Page 1

C3 Manipulator

Rev.4 EM105R2013F

EPSON ProSix

C3 series

Page 2

EPSON ProSix C3 series C3 Manipulator Rev. 4

Page 3

EPSON ProSix

C3 series

C3 Manipulator

Rev. 4

Copyright © 2009-2010 SEIKO EPSON CORPORATION. All rights reserved.

C3 Rev.4 i

Page 4

t

FOREWORD

Thank you for purchasing our robot products.

This manual contains the information necessary for the correct use of the manipulator.

Please carefully read this manual and other related manuals before installing the robot

system.

Keep this manual handy for easy access at all times.

WARRANTY

The robot and its optional parts are shipped to our customers only after being subjected to

the strictest quality controls, tests, and inspections to certify its compliance with our high

performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please ask your Regional Sales Office for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

1. Damage or malfunction caused by improper use which is not described in the manual,

2. Malfunctions caused by customers’ unauthorized disassembly.

or careless use.

3. Damage due to improper adjustments or unauthorized repair attempts.

4. Damage caused by natural disasters such as earthquake, flood, etc.

Warnings, Cautions, Usage:

1. If the robot or associated equipment is used outside of the usage conditions and produc

specifications described in the manuals, this warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3. We cannot foresee all possible dangers and consequences. Therefore, this manual

cannot warn the user of all possible hazards.

ii C3 Rev.4

Page 5

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Other brand and

product names are trademarks or registered trademarks of the respective holders.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

INQUIRIES

Contact the following service center for robot repairs, inspections or adjustments.

If service center information is not indicated below, please contact the supplier office for

your region.

Please prepare the following items before you contact us.

- Your controller model and its serial number

- Your manipulator model and its serial number

- Software and its version in your robot system

- A description of the problem

SERVICE CENTER

C3 Rev.4 iii

Page 6

MANUFACTURER & SUPPLIER

Japan & Others

Suwa Minami Plant

Factory Automation Systems Dept.

1010 Fujimi, Fujimi-machi,

Suwa-gun, Nagano, 399-0295

JAPAN

TEL : +81-(0)266-61-1802

FAX : +81-(0)266-61-1846

SUPPLIERS

North & South America EPSON AMERICA, INC.

Factory Automation/Robotics

18300 Central Avenue

Carson, CA 90746

USA

TEL : +1-562-290-5900

FAX : +1-562-290-5999

E-MAIL : info@robots.epson.com

Europe EPSON DEUTSCHLAND GmbH

Factory Automation Division

Otto-Hahn-Str.4

D-40670 Meerbusch

Germany

TEL : +49-(0)-2159-538-1391

FAX : +49-(0)-2159-538-3170

E-MAIL : robot.infos@epson.de

iv C3 Rev.4

Page 7

For Customers in the European Union

The crossed out wheeled bin label that can be found on your product indicates that this

product and incorporated batteries should not be disposed of via the normal household

waste stream. To prevent possible harm to the environment or human health please

separate this product and its batteries from other waste streams to ensure that it can be

recycled in an environmentally sound manner. For more details on available collection

facilities please contact your local government office or the retailer where you purchased

this product. Use of the chemical symbols Pb, Cd or Hg indicates if these metals are used

in the battery.

This information only applies to customers in the European Union, according to

DIRECTIVE 2006/66/EC OF THE EUROPEAN PARLIAMENT AND OF THE

COUNCIL OF 6 September 2006 on batteries and accumulators and waste batteries and

accumulators and repealing Directive 91/157/EEC and legislation transposing and

implementing it into the various national legal systems.

For other countries, please contact your local government to investigate the possibility of

recycling your product.

The battery removal/replacement procedure is described in the following manuals:

Controller manual / Manipulator manual (Maintenance section)

C3 Rev.4 v

Page 8

Before Reading This Manual

This section describes what you should know before reading this manual.

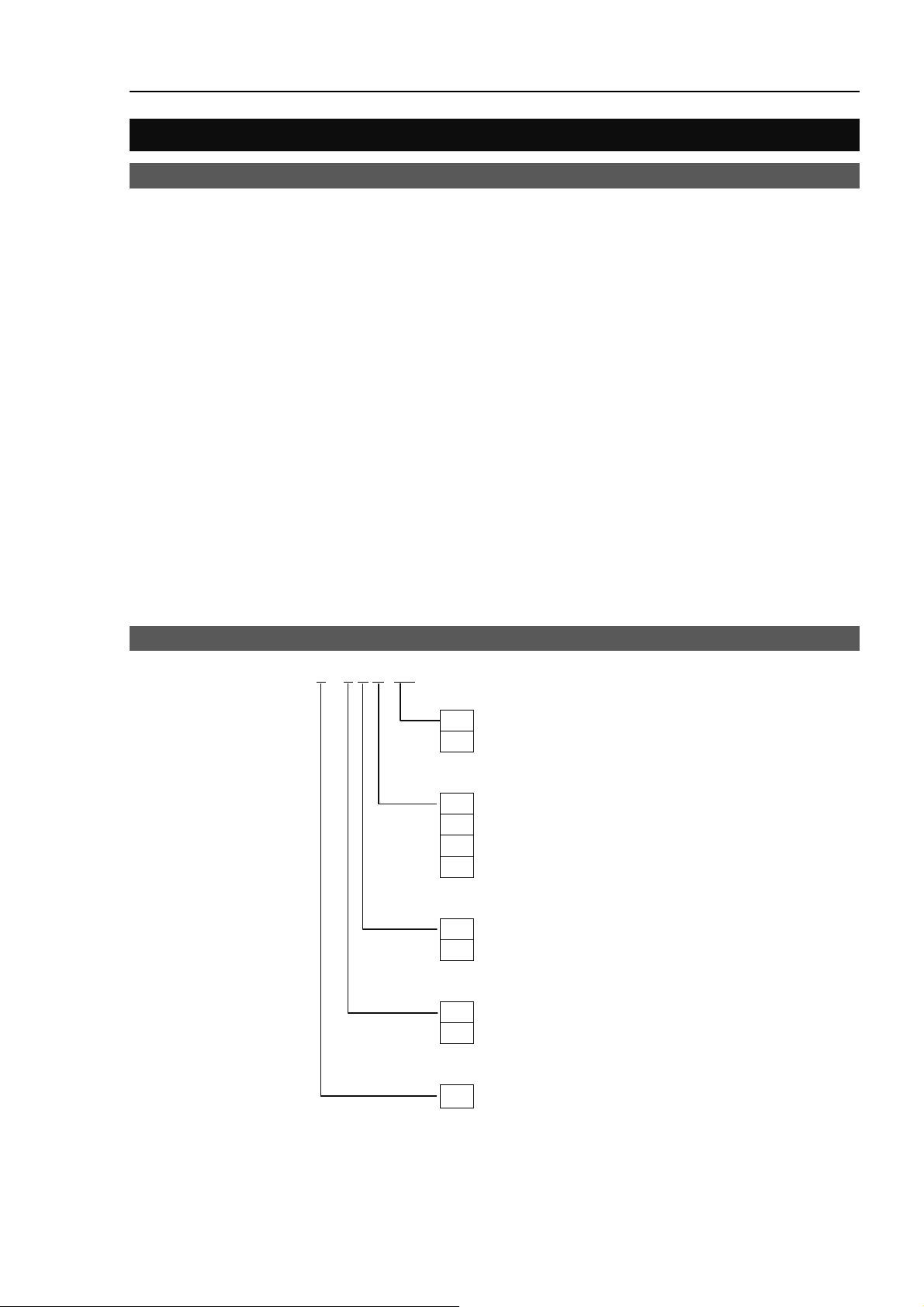

Structure of Control System

C3 Manipulators can be used with the following combinations of Controllers and software.

The operating methods and descriptions are different depending on which software you are

using. The following icons are put beside appropriate text as necessary. Use the

descriptions that pertain to the software you are using.

Controller

Name Structure

RC180 Controller EPSON RC+ 5.0

RC620

For details on commands, refer to “EPSON RC+ User’s Guide” or “On-line help”.

Control Unit

Drive Unit

EPSON RC+ 6.0 Ver. 6.0 or greater

Software

Turning ON/OFF Controller

When you see the instruction “Turn ON/OFF the Controller” in this manual, be sure to

turn ON/OFF all the hardware components.

Photos and Illustrations Used in This Manual

The appearance of some parts may differ from those on an actual product depending on

when it was shipped or the specifications. The procedures themselves, however, are

accurate.

vi C3 Rev.4

Page 9

TABLE OF CONTENTS

Before Reading This Manual ............................................................................v

Setup & Operation

1. Safety 3

1.1 Conventions .............................................................................................3

1.2 Design and Installation Safety .................................................................3

1.3 Operation Safety ......................................................................................4

1.4 Emergency Stop ......................................................................................5

1.5 How to Move Arms the Electromagnetic Brake is Applied to ...................6

1.5.1 Moving the Arm Using the Brake Release Unit ............................7

1.5.2 Moving the Arm Using the Software .............................................7

1.6 Precaution for Operation in Low Power Status ........................................8

1.7 Manipulator Labels ..................................................................................9

2. Specifications 11

2.1 Features of Manipulators ....................................................................... 11

2.2 Model Number .......................................................................................11

2.3 Part Names and Motion Range of Each Arm .........................................12

2.4 Outer dimensions ...................................................................................13

2.5 Standard Motion Range .........................................................................14

2.6 Specifications .........................................................................................15

2.6.1 Specifications table ....................................................................15

2.6.2 Option ........................................................................................17

2.7 How to Set the Model ............................................................................17

3. Environment and Installation 18

3.1 Environmental Conditions ......................................................................18

3.2 Unpacking, Transportation, and Relocation ...........................................19

3.3 Mounting Dimensions ............................................................................21

3.4 Installation .............................................................................................22

3.5 Connecting the Cables ..........................................................................24

3.6 User Wires and Pneumatic Tubes .........................................................25

3.7 Checking the Basic orientation ................................................................27

4. End Effectors 28

4.1 Attaching an End Effector ......................................................................28

4.2 Attaching Camera and Valves ................................................................29

4.3 WEIGHT and INERTIA Settings .............................................................30

4.3.1 WEIGHT Setting .........................................................................32

4.3.2 INERTIA Setting .........................................................................37

4.4 Precautions for Auto Acceleration/Deceleration .....................................41

C3 Rev.4 vii

Page 10

5. Motion Range 42

5.1 Motion Range Setting by Pulse Range (for All Arms) ............................ 42

5.1.1 Max. Pulse Range of Arm #1 ..................................................... 43

5.1.2 Max. Pulse Range of Arm #2 ..................................................... 43

5.1.3 Max. Pulse Range of Arm #3 ..................................................... 44

5.1.4 Max. Pulse Range of Arm #4 ..................................................... 44

5.1.5 Max. Pulse Range of Arm #5 ..................................................... 45

5.1.6 Max. Pulse Range of Arm #6 ..................................................... 45

5.2 Motion Range Setting by Mechanical Stops .......................................... 45

5.2.1 Motion Range Setting of Arm #1 ................................................ 46

5.2.2 Motion Range Setting of Arm #2 and #3 (Option) ...................... 46

5.2.3 Motion Range Setting of Arm #3 ................................................ 46

5.3 Restriction of Manipulator Operation

by Joint Angle Combination of Arm #1, #2, and #3 ............................... 47

5.4 Coordinate System ................................................................................ 48

5.5 Setting the Cartesian (Rectangular) Range in the XY Coordinate

System of the Manipulator .................................................................... 48

