Page 1

“)

EPSON TERM

Myk.

NAL PRINTER

800

SERVICE MANUAL

EPSON

4001968

)

Rev. A

Page 2

NOTICE

Allrightsreserved.ReproductionofanypartofthismanualinanyformwhatsoeverwithoutSEIKO

EPSON’sexpresswrittenpermission isforbidden.

The contentsof this manualare subjectsto change without notice.

Alleffortshavebeenmadetoensuretheaccuracyofthecontentsofthismanual.However,shouldany

errorsbe detected,SEIKOEPSONwould greatlyappreciatebeinginformedof them.

TheabovenotwithstandingSEIKOEPSONcanassumenoresponsibilityforanyerrorsinthismanualor

the consequencethereof.

Epsonisa registeredtrademarkofSeiko EpsonCorporation.

GeneralNotice:Otherproductnamesusedhereinareforidenticationpurposesonlyandmaybetrademarks

of theirrespective campanies.

Copyright © 1992 by SEIKO EPSON CORPORATION Nagano, Japan

-i-

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to

damage to equipment.

DANGER

WARN/NG

The precautionary measures itemized below should always be observed when performin

maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

1)

personal injury and 2)

grepair/

DANGER

1.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR

2.

WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

3.

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO.

WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION

NENTS.

IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPO-

WARNING

1.

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

2.

VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON

PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED

3.

FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

4.

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS,

WHEN ACCESSING INTERNAL COMPONENTS.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPO-

5.

NENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICS OR

REPALR

TECHNICIAN.

-

ii

-

Page 4

PREFACE

This manual describes

of stylus 800.

The instructions and procedures included

attention should be given to the precautions on the preceding page. The chapters are organized as

follows:

functions, theory of electrical and mechanical operations, maintenance, and repair

herein are intended for the experience repair technician, and

CHAPTER 1. GENERAL DESCRIPTION

Provides

a general product overview, lists specifications, and illustrates the main components of the printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a

step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives

required to service the equipment.

APPENDIX

Describes connector pin assignments,

circuit diagrams, circuit board component layout

amd

exploded diagram.

The contents of this munual are subject to change without notice.

-

iv -

Page 5

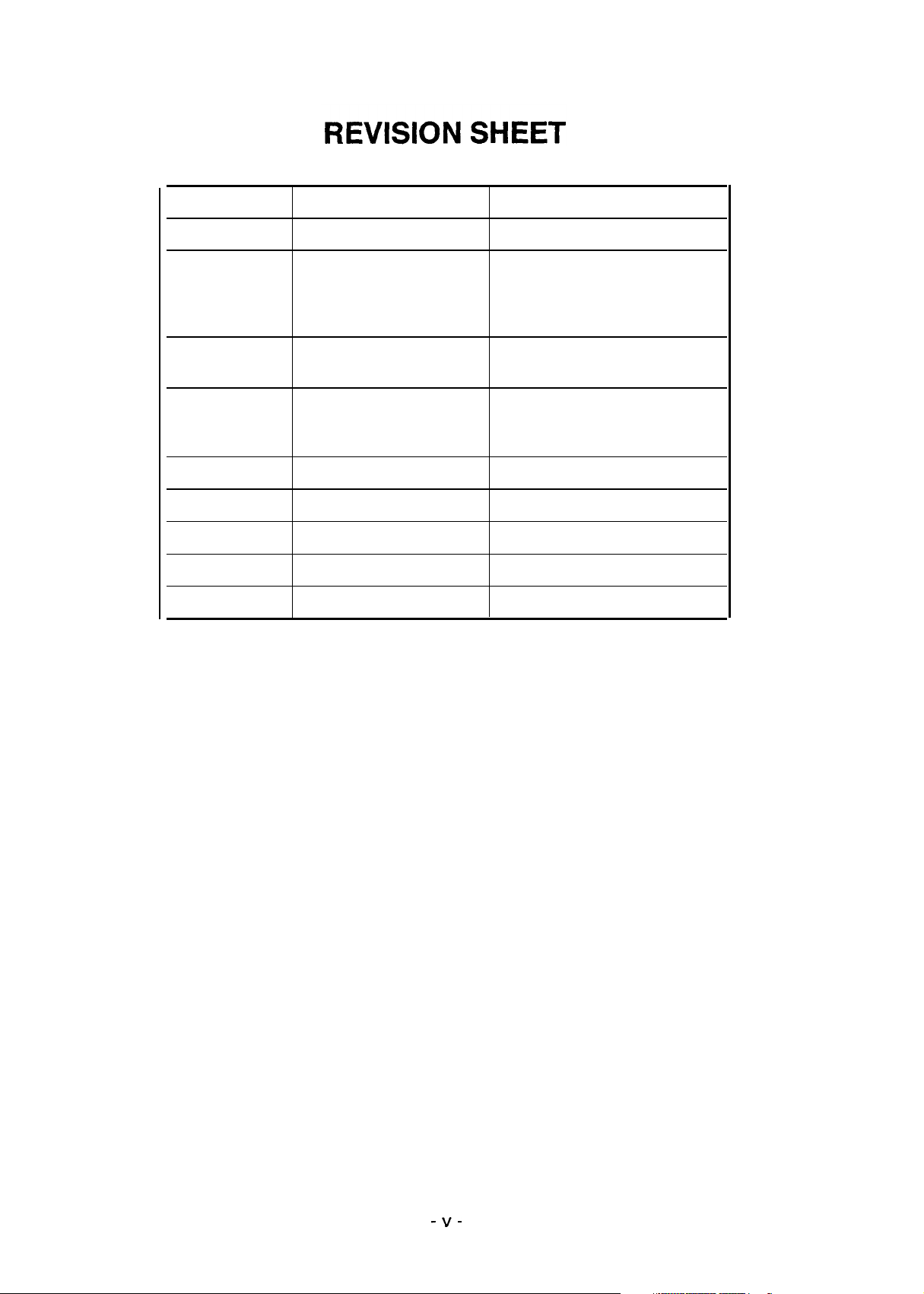

Revision

Issue Date

Revision Page

Rev. A

Rev. B

Rev. C

Rev. D

December

June 11, 1993

March 10, 1994

18, 1992

May 7, 1993

First issue

Added information:

Chapter 2 (Page 2-23)

Chapter 3 (Page 3-5/6)

Chapter 6 (Page 6-1/2)

Corrected the figure:

Chapter 2 (Page 2-8)

Added information:

Appendix (Page A-i, A-5’, A-7’,

A-8’, A-9’, A-1 O’)

-v-

Page 6

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6.

APPENDIX

GENERAL DESCRIPTION

OPERATING PRINCIPLES

DISASSEMBLY AND ASSEMBLY

ADJUSTMENTS

MAINTENANCE

-

vi -

Page 7

Chapter 1

General Description

Table of Contents

FEATURES

1.1

1.2 SPECIFICATIONS

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.2.6

1.2.7

1.2.8

1.2.9

1.3 INTERFACE SPECIFICATION

1.4 PRINTER OPERATIONS

1.4.1

1.4.2

1.4.3

1.4.4

1.4.5

Printing Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Handling Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-4

Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............1-4

Ink Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......1-6

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ....1-7

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......1-7

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .........1-8

SafetyApproval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..............1-8

Physical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..........1-8

control

Panel Operation at PowerOn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-12

1.4.3.1 Default Setting Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-12

Initial Ink Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ..1-13

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-13

panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . ~

.

................1-1

1-1

1-2

.1-2

1-9

1-11

..1-12

1

1.5 MAIN COMPONENTS

1.5.1

Main Control Board (C106 MAIN BOARD) . . . . . . . . . . . . . . . . . . . . . .. .1-14

1.5.2 Power Supply Unit

1.5.3

Printer Mechanism

Figure 1-1.

Figure l-2.

Figure 1-3.

Figure 1-4.

Figure 1-5.

Figure 1-6.

Figure 1-7.

Figure 1-8.

Figure 1-9.

Figure l-10.

Figure 1-11. Printer Mechanism

View of the Stylus 800 . . . . . . . . . . . . . . . . . . . . . ...............1-1

Nozzle Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......1-2

Printable Area - Cut Sheet (Built-in Sheet Feeder) . .............1-5

Printable Area - Cut Sheet/ Envelope (Manual Insertion Slot) .. ...1-5

Adjust Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..........1-6

Temperature

Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . .........-..1-9

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..1-11

C106 MAIN BOARD Component Layout . . . . . . . . . . . . . . . . . . . . .1-14

C106

PSB/PSE

(C106

(M-481O)

/

Humidity Range . . . . . . . . . . . . . . . . . . . . . ........1-7

1-14

PSB/PSE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-15

BOARD) . . . . . . . . . . . . . . . . . . . . .1-15

List of Figures

BOARD Component Layout . . . . . . . . . . . . .....1-15

(M-481O)

. . . . . . . . . . . . . . . . . . . . . . . . .....1-15

Rev.

A

l-i

Page 8

List of Tables

Table 1-1. Print Speed and Printable Columns . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2. Character Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table l-3. Adjust Lever Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......1-6

Table l-4. Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-7

Table l-5. Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...1-7

Table l-6. Signal and Connector Pin Assignments . . . . . ..................1-9

Table l-7. Default Setting Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-12

Table l-8. Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....1-13

I-ii

f“”-”’-

Rev. A

Page 9

STYLUS 800 Service Manual

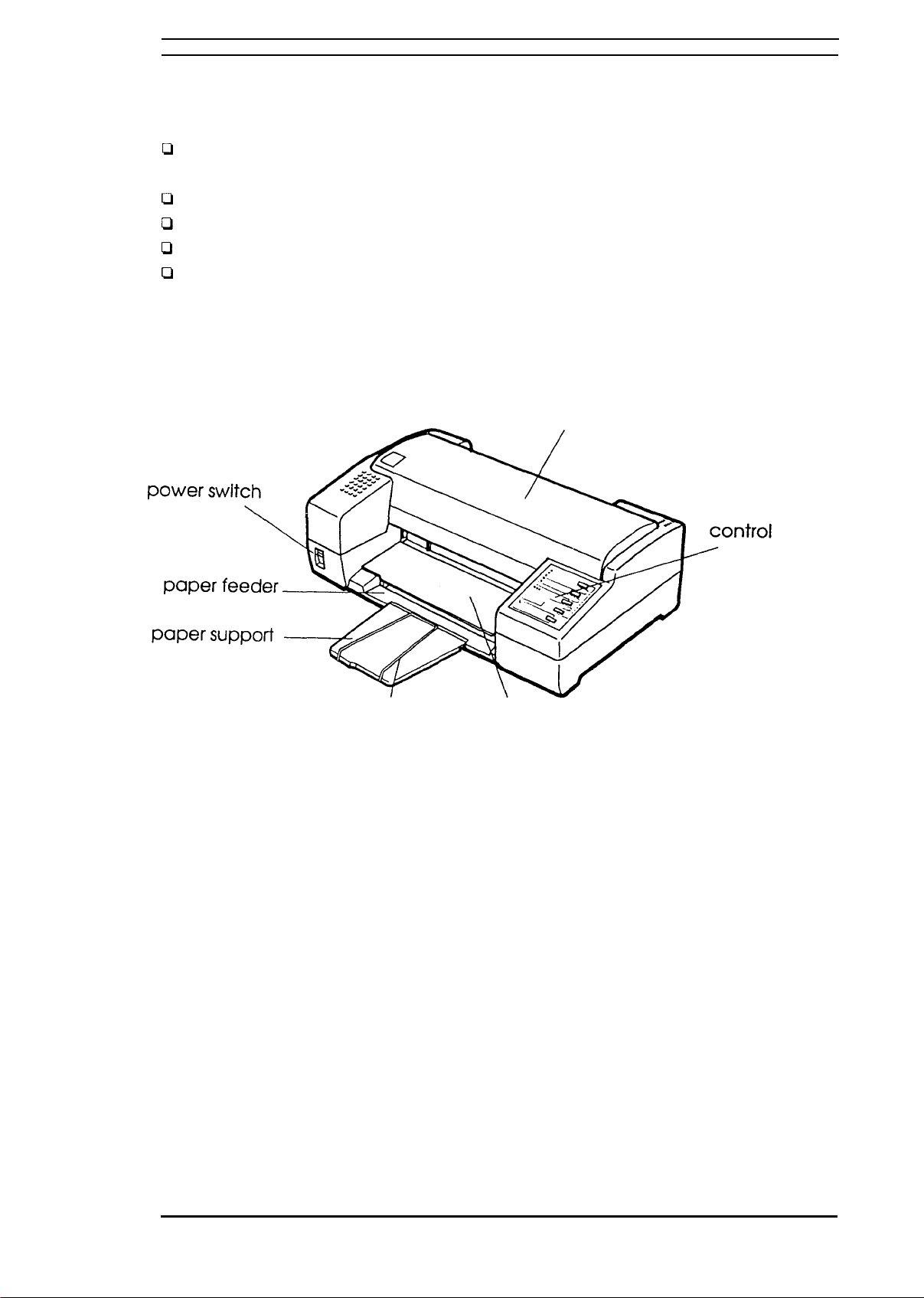

1.1 FEATURES

The Stylus 800 is a serial inkjet printer that uses a newly developed inkjet technology to accomplish

a superb quality output with high-speed printing. The major features of this printer are:

Ll

High print quality from a new inkjet technology.

Cl Fast printing of LQcharacters at 150 cps.

Cl

Compact design saves precious work space.

Ci

Built-in auto sheet feeder with a capacity fora maximum of 100 cut sheets (either A4 or Letter).

D

Equipped with 4 scalable fonts and 15 bit-mapped fonts, standard.

CI

8 character tables for the U.S.

6 character tables for Pacific countries.

16 character tables for European countries.

The figure below shows a view of the printer.

General Description

printer cover

paper separator

Figure 1-1. View of the Stylus 800

panel

paper feeder cover

Rev. A

1-1

Page 10

General Description

1.2 SPECIFICATIONS

STYLUS 800 Service Manual

This section provides detailed statistics for this printer.

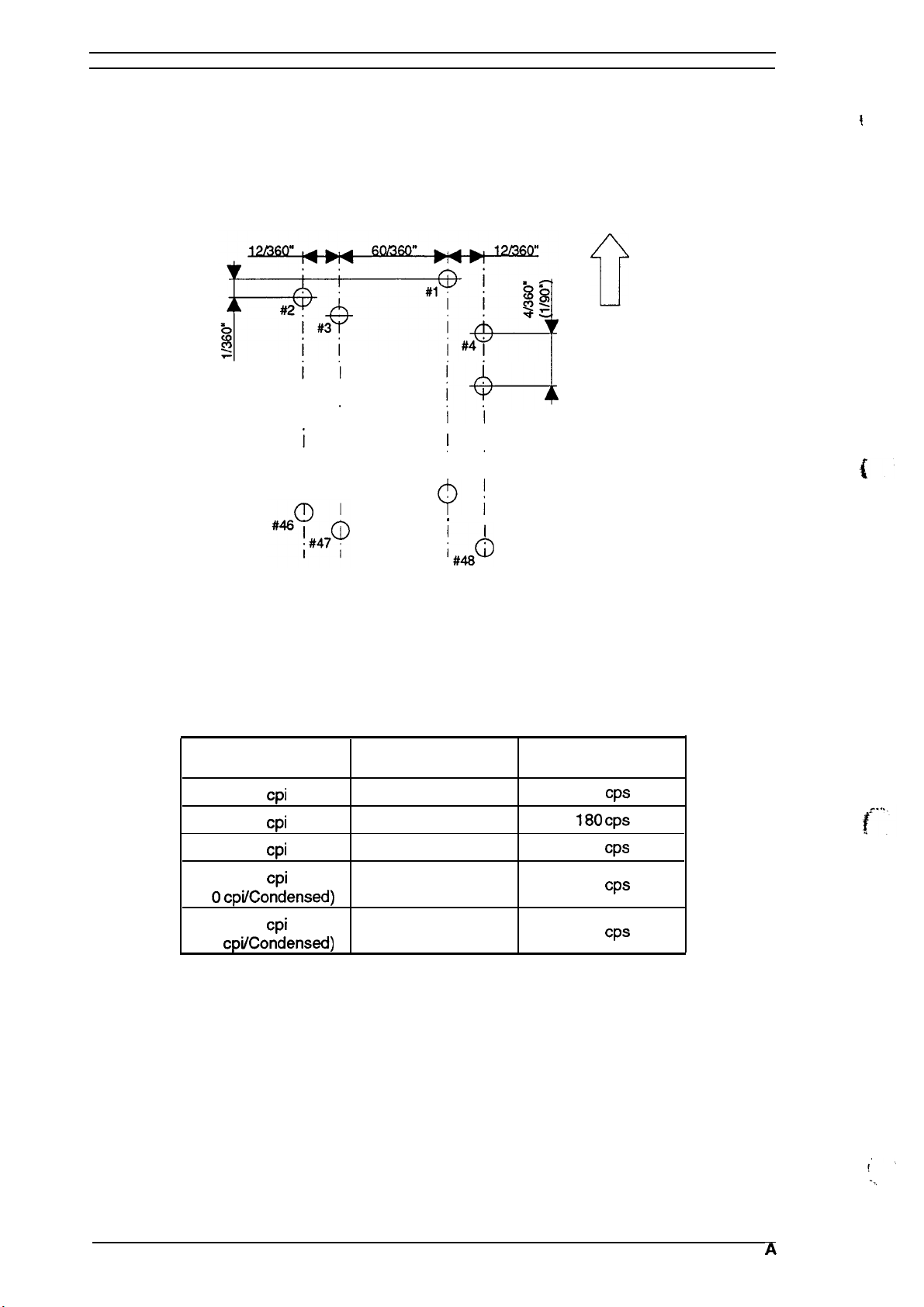

1.2.1 Printing Specification

Print system:

Nozzle configuration:

On-demand ink jet system

48 nozzles (12 nozzles x 4 staggered columns)

II

.

