Page 1

SERVICE MANUAL

Large Format Color Inkjet Printer

Epson Stylus Pro GS6000

Confidential

SEIJ08001

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2008 SEIKO EPSON CORPORATION.

Imaging Products CS, PL & Environmental Management

Confidential

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) Damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURY FROM METAL PARTS WITH

SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO

THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN AIR DUSTER IS USED ON THE REPAIR AND THE MAINTENANCE WORK, THE USE OF THE AIR DUSTER PRODUCTS CONTAINING

THE INFLAMMABLE GAS IS PROHIBITED.

Confidential

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

CHAPTER 7.APPENDIX

Provides the following additional information for reference:

• Connectors

• ASP List

• Exploded Diagrams

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Indicates that a particular task must be carried out according to a certain

standard after disassembly and before re-assembly, otherwise the quality

of the components in question may be adversely affected.

Confidential

Page 5

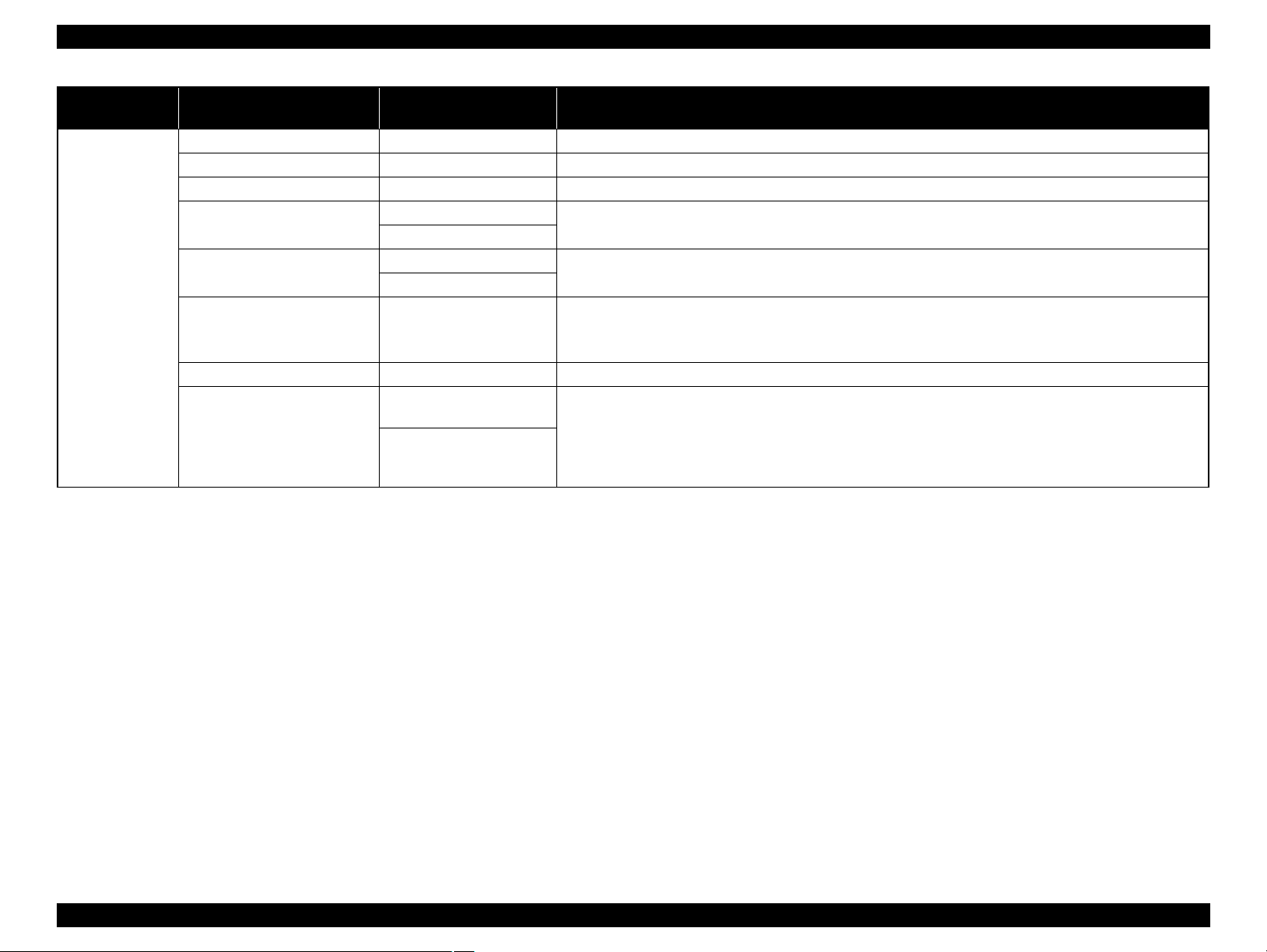

Revision Status

Revision Date of Issue Description

A July 18, 2008 First release

B December 12, 2008 Ch1:

1.2.2 Durability (p. 16)

Revised contents.

1.4.2 Panel Settings (p. 24)

Added the ROLL PAPER COUNTER menu.

1.4.3 Maintenance Mode (p. 32)

Added the REMAINING PPR SETUP menu.

1.4.4 Serviceman Mode (p. 33)

Added the menu list.

Ch4:

4.1.3 Recommended Tools (p. 66)

Added Thread-locker.

Ch5:

5.1.4 Tools for Adjustments (p. 191)

Added Thread-locker.

5.1.5 Service Program Basic Operations (p. 192)

Changed the explanation partially.

5.3.3 CR Height Adjustment (p. 204)

Corrected the values indicating the jig’s thickness.

5.4.6 Head Slant and Alignment Adjustment (p. 212)

Changed the explanation.

5.6.1 RTC and USB ID (p. 224)

Changed the explanation.

5.8.3 Electric Components Test (p. 236)

Changed the actions of the F COVER and the M COVER when checking partially.

Ch6:

6.4 Cleaning (p. 246)

Added the Carriage Rail Cleaner and the Carriage Rail Oil to the Maintenance Kit.

6.5 Lubrication (p. 253)

Added the Part No. of grease.

Confidential

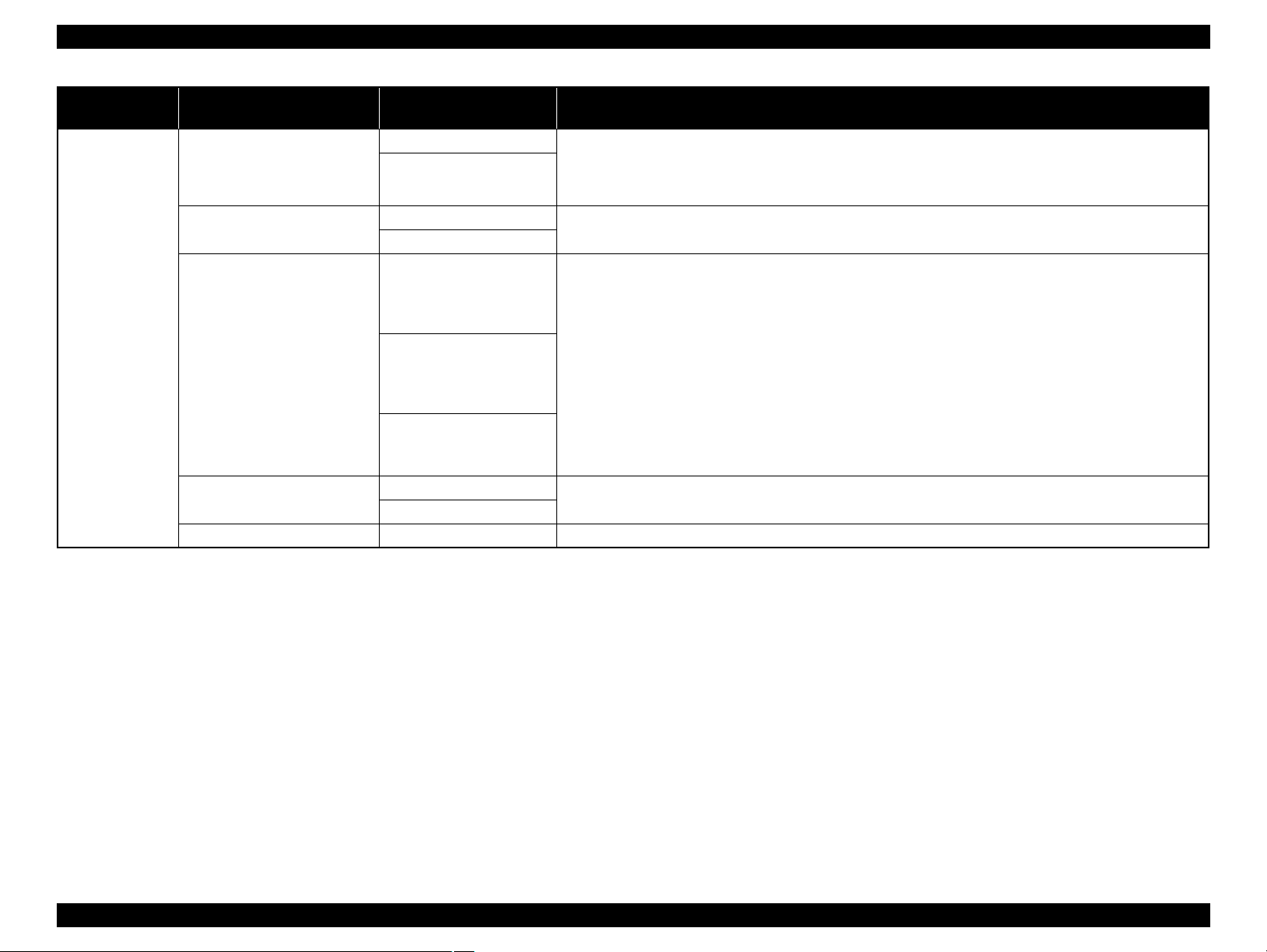

Page 6

Revision Date of Issue Description

B December 12, 2008 Ch7:

7.3 Parts List (p. 262)

Update the information to the latest.

7.4 Exploded Diagram (p. 267)

Update the information to the latest.

C June 5, 2009 Ch3:

3.3 Remedies for Maintenance Requests (p. 54)

Added a table.

3.4 Remedies for Service Call Error (p. 55)

Added the Debug error.

Ch4:

4.1.1 Precautions (p. 64)

Changed the warnings partially.

4.1.3 Recommended Tools (p. 66)

Changed the length of Hexagonal wrench.

4.4.9.6 LOWER BEARING (p. 152)

Added the disassembling/reassembling procedures.

Ch5:

5.1.4 Tools for Adjustments (p. 191)

Added 1000mm Ruler.

5.1.5 Service Program Basic Operations (p. 192)

Changed the name.

5.2 NV-RAM BACKUP UTILITY (p. 198)

Changed the steps of Restore Procedure.

5.8.2 CR Durability Test (p. 235)

Added the section.

Ch6:

6.5 Lubrication (p. 253)

Added the caution.

6.5 Lubrication (p. 253)

Change the name of grease.

6.5 Lubrication (p. 253)

Added the amount of lubricant.

Confidential

Page 7

Revision Date of Issue Description

D September 18, 2009 Ch1:

Ink set configuration (p. 14)

Added the Ink Set Configuration.

Ch5:

5.3.2 CR Reduction Belt Tension Adjustment (p. 201)

Added the procedure.

E January 15, 2010 Ch4:

4.1.1 Precautions (p. 64)

Changed the cautions partially.

4.4.6.3 MAIN BOARD ASSY (p. 110)

Modified the adjustment.

4.4.11.11 CR CURSOR ASSY (p. 175)

Modified the adjustment.

4.4.9.2 CR REDUCTION BELT (p. 144)

Modified the adjustment.

4.4.9.5 CR MOTOR (p. 151)

Modified the adjustment.

4.4.11.1 PRINT HEAD/VALVE ASSEMBLY, HEAD (p. 158)

Modified the adjustment.

Ch5:

5.1.2 Adjustment Items and the Order by Repaired Part (p. 186)

Changes partially.

5.6.4.1 IP Address Setup (p. 228)

Added the adjustment.

5.6.4.2 Network Test (p. 228)

Changed.

5.6.5 NVRAM CLEAR OK (p. 229)

Added the adjustment.

5.6.6 Rear Sensor Test/Rear AD Adjustment (p. 230)

Added the adjustment.

5.6.7 Input Serial Number (p. 231)

Added the adjustment.

5.6.8 CR Origin Adjustment (p. 232)

Added the adjustment.

5.3.2 CR Reduction Belt Tension Adjustment (p. 201)

Changed the procedure. Added the Video. (Chapter 8)

Confidential

Page 8

Revision Date of Issue Description

F December 12, 2011 Ch5:

5.3.3 CR Height Adjustment (p. 204)

Change the Figure 5-20.

Ch5:

6.5 Lubrication (p. 253)

Change Grease type.

Confidential

Page 9

Epson Stylus Pro GS6000 Revision F

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features ............................................................................................................... 12

1.2 Basic Specifications ........................................... ... ....................................... ... .... 13

1.2.1 Printer Specifications ................................................................................. 13

1.2.2 Durability ................................................................................................... 16

1.2.3 Paper size/Printable area ............................................................................ 16

1.2.4 Print Mode / Print Resolution .................................................................... 17

1.3 Dimensions and Main Components ............................................... ..................... 18

1.3.1 Dimensions and Weight ........................................................... .................. 18

1.3.2 Part Names ................................................................................................. 19

1.4 Control Panel .............................................................. ....................................... . 20

1.4.1 Buttons and Indicators ............................................................................... 20

1.4.2 Panel Settings ............................................ ........................................ ......... 24

1.4.3 Maintenance Mode .................................................................................... 32

1.4.4 Serviceman Mode ...................................................................................... 33

Chapter 2 OPERATING PRINCIPLES

2.1 Glossary .............................................................................................................. 41

2.2 Ink System ............................................................ ....................................... ....... 42

2.3 Carriage Mechanism ........................................................................................... 43

2.4 Paper Feed Mechanism ....................................................................................... 44

2.5 Heater Mechanism ..................................... ....................................... .................. 45

2.6 Boards ................................................................................................................. 46

2.7 Sensors ................................................................................................................ 47

2.8 Fans ..................................................................................................................... 48

3.1.2 Troubleshooting Procedure ........................................................................ 50

3.2 Remedies for Error Messages ............................................................................. 51

3.3 Remedies for Maintenance Requests ............................ ..................................... 54

3.4 Remedies for Service Call Error ........................................................................ 55

3.5 Remedies for Print Quality Troubles .............................................. ... ................. 60

Chapter 4 DISASSEMBLY & ASSEMBLY

4.1 Overview ................................................ ........................................ ... ................. 64

4.1.1 Precautions ................................................................................................. 64

4.1.2 Orientation Definition ................................................................................ 66

4.1.3 Recommended Tools ................................................................................. 66

4.2 Parts Diagram ..................................................................................................... 67

4.3 Disassembly Flowchart ...................................................................................... 76

4.4 Disassembly and Assembly Procedure ............................................................... 83

4.4.1 Basic Operations ........................................................................................ 83

4.4.2 Consumables/Accessories ............................................................. ............ 84

4.4.3 Housing ...................................................................................................... 85

4.4.4 Electric Components .................................................................................. 99

4.4.5 Fans ...................................................... ....................................... ............. 101

4.4.6 Boards ....................................................................................... ............... 109

4.4.7 Sensors ................................ ..................................................................... 123

4.4.8 Heaters/Thermistors ................................................................................. 137

4.4.9 Carriage Mechanism ................................................................................ 142

4.4.10 Paper Feed Mechanism .......................................................................... 155

4.4.11 Ink System Mechanism ......................................................................... 158

4.4.12 Take-Up Reel Unit ................................................................................. 177

Chapter 3 TROUBLE SHOOTING

3.1 Overview ............................................................................................................ 50

3.1.1 Preliminary Check ..................................................................................... 50

Chapter 5 ADJUSTMENT

5.1 Overview ................................................ ........................................ ... ............... 185

