Epson CW-C6000Au, CW-C6000Pu, CW-C6000Ae, CW-C6000Pe, CW-C6010A Command Reference Guide

...

Command Reference Guide

M00097706

Rev. G

Cautions

1. No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Seiko Epson

Corporation.

2. The contents of this document are subject to change without notice. Please contact us for the latest information.

3. While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

4. Neither is any liability assumed for damages resulting from the use of the information contained herein.

5. Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for

damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or abuse of

the product(s) to which this document relates or unauthorized modifications, repairs, or alterations to the product(s) to

which this document relates, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation's operating

and maintenance instructions.

6. Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original EPSON Products or EPSON Approved Products by Seiko

Epson Corporation

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/Label are registered trademarks or trademarks of Seiko Epson Corporation.

Zebra Technologies Corporation and ZPL II are the registered trademarks or trademarks of Zebra Technologies Corporation.

General Notice: Other product and company names used herein are for identification purposes only and may be trademarks of

their respective companies.

All other trademarks are the property of their respective owners and used for identification purpose only.

©Seiko Epson Corporation 2016-2020. All rights reserved.

ESC/Label Command Reference Guide

Rev. G Page 2

About this Document

Item

Description

expressions)

examples of ESC/Label commands

2 Primary Functions

Key features of the ESC/Label command

Specifications

Appendix

The list of the mode and the setting

ESC/Label commands.

(1) Scope of this document

This document describes ESC/Label commands. ESC/Label commands are used to control Epson’s

label printers.

This document is designed for those who use ESC/Label commands to develop programs to control

printers. Please refer to the ESC/Label Application Development Guide when developing programs.

Refer to the attached Command List for commands used and definition ranges for each model.

(2) Content of the specification

The content of this document is outlined below.

Content of the specification

About this Document Positioning and content of this document, definitions (terminology,

1 Commands Outline Characteristics, configuration, basic specifications, and usage

3 Detailed Command

Command List (Attachment) Indicates commands used by model and their corresponding

(3) Definitions

Hexadecimal values are expressed with numbers 0 – 9 and letters A – F, along with the letter H (first (a)

letter of HEX).

Example: 1AH

Outside of command code descriptions, commands are enclosed within double quotation marks and (b)

command codes are enclosed in parentheses.

Example: "^F(C" (field color settings)

Units are expressed by the unit name enclosed in square brackets. (c)

Examples: [dot], [mm]

The following are enclosed in angle brackets. (d)

Control codes Examples: <CR>, <STX>

Uniquely defined terms Example: <prefix character>

Non-alphanumeric characters Example: Comma <,>

Detailed specifications of the ESC/Label command

parameter definition ranges in the commands included in the

ESC/Label Command Reference Guide

Rev. G Page 3

TABLE OF CONTENTS

1. Commands Outline ......................................................................................................................................................... 8

1.1. Characteristics.......................................................................................................................................................... 8

1.2. Structure ................................................................................................................................................................... 9

1.3. Command Basic Specifications........................................................................................................................... 10

Format Commands and Control Commands .............................................................................................. 10 1.3.1

Basic Data Format for the Command ............................................................................................................ 10 1.3.2

Command Syntax ............................................................................................................................................. 12 1.3.3

About Saving the Graphics and Label Formats in the Printer .................................................................. 12 1.3.4

1.4.

Example of Command Use .................................................................................................................................. 13

Basic Label Printing .......................................................................................................................................... 13 1.4.1

Color Label Printing .......................................................................................................................................... 14 1.4.2

Serialized Printing ............................................................................................................................................. 15 1.4.3

Saving a File for a Label Format ..................................................................................................................... 16 1.4.4

Printing Using the Label Format File ............................................................................................................ 17 1.4.5

Getting Status .................................................................................................................................................... 18 1.4.6

2.

Primary Functions .......................................................................................................................................................... 19

2.1. Fonts ........................................................................................................................................................................ 19

Font type ............................................................................................................................................................ 20 2.1.1

Special symbols ................................................................................................................................................. 21 2.1.2

2.2.

Media settings ....................................................................................................................................................... 21

Media coating type ........................................................................................................................................... 21 2.2.1

Media form ......................................................................................................................................................... 22 2.2.2

Label edge detection ....................................................................................................................................... 22 2.2.3

Media source ..................................................................................................................................................... 22 2.2.4

Media shape ....................................................................................................................................................... 22 2.2.5

2.3.

Errors ........................................................................................................................................................................ 23

2.4. Print area ................................................................................................................................................................. 24

Leading edge and direction definitions ....................................................................................................... 25 2.4.1

Reference position definitions ....................................................................................................................... 26 2.4.2

Maximum printable area ................................................................................................................................. 27 2.4.3

Printable area and mount settings ................................................................................................................ 28 2.4.4

Print area and margin settings ....................................................................................................................... 29 2.4.5

Print requests outside the print area ............................................................................................................ 30 2.4.6

Print area settings using ZPL II commands .................................................................................................. 31 2.4.7

2.5.

Getting and Setting Printer Information .......................................................................................................... 32

Method for Setting Printer Information ....................................................................................................... 33 2.5.1

Method for Getting Printer Information ....................................................................................................... 34 2.5.2

2.6.

Designating Color ................................................................................................................................................. 36

2.7. Field color reversal ................................................................................................................................................ 38

2.8. Printing Graphics ................................................................................................................................................... 40

Registering a Graphic in a Printer and Printing It ....................................................................................... 40 2.8.1

Embedding a Graphic in the Field and Printing It ...................................................................................... 41 2.8.2

3.