.

II

i

i

II

i i

#45

II

I

,,

II

Qi

.

I

i

0

Paper feed

direction

{

i’

..., *

Printer direction:

PMt speed:

Printable columns:

Character Pitch

(l

Ocpi/Condensed)

(12

Figure 1-2. Nozzle Configuration

Bidirectional printing with logical seeking control

See Table 1-1.

See Table 1-1.

Table 1-1. Print Speed and Printable Columns

Print Speed (LQ)

150

Cps

180

CPS

225 CPS

257 Cf)S

300

Cps

10

cpi

12

cpi

15

cpi

17

cpi

20

cpi

cpVCondensed)

Printable Columns

80

96

120

137

160

1-2

Rev.

,,

f’

-..

A

Page 11

STYLUS 800 Service Manual

Geneml

Descri@ion

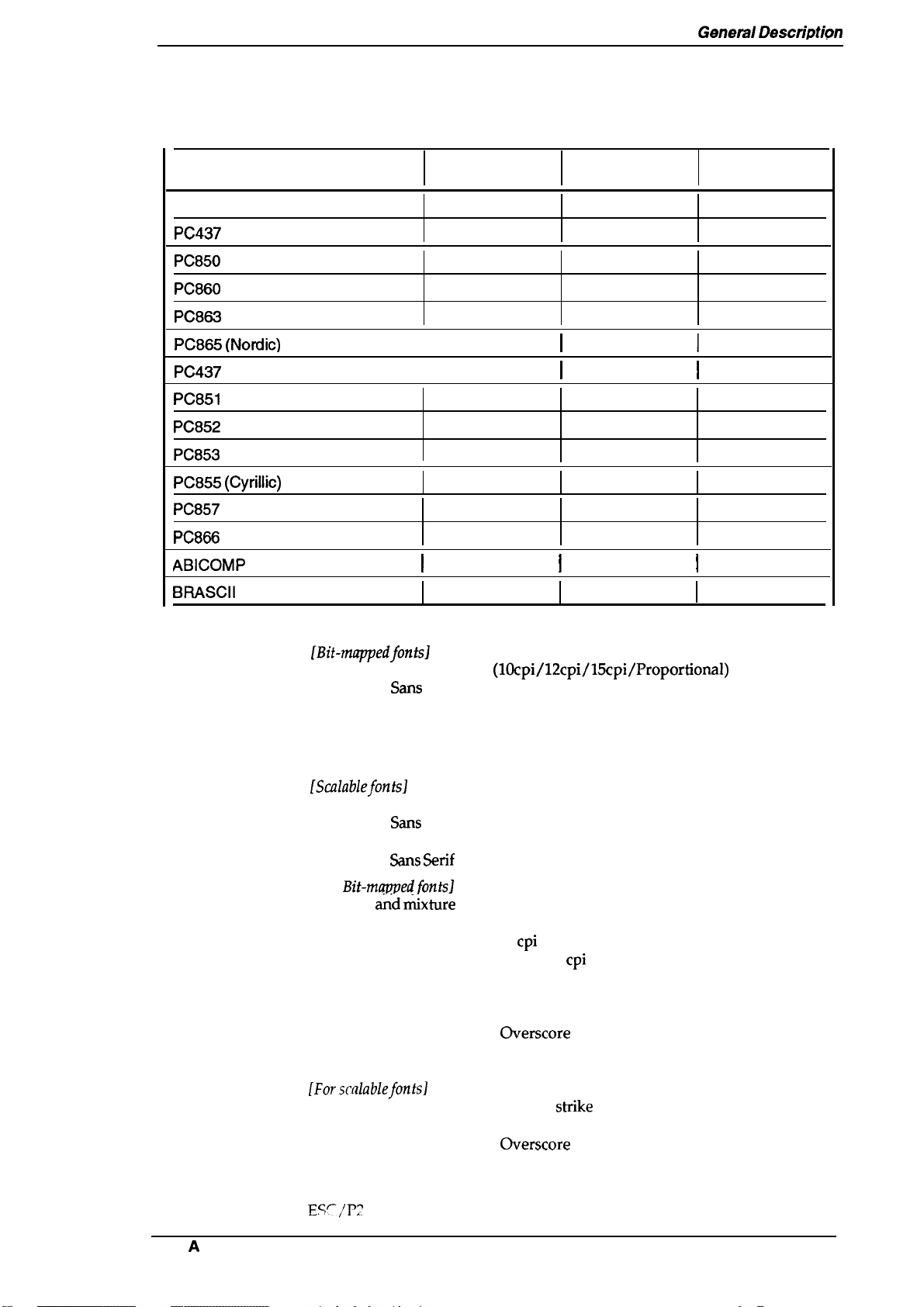

Character sets:

Character tables:

Character Table US Version European Version Pacific Version

ITALIC

PC437 (U.S./Standard Europe)

PC850 (Multilingual)

PC860 (Portuguese)

PC863 (Canadian-French)

PC865 (Nodic)

PC437 Greek

PC851

(Greek)

PC852 (East Europe)

PC853 (Turkish)

PC855

PC857 (Turkish)

(Cyrillic)

Legal and 14 international character sets.

See Table 1-2.

Table 1-2. Character Tables

o

0

o 0

o

o

0

0

o 0

I

I

o

I

x

x

x

x

x

x

I

o

o

o

o

o

o

o

0

0

0

0

0

I

I

o

x

x

x

x

x

x

PC866 (Russian)

ABICOMP

BRASCII

Fonts:

Print mode:

x

I

o

o

[Bit-mppedfonts]

-

EPSON Roman

- EPSON %ns serif

- EPSON Courier

- EPSON Prestige

- EPSON Script

IScaldlefmtsl

-

EPSON Roman

- EPSON %ns serif

- EPSON Roman T

- EPSON

[For

Bit-mppedfontsl

Selection ~-d

- Print quality (LQ)

- Character pitch (10/12/15

- Condensed (not available with 15

- Double width

- Emphasized

- Italic

- Double underline

- Strike through

!%IIS

&xture

%rif

(lOcpi/12cpi/15cpi/Proportional)

(10/12/15/Proportional)

(10/12/15)

(10/12)

(10/12)

8-32 points (Unit= 2 points)

8-32 points (Unit= 2 points)

8-32 points (Unit= 2 points)

H

8-32 points (Unit= 2 points)

of the following mode are allowed.

cpi

or proportional)

- Double height

- Double strike

- Underline

-

Overscore

- Shadow / outline

o

I

cpi

x

x

character pitch)

x

I

x

x

Control codes:

Rev.

A

IForscalablefonts]

-

Emphasized

- Italic

- Double underline

- Strike through

EC,~//~~

- Double

- Underline

-

Overscore

- Shadow / outline

stike

1-3

Page 12

General Description

1.2.2 Paper Handling Specification

STYLUS 800

Sewice Manual

Feeding system:

Feeding pitch:

Paper path:

Feeding speed:

Friction feed from built-in sheet feeder or manual insertion slot.

Notes: The following operation are not al/owed.

1. Reverse feeding within

2. Reverse feeding beyond 7.9 mm (0.3 inches).

1/6, 1/8 inch feed or progra

Built-in sheet feeder (front entry)

Manual insertion slot (Top-rear entry)

87

msec.

(at 1/6 inch feed pitch)

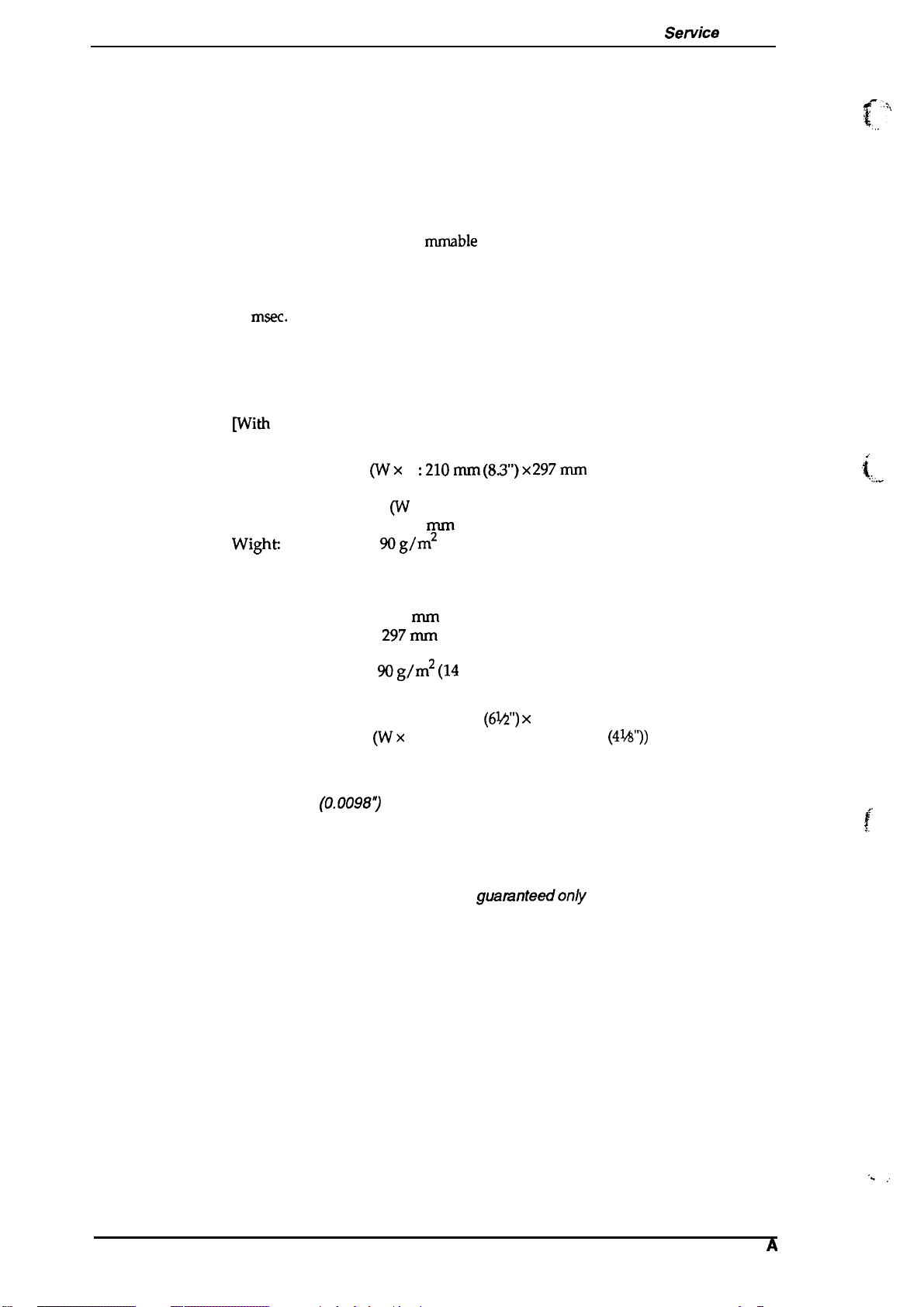

1.2.3 Paper Specification

Usable paper:

~ith

Cut sheet

Built-in sheet feeder]

Size:

Thickness:

Wighk

Quality:

3

mm (O. 12 inches) from the top edge

of the paper or 16 mm (0.63 inches) from the bottom edge of

the paper.

mmable

For European/Pacific version:

A4

(wX

L

:210mm (8.3”)X 297mm

For U.S. version:

Letter (W x L: 216 mm (8.5”) x 279 mm (11.0”))

0.065-0.14

-

90g/m2

64

Bond Paper, Photocopier paper

nun

with a 1/360 inch minimum increment.

(11.7”))

(0.0026 - 0.0055”)

(18 -24 lb./55 - 78 Kg)

.:

f“”

. .. . .

.

i.:,,-

<Envelope>

[With manual insertion]

Width:

Length:

Thickness:

Wight:

Quality:

Size:

Thickness:

Note:

Weight:

Quality:

Notes 1. Envelopes are usable only with manual insertion feed.

The variation in paper thickness within the printable area must be 0.25

mm (0.0098~ or less.

2. Printing with envelopes

3. Insert envelopes into the manual insertion slot sideways.

182-216 mm (7.2 - 8.5”)

257-

297mm

0.065-0.11 mm (0.0026- 0.0043”)

52-

90g/m2 (14

Bond Paper, Photocopier paper

#6 (W

X

#10

(Wx

0.16-0.52 mm (0.0063 - 0.0197”)

45-90 g/m2 (12 -24 lb.)

Bond paper, Airmail, Photocopier paper

and humidity condition.

(10.1 - 11.7”)

-24 lb / 45- 78 Kg)

L : 166 mm

L:

240

mm

(6%”) X

92 mm (35/8”))

(914”)

x 104 mm

guaranteedonly under normal temperature

(4%”))

f’

1-4

Rev.

,. ,.

A

Page 13

STYLUS 800 Service Manual

Geneml

Description

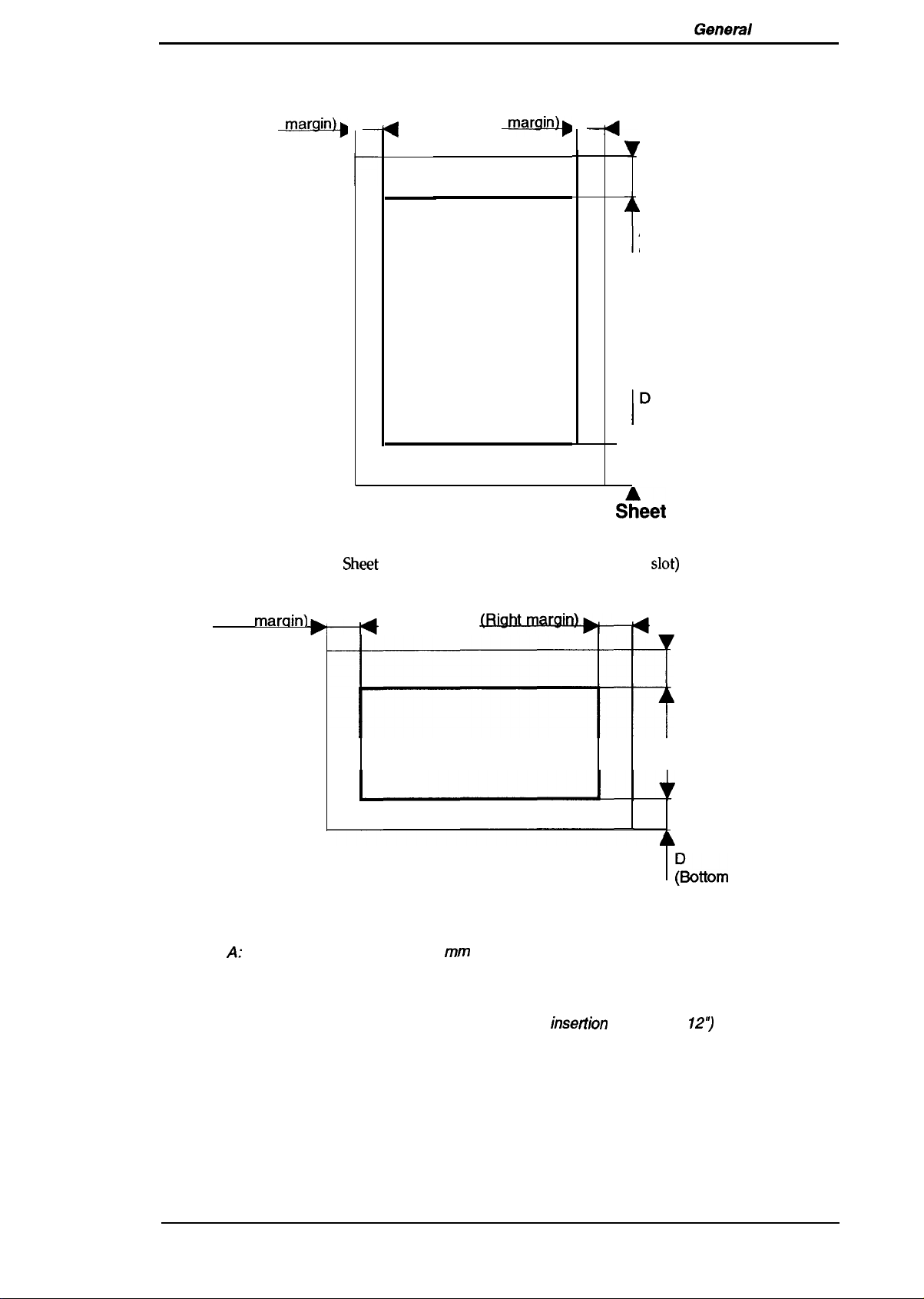

Printable area:

B

(Left marain)>

Cut Sheet (with built-in sheet feeder)

c

—

4

(Right marain]~

.

r

Printable area

Figure 1-3. Printable Area - Cut S~eet

(Built-in Sheet Feeder)

r

A

!

(Top margin)

ID

I

(Bottom margin)

1

Note:

Cut

Sheet

/ Envelope (with the manual insertion

B

(Left

marain) ~.

Figure 1-4. Printable Area - Cut Sheet/ Envelope

A:

The minimum top margin=

B: The minimum left margin= 3 mm (O. 12”)

C:

The minimum right margin is:

D: The minimum bottom margin= 13 mm (0.51’)

*

Printable area

(Manual Insertion Slot)

3 mm (0.12”)

c

A4 size= 3.8

Letter size = 9.7mm (0.38’)

Manual

mm (O.

insettion

slot)

A

(Top margin)

L

&ottom margin)

15”)

= 3 mm (O.

