Page 1

®

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Color Flat Bed Scanner

EPSON GT-10000

SESC99005

Page 2

Notice:

n

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

n

The contents of this manual are subject to change without notice.

n

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

n

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-

STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of GT-10000. The

instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on

the preceding page. The chapters are organized as follows:

CHAPTER 1. PRODUCT OUTLINE

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY & ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

CHAPTER 7. APPENDIX

Provides the following additional information for reference:

• Connector Pin Assignment

• Circuit Board Component Layout

• Circuit Board Diagram

• Exploded Diagrams & ASP List

Page 5

Revision Status

Revision Issued Date Description

A June 14, 1999 First Release

Page 6

EPSON GT-10000 Revision A

Table of Contents

CHAPTER 1 PRODUCT OUTLINE

Overview ........................................................................................................ 9

Specifications .............................................................................................. 10

Basics ..................................................................................................... 10

Image Handling Specifications .......... ..................................................... 10

Electrical Specifications .................................................... ...................... 11

Safety, EMC, EPA .................................................................................. 11

Resistance to Electric Noi se ................................................................... 11

Environmental Specifications ................................................................. 11

Reliability ................................................................................................ 11

Operating Conditions .............................................................................. 11

Original Document Condition ................................................................. 12

Physical Dimensions and Weight ........................................................... 12

Interface Specifications ............................................................................... 13

SCSI Interface ........................................................................................ 13

Basic Specifications ........................................................................... 13

Functions ............................................................................................ 13

SCSI Electrical Specifications ............................................................ 13

Connectors ... ...................................................................................... 13

Terminator .......................................................................................... 13

SCSI ID Setting .................................................................................. 13

Commands ......................................................................................... 14

Status ................................................................................................. 15

Display Messages .............................................................................. 15

Connector pin arrangement .................... ............................................ 16

IEEE 1394 Serial Bus Interface *Option* ............................................... 16

Control Code ............................................................................................... 17

Operation Specifications .............................................................................. 18

Buttons and Sw itches .............. ............................................................... 18

LED Specifications ................................................................................. 19

Switch Setting ......................................................................................... 19

Error Indication ....................................................................................... 20

Available Scan Area ............................................................................... 20

Transportation Screw ............................................................................. 21

CHAPTER 2 OPERATING PRINCIPLES

General Descript i on .... . .. .. .. . .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. . .. .. .. . .. .. .. . .. 23

Mechanical Operation of the Scan ner ..... .. .. . .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. . .. .. .. . .. .. .. . .. 24

Electrical Circuit Operations ........................................................................ 25

Control Circuit Operation ........................................................................ 25

Power Supply Circuit Operation ............................................................. 26

CHAPTER 3 TROUBLESHOOTING

Overview ..................................................................................................... 29

Errors and Causes of Errors .................................................................. 29

Troubleshooting ..................................................................................... 30

Test Points ......................................................................................... 30

Troubleshooting Other Errors ............................................................. 30

Troubleshooti ng Circui t B oard E rrors .......... . .. .... . .. .. .. ... .. .. . .. ... .. .. .. ... .. .. . .. 35

Power S upply B oard (B054 PS H B oard) ..... .. .. . .. .... . .. .. .. ... .. . .. .... . .. .. .. ... 35

Control Circuit Board (B093M AIN Board) ........................................... 35

CHAPTER 4 DISASSEMBLY & ASSEMBLY

Overview ..................................................................................................... 37

Tools ....... .. . .. .. . .. .. .. . .. .. .. . .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. ....... . .. .. .. . .. .. .. . .. .. . .. .. .. . .. .. .. ... 37

Screws ................................................................................................... 38

Disa ss embly P rocedures . .. . .. .. . .. .. .. ....... . .. .. .. . .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. ....... . .. .. .. . .. 40

Document Cover Unit Removal .............................................................. 41

Electrical Circuit Removal ...................................................................... 41

Main Boards Removal ........................................................................ 42

Scanner Body Disassembly ................................................................... 44

Upper Housing Removal .................................................................... 44

Scanner Mechanism Removal ........................................................... 45

Scanner Mechanism Disassembly ......................................................... 46

Panel Board Assembly Removal ........................................................ 46

Sub Board Assembly Removal ........................................................... 47

HP Sensor (CR) Remov al .................................................................. 48

CR Motor Assembly Removal ............................................................ 48

6

Page 7

EPSON GT-10000 Revision A

Glass Frame Assembly Removal ....................................................... 49

Lamp Assembly and Inverter Board Assembly Removal ................... 52

Option Frame Assembly Removal ...................................................... 54

CHAPTER 5 ADJUSTMENTS

Updating Firmware .............. ........................................................................ 56

Preparations Before Updating ................................................................ 56

Updating Firmware ................................... .............................................. 57

Light Correction ........................................................................................... 61

Necessary Tools ..................................................................................... 61

Light Correction Procedure .................................................................... 61

CHAPTER 6 MAINTENANCE

CHAPTER 7 APPENDIX

Connector Pin Assignment .......................................................................... 67

Connector Pin Assignment ..................................................................... 67

Connector Summary .......................................................... .................... 67

Main Board Circuit Signals ................................................................. 68

Circuit Board Component Layout ...... .......................................................... 72

Circuit Diagram ............................................................................................ 74

Exploded Diagrams & ASP List ................................................................... 76

Exploded Diagrams ................................................................................ 76

ASP List .................................................................................................. 79

7

Page 8

PRODUCT OUTLINE

CHAPTER

1

Page 9

EPSON GT-10000 Revision A

1.1 Overview

The EPSON GT-10000 is an business/office A3 size flat-bed type color image

scanner for use wi th Microsoft® Windows®. The main features of the scanner

are:

o

High resolution

Optical resolution is 600 dpi

12 bit in, 8 bit out

o

Wide readable area

Scans up to A3 size originals

o

High-speed scanni ng

A3 portrai t with full color = 4mS/line

o

Option

Auto Document Feeder (same as GT-12000)

o

Network-use software

EPSON TWAIN Pro Network

EPSON Scan Se rver

o

Scan-Navigation button support

The scan button is functional when using the EPSON TWAIN Pro Network

o

Fast SCSI support

Up to 10MB/S in synchronous data transfer mode

o

International Energy Star compliant

o

High-speed seria l interface (planned option for Windows 2000)

IEEE1394 s erial interface standard

o

Quick operation

Xenon-Gas Cold Cathode Fluorescent Lamp does not require warm-up

period (same as GT-12000).

PRODUCT OUTLINE Overview 9

Page 10

EPSON GT-10000 Revision A

1.2 Specifications

1.2.1 Basics

Type: Wide area, flat-bed color image scanner

Scanning Method: Sub-Scanning mirror movement system

Photoelectric Device: Color CCD Line senso r

Light Source: Xe-Gas Cold Cathode Fluorescent Lamp

Noise level: 50dB or less during operation

Document size: Up to A3

Max. Effective Pixels: 7020 x 10200 (600dpi)

Max. Scan Area: 297 x 432mm (11.7 x 17.0 inches)

Scanning Resolution: 600 (Main) by 1200 (Sub) dpi

Output Resolution: 50 to 4800dpi (1dp i increments)

Zoom: 50~200% (1% i ncrements)

Option: ADF (same unit as GT-12000)

Interfaces: SCSI (50 pi n connector)

IEEE1394 s erial interface (option for Windows 2000)

1.2.2 Image Handling Specifications

GAMMA CORRECTION

Five standard levels, plus one user definable

CRT A & B

Printer A, B, & C

COLOR CORRECTION

Four st andard levels, plus one user definable

Dot Matrix Printer

Thermal Printer

Ink Jet Printer

Color Monitor (CRT)

Scanning Speed: See the table below.

BRIGHTNESS CONTROL

Seven levels

Table 1-1. Scanning Speed

Setting Time required

Monochrome x2 Approx. 1.4mS/line

256 Grayscale Approx. 4.0mS/line

Full color Approx. 4.0mS/line

Note: Figures taken at 600dpi

Command Codes: ESC/I Command (B7 level)

FS Command

IMAGE PROCESSING

Two output methods: Bi-level = Fixed thres hold

TET (Text Enhancement Technology)

Half-toning: Error diffusion A, B, &C

Ditheri ng A, B, C, & D

User-defined dithering A & B

Focusing: AAS (Auto-Area Segmentation)

PRODUCT OUTLINE Specifications 10

Page 11

EPSON GT-10000 Revision A

1.2.3 Electrical Specifications

Power supply voltage: Universal pow er

Rated v oltage = AC100 - 120 V (AC ± 10%)

Rated v oltage = AC220 - 240 V (AC ± 10%)

Rated frequency range: 50~ 60 Hz (49.5 - 60.5 Hz)

Power consumpti on: Approximately 50W (wit hout opti o n)

Approximately 55W (wit h option)

Ω

Insulati on resistance: 10M

Dielectric strength: AC1.2kV rms / minute (between AC line and chassis)

or more (DC 500V between AC line and

chassis)

1.2.4 Safety, EMC, EPA

Safety : UL1950 (UL)

CSA C22.2 NO.950 (CSA)

EN60950 (VDE)

IEC950 (ROSTES T, PSB)

EN61000-3-3

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

EPA: Energy Star Program

1.2.5 Resistance to Electric Noise

Static Electricity: Panel = 10kV

Metallic parts = 7kV (150pF/150

Ω)

1.2.6 Environmental Specifications

Temperature: Operating = 5 to 35°C

When not in use =- -25 to 60°C

Humidity: Operating = 10 to 80% (no condensation)

Storage = 10 to 85% (no condensati on)

EMC: FCC Part15 Subpart B C lass B

1.2.7 Reliability

CSA C108.8 Class B

AS/NZS3548 Class B

CISPR Pub22 Class B

CNS13438 Class B

CE Marking:

Low Voltage Directive 73/23/EEC EN60950

EMC Directive 89/336/EEC EN55022 Class B

EN61000-3-2

PRODUCT OUTLINE Specifications 11

Main unit: MCBF: carriage = 100,000 cycles

Hinge = 25,000 turns

1.2.8 Operating Conditions

Dust: Ordinary office or home conditions.

(Should be kept away from extreme dust.)

Illumination: Operation under di rect sunlight or near strong light

source should be avoided.

Page 12

EPSON GT-10000 Revision A

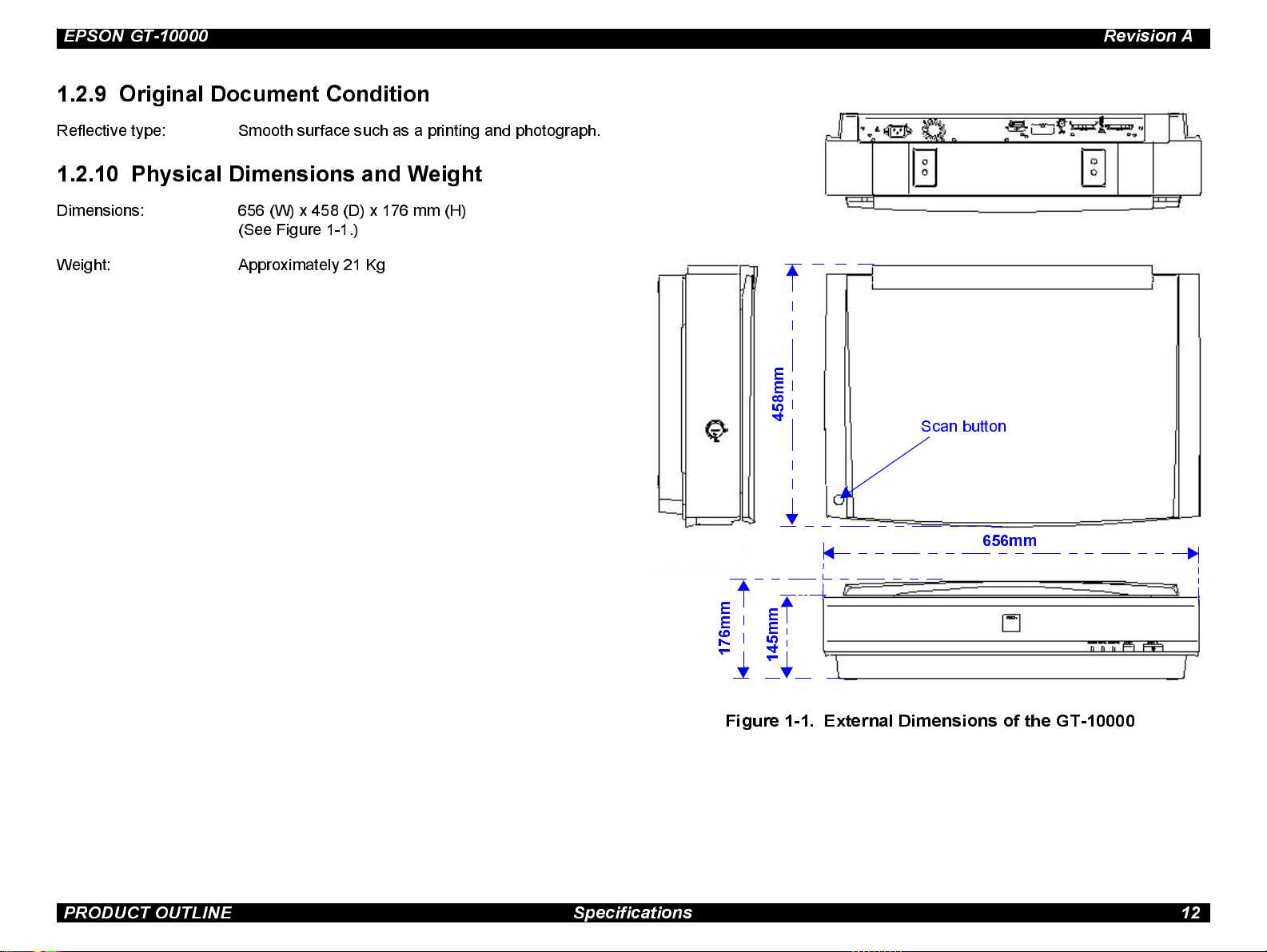

1.2.9 Original Document Condition

Reflective type: Smooth surface such as a printing and photograph.

