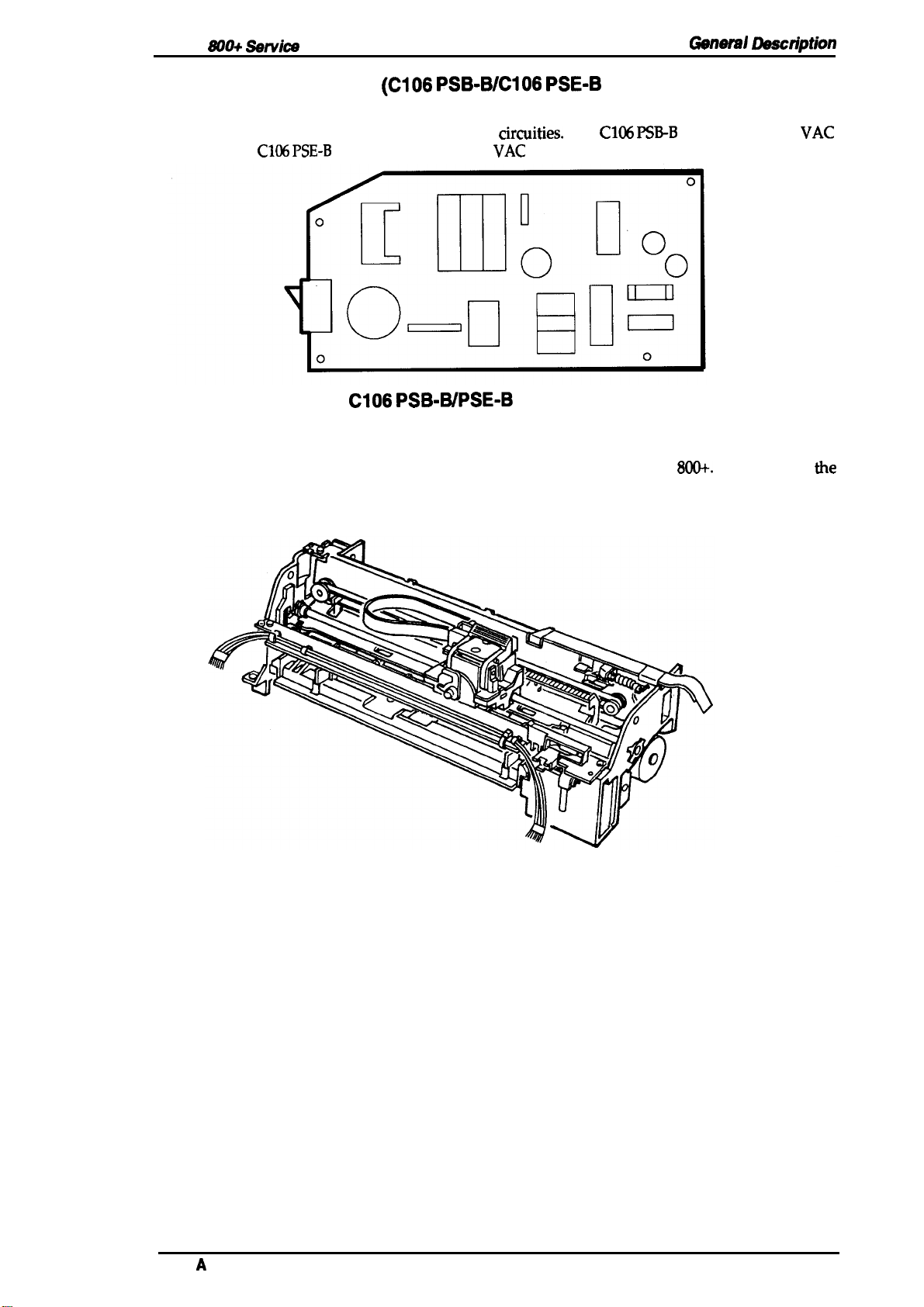

1.5.2 Power Supply Unit

The power supply unit converts input AC voltage and generates the different DC voltages required

by the printer mechanism and other electrical

input, and the

C106 PSE-B

board is for 220 to 240

Figure 1-10.

(C106 PSB-B/C106 PSE-B

circuities.

VAC

input.

CI06 PSB-WPSE-B

Board Component Layout

The

Board)

C106 PSB-B

board is for 120

VAC

1.5.3 Printer Mechanism (M-4811)

The M-4811 printer mechanism is specifically designed for the Stylus

carriage assembly, which includes the printhead and the ink supply system, the carriage motor, the

paper feed motor, the paper feeding mechanism, and the pump mechanism.

800+.

It consists of

the

Rev.

A

Figure 1-11. Printer Mechanism (M-4811)

1-17

Page 26

Chapter 2 Operating Principles

Table of Contents

“ “

. . 2-6

.

2-7

. 2-9

2-1o

2-10

2-12

2-I3

2-13

2-14

2-15

2-16

2-I7

2-1

2-1

2.1 OVERVIEW

2.2 PRINTER MECHANISM OPERATING PRINCIPLES

2.2.1

2.2.2 Carriage Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.3 Paper Feed Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.4 Ink System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5 Pump Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.6 Cap Mechanism.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3

Printer Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2.1 Adjust Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

OPERATING PRINCIPLES OF THE CIRCUITS

2.3.1

2.3.2 Operating Principles of the Main

Operating Principles of the Power

2.3.2.1 Reset Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2.2 SensorCircuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2.3 InkEnd Detection . . . . . .

2.3.2.4 Carriage

2.3.2.5 Paper Feed Motor

2.3.2.6

Printhead DriveCircuh

MotorDfiveCircuh

DriveCircufi.