5.1.1 Precautions ............................................................................................... 185

5.1.2 Adjustment Items and the Order by Repaired Part .................................. 186

9

Confidential

Page 10

Epson Stylus Pro GS6000 Revision F

5.1.3 Description of Adjustments ..................................................................... 189

5.1.4 Tools for Adjustments ............................................................................. 191

5.1.5 Service Program Basic Operations .......................................................... 192

5.1.6 Cautions and Preparation for Pattern Printing ......................................... 197

5.2 NV-RAM BACKUP UTILITY ........................................................................ 198

5.3 CR Related Adjustments .................................................................................. 199

5.3.1 CR Belt Tension Adjustment ................................................................... 199

5.3.2 CR Reduction Belt Tension Adjustment ................................................. 201

5.3.3 CR Height Adjustment ............................................................................ 204

5.3.4 Media Side Margin Adjustment ............................................................... 206

5.4 Head Related Adjustments ............................................................................... 207

5.4.1 Head Rank Input ...................................................................................... 207

5.4.2 Nozzle Check Pattern .............................................................................. 208

5.4.3 Cleaning and Washing ............................................................................. 209

5.4.4 Ink Discharge ........................................................................................... 210

5.4.5 Initial Ink Charge Flag ............................................................................. 211

5.4.6 Head Slant and Alignment Adjustment ................................................... 212

5.4.7 Head Nozzles Alignment Adjustment ..................................................... 218

5.4.8 Head Uni-D/Bi-D Low Gap Adjustment ................................................. 219

5.5 PF Related Adjustments ................................................................................... 222

5.5.1 PF Reduction Belt Tension Adjustment .................................................. 222

5.5.2 Paper Feed Adjustment ............................................................................ 223

5.6 Other Adjustments ............................................................................................ 224

5.6.1 RTC and USB ID ..................................................................................... 224

5.6.2 Firmware Update ..................................................................................... 225

5.6.3 Washing Sequence Flag ........................................................................... 227

5.6.4 IP Address Setup & Network Test ........................................................... 228

5.6.5 NVRAM CLEAR OK .............................................................................. 229

5.6.6 Rear Sensor Test/Rear AD Adjustment ................................................... 230

5.6.7 Input Serial Number ................................................................................ 231

5.6.8 CR Origin Adjustment ............................................................................. 232

5.7 Clear Counters .................................................................................................. 233

5.8 Tests .................................................................................................................. 234

5.8.1 Skew Test ................................................................................................. 234

5.8.2 CR Durability Test ................................................................................... 235

5.8.3 Electric Components Test ....................................... ................................. 236

6.1 Overview ................................................ ........................................ ... ............... 241

6.2 Setting up and Transportation .......................................................................... 242

6.2.1 Setting up ................................................................................................. 242

6.2.2 Transportation .............................................. ............................................ 243

6.3 Maintenance ............................................................ ......................................... 244

6.4 Cleaning .......................................... ....................................... ........................... 246

6.4.1 Cleaning Wiper ................................................................................. ....... 247

6.4.2 Around the Print head .............................................................................. 249

6.4.3 Cleaning the Pressure Rollers and Platen ................................................ 250

6.4.4 Cleaning and Lubricating the CR rail ...................................................... 252

6.5 Lubrication .............................................................. ......................................... 253

Chapter 7 APPENDIX

7.1 Block Wiring Diagram ..................................................................................... 258

7.2 Panel Menu Map .............................................................................................. 259

7.3 Parts List ............................................................. ....................................... ....... 262

7.4 Exploded Diagram ............................................................................................ 267

Chapter 6 MAINTENANCE

10

Confidential

Page 11

PRODUCT DESCRIPTION

CHAPTER

1

Confidential

Page 12

Epson Stylus Pro GS6000 Revision F

1.1 Features

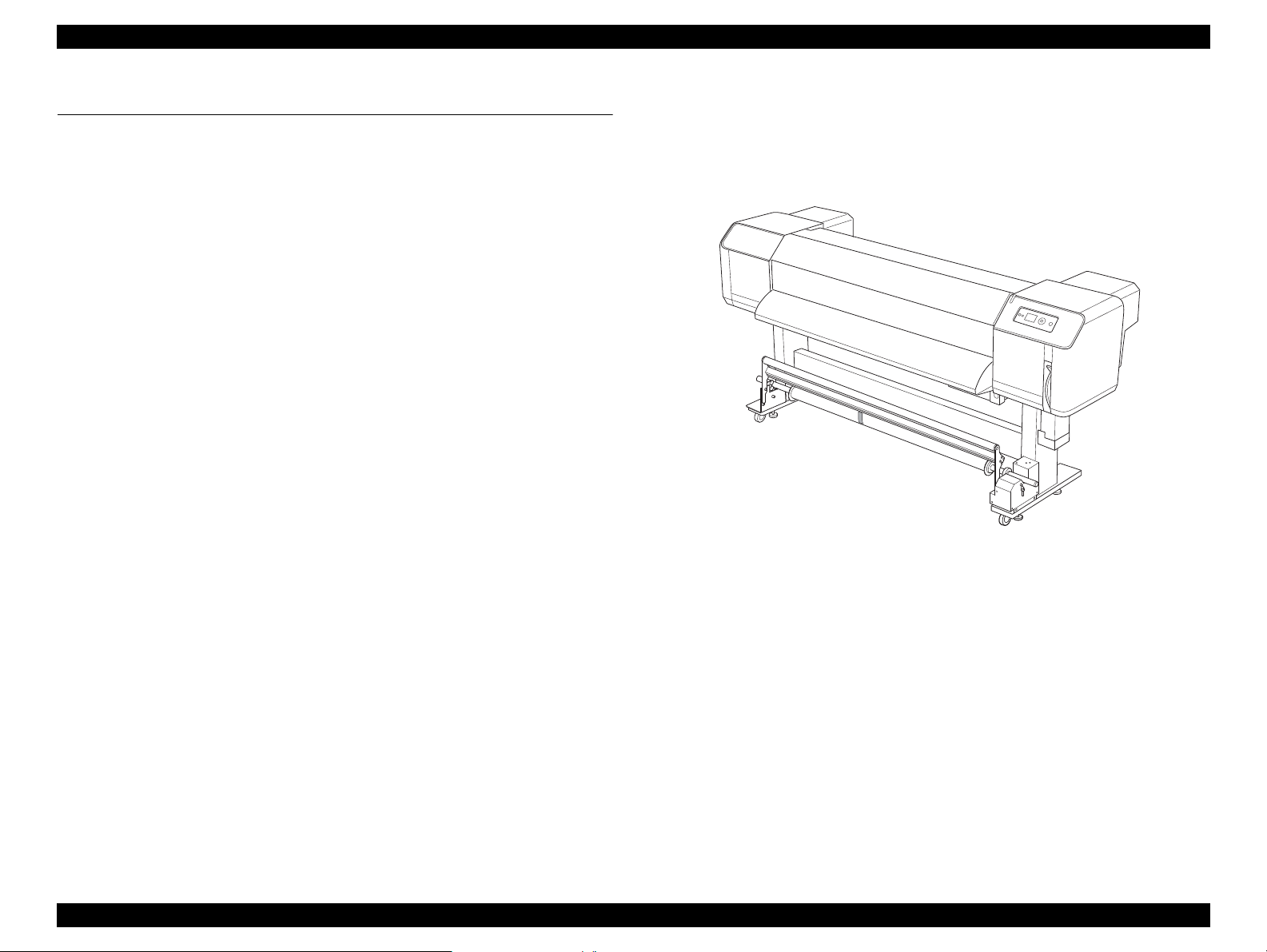

Epson Stylus Pro GS6000 is a wide-format color Eco-Solvent ink jet printer that

supports 64-inch roll paper. The features of this printer are;

High-speed output

The new type print head achieves high-speed output. It is compatible with paper

up to 1,625 mm in width.

Wide variety of compatible paper

The head is adjustable to two levels of height and compatible with paper up to

1.3 mm in thickness.

Vibrant color reproduction

Eight colors of ink are used for printing in order to reproduce sharp and vivid

colors. This printer uses 950 ml large-capacity ink cartridges. Use of variable dots

can improve color reproduction.

Multi-heater

Heaters are installed at three locations (pre, platen, after) allowing solvent ink to

fix better on paper and dry quickly.

Auto Take-Up Reel Unit

Active indicator

The Active indicator flashes when an error has occurred during operation. Since

the indicator is big, customers can easily check the operational status of the printer

at a distance.

Figure 1-1. External View

This automatically takes up printed paper, keeping it clean and free of creases. It is

also convenient for storage and transportation.

Large-capacity (950 ml) ink cartridge

Epson provides the large-capacity (950 ml) ink cartridges for this printer that

realize the high productivity required for professional work.

High speed USB 2.0 / Gigabit Ethernet

You can connect to a high-speed network (such as USB 2.0 or Ethernet 100/1000)

and that improves the file transfer speed.

PRODUCT DESCRIPTION Features 12

Confidential

Page 13

Epson Stylus Pro GS6000 Revision F

1.2 Basic Specifications

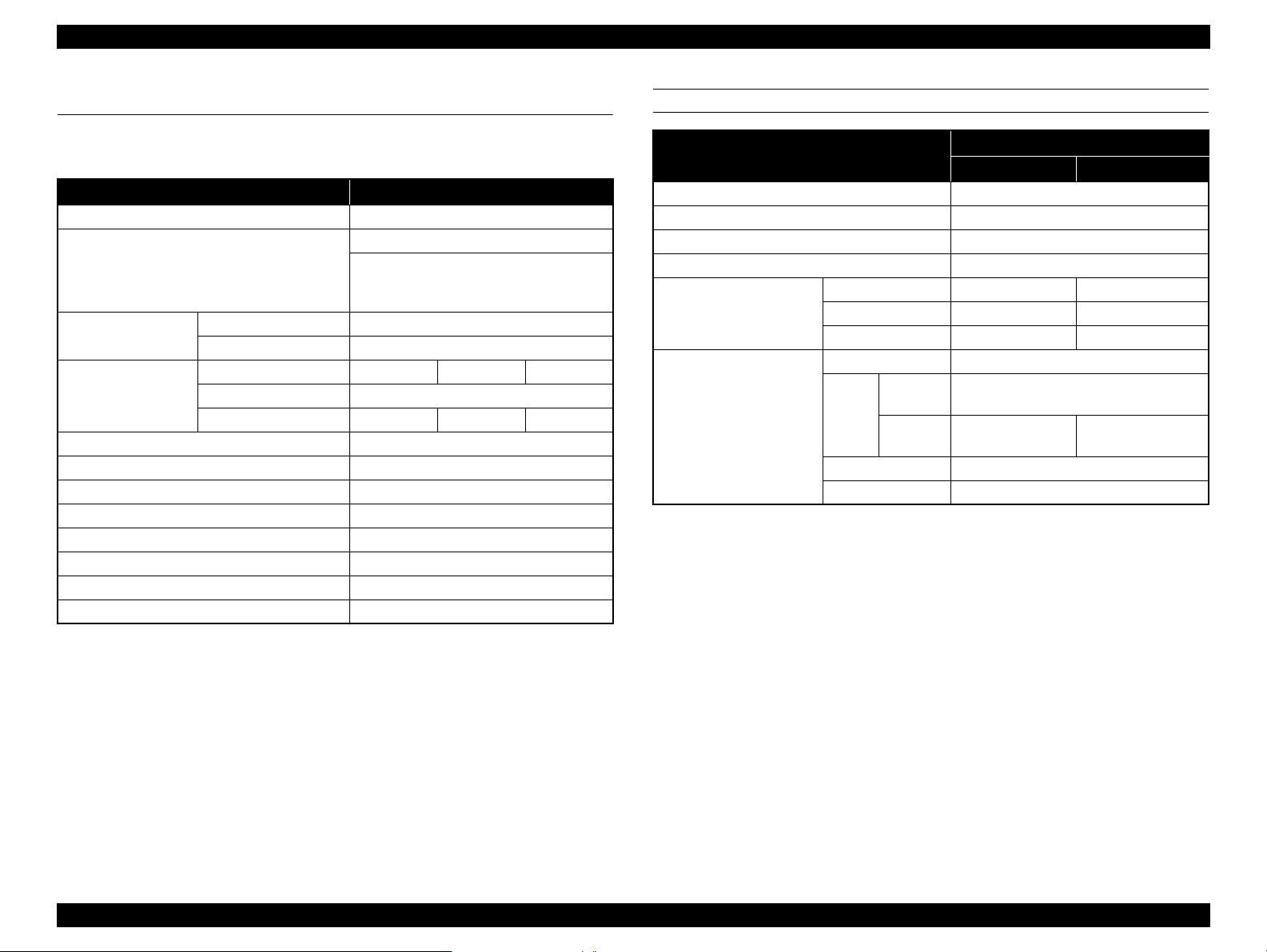

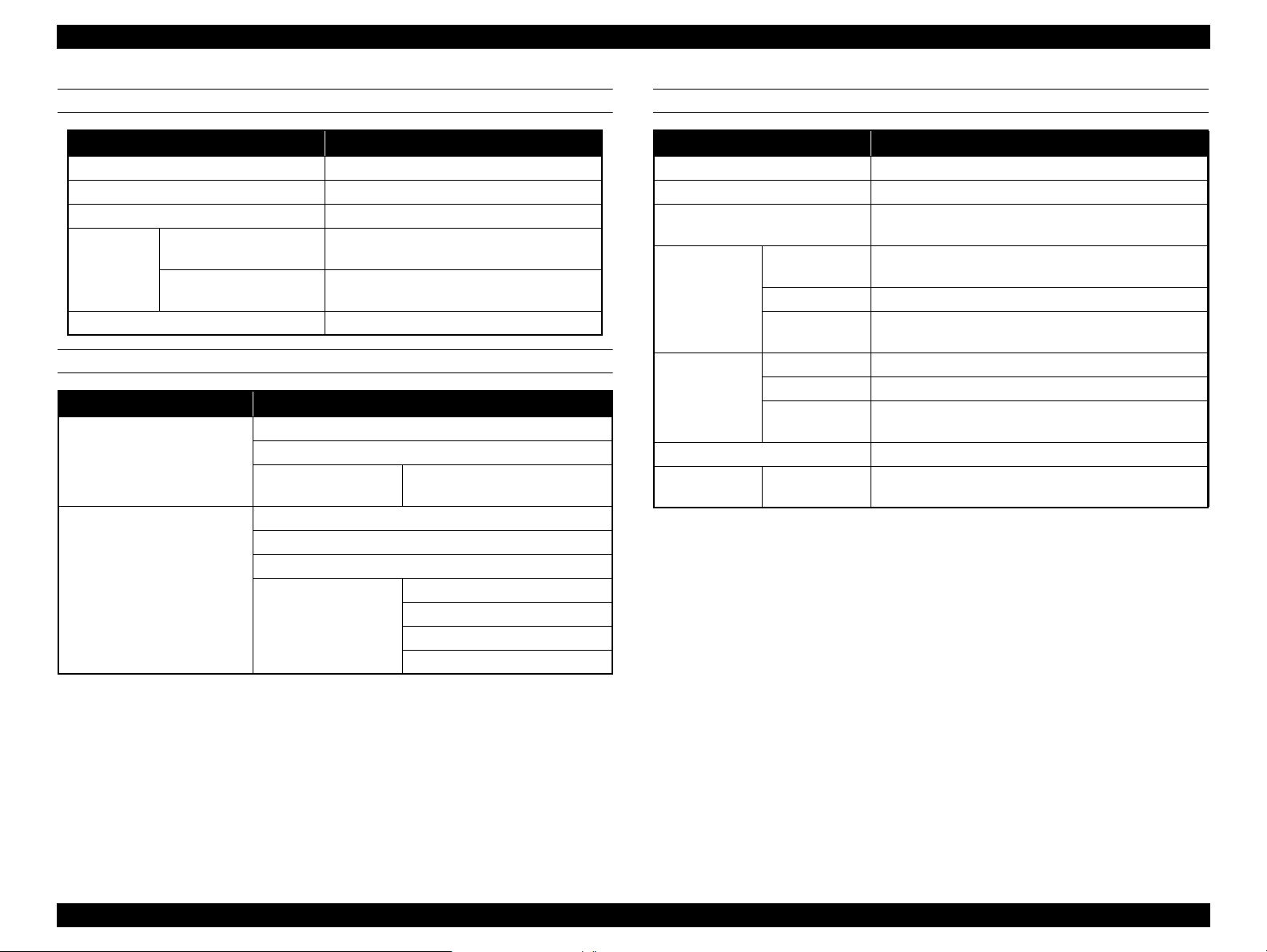

1.2.1 Printer Specifications

Item Specification

Printing method

Nozzle configuration

Character mode

Raster graphic mode

Resolution

Print direction Bidirectional

Control code

Character tables

Character sets EPSON Courier 10 cpi

Paper feed method

Paper path Roll paper

Note *1: Each color has two lines.

