Epson CW-C6000Au, CW-C6000Pu, CW-C6000Ae, CW-C6000Pe, CW-C6010A Technical Reference Guide

...Page 1

Technical Reference Guide

Describes features for the product.

Describes setup and installation of the product.

Describes how to control the printer and necessary

information when you develop applications.

Describes specications of the product.

Describes how to handle the product.

Product Overview

Setup

Handling

Information for Application

Development

Appendix

M00125305

Rev.F

Page 2

Cautions

• All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise,

without the prior written permission of Seiko Epson Corporation.

• The content of this manual is subject to change without notice. Please contact us for the latest information.

• While every precaution has been taken in the preparation of this manual, Seiko Epson Corporation assumes

no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident,

misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product, or

(excluding the U.S.) failure to strictly comply with Seiko Epson Corporation's operating and maintenance

instructions.

• Seiko Epson Corporation shall not be liable for any damages or problems arising from the use of any options

or any consumable products other than those designated as Genuine Epson Products or Epson Approved

Products by Seiko Epson Corporation.

Trademarks

EPSON, EXCEED YOUR VISION, and ESC/Label are registered trademarks of Seiko Epson Corporation.

Microsoft®, Windows®, Windows Vista®, and Windows Server® are registered trademarks of Microsoft

Corporation in the United States and/or other countries.

Mac, mac OS, OS X, and ColorSync are trademarks of Apple Inc., registered in the U.S. and other countries.

Zebra Technologies Corporation and ZPL II are the registered trademarks or trademarks of Zebra Technologies

Corporation.

Intel®, Celeron®, and Pentium® are trademarks of Intel Corporation in the U.S. and/or other countries.

Adobe, the Adobe logo, Acrobat, Adobe PDF Print Engine, the Adobe PDF Print Engine logo, Illustrator,

Photoshop, PostScript and Reader are either registered trademarks or trademarks of Adobe in the United States

and/or other countries.

BarTender® is registered trademark of Seagull Scientific, Inc. in the United States and other countries.

NiceLabel® is trademarks or registered trademarks of Euro Plus d.o.o.

CODESOFT is registered trademarks or trademarks of TEKLYNX International.

All other trademarks are the property of their respective owners and used for identification purpose only.

©Seiko Epson Corporation 2019-2021.

2

Page 3

Before Use

This chapter describes information you should know before using the product.

Manuals for This Product

Paper manual

Manual viewable

with PC

Manual viewable

with PC

Start Here

Guides you through basic setup steps from unpacking to loading paper.

User’s Guide

Describes details about the functions and operating procedures of the product, maintenance

information, and troubleshooting. Download this guide from the web site or, depending on the

country or region, this is included in the supplied CD.

CW-C6000 Series/CW-C6500 Series Technical Reference Guide

(This manual)

Provides information necessary for installing the product, performing daily tasks, and

developing a system using the product.

Manual viewable

with PC

Online Video Manual

Provides videos that show you operating procedures and troubleshooting information. Access

the videos from the following URL.

<https://support.epson.net/p_doc/790/>

T

he contents of videos are subject to change without notice.

Downloading the Latest Version

The latest versions of the printer driver, utilities, and manuals can be downloaded from the following URLs.

For customers in North America, go to the following web site:

www.epson.com/support/

For customers in other countries, go to the following web site:

www.epson-biz.com/

3

Page 4

Symbols Used in This Guide

The following symbols are used in this guide to indicate important information.

Symbols for Safety

The symbols shown below are used in this manual in order to ensure safety and proper use of this product and

to prevent danger to you and other persons, and property damage. Be sure that you completely understand their

meanings before reading this manual.

Handling the product improperly by ignoring this symbol can lead to death or serious injury.

WARNING

Handling the product improperly by ignoring this symbol can lead to injury and property damage.

CAUTION

Symbols for General Information

c

IMPORTANT

Indicates information with which you must comply when using the product. Mishandling due to

ignoring this information may cause the product to fail or malfunction.

Indicates supplementary explanations and information you should know.

4

Page 5

Safety Precautions

To ensure safe use of the product, be sure to read this manual and the other instruction manuals supplied with

the product before use. Store this manual in a safe place so that you can resolve any unclear points regarding the

product at any time.

Cautions on Installation

Do not block the air vents of the product. ("Rear" on page 21)

Doing so can result in heat accumulated in the product causing a fire.

WARNING

CAUTION

Do not cover the product with a cloth or install it in a poorly-ventilated location.

Furthermore, ensure there is the installation space specified in the manual.

• Do not install/store the product in an unstable location or in a location subject to vibration from

other devices. The product may fall or collapse, causing breakage and possible injury.

• Do not install the product in a location exposed to oily smoke or dust, or in a humid location.

Doing so may cause electric shock or fire.

• When lifting the product, perform the work with the correct posture. Lifting the product with an

inappropriate posture may cause injury.

• Because the product is heavy, do not attempt to carry the product by one person. When

unpacking or moving the product, make sure to carry the product by at least two persons. See

below for details on the mass of this product. ("Product Specifications" on page 311)

• Do

not install the product at a location exposed to strong light such as direct sun rays. Doing so

may result in printing failure due to malfunction of the detectors.

• If the printer has charged matte black ink and is more likely to be exposed to a temperature of -10

or lower degrees C, make sure to discharge ink before turning the printer off. Otherwise, the print

head may be damaged due to freezing. ("Transporting or Storing the Printer at -10°C (With Matte

Bl

ack Ink Installed)" on page 265)

5

Page 6

Cautions on Handling

• Do not use the product in a location with volatile substances such as alcohol or paint thinner

present, or near fire. Doing so may cause electric shock or fire.

WARNING

• Shut down the product immediately if it produces smoke, a strange odor, or unusual noise. If you

go on using the product, it may result in electric shock or fire. If an abnormality occurs,

immediately turn off the power and remove the plug from the outlet, and then contact qualified

service personnel for advice.

• Shut down the product immediately if a foreign object or water or other liquid gets inside the

product. If you go on using the product, it may result in electric shock or fire. Immediately turn off

the power and remove the plug from the outlet, and then contact qualified service personnel for

advice.

• Do not disassemble the areas other than those mentioned in this manual.

• Never attempt to repair the product yourself as doing so is dangerous.

• Do not use the product in a location where inflammable gas, explosive gas, etc. is present in the

atmosphere. Furthermore, do not use aerosol sprayers containing flammable gas inside or around

the product. Doing so may cause fire.

• Do not connect cables in ways other than those mentioned in this manual. Doing so may cause

fire. It may also damage the other connected devices.

• Do not touch the areas inside the product other than those mentioned in this manual. Doing so

may cause electric shock or burns.

• Do not insert metal or flammable materials, or allow them to fall into the product. Doing so may

cause electric shock or fire.

• If the screen of the printer is damaged, handle the liquid crystal inside it very carefully. Should any

of the following situations arise, take emergency measures.

∗ When any part gets onto your skin, wipe off the deposit, and wash the area properly with soap

and water.

∗ When any part gets into your eyes, flush them with clean water for at least 15 minutes, and

thereafter, consult with a doctor.

∗ When a part gets into your mouth, immediately consult with a doctor.

CAUTION

• Do not allow anyone to stand or place heavy objects on top of the product. In particular, be

careful in the case of a household with children. The product may fall or collapse, causing

breakage and possible injury.

• Install the cables and optional products in the proper direction according to the proper

procedures. If they are installed improperly, it may result in fire or injury. Follow the instructions in

this manual to install them properly.

• Before moving the product, shut down and unplug the product, and make sure that all the cables

are disconnected. Failure to do so may damage a cable, causing electric shock or fire.

• Do not store or transport the product while it is tilted, standing, or upside down. Doing so may

cause the ink to leak.

• Do not use the printer with the paper cover removed. Doing so will cause the printer to

malfunction.

6

Page 7

Cautions on Power Supply

• Do not allow dust or other foreign material to adhere to the power plug. Doing so may cause

electric shock or fire.

WARNING

• Do not use a power cord other than that supplied with the product. In addition, do not use the

supplied power cord with another device. Doing so may cause electric shock or fire.

• Do not use a damaged power cord. Doing so may cause electric shock or fire. Contact qualified

service personnel for advice if the power cord is damaged. Furthermore, observe the following

points so as not to damage the power cord.

∗ Do not modify the power cord.

∗ Do not place heavy objects on the power cord.

∗ Do not forcibly bend, twist, or pull the power cord.

∗ Do not lay the power cord near a heating appliance.

• Do not insert or remove the power plug with a wet hand. Doing so may cause electric shock.

• Do not connect many power cords to one outlet. Doing so may cause fire. Supply power directly

from a power outlet.

• Regularly disconnect the power plug from the outlet and clean the base of the prongs and

between the prongs. Leaving the power plug connected to the outlet for a long period of time

may cause dust to accumulate on the base of the power plug prongs, resulting in a short and fire.

• Hold the plug and do not pull the cord when disconnecting the power plug from the outlet.

Pulling the cord may damage the cord or deform the plug, causing electric shock or fire.

To ensure safety, unplug the product before leaving it unused for an extended period.

CAUTION

7

Page 8

Cautions on Ink Cartridges

• The ink cartridges that can be used differ depending on the model number of the product. Use

ink cartridges suitable for the model number of your printer. ("Ink Cartridges" on page 358)

• Do

CAUTION

not touch the IC chip on an ink cartridge. Doing so may result in normal operation and

printing becoming no longer possible.

• The product uses ink cartridges equipped with IC chips to manage the amount of ink used and

other information so ink cartridges are usable even if they are removed and reinstalled. However,

if an ink cartridge with not much ink remaining is removed and reinstalled, it may not be usable.

Some ink is consumed each time cartridges are installed because the product automatically

checks their reliability.

• If the firmware version of the printer is other than TS05JC, TS06JC, TS26JC, TS19K2, TS25K3, or

TS21K5, you are prompted to select black ink type when turning on the printer and installing the

ink cartridges for the first time. Once the black ink cartridge is installed and the printer charge the

ink, you cannot change the black ink type any more. The printer does not work if you replace the

black ink cartridge with a cartridge of different type of black ink.

• Install all ink cartridges. Printing is not possible if even only one ink cartridge is missing.

• Since ink cartridges are designed to stop the operation before ink runs out completely to

maintain the quality of the print head, some ink remains in the used ink cartridges.

• All the ink colors are consumed also for the maintenance operations when an ink cartridge is

replaced and for print head cleaning.

• Do not turn off the power or open the ink cartridge cover during ink charging (while the

(power) LED lamp is flashing). Opening the cover may cause the ink to be recharged, resulting in

more ink being consumed. Also, it may result in normal printing becoming no longer possible.

• Even for monochrome printing, all the ink colors are used in an operation designed to maintain

the printing and print head quality.

• Do not disassemble an ink cartridge. Doing so may cause ink to get into eyes or onto skin.

• Do not disassemble or modify an ink cartridge. Doing so may cause printing malfunction.

• Use of old ink cartridges may result in reduced print quality. Use ink cartridges up within six

months after opening the packages. The usage period for ink cartridges is printed on the

packaging of the individual ink cartridges.