Detailed Command Specifications ............................................................................................................................. 42

^A ...................................................................................................................................................................................... 43

^A@ .................................................................................................................................................................................. 44

^B(Q .................................................................................................................................................................................. 45

^B(R .................................................................................................................................................................................. 48

^B(V .................................................................................................................................................................................. 50

^B0 ^BO ........................................................................................................................................................................... 51

ESC/Label Command Reference Guide

Rev. G Page 4

^B2 .................................................................................................................................................................................... 53

^B3 .................................................................................................................................................................................... 54

^B7 .................................................................................................................................................................................... 55

^B8 .................................................................................................................................................................................... 57

^B9 .................................................................................................................................................................................... 58

^BA ................................................................................................................................................................................... 60

^BC ................................................................................................................................................................................... 63

^BD ................................................................................................................................................................................... 68

^BE .................................................................................................................................................................................... 70

^BF .................................................................................................................................................................................... 71

^BK .................................................................................................................................................................................... 73

^BQ ................................................................................................................................................................................... 74

^BR .................................................................................................................................................................................... 78

^BU ................................................................................................................................................................................... 80

^BX ................................................................................................................................................................................... 81

^BY .................................................................................................................................................................................... 85

^C(D .................................................................................................................................................................................. 86

^C(L .................................................................................................................................................................................. 87

^C(S .................................................................................................................................................................................. 88

^CC ~CC ....................................................................................................................................................................... 89

^CD ~CD ...................................................................................................................................................................... 90

^CF .................................................................................................................................................................................... 91

^CI ..................................................................................................................................................................................... 92

^CM .................................................................................................................................................................................. 94

^CT ~CT ........................................................................................................................................................................ 95

^CV ................................................................................................................................................................................... 96

^CW .................................................................................................................................................................................. 97

~DE ................................................................................................................................................................................... 98

^DF ................................................................................................................................................................................... 99

~DG ................................................................................................................................................................................. 100

~DN................................................................................................................................................................................. 102

~DU ................................................................................................................................................................................. 103

~DY ................................................................................................................................................................................. 104

^F(C ................................................................................................................................................................................ 107

^FB .................................................................................................................................................................................. 109

^FC .................................................................................................................................................................................. 110

^FD ................................................................................................................................................................................. 111

^FH ................................................................................................................................................................................. 112

^FM ................................................................................................................................................................................. 113

^FN ................................................................................................................................................................................. 114

^FO ................................................................................................................................................................................. 115

^FP .................................................................................................................................................................................. 117

^FR .................................................................................................................................................................................. 118

^FS .................................................................................................................................................................................. 119

^FT .................................................................................................................................................................................. 120

^FV .................................................................................................................................................................................. 123

^FW ................................................................................................................................................................................ 124

^FX .................................................................................................................................................................................. 126

^GB ................................................................................................................................................................................. 127

^GC ................................................................................................................................................................................. 128

ESC/Label Command Reference Guide

Rev. G Page 5

^GD ................................................................................................................................................................................. 129

^GE ................................................................................................................................................................................. 130

^GF ................................................................................................................................................................................. 131

^GS ................................................................................................................................................................................. 133

~H(C ................................................................................................................................................................................ 134

~H(I ................................................................................................................................................................................. 136

~H(Q ............................................................................................................................................................................... 139

~H(S ................................................................................................................................................................................ 142

~H(Y ................................................................................................................................................................................ 144

^HF ................................................................................................................................................................................. 146

^HG ................................................................................................................................................................................. 147

^HH ................................................................................................................................................................................. 148

~HI .................................................................................................................................................................................. 149

~HM ................................................................................................................................................................................ 150

~HS ................................................................................................................................................................................. 151

^HW ................................................................................................................................................................................ 153

^HY ................................................................................................................................................................................. 155

^ID .................................................................................................................................................................................. 156

^IL ................................................................................................................................................................................... 157

^IM .................................................................................................................................................................................. 158

^IS ................................................................................................................................................................................... 159

~J(C ................................................................................................................................................................................. 160

~J(M ................................................................................................................................................................................ 161

~JA .................................................................................................................................................................................. 162

^JB .................................................................................................................................................................................. 163

~JC .................................................................................................................................................................................. 164

^JM ................................................................................................................................................................................. 165

~JP .................................................................................................................................................................................. 166

~JR .................................................................................................................................................................................. 167

~JS ................................................................................................................................................................................... 168

^JU .................................................................................................................................................................................. 169

~JX .................................................................................................................................................................................. 170

^JZ .................................................................................................................................................................................. 171

^KL .................................................................................................................................................................................. 172

^LH ................................................................................................................................................................................. 173

^LR .................................................................................................................................................................................. 174

^LS .................................................................................................................................................................................. 175

^LT .................................................................................................................................................................................. 176

^MC ................................................................................................................................................................................ 177

^MF ................................................................................................................................................................................. 178

^MM ............................................................................................................................................................................... 179

^MN ................................................................................................................................................................................ 180

^MP ................................................................................................................................................................................ 181

^MU ................................................................................................................................................................................ 182

^PH ................................................................................................................................................................................. 184

~PH ................................................................................................................................................................................. 186

^PM ................................................................................................................................................................................ 187

^PO ................................................................................................................................................................................. 188

^PP .................................................................................................................................................................................. 191

~PP .................................................................................................................................................................................. 192

ESC/Label Command Reference Guide

Rev. G Page 6

^PQ ................................................................................................................................................................................. 193

~PS .................................................................................................................................................................................. 194

~RO ................................................................................................................................................................................. 195

^S(C ................................................................................................................................................................................ 196

^SE .................................................................................................................................................................................. 197

^SF .................................................................................................................................................................................. 198

^SL .................................................................................................................................................................................. 199

^SN ................................................................................................................................................................................. 200

^SO ................................................................................................................................................................................. 201

^ST .................................................................................................................................................................................. 202

~TA ................................................................................................................................................................................. 203

^TB .................................................................................................................................................................................. 204

^TO ................................................................................................................................................................................. 205

~W(P ............................................................................................................................................................................... 206

~WC ................................................................................................................................................................................ 207

^WD ................................................................................................................................................................................ 208

^XA ................................................................................................................................................................................. 209

^XB ................................................................................................................................................................................. 210

^XF .................................................................................................................................................................................. 211

^XG ................................................................................................................................................................................. 212

^XZ ................................................................................................................................................................................. 213

Appendix A: List of Printer Operation Modes .......................................................................................................... 214

Appendix B: List of Printer Operation Statuses ....................................................................................................... 227

Appendix C: List of Printer Information .................................................................................................................... 232

REVISION SHEET (Summary) ............................................................................................................................................... 233

REVISION SHEET (Detail) ...................................................................................................................................................... 234

ESC/Label Command Reference Guide

Rev. G Page 7

1. Commands Outline

1.1. Characteristics

ESC/Label command is a command system that has the following characteristics.

(1) It includes much of the ZPL II command and is highly compatible with your existing system.

