Page 1

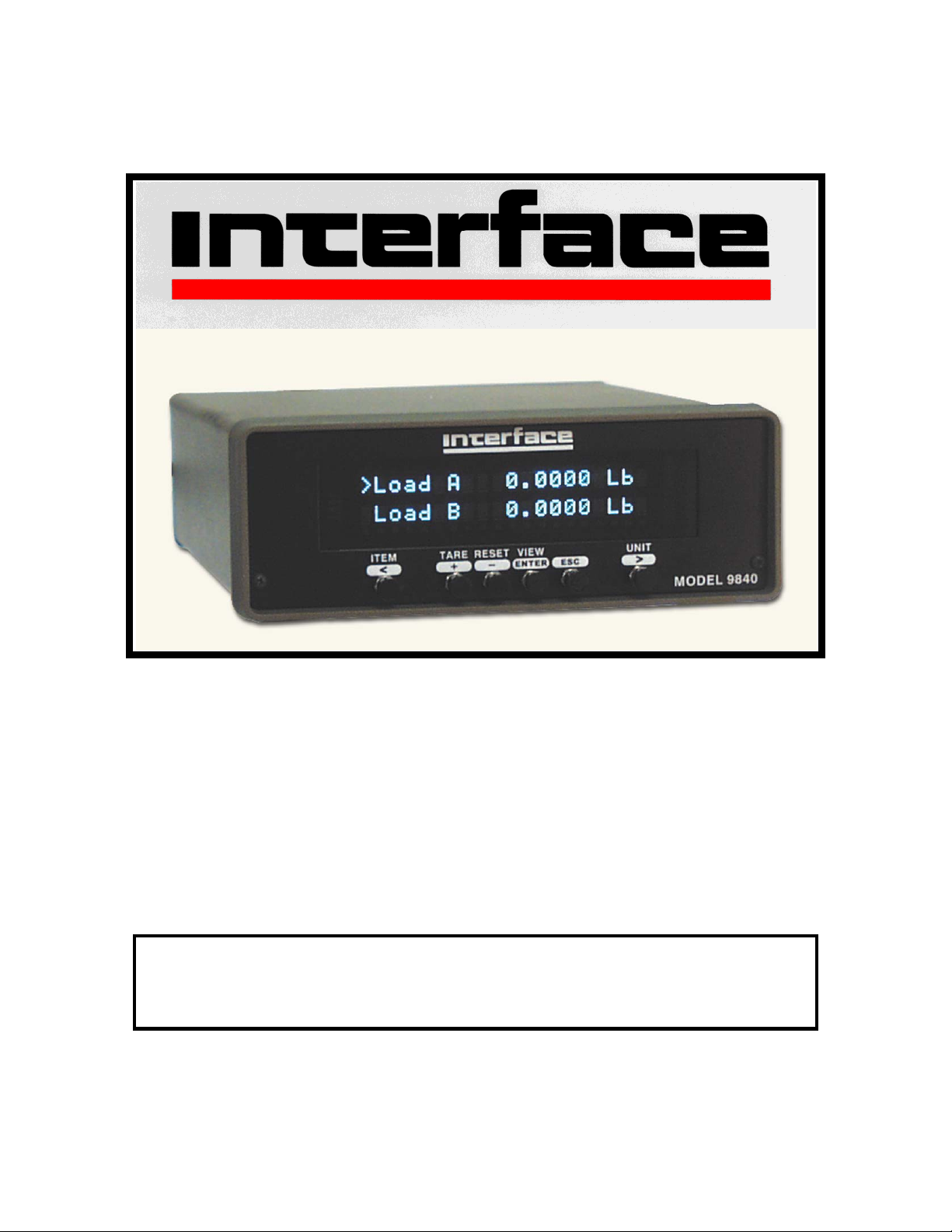

Advanced Force Measurement

Model 9840

Digital Process Monitor

Interface, Inc. 7401 E. Butherus Dr. Scottsdale, Arizona 85260 USA

Tel: (480) 948-5555, Fax: (480) 948-1924

Page 2

INTERFACE MODEL 9840 VER 6.0.2

CONTENTS

CONTENTS ..................................................................................................................................................1

INTRODUCTION ........................................................................................................................................ 4

QUICK START ............................................................................................................................................ 6

RUN MODE..................................................................................................................................................9

ITEM BUTTON................................................................................................................................................10

TARE BUTTON ...............................................................................................................................................10

RESET BUTTON..............................................................................................................................................11

VIEW BUTTON ...............................................................................................................................................11

ESC BUTTON.................................................................................................................................................. 11

UNIT BUTTON................................................................................................................................................12

SETUP MODE SUMMARY ......................................................................................................................13

SETUP MODE............................................................................................................................................ 14

ENTERING NUMERICAL DATA........................................................................................................................ 15

ENTERING ALPHANUMERIC DATA .................................................................................................................15

>USER DATA ENTRY .....................................................................................................................................15

>>Base Area Ch A/B ............................................................................................................................... 15

>>Base Length......................................................................................................................................... 15

>ANALOG OUTPUT ........................................................................................................................................ 15

>SENSOR SELECT........................................................................................................................................... 17

SENSOR DELETE ............................................................................................................................................18

>CALIBRATION.............................................................................................................................................. 18

>>Cal Check............................................................................................................................................19

>>Cal by mV/volt (2-Point or 6-Point)....................................................................................................19

>>Cal by Masses or Torque (2-Point or 5-Point)................................................................................... 19

>>Cal by Shunt Val .................................................................................................................................20

>>Counts per Inch...................................................................................................................................20

>LIMITS.........................................................................................................................................................20

>SYSTEM OPTIONS ........................................................................................................................................21

>>Printer Baud........................................................................................................................................ 21

>>Auto Identify........................................................................................................................................21

>>Auto Zero Ch A/B................................................................................................................................21

>>Com Address....................................................................................................................................... 22

>>Com Baudrate..................................................................................................................................... 22

>>Com Line Feed....................................................................................................................................22

>>Retain Tare.......................................................................................................................................... 22

>>RS232 EOT Char ................................................................................................................................22

>DISPLAY OPTIONS .......................................................................................................................................22

>>Filter Select.........................................................................................................................................22

>>Decimals Ch A/B.................................................................................................................................23

>>Count By Ch A/B.................................................................................................................................23

>>Second Line.........................................................................................................................................23

>>Filter Window ..................................................................................................................................... 23

REMOTE OPERATION ........................................................................................................................... 24

DIGITAL INPUTS............................................................................................................................................. 24

USB Driver...............................................................................................................................................24

MODEL 9840 PG 1 PUB. 2856-16

Page 3

INTERFACE MODEL 9840 VER 6.0.2

Communications Settings .........................................................................................................................25

Communications Format..........................................................................................................................25

RS232 RUN MODE COMMAND SUMMARY....................................................................................... 25

RS232 RUN MODE COMMANDS........................................................................................................... 26

HELLO COMMAND (H)................................................................................................................................... 26

QUESTION MARK COMMAND (?) ................................................................................................................... 26

FRONT PANEL DISPLAY COMMAND (F) ......................................................................................................... 27

Front Panel View Command (FV)............................................................................................................ 27

Front Panel Set Command (FS)............................................................................................................... 27

Front Panel Alternate Command (FA).....................................................................................................27

Front Panel Pointer Control to Line 1 (F1).............................................................................................27

Front Panel Pointer Control to Line 2 (F2).............................................................................................28

VALUE COMMAND (V) FOR ONE OR BOTH CHANNELS....................................................................................28

PRINT COMMAND (P)..................................................................................................................................... 29

RESET TARE, PEAK, VALLEY OR POSITION COMMAND (R)............................................................................29

FREEZE DISPLAY COMMAND (X)...................................................................................................................30

TEXT DISPLAY COMMAND (T).......................................................................................................................30

RS232 SETUP MODE COMMAND SUMMARY...................................................................................31

RS232 SETUP MODE COMMANDS.......................................................................................................32

USER DATA ENTRY COMMAND (U)............................................................................................................... 32

User Data View Command (UV)..............................................................................................................32

User Data Area Command (UA).............................................................................................................. 32

User Data Length Command (UL)...........................................................................................................32

ANALOG OUTPUT COMMAND (A)..................................................................................................................33

Analog Output View Command (AV) ....................................................................................................... 33

Analog Output Set Command (AS)...........................................................................................................33

SENSOR COMMAND (S).................................................................................................................................. 33

Sensor View Channel A or B Command (SA or SB)................................................................................. 33

Sensor View Command (SV)..................................................................................................................... 34

Sensor Select Command (SS)....................................................................................................................34

Sensor Delete Command (SD).................................................................................................................. 34

CALIBRATION COMMAND (C)........................................................................................................................35

Calibration Check Command (CC).......................................................................................................... 35

Calibration Begin Command (CB)...........................................................................................................35

Calibration Escape Command (CE)......................................................................................................... 37

Calibrate by Millivolt-Per-Volt Command for One Point (CV)............................................................... 37

Calibrate by Millivolt-Per-Volt Command for Six Points (CMV6).......................................................... 37

Calibrate by mV/V Mass and Volt Commands (CMVM and CMVV).......................................................37

Calibrate by mV/V Torque and Volt Commands (CMVT and CMVV).....................................................38