• If ink contacts your skin, eyes, or mouth, take the following actions.

∗ When ink gets onto your skin, immediately wash the area with soap and water.

∗ When ink gets into your eyes, immediately flush them with water. Leaving the ink as is may

result in bloodshot eyes or mild inflammation. If something is wrong, immediately consult with

a doctor.

∗ When ink gets into your mouth, immediately spit it out and consult with a doctor.

• There may be some ink around the ink supply port on a removed ink cartridge. Take care so that it

does not stain the desk or other surface.

• Do not open an ink cartridge package until you are ready to install the ink cartridge in the

product.

• Do not shake an ink cartridge too hard. The ink cartridge may leak if you shake it around too much

or push the sides strongly.

• Do not allow foreign objects to fall into the cartridge installation section.

Doing so may result in normal printing becoming no longer possible. Remove any object that falls

into the installation section, taking care not to damage the section.

• When ink is charged the first time (right after purchase), ink is consumed for filling the print head

nozzles (ink discharge holes) to get ready for printing. Therefore, the number of the sheets that

can be printed may be fewer than for cartridges installed later.

• When the printer is powered off with the (power) button, the print head is automatically

capped to prevent the ink from drying. When you will not use the printer after installing the ink

cartridges, be sure to turn the power off with the (power) button. Do not pull out the power

plug or turn off the breaker while the power is on.

8

Page 9

• Printing on water-repellent paper such as art paper, which is slow-drying, may cause print stains.

Also, if you print on glossy paper, fingerprints may get on the paper or ink may adhere to your

CAUTION

fingers when you touch the print surface. Select and use paper that will not cause print stains.

• Store the ink cartridges in a place out of reach of children.

• Epson recommends storing ink cartridges in a cool and dark place.

• If you wish to use ink cartridges that have been stored in a cold place for a long period of time,

leave them for at least 3 hours in a place that is at room temperature before use.

• Do not remove the ink cartridges from the product when storing or transporting the product.

Cautions on the Maintenance Box

• Store in a place out of reach of children. Do not drink any adhered ink.

• Do not disassemble or modify the maintenance box. Doing so may cause ink to get into eyes or

CAUTION

onto skin.

• Do not touch the IC chip on the maintenance box.

• If a maintenance box that can still be used has been removed and left detached for a long period

of time, do not reuse it.

• Do not peel off the film from the top surface of the maintenance box.

• If ink contacts your skin, eyes, or mouth, take the following actions.

∗ When ink gets onto your skin, immediately wash the area with soap and water.

∗ When ink gets into your eyes, immediately flush them with water. Leaving the ink as is may

result in bloodshot eyes or mild inflammation. If something is wrong, immediately consult with

a doctor.

∗ When ink gets into your mouth, immediately spit it out and consult with a doctor.

• Do not shake a used maintenance box too hard. The ink may leak from the maintenance box if

you swing or shake it too hard.

• Avoid storing the maintenance box under high temperatures or in a frozen state.

• Keep it away from direct sunlight.

9

Page 10

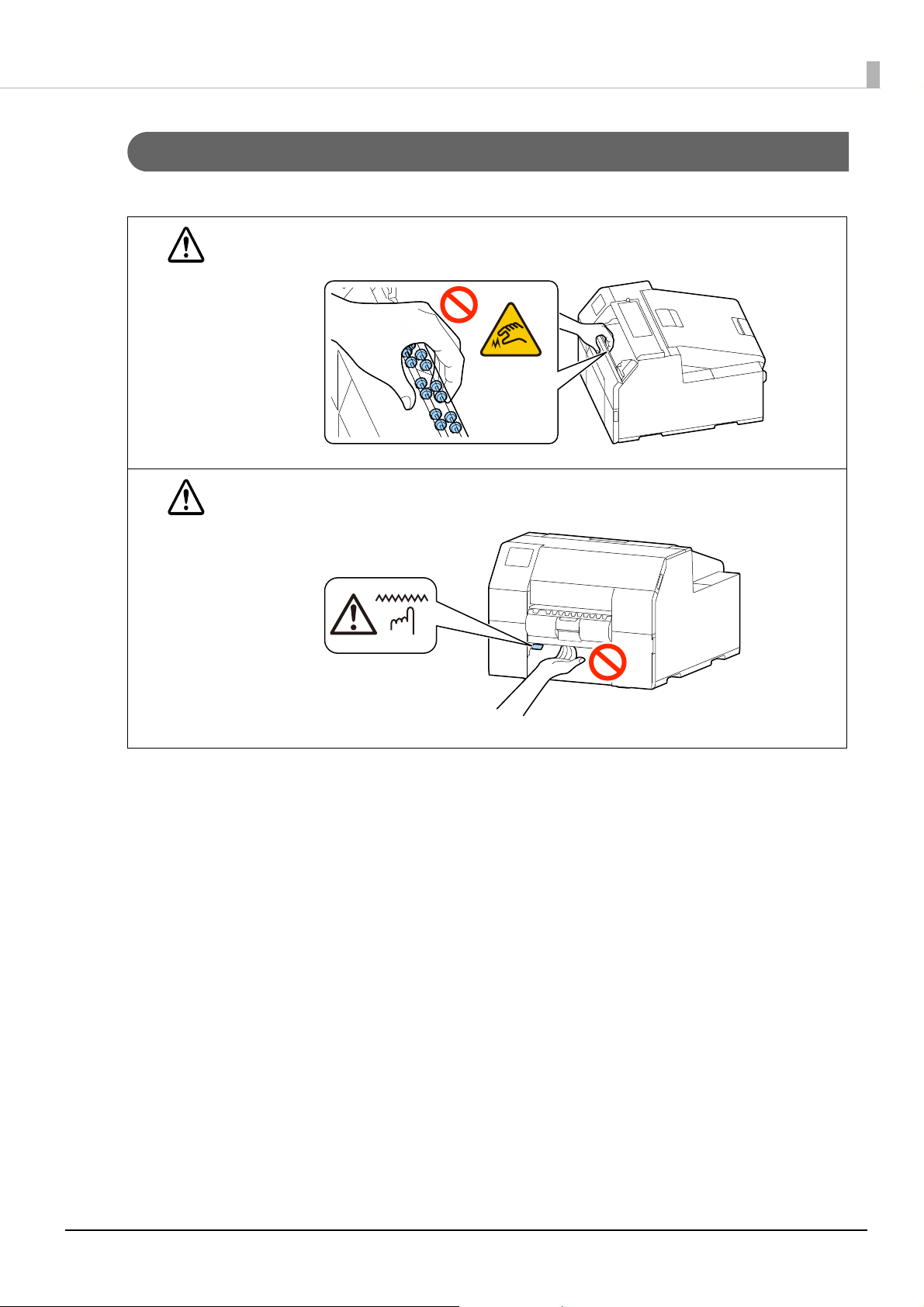

Caution Label

The labels affixed to the product indicate the following cautions.

Do not touch the roller at the bottom of the paper holder unit with your hand. Doing so may cause

injury.

WARNING

Do not touch the manual cutter at the bottom of the peeler cover with your hand. Doing so may

cause injury.

CAUTION

10

Page 11

Restriction of Use

When this product is used for applications requiring high reliability/safety such as transportation devices

related to aviation, rail, marine, automotive etc.; disaster prevention devices; various safety devices etc.; or

functional/precision devices etc., you should use this product only after giving consideration to including failsafes and redundancies into your design to maintain safety and total system reliability. This product is not

intended for use in applications requiring an extremely high level of reliability and safety, such as in aerospace

instruments, main communication equipment, nuclear power control equipment, or medical equipment, etc.

Please make your own judgment on this product's suitability after a full evaluation.

About This Manual

Aim of the Manual

This manual is intended to provide information required for developing, designing, and installing a system, and

for developing and designing printer applications for developers.

Manual Content

This manual consists of the following chapters.

Chapter 1 Product Overview

Chapter 2 Setup

Chapter 3 Handling

Chapter 4 Information for Application Development

Appendix Appendix

Screenshots

Unless otherwise noted, Windows 10 screenshots are used in this manual. Depending on the printer model and

OS version that you use, the screenshots may differ from actual Windows screens.

Depending on version of the printer driver and utility you are using, screens shown in this manual may slightly

differ from actual screens.

Illustrations

Unless otherwise noted, illustrations of CW-C6500 Series are used in this manual. They may look slightly

different from your printer.

11

Page 12

Contents

■ Before Use.................................................................................................................................3

Manuals for This Product................................................................................................................................................. 3

Symbols Used in This Guide........................................................................................................................................... 4

Safety Precautions ............................................................................................................................................................. 5

Cautions on Installation................................................................................................................................................... 5

Cautions on Handling ...................................................................................................................................................... 6

Cautions on Power Supply ............................................................................................................................................. 7

Cautions on Ink Cartridges ............................................................................................................................................. 8

Cautions on the Maintenance Box............................................................................................................................... 9

Caution Label .................................................................................................................................................................... 10

■ Restriction of Use ................................................................................................................. 11

■ About This Manual ...............................................................................................................11

Aim of the Manual ...........................................................................................................................................................11

Manual Content................................................................................................................................................................ 11

Screenshots........................................................................................................................................................................11

Illustrations.........................................................................................................................................................................11

■ Contents................................................................................................................................. 12

Product Overview ..........................................................................................18

■ About Models of this Product............................................................................................ 18

Auto cutter model ...........................................................................................................................................................18

Peeler model...................................................................................................................................................................... 18

Gloss Black Ink/Matte Black Ink ..................................................................................................................................19

About the Version of the Printer Driver and Utility.............................................................................................. 19

■ Part Names and Functions ................................................................................................. 20

Front .....................................................................................................................................................................................20

Rear ....................................................................................................................................................................................... 21

Inside .................................................................................................................................................................................... 22

Spindle and Flange..........................................................................................................................................................23

Operation Panel................................................................................................................................................................24

■ Nozzle Verification Technology ......................................................................................... 26

Nozzle Verification Technology Settings .................................................................................................................26

Dot Substitution (Supplemental Printing) Function........................................................................................... 28

■ Periodic Auto Cleaning ....................................................................................................... 29

Setting Time to Start the Periodic Auto Cleaning ................................................................................................29

Execution of the Periodic Auto Cleaning ................................................................................................................29

Examples of the Time Setting to Avoid Interrupting Printing Operation ....................................................29

■ Checking the Printer Status ............................................................................................... 30

Printing the Status Sheet .............................................................................................................................................. 30

Printing the Network Connection Check Report..................................................................................................31

Checking the Status of Consumables....................................................................................................................... 32

12

Page 13

Setup ...............................................................................................................33

■ Unpacking ............................................................................................................................. 33

■ Removing the Protective Materials .................................................................................. 34

■ Installing the Printer............................................................................................................ 35

■ Connecting the Power Cable ............................................................................................. 36

■ Turning On/Off ..................................................................................................................... 37

Turning the Power On ....................................................................................................................................................37

Turning the Power Off ....................................................................................................................................................37

■ Setting Language and Date/Time..................................................................................... 38

■ Selecting Black Ink Type ..................................................................................................... 38

■ Installing the Ink Cartridges .............................................................................................. 39

Replacing the Ink Cartridges........................................................................................................................................40