(2) The command is primarily in the text data format and is highly compatible with database or Web

technology.

(3) It can arrange text, barcodes, or graphics in any position on the label and perform color printing.

(4) It is well-suited for batch printing through the serialized designation function and the print count

designation function.

(5) Due to its simple command syntax, it helps prevent printing mistakes from failing to control the printer.

(6) Because you can save the graphic and label format in the printer, you can print labels with a small

amount of transmitted data.

(7) You can get the printer operation status or the printer operation mode whenever you like.

ESC/Label Command Reference Guide

Rev. G Page 8

1.2. Structure

Command type

Example

Thermal head device control commands

Setting the thermal head resistance value

RFID control commands

Reading, writing the RFID

Commands related to wireless

Wireless LAN settings

Commands related to battery control

Transmitting battery status

ESC/Label command consists of the major commands of the ZPL II command and Epson's original

extension.

(1) It includes the major commands for ZPL II, which is mainstream in the monochrome thermal label

printer market.

(2) Epson's original commands and parameter expansions are included to realize color label printing on an

inkjet printer.

ESC/label command

ZPL II

ZPL II

Commands necessary for label

printing and inkjet printer control

*Epson parameter expands on some

commands.

Commands not included in ESC/label

command

Epson additional

commands

Epson original expansions

Table1.2.1 indicates the parts of ZPL II commands not included in ESC/Label command.

Table 1.2.1 Excerpt of Commands Not Included in ESC/Label command

Figure 1.2.1 Structure of ESC/Label command

ESC/Label Command Reference Guide

Rev. G Page 9

1.3. Command Basic Specifications

Type

Main purpose

Prefix character

Format Command

Defining and printing labels

Caret <^>

Control Command

Controlling the printer

Tilde <~>

<Prefix character>

<Command identifier>

<Parameter>

(,<Parameter>,...)

<Command code>

<Prefix character>:

Indicate a format command with a caret <^> and a control

command with a tilde <~>.

<Command identifier>:

Indicate the command type with 1 to 3 characters of ASCII

code.

<Parameters>:

Designate 1 character or more of ASCII code. This controls

and their number depend on the command type.

Format Commands and Control Commands 1.3.1

Commands for ESC/Label command belong to either format commands or control commands,

depending on their purpose and execution priority.

Format commands are used for defining and printing labels, and control commands are used for

controlling the printer. Format commands and control commands have their own fixed prefix character,

so the type can be determined based on the prefix character in the command code.

Format commands are executed FIFO (First In, First Out). A part of control commands are executed

with priority over format commands.

Table 1.3.1 Command Type by Purpose

Basic Data Format for the Command 1.3.2

ESC/Label command is defined in a character string of ASCII code (20h to 7Eh). The command

format is as follows.

The <command code> is defined as both the <prefix character> and the <command identifier>.

Commands without a parameter will be a command with just the command code. Commands with 2

or more parameters must be punctuated by a comma <,> when listed. The number of parameters a

command can have depends on the command type.

the command functions. Whether there are parameters or not

ESC/Label Command Reference Guide

Rev. G Page 10

(1) ESC/Label command Additional Command Format

<(>, and 1 character ASCII code) indicate the command type.

Format

Conditions

Processing

designated

designated.

Value less than the lower limit is

designated

The printer assumes the lower limit was

designated.

string

Undefined length

Character string that exceeds the

designated

The printer assumes the character string

length was designated.

In order to differentiate the command added to ESC/Label command from the ZPL II command, use this

format, which has added the following limit to the command identifier.

<Command identifier>:

3 characters (1 character ASCII code, an opening parenthesis

(2) Omitted Designation of Parameters

If 2 commas <,> are input following one another and the parameters are omitted, the printer will assume

default parameters are being designated. Whether there are default command parameters depends on

the command. If you omit parameter for a command which the parameter cannot be omitted, the

command will be invalid.

(3) Parameter Rounding

Parameters must take the format of being a numerical value, a fixed character string, or an undefined

length character string. Depending on the format and conditions, the parameter may be invalid or may

be rounded.

Table 1.3.2 Parameter Rounding Processing

Numerical va lue Value that exceeds the upper limit is

Fixed character

character string

Undefined characters are designated Command invalid

maximum character string length is

The printer assumes the upper limit was

up until the maximum character string

ESC/Label Command Reference Guide

Rev. G Page 11

Command Syntax 1.3.3

Definition

Syntax rule

ends with "^XZ"(End label format).

Field

Command group that begins with "^FO"(Field position setting) and

ends with "^FS"(Field end).

Format commands have command syntax rules. Control commands do not have command syntax and

are effective with just a single command.

Table 1.3.3 Command Syntax Rules

Label format Command group that begins with "^XA"(Begin label format) and

Format commands not included between "^XA"(Begin label format) and "^XZ"(End label format) are

invalid.

"^XA"(Begin label format)

"^FO"(Field position setting) "^A"(Font designation) "^FD"(Field data

setting) "^FS"(Field end)

"^FO"(Field position setting) "^B4"(Barcode designation) "^FD"(Field data

setting) "^FS"(Field end)

"^XZ"(End label format)

About Saving the Graphics and Label Formats in the Printer 1.3.4

With ESC/Label command, you can save graphics and label formats in the printer. The printer has a file

system. Data saved in the printer is handled as files and is managed in the following way.

The file system does not have a hierarchy.

The printer has a non-volatile saving device, such as Flash ROM, and a volatile saving device, such as

RAM, and different drive letters are allocated for each device.

Files are designated as

"<drive letter> colon <:> <file name> dot <.> <extension>".

Field

Label

format

Field

Figure 1.3.1 Format and Field

ESC/Label Command Reference Guide

Rev. G Page 12

1.4. Example of Command Use

Basic Label Printing 1.4.1

Perform label printing using ESC/Label command in accordance with the syntax rules shown in Section

1.3.3.

Command

(1) "^XA"(Begin label format)

(2) "^FO"(Field position setting) "^A"(Font designation)

"^FD"(Field data setting) "^FS"(Field end)

(3) "^FO"(Field position setting) "^B1"(Barcode setting)

"^FD"(Field data setting) "^FS"(Field end)

(4) "^XZ"(End label format)

Figure 1.4.1 Example of a Basic Label Printing Command

Ex: ABC in the field data setting

Ex: 12345 in the field data setting

Render the character string

Render the barcode

Print

Printer

Printed label

ABC

|||||||||

12345

The printer operates as follows.