12’9

Rev. A

1-5

Page 14

General Description

SNLUS

800 Service Manual

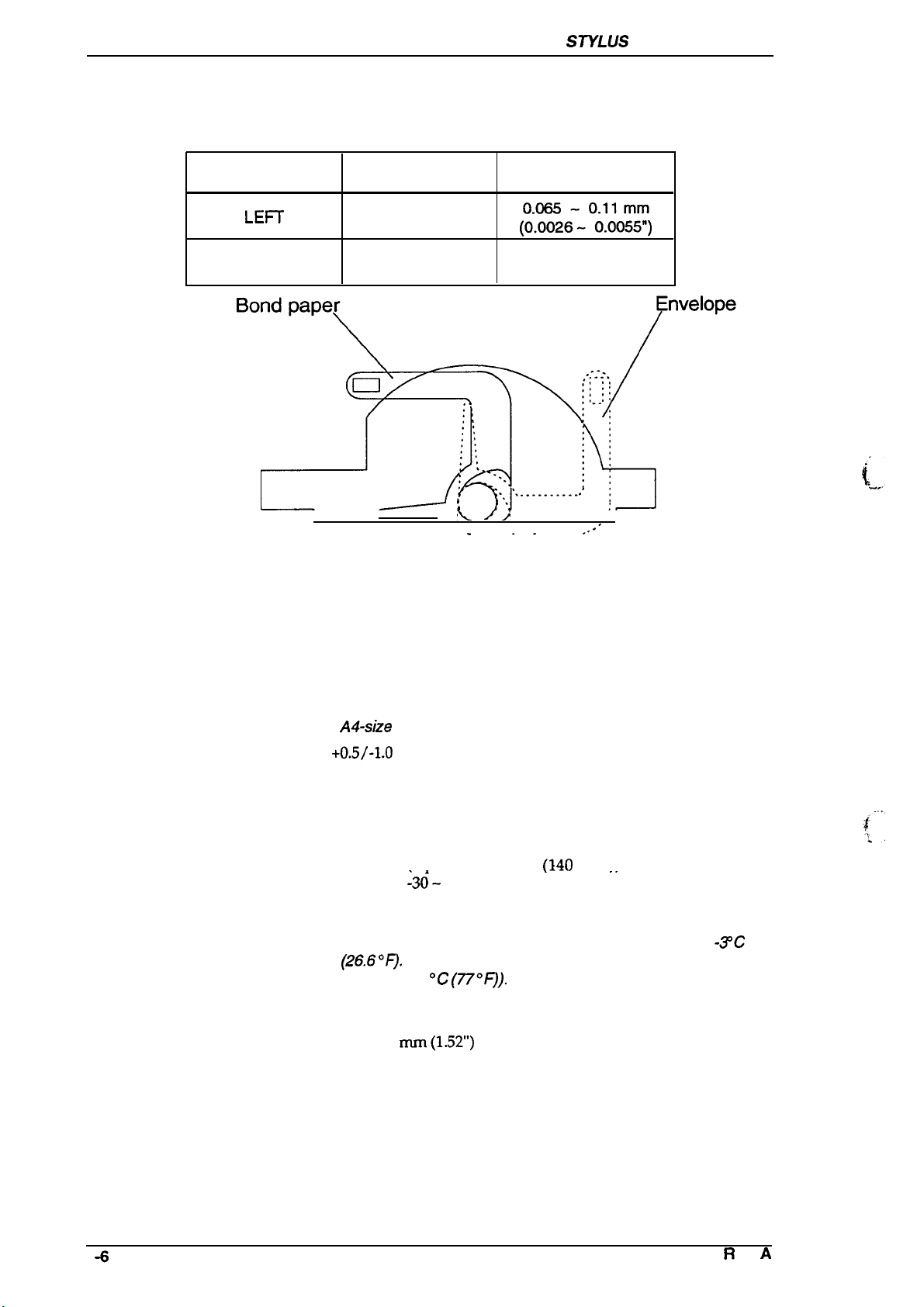

Adjust lever settings:

Lever

Plain

paper,

The adjust lever, attached to the carnage unit, must be set to proper

position for the paper thickness, as shown in Table 1-3.

Table 1-3. Adjust Lever Settings

Position Paper Type

LEFT

RIGHT

I

Cut Sheets

Envelopes

I

Figure 1-5. Adjust Lever

Paper Thickness

~;%26--00~iO!$

0.16-

(0.0063- 0.020”)

/1

\

-

. . . . . . . . . . . - . . . . . . . .

0.52 mm

I

-.

.-

(-..

1.2.4 Ink Cartridge

Type:

Ink color:

Print capacity:

Ink Capacity:

Life:

Temperature conditions:

Dimension:

Exclusive cartridge

(S020025)

Black

0.7 million characters (LQ)

Note: This figure is equivalent to a 700page print volume when

printing is performed at 1000 characters perpage on letter or

A4-size

+0.5/-1.0

29.0

effective life from the indicated production date is:

The

paper.

CC

-2 years (total period of time in package and after unpacking)

-6 months (after unpacking)

[Storage]

[Transport] ~36- 60“C (-22 -140 “F)

Note: The ink inside the ink cartridge freezes if it kept below

(26.6”F). It requires several hours to unfreeze at room tem-

perature (25

Width

Depth

Height 38.5

-30- 40“C (-22 -104 ‘F)

(UDto1monthat40‘C

(Up to 1 month at40“C

(140 ‘F))

‘C (77°~).

28.5 mm (1.12”)

54.5 mm (2.15”)

mm(l.52”)

(140

(104

“F))

““

“F) or 120 hoursat60“C

-3’C

Page 15

STYLUS 800 Service Manual

1.2.5 Environmental Conditions

Table 1-4. Environmental Conditions

Genera/

Descriptim

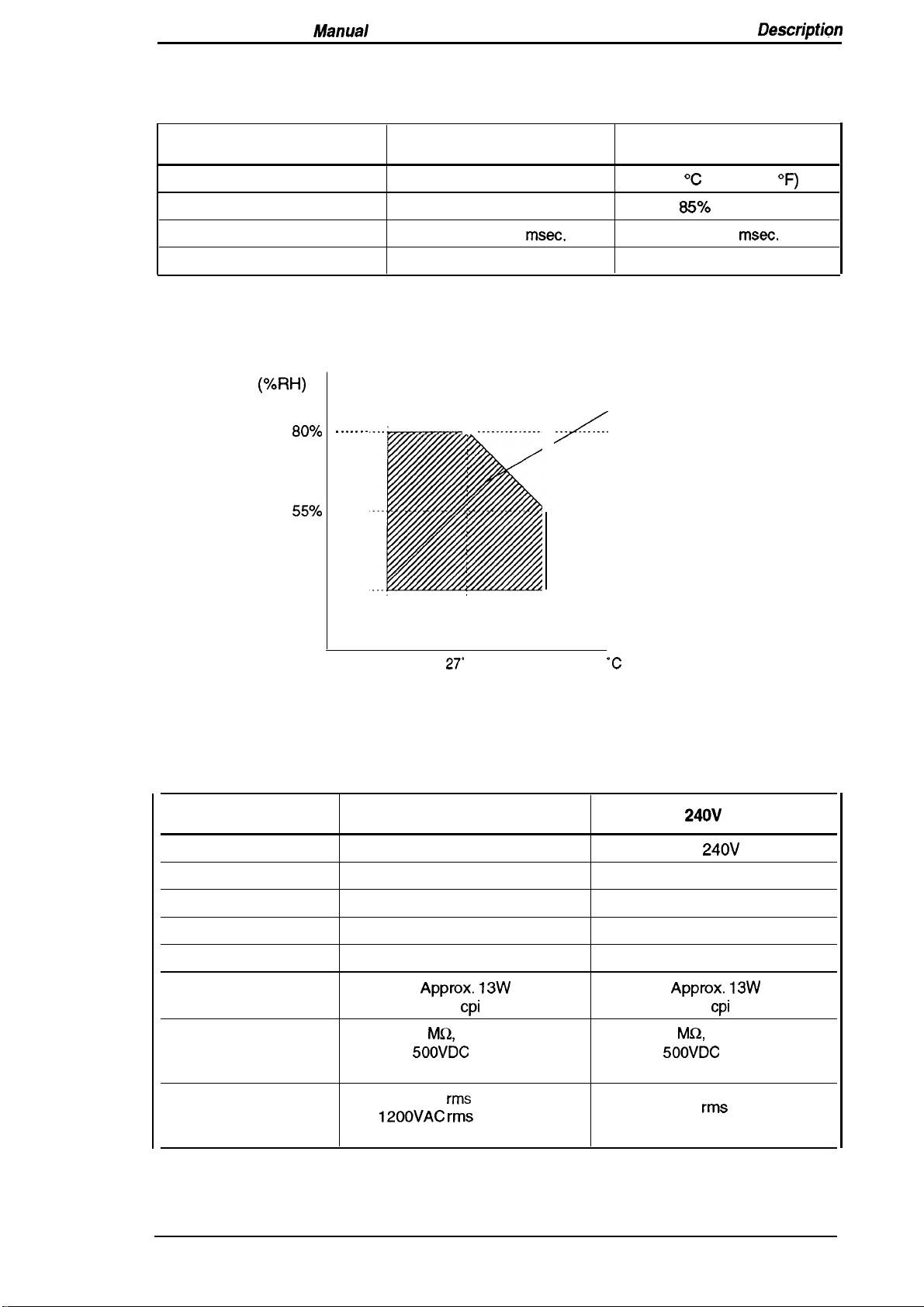

Description

Temperature

Humidity

Resistance to shock

Resistance to vibration

●

Note:

1 = Operating conditions must be in this range.

*2= When the printer is in the shipping container.

●

3 = Without condensation.

Humidity

(%RH)

80Y0

55~o

20?/0

. . . . . . .

Operating

10-35 ‘c (50 - 95 ‘I=)(*1)

20- 80% RH (*1,*3) 5-

1 G, within 1

0.15 G, 10-55 Hz 0.50 G, 10-55 Hz (*2)

msec.

. . . . . . . .

/

-20- 60

2 G, within 2

Print assured range

Storage

“C

(-4 - 140 ‘F) (*2)

85~0

RH (*2,*3)

msec.

(*2)

10” C

(50” F) (80” F)

Figure 1-6. Temperature/ Humidity Range

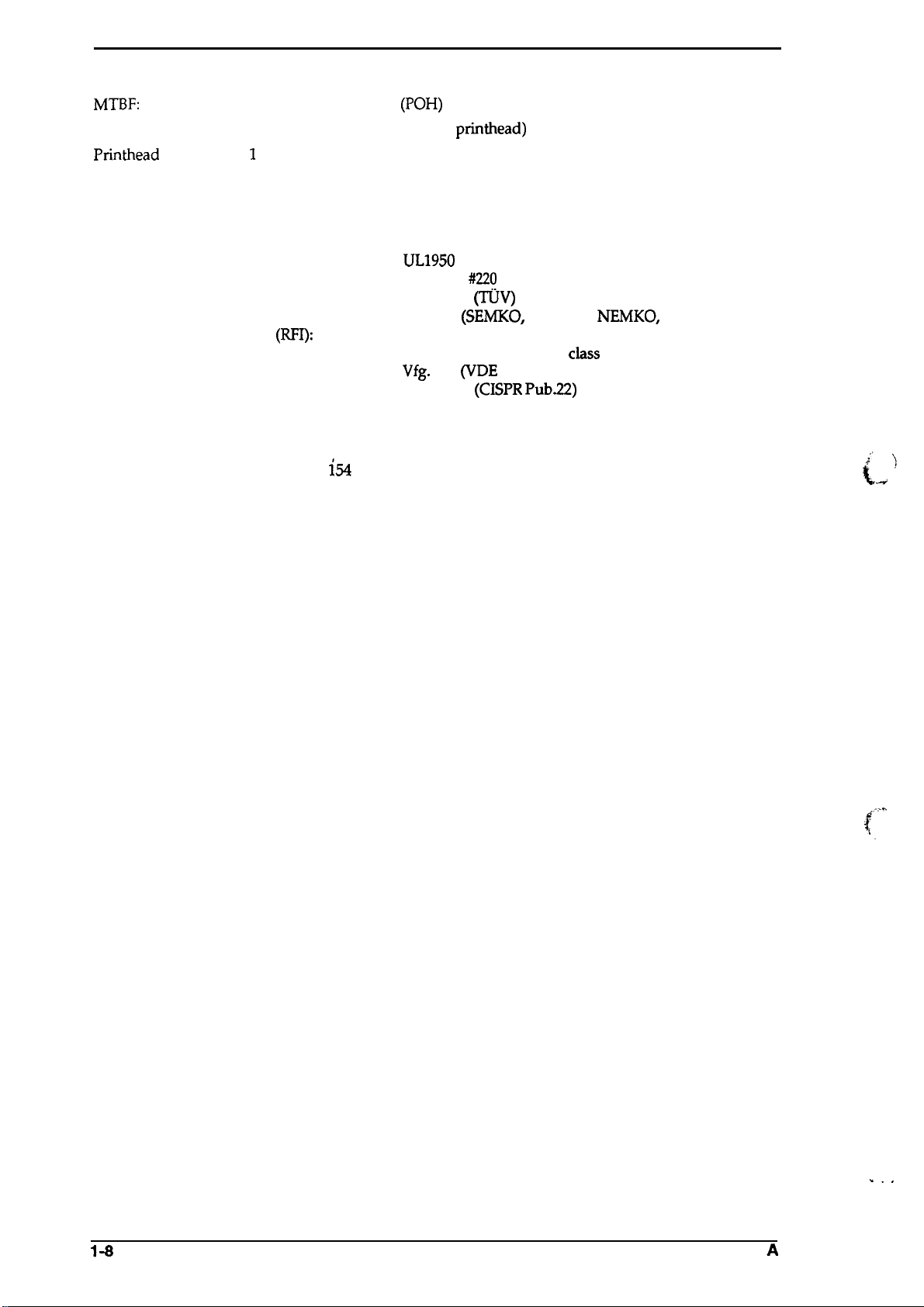

1.2.6 Electrical Specifications

Table 1-5. Electrical Specifications

Item

Rated voltage

Input voltage range

Rated frequency range

Input frequency range

Rated current

Power consumption

Insulation resistance

Dielectric strength

(self test with 10

10

(applying

10OOVAC

1200VAC rms

(between AC line and chassis)

27°

C 35°C

(95” F)

120V Version

120V AC

103.5- 132V

50- 60 Hz

49.5- 60.5 Hz 49.5- 60.5 Hz

0.5 A 0.3 A

Approx. 13W

cpi

LQ characters)

MQ,

minimum

500VDC

between AC line

and chassis)

rms

-1 minute or

-1 second

‘c

(“F)

220- 240V Version

220- 240V AC

198- 264V

50- 60 Hz

Approx. 13W

cpi

(self test with 10

MQ,

10

(applying 500VDC between AC line

and chassis)

1500VAC

(between AC line and chassis)

LQ characters)

minimum

rms

-1 minute

Rev. A

1-7

Page 16

General Description

1.2.7 Reliability

STYLUS 800 Service Manual

MTBF:

MCBF:

Printhead

Total print volume:

life:

4000 power on hours

3 million lines (excluding the

1

billion dots per nozzle

75000

pages (with A4 or Letter size paper)

1.2.8 Safety Approval

Safety standards:

Radio frequency interface

US version:

European version:

(RFI):

US version: FCC part 15, subpart B,

European version:

1.2.9 Physical Specification

Size (W x D x H):

Weight

435 X 264X

Approx. 5.0 Kg (excluding ink cartridge)

(POH)

at a duty cycle of

printhead)

UL1950

CSA22.2

EN 60950

IEC 950

Vfg.

EN 55022

i~

(mm) (17.1X 10.4X 6.1 (inch))

with D3

%220

(~V)

(SEMKO,

243

(VDE

(CISPR Pub.22)

0878 part 3, part 30)

10%

DEMKO,

Ck.S

class B

NEMKO,

B

SETI)

1-8

Rev.

,

(“”

.

.

. . .

