Page 1

SERVICE MANUAL

Color Laser Page Printer

EPSON AcuLaser C4000

AcuLaser C4100

AcuLaser C3000

SEPG01012

Page 2

Notice

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic,

mechanical, photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2004 SEIKO EPSON CORPORATION.

Imaging & Information Product Division

CS/Quality Management & PL Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO

SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, BE SURE TO WEAR GLOVES TO AVOID INJURIES FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING

PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND

SOURCE IC’S OR OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT,

OR COULD VOID THE WARRANTY OFFERED BY EPSON.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the EPSON AcuLaser

C4000, AcuLaser C4100 and AcuLaser C3000. The instructions and procedures included herein are intended for the experienced repair technicians,

and attention should be given to the precautions on the preceding page.

Page 5

Manual Configuration

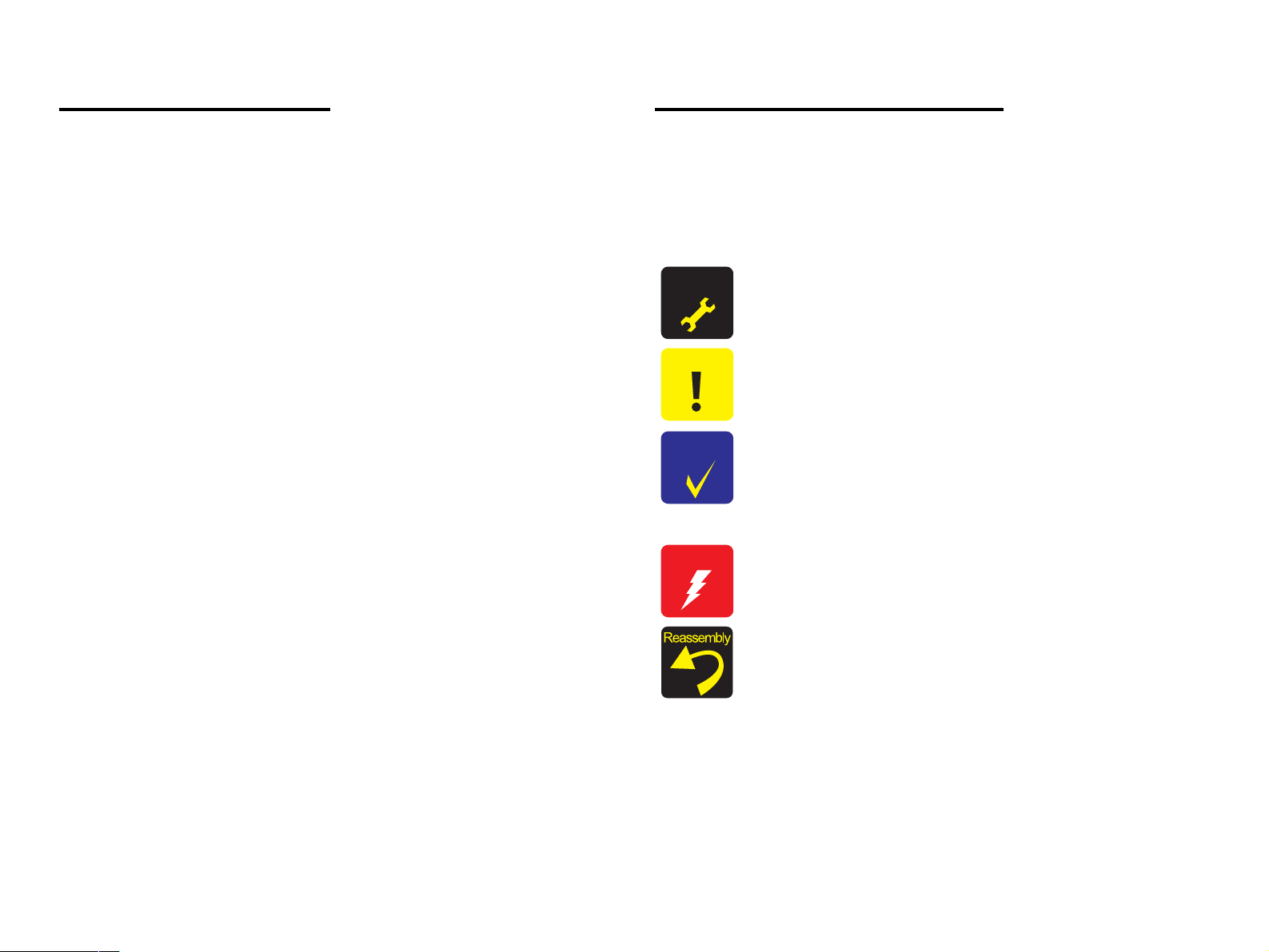

Symbols Used in this Manual

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for

troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for

disassembling/assembling and adjusting the product.

CHAPTER 5 ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicing the product.

APPENDIX. Provides the following additional information for

reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Various symbols are used throughout this manual either to provide

additional information on a specific topic or to warn of possible danger

present during a procedure or an action. Be aware of all symbols when

they are used, and always read NOTE, CAUTION, or WARNING

messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

Indicates an operating or maintenance procedure, practice

or condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice,

or condition that, if not strictly observed, could result in

damage to, or destruction of, equipment.

C H E C K

P O I N T

May indicate an operating or maintenance procedure,

practice or condition that is necessary to accomplish a task

efficiently. It may also provide additional information that is

related to a specific subject, or comment on the results

achieved through a previous action.

W A R N I N G

Indicates an operating or maintenance procedure, practice

or condition that, if not strictly observed, could result in

injury or loss of life.

Indicates that a particular task must be carried out

according to a certain standard after disassembly and

before re-assembly, otherwise the quality of the

components in question may be adversely affected.

Page 6

Abbreviation

This manual uses unique abbreviations and acronyms which may differ from those in common use. Please note that they are used in the manual

descriptions without explanation. The main abbreviations and acronyms are listed below. Because the following list was formed as a general

reference, some items on the list may not appear in this manual.

In principle most acronyms were formed from the capitalized first letters of the English term for the items (there are exceptions) and most single

word abbreviations were formed either will all capitals or with only the first letter as a capital.

[A]

ADC Auto Density Control

ALM Alarm

Assy Assembly

Aux. Auxiliary

[B]

B/W Black and White

BCR Bias Charge Roll

Bk Black

BCR Bias Charge Roll

BRKT Bracket

BTR Bias Transfer Roll

BUR Back Up Roll

[C]

CCyan

CCW Counter Clockwise

Cl. Clutch

Clk Clock

CHK Check

CK Check

Conpane Control Panel

Cont Controller

CR Charge Roll

CRU Customer Replaceable Unit

CRUM CRU Memory

CST Cassette

CVR Cover

CW Clockwise

[D]

DB Developing Bias

Deve Developer

Diag Diagnostic

dpi dots per inch

DTS Detack Saw

Dup Duplex

[E]

Elec Electric

EP Electro Photography

ESS Electric Sub System

[F]

F Front

FDR Feeder

FG Frame Ground

FIP Fault Isolation Procedure

FRU Field Replaceable Unit

FX Fuji Xerox

[G]

GG Guide Gauge

GND Ground

[H]

HHigh

H/R Heat Roll

HCF High Capacity Feeder

HCS High Capacity Stacker

Hex Hexadecimal

HVPS High Voltage Power Supply

[I]

I/F Interface

I/L Interlock

ID Image Density

[J]

Jxx Jack xx

Page 7

[L]

L Left

L Low

L/H Left Hand

L/P Low Paper

LD Laser Diode

LEF Long Edge Feed

LVPS Low Voltage Power

Supply

[M]

M Magenta

M/N Multi National

Mag Magnetic

MCU Machine Control Unit

Mech Mechanical

MOT Motor

MSI Multi Sheet Inserter

[N]

N/F Normal Force

N/P No Paper

NPS No Paper Sensor

NV Non Volatile

NVM Non Volatile Memory

[O]

OHP Overhead Projector

OPC Organic Photo Conductor

OPT Option

[P]

Pyy Plug yy

P/J Plug and Jack

P/H Paper Handling

P/R Pressure Roll

PL Plate

PLT Plate

PPM Print Per Minute

PV Print Volume

PWB Printed Wiring Board

PWBA PWB Assembly

[R]

R Right

R Rear

R/H Right Hand

RDY Ready

Regi Registration

ROS Raster Output Scanner

RRP Removal and Replacement

Procedure

RTN Return

[S]

SEF Short Edge Feed

SG Signal Ground

SNR Sensor

SNS Sensor

Sol Solenoid

SOS Start Of Scan

SPI Scan Per Inch

STD Stamdard

STK Stacker

STND Standard

SW Switch

Sync Synchronous

[T]

T Tooth (number of Gear)

Temp Temperature

TR Transfer

TTL Trangistor-Transistor Logic

[X]

Xero Xerographic

[Y]

YYellow

YMCBk Yellow/Magenta/Cyan/

Black

YMCK Yellow/Magenta/Cyan/

Black

Page 8

Safety Information

To prevent accidents during a maintenance procedure, strictly observe

the Warnings and Cautions. Do not do anything that is dangerous or not

within the scope of this document.

Do not do anything that is dangerous even if not specifically described

in this manual. In addition to the descriptions below and those given in

this manual, there are many situations and circumstances that are

dangerous. Be aware of these when you are working with the printer.

Power Supply

Before starting any service procedure, switch off the printer power and

unplug the power cord from the wall outlet. If you must service the

printer when the power is applied, be aware of the potential for electrical

shock and do all tasks by following the procedures in this manual.

W A R N I N G

Do not touch any live part unless you are instructed

to do so by a service procedure.

The LVPS power supply switch/inlet part is live even

when the power switch has been turned off. Do not

touch any live part.

Do not touch electrified components except when

instructions indicate it is permissible to do so.

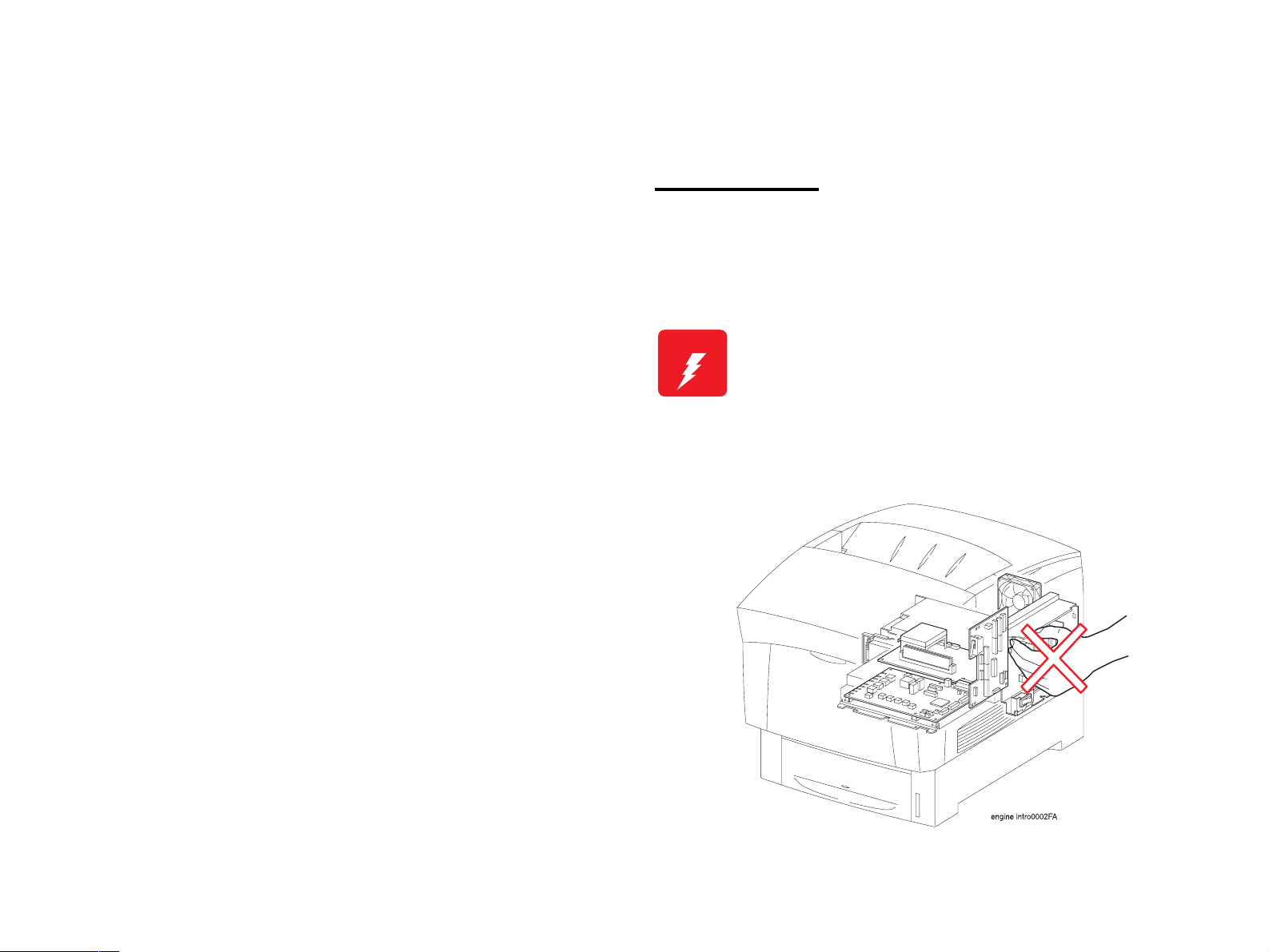

Figure 0-1. Power Supply

Page 9

Mechanical Components

High Temperature Assembly

If you service a driving assembly (e.g., gears), first turn off the power

and unplug the power cord. Then manually rotate the assembly.

.

W A R N I N G

Do not touch the driving part (e.g., gears) while the

assembly (printer) is being driven.

To prevent you from becoming injured or burned, do the following:

Before working with a high temperature Assembly (e.g., Fuser

Assembly), turn off the power, unplug the power cord and wait until it

cools down.

W A R N I N G

The high temperature Assembly is very hot immediately

after any printer operations. Wait at least 40 minutes

before you start working on the printer.

Page 10

Laser Beam

W A R N I N G

NOTE: The laser beam has a narrower frequency band and more

NOTE: The laser beam in this printer is invisible.

Do not expose yourself to the laser beam to prevent

injury (blindness).

Do not open the cover that has the laser beam

warning label.

If you disassemble or assemble the printer, turn off

the power.

If you need to work on the printer with power applied,

strictly follow the instructions in this manual.

Understand how the laser beam functions and take

maximum precautions not to injure yourself or

anyone around you.

coherent phases than any other light (sunlight, electric light).

It has excellent monochromaticity and convergence. A thin

laser beam reaches long distances. Because of its

convergence characteristic, the laser beam converges into

one point, causing high density and high temperature. A

laser beam is harmful to the human body.

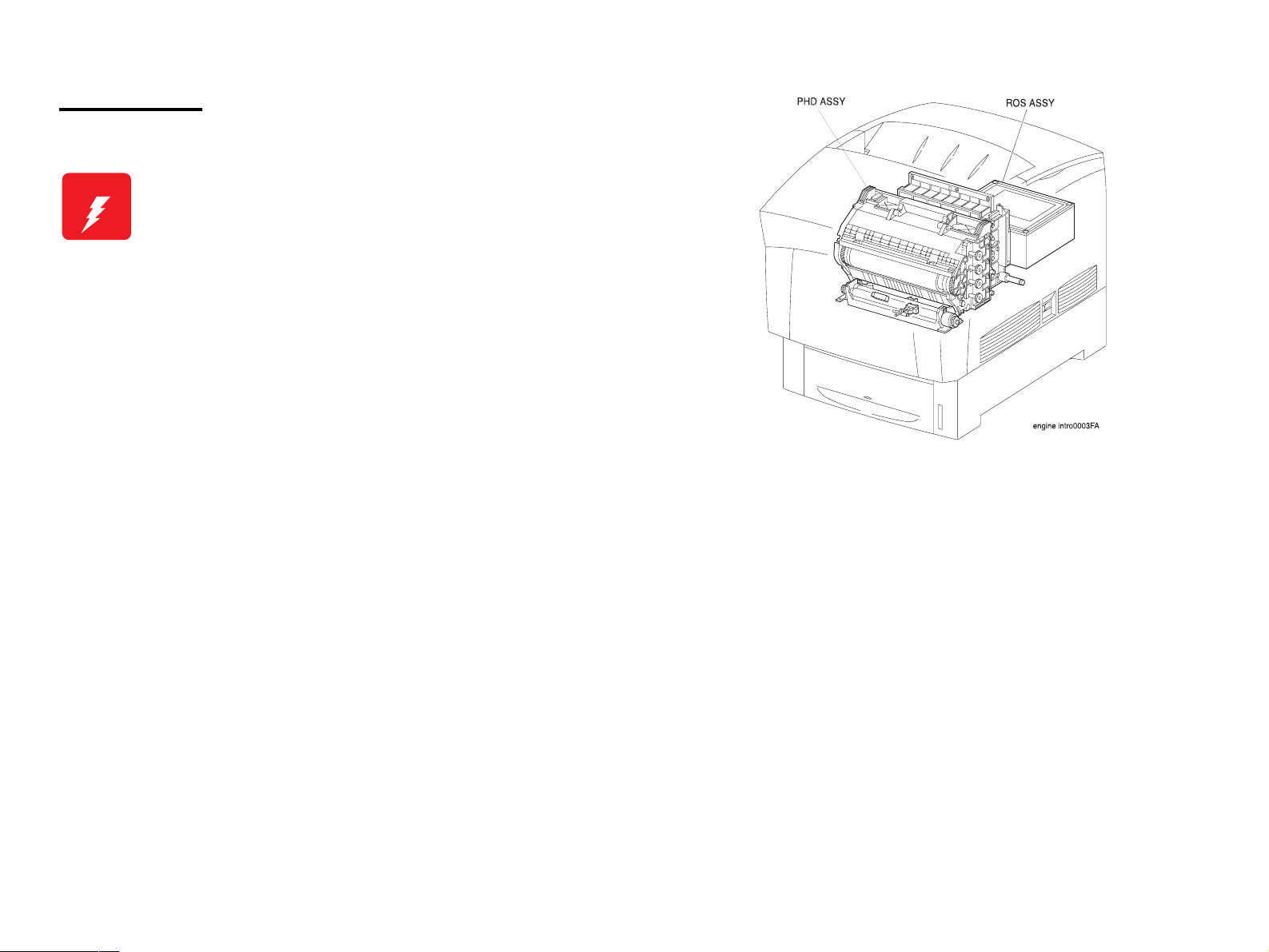

Figure 0-2. Laser Beam

Page 11

Warning and Caution Labels

Warning labels and Caution labels are placed on the printer to help

prevent accidents.

When maintaining the printer, confirm that these labels are not dirty or

peeling off.