6. Options 49

Maintenance

1. Safety Maintenance 67

2. General Maintenance 68

3. Covers 73

6.1 Brake Release Unit ............................................................................... 49

6.2 Camera Plate Unit ................................................................................. 54

6.3 PS Compatible Plate ............................................................................. 57

6.4 Base Side Angled Fittings ..................................................................... 58

6.5 Base Side Fittings ................................................................................. 61

2.1 Schedule for Maintenance Inspection ................................................... 67

2.2 Inspection Point ..................................................................................... 69

2.3 Greasing ............................................................................................... 70

2.4 Tightening Hexagon Socket Head Cap Bolts ........................................ 71

2.5 Layout of Maintenance Parts ................................................................. 72

3.1 Arm #1 Top Cover ................................................................................. 74

3.2 Arm #1 Side Cover ................................................................................ 74

3.3 Arm #2 Side Cover ................................................................................ 75

3.4 Arm #3 Head Cover .............................................................................. 76

3.5 Arm #3 Bottom Cover ............................................................................ 76

3.6 Arm #4 Side Cover ................................................................................ 77

3.7 Base Bottom Cover ............................................................................... 78

3.8 Connector Plate .................................................................................... 78

3.9 Connector Sub Plate ............................................................................. 79

3.10 User Plate .............................................................................................. 79

viii C3 Rev.4

Page 11

4. Cable Unit 80

4.1 Replacing the Cable Unit ...........................................................................80

4.2 Connector Pin Assignments ....................................................................91

4.2.1 Signal Cable ................................................................................91

4.2.2 Power Cable ................................................................................93

4.2.3 User Cable...................................................................................95

4.2.4 Color of Cables ..........................................................................95

5. Arm #1 96

5.1 Motor .......................................................................................................97

5.2 Reduction Gear Unit..............................................................................103

5.3 Timing Belt.............................................................................................106

5.4 Electromagnetic Brake ..........................................................................107

6. Arm #2 108

6.1 Motor ..................................................................................................... 110

6.2 Reduction Gear Unit.............................................................................. 115

6.3 Timing Belt.............................................................................................120

6.4 Electromagnetic Brake ..........................................................................121

7. Arm #3 122

7.1 Motor .....................................................................................................123

7.2 Reduction Gear Unit..............................................................................127

7.3 Timing Belt.............................................................................................131

7.4 Electromagnetic Brake ..........................................................................132

8. Arm #4 133

8.1 Motor ...................................................................................................134

8.2 Reduction Gear Unit..............................................................................140

8.3 Timing Belt ...........................................................................................145

8.4 Electromagnetic Brake ..........................................................................146

9. Arm #5 147

9.1 Motor .....................................................................................................148

9.2 Timing Belt.............................................................................................152

9.3 Electromagnetic Brake ..........................................................................153

10. Arm #6 154

10.1 Motor ...................................................................................................155

10.2 Timing Belt...........................................................................................161

10.3 Electromagnetic Brake ........................................................................162

11. Joint #5 and #6 Unit 163

12. Arm #5 O-Ring 168

C3 Rev.4 ix

Page 12

13. Battery Unit 169

13.1 Battery Unit (Lithium Bttery) .............................................................. 170

13.2 Battery Board .................................................................................... 172

14. LED Lamp 173

15. M/C Cable 175

16. Calibration 177

17. Maintenance Parts List 179

x C3 Rev.4

Page 13

Setup & Operation

This volume contains information for setup and operation of the

Manipulators.

Please read this volume thoroughly before setting up and operating

the Manipulators.

Page 14

Page 15

1. Safety

Installation and transportation of robots and robotic equipment shall be performed by

qualified personnel and should conform to all national and local codes.

Please read this manual and other related manuals before installing the robot system or

before connecting cables.

Keep this manual handy for easy access at all times.

1.1 Conventions

Important safety considerations are indicated throughout the manual by the following

symbols. Be sure to read the descriptions shown with each symbol.

WARNING

WARNING

Setup & Operation 1. Safety

This symbol indicates that a danger of possible serious injury

or death exists if the associated instructions are not followed

properly.

This symbol indicates that a danger of possible harm to people

caused by electric shock exists if the associated instructions are

not followed properly.

This symbol indicates that a danger of possible harm to people

CAUTION

or physical damage to equipment and facilities exists if the

associated instructions are not followed properly.

1.2 Design and Installation Safety

Only trained personnel should design and install the robot system. Trained

personnel are defined as those who have taken robot system training and

maintenance training classes held by the manufacturer, dealer, or local

representative company, or those who understand the manuals thoroughly and

have the same knowledge and skill level as those who have completed the training

courses.

To ensure safety, a safeguard must be installed for the robot system. For details

on the safeguard, refer to the Installation and Design Precautions in the Safety

chapter of the EPSON RC+ User’s Guide.

The following items are safety precautions for design personnel:

■

Personnel who design and/or construct the robot system with this product must

read the Safety chapter in the EPSON RC+ User’s Guide. Designing and/or

WARNING

constructing the robot system without understanding the safety requirements is

extremely hazardous, and may result in serious bodily injury and/or severe

equipment damage to the robot system.

C3 Rev.4 3

Page 16

Setup & Operation 1. Safety

■

The Manipulator and the Controller must be used within the environmental

conditions described in their respective manuals. This product has been

designed and manufactured strictly for use in a normal indoor environment.

Using the product in an environment that exceeds the specified environmental

conditions may not only shorten the life cycle of the product but may also cause

WARNING

serious safety problems.

■

The robot system must be used within the installation requirements described in

the manuals. Using the robot system outside of the installation requirements

may not only shorten the life cycle of the product but also cause serious safety

problems.

Further precautions for installation are mentioned in the chapter Setup & Operation

3. Environment and Installation. Please read this chapter carefully to understand

safe installation procedures before installing the robots and robotic equipment.

1.3 Operation Safety

The following items are safety precautions for qualified Operator personnel:

WARNING

■

Please carefully read the Safety-related Requirements in the Safety chapter of

the EPSON RC+ User’s Guide. Operating the robot system without

understanding the safety requirements is extremely hazardous and may result in

serious bodily injury and/or severe equipment damage to the robot system.

■

Do not enter the operating area of the Manipulator while the power to the robot

system is turned ON. Entering the operating area with the power ON is

extremely hazardous and may cause serious safety problems as the Manipulator

may move even if it seems to be stopped.

■

Before operating the robot system, make sure that no one is inside the

safeguarded area. The robot system can be operated in the mode for teaching

even when someone is inside the safeguarded area.

The motion of the Manipulator is always in restricted status (low speeds and low

power) to secure the safety of an operator. However, operating the robot

system while someone is inside the safeguarded area is extremely hazardous

and may result in serious safety problems in case that the Manipulator moves

unexpectedly.

■

Immediately press the Emergency Stop switch whenever the Manipulator moves

abnormally while the robot system is operated. Continuing the operating the

robot system while the Manipulator moves abnormally is extremely hazardous

and may result in serious bodily injury and/or severe equipment change to the

robot system.

4 C3 Rev.4

Page 17

■

Be sure to connect the AC power cable to a power receptacle. DO NOT

connect it directly to a factory power source. To shut off power to the robot

system, pull out the power plug from the power source. Performing any work

while connecting the AC power cable to a factory power source is extremely

hazardous and may result in electric shock and/or malfunction of the robot

system.

■

Before performing any replacement procedure, turn OFF the Controller and

related equipment, and then pull out the power plug from the power source.

WARNING

Performing any replacement procedure with the power ON is extremely

hazardous and may result in electric shock and/or malfunction of the robot

system.

■

Do not insert or pull out the motor connectors while the power to the robot system

is turned ON. Inserting or pulling out the motor connectors with the power ON is

extremely hazardous and may result in serious bodily injury as the Manipulator

may move abnormally, and also may result in electric shock and/or malfunction of

the robot system.

1.4 Emergency Stop

Setup & Operation 1. Safety

If the Manipulator moves abnormally during operation, immediately press the Emergency

Stop switch. The motor power will be turned OFF, and the arm motion by inertia will be

stopped with the electromagnetic brake and dynamic brake.

However, avoid pressing the Emergency Stop switch unnecessarily while the Manipulator

is running normally. Otherwise, the Manipulator may hit the peripheral equipment since

the operating trajectory while the robot system stops is different from that in normal

operation.

To place the robot system in emergency mode during normal operation, press the

Emergency Stop switch when the Manipulator is not moving.

Refer to the Controller manual for instructions on how to wire the Emergency Stop switch

circuit.

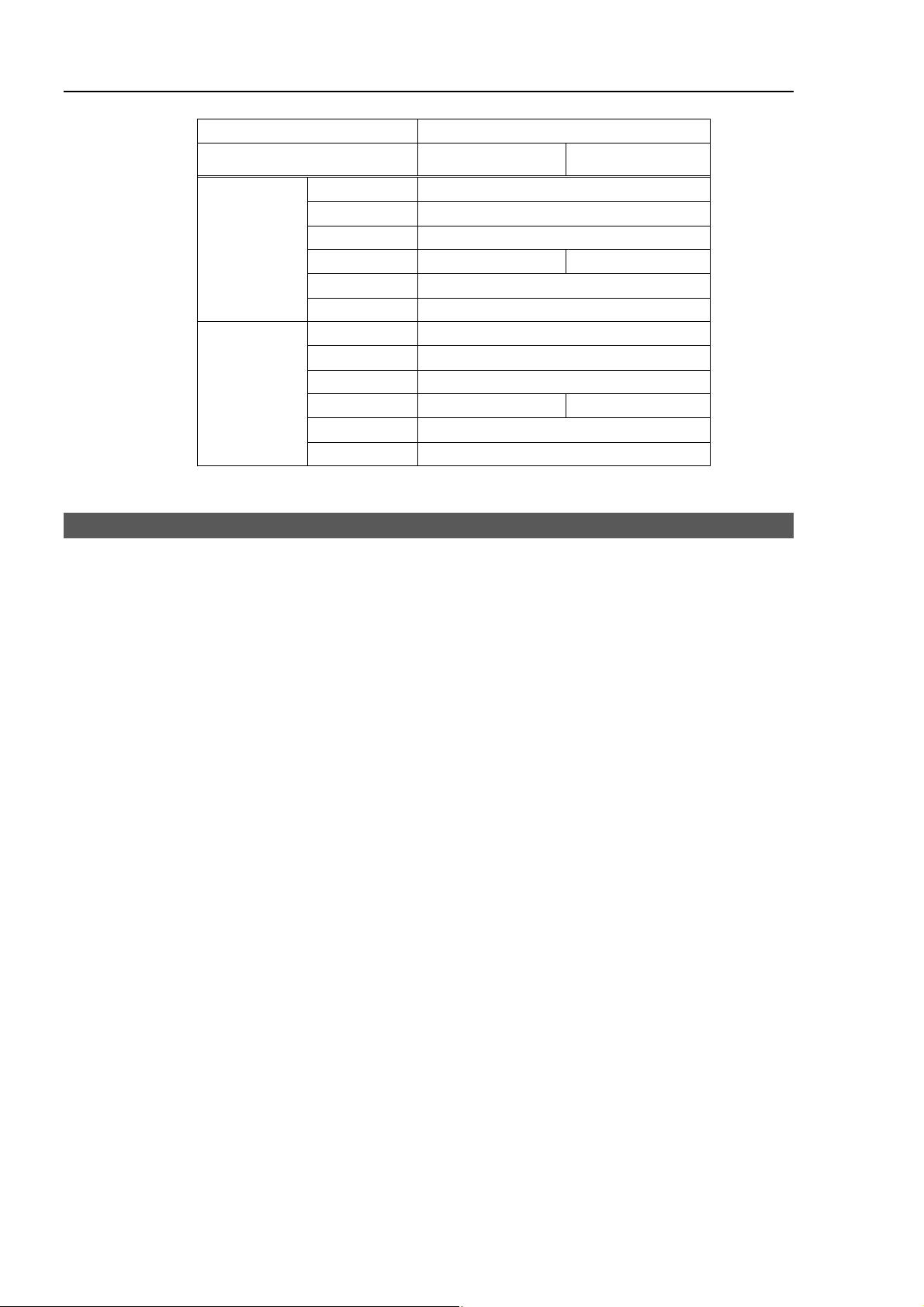

Free running distance in emergency

The operating Manipulator cannot stop immediately after the Emergency Stop switch is

pressed.

However, remember that the values vary depending on conditions such as the weight of

the end effector and work piece, WEIGHT/SPEED/ACCEL settings, operating pose, etc.

The free running time/angle/distance of the Manipulator are shown below.

Conditions of Measurement

ACCEL Setting

SPEED Setting

Load [kg]

WEIGHT Setting

100

100

3

3

C3 Rev.4 5

Page 18

Setup & Operation 1. Safety

Robot controller RC180 / RC620

Free running

time

[sec.]

Free running

angle

[deg.]

Brake

Arm #1

Arm #2

Arm #3

Arm #4

Arm #5

Arm #6

Arm #1

Arm #2

Arm #3

Arm #4

Arm #5

Arm #6

Standard

J2, J3, J5 with brake

0.4

0.4

0.4

0.5 0.3

0.3

0.1

85

60

55

55 45

45

10

Option

All joint with brake

1.5 How to Move Arms the Electromagnetic Brake is Applied to

Standard: Brakes on Joints #2, #3, #5

While the electromagnetic brake is ON (such as in emergency mode), you can move

Arms #1, #4, #6 by pushing manually.

Option : Brakes on all joints

While the electromagnetic brake is ON (such as in emergency mode), you cannot move

any arm by pushing manually.

There are two methods to release the electromagnetic brake. Follow either method to

release the electromagnetic brake and move the arms manually.