A

Page 17

SNLUS

800 Service

Manual

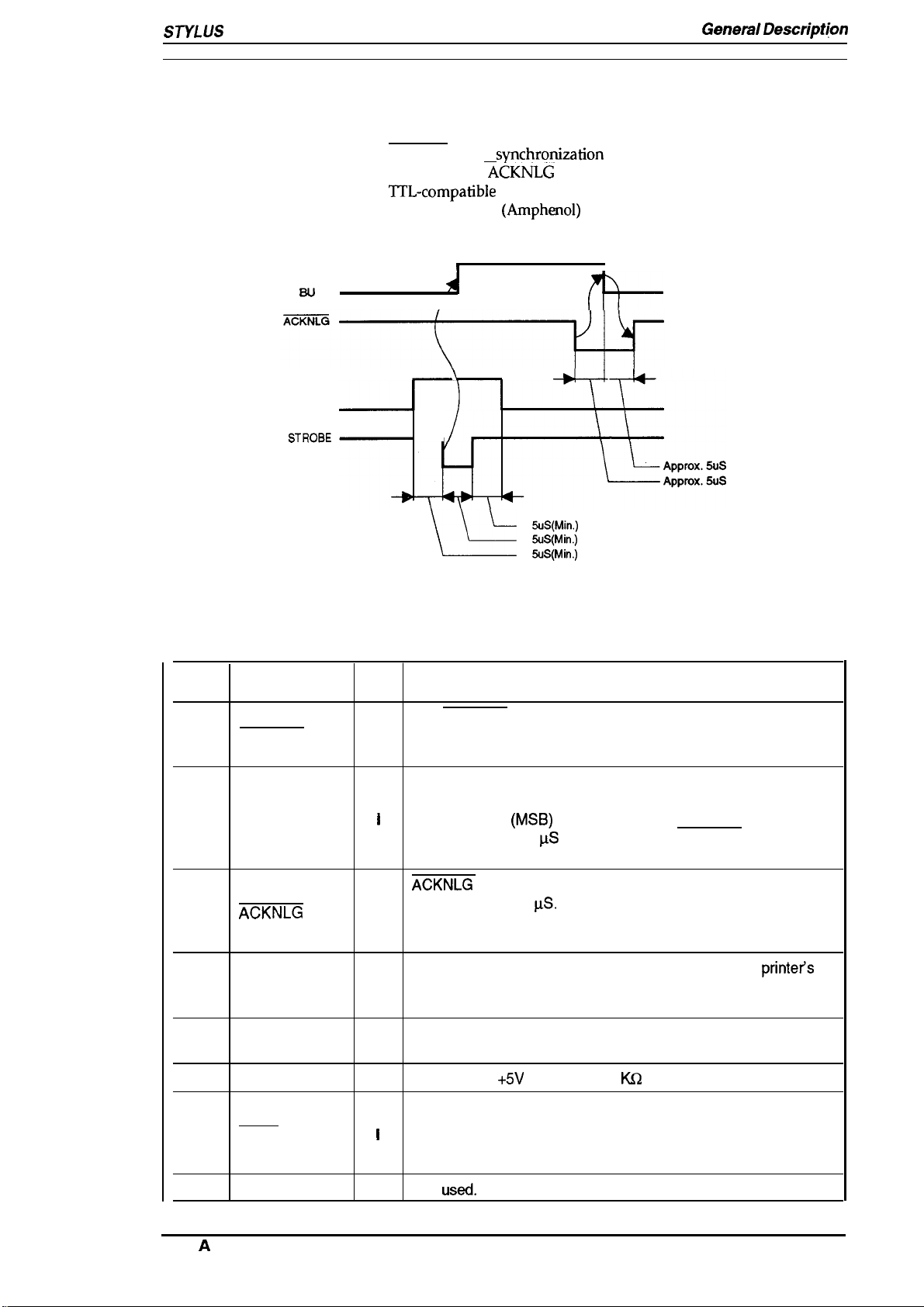

1.3 INTERFACE SPECIFICATION

The Stylus 800 is equipped with an 8 bit parallel interface, standard.

GenemlDescription

Data format:

Synchronization:

Handshaking:

Signal level:

Adaptable connector:

Data transmission timing:

DATA

STROBE—

Figure 1-7. Data Transmission Timing

8 bit parallel

STROBE pulse

By BUSY and

TTL-compatible

swchronization

ACKNLG

level

36-pin 57-30360

See Figure 1-7.

\

—

L-

L!&

signals

(Amphenol)

O. SuS(Min.)

SuS(Min.)

O.

SuS(Min.)

O.

or equivalent

i’b--

Table 1-6 shows the connector pin assignments and signal functions of the 8-bit parallel interface.

Table 1-6. Signal and Connector Pin Assignments

Pin No.

1

2-9 DATA 1-8

10

11

12 PE

Signal Name

STROBE

ACKNLG

BUSY

1/0

The STROBE pulse is used to read data from the host

I

computer. The pulse width must be 0.5@ or more. Normally,

it is HIGH, and data is latched with rising edge of this signal.

DATA 1-8 are parallel data bits. When one of these signals is

HIGH, the data bit is 1; when LOW, the

significant bit

I

maintained for 0.5 pS on either side of STROBE signal’s active

edge.

ACKNLG

approximately 10 vS. This signal goes LOW upon the

o

completion of data reception, to indicates that the printer is

ready to receive further data.

The BUSY signal informs the host computer of the

o

status. When this signal is HIGH, the printer cannot accept

further data.

This signal indicates whether paper is available in the printer

o

or not. A HIGH level indicates a no paper condition.

(MSB)

is an acknowledge pulse with a width of

Description

data

bit is O. The most

is DATA 8. The signal state must be

printe~s

Rev.

13

14

15

Pulled up to

SLCT

AFXT

NC

A

o

If this signal is set to LOW, the printer automatically performs

one line feed upon receipt of a CR (carriage return) code. The

I

status of this signal is checked only at power on and

initialization.

Not

USed.

+5V

through a 1.0 KQ resistor in the printer.

1-9

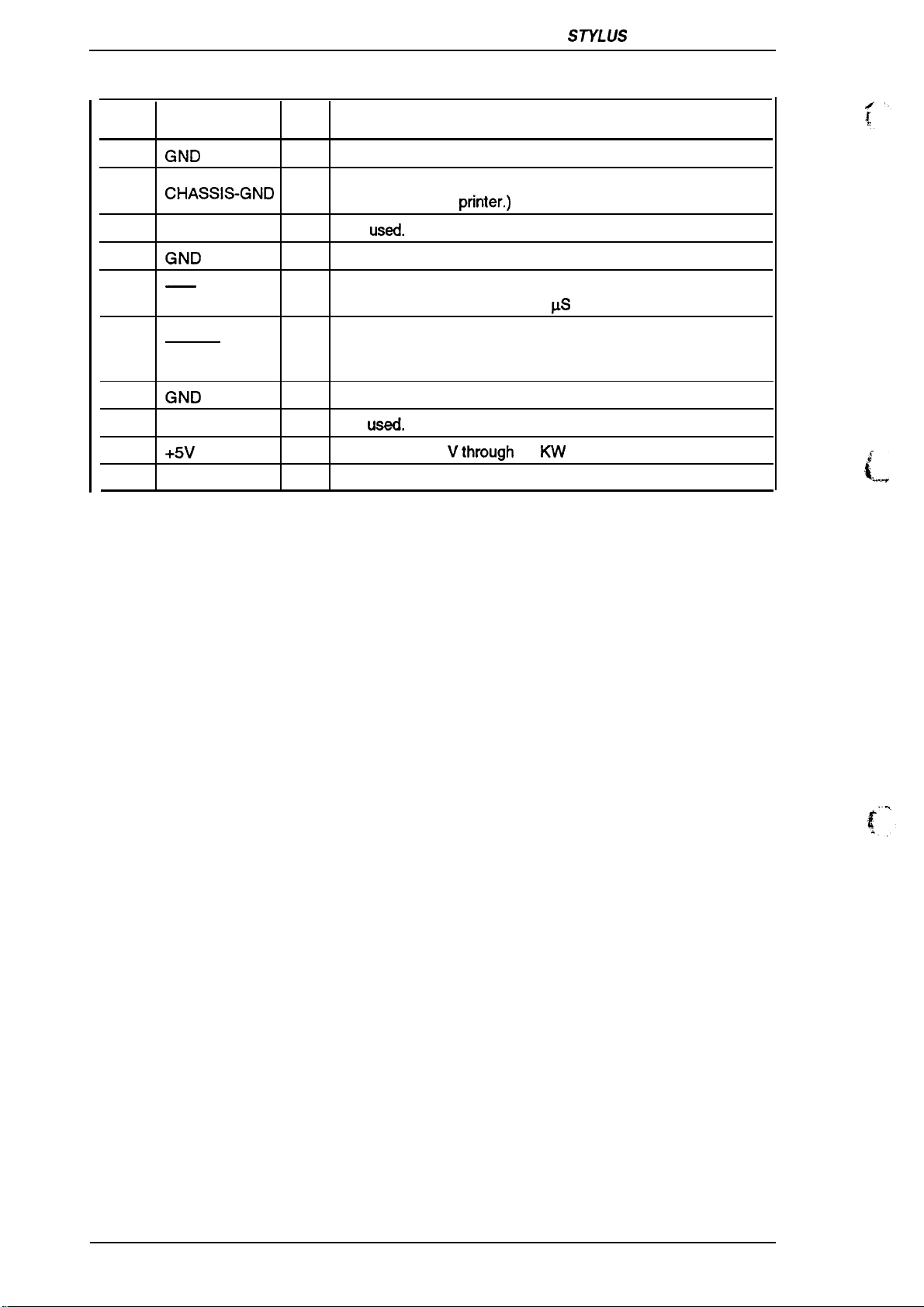

Page 18

General Description

Table 1-6. Signal and Connector Pin Assignments (Continued)

SNLUS

800 Service

Manual

Pin No.

16

17

18

19-30

31

Signal Name

GND

CHASSIS-GND

NC

GND

INIT

32 ERROR

33

34

35

36

Note: The direction of the signal is as viewed from the printer.

GND

NC

+5V

-

I/o

Signal ground.

Chassis ground. (Both chassis ground and signal ground are

connected in the

Not

USed.

Twisted-pair return signal ground.

If this signal goes LOW, the printer is initialized. The pulse

I

width of this signal must be 50

This signal goes LOW if the printer:

o

.

.

.

.

-

has a fatal error.

- runs out of paper.

Signal ground.

Not

USed.

Pulled up to +5

Not used. (* Reserved.)

ptinter.)

Vthrough

Description

pS or more.

1.0 KW resistor in the printer.

(-

1-1o

Rev. A

Page 19

STYLUS 800 Service Manual

General

DescriWion

1.4 PRINTER OPERATIONS

This section describes the basic operations of the printer.

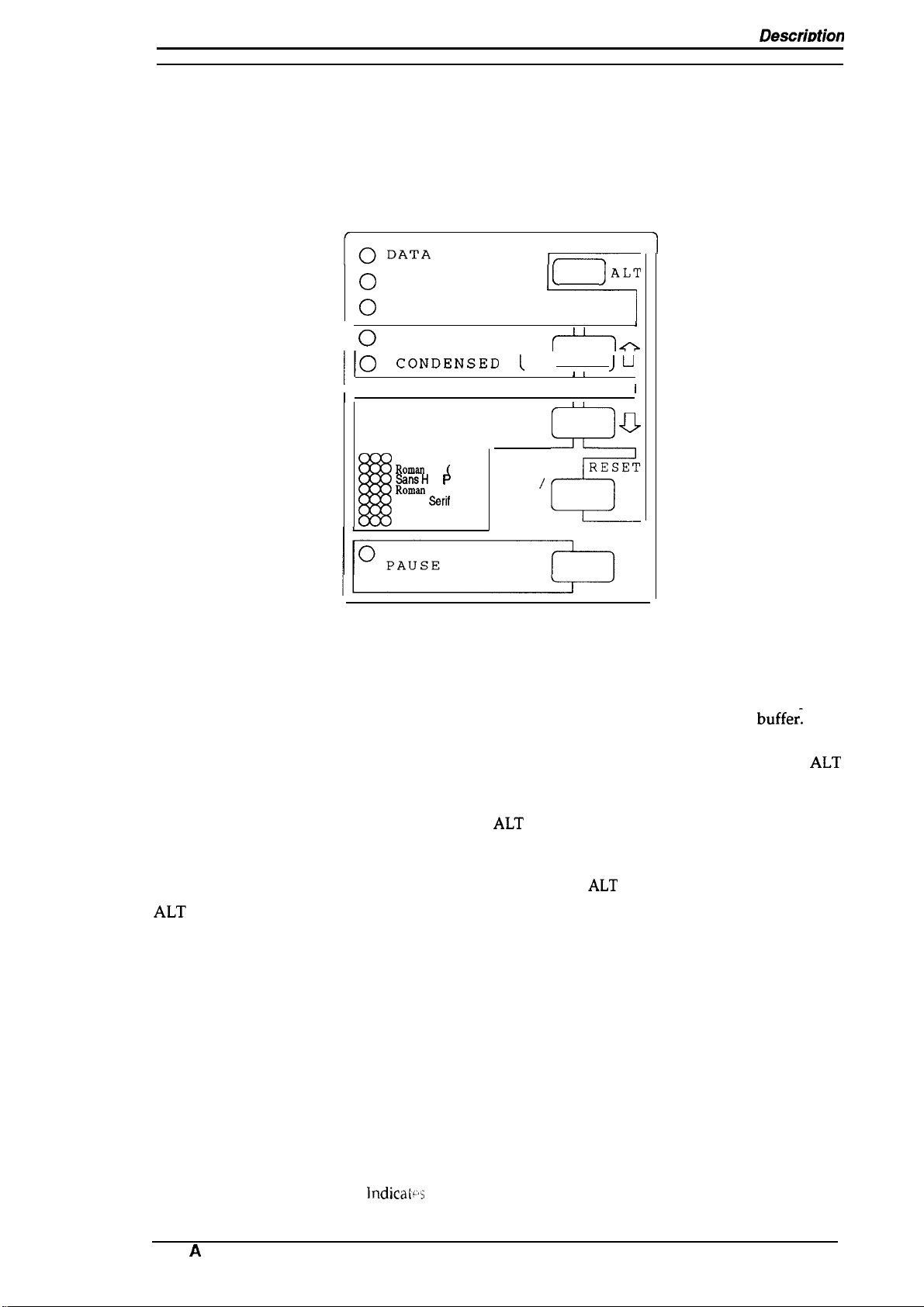

1.4.1 Control Panel

The control panel of this printer contains five non-lock type push buttons and nine LED indicators

for easy operation of the various printer functions.

r

O

PAPER OUT

O

INK OUT

I

o

ECONOMY

II

/10

1’

I

I

CONDENSED [

r

000

Courier

Romm

T PS)

~:a:

Saris

Prestige

script

Ii3

$

(

Sarif

s)

,,

FONT

LOAD

EJECT

[

5

h.

1

,

D

/

5

jALT

1

r

R E SET

ju

\

I

I

I

J

Q

[Buttons]

PAUSE

ECONOMY/CONDENSED

FONT

LOAD/EJECT

ALT

[Indicators]

PAUSE

DATA

PAPER OUT

INK OUT

ECONOMY/CONDENSED

FONT

Figure 1-8. Control Panel

Switches printer status between printing and no printing, if any

print dataexists in the input

Selects ECONOMY printing mode or CONDENSED printing mode

alternately. Also works as a reverse micro feed button, if the

button has been pressed.

Selects one of the available fonts. Also works as a forward micro

feed button, if the

When you press this button, the printer either loads new paper into

the printer or ejects paper currently in the printer paper path. Also

works as a RESET button, if the

This button alternates the function of certain buttons. When you

hold down this button in PAUSE mode for 5 seconds, the printer

moves the carriage to the ink cartridge installation/replacement

position.

Lights when the printer is in PAUSE mode.

Lights when there is print data in the input buffer.

Lights when the printer is out of paper. Blinks if a paper jam has

occurred.

Lights when the printer detects ink end in the ink cartridge. Blinks

when the ink level becomes low.

This LED shows the currently selected mode.

lndicatw

the currently selected font.

ALT

button has been pressed.

ALT

button has been pressed.

buffer:

- - - -

ALT

Rev.

A

1-11

Page 20

General Description

STYLUS 800 Service Manual

1.4.2 Panel Operation at Power On

The following functions can be activated at power on by holding down the specified button on the

control panel.

Self-test mode:

Start the self-test printing mode by turning the printer on while

holding down the FONT button.

Hex dump mode:

Start the built-in hexadecimal data dump print mode by returning

the printer on while holding down the FONT and LOAD/EJECT

buttons. Once this mode is selected, the printer prints all received

print data in hexadecimal form.

Demonstration mode:

Start printing of a demonstration page by returning on the printer

while holding down the ALT button.

Other functions that can be activated with the control panel at power on, such as the default setting

mode and the initial ink charge mode, are described in the sections that follow.