Character Pitch 10 cpi

Printing Column 635

Horizontal resolution 540 dpi 720 dpi 1440 dpi

Printable width 1615.0 mm (63.58")

Available dots 34,334 45,779 91,559

RAM 256 MB (MAIN) + 64 MB (Network)

On-demand ink jet

Black: 180 nozzles per color x 2

Color: 180 nozzles per color x 2

(Cyan, Magenta, Light Cyan, Light

Magenta, Yellow, Green, Orange)

Maximum 1440 x 1440 dpi

ESC/P Raster, ESC/P2

PC 437 (US, Standard Europe)

Friction

*1

*1

ELECTRIC SPECIFICATIONS

Item

Rated voltage

Input voltage range AC 90 to 264 V

Rated frequency range

Input frequency range 49 to 61 Hz

Rated current

Power consumption

(MAIN + HEATER)

HEATER 11 A 6 A

TAKE-UP REEL

Ready

mode

Sleep mode Approx. 24 W

Power off: Approx. 3 W

Specification

100-120V Model 220-240V Model

AC 100 to 240 V

50 to 60 Hz

MAIN

Printing Approx. 680 W

Idle heat

ON

Idle heat

OFF

11 A 6 A

0.4A 0.4 A

Approx. 680 W

Approx 48 W Approx 40 W

PRODUCT DESCRIPTION Basic Specifications 13

Confidential

Page 14

EPSON Stylus Pro GS6000 Revision F

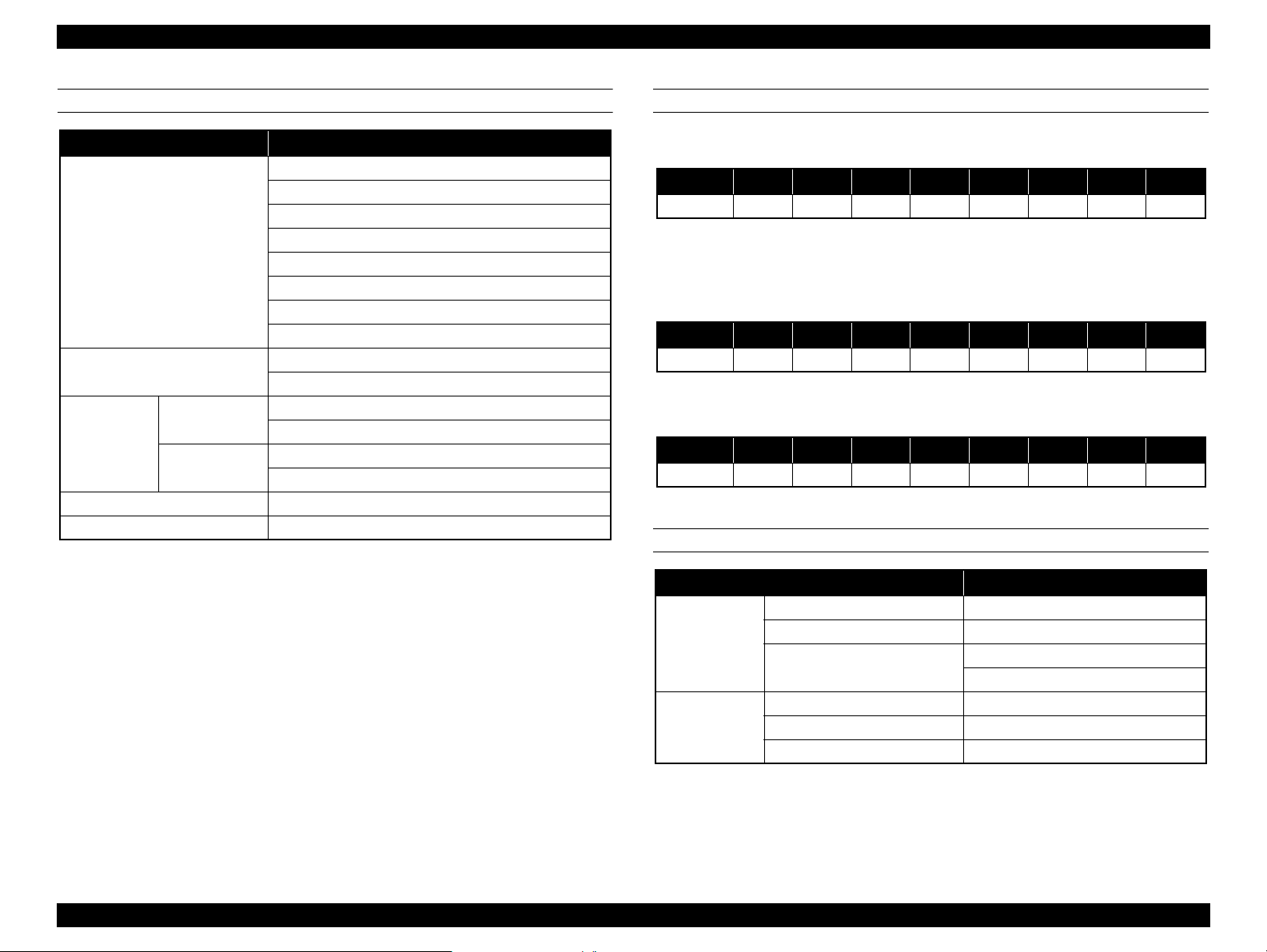

INK CARTRIDGES INK SET CONFIGURATION

Cartridge life

Temperature

Dimensions 53.1 mm (W) x 316.1 mm (D) x 146.2 mm (H)

Item Specification

Cyan

Magenta

Yellow

Colors

Capacity

Storage

(uninstalled)

Storage

(installed)

See expiry date on package or cartridge.

Within 6 months after opening package.

-20 to 40°C (-4 to 104°F)

1 month at 40°C (104°F)

-10 to 40°C (14 to 104°F)

Black

Light Cyan

Light Magenta

Green

Orange

4 days at 32°C (90°F)

950 ml

Ink Set Configuration

Ink Type 1-row 2-row 3-row 4-row 5-row 6-row 7-row 8-row

Pigment Or Gr Lm Lc K Y M C

Note : 1-row starting from the left facing the front of the printer.

Nozzle Configuration

LEFT HEAD:

Ink Type 1-row 2-row 3-row 4-row 5-row 6-row 7-row 8-row

PigmentMMCCKKYY

Note : 1-row starting from the left facing the front of the printer.

RIGHT HEAD:

Ink Type 1-row 2-row 3-row 4-row 5-row 6-row 7-row 8-row

PigmentOrOrGrGrLcLcLmLm

Note : 1-row starting from the left facing the front of the printer.

ENVIRONMENTAL CONDITIONS

Item Specification

Operation 20 to 32°C (68 to 89.6°F)

Temperature

Humidity

Note *: Without condensation

Print Quality Guarantee 22 to 32°C (72 to 89.6°F)

Storage

Operation 40 to 60% RH*

Print Quality Guarantee 40 to 60% RH*

Storage 20 to 80% RH*

-10 to 40°C (14 to 104°F)

4 days at 32°C (90°F)

PRODUCT DESCRIPTION Basic Specifications 14

Confidential

Page 15

EPSON Stylus Pro GS6000 Revision F

ROLL PAPER

Item Specification

Paper size (width)

Internal diameter 3 inches

Outer diameter

When Head height

Thickness

adjustment lever is Low

When Head height

adjustment lever is High

Weight Max. 30 kg

STANDARDS AND APPROVALS

Item Specification

Safety

EMC

Low Voltage Directive

300 mm (12") to 1625 mm (64")

Max. 170 mm (6.7")

Max 0.3 mm

Max 1.3 mm

UL 60950-1

CSA No. 60950-1

2006/95/EC

FCC part 15 subpart B class A

CAN/CSA-CEI/IEC CISPR 22 Class A

AS/NZS CISPR 22 Class A

EN 55022 Class A

EMC Directive

2004/108/EC

EN 60950-1

EN 55024

EN 61000-3-2

EN 61000-3-3

MECHANISM

CR and PF drive method

Paper feed method Loads paper at the rear and ejects paper to the front

Print Head

Ink

Waste ink tank

Take-Up Reel

Unit

Item Specification

Servo motor and DC motor are operated by the firmware

180 nozzles x 8 rows

Two Print Heads are mounted.

Ink supply

method

Ink type Eco-Solvent ink

Ink colors

Attachment Secured to the main unit

Capacity 2,000 ml

Full tank

detection

Noise 50dB or lower

Drive method Driven by DC geared motor

Ink is supplied from the independent ink cartridges

through a tubes via the sub tanks.

Black, Cyan, Magenta, Yellow, Light Cyan,

Light Magenta, Green, Orange

Detected by the float sensor

PRODUCT DESCRIPTION Basic Specifications 15

Confidential

Page 16

EPSON Stylus Pro GS6000 Revision F

300mm

1625mm

1.2.2 Durability

The following lists the parts that need periodical replacement as indicated.

Item Durability Panel message display

Head Caps

Wiper 1 year None

Head & Dumpers

CR Motor 6,220,000 passes Indicated

PF Motor

6,000,000,000 dots/nozzle None

1 year None

30,000 m. None

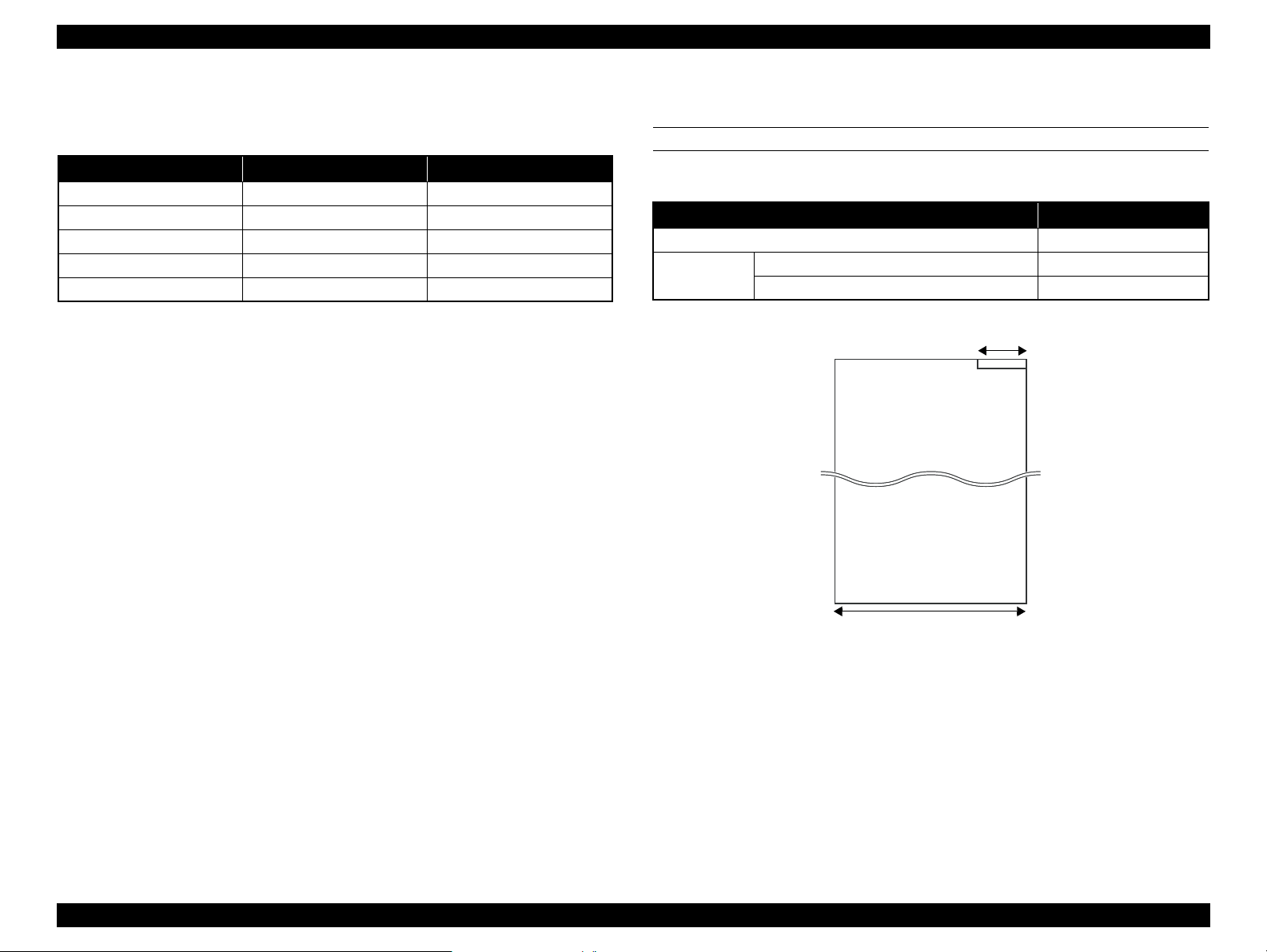

1.2.3 Paper size/Printable area

SUPPORTED PAPER SIZE/THICKNESS

The supported paper size and thickness are described below.

Item Value

Width

Thickness

When Head height adjustment lever is Low Max 0.3 mm

When Head height adjustment lever is High Max 1.3 mm

300 to 1625 mm

Figure 1-2. Supported Paper Size

PRODUCT DESCRIPTION Basic Specifications 16

Confidential

Page 17

EPSON Stylus Pro GS6000 Revision F

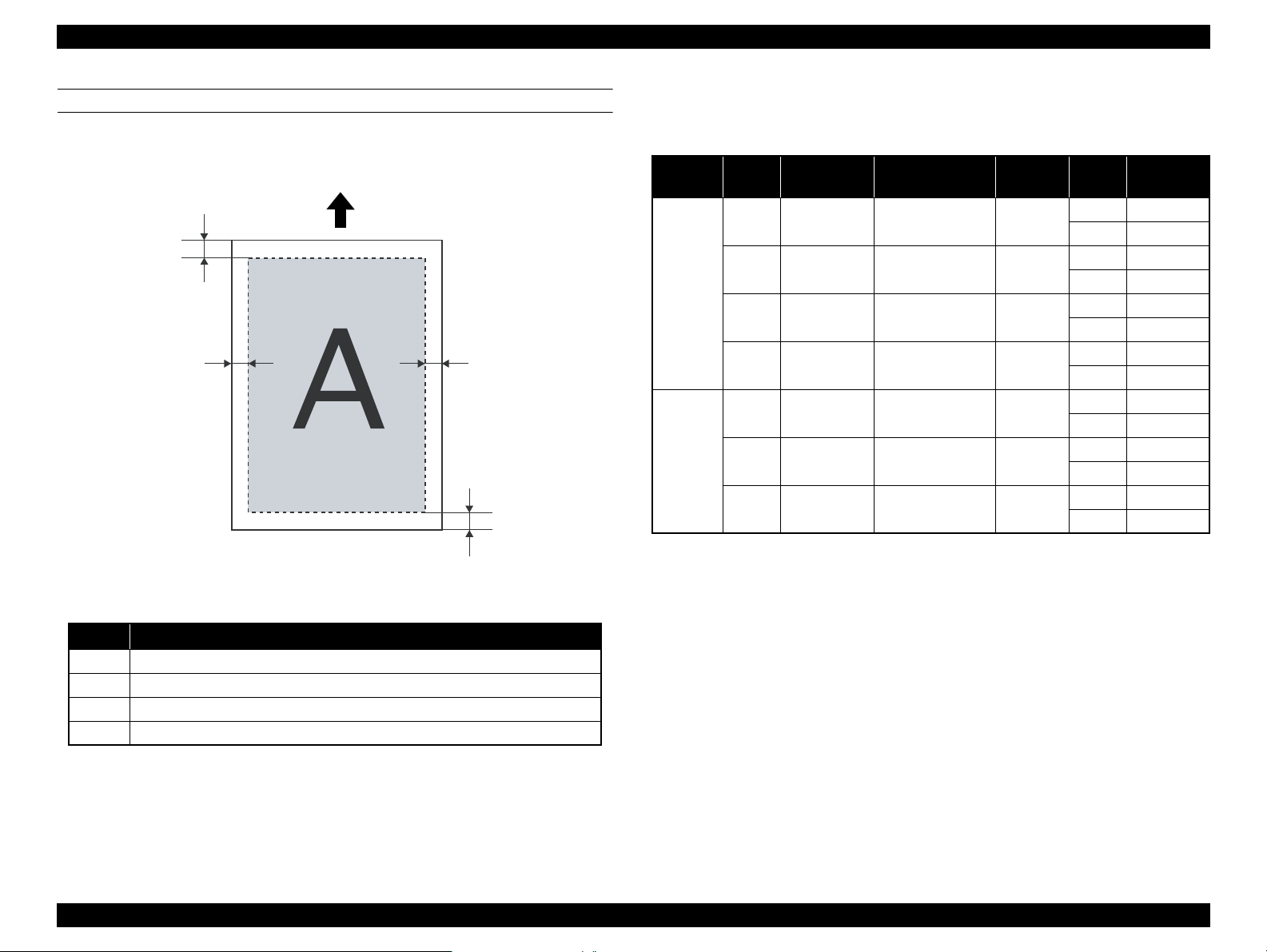

Unit: mm

C

B-R

B-L

A

Feed direction

PRINTABLE AREA

The printable area of this printer is described below.

1.2.4 Print Mode / Print Resolution

The table below lists the print mode and the resolution.

Media

Type

Marking

Film

Banner

Print

quality

Max

Quality

Quality

Quality

Quality

Speed 1 540x720dpi VSD1d-V(400cps) 3x2 pass

Speed 2 720x720dpi VSD1d-V(400cps) 2x2 pass

Speed 3 720x360dpi VSD1d-L(400cps) 2x1 pass

Print density

(HxV)

1440x1440dpi VSD3d-S(320cps) 4x4 pass

1440x720dpi VSD3d-V(320cps) 4x2 pass

1

720x720dpi VSD3d-V(400cps) 4x2 pass

2

540x720dpi VSD3d-V(400cps) 3x2 pass

3

Dot size

Pass

(CRxPF)

Uni/Bi

Uni-D 1.6

Uni-D 3.3

Uni-D 3.6

Uni-D 5.5

Uni-D 5.5

Uni-D 8.3

Uni-D 16.6

Throughput

2

(m

Bi-D 2.9

Bi-D 5.8

Bi-D 7.0

Bi-D 9.3

Bi-D 9.3

Bi-D 13.6

Bi-D 25.3

/h)

Item Value

A Min. 5 mm

B-L

B-R 5 to 25 mm

C

Min. 5 mm When end of the roll paper, the margin will be 77.4 mm.