1.5.1 Moving the arm using the brake release unit

Follow the method when you just unpack the delivered boxes or when the

Controller does not start up yet.

1.5.2 Moving the arm using the software

Follow the method when you can use the software.

6 C3 Rev.4

Page 19

Setup & Operation 1. Safety

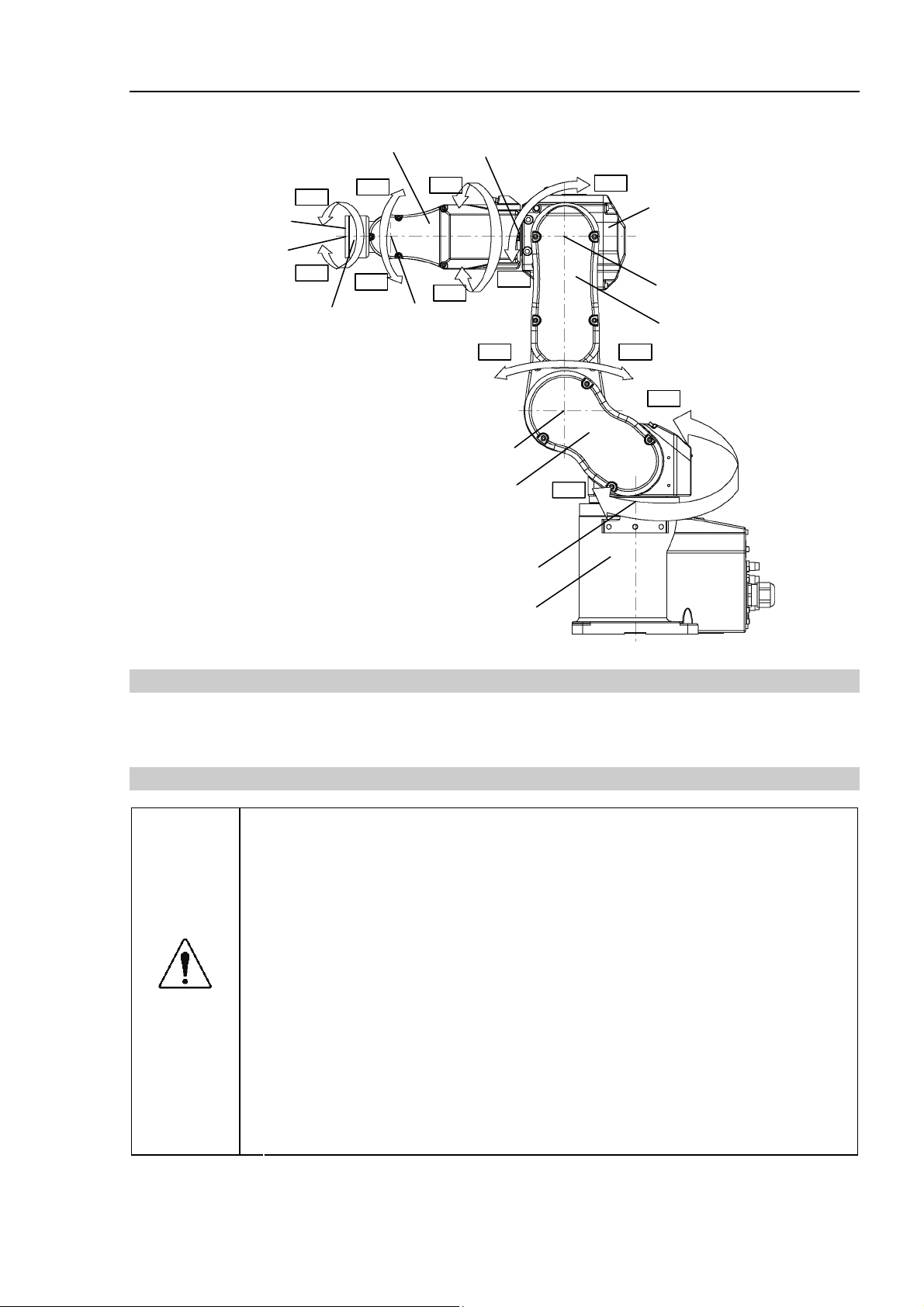

Arm Motion

J6−

J6+

Arm #5

Arm #4

J5+

J5−

Joint #5

Joint #4

J4−

J4+

Joint #2

J3−

J3+

J2+J2−

Arm #3

Joint #3

Arm #2

J1+

Arm #6

Joint #6

Arm #1 (Lower Arm)

Joint #1

Base

1.5.1 Moving the arm using the brake release unit

The C3 series has the Brake Release Unit as an option.

For details, refer to Setup & Option: 6 Options.

1.5.2 Moving the arm using the software

■

Normally, release the brake of a single joint at a time. Take extra care to release

the brakes of two or more joints simultaneously from necessity. Releasing the

brakes of two or more joints simultaneously may cause hands and fingers to be

caught and/or equipment damage to or malfunction of the Manipulator as the

arms of the Manipulator may move in unexpected directions.

J1−

■

Be careful of the arm falling when releasing the brake.

While the brake is being released, the Manipulator’s arm falls by its own weight.

CAUTION

The arm falling may cause hands and fingers to be caught and/or may cause

equipment damage to or malfunction of the Manipulator.

■

Before releasing the brake, be sure to keep the Emergency Stop switch handy so

that you can immediately press the Emergency Stop switch. If you cannot

immediately press the Emergency Stop switch, you have no means to stop the

arms urgently when a wrong operation causes the arm to fall. The arm falling

may cause equipment damage to and/or malfunction of the Manipulator.

C3 Rev.4 7

Page 20

Setup & Operation 1. Safety

EPSON

RC+

After releasing the Emergency Stop switch, Execute the following commands.

[Command Window] EPSON RC+ 5.0 (RC180) / EPSON RC+ 6.0 (RC620)

>Reset

>Brake Off,[the number (from 1 to 6) corresponding to the arm whose brake will be

turned off]

Execute the following command to turn on the brake again.

>Brake On,[The number (from 1 to 6) corresponding to the arm whose brake will be

turned on]

1.6 Precaution for Operation in Low Power Status

When the power mode is low, the Manipulator will operate at low speed and low torque.

However, comparatively high torque is generated under some circumstances so that the

Manipulator can support its own weight. The maximum torque of each joint in the low

power status is shown in the following table “Max. Joint Torque in Low Power Status”.

Even though the Manipulator is in the low power status, carefully operate the Manipulator

since a comparatively high joint torque may be generated. Be careful not to get hands or

fingers caught during operations. The Manipulator may also collide with peripheral

equipment and it may cause equipment damage to or malfunction of the Manipulator.

Max. Joint Torque in Low Power Status

#1 #2 #3 #4 #5 #6

102.28 102.28 33.51

CAUTION

Joint

Joint Torque

■

Carefully operate the Manipulator even though it is in the low power status. A

comparatively high joint torque may be generated. The comparatively high joint

torque may cause hands and fingers to be caught and/or may cause equipment

damage to or malfunction of the Manipulator as it may collide with peripheral

equipment.

[Unit: N·m]

10.31 10.31 7.98

8 C3 Rev.4

Page 21

Setup & Operation 1. Safety

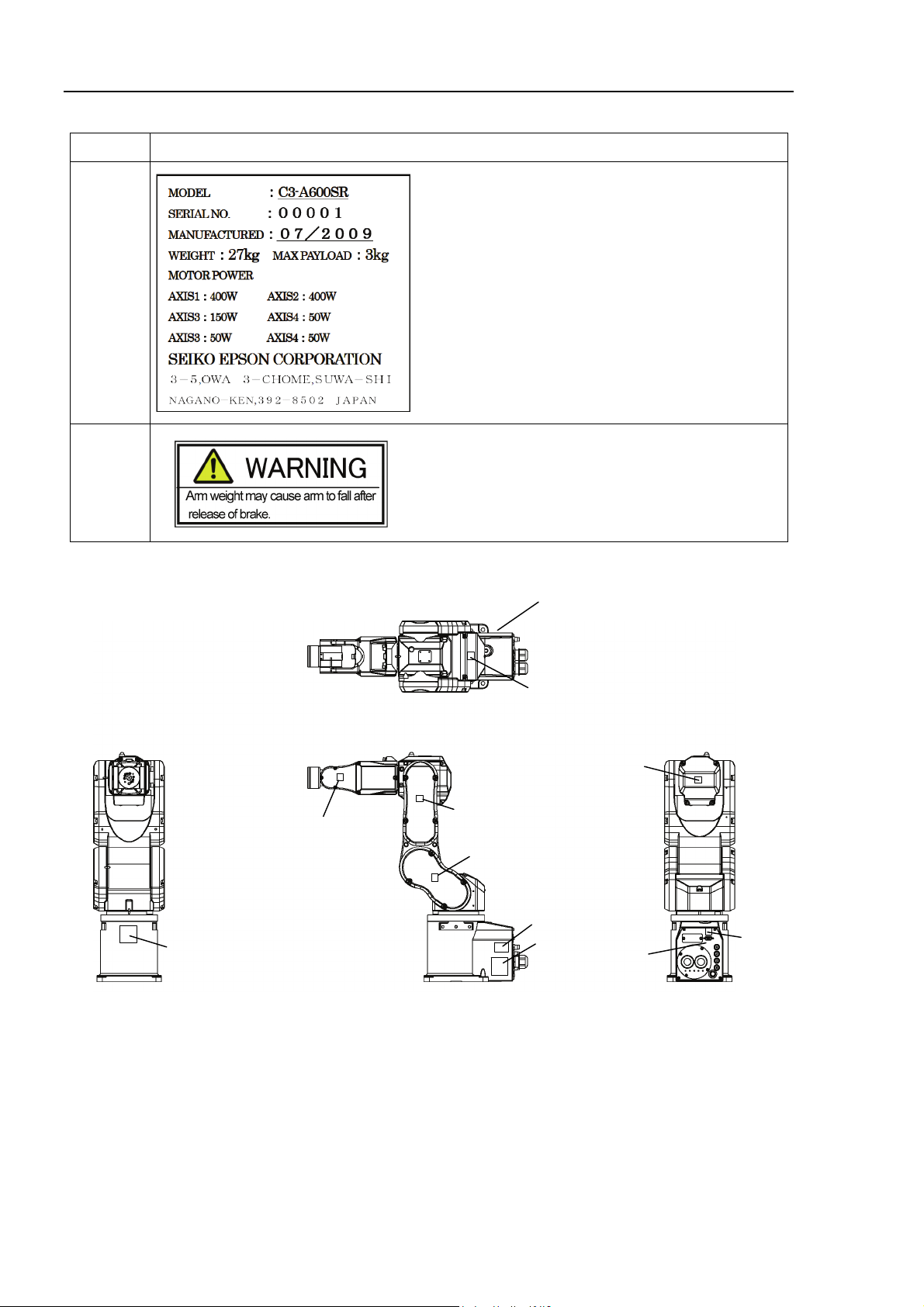

1.7 Manipulator Labels

The following labels are attached around the locations of the Manipulator where specific

dangers exist.

Be sure to comply with descriptions and warnings on the labels to operate and maintain

the Manipulator safely.

Do not tear, damage, or remove the labels. Use meticulous care when handling those

parts or units to which the following labels are attached as well as the nearby areas:

Location Label NOTE

Hazardous voltage exists while the Manipulator is ON.

(1)

(2)

To avoid electric shock, do not touch any internal electric

parts.

Only authorized personnel should perform sling work and

operate a crane and a forklift.

When these operations are performed by unauthorized

personnel, it is extremely hazardous and may result in

serious bodily injury and/or severe equipment damage to

the robot system.

(3)

(4)

(5)

C3 Rev.4 9

Page 22

Setup & Operation 1. Safety

Location Label NOTE

(6)

(7)

Location of Labels

Be careful of the arm falling / rotation while the brake

release button is being pressed.

* This label is on the Brake Release Box (Option).

(6)

(1)

Top V i e w

Front View

(3)

(1)

(1)

(1)

Lateral View

(4)

(2)

(1)

(5)

Back View

(1)

10 C3 Rev.4

Page 23

2. Specifications

2.1 Features of Manipulators

Speed & Accuracy

Increases productivity with the balanced performance of best in class speed and

accuracy

Average cycle time (300 mm) 0.39 second (Speed 100 / Accel 100)

0.37 second (Speed 120 / Accel 120)

Repeatability ± 0.02 mm

Slim Body

High space efficiency

Manipulator volume only 1/44 of its motion range

Small elbow area (Joint #3) half of current model

Less interference with peripherals, walls and ceiling permits more compact

installation

Skillful Wrist

Setup & Operation 2. Specifications

Compact wrist (Joint #5) with wide motion range enables smooth movement and the

ability to work from many angles

Minimal interference with surroundings improves flexibility in hand design

2.2 Model Number

C3 – A 6 0 0 S R -UL

NOTE

For the Wall / Skewed mounting types, brakes are equipped on all joints.

