Page 1

EPSON

EPSON

EPSON France S.A.

SERVICE MANUAL

GT-1200

PRODUIT

Page 2

SERVICE MANUAL

Color Image Scanner

EPSON GT-12000

4008511

®

Page 3

NOTICE

n

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

n

The contents of this manual are subject to change without notice.

n

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

n

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective

owners. EPSON disclaims any and all rights in those marks.

Copyright © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

Page 4

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING

Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIER WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. W HEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION I N WORKING ON POWER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED O N THE SERIAL NUMBER/RATI NG PLATE. I F

THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POW ER SOURCE, DO NOT CONNECT IT T O THE POW ER

SOURCE.

3. ALWAYS VERIFY THAT T HE EPSON PRO DUCT HAS BEEN DISCO NNECT ED FROM THE PO WER SOURCE BEFORE REMOVING OR REPLACI NG

PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. I N ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUI TRY, USE STATIC DISCHARGE EQUI PMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

Page 5

PREFACE

This manual describes basic functions, theory of electr ical and m echanical oper ations, maintenance and repair procedures of G T-12000. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be g iven to the precaution s on the preceding page. T he

chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Page 6

REVISION STATUS

Rev. Date Page(s) Contents

A 1997/10/20 All First release

Page 7

TABLE OF CONTENTS

PRODUCT DESCRIPTIONS

1.1 OVERVIEW....................................................................................................................................................................1-1

1.2 SPECIFICATION ...........................................................................................................................................................1-1

1.3........................................................................................................................................................................................1-4

1.3 INTERFACE SPECIFICATION ......................................................................................................................................1-4

1.4 CONTROL CODE..........................................................................................................................................................1-5

1.5 OPERATION SPECIFICATIONS...................................................................................................................................1-6

1.5.1 Switch Specification...........................................................................................................................................................................1-6

1.5.2 LED Specification ...............................................................................................................................................................................1-6

1.5.3 Switch Setting.....................................................................................................................................................................................1-7

1.5.4 Error Indication...................................................................................................................................................................................1-7

1.5.5 Readable Area..................................................................................................................................................................................... 1-8

1.5.6 Transportation Screw.........................................................................................................................................................................1-8

OPERATING PRINCIPLES

2.1 GENERAL DESCRIPTION ............................................................................................................................................2-1

2.2 MECHANISM OPERATING PRINCIPLES.....................................................................................................................2-2

2.3 ELECTRICAL CIRCUIT OPERATIONS.........................................................................................................................2-3

2.3.1 Control Circuit Operation...................................................................................................................................................................2-3

2.3.2 Power Supply Circuit Operation........................................................................................................................................................2-5

Page 8

TROUBLESHOOTING

3.1 OVERVIEW....................................................................................................................................................................3-1

3.1.1 Error Detection by the Self-Diagnostic Function.............................................................................................................................3-1

3.1.2 Troubleshooting .................................................................................................................................................................................3-2

3.1.2.1 Test Points................................................................................................................................................................................3-2

3.1.2.2 Check Points for Abnormal Phenomenon.................................................................................................................................3-2

3.1.3 Troubleshooting for Electrical Circuit ..............................................................................................................................................3-8

3.1.3.1 Power Supply Board (B054PSH Board)....................................................................................................................................3-8

3.1.3.2 Control Circuit Board (B054MAIN Board)..................................................................................................................................3-9

DISASSEMBLY AND ASSEMBLY

4.1 OVERVIEW....................................................................................................................................................................4-1

4.1.1 Tools....................................................................................................................................................................................................4-1

4.1.2 Screws................................................................................................................... ..............................................................................4-1

4.2 DISASSEMBLY PROCEDURES ...................................................................................................................................4-2

4.2.1 Electrical Circuit Removal..................................................................................................................................................................4-3

4.2.1.1 EPROM Replacement...............................................................................................................................................................4-3

4.2.1.2 MAIN/B054PSH Board Removal...............................................................................................................................................4-4

4.2.2 Scanner Body Disassembly...............................................................................................................................................................4-5

4.2.2.1 Upper Housing Removal...........................................................................................................................................................4-5

4.2.2.2 Scanner Mechanism Removal .............................................................................................. ....................................................4-6

4.2.3 Scanner Mechanism Disassembly....................................................................................................................................................4-7

4.2.3.1 Panel Board Assembly Removal...............................................................................................................................................4-7

4.2.3.2 Sub Board Assembly Removal..................................................................................................................................................4-8

4.2.3.3 HP Sensor (CR) Removal.........................................................................................................................................................4-9

4.2.3.4 CR Motor Assembly Removal .................................................................................................................................................4-10

Page 9

4.2.3.5 Glass Frame Assembly Removal and Pre-operation ..............................................................................................................4-11

4.2.3.6 Lamp Assembly and Inverter Board Assembly Removal ........................................................................................................4-14

4.2.3.7 HP (AF) Sensor Removal........................................................................................................................................................4-16

4.2.3.8 AF Motor Assembly Removal.................................................................................................................................................4-17

4.2.3.9 AF Motor Assembly Installation............................................................................................................................................... 4-18

4.2.3.10 Option Frame Assembly Removal.........................................................................................................................................4-19

ADJUSTMENT

5.1 OVERVIEW....................................................................................................................................................................5-1

MAINTENANCE

6.1 OVERVIEW....................................................................................................................................................................6-1

6.1.1 Cleaning...............................................................................................................................................................................................6-1

6.1.2 Lubrication..........................................................................................................................................................................................6-1

APPENDIX

7.1 OVERVIEW....................................................................................................................................................................7-1

7.1.1 Connector Pin Assignment................................................................................................................................................................7-1

7.1.2 Connector Summary...........................................................................................................................................................................7-1

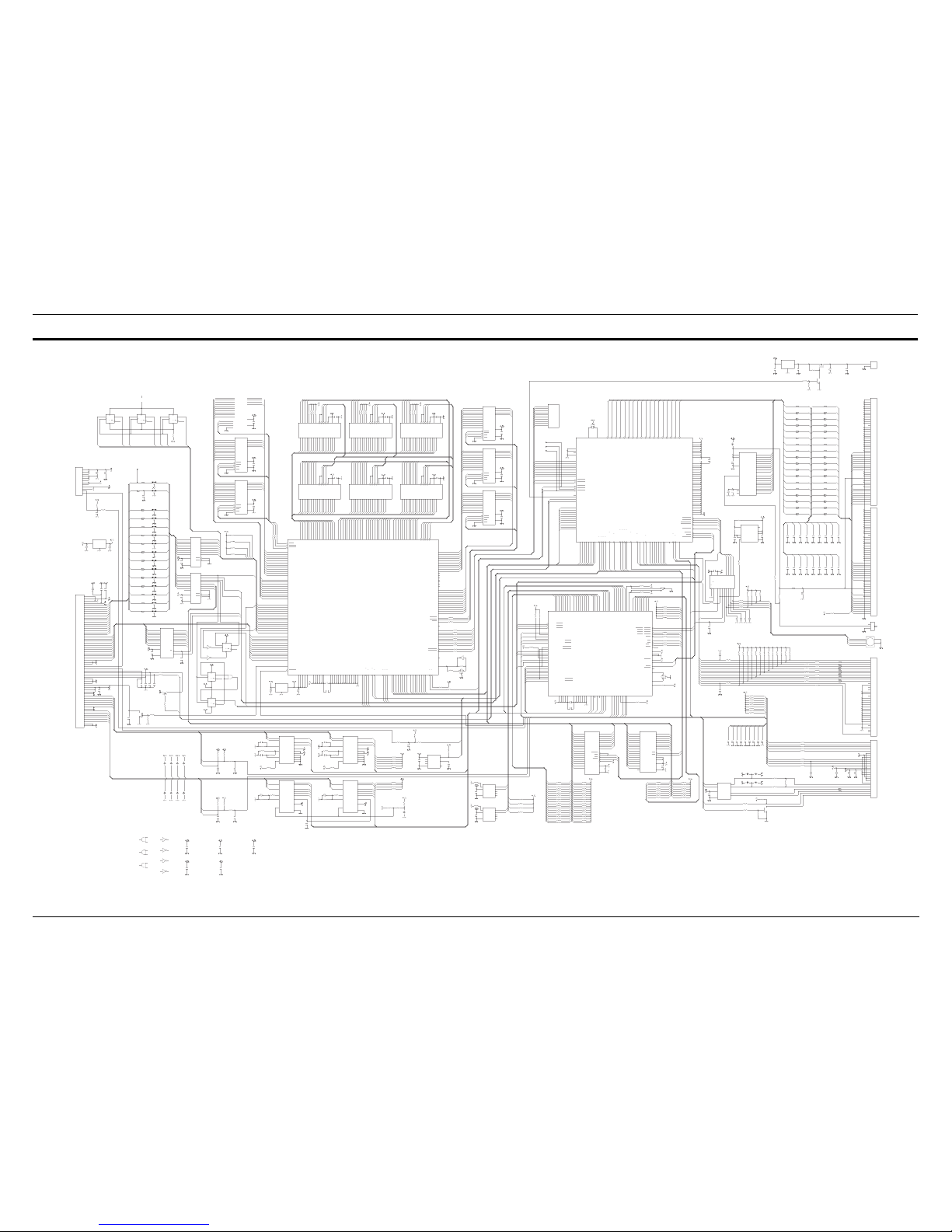

7.2 COMPONENT LAYOUT ........................................................................................................... .....................................7-6