SupplyCircufi

Control

.....:...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

2.4

INK SYSTEM MANAGEMENT

2.4.1 InkOperations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... ...

2.4.1.1

2.4.1.2

2.4.1.3

2.4.1.4

2.4.1.5

2.4.1.6

2.4.1.7

2.4.1.8

2.4.1.9

2.4.2 CounterandTimer. . . :. . : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.4.2.1 Refresh-l Timer... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.4.2.2 Flushing Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.4.2.3 CL Counter K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.4.2.4 Protect Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

PowerOnOperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standby Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Charge Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refresh Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaner Blade Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

InkCartridge(l/C) Replacement Operation. . . . . . . . . . . . . . . . 2-22

Disengage OnOperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micro Absorbing

OPeration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

....s” 2-19

2-18

---

.

z-19

2-21

2-=

2-20

2-20

2-21

Rev.A

2-I

Page 27

List

of Figures .

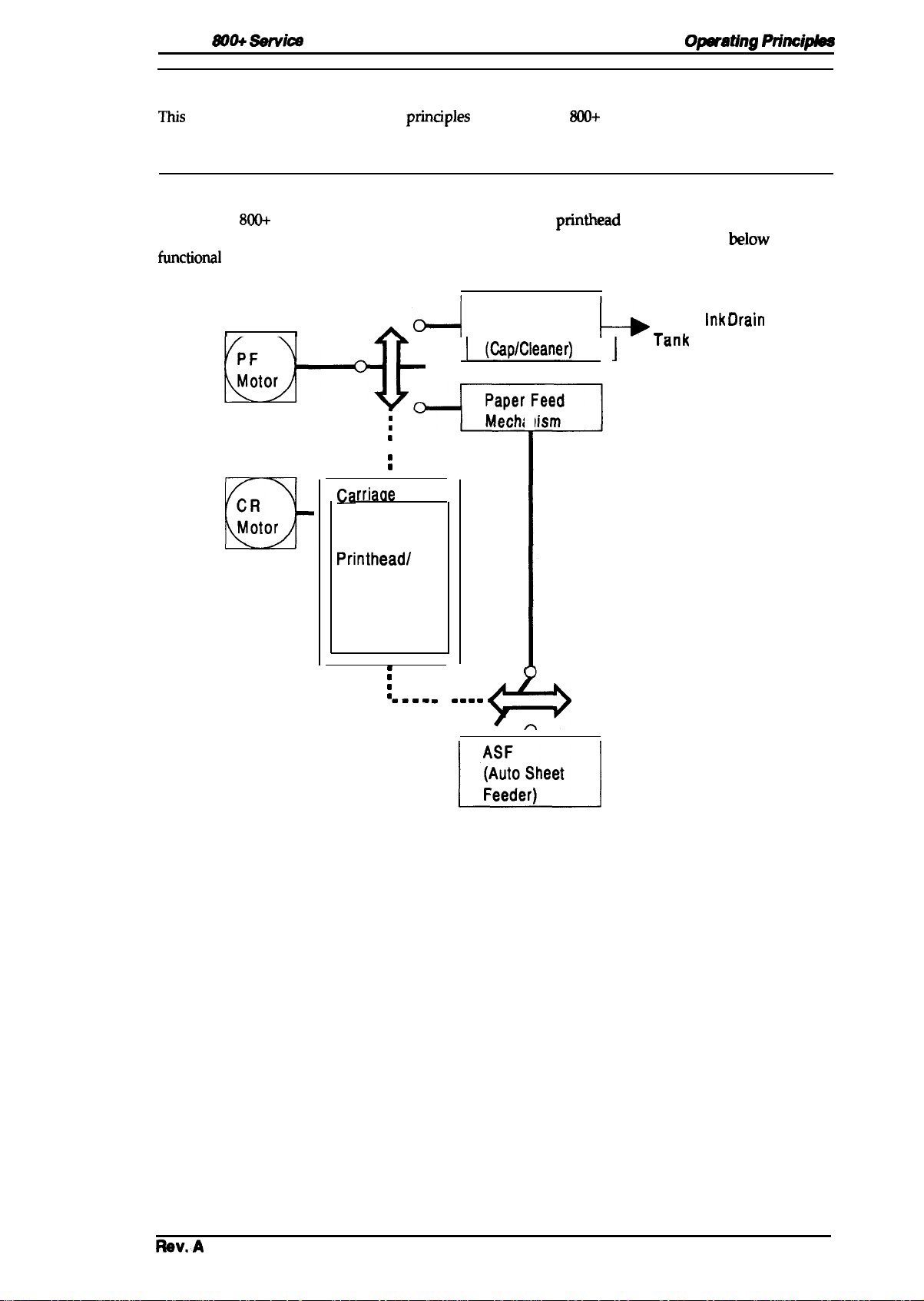

Figure 2-1. Functional Block Diagram of the Printer Mechanism. . ..........2-1

Figure 2-2. Structure of the

Figure 2-3. Structure of the

Printhead

Printhead

1 . . . . . . . . . . . . . . . . . . . . . ..........2-2

2. . . . . . . . . . . . . . . . . . . . . ..........2-2

Figure 2-4. Principles of the Printing Operation 1 . . . . . . . . . . . . . . . . . . . . . .. 2-3

Figure 2-5. Principles of the Printing Operation 2 . . . . . . . . . . . . . . . . . . . . . . .2-3

Figure 2-6. Carriage Drive Mechanism. . . . . . . . . . . . . . . . . . . . . . . . ........2-4

Figure 2-7. Adjust Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-8. Paper Feed Mechanism 1 . .

.’.

. . . . . . . . . . . . . . . . . . . . . . . .. ...2-5

Figure 2-9. Paper Feed Mechanism 2 . . . . . . . . . . . . . . . . . . . . . . ..........2-5

Figure 2-10.

Figure 2-11.

Figure 2-12.

Figure 2-13.

Figure 2-14.

Figure 2-15.

Figure 2-16.

Figure 2-17.

Figure 2-18.

Figure 2-19.

Figure 2-20.

Figure 2-21.

Figure 2-22.

Figure 2-23.