Figure 1-3. Printable Area

5 to 25 mm

PRODUCT DESCRIPTION Basic Specifications 17

Confidential

Page 18

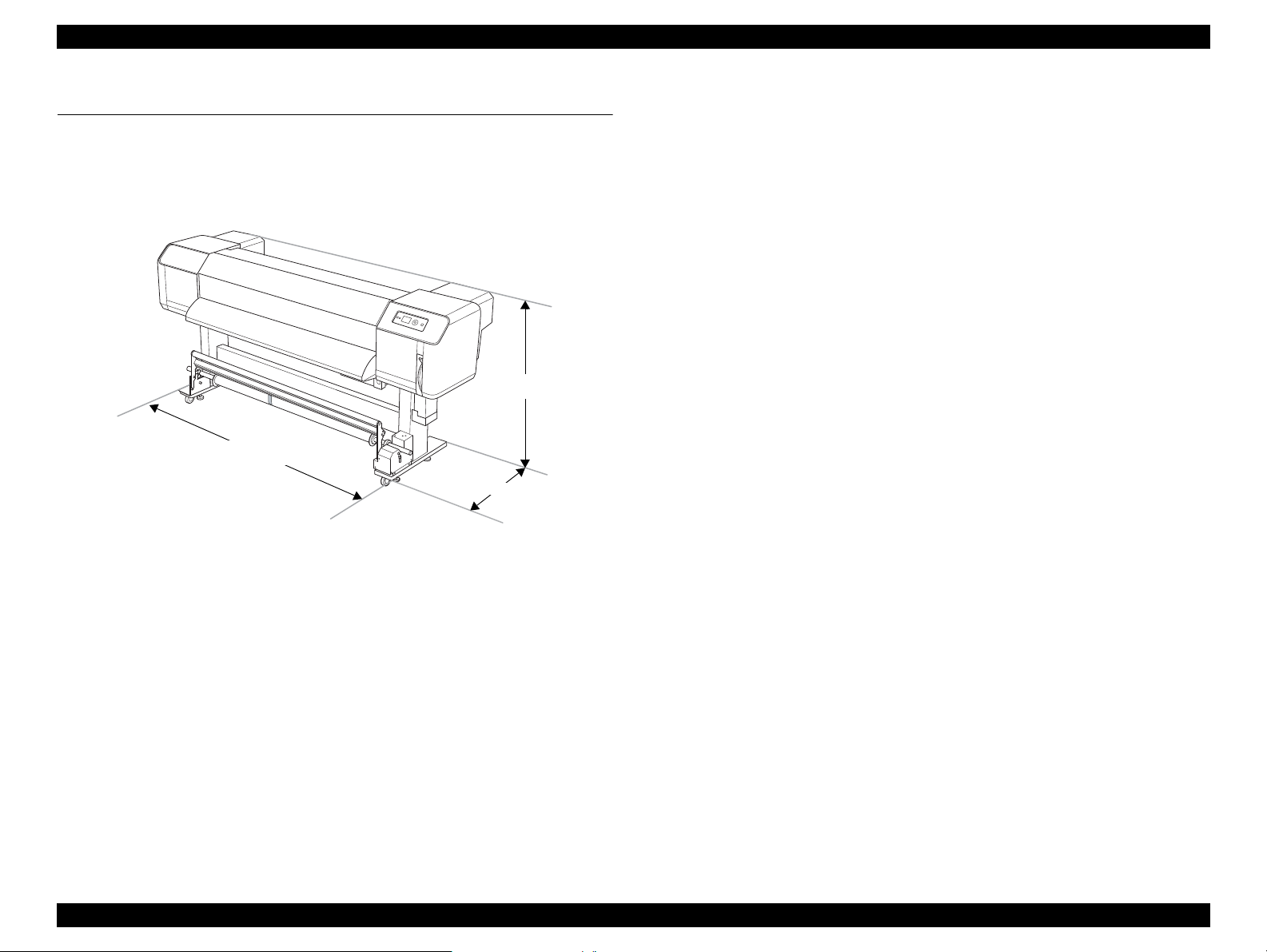

EPSON Stylus Pro GS6000 Revision F

1,045 mm

2,698 mm

1,267 mm

1.3 Dimensions and Main Components

This section describes the printer dimensions and the main components.

1.3.1 Dimensions and Weight

Figure 1-4. Printer Dimensions (standard)

Dimensions

Standard (wi th the Auto Take-up Reel Unit):

2,698 (W) x 1,045 (D) x 1,267 (H) mm

Without the Auto Take-up Reel Unit:

2,698 (W) x 943 (D) x 1,267 (H) mm

Weight

Printer main body and the Stand (excludes the ink cartridges and paper):

Approx. 183 kg

Printer main body only (excludes the ink cartridges and paper):

Approx. 150 kg

Auto Take-up Reel unit: Approx. 19 kg

PRODUCT DESCRIPTION Dimensions and Main Components 18

Confidential

Page 19

Epson Stylus Pro GS6000 Revision F

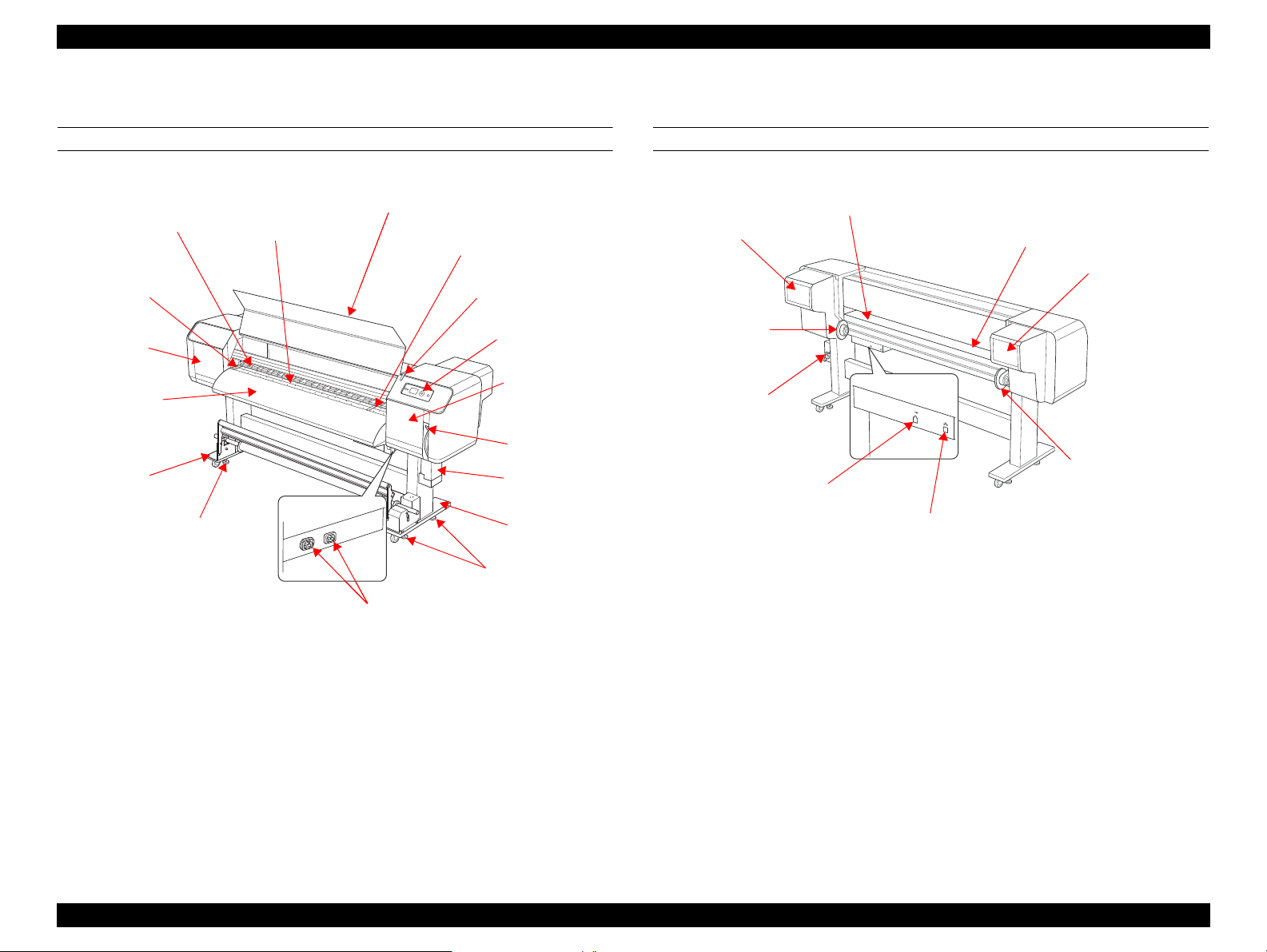

Pressure Rollers

Front Cover

Platen

Paper holder plate

Maintenance

Cover

Paper Guide

Front Cover

Paper Holder Plate

Active Indicator

Stand

Adjuster

AC inlet

Adjuster

Stand

Ink drain tank

Paper lever

Maintenance

Cover

Control panel

Paper Guide

Paper Feed Slot

Ink Cartridge

Compartment

Roll Paper Holders

Network Interface Connector

USB Interface Connector

Waste Ink Valve

Roll Paper Holders

Ink Cartridge

Compartment

1.3.2 Part Names

FRONT

Figure 1-5. Part Name (Front)

REAR

Figure 1-6. Part Name (Rear)

PRODUCT DESCRIPTION Dimensions and Main Components 19

Confidential

Page 20

EPSON Stylus Pro GS6000 Revision F

[Pause/Reset]

button

b

a

[Heater]

button

c

[Enter]

button

d

[Low Heat]

button

g

[High Heat]

button

h

[Power] button

[Paper Feed]

button

e

[Paper Feed]

button

e

[Menu]

button

f

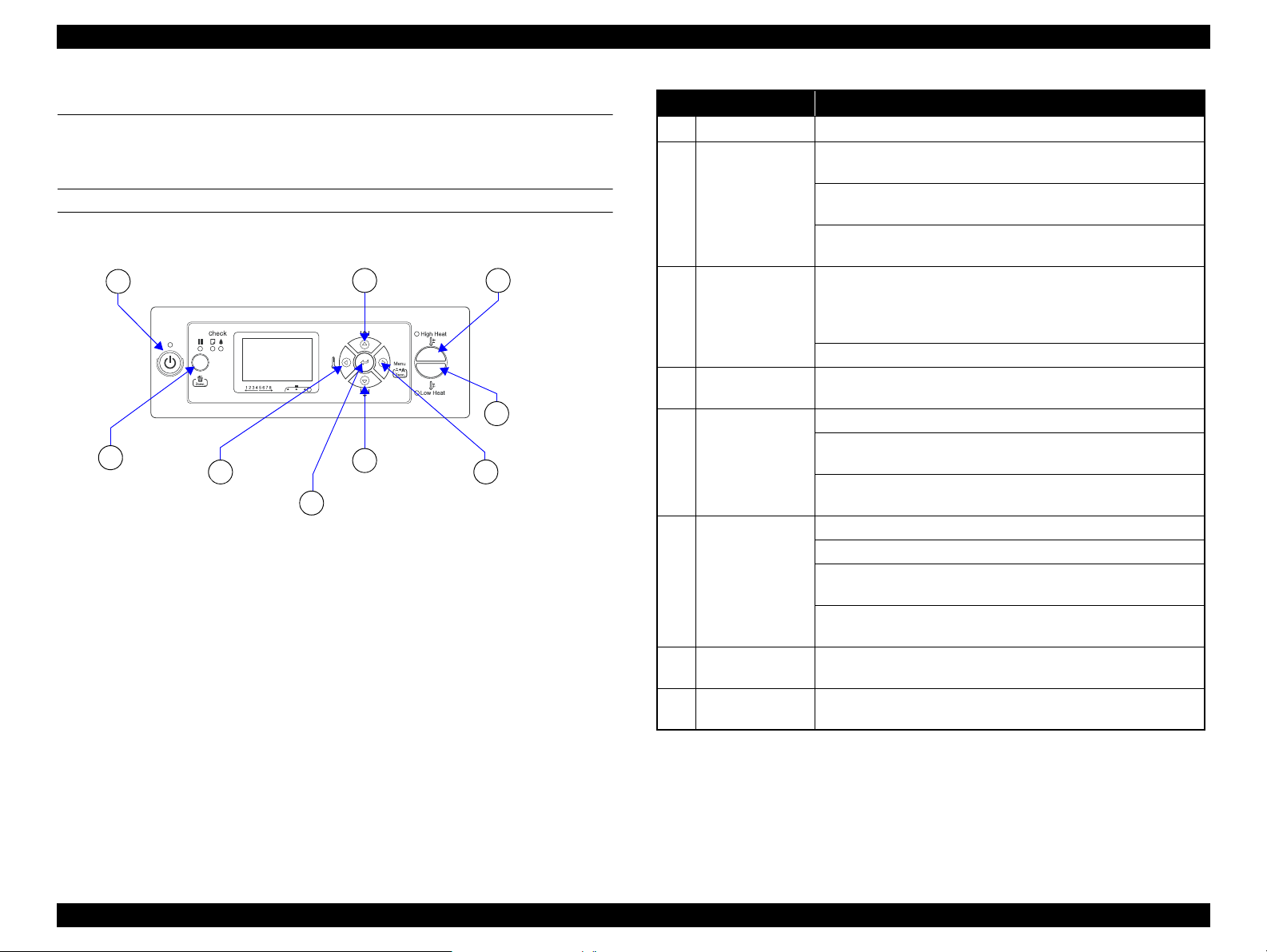

1.4 Control Panel

1.4.1 Buttons and Indicators

BUTTONS

Figure 1-7. Buttons

Button Name Function

a

b

c

d[Enter]

e [Paper Feed]

f [Menu]

g [Low Heat]

h [High Heat]

Note *1 : When AUTO TAKE-UP REEL is ON in the Menu mode, the roll paper cannot be

[Power]

[Pause/Reset]

[Heater]

fed in the reverse direction.

Turns the printer on or off.

Stops printing temporarily, or restarts printing if pressed when the

printer is in the pause mode.

Clears print data in the printer memory if pressed and held for

3 seconds.

The printer returns to the READY state when this button is

pressed in the Menu mode.

Selects a heater type. From the right, Pre Heater, Platen Heater,

and After Heater are displayed on the LCD panel. Select a heater

type, and then press the [High Heat] button or [Low Heat] button

to change the preset temperature.

Returns to the previous level when pressed in the Menu mode.

Sets the selected parameter in the selected item in the Menu mode.

Executes the item if the selected item is for execution only.

Feeds the roll paper in the forward or reverse direction.

Changes the parameter in the forward or reverse order when

selecting a desired parameter in the Menu mode.

The numeric value is decreased or increased during numerical

input.

Enters the Menu mode when pressed in the READY state.

Enters the Printer Status menu if pressed during printing.

Stops printing temporarily, or restarts When pressed in the Menu

mode, a desired menu can be selected.

Performs Cleaning (Light) to clean the print heads if pressed and

held for 3 seconds.

Decreases the preset temperature of the heater. You can also

change the preset temperature while printing.

Increases the preset temperature of the heater. You can also

change the preset temperature while printing.