Calibrate by Masses Command (CM)...................................................................................................... 39

Calibrate by Masses Point Command (CMP).......................................................................................... 40

Calibrate by Torque Command (CT) ....................................................................................................... 41

Calibrate by Torque Point Command (CTP) ........................................................................................... 41

Calibrate by Shunt Command (CS).......................................................................................................... 42

Calibrate Counts-Per-Inch Command (CI)..............................................................................................42

LIMITS COMMAND (L)................................................................................................................................... 43

Limit View Command (LiV)...................................................................................................................... 43

Limit Set Command (LiS) .........................................................................................................................43

Limit Setup Escape (LE)...........................................................................................................................44

Limit Reset Command (LiR)..................................................................................................................... 45

SYSTEM OPTIONS COMMAND (O).................................................................................................................. 45

MODEL 9840 PG 2 PUB. 2856-16

Page 4

INTERFACE MODEL 9840 VER 6.0.2

Option View Command (OV)....................................................................................................................45

Option Printer Baudrate Command (OP)................................................................................................ 45

Option Auto-Identify Command (OI)........................................................................................................46

Option Auto-Zeroing Command (OZ)...................................................................................................... 46

Option Com Address Command (OA)...................................................................................................... 46

Option Com Baudrate Command (OB).................................................................................................... 47

Option Linefeed Command (OL)..............................................................................................................47

Option Tare Retain Command (OT)......................................................................................................... 47

Option End of Transmission Character (OE)...........................................................................................47

DISPLAY OPTIONS COMMAND (D)................................................................................................................. 48

Display View Command (DV).................................................................................................................. 48

Display Filter Command (DF)................................................................................................................. 48

Display Decimal Command (DD)............................................................................................................ 48

Display Count By Command (DC)........................................................................................................... 49

Display Second Line Command (D2).......................................................................................................49

Display Second Line Text (DT) ................................................................................................................49

Display Filter Window Commands (DW)................................................................................................. 49

SYSTEM CALIBRATION MODE...........................................................................................................51

APPENDIX A -- MODEL 9840 SPECIFICATIONS..............................................................................52

APPENDIX B -- CABLES AND CONNECTORS................................................................................... 55

LOAD CELL CONNECTORS .............................................................................................................................55

SERIAL PORT CONNECTOR............................................................................................................................. 55

DIGITAL I/O CONNECTOR.............................................................................................................................. 56

CHART REC. CONNECTOR..............................................................................................................................56

USB CONNECTOR..........................................................................................................................................57

PRECISION SHUNT CALIBRATION RESISTORS.................................................................................................58

Under the copyright laws, this publication may not be reproduced or transmitted in any

form, electronic or mechanical, including photocopying, recording, storing in an

information retrieval system, or translating, in whole or part, without the prior consent of

Interface, Inc. Copyright January 8, 2008 all rights reserved.

MODEL 9840 PG 3 PUB. 2856-16

Page 5

INTERFACE MODEL 9840 VER 6.0.2

INTRODUCTION

The Model 9840 is a CE compliant and versatile precision instrument intended for the

digital readout of strain gage sensors such as load cells and torque cells. Optical

encoders are also supported.

Here is a quick listing of its features:

• Full bi-polar 6 digit display (±999,999) using two line, 20 character, vacuum

fluorescent display for clear, precise indication of measured quantities and limit status.

• No knobs or dials. No internal jumpers. All adjustment and calibration is done using

user-friendly front panel menus. Keylock option to prevent accidental or unauthorized

changes to the unit’s setup.

• Measure load and gross weight in pounds, kilograms, Newtons, PSI, MegaPascals,

kilo-pounds, kilo-Newtons, metric tons, mV/V, or grams. User defined base area for

PSI and MPa. Tare at any time. The sum of the loads on both channels is also

availabe.

• Measure torque and gross torque in Pound-Inches, Newton-Meters, Ounce-Inches,

or mV/V. Tare at any time. The sum of the torques on both channels is also availabe.

• Capture the load peak and valley, display in pounds, kilograms, Newtons, PSI,

MegaPascals, kilo-pounds, kilo-Newtons, metric tons, mV/V, or grams. Reset at any

time.

• Capture the torque peak and valley, display in in Pound-Inches, Newton-Meters,

Ounce-Inches, or mV/V. Reset at any time.

• Measure position and velocity with optional encoder input. Display in English units,

metric units, or in percent of a user defined base length. Reset at any time.

• Four contact closure Limit switches. You can set which signal drives the limit (load,

torque, peak, valley, position, or velocity), normally open / normally closed, set point,

and manual reset (latched) or automatic reset (not latched).

• Print current readings of load, torque, peak, valley, position, and velocity using the

currently selected units at the touch of one button (optional).

• Automatic identification of calibrated cells with auto-id option.

• Calibration for cells using manufacturer’s milli-volt per volt calibration factor, 6 point

mass and milli-volt per volt, 2 or 5 point known mass, 6 point torque and milli-volt per

volt, 2 or 5 point known torque, or internal precision shunt calibration. A back panel

switch allows you to choose between two values used for the shunt calibration so

there is no need to open the unit.

• Analog output of any signal (load, torque, peak, valley, position, velocity) with user

defined scale factor and offset. Large, buffered ± 10.00 volt output.

MODEL 9840 PG 4 PUB. 2856-16

Page 6

INTERFACE MODEL 9840 VER 6.0.2

• Remote operation using standard RS232 ASCII command set.

• Each unit is set up to interact with the InterView software that can save tests, export

data to a spreadsheet, and much more.

• Back panel digital inputs for tare, peak and valley reset, position reset, and print.

Other functions available as custom programmed options.

MODEL 9840 PG 5 PUB. 2856-16

Page 7

INTERFACE MODEL 9840 VER 6.0.2

QUICK START

This section will help you get your Model 9840 set up and operating in just a couple of

minutes.

The back panel is shown below. You will need to make at least two connections here.

First be sure that the power switch is off (the lower part of the rocker should be pressed

in). Connect the AC power line and plug it in.

MODEL 9840 BACK PANEL

Next connect a load or torque cell to the 9 pin female connector labeled “Load A”. You

should use the cabling supplied with your Model 9840 and Interface load or torque cell. If

you do not have a factory supplied cable see Appendix B for the recommended cell

connection.

You are now ready to turn on the power. Each time power is applied to the Model 9840

you will see a sequence of 6 messages appear on the front display. For example,

MODEL 9840 PG 6 PUB. 2856-16

Page 8

INTERFACE MODEL 9840 VER 6.0.2

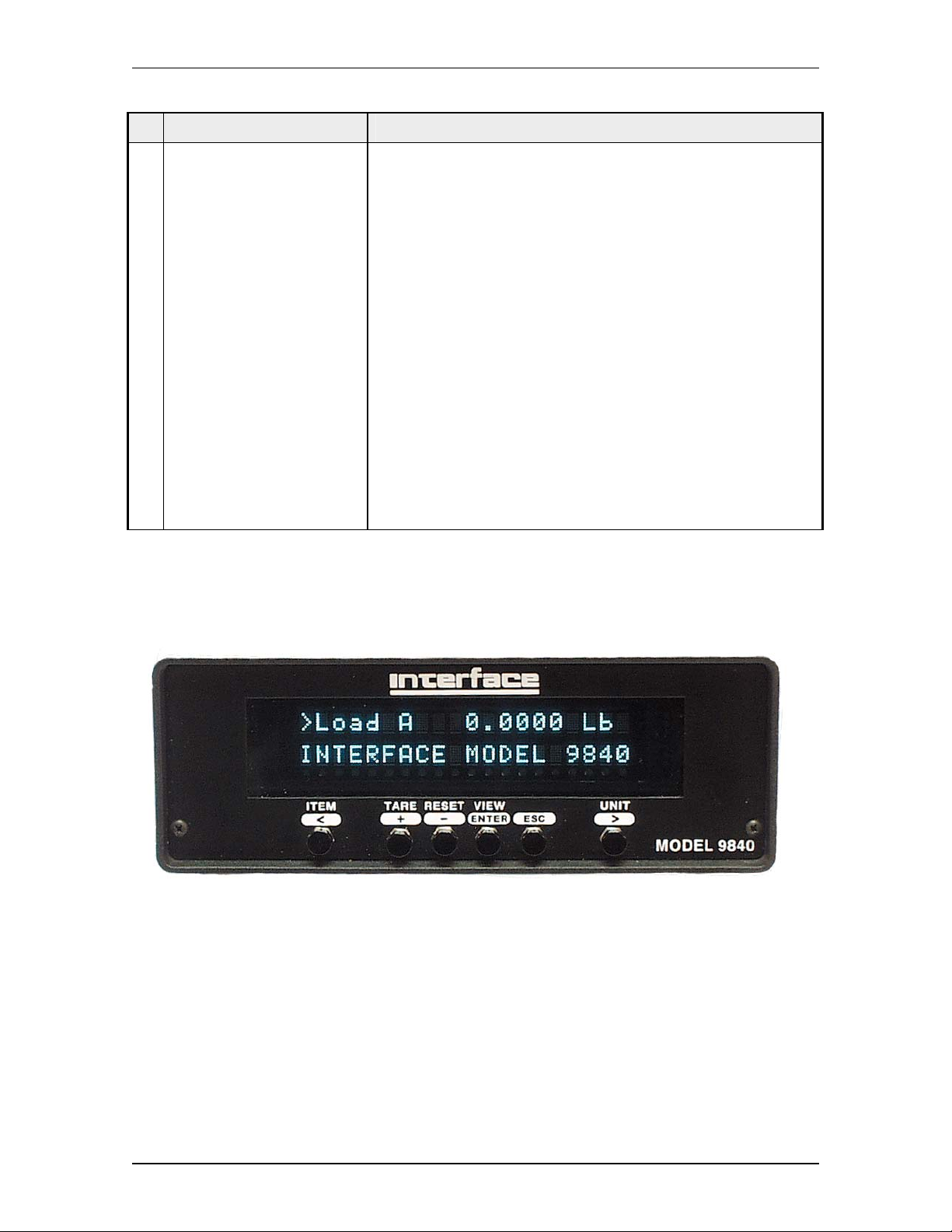

# Message Meaning

1 Interface X.Y.Z This is the version number.

2 Serial # 12345

Option # 114236

3 Last ID A LD90437

Last ID B TQ12030

4 Ch A Max 4.00Lb

Ch B Max 4.00LbI

5 Ch A Cal 4.00000 mVv

Ch B Cal 4.00000 mVv

This is the serial number.