■ Installing the Maintenance Box......................................................................................... 42

Replacing the Maintenance Box.................................................................................................................................42

■ Installing the Printer Driver and Connecting to a Computer ...................................... 44

How to Get the Software...............................................................................................................................................44

How to Connect to a Computer..................................................................................................................................44

How to Configure the Network Settings .................................................................................................................44

Setup using Install Navi .................................................................................................................................................46

■ Media Settings...................................................................................................................... 47

■ Opening the Paper Cover ................................................................................................... 48

Opening the Cover using the Lever in the Front ..................................................................................................48

Opening the Cover using the Lever in the Back....................................................................................................48

■ Loading Paper....................................................................................................................... 49

How to Load Paper (Auto Cutter Model - Supply from Inside) ........................................................................50

How to Load Paper (Auto Cutter Model - Supply from Outside) ....................................................................54

How to Load Paper (Peeler Model - Supply from Inside)...................................................................................58

How to Remove Paper (For the Auto Cutter Model)............................................................................................63

How to Remove Paper (For the Peeler Model).......................................................................................................64

How to Eject Paper at Paper End (For the Auto Cutter Model) ........................................................................66

How to Eject Paper at Paper End (For the Peeler Model) ...................................................................................67

Feeding Paper into the Printer Manually.................................................................................................................68

■ Test Print ................................................................................................................................ 69

Test Print using the Printer Driver ..............................................................................................................................70

Handling .........................................................................................................71

■ Printer Driver for Windows................................................................................................. 71

Printer Driver Screen Configuration ..........................................................................................................................72

Paper Source and Paper Detection Settings ..........................................................................................................73

User-Defined Paper .........................................................................................................................................................75

13

Page 14

Printing Barcodes .............................................................................................................................................................84

Printing 2D Symbols........................................................................................................................................................95

Printing Barcodes / 2D Symbols on .NET Environment ................................................................................... 103

Favorite Settings............................................................................................................................................................ 105

User Defined Information ..........................................................................................................................................108

Exporting/Importing Printer Driver Settings ...................................................................................................... 108

Starting PrinterSetting from the Printer Driver .................................................................................................. 111

Speeding Up Printing using High Speed Batch Label Printing Function.................................................. 112

Sharing the Printer Driver ..........................................................................................................................................115

Setting EPSON Status Monitor 3.............................................................................................................................. 137

Restrictions on Using the Printer Driver................................................................................................................ 143

■ Printer Driver for Mac........................................................................................................ 144

Basic Procedure for Printing......................................................................................................................................144

Customizing the Printer Driver................................................................................................................................. 150

Epson Label Printer Utility.......................................................................................................................................... 152

■ Printer Driver for Linux ..................................................................................................... 154

Getting the Package (epson-inkjet-printer-cw-c6000c6500) ....................................................................... 155

Installing the Printer Driver ....................................................................................................................................... 155

Installing Input/Output Modules ............................................................................................................................ 155

Adding the Printer to the CUPS ............................................................................................................................... 155

Installing Epson Label Printer Utility for Linux ................................................................................................... 157

Starting Epson Label Printer Utility for Linux...................................................................................................... 157

Exiting Epson Label Printer Utility for Linux........................................................................................................ 158

Uninstalling Printer Driver, Epson Label Printer Utility for Linux ................................................................. 158

■ Printing from SAP System ................................................................................................ 160

Methods of Printing from SAP System .................................................................................................................. 160

Direct Printing ................................................................................................................................................................ 162

Indirect Printing............................................................................................................................................................. 162

High Volume Printing .................................................................................................................................................. 163

■ PrinterSetting (Windows)................................................................................................. 164

How to Start PrinterSetting ....................................................................................................................................... 165

How to Apply Settings ................................................................................................................................................ 166

Media settings ................................................................................................................................................................ 167

Layout settings............................................................................................................................................................... 168

Position adjustment .....................................................................................................................................................170

Print results adjustment..............................................................................................................................................172

Store data in the printer.............................................................................................................................................. 173

Background image settings ...................................................................................................................................... 177

Print head maintenance ............................................................................................................................................. 181

Printer settings............................................................................................................................................................... 182

Print Head Alignment..................................................................................................................................................183

Panel settings ................................................................................................................................................................. 188

Operating Time Settings.............................................................................................................................................189

Nozzle check settings .................................................................................................................................................. 190

Advanced settings ........................................................................................................................................................ 191

Initialize printer .............................................................................................................................................................. 199

Printer information ....................................................................................................................................................... 200

Settings save and restore ........................................................................................................................................... 202

Option ............................................................................................................................................................................... 203

14

Page 15

■ Operation Panel Settings.................................................................................................. 204

■ WebConfig........................................................................................................................... 218

■ Epson Device Admin.......................................................................................................... 220

■ Spot Color Settings............................................................................................................ 221

Creating Spot Color Setting File............................................................................................................................... 221

Printing using the Spot Color Setting File............................................................................................................ 226

■ Color Correction ................................................................................................................. 227

Vivid colors ...................................................................................................................................................................... 227

Setting using OS ............................................................................................................................................................ 228

Creating an ICC Profile.................................................................................................................................................235

No composite ................................................................................................................................................................. 239

■ Printing from the First Label (Auto cutter model only) .............................................. 240

■ Setting Label Size and Paper Layout for Borderless Printing.................................... 241

Borderless Printing Concepts.................................................................................................................................... 241

Label Media Design ......................................................................................................................................................241

Borderless Printing Settings ...................................................................................................................................... 242

■ Adjusting Sensitivity of the Detectors and Threshold for Detecting Labels .......... 245

■ Detecting Differences in Paper Size Using Label Command ..................................... 245

■ Adjusting Gap Detector .................................................................................................... 246

Adjusting Label Detector for Circle Die-cut Labels (Example)...................................................................... 247

■ Restricting Operation of the Operation Panel (Lock Setting function) ................... 248

Setting an Administrator Password ........................................................................................................................ 248

Enabling the [Lock Setting] Function .................................................................................................................... 249

Changing the Administrator Password ................................................................................................................. 249

Resetting the Administrator Password.................................................................................................................. 250

■ Cleaning the Printer........................................................................................................... 251

Cleaning the Exterior ...................................................................................................................................................252

Cleaning the Auto Cutter (Auto Cutter Model Only)........................................................................................ 253

Cleaning the Peeler (Peeler Model Only).............................................................................................................. 254

Cleaning the Edge Guides..........................................................................................................................................255

Cleaning the Platen ...................................................................................................................................................... 256

Cleaning the Paper Feed Roller................................................................................................................................ 257

Cleaning the Paper Pressure Roller......................................................................................................................... 260

Print Head Cleaning .....................................................................................................................................................262

Using the Operation Panel.........................................................................................................................................263

Using the Printer Driver .............................................................................................................................................. 263

Using the WebConfig...................................................................................................................................................263

■ Storing the Printer After Ink is Charged ........................................................................ 264

Preparation for Long-Term Storage ........................................................................................................................ 264

Transporting or Storing the Printer at -10°C (With Matte Black Ink Installed) ........................................ 265

For Using the Printer after Long Storage .............................................................................................................. 265

■ For Transporting the Printer ............................................................................................ 266

■ Troubleshooting................................................................................................................. 267

A message is displayed on the operation panel. ............................................................................................... 267

Print Quality Problems ................................................................................................................................................ 271

15

Page 16

Cannot Print .................................................................................................................................................................... 274

Network Connection Check Errors.......................................................................................................................... 276

A message is displayed on the computer screen ..............................................................................................277

Printing from a computer is impossible or becomes suddenly impossible............................................. 278

Print Job is Canceled on PC but “Printing” Message on Printer Does Not Disappear........................... 280

Error Beep Sound Does Not Stop ............................................................................................................................ 280

Paper is jammed ............................................................................................................................................................ 280

Information for Application Development.............................................. 287

■ How to Control the Printer ............................................................................................... 287

■ Using the Epson Inkjet Label Printer SDK ..................................................................... 288

Operating Environment.............................................................................................................................................. 288

How to Get Software.................................................................................................................................................... 288

■ Using the ESC/Label Commands..................................................................................... 288

■ Replacing from ZPL II Compatible Monochrome Printer ........................................... 289

Changing from Two-Step Printing to One-Step Printing................................................................................ 289

Utilizing Templates ....................................................................................................................................................... 309

■ Software and Manuals ...................................................................................................... 310

Appendix...................................................................................................... 311

■ Product Specifications ...................................................................................................... 311

Operating Environment.............................................................................................................................................. 312

Paper Specifications ..................................................................................................................................................... 313

Electrical Specifications .............................................................................................................................................. 348

Reliability.......................................................................................................................................................................... 348

Environmental Specifications ................................................................................................................................... 349

Overall Dimensions ...................................................................................................................................................... 350

■ Consumables Specifications ............................................................................................ 358

Ink Cartridges ................................................................................................................................................................. 358

Maintenance Box........................................................................................................................................................... 359

■ Option Specifications........................................................................................................ 360

Roll Paper Holder...........................................................................................................................................................360

■ Requirements for External Devices ................................................................................ 361

Media Source Setting ..................................................................................................................................................361

Paper Feed Speed ......................................................................................................................................................... 361

Paper Tension.................................................................................................................................................................. 362

Paper Curl......................................................................................................................................................................... 363

Paper Angle for Feeding and Ejecting ................................................................................................................... 364

Position of Paper Feeder and Paper Rewinder ................................................................................................... 365

■ Downloading Printer Driver, Utilities, and Manuals.................................................... 366

■ Label Print Applications.................................................................................................... 366

How to Get Software.................................................................................................................................................... 366

16

Page 17

■ For Inquiries ........................................................................................................................ 367

17

Page 18

Chapter1 Product Overview

CW-C6000 Series (4-inch model)

ColorWorks C6000Au, ColorWorks C6000Ae, ColorWorks C6010A,

ColorWorks C6020A, ColorWorks C6030A, ColorWorks C6040A,

ColorWorks C6050A

CW-C6500 Series (8-inch model)

ColorWorks C6500Au, ColorWorks C6500Ae, ColorWorks C6510A,

ColorWorks C6520A, ColorWorks C6530A, ColorWorks C6540A,

ColorWorks C6550A

CW-C6000 Series (4-inch model)

ColorWorks C6000Pu, ColorWorks C6000Pe, ColorWorks C6010P,

ColorWorks C6020P, ColorWorks C6030P, ColorWorks C6040P,

ColorWorks C6050P

CW-C6500 Series (8-inch model)

