Page 1

Laser Printer

Epson AcuLaser C2900N

SEPG11001

SERVICE MANUAL

Revision B

MiS00001SA

Epson AcuLaser C2900N

Confidential

Page 2

Revision B

Cautions

Operation contents of this document may be subject to modification without notice.

SEIKO EPSON will not assume responsibility for accidental or incidental damages resulting from

technical or editorial errors or omissions in this manual, the issue of this manual, the execution of

descriptions in this manual, or the use of this manual.

This document is protected by copyright. Do not photocopy or duplicate any part of this document in

any form without written permission from SEIKO EPSON.

Epson AcuLaser C2900N Confidential

i

Page 3

1. About this manual

This manual is a standard service manual of SEIKO EPSON containing information required for

maintenance of this laser printer (standard specifications).

2. Marks giving caution

Maintenance operations requiring special cautions or additional information regarding descriptions in

this manual are presented as "Warning," "Caution," or "Note," depending on their nature.

If instructions are not observed, death or serious injury may result.

If instructions are not observed, injuries to workers or physical damage to assets

(including this laser printer) may result.

Essentials for procedures, steps, rules, and others.

Revision B

Reference Incidental information to descriptions.

3. Related documents

- Instruction manuals (standard manuals)

Describe the operation and handling of this laser printer.

- Performance specifications

Describe in detail various specifications of this laser printer.

(In the event of a discrepancy between this ma nu al an d the performance specifications, the

performance specifications take pr ec ed e nc e.)

- Spare parts list

Information on maintenance parts (spare parts) for this laser printer.

Epson AcuLaser C2900N Confidential

ii

Page 4

4. Safety

To prevent possible accidents during maintenance operation, you should observe strictly the "Warning"

and "Caution" information in this manual.

Avoid dangerous operations and opera tio ns ou t of the sco p e of this ma nu al.

Various processes not covered by this manual may be required in actual operations, and should be

performed carefully, always giving attention to safety.

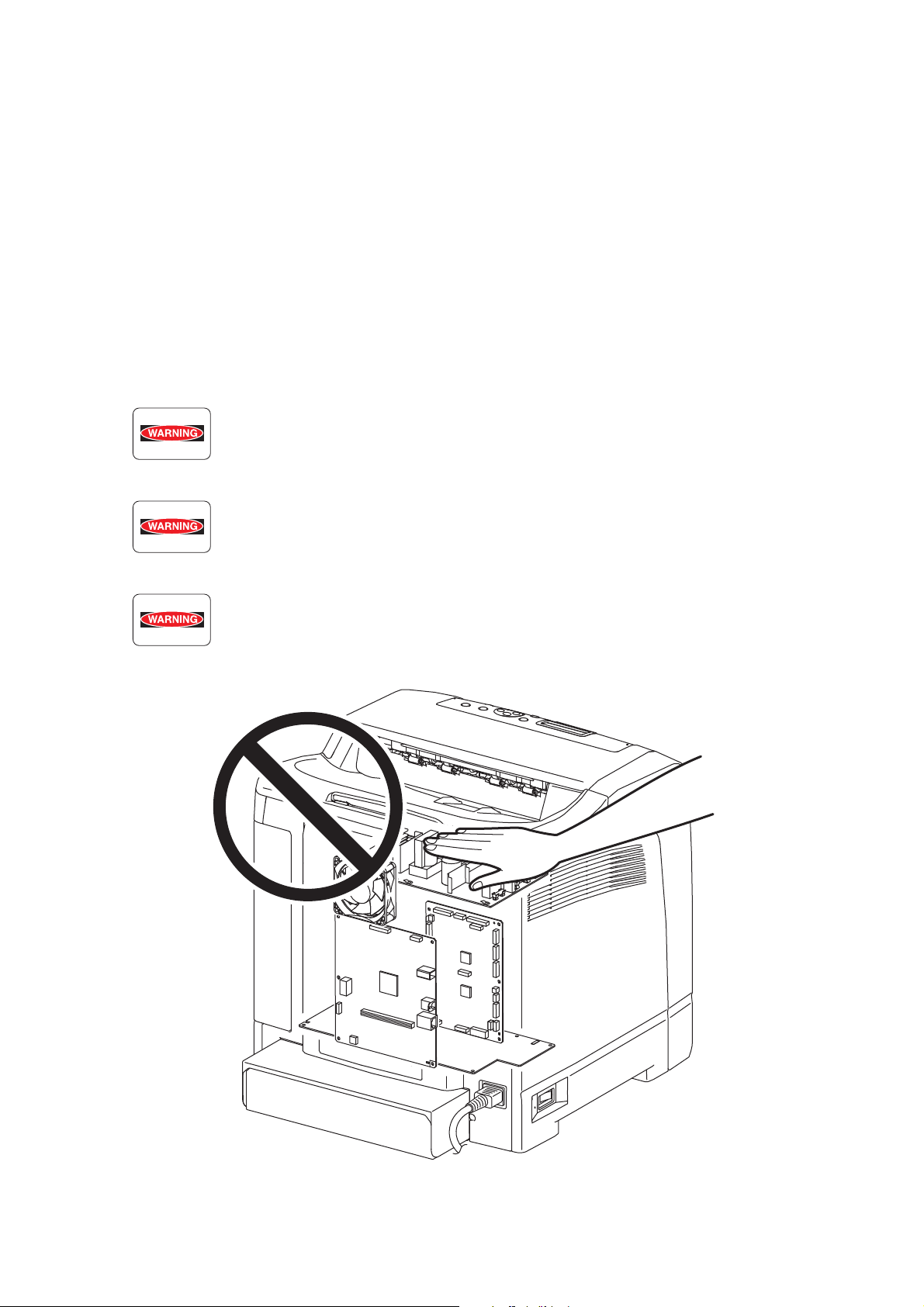

4.1 Power source

Keep the power plug disconnected during the maintenance operation to prevent electric shock, burns

and other damages.

If the power supply should be kept connected to measure voltage or for other similar reasons, take

sufficient care to prevent electric shock, by following the procedures in this manual.

While the printer is on, never touch live parts if not required.

Power is supplied to the power switch / inlet even while the printer is off. Never

touch its live components.

Revision B

Do not touch live parts unless otherwise specified.

MiS00002SA

Epson AcuLaser C2900N Confidential

iii

Page 5

4.2 Driving units

When servicing gears or other driving units, be sure to turn off the power switch and unplug the power

cord. Drive them manually when required.

Do not do the print work removing the cover of the printer to confirm the operation

of driving part.

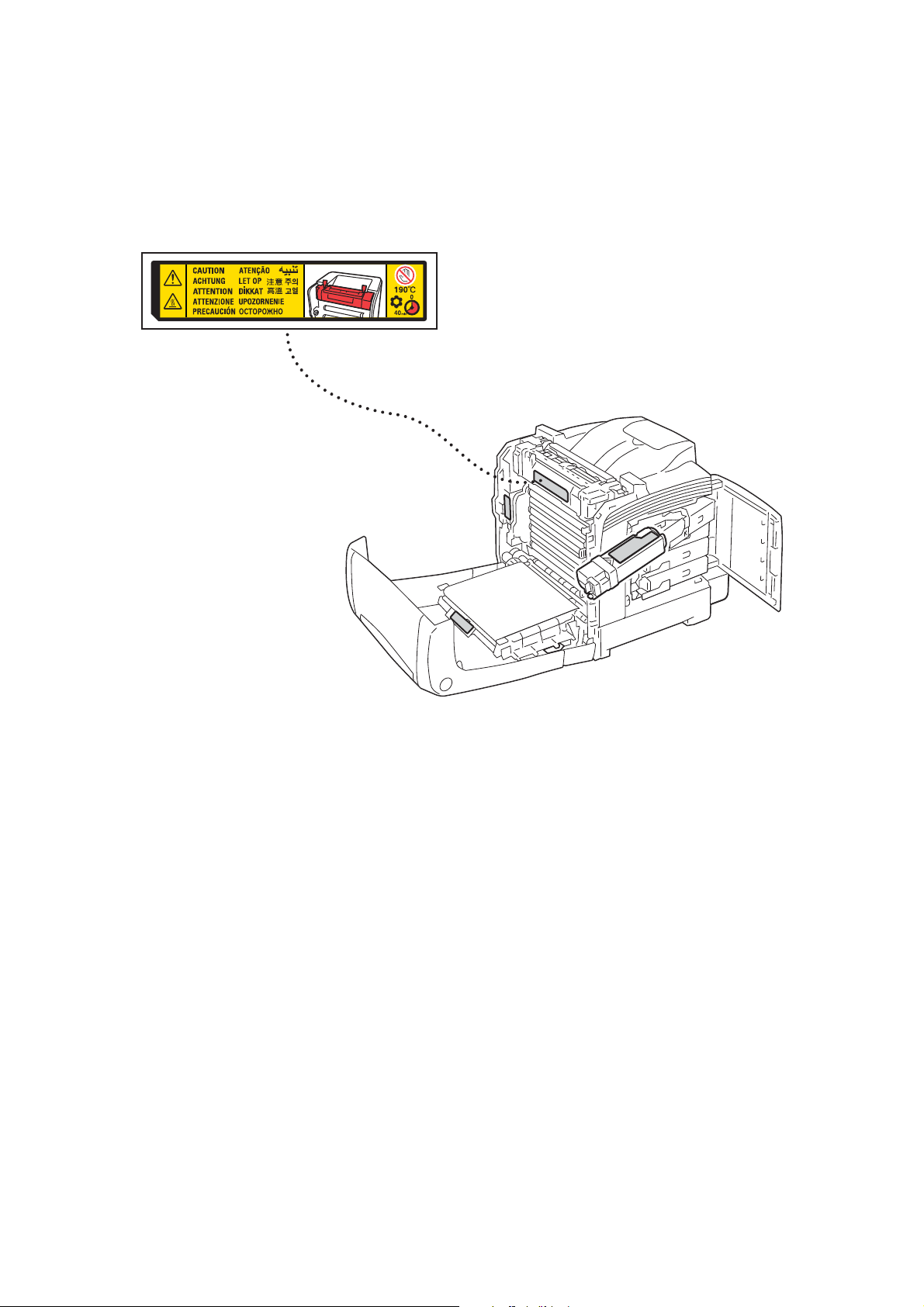

4.3 High-temperature units

When servicing high-temperature units (securing unit, etc.), be sure to turn them off to prevent burns,

injuries and other troubles. Remove the power plug and start service processes after they have cooled

down sufficiently.

Because high-temperature units are still hot after they complete an operation, wait

at least 40 minutes before starting maintenance service.

Revision B

Epson AcuLaser C2900N Confidential

iv

Page 6

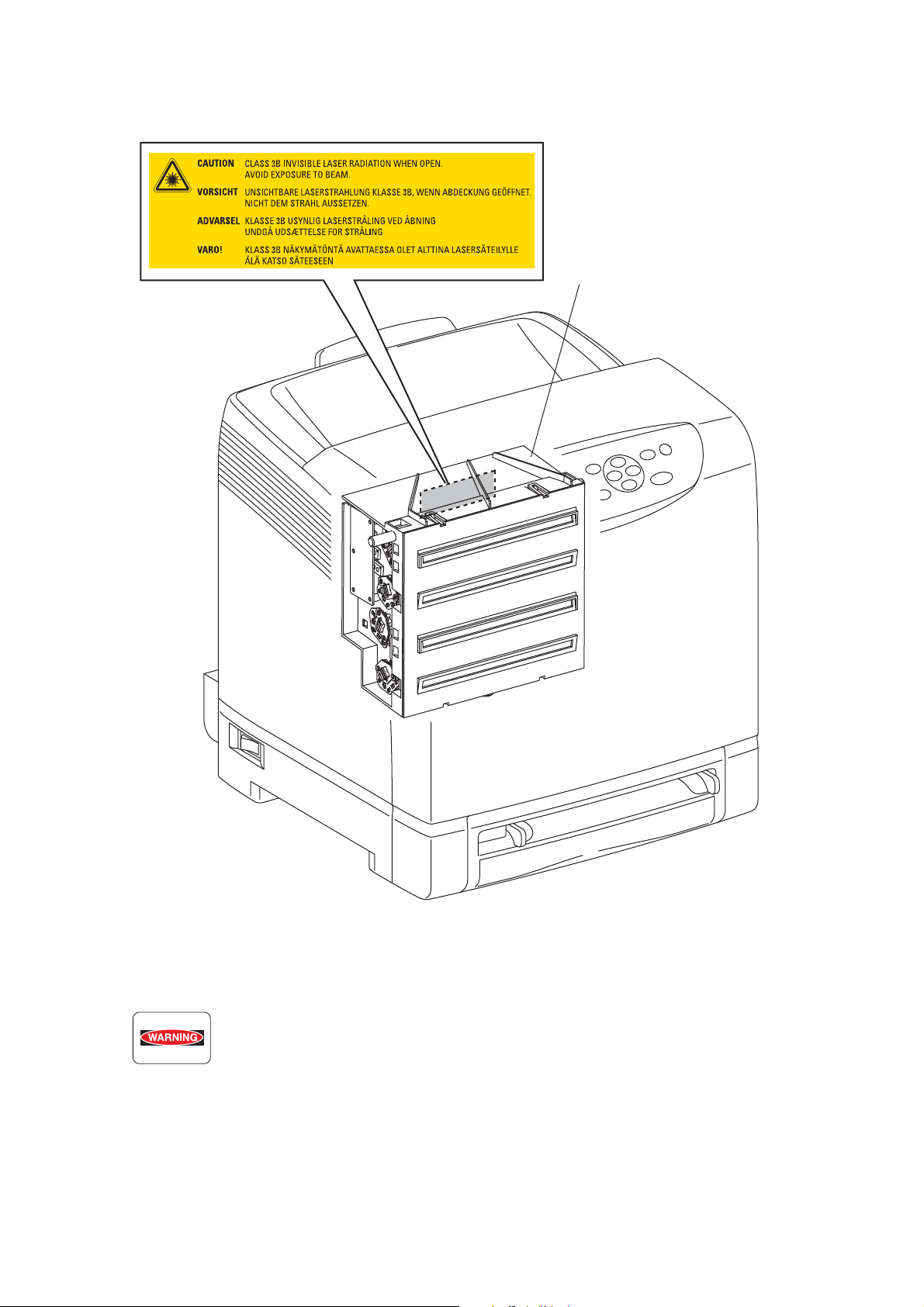

4.4 Laser beams

• If your eyes are exposed to laser beams, you may lose your eyes ight.