Caution label for high temperature components

Figure 0-3. Warning and Caution Labels

Page 12

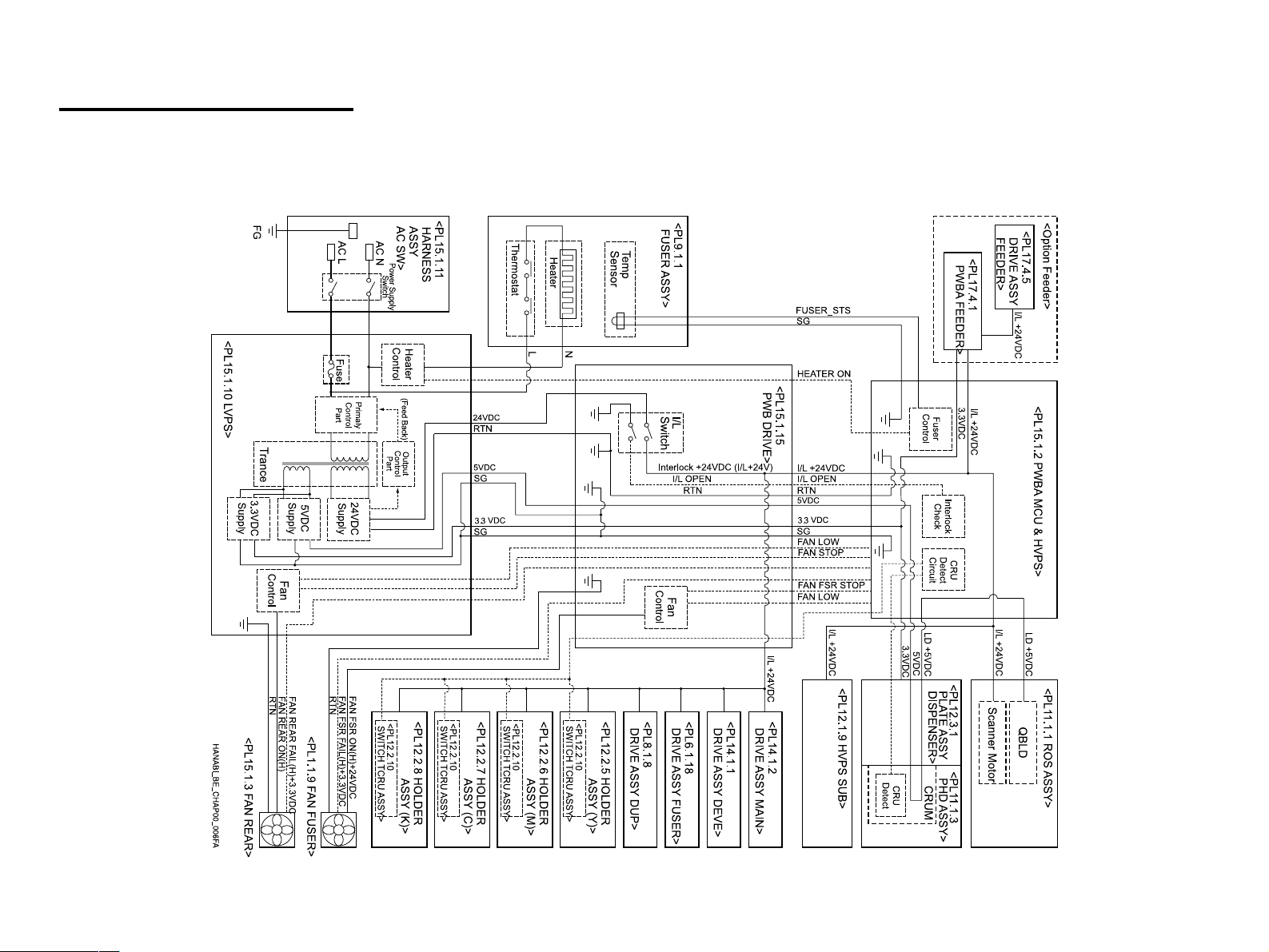

Safety System Schematic

The schematic below outlines the features of the printer's safety system.

For details about signal wires, see "Appendix - Wiring Diagram".

Page 13

Manual Contents

Chapter 1 PRODUCT DESCRIPTIONS

Chapter 2 OPERATING PRINCIPLES

Chapter 3 TROUBLESHOOTING

Chapter 4 DISASSEMBLY AND ASSEMBLY

Chapter 5 ADJUSTMENT

Chapter 6 MAINTENANCE

Chapter 7 AcuLaser C4100

Chapter 8 AcuLaser C3000

Appendix

Page 14

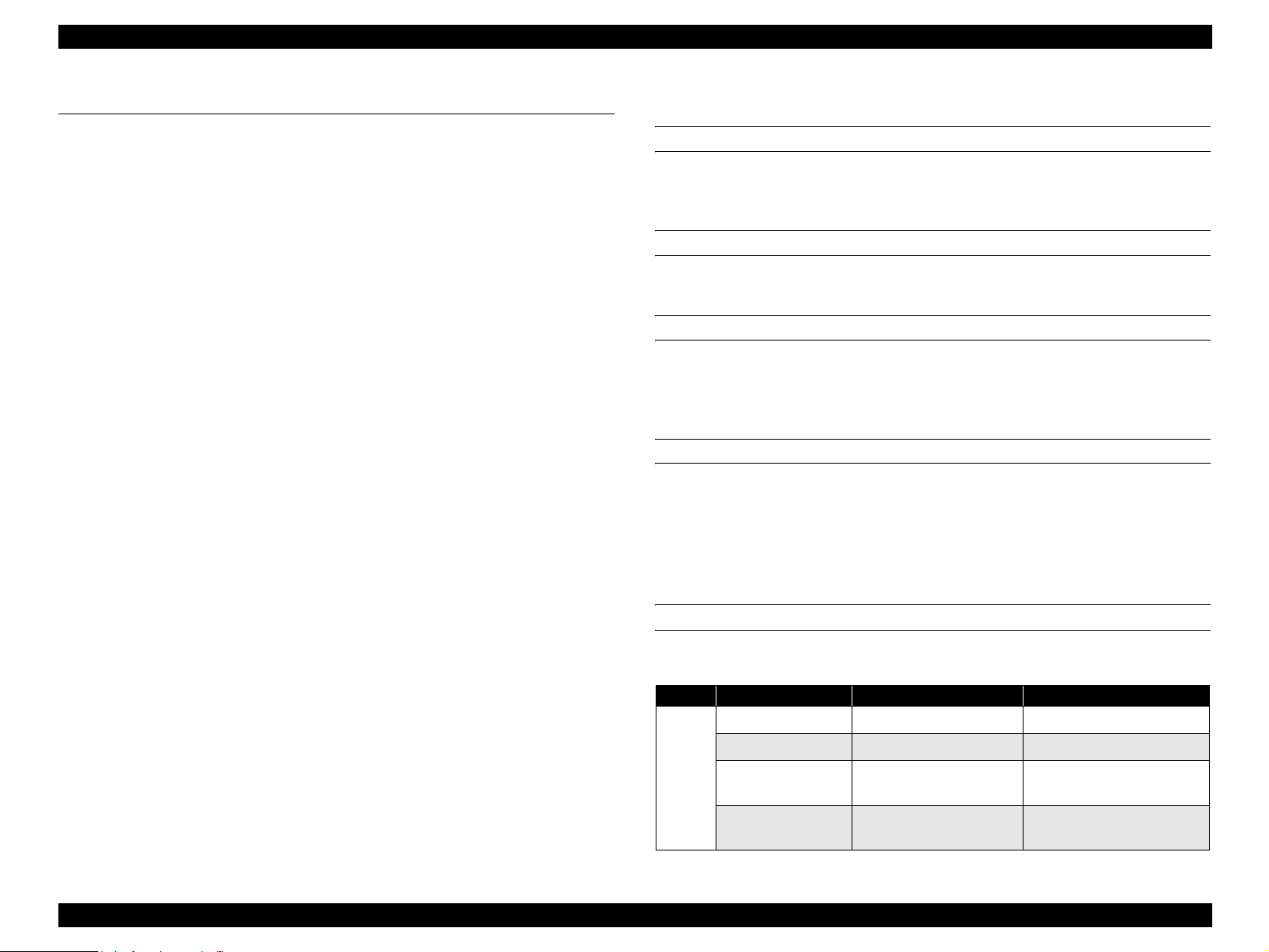

Revision Status

Revision Issued Date Description

A March 18, 2002 First Release

B April 19, 2002 Chapter 1

1.14.5 Panel Setting Item List “PRINTER ADJUST MENU”

• “Cleaning Cycle” and comment is added.

Chapter 3

• “Reference page number in FIP” is added.

3.3 Level 2 FIP

• “3.3.2 Self-Diagnostic Function by LCD Message” is added.

• “3.3.2.1 List of Printer Messages” is added.

• “3.3.2.2 Details of Status Message and Treatment” is added.

• “3.3.2.3 Details of Error Message and Treatment” is added.

• “3.3.2.4 Details of Warning Message and Treatment” is added.

• “3.3.3 Service Call Error Messages” is added.

• “FIP-16 NV-RAM Error” is added.

• “FIP-28 Fuser Life Over” is added.

• “FIP-48 Engine Communication Error” is added.

• “FIP-49 Verify (DIMM Slot Related) Error” is added.

• “FIP-50 Error in Standard RAM (Slot 0, 1)” is added.

• “FIP-51 ROM Checksum Error (MASK ROM for Font)” is added.

• “FIP-52 ROM Checksum Error (CODE, IPL)” is added.

• “FIP-53 ROM Module (DIMM Slot A Related) Error” is added.

• “FIP-54 EEPROM Writing Error” is added.

• “FIP-55 CCNV Hardware Error” is added.

• “FIP-56 Engine Initialization Error” is added.

• “FIP-57 SRAM (for Compression) Initialization Hardware Error” is added.

• “FIP-58 Video System Hardware Error (including PWM Calibration Error IC)” is added.

• “FIP-59 Built-in Network Hardware Error” is added.

• “FIP-60 DIMM SPD Error” is added.

Chapter 6

6.2 Maintenance Menu “Table 6-2. List of control information and control method”

• The range of count is changed.

• A comment is added.

Page 15

Revision Issued Date Description

C November 15, 2002 Preface

• A misdescription deleted.

Chapter3

• “3-1-4 Test print by engine itself” added.

D August 4, 2003 Chapter 1

1.5.1 “Reliability”

• The value of MPBF is fixed

1.10 “Consumable Components”

• The value of Transfer Unit Lifetime is revised

1.14.5 “Panel Setting Item List”

• PRINTER ADJUST MENU is revised

1.14.6.7 “Printer Adjust Menu”

• Part of text is revised

Chapter 6

6.1.2 “Consumable components and components that require regular replacement”

• The value of Transfer Unit Lifetime is revised

• The parts code of Roll Assy is fixed

Chapter 7

Additional information added for AcuLaser C4100

E August 19, 2004 [Revision up]

Chapter 8

Additional information added for AcuLaser C3000

F October 26, 2004 [Revision up]

Chapter 1:

1.5.2 "Durability" (1-19) (the description is revised)

Chapter 7:

7.1.2.1 "Product reliability" (7-482) (Error in “Durability” value is corrected)

Page 16

CONTENTS

Product Descriptions

Features......................................................................................................... 5

Specifications ............................................................................................... 7

Basic Specifications .................................................................................. 7

Various Sensors ......................................................................................... 14

Paper Specifications .................................................................................. 16

Paper Types ............................................................................................ 16

The paper that should not be used with this printer ................................ 16

Paper Source Classification .................................................................... 17

Printing Area............................................................................................ 17

Reliability and Durability............................................................................ 18

Reliability ................................................................................................. 18

Durability ................................................................................................. 19

Maintenance............................................................................................ 19

Operating Conditions (Including Comsumables).................................... 20

Storage and Transport of the Printer Main Unit (Consumables Packaged),

and Optional Products ............................................................................... 21

Electrical Feature........................................................................................ 22

Compliance with Standards and Regulations ......................................... 23

Consumable Components ......................................................................... 23

Maintenance................................................................................................ 24

Exterior View and Unit Names................................................................... 25

Controller Unit Specifications ................................................................... 27

Controller Basic Specifications................................................................ 27

Controller Configuration .......................................................................... 28

External Interface Specifications ............................................................. 28

Control Panel .............................................................................................. 33

Exterior View and Names........................................................................ 33

Display Elements Description.................................................................. 34

Button Functions Description .................................................................. 35

Special Operations.................................................................................. 36

Panel Setting Item List ............................................................................ 37

Explanation of Each Setting Menu and Setting Items ............................. 47

About RAM Expansion............................................................................... 54

Dimensions ................................................................................................. 54

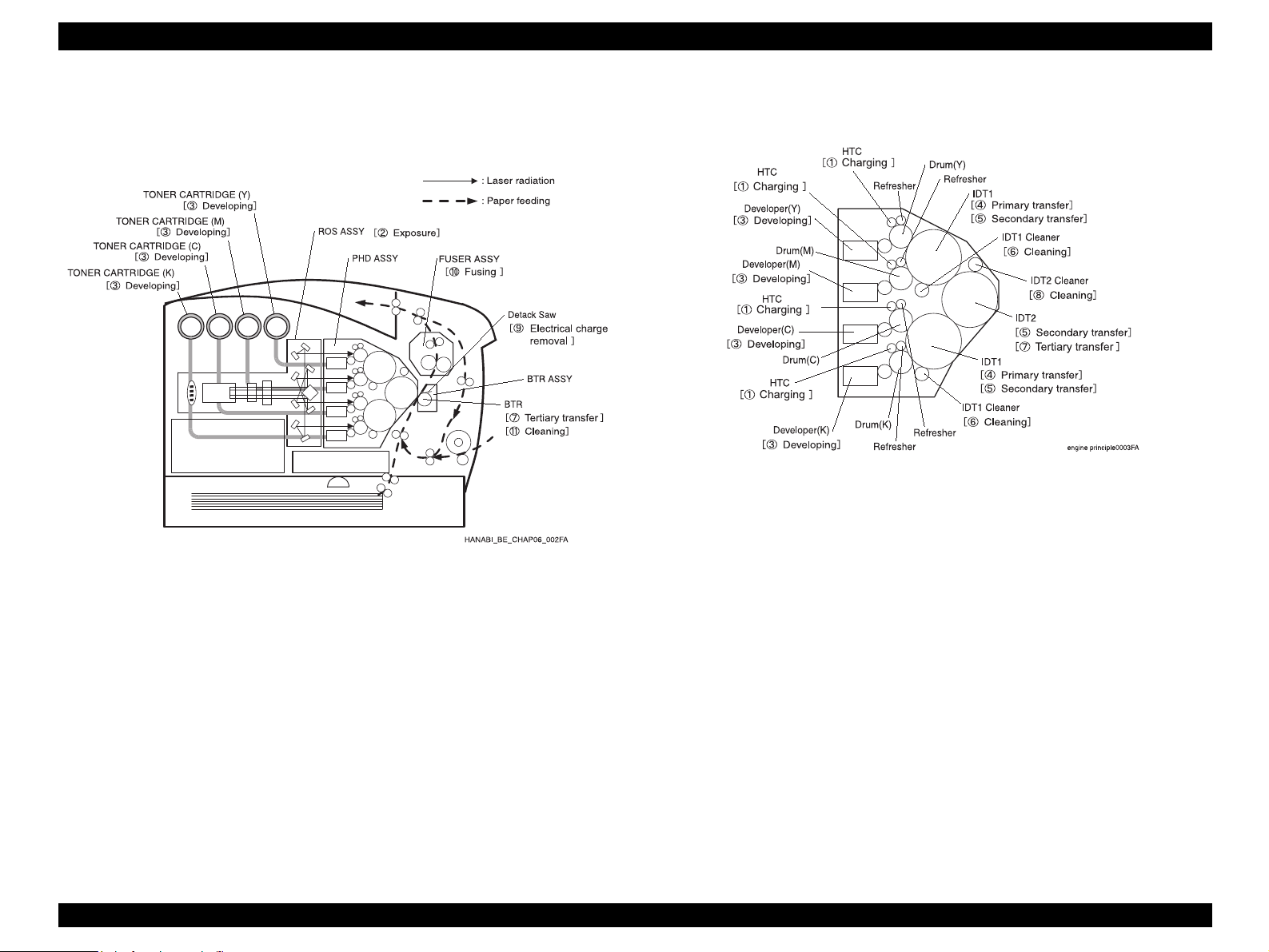

Operating Principles

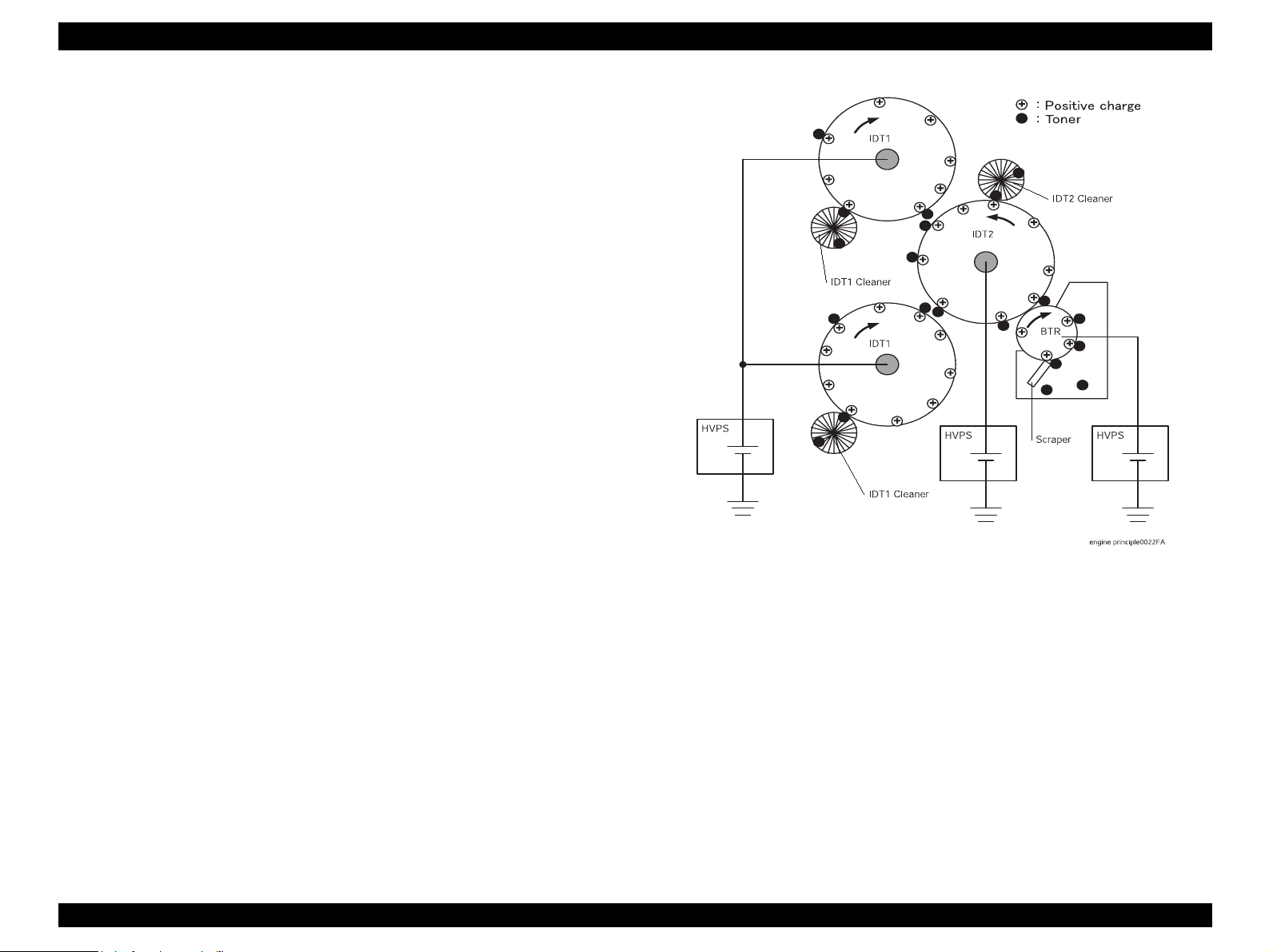

Print Process .............................................................................................. 56

Print Process Overview........................................................................... 56

Print Process Diagram ............................................................................ 57

Print Process Technical Explanation....................................................... 58

Flow of Print Data....................................................................................... 62

Data Flow ................................................................................................ 62

Drive Transmission Path ........................................................................... 63