ColorWorks C6500Pu, ColorWorks C6500Pe, ColorWorks C6510P,

ColorWorks C6520P, ColorWorks C6530P, ColorWorks C6540P,

ColorWorks C6550P

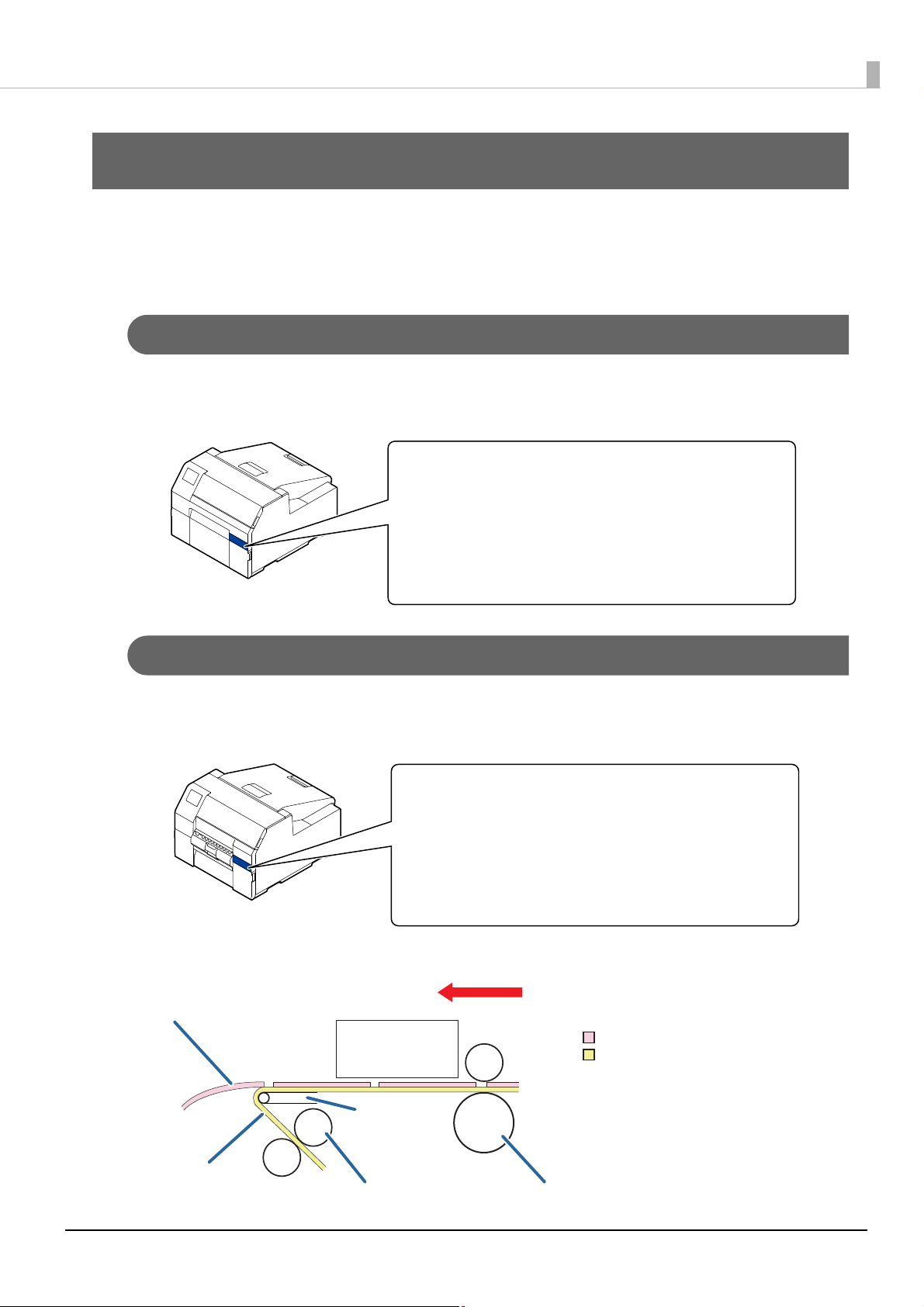

Paper feed direction

Label

Backing paper

Label

Peeling plate

Backing paper

Backing paper reed roller

Paper feed roller

Print head

Product Overview

This chapter describes features of the product.

About Models of this Product

Auto cutter model

Features: Equipped with an auto cutter. The paper can be cut either according to the application settings, or

with the help of the Cut button on the operation panel.

Model number:

Peeler model

Features: Equipped with a peeler mechanism. By passing a backing paper through the peeler, labels are printed

being peeled from the backing paper.

Model number:

Lateral view (when waiting the printed label to be removed):

18

Page 19

Chapter1 Product Overview

Gloss Black Ink/Matte Black Ink

If the firmware version of the printer is other than TS05JC, TS06JC, TS26JC, TS19K2, TS25K3, or TS21K5, you

can select which type of black ink to use from gloss black and matte black. The printer prompts you to select it

when you turn on the printer for the first time.

You cannot change the black ink type once you select the black ink type and let the printer charge

c

the ink.

IMPORTANT

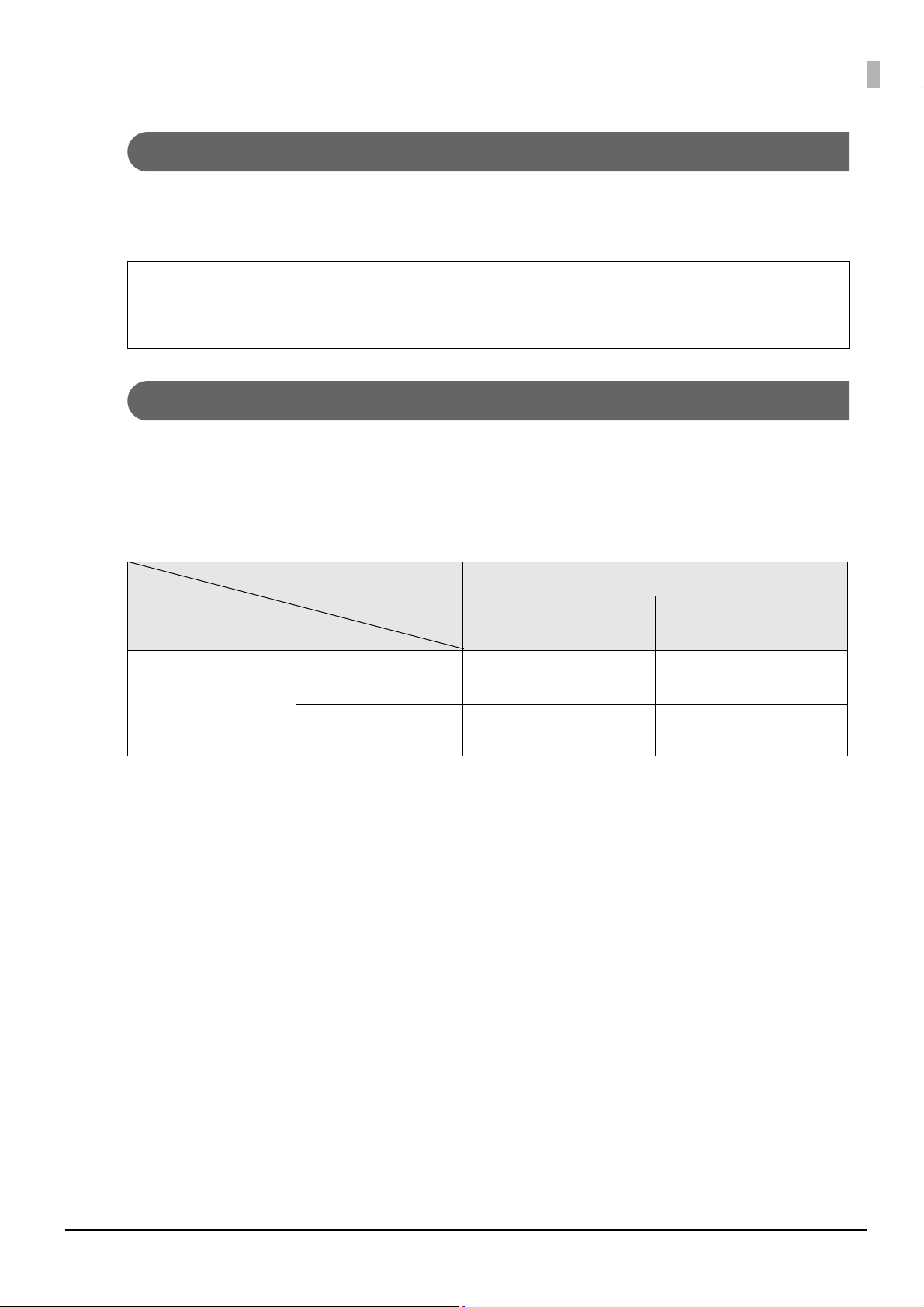

About the Version of the Printer Driver and Utility

Depending on the firmware version of the printer, available versions of the printer driver and utility vary.

Use the combination indicated as "Available (Recommended)" in the table below. In addition, download and use

the latest version of firmware.

You can use the combinations indicated as "Available", however, the printer may malfunction or there may be

restrictions on some functions.

Driver/PrinterSetting Version

Ver.1.0.0.0 / Ver.1.1.0.0

Printer firmware version TS05JC, TS06JC, TS26JC,

TS19K2, TS25K3, TS21K5

Versions higher than

those in the above row.

You can check the version of your printer firmware by using one of the following methods.

• Printing the status sheet ("Printing the Status Sheet" on page 30)

• Checking on the operation panel ("Operation Panel Settings" on page 204)

o get the latest version of the printer driver and utility, see "Downloading Printer Driver, Utilities, and

T

anuals" on page 366.

M

Available Not available

Not available Available (Recommended)