)

UL specification

UL : UL compliant

□

: Non UL compliant

Type

□

: Table Top mounting

W : Wall mounting

R : Ceiling mounting

A : Skewed mounting

Environment

S : Standard model

C : Cleanroom model

Brake equipment

0 : Standard : Brakes on Joint #2, #3, #5

1 : Option : Brakes on all joints

Arm length

6 : 600 mm

C3 Rev.4 11

Page 24

Setup & Operation 2. Specifications

−

A

A

r

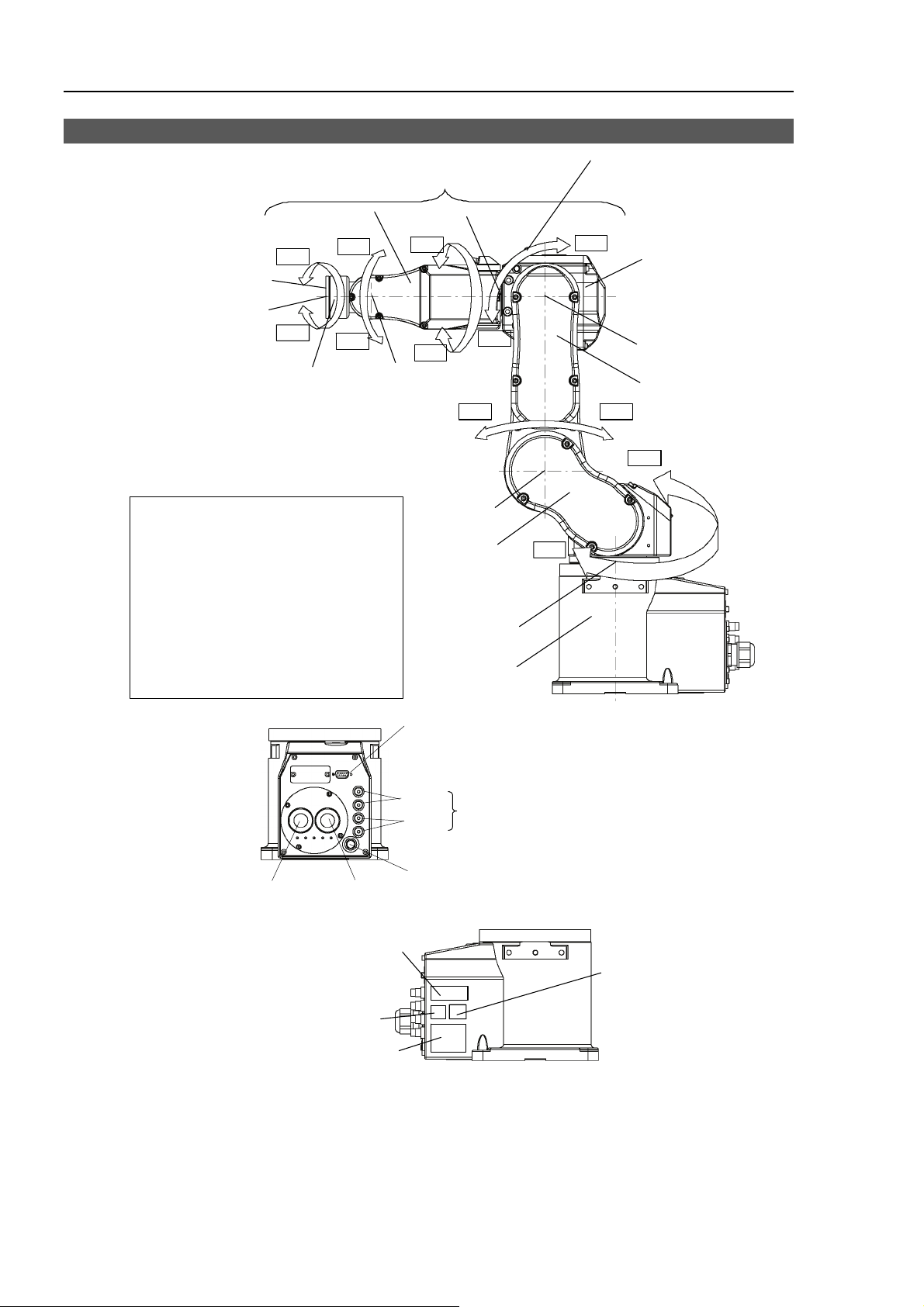

2.3 Part Names and Motion Range of Each Arm

J6−

Arm #6

Joint #6

J6+

Arm #5

Upper Arm (Arms #3 to #6)

Arm #4

J5+

J5−

Joint #5

Joint #4

J4−

J4+

J3

LED Lamp

This lamp lights up

while the motors are ON.

J3+

rm #3

Joint #3

J2+J2−

J1+

rm #2

Joint Motion

Joint #1 : The whole Manipulator revolves.

Joint #2 : The lower arm swings.

Joint #3 : The upper arm swing s.

Joint #4 : The wrist revolves.

Joint #5 : The wrist swings.

Joint #6 : The hand rotates.

Signal cable

(only for UL specification)

Power cable

MT label

(only for custom

specification)

UR label

Joint #2

Arm #1

(Lower Arm)

Joint #1

Base

User cable connecto

(9-pin D-sub connector)

White

Black

Standard-model / Clean-room type

Fitting for ø4 mm pneumatic tube

Cover Exhaust port

For ø8 mm pneumatic tube

J1−

CE label

(only for CE specification)

Signature label

(Serial No. of Manipu lator)

NOTE

)

When the LED lamp is lighting or the controller power is on, the current is being applied

to the manipulator. Performing any work with the power ON is extremely hazardous and

it may result in electric shock and/or improper function of the robot system. Make sure

to turn OFF the controller power before the maintenance work.

12 C3 Rev.4

Page 25

Setup & Operation 2. Specifications

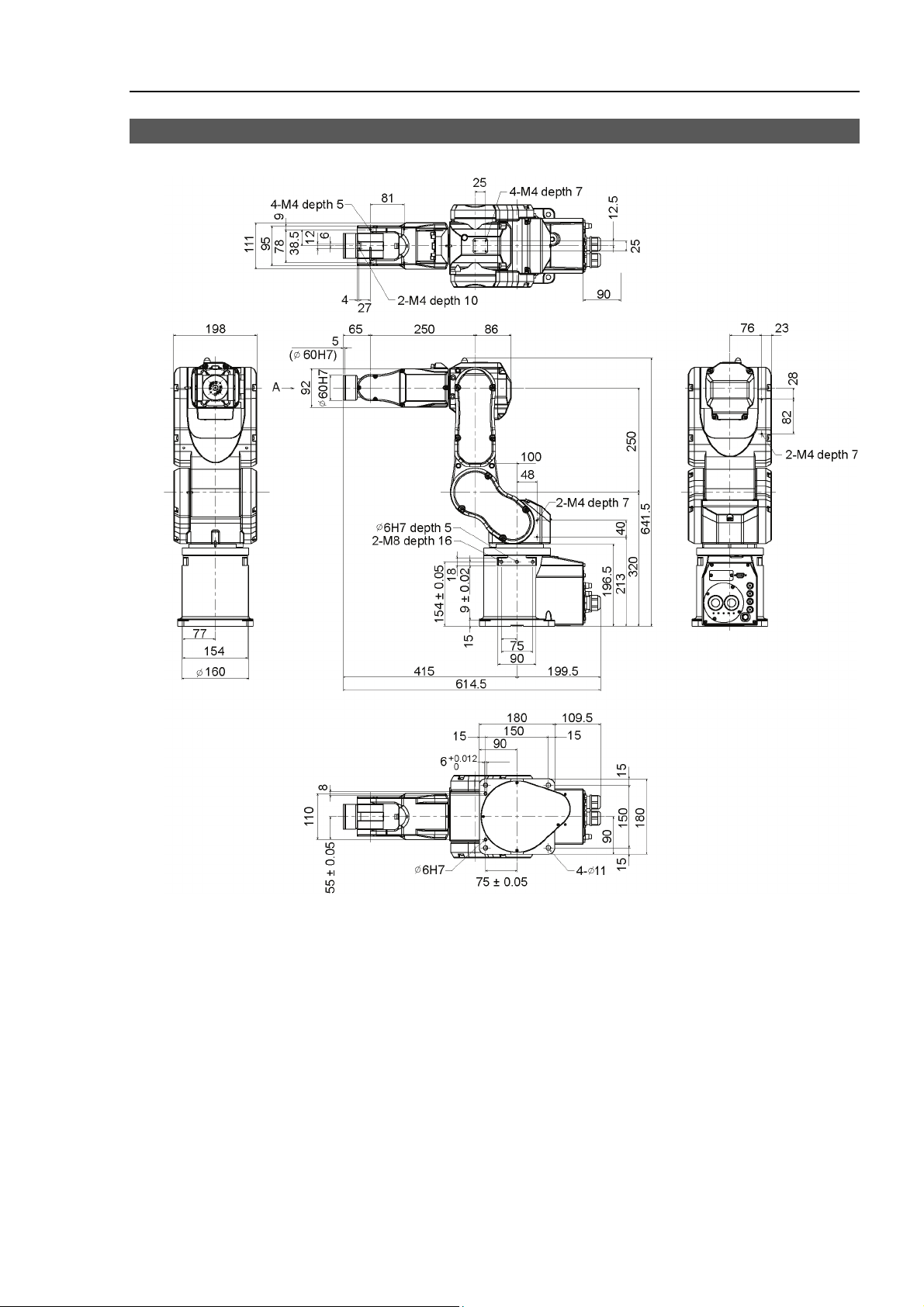

2.4 Outer Dimensions

[Unit: mm]

Space for cables

*1:

*2:

*2:

*2:

Including the lamp

(Tolerance is optimum for ø6H7)

*1: Tolerance in this range

*2: Front and back

C3 Rev.4 13

Page 26

Setup & Operation 2. Specifications

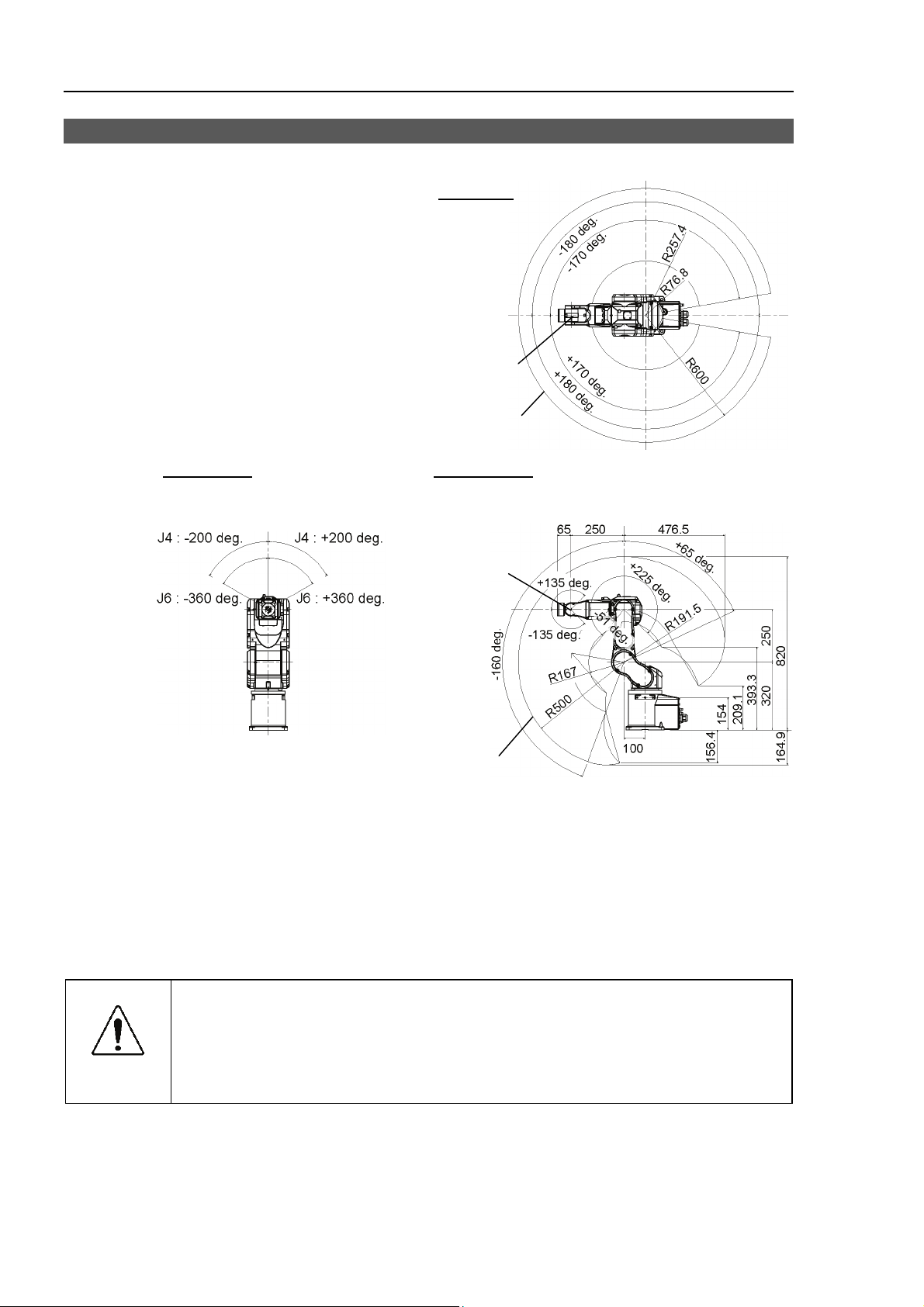

2.5 Standard Motion Range

[Unit: mm]