• Never open the cover if the warning label for laser beams is attached there.

• Before disassembling and reassembling this laser printer, be sure to turn it OFF.

• When servicing this laser printer while it is running, be sure to follow the

procedures specified in this manual.

• You should be well aware that the laser beams are capable of injuring you and

other people near the printer.

Laser beams have features as follows:

• Frequencies are smaller in width than other beams (sun and electric bulbs) and

phases are uniform so that high monochromatic and convergence performance

can be obtained and thin beams of light can reach places at a long distance.

• Being highly converged, the laser beams exert a heating action that may be

harmful to human body.

Reference: The laser beams of this laser printer are invisible rays.

Revision B

ROS ASSY

MiS00003SA

Epson AcuLaser C2900N Confidential

v

Page 7

4.5 Warning/caution labels

MiS00004SA

Warning labels and caution labels are attached to this laser printer to prevent accidents Check those

labels for peeling or stains when servicing the printer.

4.5.1 Caution label for Printer

Revision B

Epson AcuLaser C2900N Confidential

vi

Page 8

4.5.2 Caution label for ROS

MiS00005SA

ROS ASSY

Revision B

4.6 Others

• When air duster is used on the repair and the maintenance work, the use of the air

duster products containing the inflammable gas is prohibited.

• Make sure an antivirus software is installed on the computer used for service

support. Be sure to have the latest virus definition file for the software.

Epson AcuLaser C2900N Confidential

vii

Page 9

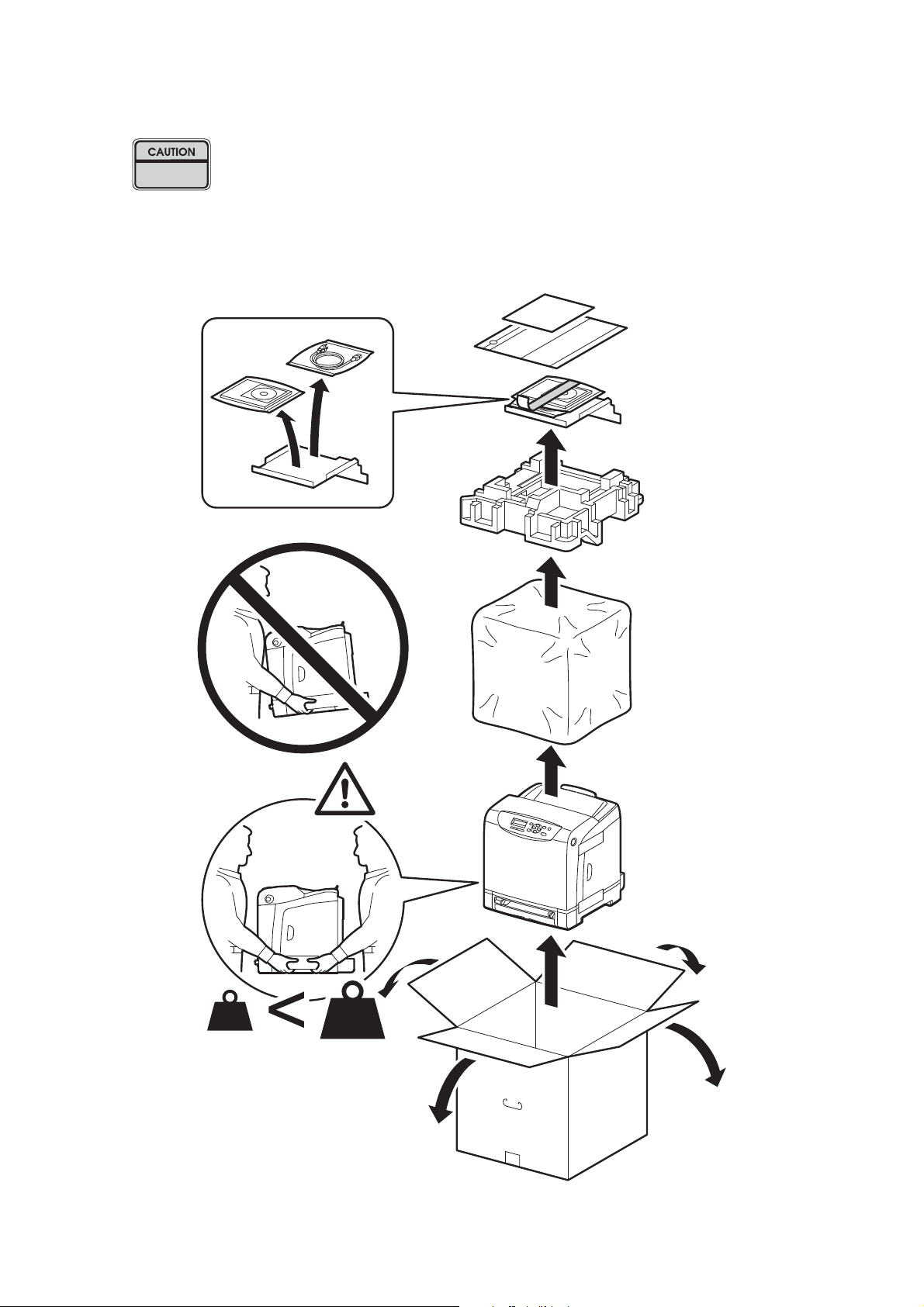

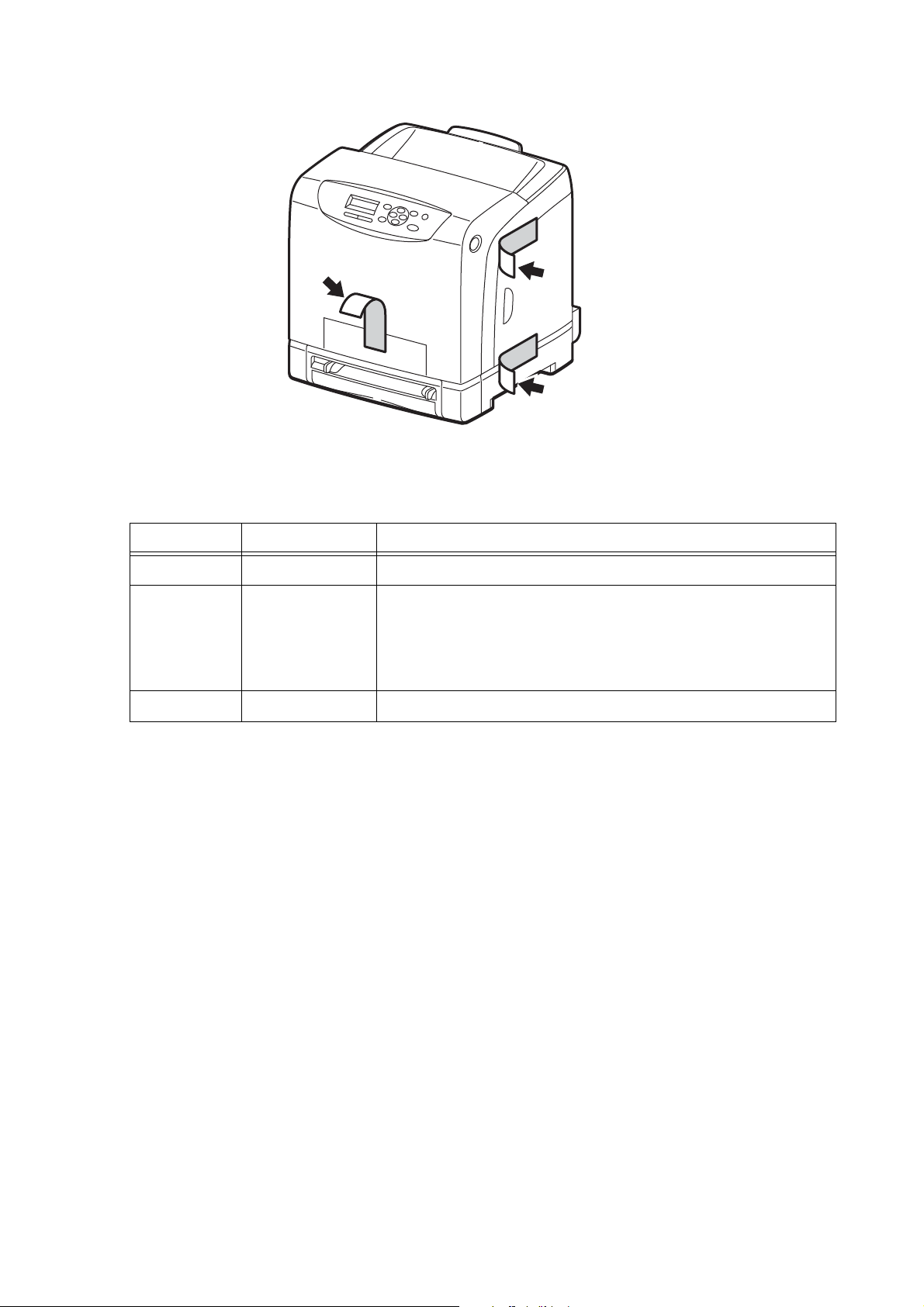

5. Unpacking the Printer

Take extreme care to avoid personal injuries.

Check the printer for evidence of any damages.

Peel all tapes off the printer.

Revision B

MiS00010GA

Epson AcuLaser C2900N Confidential

viii

Page 10

6. Revision History

MiS00007SA

Revision B

Revision Date of Issue Description

A May 20, 2011 First release

Revision up

Chapter3:

B July 7, 2011

RRP8.3 PWBA ESS SFP (PL8.1.5): revised the contents partially.

RRP8.9 PWBA MCU (PL8.2.13): revised the contents partially.

Epson AcuLaser C2900N Confidential

ix

Page 11

Revision B

CONTENTS

1. About this manual.............................................................................................................ii

2. Marks giving caution .........................................................................................................ii

3. Related documents........................................................................................................... ii

4. Safety ...............................................................................................................................iii

4.1 Power source.................................... ... .... ... ... ... .......................................... ... .... ... ... ... ...........................iii

4.2 Driving units......... ... ... .... ... ... ... .... ... .......................................... ... ... .... ... .................................................iv

4.3 High-temperature units .................................. ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... ........................................iv

4.4 Laser beams..... ... ... ... .... ... .......................................... ... ... .......................................... . ...........................v

4.5 Warning/caution labels................ ... ... ... .... ... .......................................... ... ... ... .... ... ... ... .... .......................vi

4.5.1 Caution label for Printer.................................................................................................................vi

4.5.2 Caution label for ROS...................................................................................................................vii

5. Unpacking the Printer .....................................................................................................ix

6. Revision History...............................................................................................................ix

Chapter 1 Troubleshooting.............................................................................................1 - 1

Chapter 2 Operation of Diagnostic.................................................................................2 - 1

Chapter 3 Removal and Replacement Procedures........................................................3 - 1

Chapter 4 Plug/Jack(P/J) Connector Locations..............................................................4 - 1

Chapter 5 Parts List........................................................................................................5 - 1

Chapter 6 Principles of Operation ..................................................................................6 - 1

Chapter 7 Wiring Diagrams and Signal Information.......................................................7 - 1

Chapter 8 Product Specifications...................................................................................8 - 1

Epson AcuLaser C2900N Confidential

x

Page 12

Troubleshooting

CHAPTER

1

Confidential

Page 13

Chapter 1 Troubleshooting

Chapter 1 Troubleshooting CONTENTS

1. Troubleshooting Overview...........................................................................................1 - 1

1.1 Flow of Troubleshooting................. ... ... .... ... ... ... ... .... ... .......................................... ... ... .... ..................1 - 1

1.2 Check Installation Status .................................................................................................................1 - 2

1.3 Cautions on Service Operations .......................................................................................................1 - 3

1.4 Cautions on Using FIP...................................................................................................................... 1 - 4

1.5 Items To Be Confirmed Before Going To FIP Troubleshooting ........................................................1 - 6

2. FIP............................................................................................................................1 - 12

2.1 FIP ...................................... ... .... ... ... ... .... ... .......................................... ... ... ....................................1 - 12

2.2 Flow of FIP..................................................................................................................................... 1 - 12

2.3 Status Code List............................ ... ... .... ... ... ... ... .......................................... .... ... ... ... ....................1 - 13

3. Error Code FIP ..........................................................................................................1 - 25

4. Image Quality Trouble.............................................................................................1 - 126

4.1 Entry Chart for Image Quality Troubleshooting............................................................................. 1 - 126

4.2 Print Image Quality Specifications ........................................................... ... ... .... ... ........................1 - 130

4.3 Image Quality FIP...... .... ... ... ... .... ... ... ... .......................................... .... ... ... ... ... ...............................1 - 134

5. Abnormal Noise Trouble.......................................................................................... 1 - 173

5.1 Entry Chart for Abnormal Noise Troubleshooting .........................................................................1 - 173

5.2 Operation Mode Table............ .... ... .......................................... ... ... .... ... ... ... ... .... ... ... .....................1 - 174

6. Other FIP.................................................................................................................1 - 180

Epson AcuLaser C2900N Confidential

Page 14

Chapter 1 Troubleshooting

Check installation status

Check trouble status

Execute FIP

Check for recovery

End Replace the Printer.