*1

PRODUCT DESCRIPTION Control Panel 20

Confidential

Page 21

EPSON Stylus Pro GS6000 Revision F

Ink Check

light

Pause

light

b

Paper Check

light

c

d

Active indicator

g

Low Heat

light

e

Power light

a

High Heat light

f

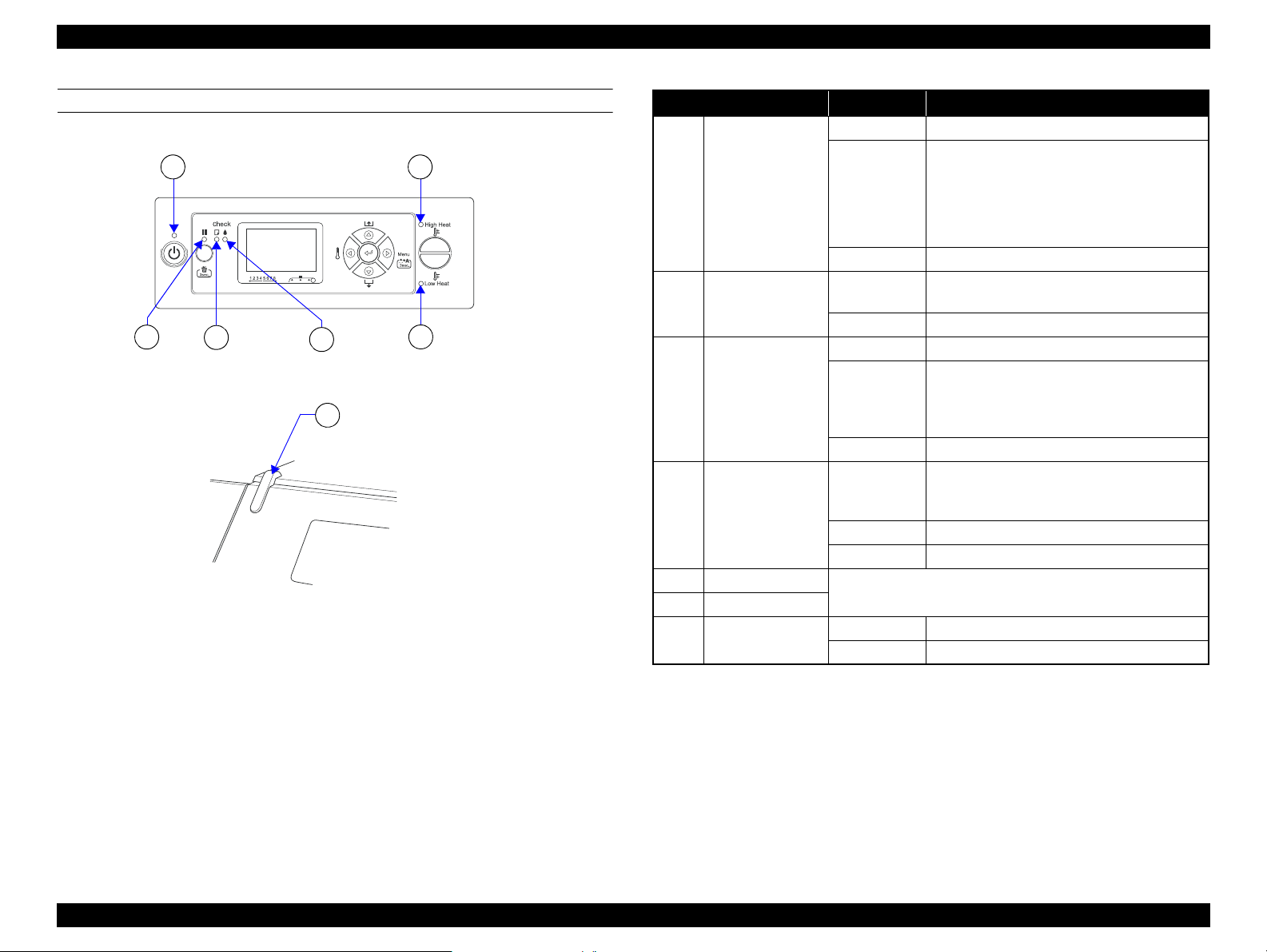

LIGHTS (LED)

Figure 1-8. Lights (LED)

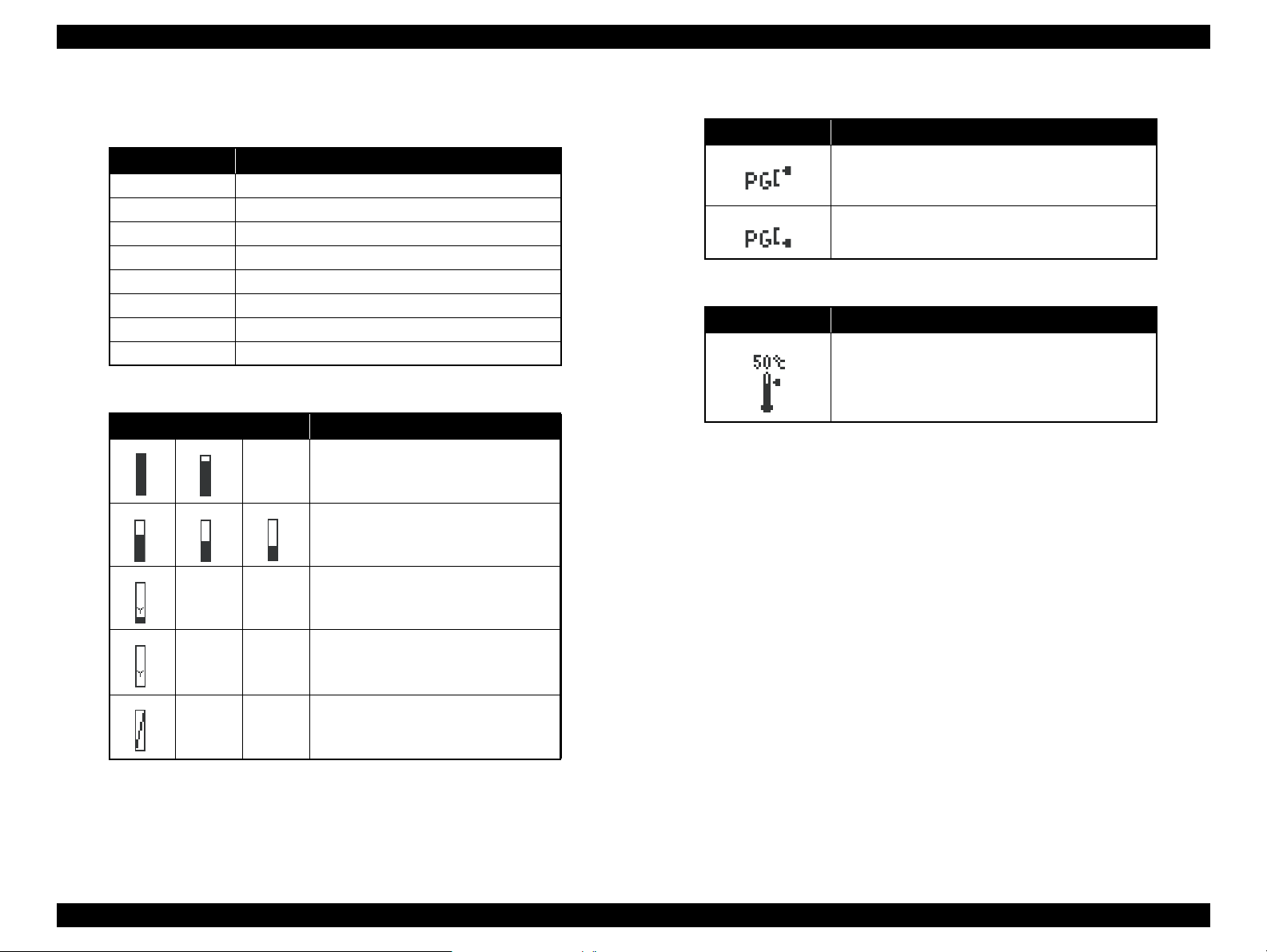

Name Status Description

Power light

a

b Pause light

c Paper Check light

d Ink Check light

e Low Heat light

f High Heat light

g Active indicator

On The printer is on.

The printer is:

• analyzing the data

Flashing

Off The printer is off.

On

Off The printer is ready to print data.

On No paper is loaded in the printer.

Flashing

Off The printer is ready to print data.

On

Flashing The installed ink cartridge is nearly expended.

Off The printer is ready to print data.

The status or the meaning is shown by combination of the light.

See ?<Combination of Low and High Heat Lights>? (p22).

Flashing An error has occurred.

Off The printer has no error.

• printing

• cleaning

• in process of turning off

The printer is in the Menu mode.

The printer is in the pause mode.

Paper is jammed.

Paper is not loaded straight.

Paper is nearly ended.

The maintenance call has occurred.

The installed ink cartridge is expended.

The ink cartridge is not installed.

The wrong ink cartridge is installed.

PRODUCT DESCRIPTION Control Panel 21

Confidential

Page 22

EPSON Stylus Pro GS6000 Revision F

a

b

c

d

e

<Combination of Low and High Heat Lights>

When the printer is READY

High Heat Low Heat Status

On On The three heaters have reached preset temperature.

Flashing Off

Flashing Flashing A heater error has occurred.

Off Off Heaters are off.

One or more of the heaters is/are trying to reach the preset

temperature.

When selecting a Heater to set the temperature.

High Heat Low Heat Status

On On

On Off

Off On

You can change the temperature to higher or lower than

the current setting.

You can change the temperature to higher than the current

setting.

You can change the temperature to lower than the current

setting.

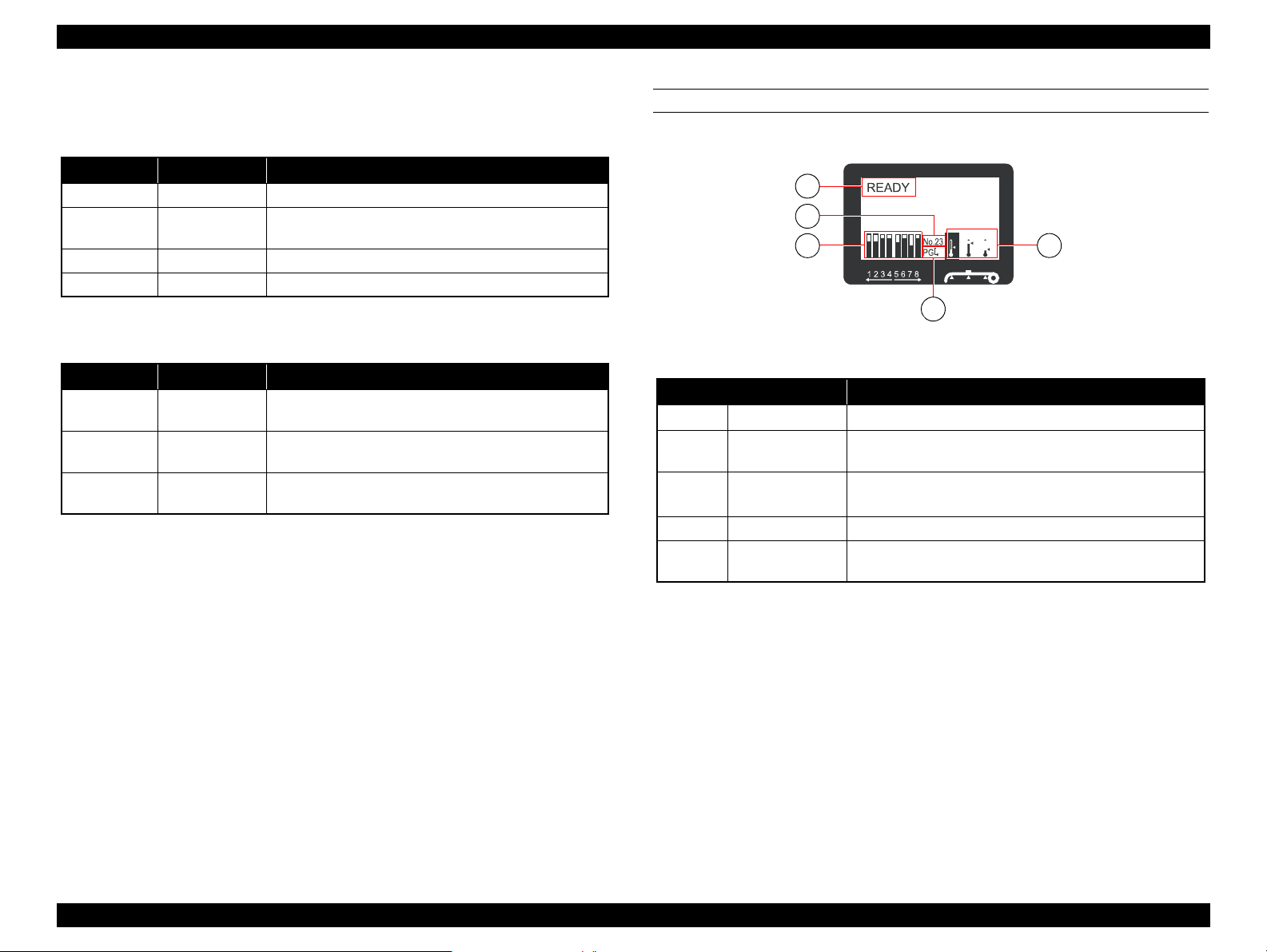

DISPLAY

Figure 1-9. Display

Name Description

a

b

c

d Platen Gap icon Displays the Platen Gap setting that is read by the sensor.

eHeater icon

Messages

Paper Type

Ink cartridge

status icon

Displays the printer status, operation, and error messages.

When you select paper type (1 to 30) in the Paper Setup

menu, the number you selected appears.

Displays the remaining amount of ink in each cartridge.

Displays the preset temperature and the current temperature

of the Pre Heater, Platen Heater, and After Heater.

PRODUCT DESCRIPTION Control Panel 22

Confidential

Page 23

EPSON Stylus Pro GS6000 Revision F

Ink cartridge status icon

Ink cartridges

No. Ink color

1 Orange (OR)

2 Green (GR)

3 Light Magenta (LM)

4 Light Cyan (LC)

5Black (BK)

6 Yellow (Y)

7Magenta (M)

8 Cyan (C)

Ink remaining

Icon Description

Platen Gap icon

Icon Explanation

High

Low

Heater icon

Icon Explanation

The preset temperature is indicated by the graduation

and the numerical value.

The current temperature is indicated by the

thermometer icon.

There is enough ink remaining.

We recommend you prepare a new ink

cartridge.

The icon flashes. The yellow ink cartridge

is nearly empty. Prepare a new ink

cartridge.

The ink is expended so you cannot print.

Replace the ink cartridge with a new one.

This icon indicates the yellow tank.

Cartridge error or no cartridge.

PRODUCT DESCRIPTION Control Panel 23

Confidential

Page 24

EPSON Stylus Pro GS6000 Revision F

1.4.2 Panel Settings

This section describes the panel settings that customers can change.

For the map of menu, see ?7.2 Panel Menu Map? (p259)

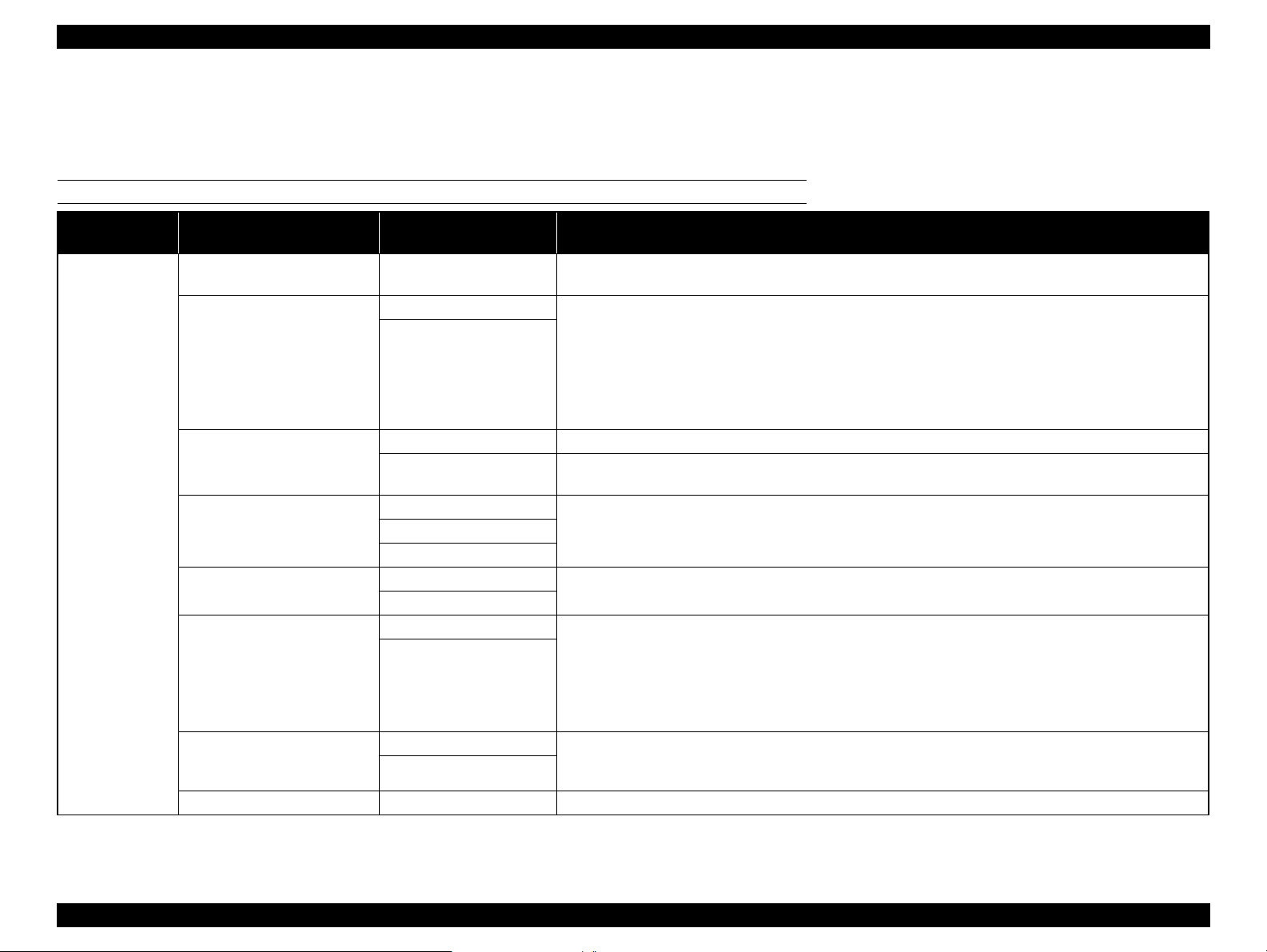

MENU LIST

.

