Page 1

®

SERVICE MANUAL

Color Inkjet Printer

Stylus C40UX/C40SX/C20UX/C20SX

SEIJ01002

Page 2

Notice

All rights reserved. No p art of t his manual may be reprod uced, stored i n a ret rieval sy stem, or t ransmit ted in any form or by a ny means el ectroni c,

mechanical, photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

The contents of this manual are subject to change witho ut notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2001 SEIKO EPSON CORPORA TION.

Imaging & Information Product Division

TPCS Quality Assurance Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO.

WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON

PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED

CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS,

WHEN ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC

OR OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE

WARRANTY OFFERED BY EPSON.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. TROUBLESHOOTING

Describes the step-by-step procedures for the

troubleshooting.

CHAPTER 4. DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures fo r disassembling

and assembling the product.

CHAPTER 5. ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicing the product.

APPENDIX Provides the following additional information for

reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide

additional information on a specific topic or to warn of possible danger

present during a procedure or an action. Be aware of all symbols when

they are used, and always read NOTE, CAUTION, or WARNING

messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice

or condition that is necessary to keep the product’s quality.

Indicates an operating or maintenan ce pr ocedure, practi ce,

or condition that, if not strictly observed, could result in

damage to, or destruction of, equipment.

May indicate an operating or maintenance procedure,

practice or condition that is necessar y to accomplish a task

efficiently. It may also provid e additional information that is

related to a specific subject, or comment on the results

achieved through a previous action.

I.ndicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or

loss of life.

Indicates that a particular task must be carried out

according to a certain standard after disassembly and

before re-assembly, otherwise the quality of the

components in question may be adversely affected.

Page 5

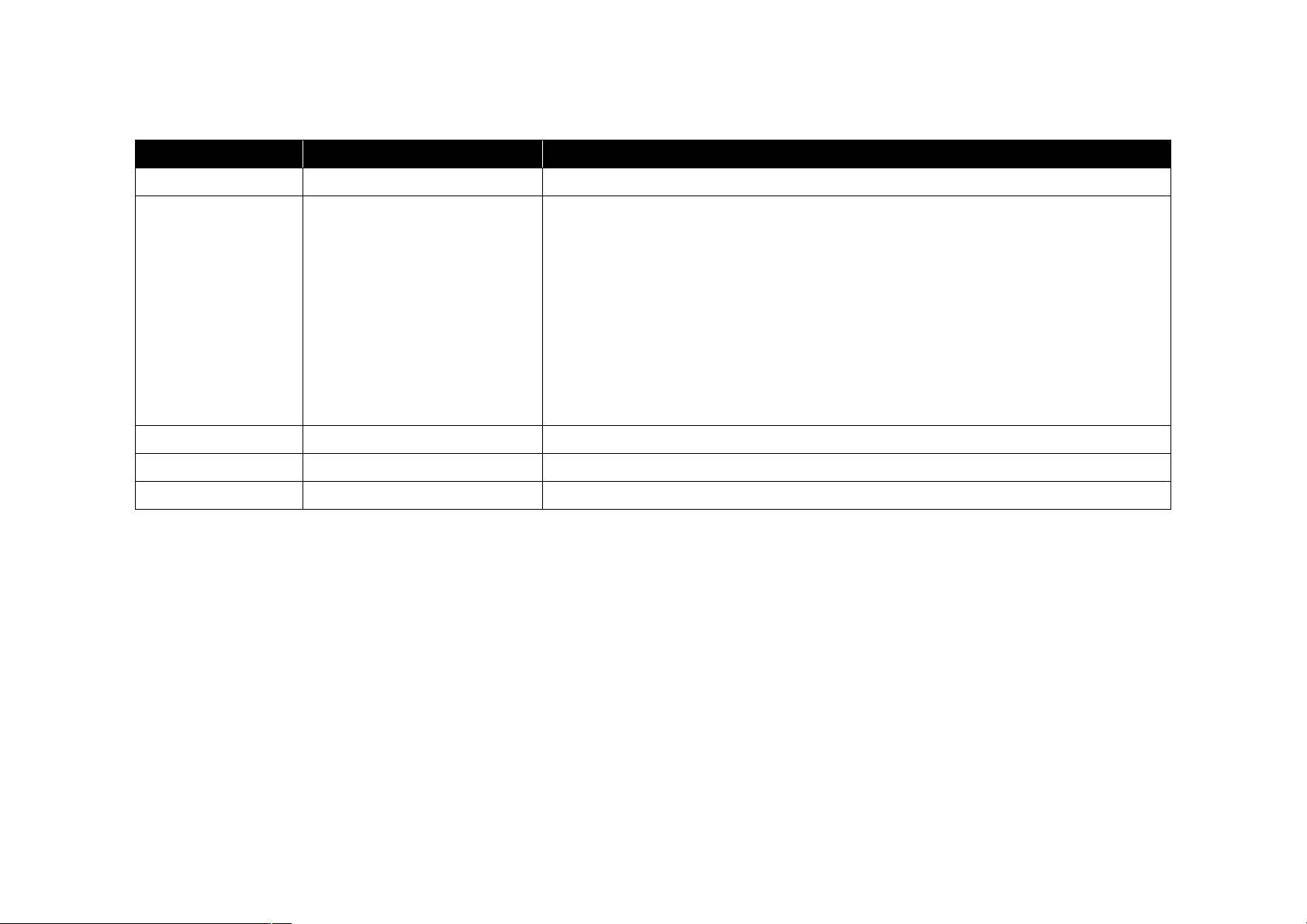

Revision Status

Revision Issued Date Description

A May 31. 2001 First Release

Chapter 2

• Page 38 : Ink consumption of Initial charge was revised.

Chapter 4

• Page 58 : Warning message was deleted.

• Page 61 : Caution message regarding disassembly and assembly was added.

B July 10. 2001

• Page 63 : Adjustment Requested message for Top Margin adjustment was added.

• Page 65 : Reassembly message for inserting PS cable was revised.

• Page 68~70 : Disassembly procedure for Paper Guide Upper/Left was added.

• Page 76 : Adjustment Requested message for Top Margin adjustment was added.

Chapter 5

• Page 88,89 : Adjustme nt procedure for Top Margin was revised.

Page 6

CONTENTS

Chapter 1 PRODUCT DESCRIPTION

1.1 FEATURES ......................................................................................................... 9

1.2 Differences between the Stylus C20 and the Stylus C40 ................................. 9

1.3 SECIFICATIONS ............................................................................................. 10

1.3.1 Physical Specification ................................................................................ 10

1.3.2 Printing Specification ................................................................................ 10

1.3.3 Paper Feeding ............................................................................................ 11

1.3.4 Input Data Buffer ....................................................................................... 11

1.3.5 Electrical specification ............................................................................... 11

1.3.6 Envirormental Condition ........................................................................... 12

1.3.7 Reliability .................................................................................................. 12

1.3.8 Safety Approvals ....................................................................................... 12

1.3.9 Acoustic Noise ........................................................................................... 12

1.3.10 CE Marking ............................................................................................. 12

1.4 INTERFACE ..................................................................................................... 13

1.4.1 USB Interface ............................................................................................ 13

1.4.2 Parallel Interface (Forward Channel) ........................................................ 13

1.4.3 Parallel Interface (Reverse Channel) ......................................................... 15

1.4.4 Prevention Hosts from Data Transfer Time-out ........................................ 16

1.4.5 IEEE1284.4 Protocol ................................................................................. 17

1.5 OPERATOR CONTROLS .............................................................................. 18

1.5.1 Operate Switch ........................................................................................... 18

1.5.2 Control Panel ............................................................................................. 18

1.5.3 Panel Functions .......................................................................................... 18

1.5.4 Printer Condition and Panel Status ............................................................ 18

1.5.5 Printer Initialization ................................................................................... 19

1.5.6 Errors ......................................................................................................... 19

1.6 PAPER ............................................................................................................... 20

1.6.1 Paper Handling .......................................................................................... 20

1.6.2 Paper Specification .................................................................................... 20

1.6.3 Printing Area .............................................................................................. 21

1.7 INK CARTRIDGE ........................................................................................... 23

1.7.1 Black Ink Cartridge ................................................................................... 23

1.7.2 Color Ink Cartridge .................................................................................... 23

Chapter 2 Operating Principles

2.1 Overview ............................................................................................................ 25

2.1.1 Printer Mechanism ..................................................................................... 25

2.1.2 Printhead .................................................................................................... 26

2.1.2.1 Printing Process ................................................................................. 27

2.1.2.2 Printing Method ................................................................................. 27

2.1.3 Carriage Mechanism .................................................................................. 28

2.1.4 Paper Feeding Mechanism ......................................................................... 30

2.1.5 Paper Loading Mechanism (ASF Unit) ..................................................... 31

2.1.6 Ink System Mechanism ............................................................................. 35

2.1.6.1 Pump Unit & Wiper mechanism ....................................................... 35

2.1.6.2 Capping Mechanism .......................................................................... 36

2.1.7 Ink Sequence .............................................................................................. 38

2.1.8 Printing mode ............................................................................................ 40

2.2 Electrical Circuit Operating Principles .......................................................... 41

2.2.1 C417 PSB/PSE board ................................................................................ 41

2.2.2 C413 MAIN/B Board ................................................................................ 43

2.2.2.1 Main elements ................................................................................... 43

Chapter 3 Troubleshooting

3.1 Overview ............................................................................................................ 45

3.2 Troubleshooting with LED Error Indications ............................................... 46

Chapter 4 Disassembly and Assembly

4.1 Overview ............................................................................................................ 57

4.1.1 Precautions ................................................................................................. 57

Page 7

4.1.2 Tools .......................................................................................................... 59

4.1.3 Screws ........................................................................................................ 59

4.1.4 Work Completion Check ........................................................................... 60

4.2 Disassembly ....................................................................................................... 61

4.2.1 Upper housing removal .............................................................................. 61

4.2.2 ASF unit removal ....................................................................................... 63

4.2.3 Waste ink pad removal .............................................................................. 64

4.2.4 PS unit removal .......................................................................................... 65

4.2.5 Paper eject roller removal .......................................................................... 66

4.2.6 Paper Guide Upper/Left removal ............................................................... 68

4.2.7 MAIN board removal ................................................................................ 71

4.2.8 CR motor removal ..................................................................................... 73

4.2.9 Printhead unit removal ............................................................................... 74

4.2.10 LD unit removal ....................................................................................... 76

4.2.11 Printer mechanism removal ..................................................................... 77

Chapter 5 Adjustment

5.1 Overview ............................................................................................................ 79

5.1.1 Required Adjustment ................................................................................. 79

5.1.2 Adjustment Program Initial Setting menu ................................................. 80

5.1.3 Adjustment Program feature ...................................................................... 81

5.1.4 EEPROM initial setting ............................................................................. 83

5.1.5 Head ID ...................................................................................................... 83

5.1.6 Bi-D ........................................................................................................... 85

5.1.7 USB ID ...................................................................................................... 86

5.1.8 Top margin ................................................................................................. 88

5.1.9 Head cleaning ............................................................................................ 89

5.1.10 Initial ink charge ...................................................................................... 90

5.1.11 Refurbishment for DOA .......................................................................... 90

5.1.12 Protection counter check .......................................................................... 92

5.1.13 EEPRON check ....................................................................................... 94

5.1.14 EEPROM back up data ............................................................................ 95

5.1.15 A4 pattern will print ................................................................................. 96

6.1.3 Lubrication ............................................................................................... 100

Chapter 7 Appendix

7.1 Connector Summary ...................................................................................... 104

7.1.1 Major Component Unit ............................................................................ 104

7.2 EEPROM Address Map ................................................................................ 106

7.3 Component Layout ......................................................................................... 110

7.4 Parts List ......................................................................................................... 112

7.5 Exploded Diagram .......................................................................................... 113

7.6 Electrical Circuits ........................................................................................... 119

Chapter 6 Maintenance

6.1 Overview ............................................................................................................ 99

6.1.1 Cleaning ..................................................................................................... 99

6.1.2 Service Maintenance ................................................................................ 100

Page 8

PRODUCT DESCRIPTION

CHAPTER

1

Page 9

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.1 FEATURES

High color print quality

- 1440 (H) x 720 (V) dpi printing

- 4 color printing (YMCK)

- Traditional and New Microweave

Built-in auto sheet feeder

- Holds 100 cut-sheets (65 g/m²)

- Holds 10 envelopes

- Holds 10 transparency films

Built-in 1 I/F

Interface specification for each model are as the following.