In (2), the character string "ABC" is rendered in the rendering area.

In (3), the character string "12345" is rendered in the rendering area as a barcode.

In (4), the contents of the rendering area are printed.

ESC/Label Command Reference Guide

Rev. G Page 13

Color Label Printing 1.4.2

With ESC/Label command, add a command to set the field color to realize color rendering. When

printing a color label, designate the rendering color with "^F(C"(Field color setting).

Command

(1) "^XA"(Begin label format)

(2) "^FO"(Field position setting) "^A"(Font designation)

"^F(C"(Field color setting) "^FD"(Field data setting) "^FS"(Field

end)

(3) "^FO"(Field position setting) "^B1"(Barcode setting)

"^FD"(Field data setting) "^FS"(Field end)

(4) "^XZ"(End label format)

Ex: ABC in the field data setting,

red as the field color

Ex: 12345 in the field data setting

Print

Printer

Render the character

string

Render the barcode

ABC

|||||||||

12345

Figure 1.4.2 Example of a Command to Print a Color Label

The printer operates as follows.

In (2), the character string "ABC" is rendered in red in the rendering area.

In (3), the character string "12345" is rendered in the rendering area as a barcode.

In (4), the contents of the rendering area are printed.

ESC/Label Command Reference Guide

Rev. G Page 14

Serialized Printing 1.4.3

If performing serialized printing, designate the field data designation section in sequence, and designate

the number of copies to print.

Command

(1) "^XA"(Begin label format)

(2) "^FO" (Field position setting) "^A"(Font designation)

"^FD"(Field data setting) "^FS"(Field end)

(3) "^FO"(Field position setting) "^B1"(Barcode designation)

"^SF"(Serialization field)

(4) "^PQ"(Print quantity)

Ex: Print 10 copies

(5) "^XZ"(End label format)

Ex: ABC in the field data setting

Ex: Set 001 as the initial number and 1 as the

increment value.

Print

Printer

Render the character string

Render the sequence

Printed label

ABC

|||||||||

010

:

: 10 copies

ABC

|||||||||

001

Figure 1.4.3 Example of Command for Serialized Printing

The printer operates as follows.

In (2), the fixed character string "ABC" is rendered in the rendering area.

In (5), the image is render in accordance with the serial setting from (3) and printed the number of times

in (4)

When the second label is being printed, the following processing is done in (3).

The character string "001" is rendered in the rendering area as a barcode.

The sequence adds 1, and renders the character string "002" in the rendering area as a barcode.

The content of the rendering area is printed.

This is repeated until the 10th copy, and 001, 002, ... 010 is printed on the sequence of 10 copies.

ESC/Label Command Reference Guide

Rev. G Page 15

Saving a File for a Label Format 1.4.4

Use "^DF"(Download label format) to save a label format. If designating a different value for each label,

designate the "^FN"(Field number) in the field.

Command

(1) "^XA"(Begin label format)

(2) "^DF"(Download label format)

(3) "^FO"(Field position setting) "^A"(Font designation) "^FD"(Field

data setting) "^FS"(Field end)

(4) "^FO"(Field position setting) "^B1"(Barcode designation)

"^FN"(Field number)"^FS"(Field end)

(5) "^XZ"(End label format)

Figure1.4.4 Example of a Command to Save a Label Format File

The printer operates as follows.

In (2), the host orders the printer to save the label format with the designated file name.

In (5), the command group written between "^XA"(Begin label format) and "^XZ"(End label format) is

saved in the memory area of the printer as "SAMPLE.FMT".

Ex: The command group after this

command is saved as "SAMPLE.FMT".

Ex: ABC in the field data setting

Ex: The field is the barcode specification and

number 1 is applied to this field.

Save

Printer

SAMPLE.FMT

ESC/Label Command Reference Guide

Rev. G Page 16

Printing Using the Label Format File 1.4.5

If printing using the saved label format file, first call the command group in the label format by using

<Call the label format file>. Next, set the field data that will be the difference and perform printing.

Command

(1) "^XA"(Begin label format)

(2) "^XF"(Call label format)

Ex: 001 for the field data setting in number 1

(3) "^FN"(Field number) "^FD"(Field data setting) "^FS"(Field

end)

(4) "^XZ"(End label format)

Ex: Call "SAMPLE.FMT"

Load the contents of SAMPLE.FMT

Render the barcode

Print

Printer

SAMPLE.FMT

ABC

|||||||||

001

Figure 1.4.5 Example of Print Command Using the Label Format File

The printer operates as follows.

SAMPLE.FMT is called by the "^XF"(Call the command file) in (2).

"ABC" is rendered.

The barcode is designated in a field and the field number 1 is allocated.

The field for number 1 in (3) is barcode designation, so it is converted into a barcode and rendered.

In (4), the contents of the rendering area are printed.

ESC/Label Command Reference Guide

Rev. G Page 17

Getting Status 1.4.6

For control commands, there are no syntax rules like for format commands. The printer receives a

request for each control command.

Command

(1) "~HS"(Status request)

Figure 1.4.6 Example of a Command to Request the Status

The printer operates as follows.

In (1), the printer receives the "~HS"(Status request), and returns the status to the host.

Status request

Status response

Printer

ESC/Label Command Reference Guide

Rev. G Page 18

2. Primary Functions

Item

Details

2.1 Font

Available fonts, and their appearance

2.2 Media settings

How to set the type and form of media used for printing

2.3 Errors

Types of error, and printer operation during error status

2.4 Print area

How to set printer’s print area for a sheet of paper

information

2.6 Designating color

How to specify colors for text and graphics

2.7 Field color reversal

How to specify reversed colors for fields

2.8 Printing Graphics

How to print color and monochrome graphics

The primary functions of the ESC/Label command added or modified in comparison with ZPL II

command are shown below.

Table 2.1 Primary Functions of the ESC/Label Command

2.5 Getting and setting printer

2.1. Fonts

A font is a set of attributes for text, including image and size.

To print text with a certain font, specify the font and then use the field to specify a character code. Only

one font can be specified per field.

Figure 2.1.1 shows examples of printed text with fonts specified in multiple fields.