Versions higher than

those in the left column

19

Page 20

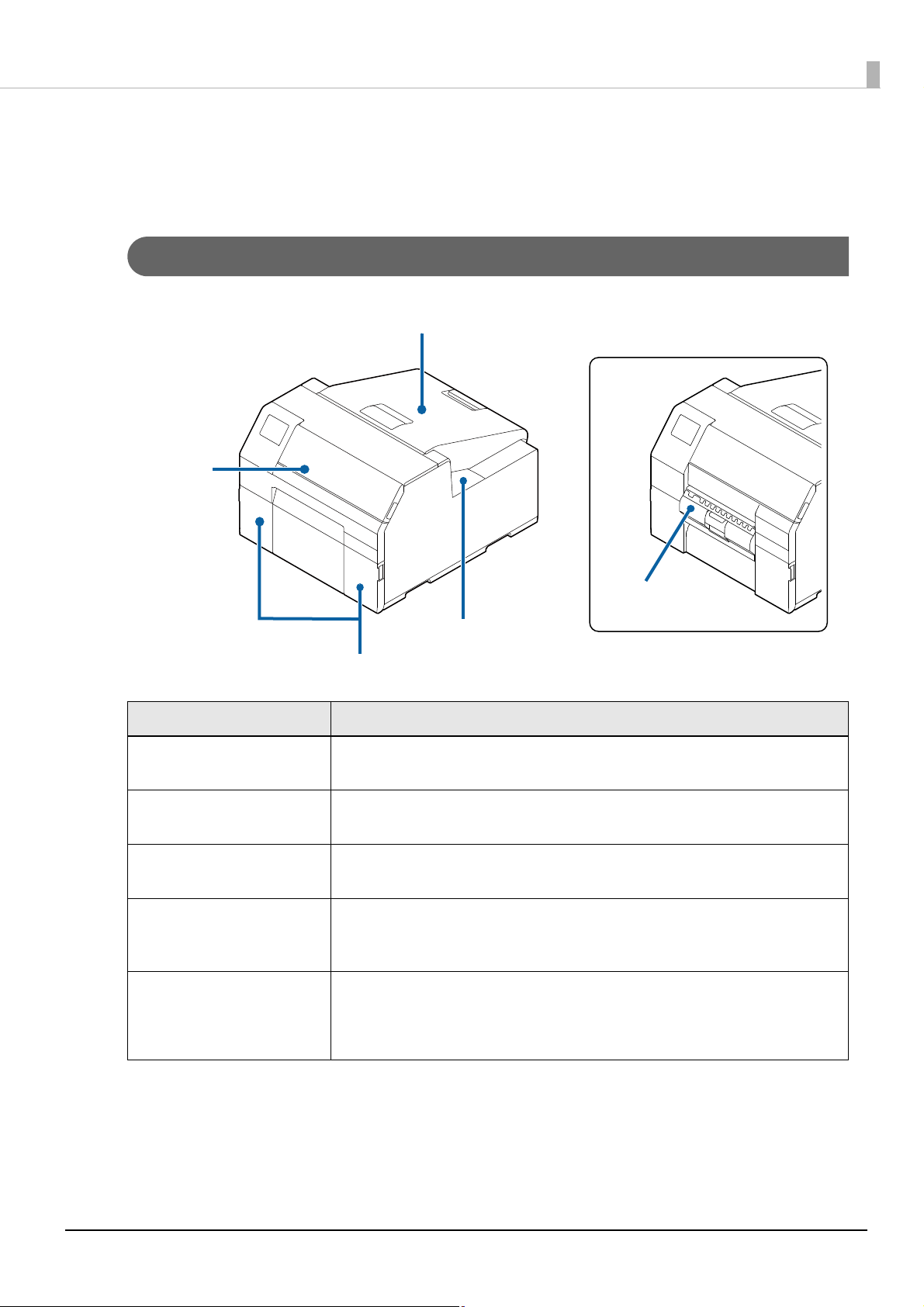

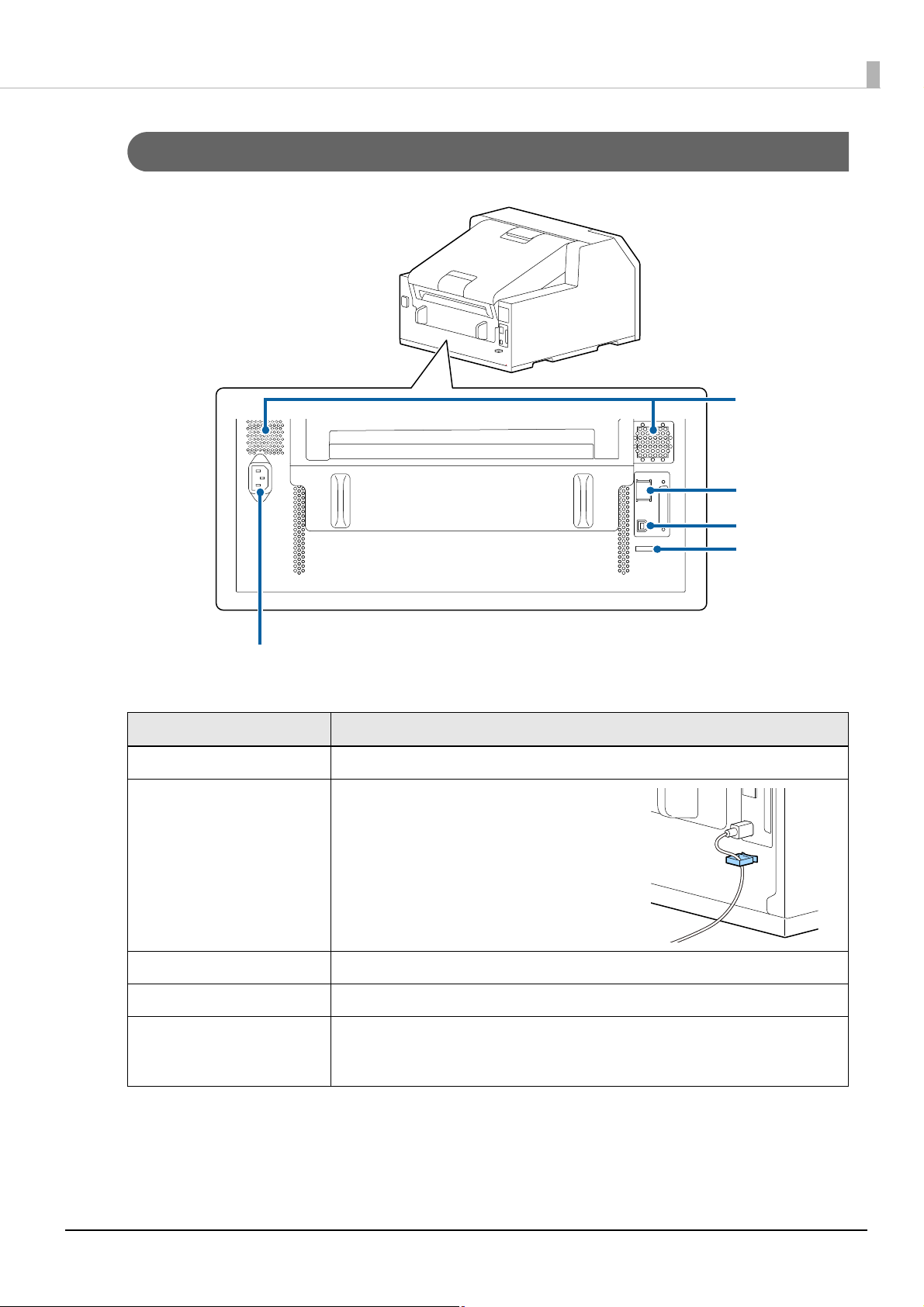

Part Names and Functions

Paper cover

Front cover

Ink cartridge cover

Maintenance box cover

Peeler cover

Peeler model

This section describes the main operation parts.

Front

Chapter1 Product Overview

Name Description

Front cover Open this cover to remove paper if it is jammed.

("Paper is jammed" on page 280)

I

nk cartridge cover Open this cover to install/replace the ink cartridge.

("Replacing the Ink Cartridges" on page 40)

Maintenanc

P

aper cover Open this cover to load or replace paper. How to open the paper cover differs

P

eeler cover

(peeler model only)

e box cover Open this cover to install/replace the maintenance box.

("Replacing the Maintenance Box" on page 42)

depending on whether the paper is to be supplied from the inside or the outside.

("Opening the Paper Cover" on page 48)

Open this cover to load paper. By passing a backing paper through the peeler, labels

are printed being peeled from the backing paper. The cover is equipped with a label

peeling detector, which detects whether a peeled label is remaining at the paper

ejection slot or not.

20

Page 21

Rear

Air vent

LAN port

USB port

Wire saddle

Power connector

Chapter1 Product Overview

Name Description

Power connector Connect the power cable.

Wire saddle Pass the USB cable through this saddle to

prevent disconnection of the cable.

USB port Connect a USB cable.

LAN port Connect a LAN cable.

Air vent Exhausts heat generated in the printer to prevent the temperature inside the printer

from rising. Provide a clearance of 10 cm {3.94"} or more from the area around the air

vent to ensure ventilation when installing the printer.

21

Page 22

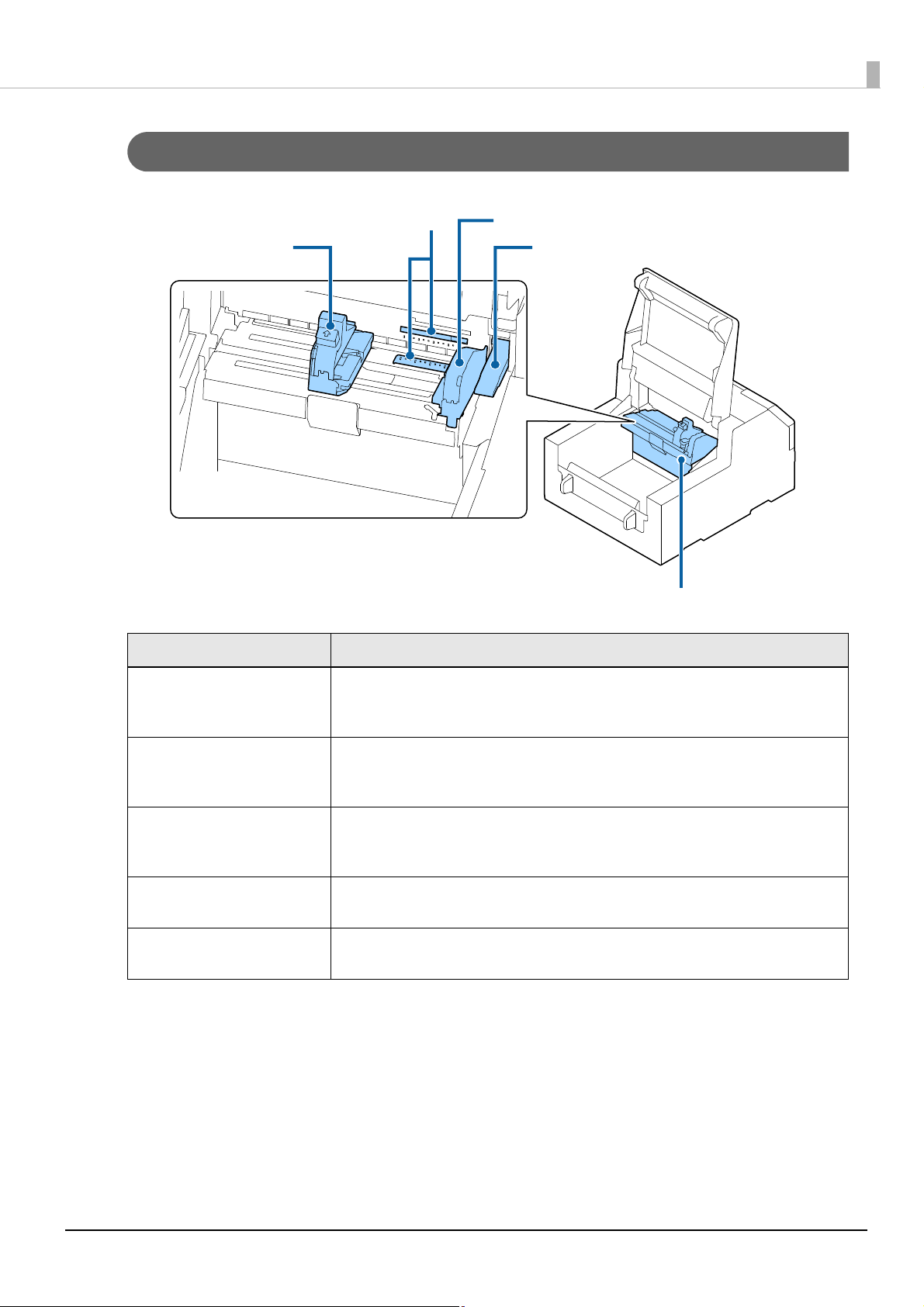

Inside

Movable edge guide

Gap detector

Edge guide

Release lever

Paper guide unit

Chapter1 Product Overview

Movable edge guide Supports paper at the paper width position while the paper is fed into the printer.