Parallel Interface .EPSON Stylus C40SX .EPSON Stylus C20SX

USB Interface .EPSON Stylus C40UX .EPSON Stylus C20UX

Windows / Macintosh exclusive

1.2 Differences between the Stylus C20 and the Stylus C40

The Stylus C20 and Stylus C40 are mechanically the same, but the throughput of the

Stylus C40 is slightly higher than that of the Stylus C20. (Refer to Table 1-1.)

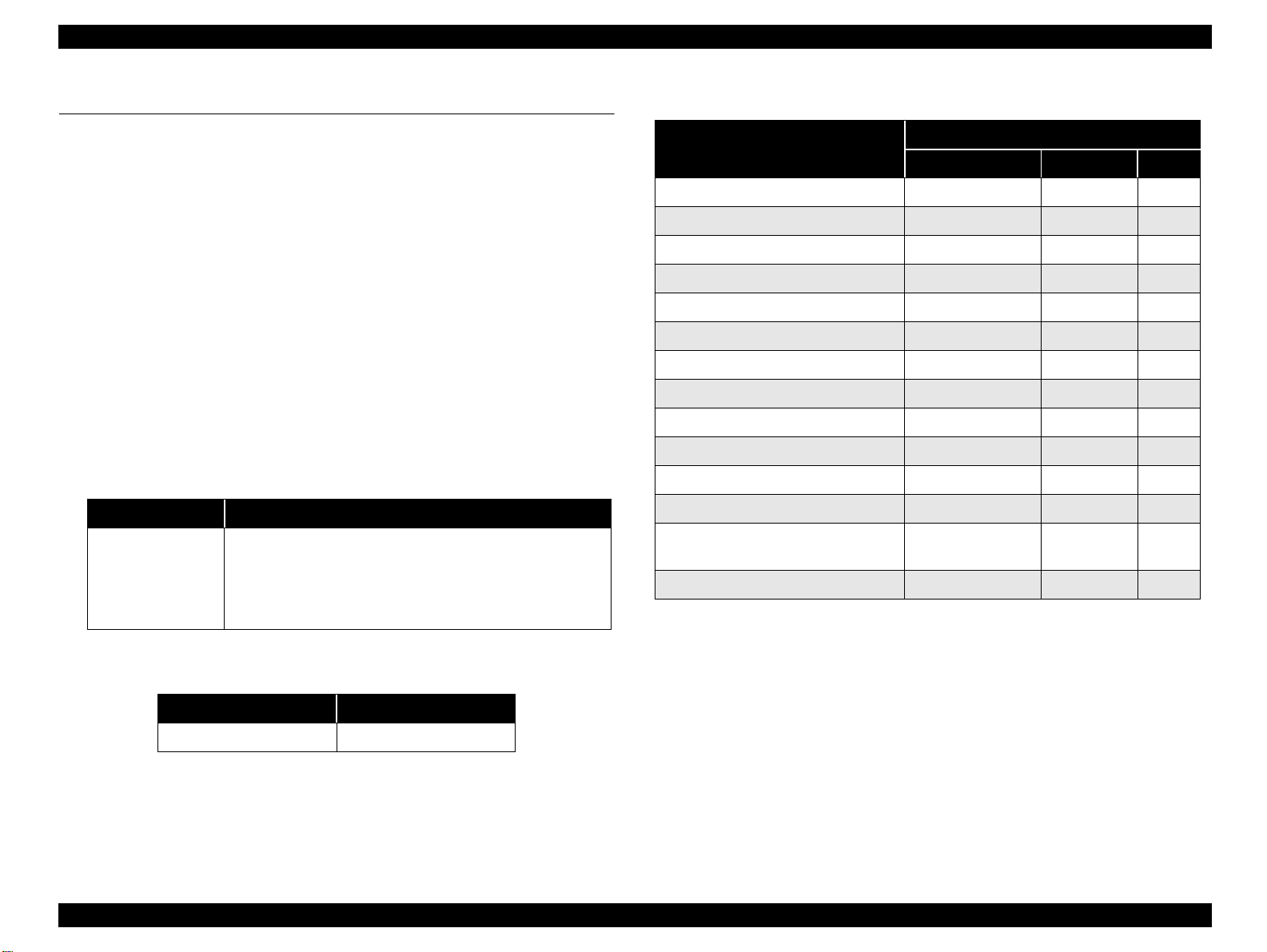

Table 1-1. Throughput

Models memo economy Normal

Stylus C20 6.5 PPM 3.0 PPM

Stylus C40 8.0 PPM 3.5 PPM

In both models, demarcation is determined by the EEPROM value 29 <H>. When the

value of bit 0 is 1, a wait of 40

msec is inserted for each CR pass during printing, then the next operation starts.

Table 1-2. Delay of oparation

EEPROM 29 <H> bit 0 v alue Model Delay time during printing

0Stylus C40None

1 Stylus C20 CR 40 msec for each pass.

PRODUCT DESCRIPTION FEATURES 9

Page 10

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.3 SECIFICATIONS

This section covers specifications of the printer.

1.3.1 Physical Specification

Weight : 2.48kg (without the ink cartridges)

Dimensio n : 424 mm(W) x 227 mm (D) x 168 mm (H) (Printing)

1.3.2 Printing Specification

Print method : On demand ink jet

Nozzle Configuration : monochrome 48 nozzles

: color 15 nozzles x 3 (Cyan, Magenta, Yellow)

Print direction : Bi-direction with logic seeking

Print speed & Printable columns

Character mode : Black only

Character Pitch Character Quality Printable Columns CR Speed

10CPI LQ 80 Columns 20IPS

Raster graphics mode

Horizontal

resolution

480 dpi 8.26 inch 3968 14.1 IPS Black mode

360 dpi 8.26 inch 2976 23.8 IPS 720 dpi 8.26 inch 5952 20 IPS -

1440 dpi 8.26 inch 11904 20 IPS -

Printable area Available dot CR Speed Notes

Control code* : ESC/P R4C7050 exclusive

: EPSON Remote command

Character tables* : none

ASCII 20h to 7Fh code support.

Figure 1-1. Stylus C40/C20 Dimensions

Typeface*

Bit map LQ font :EPSON Courier 10 CPI

International character sets * : None

* Do not mention to the user’s manual about control code, character tabl e, typeface and

International character sets.

PRODUCT DESCRIPTION SECIFICATIONS 10

Page 11

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.3.3 Paper Feeding

Feeding method : Friction feed with ASF

Paper path : Cut-sheet ASF (Top entry)

Feed speed :

Feed condition Time Speed

10.16mm(0.4 inch) feed 110msec 92.36mm (3.64inch)/sec

Continuous feed 140msec 139.7mm (5.5inch) /sec

1.3.4 Input Data Buffer

Buffer size :12 Kbytes

1.3.5 Electrical specification

120 V version

Rated voltage : AC 120 V

Input voltage range : AC 99 - 132 V

Rated frequency range : 50 - 60 Hz

Input frequency range : 49.5 - 60.5 Hz

Rated current : 0.4A

Power consumption : Approx. 16W (ISO/IEC 10561 Letter pattern

: Approx. 4W in standby mode

: Energy Star compliant

Insulation Resistance :10 M ohms min.

(between AC line and chassis, DC 500 V)

Dielectric strength : AC 1000 V rms. 1 minute or

AC 1200 V rms. 1 second

(between AC line and chassis)

220-240 V version

Rated voltage : AC 220 - 240 V

Input voltage range : AC 198 - 264 V

Rated frequency range : 50 - 60 Hz

Input frequency range : 49.5 - 60.5 Hz

Rated current : 0.2A

Power consumption : Approx. 16W (ISO/IEC 10561 Letter pattern

: Approx. 4W in standby mode

: Energy Star compliant

Insulation Resistance :10 M ohms min.

(between AC line and chassis, DC 500 V)

Dielectric strength : AC 1500 V rms. 1 minute

(between AC line and chassis)

PRODUCT DESCRIPTION SECIFICATIONS 11

Page 12

Stylus C40UX/C40SX/C20UX/C20SX Revision B

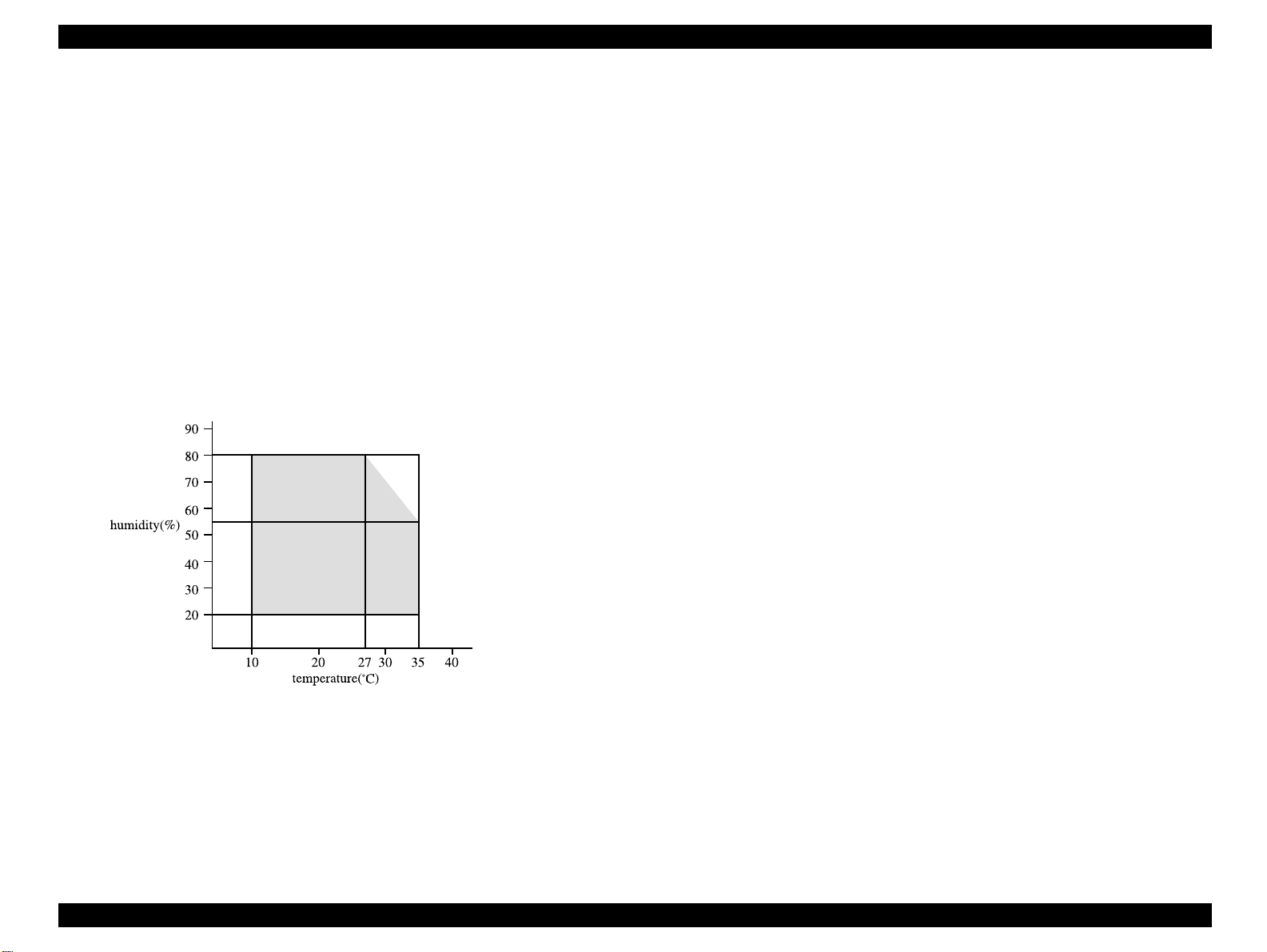

1.3.6 Envirormental Condition

Temperature : 10 to 35 ºC (operating *3 )

: -20 to 60 ºC(non-operating, *1)

1 month at 40 ºC

120 hours at 60 ºC

Humidity : 20 to 80% RH (operating, *2,*3)

: 5 to 85% RH (non-operating, *1, *2)

Resistance to shock : 1 G, within 1 ms (operating)

: 2 G, within 2 ms (non-operating, *1)

Resistance to vibration : 0.15G (operating)

: 0.50G (non-operating, *1)

*1: with shipment container

*2: without condensation

*3: Condition is as following figure.