Operation of Diagnostic

Principles of Operation

Wiring Diagrams

Reference

information

If the problem persists

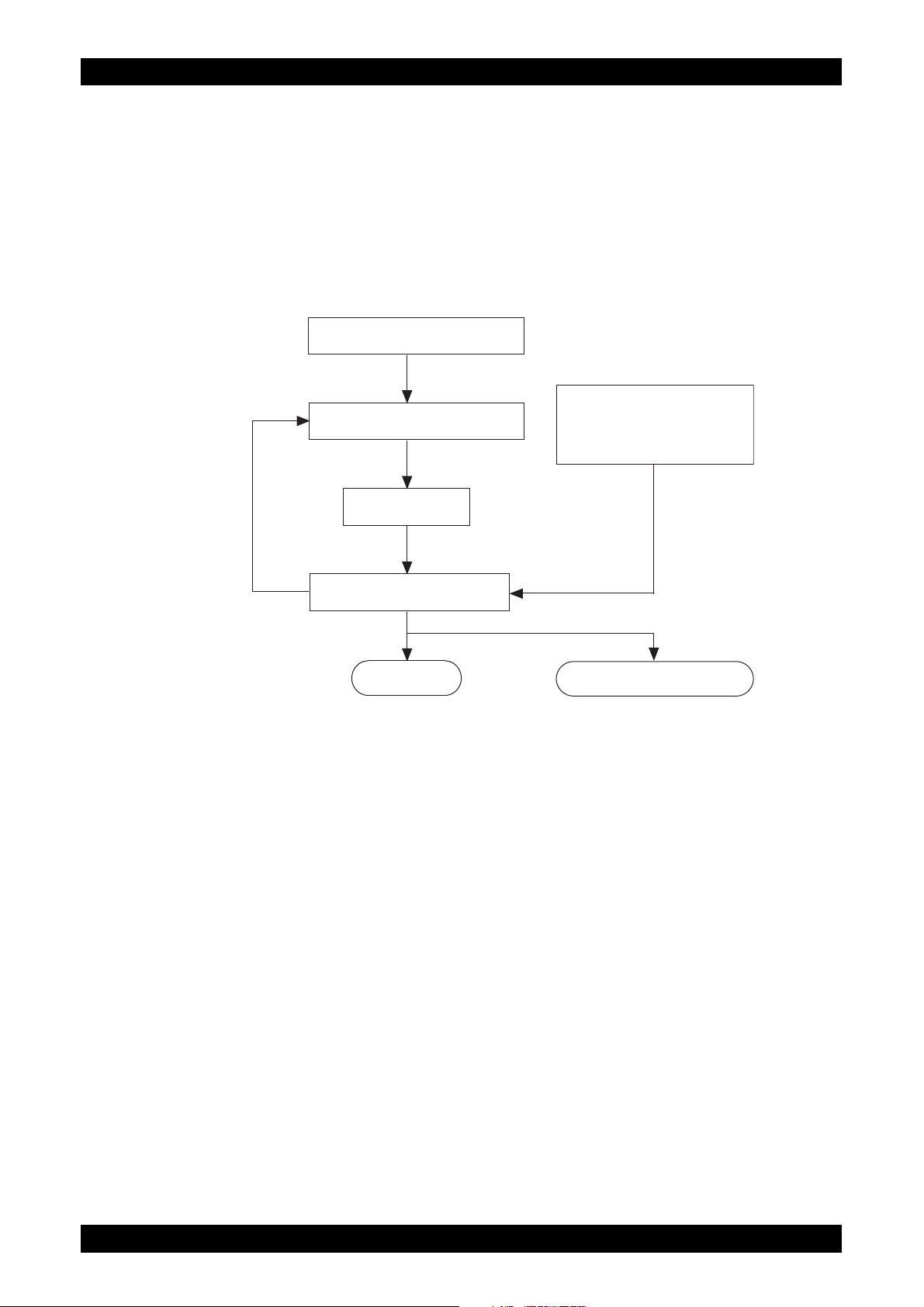

1. Troubleshooting Overview

To increase the efficiency of troubleshooting, ensure that preliminary checks should be made to confirm

the trouble status before proceeding to the Fault Isolation Procedure (FIP), Operation of Diagnostic

(Chapter 2), Wiring Diagrams (Chapter 7), and Principles of Operation (Chapter 6).

1.1 Flow of Troubleshooting

Flow of the troubleshooting is as follows:

Revision B

Epson AcuLaser C2900N

1 - 1

Confidential

Page 15

Chapter 1 Troubleshooting

1.2 Check Installation Status

Be sure to check the following items before starting the troubleshooting procedures

1) The power supply voltage is within the specifications (measure the voltage at the wall outlet).

2) Power cord is free from breakage, short-circuit, disconnected wire, or incorrect connection in the

power cord.

3) The printer is properly grounded.

4) The printer is not installed at a place subjected to high/low temperature, hum idity, and sudden te mperature changes.

5) The printer is not installed at or near water facilities, humidifier, heating appliance, fire, dust, or in

airflow from air conditioner.

6) The printer is not installed in a place subjected to volatile or inflammable gas.

Revision B

7) The printer is not installed under direct sunlight.

8) The printer is installed in a well-ventilated place.

9) The printer is installed on a firm and stable surface.

10) The paper meets the specifications (standard paper is recommended).

11) The printer is handled properly.

12) The high frequency service items are replaced at the recommended print count intervals.

Epson AcuLaser C2900N

1 - 2

Confidential

Page 16

Chapter 1 Troubleshooting

1.3 Cautions on Service Operations

1) Be sure to remove the power cord unless otherwise required.

While the printer is powered ON, never touch the conductive parts unless

otherwise required.

Never touch the conductive parts of the power switch and inlet of the LVPS,

because they are live even while the printer is powered off.

2) When checking some parts with covers removed and with the interlock, safety, and power switches

ON, disconnect the connectors (P/J411 and P/J412) on the ROS ASSY except unless otherwise

required.

When checking some parts with covers removed and with the interlock, safety, and

power switches ON, laser beams may be irradiated from the ROS ASSY. For your

safety, be sure to disconnect the connec tors (P/J411 and P/J 412 ) unless otherwise

required.

3) When checking some parts with the Front Cover removed and the printer powered ON, be sure to

remove the connector (P/J16) on the PWBA MCU unless otherwise required.

When checking some parts with the Front Cover removed and the printer powered

ON, be sure to remove the connector (P/J16 ) on the MCU. Otherwise, a high voltage

may be output from the HVPS.

When connecting the connector (P/J16) on the MCU according to the instructions

in the FIP, never touch the HVPS and high voltage parts.

Revision B

4) When outputting a high voltage using the Diag Tool, etc., keep all the covers on unless otherwise

required.

When outputting a high voltage using the Diag Tool, etc., ensure that:

- The high voltage carrying parts must never be touched.

- The instructions in this manual must be followed.

5) When operating the drive unit using the Diag Tool, etc., keep all the covers on unless otherwise

required.

When operating the drive unit using the Diag Tool, etc., ensure that:

- The drive unit must never be touched.

- The instructions in this manual must be followed.

6) When touching hot parts, be careful not to get burnt.

7) While working, be sure to wear a wrist band or the like to dissipate static charges from your body.

Epson AcuLaser C2900N

1 - 3

Confidential

Page 17

Chapter 1 Troubleshooting

1.4 Cautions on Using FIP

1) When troubleshooting according to the FIP, have on hand a normal MCU, LVPS, HVPS, Fuser

Unit, TRANSFER ASSY, etc., for possible fault isolation.

2) In the initial check according to the FIP, check only items which can be simply checked.

3) In the initial check according to the FIP, check the constitutive parts of the major check parts and

related parts, as well as major check parts.

4) When working with the printer, be sure to remove the power cord unless otherwise required. Never

touch live parts if not required, while the power cord is connected.

5) Connector condition is denoted as follows:

[P/J12]

[P12]

[J12]

Connector (P/J12) is connected.

Plug side with the connector (P/J12) removed (except when attached directly to the

board).

Jack side with the connector (P/J12) removed (except when attached directly to the

board).

Revision B

6) [P/J1-2PIN <=> P/J3-4PIN] in the FIP means measurement with the positive side of the measuri ng

instrument connected to [2PIN] of [P/J1] and the negative side to [4PIN] of [P/J3].

7) [P/J1<=> P/J2] in the FIP means measurement for all terminals corr espondin g between [P/J1] and

[P/J2] based on “Wiring Diagrams”.

8) In [P/J1-2PIN <=> P/J3-4PIN] in the FIP where voltage is measured, [P/J3-4PIN] on the rear

negative side is always at the AG (analog ground), SG (signal ground), or RTN (return).

Therefore, after checking of proper conductivity between AGs, SGs, or RTNs respectively, the rear

negative side can be connected to the PIN of AG, SG or RTN instead of [P/J3-4PIN].

However, care should be taken not to confuse [AG], [SG], and [RTN] because they are not on the

same level.

9) When measuring the voltage at small connectors, use the dedicate d tool. Handle the tool with ca re

because its business end is pointed.

10) When measuring the voltage, set the TRANSFER ASSY, toner cartridge and sheet feeder, close

the COVERs and power ON unless otherwise required .

11) Numerical values in the FIP are only for guideline. Approximate values are acceptable.

12) In each step of the FIP, parts removal and other procedures implicitly required for the ste p are

omitted.

13) In the FIP, "Replacement" means the replacement of the parts that are consider ed to be the cause

of the trouble. Replacement of those parts means the replacement of the assembly part (HIGH

ASSY) that contain them.

Epson AcuLaser C2900N

1 - 4

Confidential

Page 18

Chapter 1 Troubleshooting

14) In the FIP, the sheet feeder immediately below the printer main body is called "Tray 1", and the

cassette below it is called "Tray 2".

15) Some of the instructions in the FIP are branched off depending on the specifications. Follow the

applicable instruction.

16) For some optional components, you may have to refer to the manual of the relevant compo nent for

troubleshooting. Have the relevant manual at hand as needed.

Revision B

Epson AcuLaser C2900N

1 - 5

Confidential

Page 19

Chapter 1 Troubleshooting

1.5 Items To Be Confirmed Before Going To FIP Troubleshooting

Basic Printer Problems

Some printer problems can be easy to resolve. If a problem occurs with your printer, check each the following:

1) If a message is displayed on the LCD of operator panel, see “2.3 Status Code List”.

2) The printer power cable is plugged into the printer and a properly grounded electrical outlet.

3) The printer power is powered ON.

4) The electrical outlet is not turned off by any switch or breaker.

5) Other electrical equipment plugged into the outlet is working.

6) All options are properly installed.

7) If you have checked all of the above and still have a problem, turn off the printer, wait for 10 sec-

onds, and then turn on the printer. This often solves the problem.

8) If the printer does not start-up after downloading the ESS firmware, or does not operate normally,

execute the download of ESS firmware again by the download mode (Refer to “1.2 Firmware

version up procedure using the download mode” of Appendix_1.).

Display Problems

1) If the operator panel displays only diamonds or is blank, check and try the action below.

If the problem persists even after checking and executing the items below, execute "FIP- AC

Power" or "FIP DC Power".

a) Turn off the printer, wait for 10 seconds, and turn on the printer.

b) Self Test Message appears on the operator panel. When the test is completed, “Ready to

Print” is displayed.

2) If menu settings changed from the operator panel have no effect, check and try the actions

below.

Settings in the software program, the printer driver, or the printer utilities are overriding the settings made on the operator panel.

a) Change the menu settings from the printer driver, the printer utilities, or the software pro-

gram instead of the operator panel.

b) Disable the settings in the printer driver, the printer utilities, or the software program so you

can change settings on the operator panel.

Revision B

Printing Problems

1) If a job did not print correct or incorrect characters were printed, check and try the actions below.

a) Make sure “Ready to Print” appears on the operator panel before sending a job to print.

Press Menu to return to “Ready to Print”.

b) Make sure print media is loaded in the printer. Press Menu to return to “Ready to Print”.

c) Verify that you are using the correct printer driver.

d) Make sure you are using the correct Ethernet or USB cables and it securely connected at

the back of the printer.

e) Verify that the correct print media size is selected.

f) If using a print spooler, verify that the spooler has not stalled.

g) Check the printer interface from the “Configure” menu. Determine the host interface you are

using. Print a Panel Setting page to verify that the current interfaces settings are correct.

h) Output fonts will not print correctly using the PCL driver in its default mode. To correct this

problem, use PostScript driver when using the PCL driver.

Epson AcuLaser C2900N

1 - 6

Confidential

Page 20

Chapter 1 Troubleshooting

2) If secure print is not available or not printing, refer to the requirements below.

a) Minimum 256 MB is required.

b) RAM Disk must be enabled using the operation panel.

c) The number of secure print jobs your printer can store is dependent on the job size includ-

ing number of pages, graphics, color attributes, and the amount of memory installed. To

increase this number, add additional memory.

3) If print media misfeeds or multiple feeds occur, check and try the actions below.

a) Make sure the print media you are using meets the specifications for your printer. Refer to

Print Media Guidelines of this section.

b) Flex print media before loading it in any of the sources.

c) Make sure the print media is loaded correctly.

d) Make sure the width and length guides on the print media sources are adjusted correctly.

e) If the print media are overfilled in sources, reduce the amount of media.

f) Load the recommended print side correctly for the type of print media you are using.

g) Turn the print media over or around and try printing again to see if feeding improves.

h) Check the print media type loaded in the source, and refill only one type of print media, if

print media types are mixed.

i) Refill a new ream of print media, if some reams are mixed.

j) Remove the top and bottom sheets of a ream before loading the print media.

k) Do not reload print media until the print media source is empty.

4) If envelope misfeeds or multiple feeds occur, check and try the action below.

a) Remove the stack of envelops from the Single Sheet Inserter (SSI).

5) If page breaks in unexpected places, check and try the action below.

a) Check the “Job Time-out” in the Basic Settings menu and increase the value.