Figure 2-24.

Diagram of the Ink System. . . . . . . . . . . . . . . . . . . . . . .........2-6

Pump Mechanism Block. . . . . . . . . . . . . . . . . . . . . . ...........2-7

Pump Operation . . . . . . . . . . . . . . . . . . . . . . . . . ..............2-8

Cap Mechanism . . . . . . . . . . . . . . . . . . . . . . . . ...............2-9

Block Diagram of the Circuits. . . . . . . . . . . . . . . . . . . . . . . .. ...2-10

Power Supply Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . . . 2-11

Main Control Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . . . .2-12

Reset

CirWt

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . .....2-13

Sensor Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . .....2-13

Ink End Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-14

Carriage Motor Drive Circuit Block Diagram. . . . . . . . . . . . .....2-15

Paper Feed Motor Drive Circuit Block Diagram . . . . . . . . . .....2-16

Printhead

Printhead

Drive Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-17

Drive Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . .. .2-17

Relationship of Ink System Operation to Carriage Position .. ...2-18

List of Tables

Table 2-1. Carriage Drive Motor Specification . . . . . . . . . . . . . . . . . . . . .. ....2-4

Table 2-2. Adjust Lever Position . . . . . . . . . . . . . . . . . . . . . ...............2-4

Table 2-3. Paper Feed Drive Motor Specification. . . . . . . . . . . . . . . . . . . . . . .. 2-5

Table 2-4. Pump Mechanism Operation. . . . . . . . . . . . . . . . . . . . . . .........2-8

Table 2-5. DC Voltage Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-10

Table 2-6. Carriage Motor Drive Modes. . . . . . . . . . . . . . . . . . . . . . . . . .....2-15

Table

2-7. Paper Feed Motor Drive Modes . . . . . . . . . . . . . . . . . . . . . . .....2-16

. .

c’

I

I

1

2-ii

Rev.

A

Page 28

Stylus

800+ Satvics

Manual

2.1 OVERVIEW

OpaUng

Ftincipbs

T’& section describes the operating

circuits.

prinaples

for the Stylus

800+

printer mechanism and electrical

2.2 PRINTER MECHANISM OPERATING PRINCIPLES

The Stylus

carriage drive mechanism, pump mechanism, and various

functioml

800+

printer mechanism is composed of the

block diagram of the printer mechanism.

Pump

1

I

o-l

~toJ--w

m

●

n

m

■

rriaae

U

CR

Motor

!%

nit

Mechanism

‘(&p’c’caner)

printhead

‘

unit, paper feed mechanism,

sensors. The figure

L

Waste

+-

‘an’

-,

E

Printhead/

Filter/

Driver Circuit

below

Inl- ‘--’-

K

uraln

shows a

m

m

m

% . . .

m ■ . . .

(

.