This is the option number.

The serial number of the load cell on Ch A.

The serial number of the torque cell on Ch B

Maximum rated load of the sensor on channel A.

Maximum rated torque of the sensor on channel B.

The mV/V constant used with the load cell on channel A.

The mV/V constant used with the torque cell on channel

B.

Note: If either of these sensors was calibrated by 5 –Point

Mass, then 4 mV/V constants will be displayed here.

6 Ch A Exc 5.00 Volt

Ch B Exc 10.00 Volt

Excitation voltage used with the load cell on channel A.

Excitation voltage used with the torque cell on channel B.

Each of these messages will be displayed for about 3 seconds. After that the front display

will start showing the current readings from the sensor.

MODEL 9840 FRONT PANEL

The example above shows that Load A is 0.0000 Lb. The second line of the display

shows text.

To change what item is being displayed press the leftmost button. This will cycle through

the list of items (load A, peak A, valley A, gross A, load B, peak B, valley B, gross B,

channel A+B, pos, velocity, lim). If a torque cell is loaded on either channel, the display

will show torq rather than load for the appropriate channel. Channel A+B will only appear

when both channels are attached to sensors of the same type: load or torque.

MODEL 9840 PG 7 PUB. 2856-16

Page 9

INTERFACE MODEL 9840 VER 6.0.2

The rightmost button will change the units that are being used. Repeated presses of this

button will cycle through the list of units available for the currently displayed item. For

example, with Load A showing you would see Lb, kg, N, PSI, MPa, Klb, kN, t, mV/V,

grams, and then back to Lb. With Torq A, you will see LbI, NM, OzI, and mV/V.

Switching from a load to a torque cell and back will automatically reset Analog, Limit, and

Filter Window settings to zero and/or disabled for that particular channel. See information

under each of these options for details on how they work.

MODEL 9840 PG 8 PUB. 2856-16

Page 10

INTERFACE MODEL 9840 VER 6.0.2

RUN MODE

The Model 9840 has three modes of operation, Run mode, Setup mode, and System

Calibration mode. At power-on it will be in Run mode.

The first line of the display show an item label (Load A), a value (0.0000), and a unit label

(Lb).

The second line of the display can show the status of the 4 contact closure limit switches,

show another display, show text, or be blank. The above example shows text

(“INTERFACE MODEL 9840”).

To change what item is being displayed press the leftmost button. This will cycle through

the list of items (Load A, Peak A, Vall A, Grs A, Load B, Peak B, Vall B, Grs B, Ch A+B,

Pos, Vel, and Limits). If a torque cell is attached rather than a Load Cell, Torq A or B will

replace Load A or B. Channel A+B will only appear when both channels are attached to

sensors of the same type: load or torque.

The rightmost button will change the units that are being used. Repeated presses of this

button will cycle through the list of units available for the currently displayed item. For

example, with Load showing you would see Lb, kg, N, PSI, MPa, Klb, kN, t, mV/V, grams,

and then back to Lb. Torq will show LbI, NM, OzI and mV/V.

MODEL 9840 PG 9 PUB. 2856-16

Page 11

INTERFACE MODEL 9840 VER 6.0.2

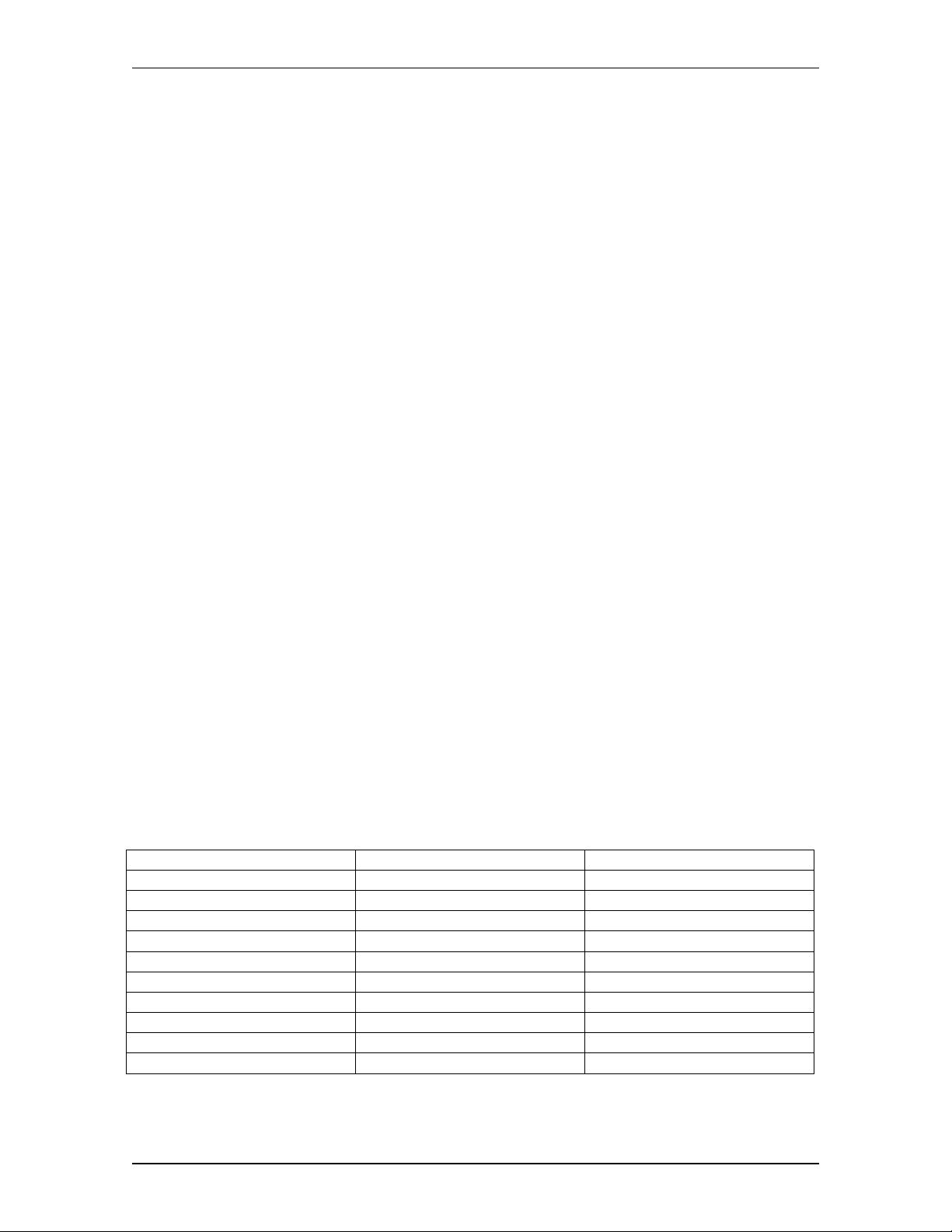

The table below summarizes the options. Whether the user sees torque or load for each

channel depends upon the cell type that was calibrated or selected for that channel.

Load A/B Pounds, Kilograms, Newtons, PSI, MegaPascals, Kilo-Pounds,

Kilo-Newtons, Metric Tons, mV/V, grams.

Peak A/B

(Load)

Valley A/B

(Load)

Gross A/B

(Load)

Channel

A+B (Ld)

Torq A/B Pound-Inches, Newton-Meters, Ounce-Inches, mV/V.

Peak A/B

(Torque)

Valley A/B

(Torque)

Gross A/B

(Torque)

Channel

A+B (Tq)

Position Inches, Centimeters, Percent of Base Length.

Velocity Inches per Minute, Centimeters per Minute.

Limits

All of these measurements are acquired by the Model 9840 at all times with torque

measurements acquired when a torque cell is attached to a channel and load

measurements acquired when a load cell is attached. The display just selects which

particular item you wish to see and what units are used to display or print this data.

The buttons have the functions indicated by the upper set of labels (Item, Tare, Reset,

View, Esc, Print, Unit). Each of these is described below.