1.3.8 Safety Approvals

120 V version :

Safety standards : UL1950 with D3

CSA C22.2 No.950 with D3

EMI : FCC part15 subpart B class B

CSA C108.8 class B

220-240 V version :

Safety standards : EN 60950(VDE)

EMI : EN 55022(CISPR Pub.22) class B

: AS/NZS 3548 class B

1.3.9 Acoustic Noise

Level : Approx. 45 dB(A) (According to ISO 7779)

1.3.10 CE Marking

220-240 V version

Low Voltage Directive 73/23/EEC : EN60950

EMC Directive 89/336/EEC : EN55022 Class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

Figure 1-2. Environmental Condition

1.3.7 Reliability

Total print volume : 10,000 pages (A4, Letter) or

20,000 pages (A4, Letter)

*refer to “EEPROM Address Map” on page -106

Print Head Life : 4000 million dots/nozzle

PRODUCT DESCRIPTION SECIFICATIONS 12

Page 13

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.4 INTERFACE

Interface specification for each model are as the following.

Parallel Interface :EPSON Stylus C40SX .EPSON Stylus C20SX

USB Interface :EPSON Stylus C40UX .EPSON Stylus C20UX

*This printer interface as standard.

1.4.1 USB Interface

Standard : based on

“Universal Serial Bus Specifications Revision 1.1”

“Universal Serial Bus Device Class Definition for Printing Devices Version

1.1”

Bit rate : 12Mbps (Full Speed Device)

Data encording : NRZI

Adaptable connector : USB Series B

Recommended cable length : 2 meters

Connect er pin assinment and signals:

Pin No. Signal name In/Out Function description

1VCC -

2 Data bi-directional Data

Cable power. Maximum power consumption is

100mA

1.4.2 Parallel Interface (Forward Channel)

Transmission mode : 8 bit parallel, IEEE-1284 compatibility mode

Synchronization : By STROBE pulse

Handshaking : By BUSY and ACKNLG signal

Signal level : TTL compatible level

Adaptable connector : 57-30360(amphenol) or equivalent

BUSY signal is set high before setting either -ERROR

low or PE high and held high until all these signals

return to their inactive state.

BUSY signal is at high level in the following cases.

-During data entry (see Data transmission timing)

-When input data buffer is full

-During -INIT signal is at low level or during

hardware initialization

-During printer error (See -ERROR signal)

ERROR signal is at low level when the printer is in one

of the following states.

-Printer hardware error (fatal error)

-Paper-out error

-Paper-jam error

-Ink-out error

-Ink overflow error

3 +Data bi-directiona data, pull up to +3.3V via 1.5K ohm resistor

4 Ground - C able ground

Data transmission timing :

DATA

-STROBE

BUSY

-ACKNLG

PE signal is at high level during paper-out error.

Figure 1-3. USB Pin Assignment

PRODUCT DESCRIPTION INTERFACE 13

Page 14

Stylus C40UX/C40SX/C20UX/C20SX Revision B

Parameter Minimum Maximum Parameter Minimum Maximum

tsetup 500 ns - treply 0 thold 500 n s - tack 500 ns 10 us

tstb 500 ns - tnbusy 0 tready 0 - tnext 0 tbusy - 500 ns

tt-out* - 120 ns * Rise and fall time of every output signals

tt-in** - 200 ns ** Rise and fall time of every input signals

***Typical time of tack is shown below.

Parallel I/F mode typical time of tack

High speed 2us

Normal speed 4usror

Signal level : TTL compatible (IEEE-1284 level 1 device)

Parameter Minimum Maximum Condition

VOH* - 5.5 V * A low logic level on the

is.

VOL* -0.5 V -

IOH* - 0.32 mA VOH = 2 .4 V

IOL* - 12 mA VOL = 0.4 V

CO - 50 pF

VIH - 2.0 V

VIL 0.8V -

IIH - 0.32 mA VIH = 2.0 V

IIL - 12 mA VIL = 0.8 V

Logic H signal is.

2.0 V or less when the

printer is powered off and

this signal is equal or

exceeding 3.0V when the

printer is powered on.

The receiver shall provide an

impedance equivalent to 7.5

K ohm to ground

Connector pin assignment and signals :

Pin No.

10 -ACKNLG 28 Out

11 BUSY 29 Out

12 PE 28 Out A high signal indicat e s paper-out error.

13 SLCT 28 Out

14 -AFXT 30 In Not used.

31 -INIT 30 In

32 -ERROR 29 Out A low signal indicates printer error condition.

36 -SLI N 30 In Not used.

18 Logic H - Out Pulled up to +5 V via 3.9 K ohm resistor.

35 +5V - Out Pulled up to +5 V via 3.3 K ohm resistor.

Signal Name

Return

1 -STROBE 19 In

2 DATA0 20 In The DATA0 through DATA7 sign als

3 DATA1 21 In

4 DATA2 22 In

5 DATA3 23 In

6 DATA4 24 In

7 DATA5 25 In

8 DATA6 26 In

9 DATA7 27 In

GND pin In/Out Functional description

The strobe pulse. Read-in of data is

performed at the falling edge of this pulse.

represent data bits 0 to 7, respectively.

Each signal is at high level when data is

logical 1 and low level when data is logical 0.

This signal is a negative pulse indicating that

the printer can again accept data.

A high signal indicates th at the printe r cannot

receive data.

Always at high level when the printer is

powered on.

The falling edge of a negative pulse or a low

signal on this line causes the printer to

initialize. Minimum 50 us pulse is necessary.

CI - 50 pF

PRODUCT DESCRIPTION INTERFACE 14

Page 15

Stylus C40UX/C40SX/C20UX/C20SX Revision B

Pin No.

17 Chassis GND - - Chassis GND.

16, 33

19-30

15, 34 NC - - Not connected.

Signal Name

Return

GND - - Signal GND.

GND pin In/Out Functional description

* In/Out refers to the direction of signal flow from the printer's point of view.

1.4.3 Parallel Interface (Reverse Channel)

Transmission mode : IEEE-1284 nibble mode

Adaptable connector : See forward channel

Synchronization : Refer to the IEEE-1284 specification

Handshaking : Refer to the IEEE-1284 specification

Data trans. timing : Refer to the IEEE-1284 specification

Signal level : IEEE-1284 level 1 device

See forward channel

Connector pin assignment and signals :

Pin No. Signal Name

2 DATA0 20 In The DATA0 through DATA7 sign als

3 DATA1 21 In

4 DATA2 22 In

5 DATA3 23 In

6 DATA4 24 In

7 DATA5 25 In

8 DATA6 26 In

9 DATA7 27 In

10 PtrClk 28 Out Printer clock signal.

11

12

13

14 HostBusy 30 In Host busy signal.

PtrBusy /

DataBit-3,7

AckDataReq /

DataBit-2,6

Xflag /

DataBit-1,5

ReturnG

ND Pin

29 Out

28 Out

28 Out

In/

Out*

Function al description

represent data bits 0 to 7, respectively.

Each signal is at high level when data is

logical 1 and low level when data is logical 0.

These signals are used to transfer the 1284

extensibility request values to the printer.

Printer busy signal and reverse cha nnel

transfer data bit 3 or 7.

Acknowledge data r equ est sign al a nd r ever se

channel transfer data bit 2 or 6.

X-flag signal and reverse channel transfer

data bit 1 or 5.

Pin No. Signal Name

1 HostClk 19 In Host clock signal.

ReturnG

ND Pin

In/

Out*

Functional descrip tion

31 -INIT 30 In Not used.

32

36 1284-Active 3 0 In 1284 active signal.

18 Logic-H - Out Pulled up to +5 V via 3.9 K ohm resist or.

35 +5V - Out Pulled up to +5 V via 3.3 K ohm resistor.

17 Chassis GND - - Chassis GND.

16, 33

19-30

15, 34 NC - - Not connected.

-DataAvail /

DataBit-0,4

GND - - Signal GND.

29 Out

Data available signal and reverse channel

transfer data bit 0 or 4.

* In/Out refers to the direction of signal flow from the printer's point of view.

PRODUCT DESCRIPTION INTERFACE 15

Page 16

Stylus C40UX/C40SX/C20UX/C20SX Revision B

Extensibility Request :

The printer responds affirmatively when the extensibility request values are 00H

or 04H, that mean,

00H : Request Nibble Mode Reverse Channel Transfer.

04H : Request Device ID;

Return Data Using Nibble Mode Rev Channel Transfer.

Device ID :

The printer sends following device ID string when it is requested.

When IEEE1284.4 is enabled,

[00H] [4EH]

MFG:EPSON;

CMD:ESCPL2,BDC,D4;

MDL:Stylus[SP]XXX;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]XXX;

When IEEE1284.4 is disabled,

[00H] [4BH]

MFG:EPSON;

CMD:ESCPL2,BDC;

MDL:Stylus[SP]XXX;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]XXX;

busy state. This slowdown is started when the rest of the input buffer becomes several

hundreds of bytes. Finally, the printer is in the busy state continuously when the input

buffer is full.

*XXX is C20 or C40

Note : (1) [00H] denotes a hexadecimal value of zero.

(2) MDL value depends on the EEPROM setting. Refer to

Appendix F.

(3) CMD value depends on the IEEE1284.4 setting, Refer to

Appendix F.

1.4.4 Prevention Hosts from Data Transfer Time-out

Generally, hosts abandon data transfer to peripherals when a peripheral is in the busy

state for dozens of seconds continuously. To prevent hosts from this kind of time-out,

the printer receives data very slowly, several bytes per minute, even if the printer is in

PRODUCT DESCRIPTION INTERFACE 16

Page 17

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.4.5 IEEE1284.4 Protocol

The packet protocol described by IEEE1284.4 standard allows a device to carry on

multiple exchanges or conversations which contain data and/or control information

with another device at the sa me time across a s ingle point-t o-point link. The prot ocol i s

not, however, a device control language. It does provide basic transport-level flow

control and multiplexing services. The multiplexed logical channels are independent of

each other and blocking of one has no

effect on the others. The protocol operate over IEEE1284.

- Automatic selection

An initial state is compatible interface and starts IEEE1284.4 communication

when magic strings (IEEE 1284.4 synchronous commands) are received.

- On

An initial state is IEEE1284.4 communication and data that received it by the

time it is able to take synchronization by magic string (IEEE 1284.4

synchronous commands) is discarded.

- Off

An initial state is compatible interface and never starts IEEE1284.4

communication even if magic strings (IEEE 1284.4 synchronous commands)

are received.

Factory setting is on.(Refer to Appendix H.EEPROM Map 09h)

PRODUCT DESCRIPTION INTERFACE 17

Page 18

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.5 OPERATOR CONTROLS

1.5.1 Operate Switch

Operate switch is located on the control panel.

1.5.2 Control Panel

Switches

There are 2 non-lock type push switches, and 2 LED.

Indicators

(1) Power (green)

Lights when the operate switch is "ON", and AC power is supplied.