7.3 CIRCUIT DIAGRAMS ....................................................................................................................................................7-8

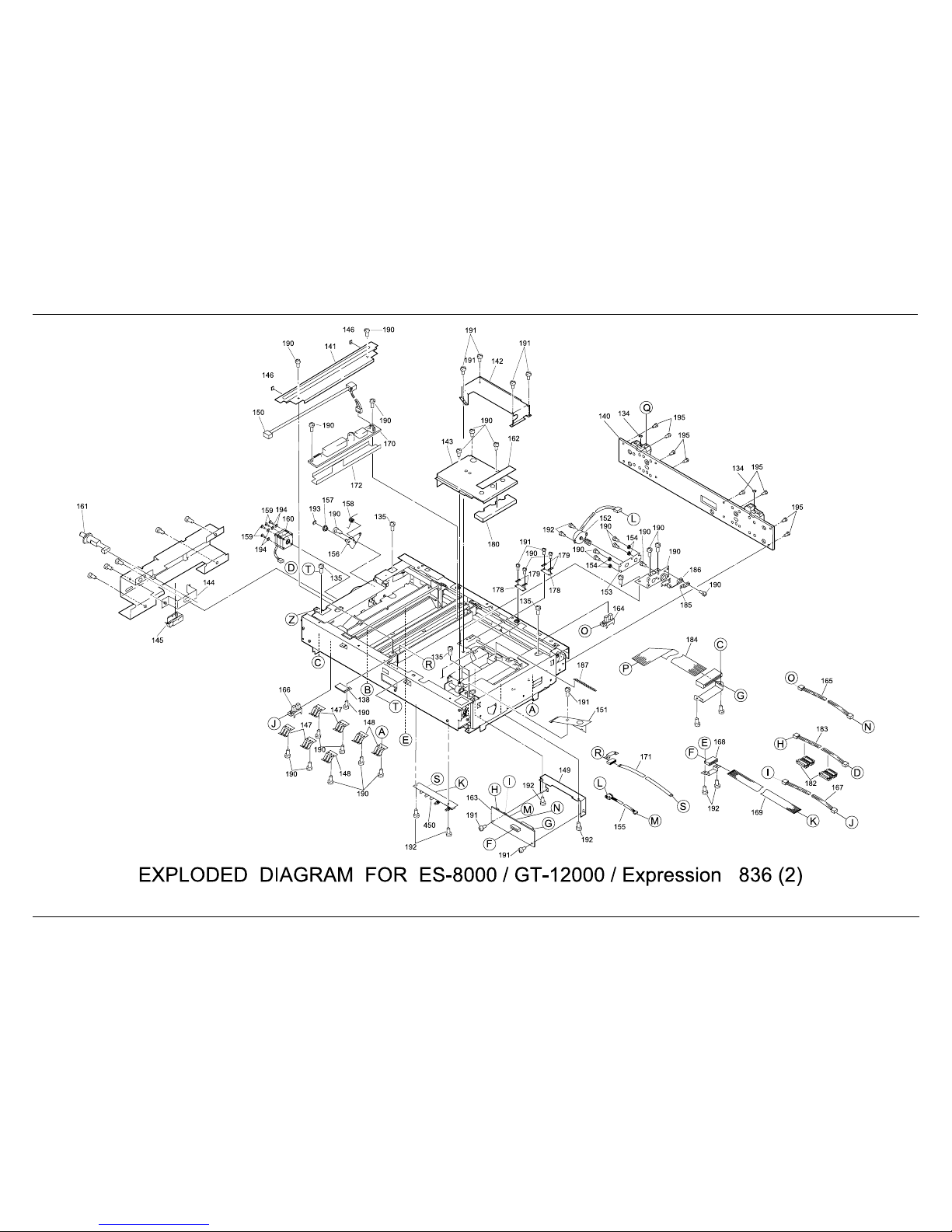

7.4 EXPLODED DIAGRAMS.............................................................................................................................................7-10

Page 10

PRODUCT DESCRIPTIONS

CHAPTER

1

Page 11

GT-12000 Product Descriptions

Rev. A

1-1

1.1 OVERVIEW

The GT-12000 is an A3 size flat-bed type color image scanner. The main

features of the scanner are:

q High resolution

Optical resolution is 800 dpi.

q Wide readable area

Accommodates up to A3 size.

q High-quality image

12bit A/D input/output (optical density is 3.0.)

q High-speed scanning

Scanning A3/Portrate At 800dpi / Draft-mode;

Full-color = Approx. 15mS/line

256 Gray = Approx. 10.8mS/line

Line art = Approx. 10.8mS/line

q Adjustable Focusing function

Adjustable up to 5mm above the surface of document table.

q Quick operation

Xe-Gas Cold Cathode Fluorescent Lamp allows no initial light-up for

immediate scanning.

q New command level: ESC/I-B8 (B6 level with Focus control)

q Optional unit enhancing the function of the unit

n Transparency Unit

n Duplex scanning ADF (Automatic Document Feeder)

1.2 SPECIFICATION

GENERAL

Type: Flat-bed color image scanner

Scanning Method: Sub-Scanning mirror movement system

Photoelectric Device: Color CCD Line sensor

Color Separation: Color filter separation

Light Source: Xe-Gas Cold Cathode Fluorescent Lamp

Scanning Resolution: 800 (Main) by 800 (Sub) dpi

Output Resolution: 50 to 3200dpi (1dpi increment)

Effective Picture Element: 9760 by 13760 pixel (Max.)

Maximum Readable Area: 12.2 by 17.2 inch (310 by 437mm)

Scanning Speed: At 800 dpi / Draft mode;

Table 1-1. Scanning Speed

Original A4/Portrait A4/Portrait - A3/Portrait

Reading Area Less than 210mm 210 to 310mm

Line Art Approx. 7.5mS/line Approx. 10.8mS/line

256 Gray-scale Approx. 7.5mS/line Approx. 10.8mS/line

Full Color Approx. 10.0mS/line Approx. 15.0mS/line

Page 12

GT-12000 Product Descriptions

Rev. A

1-

2

IMAGING FUNCTIONS

Gradation: Input/internal process = 12bit/pixel

Output = 8 or 12bit/pixel

Zoom: 50 to 200% (1% increment)

Gamma Correction: CRT (A/B)

PRINTER (A/B/C)

User definable (1 level)

Color Correction: Impact-Dot Printer

Thermal Printer

Ink jet Printer

CRT Display

User definable (1 level)

Brightness Control: 7 levels

Image Processing: Bi-level= Fixed threshold

TET

Half-toning= Error diffusion (A/B/C)

Dither (Resident) (A/B/C/D)

Dither (user definable) (A/B)

Focusing: One-piece CCD/Lens movement system

INTERFACE

Standard Interface: Bi-Directional Parallel

SCSI (50/50 pin connectors)

SOFTWARE

Commend Level: ESC/I-B8 (B6 level with Focus control)

ELECTRICAL SPECIFICATION

Power supply voltage: [120 V version]

Rated voltage = AC100 - 120 V (± 10%)

[220-240 V version]

Rated voltage = AC220 - 240 V (± 10%)

Rated frequency range: 50 / 60 Hz (49.5 - 60.5 Hz)

Power consumption: Approximately 60 W (without an optional unit)

Maximum 75 W (with an optional unit)

Insulation resistance: 10 M W at 500 VDC

(between AC line and chassis)

Dielectric strength: AC 1.5 KV / minute

(between AC line and chassis)

Static electricity: Panel = 10 KV

Metal = 7 KV / 150 pF, 150 W

SAFETY, EMC

Safety regulation: UL1950 with D3

CSA C22.2 NO. 950 with D3

Low voltage directive

73/23/EEC: EN60950 (TUV)

EN60950 Nordic Deviation (NEMKO)

EMC: FCC Part15 Subpart B Class B (USA)

CSA C108.8 Class B (Canada)

AS/NZS3548 Class B

Directive 89/336/EEC: EN55022 Class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC 801-2

IEC 801-3

IEC 801-4

Page 13

GT-12000 Product Descriptions

Rev. A

1-

3

ENVIRONMENTAL CONDITIONS

Temperature: Operating = 5 to 35°C

Storage = -25 to 60°C

Humidity: Operating = 10 to 80% (no condensation)

Storage = 10 to 85% (no condensation)

RELIABILITY

Main unit: MCBF 100,000 cycle

OPERATING CONDITIONS

Dust: Ordinary office or home conditions.