Pounds, Kilograms, Newtons, PSI, MegaPascals, Kilo-Pounds,

Kilo-Newtons, Metric Tons, mV/V, grams.

Pounds, Kilograms, Newtons, PSI, MegaPascals, Kilo-Pounds,

Kilo-Newtons, Metric Tons, mV/V, grams.

Pounds, Kilograms, Newtons, PSI, MegaPascals, Kilo-Pounds,

Kilo-Newtons, Metric Tons, mV/V, grams.

Pounds, Kilograms, Newtons, PSI, MegaPascals, Kilo-Pounds,

Kilo-Newtons, Metric Tons, mV/V, grams.

Pound-Inches, Newton-Meters, Ounce-Inches, mV/V.

Pound-Inches, Newton-Meters, Ounce-Inches, mV/V.

Pound-Inches, Newton-Meters, Ounce-Inches, mV/V.

Pound-Inches, Newton-Meters, Ounce-Inches, mV/V.

Shows state of each switch, 1 for on, 0 for off, dash for

disabled, asterisk for source error.

Item Button

The Item button cycles through the list of different items that can be displayed

(Load A, Peak A, Vall A, Grs A, Load B, Peak B, Vall B, Grs B, Ch A+B, Pos, Vel,

Limits). Torq A or B substitutes for Load A or B when appropriate. Use the Unit

button to change the units that are used for the currently displayed item. Ch A+B is

only available when the cells on both channels are of the same type (load or

torque).

Tare Button

The Tare button sets the current load or torque to zero for channel A, channel B,

or channels A and B. A submenu will allow you to select what channel you want

to tare. It does not matter what is being displayed when you press this button.

MODEL 9840 PG 10 PUB. 2856-16

Page 12

INTERFACE MODEL 9840 VER 6.0.2

The load or torque is always reset to zero. A single channel unit will automatically

set Load A or Torque A to zero.

Reset Button

The Reset button brings up a list of things that you might want to set to zero:

If this is a 2-channel unit, the following menu will appear:

> Reset Ch A + Ch B will reset the peak and valley for channels A and B.

> Reset Ch A Only will reset the peak and valley for channel A.

> Reset Ch B Only will reset the peak and valley for channel B.

> Reset Position will reset the position to zero.

> Reset Limits will reset any limits that require manual resetting.

For a single channel unit, the following menu will appear:

> Reset Peak+Vall will reset the peak and valley measurements.

> Reset Peak Only will reset the peak measurement.

> Reset Vall Only will reset the valley measurement.

> Reset Position will reset the position to zero.

> Reset Limits will reset any limits that require manual resetting.

Pressing either the “+” button or the “>“ button will scroll forward through this list.

Pressing either the “-” button or the “<“ button will scroll backward through the list.

Pressing “Enter” will reset the currently displayed item. Pressing “Esc” will return

to Run Mode without resetting anything. Note that all menu lists on the Model

9840 start with the “>“ symbol and that the Esc button will always back out of a

menu without making any changes.

View Button

The View button switches between two virtual displays stored in the memory.

Each of these displays will remember the units you have selected for each item,

and which item is currently being shown. This may save you from scrolling

through the list of items if there are two particular results that you often use. For

instance you might set the display to show Load in Lb, press View, and then set

the display for Peak in PSI. Repeated presses of the View button will now switch

back and forth between Load in Lb and Peak in PSI with a single button push. If

you choose to have the second line show a display, then the View button toggles

between the display currently being activated. The activated display will have a

“>” symbol to the left of it.

Esc Button

In Run Mode, the Esc button will freeze and unfreeze the run mode numerical

display. Press once to freeze the display at the current value. Press again to

return display to actual reading from sensor. See Setup Mode information for the

use of the Esc button during setup.

MODEL 9840 PG 11 PUB. 2856-16

Page 13

Print Button

If the Print option is purchased, the Print Button can be used to either print data or

to freeze the display. If the Hold option is purchased, the functionality of the

button is set using the System Setup options. Otherwise, the button can only

control the ability to print data.

In Run Mode, if the System Setup Options Print/Hold button is set to Hold, the

Print button will freeze and unfreeze the run mode numerical display. Press once

to freeze the display at the current value. Press again to return display to actual

reading from sensor. See Setup Mode information for the use of the Esc button

during setup.

If the Print button is set to Print, it will send a set of data to the printer. This will

contain the current readings of load, peak, valley, position, velocity, and limit

status. The units used for printing will be the units last selected on the numerical

display.

The printer must be a serial printer that supports ESC/P protocol. Many Epson

printers with serial ports are known to be compatible.

Appendix B gives the pin assignments on the serial connector.

INTERFACE MODEL 9840 VER 6.0.2

Unit Button

The Unit button cycles through the list of units that are available for the item that is

currently being displayed.

MODEL 9840 PG 12 PUB. 2856-16

Page 14

INTERFACE MODEL 9840 VER 6.0.2

SETUP MODE SUMMARY

The table below summarizes the setup mode menus. Detailed information about each

individual item is presented in the following sections.

Setup mode

╠══════

║ ╠════════

║ ╚════════

║

╠══════

║ ╚════════

║

╠══════

║ ╚════════

║

╠══════

║ ╠════════

║ ╠════════

║ ╠════════

║ ╠════════

║ ╚════════

║

╠══════

║ ╚════════

║

║

║

╠══════

║ ╠════════

║ ╠════════

║ ╠════════

║ ╠════════

║ ╠════════

║ ╠════════

║ ╠════════

╠══════ ╚════════

║

╚══════

>User Data Entry

>>Base Area Ch A/B

>>Base Length

>Analog Output

Source → Units → Full → Zero.

>Sensor Select

Channel → Serial Number List → Cal Info.

>Calibration →

>Limits

>System Options

>Display Options

╠════════

╠════════

╠════════

╠════════

╚════════

(password access and cell type)

>>Cal Check

>>Cal by mV / volt

>>Cal by Masses or Torque

>>Cal by Shunt

>>Counts / Inch

Select → NO/NC → Enable →

Source → Units →Set → Trip →

Latch → Reset → Done.

>>Printer Baud

>>Auto Identify

>>Auto Zero Ch A/B

>>Com Address

>>Com Baudrate

>>Com Line Feed

>>Retain Tare

>>RS232 EOT Char

>>Filter Select

>>Decimals Ch A/B

>>Count By Ch A/B

>>Second Line

>>Filter Window

MODEL 9840 PG 13 PUB. 2856-16

Page 15

INTERFACE MODEL 9840 VER 6.0.2

SETUP MODE

Setup mode is used to change the setup of the Model 9840. To enter setup mode press

the two end buttons at the same time ( “<“ and “>“ ). The row of four buttons will now

function as indicated by the lower set of labels (Plus, Minus, Enter, and Escape).

If the optional keylock is in the locked position you will see “>Setup is Locked” when you

try to enter setup mode. This prevents accidental or unauthorized changes to the setup of

the unit.

To exit from setup mode and return to run mode press the escape button (Esc). When

you are entering numerical data or selecting options from a sub-menu the escape button

will back you out without making any changes.

The main menu in setup mode contains the following 6 entries which will be described in

detail in the following sections. Note that all main menu items begin with the “>“ symbol

and that all submenu items begin with the “>>“ symbol.

• > User Data Entry -- allows you to set any common math options such as the base

area used to display load in PSI or the base length used to display position in percent.

• > Analog Output -- is used to select the source and scaling for the standard analog

output channel.

• > Sensor Select -- lets you manually set which load or torque cell calibration data is

used. If you use auto-id cells you will never need this menu.

• > Calibration -- provides access to calibration for cells or optical encoders.

• > Limits -- allows you to set the source and options for the 4 contact closure switches.

• > System Options -- contains entries to set the printer baud rate, enable or disable

automatic sensor identification, enable or disable automatic load or torque zeroing, set

the serial communications address, baud rate, line feed, and RS232 options, and

choose whether or not to retain the most recent tare value through power down.

• > Display Options -- lets you choose the filtering that is applied to the load or torque

measurements, an optional window of data incrementation on which to turn the filter

off, the number of decimal digits that are shown on the display and on the print, the

count by values for channels A and B (1, 2, 5, 10, or 20), and whether the second line

of the display shows the limit switch status, a blank line, another display, or text.

The Plus or Right button ( “+” or “>“ ) will scroll forward through this menu. The Minus or

Left button ( “-” or “<“ ) will scroll backward through this menu. The Enter button selects

the currently displayed menu item. The Esc button will return you to Run Mode.

MODEL 9840 PG 14 PUB. 2856-16

Page 16

INTERFACE MODEL 9840 VER 6.0.2

Entering Numerical Data

At times you will need to enter numerical data into the Model 9840. The method is

consistent in all cases. A number is presented on the left side of the display with an

underline cursor.

• Left ( “<“ ) moves the cursor left one position. If you are on the leftmost digit a new

zero will be added. Thus 1

from the tens place to the hundreds place.

• Right ( “>“ ) moves the cursor right one position. If you are at the far right a new

decimal will be added if there is room. Thus 12.34

cursor has moved from the tenths to the hundredths place.

• Plus ( “+” ) increments the digit above the cursor. Thus 12

that 9 will “wrap around” to 0.