(2) Error (red)

Lights or blinks when some error occurs to the printer.

1.5.3 Panel Functions

Panel Functions

SW Function

• Loads or Ejects the Paper(Pushing within 3seconds).

• Starts the Cleaning of head(Pushing for 3seconds)

Error Reset SW

*This function is not available in printing status.

Panel Function with Power on

• When carriage is on the Ink Cartridge ch ange position, return

carriage from Ink Cartridge change position.

• Starts the Ink Cartridge change (Pushing for 6seconds)

1.5.4 Printer Condition and Panel Status

Printer status

Power ON condition On - 10

Ink sequence Blink - 6

Ink Cartridge change mode Blink - 5

Data processing Blink - 9

Paper Out *1 - On 4

Paper jam condition*1 - On 3 3

Ink end(Black)*1 - On->On 8

Ink level low(Bl ack) - Blink->Blink 8

Ink end(Color)*1 - On->On 8

Ink level low(Color) - Blink->Blink 8

Ink end (Black and Color) - On->On 8

No Ink Cartridge (Black or Color)*1 - On 7

Maintenance request

(Ink Overflow Counter error)

Fatal error*1 Off On 1

“-”:Indicator status don’t change

“a->b”:a is a Indicator condition when carriage is on Home Position.

b is a Indicator condition in Ink exchange sequence.

Powe Error Priority

Alt blink Alt blink 2

Indicators

SW Function

Error Reset SW Starts status printings

*1 : see

PRODUCT DESCRIPTION OPERATOR CONTROLS 18

Page 19

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.5.5 Printer Initialization

There are three kinds of initialization method.

(1) Power-on initialization

This printer is initialized when turning the printer power on, or printer recognized

the cold-reset command (remote RS command).

When printer is initialized, following action is performed.

(a) Initializes printer mechanism.

(b) Clears input data buffer.

(c) Clears print buffer.

(d) Sets default values.

(2) Operator initialization

This printer is initialized when printer recognized the -INIT signal (negative pulse)

of parallel interface.

When printer is initialized, following action is performed.

(a) Cap the print head.

(b) Eject a paper.

(c) Clears input data buffer.

(d) Clears print buffer.

(e) Sets default values.

(3) Software initialization

The ESC @ command also initializes the printer.

When printer is initialized, following action is performed.

1.5.6 Errors

Ink out

When the printer runs out the most part of the ink of any one color, it warns ink-

low and keeps printing.When the printer runs out the whole ink of any one color, it

stops printing and indicates ink-out error. User is requested to install a new inkcartridge in this state.

Paper out

When printer fails to load a sheet, it goes paper out error.

Paper jam

When printer fails to eject a sheet, it goes paper jam error.

No ink-cartridge

When printer detects that ink-cartridge comes off , it goes this error mode.

Maintenance request

When the total quantity of ink wasted through the cleanings and flushing is

reaches to the limit, printer indicates this error and stops. The absorber in the

printer enclosure is needed to be replaced with new one by a service person.

Fatal errors

Carriage control error.

* panel status is described on section1.4.4.

(a) Clears print buffer.

(b) Sets default values.

(4) Power-on initialization except I/F

The printer recognized the IEEE 1284.4 “rs” command.

When printer is initialized, following action is performed.

(a) Initializes printer mechanism.

(b) Clears input data buffer.

(c) Clears print buffer.

(d) Sets default values except I/F.

PRODUCT DESCRIPTION OPERATOR CONTROLS 19

Page 20

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.6 PAPER

1.6.1 Paper Handling

Do not perform reverse feed more than 0 mm(0”).

1.6.2 Paper Specification

Cut Sheet

Size : A4 (Width 210 mm(8.3") x Length 297 mm(11.7"))

: Letter (Width 215.9 mm(8.5") x Length 279.4 mm(11.0"))

: B5 (Width 182 mm(7.2") x Length 257 mm(10.1"))

: Legal (Width 215.9 mm(8.5") x Length 355.6 mm(14.0"))

: Half Letter (Width 139.7 mm(5.5") x Length 215.9 mm(8.5"))

: Exclusive (Width 184.2 mm(7.5") x Length 266.7 mm(10"))

: A5 (Width 148 mm(5.8") x Length 210 mm(8.3"))

: A6 (Width 105 mm(4.1") x Length 210 mm(8.3"))

Thickness : 0.08 mm(0.003") - 0.11 mm(0.004")

Weight : 64 g/m 2 (17 lb.55Kg) - 90 g/m 2 (24 lb.78Kg)

Quality : Exclusive paper, Bond paper, PPC

Envelope

Size : No.10 Width 241 mm(9 1/2") x Length 104.8 mm(4 1/8")

: DL Width 220 mm(8.7") x Length 110 mm(4.3")

: C6 Width 162 mm(6.4”) x Length 114 mm(4.5”)

: Envelope220*132 Width 220 mm(8.7”) x Length 132 mm(5.2”)

: Japanese CHOUKEI 3 Width 120 mm x Length 235 mm *

: Japanese CHOUKEI 4 Width 90 mm x Length 205 mm *

: Japanese YOUKEI 1 Width 120 mm x Length 176 mm *

: Japanese YOUKEI 2 Width 114 mm x Length 162 mm *

: Japanese YOUKEI 3 Width 98 mm x Length 148 mm *

: Japanese YOUKEI 4 Width 105 mm x Length 235 mm *

* except for glue.

Thickness : N/A

Weight :#10,DL,C6 45 g/m 2 (12 lb.) - 75 g/m 2 (20 lb.)

: CHOUKEI 50 g/m 2 (43Kg) - 70 g/m 2 (60Kg)

: YOUKEI 50 g/m 2 (43Kg) - 100 g/m 2 (86Kg)

Quality : #10,DL,C6 Bond paper, Plain paper, Air mail

: CHOUKEI4,3 Kraft, new Kent paper

: YOUKEI1,2,3,4 Kraft, new Kent paper

* Envelope printing is only available at normal temperature.

* Keep the longer side of the envelope horizontally at setting.

Exclusive paper

Quality : EPSON Exclusive paper

* Transparency printing is only available at normal temperature.

< Photo Quality Ink Jet Paper >

Size :A4 (210mm x 297mm)

:A6 (105mm x 148mm)

:B5 (182mm x 257mm)

:Letter (216mm x 279mm)

:Legal (216mm x 356mm)

:5” x 8” (127mm x 203mm)

:8” x 10” (203mm x 254mm)

:Post Card (100mm x 148mm)

Thickness : 0.13 mm(0.005")

Weight : 98 g/m 2 (26 lb.84Kg)

<360 dpi Ink Jet Paper >

Size : A4 (210mm x 297mm)

: Letter (216mm x 279mm)

Thickness : 0.11 mm(0.004")

Weight : 89 g/m 2 (24 lb.78Kg)

<RC paper>

Size : A4 (210mm x 297mm)

: Letter (216mm x 279mm)

Thickness : <T.B.D.>

Weight : <T.B.D.>

<Ink Jet Transparencies>

Size : A4 (210mm x 297mm)

: Letter (216mm x 279mm)

Thickness 0.13 mm(0.005")

Weight : N/A

PRODUCT DESCRIPTION PAPER 20

Page 21

Stylus C40UX/C40SX/C20UX/C20SX Revision B

< Photo Quality Glossy Film >

Size : A4 (210mm x 297mm)

: A6 (105mm x 148mm)

: Letter (216mm x 279mm)

Thickness : 0.13 mm(0.005")

Weight : N/A

<Matte paper Heavy weight>

Size : A4 (210mm x 297mm)

: Letter (216mm x 279mm)

Thickness : 0.23 mm(0.009")

Weight : 167 g/m 2 (44 lb.143Kg)

< Iron-on Cool Peel Transfer Paper >

Size : A4 (210mm x 297mm)

: Letter (216mm x 279mm)

Thickness : 0.18 mm(0.007")

Weight : 124 g/m 2 (33 lb.107Kg)

*Base paper weight.

1.6.3 Printing Area

Cut Sheet

<Ink jet paper>

Size : A4 (210mm x 297mm)

Thickness : 0.11 mm(0.004")

Weight : 80 g/m 2 (21 lb.45Kg)

Figure 1-4. Printable Area for Cut Sheet

PRODUCT DESCRIPTION PAPER 21

Page 22

Stylus C40UX/C40SX/C20UX/C20SX Revision B

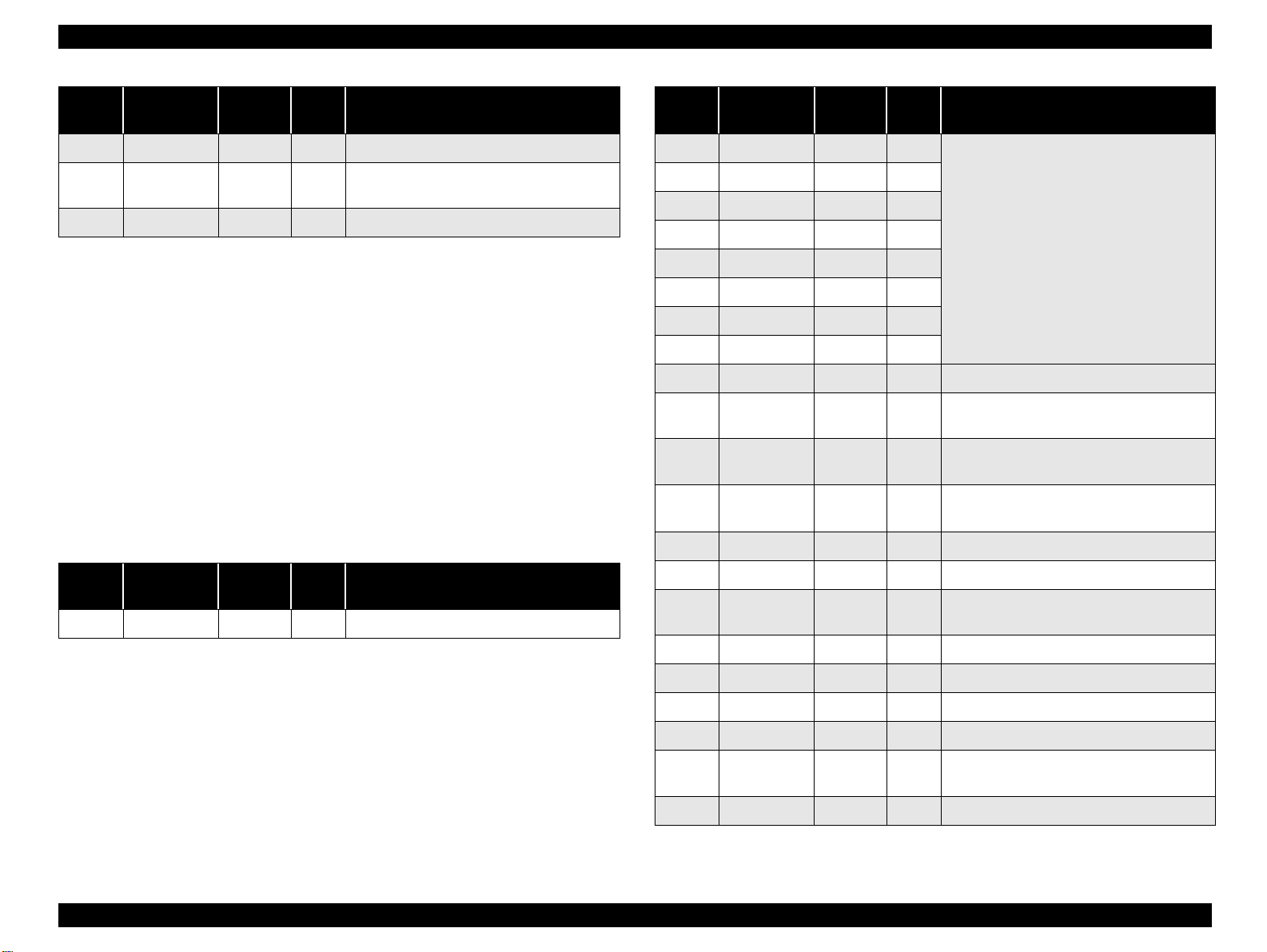

Raster Graphics mode

Paper size

A4

Letter

B5

Lega

Statement

Executive

PW

(Paper

width)

(typ.)