$+

M

Figure 2-1. Functional Block Diagram of the

Printer Mechanism

Rav.A

2-1

Page 29

Opwating

Princ@h!ss

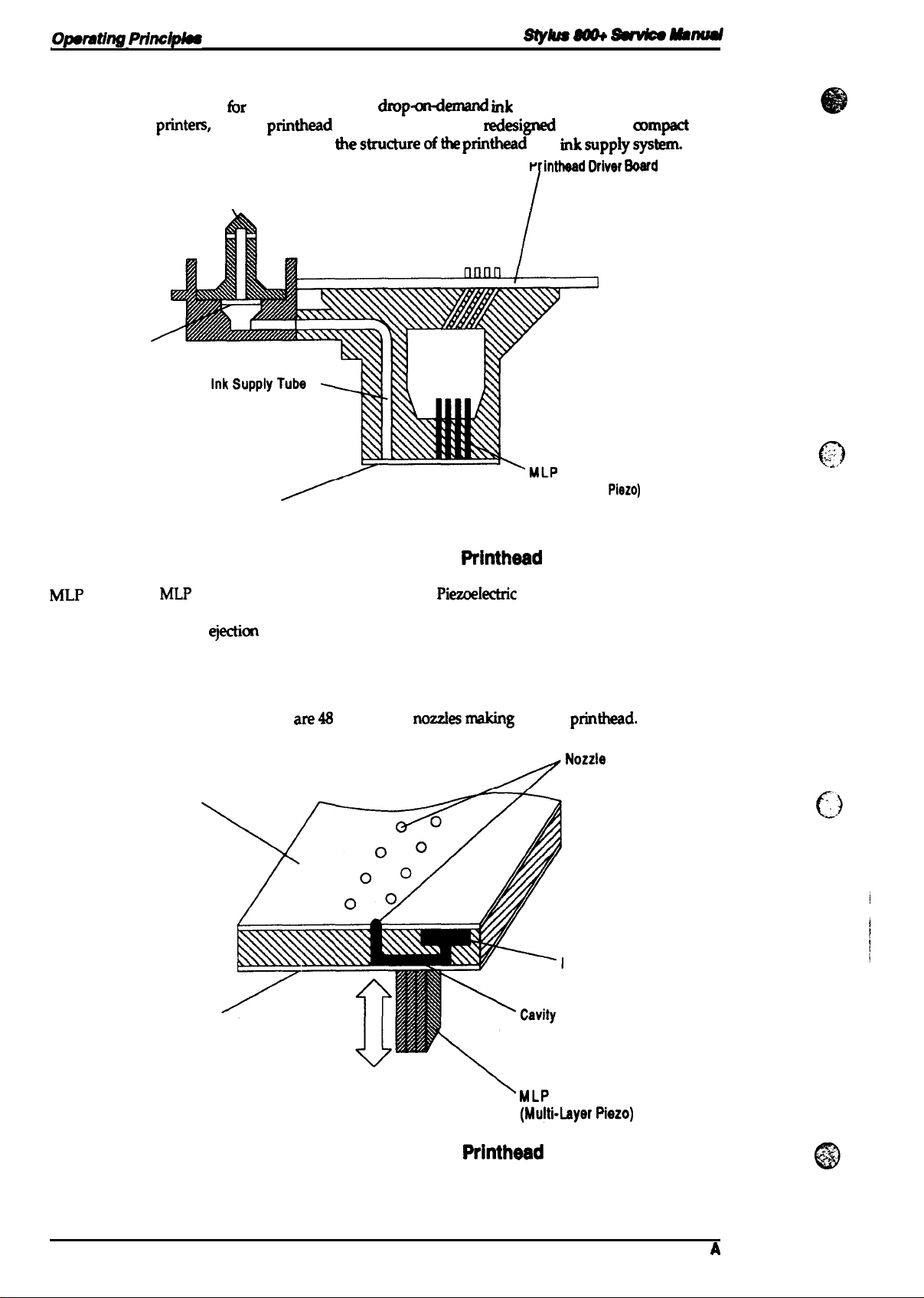

2.2.1 Printer Mechanism

Stylus Wl+

~tillad

printer mechanism

The

EPSON ink jet

highly reliable. The figure below shows

printem,

Cartridge

Filter

Needle

fbr

this printer uses a

but the

\

Cavity Set

(Nozzle)

printhead

has been completely

dmpawknand rnk

thestructureofthe

jet system similar to all other

wdesigned

printhead

to make it

and

rnksupplysystem.

P

intheed IMver Soerd

I

(Multi-Layer

Piezo)

a)mpact

and

MLP

Cavity

❑ Nozzles

Nozzle Plate

Figure

MLP

is the abbreviation for Multi-Layer

(voltage) is applied, this element pushes the vibration plate, compressing the cavity

for ink

Ink supplied from the ink cartridge is stored in this space and is ejected from the

nozzles when the vibration plate compresses this area.

These eject ink against the paper’s surface in response to the application of the

print signal. There

ejectkm

2-2.

Structure of the

from the nozzle.

are4S individual

Printhead

Piezoelectric

nmzlesmaking

1

element- When a drive pulse

up this

printhead.

>’022’8

supply

Tank

nk

i

2-2

Vibration Plate

Figure 2-3. Structure of the

‘ MLP

(Multi-byer Piezo)

Printhead

2

Rev.

A

Page 30

Stylus

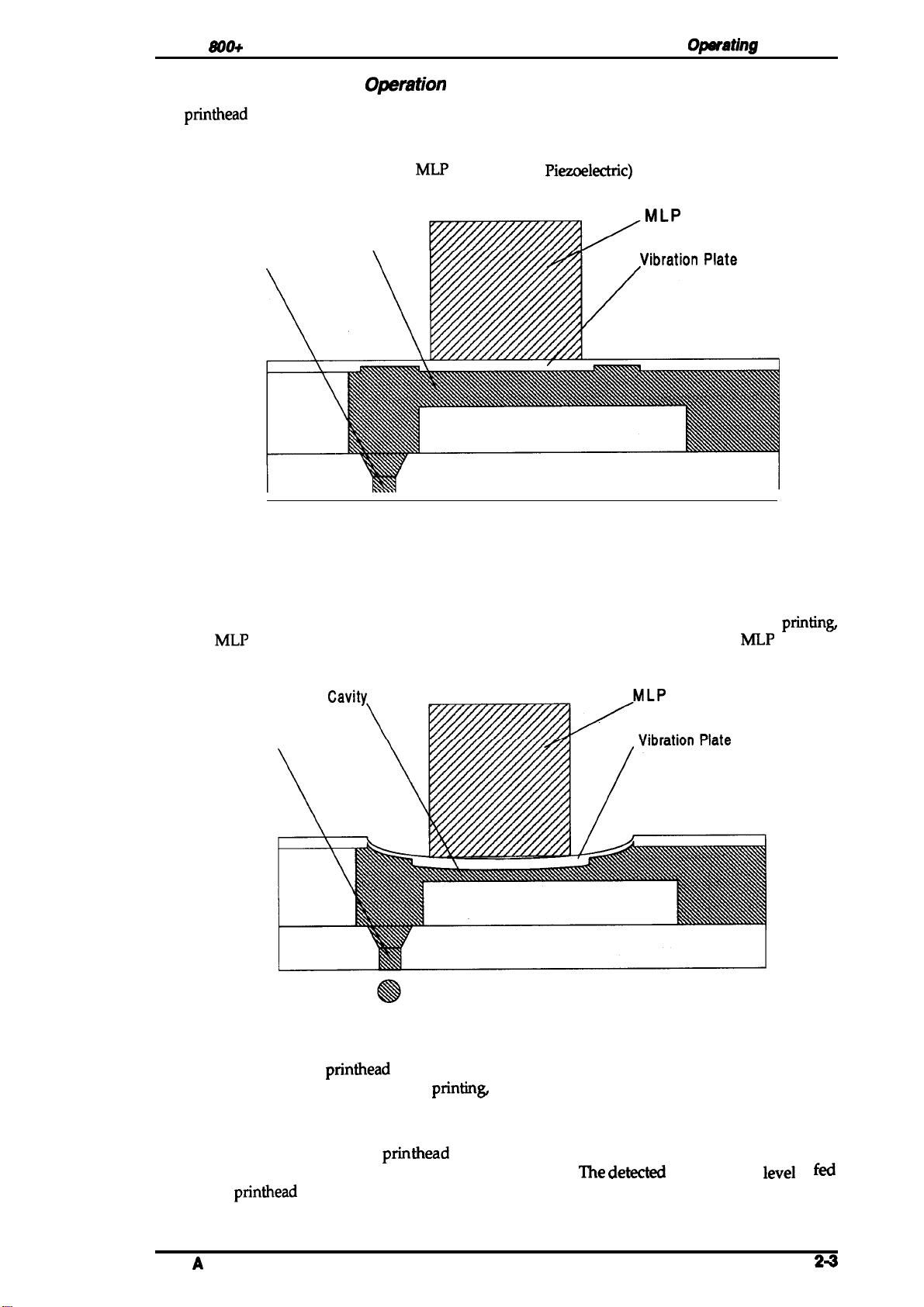

Principles of the Printing Operstion

The

1.