6) If a job prints from the wrong source or on the wrong print media, check and try the action below.

a) Check the “Paper Size” and “Paper Type” in the Tray Se ttings menu on the printer op erator

panel and in the printer driver.

7) If print media does not stack neatly in the output tray, check and try the action below.

a) Turn the print media stack over in the tray or multipurpose feeder.

Revision B

Print Media Guidelines

Print media refers to paper, labels, envelopes, and coated paper among others. Your printer provides

high-quality printing on a variety of print media. Selecting the appropriate print media for your printer

helps avoid printing troubles. This section describes selecting print media, caring for print media, and

loading the print media in the standard 250-sheet tray.

Paper

For the best print quality in color, use 75 g/m

quality in black and white, use 90 g/m

2

you perform trial print before purchasing large quantities of print media.

When loading paper, identify the recommended print side on the paper package, and load the paper

accordingly. See "Loading Print Media in the Standard 250-Sheet Tray and the Optional 2 50-Sheet

Feeder" and "Loading Print Media in the SSI" for detailed loading instructions.

Paper Characteristics

The following paper characteristics affect print quality and reliability. It is recommended that you follow

these guidelines when evaluating new paper stock.

Epson AcuLaser C2900N

2

(20 lb) xerographic, grain long paper. For the best print

(24 lb) xerographic, grain long paper. It is recommended that

1 - 7

Confidential

Page 21

Chapter 1 Troubleshooting

Weight

The tray automatically feeds paper weights from 60 g/m

The single sheet feeder automatically feeds paper weights from 60 g/m

2

bond) grain long. Paper lighter than 60 g/m

For best performance, use 75 g/m

2

(20 lb bond) grain long paper.

(16 lb) may not feed properly, and could cause paper jams.

2

to 216 g/m2 (16 lb to 80 lb bond) grain long.

2

to 216 g/m2 (16 lb to 80 lb

Curl

Curl is the tendency of print media to curve at its edges. Excessive curl can cause pape r feeding problems. Curl usually occurs after the paper passes through the printer, where it is exposed to high temperatures. Storing paper unwrapped, even in the paper tray, can contribute to paper curling prior to

printing and cause feeding problems regardless of humidity. When printing on curled paper, straighten

the paper and then insert it into the single sheet feeder.

Smoothness

The degree of paper smoothness directly affects the print quality. If the paper is too rough, the toner

does not fuse on to the paper properly, resulting in poor print quality. If the paper is too smooth, it can

cause paper feeding problems. Smoothness between 150 and 250 Sheffield points produces the best

print quality.

Moisture Content

The amount of moisture in the paper affects both the print quality and the ability of the printer to feed

the paper properly. Leave the paper in its original packaging until you are ready to use it. T his limits the

exposure of the paper to moisture changes that can degrade its performance.

Grain Direction

Grain refers to the alignment of the paper fibers in a sheet of paper. Grain is either grain long, running

the length of the paper, or grain short, running the width of the paper. For 60 g/m

36 lb bond) paper, grain long fibers are recommended. For paper heavier than 135 g/m

2

to 135 g/m2 (16 lb to

2

(36 lb bond),

grain short is preferred.

Fiber Content

Most high-quality xerographic paper is made from 100% chemically pulped wood. Paper containing

fibers such as cotton may lead to degraded paper handling.

Revision B

Recommended Paper

To ensure the best print quality and feed reliability, use 75 g/m

2

(20 lb) xerographic paper. Business

paper designed for general business use also provides acceptable pri nt quality. Only use paper able to

withstand high temperatures without discoloring, bleeding, or releasing hazardous emissions. The laser

printing process heats paper to high temperatures. Check with the manufacturer or vendor to dete rmine

whether the paper you have chosen is acceptable for laser printers.

It is recommended that you perform trial print before purchasing large quantities of print media. When

choosing any print media, you should consider the weight, fiber content, and color.

Unacceptable Paper

The following paper types are not recommended for use with the printer :

• Chemically treated paper used to make copies without carbon paper, also known as carbonless

paper, carbonless copy paper (CCP), or no carbon required (NCR) paper.

• Preprinted paper with chemicals that may contaminate the printer.

• Preprinted paper that can be affected by the temperature in the fuser unit.

• Preprinted paper that requires a registration (the precise print location on the page) greater than

±0.09 inches, such as optical character recognition (O CR) form s.

Epson AcuLaser C2900N

1 - 8

Confidential

Page 22

Chapter 1 Troubleshooting

In some cases, you can adjust registration with your software program to successfully print on these

forms.

• Coated paper (erasable bond), synthetic paper, and thermal paper.

• Rough-edged, rough or heavily textured surface paper, or curled paper.

• Recycled paper containing more than 25% post-consumer waste that does not meet DIN 19 309.

• Multiple-part forms or documents.

• Print quality may deteriorate (blank spaces or blotches may appear in the text) when printing on talc

or acid paper.

Selecting Paper

Proper paper selection helps prevent jams an d en su re s tro u ble-free printing.

To help avoid jams or poor print quality:

• Always use new, undam a ge d pa p er .

• Before loading the paper, identify the recommended print side of the paper.

This information is usually indicated on the paper package.

• Do not use paper that you have cut or trimmed.

• Do not mix print media sizes, weights, or types in the same source. This may result in a paper jam.

• Do not remove the tray while printing is in progress.

• Ensure that the paper is properly loaded in the tray.

• Flex the paper back and forth, and then fan them. Straighten the edges of the stack on a level sur-

face.

Revision B

Epson AcuLaser C2900N

1 - 9

Confidential

Page 23

Chapter 1 Troubleshooting

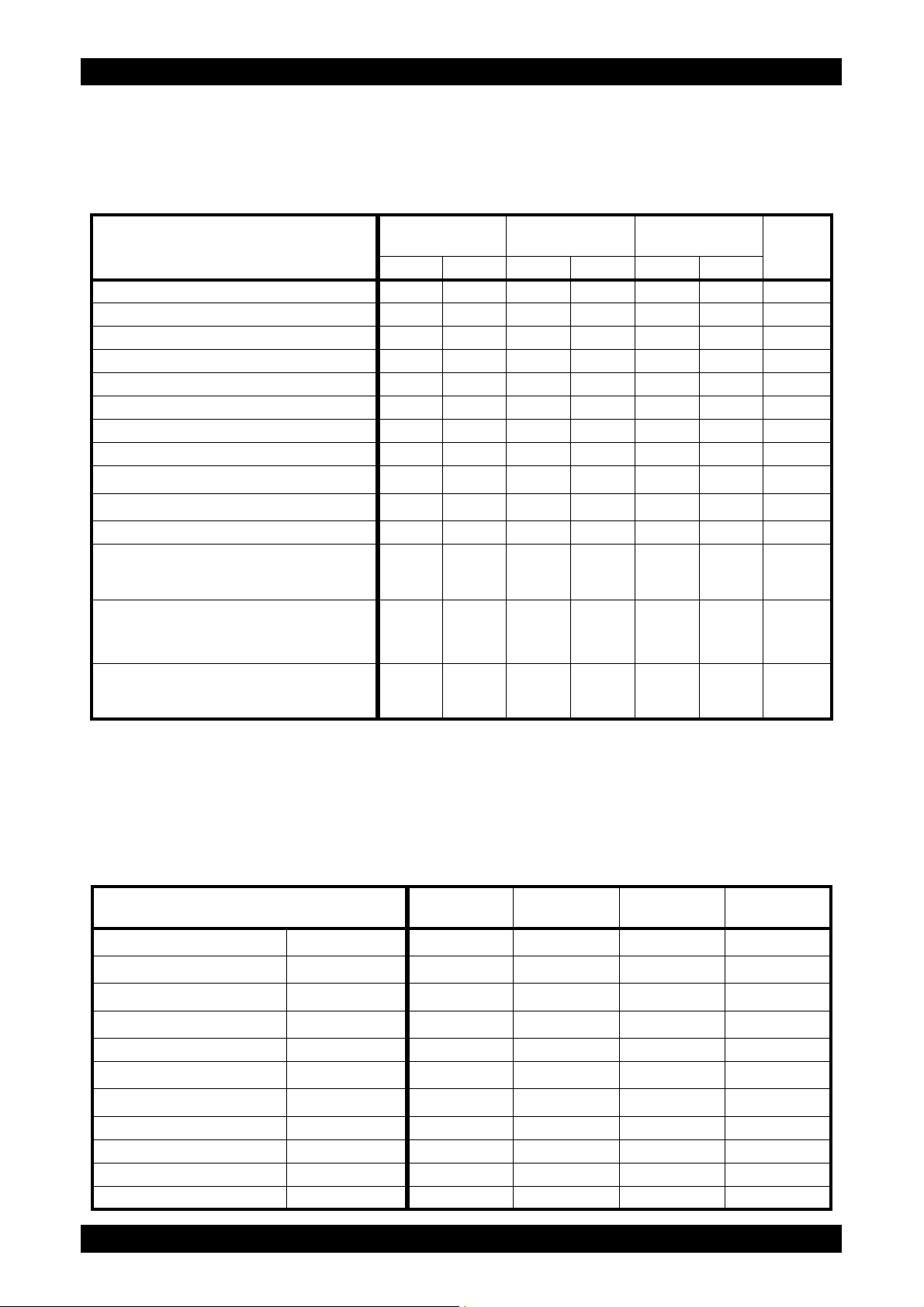

Identifying Print Media Sources and Specifications

The following tables provide information on stan d ar d an d op tio nal print me d i a so ur ces.

Supported Paper Sizes

Revision B

Paper size

Single Sheet

Inserter

Standard 250-

sheet tray

Optional 250-

sheet feeder

Duplexer

Side 1 Side 2 Side 1 Side 2 Side 1 Side 2

A4 (210 x 297 mm) YYYYYYY

B5 (182 x 257 mm) YYYYYYN

A5 (148 x 210 mm) YYYYYYN

Letter (8.5 x 11 inches) YYYYYYY

Folio (8.5 x 13 inches) YYYYYYY

Legal (8.5 x 14 inches) YYYYYYY

Executive (7.25 x 10.5 inches) YYYYYYN

Envelope #10 (4.125 x 9.5 inches) Y N Y N N N N

Monarch (3.875 x 7.5 inches)

DL (110 x 220 mm)

*3

Y

*3

Y

NYNNNN

NYNNNN

C5 (162 x 229 mm) Y N Y N N N N

Custom

Width: 76.2 to 215.9 mm (3 to 8.5 inches)

Length: 127 to 355.6 mm (5 to 14 inches)

Custom

Width: 76.2 to 215.9 mm (3 to 8.5 inches)

Length: 127 to 355.6 mm (5 to 14 inches)

Custom

Width: 148.0 to 215.9 mm (5.8 to 8.5 inches)

Length: 210.0 to 355.6 mm (8.3 to 14 inches)

*1

*2

YYNNNNN

NNYYNNN

NNNNYYN

*1: Maximum width 220 mm for envelope (DL LEF)

DL and Monarch can be supported by LEF with flap opened.

*2: Minimum length 98.4 mm for envelope (Monarch LEF)

*3: Monarch LEF and DL LEF are not available.

Supported Paper Types

Single Sheet

Inserter

2

2

2

2

YYYY

YYYY

YYYY

YYYY

Plain

Letterhead

Hole Punched

Colored

Paper type

60 to 90 g/m

60 to 105 g/m

60 to 105 g/m

60 to 105 g/m

Special --- Y Y N N

Lightweight Cardstock

Heavyweight Cardstock

106 to 163 g/m

164 to 216 g/m

2

2

YYNN

YYNN

Lightweight Glossy Card --- Y N N N

Heavyweight Glossy Card --- Y N N N

Labels --- Y Y N N

Envelopes --- Y Y N N

Epson AcuLaser C2900N

1 - 10

Standard 250-

sheet tray

Optional 250-

sheet feeder

Duplexer

Confidential

Page 24

Chapter 1 Troubleshooting

Paper Type Specifications

Paper type Weight Remarks

Plain

Plain Thick

Recycled

60 to 90 g/m

80/90 to 105 g/m

60 to 105 g/m

2

2

2

Labels --- Inkjet printer paper cannot be used.

Covers

Covers Thick

106 to 163 g/m

164 to 216 g/m

2

2

Envelope --- --Coated

Coated Thick

106 to 163 g/m

164 to 216 g/m

2

2

Letterhead --- --Preprinted

Prepunched

Colored

64 g/m

64 g/m

64 g/m

2

2

2

---

---

---

---

---

Inkjet printer paper cannot be used.

Inkjet printer paper cannot be used.