Menu Item

SIDE MARGIN

PAPER SIZE CHECK

PAPER SKEW CHECK

PRINTER SETUP

PRINT NOZZLE PATTERN

HEATING TIME

FLUSH ONTO PAPER

FLUSING FREQUENCY

PAPER ORIGIN SETUP 0mm* - 800mm You can set the beginning of printing (origin) of the horizontal direction.

Parameter

(*: Default setting)

5mm* - 25mm

(0.2inch* - 1.00inch)

ON* You can select whether to check the paper width.

OFF

ON* If the paper is not straight, “PAPER SKEW” appears on the LCD panel and the printer stops printing.

OFF

OFF*

ON: EVERY PAGE

ON: EVERY 10 PAGES

OFF

10min* - 240min

YES* You can set up the flushing operation while printing.

NO

5PASS* You can set the frequency that the print head returns to the flushing box when setting YES in the FLUSH ONTO

1PASS - 999PASS

You can set the margin for left and right side.

ON:

Check the paper width and top edge of the paper.

NO:

Do not check the paper width and top edge of the paper. The printer continues to print even if the paper width

does not match the data width, and the printer may print beyond the paper. Because this soils the inside of the

printer, we recommend you select ON. This may result in a wider blank margin at the top of each page.

A paper align error does not occur even if the printed data is out of range of the paper, and the printer continues

to print.

When you select ON, the printer prints the nozzle check pattern before printing each print job or the 10th sheet,

depending on the setting you have set.

You can set the length of time to preheat the heaters. When more than the set time has passed after turning on

the printer or after printing is finished, each heater turns off.

YES:

The printer performs the flushing operation on the page margins. The printing speed improves since the

number of times to return to the flushing box is decreased.

NO:

Performs the flushing operation to return to the flushing box every time the print head goes and returns.

PAPER setting. (When you select 5PASS, the print head returns to the flushing box every time the print head

goes and returns five times.)

Explanation

PRODUCT DESCRIPTION Control Panel 24

Confidential

Page 25

EPSON Stylus Pro GS6000 Revision F

C A U T I O N

C H E C K

P O I N T

Menu Item

AUTO TAKE-UP REEL

HEAD FAN (COOLING FAN)

PRINTER SETUP

REGULAR CLEANING

ROLL PAPER COUNTER

INITIALIZE SETTINGS EXECUTE You can return all setting values you have made in the Printer Setup menu to their factory set value.

PAPER TYPE

PAPER SETUP

PAPER SETUP

Parameter

(*: Default setting)

Explanation

ON* Use this setting when using the Auto Take-Up Reel Unit. When ON is selected, you cannot feed the roll paper in

the reverse direction.

OFF

When the Auto Take-Up Reel Unit is not installed, do not set to ON. By doing so, the product will be

unable to function properly.

ON*

OFF

You can set up the head fan operation. If print blurring or dot losses occur, select ON.

OFF Yo u can set the auto cleaning interval of this printer. When more than the set time ha s passed since t he previ ous

print job, the print head is cleaned automatically to prevent it from clogging.

The timer will be reset at the following timing:

1h, 2h, 3h, 4h, 5h, 6h*,

9h, 12h, 18h, 24h

when turning on the printer

when changing the interval of the auto cleaning

when performing the cleaning manually

OFF* In this setting, the alert can be set off when the remaining paper falls below 2m. Enter the remaining amount

5 - 99.5m (15 - 300ft)

STANDARD*

PAPER No.1 - 30

(length) of paper currently set on the printer. This menu is displayed only when the REMAINING PPR SETUP

in Maintenance Mode is set to ON.

You can select the paper type to print.

STANDARD* When you select STANDARD, the default settings are used.

When you select a number (between 1 to 30), you can register the settings (such as Print Mode, Paper Feed

Adjust, Head Alignment, Pre Heater, Platen Heater, After Heate r, M/W Adjus tme nt, Paper Suction, Drying

PAPER No.1 - 30

Time, Carriage Movement, Print Multiple Layer) or to recall these settings you have made. The number you

select here is displayed on the LCD panel.

See ?Details of PAPER SETUP? (p29).

PRODUCT DESCRIPTION Control Panel 25

Confidential

Page 26

EPSON Stylus Pro GS6000 Revision F

C H E C K

P O I N T

Menu Item

CLEANING (VERY LIGHT) EXECUTE You can perform very light cleaning. It discharges a smaller amount of ink compared to CLEANING (LIGHT).

CLEANING (LIGHT) EXECUTE You can perform normal cleaning. Select this mode normally.

CLEANING (MEDIUM) EXECUTE

MAINTENANCE

CLEANING (HEAVY) EXECUTE

HEAD WASHING EXECUTE

CARRIAGE MAINTENANCE EXECUTE The carriage will move into a position allowing you to clean the cleaning wiper and around the print head.

MAINTENANCE

CLOCK SETTING MM/DD/YY HH:MM You can set year, month, date, hour, and minute.

CONTRAST ADJUSTMENT -20 - 0 - +20 You can adjust the contrast of the LCD panel.

NOZZLE CHECK PRINT

STATUS SHEET PRINT You can print the current printer status.

TEST PRINT

NETWORK STATUS SHEET PRINT You can print the current network status.

JOB INFORMATION PRINT You can print the job information saved in the printer (up to 10 jobs).

CUSTOM PAPER PRINT You can print custom paper information registered in the Paper Setup menu.

Parameter

(*: Default setting)

Explanation

You can perform strong cleaning. It discharges a larger amount of ink compared to CLEANING (LIGHT). Use

this mode when the print head clog situation does not improve by CLEANING (LIGHT).

You can perform stronger cleaning. It discharges a larger amount of ink compared to CLEANING (MEDIUM).

Use this mode when the print head clog situation does not improve by CLEANING (MEDIUM).

You can perform the head washing.

Cleaning cartridge (option) is needed to perform head washing.

You can print a print head nozzle check pattern for each ink cartridge. It also prints the firmware version and the

ink usage.

PRODUCT DESCRIPTION Control Panel 26

Confidential

Page 27

Epson Stylus Pro GS6000 Revision F

Menu Item

VERSION T0xxxx-xx xx IBCC You can see the firmware version.

PRINTABLE PAGES (ink color) nnnnnn PAGES Yo u can see the number of pages printable for each ink cartridge.

INK LEVEL (ink color) nn% You can see the status of each ink cartridge.

USAGE COUNT

CLEAR USAGE COUNT

PRINTER

STATUS

JOB HISTORY

TOTAL PRINTS nnnnnn PAGES You can see the total amount of pages you have printed.

EDM STATUS

Parameter

(*: Default setting)

INK xxxxx.xml

PAPER xxxxx.xcm

INK EXECUTE

PAPER EXECUTE

No. 0-No. 9

INK xxxxx.xml

PAPER xxx.x cm2

NOT STARTED,

ENABLED, DISABLED

LAST UPLOADED

MM/DD/YY HH:MM GMT,

(NOT UPLOADED)

Explanation

You can see the ink consumption in milliliters and paper consumption amount in centimeters. Values shown in

USAGE COUNT are rough indications.

You can clear the values set in USAGE COUNT.

You can see ink consumption (INK) in milliliters and paper size (PAPER) for e ach print job saved in t he printer.

The latest job is saved as No. 0.

You can see if the EDM is enabled or disabled. If the EDM is enabled, the time that the EDM status was last

uploaded is displayed.

PRODUCT DESCRIPTION Control Panel 27

Confidential

Page 28

Epson Stylus Pro GS6000 Revision F

Menu Item

NETWORK SETUP

IP ADDRESS SETTING

NETWORK

SETUP

IP, SM, DG SETTING

BONJOUR

INIT NETWORK SETTING EXECUTE You can return the network settings of the printer to the factory default value.

Parameter

(*: Default setting)

DISABLE You can configure the network setting of the printer. The following items appear only when ENABLE is

selected. After setting the items, press the button in the Network Setup menu, so the network is reset and the

ENABLE

AUTO

PANEL

IP ADDRESS

000.000.000.000 -

192.168.192.168* -

255.255.255.255

SUBNET MASK

000.000.000.000 -

255.255.255.000* -

255.255.255.255

DEFAULT GATEWAY

000.000.000.000 -

255.255.255.255*

ON

OFF

network connection is available after 15 seconds. The Network Setup menu does not appear while resetting the

network.

You can select the method to set the IP address to the printer. When you select PANEL, IP, SM, DG SETTING

appears.

You can change settings of IP address, subnet mask, and default gateway.

You can enable or disable the Bonjour setting.

Explanation

PRODUCT DESCRIPTION Control Panel 28

Confidential

Page 29

Epson Stylus Pro GS6000 Revision F

a

b

c

C H E C K

P O I N T

Details of PAPER SETUP

After you have selected the paper number, make the following settings.

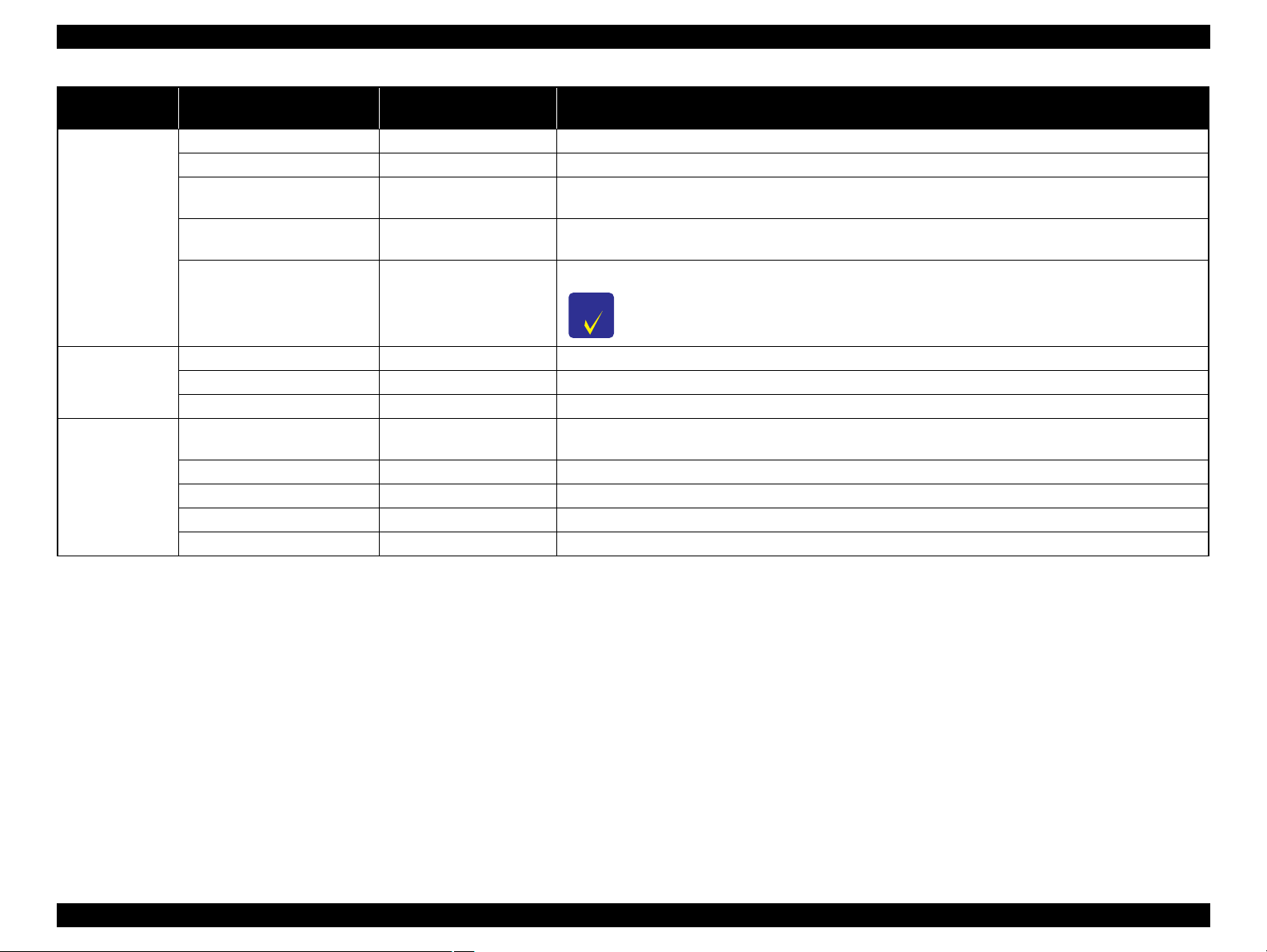

Item Parameter Explanation

MAX QUALITY You can select the print quality (print mode) according to the usage of print data or print speed.

QUALITY1

QUALITY2

QUALITY3

PRINT MODE

SPEED1

SPEED2

SPEED3

PAPER FEED ADJUST

LINE FEED ADJUST

PRINT SAMPLE PATTERN

HEAD ALIGNMENT BI-D ALL You can perform print head alignment. Check the pattern and enter the value that has the smallest gaps.

OFF You can set the Pre Heater temperature. The Pre Heater is located under the rear paper guide. Set up to preheat

MAX QUALITY, QUALITY1, QUALITY2:

Performs high-quality printing. Use this mode when printing high quality graphic data that includes photo

data. MAX QUALITY provides priority to print quality. QUALITY1 is balanced between quality and

efficiency. QUALITY2 provides priority to print efficiency.

QUALITY3:

Performs standard printing. Use this mode when printing graphic data.

SPEED1, SPEED2, SPEED3:

Performs high-speed printing. Use this mode when printing text or graphics. SPEED1 provides priority to

print quality. SPEED2 is balanced between quality and efficiency. SPEED3 provides priority to print

efficiency.

You can set the paper feed amount of the printable area. If the paper feed value is too large, white horizontal

micro-banding may appear. If the paper feed value is too small, dark horizontal micro-banding may appear.

the paper before printing and insulate the temperature change in the printer section.