Gap detector You can adjust the position of the gap detector. The adjustment is necessary before

Rele

ase lever Use this lever when removing a jammed paper. By moving the lever up, the paper

Edge guide Supports paper while the paper is fed into the printer. When loading paper, load the

Paper guide unit Move this unit when cleaning the paper feed roller. If you pull the blue lever, the entire

Name Description

Squeeze the blue lever to move the edge guide. Adjust them to match the paper

width.

printing on odd-shaped labels such as circle or oval. ("Adjusting Gap Detector" on page

246)

pressure rollers are unlocked and you can remove paper jammed inside the front

cover.

paper along this guide.

unit moves, and you can check the paper feed roller.

22

Page 23

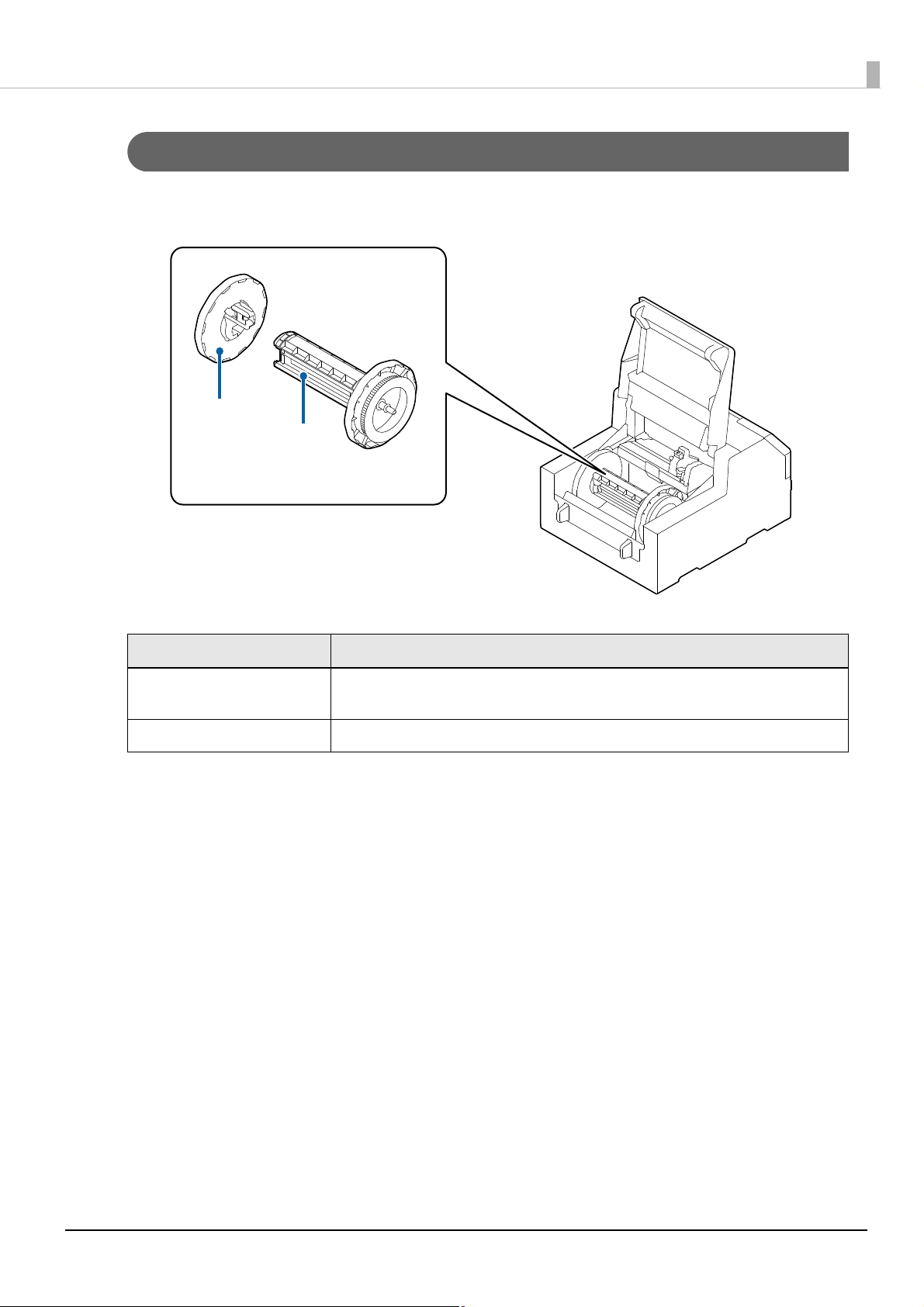

Spindle and Flange

Flange

Spindle

Used to supply the paper from the inside.

Chapter1 Product Overview

Name Description

Flange Attach this to the spindle to fix the roll paper loaded on the spindle. Squeeze the blue

lever to attach or remove to/from the spindle.

Spindle Load roll paper on this spindle.

23

Page 24

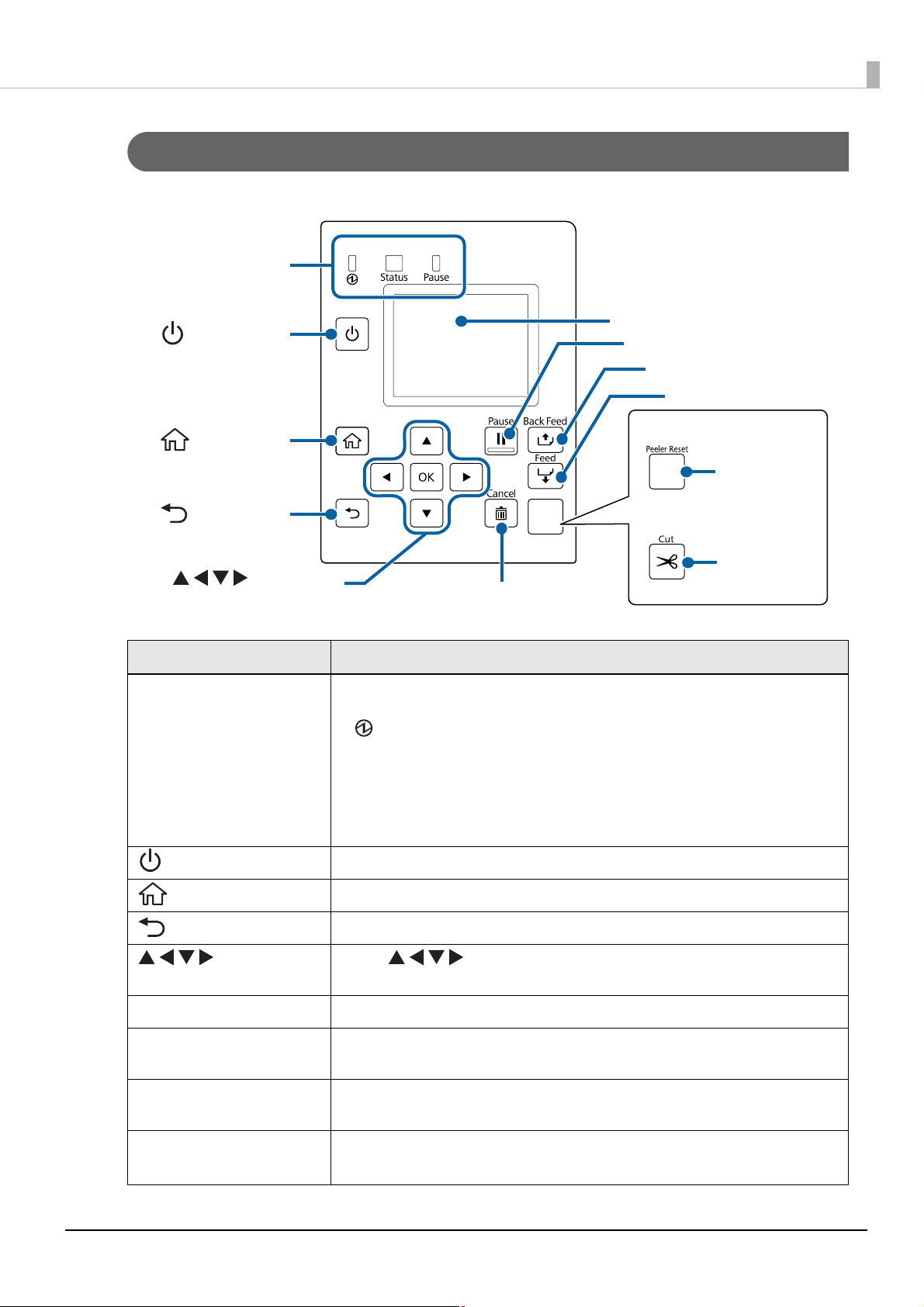

Operation Panel

LED

Peeler model

Auto cutter model

Screen

Cancel button

Pause button

Back Feed button

Feed button

Peeler Reset

button

Cut button

(power) button

(select) button,

OK button

(home) button

(back) button

Chapter1 Product Overview

Name Description

LED The status of the printer can be checked from the flashing of the LEDs. This allows you

to know the cause of an error and how to resolve the problem.

• (power) LED

Stays on while the printer is on. Flashes during printing or charging ink.

• Status LED

Stays on or flashes while an error or problem is occurring.

• Pause LED

Stays on or flashes while the printer is paused.

(power) button Turns on/off the printer.

(home) button Displays the Home screen.

(back) button Use to return to the previous screen.

(select) button,

OK button

Cancel button Press this to cancel a print job.

Cut button

(Auto cutter model only)

Peeler Reset button

(Peeler model only)

F

eed button Press this briefly to feed paper by one page.

Use the keys to select a menu item, and then press the OK button to

activate the selected menu or setting.

Use to cut paper. The paper cannot be cut twice at the same position.

Press this button if printing of the next data does not start even after removing printed

labels. For details, refer to "Cannot Print" on page 274.

Hold down to feed paper continuously.