1.2.10 Phy s ica l Dimens ion s and Weig h t

Dimensions : 656 (W) x 458 (D) x 176 mm (H)

(See Fig ure 1 -1.)

Weight: Approximately 21 Kg

m

m

8

5

4

Scan but ton

656mm

m

m

6

7

1

m

m

5

4

1

Figure 1-1. External Dimensions of the GT-10000

PRODUCT OUTLINE Specifications 12

Page 13

EPSON GT-10000 Revision A

1.3 Interface Specifications

This s canner is equipped with two standard SCSI interfaces.

1.3.1 SCSI Interface

1.3.1.1 Basic Specifications

The SCSI interface specifications are described below, any items not included

in the following pages are in conformance with ANSI X3T9.2/375R revision 10L

(SCSI-2).

1.3.1.2 Functions

The following functions are included in ANSI X3T9.2/375R revision 10L

(SCSI-2).

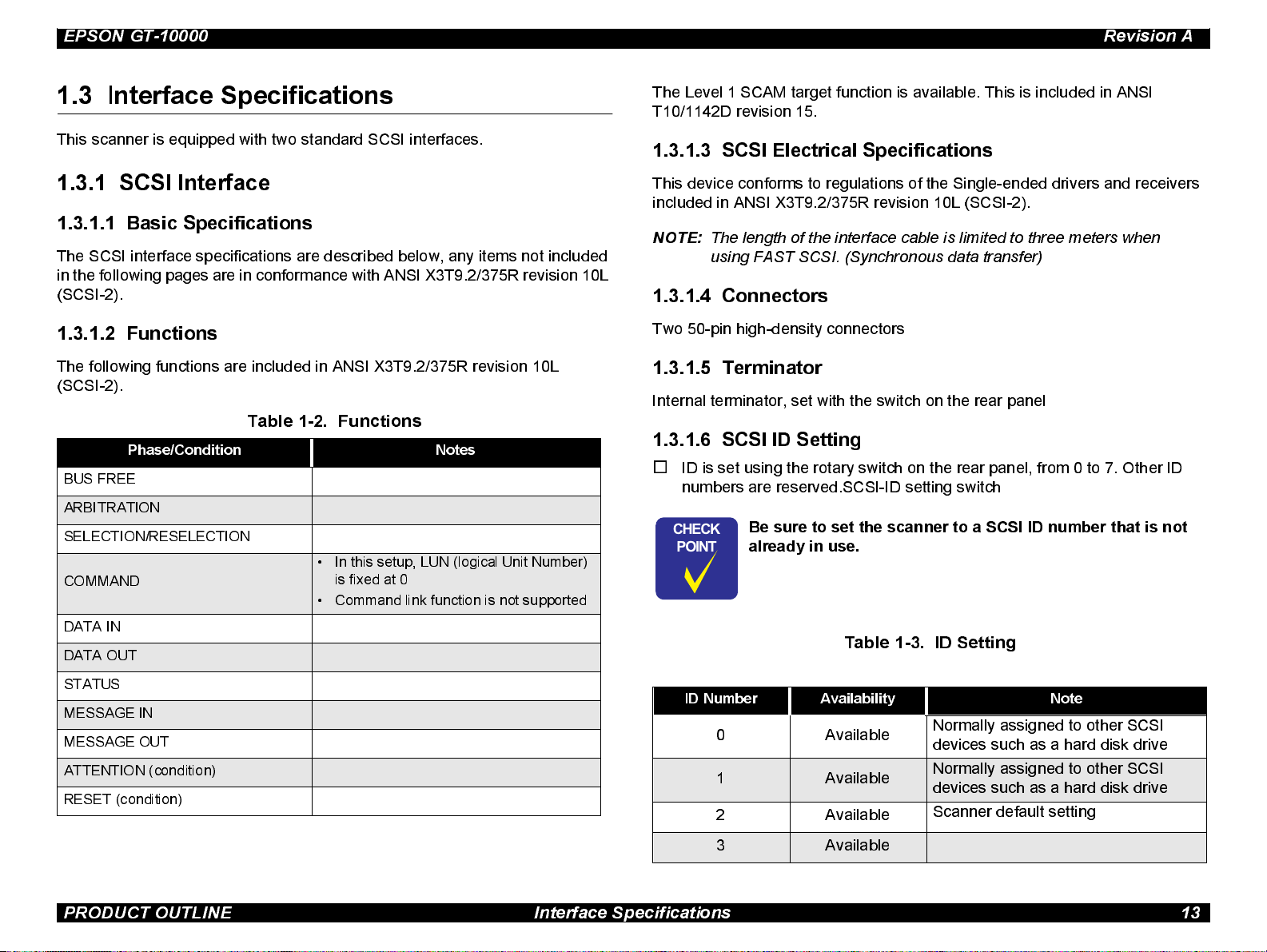

Table 1-2. Functions

Phase/Condition Notes

BUS FREE

ARBITRATION

SELECTION/RESELECTION

• In this setup, LUN (logical Unit Number)

COMMAND

DATA IN

DATA OUT

is fixed at 0

• Command link function is not supported

The Level 1 SCAM target function is available. This is included in ANSI

T10/1142D revis ion 15.

1.3.1.3 SCSI Electrical Specifications

This devi ce conforms to regulations of the Single-ended drivers and receivers

included in ANSI X3T9.2/375R revision 10L (SCSI-2).

NOTE:

The length of the interface cable is limited to three meters when

using FAST SCSI. (Synchronous data transfer)

1.3.1.4 Connectors

Two 50-pin high-density connectors

1.3.1.5 Terminator

Internal terminator, set with the switch on the rear panel

1.3.1.6 SCSI ID Setting

o

ID is s et using the rotary switch on the rear panel, from 0 to 7. Other ID

numbers are reserved.SCSI-ID setting switch

CHECK

PO INT

Be sure to set the scanner to a SCSI ID number that is not

already in use.

Table 1-3. ID Setting

STATUS

MESSAGE IN

MESSAGE OUT

ATTENTION (condition)

RESET (condition)

ID Number Availability Note

0Available

1 Available

2Available

3 Available

Normally assigned to other SCSI

devices such as a hard disk drive

Normally assigned to other SCSI

devices such as a hard disk drive

Scanner default setting

PRODUCT OUTLINE Interface Specifications 13

Page 14

EPSON GT-10000 Revision A

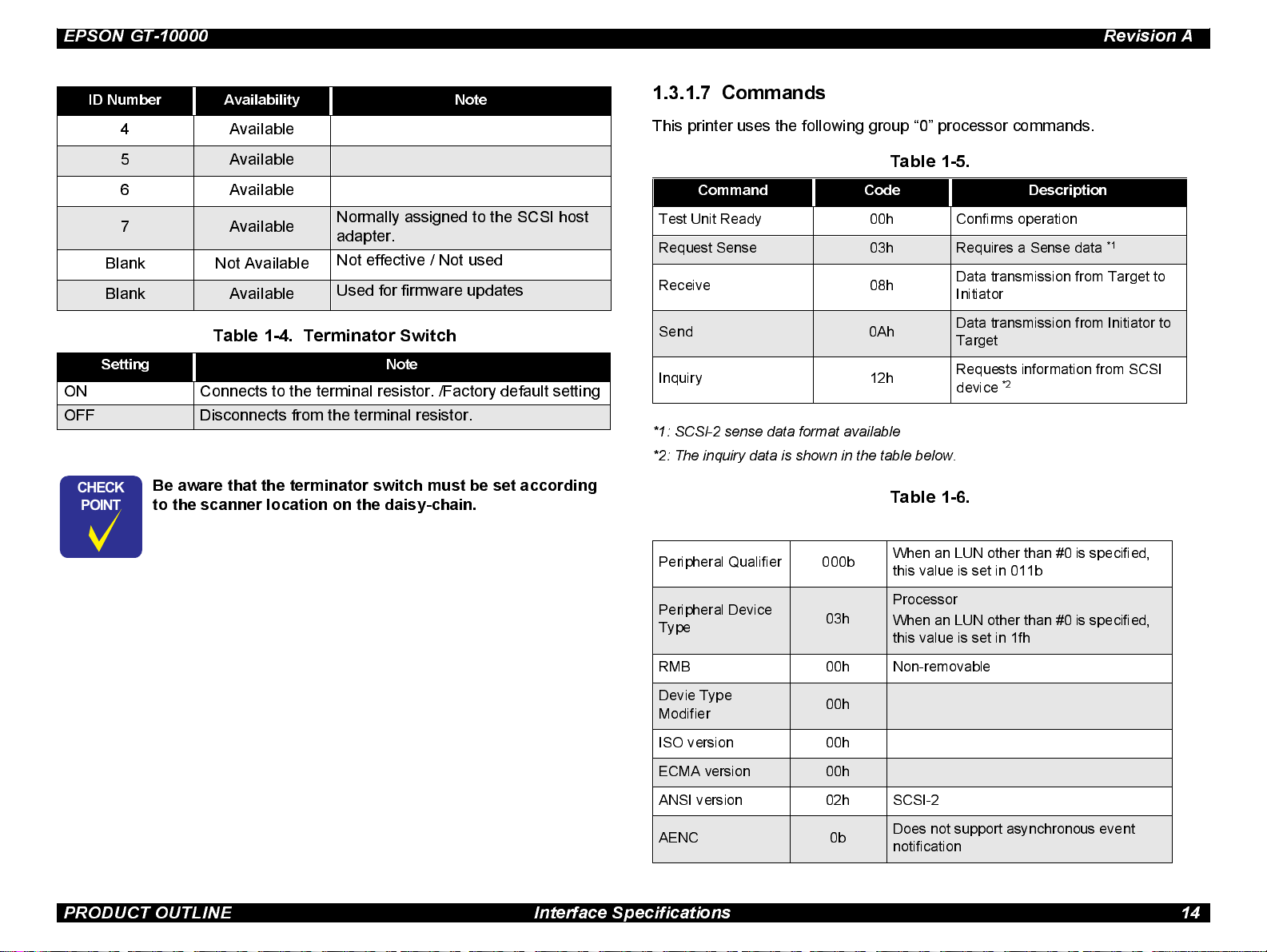

ID Number Availability Note

4 Available

5 Available

6 Available

7 Available

Blank Not Available

Blank Available

Normally assigned to the SCSI host

adapter.

Not effective / Not used

Used for firmware updates

Table 1-4. Terminator Switch

Setting Note

ON Connects to the terminal resi stor. /Factory default setting

OFF Disconnect s from the terminal resistor.

CHECK

PO INT

Be aware that the terminator switch must be set according

to the sc anner location on the daisy-chain.

1.3.1.7 Commands

This printer uses the following group “0” processor commands.

Table 1-5.

Command Code Description

Test Unit Ready 00h Confirms operation

Request Sense 03h Requires a Sense data

Receive 08h

Send 0Ah

Inquiry 12h

*1: SCSI-2 sense data format available

*2: The inquiry data is shown in the table below.

Table 1-6.

Peripheral Qualifier 000b

When an LUN other than #0 is specified,

this value is set in 011b

Data transmission from Target to

Initiator

Data transmission from Initiator to

Target

Requests information from SCSI

*2

device

*1

Peripheral Device

Type

RMB 00h Non-removable

Devie Type

Modifier

ISO version 00h

ECMA version 00h

ANSI version 02h SCSI-2

AENC 0b

03h

00h

Processor

When an LUN other than #0 is specified,

this value is set in 1fh

Does not support asynchronous event

notification

PRODUCT OUTLINE Interface Specifications 14

Page 15

EPSON GT-10000 Revision A

TrmIOP 0b

Respo nse Data

Format

Additional length 23h

RelAdr 0b

Wbu s32 0b Does not support 32-bit wide data transfers

Wbus16 0b Does not support 16-bit wide data transfers

Sync 1b Supports synchronous data transfer

Linked 0b

CmdQue 0b

SftRe 0b Har d res et alternative

Vendor ID

Product ID

02h

“EPSON”,

20h, 20h,

20h

“Scanner”,

20h, “******”,

20h

Does not support Terminate I/O Process

messag e

Doe s not support relative addr essing for

this logical unit

Does not support linked commands for this

logical unit

Does not support tagged command

queuing for this logical unit

Note:: ****** = the product name

1.3.1.8 Status

The stat us is determined as follows.