• Minus ( “-” ) decrements the digit above the cursor. Thus 12

Note that 0 will “wrap around” to 9.

• Plus and Minus (both “+” and “-” at the same time). This will change the sign of the

number. Thus 12

you change the sign.

• Enter accepts the currently displayed number.

• Esc escapes from numerical entry and discards any changes that have been made.

.34 becomes -12.34. Note that cursor position does not matter when

0.000 will become 010.00 where the cursor has moved

will become 12.340 where the

.34 becomes 13.34. Note

.34 becomes 11.34.

Entering Alphanumeric Data

When entering cell serial numbers, the option of using numbers and/or letters from A to Z

is available. This works in the same way as entering numerical data with the exception

that no decimal point exists in the display.

>User Data Entry

This menu is used to enter numerical constants used by the math options. These

constants are listed in a submenu that works exactly like the main setup mode menu.

Typical items in this submenu are:

>>Base Area Ch A/B

This is the area in square inches that is used to calculate load in pounds per square

inch (PSI) or Mega Pascals (MPa).

>>Base Length

This is the length in inches that is used to calculate position in percent.

>Analog Output

This menu is used to set up the standard analog output. Instead of a submenu there is a

series of selections. Pressing escape at any time will leave the analog output unchanged

and return you to the setup mode main menu. Note that when you change a cell type

(from load to torque or back again) these settings must be reset for the new cell. If the

unit is a 2-channel unit and the Analog Output B option has been enabled, the first option

asks the user for the Analog Output channel. Select A or B. Then begin selecting the

following settings.

MODEL 9840 PG 15 PUB. 2856-16

Page 17

INTERFACE MODEL 9840 VER 6.0.2

1. Source: -- This entry allows you to scroll through a list (using the left/right or

plus/minus buttons) to select the source of the data that will drive the analog output.

The standard list will include load or torque, peak, valley, gross, position, and velocity.

Channel A+B is an option which, if chosen, will appear only if the cells on both

channels are of the same type. Press enter to select the displayed item.

2. Units: -- This entry allows you to scroll through the list of available units for the data

source you have chosen in the previous step.

3. Full -- This entry specifies the value of source data (in the selected units) that will

cause the Model 9840 to output positive full scale analog voltage (+10.0 volts).

4. Zero -- This entry specifies the value of source data (in the selected units) that will

cause the Model 9840 to output zero analog voltage (0.0 volts).

Once you have entered these 4 selections the analog output is setup.

4-20MA Output Option

This option allows the user to output with current (milliamps) rather than voltage. It

operates similarly to Analog Output using the same submenus, but, in this case, the Full

and Zero data entered control the distribution of output in milliamps from the unit given

certain inputs to the cell. Particularly, the number entered for Zero will set the

corresponding input in Lbs to output 12 milliamps (the mid-point between four and twenty

milliamps) and the unit will extrapolate other output values between 4 and 20 milliamps.

If this option is enabled, the following steps will set up the unit: follow the instructions for

Analog Output until "Source:" is displayed. Toggle through until the "Load A" is on the

display. Press the enter button to bring up the "Lb" menu. Press the enter button again

and the "4.0000 Lb Full" menu will be displayed. This is where the maximum Lbs for the

cell should be entered. Press enter and the "0.0000 Lb Zero" menu will be displayed.

This is where the offset from zero (the value in lbs that will give a 12 milliamp) should be

entered. Press the enter button to return to the Analog Output menu and then press the

escape button to return to the normal display.

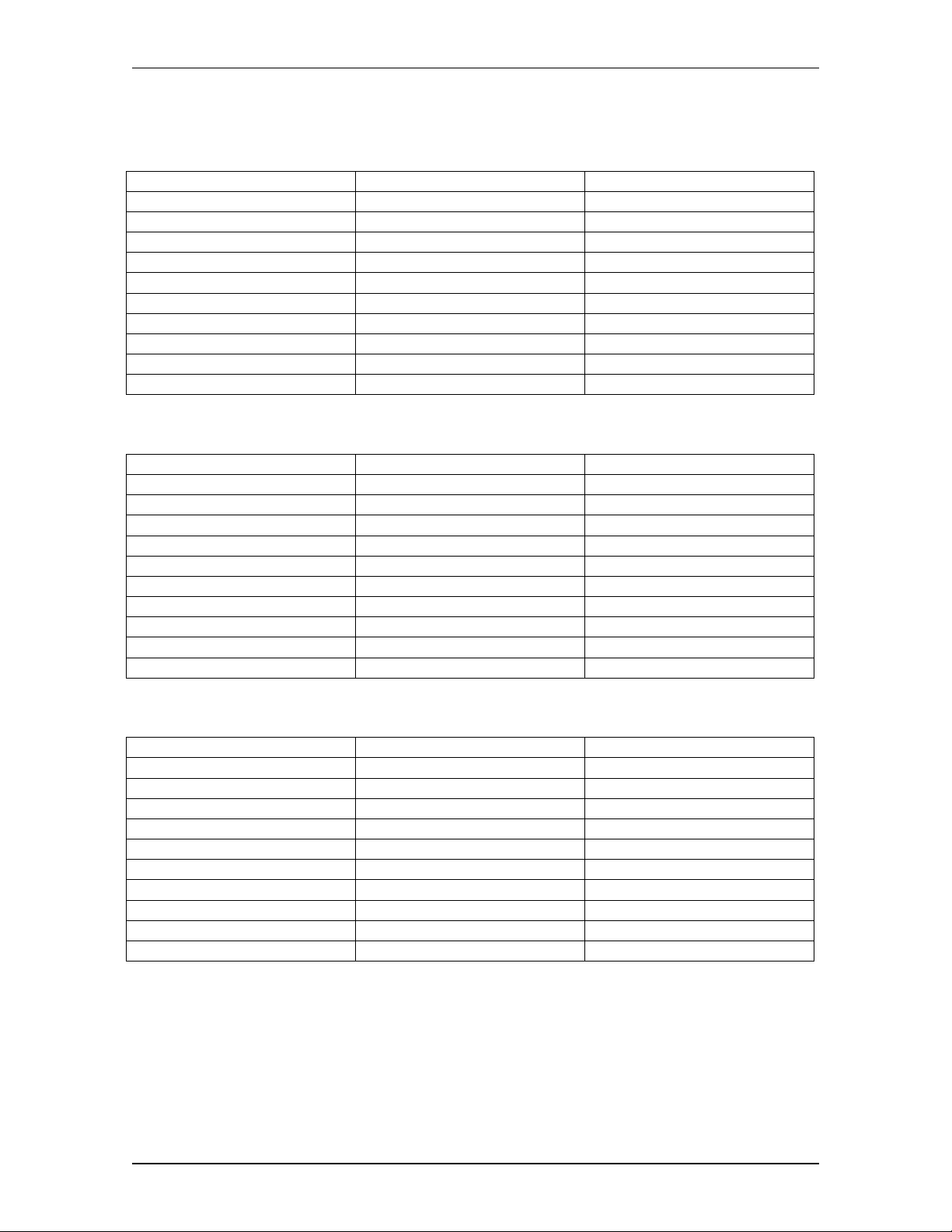

Example outputs with varying Full and Zero Values (assuming a 4.00 Lb calibrated cell

with 10 V excitation):

1. Full = 4.0000 Lb Zero = 0.0000 Lb

(Input) Mv/V (Output) Volt (Output) MA

4 10v 20mA

3 7.5v 18mA

2 5.0v 16mA

1 2.5v 14mA

0 0v 12mA

-1 -2.5v 10mA

-2 -5.0v 8mA

-3 -7.5v 6mA

-4 -10.0v 4mA

MODEL 9840 PG 16 PUB. 2856-16

Page 18

INTERFACE MODEL 9840 VER 6.0.2

2. Full = 4.0000 Lb Zero = 4.0000 Lb

(Input) Mv/V (Output)Volt (Output) MA

4 0v 12mA

3 -2.5v 10mA

2 -5.0v 8mA

1 -7.5v 6mA

0 -10.0v 4mA

-1 -10.0v 4mA

-2 -10.0v 4mA

-3 -10.0v 4mA

-4 -10.0v 4mA

3. Full = 2.0000 Lb Zero = 0.0000 Lb

(Input) Mv/V (Output) Volt (Output) MA

4 10.0v 20mA

3 10.0v 20mA

2 10.0v 20mA

1 5.00v 16mA

0 0v 12mA

-1 -5.0v 8mA

-2 -10.0v 4mA

-3 -10.0v 4mA

-4 -10.0v 4mA

4. Full = 2.0000 Lb Zero = 2.0000 Lb

(Input) Mv/V (Output) Volt (Output) MA

4 10.0v 20mA

3 5.0v 16mA

2 0v 12mA

1 -5.00v 8mA

0 -10.00v 4mA

-1 -10.0v 4mA

-2 -10.0v 4mA

-3 -10.0v 4mA

-4 -10.0v 4mA

>Sensor Select

This menu is used to manually select load or torque cell calibration data from a list stored

in the Model 9840. When you select this menu on a 2 channel unit, you are asked to

select Channel A or B. The cell serial number of the selected channel is displayed. Use

either the left/right or plus/minus buttons to page through the list. The escape button will

MODEL 9840 PG 17 PUB. 2856-16

Page 19

INTERFACE MODEL 9840 VER 6.0.2

return to the setup mode main menu without changing the cell that is selected. The enter

button will select the currently displayed cell and briefly display the rated load or torque,

last calibration date, and excitation voltage.