210mm

(8.3”)

216mm

(8.5”)

182mm

(7.2”)

216mm

(8.5”)

139.7mm

(5.5”)

190.5mm

(7.5”)

PL

(Paper

length)

(typ.)

297mm

(11.7”)

279mm

(11.0”)

257mm

(10.1”)

356mm

(14.0”)

215.9mm

(8.5”)

254mm

(10”)

LM

(left

margin)

(min.)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

RM

(Right

margin)

(min.)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

TM

(Top

margin)

(min.)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

3mm

(0.12”)

Black BM

(Bottom margin)

(min.)

14mm (0.54”)

/3mm (0.12”)

14mm (0.54”)

/3mm (0.12”)

14mm (0.54”)

/3mm (0.12”)

14mm (0.54”)

/3mm (0.12”)

14mm (0.54”)

/3mm (0.12”)

14mm (0.54”)

/3mm (0.12”)

Color BM

(Bottom margin)

(min.)

21mm (0.83”)

/3mm (0.12”)

21mm (0.83”)

/3mm (0.12”)

21mm (0.83”)

/3mm (0.12”)

21mm (0.83”)

/3mm (0.12”)

21mm (0.83”)

/3mm (0.12”)

21mm (0.83”)

/3mm (0.12”)

* Bottom margin is expanded to 3mm when paper dimension is defined by using

command(ESC (S), otherwise it is not expanded (Black,14mm Color 21mm). Refer to

Appendix C.

** Print quality may decline in the expanded areas(For 3 mm to 14 mm (Color 21mm)

of the printing areas).

Paper

size

#10

Envelope

LM(Left

margin)

(min.)

28mm(1.10

”)

Figure 1-5. Printable Area for Envelopes

RM(Right

margin)

(min.)

3mm(0.12”) 3mm(0.12”)

TM(Top

margin)

(min.)

Black BM

(Bottom margin )

(min.)

14mm(0.54”0

/3mm(0.12”)*

Color BM

(Bottom margin)

(min.)

21mm(0.83”)

/3mm(0.12”)*

DL 7mm(0.28”) 3mm(0.12”) 3mm(0.12”)

C6 3mm(0.12”) 3mm(0.12”) 3mm(0.12”)

14mm(0.54”0

/3mm(0.12”)*

14mm(0.54”0

/3mm(0.12”)*

21mm(0.83”)

/3mm(0.12”)*

21mm(0.83”)

/3mm(0.12”)*

* Bottom margin is expanded to 3mm when paper dimension is defined by using

command ESC (S), otherwise it is not expanded (Black,14mm Color 21mm). Refer to

Appendix C .

** Print quality may decline in the expanded areas(For 3 mm to 14 mm (Color 21mm)

of the printing areas).

PRODUCT DESCRIPTION PAPER 22

Page 23

Stylus C40UX/C40SX/C20UX/C20SX Revision B

1.7 INK CARTRIDGE

1.7.1 Black Ink Cartridge

Type : Exclusive cartridge

Color : Black

Print capacity : 270 pages / A4 (ISO/IEC10561 Letter Pattern at 360 dpi)

Ink life : 2 years from production date

Storage temperature : -20°C - 40°C (Storage, within a month at 40°C)

: -30°C - 40°C (Packing storage, within a month at 40°C)

: -30°C - 60°C (Transit, within 120 hours at 60°C and

within a month at 40)

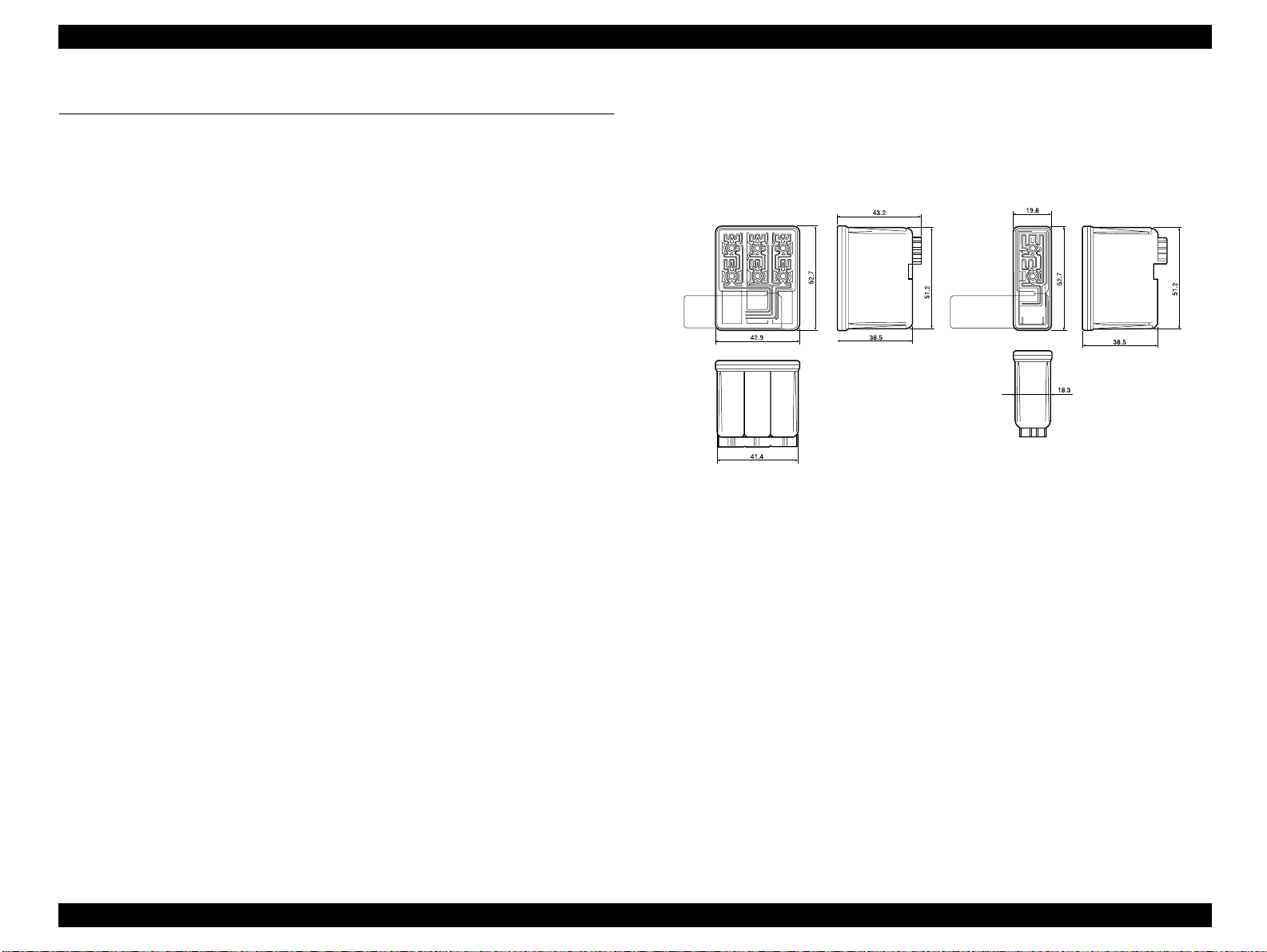

Dimension : 19.8 mm(W) x 52.7 mm(D) x 38.5 mm(H)

1.7.2 Color Ink Cartridge

Type : Exclusive cartridge

Color : Magenta, Cyan, Yellow

Print capacity : 150 pages /A4 (360 dpi, 5% duty each color)

Ink life : 2 years from production date

Storage temperature : -20°C - 40°C (Storage, within a month at 40°C)

: -30°C - 40°C (Packing storage, within a month at 40°C)

: -30°C - 60°C (Transit, within 120 hours at 60°C and

within a month at 40)

Dimension : 42.9 mm(W) x 52.7 mm(D) x 38.5 mm(H)

* Ink cartridge can not re-fill, only ink cartridge is prepared for article of consumption.

* Do not use the ink cartridge which was passed away the ink life.

* Ink will be frozen under -18 to -21 o C environment, however it will be usable after

placing it more than 3 hours at room temperature. mm (0.12”) *

Ink cartridge (color) Ink cartridge (black)

PRODUCT DESCRIPTION INK CARTRIDGE 23

Page 24

OPERATING PRINCIPLES

CHAPTER

2

Page 25

Stylus C40UX/C40SX/C20UX/C20SX Revision B

2.1 Overview

Paper Eject Roller

This section describes the operating principles of the printer mechanism and electrical

circuit boards. The Sty lus C40UX/C40SX/C20UX/C20SX has on ly the following two

circuit boards:

Main board: C413 MAIN/MAIN-B

Power supply board: C417 PSB/PSE

PF Motor

Star Wheel Roller

PF Roller

CR Timing belt

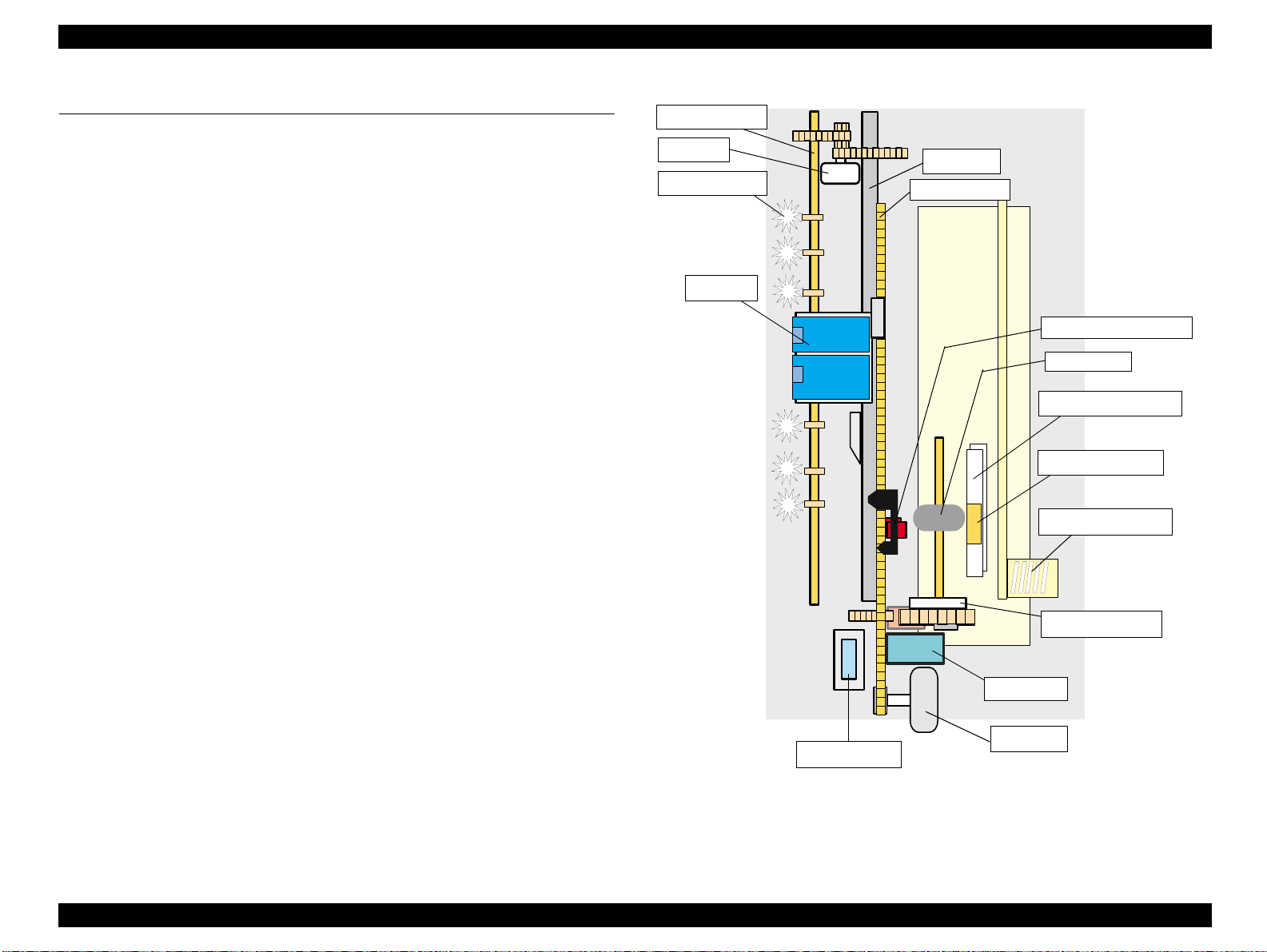

2.1.1 Printer Mechanism

The printer mechanism for Stylus C40 UX /C40 SX/ C2 0UX /C20SX is designed newly.