---

---

---

Revision B

Epson AcuLaser C2900N

1 - 11

Confidential

Page 25

Chapter 1 Troubleshooting

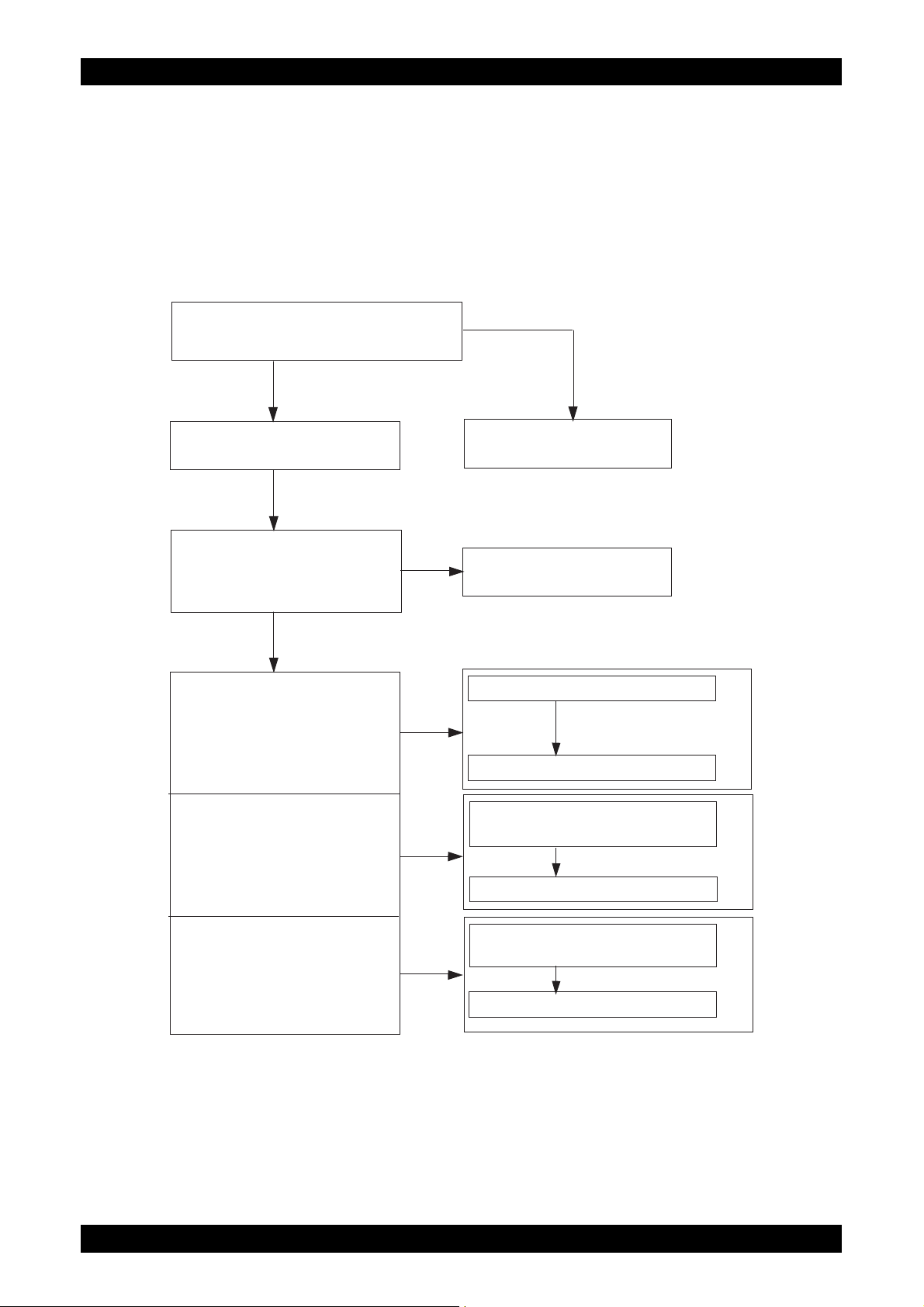

N

Y

Y

N

Ask the operator about trouble status.

Is operator’s operating method correct?

Turn off and turn on the Power.

Does error still occur when print

is done by the problem mode?

When status code or LCD

display is displayed:

When image quality trouble

is occurred:

When abnormal noise

is occurred:

Instruct how to operate

End of work

Refer to "2.3 Status Code List."

Refer to "3 Error Code FIP."

Refer to "4.1 Entry Chart for Image

Quality Troubleshooting."

Refer to "4.3 Image Quality FIP."

Refer to "5.1 Entry Chart for

Abnormal Noise Troubleshooting."

Refer to "5.2 Operation Mode Table."

2. FIP

2.1 FIP

The FIP is the first step for trouble diagnosis. The FIP isolates the presence of various troubles

including error codes, and guides the troubleshooting procedure.

2.2 Flow of FIP

Revision B

Epson AcuLaser C2900N

1 - 12

Confidential

Page 26

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

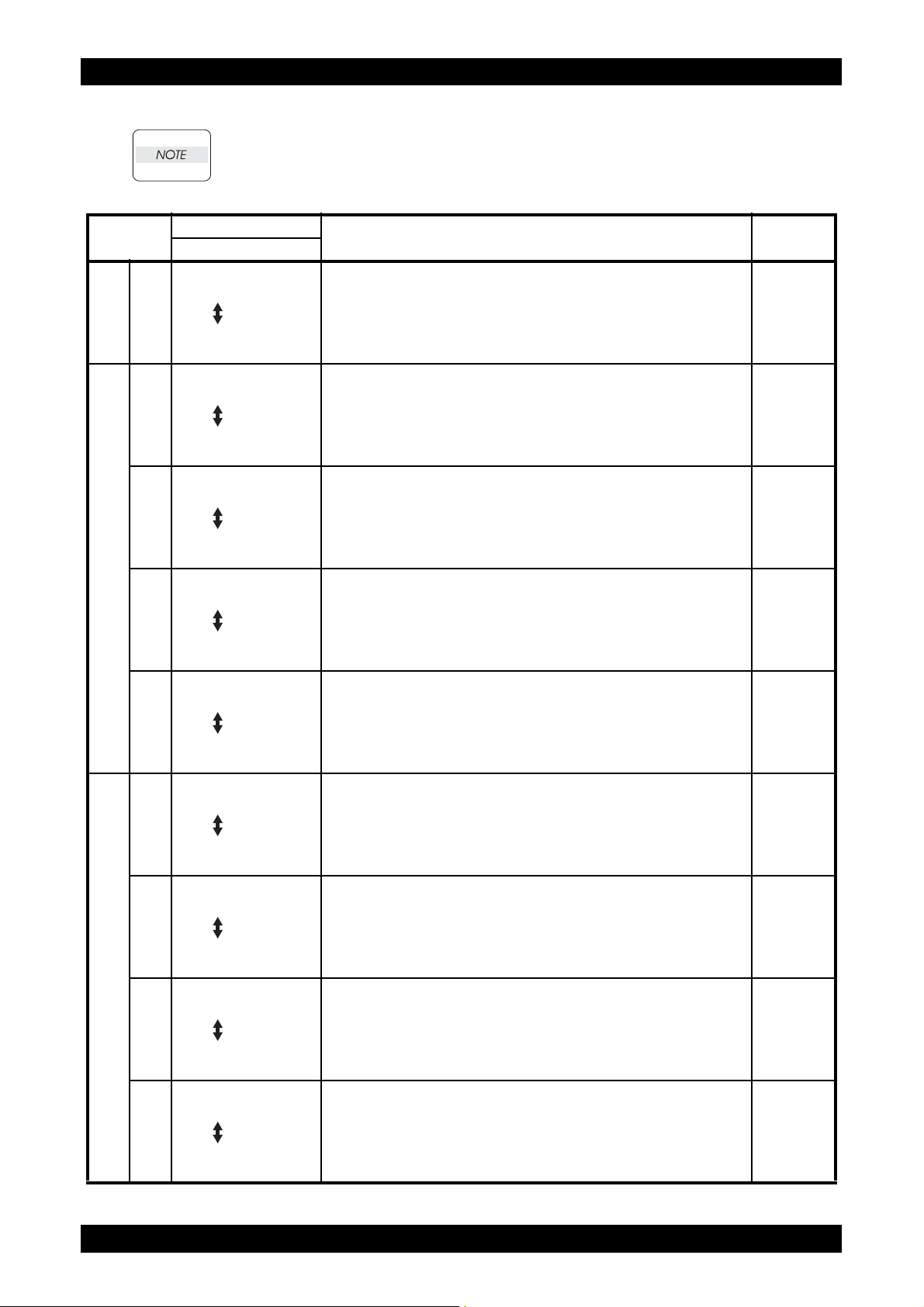

2.3 Status Code List

Errors that occur when optional components are installed are gray-shaded.

Revision B

Status

Code

004 310

317

351

010

397

421

500

501

016

502

520

Error Message

LCD

Reseat Feeder

Restart Printer

Error 004-310

Restart Printer

Insert Fuser

010-317

Insert Fuser

Restart Printer

Replace Fuser

010-351

Replace Fuser

Restart Printer

Fuser Error

Restart Printer

Error 010-397

Restart Printer

Ready to Print

Fuser Life

Ready to Print

Replace Soon

Erase Flash Err

Restart Printer

Error 016-500

Restart Printer

Write Flash Err

Restart Printer

Error 016-501

Restart Printer

Verify Flash Err

Restart Printer

Error 016-502

Restart Printer

Certificate Fail

Contact Admin.

Error 016-520

Restart Printer

Status Contents

<IOT Option Feeder I/F Failure>

The Option Feeder communication failure is detected.

<IOT Fuser Unit Detached>

Fuser unit detached is detected.

<IOT Fuser Unit Life Over>

The value of fuser unit counter has reached the replacement

time.

<IOT Fuser Unit Failure>

The operation error of fuser unit (Temperature anomaly error

etc.) is detected.

<IOT Fuser Unit Near Life>

The fuser unit is approaching the replacement time.

<Download Delete Error>

Flash memory erase error occurred.

<Download Write Error>

Flash memory write error occurred.

<Download V erify Error>

Flash memory verify error occurre d .

<Ipsec Certificate Error>

Ipsec Certificate Error.

FIP to be

referred

FIP-1.1

FIP-1.2

FIP-1.3

FIP-1.4

FIP-1.5

FIP-1.6

FIP-1.6

FIP-1.6

FIP-1.7

Epson AcuLaser C2900N

1 - 13

Confidential

Page 27

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

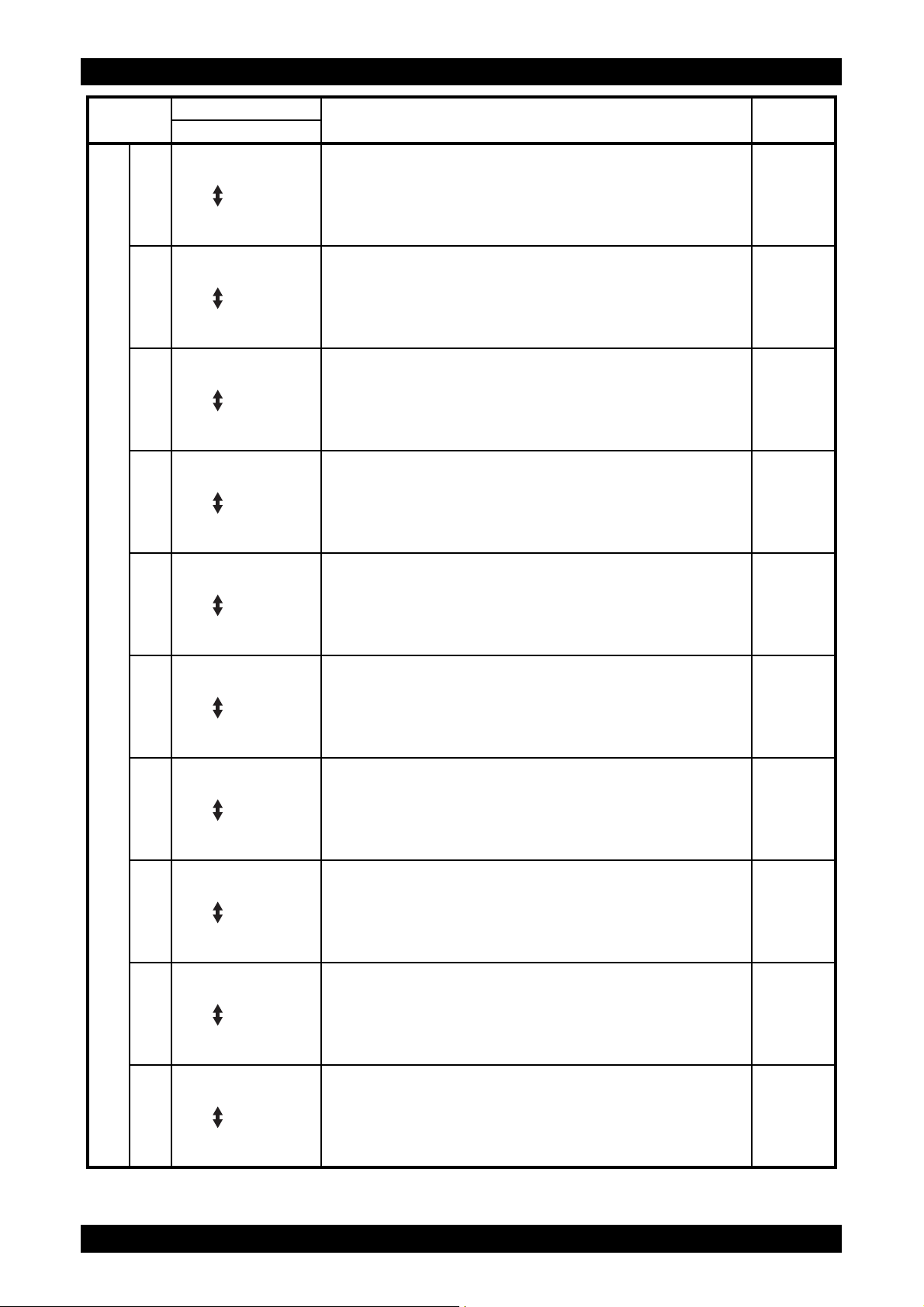

Revision B

Status

Code

016

Error Message

Out of Memory

Press Ok Button

718

Error 016-718

Press Ok Button

PDL Error

Press Ok Button

720

Error 016-720

Press Ok Button

Format Error

Press Ok Button

737

Error 016-737

Press Ok Button

Protection Error

Press Ok Button

741

Error 016-741

Press Ok Button

Invalid ID

Press Ok Button

742

Error 016-742

Press Ok Button

Range Chk Error

Press Ok Button

743

Error 016-743

Press Ok Button

Check Sum Error

Press Ok Button

744

Error 016-744

Press Ok Button

Header Error

Press Ok Button

745

Error 016-745

Press Ok Button

Wrong Password

Press Ok Button

753

Error 016-753

Press Ok Button

PDF Print

Disabled

755

Error 016-755

Press Ok Button

LCD

Status Contents

<Memory Over flow>

The current printing job process cannot be continued because

the memory capacity is exceeded.

<PDL Error>

The print data cannot be processed by PDL.

<Download Format Error>

Download file format is invalid.