S00+

service Manual

printhead

Normal state

performs the following operations to eject ink from each nozzle:

Opsfating

Principles

No electrical charge is applied to the

of the cavity, and pressure in the cavity is kept at a constant level.

Cavity

\

Nozzle

MLP

(Multi-Layer

Piezoelectric)

Figure 2-4. Principles of the Printing Operation 1

2. Ejection

element attached to the back

MLP

The head data signal is applied to the control line of a nozzle to select the active nozzle for

and the

bends the vibration plate to compress the cavity. Then, ink is ejected from the nozzle.

MLP

element is gradually charged with the drive voltage. Charging the

Nozzle

MLP

printin~

element

Figure 2-5. Principles of the Printing Operation 2

When the ink charge or

out with the pump mechanism. During

from the ink cartridge and ejected from the nozzle, according to the change in the volume of the

cavity.

printhead

cleaning operation is performed, ink in the cavity is vacuumed

printin~

on the other hand, ink is simultaneously supplied

A thermistor is attached to the

viscosity of the ink varies, depending on the temperature.

back to the

Rev.

A

printhead

drive voltage control circuit to regulate the drive voltage to a proper level.

printhead

drive board to monitor the temperature, because the

The dew

temperature

level

is

fed

24

Page 31

Opmtmg Princ@ks

Stylus m Swv4c9 Aanud

2.2.2

The

carriage unit to move along the carriage guide shaft from left 10 right or vice versa.

drive motor on this printer is a 4-phase,

the printer to stop the carriage or change carriage

carriage is

carriage drive control

Carriags

timing belt attached to the base of the carriage unit is driven by the

Drive Mechanism

reqnimd

by the home

arcuit

to determine

Table 2-1.

ttem

Motor Type

Drive Voltage

Coil

Reaietance

Drive Frequency

Excitation Mode

2@ole,

positkm

Carriags Orive

4-phaae / 200Do19 hybrid-tyPe etapping

35

v

10.00 t

9601-2

phaee

hybrid-type stepping motor

movement at any position.

sensor, and

the motor phase switching mode.

Motor

i

5ek

7%/pale (at

6oooppe

excitation

poeition rnformatkm

SpSCifkation8

Deaoriptlon

250

C,

770 F)

carriage

motor

tir,

mechanb,

The

position cd the

is fed back to the

causing*

The mrriage

allowing

.:;,.,

.,

0

Figurs

2-6.

Carriags

Drive Mechanism

2.2.2.1 Adjust Lever

Set the adjust lever, attached to the carriage unit, to the appropriate

paper used for printing.

positicm

Table 2-2. Adjust Lever Position

Paper

Type

cut

aheet

Envebpee

Plain paper, bond paper

\

Figure 2-7.

Levar

Poeitbn

Horizontal (A)

Vertical (B)

. .

. . . . . . . . . . . . . . . . . . .

Adjust

‘

Lever

Platen Gap

—

+0.7

mm

/“

.

for the thickness of the

.

Envelopes

.

.,.

.

u

Page 32

Stylus

800+ Sawica

Manual

2.2.3 Paper Feed Mechanism

Opwating

Principles

This printer’s paper feed mechanism

or the manual feed slot. The paper feed drive motor is a

that directly drives the paper feed mechanism (paper advancing operation, paper pickup

operation). This motor also drives the pump mechanism, but only when the printer is in the

cleaning state.

can

feed paper either from the built-in

4phase, 46-pole, PM-type stepping motor

ASF

(auto sheet feeder)

Table 2-3. Paper Feed Drive Motor Specifications

Item

Motor Type

Drive Voltage

Coil Resistance

Drive Frequency

Excitation Mode

4-phase /48-pole PM-type stepping motor

35 v k

54&

650-800

I

2-2 phase excitation

570

3 QI pole (at 25° C, 77°

PPS

Description

I

F)

I

Rev.

Figure 2-8. Paper Feed Mechanism 1

Figure 2-9. Paper Feed Mechanism 2

A

24

Page 33

Opemting

Princlpks

2.2.4 Ink System

W

printer’s ink system is composed of the

❑ Ink cartridge

Pump

0

Cap mechanism

❑

Printhead cleanin

❑ Waste inkdraintank

The

figure below shows a diagram of the

mechams

“m

g mechanism

lbllowing

rnk

system.

mechanisms:

=

Ink Cartridge

Sl)w8 m

S&wm Rbud

Head Driver

Board

Cleaner

Filter

\

I

1

/

I

/

I

!

I

Printhead

./

Pump

@

,.

/

1

i

Figure 2-10. Diagram of the Ink System

2-6

Rev.

A

Page 34

Stylus

2.2.5 Pump Mechanism

800+ Sarvica

Manual

Opwating Prlnc@las

The paper

position where the paper feed motor engages the pump mechanism gear trains, when the carriage

unit is at the ink system home position. The figure below shows a block of the pump mechanism.

Pump system operation depends on the rotational direction of the paper feed drive motor, as

shown in table below.

<Drive: Pump mechanism>

rl

-----

-----

-l

4

L--–

---

lked

motor drives the pump mechanism when the transmission gear is moved to the

A

I

J

L.. 2

<Switch lever:

Set>

<Drive: Paper

feed mechanism>

n-f

Figure 2-11. Pump Mechanism Block

<Switch

lever:

Reset>

0

Rev.

A

2-7

Page 35

Opmthg

FY’hw@9s

Siyhm

m

~

Manual

Table

r

PF

Motor Rotational

24.