Printer information, and how to get/set it

FontP sample

FontC sample

FontA sample

Figure 2.1.1 Examples of Printed Text Images by Specifying Fonts

Multiple fonts are included in the printer when shipped from the factory. The user can also download

fonts to the printer at a later time.

Font types include fixed-size fonts, for which the character width and height can be specified as fixed

values or integer multiples, and scalable fonts, for which the character width and height can be specified

separately in units of [dots].

The fonts included in the printer are both fixed-size fonts and scalable fonts. However, only scalable

fonts can be downloaded.

ESC/Label Command Reference Guide

Rev. G Page 19

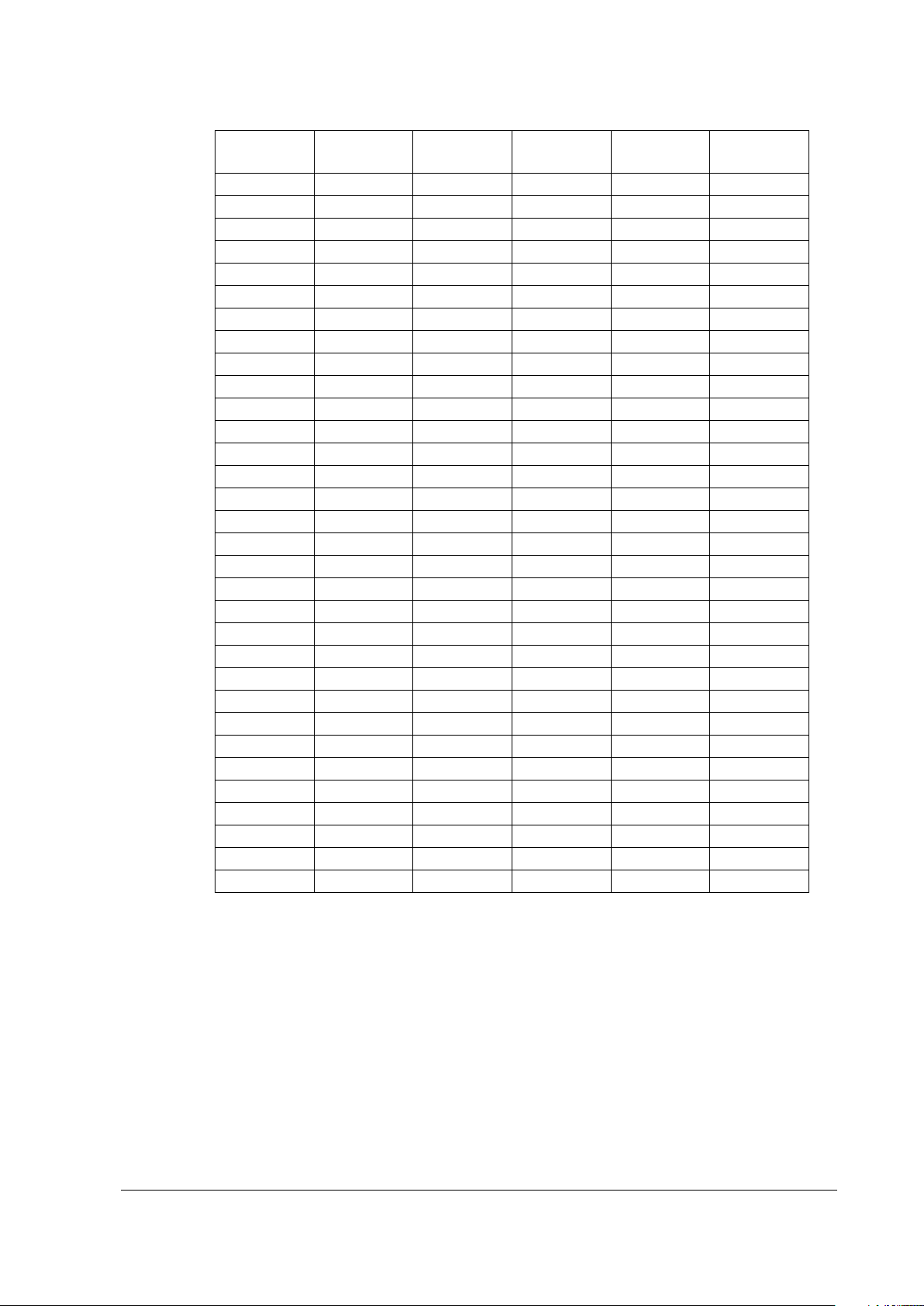

Font type 2.1.1

Fonts that can be specified by the user are shown in Table 2.1.1.

Table 2.1.1 Font List

Font

identifier

Font

"A"

Font

"B"

Font

"C"("D")*1

Font

"E"

Font

"F"

Font

"G"

Font

"H"

Font

"GS"

Font

Sans serif 9 × 5 No

Sans serif

(All Caps)

Sans serif 18 × 10 No

OCR-B 42 × 20 No

Sans serif 26 × 13 No

Sans serif 60 × 40 No

OCR-A 34 × 19 No

SYMBOL 24 × 24 No

Size

(H × W dot)

11 × 7 No

Scalable Character image

Font

"P"

Font

"Q"

Font

"R"

Font

"S"

Font

"T"

Font

"U"

Font

"V"

Font

"0"*2

*1 Font "C" and "D" are the same font.

*2 Zero

Sans serif 20 × 18 No

Sans serif 28 × 24 No

Sans serif 35 × 31 No

Sans serif 40 × 35 No

Sans serif 48 × 42 No

Sans serif 59 × 53 No

Sans serif 80 × 71 No

Sans serif

15 × 12

(Default)

Yes

ESC/Label Command Reference Guide

Rev. G Page 20

Special symbols 2.1.2

Character code

Character image

Setting item type

Description

layer.

Media form

Sets differences between media forms, such as gap and adhesive.

of label, such as black mark and gap.

Media source

Sets the method for supplying paper to the printer

shape.

format

Plain Paper

Paper without ink receiving layer

^S(CLM,T,P*

Matte Paper

Paper with ink receiving layer

^S(CLM,T,M*

Synthetic

Synthetic with ink receiving layer

^S(CLM,T,S*

Glossy Paper

Paper with ink receiving layer and luster processing

^S(CLM,T,G*

Glossy Film

Glossy synthetic with an ink receiving layer on a film

^S(CLM,T,GS*

High Glossy Paper

Glossy paper that is glossier than regular glossy paper

^S(CLM,T,PG*

Font GS is a special symbol font. See Table 2.1.2 Special Symbols for details about character code and

character image.