Ta ble 1- 7 . Status Conditions

Status bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

GOOD R R 0 0 0 0 0 R

CHECK CONDITION R R 00001R

BUSY R R 0 0 1 0 0 R

Note: R = reserved

1.3.1.9 Display Messages

Table 1- 8. Messa ge Summary

Code Message Direction

00h Command complete In -

01h (Extended messages)

02h Save Data Pointer In -

03h Restore Pointer In -

04h Disconnect In -

05h Initiator Detected Error Out Yes

Negate ATN

before last ACK

Product Revision “****” Note:: ****** = the product name

Vendor Specific

00h, 00h,

00h, ffh

06h Abort Out Yes

07h Message Rejection In/Out Yes

08h No Operation Out Yes

09h Message Parity Error Out Yes

0ch Bus Device Reset Out Yes

80h-ffh Identify In/Out No

In = Target to Initiator

Out = Initiator to Target

Yes = Initiator shall negate ATN before last ACK of message

No = Initiator may or may not negate ATN before last ACK of message

PRODUCT OUTLINE Interface Specifications 15

Page 16

EPSON GT-10000 Revision A

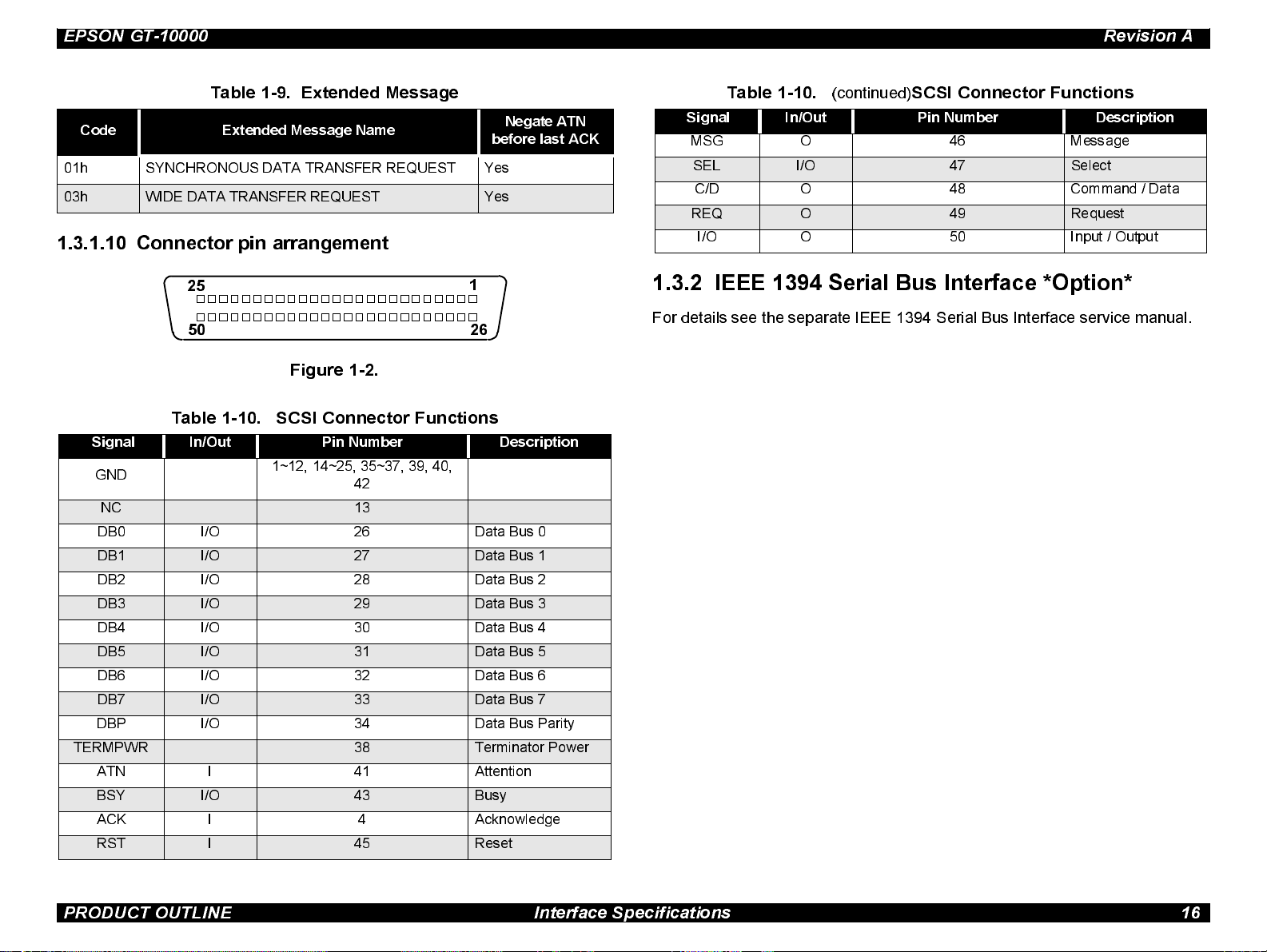

Table 1-9. Extended Message

Code Extended Message Name

01h SYNC HRONOUS DATA TRANSFER REQUEST Ye s

03h WIDE DATA TRANSFER REQUEST Yes

Negate ATN

before last ACK

1.3.1.10 Connector pin arrangement

25

50

Figure 1-2.

Table 1-10. SCSI Connector Functions

Signal In/Out Pin Number Description

GND

NC 13

DB0 I/O 26 Data Bus 0

DB1 I/O 27 Data Bus 1

DB2 I/O 28 Data Bus 2

DB3 I/O 29 Data Bus 3

DB4 I/O 30 Data Bus 4

DB5 I/O 31 Data Bus 5

DB6 I/O 32 Data Bus 6

DB7 I/O 33 Data Bus 7

DBP I/O 34 Data Bus Parity

TERMPWR 38 Terminator Power

ATN I 41 Attention

BSY I/O 43 Busy

ACK I 4 Acknowledge

RST I 45 Reset

1~12, 14~25, 35~37, 39, 40,

42

1

26

Table 1-10.

Signal In/Out Pin Number Description

MSG O 46 Message

SEL I/O 47 Select

C/D O 48 Command / Data

REQ O 49 Request

I/O O 50 Input / Output

(continued)

SCSI Connector Functions

1.3.2 IEEE 1394 Serial Bus Interface *Optio n*

For detai ls see t he sep arate IEE E 1394 S eri al Bus Inte rface serv ice manual.

PRODUCT OUTLINE Interface Specifications 16

Page 17

EPSON GT-10000 Revision A

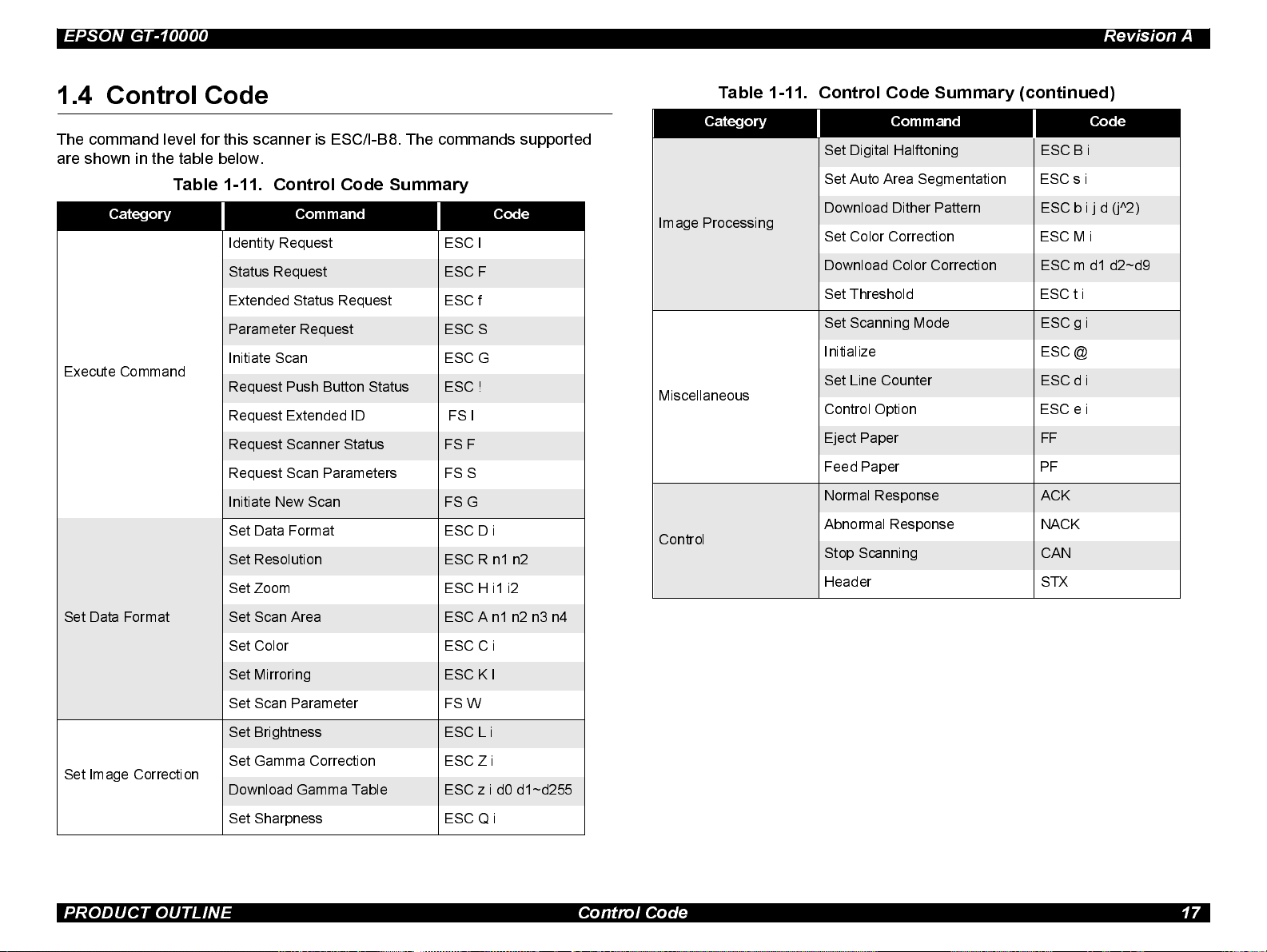

1.4 Control Code

The command level for this scanner is ESC/I-B8. The commands supported

are shown in t he table below.

Table 1-11. Control Code Summary

Category Command Code

Iden tity Request ESC I

Status Request ESC F

Exten d ed Status Request ESC f

Param et er Request ESC S

Initiate Scan ESC G

Execute Command

Request Push Button Status ESC !

Request Extended ID FS I

Request Scanner Status FS F

Request Scan Parameters FS S

Initiate New Scan FS G

Set Data Format ESC D i

Set Resolution ESC R n1 n2

Set Zoom ESC H i1 i2

Table 1-11. Control Code Summary (continued)

Category Command Code

Set Digi t al Half toni ng ESC B i

Set Auto Area Se gment at i on ESC s i

Download Dit her Pat te rn ESC b i j d (j^2)

Image Processing

Set Color Corre ction ESC M i

Download Color Corre cti on ESC m d1 d2~d9

Set Threshol d ESC t i

Set Scanning Mode ESC g i

Ini ti a liz e ESC @

Set Line Counter ESC d i

Miscellaneous

Control Opti on ESC e i

Eject Paper FF

Feed Paper PF

Normal Res ponse ACK

Abnormal Response NACK

Control

Stop Scanning CAN

Header STX

Set Data Format

Set Image Correct ion

Set Scan Area ESC A n1 n2 n3 n4

Set Color ESC C i

Set Mirroring ESC K I

Set Scan Parameter FS W

Set Brightness ESC L i

Set Gamma Correction ESC Z i

Download Gamma Tabl e ESC z i d0 d1~d255

Set Sharpness ESC Q i

PRODUCT OUTLINE Control Code 17

Page 18

EPSON GT-10000 Revision A

1.5 Operation Specifications

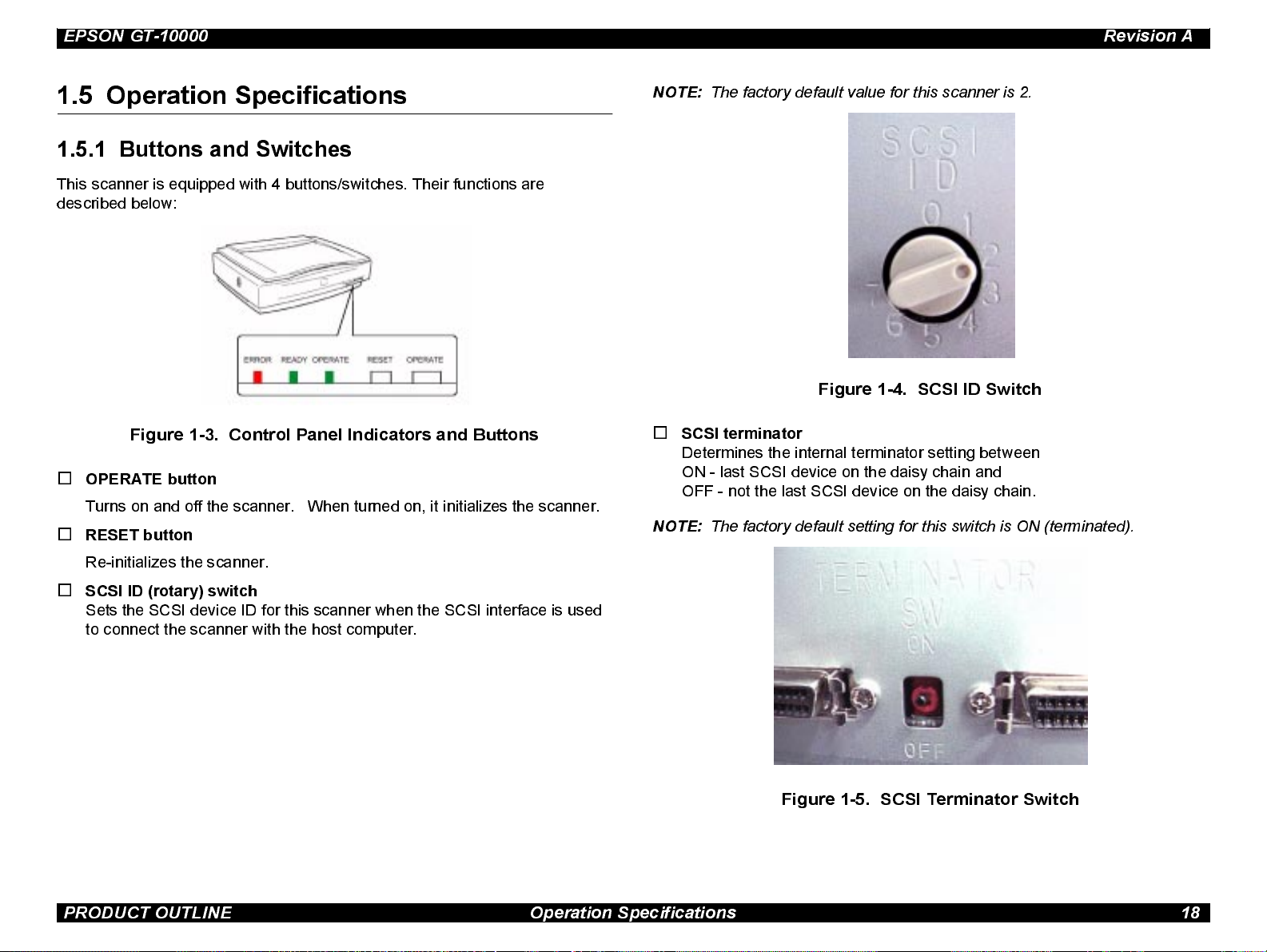

1.5.1 Buttons and Switches

This s canner is equipped with 4 buttons/switches. Their functions are

described below:

Figure 1-3. Control Panel Indicators and Buttons

o

OPERATE button

Turns on and off the scanner. When turned on, it initializes the scanner.

o

RESET button

NOTE:

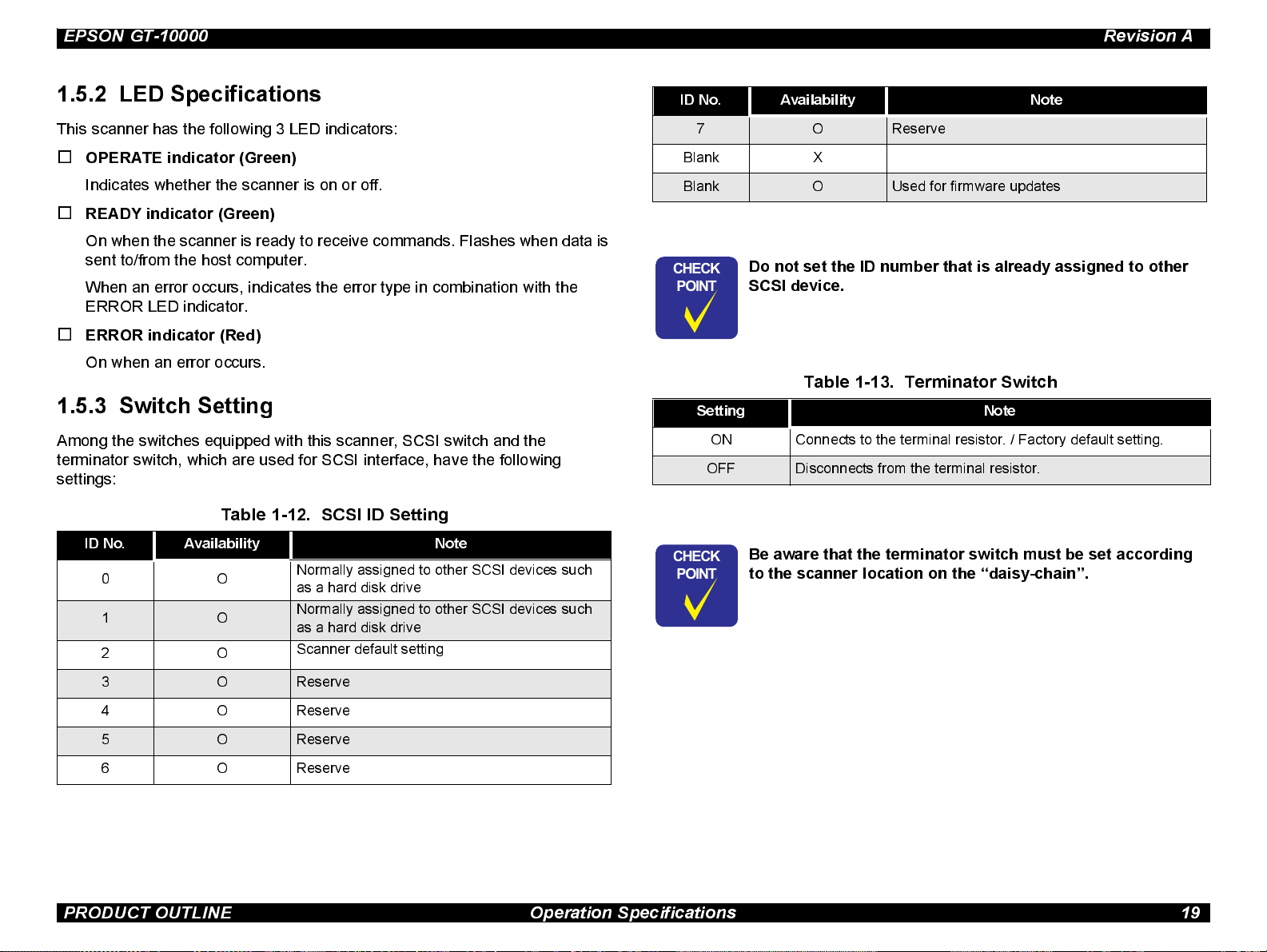

The factory default value for this scanner is 2.

Figure 1-4. SCSI ID Switch

o

SCSI terminator

Determines the internal terminator setting between

ON - last SCSI device on the daisy chain and

OFF - not the last SCSI device on the daisy chain.

NOTE:

The factory default setting f o r this switch is ON (terminated).

Re-initializes the scanner.

o

SCSI ID (rotary) switch

Sets the SCSI device ID for this scanner when the SCSI interface is used

to connect the scanner with the host computer.

Figure 1-5. SCSI Terminator Switch

PRODUCT OUTLINE Operation Specifications 18

Page 19

EPSON GT-10000 Revision A

1.5.2 LED Specifications

This s canner has the following 3 LED indicators:

o

OPERATE indicator (Green)

Indicates w hether the scanner is on or off.

o

READY indicator (Green)

On when the scanne r is ready to receive commands. Flashes when data is

sent to/from the host computer.

When an error occurs, indicates the error type in combination with the

ERROR LED indi cator.

o

ERROR indicator (Red )

On when an error occurs.

1.5.3 Switch Setting

Among the switche s equipped with this scanner, SCSI switch and the

terminator s witch, which are used for SCSI interface, have the following

settings:

Table 1-12. SCSI ID Setting

ID No. Availability Note

0O

1 O

2O

Normally assigned to other SCSI devices such

as a hard disk drive

Normally assigned to other SCSI devices such

as a hard disk drive

Scanner default setting

ID No. Availability Note

7 O Reserve

Blank X

Blank O Used for firmware updates

CHECK

PO INT

Do not set the ID number that is already assigned to other

SCSI device.

Table 1-13. Terminator Switch

Setting Note

ON Connects to the terminal resistor. / Factory default setting.

OFF Disconnects from the terminal resistor.

CHECK

PO INT

Be aware that the terminator switch m ust be set according

to the scan ner location on the “daisy-chain”.

3 O Reserve

4 O Reserve

5 O Reserve

6 O Reserve

PRODUCT OUTLINE Operation Specifications 19

Page 20

EPSON GT-10000 Revision A

1.5.4 Error Indication

If an error occurs, determine the error type referring to the status of the READY

and ERROR LED i ndicators.

Table 1-14. Indicator Status and Corresponding Errors

READY ERROR Error Type

On On Command error

Off Flashing Communication error

Flashin g Flashing Fatal error

Off Off Option error

Note: See Chapter 3 Troubleshooting for details on solving the error.

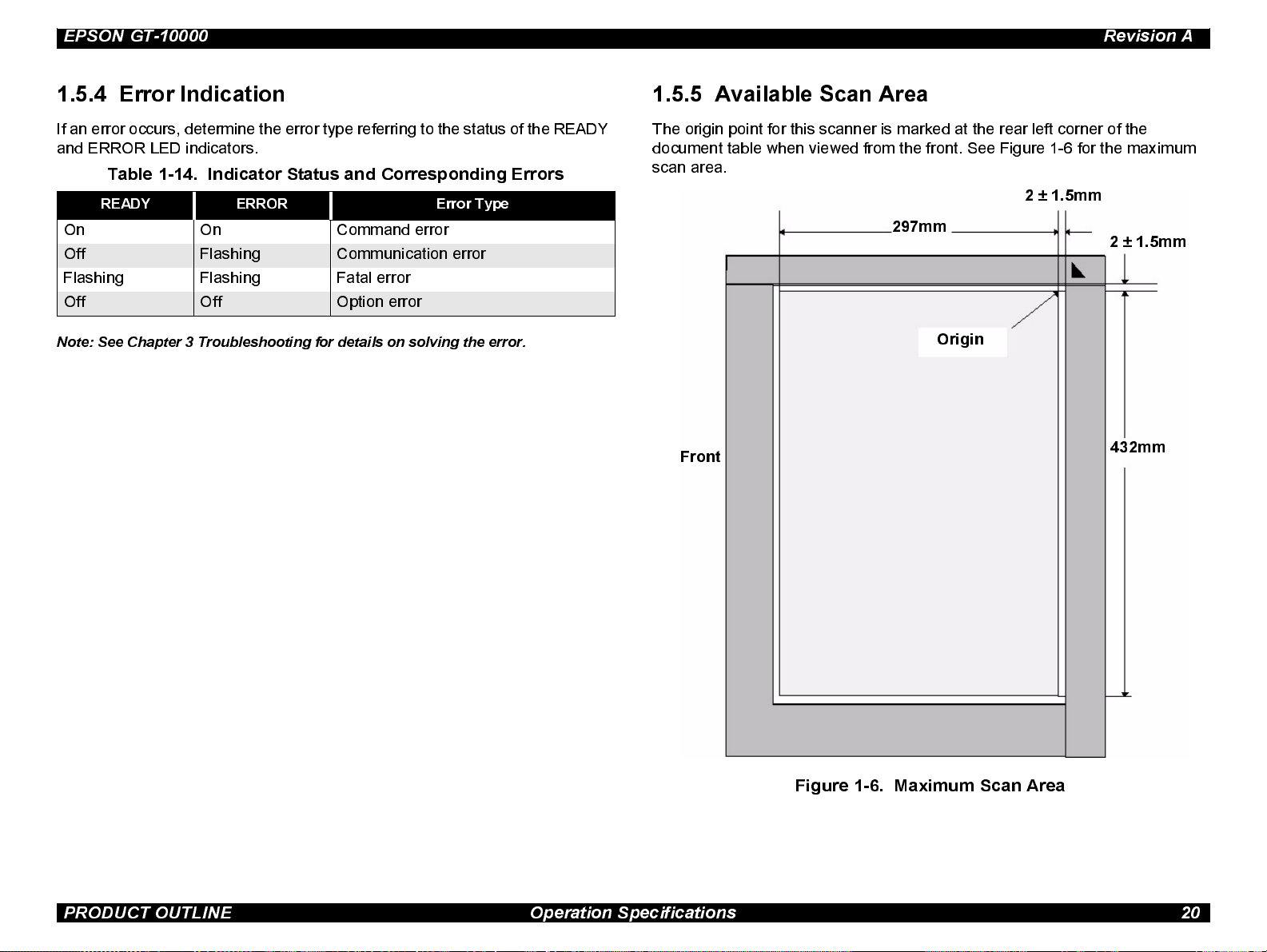

1.5.5 Available Scan Area

The origi n point for this scanner is marked at the rear left corner o f the

document table when viewed from the front. See Figure 1-6 for the maximum

scan area.