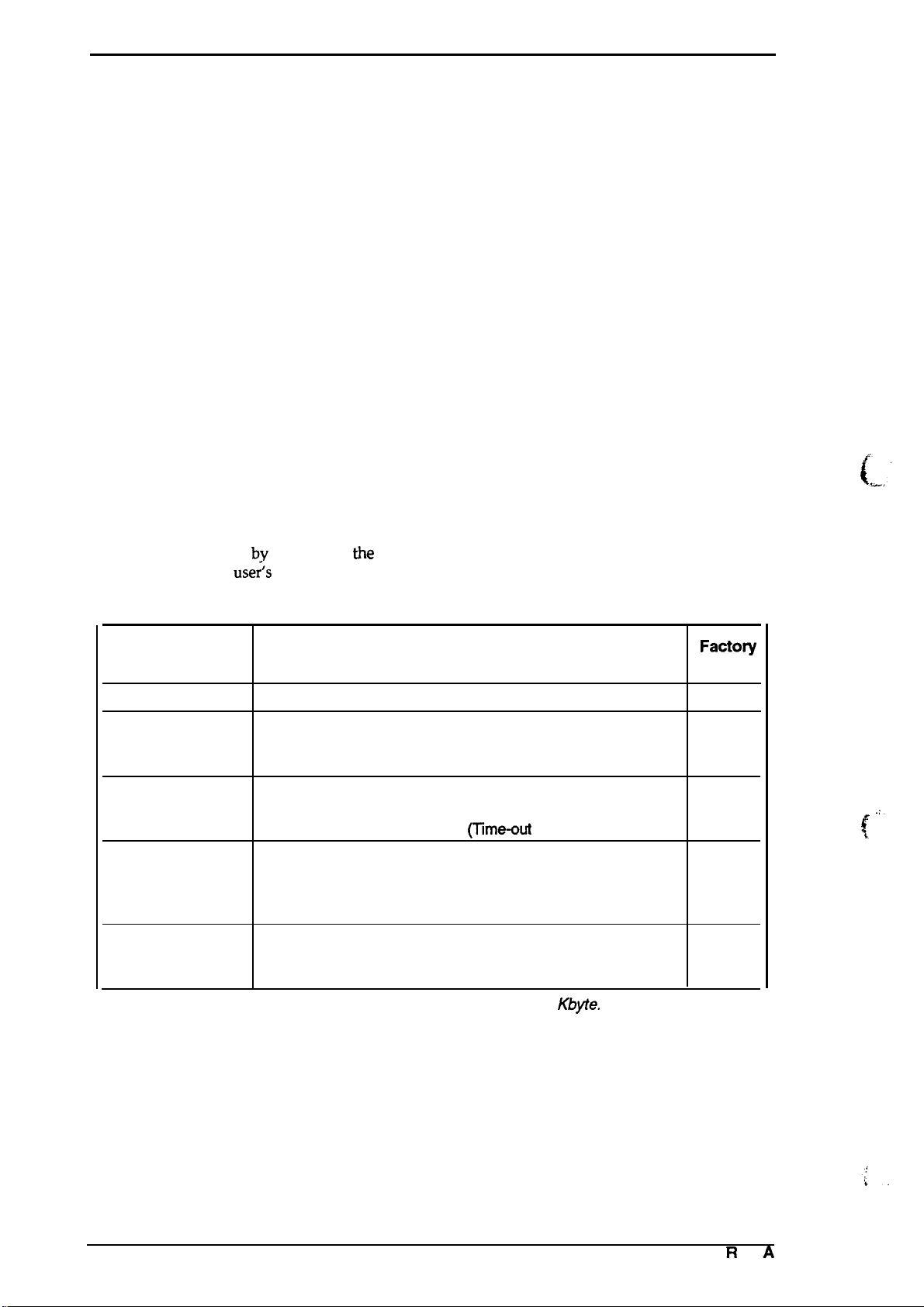

1.4.3 Default Setting

The printer can memorize certain number of printer setting parameters that defines its functions at

the initialization. You can change these parameters with the default setting mode for your specific

preference of the printer setting.

1.4.3.1 Default Setting Item

The settings listed in the table below can be made with the default setting mode. The default-setting

mode can be activated

printer. (Refer to the

by

hold down

use~’s

guide for the detail operation of the default-setting mode.)

the

ECONOMY/CONDENSED button while turning on the

Table 1-7. Default Setting Item

Menu

Contents

Character Table

Auto Print Direction

Network l/F Mode

Mixed Text/Graphics

Mode

Auto Line Feed

Note:

*1= If set to ON, the capacity of input buffer is limited to 8

Description

Select the character table

ON: Print direction is automatically selected as to maintains

optimal print quality (alignment).

OFF: Depends on the command ‘ESC U’.

ON: For network environment, such as LocalTalk.

(Time-out printing is disabled.)

ON: For normal environment.

ON: To ensure proper printing of the image containing

graphics and scalable font, with certain applications,

such as MS Word, WordPerfect

OFF: For normal use.

ON: Line feed operation is automatically performed by CR

code input.

OFF:NO line feed operation with single CR code.

(llme-out

V.5. I

printing is enabled.)

or earlier. ● 1

Kbyte,

Facto~

Setting

ON

OFF

OFF

OFF

. .. .

.

f

Page 21

SWLUS

800 Service

Manual

General Description

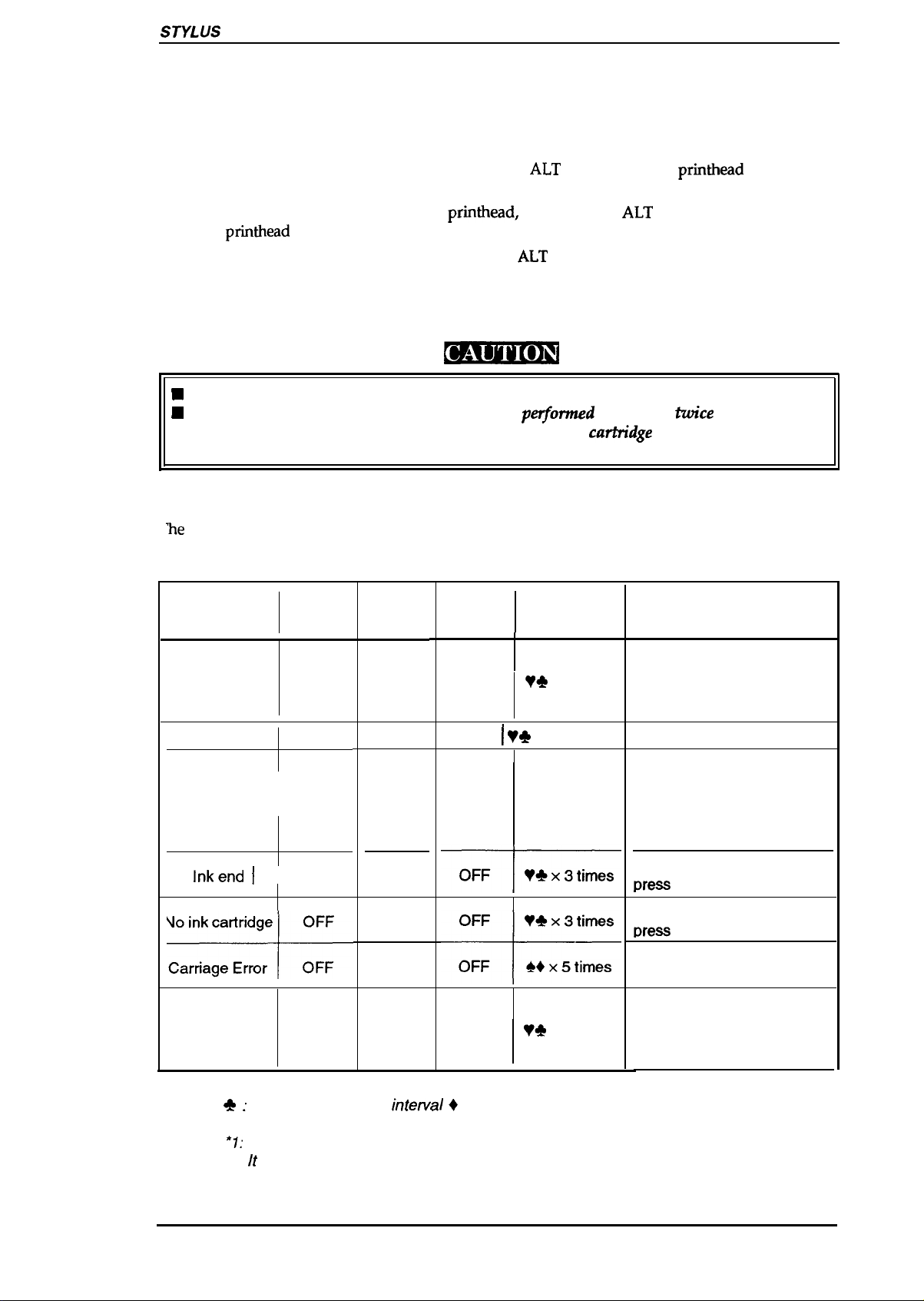

1.4.4 Initial ink Charge

When the printer is to be set up for primary use, whole ink supply path of the printer must be filled

with a new ink, by performing the initial ink charge operation.

[Step 1]

[Step

[Step 3]

[Step 4]

The PAUSE LED blinks while the initial ink charge operation is in progress, and when it completes,

the printer automatically becomes ready state.

W

H

Turn the printer on and press the PAUSE button to pause the printer.

Open the printer cover and hold down the

2]

ink cartridge replace position.

Install the ink cartridge on the

printhead

Turn the printer on while holds down the

charge operation.

The ink cartridge must be installed just after unpacking the package.

The initial ink charge operation should not be

printer. It, otherwise, consumes too much ink in the ink

ink tank life.

to capping position. Then, turn off the printer.

printhead,

ALT

button until the

and press the

ALT

and the PAUSE buttons to start the initial

pe@ormed

ALT

more than

carh”dge

printhead

button again to move the

trm”ce

and shorten the waste

moves to the

on the same

1.4.5 Error Conditions

he

printer detects various errors and indicates them with the LED indicators and the buzzer.

Table 1-8. Error Codes

Error

Paper out

Paper jam

Ink low ● 1

Inkend I OFF

Waste ink tank

over-flow

PAPER

LED

ON

BLINKS

I

OFF

I

OFF

INK END

LED

OFF

OFF

BLINKS

ON

ON

OFF

ON

PAUSE

LED

OFF

OFF [ V4 x 3 times

=t==

=-l--==

BLINKS

Buzzer

V4

x 3 times

No beeps

V+

x 3 times

Load the paper and press the

buttons as follows:

1. PAUSE

2. LOAD/EJECT

Same as above.

Press PAUSE button and

replace the ink cartridge with

a new one. Then, press

PAUSE button again to

resume printing. ● 2

Replace the ink cartridge and

press

Install the ink cartridge and

mess

Turn off the printer, and turn

it on again.

Service

required. (Replace the waste

ink absorbing material and

reset the protect counters.)

Recovery

PAUSE button.

PAUSE button.

maintenance

Notes: V :

+ :

‘1:

*2:

Rev. A

0.1 second beep

0.1 second

This is

not treated as an error.

It

is not necessary to replace the ink cartridge until the printer detects the ‘Ink

End’ error.

4 :

intetval +

0.5 second beep

0.2 second interval

:

1-13

Page 22

General Description

STYLUS 800 Service Manual

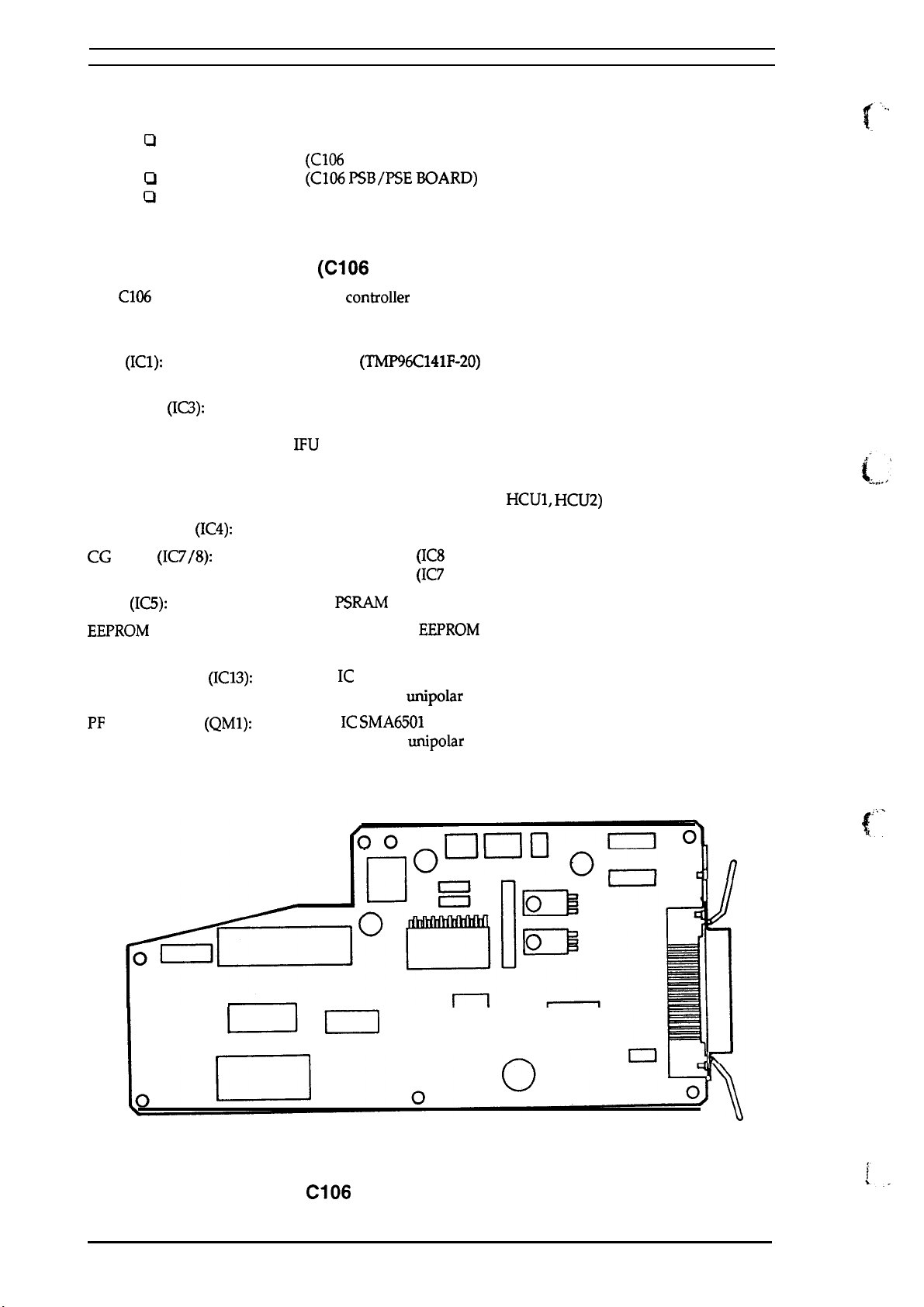

1.5 MAIN COMPONENTS

The main components of this printer are:

O

Printer mechanism (M-481O)

Q Main control board

~

Power supply unit

Cl

Control panel

Cl Housing

1.5.1 Main Control Board (C106 MAIN BOARD)

The

C106

MAIN BOARD is the main

the host computer and processing of received print data, as well as control of the whole printer

mechanism. This board consists of the following components.

(C106

MAIN BOARD)

(C106PSB/PSEBOARD)

conboller

of the Stylus 800. It takes charge of interfacing with

,. ..,,

.!

(.

CPU

(IC1):

Gate-array

Program ROM

CG

ROM

RAM

EEPROM

CR Motor driver

PF

Motor driver

(IC3):

(IC4):

(IC7/8):

(IC5):

(IC1O):

(IC13):

(QM1):

8-bit CPU

19.6608 MHz operating clock

Includes the following functions:

- MMU (Memory Management Unit)

-

IFU

- BMU (Bit Manipulation Unit)

- PCU (1/0 Port Control Unit)

- Head control unit (2 channel:

1 Mbit EPROM

4 Mbit Mask ROM

8 Mbit Mask ROM

1 Mbit

1 Kbit (64

3 lines serial bus

Hybrid

Constant current

Hybrid IC

Constant voltage

(TMP96C141F-20)

(Interface Control Unit)

(IC8

/ for US, Pacific version)

(IC7

/ for European version)

PSRAM

x

16

Bit)

EEPROM

IC

SMA7024MEL

unipolar

SMA6501

unipolar

drive

drive

HCU1, HCU2)

.,.

c

1-14

I

Un

Figure 1-9. C106 MAIN BOARD Component Layout

u

u

n

Rev. A

Page 23

STYLUS 800 Service Manual

General Description

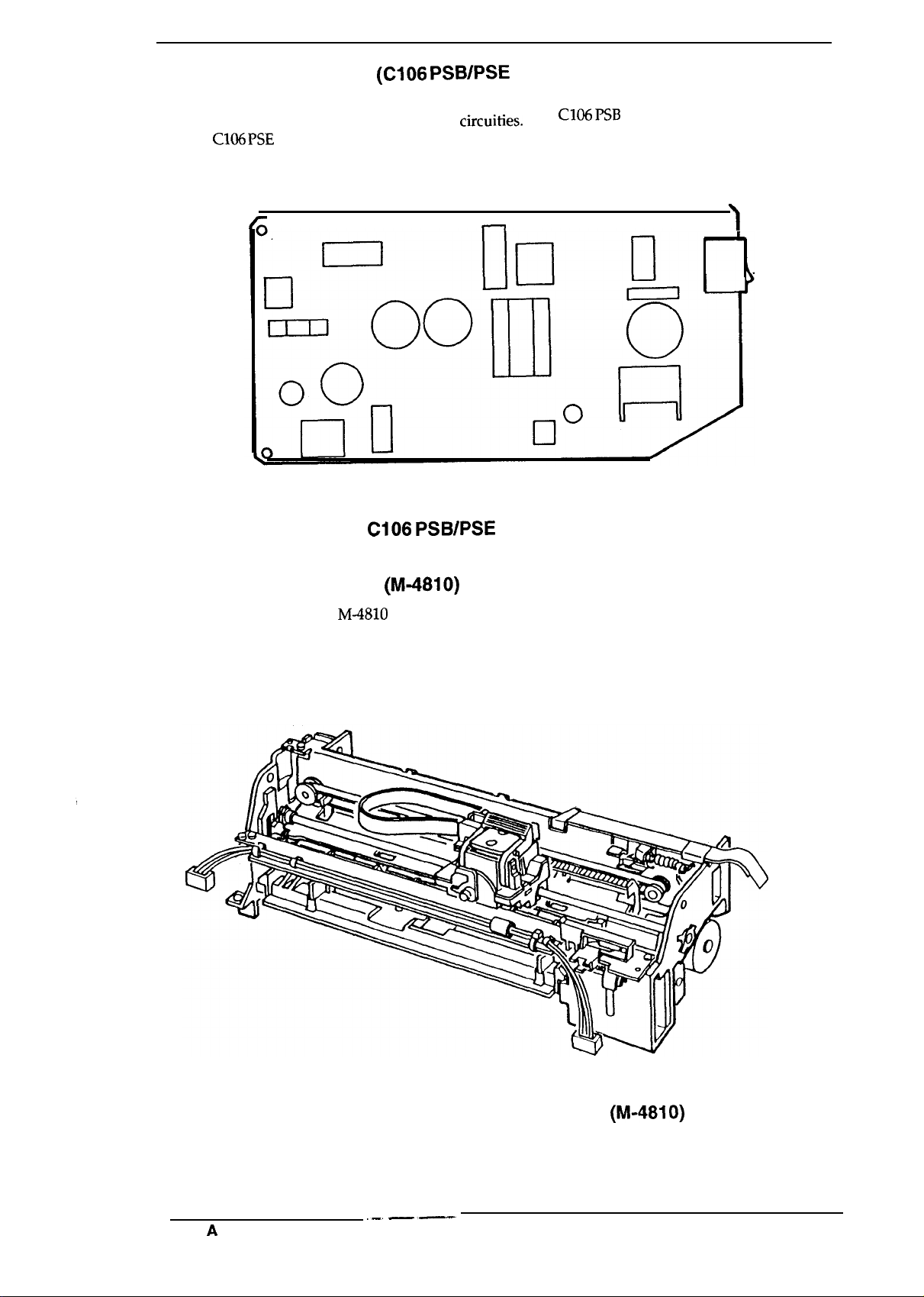

1.5.2 Power Supply Unit (C106

The power supply unit converts input AC voltage and generates different DC voltages required by

the printer mechanism and other electrical

and the

C106 PSE

/-

BOARD is for 220 to 240VAC input.