<Download Protect Error>

Performed FW download although FW update is prohibited by

panel settings.

<Download ID Error>

Download file ID is invalid.

<Download Range Error>

At download, write-in destination address is invalid. Range

check error.

<Download Check Sum Error>

Download file checksum is invalid.

<Download header Error>

Download file header is invalid.

<PDF password error>

PDF password error.

<PDF print disabled error>

PDF print is not allowed.

FIP to be

referred

FIP-1.8

FIP-1.9

FIP-1.10

FIP-1.10

FIP-1.10

FIP-1.10

FIP-1.10

FIP-1.10

FIP-1.11

FIP-1.11

Epson AcuLaser C2900N

1 - 14

Confidential

Page 28

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

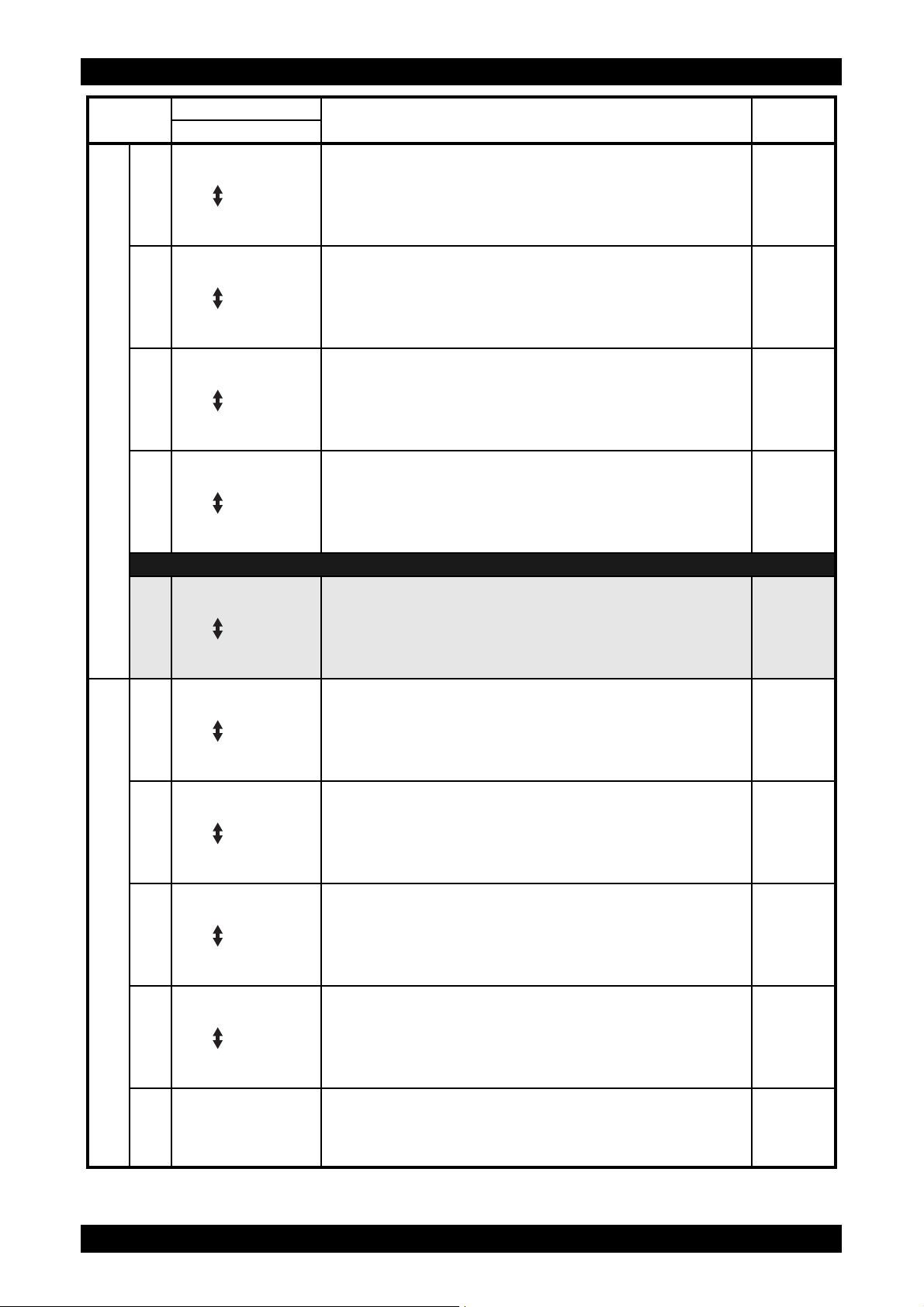

Revision B

Status

Code

016

024

Error Message

Invalid User

Press Ok Button

757

Error 016-757

Press Ok Button

Disabled Func

Press Ok Button

758

Error 016-758

Press Ok Button

Limit Exceeded

Press Ok Button

759

Error 016-759

Press Ok Button

Invalid Job

Press Ok Button

799

Error 016-799

Press Ok Button

Disk Full

Press Ok Button

982

Error 016-982

Press Ok Button

MCU Firmware Err

Restart Printer

340

Error 024-340

Restart Printer

Download Mode

Send FW Data

360

Error 024-360

Send FW Data

PAGEC Time Error

Restart Printer

362

Error 024-362

Restart Printer

MCU Comm. Error

Restart Printer

371

Error 024-371

Restart Printer

Press Ok Button

985

to continue

LCD

<Auditron - Invalid User>

An error occurred because the user's account settings did not

match those of the Administrator.

<Auditron - Disabled Function>

An error occurred because a user authorized only for B&W

print attempted to execute color printing.

<Auditron - Reached Limit>

An attempt was made to print more copies than the print count

limit.

<Job Environment Violation>

Detects violation data for the print condition. The print data

specifies paper type/ size not available for the printer.

This code is given when the Optional Memory Module is installed.

<Disk Full>

The current printing job process cannot be continued because

the RAM disk is full.

<IOT Firmware Error>

MCU firmware error occurs.

<MCU DownLoad Error>

Download failure of MCU firmware.

<IOT Start Image Marking Timeout>

"Start Image Making" has not been issued within the time

allowed.

<MCU-ESS Communication Fail>

Communication fail between MCU and ESS.

<Waiting for "Continue" key to be pressed afte r reloading

paper to the SSI>

Printer starts printing automatically after a certain period of

time even if the key is not pressed.

Status Contents

FIP to be

referred

FIP-1.12

FIP-1.13

FIP-1.14

FIP-1.15

FIP-1.16

FIP-1.17

FIP-1.18

FIP-1.19

FIP-1.20

FIP-1.21

Epson AcuLaser C2900N

1 - 15

Confidential

Page 29

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

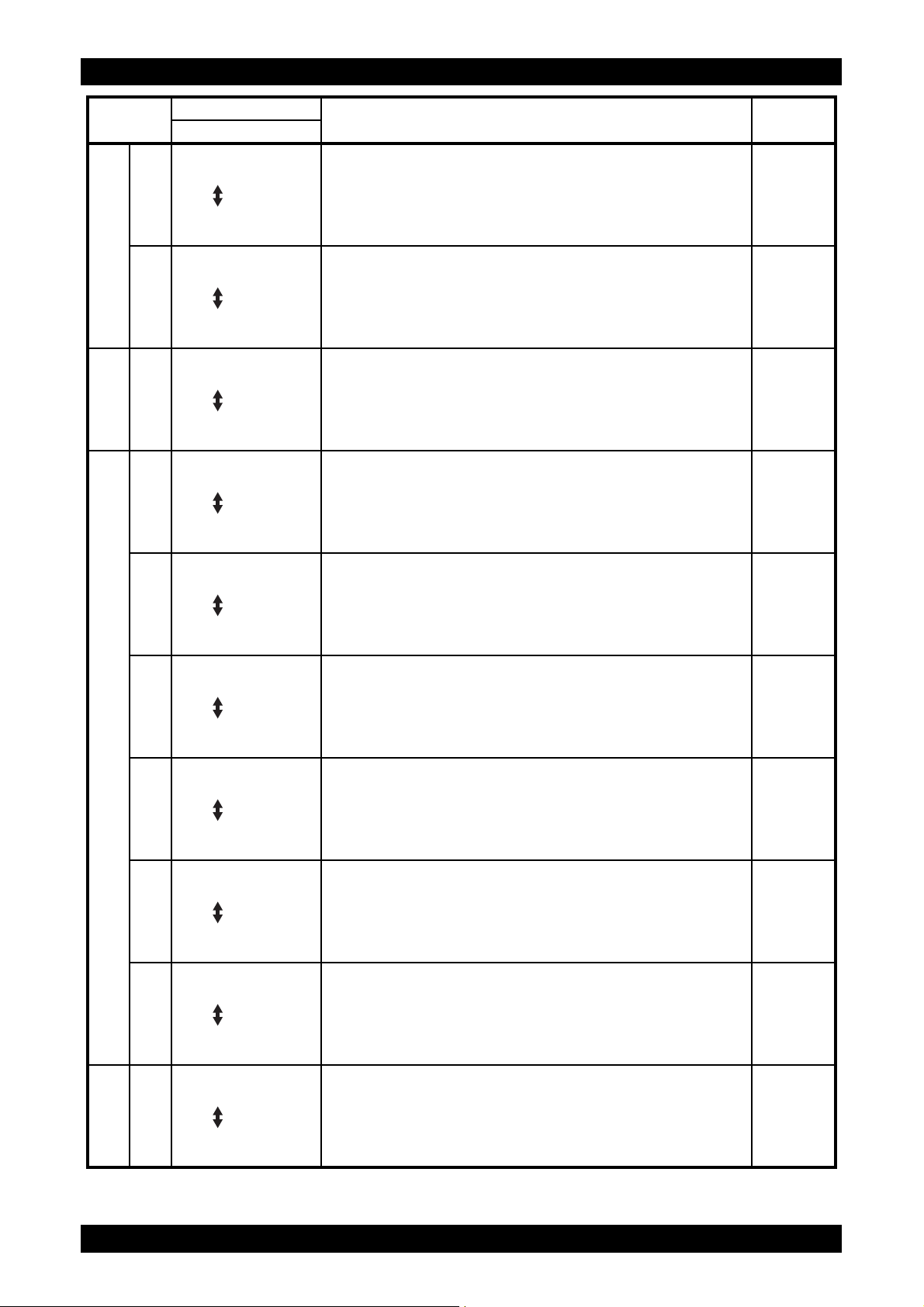

Revision B

Status

Code

446

027

452

041 340

313

325

326

042

372

373

700

061 370

Error Message

LCD

Ready to Print

IPv6 Duplicate

Change IPaddress

Ready to Print

IPv4 Duplicate

Change IPaddress

MCU NVRAM Error

Restart Printer

Error 041-340

Restart Printer

Fan Motor Error

Restart Printer

Error 042-313

Restart Printer

Motor Error

Restart Printer

Error 042-325

Restart Printer

Motor Error

Restart Printer

Error 042-326

Restart Printer

K Mode Sol Error

Restart Printer

Error 042-372

Restart Printer

K Mode Sol Error

Restart Printer

Error 042-373

Restart Printer

Over Heat

Please Wait...

Error 042-700

Please Wait...

Laser Error

Restart Printer

Error 061-370

Restart Printer

Status Contents

<IPv6 duplicate>

Duplicate IPv6 addresses detected upon startup.

<IPv4 duplicate>

Duplicate IPv4 addresses detected upon startup.

<IOT NVRAM Error>

The operation error of NVM (read/write check error etc.) is

detected.

<IOT Fan Motor Failure>

MCU detects an error upon receiving error signal from the

Fan.

<IOT Main Motor Failure>

Main Motor failure is detected.

<IOT Sub Motor Failure>

Sub Motor failure is detected.

<IOT K Mode Solenoid Error 1>

The error is generated when K Mode Solenoid (Color Mode

Switching Solenoid) does not operate in specified time.

<IOT K Mode Solenoid Error 2>

The error is generated when the gear which ope rates by K

Mode Solenoid (Color Mode Switching Solenoid) rotates two

times.

<IOT Over Heat Stop>

The temp. Sensor sensed high temperature.

<IOT ROS Failure>

The operation error of ROS (rotational error etc.) is detected.

FIP to be

referred

FIP-1.22

FIP-1.22

FIP-1.23

FIP-1.24

FIP-1.25

FIP-1.26

FIP-1.27

FIP-1.27

FIP-1.28

FIP-1.29

Epson AcuLaser C2900N

1 - 16

Confidential

Page 30

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Revision B

Status

Code

071 100

100

101

072

215

216

900

101

075

102

923

100

077

101

Error Message

LCD

Jam at Tray 1

Check Tray 1

Open Front Cover

This code is given when the Option 250 Sheet Feeder is installed.

Jam at Tray 2

Check Tray 2

Open Front Cover

Jam at Tray 2

Open Tray 2

Open Front Cover

This code is given when the Optional 250-Sheet Feeder is installed.

250 Feeder Error

Restart Printer

Error 072-215

Restart Printer

Motor Error

Restart Printer

Error 072-216

Restart Printer

Jam at

Tray 1 or 2

Open Tray 1 or 2

Open Front Cover

Jam at Front

Cover

Open Front Cover

and Remove Paper

Chk Manual Feed

Remove Paper

Open and close

Front Cover

Reseat paper

of Manual Feed

Jam at Front

Cover

Open Front Cover

and Remove Paper

Jam at Front

Cover

Open Front Cover

and Remove Paper

Status Contents

<IOT Tray1 Misfeed JAM>

The Regi Sensor is not turned ON within the specified time

after feeding a paper from Tray 1.

<IOT Tray2 Misfeed JAM>

The Paper Path Sensor of Tray 2 is not turned ON within the

specified time after feeding a paper from Tray 2.

<IOT Feeder 2 JAM>

A jam has been detected between the Regi Sensor and the

Paper Sensor of Tray 2.

<IOT Feeder Configuration Failure>

Option Sheet Feeder Configuration error is detected.