(Should be kept away from extreme dust.)

Illumination: Operation under direct sunlight or near

strong light source should be avoided.

DOCUMENT

Reflective type: Smooth surface such as a printing and

photograph.

Transparency type: Reversal film, Negative film

Note: The optional transparency unit must be

used.

PHYSICAL DIMENSIONS AND WEIGHT

Dimensions: 656 (W) x 458 (D) x 170 mm (H)

(See Figure 1-1.)

Weight: Approximately 20 Kg

656mm

458mm

170mm

(6.7")

(25.8")

(18")

Figure 1-1. External Dimension of the GT-12000

Page 14

GT-12000 Product Descriptions

Rev. A

1-

4

1.3 INTERFACE SPECIFICATION

This scanner is equipped with the following interfaces:

q Bi-directional Parallel Interface

n Data: 8 bit parallel

n Handshake: BUSY, /ACK handshaking

n Signal: TTL level

n Connector: 36 pins (Amphenol)

q SCSI interface

n Function: Conforms to ANSI Standard X3.131-1986.

n Electrical specification:Conforms to ANSI Standard X3.131-1986.

(TTL compatible level)

n Connector: 50 / 50 pin (Amphenol)

n Terminator: Internal terminator

Switches between “active” and “ inactive”

n SCSI ID Set with an internal rotary switch

(Range: 0 - 7)

Page 15

GT-12000 Product Descriptions

Rev. A

1-

5

1.4 CONTROL CODE

The command level for this scanner is ESC/I-B8. The commands

supported are shown in the table below.

Table 1-2. Control Code Summary

Category Command Name Code

Execute Command Identity Request ESC I

Status Flag Request ESC F

Extended Status Flag

Request

ESC f

Parameter Request ESC S

Scanning Start ESC G

Data Format Setting Set Data Format ESC Di

Set Resolution ESC R n1 n2

Set Zooming ESC H i1 i2

Set Read Area ESC A n1 n2 n3 n4

Set Color ESC Ci

Mirroring ESC Ki

Image Setting Set Brightness ESC Li

Set Gamma Correction ESC Zi

Download Gamma Table ESC zi d0 d1 - d255

Set Sharpness ESC Qi

Image Processing Set Digital Halftoning ESC Bi

Set Auto Area

Segmentation

ESC si

Download Dither Pattern ESC b I I j d (j2)

Set Color Correction ESC Mi

Download Color Correction ESC m d1 d2 - d9

Set Threshold ESC t

Table 1-3. Control Code Summary (continued)

Category Command Name Code

Auxiliary Set Scanning Mode ESC gi

Initnialize ESC @

Set Line Counter ESC di

Control Option ESC ei

Set Focus ESC pi

Focus Position Request ESC q

Set Ratio Correction for

Main and Sub Scan

ESC Wi

Set the Film type ESC Ni

Eject Paper ESC FF

Feed Paper ESC PF

Control Normal Response ACK

Abnormal Response NACK

Abort Scanning CAN

Header STX

Page 16

GT-12000 Product Descriptions

Rev. A

1-

6

1.5 OPERATION SPECIFICATIONS

1.5.1 Switch Specification

This scanner is equipped with 4 switches. Their functions are described

below:

q “

OPERATE

“

n Turns on and off the scanner.

n Pressing this switch for power-on initializes the scanner.

q “

RESET

”

Initializes the scanner.

q

SCSI ID rotary switch

(located at the back of the scanner)

Sets the SCSI device ID for this scanner when the SCSI interface is

used to connect the scanner with the host computer.

Note: The factory default value for this scanner is “2”.

q

SCSI terminator setting switch

(located at the back of the scanner)

Alternates the internal terminator setting between “Connected” and

“Disconnected” when the SCSI interface is in use.

Note: The factory default setting for this switch is “On” (Connected).

1.5.2 LED Specification

This scanner has the following 3 LED indicators:

q

OPERATE

n

Indicates the scanner’s power On/Off status. It is on when the scanner

power is on.

q

READY

n

n Comes on when the scanner is ready to receive commands. It

flickers during scanning due to data transmission between the host

computer and the scanner.

n Indicates an error type in combination with the ERROR LED

indicator when an error has occurred.

q

ERROR

nnnn

Comes On when an error has occurred.

ERROR

READY

OPERATE RESET OPERATE

ON

OFF

SW

0

1

5

2

3

4

7

6

Figure 1-2. Buttons, Switches and LED Indicators

Page 17

GT-12000 Product Descriptions

Rev. A

1-

7

1.5.3 Switch Setting

Among the switches equipped with this scanner, SCSI switch and the

terminator switch, which are used for SCSI interface, have the following

settings:

q SCSI-ID setting switch

ID No. Availability Note

0 Available Normally assigned to other SCSI device such

as a hard disc.

1 Available Normally assigned to other SCSI device such

as a hard disc.

2 Available Set at the factory to the scanner.

3 Available

4 Available

5 Available

6 Available

7 Available Normally assigned to the SCSI host adopter.

(Blank) Not Available Not effective / Not used

*

Not Available Not effective / Not used

CHECK POINT

üüüü

Do not set the ID number that is already assigned

to other SCSI device.

q Terminator switch

Setting Note

ON Connects to the terminal resistor. /Factory default

setting

OFF Disconnects from the terminal resistor.

CHECK POINT

üüüü

Be aware that the terminator switch must be set

according to the scanner location on the “daisychain”.

1.5.4 Error Indication

When an error has occurred, the error type is indicated by the

corresponding combination of the “READY” and “ERROR” LED indicators.

Table 1-4. Error Types and Corresponding Indications

READY

n

ERROR

nnnn

Error Type

ON ON Command error

OFF Blinks Communication error

Blinks Blinks Fatal error

OFF OFF Option error

Note: The remedies for these errors are provided in Chapter 3

“Troubleshooting”.

Page 18

GT-12000 Product Descriptions

Rev. A

1-

8

1.5.5 Readable Area

The origin point for this scanner is marked at the rear left corner of the

document table viewed from the front. See Figure 1-3 for the maximum

readable area of the scanner.

310mm

437mm

2 ±1.5mm

2 ±1.5mm

2 ±1.5mm2 ±1.5mm

Sub Scan Direction

Main Scan Direction

Front

Origin Point

Maximum Readable Area

(12.2")

(17.2")

Figure 1-3. Maximum Readable Area

1.5.6 Transportation Screw

A transportation screw is attached to the left side of the scanner viewed

from the front. Fastening the screw fixes the CR to protect the scanner

from the shock while the scanner is transported or moved. Be sure to turn

the screw to the unlocking position (Described in the figure below.) before

turning the scanner power on.

Locking position set w hile

transporting/m oving the scanner.

U n lo c k in g p o s it io n s e t w h ile

the scanner is used.

Figure 1-4. Transportation Screw

Page 19

OPERATING PRINCIPLES

CHAPTER

2

Page 20

GT-12000 Operating Principles

Rev. A

2-1

2.1 GENERAL DESCRIPTION

The EPSON GT-12000 is mainly composed of the following units:

q Scanner mechanism

(Lamp/Mirror units, CR drive mechanism, integral lens/CCD sensor

unit drive mechanism)

q Control Circuit

q Power supply circuit

The EPSON flat-bed type scanners usually read images by moving the

integral CR unit which consists of the lamp, m irror, lens/CCD sensor. This

scanner, however, characteristically has the CCD sensor and the lens in

the whole unit attached onto the mechanism as an independent unit. This

scanner is also equipped with the newly designed focusing function which

enables the scanner to focus by adjusting the distance between the lens

and the CCD sensor. Therefore, the lens unit is set m ovable and driven by

the specified motor. Since the separate units in the mechanism such as

the lamp (light source) and the mirrors move at their own speed for

reading, the incident distance of the reflected light f rom the document to

the CCD sensor is kept constant.

The control circuit board and the power supply circuit board are stored in

the separate shield compartment. Since it is only connected to the

connector board in the scanner mechanism, it is removed and maintained

with ease.