2 ± 1.5mm

297mm

Origin

Front

2 ± 1.5mm

432mm

Figure 1-6. Maximum Scan Area

PRODUCT OUTLINE Operation Specifications 20

Page 21

EPSON GT-10000 Revision A

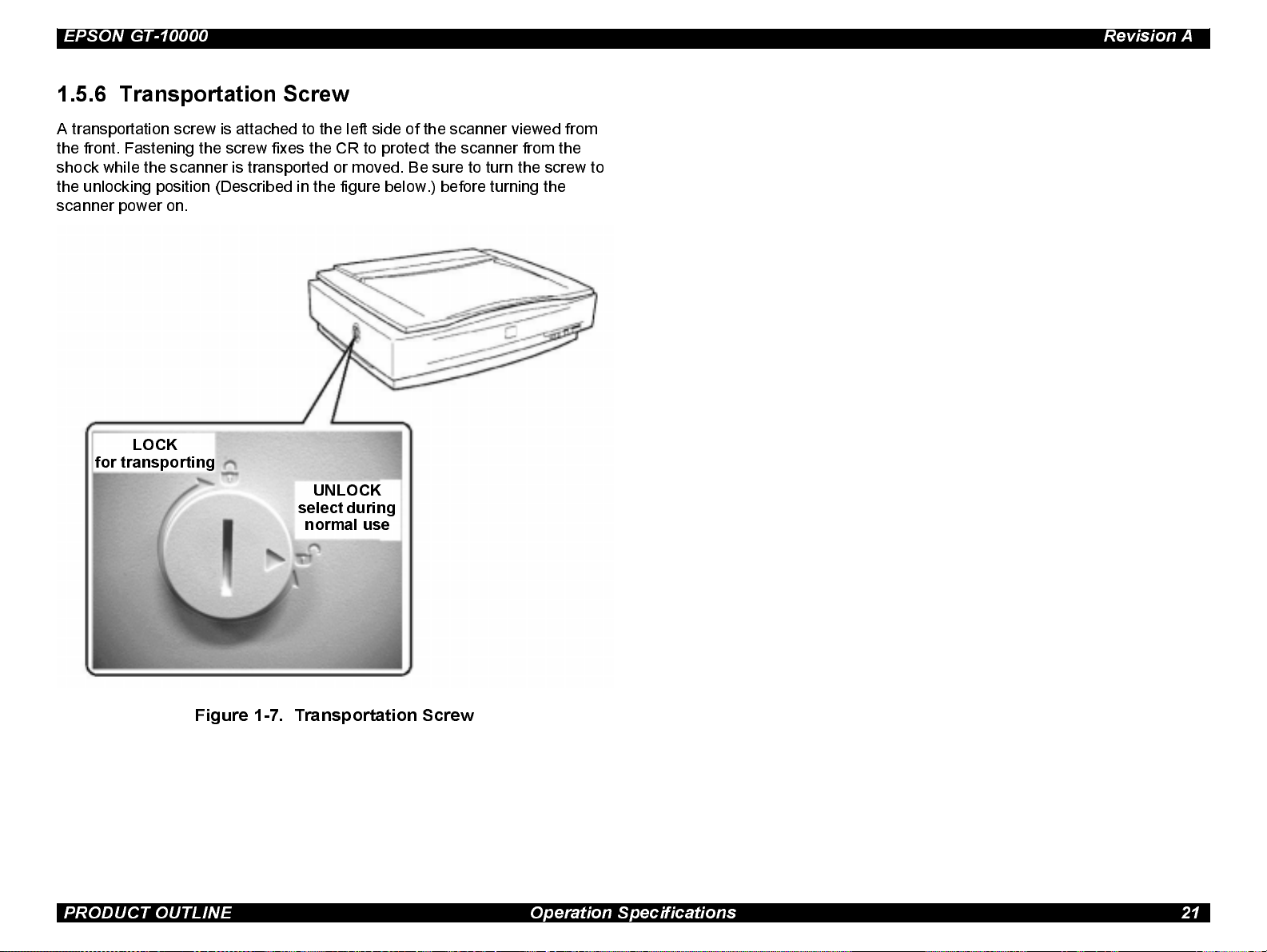

1.5.6 Transpo rtat io n Screw

A transporta ti on screw i s attached to th e left side of the scanner view ed from

the front. Fastening the screw fixes the CR to protect the scanner from the

shock while the scanner is transported or moved. Be sure to turn the screw to

the unlocking position (Described in the figure below.) before turning t he

scanner power on.

LOCK

for transportin g

UNLOCK

select during

normal use

Figure 1-7. Transportation Screw

PRODUCT OUTLINE Operation Specifications 21

Page 22

OPERATING PRINCIPLES

CHAPTER

2

Page 23

EPSON GT-10000 Revision A

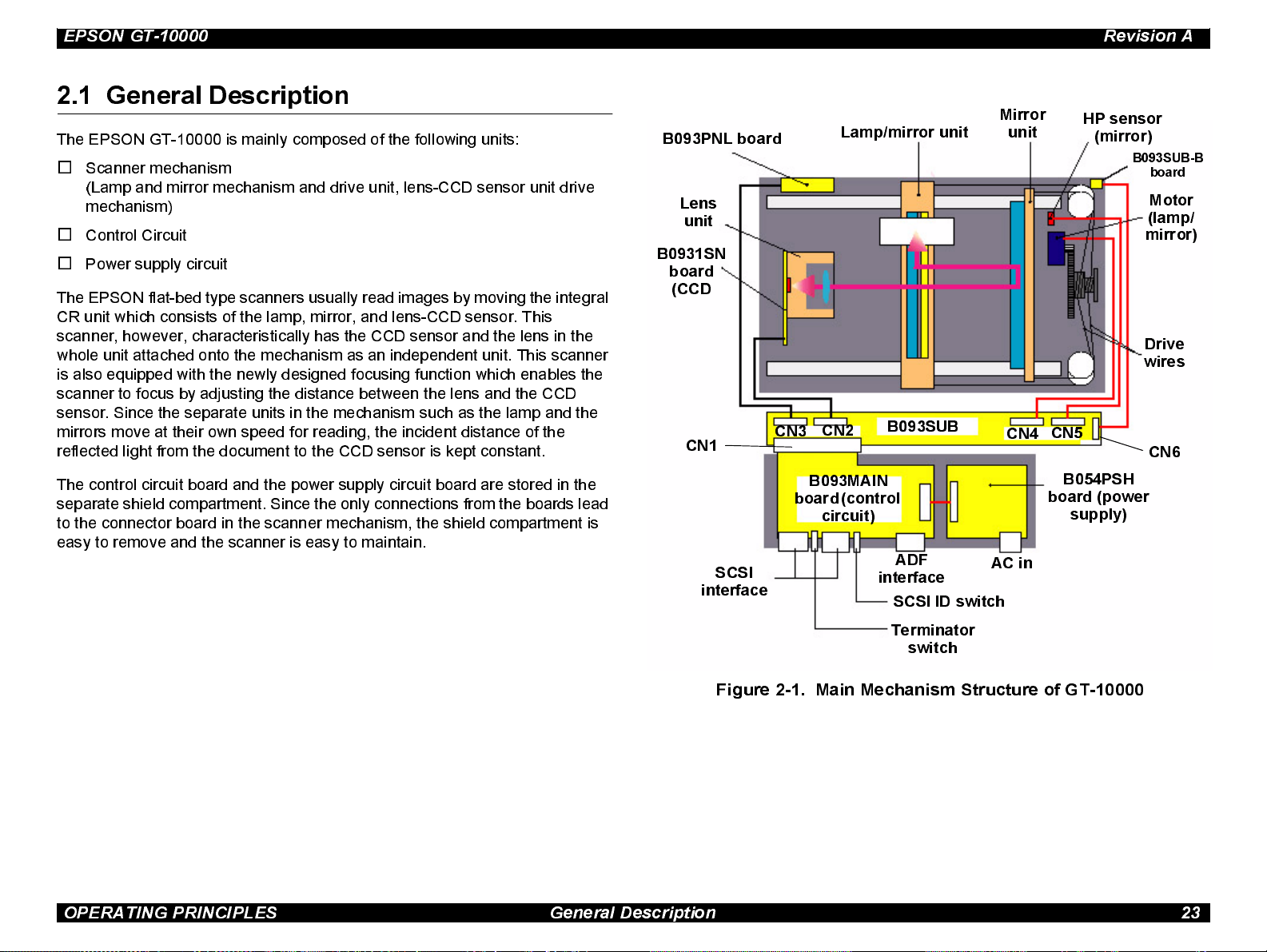

2.1 General Description

The EPSON GT-10000 i s mainly composed of the following uni ts :

o

Scanner mechanism

(Lamp and mirror mechanism and drive unit, lens-CCD sensor unit drive

mechanism)

o

Control Circuit

o

Power supply circuit

The EPSON flat-bed type scanners usually read images by moving the integral

CR unit which consists of the lamp, mirror, and lens-CCD sensor. This

scanner, however, characteristically has the CCD sensor and the lens in the

whole unit attached onto the mechanism as an independent unit. This scanner

is also equipped with the newly designed focusing function which enables the

scanner to focus by adjusting the distance between the lens and the CCD

sensor. Since the separate units in the mechanism such as the lamp and the

mirrors move at their own speed for reading, the incident distance of the

reflected light from the document to the CCD sensor is kept constant.

B093PNL board

Lens

unit

B0931SN

board

(CCD

CN1

CN3

Lamp/mirror unit

CN2

B093SUB

Mirror

unit

CN4

HP sensor

(mirror)

B093SUB-B

board

Motor

(lamp/

mirror)

Drive

wires

CN5

CN6

The control circuit board and the power supply circuit board are stored in the

separate shi eld compartment. Since the only connections from the boards lead

to the connector board in the scanner mechanism, the shield compartment is

easy to remove and the scanner is easy to maintain.

SCSI

interface

B093MAIN

board (control

circuit)

interface

Terminator

ADF

SCSI ID switch

switch

AC in

B054PSH

board (power

supply)

Figure 2-1. Main Mechanism Structure of GT-10000

OPERATI N G PRINC IPLE S Gene ral Des c ript ion 23

Page 24

EPSON GT-10000 Revision A

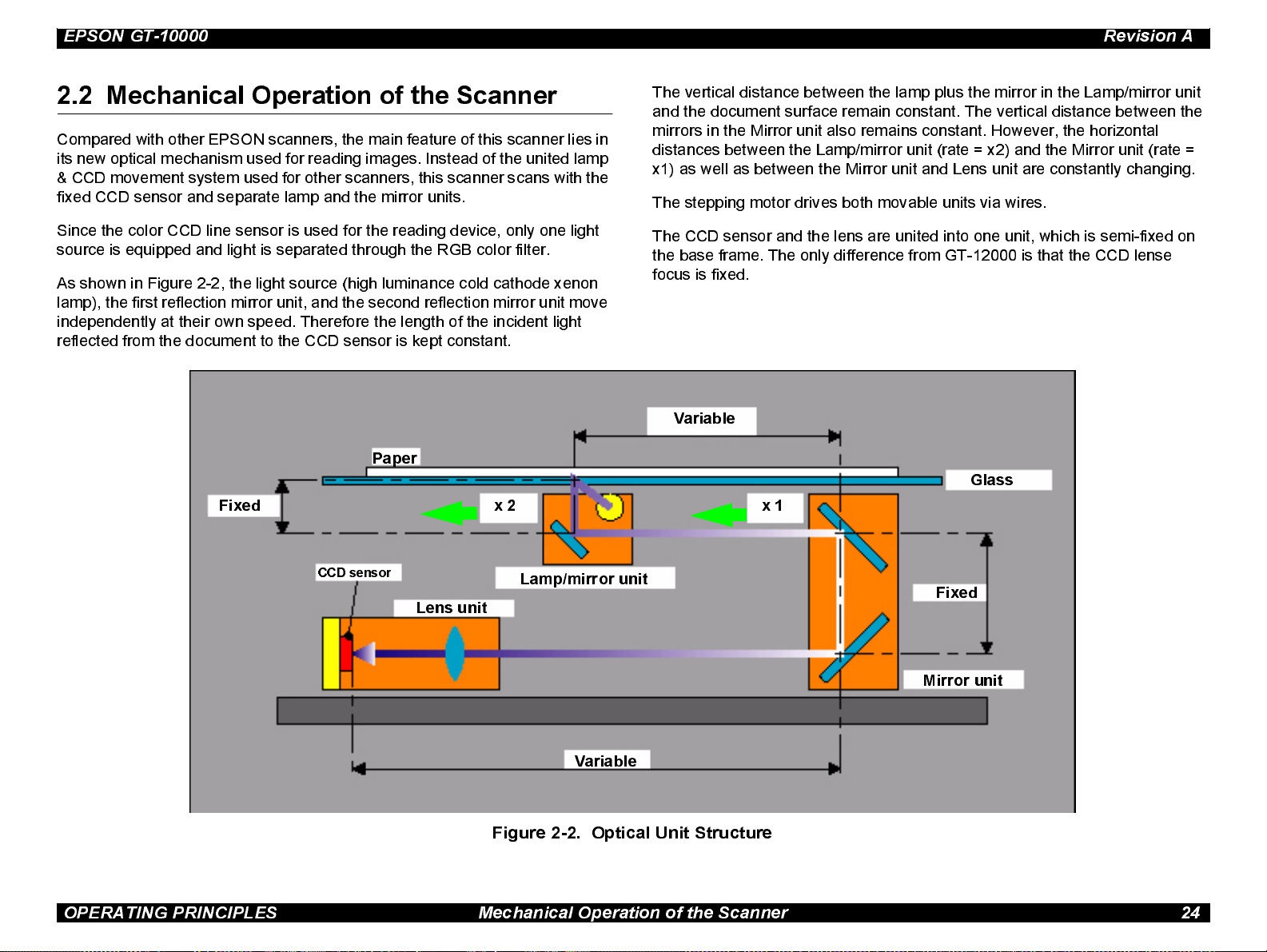

2.2 Mechanical Operation of the Scanner

Compared with other E PSON scanners, the main feature of this scanner lies in

its new optical mechanism used for reading images. Instead of the united lamp

& CCD movement system used for other scanners, this scanner scans with the

fix ed CCD sensor and separate lamp and the mirror units.

Since the color CCD line sensor is used for the reading device, only one light

source is equi pped and light is separated through the RGB color filter.

As shown in Figure 2-2, the light source (high luminance cold cat hode xenon

lamp), the first reflection mirror unit, and the second reflection mirror unit move

independently at their own speed. Therefore the length of the i ncident light

reflected from the document to the CCD sensor is kept constant.

Paper

Fixed

x 2

The ve rtical distance between the lamp plus the mirror in the Lamp/mirror unit

and the document surface remain constant. The vertical distance between the

mirrors i n the Mirror unit also remains constant . However, the horizontal

distances between the Lamp/mirror unit (rate = x2) and the Mirror unit (rate =

x1) as w ell as between the Mirror unit and Lens unit are constantly changing.

The stepp ing motor drives both movable units via wires.

The CCD sensor and the lens are united into one unit, which is semi-fixed on

the base frame. The only difference from GT-12000 is that the CCD lense

focus is fixed.