Pump Mechanism Operation

1

Diraotion

Oparatiort

1

Pumping

clockwise

(forward rotation)

(Cw)

Pseudo-pumping

Gear

backruah mmpenaation

(falee abeorbing)

Micro absorbing

Countedockwiee (CCW)

(baclward

The pump draws

rotation)

rnk

from the printhead nozzles and drains it to the waste ink drain tank.

operation is performed by the printer to eli

below

illustrates pump operation. When the paper

pulley pump in the wheel pump unit rotates in the direction of the arrow, while

Pump pulley reeet

Gear

backrueh compenaatiort

.

This

minate dust/bubbles within the nozzles. The figure

tked

drive motor rotates CW (forward), the

squ

eezing

the ink

tube to push the ink out of the tube and into the waste ink drain tank. On the other hand, when the

motor rotates CCW, the pulley pump moves inward along the grooves of the wheel pump,

releasing the pressure applied to the ink tube.

Vaammin~ No

Pumping

Ftubbsf

bkdo

Rotation:

(Rubber

blado pushes tho

pulley to outcrsido of

W!IOOI, and tha

the Ink tub..)

CCW

pump

(CCW)

Pump

whoci

pUlllp

tho

PUMP

pullay caotacts

Vauwrling

No Pumping

Rotation: CW

(Rubber

blado

by pushing II to

(CW)

rsaotstho pump

tho

Inn-r MD.)

pullay

2-8

Figure 2-12. Pump Operation

Rev.

A

Page 36

Stylus

2.2.6 Cap Mechanism

800+

Service

Manual

Operating

Principiss

The cap mechanism prevents the

the nozzle while the printer is not in use.

automatically so that a cap closely contacts the

to the ink system home position.

1

\

1+

‘

-

\

printhead

Carriage

(Printhead)

nozzles from drying or bubbles from forming inside

e

The

printhead

printhead

capping operation is performed

surface when the carriage unit is moved

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

&

\

Slider Valve

■

‘/

Cap Unit

,..

Figure 2-13. Cap Mechanism

Rev.

A

2-s

Page 37

Opening

Prfnc@hw

Slylus SW+

2.3 OPERATING PRINCIPLES OF THE CIRCUITS

~

-In@

The Stylus

C134

C106PSB-B/PSE-Bboad

In addition to the

circuit

figure below shows a block

AC Input

8(M+

contains the following circuit board units:

MAIN board

tnrd

installed in the

(maincontrol

arcuit boards above, part of the

carriage unit, and the

diagr&

M-481 1

Printer Mechanism

,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

\/

Cl 06

PSB-B/

PSE-B

+35

VDC

+5 VDC

circuit board)

(powersupplycircuitboard)

printhead

printhead

of the arcuits.-

Carriage

/

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Head Driver

Board

CR Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PF Motor

d

drive circuit is

is attached directly to this board.

built

on a separate

Head Drive

I

~

Voltage

(+35 VDC)

The

I

C134

MAIN

~

~

L

,.. . . . . . . . -. - . . -- . . . . . . .- . . . . ---- . --- . . . . . . . . . . . .- .- -. . . . . . . . .,

I

C106

Control

Panel

Figure 2-14.

2.3.1 Operating Principles of the Power Supply Circuit

The power supply

VAC)

or the

functionality, except for components in the primary arcuit that

voltage. The application of output voltages is summarized in the table below.

arcuitry fbr

C106 PSE-B

BOARD (220-240

Tabie

Vottago

+35VDc

Motor

Printhead

Biock

this printer is provided either by the

2-5. DC

drive

Diagram of the Circuits

VAC).

Both boards am identical in design and

Voitage

(caniage

(through the drive

Distribution

Applkation

and

paper

vottage

feed)

accomm

generation circuit)

C106 PSB-B

odate the specified input

PNL

BOARD (120

2-1o

I

C134

I

+5

VDC

MAIN

Sensors (home

control panel

(PF motor holding

bad

poeition

and paper end)

vottage)

Rw. A

Page 38

Stylus 800+ Sarvica Manual

Oparating Princ@9s

The figure below shows a block diagram of the power supply circuit (CIM

power supply circuit employs the RCC (ringing choke converter) switching control system. The

input AC voltage supplied from the external AC source is first input to the filter circuit for higher

TRe

harmonics absorption.

converting it into DC voltage.

operation. Along with the switching operation on the primary side, +35

passing through the smoothing circuit. The +35

circuit through the +35 V line voltage detection circuit and, thus, the +35

stabilized. This +35

VDC

Primary

AC voltage is

This DC voltage is input to the switching circuit for switching

is

also

input to the +5

Side

fhen

input to the rectification and smoothing circuit,

VDC

VDC

regulation arcuit to regulate a stable +5

Secondary

level is fed back to the primary switching

Side

m

cl 1

—~

Smoothing

Circuit

Q1

b

DB1

Full-wave

Rectifier

Circuit

F?

Filter

Circuit

T1

,.—.

,,

—.—

1

*

~

I

ZD52

+35

v

ZD8 1/82183/84185151

+35

v

Voltage Drop

Sensing

Circuit

ZD53

+5

v

I

PSB-B/PSE-B).

VDC

is generated after

VDC

output level is

~+5

~+35

This

VDC.

VDC

VDC

Pcl

!–

L

$

AC Input

Figure 2-15. Power Supply Circuit Block Diagram

This circuit contains the protection circuits described below.

1.

+5

VDC

line overvoltage protection circuit

The output voltage level of the +5 V line is monitored with a

voltage level exceeds the predefine level (+7

switching circuit through a

+5

VDC

2.

The output current is monitored with detection resistors

+5

control

voltage level (constant current operation).

+35

3.

The output level is monitored with

level drops below the limit level (+32 V), it activates

primary switching circuit operation.

+35

4.

The output level of the +35

diode

the primary switching circuit to control the

constant output voltage control.

line over current protection circuit

VDC

generation switching control IC

IC

shortens the ON time of the switching transistor

VDC

line voltage drop sense circuit

VDC

line constant

(ZD52).