To add new cells to this list use the Calibration entry on the setup mode main menu

described below.

If you are using auto-id load cells this menu will allow you to see which cell is selected but

will not allow you to change the selection. This ensures that the correct calibration

information is always used when you use Auto-ID load cells.

If the selected cell is of a different type (load or torque) than that previously displayed on

the channel, the display item and units will change accordingly.

Sensor Delete

The Model 9840 can store calibration data for 25 different cells. To delete a cell from this

list choose “>Sensor Select” from the setup mode main menu. Press the left/right or

plus/minus keys until the serial number of the cell you wish to delete is displayed. (You

may need to shut off auto-id if it is on, see the System Options menu for details). Then

press both the plus and minus keys at the same time. The Model 9840 will ask “Delete

Sensor?” to be sure that you intend to delete this calibration data. Pressing Enter will

delete the cell data from the list. Pressing Escape will return to the cell select without

changing the list.

>Calibration

This menu is used to access all methods of calibration that are supported by the Model

9840. Selecting calibration from the setup mode main menu will bring up a password

entry field. Successful entrance of the password (888) will bring up a submenu which

asks for the cell type. Toggle through either Load or Torque and press enter when

appropriate. Another submenu will appear listing the various types of calibration. This

submenu is used exactly like the main menu. Press left/right or plus/minus to change the

menu item. Press escape to return to the setup mode main menu. Press enter to select

the displayed menu item.

If you are re-calibrating a cell, the Model 9840 will recognize it using either the auto-id or a

manually entered serial number. Any time you overwrite existing cell calibration data you

will first be warned with the “Overwrite Data?” message. Pressing enter will overwrite;

pressing escape will cancel the calibration. Another method of overwriting existing data is

to delete the sensor first and then calibrate.

If a cell with a new serial number (or new auto-id) is calibrated the data is added as a new

entry in the cell list.

Cells must be calibrated for the channel on which they will be used.

MODEL 9840 PG 18 PUB. 2856-16

Page 20

INTERFACE MODEL 9840 VER 6.0.2

>>Cal Check

Selecting this item will run a calibration check on the cell attached to Channel A or B.

The Model 9840 will measure the shunt value of the cell and compare it to the shunt

value that was recorded when the cell was last calibrated. The rated load or torque

and last calibration date for the cell are displayed followed by the currently measured

shunt value and the shunt value that was recorded when the cell was calibrated.

Note that the Model 9840 has a switch on the back panel that allows you to select

either a 30K shunt or a 60K shunt. Be sure that this switch is set correctly for the cell

that you are using.

Since this shunt check electronically applies approximately half the rated load or

torque, it is important that the cell is not loaded when this check is run. If you see the

“Cell Overloaded” message, remove any load or torque on the cell and try the check

again.

>>Cal by mV/volt (2-Point or 6-Point)

This item is used to calibrate a cell using the manufacturer’s milli-volt per volt

calibration factor (the second point of a two point calibration that automatically sets the

first point at zero) or a series of six milli-volt per volt points with corresponding masses

(usually listed on the load cell calibration certificate) or torques. Before you enter in

the desired information, another menu will ask you if you want to calibrate by milli-volt

per volt or 6 point milli-volt per volt. Pressing the arrow keys will allow you toggle

between mV/volt and 6 point mV/volt modes. You will then be asked for the channel,

the cell serial number, the current date, the calibration unit, the cell’s maximum rated

load or torque, and the desired excitation voltage (5.0 or 10.0 volts). If milli-volt per

volt calibration was selected, you are then prompted to enter the manufacturer’s millivolt value. If 6 point milli-volt per volt calibration was selected, you are prompted for

each mass or torque and milli-volt per volt value. A piece-wise linear interpolation is

then performed between adjacent points. One of these points should be zero mass

and zero milli-volts per volt. Enter each of these selections as prompted or press the

escape button at any time to return to the setup mode main menu without changing

the calibration. The cell should not be under load or torque when this calibration

method is used since a shunt value will be measured and recorded for later use with

“Cal Check” feature described above. The “No Masses Ready” or “No Torque Ready”

message is intended to remind you of this fact. This general sequence of prompts

and user responses also applies to the 5 point mass or torque calibration.

>>Cal by Masses or Torque (2-Point or 5-Point)

These items are used to calibrate a load or torque cell using known masses or

torques. The appropriate choice will be available depending on which cell type was

chosen at the beginning of calibration: a load cell will show Masses as an option and a

torque cell will show Torque as an option. Before you enter in the desired information,

another menu will ask if you want to calibrate by 2 Point or 5 Point. You will then be

asked for the channel, the cell serial number, the date, the calibration unit, the cell’s

maximum rated load or torque, and the desired excitation voltage (5.0 or 10.0 volts).

You are then prompted to enter the value of the first mass or torque. The “Mass 1

Ready?” or "Torque 1 Ready?" message will wait while you actually hang the mass or

MODEL 9840 PG 19 PUB. 2856-16

Page 21

INTERFACE MODEL 9840 VER 6.0.2

set the torque. When the Model 9840 is reading the cell it will display the “Reading...”

message for about 10 seconds. During this time it is important that the masses or

torque are not disturbed since all the readings taken are averaged together to obtain

the calibration data. The second mass/torque is then entered and read. If 5 Point

calibration was selected, masses/torque three through five will be entered and read.

One of these readings should be at zero. A "No Masses Ready?” or "No Torque

Ready" reading is also required. During this reading, a shunt check value is recorded.

>>Cal by Shunt Val

This item is used to calibrate a cell using the manufacturer’s shunt calibration factor

expressed in pounds or pound-inches. You will be asked for the channel, the cell

serial number, the date, the calibration unit, the cell’s maximum rated load or torque,

the desired excitation voltage (5.0 or 10.0 volts), and the shunt calibration constant.

The Model 9840 will then automatically perform the shunt calibration of the cell using

its internal precision shunt resistor. Note that there is a back panel switch that allows

you to select either a 30K or 60K resistor for shunt measurements (see Appendix B for

a circuit diagram). Be sure to select the appropriate value for your cell. During this

calibration the “Reading...” message will be displayed. Do not disturb the cell while it

is being read. Like the “Cal by mV/volt” option, the cell should be free of load or

torque during this calibration.

>>Counts per Inch

This entry allows you to set the number of counts per inch that the quadrature encoder

input will use.

>Limits

This menu is used to set up the 4 contact closure switches. Instead of a submenu there

are a series of selections. Pressing Enter will accept the displayed entry. Pressing

Escape will return to the setup mode main menu without changing the limit setup. Note

that changing a cell type on a channel will automatically erase limits that were set for that

channel. These limits must then be reset by the user.

1. Select Limit X -- The first selection chooses which of the limits you want to set up (1-

4). Use the left/right or plus/minus buttons to change the number. Press enter to

accept the displayed number. Press escape to return to the setup mode main menu.

2. Normally Open / Closed -- This selection determines if the switch contacts are open

or closed when the limit is de-activated.

3. Enabled / Disabled -- Choosing enable allows the limit to operate as specified by the

following selections. Choosing disable places the limit in its “normal” state and

completes the limit setup.

4. Source: -- This selection allows you to scroll through a list (use either the left/right or

plus/minus buttons) to select the source of the data that will drive the limit. The

standard list will include load or torque, peak, valley, position, and velocity. Press

enter to select the displayed item.

5. Units: -- This entry allows you to scroll through the list of available units for the data

source you have chosen in the previous step.

6. Set -- This is the numerical value of the source at which the limit will be activated (set

point). It is specified in the units you chose in the previous step.

MODEL 9840 PG 20 PUB. 2856-16

Page 22

INTERFACE MODEL 9840 VER 6.0.2

7. Trip if source < / > Set -- Choosing source>set means that the limit will be activated

when the source becomes larger than the set point. Choosing source<set means the

limit will be activated when the source becomes less than the set point.

8. Latching on/off -- Selecting latching off means that the limit will be de-activated

automatically when the source passes the reset point (see next selection). Selecting

latching on means that once the limit is activated you must manually reset it using the

Reset button. If you select latching on then the limit setup is done.

9. Rst -- This selection determines the numerical value of the source at which the limit

will be deactivated (reset point). If you selected “source>set” in step 7 then the limit is

deactivated when the source is less than the reset point. If you selected “source<set”

in step 7 then the limit is deactivated when the source is greater than the reset point.

Notes:

The Set and Reset conditions for each limit are evaluated independently. If both

conditions are met then Reset will take priority over Set.

Limit status may show an asterisk if the limit is enabled but there is an error in the signal

source. For example, if the limit source is load but there are no load cells currently

calibrated, or the load cell has a rating of 0.0 Lb, or a millivolt per volt constant of zero.

Another example would be if the limit source is position and zero has been entered for the

encoder counts-per-inch constant. Limits that are in this error condition will be forced to

the off position as if they were disabled.

>System Options

This menu contains some system wide parameters that are seldom changed. These are

listed in a submenu that works exactly like the setup mode main menu.