Variable

Glass

x 1

CCD sensor

Lens unit

Lamp/mirror unit

Fixed

Mirror unit

Variable

Figure 2-2. Optical Unit Structure

OPERATING PRINCIPLES Mechanical Ope ration of the Scanner 24

Page 25

EPSON GT-10000 Revision A

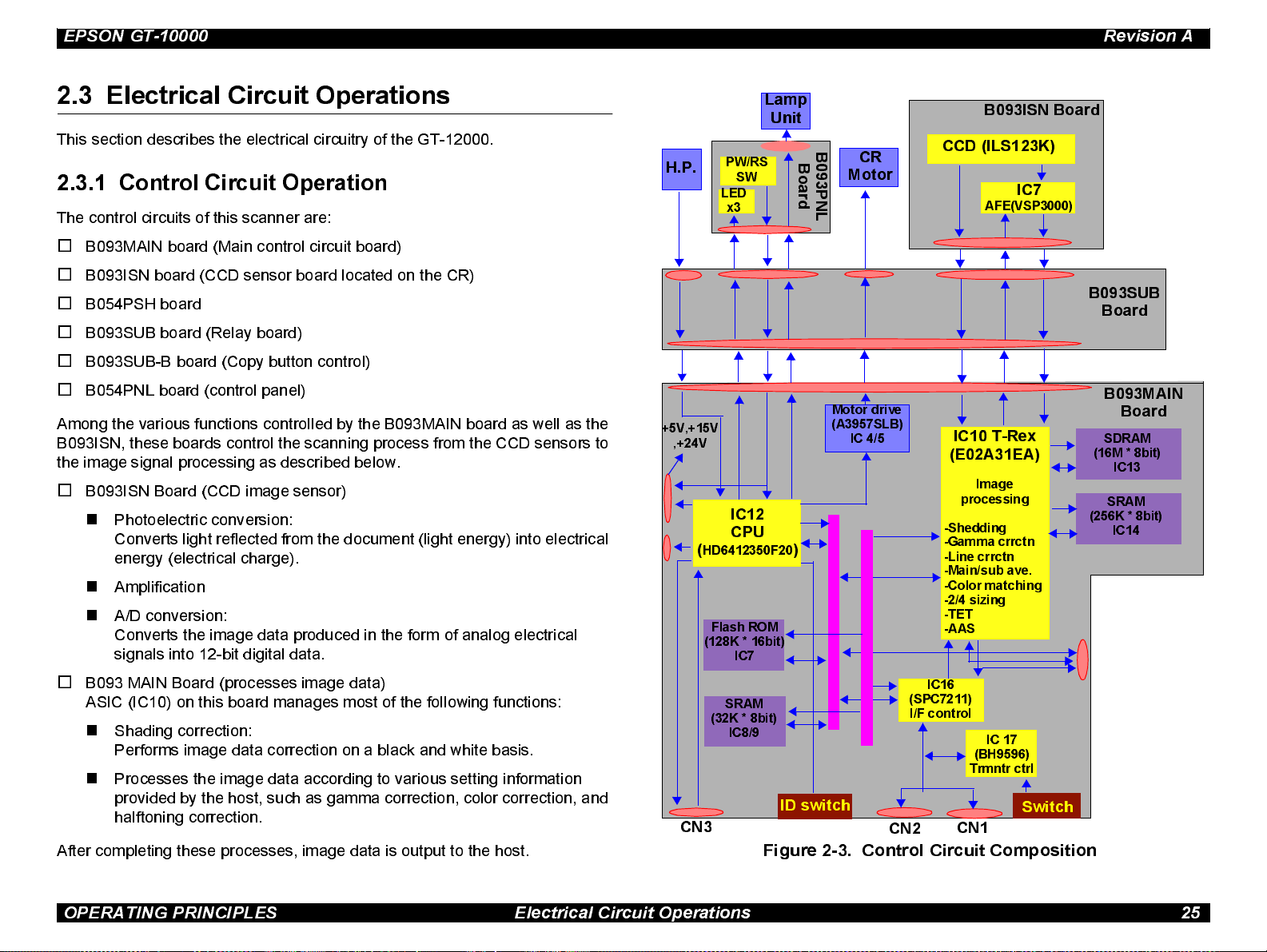

2.3 Electrical Circuit Operations

This section describes the electrical circuitry of the GT-12000.

2.3.1 Control Circuit Operation

The control circuits of this scanner are:

o

B093MAIN board (Main control circuit board)

o

B093ISN board (CCD sensor board located on the CR)

o

B054PSH board

o

B093SUB board (Relay board)

o

B093SUB-B board (Copy button control)

o

B054PNL board (control panel)

Among the various functions controlled by the B093MAIN board as well as the

B093ISN, thes e boards control the scanning process from the CCD sensors to

the image signal processing as described below.

o

B093ISN Board (CCD image sensor)

n

Photoelectric conversion:

Converts light reflected from the document (light energy) into electrical

energy (electrical charge).

n

Amplification

n

A/D conversi on:

Converts the image data produced in the form of analog electrical

signals into 12-bit digital data.

H.P.

+5V,+15V

,+24V

(

HD6412350F20

(128K * 16bit)

PW/RS

SW

LED

x3

IC12

CPU

Flash ROM

IC7

Lamp

Unit

B

o

a

r

d

)

B

CR

0

9

Motor

3

P

N

L

Motor drive

(A3957 SL B )

IC 4/5

B093ISN Board

CCD (ILS123K)

IC7

AFE(VSP3000)

IC10 T-Rex

(E02A31EA)

Image

processing

-Shedding

-Gamma crrctn

-Line crrctn

-Main/sub ave.

-Color matching

-2/4 sizing

-TET

-AAS

B093SUB

Board

B093MAIN

Board

SDRAM

(16M * 8bit)

IC13

SRAM

(256K * 8bit)

IC14

o

B093 MAIN Board (processes image data)

ASIC (IC10) on this board manages most of the following functions:

n

Shading correction:

Performs image data correction on a black and white basis.

n

Processes the image data according to various setting information

provided by the host, such as gamma correction, color correction, and

halftoning correction.

After completing these processes, image data is output to the host.

SRAM

(32K * 8bit)

IC8/9

ID switch

CN3

Figure 2-3. Control Circuit Composition

(SPC7211)

I/F control

CN2

IC16

IC 17

(BH9596)

Trmntr ctrl

Switch

CN1

OPERATING PRINCIPLES Electrical Circuit Operations 25

Page 26

EPSON GT-10000 Revision A

B093MAIN BOARD

Name Location Description

CPU

HD6412350F20

T-REX

E02A31EA

SPC7211 IC16

A3957SLB IC4/5 Motor drive control

BH9596 IC17 Terminator control

IC12

IC10

The CPU that controls this entire operation

of this board and operates at 20 MHz.

Voltage = 5.0V

The image processor that controls the

functions described below, operates at

48Mhz. Voltage = 3.3V

• CCD control

• Line correction processing

• Buffer memory

• Image processing

The SCSI interface processor operates at

40Mhz. Voltage = 5.0V

B093ISN BOARD

Name Location Description

Color CCD line sensor outline:

• Effective pixel = 7250 pixels x 3 colors

CCD sensor

ILX123K

IC9

• Light shield = 16 pixels x 3 colors

• Bi-D scanning rate = Max. 6 million

pixels/second

• Shutter function

±

10%

± 0.3V

± 10%.

B054PNL BOARD

This board has a power switch (push-lock), RESET switch and LED indicators

(OPERATE, READY, ERROR). (Same board used in GT-12000; compatible.)

2.3.2 Power Supply Circuit Operation

Since the power supply circuit board B054PSH for this scanner meets the

universal specification requirements, it can be used with rated voltage from

100V to 240V AC.

The electrical circuit for the AC input part is designed on the basis of

200V li ne. In case the input voltage is 200V line level, the ordinary full wave

rectifying system is used. With this system, the voltage is rectified by the diode

bridge DB1 and then smoothed by th e seri a l smoothing capacit ors C11 and

C32 to produce approximately 250 VDC.

On the other hand, if the input voltage is 100V line level, the double-voltage

rectifying system is used instead. With this system, the input AC current is

separated into the following 2 flows; the positive half cycles of the current flow

through the control IC (IC2) (from Pin 2 to Pin 3) via the diode bridge (DB1) and

the smoothing capacitor C11, and the negative half cycles of the current flow

through the smoothing capacitor (C32) and DB1 via IC2 (from Pin 3 to Pin 2).

Through these flows, the positive and negati ve AC current are separat ely

charged in the s moothing capacitors C11 and C32, respectively. The final

VDC (approximately 250 VDC) is equivalent to the output voltage produced by

the 200V line. At power-on, the control circuit (IC2) is activated by the full wave

rectifying system. Then, if the input voltage is the 100 VDC line level, the

system automatically switches to the double-voltage rectifying system after a

certain period set by the circuit.

ADC

VSP3000

IC2

A/D converter processing IC

Resolution = 12 bit

B093SUB BOARD

This relay board connects the B093MAIN board (which is located on a metal,

shielded tray) w ith the B093ISN and B054PNL boards.

OPERATING PRINCIPLES Electrical Circuit Operations 26

Page 27

EPSON GT-10000 Revision A

Except for the full wave rectifier circuit/voltage doubler rectifier circuit at the AC

input part , the normal RCC (Ringing Choke Converter) regulator circuit is used

for the rest part of the power supply circuit, and the different levels of VDC are

distributed to corresponding mechanisms, as shown in Table 2-1:

Table 2-1. DC Output Power

Output VDC Application

+5 V Logic power lines

+24 V

+15 V

• Motor drive power source

• Power source for the lamp (inverter)

+12 V production

(Drives the cooling fan for the metal, shielded tray that contains

the B093MAIN and B054PSH boards.)

Positive

Voltage

input

DB1

C11

Voltage

Negative

output

C32

IC2

AC input

100V = on

200V = off

Figure 2-4. Double-voltage Rectifier Circuit Operation

OPERATING PRINCIPLES Electrical Circuit Operations 27

Page 28

TROUBLESHOOTING

CHAPTER

3

Page 29

EPSON GT-10000 Revision A

3.1 Overview

This chapter describes troubleshooting techniques to help you solve any

scanner problems you may encounter. First see the next section to determine

what kind or error ha s occurred, and then see the appropriate explanation in

the following pages to determine the correct solution.

3.1.1 Errors and Causes of Errors

The self-diagnostic function equipped with this scanner automatically detects

the operating st atus of all major parts. The scanner communicates any

detected error and the cause of the error using a combination of the indicator

lights as described below.

COMMAND ERROR

Table 3-1.

LED Status Cause Operation/Condition

Ignores the wrong command

/parameter (no change made to

the current settings), and

returns NACK to wait for the

next command/ parameter.

Remedy

READY

ERROR

Received

undefined

command or illegal

parameter.

The error is cleared when a legal command or

parameter is received.

COMMUNICATION ERROR

Table 3-2.

LED Status Cause Operation/Condition

• Wrong communicati on

procedure or opera ti on

READY

ERROR

(flashing)

Remedy

detecte d.

• For SCSI I/F, if the error

occurred in any phase ex ce pt

“bus free ”, communica ti on

and operations stop for over

30 seconds.

• Turn the scanner off and back on or press the RESET button.

• For SCSI, se nd “RESET” signal.

The lamp goes off and the

scanner s tops oper at i ng.

FATAL ERROR

Table 3-3.

LED Status Cause Operation/Condition

• The lamp goes off and the

scanner s tops oper at i ng.

• Sets the sta tus bit to bit

“7”.

Remedy

READY

ERROR

(both

flashing)

Hardware error, such as

• The lam p does not li ght.

• Scanner turned on wit h the

CR unlocked.

• Other defects in the scanner.

• Turn the scanner off a nd back on or press the “ RESET”

switch.

• Send ini ti lia ze command *ESC @”.

• Send SCSI “bus device reset”

• For SCSI, se nd “RESET” signal.

TROUBLESHOOTING Overview 29

Page 30

EPSON GT-10000 Revision A

OPTION ERROR

Table 3-4.

LED Status Cause Operation/Condition

Option error, such as

REA DY

ERROR

Remedy Solve the error.

CHECK

PO INT

• The scanner cover is open.

• Paper out

• Other similar error

Sets the status bit to bit “7”.

An [Op tio n Error] can be detec ted on ly wh en the

optio n is pro pe rly ins talled .

3.1.2 Troubleshooting

This sect ion provides test points for each major unit and check points for each

abnormal phenomenon.

3.1.2.1 Test Points

Test poi nts for the motors and sensors are shown in the tables below .

MOTORS

Condition: Test the motor without any cables connected.

Table 3-5. Motor Check Points

Motor Test Point Signal Level

SENSORS

Condition: Test the sensors with the power on.

T able 3-6 . Sensor Check Points

Motor Te st Point Signal Level

• High when the mirror unit is

in the home position.

• Low when it is outside of its

home position.

HP sensor (Mirror)

CAUTION

Be careful no t to sho rt-c ircu it the signals while

<B093SUB board>

CN4: Pin 1 (Signal)

Pin 2 (GND)

checking them.

3.1.2.2 Troubleshooting Other Errors

See the table below for miscellaneous errors not covered in the previous

sections.

Table 3-7. In case of abnormal performance

Phenomenon Description Refer to Flowchart

The scanner doesn’t

operate at power on.

“Fatal Error” is indicated

and does not clear after the

scanner is turned off and

back on

“Communication Error” is

indicated

“OPERATE” LED d oes

not light.

CR does not move. Figure 3-1

Abnormal movement

of CR, such as

crashing into the

frame.

Lamp does not light. Figure 3-4

SCSI not set properly

or defective

Figure 3-1

Figure 3-3

Figure 3-5

Motor (for driving

the mirror)

<Cable connector>

Between Pins 1 and 3

Between Pins 2 and 4

15.0

Ω

The scanner does not scan

images properly.

Black lines, White

banding, and so on

Figure 3-6

TROUBLESHOOTING Overview 30

Page 31

EPSON GT-10000 Revision A

Flowchar t 3- 1. COperate light does not light up

Start

CN1 on B093SUB

not grounded

properly?

No

Has the fuse F1/F2

(B054SUB) blown?