Table 2.1.2 Special Symbols

2.2. Media settings

Media settings instruct the printer about the type and form of media to be used for printing. The

printer performs printing control and media control based on these settings. The media setting items

are shown in Table 2.2.1.

Media coating type Sets differences between media material, such as an ink receiving

Label edge detection Sets differences between methods of detecting leading edge position

Media shape Sets differences between media shape, such as roll shape and folded

41h

42h

43h

44h

45h

Table 2.2.1 Media Setting Items

Media coating type 2.2.1

Media coating type sets the differences between media material, such as ink receiving layer.

Name Description

"*" in the command format indicates a figure.

Table 2.2.2 Media Coating Type

Command

ESC/Label Command Reference Guide

Rev. G Page 21

Media form 2.2.2

Name

Description

Command

format

Continuous paper

Paper without adhesive

^S(CLM,F,CP

Die cut label

Labels with adhesive and cut to a specific size, with gaps

between labels

^S(CLM,F,DL

size like die cut labels

format

Black mark detection

The black mark attached at the leading edge of the label is

detected.

^S(CLM,D,M

Gap detection

The gap between labels is detected.

^S(CLM,D,W

No detection

Printer does not detect the leading edge of the label.

^S(CLM,D,N

Name

Description

Command

format

supply mechanism.

External feed

The printer receives paper from an external paper supply.

^S(CLM,P,ER

Name

Description

Command

format

Roll paper

Paper formed to roll shape.

^S(CLM,S,RP

Fanfold paper

Paper folded

^S(CLM,S,FP

Media form sets the differences between media forms, such as gap and adhesive.

Table 2.2.3 Media Forms

Continuous label Continuous label with adhesive, and not cut to a specific

Label edge detection 2.2.3

Label edge detection sets the detection methods, such as black mark and gap.

Table 2.2.4 Label edge detection

Name Description

Media source 2.2.4

The media source sets the method for supplying paper to the printer.

Table 2.2.5 Media Source

Internal roll media The printer receives paper from the internal roll paper

^S(CLM,F,CL

Command

^S(CLM,P,IR

Media shape 2.2.5

The media shape sets differences between media shape, such as roll shape and folded shape.

Table 2.2.6 Media Source

ESC/Label Command Reference Guide

Rev. G Page 22

2.3. Errors

Name

Description

Example causes

when the user removes the cause of the error.

Unrecoverable error

An error condition that cannot be reset by

cause of the error.

Detector failure or motor failure

Errors indicate that something has occurred to prevent the printer from printing or executing other

primary functions. Errors are classified as Table 2.3.1 according to their cause and how they are

resolved.

Table 2.3.1 Types of Error

Recoverable error An error condition that can be reset by the

user. The printer returns to normal status

the user because the user cannot remove the

Error status occurs when there is some cause of error in the printer. When the printer recognizes that

all causes of the error have been removed, it returns to idling status.

Power ON

Cause of recoverable error

Recoverable

error

All causes of recoverable

error removed

Idling

Error

Cause of unrecoverable error

Open cover, paper out, paper jam,

caused by aging equipment.

Unrecoverable error

When the printer is in error status, the printer behaves differently than the normal idling status as

described below.

Commands for printer mechanisms, such as print requests, cannot be executed.

Indicators (LEDs/LCDs) indicate errors.

"~H(SMA,S"(Send printer operation status ): ER (error status) is returned.

"~H(SEA,E"(Send error status): the cause of the error is returned.

Figure 2.3.1 Error Status Transition Diagram

ESC/Label Command Reference Guide

Rev. G Page 23

2.4. Print area

Print area is the area of a full sheet of paper where the printer will print. Print area is a logical

rectangular area in the printer, corresponding to one logical label on a sheet of paper. The top left

corner of the print area is the initial home position, which is used as the starting point for printing text

and graphics.

In the printer specifications, the printing limit area is defined as the maximum printable area.

Within the maximum printable area, the area minus the mount (gap) is defined as the printable

area.

Within the printable area, the area minus margins is defined as the print area.

Examples of maximum printable area, printable area, and print area are shown in Figure 2.4.1.

Printer

Home position

Mount (gap)

Label

Figure 2.4.1 Examples of Maximum printable area, Printable Area, and Print Area

Paper

Maximum printable area

Printable area

Print area

ESC/Label Command Reference Guide

Rev. G Page 24

Leading edge and direction definitions 2.4.1

The leading edge, top, bottom, left, and right directions, and X and Y directions of the paper are defined

as described below.

The edge in the feed direction of the paper is defined as the leading edge.

The direction of the leading edge of the paper is defined as the bottom direction, and its opposite

direction is defined as the top direction.

When looking at the print surface of the paper, the left side is defined as the left direction, and the

opposite side is defined as the right direction.

The left-right direction is defined as the X axis, with the right direction defined as the positive X

direction.

The up-down direction is defined as the Y axis, with the down direction defined as the positive Y

direction.

The leading edge, top, bottom, left, and right directions, and the X and Y directions of the paper are

shown in Figure 2.4.2.

X direction

Y direction

Paper

Top direction

Left direction Right direction

Bottom direction

Leading edge

Figure 2.4.2 Leading Edge and Directions

Feed direction

ESC/Label Command Reference Guide

Rev. G Page 25

Reference position definitions 2.4.2

Method of detecting leading edge

position of label

Description

edge position of the label.

Gap detection

The position where the leading edge of the label is detected

is the leading edge position of the label.

Setting item

Setting command format

Leading edge position adjustment

^S(CLE,T,c ¹

When the logical area for a sheet of paper in the printer is arranged on a physical sheet of paper, the 1st

dot position on the left edge of the paper and the leading edge position of the label on the bottom edge of

the paper are used as references. The 1st dot position is the left edge reference position for the

maximum printable area. One of the following methods is used to detect the leading edge position of

the label.