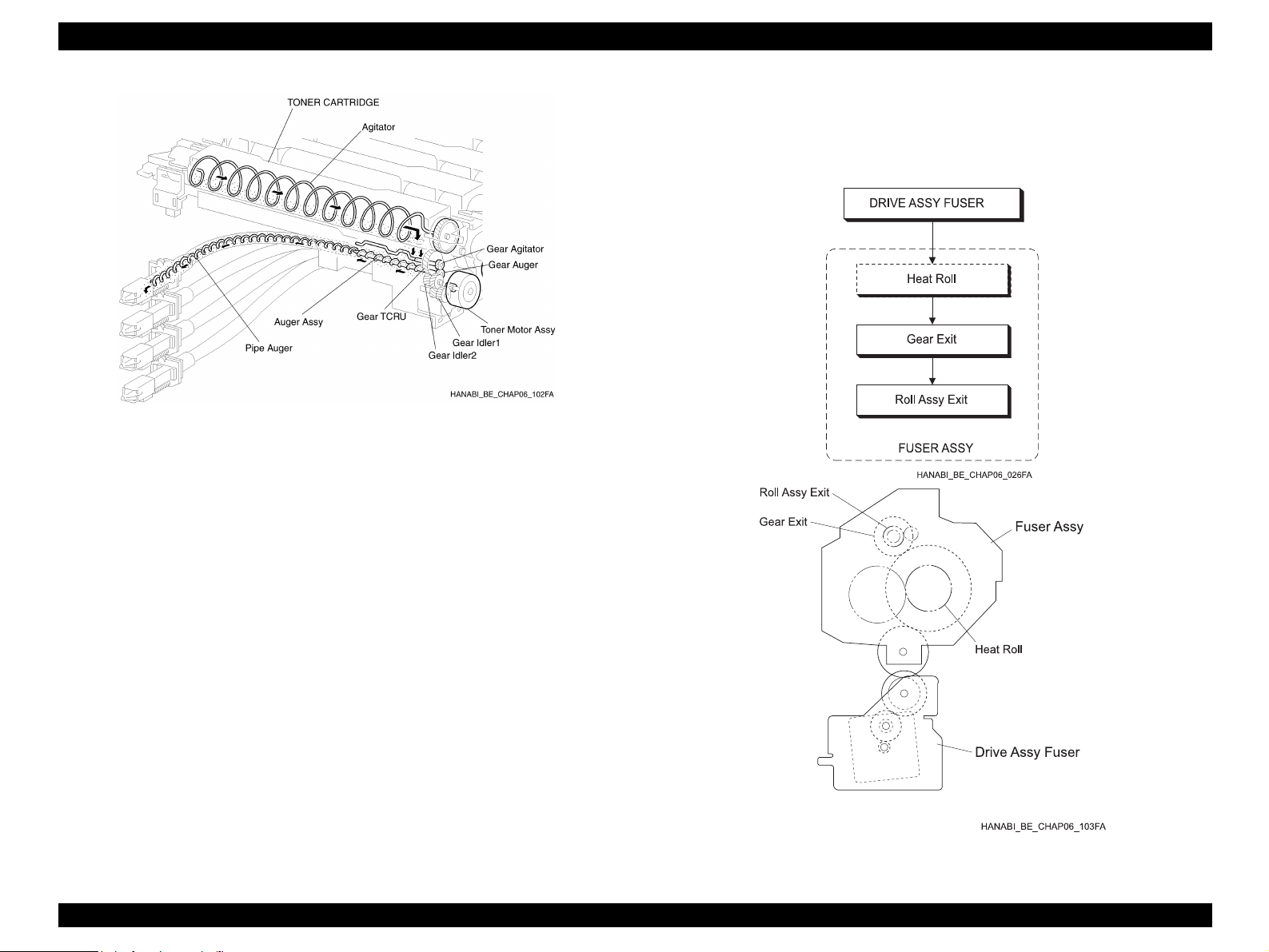

DRIVE ASSY MAIN (PL14.1.2) ............................................................... 63

DRIVE ASSY DEVE (PL14.1.1) .............................................................. 64

HOLDER ASSY (PL12.2.5 ~ 8) (Y, M, C, K) ........................................... 64

DRIVE ASSY FUSER (PL6.1.18)............................................................ 65

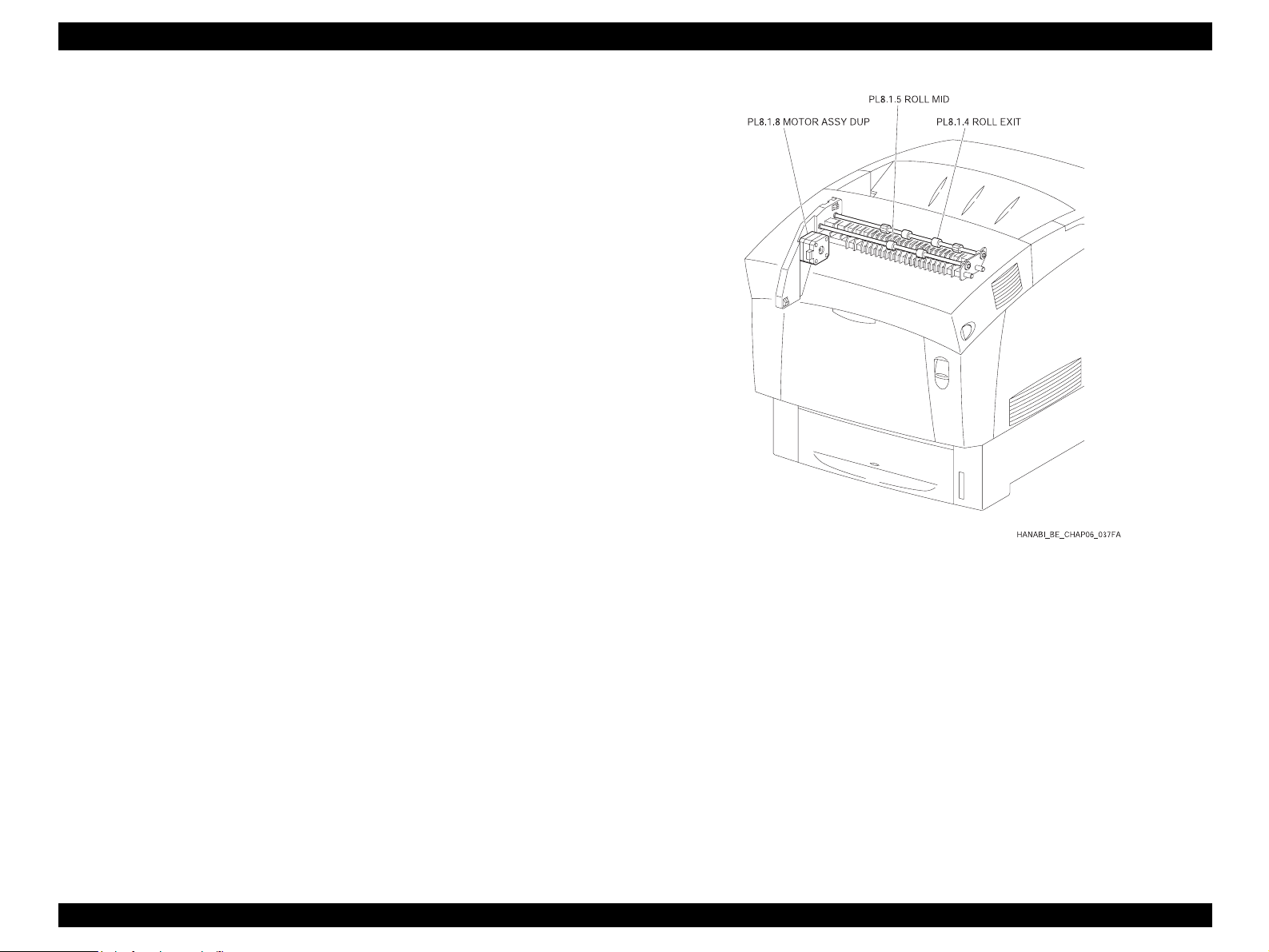

MOTOR ASSY DUP (PL8.1.8)................................................................ 66

Paper Feed .................................................................................................. 67

Paper Feed Path (without options in use) ............................................... 67

Paper Feed Path Diagram ...................................................................... 67

Functions of Main Components................................................................ 69

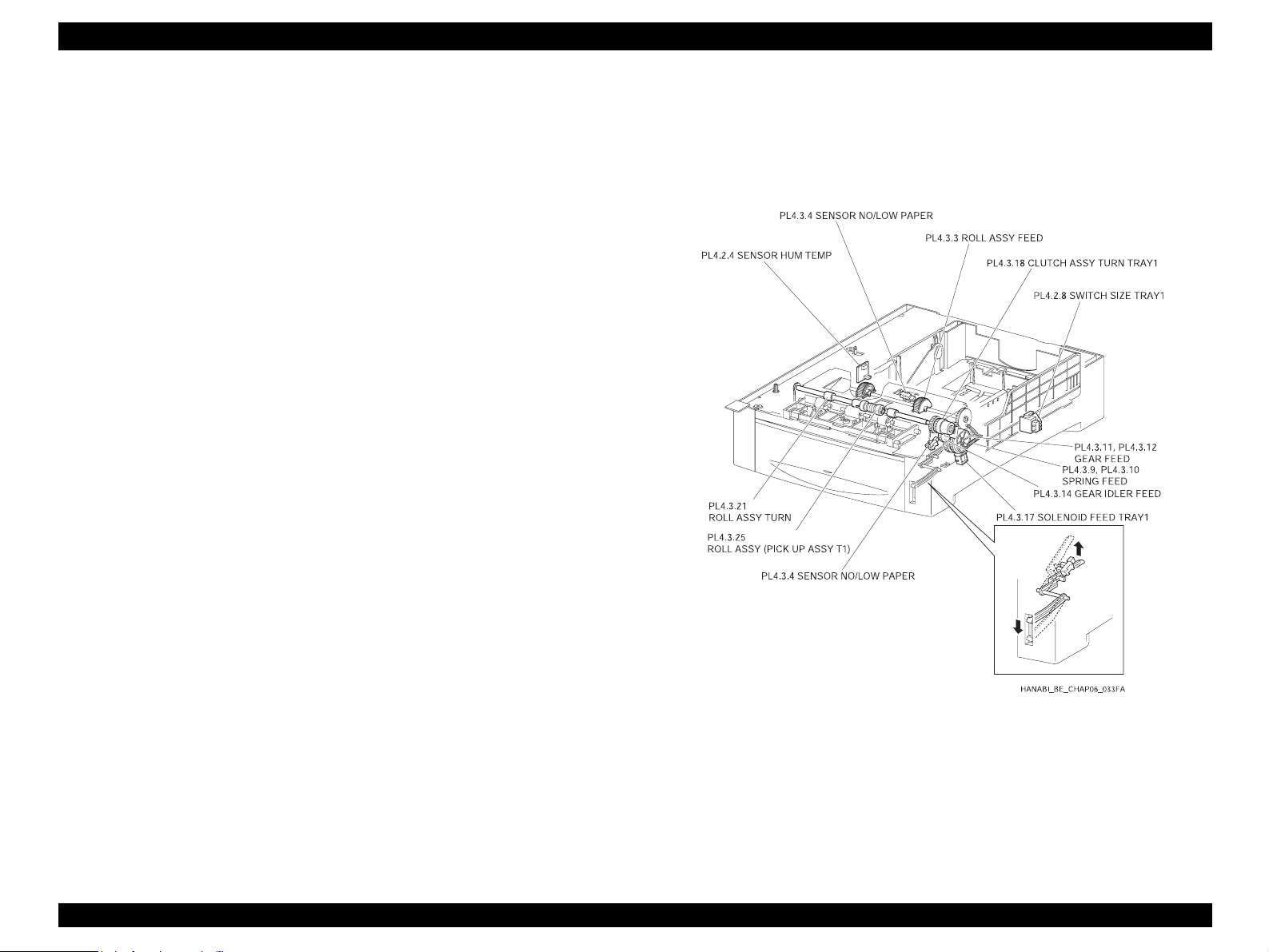

Paper Cassette (PL3.1 ~ 2)..................................................................... 69

Paper Feeder (PL4.1 ~ 3) ....................................................................... 70

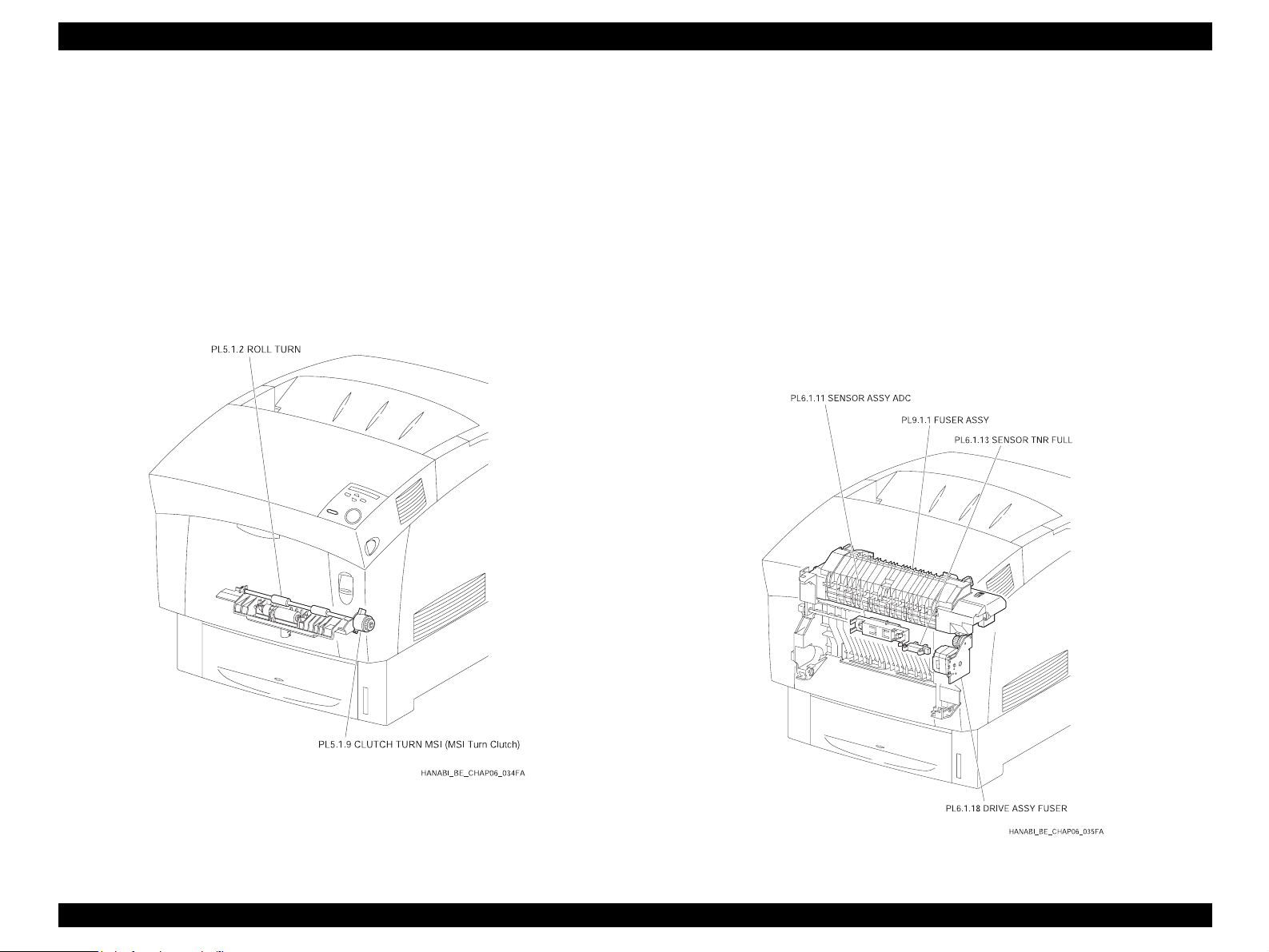

Housing Assy Retard (PL5.1).................................................................. 71

Chute Assy In (PL6.1) ............................................................................. 71

Chute Assy Out (PL7.1) .......................................................................... 72

Chute Assy Exit (PL8.1) .......................................................................... 73

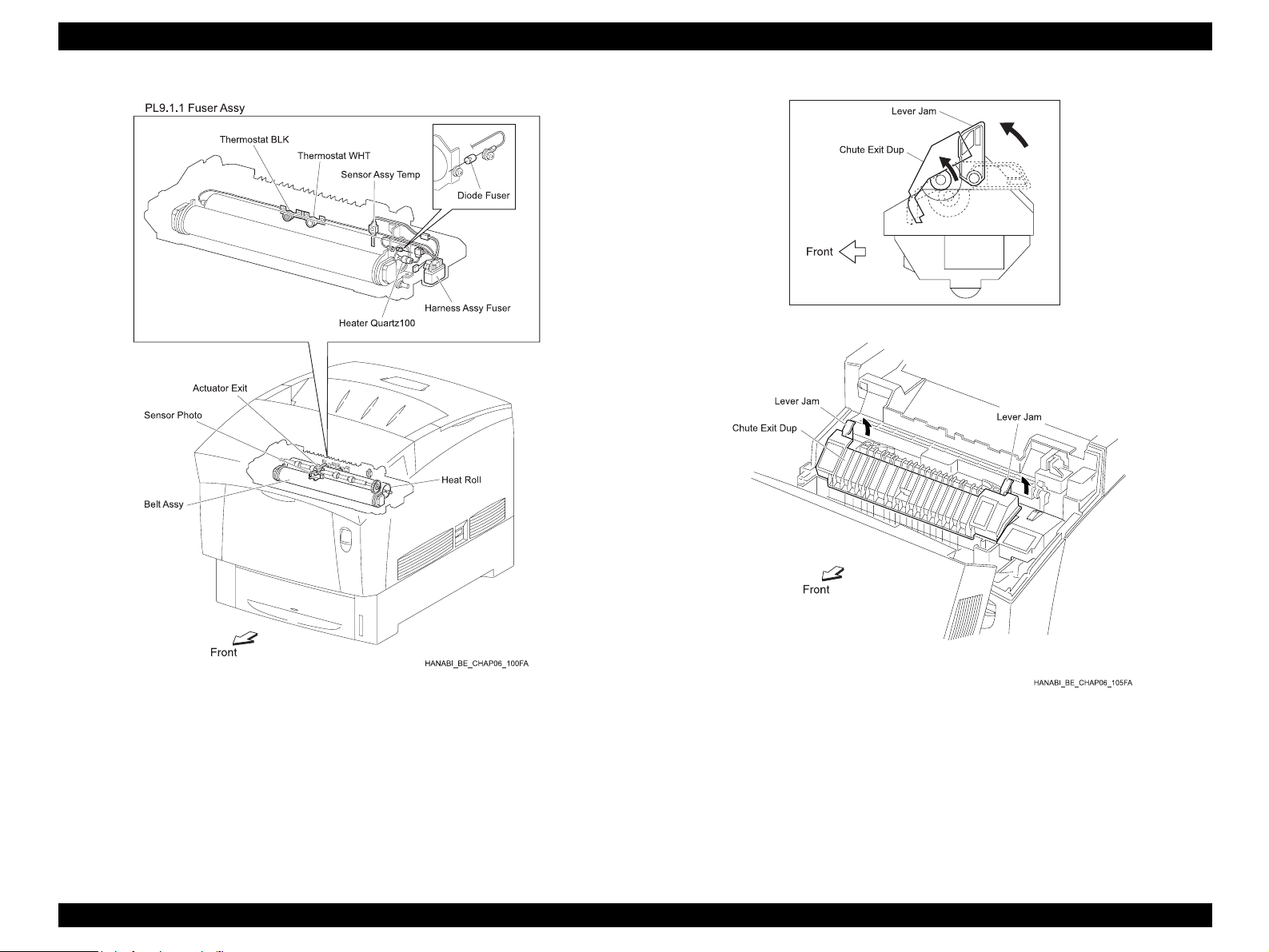

Fuser Assy & BTR Assy (PL9.1) ............................................................. 74

Page 17

Xerographics (PL11.1) ............................................................................ 77

TCRU Assy (PL12.1 ~ 3)......................................................................... 78

Frame (PL13.1) & Drive (PL14.1)............................................................ 79