<Option Feeder Motor Failure>

Option Feeder Motor failure is detected.

<IOT Remain Option Feeder JAM>

The paper remains at the Paper Path Sensor of Tray 2.

<IOT SSI Insert JAM>

SSI No Paper Sensor detect when a paper is inserted from

SSI.

<IOT SSI Paper Pullout JAM>

Though it tried to feed a paper from SSI, the paper was not

loaded or it was pulled out forcibly from SSI.

<Waiting for reseat paper of SSI>

Wait for the paper on SSI to be reseated.

<IOT Regi On early JAM>

The paper remains at the paper transfer path between the

Tray 1 and the Regi Sensor.

<IOT Regi OFF Jam>

The paper does not pass through the Regi Sensor within the

specified time.

FIP to be

referred

FIP-1.30

FIP-1.31

FIP-1.32

FIP-1.33

FIP-1.34

FIP-1.35

FIP-1.36

FIP-1.36

FIP-1.36

FIP-1.37

FIP-1.38

Epson AcuLaser C2900N

1 - 17

Confidential

Page 31

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Revision B

Status

Code

077

Error Message

Jam at Exit

102

Open Front Cover

and Remove Paper

Jam at Exit

103

Open Front Cover

and Remove Paper

Jam at Exit

104

Open Front Cover

and Remove Paper

Jam at Exit

105

Open Front Cover

and Remove Paper

Jam at Front

Cover

106

Open Front Cover

and Remove Paper

Jam at Duplexer

107

Open Front Cover

Lift Duplexer

Jam at Duplexer

108

Open Front Cover

Lift Duplexer

Duplexer Error

Restart Printer

215

Error 077-215

Restart Printer

Front Cover Open

300

Close FrontCover

Side Door Open

301

Close Side Door

Jam at Exit

900

Open Front Cover

and Remove Paper

Jam at Front

Cover

901

Open Front Cover

and Remove Paper

Jam at Duplexer

907

Open Front Cover

Lift Duplexer

LCD

Status Contents

<IOT Exit On JAM>

The paper does not reach the Exit Sensor within the specifie d

time.

<IOT Exit On early JAM>

The paper remains at the paper transfer p ath between the Exit

Sensor and the Regi Sensor.

<IOT Exit Off JAM>

The paper does not pass through the Exit Sensor within the

specified time.

<IOT Exit Off early JAM>

The paper passed through the Exit Sensor earlier than the

specified time.

<IOT Stop Reservation JAM>

Detect jam when stopped before fuser unit in forced stop

mode.

<IOT Duplex Misfeed JAM>

In the duplex printing mode, the lead edge do es no t re ach the

Regi Sensor when the sheet changes the direction in the

Duplexer after the standby.

<IOT Duplex JAM>

In the duplex printing mode, the lead edge do es no t re ach the

SSI No Paper Sensor when the sheet changes the direction in

the Duplexer after the standby.

<IOT Duplexer Failure>

The error is detected by Duplexer communication check.

<IOT Cover Front Open>

The Front Cover is open.

<IOT Side Cover Open>

The Toner Access Cover is open.

<IOT Exit JAM>

The paper remains at the Exit Sensor.

<IOT Remain Registration JAM>

The paper remains at the Regi Sensor.

<IOT Remain Duplex JAM>

The paper remains at the Duplex area.

FIP to be

referred

FIP-1.39

FIP-1.39

FIP-1.40

FIP-1.40

FIP-1.39

FIP-1.41

FIP-1.41

FIP-1.42

FIP-1.43

FIP-1.44

FIP-1.45

FIP-1.46

FIP-1.47

Epson AcuLaser C2900N

1 - 18

Confidential

Page 32

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Revision B

Status

Code

402

912

916

935

091

941

942

943

944

972

310

410

092

661

910

093 423

Error Message

LCD

Ready to Print

ImagingUnit Life

Ready to Print

Replace Soon

Check Unit

Imaging Unit

I U CRUM Error

Restart Printer

Error 091-916

Restart Printer

Replace

Imaging Unit

Waste Full

Yellow Cartridge

Waste Full

MagentaCartridge

Waste Full

Cyan Cartridge

Waste Full

Black Cartridge

Insert

Imaging Unit

CTD Sensor Error

Restart Printer

Error 092-310

Restart Printer

Ready to Print

CTD Sensor

Env Sensor Error

Restart Printer

Error 092-661

Restart Printer

Check Unit

CTD Sensor

Ready to Print

Yellow Low

Ready to Print

Replace Soon

Status Contents

<IOT PHD Life Pre Warning>

The drum cartridge is approaching the replacement time.

<PHD Tape Staying>

Detect the tape staying on the drum cartridge.

<IOT PHD CRUM ID Error>

An unsupported drum cartridge is detected.

<IOT PHD Life Over>

The drum cartridge has reached the replacement time.

<IOT CRU Waste (Y) Full>

Waste Toner (Y) Counter value has reached replacement

time.

<IOT CRU Waste (M) Full>

Waste Toner (M) Counter value has reached replacement

time.

<IOT CRU Waste (C) Full>

Waste Toner (C) Counter value has reached replacement

time.

<IOT CRU Waste (K) Full>

Waste Toner (K) Counter value has reached replacement

time.

<IOT PHD Detached>

The drum cartridge is not installed in the printer.

<IOT CTD(ACD) Sensor Error>

CTD(ACD) sensor error (analog to digital conversion etc.) is

detected.

<CTD (ADC) Sensor Dustiness Warning>

The CTD (ADC) Sensor is approaching the Cleaning time.

<IOT Environment Sensor Error>

The Temperature sensor detected the temperature anomaly.

<IOT CTD (ADC) Sensor Dustiness>

The CTD (ADC) Sensor has reached the Cleaning time.

<IOT Toner Cartridge (Y) Near Life>

The Toner Cartridge (Y) is approaching the replacement time.

When all the toner cartridges are simultaneously approaching

the replacement time, a warning is indicated on the LCD panel

in the following order: 1)Black → 2)Cyan → 3)Magenta →

4)Yellow

FIP to be

referred

FIP-1.48

FIP-1.49

FIP-1.50

FIP-1.51

FIP-1.52

FIP-1.52

FIP-1.52

FIP-1.52

FIP-1.53

FIP-1.54

FIP-1.55

FIP-1.56

FIP-1.55

FIP-1.57

Epson AcuLaser C2900N

1 - 19

Confidential

Page 33

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Revision B

Status

Code

424

425

426

919

920

921

922

093

925

926 Invalid Black

930

931

932

Error Message

LCD

Ready to Print

Magenta Low

Ready to Print

Replace Soon

Ready to Print

Cyan Low

Ready to Print

Replace Soon

Ready to Print

Black Low

Ready to Print

Replace Soon

Low Density

Yellow Cartridge

Low Density

MagentaCartridge

Low Density

Cyan Cartridge

Low Density

Black Cartridge

Blk - CRUM Error

Restart Printer

Error 093-925

Restart Printer

Replace

Yellow Cartridge

Replace

MagentaCartridge

Replace

Cyan Cartridge

Status Contents

<IOT Toner Cartridge (M) Near Life>

The Toner Cartridge (M) is approaching the replacement time.

When all the toner cartridges are simultaneously approaching

the replacement time, a warning is indicated on the LCD panel

in the following order: 1)Black → 2)Cyan → 3)Magenta →

4)Yellow

<IOT Toner Cartridge (C) Near Life>

The Toner Cartridge (C) is approaching the replacement time.

When all the toner cartridges are simultaneously approaching

the replacement time, a warning is indicated on the LCD panel

in the following order: 1)Black → 2)Cyan → 3)Magenta →

4)Yellow

<IOT Toner Cartridge (K) Near Life>

The Toner Cartridge (K) is approaching the replacement time.

When all the toner cartridges are simultaneously approaching

the replacement time, a warning is indicated on the LCD panel

in the following order: 1)Black → 2)Cyan → 3)Magenta →

4)Yellow

<IOT Y Toner Low Density>

Detects low density of yellow.

<IOT M Toner Low Density>

Detects low density of magenta.

<IOT C Toner Low Density>

Detects low density of cyan.

<IOT K Toner Low Density>

Detects low density of black.

<IOT Black Toner CRUM Comm Fail>

The Black Toner Cartridge CRUM communication failure is

detected.

<IOT (K) CRUM ID Error>

An unsupported Toner Cartridge (K) is detected.

<IOT Toner Cartridge (Y) Life Over>

The Toner Cartridge (Y) has reached the replacement time.

When all the toner cartridges have simultaneously reached

the replacement time, a warning is indicated on the LCD panel

in the following order: 1)Black → 2)Cyan → 3)Magenta →

4)Yellow

<IOT Toner Cartridge (M) Life Over>

The Toner Cartridge (M) has reached the replacement time.

When all the toner cartridges have simultaneously reached

the replacement time, a warning is indicated on the LCD panel

in the following order: 1)Black → 2)Cyan → 3)Magenta →

4)Yellow

<IOT Toner Cartridge (C) Life Over>

The Toner Cartridge (C) has reached the replacement time.

When all the toner cartridges have simultaneously reached

the replacement time, a warning is indicated on the LCD panel

in the following order: 1)Black → 2)Cyan → 3)Magenta →

4)Yellow

FIP to be

referred

FIP-1.57

FIP-1.57

FIP-1.57

FIP-1.58

FIP-1.58

FIP-1.58

FIP-1.58

FIP-1.59

FIP-1.60

FIP-1.61

FIP-1.61

FIP-1.61

Epson AcuLaser C2900N

1 - 20

Confidential

Page 34

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Revision B

Status

Code

Replace

933

Black Cartridge

Y - CRUM Error

Restart Printer

950

Error 093-950

Restart Printer

M - CRUM Error

Restart Printer

951

Error 093-951

Restart Printer

C - CRUM Error

Restart Printer

952

Error 093-952

Restart Printer

960 Invalid Yellow

093

961 Invalid Magenta

962 Invalid Cyan

Insert

970

Yellow Cartridge

Insert

971

MagentaCartridge

Insert

972

Cyan Cartridge

Insert

973

Black Cartridge

Ready to Print

TransferUnitLife

094 422

Ready to Print

Replace Soon

Error Message

LCD

Status Contents

<IOT Toner Cartridge (K) Life Over>

The Toner Cartridge (K) has reached the replacement time.

When all the toner cartridges have simultaneously reached

the replacement time, a warning is indicated on the LCD panel

in the following order: 1)Black → 2)Cyan → 3)Magenta →

4)Yellow

<IOT Yellow Toner CRUM Comm Fail>

The Yellow Toner Cartridge CRUM communication failure is

detected.

<IOT Magenta Toner CRUM Comm Fail>

The Magenta Toner Cartridge CRUM communication failure is

detected.

<IOT Cyan Toner CRUM Comm Fail>

The Cyan Toner Cartridge CRUM communication failure is

detected.

<IOT (Y) CRUM ID Error>

An unsupported Toner Cartridge (Y) is detected.

<IOT (M) CRUM ID Error>

An unsupported Toner Cartridge (M) is detected.

<IOT (C) CRUM ID Error>

An unsupported Toner Cartridge (C) is detected.

<IOT Toner Cartridge (Y) Detached>

The Toner Cartridge (Y) is not installed in the printer. If no

toner cartridge has been installed in the printer, a warning is

indicated on the LCD panel in the following order: 1)Black →

2)Cyan → 3)Magenta → 4)Yellow

<IOT Toner Cartridge (M) Detached>

The Toner Cartridge (M) is not installed in the printer. If no

toner cartridge has been installed in the printer, a warning is

indicated on the LCD panel in the following order: 1)Black →

2)Cyan → 3)Magenta → 4)Yellow

<IOT Toner Cartridge (C) Detached>

The Toner Cartridge (C) is not installed in the printer. If no

toner cartridge has been installed in the printer, a warning is

indicated on the LCD panel in the following order: 1)Black →

2)Cyan → 3)Magenta → 4)Yellow

<IOT Toner Cartridge (K) Detached>

The Toner Cartridge (K) is not installed in the printer. If no

toner cartridge has been installed in the printer, a warning is

indicated on the LCD panel in the following order: 1)Black →

2)Cyan → 3)Magenta → 4)Yellow

<IOT Belt Unit Near Life>

The Belt Unit has reached the replacement time.

FIP to be

referred

FIP-1.61

FIP-1.59

FIP-1.59

FIP-1.59

FIP-1.60

FIP-1.60

FIP-1.60

FIP-1.62

FIP-1.62

FIP-1.62

FIP-1.62

FIP-1.63

Epson AcuLaser C2900N

1 - 21

Confidential

Page 35

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Revision B

Status

Code

094 911

315

316

317

320

116

323

324

326

327

328

Error Message

LCD

Replace

Transfer Unit

RAM Error

Restart Printer

Error 116-315

Restart Printer

This code is given when the Optional Memory Module is installed.

RAM Error

Restart Printer

Error 116-316

Restart Printer

Controller Error

Restart Printer

Error 116-317

Restart Printer

This code is given when the Optional Memory Module is installed.

RAM Error

Restart Printer

Error 116-320

Restart Printer

NV RAM Error

Restart Printer

Error 116-323

Restart Printer

Controller Error

Restart Printer

Error 116-324

Restart Printer

NV RAM Error

Restart Printer

Error 116-326

Restart Printer

Controller Error

Restart Printer

Error 116-327

Restart Printer

Controller Error

Restart Printer

Error 116-328

Restart Printer

Status Contents

<IOT Belt Unit Life Over>

The Belt Unit has reached the replacement time.

<ESS On Board RAM R/W Check Fail>

An error occurred during the onboard RAM read/write che ck at

the time of initialization.

<ESS DIMM Slot RAM R/W Check Fail>

Unsupported additional memory module is detected in the

memory slot.

<ESS ROM Check (Main) Fail>

Checksum error occurred in the main program ROM.