B054SUB Board

CN1

CN2

CN3

CN6

CN7 CN5

CN4

B054PNL Board Motor

(for Lens Unit Drive)

Lamp/Mirror Unit

Mirror Unit

HP Sensor

(for Mirror)

Motor

(for Lamp/Mirror Drive)

Drive Wires

B054PSH Board

(Power Supply Circuit)

AC Input

SCSI

ID Switch

Terminator Switch

HP Sensor (Lens)

B054ISN Board

(CCD Sensor)

Lens Unit

(Optional)

I/F

B054MAIN Board

(Control Circuit)

SCSI

I/F

Bi-D

I/F

Document

Figure 2-1. Main mechanism Structure of the GT-12000

Page 21

GT-12000 Operating Principles

Rev. A

2-

2

2.2 MECHANISM OPERATING PRINCIPLES

Compared with other EPSON scanners, the main feature of this scanner

lies in its new optical mechanism used for reading images. Instead of the

united lamp & CCD movement system used for other scanners, this

scanner scans with the fixed CCD sensor and separate lamp and the

mirror units. Since the color CCD line sensor is used for the reading

device, only one light source is equipped and light is separated through

the RGB color filter.

As shown in Figure 2-2, the light source (high luminance cold cathode

xenon lamp), the first reflection mirror unit and the second reflection mirror

unit move independently at their own speed. Therefore the length of the

incident light reflected from the document to the CCD sensor is kept

constant. (Otherwise, excluding the fixed L1 and L2, LV1 and LV2 keep

changing to make the incident light length “L” constant.) Drive from the

stepping motor moves each mirror unit via the wires.

The CCD sensor and the lens are united into one unit, which is semi-fixed

on the base frame. For focusing function, it moves toward the optic with

the drive sent from the motor. (The focusing area with this function is from

0 to 5 mm (maximum) above from the glass surface.

x1

x2

L1

(Fixed)

Document

LV1 (Variable)

Document

Glass

L2

(Fixed)

Mirror Unit

Lamp/Mirror unit

Lens Unit

CCD Sensor

LV2 (Variable)

Figure 2-2. Optical Unit Structure

Page 22

GT-12000 Operating Principles

Rev. A

2-

3

2.3 ELECTRICAL CIRCUIT OPERATIONS

This section describes the electrical circuit of the GT-12000.

2.3.1 Control Circuit Operation

The control circuits of this scanner are:

q B054MAIN board (Main control circuit board)

q B054SUB board (Relay board)

q B054PNL board (Control panel board)

q B054ISN board (CCD sensor board located on the CR)

Among various functions controlled by B054MAIN board, the core control

circuit of the scanner, and B054ISN, process from reading image with the

CCD sensor to processing image signals is described below:

q B054ISN Board (CCD image sensor)

n Photoelectric conversion:

Converts light reflected from the document (light energy) into

electrical energy (electrical charge).

n Amplification

n A/D conversion:

Converts the image data produced in the form of analog electrical

signal into 12-bit digital data.

q B054 MAIN Board (processing image data)

ASIC (IC24) on this board manages most of the following functions:

n Shading correction:

Performs image data correction on a black and white basis.

n Numbers of image correction such as gamma correction, color

correction, halftoning correction. (They are carried out according to

the settings on the host side.)

After passed these processes, image data is finally output to the host.

CCD

CPU

IC 1 3

(H D 6413003TF)

M PX A/D

IC 2

(A D 9807)

R

G

B

12bit

IC 2 4

(M ERCURY)

IC 2 8

(GGIF)

IC 1

EPRO M (1Mbit)

IC 1 7

PSRAM (1Mbit)

Motor driver

IC 3/4/5/6

DRAM (1M x 4)

IC 7/8/9

PSRAM (1Mbit)

IC 1 8 - 2 3

DRAM (1M x 4)

IC 10/11/12

CN2

B i-D I/F

CN1/3

SCSI I/F

CN6

Option

Document

In v e r te r

B054 ISN Board

<Line C orrection

M e m o ry >

<R GB Im age M em ory>

<Buffer Memory>

TPU

ADF

<I/F C ontrol P rocessor>

<Im aging P rocessor>

Shading

G am m a Correction

Line C orrection

M ain/S ub Average

Color Correction

Sm oothing

Zoom

Bi/Q uad Form atting

TET

AAS

M irro r S h ift

Lens Shift

H P Sensor 1/2

B054 MAIN Board

Light

Quanti

t

y

Mon

i

t

or

Figure 2-3. Control Circuit Block Chart

Page 23

GT-12000 Operating Principles

Rev. A

2-

4

B054MAIN BOARD

Name Location Description

CPU

HD6413003TF

IC13 The CPU, which operates at 16 MHz,

controls this board.

ASIC

MERCURY

IC24 an image processor which controls the

followings:

· CCD

· Line correction memory

· Buffer memory

· Image processing

ASIC

CGIF

IC28 This I/F control processor controls the

followings:

· SCSI I/F

· Bi-D I/F

· Address decode

· PSRAM refresh

· Reset control

DRAM

(1MX4)

IC7-9

IC10-12

Line correction memory

Buffer memory

PSRAM (1M) IC8-23 RGB image memory

ROM (1M) IC1 Firmware memory

B054ISN BOARD

Name Location Description

CCD sensor

ILX734K

IC1 Color CCD line sensor

· Effective pixel = 10500x3 lines

· Single side reading system

· Shutter function

ADC

AD9807

IC2 A/D converter processing IC

Minimum resolution = 12 bit

B054SUB BOARD

This is a relay board, a module is in the shield compound along with the

PSB/PSE board, which connects the B054ISN in the mechanism with the

B054PNL board.

B054PNL BOARD

This board has a power switch (push-lock), RESET switch and LED

indicators (OPERATE, READY, ERROR).

Page 24

GT-12000 Operating Principles

Rev. A

2-

5

2.3.2 Power Supply Circuit Operation

Since the power supply circuit board B054PSH for this scanner meets the

universal specification, it can use the rated voltage in the range from 100V

to 240V.

The electrical circuit for the AC input part is designed on the basis of

200V line. In case the input voltage is 200V line level, the ordinary full

wave rectifying system is used. With this system, the voltage is rectified by

the diode bridge DB1 and then smoothed by the serial smoothing

capacitors C11 and C32 to produce approximately 250 VDC.

On the other hand, if the input voltage is 100V line level, the doubled

voltage rectifying system is used instead. With this system, the input AC

current is separated into the following 2 flows; the positive half cycles of

the current flow through the control IC (IC2) (from Pin 2 to Pin 3) via the

diode bridge (DB1) and the smoothing capacitor C11, and the negative

half cycles of the current, however, flow through the smoothing capacitor

(C32) and DB1 via IC2 (from Pin 3 to Pin 2). Through these flows, the

positive and negative AC current are separately charged in the smoothing

capacitors C11 and C32, respectively, and the doubled VDC

(approximately 250 VDC) equivalent to the input voltage of the 200V line

is produced. At power-on, the control circuit (IC2) is activated by the full

wave rectifying system. Then, if the input voltage is 100 VDC line level,

the system is automatically switched to the doubled voltage rectifying

system after certain period set by the circuit constant.

Except for the full wave rectifier circuit/voltage doubler rectifier circuit at

the AC input part, the normal RCC (Ringing Choke Converter) regulator

circuit is used for the rest part of the power supply circuit, and the dif f er ent

levels of VDC are distributed to corresponding mechanisms, as shown in

Table 2-1:

Table 2-1. DC Output Power

Output VDC Application

+5 V Logic power lines

+24 V q Motor drive power source

q Power source for the lamp (inverter)

+15 V +12 V production

(Power used to drive the cooling fan for the shield

compartment which stores B054 MAIN and B054PSH.)

+

+

Positive

Component

AC input

DB1

C11

C32

IC2

Negative

Component

Doubled Voltage

Output

[AC Input]

100 V = On

200 V = Off

Figure 2-4. Voltage Doubler Rectifier Circuit Operation

Page 25

TROUBLESHOOTING

CHAPTER

3

Page 26

GT-12000 Troubleshooting

Rev. A

3-1

3.1 OVERVIEW

This chapter describes the troubleshooting which enables you to solve the

problem efficiently when the scanner is operating abnormally. The

remedies for the errors detected by the self-diagnostic function and the

check point for each phenomenon are described in the following sections.

3.1.1 Error Detection by the Self-Diagnostic Function

The self-diagnostic function equipped with this scanner automatically

detects operating status of each part. The abnormal phenomenon

detected by the function and remedies are as follows:

Command Error

LED Status Cause Operation/Condition

READY

ERROR

Undefined command

is detected.

Ignores the wrong command

/parameter (No change made

for the current settings.), and

returns NACK to wait for the

next command/ parameter.

Remedy

The error is cleared by the correct command/

parameter.

Communication Error

LED Status Cause

Operation/

Condition

READY

ERROR

· Wrong procedure/operation is

detected in communication.

· In case of SCSI, communication

stops for over 30 seconds in

any phase other than bus free

phase.