Electrical (PL15.1 ~ 2) & CONTROLLER BOARD (ESS) (PL16.1)......... 79

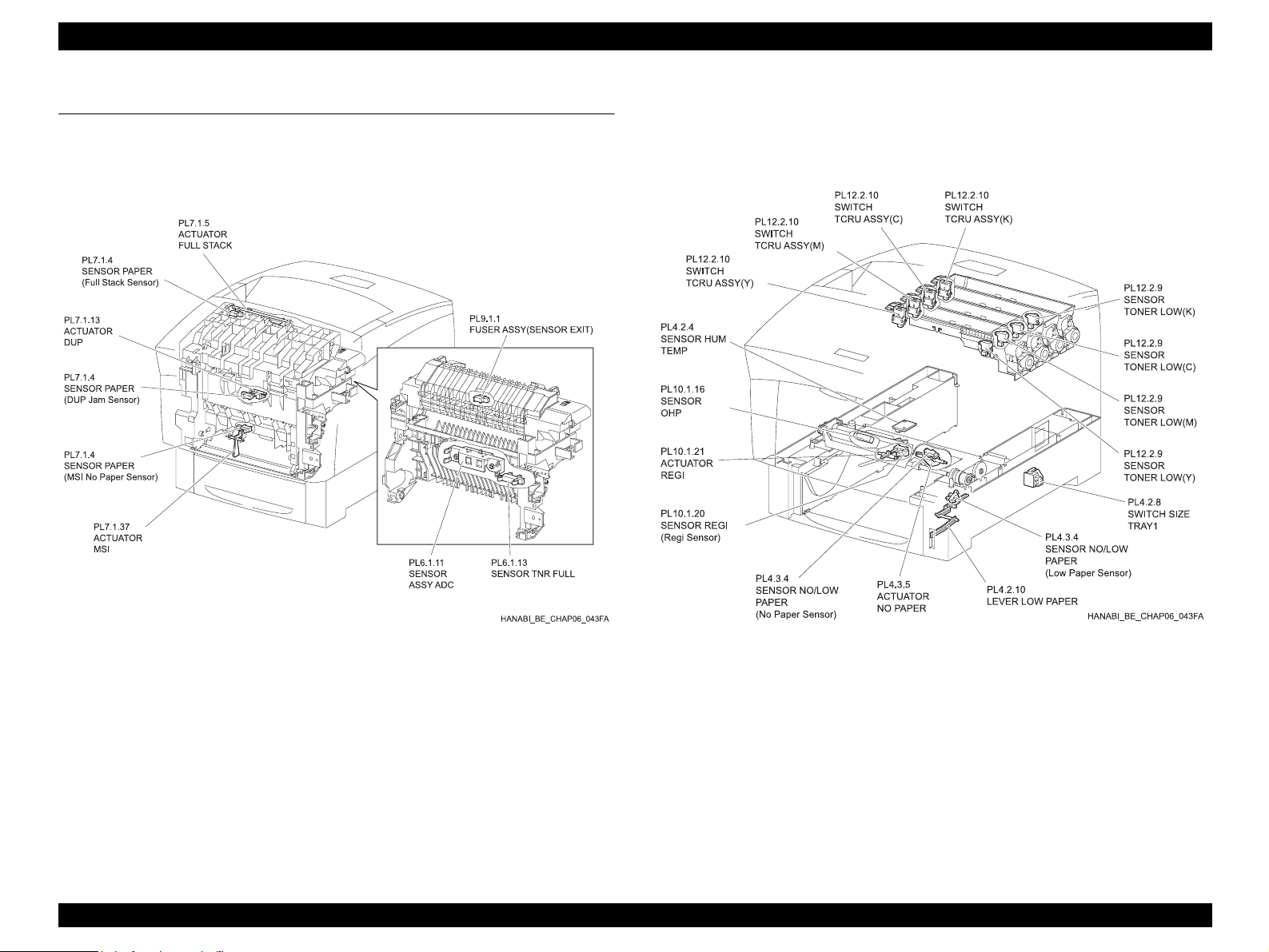

Switches and Sensors ............................................................................... 81

Mode ............................................................................................................ 82

Print Mode............................................................................................... 82

Operation Mode....................................................................................... 82

Control......................................................................................................... 83

Paper Size Control .................................................................................. 83

Paper Supply Selection Control .............................................................. 83

ROS Light Control ................................................................................... 83

PROCESS CONTROL ............................................................................ 84

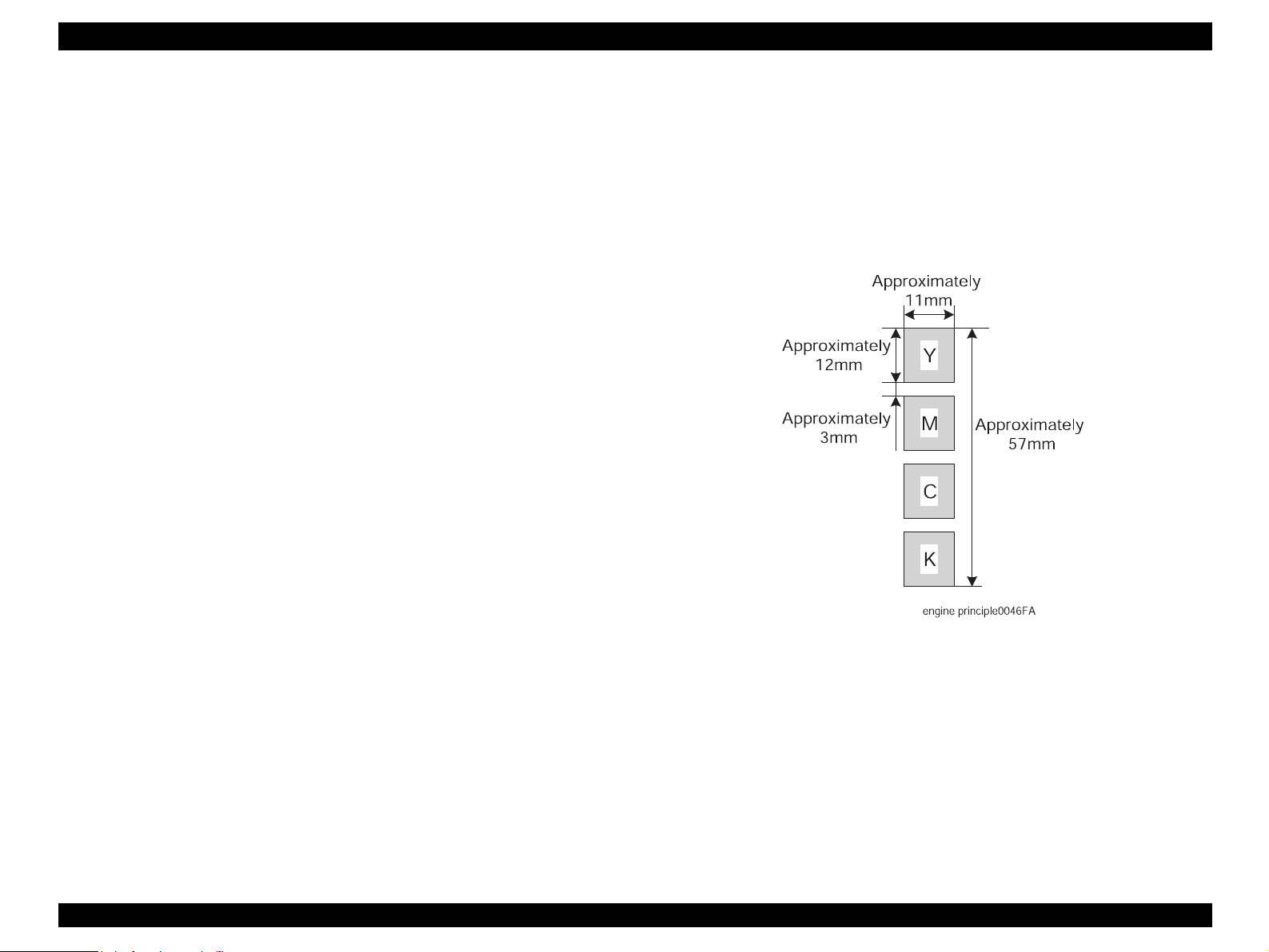

Color Registration Control ....................................................................... 87

BTR ASSY (PL9.1.2) Control .................................................................. 88

Toner Control .......................................................................................... 89

Fuser Control........................................................................................... 90

Operating Principles for the Large Capacity Paper Unit (Option Feeder)..

91

Drive Transmission Path ........................................................................... 91

DRIVE ASSY FEEDER ........................................................................... 91

Gear Layout............................................................................................. 92

Paper Feed .................................................................................................. 93

Paper Feed Path ..................................................................................... 93

Paper Feed Path Diagram....................................................................... 93

Functions of Main Components................................................................ 94

Two Tray Module II/III (PL17.2 ~ 3) ........................................................ 94

Two Tray Module IV (PL17.4) ................................................................. 96

Switches and Sensors ............................................................................... 97

Controller Operating Principles ................................................................ 98

Troubleshooting

Overview.................................................................................................... 103

Troubleshooting Procedure ................................................................... 103

Preliminary Checks ............................................................................... 103

Precautions When Performing Work ..................................................... 104

Test print by engine itself ...................................................................... 105

Precautions When Using FIP ................................................................ 106

Level 1 FIP................................................................................................. 107

Level 1 FIP Flowchart ........................................................................... 107

Level 2 FIP................................................................................................. 108

Level 2 FIP ............................................................................................ 108

Self-Diagnostic Function by LCD Message........................................... 108

Service Call Error Messages................................................................. 118

Image Quality Troubleshooting FIP....................................................... 246

Printer Operation Troubleshooting FIP ................................................. 267

Other FIP............................................................................................... 279

Level 2 FIP –Large Capacity Paper Unit–............................................... 284

Level 2 FIP ............................................................................................ 284

Disassembly and Assembly

Overview ................................................................................................... 303

Precautions for Disassembly and Assembly ......................................... 303

Tools ..................................................................................................... 303

Items to Check after Assembly ............................................................. 303

Disassembly Assembly Procedures....................................................... 304

Large capacity paper unit removal ........................................................ 305

Removing/Replacing the Consumables ................................................ 306

Updating the Main Controller Program ROM ........................................ 306

COVER ................................................................................................. 309

CHASIS & FEEDER/CASSETTE .......................................................... 319

PAPER CASSETTE .............................................................................. 321

PAPER FEEDER .................................................................................. 323

HOUSING ASSY RETARD ................................................................... 356

CHUTE ASSY IN................................................................................... 360

CHUTE ASSY OUT............................................................................... 365

CHUTE ASSY EXIT .............................................................................. 377

FUSER ASSY & BTR ASSY ................................................................. 381

REGISTRATION ................................................................................... 383

XEROGRAPHICS ................................................................................. 387

TCRU ASSSY ....................................................................................... 389

FRAME.................................................................................................. 397

DRIVE ................................................................................................... 403

ELECTRICAL ........................................................................................ 404

CONTROLLER BOARD........................................................................ 413

Page 18

Large Capacity Paper Unit

(Option FEEDER UNIT) ........................................................................ 415

Adjustment

USB ID Input.............................................................................................. 458

Installation Procedure for Program........................................................ 458

Procedure for program operation .......................................................... 458

USB ID Confirmation ............................................................................. 460

Details of Warning Message and Treatment......................................... 498

Maintenance.............................................................................................. 499

Consumable components and regularly replaced parts........................ 499

Engine Status Sheet ............................................................................. 502

List of control information and control methods .................................... 503

Parts List for AL-C4100............................................................................ 504

Exploded Diagram.................................................................................... 508

Circuit Schematic ..................................................................................... 532

Maintenance

Maintenance.............................................................................................. 463

Preparatory Maintenance ...................................................................... 463

Consumable components and components that require regular replacement

463

Cleaning ................................................................................................ 465

Maintenance Menu ................................................................................... 466

Entry to the Maintenance Menu ............................................................ 466

Engine Status Sheet.............................................................................. 466

Clear Error Log...................................................................................... 467

Consumable components replacement ................................................. 469

Toner Cartridge replacement ................................................................ 469

Photoconductor Unit replacement ......................................................... 471

Fuser Unit replacement ......................................................................... 473

Transfer Unit replacement..................................................................... 474

Components that require regular replacement ..................................... 474

Color Registration Adjustment ............................................................... 475

AcuLaser C4100

Product Descriptions ............................................................................... 478

Features ................................................................................................ 478

Printer Basic Specification..................................................................... 479

Control Panel......................................................................................... 484

Status Sheet.......................................................................................... 495

Panel Message For Troubleshooting...................................................... 496

List of Printer Messages........................................................................ 496

Details of Error Message and Treatment .............................................. 497

AcuLaser C3000

Product Descriptions ............................................................................... 541

Features ................................................................................................ 541

Printer Basic Specification .................................................................... 543

Control Panel ........................................................................................ 544

Panel Message ..................................................................................... 549

Printer Status Information ..................................................................... 552

Main Controller ......................................................................................... 557

Major Components................................................................................ 557

Parts List for AL-C3000............................................................................ 558

Exploded Diagram.................................................................................... 561

Circuit Schematic ..................................................................................... 563

Appendix

Parts List and Explodede Diagram for Main Unit of The AcuLaser C4000

570

Attention on handling the parts list ........................................................ 570

Parts List Tables ................................................................................... 571

Exploded Diagrams............................................................................... 575

Wiring Diagrams....................................................................................... 599

P/J Locations......................................................................................... 599

Plug and Jack (P/J) Location Tables..................................................... 603

High-pressure electrode Location Tables ............................................. 607

Wiring Diagrams and Signal Information ............................................... 609

Overall Wiring Connection Diagram...................................................... 609

Wiring and Signal Descriptions between Components ......................... 611

Page 19

Notation on the Diagrams for the Wiring and Signal Descriptions between

Components.......................................................................................... 613

Parts List and Exploded Diagram for Large Capacity Paper Unit of The

AcuLaser C4000........................................................................................ 637

Attention on handling the part list .......................................................... 637

Parts List Tables.................................................................................... 638

Exploded Diagrams ............................................................................... 639

Wiring Diagrams ....................................................................................... 644

P/J Locations......................................................................................... 644

Plug and Jack (P/J) Location Tables..................................................... 645

Wiring Diagrams and Signal Information ............................................... 646

Overall Wiring Connection Diagram ...................................................... 646

Wiring and Signal Descriptions between Components ......................... 648

Notation on the Diagrams for the Wiring and Signal Descriptions between

Components.......................................................................................... 649

Component Layout................................................................................... 656

Circuit Diagrams....................................................................................... 658

Page 20

PRODUCT DESCRIPTIONS

CHAPTER

1

Page 21

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.1 Features

This printer is a non-impact color page printer that takes advantage of a laser

and electrophotographic technologies. It provides 1200/600/300 dpi of

resolution and 16 ppm (A4/LT) of printing speed for both color and

monochrome printing. The main features of the printer are as follows:

ENGINE FEATURES

1. A4 tandem engine, a high-speed engine which printing speed is 16 PPM

for both color and monochrome printing (when printing A4/LT).

Engine for True 1200 dpi of high resolution and full-color printing (however

printing speed is reduced by half).

2. The Duplex Print Unit is equipped as standard. Special types of paper such

as thick paper, OHP sheets (transparency), label sealing sheets, and

envelopes cannot be printed in duplex.

3. By using high quality plain paper, higher quality printing is possible.

4. Capable of printing on thick paper and OHP sheets for laser printers.

5. Provides easy maintenance of a color laser printer. The users can replace

all consumables.

Toner cartridges (C, M, Y, K)

Photoconductor Unit

Transfer Unit

Fuser Unit

6. Standard paper feed devices are the following 2-bin; the MP Tray

(up to 100 sheets) and the Lower Cassette (up to 500 sheets, A4/LT).

By adding the two optional Lower Cassette (up to 500 sheets * 2 cassettes,

A4/LT), a maximum of 1600 sheets can be fed from the 4-bin in total.

7. Standard paper eject is up to 250 sheets into the Face-down tray.

CONTROLLER FEATURES

1. High-speed controller with a new CPU adopted

64-bit RISC CPU ---- PowerPC 750CX 400 MHz

64-bit high-speed memory ---- PC100 SDRAM DIMM

64 MB of standard RAM

By installing additional RAM, the memory can be expanded up to 576

MB (64 MB + 512 MB)

(Furthermore, by replacing the standard RAM with a 512 MB RAM, the

memory can be expanded up to 1024 MB)

2. Enhanced ASIC is equipped (VIP2, CDMC)

The color management technologies shown below have been incorporated

into the hardware to achieve high-speed processing.

CCNV3 (color conversion of RGB into CMYK)

CCMP (color compression for RGBX or CMYKX and expansion)

CLRCTL (color adjustment)

3. Three types of standard interface are available

IEEE 1284 compatible and ECP compatible parallel Interface

Ethernet interface (100 Base-TX/10 Base-T)

Universal Serial Bus (USB) 1.1

4. By expanding memory with RAM DIMMs, the following functions can be

enhanced and speeded up

CPGI drawing area

Image creating speed

Resolution

5. Firmware update function is possible (RCC compatible) when a Flash

DIMM is installed

6. HDD can be installed

Product Descriptions Features 1-5

Page 22

EPSON AcuLaser C4000/C4100/C3000 Revision F

SOFTWARE FEATURES

1. Color technologies

Smooth expanding of color images by ESC/ Page-Color

2. Reserve job function

When the printer is equipped with Option HDD, the following "Reserve Job"

can be used.

Re-print Job

Verify Job

Stored Job

Confidential Job

Registration of job information is performed by the ESC/Page-Color driver.

NOTE: Password protection is only available for "Confidential Jobs."

3. Monitoring of the printer status and printer environment by bi-directional

EJL and MIB

4. Remote panel function through a Web browser (compatible with Java

JDK1.1)

5. HDD (option)

Electronic sorting

I/F receive buffer expansion (only for Ethernet I/F)

7. Installed emulation

Standard ESC/Page-Color, PCL5e (B/W), GL-Like (B/W),

FX (B/W), ESCP2(B/W), I239X (B/W), ESC/Page

(B/W)

Options Adobe Postscript3

Others EJL, PJL mode

RCC mode (firmware update)

DIAG mode (engine adjustment)

Auxiliary software Status Sheet (description of remaining levels of

current consumables, warning occurrences, Part

Numbers)

Reserve Job List

Form Overlay List

Network Status Sheet

AUX Status Sheet (only when Type-B Level 3 is

installed)

PS3 Status Sheet (only when PostScript 3 module

is installed)

Font Sample (for each mode)

Hex dump

Support Mode

• Standby Mode setting

• Printer Adjust Menu

Maintenance Mode (Engine Status Sheet)

Font registration in the PostScript3 mode

Registration of Reserve Job and Confidential Job

Registering Form Overlay (only available for Windows environment)

6. Changing the Manual Feed specification.

Same as EPL–5900

Figure 1-1. Exterior View of the EPSON AcuLaser C4000

Product Descriptions Features 1-6

Page 23

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.2 Specifications

This section describes specifications for EPSON AcuLaser C4000.

1.2.1 Basic Specifications

1.2.1.1 Process Specifications

Printer Type Semi-conductive laser beam+Electrophotographic

with dry 2 ingredients nonmagnetic toner

Light Source 4 beam semi-conductor laser

Photoconductor Unit OPC (Organic Photoconductor) drum

Charging Roller charger

Development Exposed area development

Toner Chemical spherical toner and carrier

(in development unit)

Transfer Roller transfer method

Fixing Heated roller method and flexible belt nip method

1.2.1.2 Printer Basic Specification

METHOD

Electrophotographic method using scanning semiconductor laser beam and

dry two-component toner.