PSBIPSE

circuities.

—

BOARD)

The

C106 PSB

BOARD is for 120VAC input,

o

Figure 1-10. C106 PSBIPSE BOARD Component Layout

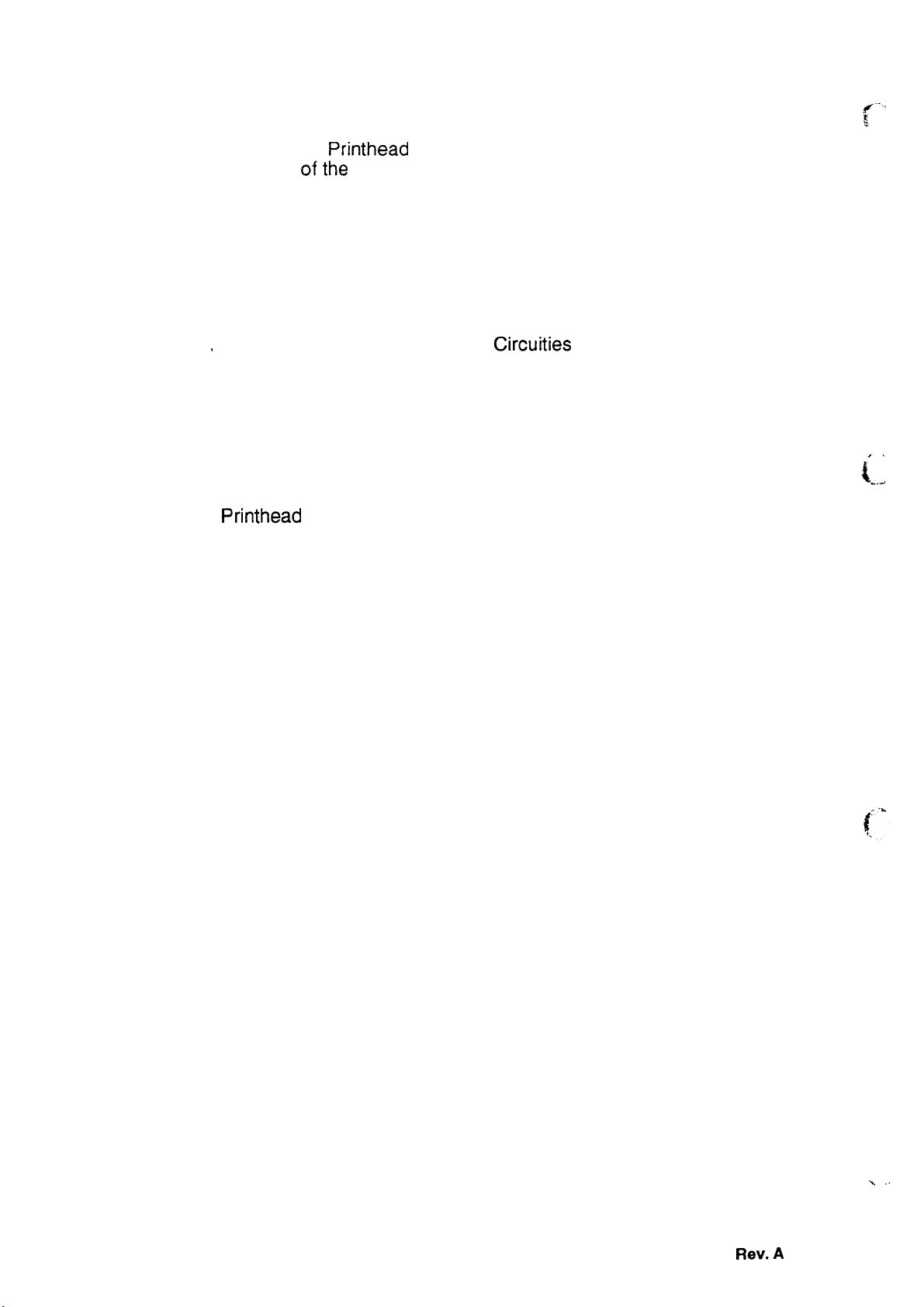

1.5.3 Printer Mechanism

This printer mechanism

carriage assembly, which includes the printhead and the ink supply system, the carriage motor, the

paper feed motor, the paper feeding mechanism, and the pump mechanism.

M-481O

(M-481O)

is specifically designed for the Stylus 800, and it consists of the

Rev.

Figure 1-11. Printer Mechanism

.—. —.—.

A

(M-481O)

1-15

Page 24

,. . . . .

f.:,’

.

Page 25

Chapter 2

Operating Principles

Table of Contents

2.1 OVERVIEW

2.2 OPERATING PRINCIPLES OF THE PRINTER MECHANISM

2.2.1 Printer Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .2-2

2.2.2 Carriage Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . ...............2-4

2.2.2.1 Platen Gap Adjust Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.3 Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......2-5

2.2.4 Ink System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..................2-6

2.2.5 Pump Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..........2-7

2.2.6 Cap Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........2-9

2.3 OPERATING PRINCIPLES OF THE ELECTRICAL

2.3.1 Operating Principles of the Power Supply Circuit . . . . . . . - . . . . . .....2-10

2.3.2 Operating Principles of the Main Control Circuit . . . . . . . . . . . . . . .....2-12

2.3.2.1 Reset Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-13

2.3.2.2 Sensor Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-13

2.3.2.3 Ink End Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-14

2.3.2.4 Carriage Motor Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2.5 Paper Feed Motor Drive Circuit . . . . . . . . . . . . . . . . . . . . . .....2-16

2.3.2.6

Printhead

Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-17

CIRCUITRIES

2-1

2-1

2-1o

.2-15

2.4 INK SYSTEM MANAGEMENT

2.4.1 Ink Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-19

2.4.1.1 PowerOn Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-19

2.4.1.2 Cleaning Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-19

2.4.1.3 Standby Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-20

2.4.1.4 Initial Charge Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-20

2.4.1.5 Refresh Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-20

2.4.1.6 Cleaner Blade Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1.7 l/C

2.4.1.8 Disengage On Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...2-22

2.4.1.9 Micro Absorbing Operation . . . . . . . . . . . . . . . . . . . . . . . . .. ...2-22

2.4.2 Counter and Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-22

2.4.2.1 Refresh-l Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-22

2.4.2.2 Flushing Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-22

2.4.2.3

2.4.2.4 Protect Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-23

Replacefnent

CLCounter K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-22

Operation . . . . . . . . . . . . . . . . . . . . . . . . .....2-21

2-18

.2-21

Rev.A

2-i

Page 26

Figure 2-1.

Figure 2-2.

Figure 2-3.

Figure 2-4.

Figure 2-5.

Figure 2-6.

Figure 2-7.

Figure 2-8.

Figure 2-9.

Figure 2-10

Figure 2-11

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure 2-16.

Figure 2-17.

Figure 2-18.

Figure 2-19.

Figure 2-20.

List of Figures

Functional Block Diagram of the Printer Mechanism . ...........2-1

Structure of Printhead . . . . . . . . . . . . . . . . . . . . . ...............2-2

ofthe

Principles

Carriage Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Platen Gap Adjust Lever . . . . . . . . . . . .......................2-4

Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . .............2-5

Diagram ofthelnkSystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-6

Pump Mechanism Block . . . . . . . . . . . . . . . . . . . . . .............2-7

Pump Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .........2-8

Cap Mechanism . . . . . . . . . . . . . . . . . . . . . ..................2-9

Block Diagram of the Electrical

~D•Œ

Power Supply Circuit Block Diagram . . . . . . . . . . . . . . . . . .....2-11

Main Control Circuit Block Diagram . . . . . . . . . . . . . . . . . . .....2-12

ResetCircuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . .....2-13

Sensor Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . .....2-13

Ink End Detection Sequence . . . . . . . . . . . . . . . . . . . . . . . .....2-14

Carriage Motor Drive Circuit Block Diagram . . . . . . . . . . . . .....2-15

Paper Feed MotorDriveCircuit Block Diagram . . . . . . . . . .....2-16

Printhead Drive Circuit Block Diagram . . . . . . . . . . . . . . . . .....2-17

Relation oflnkSystem Operation and Carriage Position . . .....2-18

Printing Operation . . . . . . . . . . . . . . . . . . . . . ....2-3

Circuities . . . . . . . . . . . . . . .....2-10

~...,,

~:

(,:

,

Table 2-1.

Table 2-2.

Table 2-3.

Table 2-4.

Table 2-5.

Table 2-6.

Table 2-7.

List of Tables

Carriage Drive Motor Specification . .........................2-4

Platen

Paper Feed Drive Motor Specification . .......................2-5

Pump Mechanism Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

DC Voltage Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ..2-10

Carriage Motor Drive Modes . . . . . . . . . . . . . . . . . . . . . . . . . ....-2-15

Paper Feed Motor Drive Modes . . . . . . . . . . . . . . . . . . . . . . . .....2-16

-

Gap Adjust Lever Position . ..........................2-4

2-ii

., .,

Rev.A

Page 27

STYLUS 800 Service Manual

2.1 OVERVIEW

This section describes the operating principles of the printer mechanism and the electrical circuits of

the Stylus 800.

2.2 OPERATING PRINCIPLES OF THE PRINTER MECHANISM

The Stylus 800 printer mechanism is composed of the printhead unit, paper feed mechanism,

carriage drive mechanism, pump mechanism, and various sensors. The figure below shows a

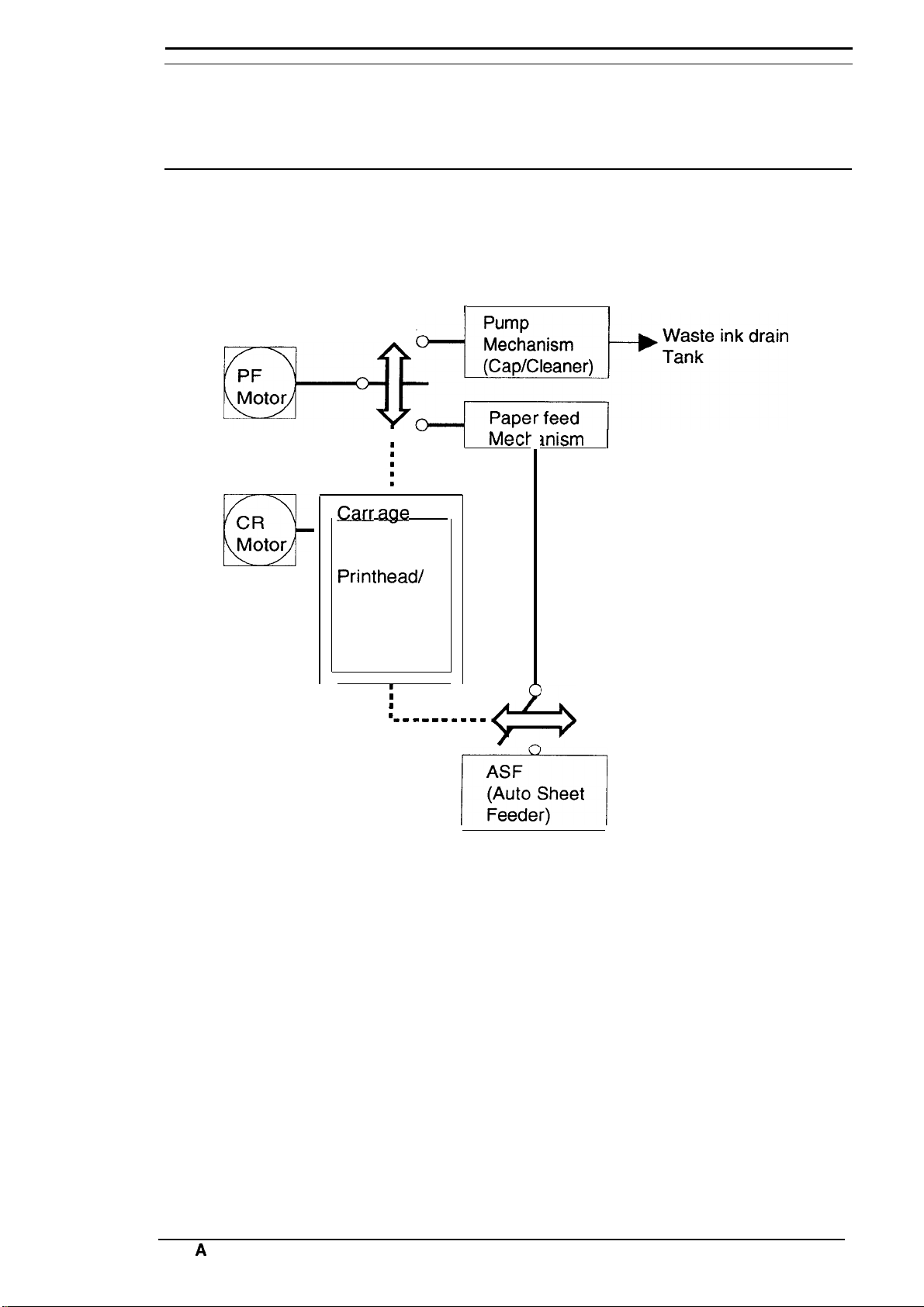

functional block diagram of the printer mechanism.

Operating Principles

w.

i

Garr

CR

Motor

D

age

Printhead/

Filter/

Driver circuit

I

%“’einkdrain

m

n

i

Un t

1

m

m

~. . . . . . . . . .

MecK

*

mism ]

I

ASF

(Auto Sheet

Feeder)

n

Figure 2-1. Functional Block Diagram of the

Printer Mechanism

Rev.

A

2-1

Page 28

Operating Principles

2.2.1 Printer Mechanism

STYLUS 800 Service Manual

The printer mechanism of this printer uses a drop-on-demand ink jet system similar to the system

used on all other Epson ink jet printers.

redesigned to make it compact and highly reliable.

printhead and ink supply system.

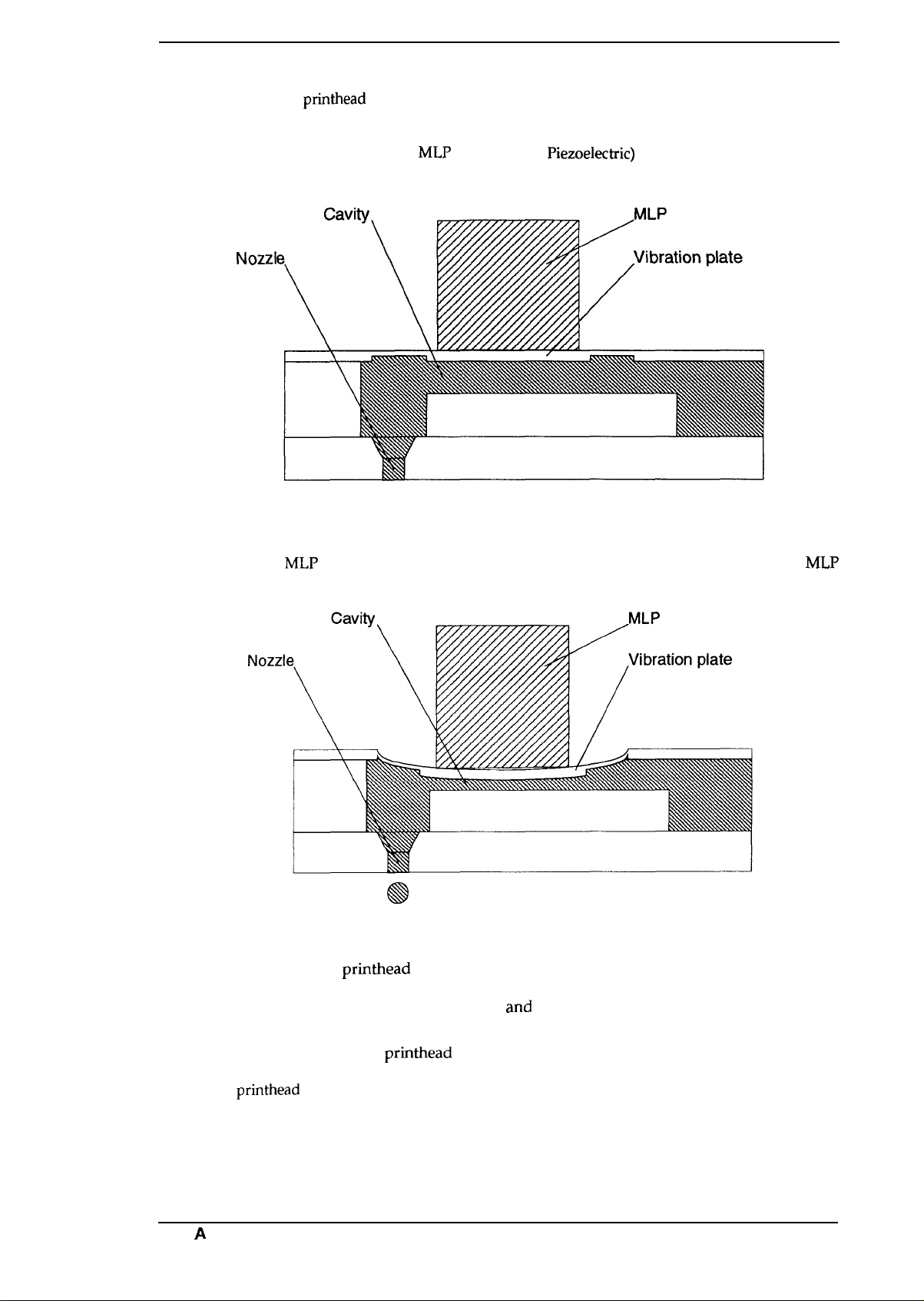

■ MLP

■ Cavity

■ Nozzles

Cartridge needle

MLP is the abbreviation for Multi-Layer Piezoelectric element. When a drive pulse

(voltage) is applied, this element pushes the vibration plate, compressing the cavity

for ink injection from the nozzle.