Table 2.4.1 Methods of Detecting the Leading Edge Position of Labels

Black mark detection The position where a black mark is detected is the leading

Paper with black mark

Paper consisting of mount and

labels

Leading edge position of label

Black mark detector

Leading edge position adjustment

1st dot position

Figure 2.4.3 Methods of Detecting the Leading Edge Position of Labels

The leading edge position of a label can be corrected by making changes to the leading edge position

adjustment, to account for detection deviation in the detector (caused by deterioration due to aging).

Table 2.4.2 Setting the Leading Edge Position Adjustment for Labels

Leading edge detector

1st dot position

¹ The unit of the setting value can be selected from dot/mm/inch by ^S(CMP,U or ^MU command.

ESC/Label Command Reference Guide

Rev. G Page 26

Maximum printable area 2.4.3

The maximum printable area is defined as shown below, using the 1st dot position and leading edge

position of the label as references.

The width of the maximum printable area is the maximum media width of the printer.

The length of the maximum printable area is the maximum paper length of the printer.

The left bottom edge of the maximum printable area is the point of intersection between the 1st

dot position and the leading edge position of the label.

Maximum printable

area

Maximum media width

1st dot position

Figure 2.4.4 Maximum printable area

Leading edge position of label

Maximum paper length

ESC/Label Command Reference Guide

Rev. G Page 27

Printable area and mount settings 2.4.4

Direction

Setting items

Setting command format

Left gap

^S(CLS,G,c ¹

Label width

^S(CLS,P,c ¹

Y direction

Label length

^S(CLS,L,c ¹

Within the maximum printable area, the area minus the mount area (gap) is defined as the printable area.

The size of the label area and mount area are set according to the actual paper printed on by the printer.

Table 2.4.3 Mount Settings

X direction

¹ The unit of the setting value can be selected from dot/mm/inch by ^S(CMP,U or ^MU command.

Paper

Next label

Maximum printable area

Left gap Label width

Printable area

Media width

Figure 2.4.5 Printable Area and Gap Settings

Label length

ESC/Label Command Reference Guide

Rev. G Page 28

Print area and margin settings 2.4.5

Direction

Setting items

Setting command format

Left margin

^S(CLW,L,c ¹

Right margin

^S(CLW,R,c ¹

Top mar g in

^S(CLW,T,c ¹

Bottom margin

^S(CLW,B,c ¹

Within the printable area, the area minus margins is defined as the print area. The size of margins is set

in the printer according to printer and paper specifications.

If all margins are set to 0, the printable area and print area will be the same.

Table 2.4.4 Margin Settings

X direction

Y direction

¹ The unit of the setting value can be selected from dot/mm/inch by ^S(CMP,U or ^MU command.

Paper

Left margin

Printable area

Top margin

Right margin

Print area

Bottom margin

Figure 2.4.6 Printable Area and Mount Settings

ESC/Label Command Reference Guide

Rev. G Page 29

Print requests outside the print area 2.4.6

The user prints text and graphics within the print area set in the printer, with the home position as the

starting point. If you attempt to print text or graphics outside the print area, the portion that falls

outside the print area will not be printed.

For example, if a portion of the text string "CDE" falls outside of the print area, as shown in Figure 2.4.7,

only the portion that falls within the print area will actually be printed on the paper.

Paper

Print area

Home

position

Figure 2.4.7 Example of Printing Outside the Print Area

CDE

ESC/Label Command Reference Guide

Rev. G Page 30

Print area settings using ZPL II commands 2.4.7

ZPL II command

Function

Print area setting

adjustment.

label

^PW

Sets the label width

Label width + left gap (mount)

ZPL II commands can be used to change some print area settings. These ZPL II commands and the

corresponding print area settings are shown in Table 2.4.5.

Table 2.4.5 ZPL II Commands for Setting the Print Area

^LT Sets the vertical printing position

Paper

Next label

Maximum printable area

Printable area

Left gap Label width

Adjustment of leading edge position of

Adjustment of leading

edge position of label

(^LT)

Label width specified with ^PW

Figure 2.4.8 ZPL II Commands for Setting the Print Area

The ^PW command specifies the sum of the left gap (mount) and label width. When the label width is

specified with ^PW, the left gap is fixed and cannot be changed, and the value specified by ^PW minus

the current left gap is set as the label width.

ESC/Label Command Reference Guide

Rev. G Page 31

2.5. Getting and Setting Printer Information

Information type name

Description

Example

Label width

Printer operation status

Information that indicates the printer status /

Cover is open

Replace ink cartridge

Serial number

The printer maintains 3 types of information with different properties.

Table 2.5.1 Information Types Maintained by the Printer

Printer operation mode Information that determines the printer

Printer unique

information

Section 2.5.1 describes the method for setting the printer information, and section 2.5.2 describes the

method for getting the printer information.

operation

condition at that time

Information that indicates the printer unit /

characteristics

Resolution

Printer name

ESC/Label Command Reference Guide

Rev. G Page 32

Method for Setting Printer Information 2.5.1

^XA

^S(CLR, R, 600

Sets the rendering resolution at 600 [dpi].

^S(CLR, P, 600

Sets the printing resolution at 600 [dpi]

^S(CLS, P, 2400

Sets the label width at 4 inches.

^XZ

^S(C

LS,

P,

2400

Command code

<Function identifier>

<Object identifier>

<Setting value>

<Function identifier>

: Function type you want to set. Specified in 2 alphanumeric characters.

<Object identifier>

: Object you want to set. Specified in 1 alphanumeric character.

character string, or an undefined length character string.

Object

Format

Setting value format

Definition range

600: Resolution 600 [dpi]

Label width

^S(CLS,P,v

Numeral value

Minimum: 1, Maximum: Value

depend on the model

The printer operation mode is set using commands. Commands that set information are all defined as

"printer information setting commands". Printer information setting commands share properties and

formats with command codes and parameters.

Setting commands operate as format commands.

The first parameter of the setting command indicates the <Function identifier> in 2 alphanumeric

characters.

The second parameter of the setting command indicates <Object identifier> in 1 alphanumeric

character.

The third parameter of the setting command indicates <Setting value> in alphanumeric characters.

Figure 2.5.1 Sample Code of a Printer Information Setting Command

^S(C<Function identifier>,<Object identifier>,<Setting value> Setting the printer operation mode

<Setting value> : Specify the setting value with 1 or more alphanumeric character(s).