Motion range of P point*

Top Vi e w

*1

*2

*3

Joint #1

0 pulse position

P point*

Lateral viewFront View

Joints #4, #6

0 pulse position

P point*

Joints #3, #5

0 pulse position

Joint #2

0 pulse position

*5

CAUTION

*4

Motion range of P point*

* P point : Intersection of the rotation centers for Joint #4, #5, and #6

*1 : Joint #1 without mechanical stop (

*2 : P point from top with Joint #3 declining

*3 : P point from top with Joint #3 tilting up

*4 : P point from lateral with Joint #3 declining (51 deg. (Joint #2 center – P point center)

*5 : P point from lateral with Joint #3 tilting up (225 deg. (Joint #2 center – P point center)

Pay attention to the arm pose of the basic arms (Arms #1, #2, and #3) when

±180 deg.)

−51 deg. (Joint #1 center – P point center)

+225 deg. (Joint #1 center – P point center)

operating the Manipulator. Arm #5 moves keeping a constant angle regardless

of the arm pose. Depending on the arm pose of the basic arms, the wrist may

collide with the Manipulator. The collision may cause equipment damage to

and/or malfunction of the Manipulator.

14 C3 Rev.4

Page 27

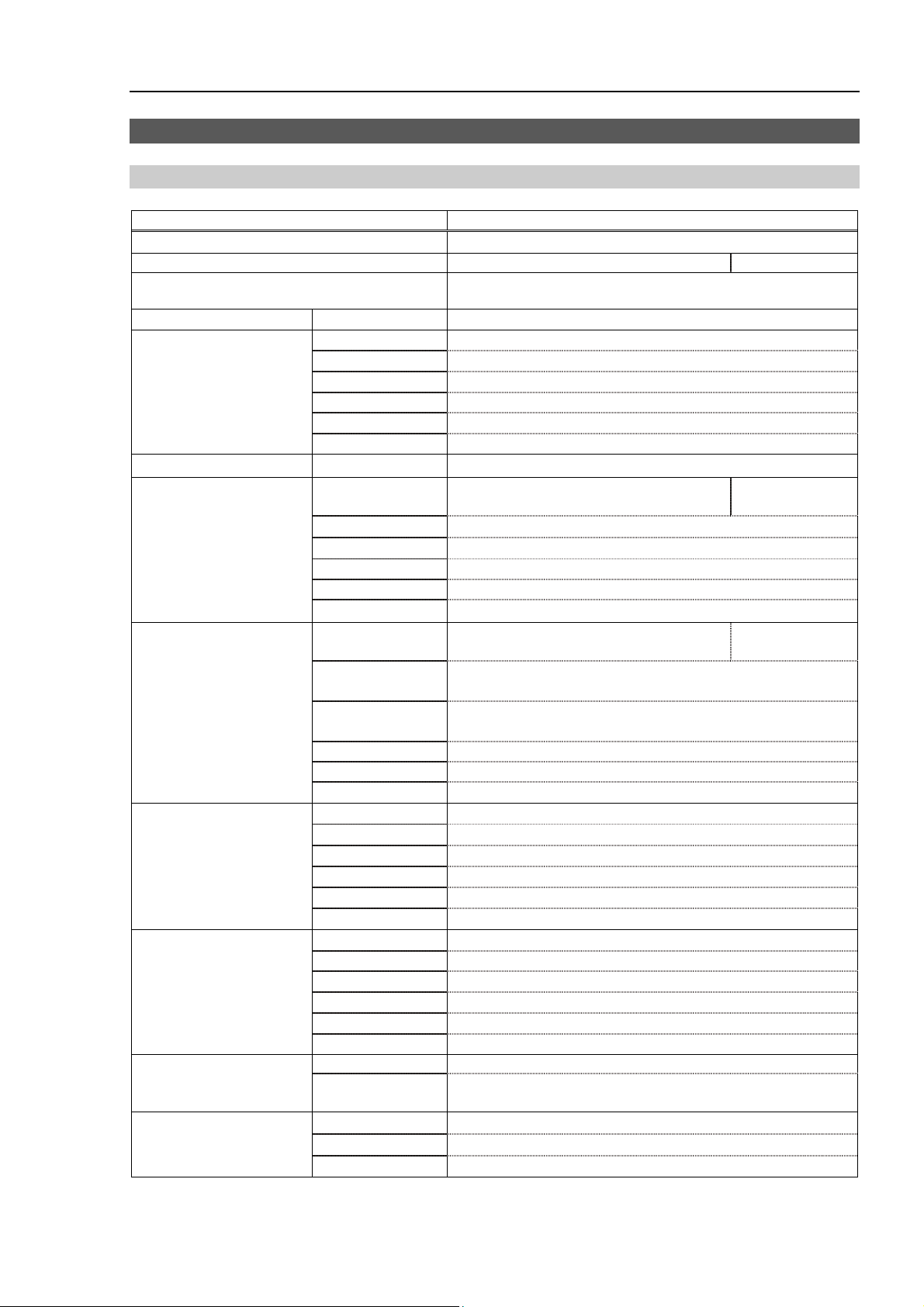

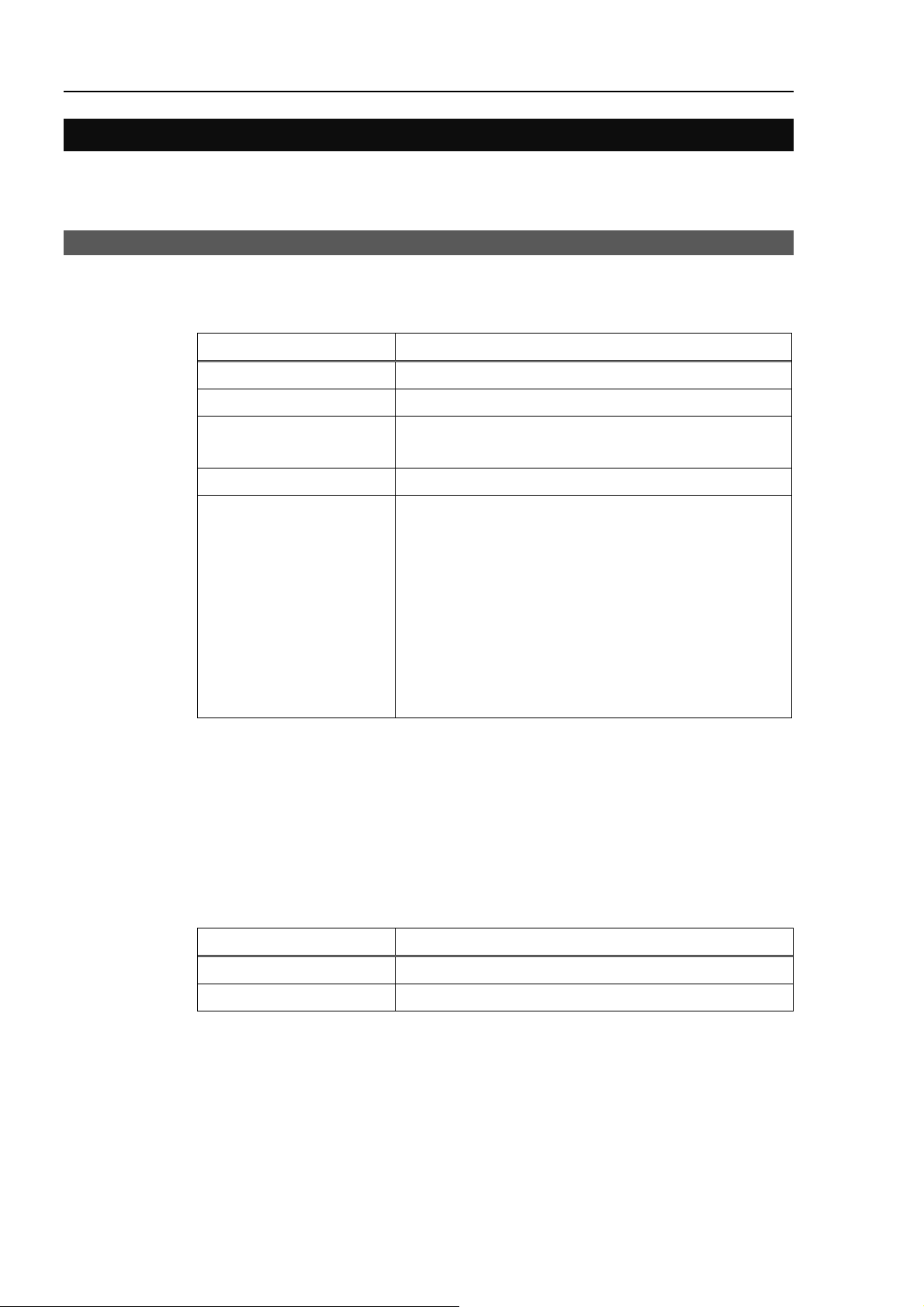

2.6 Specifications

2.6.1 Specifications table

Item Specification

Model Number

Mounting type

Weight (not include the weight of cables

or shipping jigs)

Driving method All joints

Joint #1

Joint #2

Max. operating

*1

speed

Repeatability Joint #1 ~ #6

Max. motion range

Max. pulse range

Resolution

Motor power consumption

Payload *2

Allowable moment

Joint #3

Joint #4

Joint #5

Joint #6

Joint #1

Joint #2

Joint #3

Joint #4

Joint #5

Joint #6

Joint #1

Joint #2

Joint #3

Joint #4

Joint #5

Joint #6

Joint #1

Joint #2

Joint #3

Joint #4

Joint #5

Joint #6

Joint #1

Joint #2

Joint #3

Joint #4

Joint #5

Joint #6

Rated

Max.

Joint #4

Joint #5

Joint #6

Setup & Operation 2. Specifications

C3

Table Top, Ceiling, Skewed mounting Wall mounting

27 kg (59.5 lb.)