This circuit feeds back the output voltage level status througha photocouplerto

photocoupler (PCl)

vokage

output control circuit

VDC lhe

Zener

is monitored by a detection circuit that consists of a

V),,

this status is fed back to the primary

to stop the +35 V generation.

(IC51).

If the current level exceeds the limit, the

diodes

(ZD81,

ON/OPF

82,83,84,85, and 51). If the voltage

photocoupler PCl,

time of the switching transistor for

1

(R53

Zener

diode

and

R81)

(Q51)

to decrease the output

(ZD53),

and fed back to the

and this stops the

and if the

Zener

Rav. A

2-11

Page 39

WW

Pril?+hm

SiyIl#8

U@+

su’ldco

Manual

2.3.2

The

l&bit

making it capable of handling data a an 6-bit bus width data bus or a 16-bit bus width data bus.

Themtbre,

speed. Gate array

Centronics

drive motor and the paper feed motor. This board also is equipped witha

to store parameters, such as the

as well as the special counter value used for

Operating

C134

MAIN board is the main

TMP96C141F

a

l~bit

parallel

I

IC3

Prlnciplea

CPU (ICI),

data bus width ROM is used cm this board, increasing the internal process”

E05BW (IC3)

interhce),

l—l

of

tha

Main Control Circuit

cxmtrol

running at

manages

and the control panel. The CPU directly

pMter

+35 VDC

circuit of this printer.

19.6fXXl MHz

printhead

mechanism control parameter, default setting parameters,

printhead

This CPU has a unique architecture,

drive control,

protection.

‘his

circuit is controlled by the

extemaI

mntrola

I/F control (fir%

both the carriage

93C46

EEPROM (IC1O)

ri

Control

Panel

‘05’00

CRO-3

I

P61x

mmm

]

(Program)

~

I

IC13

SLA7024

;ti

CR Motor

Figure 2-16. Main Control Circuit Block Diagram

II

ADO-15

(CG/4,

QM1

SMA6501

8, 16M) ]

PF Motor

l(CG/4,

IC14

Mask ROM

(CG/

--l

4,8,

8,

16M)

m

16M)j

(lM)

IC15

Mask ROM

l(CG/4,

8,

16M) I

2-12

Rev.

A

Page 40

Stylus Wlh

Servke Manual

Optwating

Principks

2.3.2.1

The

Reeet Circuita

C135

MAIN board contains two reset circuits: the +5 V monitor reset circuit and the +35 V

monitor reset circuit. The +5 V monitor reset circuit monitors the voltage level of the +5 V line,

using reset IC

E05BO0

gate array

circuit, on the other hand, monitors the voltage level of the +35 V line, using reset IC

(IC1l), and outputs a reset signal to the CPU. The reset signal is generated when the voltage

drops, and this causes a

PST592 (IC12),

(IC3),

when the voltage level drops below +4.2 V. The +35 V monitor reset

non-maskable

and outputs a reset signal to both the CPU (ICI,

interrupt

(NMI).

TMP96C141)

and the

51955BFP

level

&&

23

RESET

~

E05A85EB

(IC3)

1

27

21

NMI

RESET

CPU

(ICI)

3

Figure 2-17. Reset Circuit Block Diagram

2.3.2.2 Sensor Circuits

The following sensor circuits

1. HP sensor

A photocoupler-type HP (home position) sensor is attached to the back of the

emble

carnage unit to detect the carriage home position as a print reference position. A

HIGH level from the signal indicates that the

2.

PE

sensor

A mechanical switch PE (paper end) sensor is built into the printer mechanism to

determine whether there is paper in the printer or not.

3.

IE

sensor

Two electrical contacts are attached to the ink cartridge holder in the carriage unit,

and when the ink cartridge is installed, the metal pins built into the ink cartridge

touch these contacts. “he IE (ink end) sensor circuit applies a HIGH level signal

when performing the ink end status detection operation. The ink level is

determined by the resistance between the two contacts by measuring the input

signal level with analog port ANO (pin 73) of CPU.

4. Thermistor

A thermistor is attached to theprinthead unit to monitor its temperature. The CPU

changes the printhead drive signal’s pulse width (charge pulse width) based on the

temperature level.

PE

(CN4)

+5

v

-

79 80

SW8

E05BO0

(IC3)

I

the main board to monitor printer mechanism status:

carriage is in home position.

+5 v +5 v

10 I

~3r7!3)

+5 v

Sw

INK

46

48

777-

IC9

1

Rev.

CPU

(ICI)

AN1 ’

74

+5 v

Figure 2-18. Sensor Circuit Block Diagram

A

2-13

Page 41

Opmthg

2.3.2.3

Pdnc@k8

Ink End Detection

S&h m

Su’vko

hmnml

The IE (Ink

low and whether an

modes based on the output voltage level of the

Cl

Cl

Inklow

0

End) sensor

Abnormal condition mode:

Normal

Mode A:

conditon

mode:

attached to

rnk

cartridge

mode:

❑ Mode B:

Cl Inkend

Cl

No

mode:

inkcartridge

mode:

the

-ge

(I/C)

is installed. The detected status is divided into seven

Errormnditkm

Normal amditim

Ink is low

Ink is low (during printing) (printable)

Inkend

Jnkend

No I/C (not

detects, not

IE

sensor.

(during pumping) (not printable)

rnstalled)

High

Mode \

Resistance

Value

ody

the ink end, but&m when ink is

(not

printable)

(prin-table)

@intable)

(not printable)

(not printable)

-

Ink

End

I

/

No Ink

Cartridge

o

if.;

.

Normal

Condition

Abnormal

d

Low

Condition

Full

Ink Remaining

Figure 2-19. Ink End

When the ink end detection operation has d

the control panel,

1. During

2. During pump operation:

3. In standby

as described below:

pMting

State:

If an ink end is detected, the printhead is

panel indicates an INK END error.