<ESS DIMM Slot RAM Error>

Additional memory module is not completely inserted in the

slot.

<ESS NVRAM 1 R/W Check Fail>

An error occurred during the master NVRAM 1 read/write

check at the time of initialization.

<ESS Illegal Exception>

The Exception error occurred.

<ESS NVRAM 2 R/W Check Fail>

An error occurred during the slave NVRAM 2 read /write check

at the time of initialization.

(Reserved)

<ESS Instruction Cache Error>

The CPU instruction cache error occurred.

<ESS Data Cache Error>

The CPU cache error occurred.

FIP to be

referred

FIP-1.64

FIP-1.6

FIP-1.65

FIP-1.6

FIP-1.65

FIP-1.6

FIP-1.6

FIP-1.6

FIP-1.6

FIP-1.6

Epson AcuLaser C2900N

1 - 22

Confidential

Page 36

Chapter 1 Troubleshooting

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Flip

Revision B

Status

Code

116

ASIC Error

Restart Printer

343

Error 116-343

Restart Printer

Network Error

Restart Printer

350

Error 116-350

Restart Printer

Network Error

Restart Printer

355

Error 116-355

Restart Printer

PCI Error

Restart Printer

361

Error 116-361

Restart Printer

PCI Error

Restart Printer

362

Error 116-362

Restart Printer

PCI Error

Restart Printer

363

Error 116-363

Restart Printer

PCI Error

Restart Printer

366

Error 116-366

Restart Printer

PCI Error

Restart Printer

368

Error 116-368

Restart Printer

PCI Error

Restart Printer

369

Error 116-369

Restart Printer

NV RAM Error

Restart Printer

390

Error 116-390

Restart Printer

Error Message

LCD

Status Contents

<ESS ASIC Fail>

The ASIC error occurred.

<ESS Network Communication Fail>

A communication error occurred between the On Board

Network and ESS firmware.

<On Board Network Fatal Error>

A fatal error occurred the on board network communica tion.

<PCI Bus#0 Error Detected>

Connection error occurred between the PCI BUS port and the

port of peripheral devices.

<PCI Bus#0 Host Bridge Controller Error>

Connection error occurred between the PCI BUS port and the

port of peripheral devices.

<PCI Bus#1 Host Bridge Controller Error>

Connection error occurred between the PCI BUS port and the

port of peripheral devices.

<PCI Bus#1 Error Detected>

Connection error occurred between the PCI BUS port and the

port of peripheral devices.

<PCI Error Messages received from Bus#0-Device#1>

Connection error occurred between the PCI BUS port and the

port of peripheral devices.

<PCI Error Messages received from Bus#0-Device#0>

Connection error occurred between the PCI BUS port and the

port of peripheral devices.

<ESS NVRAM 1 SIZE And ID Check Fail>

Upon turning the power ON, an error occurred during checks

on consistency of the NVRAM size between the systemrequired one and actual one and on consistency of the

recorded IDs.

FIP to be

referred

FIP-1.6

FIP-1.6

FIP-1.66

FIP-1.67

FIP-1.67

FIP-1.67

FIP-1.67

FIP-1.67

FIP-1.67

FIP-1.6

Epson AcuLaser C2900N

1 - 23

Confidential

Page 37

Chapter 1 Troubleshooting

Flip

Revision B

Status

Code

116

721

193 700

Error Message

LCD

This code is given when the Optional Memory Module is installed.

Collate Full

Press Ok Button

Error 116-721

Press Ok Button

Ready to Print

Non-GenuineToner

Status Contents

<Collate Full>

Unable to collate due to insufficient memory.

<Custom Toner Mode>

The printer is in custom toner mode.

FIP to be

referred

FIP-1.68

FIP-1.69

Epson AcuLaser C2900N

1 - 24

Confidential

Page 38

Chapter 1 Troubleshooting

3. Error Code FIP

FIP-1.1 004-310: IOT Option Feeder I/F Failure

Revision B

Step Check

Possible causative parts:

HARN ASSY OPTION (PL3.1.20)

PWBA MCU (PL8.2.13)

FEEDER ASSY OPT (PL12.1.3)

HARN ASSY TRAY (PL12.3.23)

Checking the Optional Feeder for installation.

1

Is the Optional Feeder installed correctly?

2 Does the error still occur when printing? Go to step 3. End of work.

Checking the connectors for connection.

Check the connections between the PWBA FEED H and

3

PWBA MCU.

Are P/J27, P/J273, and P/J419 connected surely?

4 Does the error still occur when printing? Go to step 5. End of work.

Checking the HARN ASSY TRAY for continuity.

Disconnect P/J419 from the PWBA FEED H.

5

Disconnect P/J273 from the HARN ASSY OPTION.

Is each cable of P/J419 <=> P/J273 continuous?

Checking the HARN ASSY OPTION for continuity.

Disconnect P/J27 from the PWBA MCU.

6

Disconnect P/J273 from the HARN ASSY TRAY.

Is each cable of P/J27 <=> P/J273 continuous?

Checking after replacing the FEEDER ASSY OPT.

7

Replace the FEEDER ASSY OPT. (Refer to RRP10.1.)

Does the error still occur when the power is turned ON?

Go to step 3.

Go to step 5.

Go to step 6.

Go to step 7.

Replace the

PWBA MCU.

(Refer to RRP8.9.)

Yes No

Remedy

Reseat the

Optional Feeder ,

then go to step 2.

Reconnect the

connector(s)

P/J27, P/J273

and/or P/J419

surely, then go to

step 4.

Replace the

HARN ASSY

TRAY.

Replace the

HARN ASSY

OPTION.

End of work.

Epson AcuLaser C2900N

1 - 25

Confidential

Page 39

Chapter 1 Troubleshooting

FIP-1.2 010-317: IOT Fuser Unit Detached

Revision B

Step Check

Possible causative parts:

FUSER UNIT (PL6.1.1)

HARNESS ASSY FUSING UNIT MG SFP (PL6.1.2)

PWBA MCU (PL8.2.13)

PWBA LVPS (PL8.2.1)

Checking after resetting the fuser unit

Reseat the fuser unit.

Warning: Start the operation after the fuser unit has

1

cooled down.

Does the error still occur when the power is turned OFF and

ON?

Checking the connectors for connection.

Remove the fuser unit.

Warning: Start the operation after the fuser unit has

cooled down.

Check the connections between the PWBA MCU (P/J17)

and fuser unit (P/J171).

Check the connections between the fuser unit (P/J171) and

PWBA LVPS (P/J47).

Check the connections between the PWBA LVPS (P/J501

and P/J502) and PWBA MCU (P/J14 and P/J15).

Are these connectors connected correctly?

2

Remedy

Yes No

Go to step 2. End of work.

"Reconnect the

connector(s) P/

J17, P/J47, P/

Go to step 4.

J171, P/J501, P/

J502, P/J14 and/

or P/J15 correctly,

then go to step 3."

Does the error still occur when the power is turned OFF and

3

ON?

Checking the HARNESS ASSY FUSING UNIT MG SFP for

continuity.

Disconnect J17 from the PWBA MCU.

4

Disconnect J47 from the PWBA LVPS.

Is each cable of J17 and J47 <=> P171 continuous?

NOTE: P171 is attached to the frame.

Epson AcuLaser C2900N

1 - 26

Go to step 4. End of work.

Replace the

Go to step 5.

HARNESS ASSY

FUSING UNIT MG

SFP.

Confidential

Page 40

Chapter 1 Troubleshooting

Revision B

Step Check

Checking the resistances of Temp. Sensor in the fuser unit.

Remove the fuser unit.

Warning: Start the operation after the fuser unit has

cooled down.

Check the resistances across the following pins of the

removed fuser unit.

J171-5pin <=> J171-4pin

J171-6pin <=> J171-8pin

J171-6pin <=> J171-7pin

Can the resistances be measured? (The resistances are 7

k-ohm at 180 degrees C).

5

Checking after the PWBA LVPS.

Replace the PWBA LVPS. (Refer to RRP8.5.)

6

Does the error still occur when the power is turned off and

on?

Remedy

Yes No

Go to step 6.

Replace the

PWBA MCU.

(Refer to RRP8.9.)

Warning: Start the

operation after the

fuser unit has

cooled down.

Replace the fuser

unit. (Refer to

RRP6.1.) After

replacement, be

sure to clear the

life counter value.

End of work.

Epson AcuLaser C2900N

1 - 27

Confidential

Page 41

Chapter 1 Troubleshooting

FIP-1.3 010-351: IOT Fuser Unit Life Over

Revision B

Step Check

Possible causative parts:

FUSER UNIT (PL6.1.1)

PWBA MCU (PL8.2.13)

Checking the life counter value of the fuser unit.

1

Does the life counter value show the near of the end?

Checking after resetting the fuser unit.

Reseat the fuser unit.

Warning: Start the operation after the fuser unit has

2

cooled down.

Does the error still occur when the power is turned OFF and

ON?

Checking after replacing the fuser unit.

Replace the fuser unit. (Refer to RRP6.1.)

Warning: Start the operation after the fuser unit has

cooled down.

3

Does the error still occur when the power is turned OFF and

ON?

NOTE: After replacement, be sure to clear the life

counter value.

Remedy

Yes No

Warning: Start the

operation after the

fuser unit has

cooled down.

Replace the fuser

unit. (Refer to

RRP6.1.) After

replacement, be

sure to clear the

life counter value.

Go to step 3. End of work.

Replace the

PWBA MCU.

(Refer to RRP8.9.)

Go to step 2.

End of work.

Epson AcuLaser C2900N

1 - 28

Confidential

Page 42

Chapter 1 Troubleshooting

FIP-1.4 010-397: IOT Fuser Unit Failure

Revision B

Step Check

Possible causative parts:

FUSER UNIT (PL6.1.1)

HARNESS ASSY FUSING UNIT MG SFP (PL6.1.2)

PWBA LVPS (PL8.2.1)

PWBA MCU (PL8.2.13)

HARNESS ASSY LVPS MAIN MG SFP (PL9.1.3)

Does the error still occur when the power is turned OFF and

1

ON?

Checking after resetting the fuser unit.

Reseat the fuser unit.

Warning: Start the operation after the fuser unit has

2

cooled down.

Does the error still occur when the power is turned OFF and

ON?

Checking the connectors for connection.

Remove the fuser unit.

Warning: Start the operation after the fuser unit has

cooled down.

Check the connections between the PWBA MCU (P/J17)

and fuser unit (P/J171).

Check the connections between the fuser unit (P/J171) and

PWBA LVPS (P/J47).

Check the connections between the PWBA LVPS (P/J501

and P/J502) and PWBA MCU (P/J14 and P/J15).

Are these connectors connected correctly?

3

Remedy

Yes No

Go to step 2. End of work.

Go to step 3. End of work.

"Reconnect the

connector(s) P/

J17, P/J47, P/

Go to step 5.

J171, P/J501, P/

J502, P/J14 and/

or P/J15 correctly,

then go to step 4."

Does the error still occur when the power is turned OFF and

4

ON?

Checking the HARNESS ASSY FUSING UNIT MG SFP for

continuity.

Disconnect J17 from the PWBA MCU.

5

Disconnect J47 from the PWBA LVPS.

Is each cable of J17 and J47 <=> P171 continuous?

NOTE: P171 is attached to the frame.

Checking the HARNESS ASSY LVPS MAIN MG SFP for

continuity.

6

Disconnect J14 from the PWBA MCU.

Disconnect J501 from the PWBA LVPS.

Is each cable of J14 <=> J501 continuous?

Epson AcuLaser C2900N

1 - 29

Go to step 5. End of work.

Replace the

Go to step 6.

Go to step 7.

HARNESS ASSY

FUSING UNIT MG

SFP.

Replace the

HARNESS ASSY

LVPS MAIN MG

SFP.

Confidential

Page 43

Chapter 1 Troubleshooting

Revision B

Step Check

Checking after replacing the fuser unit

Replace the fuser unit. (Refer to RRP6.1.)

Warning: Start the operation after the fuser unit has

cooled down.

7

Does the error still occur when the power is turned OFF and

ON?

NOTE: After replacement, be sure to clear the life

counter value.

Checking after the PWBA LVPS.

Replace the PWBA LVPS. (Refer to RRP8.5.)

8

Does the error still occur when the power is turned off and

on?

Remedy

Yes No

Go to step 8. End of work.

Replace the

PWBA MCU.

(Refer to RRP8.9.)

End of work.

Epson AcuLaser C2900N

1 - 30

Confidential

Page 44

Chapter 1 Troubleshooting

FIP-1.5 010-421: IOT Fuser Unit Near Life

Revision B

Step Check

Possible causative parts:

FUSER UNIT (PL6.1.1)

PWBA MCU (PL8.2.13)

Checking the fuser unit for installation.

Is the fuser unit installed correctly?

1

Warning: Start the operation after the fuser unit has cooled

down.

Does the error still occur when the power is turned OFF and

2

ON?

Checking after replacing the fuser unit.

Replace the fuser unit. (Refer to RRP6.1.)

Warning: Start the operation after the fuser unit has

cooled down.

3

Does the error still occur when the power is turned OFF and

ON?

NOTE: After replacement, be sure to clear the life

counter value.

Remedy

Yes No

Reseat the fuser

Go to step 3.

Go to step 3. End of work.

Replace the

PWBA MCU.

(Refer to RRP8.9.)

unit, then go step

2.

End of work

Epson AcuLaser C2900N

1 - 31

Confidential

Page 45

Chapter 1 Troubleshooting

Revision B

FIP-1.6 016-500 / 016-501 / 016-502 / 116-315 / 116-317 / 116-323 / 116-324 / 116-326 /

116-327 / 116-328 / 116-343 / 116-350 / 116-390: ESS Error

Step Check

Possible causative parts:

PWBA ESS SFP (PL8.1.7)

Does the error still occur when the power is turned OFF and

1

ON?

Remedy

Yes No

Replace the

PWBA ESS SFP.