But, the basic component of the printer mechanism is same as previous product.

This printer consists of Print Head, Carriage Mechanism, Paper Feeding Mechanism,

Paper Loading Mechanism, Ink System (Pump Mechanism, Cap Mechanism, and

Carriage Lock Mechanism).

Like other EPSON ink jet printers, the Stylus C40UX/C40SX/C20UX/C20SX is

equipped with two stepping motors; one for ASF, Paper feeding/ Pump mechanism,

and one for CR mechanism. ASF unit uses rear entry fr ont eject s ystem. Th is ASF unit

is also designed newly and single LD roller loads the paper to the printer mechanism.

For cap assembly, Stylus C40UX/C40SX/C20UX/C20SX uses valveless mechanism;

new design for this model.

CR unit

HP/PE/IC Sensor sensor

LD Roller

Paper feed back plate

Paper separation pad

ASF Hopper Spring

Clutch mechanism

Pump unit

CR Motor

Cap Assembly

Figure 2-1. Printer Mechanism block diagram

Operating Principles Overview 25

Page 26

Stylus C40UX/C40SX/C20UX/C20SX Revision B

2.1.2 Printhead

The printhead uses a new developed U-CHIPS head and Stylus C40UX/C40SX/

C20UX/C20SX can perform multiple shot printing and variable printing. Printhead

nozzle configuration is as follows.

48 nozzles x 1 row: Black (nozzle pitch of the row: 1/120 inch)

45 nozzles x 1 row: Color (nozzle pitch of the row: 1/120 inch)

In the one row for the color, 15 nozzles are assigned for each yellow,

magenta, cyan color)

The basic operating principles of the printhead, which plays a major role in printing,

are the same as previous models; on-demand method which uses PZT (Piezo Electric

Element). In order to uniform the amount of ejecting ink, the printhead has its own

head ID (6 digits for this printhead) which adjust PZT voltage drive features.

The printer read the head ID form EEPROM and generates appropriate PZT drive

voltage to prevent amount of ink from varying by printheads.

Following explains printhead basic components.

PZT

PZT is an abbreviation of Piezo Electric Element. Certain amount of voltage

expands and contracts PTZ. The dri ve wave generated o n MAIN board driv es PZT

and PZT pushes the top cavity which has ink stored to disc harge the ink fr om each

nozzle on the nozzle plate.

Nozzle Plate

Head Driver Board

Ink Cartridge

PZT

Needle

Filter

Cavity

Figure 2-2. Printhead Sectional Drawing

Ink Cavity

The ink absorbed from the ink cartridge goes through the filter and then is stored

temporarily in this tank called “cavity” until PZT is driven.

Nozzle Plate

The board with nozzle holes on the printhead surface is called Nozzle Plate.

Filter

When the ink cartridge is installed, if any dirt or dust around th e cartridge needle is

absorbed into the head, there is a great possibility of causing nozzle clog and

disturbance of ink flow, and finally causing alignment failure and dot missing. To

prevent this problem, a filter is set below the cartridge needle, wh ere ink is filtered.

Operating Principles Overview 26

Page 27

Stylus C40UX/C40SX/C20UX/C20SX Revision B

2.1.2.1 Printing Process

This section explains the process in which the printheads of On- Demand inkj et printers

eject ink from each nozzle.

1. Normal State:

When no printing signal is sent from PC, or no PZT drive voltage is applied, PZT

does not change shape, therefore PZT does not squeeze the cavity. Ink pressure

inside the cavity is kept normal. (Refer to Figure 2-3.)

2) Ejecting State:

When the print signal is output from the C413MAIN/B board, IC (Nozzle

Selector) located on the printhead unit latches data once by 1-byte unit. An

appropriate PZT latched by the nozzle selector is pushed into the cavity by the

common voltage applied from the main board. By this operation, ink stored in the

cavity spurts out from nozzles.(Refer to Figure 2.1.2.2.)

Ink Path

Nozzle

PZT

Ink Cavity

Nozzle plate

2.1.2.2 Printing Method

For print dot system, Stylus C40UX/C40SX/C20UX/C20SX has the following two

kinds of printing modes.

Multiple shot printing

Variable dot printing

The above two printing modes are automatically selected depending on the media and

the resolution setting of the printer driver. The following explains each printing mode.

Multiple shot printing

This printing mode is developed to improve the print quality on plain paper or

transparencies in low resolution. The multiple shot printing mode uses normal dot

and the number of dot shots varies from 1 shot to maximum 4 shots depending on

the print data to enable sharp image output even in a low resolution.

Variable dot printing

This printing mode is developed to improve the print quality on exclusive paper.

This mode is basically the same as variable dot printing mode used on other

products /; micro dot, middle dot, and large dot compose this mode. Print dot size

varies according to print data and this mode enables even sharper im age ou tput o n

exclusive paper.

PZT drive voltage

Figure 2-3. Printhead printing process

Operating Principles Overview 27

Page 28

Stylus C40UX/C40SX/C20UX/C20SX Revision B

2.1.3 Carriage Mechanism

The carriage mechanism consists of Carriage motor (CR motor), Carriage unit

(including printhead), CR timing belt, CR guide shaft, CR guide frame, CR home &

I/C detector (HP/PE/IC sensor) etc. The carriage mechanism moves the carriage back

and forth according to the dr ive from the carriage motor. Th e following steppi ng motor

is mounted to drive CR mechanism. (See the table below.)

Table 2-1. Carriage Motor Specification

Items Specifications

Type 4-Phase/ 48-Pole PM Stepping motor

Drive Voltage +42 V +/ - 5% (DRV IC voltage)

Coil Resistance 10.8 Ω +/ - 10% (per phase at 25 degree)

Inductance 15 mH +/ - 20%(1KH 1VmA)

Drive Method Bi-Polar drive

Driver IC XC901503FNR2

The drive from CR motor is transferred to the CR unit via CR timing belt. And the CR

home position is detected with the HP/PE/IC sensor. This sensor is available as CR HP

detector only in the HP (home position) detection sequence & pump operation

sequence. (not available in the paper feeding sequ ence fo r the C R HP detector becaus e

it is used for only PE sensor during the paper feeding sequence.) Moreover, unlike the

previous products, this printer dose not have the PG adjustment mechanism.

CR home position is detected with the HP/PE/IC sensor and the d etection plate molded

in the CR unit as following figure. When the CR home position is detected with this

sensor, HIGH signal is output to the CPU.

HP/IC detection Lever

CR HP dete ction plate

Right side view

CR HP detection plate

HP/IC detection

Lever

Low signal

High signal

Figure 2-5. CR home position

Unlike the previous products, I/C detection sensor is not built in the CR unit.

The I/C is detected with the HP/PE/IC sensor and the detection plate mo lded on the I/C

cover as following figure. The I/C installation condition is monitored only when the

CR unit moves to the I/C detection position (HP detection sequence). So, this sensor

function is not available in the paper feeding sequence. When the I/C is not installed

into the CR unit, HIGH signal is output to the CPU.

HP/IC detection Lever

Right side view

I/C detection plate

HP/PE/ICSensor

CR Motor

High signal

I/C detection plate

HP/IC detection

Lever

Low signal High signal

Figure 2-6. I/C detection position

CR unit

CR Timing belt

Figure 2-4. Carriage Mechanism (Top view)

Operating Principles Overview 28

Page 29

Stylus C40UX/C40SX/C20UX/C20SX Revision B

Also, when replacing ink use this lever to confirm whether the cover cartridge is open

or closed.

There are separate replacement positions for replacing the Black and Color ink

cartridges. If the cover cartridge is open, the I/C detection plate makes contact with the

HP/IC detection lever, causing the HP/IC sensor to detect a high signal.

HP/IC detection Lever

I/C detection plate

Right side view

High signal

I/C detection plate

HP/IC

detection Lever

Low signal

Figure 2-7. I/C change position

If a High signal is detected even once, it is regarded as if that ink cartridge was

replaced and the cleaning and ink counters are cleared.

If the High signal is not detected even once, the cleaning and ink counter are not

cleared.

If both the ink cartridges have not been set before carrying out initial filling, the

carriage moves to the position where both ink cartridges can be set, but checking if the

cartridge is open or closed is not done.

If one of the ink cartridges has not been set, the carriage moves to the replacement

position of the ink cartridge that is not set due to one time prevention of the set ink

cartridge.

Operating Principles Overview 29

Page 30

Stylus C40UX/C40SX/C20UX/C20SX Revision B

2.1.4 Paper Feeding Mechanism

The paper feeding mechanism consists of Paper feed motor (PF motor), PF roller,

Paper eject roller, Star wheel roller, and so on. The paper feeding mechanism feeds

paper loaded from ASF using the PF roller and Paper Eject Roller & Star wheel roller.

For this mechanism, the PF motor mentioned in the right Table 2-2 is used on this

product.

The drive of the PF motor is transfer to the PF roller and the Paper Eject Roller as

following Figure 2-8. Following shows you how to transfer the PF motor drive to the

PF roller and the Paper Eject Roller.

PF motor drive transmission path

PF Motor Pini on Gear (CW)

→

Spur Gear 60 (PF roller)(CCW)

→

Spur Gear 60 (PF roller)(CCW)

Table 2-2.

Item Description

Motor type 4-Phase/ 48-Pole PM Stepping motor

Drive voltage +42 V +/ - 5% (DRV IC voltage)

Coil Resistance 10 Ω +/ - 10% (per phase)

Inductance 10.5 mH +/ - 20%(1kH 1Vrms)

Driving method Bi-Polar drive

Driver IC XC901503FNR2

Change Lever

PF Motor Specifications

Spur Gear 35.2

Combination

Gear 16, 32

PF roller

Spur Gear 10. 8

Spur Gear 18. 28

Spur Gear 25.6

Spur Gear 27. 2

Figure 2-8. Paper Feeding Mechanism

Paper loaded from ASF is advanced by the following roller.

Paper feed roller & Paper guide roller (assembled on the Top Frame)

eject roller & Star wheel roller (assembled on the Paper eject frame).

→ Paper

Operating Principles Overview 30

Page 31

Stylus C40UX/C40SX/C20UX/C20SX Revision B

Additionally, the top & end of the paper is detected with the HP/PE/IC sensor.

In case the PE sensor dose not detect the paper in the paper loading sequence, the

printer detects the “Paper out error”. If the paper is detected after complete the paper

eject sequence, the printer detects the “Paper jam error”.

2.1.5 Paper Loading Mechanism (ASF Unit)

The Paper loading mechanism is positioned at the printer rear. The Paper loading

mechanism loads paper at the ASF unit and feeds paper to the PF roller.

This ASF unit was designed newly for this product and consists of LD roller, Pad

holder (Paper return plate), ASF Frame, Hopper, and so on.

For the major feature of this ASF unit, ASF HP sensor is not used and the single LD

roller is built in the ASF unit.