The lamp goes

off and the

scanner stops

operating.

Remedy

Turn the scanner Off and back On or press the

“RESET” switch.

Fatal Error

LED Status Cause Operation/Condition

READY

ERROR

<Defect in the hardware>

· The lamp does not light.

· Scanner is turned on with

the CR unlocked.

· Other defects in the

scanner.

· The lamp goes off

and the scanner

stops operating.

· Sets the status bit

“7”.

Remedy

Turn the scanner Off and back On or press the

“RESET” switch.

Option Error

LED Status Cause Operation/Condition

READY

ERROR

<Defect in the options>

· The scanner cover is left

open.

· Paper end, etc..

Sets the status bit “7”.

Remedy

Remove the cause of the error.

CHECK POINT

üüüü

[Option Error] is detected when the option is

installed in the operative condition only.

Page 27

GT-12000 Troubleshooting

Rev. A

3-

2

3.1.2 Troubleshooting

This section provides test points for each major unit and check points for

each abnormal phenomenon.

3.1.2.1 Test Points

Test points for the motors and sensors are shown in the tables below.

Motors

q

Condition: Test the motor without any cables connected.

Motor Test Point Signal Level

Motor (for driving

the mirror)

<Cable connector>

Between Pin 1 and Pin3

Between Pin 2 and Pin 4

15.0 W

Motor (for driving

the focusing

mechanism)

<Cable connector>

Between Pin 1 and Pin3

Between Pin 2 and Pin 4

15.5 W

Sensors

q

Condition: Test with the scanner power on.

Motor Test Point Signal Level

HP sensor (Mirror)

<B054SUB board>

CN6: Pin 1 (Signal)

Pin 2 (GND)

H: In the home position

L: Off the home position

HP sensor

(Lens/CCD)

<B054SUB board>

CN4: Pin 1 (Signal)

Pin 2 (GND)

H: In the home position

L: Off the home position

CAUTION

Be careful not to short-circuit the signals while

checking them.

3.1.2.2 Check Points for Abnormal Phenomenon

See the table below which shows the abnormal phenomenon typically

occurs.

Table 3-1. Abnormal Phenomenon

Abnormal Phenomenon Description

Flowchart

to refer

The scanner doesn’t operate

at power on.

“OPERATE” LED does not

light.

3-1

“Fatal Error” is indicated and. CR does not move. 3-2

is not cleared after the

scanner is turned off and

back on

Abnormal movement of

CR, such as crashing into

the frame.

3-3

Lamp does not light. 3-4

“Communication Error” is

indicated.

Error when Bi-directional

parallel I/F is used.

3-5

Error when the SCSI is

used.

3-6

Scanned image is abnormal.

Black lines, White

banding, and so on

3-7

Check points for the major units listed for each phenomenon are shown in

the following pages.

Page 28

GT-12000 Troubleshooting

Rev. A

3-

3

Flowchart 3-1

Phenomenon: “Operate” LED does not light.

Disconnect the cables from the

connectors CN2/4/5/6/7 on the

B054MAIN board, then, with the

scanner power on, check the

connector CN 5 on the B054MAIN

board for the correct voltages shown

below:

Between Pins 1 and 4 : +24VDC

Between Pins 7 and 4 : + 5 VDC

Between Pins 9 and 10 : +15VDC

Are the

CN1 on the B054SUB

board and the shield

compartment connected

properly?

Yes

Yes

No

No

Start

Has the

fuse F1/F2 on the

B054PSH board

blown out?

Yes

No

Are the outputs all corrects?

A

Replace the B054PSH

board.

Yes

No

Connect the m properly.

Replace the

fuse. Has the fuse

blown again at turning

on the scanner?

A

Replace the B054PSH

board.

Disconnect the connector

cables from the connectors

CN2/4/5/6/7 on the B054SUB

board.

No

Yes

A

Check the following motors for

the correct res i s tance:

- Motor (for mirror) : 15.0

Ω

- Motor (for focus) : 15.5

Ω

Are the resistances correct?

Check the motor driver ICs on

the B054MAIN boar d.

<Motor (for mirror) >

Check if the resistanc e

between Pin 8/ 6 of IC4/3 and

the GND is infinitive.

<Motor(focus)>

Check if the resistanc e

between Pin 1/ 15 of IC5/6 and

the GND is infinitive.

Replace the

B054MAIN

board.

Are they correct?

Replace the

motor.

Yes

No

Replace the

B054MAIN

board.

Page 29

GT-12000 Troubleshooting

Rev. A

3-

4

Flowchart 3-2

Phenomenon: CR (Mirror/Lamp) does not move.

Start

With the scanner power On, check the

connector CN5 on the B054MAIN

board for the correct +24 VDC output

from the following :

Between Pin 1 and Pin 4 : +24 VDC

Turn th scanner off and move the CR

manually to chec k i f it move s smoothly.

Does the CR move abnomrmally?

The mechanism is

abnormal.

(Needs replacing.)

Unlock the screw.

No

Yes

No

Yes

Is the transportation

screw set to the locking

position?

Is the correct voltage output?

Replace the

B054PSH board.

A

Yes

No

No

Yes

A

Check the following motors for

the correct resistance:

- Motor (for mirro r) : 15.0

W

- Motor (for focus) : 15.5

W

Are the resistances correct?

Check the motor driver ICs on

the B054MAIN board.

<Motor (for mirror) >

Check if the resistance

between Pin 8/6 of IC4/3 and

the GND is infinitive.

<Motor(focus)>

Check if the resistance

between Pin 1/15 of IC5/6 and

the GND is infinitive.

Replace the

B054MAIN

board.

Are they correct?

Replace the

motor.

Yes

No

Replace the

B054MAIN

board.

Page 30

GT-12000 Troubleshooting

Rev. A

3-

5

Flowchart 3-3

Phenomenon: CR moves abnormally. (Crashing into the frame)

Start

Replace the HP

sensor (for mirror).

Set the screw to

the unlocking

position.

No

Yes

Check the connector CN4 on the B054

MAIN board for the HP s i

g

nal level.

Is the signal

level "HIGH" when the

CR is at the home

position?

Replace the

B054MAIN boar d.

No

Yes

Is the transportation

screw set to the lockin

g

position?

Flowchart 3-4

Phenomenon: Lamp does not light.

Start

Replace the

B054MAIN board.

Does the lamp l ight

normally?

Lamp is

defective.

No

Yes

Replace the inverter board on the CR.

Does the l amp light normally?

Inverter board

is defective.

No

Yes

Replace the lamp on the CR.

Page 31

GT-12000 Troubleshooting

Rev. A

3-

6

Flowchart 3-5

Phenomenon: “Communication Error

” (Bi-directional I/F)

” (Bi-directional I/F)” (Bi-directional I/F)

” (Bi-directional I/F)

is indicated.

Start

Repace the

B054MAIN board.

No

Yes

Replace the int erface cable.

Does the scanner

operate normally?

Replace the I/ F cable.

Flowchart 3-6

Phenomenon: “Communication Error

” (SCSI)

” (SCSI)” (SCSI)

” (SCSI)

is indicated.

Replace the

B054MAIN board.

Are the settings correct?

Set them

correctly.

No

Yes

Replace the I/F c able.

I/F cable is

defective.

No

Yes

Does the scanner

operate normally?

Start

Check the SCSI for the following

settings:

- Terminator settin

g

- SCSI ID settin

g

Page 32

GT-12000 Troubleshooting

Rev. A

3-

7

Flowchart 3-7

Phenomenon: Scanned image is abnormal.

Start

B054MAIN

board is

defective.

Clean the

glass.

No

Yes

Clean the

mirror.

No

Yes

Replace the B054MAIN board and

perform a test scannin

g

.

Is the image normal?

The mechnasim is

defective.

(Needs replacing.)

No

Is the glass free of stain

and foreign matter?

Wipe the mirror with

a dr

y

, clean cloth only.

Is the mirror free of stain

and forei

g

n matter?

Yes

Page 33

GT-12000 Troubleshooting

Rev. A

3-

8

3.1.3 Troubleshooting for Electrical Circuit

This section describes the abnormal phenomenon and corresponding

check points for each electrical circuit board.

3.1.3.1 Power Supply Board (B054PSH Board)

Phenomenon Check Points

<Abnormal voltage>

+5VDC is not output.

Check IC51 (TL494):

· Signal waveform output from

Pin 8/11 (chopping waveform)

<Abnormal voltage>

+24 VDC is not output.

Check the Switching FET/Q1:

· Waveform at the drain

<Abnormal voltage>

+15 VDC in not output.