Table 2.5.2 indicates sample of command which has the setting value format of fixed character string or

numeral value.

Table 2.5.2 Sample of printer information setting command

Printing

Resolution

^S(CLR,P,v Fixed character string 300: Resolution 300 [dpi]

Depending on information type, it will take the format of a numeral, a fixed

ESC/Label Command Reference Guide

Rev. G Page 33

Method for Getting Printer Information 2.5.2

~H(CLR, P

Gets the printing resolution.

~H(SMA, S

Gets the printer operation status.

~H(IMP, S

Gets the serial number.

~H(I

M P,

S

Command code

<Function identifier>,

<Object identifier>

<Function identifier>

: Function type you want to get. Designated in 2 alphanumeric characters.

<Object identifier>

: Object you want to get. Designated in 1 alphanumeric character.

The printer operation mode, the printer operation status, and the printer unique information are each

received from the printer using a command. Commands that request information are generally defined

as "printer information request commands". Printer information request commands share properties

and formats with command codes and parameters.

Commands that request information operate as control command.

The first parameter of the setting command indicates the <Function identifier> in 2 alphanumeric

characters.

The second parameter of the setting command indicates <Object identifier> in 1 alphanumeric

character.

Figure 2.5.2 Sample Code of a Printer Information request Command

~H(C<Function identifier>,<Object identifier> Gets the printer operation mode

~H(S<Function identifier>,<Object identifier> Gets the printer operation status

~H(I<Function identifier>,<Object identifier> Gets the printer unique information

The printer returns the response data based on the printer information request command. The

response data is equal to the setting command that corresponds to the request command, and will take

the command code <Function identifier>,<Object identifier> format.

ESC/Label Command Reference Guide

Rev. G Page 34

Command

Printer operation

~H(C<Function identifier>,<Object

<STX>^S(C<Function identifier>,

value<ETX><CR><LF>

value<ETX><CR><LF>

Printer unique

~H(I<Function identifier>,<Object

<STX>^S(I<Function identifier>,

value<ETX><CR><LF>

~H(CLR,P

Request to send current printing resolution.

Example of response data from the printer:

-><STX>^S(CLR,P,600<ETX><CR><LF>

The printing resolution is 600 [dpi].

~H(IMF,V

Request to send the firmware version.

Example of response data from the printer:

-><STX>^S(IMF,V,AAA01234<ETX><CR><LF>

The firmware version is "AAA01234".

~H(SEA,E

Request to send current error status.

Example of response data from the printer:

-><STX>^S(SEA,E,NE<ETX><CR><LF>

Currently no error.

Information type

Table 2.5.3 Response Data for the Printer Information Request Commands

Printer information Request

Response data

mode

Printer operation

status

information

identifier>

~H(S<Function identifier>,<Object

identifier>

identifier>

<Object identifier>,

<STX>^S(S<Function identifier>,

<Object identifier>,

<Object identifier>,

An example of the data sent and received when request the resolution is shown below.

An example of sending and receiving data when request firmware version is shown below.

An example of sending and receiving data when request the printer error status is shown below.

ESC/Label Command Reference Guide

Rev. G Page 35

2.6. Designating Color

With ESC/Label command, you can designate the color of text or diagram and print labels. Color can

be designated for the following applicable renderings.

Text

Diagram (Rectangles, circles, ellipses, diagonal lines)

1-dimensional barcodes, 2-dimensional codes (However, the background color is fixed to

transparent.)

Monochrome bit-mapped graphics

As shown in Figure 2.6.1, rendered images have a foreground part and a background part, and you can

designate the color and the opacity for these parts. If you do not designate it, the foreground will be

treated as black at 100% opacity, and the background as transparent (0% opacity).

Text Diagram (Circle)

Foreground

A

Background

Figure 2.6.1 Foreground and Background in Text / Diagram / Barcodes

Here is the color combination of print result (it isn’t the color of drawing barcode) to ensure decoding

barcodes and 2-dimensional codes.

Foreground of symbol: opacity 100% black (black)

Background of symbol and quiet zone: opacity 100% white (white) or opacity 0% (Transparent)

Label media: white

Please refer to the product specification of the printer for a detailed guarantee condition.

Foreground

Barcode

Foreground

Background

Background

<Legend>

Black: Foreground

Green-yellow: Background

ESC/Label Command Reference Guide

Rev. G Page 36

Color designation uses "^F(C"(field color designation) command. The "^F(C" command is a format

^XA

^FO0.0^ABN

^F(C255,0,0,255,0,0,0,0,0,0^FDNo.^FS

Arrange "No." as red characters

(No color designated.)

^XZ

command and can be used in the field, like mentioned above in section 1.4.2 Color Label Printing

^F(C r1, g1, b1, a1, i1, r2, g2, b2, a2, i2 Field Color Designation

r1 g1 b1 : Designate foreground color (Each 0 to 255)

a1 : Designate foreground opacity (0 to 255)

i1 : Invert the foreground

r2 g2 b2 : Designate background color (Each 0 to 255)

a2 : Designate background opacity (0 to 255)

i2 : Invert the background

^FO200,0^ABN^FD012356^FS Arrange "0123456" as black characters

ESC/Label Command Reference Guide

Rev. G Page 37

2.7. Field color reversal

Command

Description

N: Cancels reversal of all field being contained in the label.

^FR

Field reverse print

"^FR" specifies reversal of the current field.

The setting of "^FR" have priority over setting "^LR".

N: Cancels reversal of the current field.

drawing field

fields

present

specified

reverse

no present

specified

no reverse

A field which was drawn by

reversal specification is present.

cancel

no reverse

The field color reversal means drawing a field to be able to see field overlapping by means of changing

color of overlapping area of fields when drawing a field over an existing field.

The user can set the field color reversal by using commands defined in Table 2.7.1.

Table 2.7.1 Commands for Field Color Reversal Setting

^LRa

Label reverse print

^F(Cr1,g1,b1,a1,i1,r2,g2,b2,a2,i2

Field color settings

Both of foreground and background can be targets of field color reversal.

Opacity of foreground and background affects to a color reversing. The effect of reversing becomes

small with a fall of the opacity.

The effect by specifying to reversal appears only when a field specified to reversal is drawn over an

existing field. The relation of an existing field and reversal specification of a drawing field is shown in

Table 2.7.2.