RESOLUTION

600dpi and 1,200dpi

WARMING UP TIME

30 or less seconds : when printer is powered on,

or standby mode

(22°C 55% RH environment, at rated voltage)

PRINT MODE

600dpi Mode (Normal paper): Full speed

600dpi Mode (Special paper): Low speed

1200dpi Mode: Low speed

High gross Mode: Low speed

PRINTING MODE BY PAPER TYPE

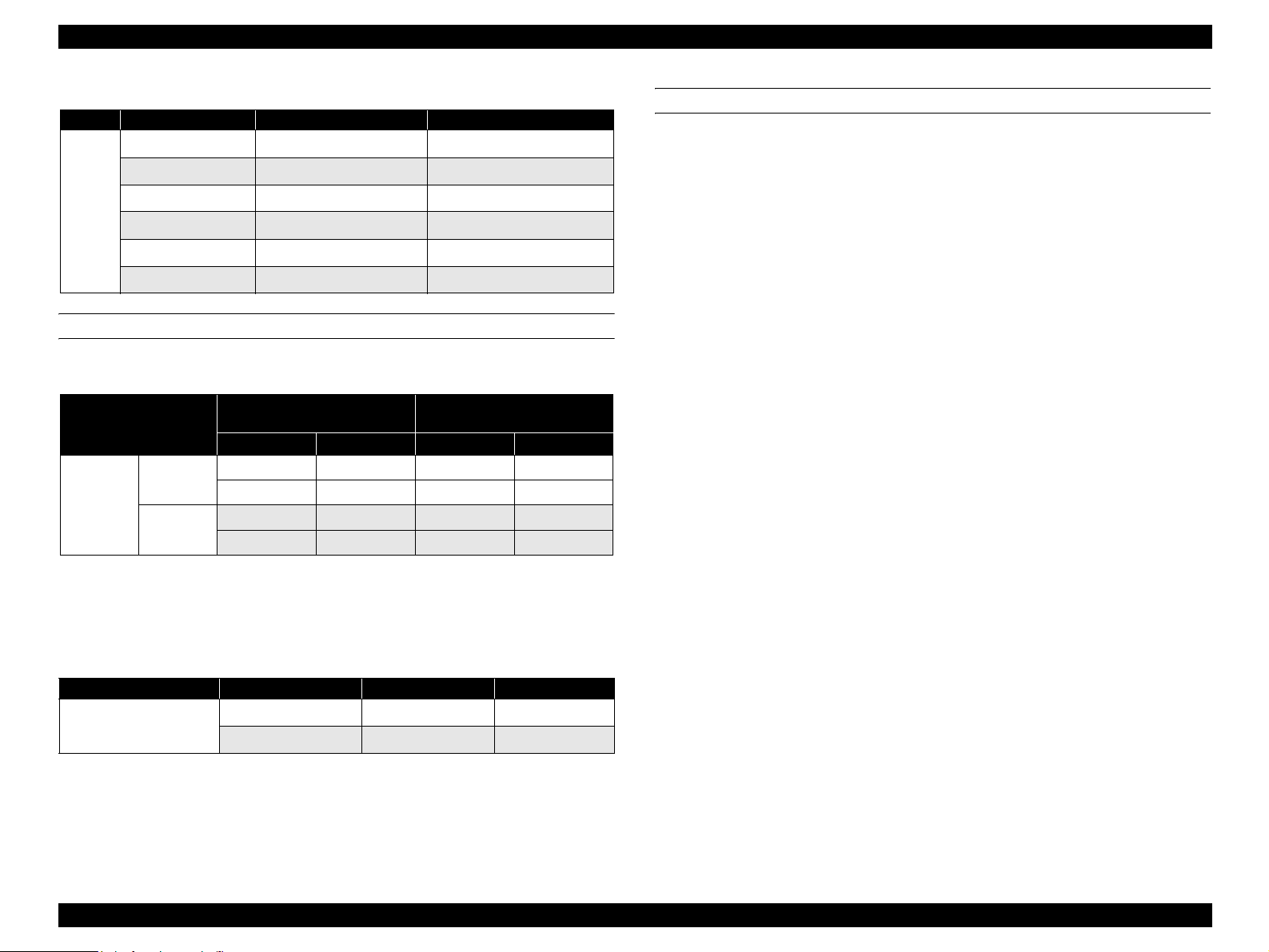

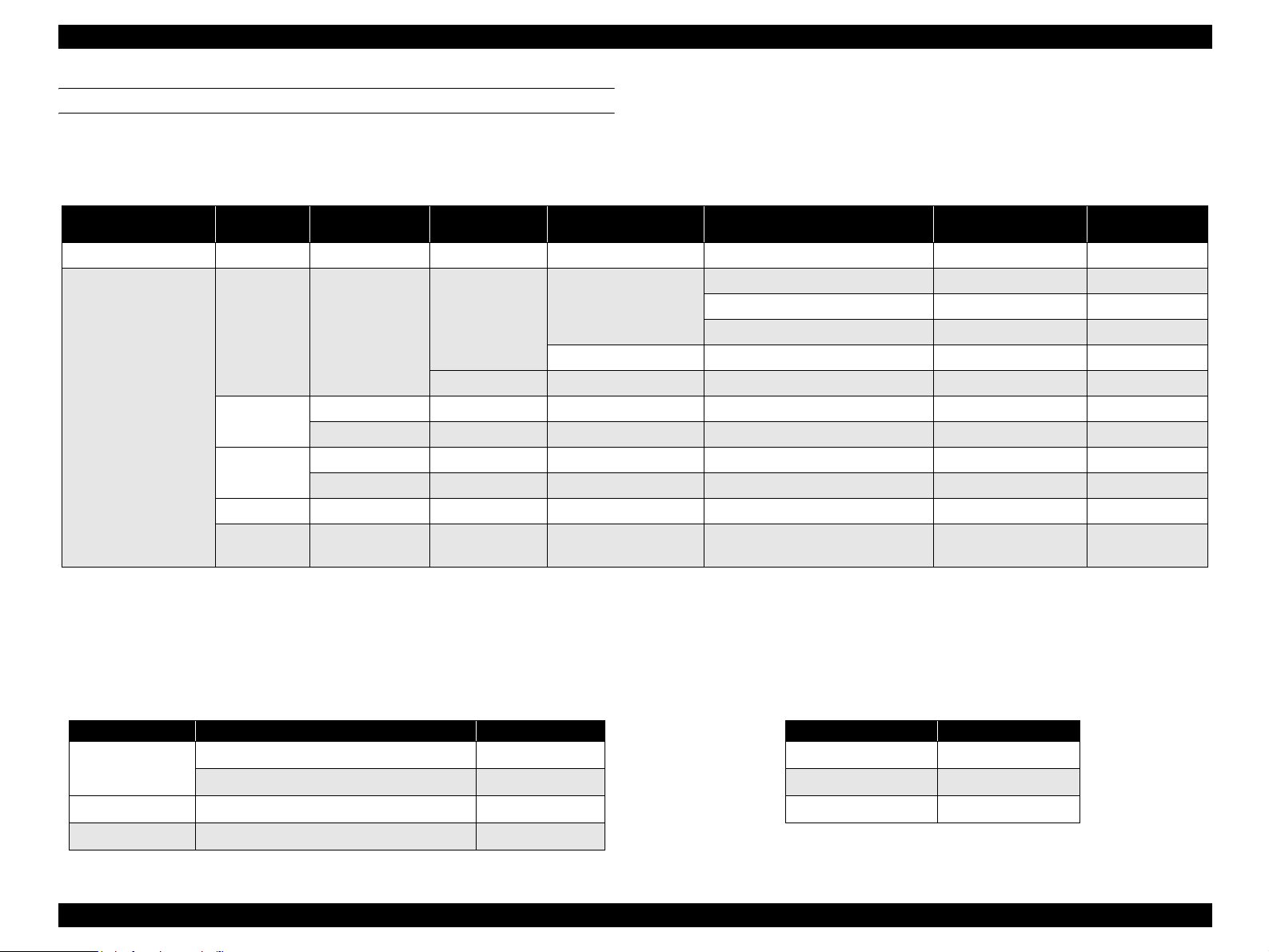

Table 1-1. Printing mode by paper type

Mode <video I/F name> Paper type, thickness

Normal (low temp) <Plain paper-L mode> Plain paper: 60~75g/m2

Normal (high temp) <Plain paper-H mode> Plain paer: 65~85g/m2

Normal

paper

High quality

(low temp)

High qality

(high temp)

<Thicker paper-L mode>

<Thicker paper-H mode)

High quality paper: 76~99g/

m2

High quality paper:

85~105g/m2

Product Descriptions Specifications 1-7

Page 24

EPSON AcuLaser C4000/C4100/C3000 Revision F

Table 1-1. Printing mode by paper type

Mode <video I/F name> Paper type, thickness

Thick1 <Heavier paper-L mode> Thick paper: 100~159g/m2

Thick2 <Heavier paper-H mode> Thick paper: 160g/216m2

Special

paper

Label (low temp) <Label-L mode> Label

Label (high temp) <Label-H mode> Label

OHP <OHP mode> OHP films

Envelope <Envelope mode> Envelope

PRINTING SPEED

Simplex

A4

(SEF)

Printing

Duplex

Printing

Table 1-2. First Printing Time

Standard

MP Tray Cassette 1 Cassette 2 Cassette 3

15.0 15.5 17.0 18.5

24.0 24.5 27.5 30.5

23.0 23.5 25.0 26.5

39.0 39.5 42.5 35.5

Optional Feeder 500 Sheets

Unit

PAPER FEED REFERENCE

Centerline reference for each paper size and each paper feeder.

NOTE: Printing Speed values at full speed mode are stated upper rows of

the each column, and values at low speed mode are in lower rows

of each column.

Table 1-3. Continuous printing speed

Paper size Print mode Sinplex printing Duplex printing

A4/Letter

Full speed mode 16 10

Low speed mode 8 5

NOTE 1: Speeds shown are for plain paper L and H modes.

NOTE 2: Cleaning cycles occur during printing.

Product Descriptions Specifications 1-8

Page 25

EPSON AcuLaser C4000/C4100/C3000 Revision F

PAPER FEED

Paper

Source

MP Tray

Standard

Cassette

Table 1-4. Paper Feed

Sheets

Containing

Capacity *

1

A4, A5, B5, EXE, LT, GLG, LGL,

100 Sheets *

TBD Sheets *

(10mm)

3

GLT*

2

Unspecified sizes

Min size : 88.9 x 139.7 mm

Max size : 215.9 x 355.6 mm

1 Sheet 900mm in length

TBD Sheets A4, LT

TBD Sheets Official Postcard 190 g/m

Envelopes

(Monarch, C10, DL, C5, C6*

ISO-B5*

TBD Sheets

(10mm)

(Yokei #2, 3, 4, Youchoukei #3)*

Unspecified size

Min size :

90mm (width) × 143mm (length)

500 sheets *

(58mm)

2*3

A4, A5, B5, EXE, LT, GLG, LGL

Paper Size

5

, HLT, F4*

5

)

5

5

,

(with flap opened)

Paper Type *

Standard Paper

Normal Paper

Standard Paper

Normal Paper

Special

Applications

(Labels,

Transparencies)

5

---

Standard Paper

Normal Paper

Applicable

2

Table 1-5. Optional Paper Source Combination

Combination (1) (2)

Standard

−

4

Optional

First Cassette Cassette 1 (500 Sheets)

Second and

Third Cassette

500 Sheets x 2 Cassette Unit

Total Sheets 600 1,600

2

*1: RX-80 (80g/m

)

MP Tray

(100 sheets*

1

)

−

500

Sheets

Unit

Optional

500 sheets *

(58mm)

2*3

A4, A5, B5, EXE, LT, GLG, LGL

Standard Paper

Normal Paper

*1: The values in ( ) is capable containing height

*2: Standard Paper : at FX P Paper (64g/

*3: Standard Paper : at Fuji XEROX 4024 DP 20lb (75 g/

2

m

)

2

m

)

*4: Refer to 1.4 "Paper Specifications"

*5: Paper size supported by the firmware (unsupported by the video I/F)

Product Descriptions Specifications 1-9

Page 26

EPSON AcuLaser C4000/C4100/C3000 Revision F

APPLICABLE PAPER SIZES, PAPER TYPES, AND PAPER ORIENTATION

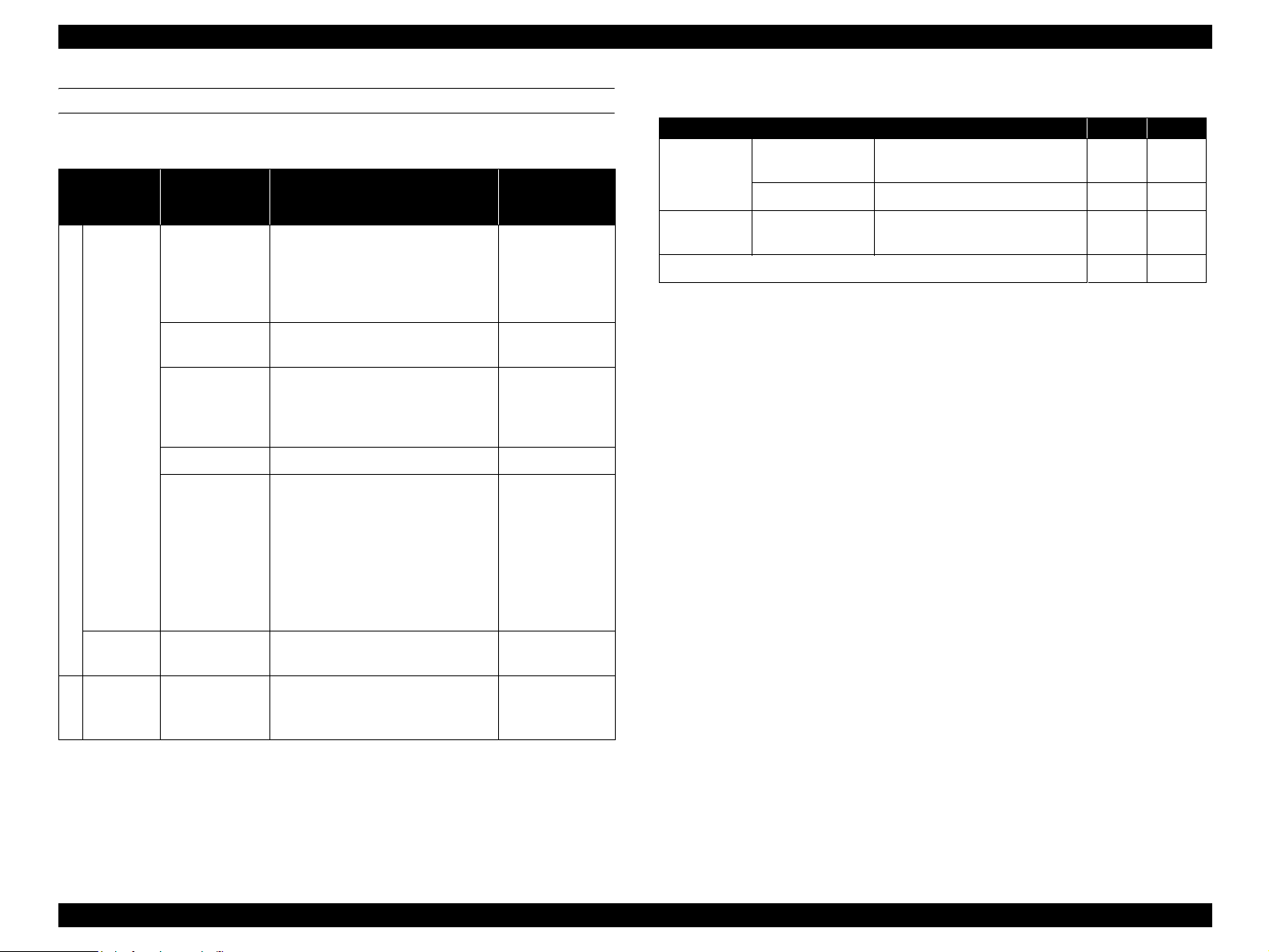

Table 1-6. Applicable Paper Sizes, Paper Types, and Paper Orientation 1

Paper Size

Dimensions in mm

(inches)

MP Tray

A4 210.00 x 297.00

6

A5*

148.00 x 210.00 SEF

B5 182.00 x 257.00 SEF

LT 215.90 x 279.40 (8.50 x 11.00”)

Standard Optional

cassette

(500 Sheets)

500 Sheets

2

Unit *

Duplex Printing

3

*

SEF

SEF

Paper

Orientation

HLT 139.70 x 215.90 (5.50 x 8.50”)

−−− −−− −−− SEF

GLG 215.90 x 330.00 (8.50 x 13.00”) SEF

LGL 215.90 x 335.60 (8.50 x 14.00”)

Normal Paper

EXE 184.15 x 266.70 (7.25 x 10.50”) SEF

5

GLT*

5

F4*

Uncut Paper *

203.20 x 266.70 (8.00 x 10.50”)

210.00 x 330.00 −−− −−− −−− SEF

Width: 88.90 ~ 215.90

1

Length: 139.70 ~ 900.00

−−− −−−

−−−SEF

SEF

−−−

*1: Paper of more than 355.60mm (14 inches) in length must be fed manually.

*2: Supported envelope sizes differ by destinations.

*3: Refer to "Envelope Orientation" for details on feeding direction of envelopes.

*4: Flatten the curling paper.

*5: Paper size supported by the firmware (unsupported by the video I/F)

*6: When installing the A5 paper to cassette, set exclusive adapter in cassette.

• LEF (Long Edge Feed) : the long edge of the paper is fed to the printer.

• SEF (Short Edge Feed) : the short edge of the paper is fed to the printer.

• ---: Unsupported

SEF

Product Descriptions Specifications 1-10

Page 27

EPSON AcuLaser C4000/C4100/C3000 Revision F

Special Applications : See Table 1-7

Table 1-7. Applicable Paper Sizes, Paper Types, and Paper Orientation 2

Standard Optional

cassette

(500 Sheets)

−−− −−−

500 Sheets

2

Unit *

Duplex Printing

3

*

−−−

Paper

Orientation

SEF

−−− −−− −−− SEF

Paper Size

Official Postcard *

Transparency

Dimensions in mm

(inches)

4

100.00 x 148.00

A4:210 x 297,

LT:215.9 x 279.4

Paper

Tray

Labels

A4:210 x 297,

LT:215.9 x 279.4

Monarch 98.43 x 190.50 (3 7/8” x 7 1/2”)

4

*

Com-10 104.78 x 241.30 (4 1/8” x 9 1/2”) −−− −−− −−− SEF*

3

*

2

DL 110.00 x 220.00 −−− −−− −−− SEF*

Special Applications

C5 162.00 x 229.00

5

C6*

Envelopes *

ISO-B5*

5

114.00 x 162.00 −−− −−− −−− SEF*

176.00 x 250.00 −−− −−− −−− SEF*

*1: Paper of more than 355.60mm (14 inches) in length must be fed manually.

*2: Supported envelope sizes differ by destinations.

*3: Refer to Section "Envelope Orientation" for details on feeding direction of envelopes.

*4: Flatten the curling paper.

*5: Paper size supported by the firmware (unsupported by the video I/F)

*6: When installing the A5 paper to cassette, set exclusive adapter in cassette.

• LEF (Long Edge Feed) : the long edge of the paper is fed to the printer.

• SEF (Short Edge Feed) : the short edge of the paper is fed to the printer.

• ---: Unsupported

−−− −−− −−− SEF

−−− −−−

−−− −−−

−−− SEF*

−−−

SEF*

3

3

3

3

3

3

Product Descriptions Specifications 1-11

Page 28

EPSON AcuLaser C4000/C4100/C3000 Revision F

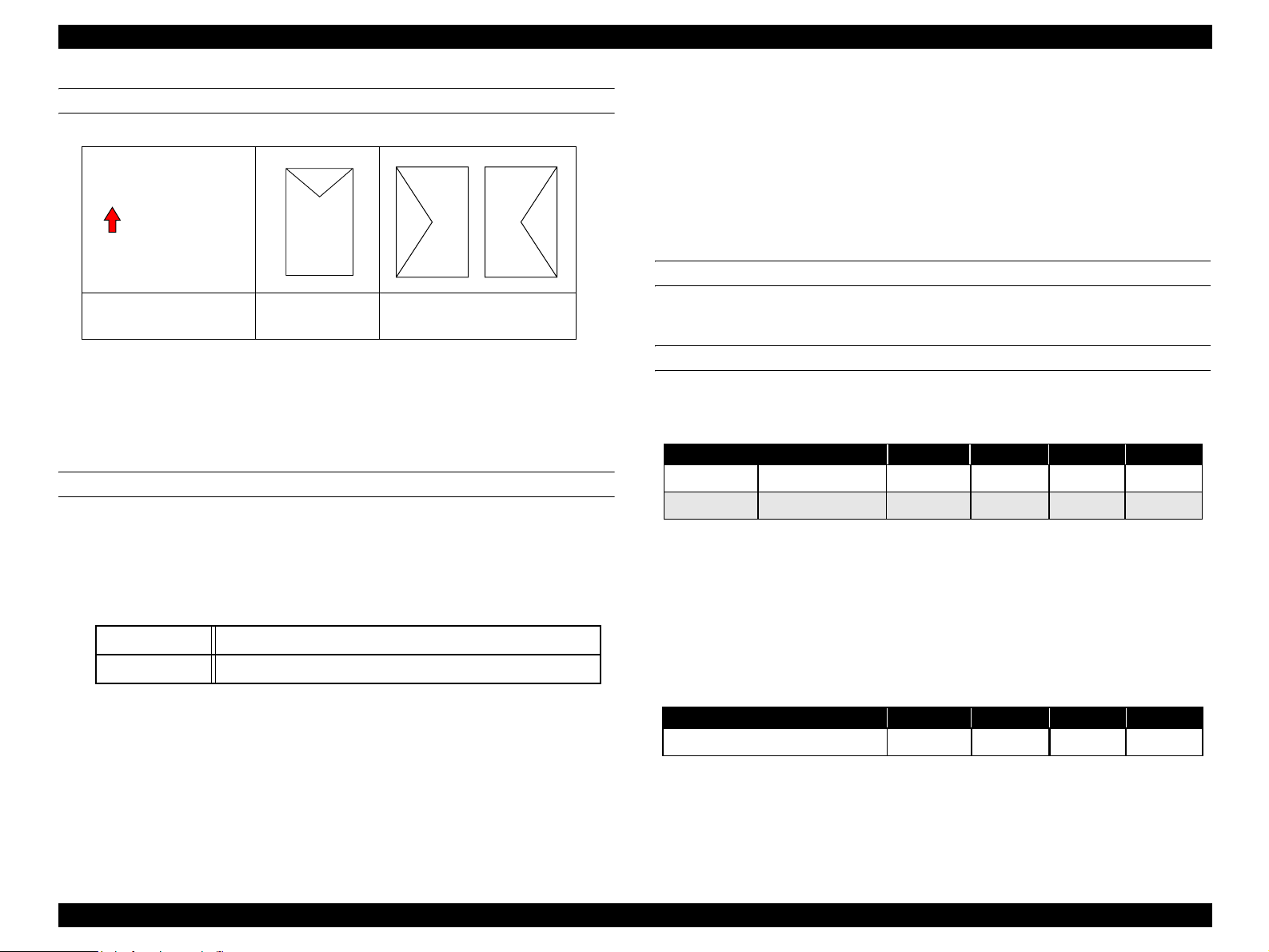

ENVELOPE ORIENTATION

Feeding Direction

Envelope Type C5, ISO-B5

Com-10, DL, C6

Monarch

NOTE 1: Only envelopes without adhesive or adhesive tapes can be used.