Check IC52 (78M15):

· Signal waveform output from

Pin 1

Page 34

GT-12000 Troubleshooting

Rev. A

3-

9

3.1.3.2 Control Circuit Board (B054MAIN Board)

Phenomenon Check Points

<No operation at all>

Reset IC is defective.

Check the reset IC (IC2) for the signal

waveforms output from the following pins:

· Pin 7 (for +5V input)

· Pin 6 (for PWRES output)

<No operation at all>

ROM access is bad.

Check the CPU (IC13) for the ROM

access signal waveforms output from the

following pins:

· Pin 104 (for CS0 signal)

· Pin 78 (for RD signal)

<No operation at all>

CPU is defective.

Check the clock signal waveform input to

the following pin:

· Pin 75 (for XTAL input)

Page 35

GT-12000 Troubleshooting

Rev. A

3-1

0

Phenomenon Check Points

<”Fatal Error”>

Motor (for mirror) driver circuit

is defective.

Check the Driver IC (IC3/4:

· Phase drive signal waveform

output from Pin 8/6

<”Fatal Error”>

Motor (for focus) driver circuit

is defective.

Check the driver IC (IC5/6):

· Phase drive signal waveform

output from Pin 1/15

<”Fatal Error”>

CR does not stop at the home

position.

· Check if the signal waveform

input to Pin 91 of CPU (IC13)

changes in accordance with the

CR position.

<”Fatal Error”>

Lamp does not light.

Check the following for the lamp

signal output:

· Output from Pin 166 of ASIC

(IC24)

· Emitter waveform at Tr (Q1)

<”Fatal Error”>

White standard level is not

read properly.

Check ASIC (IC28):

· Signal waveform output from

Pin 161

<”Communication Error”>

Bi-directional I/F / SCSI I/F

Main cause: ASIC (IC28) is

defective. (Replace IC28 or

B054MAIN board.)

<Image is read abnormally> Main cause: ASIC (IC24) is

defective. (Replace IC24 or

B054MAIN board.)

Page 36

DISASSEMBLY AND ASSEMBLY

CHAPTER

4

Page 37

GT-12000 Disassembly and Assembly

Rev. A

4-1

4.1 OVERVIEW

This chapter describes how to disassemble this scanner. Unless otherwise

specified, assembly can be accomplished by following disassembly

procedures in reverse order.

WARNING

n

n n

n Be sure to disconnect the power cable from the

AC power socket prior to servicing.

n

n n

n Since this scanner weighs heavy

(approximately 20 Kg), it must be carried by

2 people.

CAUTION

n

n n

n Never disassemble any scanner parts unless

specified to do so, because this scanner

mechanism needs assembling and adjusting

rather exactly to preserve accurate control

system at its satisfactory level.

n

n n

n Get yourself enough room for servicing,

considering the size of the scanner.

n

n n

n Since this scanner weighs as heavy as

approximately 20 kg, be sure to perform

servicing on a heavy-duty, level table.

n

n n

n Make sure that the “CR fixing knob” is set to

the locking position to fix the CR by the rear

before packing the scanner.

4.1.1 Tools

Tools used for servicing are as listed in the table below:

Table 4-1 .Tool List

Description Availability SE Part No.

Exclusive adjusting tools

(Leveling tools)

EPSON exclusive Code: 1039140

Phillips screw driver (No.2)

¡

–

Standard screw driver (No.1)

¡

–

Tweezers

¡

–

4.1.2 Screws

Screws used in this scanner are listed in the table below. Be sure to use

the correct types and numbers of screws for each part when assembling

the scanner.

Table 4-2. Screw List

No.

Screw Type /

Specification

Appearance Color

1 CBP M4x12 Silver

2 CB M4x10 Gold

3 CBS M3x6 Red copper

4 CB M3x4 Gold

5 CBP M3x8 Gold

6 CB M3x6 Gold

7 CB M3x12 Black

8

CR;B damper shaft

(Thread part: M3x3)

Gold

9 CP M3x6 Silver

10

Screw lock screw

(Diagonal: 5 mm)

Silver

Page 38

GT-12000 Disassembly and Assembly

Rev. A

4-

2

4.2 DISASSEMBLY PROCEDURES

This section describes disassembling and removing procedures for each

major unit of the scanner.

See the flowchart in Figure 4-1. The jobs in the yellow boxes involve using

the adjustment tools exclusively designed for this scanner. Therefore,

make sure that you read the instruction for the section to refer to carefully

to figure out the procedure before servicing.

Start

Electrical Circuit

Remova

(Section 4.2.1)

EPROM Replacement

(Section 4.2.1.1)

MAIN/Power Supply Board

Removal (Section 4.2.1.2)

Scanner Body

Disassembly

(Section 4.2.2)

Upper Housing Removal

(Section 4.2.2.1)

Mechanism Removal

(Section 4.2.2.2)

Panel Board Assembly Removal

(Section 4.2.3.1)

Sub Board Assembly Remvo al

(Section 4.2.3.2)

HP Sensor (CR) Removal

(Section 4.2.3.3)

Motor (CR) Assembly Removal

(Section 4.2.3.4)

Glass Frame Assembly Removal

(Section 4.2.3.5)

Scanner Mechanism

Dsassembly

(Section 4.2.3)

Lamp/Inverter Board Assembly

Removal (Section 4.2.3.6)

HP Sensor (AF)

Removal (Section 4.2.3.7)

Option Frame Assembly

Removal (Section 4.2.3.9)

Figure 4-1. Procedure for Disassembling the GT-12000

Page 39

GT-12000 Disassembly and Assembly

Rev. A

4-

3

4.2.1 Electrical Circuit Removal

The major electrical circuit boards (B054MAIN and B054PSH) of this

scanner are all stored in one independent shield compartment. Therefore,

they can be removed in one unit (board unit) from the scanner with ease.

1. Disconnect the AC power cable from the scanner.

2. Remove 3 screws (No.5) securing the shield compartment which

contains the electrical circuit boards at the back of the scanner. Then

take out the compartment from the scanner to remove.

CHECK POINT

üüüü

For easy removal, insert a driver or equivalent

into the bail lock of the interface and pull it.

4.2.1.1 EPROM Replacement

In case of EPROM replacement, remove the ROM cover attached on the

board unit.

1. Remove the board unit. (See Section 4.2.1.)

2. Remove 1 screw (No.3) fixing the ROM cover, and remove the cover.

3. Remove the EPROM from the IC socket and install a new EPROM.

CAUTION

When installing the ROM, make sure that the leads

are not bent and the ROM is installed in the right

direction.

S c re w (N o .5 )

Take out

Figure 4-2. Shield Compartment Removal

Screw (No.3)

ROM Cover

Figure 4-3. ROM Cover Removal

Page 40

GT-12000 Disassembly and Assembly

Rev. A

4-

4

4.2.1.2 MAIN/B054PSH Board Removal

B054MAIN and B054PSH boards stored in the shield compartment are

removed in the following procedure:

1. Remove the shield compartment. (See Section 4.2.1.)

2. Remove 12 screws (No.3) securing the top shield of the board unit,

then remove the top shield.

3.

[MAIN board assembly removal]

Disconnect the connector cables from the connector CN5 and CN9 on

the MAIN board.

4. Remove the following screws securing the MAIN board, and remove

the MAIN board:

Ÿ

6 screws (No.3): Fixing the board along the edges.

Ÿ

6 screws (No. 9): Securing the I/F connector.

Ÿ 2 screws (No.10): Securing the optional I/F connector.

.

5.

[Power supply board assembly removal]

Remove the connector cables from the connector CN1 on the power

supply board assembly

and the connector CN5 on the MAIN board

assembly.

6. Remove 6 screws (No.3) securing the power supply board assembly

and remove the power supply board.

S c re w (N o .9 )

Screw Lock Screw

(N o.10)

Figure 4-4. I/F Connector Fixing Screw Removal

Connector (CN5) Connector (CN9)

Screws (No.3)

B054MAIN Board

Figure 4-5. MAIN Board Removal

Connector (CN5)

Screws (No.3)

Connector (CN1)

B054PSH Bo a r d

Figure 4-6. Power Supply Board Removal

Page 41

GT-12000 Disassembly and Assembly

Rev. A

4-

5

4.2.2 Scanner Body Disassembly

This section describes procedures for disassembling the major units of the

scanner.

CAUTION

When removing the CR fixing knob or screw caps,

be careful not to damage the upper housing.

4.2.2.1 Upper Housing Removal

1. Remove the document cover.

2. Using tweezers, remove the CR fixing knob attached to the left side of

the scanner.

3. Remove 4 screws (2 for each of No1 and No.2) securing the upper

housing to the chassises on the scanner. Note that the front 2 screws

are covered with the screw caps. Using tweezers, pinch them out prior

to removing the screws.