No

Disconnect cables from

CN2/4/5/6 on B093SUB, and

then with power on test CN5

for the following voltages.

Bet ween Pin s:

1 and 4: +24V DC

7 and 4: +5V DC

9 and 10: +15V DC

Yes

Connect properly

Yes

Disconnect cables

from CN2/4/5/6 on

B093SUB, and replace

the fuse. Then turn on.

Did the fuse burn

out again?

Replace B054PSH

Yes

No

A

Check the resistance of

the mirror drive motor

coil: 15.0

A

Ω

Is it correct?

Yes

Replace

B093MAIN

No

Check the motor driver

IC on B093MAIN.

For Mirror motor

resistance between Pin

15/22 of IC4/5 and GND =

infinite

Yes

Is it correct?

No

Replace

B093MAIN

Are they correct?

No

Replace B054PSH

Replace the

motor

Yes

A

TROUBLESHOOTING Overview 31

Page 32

EPSON GT-10000 Revision A

Flowchar t 3- 2. CR (Mirror/ l amp) does not move

Star t

Transportation

screw set to locked

position?

No

Turn off the scanner and

manually move the carriage.

Does it move smoothly?

Yes

With power on, test CN5 on

B093MAIN.

Between Pin 1 and 4: +24V DC

Yes

No

Unlock the screw

Th e mech anism

is defective.

Replace it

A

Check the resistance

of the mirror motor

coil: 15.0

Ω

Is it correct?

Yes

Replace

B093MAIN

Replace the

motor

No

Check the motor driver

IC on B093MAIN.

For the mirror motor,

resistance between Pin

15/22 of IC4/5 and GND

= infinite

Yes

Is it correct?

No

Is it correct?

No

Replace

B054PSH

Yes

A

Replace

B093MAIN

TROUBLESHOOTING Overview 32

Page 33

EPSON GT-10000 Revision A

Flowchar t 3- 3 . CR moves abnormally (crashes into frame) Flowchart 3-4.

Start

Transportation

screw set to locked

position?

No

Test CN4 on B093MAIN for the HP

signal level.

Is the signal “High” when

CR is in home position?

Yes

Yes

Replace the lamp on the

Unlock the

screw

Does the lamp operate

Replace the inverter board on the

Replace

B093MAIN

Start

carriage.

normally?

No

carriage.

Lamp does not light

Yes

Old lamp was

defective.

No

Replace the HP

sensor (for mirror)

Does the lamp operate

normally?

No

Replace

B093MAI N

Yes

Old inver ter

was defective.

TROUBLESHOOTING Overview 33

Page 34

EPSON GT-10000 Revision A

Flowchart 3-5. SCSI I/F communication error occurs Flowchart 3-6. Scanned image is abnormal

Start

Make sure only the last SCSI

device in Daisy Chain is terminated

Make sure there are no SCSI ID

conflicts.

Are the settings correct?

Yes

Try another SCSI cable.

Does the scanner

operate properly?

No

Yes

Set them

correctly.

Old cable was

defective.

Replace.

Start

Stains or foreign

material on glass?

No

Stains or forei gn

material on mi rror ?

No

Replace B093M AI N an d perfo rm a

test scan.

Does the scanner

operate normally?

No

Yes

Yes

Yes

Clean the

glass

Clean the

mirro r

Old B093MAIN

was defective

No

Replace

B093MAIN

Replace the

mechans im

TROUBLESHOOTING Overview 34

Page 35

EPSON GT-10000 Revision A

3.1.3 Troubleshooting Circuit Board Errors

This s ection describes the check points for the electrical circuit boards.

3.1.3.1 Power Supply Board (B054PSH Board)

Tabl e 3- 8. B054PSH Board T r ouble sh ooti ng

Phenomenon Check Points

<Abnormal voltage>

+5VDC is not output.

<Abnormal voltage>

+24 VDC is not output.

<Abnormal voltage>

+15 VDC in not output.

3.1.3.2 Control Circuit Board (B093MAIN Board)

Table 3-9. B093MAIN Board Troubleshooting

Phenomenon Check Points

<No operation at all>

Reset IC is defective.

Test the signal waveform output between Pins 8

and 11 (chopping waveform) for IC51 (TL494)

Test the drain waveform at the Switching FET/Q1

Test the signal waveform output from Pin 1 for

IC52 (78M15)

Check the reset IC (IC11) for the signal

waveforms output from the following

pins:

Pin 7 (for +5V input)

Pin 5 (for PWRS output)

Table 3-9. B093MAIN Board Troubleshooting (continued)

Phenomenon Check Points

<”Fatal Error”>

Carriage does not stop at the home

position.

<”Fatal Error”>

Lamp does not light.

<”Fatal Error”>

White standard level is not read

properly.

<”Communication Error”>

Bi-directional I/F and SCSI I/F

<Image is read abnormally>

Check if the signal waveform input to Pin

110 of the CPU (IC12) changes in

accordance with the CR position.

Check the output from Pin 95 of ASIC

(IC12)

Check the signal output waveform for

ASIC (IC12) Pin 202:

Main cause: ASIC (IC16) is defective.

(Replace IC16 or B093MAIN board.)

Main cause: ASIC (IC10) is defective.

(Replace IC10 or B093MAIN board.)

Check the CPU (IC12) for the ROM

<No operation at all>

EPROM access error

<No operation at all>

CPU is defective.

<”Fatal Error”>

Motor (for mirror) drive circuit is

defective.

access signal waveforms output from the

following pins:

Pin 2 (for CS0 signal)

Pin 91 (for RD signal)

Check the clock signal waveform input to

the following pin:

Pin 85 (for XTAL input)

Check the Driver IC (IC 4/5) Phase drive

signal waveform output from Pin 15/22

TROUBLESHOOTING Overview 35

Page 36

DISASSEMBLY & ASSEMBLY

CHAPTER

4

Page 37

GT-10000 Revision A

4.1 Overview

This chapter describes how to disassemble this scanner. Unless ot herwise

specifi ed, assembly can be accomplished by following disassembly procedures

in reverse order.

n

W ARNING

CAUTION

Be sure to disconnect the power cable from the AC power

socket prior to servicing.

n

Since this scanner weighs h eavy (approximately 20 kg), it

must be carried b y two people.

n

Never disassemble any scanner parts unless specified to

do so, because th is scanner mechanism needs precise

assembly and adj ustment to maintain accurate control

system at its satisfactory level.

n

Secure yourself enough roo m for servicing, considering

the size o f the scanner.

n

Since this scanner weighs as heavy as approximately 20

kg, be sure to perform servicing on a heavy-duty, level

table.

n

Make sure that the “CR fixing knob” is set to the locking

position to fix the CR by the rear before packing the

scanner for transportati on.

4.1.1 Tools

Tools used for servicing are as listed in the table below:

Table 4-1. Tool List

Description Availability SE Parts Code Reference

(+) Screw Driver (No. 2)

(+) Screw Driver (No. 1)

Box Driver (Diagonal: 6mm)

Box Driver (Diagonal: 5mm)

Tweezers

Leveling Tools (3 stages and 1

adjuster as 1 set)

Mechanism Lift Handle

Light Correcting Panel

White Standa rd Char t

¤

¤

¤

¤

¤

¢

¢

¢

¢

- Versatile

- ditto

- ditto

- ditto

- ditto

1039140

1040176 ditto

1050003

1050004

Same as

GT-12000

Exclusively

desi gned for GT-

10000.

Exclusively

designed for GT-

10000.

(Must be attached

to the Light

Correcting Panel

before use.)

¤

Commercially available.

¢

Not commercially available.

DISASSEMBLY & ASSEMBLY Overview 37

Page 38

GT-10000 Revision A

4.1.2 Screws

Screws used in this scanner are listed in the table below. However, the list

does not include the screws which are used for servicing not specified in this

manual. Be sure to use the correct types and numbers of screws for each part

when assembling the scanner.

Table 4-2. Screw List

No.

1 CPFS M3x8 Black

2 CB M3x6 Gold

3 CP M2.5x8 Silver

Screw Type /

Specification

Appearance Color

Table 4-2. Screw List (continued)

No.

6 CPS M4x12 Silver

7 CB M4x10 Gold

8 CPS M4x18 Gold

Screw Type /

Specification

Appearance Color

9 CR; B Damper Shaft Gold

4

5

Screw Lock Screw

(Diagonal: 5 mm)

Brass Spacer (Hexagon)

(Diagonal: 6mm)

Silver

10 CB M3x3 Gold

Silver

DISASSEMBLY & ASSEMBLY Overview 38

Page 39

GT-10000 Revision A

Table 4-2. Screw List (continued)

No.

11 CB M3x12 Black

12 CB M4x6 Gold

13 CPFS M3x8 Gold

Screw Type /

Specification

Appearance Color

DISASSEMBLY & ASSEMBLY Overview 39

Page 40

GT-10000 Revision A

4.2 Disassembly Procedu res

Document Cover

This section describes disas se mbling and removing procedures for each major

unit of the scanner.

Removal

(Section 4.2.1)

See the flowchart in F i gure 4-1. The jobs in the yellow box i nvolve use of the

adjusting tools exclusi vely designed for this scanner. Therefore, make sure that

you read the i ns tructions in each secti o n carefully t o figure out the procedures

before servi ci ng.

Electrical Circuit

Removal

(Section 4.2.2)

Scanner Body

Disassembly

(Section 4.2.3)

Scanner Mechanism

Disassembly

(Section 4.2.4)

Main Boards Removal

(Section 4.2.2.1)

Upper Housing Removal

(Section 4.2.3.1)

Mechanism Removal

(Section 4.2.3.2)

Panel Board Assembly Removal

(Section 4.2.4.1)

Sub Board Assembly Removal

(Section 4.2.4.2)

HP Sensor (CR) Removal

(Section 4.2.4.3)

Motor (CR) Assembly Removal

(Section 4.2.4.4)

Glass Frame Assembly Removal

(Section 4.2.4.5)

Lamp/Inverter Board Assembly

Removal (Section 4.2.4.6)

Option Frame Assembly Removal

(Section 4.2.4.7)

Figure 4-1. Disassembly Procedure for GT-10000

DISASSEMBLY & ASSEMBLY Disassembly Procedures 40

Page 41

GT-10000 Revision A

4.2. 1 Docum ent Cover Unit Removal

4.2.2 Electrical Circuit Removal

The major electrical circuit boards (B093MAIN and B054PSH) of this scanner

are all stored in one independent shield compartment. Therefore, they can be

removed in one unit (board unit) from the scanner with ease.

1. Disconnect the AC power cable from the scanner.

2. Remove 3 screws (No.1) securing the shield compartment which contains

the electrical circuit boards at the back of the scanner. Then take out the

compartment from the scanner.

Figure 4- 3. Shiel d Compar t me nt Remov a l

CHECK

PO INT

For easy removal, pull the translucent card spacers located

at both sides of the shield compartment.

Figure 4-2. Document Cover Unit Removal

DISASSEMBLY & ASSEMBLY Disassembly Procedures 41

Page 42

GT-10000 Revision A

4.2.2.1 Main Boards Removal

Main boards stored in the shield compartment should be removed in the

following procedure:

1. Remove the shield compartment. (See 4.2.2.)

2. Remove 18 screws (No.2) securing the top shield and the top shield cover,

and remove both units together.

Figure 4- 4. Removal of Top Shiel d and Shield Cove r

3. Main Boar d Assembly Rem o val

Disconnect the connector cables from connectors CN5 and CN7 on the main

board assembly.

4. Remove the following s crews securing the main board assembly, and a

brass spacer securi ng the top shield, and remove the main board:

n

6 screws: No. 2, securing the board along the edges.

n

6 screws: No. 3 = 4 screws securing the SCS II I/F connector; No. 4 = 2

screws securing the ADF OPTION connector.

DISASSEMBLY & ASSEMBLY Disassembly Procedures 42

Page 43

GT-10000 Revision A

5. Power Supply Board Assembly Removal

Connector CN7

Connector CN5

Fixing Screws (No.2)

Brass Spacer (Hexagon)

n

Remove the connector cables from connector CN1 on the power

supply board ass embly and connector CN5 on the main board

assembly.

6. Remove 6 screws (No.2) securing the power supply board assembly and

remove the power s upply board.

Power Supply Connector CN1

Figure 4-5. Main Board Assembly Removal (a)

Power Sup ply Board Fixing

Screws (No.2)

Main Board

Connector CN5

Figure 4-7. Power Supply Board Assembly Removal

SCSI I/F Fixing Screws

ADF Option I/F

Fixing Screws

Figure 4-6. Main Board Assembly Removal (b)

DISASSEMBLY & ASSEMBLY Disassembly Procedures 43

Page 44

GT-10000 Revision A

4.2.3 Scanner Body Disassembly

This s ection describes procedures for disassembling the major units of the

scanner.

4.2.3.1 Upper Housing Removal

CAUTIO N

1. Remove the document cover (See Figure 4.2).

2. Usi ng tw e ezers, remove t he CR fixi ng knob at tached to the left si de of the

scanner.

3. Remove 4 screw s (2 for each of No.6 and No.7) securing the upper

housing to the chass i s on the s canner. Note that the 2 front screw s are

covered w i th the screw caps. Pinch them out wit h tw eezers pri or to

removing the screws.

4. Lift up th e upper hous ing to remov e i t.

CHECK

PO INT

When removing the CR fixing knob or screw caps, take

cautions not to damage the upper housing.

When reinstalling the upper housing, make sure that the

optical plate is installed on the specified position.

Screw

6

(No.6)

CR Fixing Knob

Screw

Cap

Screw

(No.7)

Screw Cap

Figure 4-8. Upper Housing Removal

Remove the cap by lifting it up

while pushing it toward the other

side of the cutout.

Cross-section

Screw Cap

Be careful not to damage

the upper housing.