NOTE 2: Envelopes have to be set with flap opened, and should be fed by LEF

if width dimension is longer than length dimension.

NOTE 3: A printing side is set to the bottom.

PAPER FEED SIZES

Main Unit

MP Tray

Paper size: Regular paper sizes or unspecified paper sizes within

following useable paper size.

Duplex Unit

Paper size: The regular size and unspecified size described in the

Table 1-6 and 1-7 can be fed.

Paper thikneess: 64 ~ 105g/m

2

500 sheets x 2 unit (Large capacity paper unit)

Same specification as cassette of the main unit

OUTPUT PAPER CAPACITY

Maximum of 250 sheets to face-down tray (at 22°C, 55%RH, standard paper).

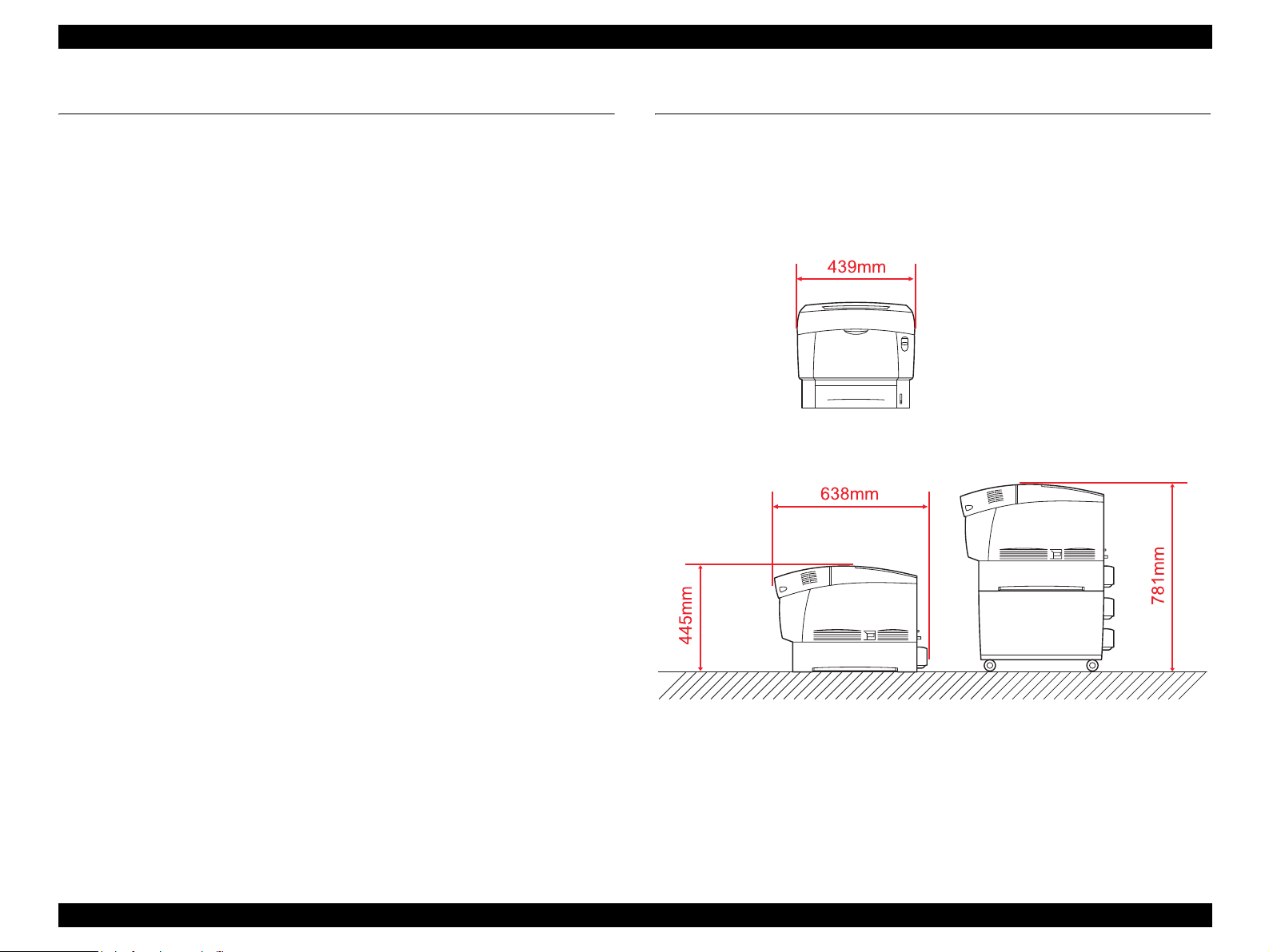

DIMENSIONS

Stand Alone Outline Dimensions and Weights

Table 1-8. Stand Alone Outline Dimensions and Weights

Width Depth Height Weight

Standard Main Unit only 439 638 445 29.8

Optional 500 Sheets Unit 439 563 336 19.0

Unit: mm, kg

NOTE 1: Unpacked dimensions are stated.

NOTE 2: Dimensions has ±1%mm difference, weights are ±1%kg difference.

NOTE 3: Main unit weights do not including consumable items

Minimum Width 88.9mm x to Length 139.7mm

Maximum Width 215.9mm x to Length 355.6mm to 900.0mm

Paper thikneess: 60 ~ 216g/m

900.0mm are 64 ~ 105g/m

2

(Uncut paper for length 355.6mm to

2

)

Outline Dimensions and Weights with Options Installed

Table 1-9. Outline Dimensions and Weights with Options Installed

Width Depth Height Weight

Main Unit and 500 Sheets Unit 439 638 781 48.8

Cassette

Paper size: Only the regular size described in the Table 1-6 and 1-7

can be fed.

Paper thikneess: 60 ~ 105g/m

2

NOTE 1: Unpacked dimensions are stated.

NOTE 2: Dimensions has ±1%mm difference, weights are ±1%kg difference.

NOTE 3: Main unit weights do not including consumable items.

Unit: mm, kg

Product Descriptions Specifications 1-12

Page 29

EPSON AcuLaser C4000/C4100/C3000 Revision F

CONSUMABLE COMPONENTS

Toner Cartridge: Black (K), Cyan (C), Magenta (M), Yellow (Y)

Photoconductor Unit

Transfer Unit

Fuser Unit

* Refer to Consumable Components on Page 23.

NOTE: Refer to Ch6 about handling the consumable components.

COMPONENTS THAT REQUIRE REGULAR REPLACEMENT

The life of regular replacement parts which are not replaced by the user.

Pickup Roller 100K pages

NOTE: Refer to Ch6 about handling the components require regular

replacement.

POWER SUPPLY

115V / 120V ± 10% 50 to 60Hz ± 3Hz

220V / 240V ± 10% 50 to 60Hz ± 3Hz

Supply to controller: 3.3V/5.0A

5.0V/1.0A

POWER CONSUMPTION

120V 240V

Maximum current rated TBD TBD

PRODUCT LIFETIME

Main unit

300K printed pages or 5 years, whichever comes first.

(with periodic part replacement. See Components that require regular

replacement on Page 13)

NOISE

Table 1-10. Noise

Main Unit With Options Installed

MP Tray Cassette MP Tray Cassette

During printing Full

Speed Mode

During Printing Low

Speed Mode

During standby 35 dB (A)

Saving Electricity Mode Back Ground Noise

54.0 dB (A) 52.0dB (A) 54.0dB (A) 54.0dB (A)

54.0 dB (A) 55.0 dB (A) 55.0 dB (A) 55.0 dB (A)

NOTE 1: Values measured by ISO7779 9-point method.

NOTE 2: Measured with MP tray closed.

NOTE 3: Simplex and duplex printing are the same values.

EMISSION

Ozone Concentration: 0.01ppm or less (New Blue Angel standard compliance).

Dust Concentration: 0.1mg/m

3

Maximum at continuous printing 850W 850W

Average at continuous printing 450Wh 450Wh

Average during standby with heating on 850Wh 850Wh

Power

Average during power save mode with

consumption

heating off

45Wh or less 45Wh or less

HAZARDOUS MATERIALS

None of the OPC, toner or plastic contains hazardous materials.

Product Descriptions Specifications 1-13

Page 30

EPSON AcuLaser C4000/C4100/C3000 Revision F

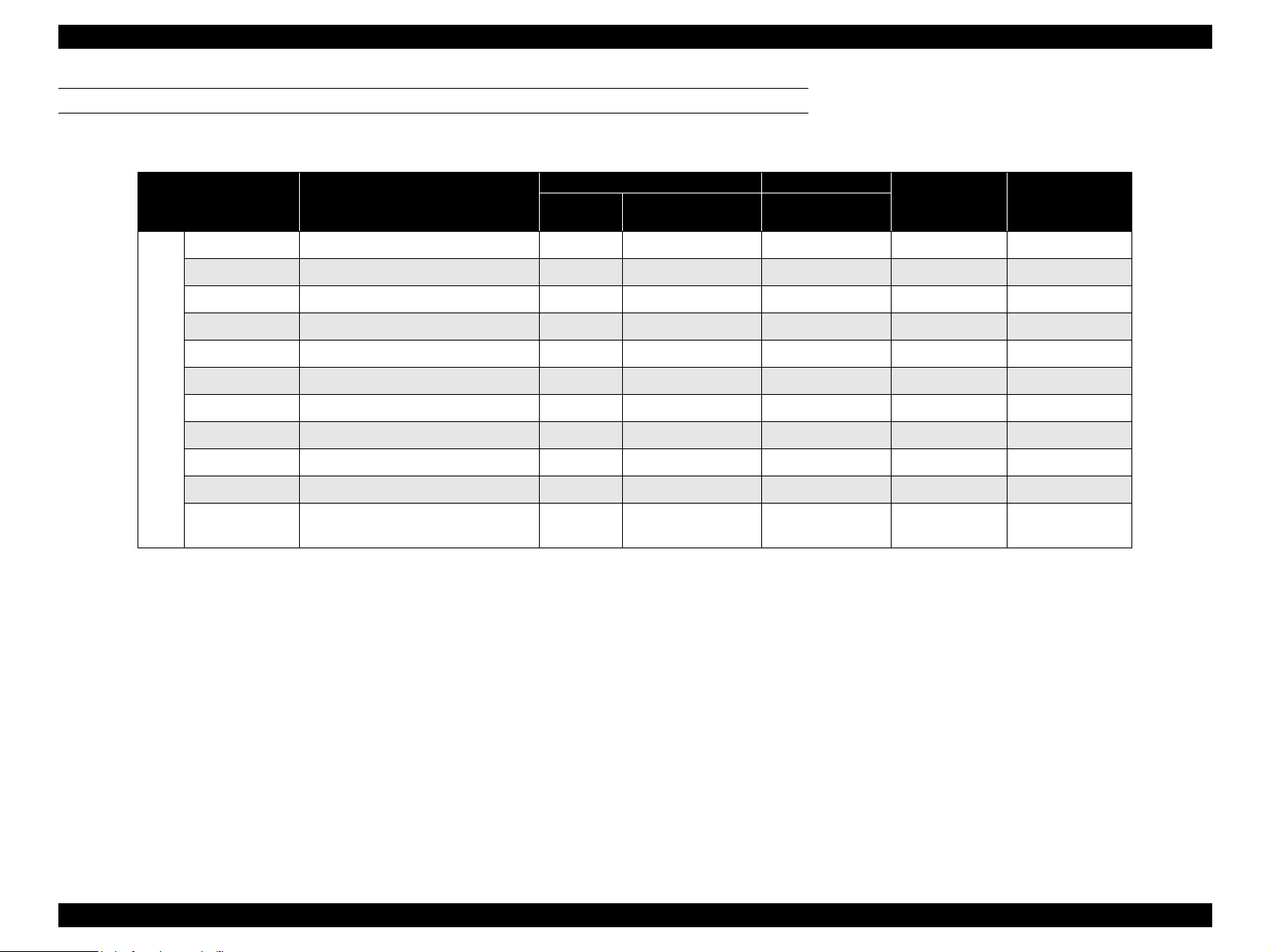

1.3 Various Sensors

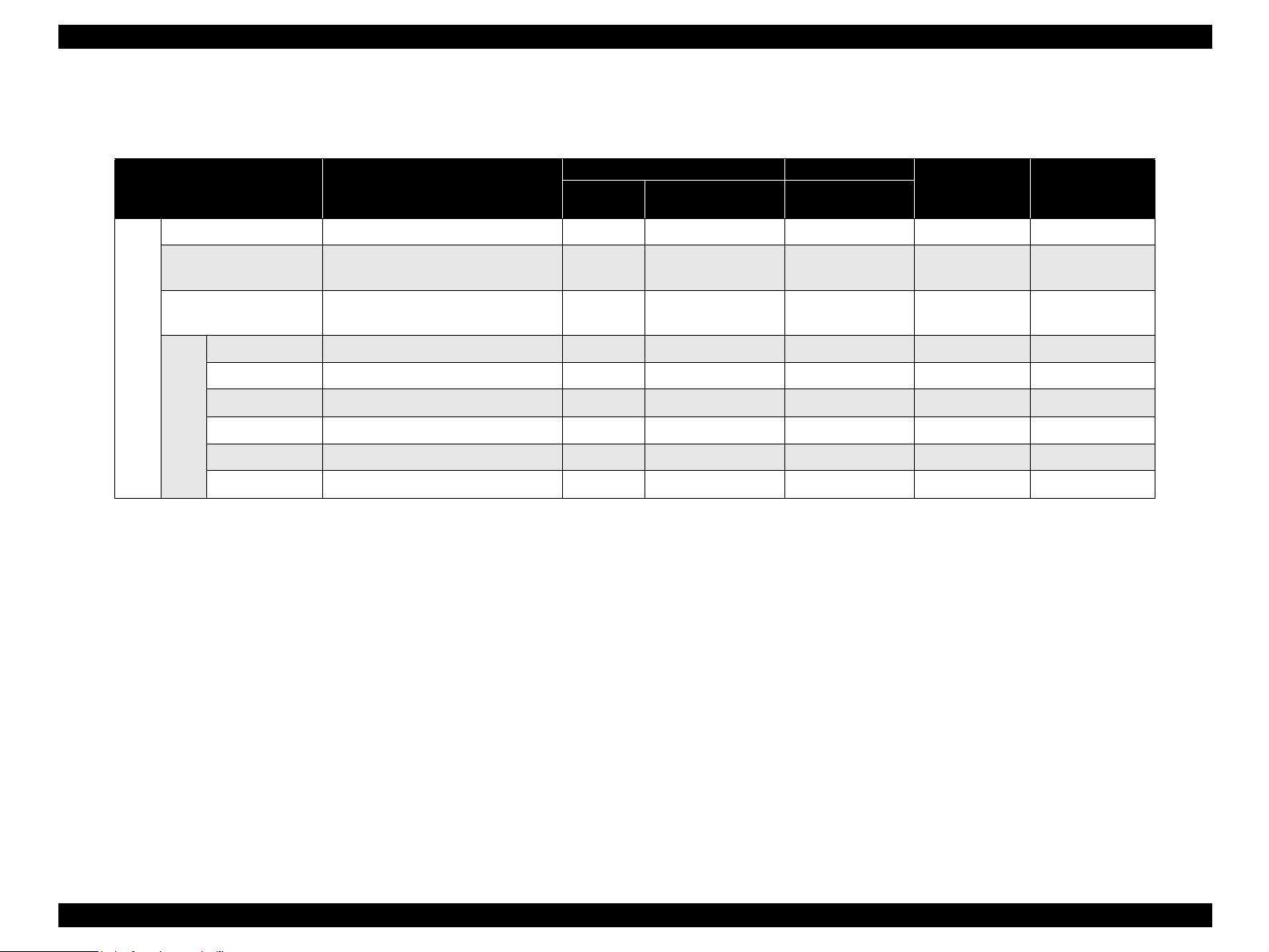

Table 1-11. Various Sensors

Unit Detectable Matter Detectable Device Remarks

Cartridge mounted/unmounted Automatic detection (switch method)

1

Toner Cartridge

(Cyan, Magenta, Yellow, Black)

New cartridge Automatic detection*

Cartridge type --- Refer to *9

Near life end Sensor detection

Work life end Softcounter

Cartridge mounted/unmounted Automatic detection (By IC chip)

Photoconductor Unit

Transfer Unit

Fuser Unit

Standard Paper Feeder

Optional

Paper Feeder

MP Tray

Cassette

500 Sheets x 2 cassette unit

Near life end Softcounter Refer to *2

Work life end Softcounter Refer to *2

Cartridge mounted/unmounted Automatic detection

Near life end Sensor detection Refer to *2

Work life end Softcounter Refer to *2

Cartridge mounted/unmounted Automatic detection

Near life end Softcounter Refer to *2

Work life end Softcounter Refer to *2

Paper size Automatic detection

Out of Paper Automatic detection by Photo Sensor and Mechanical Lever

Cassette mounted/unmounted Automatic detection by Mycro Switch

Paper size Automatic detection by Paper Regulation Board

Paper near end*

Out of paper Automatic detection by Photo Sensor and Mechanical Lever

Cassette mounted/unmounted

Paper size

Paper near end

Out of Paper

2

Automatic detection by Photo Sensor and Mechanical Lever

Identical to standard cassette

Detects 50 ± 20sheets

(FX-P paper 64g/m

2

)

Product Descriptions Various Sensors 1-14

Page 31

EPSON AcuLaser C4000/C4100/C3000 Revision F

*1: A used cartridge (with toner remaining) will be detected as a new cartridge if installed after Near End has been detected. Replacement of a toner cartridge before

Near End has been detected will result in erroneous detection of Near End and End.

*2: The following table describes detection consumables life end.

Name Detection Near end End Engine stop*

Toner Cartridge*

4

Photoconductor Unit*

Transfer Unit*

Fuser Unit*

6

8

*3: If the Engine Stop function activates, be sure to allow the engine to stop. Continued operation could damage the printer.

*4: Near End and End activation times can be adjusted by the Controller.

*5: Differs according to usage conditions.

*6: Near End, End and Engine Stop will activate when either the page count or the Dispense Time for any color is reached. Near End and End activation times can

be adjusted by the Controller.

*7: End and Engine Stop will activate when either the page count or the Dispense Time for any color is reached.

*8: After replacement, resetting the item in the control panel will detect the new part.

*9: The shape of cartridge housing is unique to each color, and this prevents it from installing on the wrong cartridge holder.