Drive sent from the PF motor is always transmitted to the ASF unit side. But, the

Change lever and the Clutch mechanism switch ON/OFF the PF motor drive to the LD

roller with the motor rotational direction.

Drive from the PF motor is transmitted to the ASF unit as described below:

Switch the PF motor drive to ASF unit side

→

PF Motor Pinion Gear (CCW)

→

10.8 (CW)

Gear 25.6 (CCW)

lock position

Combination Gear

→

Change Laver Rotates (CCW)

Following Figure 2-9 shows you the switching path for PF motor drive to ASF unit

side.

Change Lever

Spur Gear 60 (PF Roller) (CW) → Spur Gear

18, 28 (CCW) → Spur Gear 27.2 (CW) → Spur

→

Release the Clutch mechanism

Spur Gear 35. 2

Combination

Gear 35. 2

Spur Gear 10. 8

Combination Gear 18, 28

Spur Gear 25. 6

Spur Gear 27. 2

Figure 2-9. Switch the PF motor drive to ASF unit side

Operating Principles Overview 31

Page 32

Stylus C40UX/C40SX/C20UX/C20SX Revision B

Transfer the PF motor drive to LD roller

PF Motor Pini on Gear (CW)

(CCW)

25.6 (CW) →

Spur Gear 35.2 (CW) (include the clutch mechanism) →

→

Combination Gear 18, 28 (CW) →

Change Laver rotates (CW) → Combination Gear 16, 32 (CCW) →

→ Spur Gear 60 (PF Roller) (CCW) →

Spur Gear

27.2 (CCW)

LD Roller (CW)

Spur Gear

→ Spur Gear

10.8

Following Figure 2-9 shows the PF motor drive transmission path to the LD roller unit

built in the ASF unit. The LD roller is assembled on the same shaft that the Spur gear

35.2 is assembled.

Figure 2-10. PF motor drive transmission path

When the PF motor torque is switched to the ASF unit side by the clutch mechanism,

the function of the ASF mechanism varies depending on the rotational direction of the

PF motor, as shown in the table below.

Table 2-3. ASF unit function & PF Motor rotational direction

Change Leve r

Spur Gear 10, 8

Combination Gear 18, 28

Spur Gear 27. 2

Spur Gear 35. 2

Combination

Gear 35. 2

Spur Gear 25. 6

Clutch Mechanism

Unlike the previous products, this product dose not have a ASF HP sensor.

Instead of the ASF HP sensor, Change lever and the Clutch mechanism are used to

detect the ASF home position. Following figures describe the mechanism.

Directions Corresponding Functions

Clockwise (*1)

Counterclockwise (*1)

• Picks up and loads paper

• Release the DE lever & Clutch mech anism

(*1): The PF Motor rotational direction = seen from the right side of the printer.

Operating Principles Overview 32

Page 33

Stylus C40UX/C40SX/C20UX/C20SX Revision B

NOTE:

The Clutch gear is molded on

the back side of the Spur gear

35.2 such as Combination gear.

Spur gear 35.2

Clutch lever

Step1

Change Lever

Figure 2-11. Disengage & Clutch mechanism

The Clutch mechanism transmits the PF motor drive to the LD roller shaft only when

the Clutch gear rotates CW direction after the Change lever releases the Clut ch lever. If

the Clutch gear rotates CCW direction, the PF motor drive is not transmitted to the LD

roller. This is due to the combination of the shape of the Clutch gear and the Clutch

lock tooth su ch as described on the figure.

1. When the paper is advanced with the PF roller, the Change lever is set on the

Clutch lever and the Clutch is pushed down as above Step1’s figure. As the

result, the Clutch gear (*1) is released from the Cluck lock tooth and the drive

from the PF motor is not transmitted to the LD roller shaft.

Clutch gear

Clutch

Step2

Tension spring 0.143

Clutch lock tooth

Step3

LD roller shaft

Paper Return Plate (Pad holder)

Unlike the previous products, The Paper return plate is built in the ASF frame instead

of the Paper return lever. The Paper separation pad is also stacked on the plate.

It works with the spring force of the Torsion sprin g 26 (mo unted in the ASF f rame) as

following figure.

LD roller

Paper Return

Plate

Hopper

2. When the PF pinion gear rotates CCW direction in the above Step2’s figure, the

Change lever moves to the left direction with the CCW rotation of Spur gear 25.6.

The Clutch turns back to the engagement position by the tension force of the

Tension spring 0.143 and the Cl utch gear is engaged with the Clutch lock tooth as

above Step2’s center figure.

ASF frame

Torsion spring 26

Figure 2-12. Paper Return Plate

Compression spring 2.11

3. When the PF pinion gear rotates CW direction in the above Step3’s figure, the

Change lever moves to the right direction with the CW rotation of the Spur gear

25.6. And the drive from the PF motor is transmitted to the LD roller shaft via

Clutch gear and Clutch lock tooth.

4. The LD roller shaft rotates about 360 degree and the Ch ange lever p ush the Clutch

lever and the PF motor drive is interrupted. This position is the ASF home

position.

The Paper return plate is set to return the paper to the paper stand-by position in the

ASF unit when the ASF unit is in the standby mode. When the paper is fed with the

LD roller, the Paper return plate is stored in the ASF frame by the LD roller.

Following figures show you the ASF paper loading sequence and the operation of the

each mechanism.

Operating Principles Overview 33

Page 34

Stylus C40UX/C40SX/C20UX/C20SX Revision B

.

When the paper is advanced with

the PF roller, Change lever push

down the Clutch lever as right

figure and the Clutch lock tooth is

disengaged from the Clutch gear.

As the result, the drive from the PF

motor is interrupted and the LD

roller dose not rotate.

This position is the ASF home

position.

The Paper return plate is set to

avoid that the paper is slipped

down from the paper set position.

The PF motor pinion gear rotates

CW direction and the drive from the

PF motor is transmitted to the ASF

LD roller shaft through the Clutch

lock tooth and the Clutch gear.

The ASF hopper release lever rotates

with the ASF LD roller and release

the ASF Hopper. The ASF hopper is

pushed with the Compression spring

2.11 and the paper is picked up with

the ASF LD roller.

LD roller shaft

Paper return plate

PF roller CCW

rotation

ASF Hopper

release lever

LD roller

Clutch lever

Step 1

Change lever

Step 3

Clutch gear

Clutch lock tooth

Clutch

LD roller shaft

Hopper

Compression

spring 2.11

Printer front si de

PF roller CW

rotation

ASF Frame

Step 2

Tension spring 0.143

Step 4

Paper return plate

When the paper is loaded (pick up) from

the ASF unit, the Change lever moves to

the printer front side with the CCW

rotation of the PF motor pinion gear and

releases the Clutch lever. As the result,

the Clutch turns back to the engagement

position by the tension force of the

Tension spring 0.143.

And the Clutch lock tooth is engaged

with the Clutch gear as right figure.

The ASF LD roller rotates CW direction

moreover and the Paper return plate is

stored under the ASF frame.

The paper is advanced up to the PF roller

and the ASF LD roller & the clutch rotate

to the “Step1” position. The Clutch lever

is locked with the Change lever.

The drive from the PF motor is

interrupted and the drive is transmitted to

the PF roller side.

PF roller CCW

rotation

ASF hopper

release lever

PF roller CCW

rotation

Figure 2-13. ASF Paper Loading Sequence

Operating Principles Overview 34

Page 35

Stylus C40UX/C40SX/C20UX/C20SX Revision B

2.1.6 Ink System Mechanism

Ink system mechanism consists of pump unit (include the CR lock lever) and capping

mechanism. Ink system mechanism drives the pump unit that presses cap to the

printhead and ejects ink from ink cartridge, head cavity and cap to the waste ink pad.

2.1.6.1 Pump Unit & Wiper mechanism

The pump unit is driven by PF motor. PF motor drive is always transmitted to the paper

feeding mechanism and pump unit through the following gears. Refer to the Figure

2-15.

PF Motor Pinion Gear (CCW)

Combination Gear 18, 28 (CCW) → Spur Gear 27.2 (CW)(Pump unit)

→

Spur Gear 60 (PF Roller)(CW) → Spur Gear 10.8(CW)

→

Pump unit

Table 2-4. PF motor rotational direction & Ink System Mechanism

Directions Functions

Counterclockwise (*1)

• Absorbs ink by the pump unit

• Set the CR lock lever

(*1): The PF Motor rotational direction = seen from the right side of the printer.

Following figure shows the overview of the pump mechanism operation.

Figure 2-14. Pump mechanism

Spur Gear 10. 8

Cap unit

Pump unit

Combination Gear 18, 28

Spur Gear 27. 2

Figure 2-15. PF motor drive transmission path to the Pump unit

Operating Principles Overview 35

Page 36

Stylus C40UX/C40SX/C20UX/C20SX Revision B

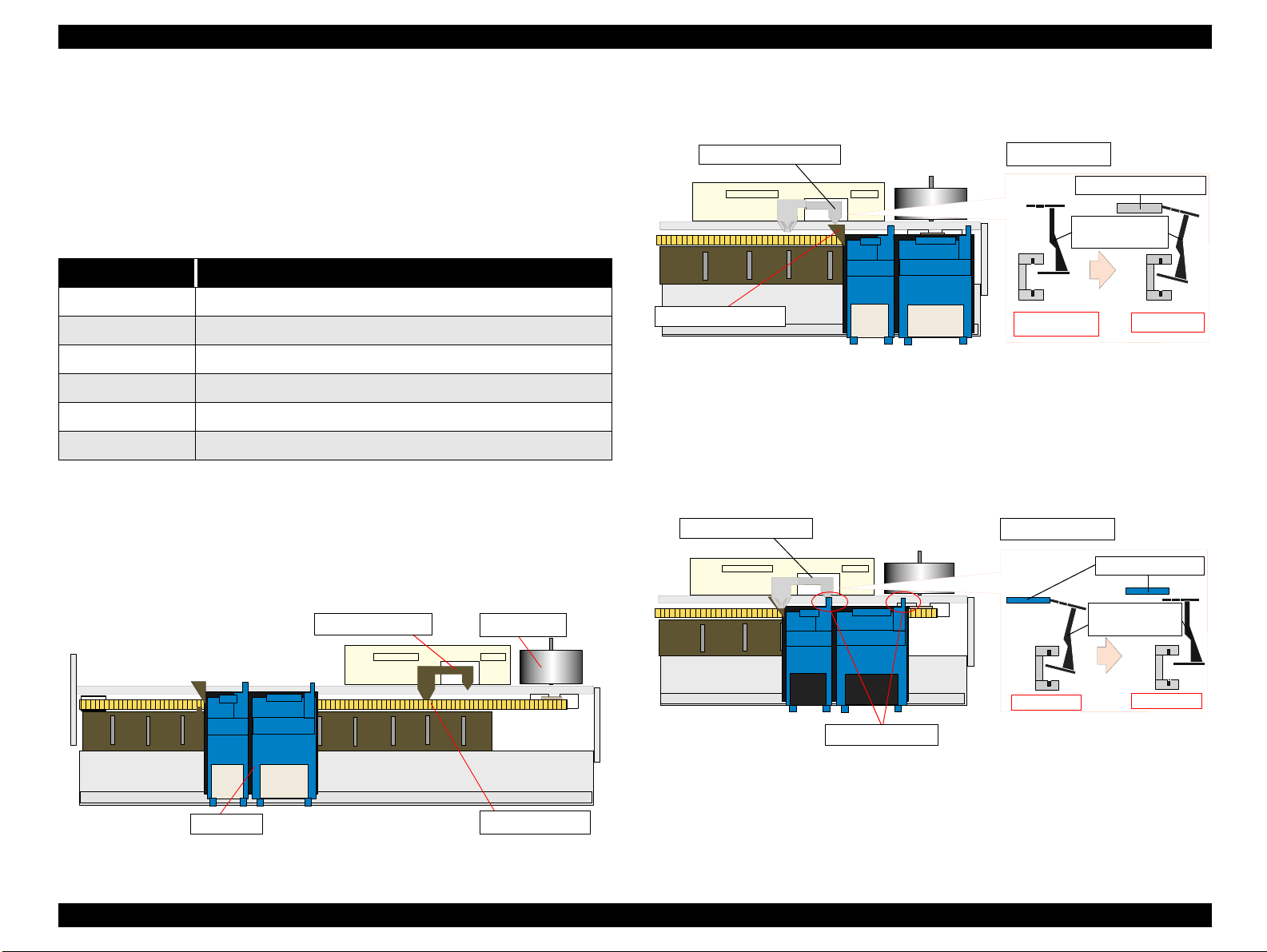

2.1.6.2 Capping Mechanism

The capping mechanism covers the p rintheads with the cap holder to p revent the nozzle

from increasing viscosity when the printer is in stand-by mode or when the printer is

off. This product has valveless cap system. Air valve function used for the previous

models pumps and ejects ink only inside the cap by absorbing ink with the valve open.