Ink supplied from the ink cartridge is stored in this space and is injected from the

nozzles when the vibration plate compresses this area.

These inject ink against the paper’s surface in response to the application of the

print signal. There are 48 individual nozzles making up this printhead.

\

However, the printhead in this system is completely

The figure below shows the structure of the

Printhead driver board

I

f-”

Filter

Cavity set

(Nozzle)

Nozzle plat

(Multi-Layer

Piezo)

A7’Nozz’e

tank

supply

nk

,,, . . .

f

‘

2-2

Viblation

p

Figure 2-2.

\

MLP

(Multi-byer Piezo)

Structure of Printhead

-. . .

Rev. A

Page 29

STYLUS 800 Service Manual

Principles of the Printing Operation

Operating Principles

The operation of the

printhead

to inject ink from each nozzle is:

(1) Normal state

No electrical charge is applied to the

MLP

(Multi-Layer

Piezoelectric)

element attached to the back

of the cavity, and pressure inside the cavity is kept at constant level.

Nozzl

(2) Injecting state

The head data signal is applied to the specific nozzle control line to select the active nozzle for

printing, and the

MLP

element is gradually charged by the drive voltage. By charging the

MLP

element, the vibration plate is bent to compress the cavity. Then, ink is injected from the nozzle.

@

Figure 2-3. Principles of the Printing Operation

When the ink charge or

vacuumed out with the pump mechanism.

simultaneously supplied from the ink

change of volume in the cavity.

printhead

cleaning operation is performed, the ink in the cavity is

During printing, on the other hand, the ink is

cartridge

and

injected from the nozzle, according to the

A thermistor is attached to the

printhead

drive board to monitor the temperature, because the

viscosity of the ink varies, depending on the temperature.

back to the

Rev.

A

printhead

drive voltage control circuit to regulate the drive voltage to a proper level.

The detected temperature level is fed

2-3

Page 30

Operating Principles

2.2.2 Carriage Drive Mechanism

The timing belt attached to the base of the carriage unit is driven by the carriage motor, causing the

carriage unit to

motor on this printer is a 4-phase, 200-pole, hybrid-type stepping

printer to stop the carriage or change the carriage movement at any position. The position of the

carriage is recognized by the home position sensor and position information is fed back to the

carriage drive control circuit to determine the motor phase switching mode.

move

along

the

carriage

Table 2-1. Carriage Drive Motor Specifications

guide shaft left to right, or vice versa. The carriage

STYLUS 800 Service Manual

drive

motor mechanism, allowing the

(’

‘-i.,

.

Item

Motor Type

Drive Voltage

Coil Resistance

Drive Frequency

Excitation Mode

I

4-phase

35 V f 10Yo (31.5 -38.5 V)

10.0 Qt 7%/ pole (at 25° C, 77°

960

1-2 phase excitation

Figure 2-4. Carriage Drive Mechanism

/

200-pole hybrid-type stepping motor

-5400 pps

Description

F)

I

2.2.2.1 Platen Gap

Set the platen gap adjust lever, attached to the carriage unit, to an appropriate position for the

paper thickness used for printing.

Plain paper, Bond paper

Adjust Lever

Table 2-2. Platen Gap Adjust Lever Position

Paper Type

Cut sheet

Envelope

Figure 2-5. Platen Gap Adjust Lever

Lever Position

Horizontal (A)

Vertical (B)

\

\

(gn~

r

>

:,

: .

P

<.~j

-..

/

)

-. . . . . . . . . . . . . . . --

Platen Gap

—

+0.7 mm

. . .

. . . . .

: : :

,,

,. .:

, . . . .

::

::

::

::

‘L

:,

. . . . . . . . . . . . .

.

.

;:

/

:

.’

Envelope

/

. .,

Page 31

STYLUS 800 Service Manual

Paper Feed Mechanism

2.2.3

Operating Principles

This printer’s paper feed mechanism can feed paper either from the built-in ASF (auto sheet feeder)

or the manual feed slot. The paper feed drive motor is a 4-phase,

4t3-pole,

PM-type stepping motor

that directly drives the paper feed mechanism (paper advancing operation, paper pick-up

operation). This motor also drives the pump mechanism,

but only when the printer is in the

cleaning state.

Table 2-3. Paper Feed Drive Motor Specification

Item

Motor Type

Drive Voltage

Coil Resistance

Drive Frequency

Excitation Mode

Description

4-phase / 48-pole PM-type stepping motor

35 V + 10% (31.5 - 38.5

54 ~ 3 Q/ pole (at 25° C, 77° F)

650-800

2-2 phase excitation

ppS

V)

)

Rev.

A

Figure 2-6. Paper Feed Mechanism

2-5

Page 32

Operating Principles

STYLUS 800

2.2.4 Ink System

This printer’s ink system is composed of the following mechanisms:

■ Ink cartridge

■ Pump mechanism

E Cap mechanism

H

Printhead cleaning mechanism

■ Waste ink drain tank

The figure below shows a diagram of the ink system.

Ink Cartridge

Sewice Manua)

!-.

.:,,

(..

Head Driver

Boar

Filter

)

{-

!

2-6

Figure 2-7. Diagram of the Ink System

Rev.

1

.

. .

A

Page 33

STYLUS 800 Service Manual

Operating Principles

2.2.5 Pump Mechanism

The paper feed motor drives the pump mechanism when the transmission gear is moved to the

position where the paper feed motor engages the pump mechanism gear trains, when the carriage

unit is at the ink

Pump system operation depends on the rotational direction of the paper feed drive motor, as

shown in table below.

system home

position. The figure below shows a block of the pump mechanism.

<Drive: Pump mechanism>

~-

-——

rl

-----

-----

-1

;

cDrive: Paper feed mechanism>

L.+

k--;

L--– J

L

\

;

LJ

<Switch lever:

<Switch lever:

Set>

Reset>

I

5$7

I

I

1P

II

IJ

s)’

Figure 2-8. Pump Mechanism Block

Rev.

A

2-7

Page 34

Operating Principles

PF Motor Rotational Direction

CW (forward rotation) Pseudo-pumping (False absorbing)

STYLUS 800 Service Manual

Table 2-4. Pump Mechanism Operation

Operation

Pumping

Gear

backrush com~ensation

f“’.,

1

(,

CCW

(backward rotation)

Pump pulley reset

Gear

backrush

compensation

The pump draws ink from the printhead nozzles and drains it into the waste ink drain tank. The

printer performs this operation to eliminate dust or bubbles within the nozzles. Figure 2-9

illustrates the pump operation. When the paper feed drive motor rotates CW (forward), the pulley

pumps in the wheel pump unit rotate in the direction of the arrow while squeezing the ink tube to

push the ink inside the tube out to the waste ink drain tank. On the other hand, when the motor

rotates

CCW,

the pulley pumps move inward along the grooves of the wheel pump so that pressure

applied to the ink tube is released.

Pumping (Pump motor:

Uflfouch

Cw)

“L’

@+@

Wheel Pump

/

Pulley Pump

Pumping (CW)

No pumping (Pump motor: CCW)

No pumping

Figure 2-9. Pump Operation

(CCW)

~..

,...

Page 35

STYLUS 800 Service Manual

Cap Mechanism

2.2.6

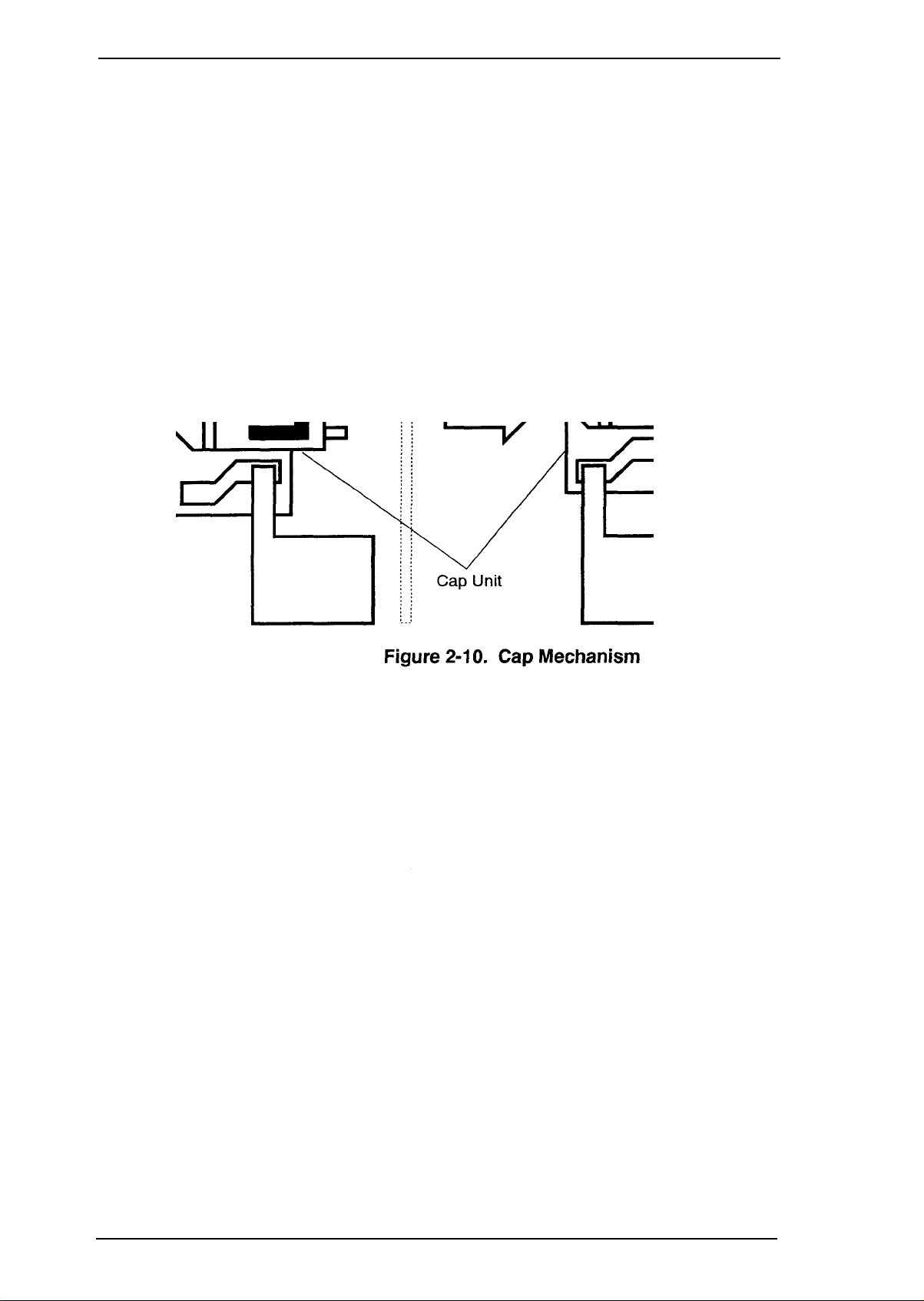

The

cap mechanism

nozzle while the printer is not in use.

so that a cap closely contacts the printhead surface when the carriage unit is moved to the ink

system home position.

1

prevents the printhead nozzles from drying or bubbles from forming inside the

The printhead capping operation is performed automatically

Carriage

I

(Printhead)

:--,

::

::

::

::

::

‘d

::

. .

I

w

I

I

.

Operating Principles

[

I*

. . . . . . . .

. . . . . . .

\

Slider Valve

F

,,

::

c,

::

:.

..:

Figure 2-10. Cap Mechanism

Rev. A

2-9

Page 36

Operating Principles

STYLUS 800 Service Manual

2.3 OPERATING PRINCIPLES OF THE ELECTRICAL CIRCUITRIES

The

Stylus

800 contains the

■

C106 MAIN BOARD (Main control circuit board)

■

C106 PSB/PSE BOARD (Power supply circuit board)

In addition to the circuit boards above, part of the printhead drive circuit is built on a separate

circuit board installed in the carriage unit, and the printhead is attached directly to this board. The

figure below shows a block diagram of the electrical circuitries.

following circuit board units:

,,,

1,

f

. .

.

AC Input

C106

PSB/PSE

+35VDC

+5VDC

L

M-481 O

/Carriage

Printer mechanism

,-------

,\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

/

1.....

Head driver

Board

I Printhead I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EEJ+

. . . . . . . . . . -. . . . . . . . . . . . . . . . . - . . . . . . . . . .- - -- - - . . . . . . . - - - --

Head drive

*

voltage

(+35VDC)

C106

(’,”

MAIN

.-’

C106

PNL

L

Figure 2-11. Block Diagram of the Electrical

Circuities

2.3.1 Operating Principles of the Power Supply Circuit

The power supply circuitry for this printer is provided either by the

or the

except for components in the primary circuit that accommodate the specified input voltage.

input voltage and the application of output voltages are summarized in table below.

C106 PSE

BOARD (220-240

VAC).

Both boards are identical in design and functionality,

C106 PSB

BOARD (120

VAC)

l%e

Table 2-5. DC Voltage Distribution

I

Voltage

+35

VDC

+5 VDC I

~

~

Motor drive (carriage and paper feed)

~ Printhead

/

C106 MAIN BOARD

Sensors (home position and paperend)

1

Control panel

~

(PF motor holding voltage)

(through the drive voltage generation circuit)

Application

I

,. .,%

{.

.,

2-1o

Rev. A

Page 37

STYLUS 800 Service Manual

Operating Principles

The figure below shows a block diagram of the power supply circuit (C106

supply circuit employs the

voltage supplied from the external AC source is first input to the filter circuit for higher harmonics

absorption. The AC voltage is then input to the rectification and smoothing circuit, converting it

into DC voltage. This DC voltage is input to the switching circuit for switching operation. Along

with the switching operation on the primary side, +35

smoothing circuit.

V line voltage detection circuit and, thus, the +35

also input to the +5

C7

~~

Smoothing

Circuit

The +35

VDC

Primary-side

QI

Main

Switching

4

w-J----

Full-wave

Rectifier

Circuit

C21C

k

L1/C6 CIIR1

Filter

Circuit

RCC

(ringing choke converter) switching control system. The input AC

VDC

is generated after passing through the

VDC

level is fed back to the primary switching circuit through the +35

VDC

output level is stabilized. This +35

generation circuit to generate a stable +5

Secondary-side

I--Id

T1

,.—.

.—,

C51/C52

ZD52

I

VDC.

lC51/Q51/L51

D5!YR53/C55

*“V”’

1-

+

ZD511R70/R711R72/Q52

+35V

—

—

Constant

Voltage Control

. .

Crcult

ZD53

-

-44+

PSB/PSE).

+5V

Over-current

Protection

. .

u

This power

VDC

is

+35VDC

L

Pcl

!–

9

AC Input

Figure 2-12. Power Supply Circuit Block Diagram

This circuit contains the protection circuits described below.

+5

VDC

1)

The output voltage level of +5 V line is monitored with a

level exceeds predefined level (+7 V), the status is fed back to the primary switching circuit

through a

+5

2)

The output current is monitored with a detection resistor

generation switching control IC

shortens the ON

(constant current operation).

+35

3)

The output level is monitored with a

level (+36 V), it activates a photocoupler

operation.

+35

4)

The output level of +35

diode

output voltage level status through a

the ON/OFF time

line over voltage protection circuit

photocoupler (PC1)

VDC

line over current protection circuit

time

VDC

line over voltage protection circuit

VDC

line constant voltage output control circuit

(ZD51),

a transistor

of

the switching transistor for constant output voltage control.

to stop the +35 V generation.

of the switching transistor

VDC

line is monitored by a detection circuit that consists of a

(Q52),

-

Zener

diode

(R53)

(IC51).