Sensor detection + Dispense Time ON Sensor ON + 75 Sensor ON + 86

Black (3,350) (3,425) (3,436)

(Near End, End and Engine

Yellow (2,975) (3,050) (3,061)

Stop sensor Dispense Time

for reference only) *5

Magenta (2,975) (3,050) (3,061)

Cyan (2,975) (3,050) (3,061)

Printing page count 24k 30k 45k

Black 39,040 48,800 73,200

5

Yellow 32,800 41,000 61,500

Dispense Time

Magenta 32,800 41,000 61,500

Cyan 32,800 41,000 61,500

Detection sensor

Printing page count

ON

Sensor ON + 500 Sensor ON + 600

Dispense Time Sensor ON + 1,875 Sensor ON + 2,250

(Printing page count: reference only) (17.5k) (18.0k) (18.1k)

Printing page count 80k 100k ---

3

NOTE: Dispense Time is a controller count value. Units are seconds.

Product Descriptions Various Sensors 1-15

Page 32

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.4 Paper Specifications

1.4.1 Paper Types

Standard Paper

FX P Paper (64g/m

XEROX 4024 DP 20lb (75g/m

Normal Paper

2

60g/m

generally applied copy paper, recycled paper

to 105g/m

Special Applications

Labels

Transparencies

Thick paper (105 to 216g/m

NOTE 1: lb : Ream weight = lb / 500 sheets / 17”×22” (431.8X558.8mm)

2

g/m

: 1 g/m2= 0.2659763 lb

1.4.2 The paper that should not be used with this printer

The following types of paper should not be used with this printer.

They could cause printing defects, paper jams or printer malfunctions.

2

) : A4

2

) : LT

2

(16 lb to 28lb)

2

)

Paper with punch holes or perforations.

Creased, curled or torn paper.

Irregularly shaped paper or paper with non-perpendicular corners.

Labels that peel off easily.

Paper with glue, staples or paper clips attached to it.

Ink jet paper for special applications (super-fine, glossy, glossy

film, etc.).

Sheets already printed on other color/monochrome laser printers

or photocopiers.

OHP transparency sheets for color copiers or color laser printers.

Iron applied cloth transfer materials (for ink jets, laser printers).

Postcards of any type for ink jets.

Sheets of paper stuck together.

Sheets deteriorate or discolor by heat of the Fuser Unit (about

TBD °C or less).

When non-official postcards with illustrations are used, paper feed

roller may be soiled with paper dust, and these postcards are not

fed properly. In this case cleaning is required following the 1.11

"Maintenance"

Copy paper (Carbon paper, non-carbon paper), thermal paper,

impact paper, acid-based paper.

Paper that was previously used in a thermal or ink jet printer.

Paper that is too thin or too thick.

Paper that is wet or damp.

Paper with special coatings or colored printer paper with

processed surfaces.

Glossy (too slick on its surface) paper, or paper with too smooth /

rough surfaces.

Paper with significantly different roughness on each surface.

Product Descriptions Paper Specifications 1-16

Page 33

EPSON AcuLaser C4000/C4100/C3000 Revision F

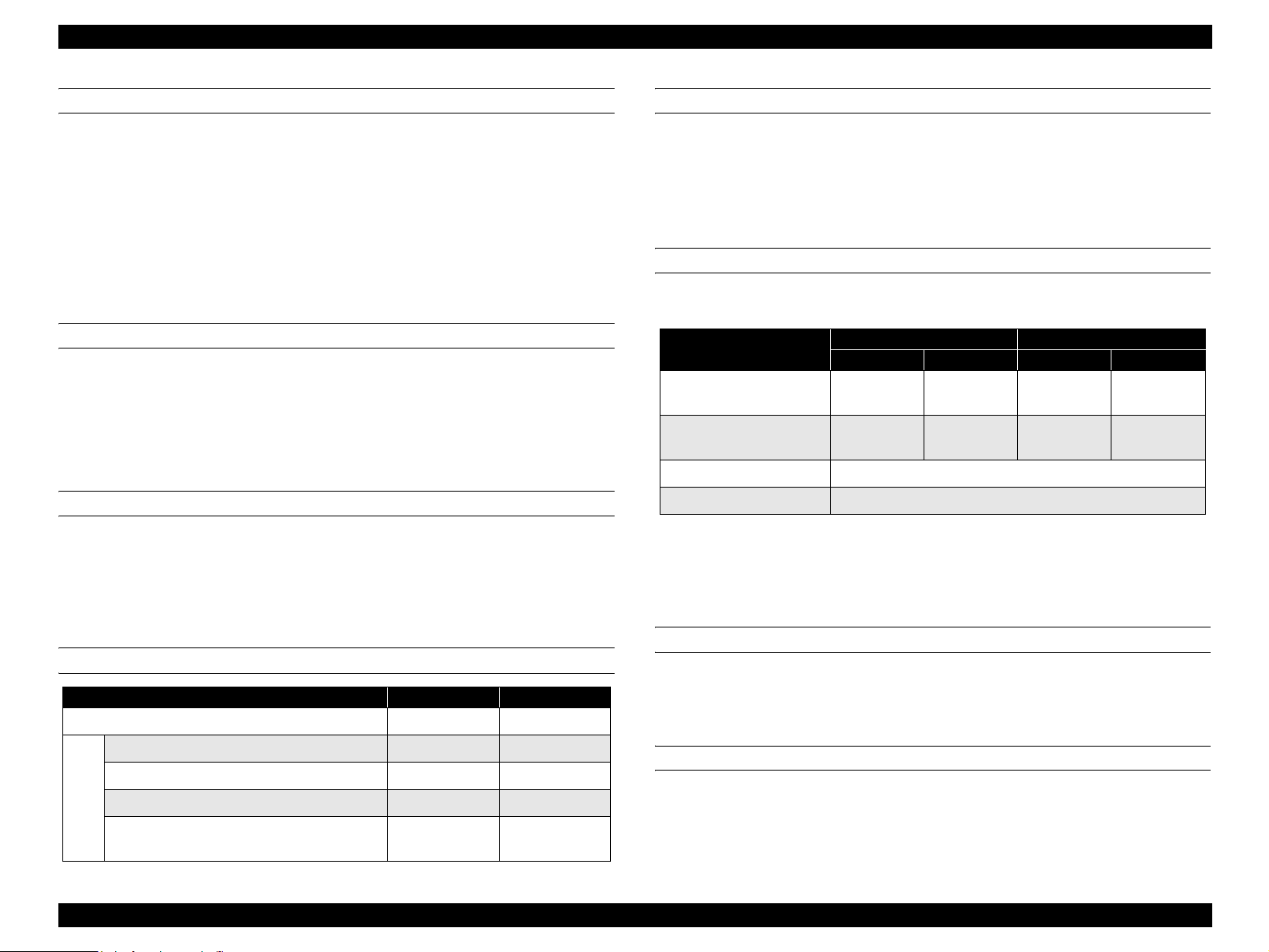

1.4.3 Paper Source Classification

Table 1-12. Paper Usability for Each Paper Source

Special Applications

Standard

Paper

MP tray

Standard

Optional

Cassette

Duplex

500 Sheet

Unit

A: Paper feed reliability and image quality assured.

B: Paper feed reliability and image quality assured, but only for the use

of generally applied types of paper.

C: Paper feed and Printing are possible for only generally applied types

of paper.

D: Sheets cannot be fed.

Normal

paper

Transparencies

ABCCCCC

A B D D D D D

ABDDDDD

A B D D D D D

Official

Postcard

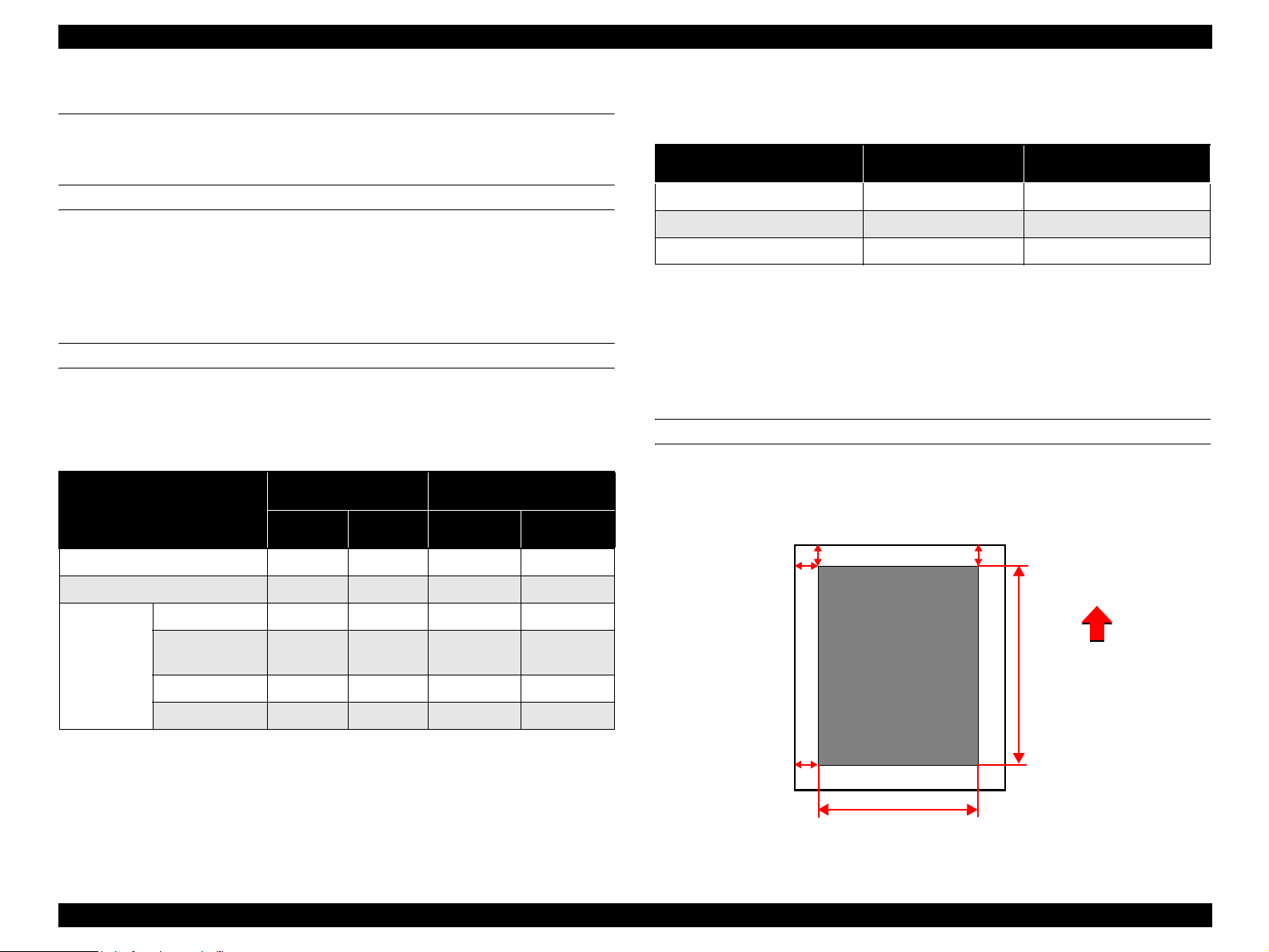

1.4.4 Printing Area

PRINTABLE AREA

210.9 x 351.6

210.9 x 896.0 (at the time of setting uncut paper)

Labels

Thick paper

Envelope

GUARANTEED PRINTING AREA

Area with a margin of 4 mm from each side. Refer to the following

figure. (Uncut paper is not applicable.)

4 mm

4 mm

Guaranteed

Printing

Area

4 mm

4 mm

Figure 1-2. Guaranteed Print Area

Product Descriptions Paper Specifications 1-17

Page 34

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.5 Reliability and Durability

1.5.1 Reliability

MPBF

100K pages

NOTE: Average number of pages printed until the occurrence of a

malfunction which either cannot be solved by the user or requires

the replacement of a part.

PAPER FEED RELIABILITY

Paper Jam Rate

Table 1-13. Paper Jam Rate

Standard MP Tray

Paper Type

Standard Paper 1/1,300 1/1,800 1/5,000 1/3,000

Normal Paper 1/2,000 1/1,200 1/3,000 1/1,800

Labels 1/100 −− −

Special

Applications

Official

Postcards

Transparencies 1/100 −− −

Thick Paper 1/100 − 1/100 −

Simplex

Printing

1/100 − − −

Duplex

Printing

Standard Cassette and

Optional 500 Sheets Unit

Simplex

Printing

Duplex

Printing

Multiple-Sheet Feed Rate

Table 1-14. Multiple-Sheet Feed Rate

Paper Type Standard MP Tray

Standard Paper 1/1,500 1/2,500

Normal Paper 1/1,000 1/1,500

Special Applications 1/50 1/50

NOTE 1: Based on the use of paper taken from a newly opened package.

NOTE 2: Does not include multiple-sheet feed at the boundary.

* Boundary means sheets boundary between original paper and

replenished paper, occurring after paper is replenished.

Standard Cassette and

Optional 500 Sheets Unit

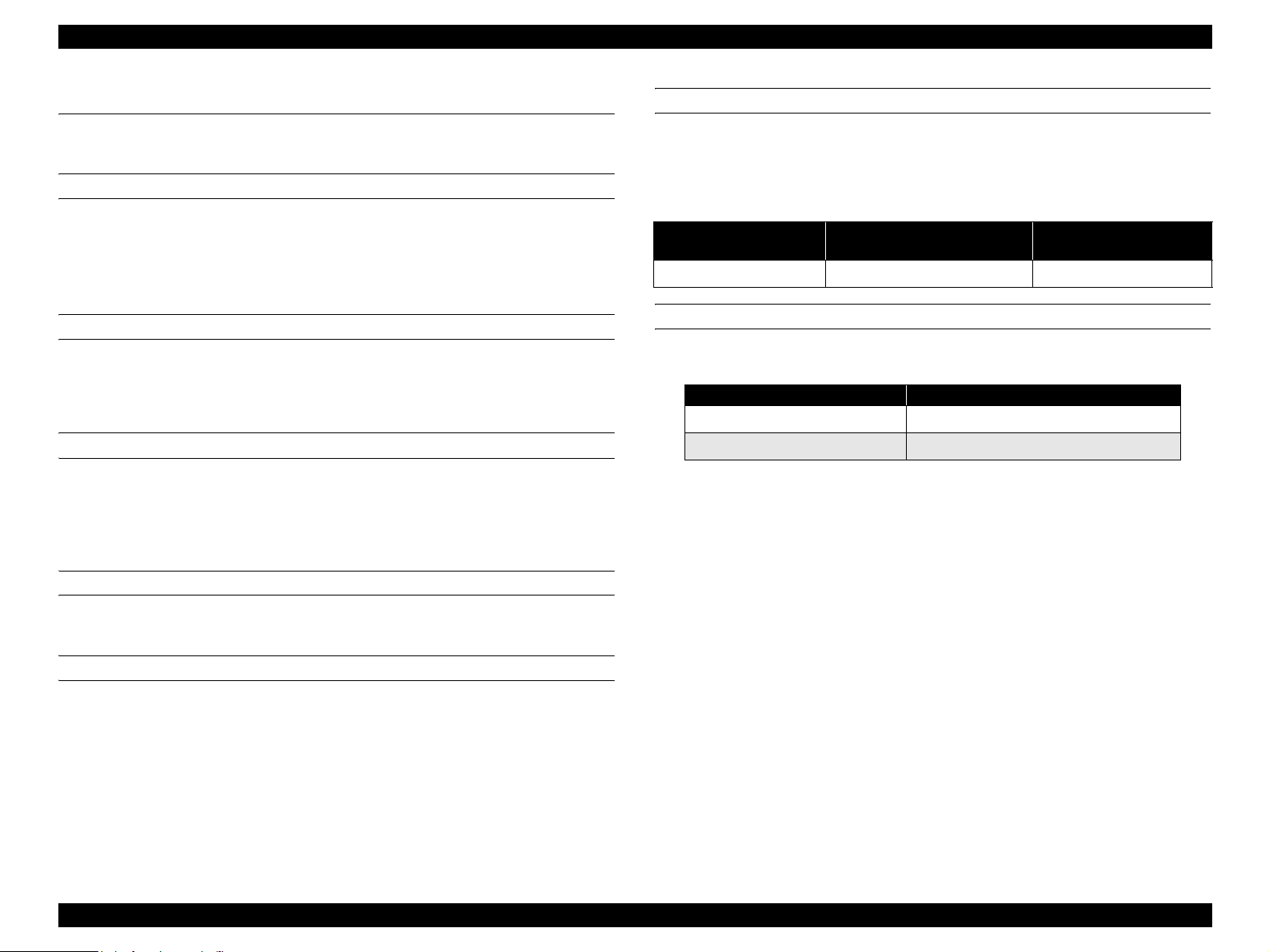

PRINTING START POSITION ACCURACY

(With standard paper fed from MP tray or paper cassette)

Reference point of main scanning direction (c) ±2.5mm

Reference point of sub-scanning direction (a) ±2.0mm

.

a

c

Printing Area

b

Paper Feed

f

Direction

NOTE 1: Based on the use of paper taken from a newly opened package.

d

NOTE 2: Includes miss feeds, multiple-sheet feed, and other kind of jams.

Does not include multiple-sheet feed at the boundary.

e

Figure 1-3. Print Position Accuracy

Product Descriptions Reliability and Durability 1-18

Page 35

EPSON AcuLaser C4000/C4100/C3000 Revision F

SKEW

(With standard paper fed from MP tray or Paper cassette)

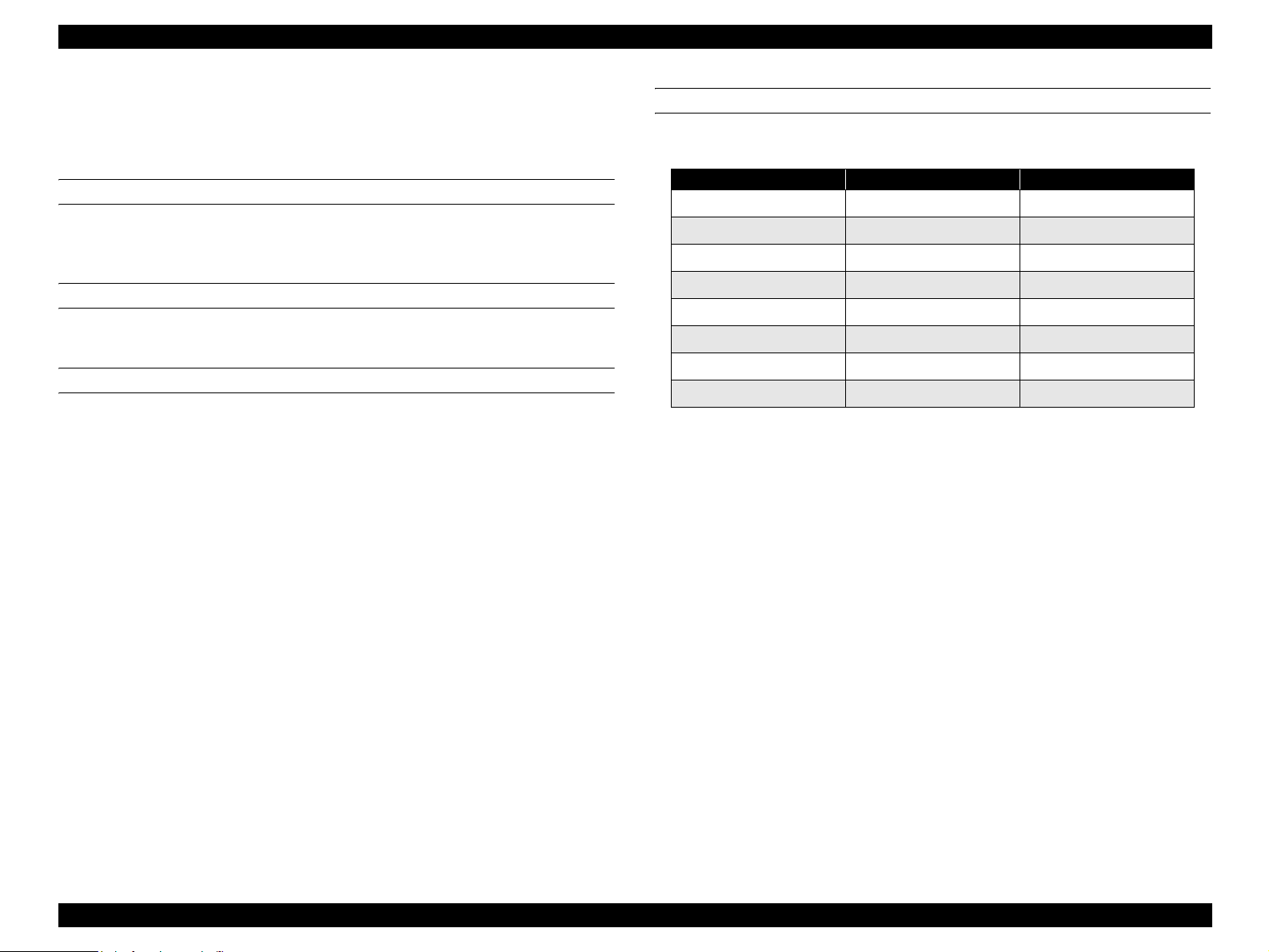

Table 1-15. Paper Skew

Printing Page Scanning Direction A4

Main Scanning Direction |a - b| 1.23

Simplex

Sub Scanning Direction |c - d| 1.78

Main Scanning Direction |a - b|

Duplex

Sub Scanning Direction |c - d|

Table 1-16. Measured by Dot 2 pattern

A4

Between a to b 195.58mm

Between c to d 282.61mm

HEIGHT OF CURL OF PRINTED PAGES

± 15mm or less (at the standard paper)

1.5.2 Durability

PRINTING VOLUME

Maximum 30K pages

Average 5K pages / month

1.5.3 Maintenance

MTTR

Averages within 30 minutes. 95% is complete within 50 minutes. Time for

examining malfunction is not included.