By opening the Air valve, the negative pressure is decreased and only the ink inside the

cap is ejected. (the ink is not absorbed from Ink cartridge or head cavity.)

But, valveless cap system, this operation is done out side of the capping area.

The CR moves to left side of the Cap assembly and the pump abs orbs the in k inside the

cap.

Viewed from front side

CR unit

Slider cap

Printhead

Cap

Waste Ink tube

Figure 2-16. Cap Mechanism

Slide up

3. If the carriage moves to the left side, spring forces tends to force the cap back to its

original position, but it stops at the wiping position due to the lever lock slider.

(Refer to Figure 2-17. Wiping Position)

4. When the carriage moves to the left side, the head surface and wiper makes contact

and wiping is performed. (Refer to Figure 2-17. Wiping Position)

5. Even when wiping is completed, the carriage moves further to the left side and

when the hook on the carriage’s right side hits the lever lock slider lever, the lever

lock slider’s hook is released. (Refer to Figure 2-17. Wiper Set Release)

Carriage unit

The carriage

pushes the lever.

Right side from

capping position

Hook

Figure 2-17. Wiper Set Position

Print head

Wiper

Figure 2-17. Wiping Position

Carriage unit

Print head

Hook

The hook is

released.

Also, unlike previous models, the cap unit is newly designed for this model as follows.

2.1.6.2.1 Wiper with the cap unit

Wiping control is carried out by the procedure shown below.

1. The carriage is moved to the wiper set position. (Refer to Figure 2-17. Wiper Set

Position)

2. When the carriage moves to the wiper set position, the hook on the lever lock

slider engages, locking the lever lock slider. (Refer to Figure 2-17. Wiper Set

Position)

Wiper

Figure 2-17. Wiping

Print head

Figure 2-17. Wiper Release

Operating Principles Overview 36

Page 37

Stylus C40UX/C40SX/C20UX/C20SX Revision B

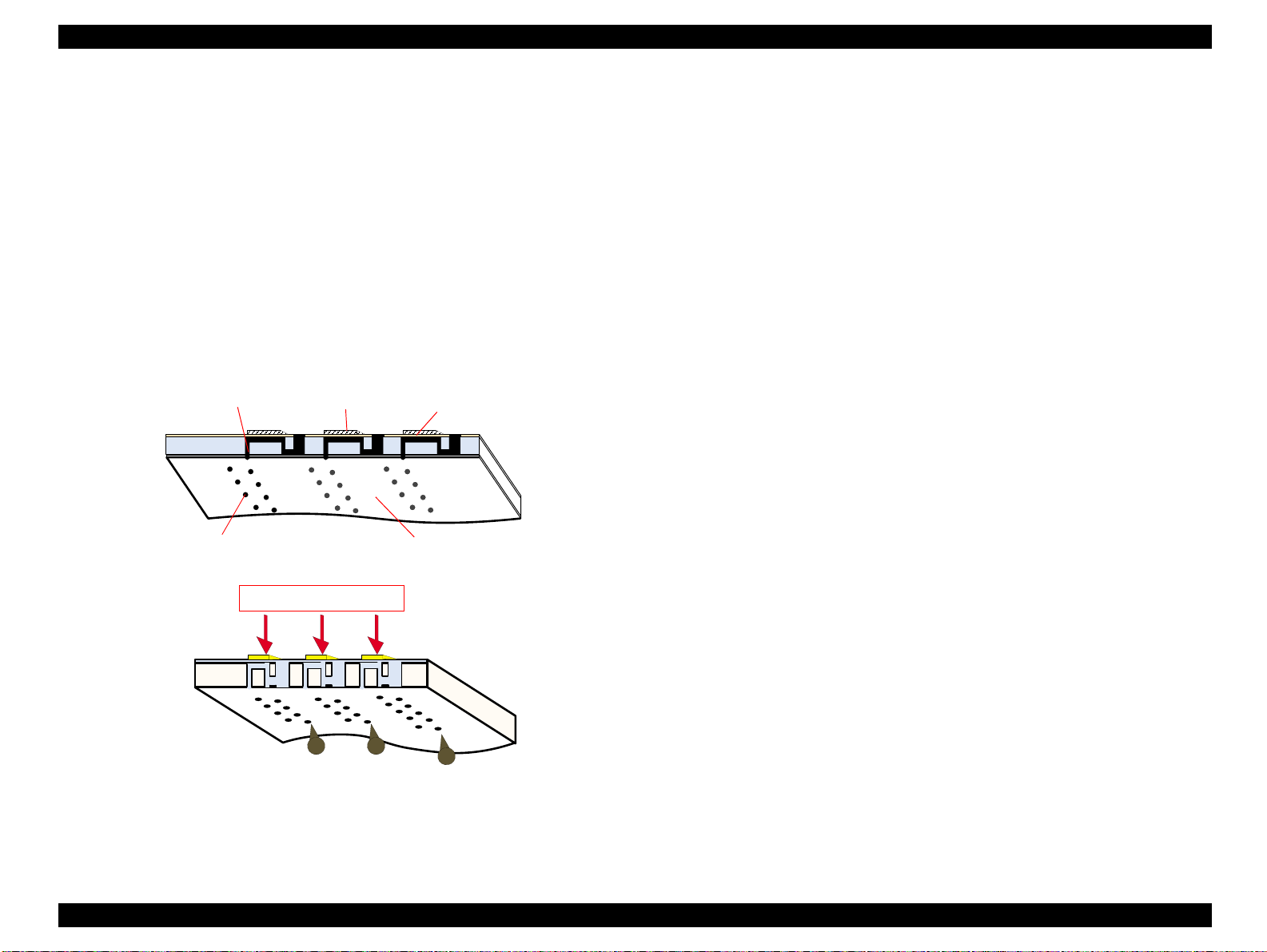

2.1.6.2.2 Non porous pad in cap

Due to this, the cap is newly designed as follows.

Stylus C40/C20

seal rubber

ink eject hole

Stylus COLOR 480

porous pad

Figure 2-18. non porous pad in cap (Stylus C40/C20)

The cap unit used for the previous models has the porous pad to keep the moisture in

the cap and prevent that the air bubble occurs in CL sequence.

To get the same effects on new cap unit without the porous pad.

For keep the moisture in the cap

The diameter of the ink eject hole is smaller than that of Stylus COLOR 480

For prevent that the air bubble occurs in CL sequence

The cap is modified so that ink flows to ink eject hole with air bubble in CL

sequence.

Operating Principles Overview 37

Page 38

Stylus C40UX/C40SX/C20UX/C20SX Revision B

2.1.7 Ink Sequence

Initial ink charge

After the product is purchased and the printer is turned on for the first time, the

printer must be performed the initial ink charge and charges ink inside the head

cavity. When the initial ink charge is completed properly, the printer releases the

flag inside the EEPROM and no initial ink charge will be performed next time the

power is turned on. Stylus C40UX/C40SX/C20UX/C20SX takes 70 seconds to

complete the initial ink charge sequence and consume about 1/4 of the brand-new

black ink cartridge. If the power is turned off during initial filling, CL1 is

performed when the power is turned on the next time.

Manual Cleaning

Stylus C40UX/C40SX/C20UX/C20SX provides three type of manual cleaning to

clean air bubbled or clogged ink with viscosity or foreign substances.

The following manual CL sequences can be executed by the utility included in the

printer driver.

CL1

The above mentioned manual CL is executed by performing nozzle check pattern and

manual CL alternately. The cleaning order is CL1

Like the previous products, CL1 is selected automatically and performed in case any

print check is not executed between each manual C L. Additionally, if the m anual CL is

performed with over 5 pages printing cycle, CL1 is always selected and performed.

Additionally, if either black or color I/C is ink low or end condition, any manual

cleaning is prohibited and it is displayed on the LED indicators.

CL2

- Ink absorption

Black Ink: 0.3g, Color Ink: 0.3g

-Wiping operation

Wipes nozzle plate by the rubber part on the right half of the wiper.

-Flashing operation

Prevents color from mixing. Stabilizes ink surface inside the nozzle.

→

CL2→ CL1→ CL1’→ CL1.

- Ink absorption

Black Ink: 0.175g, Color Ink: 0.175g

-Wiping operation

Wipes nozzle plate by the rubber part on the right half of the wiper.

-Flashing operation

Prevents color from mixing. Stabilizes ink surface inside the nozzle.

CL1’

- Ink absorption

Black Ink: 1.02g, Color Ink: 1.02g

-Wiping operation

Wipes nozzle plate by the rubber part on the right half of the wiper.

-Flashing operation

Prevents color from mixing. Stabilizes ink surface inside the nozzle.

Timer Cleaning

Unlike the previous product, this printer dose not have Timer IC and Lithium battery

which is used for the backup power source for Timer IC. So, this printer manages the

printer off period or cleaning cycle by using the following method.

The timer command is sent to the printer by the printer driver before printing. The

timer command s generated based on the PC’s timer and is configured from the year,

month, day, hour, minute and secon d. When the printer receiv es the timer comm and, it

generates data which include the mont h, day and time and stores it at addres ses 04 <H>

and 05 <H> in the EEPROM.

The printer compares the values stored in addresses 02 <H> and 03 <H> with the

values stored in addresses 04 <H> and 05 <H> of the EEPROM, and if the compared

value is greater than the specified time, timer cleaning is performed automatically.

The printer writes the values in EEPROM addresses 02 <H> and 03 <H> in addresses

04 <H> and 05 <H> when cleaning (timer cleaning, manual cleaning, ink cartridge

replacement cleaning, etc.) is performed.

A maximum of 0.48 g of ink is consumed (0.24 g each for the single color and color

ink cartridges) during timer cleaning.

Operating Principles Overview 38

Page 39

Stylus C40UX/C40SX/C20UX/C20SX Revision B

Flashing

This printer performs the following two kinds of the Flashing for the following

purpose.

Periodical Flashing

This is due to avoid the increment of both ink’s viscosity in the printhead

nozzle during the continuous printing and the specific small amount of the ink

is ejected in the cap based on the periodical flashing timer.

Periodical large amount Flashing

This is due to avoid the increment of black ink’s viscosity in the printhead

nozzle during the continuous printing and larg e amount of the ink is ejected in

the cap based on the periodical large mount flashing timer.

Operating Principles Overview 39

Page 40

Stylus C40UX/C40SX/C20UX/C20SX Revision B

2.1.8 Printing mode

The print resolution and printing method are determined automatically by setting the

media type and print quality (It is able to set by slider bar) in the printer driver as

following table. Following table show you the detail setting in the “Auto” mode.

Print media Slide bar Resolution Print mode

Table 2-6. Printing mode for Black mode

High

Speed*1

Micro

weave

Dot size*2

Table 2-5. Printing mode for Color mode

Print media Slide bar Resolution Print mode

Speed 120 x 120 Economy ON OFF ND-3dot

Plain paper

360 dpi Ink jet

paper

Photo Quality

ink jet paper

Matte Paper-

Heavyweight

Photo paper

Photo Quality

Glossy Film

Ink Jet

transparencies