24

Page 25

Chapter1 Product Overview

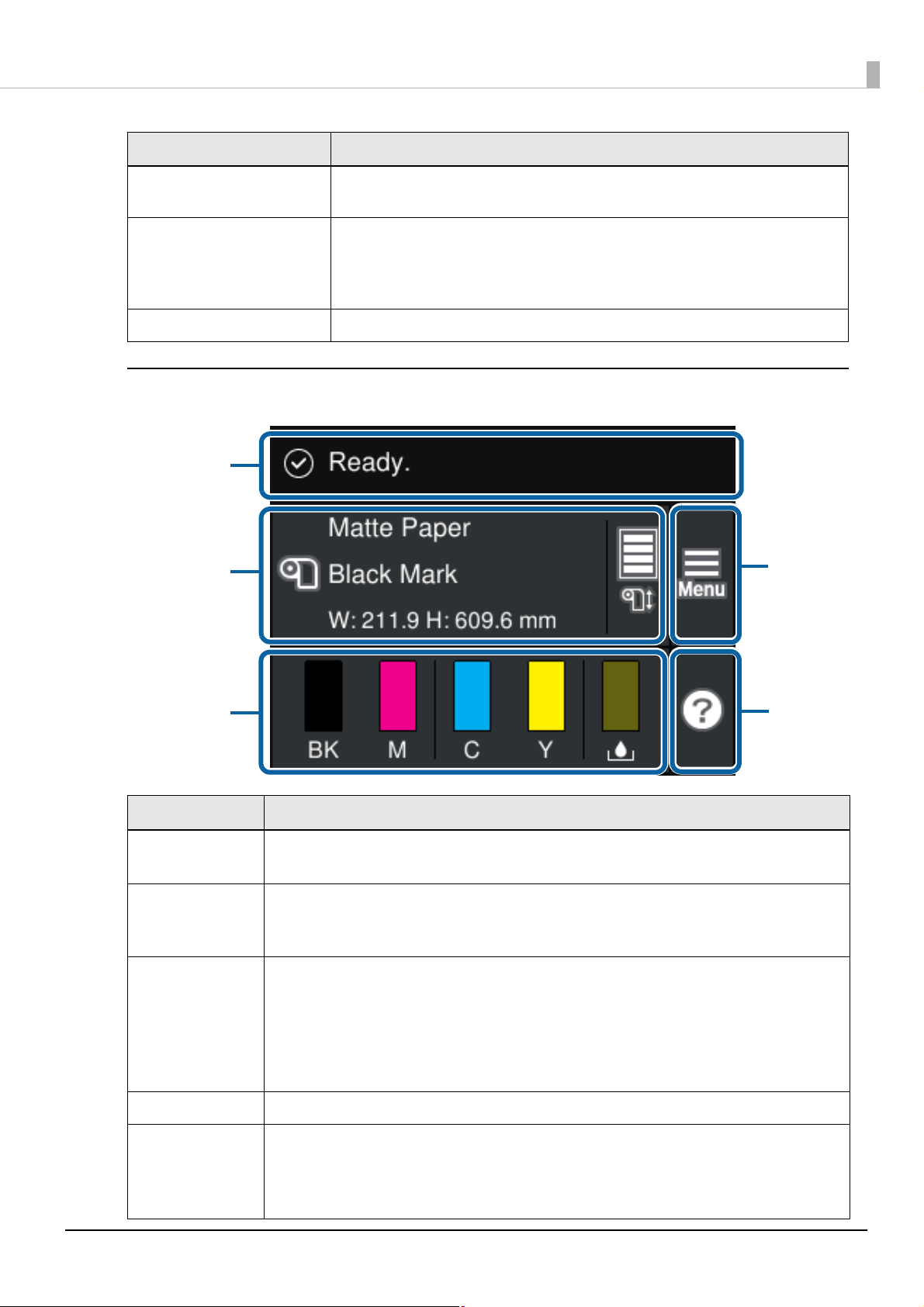

Message

Paper information

Ink levels/

Waste ink level

Settings

menu

Help

menu

Name Description

Back Feed button Use to replace paper. Hold down this button to feed the paper backward until you can

pull the paper out of the printer.

Pause button While printing: Press to stop printing after printing the current page. Press again to

resume printing.

During standby: Press to stop the printer temporarily. Press again to put the printer

back into the standby state.

Screen Status of the printer, menus, and error messages are displayed.

Home Screen

Name Description

Message A printer status or an error message is displayed.

("A message is displayed on the operation panel." on page 267)

P

aper information The current paper settings are displayed. For a roll paper, approximate remaining paper length of

the roll is also displayed.

Touch this area to directly access the [Paper Settings] menus.

Ink levels/

Waste ink level

Help menu button You can see troubleshooting information and basic operating procedures.

Settings button Allows you to access the maintenance menus, various printer settings, and network settings.

The length of the bars indicate how much ink of each color is remaining, and how much space in

the maintenance box is remaining. The shorter the bars are, the lower the ink levels and remaining

space are.

A [ ! ] mark will appear when the ink cartridge or the maintenance box needs to be replaced soon.

A [ x ] mark will appear when the ink cartridge or the maintenance box needs to be replaced.

Matte black ink is displayed as "MK".

Throughout this manual, touching this button is indicated as [Menu].

All the settings available from this button are listed in the link below.

("Operation Panel Settings" on page 204)

25

Page 26

Chapter1 Product Overview

Nozzle Verification Technology

The “Nozzle Verification Technology” allows the printer to detect clogging of the print nozzles by self-check.

Depending on required print quality, you can enable or disable the “Nozzle Verification Technology” function,

set how often to run the self-check, threshold for the check, and whether to run a cleaning after the check. In

addition to that, if nozzle clogging is not cleared by the cleaning, the printer carries out supplemental printing

using nozzles adjacent to the clogged nozzles.

By using this function, you can prevent sharp decline in the print quality and barcode quality.

Nozzle Verification Technology Settings

Self nozzle check is run at the following times.

• When the printer is turned on.

• When the front cover or the paper cover is closed after a paper jam.

• Just before running a regularly scheduled cleaning.

("Periodic Auto Cleaning" on page 29)

f the “Nozzle Verification Technology” function is enabled, self nozzle check is run at the following time.

I

• When the number of printouts has reached the number specified as the interval of the self-check.

If the result of self nozzle check exceeds the specified threshold, a head cleaning is run automatically to clear the

nozzle clogging. After the cleaning, the self nozzle check is run again. If the result of the check still exceeds the

threshold, auto cleaning is also run again.

This function cannot provide 100% accuracy guarantee for preventing drop in print quality due to

nozzle clogging. The printer cannot perfectly detect missing dots and skewed ink drops on printouts.

CAUTION

• The cleaning cleans the entire print head. It does not clean the print head partially for cleaning

only the clogged nozzles.

• A small amount of ink is consumed for this Nozzle Verification Technology function.

• The print head cleaning is run automatically after the self nozzle check when set to do so. Ink is

consumed for the head cleaning.

Enabling/Disabling the Nozzle Verification Technology

You can enable or disable the Nozzle Verification Technology function.

The factory default is “Enable”.

How to Set

Set using the operation panel of the printer, or using PrinterSetting.

See "Operation Panel Settings" on page 204 or "PrinterSetting (Windows)" on page 164.

26

Page 27

Chapter1 Product Overview

Setting Auto Nozzle Check Interval

Specify the number of printouts to let the printer run the nozzle check when reached the number. The printer

will stop while running the check.

How to Set

Set using the operation panel of the printer, or using PrinterSetting.

Specify the number in the range of 1 to 13000.

See "Operation Panel Settings" on page 204 or "PrinterSetting (Windows)" on page 164.

• The count of printouts is reset when the specified number is reached and nozzle check is performed,

and when the printer is turned off.

• The factory default is “500”.

Setting Threshold of Nozzle Clogging

Specify the threshold of nozzle clogging. If the number of detected clogged nozzles exceed the threshold, a

message is displayed on the printer’s screen. You can set to run an auto head cleaning in such a case. If the

number of clogged nozzles is below the threshold, you can use the supplemental printing function.

How to Set

Set using the operation panel of the printer, or using PrinterSetting.

Specify the number in the range of 0 to 16 nozzles.

See "Operation Panel Settings" on page 204 or "PrinterSetting (Windows)" on page 164.

• The number of nozzles is the total of four color (BK (MK), C, M, Y) nozzles.

• The factory default is “6”.

Setting Auto Cleaning after Nozzle Check

You can set to run an auto head cleaning when the number of detected clogged nozzles exceeds the threshold.

When this setting is enabled: A message is displayed on the printer’s screen and the cleaning is run

automatically when the number of detected clogged nozzles exceeds the threshold.

When this setting is disabled: A message is displayed on the printer’s screen when the number of detected

clogged nozzles exceeds the threshold, but the cleaning is not run.

How to Set

Set using the operation panel of the printer, or using PrinterSetting.

The factory default is “Enable”.

See "Operation Panel Settings" on page 204 or "PrinterSetting (Windows)" on page 164.

27

Page 28

Chapter1 Product Overview

Dot Substitution (Supplemental Printing) Function

The “Dot Substitution” function automatically supplements missing dots caused by clogged nozzles with dots

generated by nozzles adjacent to the clogged nozzles. The number of nozzles that can be supplemented is up to

16 nozzles. However, if the clogged nozzles are located next to each other, the supplementation does not work

well. If the number of clogged nozzles exceeds 16, supplementation for 16 nozzles is performed without

stopping the printing operation.

You cannot use this function if you have disabled the Nozzle Verification Technology function. Enable the

Nozzle Verification Technology function to use this function.

• This function cannot perfectly supplement missing dots, so drop in print quality or barcode quality

can occur even if this function is used.

• Since the supplementation is performed according to information of clogged nozzles that has been

acquired when starting printing, nozzles that get clogged during printing are not supplemented.

How to Set

Set using the operation panel of the printer, or using PrinterSetting.

The factory default is “Enable”.

See "Operation Panel Settings" on page 204 or "PrinterSetting (Windows)" on page 164.

28

Page 29

Chapter1 Product Overview

Periodic Auto Cleaning

Sometimes, the printer runs a periodic cleaning automatically to maintain the print head in good condition.

The cleaning takes 3 to 14 minutes, and printing is disabled during the cleaning. To prevent the cleaning from

running when you want to print, set the time to start the periodic auto cleaning.

The cleaning will start at the specified time. However, the cleaning is not run if the printer determines that the

print head does not need to be cleaned.

Setting the cleaning start time allows you to clean the print head without interrupting printing operation. The

default time is “0:00”.

Setting Time to Start the Periodic Auto Cleaning

Set using the operation panel of the printer, or using PrinterSetting.

During the cleaning, printing is disabled. Specify a time when the printer is on but not in use. The time can be

set in one-minute increments.

For the setting procedure, see "Operation Panel Settings" on page 204 or "Printer settings" on page 182.

• The cleaning takes 3 to 14 minutes.

• If you set a time within less than 10 minutes from the current time, the cleaning is run at the set time

24 hours later.

Execution of the Periodic Auto Cleaning

At the set time, the cleaning is automatically run if the printer is on and it determines that the cleaning is

necessary.

• If the printer has been left unused without being powered on for a long time, the cleaning may be run

when the printer is turned on.

• In the following cases, the cleaning is not run at the set time. It is run next time the printer is turned

on.

- The printer is not powered on.

- The ink level is too low to run the cleaning, or some ink cartridge(s) needs to be replaced.

- The remaining amount of space in the maintenance box is too low to run the cleaning, or the box

needs to be replaced.

Examples of the Time Setting to Avoid Interrupting Printing Operation

The followings are examples of the cleaning start time setting to reduce the likelihood of unintended cleaning

during printing.

In the case that the printer is always powered on

Set the time to a time that printing work is not performed, such as midnight.

In the case that the printer is powered on and off every day

• Set the time to a time that the printer is off, such as midnight, to let the printer run the cleaning right after it

is powered on.

• If printing work is not performed during lunch break, set the time to a time such as 12:00 in order to let the

printer run the cleaning during the lunch break.