If Mode B is detected, the printer indicates an INK END error after

the detection operation sequence completes and

operatkm.

If Ink ad mode, Abnormal mode, or No ink cartridge mode is

detected, the printer indicates an INK END error after interrupting

pump operation.

If Ink end mode, Abnormal mode, or No ink cartridge

detected, the

m.

etermined ink status, the

/

Empty

--+

Detect}on

pMter indicates the status on

cxipped

ptiter

indicates an INK END error on the control

and the control

interrupk

pump

tie

c’

is

2-14

Rev.

A

Page 42

Stylus

2.3.2.4 Carriage Motor Drive Circuit

The

using a constant current,

drive current level using the output signals from ports

switching operation is directly controlled by the phase control signals output from ports

P603 (p=

800+

service Manual

SLA7024

carriage motor drive IC

unipolar

l-to 4) of the CPU. The table below shows the carriage

(IC13)

drives the carriage motor for the printer mechanism

drive system. Gate array

E05BO0 (IC3)

CRO

to

CR3

rnotordrive

Oparating Principbs

selects the motor phase

(pins 75 to 78). The phase

modes

-

Table 2-6. Carriage Motor Drive Modes

P600

to

CR Speed

(CPS)

250 6000

165

63

40 960

HOLD

CPU

(ICI)

E05B00 CR()

(IC3)

r

P600

P601

P603

P602

CR1

CR2

CR3

Frequency

~

-

6

‘7INB

5

‘6

R224

Acceleration

Current

0.60 0.4W0.45

0.60 0.30/0.60

0.60 0.

0.60 0.

SLA7024

(IC13)

INA

IN-A

IN-B

RFA

RFB

I

Drive

(PPS) (A/Phase)

3960

2000 1-2

—

2

3

4

+5V

d

78

77

76

75

s

R33

R34

R35

R36

Phase

Excitation

1-2

phaee

1-2

phaae

phaae

1-2

phaae

2-2 phase

R59 R223

I

NormeUDeoeleretion

current

(NPhase)

SWO.60

WO.60

Approximately 0.15

+35V

;

*

a

~

“

-A

-B

A

B

8

1

18

11

CR

Motor

(CN6)

CRCOM

CRA

CR-A

CRB

CR-B

Rev. A

Figure 2-20. Carriage Motor Drive Circuit

Biock

Diagram

2-15

Page 43

Op9mting Princ@8s

S@8 *

SUvics

~

2.3.2.5 Paper Feed Motor

The paper

❑

Paperpickupmechanism

Pump mechanism

The

system. The CPU outputs phase

switching operation.

TCJ3 (orn 12)

HOLb mode. The drive

fked

motor

Paper feed mechanism

SMA6501

driver IC

to switch the

lbr

(QM1)

‘Ihe

Tabie

Driw!

this printer drives the

drives the paper feed motor using a constant voltage,

control signals

CPU also outputs the supply voltage switching

supply

mod~~shom-rn

2-7. Paper Feed Motor Drive Modes

M*

Continuous feed

pump

drive

CPU

(lCl)

P61O

P611

P612

P613

5

6

7

8

El

T03

12

J

Circuit

tdkmving nwchams

from ports

voltage to +5

the

Phase Excitation

2-2

phaae

2-2

ptlaae

10 BP

Q1..

. .

.

“nw

unipolar

P61O

to

P613

(pins 5 to 8) for the phase

amtrol

signal

VDC

wkm the paper feed motor control is m

tabiebelow.

Drive

Fmquency(PPS)

800

650

SMA6501

(QM1)

‘ B1

3

B2

6

B3

8

B4

1

1

2

cl

C2 ;

C3

9

C4

B

D1

T

PF Motor

(CN5)

)

‘

PFA

5

PF-A

2

PFB

8

PF-B

1

fmm

drive

port

. . . . . . . .

.

+’

+’

777

Figure 2-21. Paper Feed Motor Drive Circuit Block Diagram

2-16

Rev.

A

Page 44

Stylus

4MI+ Ssrvks

hknusl

OpmWng

Princ@lss

2.3.2.6

The

•l

The

nozzle selector to drive the

gate array

printhead

gate array

one bit corresponding to each nozzle of the

complete, gate array

(discharge pulse) to the common drive

trapezoidal pulse and applies it to the

selected by the head data is activated to inject ink by energizing the MLP element drive with the

applied trapezoidal drive pulse.

Printhead

printhead

Commondrivecircuit(trapezoidal drivepulsegeneration)

❑

Head drive circuit (nozzle control built on

SED5620D

drive circuit for this printer is composed of the following two parts:

E05BO0 (IC3)

as data for each nozzle.

E05BO0

Drive Circuit

theprinthead)

64-bit thermal head driver in the head drive circuit on the

printhead

and is output from port S1 (pin 63) to the head drive circuit on the

outputs the

E05BW

nozzles selectively. Print data is converted into serial data by

Then, the

LAT

signal, and the latched data becomes 48-bit parallel data, with

outputs the common drive pulse

printhead

SED5620D

printhead.

arcuit.

head driver latches the head data when

When data transfer and nozzle selection is

The

common drive circuit then generates the

as a common drive pulse. After this, the nozzle

::

printhead

PWC

(charge pulse) and

is used as a

PWD

(IC3)

CPU

(lCl)

Pwc

PWD

:

j

Figure 2-22.

HCLK

LAT

~,

AN1

65

M

63

74

Printhead

.:- - - - ; - - - - -: - - - - - - -

::

1

Drive

Pulae

+5 v

+

HEAD-1

2

HCLK

:“

IAT

SI

‘2TH

HEAD-2

(CN3)

Rev.

A

Figure 2-23.

Printhead

Drive Circuit Diagram

2-17

Page 45

Openlting Princ@b98