4. Lift up the upper housing to remove it.

CHECK POINT

üüüü

When installing the upper housing, make sure

that the optical plate is installed on the specified

position.

Optical Plate

Inner S ide of the

Upper Housing

Screw Cap

Be careful not to dam age

the upper housing.

C ro ss-se ctio n

U sing the tw eezers, rem ove the cap

by lifting it up w hile pushing it tow ard

the other side of the cutout.

Figure 4-7. Screw Cap Removal

S c re w s (N o .1 )

Screw Cap

C R Fixing Knob

Screw Cap

S c re w s (N o .2 )

Figure 4-8. Upper Housing Removal

Page 42

GT-12000 Disassembly and Assembly

Rev. A

4-

6

4.2.2.2 Scanner Mechanism Removal

The scanner mechanism can be removed from the lower housing in the

following procedure:

1. Remove the upper housing. (See Section 4.2.2.1.)

2. Remove 4 screws (No.1) securing the scanner mechanism to the lower

housing at the bottom. Then remove the mechanism from the lower

housing.

CHECK POINT

üüüü

n

n n

n Note the following when installing the scanner

mechanism:

1) Remove the key tops for the power switch

and reset switches from the lower housing.

2) Install the scanner mechanism to the lower

housing.

3) Reinstall the key tops.

n

n n

n Place the removed mechanism on flat stable

surface.

Screws (No.1)

Front Side of the Scanner

Scanner Me chanism

Figure 4-9. Scanner Mechanism Removal

Page 43

GT-12000 Disassembly and Assembly

Rev. A

4-

7

4.2.3 Scanner Mechanism Disassembly

The rest part of the chapter describes the procedures for removing the

major parts/units in the scanner mechanism.

CAUTION

Note that producing this scanner requires rather

precise assembly and adjustment to ensure

accurate control system. Therefore, never

disassemble any scanner parts unless specified to

do so.

4.2.3.1 Panel Board Assembly Removal

1. Remove the scanner mechanism. (See Section 4.2.2.2.)

2. Turn the mechanism over and place it on a flat surface.

3. Disconnect all connector cables from the panel board assembly.

4. Remove 2 screws (No.6) securing the panel board assembly and

remove it.

CHECK POINT

üüüü

Unit arrangement at the bottom of the mechanism

is as shown below.

Motor (CR)

HP Sensor (CR)

Panel Board Assembly

Sub Board Assembly

HP Sensor (AF)

Screws (No.6)

Panel Board Assembly

Figure 4-10. Panel Board Assembly Removal

Page 44

GT-12000 Disassembly and Assembly

Rev. A

4-

8

4.2.3.2 Sub Board Assembly Removal

1. Remove the scanner mechanism. (See Section 4.2.2.2.)

2. Turn the mechanism over and place it on a flat surface.

3. Disconnect all connector cables from the sub board assembly

(B054SUB board).

4. Remove 2 screws (No.3) securing the board to the br acket and r emove

the sub board.

CHECK POINT

üüüü

When placing the scanner up side down, lay a

clean soft cloth under the scanner to protect the

glass surface.

Screws (No.6)

Sub Board Assembly

Figure 4-11. Sub Board Assembly Removal

Page 45

GT-12000 Disassembly and Assembly

Rev. A

4-

9

4.2.3.3 HP Sensor (CR) Removal

This section describes procedure for removing the HP sensor which

detects the reference position for the carriage mirror assembly.

1. Remove the scanner mechanism. (See Section 4.2.2.2.)

2. Move the carriage mirror assembly away from the HP (home position).

3. Turn the mechanism over and place it on a flat surface.

4. Release the hook fixing the HP sensor at the bottom of the mechanism

and remove the HP sensor unit. Then disconnect the connect or cable

from the removed HP sensor.

HP Sensor (AF)

Sub Board Assembly

Panel Board AssemblyHP Sensor (CR)

Motor (CR)

Figure 4-12. HP Sensor (CR) Removal

Page 46

GT-12000 Disassembly and Assembly

Rev. A

4-1

0

4.2.3.4 CR Motor Assembly Removal

This section describes procedure for removing the motor unit which drives

the carriage mechanism (mirror/lamp).

1. Remove the scanner mechanism. (See Section 4.2.2.2.)

2. Turn the mechanism over and place it on a flat surface.

3. Unhook the torsion spring from the tension lever assembly, then

remove 1 screw (No.6) to remove the tension lever assembly.

4. Disconnect the cable for the motor from the relay connector and

remove 4 CR damper shafts; B (No.8) securing the motor, then remove

the motor.

CHECK POINT

üüüü

When assembling, hook the spring to the tension

lever assembly first, then fasten the screw.

Screw (No.6)

CR Damper Shafts ;B

(No.8)

Torsion Sprin

g

Tension Lever Assembly

Motor (CR) As s emb ly

Bottom of the Scanner Facing Upward

Figure 4-13. CR Motor Assembly Removal

Page 47

GT-12000 Disassembly and Assembly

Rev. A

4-11

4.2.3.5 Glass Frame Assembly Removal and Pre-operation

Since the glass frame assembly is one of the reinforcing parts of the

mechanism, whole mechanism may be deformed if it is removed. Be sure

to follow the instruction provided in this section during any service which

involves removing the glass frame assembly.

CAUTION

Be aware the following when removing the

document glass during any service:

n

n n

n Always set the scanner on the adjusting tools

exclusively designed for this scanner.

n

n n

n Set the scanner on a stable, level table.

n

n n

n Make sure that the scanner mechanism is

installed to the lower housing while servicing.

n

n n

n Be sure to fit all the rubber foot at the bottom

of the scanner in the top indents of the stages

and the adjuster. (Any of the foot must not be

placed over the top surface of the tool.)

1. Remove the upper housing. (See Section 4.2.2.1.)

2. Refer to the figures in the right column and set the adjusting tools

(leveling tools) under the scanner to level the scanner, as instructed

below:

1) Set the scanner on 3 stages, making each of the specified feet of

the scanner sit on the corresponding stage.

2) Set the adjuster under the rubber foot in the front right corner of the

scanner bottom, aligning the center of the adjuster with the one of

the rubber foot. Make sure that you can see the groove on the

adjuster when it is set.

3) Hold the base of the adjuster with a hand and spin the table to

make it reach the bottom of the scanner by its own forth.

4) Turn the table

[2 quarters]

manually, which can be measured by 4

divisions on the table and the groove on the base, to push the table

up from the position where the table was moved up to by the spin.

5) After adjusting, make sure that each corner of the scanner is

securely in contact with the corresponding tool.

Note: Directions are described when the scanner is viewed from the front.

<Continued to the next page.>

Stage

(3 pieces)

Adjuster

Turning Table

(w ith 4 devisions)

Base

(w it h1 groove)

Figure 4-14. Adjusting Tools

Stage

(S et in the front left, rear

right and rear left coners.)

Adjuster

(S et in the front

right coner.)

Turn the turning table

to m o v e th e ta b le u p

and dow n to adjust

height.

Figure 4-15. Tool Position and Adjusting Method

Page 48

GT-12000 Disassembly and Assembly

Rev. A

4-1

2

3. Remove 9 screws and remove the glass frame assembly. The screws

to be removed and their locations are as follows:

· No.4: 5 screws securing the glass frame assembly by the right

and left sides.

· No.1: 2 screws securing the glass frame assembly by the rear

edge.

· No.3: 2 screws securing the glass frame assembly by the front

edge.

Note: Directions are described when the scanner is viewed from

the front.

CAUTION

When reinstalling the glass frame assembly, refer

to Section 4.2.3.5.1 to set the glass frame assembly

on the correct position. Failure in this operation

will cause the CR to start scanning at a wrong

position.

Screws (No.1)

Screws

(No.4)

Screws (No.3)

Front Side of the Scanner

Glass Frame Assembly

Screws

(No.4)

Glass Fixing Plate

(Color : Silve)

Glass Fixing Plate

(Color : Silve)

Figure 4-16. Glass Frame Assembly Removal

Page 49

GT-12000 Disassembly and Assembly

Rev. A

4-1

3

4.2.3.5.1 Glass Frame Assembly Installation

After the glass frame assembly has been removed for any purpose, it

must be reinstalled in the following procedure.

1. Place the glass frame assembly to the specified position in the scanner

mechanism.

2. Referring to the Figure 4-17, determine the installation position for the

glass frame assembly.

1) Push the whole glass frame assembly from the front against the

positioning bushes (color: silver) on the top side of the rear frame.

(Glass edge is in contact with the bushes with this operation.)

2) Keeping the glass frame assembly in contact with the bushes, move

the assembly left to push it against the positioning bump on the top

surface of the left side frame.

3. When the glass frame assembly is correctly positioned, fix it with 9

screws.