PRE HEATER

30oC to 50oC (86oF to 122oF)

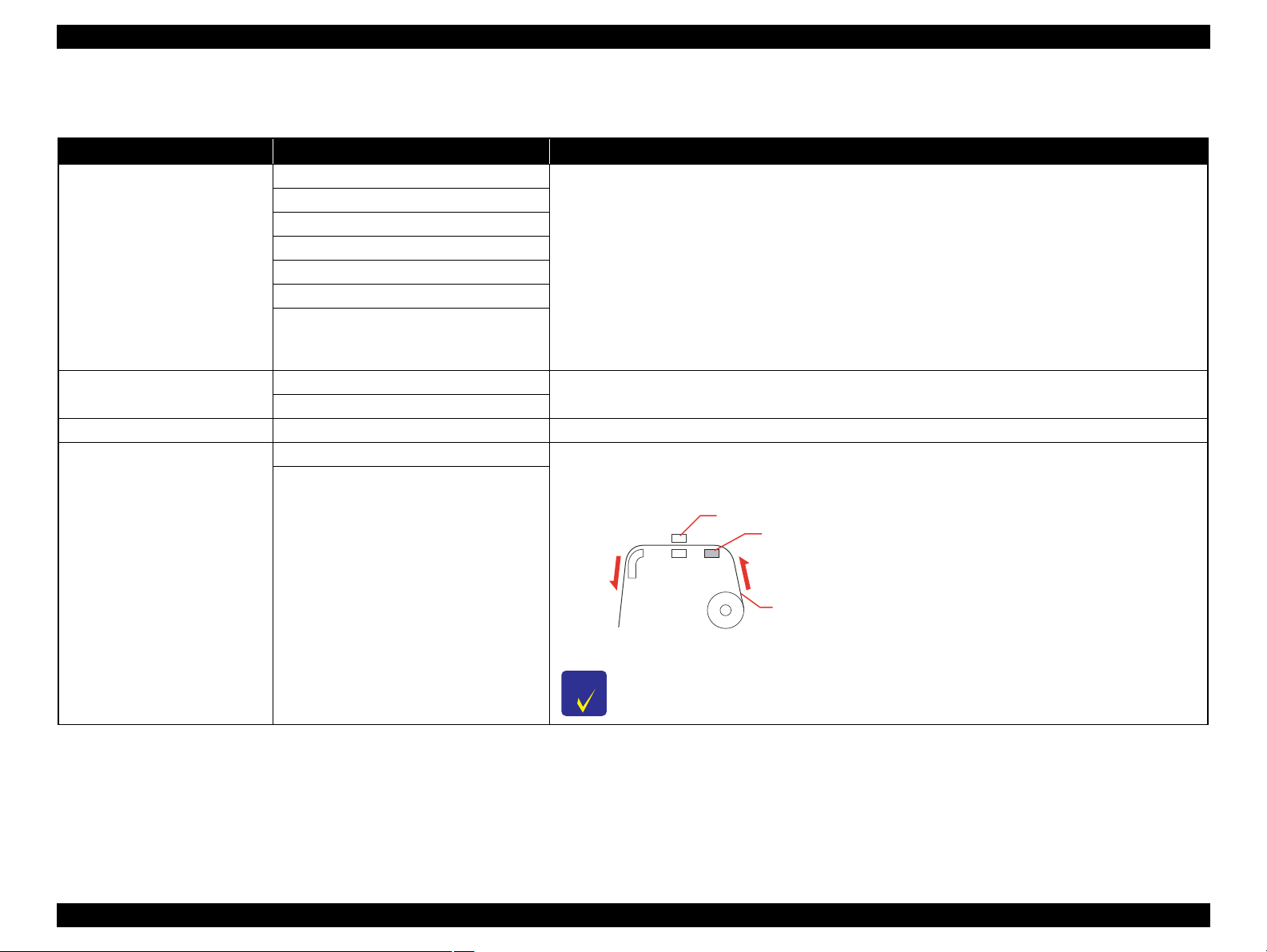

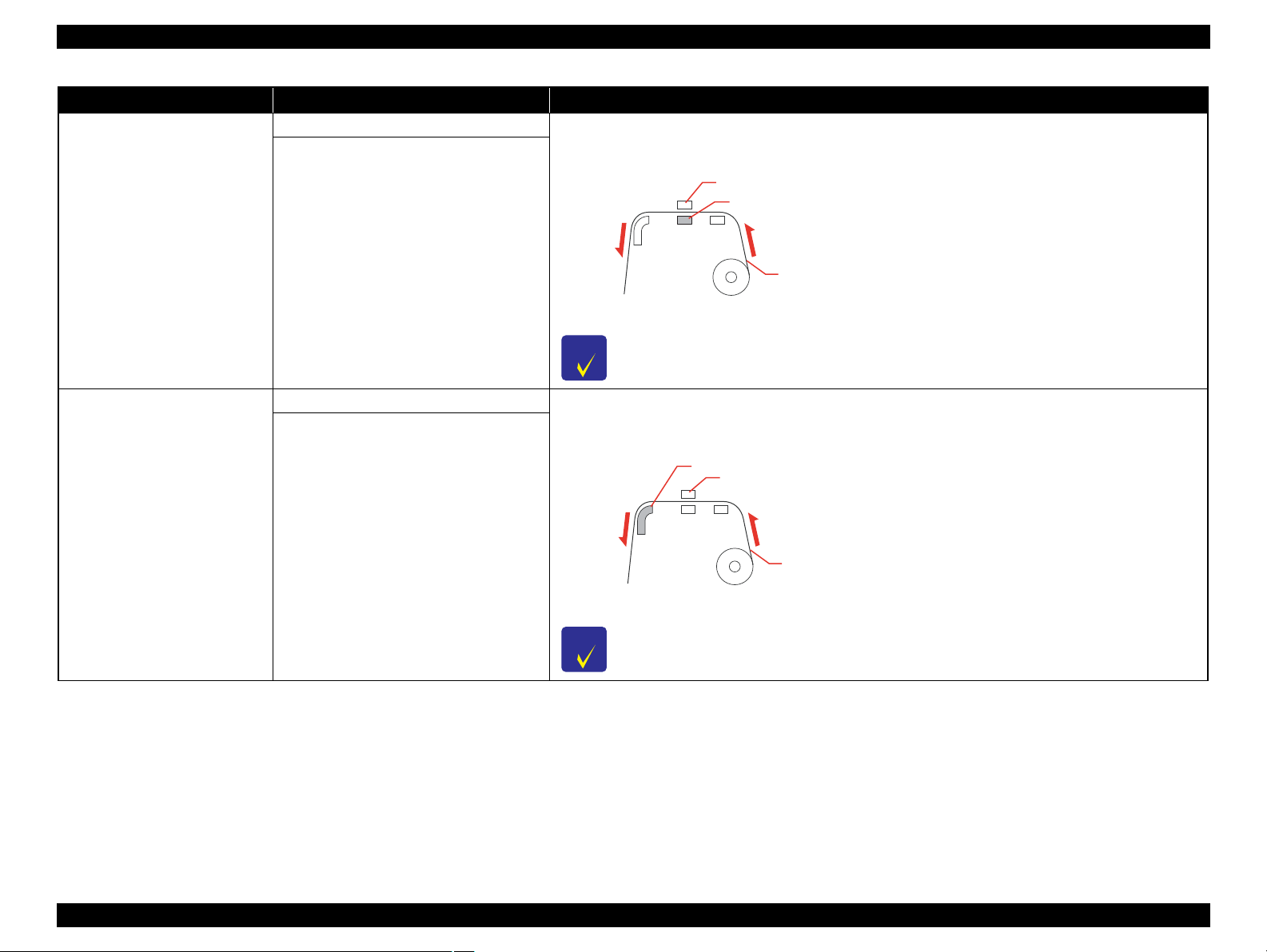

a. Print head, b. Pre Heater, c. Roll paper

For appropriate temperatures to set to this function, see the instructions included with the paper, or

contact your supplier.

PRODUCT DESCRIPTION Control Panel 29

Confidential

Page 30

Epson Stylus Pro GS6000 Revision F

a

b

c

C H E C K

P O I N T

a

b

c

C H E C K

P O I N T

Item Parameter Explanation

OFF You can set the Platen Heater temperature. The Platen Heater is locate d und er the print heads. Set this menu to

warm up ink and improve print quality.

PLATEN HEATER

AFTER HEATER

30oC to 50oC (86oF to 122oF)

a. Print head, b. Platen Heater, c. Roll paper

For appropriate temperatures to set to this function, see the instructions included with the paper, or

contact your supplier.

OFF You can set the After Heater temperature. The After Heater is located under the front paper guide. Set this menu

to dry printed paper.

30oC to 50oC (86oF to 122oF)

a. After Heater, b. Print head, c. Roll paper

For appropriate temperatures to set to this function, see the instructions included with the paper, or

contact your supplier.

PRODUCT DESCRIPTION Control Panel 30

Confidential

Page 31

Epson Stylus Pro GS6000 Revision F

C A U T I O N

Item Parameter Explanation

LOW A to B You can improve the print quality by adjusting the print mode you have set.

MEDIUM A to D

HIGH A to D

M/W ADJUSTMENT

(Micro Weave Adjustment)

EXTRA HIGH A to B

PAPER SUCTION

HIGH

LOW

DRYING TIME 0.0sec to 10.0sec

LOW A, B:

The effect of M/W Adjustment function will be minimized. If obvious white lines or uneven print density

appear on printed paper in LOW A, set to LOW B.

MEDIUM A, B, C, D:

The printing joint between two head passes will have a wave form. If obvious white lines or uneven print

density appear on printed paper in MEDIUM A, print samples using the other settings and select the best print

result from MEDIUM B to MEDIUM D.

HIGH A, B, C, D:

Perform printing at a slow speed compared with “MEDIUM”. Set up this menu when improving the print

quality compared with “MEDIUM”. If obvious white lines or uneven print density appear on printed paper in

HIGH A, change the setting to the one with the best print result in HIGH B to HIGH D.

EXTRA HIGH A:

Performs “MEDIUM” printing using half of the nozzles of the print head. Since only a half of the nozzles is

used, printing speed becomes half of MEDIUM A to MEDIUM D. Set up this menu when improving the print

quality compared with HIGH A to HIGH D.

EXTRA HIGH B:

Performs “MEDIUM” printing using the other half of the nozzles of the print head that is used for EXTRA

HIGH A. Since only a half of the nozzles is used, printing speed becomes half of MEDIUM A to MEDIUM D.

Set up this menu when improving the print quality compared with HIGH A to HIGH D.

You can set the suction pressure used to feed the printed paper.

You can set the ink drying time for each print head pass. The range is 0 to 10 seconds. Depending on the ink

density, paper type or printing speed, the ink does not dry soon. In this case, set the drying time longer.

When you set the drying time longer, missing dots might occur in the printing.

DATA WIDTH You can set the range that the print head moves while printing.

DATA WIDTH:

The print head moves between the print data width. This improves the print speed since decreasing the

CARRIAGE MOVEMENT

PRINTER FULL WIDTH

transferring range of the print head.

PRINTER FULL WIDTH:

The print head moves from origin to the maximum paper width. This keeps printing quality the same even though

the printing size (width) differs.

PRINT MULTIPLE LAYER

OFF

2 to 8

You can set the overwrite count per line.

PRODUCT DESCRIPTION Control Panel 31

Confidential

Page 32

Epson Stylus Pro GS6000 Revision F

1.4.3 Maintenance Mode

You can change the language or unit used on the display or return all the setting values

to their factory default.

HOW TO ENTER & EXIT

1. Turn off the printer by pressing the [Power] button.

2. Turn the printer on while pressing the

3. To exit the Maintenance mode, press the [Power] button to turn off the printer.

MAINTENANCE MODE LIST

Item Parameter Explanation

ENGLISH

FRENCH

ITALIAN

LANGUAGE

LENGTH UNIT

THERMOMETER UNIT

GERMAN

SPANISH

PORTUGUE

DUTCH

JAPANESE

METRIC

FEET/INCH

o

C

F

[Pause/Reset] button.

You can select the language to be

displayed on the LCD panel.

You can select a unit of measurement

to use to display length.

You can select a thermometer unit.

Item Parameter Explanation

DEFAULT PANEL EXECUTE

CUSTOM 0 - 255 Not available currently.

OFF ROLL PAPER COUNTER menu is

REMAINING PPR SETUP

ON

You can set all setting values you

made in the Menu mode to their

factory set value.

added to the PRINTER SETUP menu

when set to ON.

PRODUCT DESCRIPTION Control Panel 32

Confidential

Page 33

Epson Stylus Pro GS6000 Revision F

C A U T I O N

1.4.4 Serviceman Mode

This printer has the Serviceman Mode which is provided for serviceman to

troubleshoot problems and so on. This section explains how to enter into the

Serviceman mode.

See ?7.2 Panel Menu Map? (p259) for explanation about menus provided in the mode.

Do not disclose the Serviceman Mode to the users.

HOW TO ENTER THE SERVICEMAN MODE

1. Turn off the printer by pressing the [Power] button.

2. Turn the printer on while pressing the

[Menu] buttons.

3. To exit the Serviceman mode, press the [Power] button to turn off the printer.

[Pause/Reset], [Paper Feed ], and

PRODUCT DESCRIPTION Control Panel 33

Confidential

Page 34

Epson Stylus Pro GS6000 Revision F

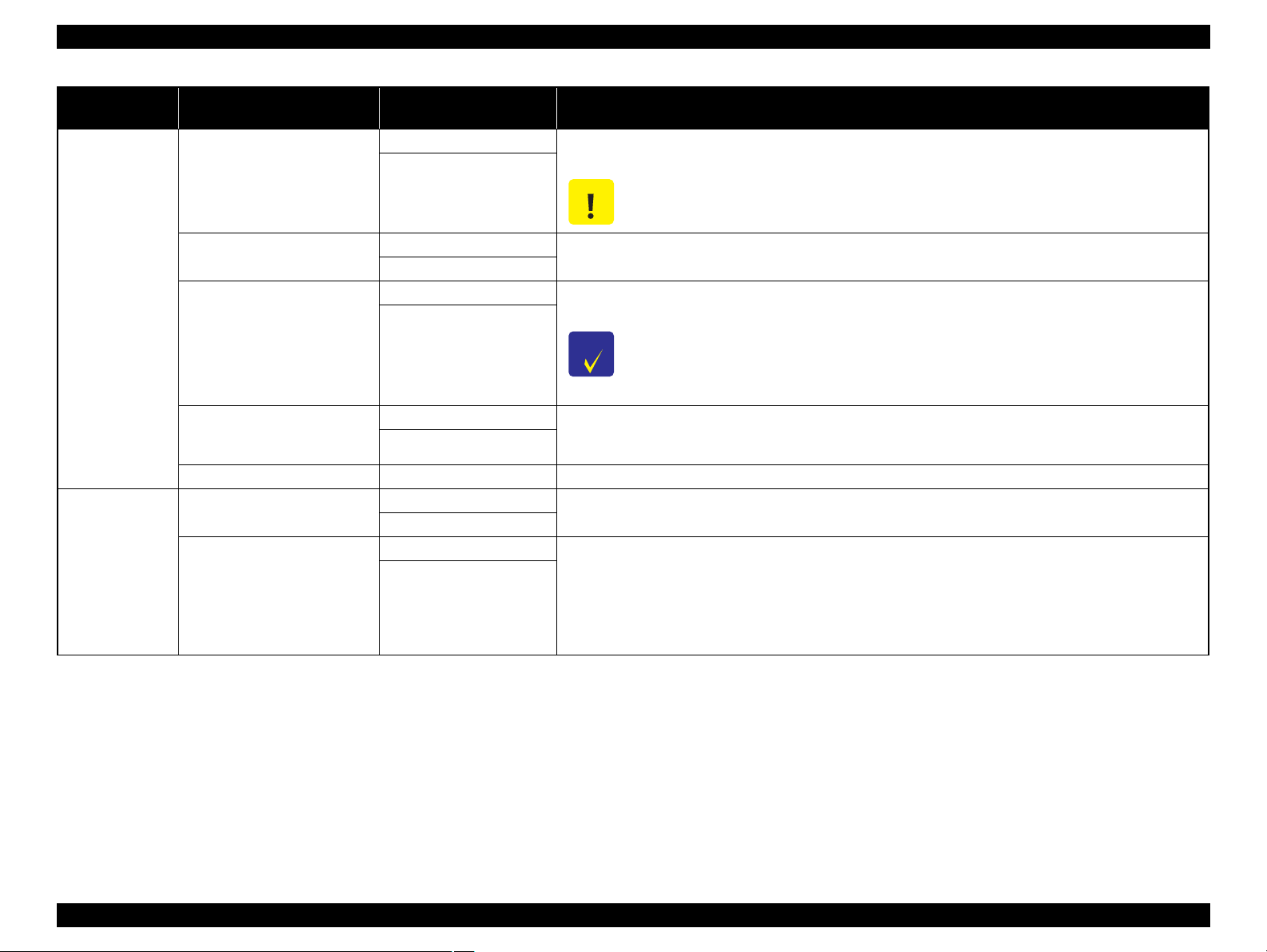

MENU LIST

Table 1-1. Menu List

Menu Explanation

F/W

BOOT

Pram1

Pram2

Serial No.

USB Serial No.

Key

LCD

LED

Printer Check LED

Paper Lever

Mtank

Cartridge Not

Rear AD

Head Temp

Drv Temp

PG

CR Origin

EdgeAD

Paper (All)

Paper (Duty)

Paper1

Paper2

Paper3

Paper4

HT Fan

Head Fan 1

Head Fan2

Displays the F/W version and other parameters.

Checks the operation of the control panel and active indicator.

Checks the sensors operation.

Checks the fans operation.

Test

Version

Panel

Sensor

Encoder CR/PF Checks the encoders operation.

Fan

PRODUCT DESCRIPTION Control Panel 34

Confidential

Page 35

Epson Stylus Pro GS6000 Revision F

Table 1-1. Menu List

Menu Explanation

Actuator CrLock Sol. Checks the CR Lock Solenoid.

CtrlVer.AP

CtrlVer.PCB

1

2

3

CtrlSns.Tank

CtrlSns.Etc

Mist Fan

Box Fan Checks the box fan (cooling fan PE) operation.

Pre.Heater

Platen.Heater

After.Heater

4

5

6

7

8

Mainte Cover Displays the open/close status of the maintenance cover.

Ink Cover Displays the open/close status of the ink cover.

Front Cover Displays the open/close status of the ink cover.

Pre. Heater

After. Heater

Mist Fan All

Mist Fan 1

Mist Fan 2

Mist Fan 3

Pre. Heater 1

Pre. Heater 2

Pre. Heater 1

Pre. Heater 2

Pre. Heater 1

Pre. Heater 2

Displays the heater control board version.

Display the status of the sub tank sensors.

Displays the temperature sensed for each heater posi tion.Platen. Heater

Checks the mist (cooling) fans operation.

Check if the heaters are warming correctly.

Test

Ctrl.Ver

Ctrl.Sns

Ctrl.Test

Ctrl.Fan

Ctrl.Heater

PRODUCT DESCRIPTION Control Panel 35

Confidential

Page 36

Epson Stylus Pro GS6000 Revision F

Table 1-1. Menu List

Menu Explanation

Valve1 On

Valve2 On

Valve3 On

Valve4 On

Valve5 On

Valve6 On

Valve7 On

Valve8 On

Valve1 On

Valve2 On

Valve3 On

Valve4 On

Operates the solenoids of the sub tank valves.