>>Printer Baud

The front panel print button and the RS232 print commands will use this baud rate for

communication with your printer. This setting has no effect on units that are not

equipped with the printing option. 57.6 K baud is commonly used on older serial

printers (Epson Stylus II), 230.4 K baud is used on more recent serial printers (Epson

Stylus Color 600, Color 800).

>>Auto Identify

This allows you to turn automatic cell identification on or off. Usually you can leave

auto-id on even if you never use automatic cell identification. In order to use this

function you must either have an auto-id equipped cell or use an in-line auto-id module

attached to your cell cable.

>>Auto Zero Ch A/B

This menu lets you enable or disable auto zeroing for measurements on Channel A or

B. When enabled, this function will tare the load or torque to zero any time that it has

remained within 10 counts of zero on the display for 10 seconds.

MODEL 9840 PG 21 PUB. 2856-16

Page 23

INTERFACE MODEL 9840 VER 6.0.2

>>Com Address

This item allows you to set the address of this unit used for the RS232 ASCII

command set. Valid values are 1 through 254. If the RS232 multi-drop option is

installed you must be sure that all the attached units have different addresses to

prevent data collisions.

>>Com Baudrate

This sets the baud rate for the RS232 ASCII command set. Available values are: 300,

600, 1200, 2400, 4800, 9600, and 19.2k. Note that the “Special” entry is reserved for

future use.

>>Com Line Feed

This controls whether a line feed is added to each carriage return that is sent out by the

Model 9840 when the RS232 ASCII command set is being used.

>>Retain Tare

This controls whether the most recent tare value is retained through power down of the

unit and used again immediately on power up. Choosing this option will retain tare on

channel A in a single channel unit and both channels A and B in a two-channel unit.

>>RS232 EOT Char

The end of transmission character is a non-visible character (hexadecimal 0x04) that is

sent at the end of each response by the unit to an RS232 command. The character is

sent after the last carriage-return line-feed returned by the unit with one exception:

when the user is viewing channel values with the RS232 command

@123V(item)(unit)(repeat) and sets the value of repeat to 2 (streaming output), the

character is sent immediately prior to the streaming output that the unit will send. The

user can turn this option on or off.

>Display Options

This menu contains options that effect how load or torque, peak, and valley are displayed

and printed. These are listed in a submenu that works exactly like the setup mode main

menu.

>>Filter Select

There are two types of filters available on the Model 9840: Type I, and Type II. Type I

filters are good for removing most kinds of noise but may leave some jitter on the end

digits. Type II filters are more advanced and are optimized for the typical industrial

environment. Both filter types allow you to select from 4 levels of filtering with Level 1

being the least filtering and Level 4 being the most filtering.

The settling time for each of the 4 levels of filtering is shown in the table below

Level 1 2 3 4

Settling Time (seconds) <1 2 10 30

Read Rate (per second) 60 60 30 10

MODEL 9840 PG 22 PUB. 2856-16

Page 24

INTERFACE MODEL 9840 VER 6.0.2

>>Decimals Ch A/B

This lets you set the maximum number of digits to the right of the decimal that are

displayed or printed for load or torque, peak, and valley. When large cells are selected

the number of decimal digits shown may be limited, for example a 100 Lb cell will allow

3 digits, while a 1000 Lb cell will only allow 2 digits. Also if a number is too large to fit

on the display some decimal digits may be dropped (the display will “auto-range”). The

number of digits shown for position data depends only on the number of counts per

inch of the encoder and is not affected by this setting.

>>Count By Ch A/B

This allows you to choose the smallest unit of counting for the display of load or torque,

peak, and valley. Counting by 1, 2, 5, 10, and 20 are the options.

Note that the operation of the analog outputs and the limits is not effected by the

settings of “decimal point” or “smallest count”. Thus if you set a limit to be activated at

10.001 Lbs, and have “smallest count” set for 20, the limit is activated at 10.001 Lbs

even though the display is only showing 10.000.

>>Second Line

This option allows you to choose what you want to have displayed on the second line.

You can select limits, select a display, select text, or leave the line blank. Changing the

type of cell attached to the unit from load to torque or back will reset the display such

that both the top and bottom line will revert to the new cell type and its initial display Load for a load cell, and Torq for a torque cell - for the channel on which the cell type

was changed.

>>Filter Window

This option allows you to enable and set, or disable, a window to be used to turn the

filters on or off. If there is a sudden change in the measurement that exceeds this set

window, the filter is turned off and immediately turned back on so that this change of

data will be visible to the user rather than filtered out. To turn the window on, press

enter under the Filter Window option and toggle between on and off using the > and <

buttons. Once the window is turned on, pressing enter and will display the current

window's value and units (0 and Lbs. or LbI, respectively). Press enter again and you

will be asked to set the units (toggle buttons take you through the list). Press enter

once more and you reach the screen to set the value of the window. Once the value is

set, press enter and you will return to the Filter Window option.

To change the window, simply repeat the steps above. Instead of 0 and Lbs. in the

current window display, you will see the most recently entered values. Turning the

window off resets the window value to 0 and Lbs (or LbI for torque).

Note that changing a cell type on a channel will automatically disable the filter window

for that channel, reset the units to Lb or LbI, and set the window value to 0. The

window must then be reset and re-enabled by the user.

MODEL 9840 PG 23 PUB. 2856-16

Page 25

INTERFACE MODEL 9840 VER 6.0.2

REMOTE OPERATION

Digital Inputs

There are 4 digital inputs available on the Model 9840. They are accessible on the Digital

I/O connector on the back panel (pins 9 - 16). These inputs are individually opto-isolated

and include current limiting resistors. An input voltage anywhere from +4 to +22 volts DC

may be used to obtain the “on” state. See Appendix B for a full description of the Digital

I/O connector.

If you do not require isolation for your application you can use the +5 or +12 volt and GND

available on the Digital I/O connector (pins 24-26).

These 4 inputs are called IN1 through IN4 and have the following standard functions:

IN1 will Tare the Load or Torq to zero while it is in the On state.

IN2 will Reset the Peak and Valley measurements while it is in the On state.

IN3 will Reset the Position measurement while it is in the On state.

IN4 will send one set of measurements (load or torque, peak, valley, position, velocity,

and limits) to the serial printer when it transitions from Off to On.

Other functions may be assigned to these inputs by custom programming at the factory.

All the features and settings of the Model 9840 can be accessed remotely using the

Remote ASCII command set. These commands fall into two groups: commands that are

similar Run Mode pushbutton commands; and commands are similar to Setup Mode

pushbutton commands.

Communications can be established via RS232/RS485 protocols through the serial port

on the rear panel of the unit, or via USB communications through the USB port on the rear

panel of the unit in conjunction with the USB driver installed on the host PC. The

commands and command formats are the same for each method of communications.

Pinouts for the RS232/RS485 serial port communications are listed in Appendix B of this

manual. For older computers, USB communication may require the installation of the

USB driver located on the CD-ROM that accompanies this product. If the host PC can

communicate with the Model 9840 via USB, no driver is needed.

USB Driver

If the host PC cannot communicate with the Model 9840 via USB, install the USB driver

that accompanies this product on CD-ROM. To install the USB Driver, place the CD in

your CD-ROM drive. Select Run from your Windows Start menu. Type

D:\USB_Driver\CDM_Setup.exe (“D” or the corresponding CD-ROM drive letter for your

computer) in the box and hit Enter. You will be notified when the driver has finished

installing.

MODEL 9840 PG 24 PUB. 2856-16

Page 26

INTERFACE MODEL 9840 VER 6.0.2

Communications Settings

The Model 9840 supports remote operation using a standard Remote interface consisting

of ASCII characters and terminal emulation software package such as HyperTerminal or

ProComm. The baud rate is set using the Com Baud rate item on the System Options

menu. Supported rates are 300, 600, 1200, 2400, 4800, 9600, and 19.2k baud. There

must be 8 data bits, no parity, and 1 stop bit.

To support the multi-drop Remote option each unit is assigned a communications

address, which is set using the Com Address item on the System Options menu.

Communications Format

All the commands have the following format:

@123XYZ<CR>

The @ symbol initiates the command, all commands must begin with this symbol. The

number 123 is the address of the Model 9840 which should respond to this command.

This MUST be 3 digits so type 001 for unit one, and 026 for unit twenty-six. The

command itself will be a sequence of letters such as the XYZ shown above. If the

command requires a number as one of its parameters the number must be followed by the

pound sign “#”. Numbers that are less than one should include a leading zero so you

should type 0.123# to enter one hundred-twenty three thousandths. Commands are not

processed until a carriage return <CR> is sent.

No Model 9840 will respond to address 000. All Model 9840’s will respond to address

255. Throughout the rest of this section we will assume that you are using address 123.

Whenever an Model 9840 executes a remote command it will issue an acknowledge that

includes the address and any required data.