CHECK POINT

üüüü

When installing the glass frame assembly, ensure

that 4 glass fixing plates are properly positioned.

(See Figure 4-16.)

G lass Fram e A ssem bly

Scanner Front S ide

G lass edge

Positioning Bush

(C olor: S ilver)

Fram e P ositioning

Bum p

Figure 4-17.

Determining the Glass Frame Assembling Installation position

Page 50

GT-12000 Disassembly and Assembly

Rev. A

4-1

4

4.2.3.6 Lamp Assembly and Inverter Board Assembly Removal

This section describes how to remove the lamp assembly and the inverter

board assembly from the carriage.

1. Remove the glass frame assembly. (See Section 4.2.3.5.)

2. Move the CR to the position indicated in Figure 4-19. (The position

where the front and rear frames are indented.)

3. Remove 2 screws (No.6) securing the carriage mirror cover and slide

the cover toward the rear side of the scanner to release the

engagement with the hook on the carriage. Then lift up the cover and

remove it.

<Continued to the following page.>

Screws (No.6)

CR Mirror Cover

Figure 4-18. CR Mirror Cover Removal

Page 51

GT-12000 Disassembly and Assembly

Rev. A

4-1

5

4. Disconnect the connector cable for the lamp from the connector CN2

on the inverter board assembly. Then remove the lamp from the

carriage.

5. Disconnect the cable (black) from the connector CN1 on the inverter

board assembly. Then remove the bracket (silver) fixing the ferrite core.

6. Remove 2 screws (No.6) securing the inverter board assembly.

7. Slide the inverter board assembly toward the front side of the scanner

to release the engagement with the hook on the carriage. Then remove

the inverter board.

CHECK POINT

üüüü

When assembling, make sure that the cover is

securely engaged with the hook on the carriage.

Hook

Cover

C arriage Base

Rear

Front

Lift up to remove.

Cut Part

of the Board

Screws (No.6)

Lamp

Inverter Board

CN1

CN2

Figure 4-19.

Lamp Assembly and Inverter Board Assembly Removal

Page 52

GT-12000 Disassembly and Assembly

Rev. A

4-1

6

4.2.3.7 HP (AF) Sensor Removal

This section describes the procedure for removing the HP sensor which

detects the reference position for the AF drive mechanism (lens/CCD

sensor unit).

1. Remove the glass frame assembly. (See Section 4.2.3.5.)

2. Remove 4 screws (No.3) securing the AF drive mechanism cover which

covers the AF drive mechanism and remove the cover.

3. Rotate the screw pulley at the end of the screw shaft (a thread shaf t)

manually to move the detection flag to the area where it does not

overlap with the HP sensor.

4. Release the hook fixing the HP sensor and remove it, then disconnect

the cable from the sensor.

Screws (No.3)

Cover

Figure 4-20. AF Drive Mechanism Cover Removal

Rotate this pulley manually.

HP Sensor (AF)

Detection Flag

Figure 4-21. HP Sensor (AF) Removal

Page 53

GT-12000 Disassembly and Assembly

Rev. A

4-1

7

4.2.3.8 AF Motor Assembly Removal

This section describes how to remove the motor which drives AF drive

mechanism.

1. Remove the glass frame assembly. (See Section 4.2.3.5.)

2. Remove 4 screws (No.3) and remove the cover which covers the AF

drive mechanism.

3. Remove 2 screws (No.6) and remove the tension plate assembly,

spring plate and fixing tension plate to loosen the timing belt.

4. Disconnect the cable for the motor from the relay connector, then

remove 4 screws (No.4) securing the motor and remove the motor.

Screws (No.6)

Tension Plate Assembly

Fixing Tension Plate

Spring Plate

Figure 4-22. Tension Plate Assembly Removal

Screws (No.4)

Motor Assembly (AF)

Figure 4-23. AF Motor Assembly Removal

CAUTION

You are required to set the timing belt with a

special care while installing the AF motor

assembly. Be sure to follow the instruction

provided in the next page to set the timing belt

peoperly.

Page 54

GT-12000 Disassembly and Assembly

Rev. A

4-1

8

4.2.3.9 AF Motor Assembly Installation

Follow the steps below when installing the AF motor assembly to the

scanner body.

1. Engaging the timing belt with the pinion gear of the motor, install the

motor to the frame with 2 screws (No. 4).

2. Mount the sprint plate, fixing tension plate, and the tension plate

assembly, and fix them with 2 screws (No. 6) temporarily. Ensure that

the tension plate assembly is upheld by this operation.

3. Turning the screw pulley attached to the screw shaft end manually,

loosen the screw fixing the tension plate assembly to tense the belt,

then fasten the screw again.

CAUTION

When fixing the tension plate assembly, be careful

not to apply excessive tension, since it may cause

the motor to rotate improperly.

Fixing Tension Plate

Spring Plate

Tension Plate A ssem bly

Screws

(N o. 6)

Figure 4-24. Tension Plate Assembly

CHECK POINT

üüüü

When installing the tension plate assembly, make

sure that the location bump is not covered with the

plate.

Tension Plate A ssem bly

Screw Pulley

(rotated counterclockwise)

Figure 4-25. Timing Belt Tension

Page 55

ADJUSTMENT

CHAPTER

5

Page 56

GT-12000 Adjustment

Rev. A

5-1

5.1 OVERVIEW

This scanner requires no adjustment for any service such as

disassembling and assembling the scanner including part replacement is

provided within the specification in Chapter 4 “Disassemble and

Assembly”.

Page 57

MAINTENANCE

CHAPTER

6

Page 58

GT-12000 Maintenance

Rev. A

6-1

6.1 OVERVIEW

This chapter provides information necessary to keep the scanner function

in optimum condition constantly and to prevent troubles.

6.1.1 Cleaning

Perform cleaning when stain is noticeable. Stain on the document glass,

particularly, has direct effect on scanned image. Therefore, be sure to

clean the glass well to remove stain thoroughly.

CAUTION

Never apply any organic solvent such as thinner

and benzine , since these may deteriorate plastic

and rubber parts.

q Outer cases

Wipe stain off with a clean cloth which is moistened with water and

then squeezed tightly. To remove severe stain, use neutral detergent.

q Document glass

Remove dust and paper debris with a dry clean cloth. If stain is severe

or foreign matter is stuck, use a cloth absorbed with neutral detergent.

If trace is left, wipe it off well with a dry, clean cloth again.

CAUTION

If you need to clean the reverse side of the glass,

be sure to remove the glass using the specified

adjusting tools.

6.1.2 Lubrication

This scanner needs no lubrication at the level of service specified in the

service manual.

Page 59

APPENDIX

CHAPTER

7

Page 60

GT-12000 Appendix

Rev. A

7-1

7.1 OVERVIEW

This chapter provides information necessary for servicing.

7.1.1 Connector Pin Assignment

CN3

CN2 CN4 CN7

CN5

CN6

CN1

CN5

CN4

CN1

CN2

CN2 CN1

CN3 CN6

Scanner M echanism

B054M A IN Board

B054P S H Board

SCSI I/F SCSI I/F

O p tio n a l I/F

AC Input

Bi-directional

I/F

B054S U B Board

B054PN L

Board

H P S ensor

(M irro r)

Motor

(M irro r)

Motor

(A F )

H P S ensor

(A F )

B054IS N

Board

Figure 7-1. Connector Pin Assignment

7.1.2 Connector Summary

Connectors used on the electrical circuit boards are summarized in the

table below.

Table 7-1. Connector Summary

Board

CN

No.

Function Ref.

B054MAIN CN1/3 For connection with SCSI I/F GT-9500

CN2 For connection with Bi-directional I/F GT-9500

CN4

For connection with B054SUB Board

(In a card-edge format)

Page 7-2

CN5

Power supply line from the B054PSH

board

Page 7-3

CN6 For connection with the option Page 7-3

B054PSH CN1 For connection with AC inlet –

CN2

ðPower supply line for B054MAIN

board

Page 7-3

B054SUB

CN1

ðFor connection to B054MAIN

board

Page 7-2

CN2

ðFor connection to B054ISN board

(CCD sensor, Inverter board)

Page 7-4

CN3 ðFor connection to B054PNL board Page 7-4

CN4

ðFor connection to the HP sensor

(for focus)

Page 7-4

CN5

ðFor connection to the motor

(for mirror)

Page 7-4

CN6

ðFor connection to HP sensor

(for mirror)

Page 7-5

CN7

ðFor connection to the motor

(for focus)

Page 7-5

Page 61

GT-12000 Appendix

Rev. A

7-

2

B054MAIN – CN4

No. Signal Name Function

A1 GND GND

A2 GND GND

A3 ADD2 Address (2)

A4 ADD0 Address (0)

A5 A/D AD clock

A6 WR WR signal for ADC