AC servo motor

450 deg/s

450 deg/s

514 deg/s

553 deg/s

553 deg/s

720 deg/s

± 0.02 mm

± 170 deg

(± 180 deg without the mechanical stop)

± 30 deg

− 160 deg ~ + 65 deg

− 51 deg ~ + 225 deg

± 200 deg

± 135 deg

± 360 deg

± 4951609

(± 5242880 without the mechanical stop)

± 873814

− 4660338

+ 1893263

− 1299798

+ 5734400

± 4700057

± 3217222

± 6553600

0.00000429 deg /pulse

0.00000429 deg /pulse

0.00000490 deg /pulse

0.00000531 deg /pulse

0.00000524 deg /pulse

0.00000686 deg /pulse

400 W

400 W

150 W

50 W

50 W

50 W

1 kg

3 kg

5 kg with arm downward positioning

4.41 N·m (0.45 kgf·m)

4.41 N·m (0.45 kgf·m)

2.94 N·m (0.3 kgf·m)

C3 Rev.4 15

Page 28

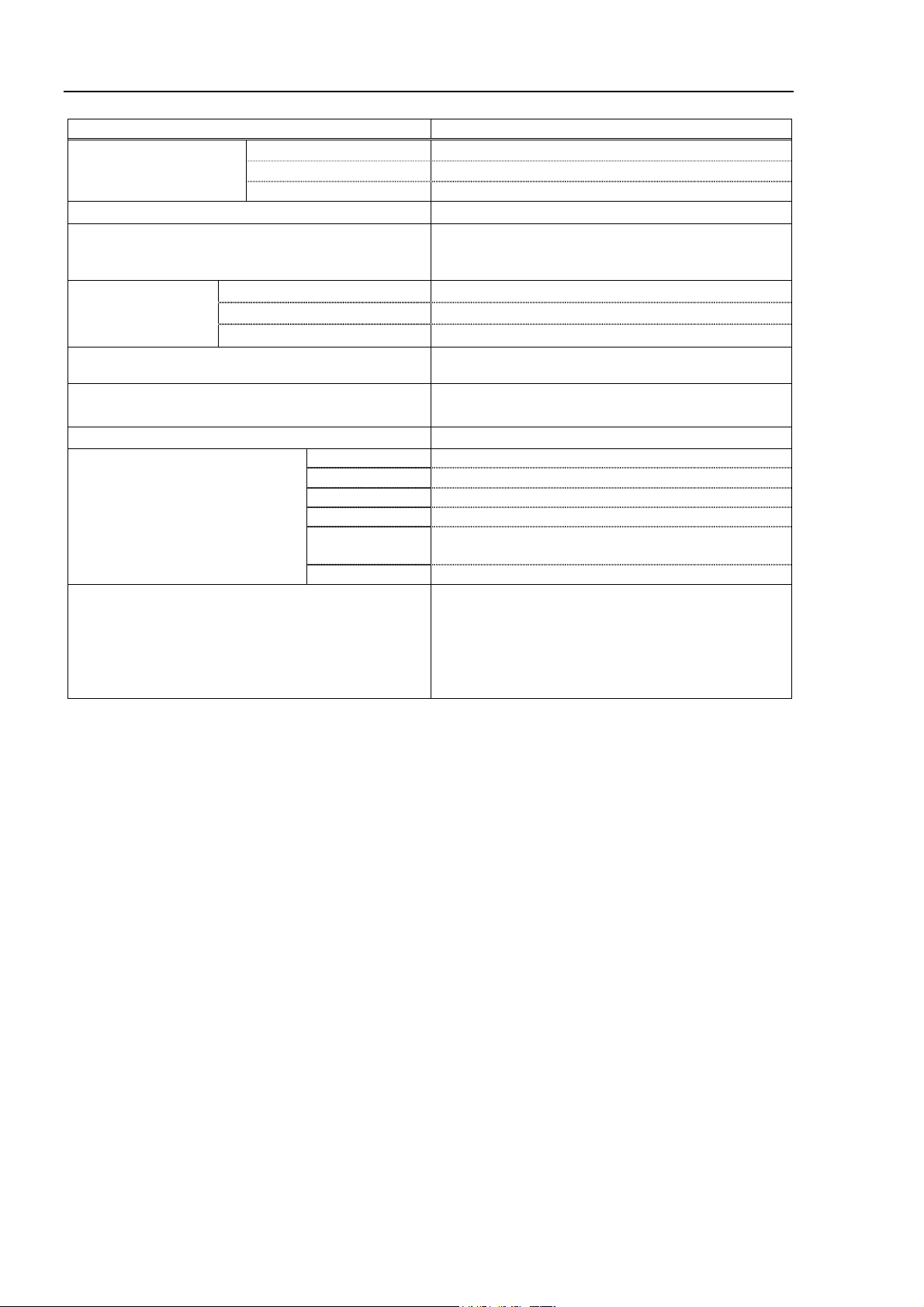

Setup & Operation 2. Specifications

Item Specification

Allowable moment of

inertia (GD

Installed wire for customer use

Installed pneumatic tube for customer use *4

Environmental

requirements

Equivalent continuous A-weighted sound pressure level

*6

Environment

Applicable Controller

Default values

(Max. setting values)

Safety standard

2

/4) *3

*5

Joint #4

Joint #5

Joint #6

Ambient Temperature

Ambient relative humidity

Vibration

SPEED

ACCEL

SPEEDS

ACCELS

FINE

WEIGHT

*1 In the case of PTP control

0.15 kgxm2

0.15 kgxm2

0.1 kgxm2

9 wires (D-sub)

4 pneumatic tubes,

Allowable pressure: 0.59Mpa

(6 kgf/cm

2

) (89 psi)

5 ~ 40 deg C

20 ~ 80 % (no condensation)

4.9 m⋅s2 (0.5 G) or less

LAeq = 76 dB (A) or under

Standard model

Cleanroom model

*7

& ESD

RC180, RC620

5 (100)

5, 5 (120, 120)

50 (2000)

200 (25000)

10000, 10000, 10000, 10000, 10000, 10000

(65535, 65535, 65535, 65535, 65535, 65535)

1, 0

UL1740 (Third Edition, Dated December 7,2007)

ANSI/RIA R15.06-1999

NFPA 79 (2007 Edition)

CSA/CAN Z434-03 (February 2003)

CE Marking − Machinery Directive,

Low Voltage Directive, EMC Directive

*2 When the setting payload is more than 3 kg and less than or equal to 5 kg, refer to the

section “Restrictions on payload exceeding 3 kg (more than 3 kg and less than or equal

to 5 kg)” in the Setup & Operation 4.3.1 WEIGHT Setting.

*3 In the case where the center of gravity is at the center of each arm. If the center of

gravity is not at the center of each arm, set the eccentric quantity using INERTIA

mmand.

*4 For details of the installed pneumatic tube for customer use, refer to the Setup &

Operation 3.6 User Wires and Pneumatic Tubes.

*5 For details of the environmental requirements, refer to the Setup & Operation 3.1

Environmental Conditions.

*6 Conditions of Manipulator at measurement are as follows:

Operating conditions: Under rated load, 6 arms simultaneous motion, maximum speed,

maximum acceleration, and duty 50%.

Measurement point: 1000 mm apart from the rear of Manipulator

16 C3 Rev.4

Page 29

Setup & Operation 2. Specifications

*7: The exhaust system in the Cleanroom-model Manipulator draws air from the base

interior and arm cover interior.

A crack or other opening in the base unit can cause loss of negative air pressure in the

outer part of the arm, which can cause increased dust emission.

Do not remove the covers.

Seal the exhaust port and the exhaust tube with vinyl tape so that the joint is airtight.

If the exhaust flow is not sufficient, dust particle emission may exceed the specified

maximum level.

Cleanliness level : Class ISO 3 (ISO14644-1)

In previous criteria; Clean Class: 10 or its equivalent

Amount of Dust (0.1 µm diameter or larger) in

28317 cm

of the motion rang: 10 particles or less.)

Exhaust System : Fitting for ø8 mm pneumatic tube

Refer to Setup & Operation: 3.6 User Wires and Pneumatic Tubes.

60 L/min vacuum

Exhaust tube : Polyurethane tube

Outer diameter: ø8 mm (Inner diameter: ø5 to 6 mm)

3

(1cft) sample-air around the center

2.6.2 Option

C3 series has the options below. For details of options, refer to Setup& Operation: 6.

Options.

Brake release unit

Camera plate unit

PS compatible plate

Base side angled fittings

Base side fittings

2.7 How to Set the Model

The Manipulator model for your system has been set before the shipment from the factory.

It is normally not required to change the model when you receive your system.

■

When you need to change the setting of the Manipulator model, be sure to set the

Manipulator model properly. Improper setting of the Manipulator model may

CAUTION

NOTE

)

result in abnormal or no operation of the Manipulator and/or cause safety

problems.

If an MT label is attached to the side of a Manipulator, the Manipulator has custom

specifications. If the Manipulator has custom specifications, the methods for setting the

model may differ from those described below. Please contact us with the number on the

MT label.

The method for setting the Manipulator model depends on the software used.

Refer to the chapter Robot Configuration in the EPSON RC+ User’s Guide.

C3 Rev.4 17

Page 30

Setup & Operation 3. Environment and Installation

3. Environment and Installation

Installation and transportation of robots and robotic equipment shall be performed

by qualified personnel and should conform to all national and local codes.

3.1 Environmental Conditions

A suitable environment is necessary for the robot system to function properly and safely.

Be sure to install the robot system in an environment that meets the following conditions:

Item Conditions

Ambient temperature* 5 deg C ~ 40 deg C

Ambient relative humidity 20 % ~ 80 % (no condensation)

First transient burst noise 2 kV or less (Power supply wire)

1 kV or les (Signal wire)

Electrostatic noise 4 kV or less

Environment · Install indoors.

· Keep away from direct sunlight.

· Keep away from dust, oily smoke, salinity, metal

powder or other contaminants.

· Keep away from flammable or corrosive solvents

and gases.

· Keep away from water.

· Keep away from shock or vibration.

· Keep away from sources of electric noise.

* The ambient temperature conditions are for the Manipulators only. For the Controller

the Manipulators are connected to, refer to the Controller manual.

NOTE

)

When using the Manipulators in inadequate environments that do not meet the above

conditions, please consult your distributor.

Be sure to transport and store the robot system in environments that meet the following

conditions:

Item Conditions

Ambient temperature 0 ~ 45 deg C

Ambient relative humidity 20 ~ 80 %

18 C3 Rev.4

Page 31

Setup & Operation 3. Environment and Installation

3.2 Unpacking, Transportation, and Relocation

Using a cart or similar equipment, transport the Manipulator in the same conditions as it

was delivered. Observe the following when unpacking the Manipulator.

THE INSTALLATION SHALL BE MADE BY QUALIFIED INSTALLATION

PERSONNEL AND SHOULD CONFORM TO ALL NATIONAL AND LOCAL

CODES.

■

Only authorized personnel should perform sling work and operate a crane or

forklift. When these operations are performed by unauthorized personnel, it is

extremely hazardous and may result in serious bodily injury and/or severe

WARNING

equipment damage to the robot system.

■

Stabilize the Manipulator with your hands when hoisting it. Unstable hoisting is

extremely hazardous and may results in serious bodily injury and/or severe

equipment damage to the robot system as the fall of the Manipulator.

■

When removing the anchor bolts, support the Manipulator to prevent falling.

Removing the anchor bolts without supporting the Manipulator may get hands,

fingers, or feet caught as the Manipulator will fall.

CAUTION

■

To carry the Manipulator, have at least 2

people to work on it and secure the

Manipulator to the delivery equipment or

hold it by hand.

Do not hold the bottom of the base (the

screened parts in the figure). Holding

these parts by hand is extremely

hazardous and may cause your hands

and fingers to be caught.

■

Avoid excessive vibration or shock during Manipulator transporting. Excessive

vibration or shock may cause equipment damage to and/or malfunction of the

Manipulator.

During unpacking and relocation avoid applying external force to the arms and motors of

the Manipulator.

When transporting the Manipulator for a long distance, secure it to the delivery equipment

so that the Manipulator cannot fall. If necessary, pack the Manipulator in the same way

as it was delivered.

When condensation occurs on the Manipulator during transport or storage, turn ON the

power only after the condensation dries.

When using the Manipulator for the robot system again after long-term storage, perform a

test run to verify that the Manipulator works properly. Then, operate the Manipulator

thoroughly.

Manipulator weight

: 27 kg (59.5 lb.)

DO NOT hold

the bottom of the

base by hand.

C3 Rev.4 19

Page 32

Setup & Operation 3. Environment and Installation

Relocating

Follow the procedures described below when relocating the Manipulator.

(1) Turn OFF the power for all devices and unplug the power cable connector and signal

cable connector from the controller.

Do not unplug the M/C cable (power cable and signal cable) from the manipulator.

NOTE

Remove the mechanical stops if using them to limit the motion range.

)

For details on the motion range, refer to the Setup & Operation 5.2 Motion Range

Setting by Mechanical Stops.

(2) Unscrew the anchor bolts. Then, remove the Manipulator from the base table.

(3) Position the Manipulator as shown in the

figure. Then, secure the Manipulator to the

delivery equipment or have 2 or more people

to carry the Manipulator.

Recommend : Joint #2 +65 deg.

Joint #3 −51 deg.

Manipulator weight

: 27 kg (59.5 lb.)

Do not hold the bottom of the base (the

screened parts in the figure). Holding these

parts by hand is extremely hazardous and may

cause your hands and fingers to be caught.

DO NOT hold

the bottom of the

base by hand.

Using Eyebolt

Check that the eyebolts are securely fastened before carrying the Manipulator.

After transporting the Manipulator, remove the eyebolts and keep them for future use.