29

Page 30

Chapter1 Product Overview

Checking the Printer Status

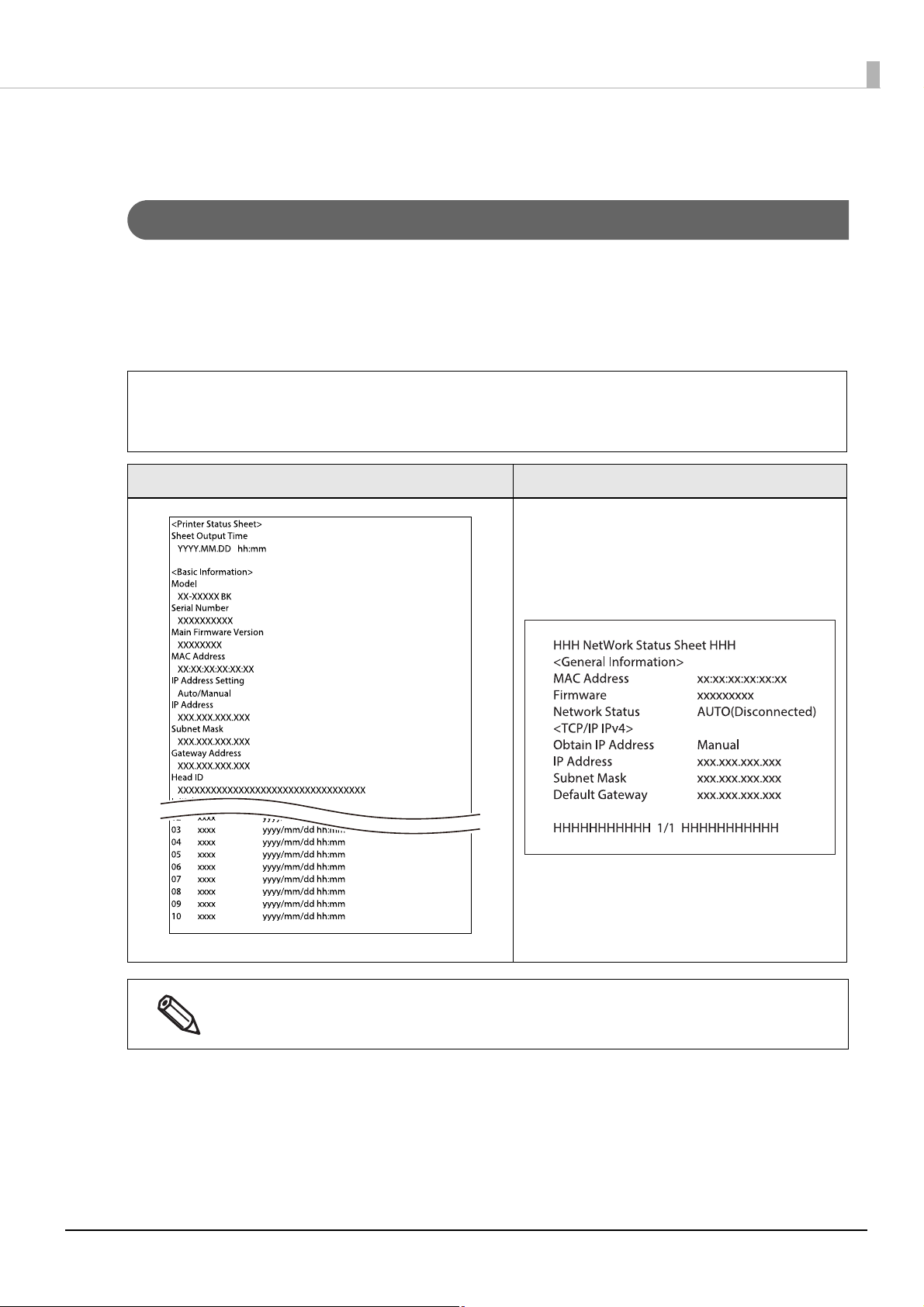

Printing the Status Sheet

By printing the status sheet, you can check the firmware version and the current printer settings, such as print

mode and media detection settings.

On the operation panel, select the menu in the order shown below to print the status sheet.

[Menu] - [Printer Status/Print] - [Print Status Sheet]

To print the status sheet, load paper that has a label that measures at least 4 inches width and 6

c

IMPORTANT

inches long.

Status Sheet Example Status Sheet (Network Settings) Example

You can also print a list of registered fonts, barcode fonts, images or templates.

30

Page 31

Chapter1 Product Overview

Printing the Network Connection Check Report

By printing the network connection check report, you can check the network connection status and the network

settings.

On the operation panel, select the menu in the order shown below to print the report.

[Menu] - [General Settings] - [Network Settings] - [Connection Check]

To print the network connection check report, load paper that has a label that measures at least 4

c

IMPORTANT

inches width and 6 inches long.

Network Connection Check Report Example

31

Page 32

Chapter1 Product Overview

Checking the Status of Consumables

On the home screen of the printer, you can check the following information; the status of the ink cartridges and

the maintenance box, paper settings (paper type, detection method, label width/length), remaining amount of

paper. ("Home Screen" on page 25)

32

Page 33

Setup

This chapter describes procedures for installing and setting up the printer that are required before using the

printer.

Unpacking

After unpacking, make sure that all the printer and the accessories are included and they have no damages.

The included items are as follows.

Chapter2 Setup

1 Printer (CW-C6000 Series or CW-C6500 Series) 2 Ink cartridges for initial setup; C, M, Y, BK (MK)*

* Either one of a BK (gloss black) cartridge or MK

(matte black) cartridge is included.

3 Roll paper (for initial operation check) 4 Flange and Spindle

5 Power cable 6 USB cable

7 CD-ROM (not included depending on country or

region)

9 Power cable for specific regions (not included

depending on country or region)

8Manual

33

Page 34

Removing the Protective Materials

Remove the all protective materials such as pieces of tape and cushion materials. There are about eight

protective materials and some of them have been attached to inside the printer.

Chapter2 Setup

34

Page 35

Chapter2 Setup

Installing the Printer

Allow sufficient space for the printer. Make sure that the installation location meets the following requirements.

• On a level and stable surface with sufficient strength to support the weight of the printer

Auto cutter model Peeler model

CW-C6000 Series Approx. 22.5 kg Approx. 22.8 kg

CW-C6500 Series Approx. 25.5 kg Approx. 26.3 kg

• On an area larger than the bottom surface of the printer.

• A location that is not subject to vibrations and impacts.

• A location where a dedicated power outlet is available.

• A location where you can load and remove paper without difficulty.

• A location with sufficient space around the printer to allow for installation of accessories, replacement of

consumable products, and daily cleaning.

• A location that meets the following environmental requirements.

For more details, see "Environmental Specifications" on page 349.

Te mp e ra tu r e Humidity

Printing 5 to 35°C 20 to 80% RH, No condensation

Storage Gloss black ink -20 to 40°C 5 to 85% RH, No condensation (without being unpacked)

Matte black ink -10 to 40°C

• Make sure to carry the printer by two or more persons.

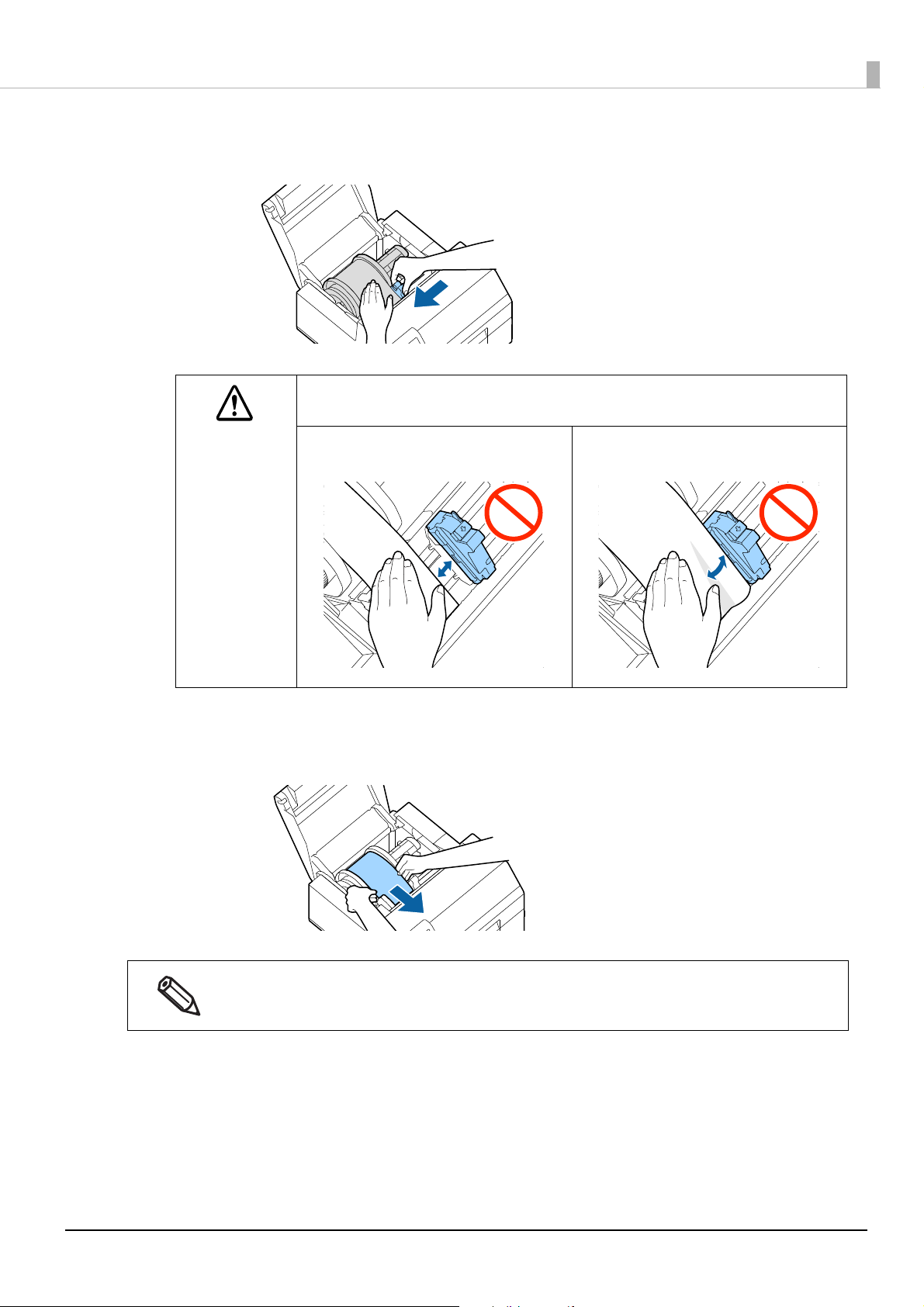

• To lift the printer, put your hands on the indented portions on the side of the printer as shown

CAUTION

below. If you put your hands on the other portions of the printer to lift it, the printer may get

damaged.

• Do not install the product at a location exposed to strong light such as direct sun rays. Doing so

may result in printing failure due to malfunction of the detectors.

• If the printer has charged matte black ink and is more likely to be exposed to a temperature of -10

or lower degrees C, make sure to discharge ink before turning the printer off. Otherwise, the print

head may be damaged due to freezing. For more details, see

on page 264

.

"Storing the Printer After Ink is Charged"

35

Page 36

Connecting the Power Cable

Follow the procedure below to connect the power cable.