Operates the solenoids of the ink valves.

Displays the error history in reverse chronological order.

Sets the temperature of the heaters.

(The settings are cancelled when exiting the Serviceman Mode)

Test

Adjustment

Tank Valve

Ctrl.Test Ctrl.Actuator

Ink Valve

Ink Pump Rotates the pump motors.

Wiper Operates the wiper (head cleaner).

Error0

Error1

Error History

Edge Sns Lvl Adjusts the media side detection sensor.

CR Origin Adjust Adjusts the CR HP sensor position.

Platen Adjust Used in the factory to warm the platen in a way to do a precise horizontal adjustment.

Heater Temp

Rear AD Adjusts AD value of the paper rear sensor.

Init.Fill Executes the initial ink charge.

Nozzle Check Output Pattern Prints the nozzle check pattern.

Error2

Error3

Error4

Error5

Pre Heater Temp

Platen Heater Temp

After Heater Temp

PRODUCT DESCRIPTION Control Panel 36

Confidential

Page 37

Epson Stylus Pro GS6000 Revision F

Table 1-1. Menu List

Menu Explanation

Nozzle Alignment Output Pattern Checks the nozzle alignment.

Adjust

Confirm

VSD1 400

VSD3 320

VSD3 400

ALL

VSD1 400

VSD3 320

VSD3 400

ALL

VSD1 400

VSD3 320

VSD3 400

ALL

VSD1 400

VSD3 320

VSD3 400

ALL

Prints the CR head slant adjustment pattern.

Runs the gap adjustment.

Configures the durability test settings of the mechanism.

Head Slant

Skew Check Runs the skew check.

Feed Adj. +Side Runs the paper feed & side adjustment.

Adjustment

Gap Adj.

Print Adj.Variable Prints the adjustment variables.

All Pattern Prints the all adjustment patterns.

Life CR Motor

CR Head Slant

PF Head Slant Prints the PF head slant adjustment pattern.

Uni-D Low

Bi-D Low

Uni-D High

Bi-D High

Speed CW

Speed CCW

PageSize

Paper Fan

Head Fan

LifeCount

PRODUCT DESCRIPTION Control Panel 37

Confidential

Page 38

Epson Stylus Pro GS6000 Revision F

Table 1-1. Menu List

Menu Explanation

PF Motor

Pump

Head Fan

CR Lock

Life

Ink Valve

Tank Valve

FeedAmount

LifeCount

Pump Speed

LifeCount

Head Fan1 ON Time

Head Fan1 OFF Time

Head Fan2 ON Time

Head Fan2 OFF Time

LifeCount

WaitTime(Sec.)

LifeCount

Valve1 On

Valve2 On

Valve3 On

Valve4 On

Valve All On

Sol. ON Time

Sol. OFF Time

LifeCount

Valve1 On

Valve2 On

Valve3 On

Valve4 On

Valve5 On

Valve6 On

Valve7 On

Valve8 On

Valve All On

Configures the durability test settings of the mechanism.

PRODUCT DESCRIPTION Control Panel 38

Confidential

Page 39

Epson Stylus Pro GS6000 Revision F

Table 1-1. Menu List

Menu Explanation

Feed

Status

Key: Backward

Key: Forward

Feeds the paper to backward or forward.

Displays the following statuses.

Ink remaining

Set status of ink cartridge

PG status

Cover status

PRODUCT DESCRIPTION Control Panel 39

Confidential

Page 40

OPERATING PRINCIPLES

CHAPTER

2

Confidential

Page 41

Epson Stylus Pro GS6000 Revision F

2.1 Glossary

This chapter provides description of operation principles. To begin with, the

abbreviations used in this chapter are explained below.

Abbreviation Full Spelling

CR Carriage

F Front

HP Home Position

IC

M Maintenance

P Edge Paper Edge

P/S Power Supply

PE Paper End

PF Paper Feed

PG Platen Gap

Ink Cartridge

OPERATING PRINCIPLES Glossary 41

Confidential

Page 42

Epson Stylus Pro GS6000 Revision F

2.2 Ink System

Diagram Name Description

1 Ink Cartridges

2 Two-way valves

3 Sub Tanks

4 Valve Assembly

5 Print Heads

6 Head Cleaner Cleans the nozzle surface of the Print Head.

7 Flushing Box The box where the ink is flushed.

8 Pump Assys The pumps to suck ink.

9 Caps Cap the Print Heads to protect thei r nozzl e surfac es.

The cartridges storing ink.

They mount CSIC.

The valves are located in the ink flow between the Ink

Cartridges and the Sub Tanks.

Relays ink, are located between the Ink Cartridges and

the Print Head.

They prevent stopping printing due to an ink end

during printing operation.

The valves are driven by solenoids. They operate when

carrying out the initial ink charge.

The Carriage Unit has two print head mounted. Each

head has eight 180 nozzle-rows.

Figure 2-1. Ink System

OPERATING PRINCIPLES Ink System 42

Confidential

Page 43

Epson Stylus Pro GS6000 Revision F

2.3 Carriage Mechanism

Figure 2-2. Carriage Mechanism

Diagram Name Description

1 CR Motor The motor to drive the Carriage Unit.

2 CR Lock

3 CR Encoder

4 CR Cursor Assy The unit mounting the Print Heads.

5 CR Belt

6 CR Reduction Belt Conveys the drive force of the CR motor to the CR Bel t.

Locks the Carriage Unit to the home position. It is

driven by a solenoid.

Detects the scale patterns to control the position of the

Carriage Unit.

Conveys the drive force of the CR Motor to the

Carriage Unit.

OPERATING PRINCIPLES Carriage Mechanism 43

Confidential

Page 44

Epson Stylus Pro GS6000 Revision F

䎳䎤䎳䎨䎵䎃䎯䎨䎹䎨䎵

2.4 Paper Feed Mechanism

Figure 2-3. Paper Feed Mechanism

Diagram Name Description

1 PF Encoder Detects the scale patterns to control the paper feeding.

2 PF Motor The motor to drive the Feed Roller.

Hold and feed paper. By switching the Paper Lever up

3 Pressure Rollers

4 PF Reduction Belt

and down, they separate from the Feed Roller or move

back in position.

Conveys the drive force of the PF motor to the Feed

Roller.

OPERATING PRINCIPLES Paper Feed Mechanism 44

Confidential

Page 45

Epson Stylus Pro GS6000 Revision F

2.5 Heater Mechanism

Figure 2-4. Heater Mechanism

Diagram Name Description

Heat paper before printing.

This pre-heating combined with the heating on the

Platen Heaters and the After Heaters allows raising the

1Pre Heaters

2 Platen Heaters

3 Thermistors Detect the temperature of each heater.

4 After Heaters Heat paper to dry ink after printing.

paper temperature successfully after the paper feeding

starts.

The pre-heating also prevents the paper from deforming

when heating during printing operation.

Heat paper to control the sizes of dots landed on the

paper (so as to prevent the ink to spread).

OPERATING PRINCIPLES Heater Mechanism 45

Confidential

Page 46

Epson Stylus Pro GS6000 Revision F

2.6 Boards

Figure 2-5. Boards

Diagram Name Description

1 Main Board Assembly

2 Sub-A Board Assembly

Communicates with the computer.

Processes received data.

Controls the printer mechanism.

Stores the correction values and various counters.

Generates the voltages for the logic system from the

voltage of 42V supplied from the P/S Board

Assembly.

Relays the connection between the Main Board

Assembly and the following parts.

CR Encoder

P Edge Sensor

PG HP Sensor

Print Heads

Cooling Fans

Diagram Name Description

Relays the connection between the Main Board

Assembly, P/S Term Board Assembly, Heater Cont

Board Assembly, Sub-C Board Assembly, and the

following parts.

IC Cover Sensor (right)

3 Sub-B Board Assembly

4 Sub-C Board Assembly

5 Sub-D Board Assemblies

Heater Relay Board

6

Assembly

Heater Cont Board

7

Assembly

P/S Term Board

8

Assembly

9 P/S Board Assembly

F Cover Sensor (right)

M Cover Sensor (right)

Sub Tank Sensors (right)

Pump Motors

Lever Sensor

Paper Rear Sensor

CR HP Sensor

Relays the connection between the Main Board

Assembly, P/S Term Board Assembly, Sub-B Board

Assembly and the following parts.

IC Cover Sensor (left)

F Cover Sensor (left)

M Cover Sensor (left)

Sub Tank Sensors (left)

PF Encoder

Relay the connection between the Main Board

Assembly and the following parts.

Ink Cartridges (CSIC)

The assembly mounting the relays to control the

heaters.

Controls the heaters.

Interface between the Main Board and the printer.

Generates the voltage for this printer from the AC

power supply.

OPERATING PRINCIPLES Boards 46

Confidential

Page 47

Epson Stylus Pro GS6000 Revision F

2.7 Sensors

Figure 2-6. Sensors

Diagram Name Description

1 PG HP Sensor Detects the home position of the platen gap.

2 Paper Edge Sensor Detects the right and left ends of paper.

3 Paper Rear Sensor Detects the presence of paper.

4 CR HP Sensor

5 M Cover Sensors

6 Lever Sensor Detects the position of the paper lever.

Waste Fluid Level

7

Switch Assy

8 Sub Tank Sensors

9 IC Cover Sensors Detect the opening/closing status of the Ink Covers.

10 F Cover Sensors Detect the opening/closing status of the Front Cover.

Detects the home position of the Carriage Unit (CR

Cursor Assy.).

Detect the opening/closing status of the Maintenance

Covers.

Detects the amount of waste ink. If the waste ink

exceeds specified level, the sensor reacts.

Detect the remaining ink in the Sub Tanks. Each tank

has two sensors, and the remaining ink is detected in

stages.

OPERATING PRINCIPLES Sensors 47

Confidential

Page 48

Epson Stylus Pro GS6000 Revision F

䎦䏄䏕䏕䏌䏄䏊䏈䎃䎸䏑䏌䏗

䎨䏏䏈䏆䎃䎥䏒䏛

2.8 Fans

Figure 2-7. Fans

Diagram Name Description

1 Cooling Fan PE Cools the Main Board Assembly.

2 Cooling Fans Prevent dew condensation on the platen.

3 Cooling Fans (24V)

4 Vacuum Fans

Heater Board Cooling

5

Fan

Sucks the mist of ink when printing so as to prevent

contamination of the inside.

Suck paper to the platen so as to stabilize the position of

paper when printing.

Cools the Heater Cont Board Assembly.

OPERATING PRINCIPLES Fans 48

Confidential

Page 49

TROUBLE SHOOTING

CHAPTER

3

Confidential

Page 50

Epson Stylus Pro GS6000 Revision F

W A R N I N G

C A U T I O N

Error message is displayed on

the LCD display.

(See P.51)

Print Quality Troubles

(See P.60)

Occurrence of Troubles

3.1 Overview

This section explains the basic procedure for troubleshooting problems on the printer

quickly and efficiently.

3.1.1 Preliminary Check

Make sure to verify or perform the following basic items whenever servicing the

printer.

1. There is no foreign material which interferes with the proper operation of the

printer.

2. Print the status sheet, and check the information printed on the sheet to find out

possible causes of the error; if the main units have reached their end of life, or if

there is something wrong with the user-defined panel settings.

3. Both outside and inside of the printer are free of significant dirt. Clean it if

significant dirt is observed.

4. None of the parts or components of the printer are missing, chipped or damaged.

5. All of the harnesses are free from damages and connected properly (vertically and

correctly) to their connectors.

6. The cams and gears in the printer mechanism are engaged correctly showing no

signs of wear.

7. When smudges appear on printed pages, clean the rubber rollers in the printer

mechanism if it solves the problem.

8. The rubber rollers in the printer mechanism are engaged correctly showing no

signs of wear.

When handling the lithium battery used for backup of the RTC on

the main board, strictly follow the safety instructions given in

"4.1.1 Precautions" (See P 64).

Before disassembling/reassembling the printer, be sure to turn

the power OFF, confirm the panel display disappears, and

unplug the three power cords (Printer, heaters and Take-up

Reel).

Be sure to use the specified tools for maintenance/repair.

To maintain the product’s quality, be sure to use the specified

lubricant and adhesive.

Be sure to perform the adjustments as required.

3.1.2 Troubleshooting Procedure

Follow the flowchart given below to troubleshoot problems efficiently.

TROUBLE SHOOTING Overview 50

Confidential

Page 51

Epson Stylus Pro GS6000 Revision F

3.2 Remedies for Error Messages

The Error messages and their corresponding remedies are explained below.

Message on LCD Description Remedy/Point to be checked

INK LOW The ink cartridge is nearly expended. The ink cartridge is nearly empty. Although you can continue printing in

the INK LOW status, it may decrease the print quality.

DRAIN TANK FULL

DRAIN WASTE INK FROM THE

DRAIN TANK

INK CARTRIDGE INSTALL

INK CARTRIDGE

LEVER RELEASED

LOWER THE PAPER SET LEVER

LEVER RELEASED

LOAD PAPER

FRONT COVER OPEN

CLOSE FRONT COVER

MAINT COVER OPEN

CLOSE RIGHT MAINT COVER

MAINT COVER OPEN

CLOSE LEFT MAINT COVER

INK COVER OPEN CLOSE RIGHT AND

LEFT INK COVERS

INK COVER OPEN

CLOSE RIGHT INK COVER

INK COVER OPEN

CLOSE LEFT INK COVER

NOT ENOUGH INK REPLACE INK

CARTRIDGE WITH A NEW ONE

The ink drain tank is full. Drain waste ink from the ink drain tank immediately.

Malfunction of the WASTE FLUID LEVEL SW ASSY. Check whether the WASTE FLUID LEVEL SW ASSY operates

normally or not (p.234). If any abnormality is found, check the cable

connection status, and replace the WASTE FLUID LEVEL SW ASSY if

necessary.

This message appears when replacing the ink cartridge. Install an ink cartridge.

The paper lever (PRESSURE LEVER) is in the released position. Move the paper lever (PRESSURE LEVER) to its lowest position to

secure paper.

If this message appears although the lever is lowered, there is something

wrong with the LEVER SENSOR.

The FRONT CLEAR COVER is open. Close the FRONT CLEAR COVER.

The F COVER SENSOR is not installed correctly, or there is something

wrong with the sensor.

The MAINTENANCE COVER ASSY(s) is open. Close the MAINTENANCE COVER ASSY(s).

If this message appears although the cover is closed, there is something

wrong with the M COVER SENSOR.

The Ink Cover(s) is open. Close the Ink Cover(s).

If this message appears although the cover is closed, there is something

wrong with the IC COVER SENSOR.

The ink cartridge is nearly expended. Replace the ink cartridge with a new one.

Check whether the LEVER SENSOR operates normally or not (p.234). If

any abnormality is found, check the cable connection status, and replace

the LEVER SENSOR (p.133) if necessary.

Check whether the FRONT CLEAR COVER properly pushes the sensor.

If not, adjust the sensor position.

When the sensor does not operate, check the cable connection status and

replace the F COVER SENSOR (p.133) if necessary.

Check whether the M COVER SENSOR operates normally or not

(p.234). If any abnormality is found, check the cable connection status,

and replace the M COVER SENSOR (p.133) if necessary.

Check whether the IC COVER SENSOR operates normally or not

(p.234). If any abnormality is found, check the cable connection status,

and replace the IC COVER SENSOR (p.133) if necessary.

TROUBLE SHOOTING Remedies for Error Messages 51

Confidential

Page 52

Epson Stylus Pro GS6000 Revision F

Message on LCD Description Remedy/Point to be checked

NO CARTRIDGE

INSTALL INK CARTRIDGE

INK CARTRIDGE ERROR

REPLACE CARTRIDGE

INK CARTRIDGE

PLEASE USE GENUINE EPSON INK

CARTRIDGES

INK CARTRIDGE

NON-GENUINE CARTRIDGE MAY

NOT PERFORM AT OPTIMUM

CONTINUE?

<YES NO>

INK CARTRIDGE

THIS MAY VOID EPSON'S

WARRANTY.

DO YOU ACCEPT THIS?

<ACCEPT DECLINE>

INK CARTRIDGE

REPLACE INK CARTRIDGE

COMMAND ERROR

CHECK DRIVER SETTINGS

PAPER SKEW

LOAD PAPER PROPERLY

PAPER ERROR

LOAD PAPER PROPERLY

REFER TO THE MANUAL

No ink cartridge is installed. Install an ink cartridge correctly.

The ink cartridge cannot be detected correctly. Replace the ink cartridge. When the error still occurs after the

replacement, check the connection status from the cartridge holder to the

main board.

The ink cartridge was found faulty. There may be some bad contact or

dew condensation in the cartridge.

Non-genuine ink cartridge is installed. Replace the ink cartridge with a genuine Epson ink cartridge. Using a

The ink cartridge is expended. Replace the ink cartridge with a new one.

The printer received damaged or collapsed print data. Cancel the print job, and try another one.

The printer received print data with a wrong command.