The weight of the Manipulator is approx. 27 kg (59.5 lb). The eyebolts and wire must be

strong enough to withstand the weight.

or more

or less

Holes for eye bolt

2-M6 depth 12.5

Use the wire of

1000 mm or more

to avoid contact

with Manipulator.

If you use the eyebolts to lift up the Manipulator, be sure to use the bifilar wire of 1000

mm-long or more to avoid contact with the Arm #4 side cover.

However, the Manipulator can swing while lifting up even with the appropriate length of

wire, so be sure to handle it with care.

Take extra care if you use the wire of 240 mm-long or more to lift the Manipulator,

because the wire is likely to touch the Arm #4 side cover and break the Manipulator.

20 C3 Rev.4

Page 33

3.3 Mounting Dimensions

Mounting Area

Be sure to have the following space available in addition to the space for mounting the

Manipulator, Controller, and peripheral equipment.

Space for teaching points

Space for maintenance and inspections

Space for cables

NOTE

)

The minimum bend radius of the power cable is 90 mm. When installing the cable, be

sure to maintain sufficient distance from obstacles. In addition, leave enough space for

other cables so that they are not bent forcibly.

Mounting Dimensions [Unit: mm]

Setup & Operation 3. Environment and Installation

(Reference through hole)

Space for cable

(Mounting hole)

C3 Rev.4 21

Page 34

Setup & Operation 3. Environment and Installation

3.4 Installation

THE INSTALLATION SHALL BE MADE BY QUALIFIED INSTALLATION

PERSONNEL AND SHOULD CONFORM TO ALL NATIONAL AND LOCAL

CODES.

■

To ensure safety, a safeguard must be installed for the robot system. For details

on the safeguard, refer to the Installation and Design Precautions in the Safety

chapter of the EPSON RC+ User’s Guide.

■

Install the Manipulator at a location with sufficient space so that a tool or a work

piece on the end effector does not reach a wall or a safeguard when the

Manipulator extends its arm fully while holding a work piece. Installing the

Manipulator at a location with insufficient space is extremely hazardous and may

result in serious bodily injury and/or severe equipment damage to the robot

system as a tool or a work piece may collide with a wall and a safeguard.

■

Anchor the Manipulator before turning ON the power to or operating the

WARNING

Manipulator. Turning ON the power to or operating the Manipulator that is not

anchored is extremely hazardous and may result in serious bodily injury and/or

severe equipment damage to the robot system as the Manipulator may fall down.

CAUTION

■

Before installing and operating the Manipulator, make sure that all parts of the

Manipulator are in place and have no external defects. Missing or defective

parts may cause improper operation of the Manipulator. Improper operation of

the Manipulator is extremely hazardous and may result in serious bodily injury

and/or severe equipment damage to the robot system.

■

The robot system must be installed to avoid interference with buildings,

structures, utilities, other machines and equipment that may create a trapping

hazard or pinch points.

Mounting bolt

There are 4 threaded holes for the Manipulator base. Use M8 mounting bolts

conforming to the strength, ISO898-1 property class: 12.9. For the dimensions, refer to

Setup & Operation 3.3 Mounting Dimensions.

Base table

A base table for anchoring the Manipulator is not supplied. Please make or obtain the

base table for your Manipulator. The shape and size of the base table will differ

depending on the use of the robot system. For your reference, we list some basic

Manipulator table requirements here.

The base table must not only be able to bear the weight of the Manipulator but also be able

to withstand the dynamic movement of the Manipulator when it operates at maximum

acceleration. Ensure that there is enough strength on the base table by attaching

reinforcing materials such as crossbeams.

22 C3 Rev.4

Page 35

Setup & Operation 3. Environment and Installation

The torque and reaction force produced by the movement of the Manipulator are as

follows:

Max. Horizontal rotating torque : 500 N·m

Max. Horizontal reaction force : 800 N

Max. Vertical rotating torque : 600 N·m

Max. Vertical reaction force : 2500 N

The plate for the Manipulator mounting face should be 30 mm thick or more and made of

steel to reduce vibration. The surface roughness of the steel plate should be 25 μm or

less.

The base table must be secured on the floor to prevent it from moving.

The Manipulator must be installed horizontally.

When using a leveler to adjust the height of the base table, use a screw with M16 diameter

or more.

Connector

If you are passing cables through the holes on the base table, see the figures below.

[unit : mm]

95

47

26

53

18

NOTE

)

Power Cable

Connector

M/C Cables

Signal Cable

Connector

Do not remove the M/C cables from the Manipulator.

For environmental conditions regarding space when placing the Controller on the base

table, refer to the Controller manual.

Cleanroom-model Manipulator

For the Cleanroom-model, follow the steps below before the installation.

(1) Unpack it outside of the clean room.

(2) Secure the Manipulator to delivery equipment such as a pallet with bolts so that the

Manipulator does not fall.

(3) Wipe off the dust on the Manipulator with a little alcohol or distilled water on a

lint-free cloth.

(4) Carry the Manipulator in the clean room.

(5) Secure the Manipulator to the base table.

(6) Connect an exhaust tube (ø 8 mm) to the exhaust port.

C3 Rev.4 23

Page 36

Setup & Operation 3. Environment and Installation

3.5 Connecting the Cables

■

Before performing any replacement procedure, turn OFF the Controller and related

equipment, and then pull out the power plug from the power source.

Performing any replacement procedure with the power ON is extremely hazardous

and may result in electric shock and/or malfunction of the robot system.

■

Be sure to connect the AC power cable to a power receptacle. DO NOT connect

it directly to a factory power source. To shut off power to the robot system, pull

out the power plug from the power source. Performing any work while

connecting the AC power cable to a factory power source is extremely hazardous

and may result in electric shock and/or malfunction of the robot system.

■

Be sure to connect the cables properly. Do not allow unnecessary strain on the

cables. (Do not put heavy objects on the cables. Do not bend or pull the

WARNING

cables forcibly.) The unnecessary strain on the cables may result in damage to

the cables, disconnection, and/or contact failure. Damaged cables,

disconnection, or contact failure is extremely hazardous and may result in electric

shock and/or improper function of the robot system.

CAUTION

■

Before wiring, turn OFF the Controller and related equipment, and then pull up a

warning sign (e.g. DO NOT TURN ON THE POWER.). Wiring with the power

ON is extremely hazardous and may result in electric shock and/or malfunction of

the robot system.

■

Grounding the manipulator is done by connecting with the controller. Ensure that

the controller is grounded and the cables are correctly connected. If the ground

wire is improperly connected to ground, it may result in the fire or electric shock.

■

When connecting the Manipulator and the Controller, make sure that the serial

numbers on each equipment match. Improper connection between the

Manipulator and Controller may not only cause improper function of the robot

system but also safety problems. The connection method varies with the

Controller used. For details on the connection, refer to the Controller manual.

■

Only authorized or certified personnel should be allowed to perform wiring.

Wiring by unauthorized or uncertified personnel may result in bodily injury and/or

malfunction of the robot system.

Cleanroom-model Manipulator

For the Cleanroom-model, an exhaust system is necessary. For details, refer to Setup &

Operation: 2.6 Specifications.

Connect

Connect the power

connector and signal

connector of the M/C

cables to the Controller.

24 C3 Rev.4

M/C power cable

M/C signal

Page 37

Setup & Operation 3. Environment and Installation

r

3.6 User Wires and Pneumatic Tubes

■

Only authorized or certified personnel should be allowed to perform wiring.

CAUTION

Wiring by unauthorized or uncertified personnel may result in bodily injury and/or

malfunction of the robot system.

User electrical wires and pneumatic tubes are contained in the cable unit.

Electrical Wires

Rated Voltage

Allowable

Current

Wires

AC/DC30 V 1 A 24 0.211 mm2

Maker Standard

9 pin

Suitable Connector JAE

Clamp Hood JAE

Pins with the same number, indicated on the connectors on both ends of the cables, are

connected.

Nominal Sectional

Area

Outer Diameter Note

ø8.3±0.3 mm

Shielded

DE-9PF-N (Solder type)

DE-C8-J9-F2-1R (Connector setscrew: #4-40 NC)

Pneumatic Tubes

Max. Usable Pneumatic Pressure Pneumatic Tubes Outer Diameter × Inner Diameter

0.59 MPa (6 kgf/cm2 : 86 psi)

4 ø4 mm × ø2.5 mm

Tubes with the same number, indicated in details of A and B, are connected.

B

Detail of “B”

No.1 No.2 No.3 No.4

Detail of “A”

A

User cable connector

(9-pin D-sub connector)

User cable connecto

(9-pin D-sub connector)

No.1 : White

No.2 : White

No.3 : Black

No.4 : Black

Standard-model : Cover

Clean-room type : Exhaust port

( For ø8 mm pneumatic tube)

Fitting for

ø4 mm

pneumatic tube

We prepare the part that can be mounted to the position shown in “Detail of B”.

C3 Rev.4 25

Page 38

Setup & Operation 3. Environment and Installation

One Touch Fittings Kit (Set of four: M5-ø4 mm one touch fittings for tubes)

Straight Elbow

User Connector kit (Single: 9 pins D-sub connector)

26 C3 Rev.4

Page 39

3.7 Checking the Basic orientation

After parts have been replaced (motors, reduction gear units, belts, etc.), the Manipulator

cannot operate properly because a mismatch exists between the origin stored in each motor

and its corresponding origin stored in the Controller.

The process of aligning the two origins is called “Calibration”.

At shipment, the following basic orientation is configured as origin.

After all setting is done, go through an origin return run and make sure the manipulator

moves to the right basic orientation.

To make the manipulator return to origin, select the [Tool]-[Robot Manager]-[Control

Panel] and click the <Home> button.

If the manipulator cannot be in the basic orientation after the origin return run (not like as

the figure below), refer to Maintenance 16. Calibration to calibrate the manipulator.

Setup & Operation 3. Environment and Installation

Basic orientation

C3 Rev.4 27

Page 40

Setup & Operation 4. End Effectors

4. End Effectors

4.1 Attaching an End Effector

Create an end effector for your Manipulator that will attach to Arm #6. Before attaching

the end effector to the end of Arm #6, observe these guidelines.

■

If you use an end effector equipped with a gripper or chuck, connect wires and/or

pneumatic tubes properly so that the gripper does not release the work piece

when the power to the robot system is turned OFF. Improper connection of the

wires and/or pneumatic tubes may damage the robot system and/or work piece

CAUTION

as the work piece is released when the Emergency Stop switch is pressed.

I/O outputs are configured at the factory so that they are automatically shut off (0)

by power disconnection, the Emergency Stop switch, or the safety features of the

robot system.

Wrist Flange

Toleranc e in this range

A

Detail of “A”

Arm #6

Attach an end effector to the end of the Arm #6 using an M4 bolt.

Layouts

When you operate the Manipulator with an end effector, the end effector may interfere

with the Manipulator because of the outer diameter of the end effector, the size of the work

piece, or the position of the arms. When designing your system layout, pay close

attention to the interference area of the end effector.

Standard specification (Brakes on Joints #2, #3, #5)

When the end effector is mounted, the joint may rotate by the hand weight or inertia in

Emergency Stop status. The end effector may contact the manipulator body depending

on the diameter of end effector, size of part, or arm position. Be careful about the area of

interference of the end effector for the system layout.

Compatibility with PS series

To mount the end effector used in the PS series to the C3 series, we prepare the option –

PS Compatible Plate. For details of the option, refer to Setup & Operation: 6. Options.

28 C3 Rev.4

Page 41

4.2 Attaching Camera and Valves

Decks are equipped to Arms #3 and #5 to enable the easy installation of air valve.

Deck

Setup & Operation 4. End Effectors

Deck

Rotation Center

of the Upper

Space for cable

[Unit: mm]

For details of the payload exceeding 3 kg, refer to the section “Restriction on payload

exceeding 3 kg (more than 3 kg and less than or equal to 5 kg)” in the Setup & Operation

4.3.1 WEIGHT Setting.

To mount the camera, the camera plate unit is necessary.

We prepare the option – Camera Plate Unit. For details of the option, refer to Setup &

Operation: 6. Options.

C3 Rev.4 29

Page 42

Setup & Operation 4. End Effectors

4.3 WEIGHT and INERTIA Settings

The WEIGHT and INERTIA commands are for setting the load parameters of the

Manipulator. These settings optimize the Manipulator motion.

WEIGHT Setting

The WEIGHT command is for setting the load weight. The more the load weight

increases, the more the speed and acceleration/deceleration for the Manipulator movement

are reduced.