RS232 RUN MODE COMMAND SUMMARY

@(addr)

╠═

╠═

╠═

╠═

╠═

╠═

╠═

╠═

╠═

╠═

╠═

╚═

MODEL 9840 PG 25 PUB. 2856-16

H Hello fetches unit description

? Get item and unit numbers

FV View item and unit settings

FS (item)(unit) Set displayed item and unit

FA Alternate display, like view button

F1 Switches view pointer to display

line 1 (upper)

F2 Switches view pointer to display

line 2 (lower), or virtual display if

line 2 is disabled

V (item)(unit)(repeat) Get Value of an item and unit

P (repeat) Print a set of readings

R (tare)(peak)(vall)(pos) Reset readings

X Freeze display

T (hold)(text) Place text on display

Page 27

INTERFACE MODEL 9840 VER 6.0.2

RS232 RUN MODE COMMANDS

The commands listed in this section mirror (and in some cases extend) the functions that

are available from the front panel of the Model 9840 when it is in Run Mode.

Each entry will include the name of the command, followed by a short description that

includes the command format, an example that shows what you would type (shown in

plain font) and what the Model 9840 would return (shown in italics).

Hello Command (H)

This command fetches the model, version, and serial number of any unit at the specified

address.

Example:

@123H

Acknowledge:

@123 Interface Model 9840 Version 6.0.0 Serial #-980500 Option #

457977664

Question Mark Command (?)

This command returns a list of item numbers and unit numbers that are available on the

Model 9840 that is addressed. These numbers are used as arguments for the many of

the commands shown below**.

Example:

@123?

Acknowledge:

@123 These are the Item numbers:

00 - Load A 01 - Peak A 02 - Vall A 03 – Load B

04 - Peak B 05 – Vall B 09 - Pos 10 - Vel

13 - Limits 14 - Grs A 15 - Grs B 16 - Ch A+B

**Alternatively torque units may be displayed or a combination of

both depending upon which cell is loaded on which channel:

17 - Torque A 18 - Peak A 19 - Vall A 20 – Gross A

21 - Torque B 22 - Peak B 23 - Vall B 24 – Gross B

25 - Ch A+B

These items are for value display purposes only:

50 – Cell

*

Note: If the channel is set as a load channel, the cell type implied is a LOAD

CELL; if the channel is configured as a torque channel, the cell type implied is a

TORQUE CELL.

*

AB 51 - Peak AB 52 - Vall AB

These are the units for Load, Peak, and Valley:

00 - Lb 01 - kg 02 - N 03 - PSI

04 - MPa 05 - Klb 06 – kN 07 - t

08 – mVv 09 - g

These are the units for Torque:

00 – LbI 01 – NM 02 - OzI 03-mVv

These are the units for Position:

00 – In 01 – Cm 02 - %

MODEL 9840 PG 26 PUB. 2856-16

Page 28

INTERFACE MODEL 9840 VER 6.0.2

These are the units for Velocity:

00 – I/M 01 – C/M

Front Panel Display Command (F)

This command is used to set the front panel display of the Model 9840 to a desired

combination of item and unit. There are five subcommands: Front panel View (FV), Front

panel Set (FS), Front panel Alternate(FA), Front panel pointer control to line 1 (F1), and

Front panel pointer control to line 2 (F2) .

Front Panel View Command (FV)

The Front panel View (FV) command just tells you what is currently on the display, and

what will be displayed when the View button on the front panel is pressed.

Example:

@123FV

Acknowledge:

@123 Active Display shows Load A in Lb

Other Display shows Peak A in Lb

Front Panel Set Command (FS)

The Front panel Set (FS) command allows you to specify the item number and unit

number for what is currently on the front panel display. The format is FS (item

number)(unit number), where the first item and unit numbers are 2 digits each and may

be found using the question mark command (?).

Example:

@123FS0200

Acknowledge:

@123 Active Display shows Vall A in Lb

Other Display shows Peak A in Lb

Front Panel Alternate Command (FA)

The Front panel Alternate (FA) command allows you to switch between the currently

displayed item and unit and the alternate item and unit just as if you had pressed the

View button.

Example:

@123FA

Acknowledge:

@123 Active Display shows Peak A in Lb

Other Display shows Vall A in Lb

Front Panel Pointer Control to Line 1 (F1)

The Front Panel Pointer Control to Line 1 (F1) assigns the view pointer control to

display line 1 (upper line of the display) and shows what is on the display. This

allows the operator to know which line will be configured or accessed.

Example:

MODEL 9840 PG 27 PUB. 2856-16

Page 29

INTERFACE MODEL 9840 VER 6.0.2

@123F1

Acknowledge:

@123 Active Display shows Load A in Lb

Other Display shows Peak A in Lb

Front Panel Pointer Control to Line 2 (F2)

The Front Panel Pointer Control to Line 2 (F2) assigns the view pointer control to

display line 2 (lower line of the display, or the virtual display line if line 2 is

disabled) and shows what is on the display. This allows the operator to know

which line will be configured or accessed.

Example:

@123F2

Acknowledge:

@123 Active Display shows Peak A in Lb

Other Display shows Load A in Lb

Value Command (V) for one or both channels

The value command for one channel is used to read the numerical value of a desired item

and unit without altering the front panel display. The format is V(item number)(unit

number)(repeat), where the item and unit numbers can be found using the question mark

command (see above), and the repeat number must be 0,1, or 2. Choosing repeat 1 will

make the Model 9840 send you the desired value once. Choosing repeat 2 will make the

Model 9840 send the value at approximately 3 second intervals. Choosing repeat 0 will

turn off any values that are being sent by a repeat 2 command. Note: when choosing to

view Limits, use "00" for the unit part of the command.

Example:

@123V01021

Acknowledge:

@123 Peak A 55.676 N

Example 2:

@123V00002

Acknowledge 2:

@123 Load A 120.45 Lb

@123 Load A 125.29 Lb

.....

@123 Load A 137.81 Lb

The value command for both channels is similar to the command for one channel with the

following exceptions:

The item numbers available for two channel value display are 50 (Cells AB), 51 (Peak

AB), and 52 (Valley AB).

The format is V(item number)(unit number channel A) (unit number channel B)(repeat).

where the item must be 50, 51, or 52 and unit numbers can be found using the question

mark command (see above). Make sure to use the proper unit numbers for the proper cell

type. A unit number of 08 for a torque cell will result in an unusable argument message.

MODEL 9840 PG 28 PUB. 2856-16

Page 30

INTERFACE MODEL 9840 VER 6.0.2

The repeat number is exactly like the one channel command. It must be 0, 1, or 2.

Choosing repeat 1 will make the Model 9840 send you the desired value once. Choosing

repeat 2 will make the Model 9840 send the value at approximately 3 second intervals.

Choosing repeat 0 will turn off any values that are being sent by a repeat 2 command.

Example 1:

@123V5000002

Acknowledge 2:

@123 Load A 120.45 Lb Torq B 120.45 LbI

@123 Load A 125.29 Lb Torq B 137.81 LbI

.....

@123 Load A 128.29 Lb Torq B 146.81 LbI

Print Command (P)

If the print option is purchased, the print command will fetch a full set of readings (like

pressing the front panel print button). These will be in the units that are currently selected

on the numerical display. The format is P(repeat number), where the repeat number must

be 0, 1, 2, or 3. Repeat 1 will return 1 set of readings to the RS232 terminal. Repeat 2

will return a set of readings approximately every three seconds (like the value command).

Repeat 0 will turn off printing that was started with repeat 2. Repeat 3 will send one set of

readings to the serial printer attached to the Model 9840 instead of to the RS232 terminal.

Example:

@123P1

Acknowledge:

@123 Load A 45.625 Lb

Peak A 82.396 Lb

Vall A -0.005 Lb

Load B 32.415 Lb

Peak B 47.483 Lb

Vall B –0.0001 Lb

Pos 3.500 In

Vel 0.0 I/M

Grs A 45.625 Lb

Grs B 32.415 Lb

Ch A+B 78.040 Lb

Limits 0 0 0 1

Reset Tare, Peak, Valley or Position Command (R)

This command allows you to reset the tare, peak, valley, or position readings. The format

is R(tare A)(peak A)(valley A) (tare B)(peak B)(valley B)(position select), where the selects

are either a 0 (don’t reset) or a 1 (reset). Thus you can reset any combination of these

readings with a single command.

Example:

MODEL 9840 PG 29 PUB. 2856-16

Page 31

INTERFACE MODEL 9840 VER 6.0.2

@123R1000000

Acknowledge:

@123 Reset – Tare A

Example 2:

@123R0111000

Acknowledge 2:

@123 Reset – Peak A Valley A Tare B

Freeze Display Command (X)

In Run Mode, the freeze display command will freeze and unfreeze the run mode

numerical display and the values sent from the unit for RS232 output using either the

remote Value or Print command. Send the command once to freeze the display and

output at the current value. Send again to return display and output to actual reading from

sensor.

Text Display Command (T)

This command allows you to put a line of text on the front panel display of the Model

9840. The format is T (text), where text is the message that you want to display. The

text is limited to the number of characters that can be shown on the front panel display.

Example:

@123TStress Test Ready

Acknowledge:

@123 Text Displayed - Stress Test Ready

MODEL 9840 PG 30 PUB. 2856-16

Page 32

INTERFACE MODEL 9840 VER 6.0.2

RS232 SETUP MODE COMMAND SUMMARY

@(addr)

╠═

║ ╠═

║ ╠═

║ ╚═

║

╠═

║ ╠═

║ ╚═

║

╠═

║ ╠═

║ ╠═

║ ╠═

║ ╠═

║ ╚═