(time required for service personnel to determine and correct the cause of the

malfunction)

Product Descriptions Reliability and Durability 1-19

Page 36

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.6 Operating Conditions

(Including Comsumables)

AIR TEMPERATURE AND HUMIDITY

Table 1-17. Air Temperature and Humidity

Temperature (°C) Humidity (%RH) Others

Printer is under operation

Printer is stopped - 20 to 40 5 to 85

AIR PRESSURE

Altitudes : 0 to 3,100m

LEVEL

Front and Back : ± 5 degrees

Left and Right : ± 5 degrees

LIGHTING

5 to 32 15 to 85

With no

condensation

SPACE REQUIREMENTS

In order to ensure that the printer operates properly, provide at least as

much space as shown in the diagram below.

To open the cover and be able to replace the consumables easily, provide

at least 350 mm of space above the top of the printer.

3,000 lx or less (no exposure to direct sunlight)

Figure 1-4. Space Requirement

Product Descriptions Operating Conditions (Including Comsumables) 1-20

Page 37

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.7 Storage and Transport of the Printer Main Unit

(Consumables Packaged), and Optional

Products

TEMPERATURE AND HUMIDITY CONDITIONS

Main unit (Consumables packaged)

Table 1-18. Temperature and Humidity

Temperature

(°C)

Normal

Conditions

Severe

Conditions

0 to 35 15 to 80 12 months

High

temperature :

35 to 40

Low

temperature :

-20 to 0

500 sheets x 2 cassette unit (Oprion)

Humidity

(%RH)

High

humidity :

80 to 95

Low

humidity :

5 to 15

Warranty

Period

Maximum

of 48 hours

Altitude (m) Others

No

0 to 3,100

condensation

allowed

TRANSPORT BAROMETRIC PRESSURE

70.9275 kPa Minimum (15,000m) *

*: In pressurized luggage compartment

DROPPING

Table 1-20. Dropping

Dropping Height (cm) Dropping Direction

Main Unit 46

Optional 500 Sheets Unit 76

1 corner, 3 edges,

6 sides, one time each

VIBRATION

Frequency : 5 to 100Hz, 100 to 5Hz

Acceleration : 6.86m/s

2

(0.7 G)

Direction of application : 3 dimensional

Time of application : 50 minutes along each X, Y, Z axis, total of 150

minutes

Table 1-19. Temperature and Humidity

Normal

Conditions

Severe

Conditions

Temperature

(°C)

-20 to 50 5 to 85 12 months

High

temperature :

50 to 60

Humidity

(%RH)

High

humidity :

85 to 95

Warranty

Period

Maximum

of 48 hours

Altitude (m) Others

No

0 to 3,100

condensation

allowed

Product Descriptions Storage and Transport of the Printer Main Unit (Consumables Packaged), and Optional Products 1-21

Page 38

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.8 Electrical Feature

Specifications here are not applicable to any optional units.

FAST TRANSIENT / BURST (AC LINE NOISE)

EN61000-4 (IEC1000-4-4 ; 1995) compliance

Voltage 1kv : no malfunction occurs such as defective image quality.

2kv : no damage allowed.

INSTANTANEOUS OUTAGES

DIP 95% (at -10% of rated current) 0.5 cycle

No effect on printing quality

RESISTANCE TO STATIC ELECTRICITY

EN61000-2 (IEC1000-4-2 ; 1995) compliance

No malfunction such as defective image quality or no errors allowed even

if ± 4kv of static electricity noise is in contact discharge.

DIELECTRIC STRENGTH

No break down during application of the voltages shown below for a one

minute period.

Table 1-21. Dielectric Strength

Across primary and chassis

of power supply transformer

For 200V system models AC 3,000V AC 1,500V

(Across primary

and chassisi)

LEAK CURRENT

Table 1-22. Leak Current

Destination Leak Current

Taiwan (110 V) 3.5 mA or less

China (230 V) 3.5 mA or less

INRUSH CURRENT

0.5 cycle 100 A or less (The time of heater inrush is included.)

INSULATION RESISTANCE

10MΩ or more

Product Descriptions Electrical Feature 1-22

Page 39

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.9 Compliance with Standards and Regulations

SAFETY STANDARDS

For 200V system models:

IEC 60950 2

SAFETY STANDARDS (LASER TRANSMISSION)

IEC825

FDA

EMI

For 120V system models (US models) : FCC class B

For 200V system models : EN55022

ELECTRICAL POWER HIGH FREQUENCY

None

ELECTRICAL POWER CONSUMPTION

Conforms to International Energy Star Program standard

60 minutes / 45W or less

nd

Edition / EN60950 / A1 - A4 / CE Mark

1.10 Consumable Components

SPECIFICATIONS

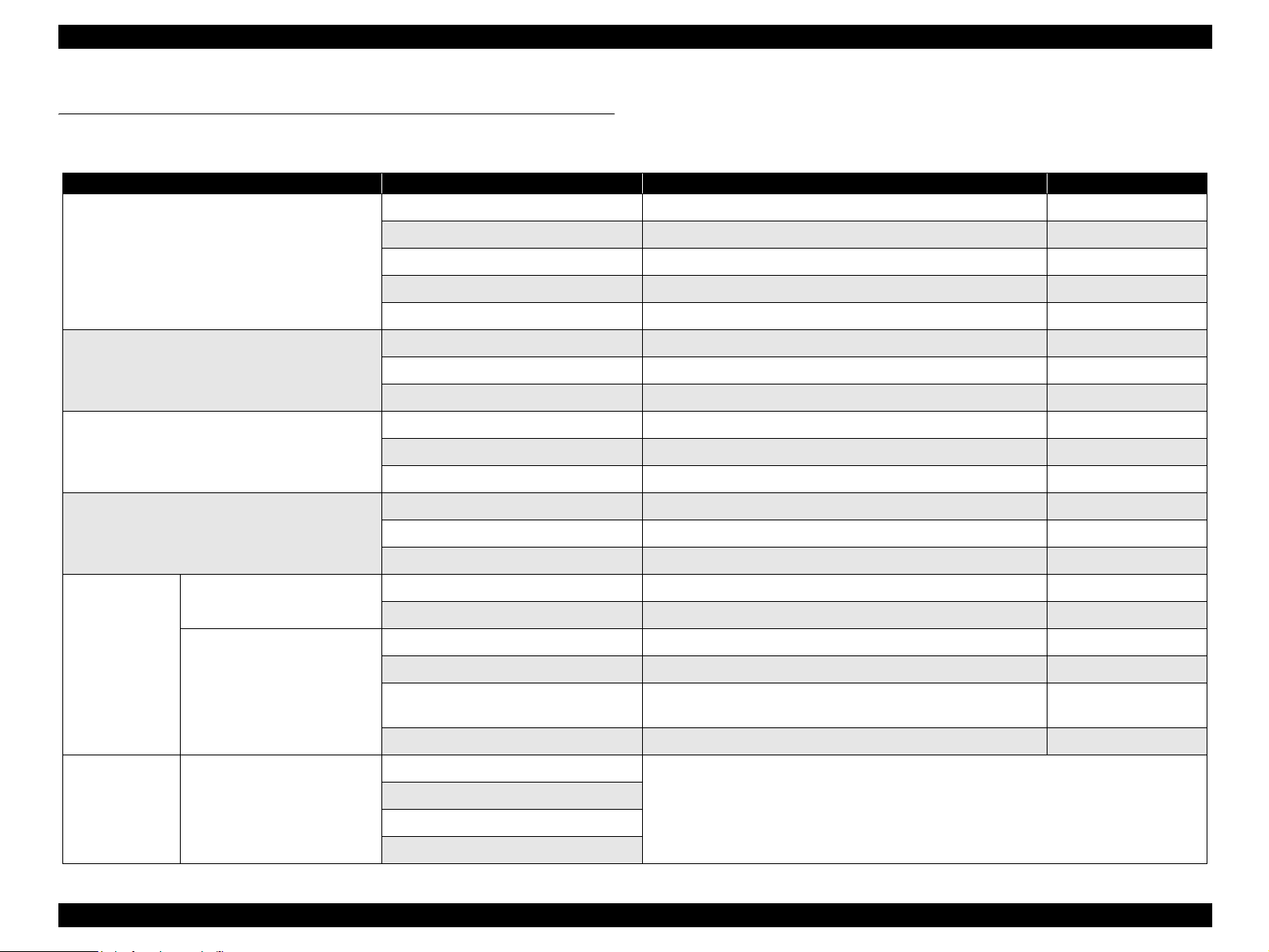

Table 1-23. Specifications

Name Lifetime Dimensions (mm) Weight (kg)

Toner Cartridge

(Black)

Toner Cartridge

(Cyan)

Toner Cartridge

(Magenta)

Toner Cartridge

(Yellow)

Photoconductor

Unit

Transfer Unit 25K sheets W:309, D : 85, H : 60 0.5

Average of 8,500

printed sheets*

Average of 6,000

printed sheets*

30 to 50K sheets*

1

1

2

W:339, D : 146, H : 179 4.5

*1: The number of sheets is the approximate number of printable images using

A4 landscape continuous printing at 5% image occupation rate.

The first cartridge will Near End for TBD page count. (In order to fill the

developer with toner.)

*2: Work life will differ with usage conditions.

W :340

D : 51

H : 55

W :329

D : 51

H : 53

0.32

0.295

0.285

OTHERS

Toner : No materials hazardous to human health

(conform to OSHA, TSCA, EINECS)

OPC : No materials hazardous to human health

(OSHA compliance)

Ozone generation : Conform to UL 478, 5th printing

Materials : Swiss Environmental Protection Standards

compliance (contains no Cds)

Product Descriptions Compliance with Standards and Regulations 1-23

Page 40

EPSON AcuLaser C4000/C4100/C3000 Revision F

PACKING STORAGE AND TRANSPORT ENVIRONMENTS

Temperature and Humidity Conditions

Table 1-24. Temperature/Humidity

Conditions Temperature Humidity Warranty Period

Normal 0 to 35

High temp. 35 to 45

Severe

Low temp. -20 to 0

°C 15 to 80% 24 months

°C 80 to 95%

°C 5 to 15%

Maximum of one

month

TRANSPORT BAROMETRIC PRESSURE

70.9275 kPa Minimum (15,000m) *

*: In pressurized luggage compartment

DROPPING

Table 1-25. Dropping

Dropping Height (cm) Dropping Direction

Consumables 91.0 1 corner, 3 edges, 6 sides

1.11 Maintenance

Table 1-26. Maintenance

Maintenance Item Period Maintenance Method

Pickup roller

(Roll Assy)

At the time of paper feed

performance degradation

Wipe with a dry cloth.

VIBRATION

Frequency : 5 to 100Hz, 100 to 5Hz

Acceleration : 6.86m/s

2

(0.7 G)

Direction of application : 3 dimensional

Time of application : 50 minutes along each X, Y, Z axis, total of 150

minutes

Product Descriptions Maintenance 1-24

Page 41

EPSON AcuLaser C4000/C4100/C3000 Revision F

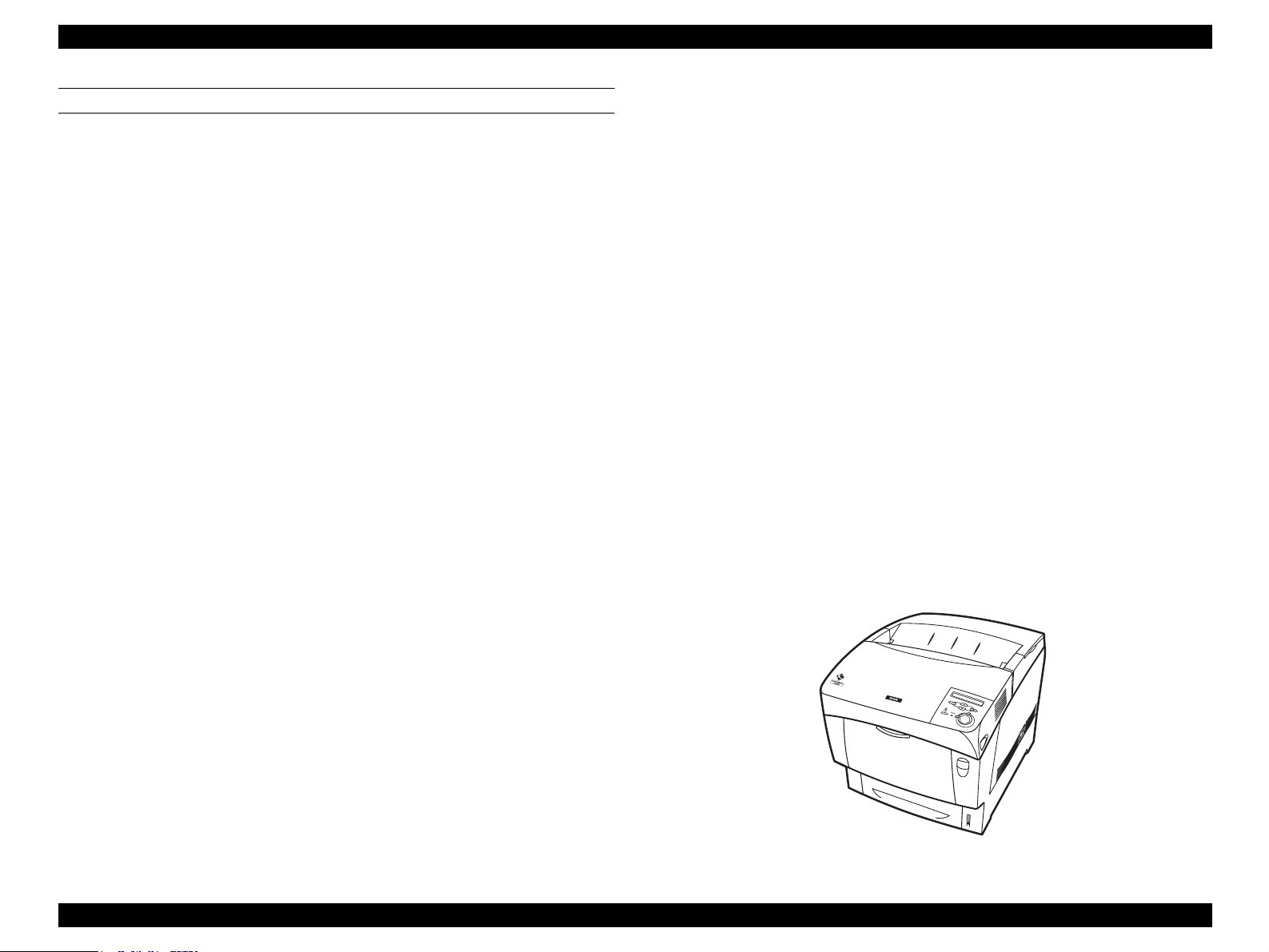

1.12 Exterior View and Unit Names

The table below lists the major exterior parts names. For the corresponding

location, see the following figures. Note if any part names differ from the

descriptions in the User’s Guide, they are shown in the brackets.

Table 1-27. Exterior View and Unit Parts

No. Part name

1 Control panel

2 Top cover

3 Output tray

4 Power switch

5 Latch on cover A

6 Latch on cover B

7 Standard lower cassette

8 MP tray (Multi-Purpose tray)

9 Expansion tray

10 Large capacity paper unit (option)

Figure 1-5. Exterior view and Unit parts 1

11 AC inlet

12 Stopper

13 Interface card slot cover

14 Ethernet interface connector

15 Parallel interface connector

16 USB interface connector

17 Transfer unit

18 Fuser unit

19 Photoconductor unit

20 Toner cartridge

21 Cover D (cover assy top PHD)

Product Descriptions Exterior View and Unit Names 1-25

Page 42

EPSON AcuLaser C4000/C4100/C3000 Revision F

Figure 1-6. Exterior view and Unit parts 2

Figure 1-7. Exterior view and Unit parts 3

Product Descriptions Exterior View and Unit Names 1-26

Page 43

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.13 Controller Unit Specifications

1.13.1 Controller Basic Specifications

CPU

CPU : 64-bit RISC PowerPC 750CX 400 MHz

ASIC : VIP2

CDMC (color conversion, color compression,

color adjustment)

RAM

SDRAM : 64-bit width DIMM (168 pins, 3.3V, PC100)

2 slots (the standard RAM must be installed to

slot-1 and SDRAM DIMM must be installed to

slot-0)

Standard : 64 MB

Optional RAM : 32 MB, 64 MB, 128 MB, 256 MB, 512 MB

A maximum of 1024 MB for both two slots by

installing 512MB

NOTE: The standard 64 MB RAM must be removed

HOST INTERFACE

Standard Parallel 1ch Bi-directional compatible with IEEE 1284

standard, B-type connector

Compatibility, Nibble, ECP

Ethernet 100 Base-TX/10 Base-T

USB 1.1

Option :Type-B1 slot (Level 3 compatible)

PRINTER SETTINGS

Printer Settings : Panel settings, EJL, PJL, HTTP, SNMP and

ENPC

Storage cell : EEPROM 32 Kbytes

CONTROL PANEL

20-digit LCD, 3 LEDs, 6 buttons

HDD

1 (optional) IDE type

ROM

32 - bit width

INSTALLATION METHOD

The slide drip method that inserts from the back of the main unit

Program : 4 MB (Flash ROM DIMM)

Fonts : 4 MB

Expansion ROM : 1 slot (ROM DIMM slot) (can be installed and

removed only when turning off the printer)

A slot : PS3, font ROM module

Product Descriptions Controller Unit Specifications 1-27

Page 44

EPSON AcuLaser C4000/C4100/C3000 Revision F

1.13.2 Controller Configuration

This printer can set the following configurations for each destination. Since

jumper resistors are used for the settings, these settings are determined when

the printers are shipped from the factory.

NOTE: Destination settings as controller configurations of the 120 V

model (LT) for North/South America are not provided.

Destination Setting A4/LT switching

120 V model for North/South America LT is set

Other destinations A4 is set

1.13.3 External Interface Specifications

This printer is equipped with the following host interfaces.

1. Parallel Interface -- Standard

2. Ethernet Interface -- Standard

3. USB 1.1 Interface -- Standard

4. Optional Interface (Type-B) 1 slot

The positions of the respective interfaces are shown in the Figure 1-8

.

USB Interface

Type-B Conector

Optinal Interface

Optinal Interface

Parallel Interface

IEEEE 1284 B-Type

1)

2)

Ethernet Interface

(100 Base-TX/10 BaseT)

Figure 1-8. Positions of Host Interface

Explanation of LEDs

1) Link/receive light (color: green)

2) 100 Base/10 Base light (color: orange)