INERTIA Setting

The INERTIA command is for setting the moment of inertia and the eccentricity of the

load. The more the moment of inertia increases, the more the acceleration and

deceleration of the Arm #6 are reduced. The more the eccentricity increases, the more

the acceleration and deceleration for the Manipulator movement are reduced.

To ensure optimum Manipulator performance, it is important to make sure that the load

(weight of the end effector and work piece) and moment of inertia of the load are within

the maximum rating for the Manipulator, and that Arm #6 does not become eccentric.

If the load or moment of inertia exceed the ratings or if the load becomes eccentric, follow

the steps in the Setup & Operation 4.3.1 WEIGHT Setting and 4.3.2 INERTIA Setting, to

set parameters.

Setting parameters makes the operation of the Manipulator optimal, reduces vibration to

shorten the operating time, and improves the capacity for larger loads. In addition, it

reduces persistent vibration produced when the moment of inertia of the end effector and

work piece is bigger.

The allowable weight for C3 Manipulators is up to 3 kg (5 kg*). However, the moment

and the moment of inertia should also be considered due to limitations for these factors.

If force is applied to the Manipulator instead of the weight, force on the Arms #4, #5, and

#6 should be within the values shown in the table “Allowable Moment and Moment of

Inertia for C3 Manipulators”.

* When the load of the Manipulator is more than 3 kg and less than or equal to 5 kg,

refer to the section “Restriction on payload exceeding 3 kg (more than 3 kg and less

than or equal to 5 kg)” in the Setup & Operation 4.3.1 WEIGHT Setting.

Allowable Moment and Moment of Inertia for C3 Manipulators

Arm Allowable Moment

*1

GD2/4 Allowable Moment of Inertia

#4 4.41 N·m (0.45 kgf·m) 0.15 kg·m2

#5 *2

4.41 N·m (0.45 kgf·m) 0.15 kg·m

2

#6 2.94 N·m (0.3 kgf·m) 0.1 kg·m2

*1 Gravitational unit

*2 The allowable moment and allowable moment of inertia of Arm #5 are calculated by

the distance from the Arm #5 rotation center (a + 65 mm). (Refer to the figure in the

“Critical Location of the Load on C3 Manipulators”).

30 C3 Rev.4

Page 43

Setup & Operation 4. End Effectors

Critical Location of the Load on C3 Manipulators

Position of

Load’s Center

of Gravity

Arm #J6

Rotation

Center

Flange

Arm #J5

Rotation Center

[Unit: mm]

Rotation Center

Distance from the Arm #J6

Distance from the Flange

When calculating the critical location of the load on the Arm #5 using the allowable

moment and allowable moment of inertia, the calculated value represents a distance from

the Arm #5 rotation center, not the distance from the flange. Therefore, to get a value of

the critical location of the load on Arm #5, subtract 65 (mm) from the calculated distance

from the Arm #5 rotation center as shown the example below.

Example: Calculate the critical location of the load on the Arm #5 (c) when a 2.5 kg load is

on the Arm #6 rotation center line (b = 0).

Allowable Moment of the Arm #5 (N·m) / Load (kg)

= Distance from the Arm #5 rotation center (m)

4.41 (N·m) / 9.8 / 2.5 (kg) = 0.18 → 0.18 (m) = 180 (mm)

c (mm) = Distance from the Arm #5 rotation center (mm) − 65 (mm)

c = 180 (mm) − 65 (mm) = 115 (mm)

C3 Rev.4 31

Page 44

Setup & Operation 4. End Effectors

Moment

A moment is a necessary torque (holding torque) to counteract the gravity affecting the

load.

Design an end effector so that the eccentric quantity at the position where the load is

attached is within the allowable moment.

A maximum torque (T) is calculated by the following formula.

T = m (kg) × L (m) × g (m/s

m: Weight of load (kg)

L: Eccentric quantity of load (m)

g: Gravitational acceleration (m/s

Max. Eccentric Quantity of Load

(Distance between the joint rotation center and the load’s center of gravity)

Axis WEIGHT 1 kg WEIGHT 2 kg WEIGHT 3 kg

#4

#5

200 mm 200 mm 150 mm

200 mm 200 mm 150 mm

#6 200 mm

(The maximum eccentric quantity of load is restricted to 200 mm or less.)

4.3.1 WEIGHT Setting

■

Set the total weight of the end effector and the work piece to 3 kg or less.

The C3 Manipulators can operate without limitations on the condition that the

load of the Manipulator should be 3 kg or less. When the payload of the

Manipulator is more than 3 kg and less than or equal to 5 kg, refer to the section

“Restrictions on payload exceeding 3 kg (more than 3 kg and less than or equal

CAUTION

to 5 kg)” in the later part of this section for details.

Always set the Weight parameters of the WEIGHT command according to the

load. Setting a value that is smaller than the actual load may cause errors,

excessive shock, insufficient function of the Manipulator, and/or shorten the life

cycle of parts/mechanisms.

2

)

2

)

150 mm 100 mm

L

Joint Rotation Center

T

The acceptable weight capacity (end effector and work piece) for C3 Manipulators is 1 kg

nominal rating and 3 (5) kg maximum*. When the load (weight of the end effector and

work piece) exceeds the rating, change the setting of the Weight parameter.

After the setting of the Weight parameter is changed, the maximum

acceleration/deceleration and speed of the robot system corresponding to the Weight

parameter is set automatically.

* When the payload of the Manipulator is more than 3 kg and less than or equal to 5 kg,

refer to the section “Restrictions on payload exceeding 3 kg (more than 3 kg and less

than or equal to 5 kg)” in the later part of this section for details.

32 C3 Rev.4

Page 45

Setup & Operation 4. End Effectors

Setting method of Weight parameters

The method for setting Weight parameter varies with the software used.

EPSON

RC+

EPSON RC+ 5.0 (RC180) / EPSON RC+ 6.0 (RC620)

Enter into the [Weight:] text box on the [Weight] panel ([Tools]-[Robot Manager]).

You may also execute the Weight command from [Command Window].

Load on the Manipulators

The Manipulator can load valves or any other devices onto the following three points.

Top View

Load on the

Fore – end of Arm #6

Arm #5 Deck

Arm #3 Deck

Deck detailed

approx.

approx.

approx.

approx.

Arm #5 Deck Arm #3 Deck

[Unit: mm]

When you attach the equipment to the decks on the upper arm, convert its weight into

equivalent weight assuming that the equipment is attached to the end of the Arm #6.

Then, this equivalent weight added to the load will be a Weight parameter.

C3 Rev.4 33

Page 46

Setup & Operation 4. End Effectors

w

Calculate the Weight parameter by following the formula below and enter the value.

Weight Parameter Formula

Weight parameter = M

Mw

: Load on the fore-end of Arm #6 (kg)

W

: Equivalent weight of the Arm #3 deck (kg)

a

W

: Equivalent weight of the Arm #5 deck (kg)

b

W

= Ma (La)²/ (L)²

a

= Mb (Lb)²/ (L)²

W

b

M

: Weight of the air valve on the Arm #3 deck

a

M

: Weight of the camera on the Arm #5 deck

b

L

: Length of the upper arm (315 mm)

L

: Distance between the Joint #3 and the center of gravity of

a

the air valve on the Arm #3 deck (mm)

L

: Distance between the Joint #3 and the center of gravity

b

of the camera on the Arm #5deck (mm)

+ Wa + Wb

w

M

<Example> The fore-end of Arm #6 is 315 mm (L) away from the Joint #3.

Load on the fore-end of Arm #6 is 1 kg (M

Load on the Arm #3 deck is 1.5 kg (M

The deck is 0 mm (L

) away from Joint #3.

a

Load on the Arm #5 deck is 0.5 kg (M

The deck is 280 mm (L

) away from the Joint #3.

b

).

w

).

a

).

b

=1.5 × 02/3152=0

W

a

=0.5 × 2802/3152=0.395 → 0.4(round up)

W

b

M

+ W

w

=1 + 0 + 0.4=1.4

+ W

a

b

Enter “1.4” for the Weight parameter.

34 C3 Rev.4

Page 47

Setup & Operation 4. End Effectors

Automatic speed setting by Weight parameter

Acceleration

/ Deceleration

Speed

Weight Parameter

* The percentage in the graph is based on the speed at rated weight (1 kg) as 100%.

* When the payload of the Manipulator is more than 3 kg and less than or equal to 5 kg,

refer to the section “Restrictions on payload exceeding 3 kg (more than 3 kg and less

than or equal to 5 kg)” in the later part of this section for details.

Restrictions on payload exceeding 3 kg

(more than 3 kg and less than or equal to 5 kg)

Although the maximum payload of the C3 Manipulator is 3 kg, you can increase up to 5

kg when you restrict the arm pose range of Arm #5 with arm downward positioning.

When the load is over 3 kg, the Arm #5 orientation must be within the angle indicated in

the following graph.

1

The graph shows the relation of the load weight and Arm #5 angle limit (A

vertical direction (direction of gravity). Note that the heavier load Arm #6 holds, the

smaller the angle limit becomes.

When the manipulator operates vertically to the operating surface, the limit of Arm #5 is

2

equivalent to the limit of operating angle (A

).

In addition, for the eccentric load, the angle limit is an angle of the line joining the center

of load and Arm #5 rotation axis with the vertical direction (B).

) measured in

The eccentric quantity of load should be within the allowable moment and the allowable

moment of inertia of Arms #4, #5, and #6.

C3 Rev.4 35

Page 48

Setup & Operation 4. End Effectors

1

2

Relation of load weight and Arm #5 angle limit

Arm #5 Angle Limit

Arm #5 rotation axis

Arm #5

Arm #6

Load on Arm #6 End

Arm #4

Vertical direction

Load on

Arm 6 end

: Arm #5 angle

A

from vertical direction

Operating surface

A

Plane

: Angle of operating

surface form plane

Arm #5

Arm #6

Angle limit for eccentric load Relation of Arm #5 angle and operating surface

Vertical direction

Arm #5 rotation axis

Gravity

Load on

Arm #6 end

B

36 C3 Rev.4

Page 49

y

4.3.2 INERTIA Setting

Moment of Inertia and the INERTIA Setting

The moment of inertia is defined as “the ratio of the torque applied to a rigid body and its

resistance to motion”. This value is typically referred to as “the moment of inertia”,

“inertia”, or “GD

attached to the Arm #6, the moment of inertia of load must be considered.

■

The moment of inertia of load (weight of the end effector and work piece) must be

0.1 kg·m

2

of inertia exceeding 0.1 kg·m

CAUTION

Always set the moment of inertia (INERTIA) parameter according to the moment

of inertia. Setting a value that is smaller than the actual moment of inertia may

cause errors, excessive shock, insufficient function of the Manipulator, and/or

shorten the life cycle of parts/mechanisms.

The acceptable moment of inertia of load in C3 Manipulator is 0.1 kgxm2 nominal rating

and 0.1 kgxm

the setting of the moment of inertia using the INERTIA command. After the setting has

been changed, the maximum acceleration/deceleration speed of Arm #6 responding to

“moment of inertia” is set automatically.

Moment of inertia of load on Arm #6

The moment of inertia of load (weight of the end effector and work piece) on Arm #6 can

be set by the “moment of inertia (INERTIA)” parameter of the INERTIA command.

The method for setting the parameter varies with the software used.

EPSON

RC+

EPSON RC+ 5.0 (RC180) / EPSON RC+ 6.0 (RC620)

Enter into the [Load inertia:] text box on the [Inertia] panel ([Tools]–[Robot Manager]).

You may also execute the Inertia command from [Command Window].

Setup & Operation 4. End Effectors

2

”. When the Manipulator operates with objects such as an end effector

or less. The C3 Manipulators are not designed to work with moment

2

.

2

maximum. When the moment of inertia of load exceeds the rating, change

Eccentric Quantity and the INERTIA Setting

■

The eccentric quantity of load (weight of the end effector and work piece) must be

200 mm or less. The C3 Manipulators are not designed to work with eccentric

quantity exceeding 200 mm.

.

CAUTION

Always set the eccentric quantity parameter according to the eccentric quantit

Setting a value that is smaller than the actual eccentric quantity may cause

errors, excessive shock, insufficient function of the Manipulator, and/or shorten

the life cycle of parts/mechanisms.

The acceptable eccentric quantity of load in C3 Manipulators is 30 mm nominal rating and

200 mm maximum. When the eccentric quantity of load exceeds the rating, change the

setting of eccentric quantity parameter using the INERTIA command. After the setting

has been changed, the maximum acceleration/deceleration speed of Manipulator

corresponding to “eccentric quantity” is set automatically.

C3 Rev.4 37

Page 50

Setup & Operation 4. End Effectors

Rotation Center

a