Figure 4-9. Screw Caps Removal

DISASSEMBLY & ASSEMBLY Disassembly Procedures 44

Page 45

GT-10000 Revision A

Optical Plate

Figure 4-10. Optical Plate Installation

Inner Side of the

Upper Housing

CHECK

PO INT

Note the following when installing the scanner mechanism:

n

Remove key tops for the power switch and reset

switches from the lo wer housing.

n

Install the sca nner mechanism to the lower housing.

n

Reinstall the key tops.

Place the removed mechanism on flat stable surface.

4.2.3.2 Scanner Mechanism Removal

The scanner mechanism can be removed from the lower housing in the

following procedure:

1. Remove the upper housing (See 4.2.3.1).

2. Remove 4 screws (No.8) securing the scanner mechanism to the lower

housing. Then remove the mechanism from the lower housing.

DISASSEMBLY & ASSEMBLY Disassembly Procedures 45

Page 46

GT-10000 Revision A

4.2.4 Scanner Mechanism Disassembly

The rest of the chapter describes procedures for removing the major parts/

units in the scanner mechanism.

CAUTIO N

Note that producing this scanner requires precise assembly

and adjustment to ensure ac curate control system.

Therefore, n ever disassemble any scanner parts unless

specified to do so.

4.2.4.1 Panel Board Assembly Removal

1. Remove the scanner mechanism (See 4.2.3.2).

2. Turn the mechanism over and place it on a flat surface.

3. Disconnect the white cable from CN1 and the black cable from CN2 of the

panel board as sembly.

4. Remove 2 screws (No.2) securing the panel board assembly, and remove

the assembly.

CHECK

PO INT

Unit arrangement at the bottom of the mechanism is as

shown on the following page.

Figure 4-11. Scanner Mechanism Removal

DISASSEMBLY & ASSEMBLY Disassembly Procedures 46

Page 47

GT-10000 Revision A

4.2.4.2 Sub Board Assembly Removal

CR Motor Assembly

Figure 4- 12 . Unit Arrangement

CR HP Sensor

Sub Board Assembly

CN1CN2

Panel Board Assembly

1. Remove the scanner mechanism (See 4.2.3.2).

2. Turn the mechanism over and place it on a flat surface.

3. Disconnect all connector cables from the sub board assembly (B093SUB).

4. Remove 4 screws (No.3) securing the board to the bracket, and remove

the board.

CHECK

PO INT

CN6 CN2

When placing the scanner up side down, lay a clean soft

cloth under the scanner to protect the glass surface.

CN5

CN4

CN3

Panel Board Assy

Screws (No.2)

Screws (No.2)

Figure 4- 14 . Sub Board Assembl y Remov al

Figure 4-13. Panel Board Assembly Removal

DISASSEMBLY & ASSEMBLY Disassembly Procedures 47

Page 48

GT-10000 Revision A

4.2.4.3 HP Sensor (CR) Removal

This section describes procedure for removing the HP sensor which detects

reference position of the carriage mirror assembly.

1. Remove the scanner mechanism (See 4.2.3.2).

2. Unlock the carriage fixing screws, and move the carriage mirror assembly

away from the HP.

3. Turn the mechanism over and place it on a flat surface.

4. Release the hook fixing the HP sensor at the bottom of the mechanism and

remove the HP sensor unit. Then disconnect the connector cable from the

removed HP sensor.

CR Motor Assembly

CR HP Sensor

Panel Board Assembly

4.2.4.4 CR Motor Assembly Removal

This section describes procedure for removing the motor unit which drives the

carriage mechanism (mirror/lamp).

1. Remove the scanner mechanism (See 4.2.3.2).

2. Turn the mechanism over and place it on a flat surface.

3. Unhook the torsion spring from the tension lever assembly, then remove 1

screw (No.13) and the bush to remove the tension lever assembly.

4. Disconnect the cable for the motor from the relay connector and remove 4

CR; B damper shafts (No.9), and then remove the motor.

CHECK

PO INT

When assembling, hook the spring to the tension lever

assembly first, and fasten the screws.

Sub Board Assembly

Figure 4-15. HP Sensor (CR) Removal

DISASSEMBLY & ASSEMBLY Disassembly Procedures 48

Page 49

GT-10000 Revision A

4.2.4.5 Glass Frame Assembly Removal

CR; B Damper Shafts

Top of the Scanner

Screw (No.13)

Figure 4-16. CR Motor Assembly Remova l

Since the glass frame assembly (document glass) is one of the reinforcing

parts of the mechanism, the whole scanner mechanism may be deformed if it is

removed. Be sure to follow the instruction provided in this section during any

servicin g whic h involves rem oving the gla ss frame assembly.

.

n

CAUTIO N

When removing the document glass, m ake sure to set the

scanner on the ad justing tools exclusively designed for

this scanner.

n

Be sure to fit all the rubber feet of the scanner in the top

indents of the stages and the adjuster (Any of the feed

should not be placed over the top surface of the tools).

n

Set the scanner on a stable and level table.

n

Make sure that the scanner mechanism is installed in the

lower housing when removing the glass frame assembly.

Turning Table

(with 4 divisions)

Base

(with 1 groove)

Stage

(3 pieces)

Adjuster

Figure 4- 17 . Adjusting T ools

DISASSEMBLY & ASSEMBLY Disassembly Procedures 49

Page 50

GT-10000 Revision A

n

Turn the t able manually [2 quarters], which can be measured by 4

divis ions on the table and the groove on the base, to push the table up

from the posi tion where the table was moved up to by the spin.

n

After adjusting, make sure that each corner of the scanner is securely

in contact with the corresponding tool.

3. Remove 9 screws (No.10) and remove the glass frame assembly. The

screws to be removed and their locations are shown on the following page.

Stage

(Set in the front left,

rear right and rear

left corners.)

Adjuster

(Set in the front

right corner.)

Turn the turning table to

move the table up and

down to adjust height.

Figure 4-18. Tool Position and Adjusting Method

1. Remove the upper housing (See 4.2.3.1).

2. Referring to Figure 4-18, set the scanner on the adjusting tools (leveling

tools) and level the scanner according to the following procedure:

n

Set the scanner on 3 stages, placing each of the specified rubber feet

on the corresponding stage.

n

Set the adjuster under the rubber foot in the front right corner of the

scanner bottom, aligning the center of the adjuster with the foot. Make

sure that you can see the groove on the base of the adjuster when it is

set.

CAUTIO N

When reinstalling the glass frame assembly, refer to

Section 4.2.3.5 .1 to confirm the correct installation position.

Misplacing of the glass frame assembly will cause the CR to

scan the document from a wrong position.

n

Hold the bas e of the adjuster with a hand and spin the table until i t

reaches the bottom of the scanner by its own force.

DISASSEMBLY & ASSEMBLY Disassembly Procedures 50

Page 51

GT-10000 Revision A

n

Push the whole glass frame assembly from the front against the frange

Screws (No.10)

Screws

(No.10)

Screws

(No.10)

shaft stoppers until the glass edge is in contact with the bus hes.

n

Keeping the glas s frame assembly in contact with the stoppers, move

the assembly toward left and push it against the positioning bump

located on t he top surface of the left side frame.

n

When the glass frame assembly is in the correct position, fix it with 9

screws.

Screws

(No.10)

Front of the Scanner

Figure 4-19. Glass Frame Assembly Removal

4.2.4.5.1 Glass Frame Assembly Installation

After the glass frame assembly has been removed for any purpose, it must be

reinstalled in the following procedure.

1. Place the glass frame assembly on the specified position in the scanner

mechanism.

2. While referring to Figure 4-20, determine the installation position according

to the following procedure:

CHECK

PO INT

Positioning Bump

When installing the glass frame assembly, ensure that

glass fixing plates (one for each of the front and rear) are

properly positioned (See Figure 4-19).

Frange Shaft Stoppers

Figure 4-20. Determining the Glass Frame Assembly Position

n

Install the frange shaft stoppers at the 2 bumps located in the rear

frame.

DISASSEMBLY & ASSEMBLY Disassembly Procedures 51

Page 52

GT-10000 Revision A

4.2.4.6 Lamp Assembly and Inverter Board Assembly

Removal

This section describes how to remove the lamp assembly and the inverter

board assembly from the carriage.

1. Remove the glass frame assembly (See 4.2.3.5).

2. Move the CR to the position indicated in Figure 4-22 (the position where

the front and rear frames are indented).

3. Remove 2 screws (No.2) securing the carriage mirror cover, and slide the

cover toward the rear side of the scanner to release the engagement with

the hook on the carriage. Then lift up the cover and remove it.

Screw (No.2)

4. Disconnect the connector cable for the lamp from the connector (CN2,

white) on the inverter board assembly. Then remove the lamp from the

carriage.

5. Disconnect the cable (black) from the connector (CN1) on the inverter

board ass embly. Then remove the bracket (silver) fixing t he ferrite core.

6. Remove 2 screws (No.2 ) securing the inverter board assembly.

7. Slide the inv erter board assembly toward the front side of the scanner to

release the engagement with the hook on the carriage. Then remove the

inverter board.

Figure 4-21. Carriage Mirror Cover Removal

DISASSEMBLY & ASSEMBLY Disassembly Procedures 52

Page 53

GT-10000 Revision A

Lift up to remove.

p

m

a

L

CN2

Cut Part of the Board

Screws (No.2)

CHECK

PO INT

When assembling , make sure that the cover is securely

engaged with the hook on the carriage.

Hook

Rear

Cover

Carriage Base

Front

CN1

Figure 4-22. Lamp Assembly and Inverter Board Assembly

Removal

DISASSEMBLY & ASSEMBLY Disassembly Procedures 53

Page 54

GT-10000 Revision A

4.2.4.7 Option Frame Assembly Removal

This s ection describes how to remove the option frame assembly attached to

the back of this scanner.

1. Remove the upper housing (See 4.2.3.1).)

2. Remove 8 screws securing the option frame assembly to the back of the

scanner and remove it. The types and locations of the screws to be

removed are as follows:

n

No.11: Locat ed in the upper right corner of the option frame assembly

(when view ed from the back of the scanner).

n

No.12: Rest of the positions are indicated in Figure 4-23 Option Frame

Assembly Removal below.

Screw (No.11)

Screws (No.12)

Figure 4-23. Option Frame Assembly Removal

DISASSEMBLY & ASSEMBLY Disassembly Procedures 54

Page 55

ADJUSTMENTS

CHAPTER

5

Page 56

EPSON GT-10000 Revision A

Confirm the installation folder, and click “OK”. The program will be

5.1 Upd ating Firmware

To update the firmware, the following are necessary:

o

Update Program (K90E02V)

o

SCSI Cable

o

automatically installed (data file of the firmware will be placed in the same

installation folder), and the following program group will be created on the

PC.

5.1.1 Preparations Before Updating

1. Select non-synchronized connection for SCSI on the PC (See manual for

each SCSI board). However, since the selection of non-synchronized or

synchronized setting cannot be made for the SCSI board which is not

equipped with BIOS, it is necessary to check each SCSI board beforehand.

2. Install the Update Program for the firmware according to the procedure

shown below.

o

Double-click the program “K90E02V.exe” located in the “Firmware” folder,

and the following screen will appear.

Figure 5-2.

Figure 5-1. Installation of Firmware Program

ADJUSTMENTS Updating Firmware 56

Page 57

EPSON GT-10000 Revision A

5.1.2 Updating Firmware

1. Connect the scanner to the PC v ia SCSI.

2. Turn on the PC and Windows.

3. Bring up EFlash, and the EFlash start screen shown in Figure 5-3 will

appear.

4. Click “About” button to display information on the program and the required

environment as shown in Figure 5-4.

Figure 5-4. Firmware Update Requirements and Environment

5. Double-click anywhere in the above screen other than “OK” button to

Figure 5-3. Firmware Update Start Screen

display “Option” screen (shown in Figure 5-5 on the following page), and

select light correction value setting for the firmware update at “Light

Correction Value”. If the light correction is necessary after updating the

firmware, select “[Production] Perform Light Correction after EFlash”. If

firmware updat e only is desired, select “[User Update] Save and Restore

the current value”. To specify the light v alue, select “[Special] Force t o

wri te the specified value” and enter the light value.

ADJUSTMENTS Updating Firmware 57

Page 58

EPSON GT-10000 Revision A

10. 1). In Figure 5-6, confirm the version of writing firmware. Name of the

scanner and the current version of ROM are shown at “Target Scanner”,

and the latest version of firmware data is shown right below.

Figure 5-6.

2). Click “Next” button for Flash Reservation.

Figure 5-5. Option Window

6. Click “OK” button in Fi gure 5-5 to go back to Figure 5-4.

7. Click “OK” button in Fi gure 5-4 to go back to Figure 5-3.

8. Make sure that the scanner is ready (green lamp is on).

9. In Figure 5-3, click “Next” button and upload the firmware according to the

following procedure:

ADJUSTMENTS Updating Firmware 58

Page 59

EPSON GT-10000 Revision A

3). When the Flash Reservation is complete, “REBOOT SCANNER!”

message box will appear (Figure 5-5).

Figure 5-7.

4). Reboot the scanner. You cannot proceed to the next step without

rebooting the scanner. Make sure that “Ready” lamp is on.

5). Click “O K” to start writing the firmware. Writi ng status is indicated by

the progress bar as shown in Figure 5-8 below. When writi ng process is

complete, “REBOOT SCANNER!” message will appear on the screen

again.

Figure 5-8.

ADJUSTMENTS Updating Firmware 59

Page 60

EPSON GT-10000 Revision A

6). Reboot the scanne r and click “OK”. The reboot message box will be

closed and Figure 5-9 will appear on the screen.

Figure 5-10.

Figure 5-9.