If the current level exceeds the limit, the control IC

(Q51)

to decrease the output voltage level

Zener

diode

(PC1),

and resistors

photocoupler

(ZD36).

and this stops the primary switching circuit

(R70,

If the voltage level exceeds the limit

R71,

R72).

to the primary switching circuit to control

(ZD53)

and if the voltage

and fed back to the +5

This circuit feeds back the

VDC

Zener

Rev. A

2-11

Page 38

Operating Principles

2.3.2 Operating Principles of the Main Control Circuit

STYLUS 800 Service

Manual

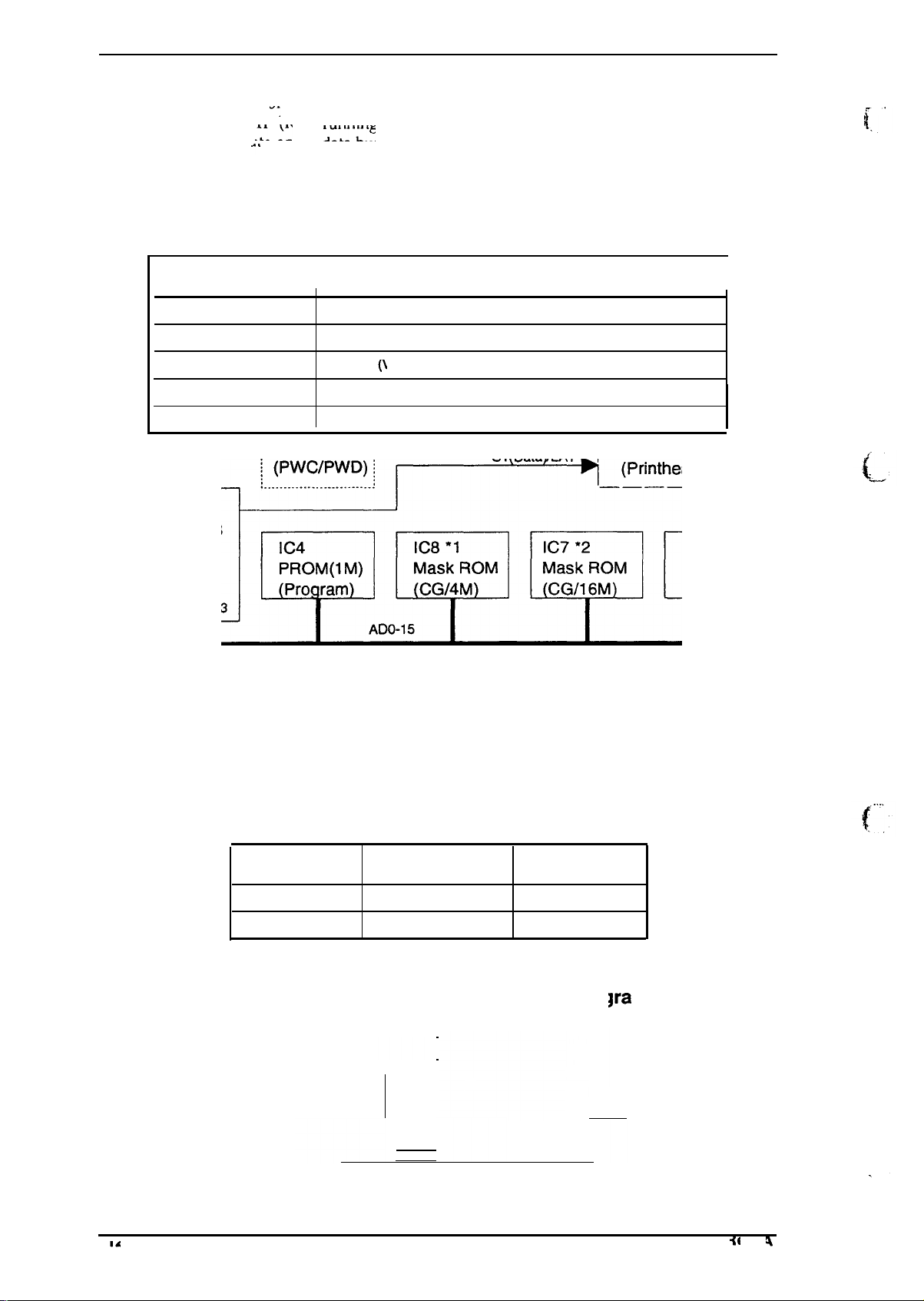

The main control circuit of this printer is the

8-bit CPU

capable of handling data on the data bus at either an 8-bit bus width or a 16-bit bus width. Due to

this, a 16-bit data bus width-type ROM is used on this board, increasing the internal processing

speed.

(Centronics

motor and the paper feed motor. This board is also equipped with EEPROM 93C46 (IC1O) to store

certain parameters, such as the printer mechanism control parameter, default setting parameters, as

well as a special counter value used for

TMP96C141F

Gate array

parallel I/F), and the control panel. The CPU directly controls both the carriage drive

(ICI), running at 19.6608 MHz.

E05A85EB (IC3)

manages

,....:;c......;

\

Common

Pwcl

PWD

IC3

E05A85EB

t

I

I

I

CRO-3

I

I

*

Drive Circuit

;

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

(PWC/PWD) ~

IC4

PROM(1 M)

(Program)

C106

MAIN BOARD. This circuit is

This CPU has a unique architecture

pririthead

protection.

pnnthead

drive control, external I/F control

~’--”;.

! ~’

~

I

IC8

*1

Mask ROM Mask ROM

(CG14M)

ADO-15

Sl(Data)iLAT

. .

IC7

*2

(CGI16M)

r–––––

Head driver

(Printhead)

I

——————

controlled

IC5

PS-RAM

(1 M)

by the

(-

Icl

(CPU)

TMP96C141

V

Control

Panel

(C106 Pt’d;)

Note: .

●

2:.

BzEl

P60x

P61x

E41/Pacific

Europe only

Figure 2-13. Main Control Circuit Block Diagram

1

IC13

?

CR Motor

only

QMI

SMA6501

PF

Motor

—

(

,. .,.

,’

Page 39

STYLUS 800 Service Manual

Operating Principles

2.3.2.1

The

monitor reset circuit. The +5 V monitor reset circuit monitors the voltage level of the +5 V line,

using reset IC PST592

E05A85EB

circuit, on the other hand, monitors the voltage level of the

(IC1l), and outputs a reset signal to the CPU. The reset signal is generated when the voltage level

drops below +28 V, and this causes a non-maskable interrupt

Reset Circuits

C106

MAIN BOARD contains two reset circuits: the +5 V monitor reset circuit and the +35 V

(IC12),

gate array

and outputs a reset signal to both the CPU (ICI,

(IC3),

when the voltage level drops below +4.2 V. The +35 V monitor reset

+35V

line, using reset IC

(NMI).

+5VDC

&&

237

RESET

+3SVDC

TMP96C141)

51955BFP

and the

7

E05A85EB

2.3.2.2

(IC3)

Figure 2-14. Reset Circuit Block Diagram

Sensor Circuits

I_-EL.J

The following sensor circuits enable the main board to monitor printer mechanism status:

1) HP sensor

2) PE sensor

3) IE sensor

4)

Thermistor

A photocoupler-type HP (home position) sensor is attached to the back of the

carriage unit to detect the carriage home position as a print reference position. A

HIGH level from the signal indicates that the carriage is in home position.

A mechanical switch PE (paper end) sensor is built into the printer mechanism to

determine whether there is paper in the printer or not.

Two electrical contacts are attached to the ink cartridge holder in the carriage unit,

and when the ink cartridge is installed, the metal pins built into the ink cartridge

touch these contacts. The

when

determined by the resistance between the two contacts by measuring the input

signal level with analog port ANO (pin 73) of CPU.

A thermistor is attached to the

changes the

temperature level.

P

PE

(CN4)

x

performin

printhead

+5V

9

slve

E05A85E9

(IC3)

Cl=u

(lCl)

g the ink end status detection operation. The ink level is

IE

(ink end) sensor circuit applies a HIGH level signal

printhead

drive signal’s pulse width (charge pulse width) based on the

80

w

INK

~

unit to monitor its temperature. The CPU

+5V +5V

10 I

JJrk)

+5V

m

IC9

+5V

‘+”

Ink

cartlt@l?

“1

i ..~:~ i

,.

.

,,,

L.—.

J

‘

Rev. A

I

Figure 2-15. Sensor Circuit Block Diagram

2-13

Page 40

Operating Principles

2.3.2.3 Ink End Detection

The IE (Ink End) sensor attached to the carriage detects, not only the ink end, but also when ink is

low and whether an ink cartridge is installed.

according to the output voltage level of the IE sensor.

The detected status is classified to five modes

STYLUS 800 Service Manual

❑ Mode A:

❑ Mode B:

9

Mode C:

■ Mode D:

■ Mode E:

No I/C (Abnormal conduction)

Ink is low

Ink end (During pump operation)

Ink end (During printing)

No I/C (not installed)

r=l

Ist check

< Vout c

A

B ?

r-

(not printable)

(printable)

(not printable)

(not printable)

(not printable)

,.,

(

u’

L*-,

a

r--+

b&K-.l

Figure 2-16. Ink End Detection Sequence

When the ink end detection operation has determined ink status, the printer indicates the status on

the control panel, as described

1) During printing:

2) During pump operation:

3)

In stand-by state:

below:

If Mode D (ink end) or Mode A or E (no I/C) is detected, the

pnnthead

error.

If Mode C is detected, the printer indicates an “INK END” error after

the detection operation sequence completes and interrupts pump

operation.

If Mode A or E is detected, the printer indicates an “INK END” error

after interrupting the pump operation.

If Mode D or Mode A or E is detected, the printer indicates an “INK

END” error on the control panel.

is capped and the control panel indicates an “INK END”

.,>

f,

4,,,,,

2-14

Rev.

A

Page 41

STYLUS 800 Service Manual

2.3.2.4 Carriage Motor Drive Circuit

Operating Principles

I

Carriage motor drive IC SLA7024

constant current,

unipolar

drive system. Gate array

current level using the output signals from ports

operation is directly controlled by

to

4)

of the CPU. The table below shows the carnage m-otor drive modes.

(IC13)

drives the carriage motor for the printer mechanism by a

E05A85EB (IC3)

CRO

to

CR3

the

phase control signals output from ports

selects the motor phase drive

(pins 75 to 78). The phase switching

P600

to

-

P603

(pins 1

Table 2-6. Carriage Motor Drive Modes

CR

CPU

(ICI)

speed

(CPS)

Frequency

225

150

83 2000

40 960

HOLD

P600

P601

P603

P602

‘

2

3 5

4

Drive

(PPS)

5400

3600

—

+5V

Phase

Excitation

1-2 phase

1-2 phase

1-2 phase

1-2 phase 0.45

2 phase

R59

WRM26

RM25

Acceleration

Current Current

(A/Phase) (A/Phase)

0.80

0.60

0.80

SLA7024MEL

(IC13)

6

INA

7

‘

INB

IN-A

16

IN.B

RFA

RFB

Normal/Deceleration

0.45/0.80

0.30/0.60

0.80

0.30/0.45

Approx. 0.15

+35V

8

A

1

-A

18

B

11

-B

—

CR

Motor

(CN6)

;

CRCOM

*

CRA

s

CR-A

b

CRB

CR-B

E05A85EB

(IC3)

CRO

CR1

CR2

CR3

-

78

77

76

75

R33

R34

R35

R36

Figure 2-17. Carriage Motor Drive Circuit Block Diagram

Page 42

Operating Principles

STYLUS 800 Service Manual

2.3.2.5

Paper Feed Motor Drive Circuit

The paper feed motor for this printer drives the following mechanisms:

9

Paper feed mechanism

■ Paper pickup mechanism

■ Pump mechanism

Driver IC

system. The CPU outputs phase control signals from ports

SMA6501 (QM1)

drives the paper feed motor by a constant voltage,

P610

to

P613

(pins 5 to 8) for the phase

unipolar

drive

switching operation. The CPU also outputs the supply voltage switching control signal from port

T03

(ph-

12) to switch

HOLD mode. The drive modes are shown in

tie

supply volkge to +5 V-DC wh& the paper feed motor control is in

table

below.

Table 2-7. Paper Feed Motor Drive Modes

Phase Excitation

2-2phase

I

2-2phase

~

6

7

8

QI

SMA6501

(QM1)

‘

01

3

62 C2

6

63

8

64

0

‘

BP ~ CP

Drive Frequency

I

I

~,

C3

C4

800

650

2

4

7 2

9

“

12

D1

R4

(PPS)

‘

PFA

5.

PF-A

PFB

6

PF-B

3

PFCOM

4

PFCOM

PF

Motor

(CN5)

CPU

(ICI)

Mode

Continuousfeed j

Pump

drive

P610

P611

P612

P613

T03

12

~.,,

;

‘

c

.

.

(.e

‘

. . . . . . .

. .

.

+35V

+5V

777-

Figure 2-18. Paper Feed Motor Drive Circuit Block Diagram

f“’”

. .

2-16

Rev.

A

Page 43

STYLUS 800 Service Manual

Operating Principles

2.3.2.6

The

The 64-bit thermal head driver

nozzle selector to drive the

gate array E05A85EB

printhead

array

bit corresponding to each nozzle of the

complete, gate array

(discharge pulse) to the common drive circuit. The co

trapezoidal pulse and applies it to the

selected by the head data is activated to inject ink by energizing the MLP element drive with the

applied trapezoidal drive pulse.

Printhead

printhead

❑

Common drive circuit (trapezoidal drive pulse generation)

■

Head drive circuit (nozzle control built on the

E05A85BE

drive circuit for this printer is composed of the following two parts:

as data for each nozzle.

Drive Circuit

(IC3)

outputs the

E05A85BE

printhead)

SED5620D

printhead

and is output from port S1 (pin 63) to the head drive circuit on the

Then, head driver

LAT

signal, and the latched data becomes 48-bit parallel data, with one

outputs the common drive pulse

in the head drive circuit on the

nozzles selectively. Print data is converted into serial data by

SED5620D

printhead.

printhad

When data transfer and nozzle selection is

mmon drive circuit then generates the

as a common drive pulse. After this, the

printhead

latches the head data when gate

PWC

(charge pulse) and

is used as a

PWD

nozzle

JAIL

GND .--------: ------- j-----------------------

--’-------------------------

L

(IC3)

CPU

(lCl)

Pwc

HCLK

LAT

~1

AN1

;

5

‘

4

‘

63

74

+5V4

Figure 2-19. Printhead Drive Circuit Block Diagram

I

2

HCLK

;

LAT

SI

‘2TH

I I

HEAD-2

(CN3)

Rev.

A

2-17

Page 44

Operating Principles

SNLUS

800 Service

Manual

2.4 INK SYSTEM MANAGEMENT

This section

system and to ensure highquality output.

operations:

■ Power on

■ Cleaning

■ Standby

■ Refresh

■ False absorbing

■ Cleaner blade

■ Ink end process

These ink system operations are controlled with the values indicated by the following counters and

timers:

H

Refresh timer

■ Flashing counter

■ Protect counter

The figure below shows how the carriage position determines which ink system operation is to be

executed.

explains how the

ink system is controlled to protect the printhead and the ink supply

The ink system control is composed of the following

Ink system

Home

po~ition

(HP)

#“’ ,,,

t..

(.

%-’

““

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

;

Printer mechanism

:

(M-481O)

:.

. .+.

.

i.;....

I

ASF

Sheet loading

position

. . . . . . . . . . . . .

Cleaner end position

.

. . . .

.

. . . . . . . . . . . . . . . . . . . . .

~“’’’sta”a”

.

. . . . . . .

Flashing

Position

False absorbing

position

-

. . . . . . -

-

- --- -------

#

‘

‘------

Rubbing

-------i---:

~

I

Cap/Pump

~

Mechanism

i~

i....: ~

. . . . . . . .

.

/

i

~:

‘--------i ------

-.

------, --------

i

i

~

w

‘

~

2-18

Cleaner reset position

~

I

I

I

Ink catridge

Replacement

Position

Figure 2-20. Relation of Ink System Operation and

Carriage Position

I

I

Rev.

A

Page 45

STYLUS 800 Service Manual

Opmeting Principles

2.4.1 Ink Operations

There are various ink operations that can be performed selectively by the printer.

2.4.1.1 Power on Operation

Power on consists of the following operations, and only one of these operations is performed,

depending on the position of the carnage when the printer is turned on.

■

At ink system home position

N

Notat ink system home position

1) Moves the carriage to the flushing position and

performs the flushing operation.

2) Returns the carnage to the home position (standby for

printing).

Note: The false absorbing operation

ceding the above-mentioned sequence, depending

on the protect counter R value.

ispetformedpre-

1) Returns the carriage to home position.

2) Performs cleaner blade- I operation.

3) Performs ink absorbing operation.

4) Performs pressure release operation.

5) Performs micro absorbing operation.

6) Performs false absorbing operation.

7) Performs cleaner blade-II operation (including the

flushing operation).

8) Moves the carriage to the standby position.

2.4.1.2 Cleaning Operation

This operation is performed when cleaning is selected by pressing the ALT and PAUSE buttons

simultaneously. There are three cleaning modes, each of which is selectively performed, depending

on the cleaning counter K value and the number of printed lines from the previous cleaning

operation.

■

CL1

(Normal)

1) If the carriage is out of home position, return it to the home position.

2) Cleaner blade - I operation.

3) Change the gear engagement. (pump drive ON)

4) Ink absorbing operation.

5) Performs pressure release operation and micro absorbing operation.

6) Cleaner blade -II operation. (including the flashing operation)

7) Move the carnage to the stand-by position, and change the printer state to

the PAUSE state.

■

CL2

(Intensive)

1) If the carriage is out of home position, return it to the home position,

2) Cleaner blade - I operation.

3) Change the gear engagement (pump drive ON)

4) Ink absorbing operation.

5) Pressure release operation.

6) False absorbing operation.

7) Rubbing operation.

8) Change the gear engagement. (pump drive ON)

9) Micro absorbing operation.

10) False absorbing operation.

11) Cleaner blade - II operation. (including the flashing operation)