Page 1

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Color ink jet printer

EPSON Stylus Color 980

®

SEIJ00012

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTISTATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of Stylus Color 980. The

instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on

the preceding page. The chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

CHAPTER 7. APPENDIX

Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Page 5

Contents

Product Description

Features

Specifications

Printing Specifications .............................................................................. 6

Options and Consumable Products .......................................................... 9

Paper Specifications ............................................................................... 11

Printable Area ......................................................................................... 13

Ink Cartridge Specifications .................................................................... 15

Electrical Specifications .......................................................................... 17

Environmental Condition ........................................................................ 17

Reliability ................................................................................................ 18

Safety Approvals .................................................................................... 18

Acoustic Noise ........................................................................................ 18

CE Marking (220 ~ 240 V version) ......................................................... 18

Physical Specifications ........................................................................... 18

Interface

Parallel Interface (Forward Channel) ..................................................... 19

Parallel Interface (Reverse Channel) ..................................................... 22

USB Interface ......................................................................................... 24

Optional interface ................................................................................... 24

Printer Language and Emulation ............................................................ 27

Prevention Hosts from Data Transfer time-out ....................................... 27

Auto Interface Selection ......................................................................... 27

........................................................................................................ 5

.............................................................................................. 6

Cut Sheet ........................................................................................... 11

Transparency, Glossy Film ................................................................. 11

Envelope ............................................................................................ 11

Index Card .......................................................................................... 11

Self Adhesive Sheets ......................................................................... 11

Photo Paper ....................................................................................... 12

Photo Stickers .................................................................................... 12

Black Ink Cartridge ............................................................................. 15

Color Ink Cartridge ............................................................................. 16

...................................................................................................... 19

IEEE 1284.4 Protocol ......................................................................... 28

Control Panel Operation

Indicators (LEDs) ................................................................................... 29

Panel Functions ..................................................................................... 30

Printer Setting Mode ........................................................................... 30

Special Setting Mode ......................................................................... 32

Printer Condition and Panel Status ........................................................ 33

Error Status

Ink Out .................................................................................................... 34

Paper Out ............................................................................................... 34

Paper Jam .............................................................................................. 34

No Ink Cartridge ..................................................................................... 34

Maintenance Request ............................................................................ 34

Fatal Errors ............................................................................................ 34

Double Feed Errors ................................................................................ 34

Printer Initialization

Component Layout

Printer Mechanism ................................................................................. 36

C380 Main Board ................................................................................... 37

C265 PSB/PSE Board ............................................................................ 39

C265 PNL Board .................................................................................... 40

C265 Relay Board .................................................................................. 40

................................................................................................ 34

........................................................................... 29

................................................................................... 35

.................................................................................... 36

Operating Principles

Overview

Printer Mechanism Operating Principles

Carriage Mechanism .............................................................................. 44

Printing Mechanism ................................................................................ 46

Paper Load Mechanism ......................................................................... 47

Paper Feed Mechanism ......................................................................... 49

Pump/ASF Switch Mechanism ............................................................... 50

.................................................................................................... 42

................................................ 42

Page 6

Pump / Carriage Lock / Head Cleaner Mechanism ................................ 52

Electrical Circuit Operation Principles

C265 PSB/PSE Power Supply Board ..................................................... 54

C380Main Board .................................................................................... 57

CR Motor Driver Circuit .......................................................................... 65

PF Motor Driver Circuit ........................................................................... 67

Pump/ASF Motor Driver Circuit .............................................................. 69

Printhead Driver Circuit .......................................................................... 70

Cooling Fan Driver Circuit ...................................................................... 72

ASF Solenoid Driver Circuit .................................................................... 74

EEPROM Control Driver Circuit ............................................................. 75

.................................................... 54

Troubleshooting

Overview

Troubleshooting with LED Error Indications ........................................... 78

Isolating the Faulty Part on the Power Supply Board ............................. 88

Isolating the Faulty Part according to the Phenomenon ......................... 90

..................................................................................................... 77

Remedies for Paper Out Error ............................................................ 79

Remedies for the Paper Jam Error ..................................................... 81

Remedies for No I/C and Ink Out Errors ............................................. 83

Remedies for the Maintenance Error ................................................. 85

Remedies for Fatal Error .................................................................... 86

Disassembly and Assembly

Overview

Precautions for Disassembling the Printer ........................................... 100

Disassembly Procedures

Upper Case and Control Panel Removal ............................................. 104

Printer Mechanism Removal ................................................................ 105

C380 Main Board Unit Removal ........................................................... 106

Relay Board and Cooling Fan Removal ............................................... 107

Shield Plate on the C380 Main Board Removal ................................... 108

C265 PSB/PSE Board Removal ........................................................... 109

Printer Mechanism Disassembly .......................................................... 111

................................................................................................... 100

........................................................................ 102

Printhead Removal ........................................................................... 111

CR Motor Removal ........................................................................... 113

PF Motor Removal ........................................................................... 114

Pump/ASF Motor and Solenoid Removal ......................................... 115

ASF Unit Removal ............................................................................ 115

ASF Disassembly 116

ASF Sensor Removal ....................................................................... 120

CRHP Sensor Removal .................................................................... 121

PE Sensor Removal ......................................................................... 121

Encoder Belt Sensor Removal ......................................................... 122

Carriage Unit Removal ..................................................................... 123

Pump Unit Removal ......................................................................... 124

Paper Eject Frame Removal ............................................................ 125

Paper Eject Roller Removal ............................................................. 125

Platen Removal ................................................................................ 126

PF Roller Removal ........................................................................... 127

Adjustment

Overview

Conditions for Each Adjustment ........................................................... 130

Adjustments

Preliminary Operation .......................................................................... 133

Head Actuator Voltage Input ................................................................ 135

Head ID Retrieval ................................................................................. 136

Head Angular Adjustment .................................................................... 136

Bi-Directional Adjustment ..................................................................... 137

USB ID Input ........................................................................................ 140

USB ID Retrieval .................................................................................. 141

Printhead Cleaning Using the Program ................................................ 142

Initial Ink Charge .................................................................................. 143

Refurbishment for DOA ........................................................................ 143

Indication of the Counter Value for the Waste Ink Pad ........................ 144

Fan Check ............................................................................................ 146

Paper Gap Adjustment ......................................................................... 147

.................................................................................................. 130

............................................................................................. 133

Maintenance

Overview

Maintenance ......................................................................................... 151

Lubrication and Adhesion

Lubricating the Carriage Guide Shaft ................................................... 155

.................................................................................................. 151

Cleaning the Printhead ..................................................................... 152

Maintenance Request Error ............................................................. 153

...................................................................... 154

Page 7

Appendix

Connector Summary

EEPROM ADDRESS MAP

Component Layout

Parts List

Exploded Diagrams

Circuit Diagrams

.................................................................................................. 173

............................................................................... 161

.................................................................................. 169

................................................................................. 176

...................................................................................... 184

....................................................................... 165

Page 8

PRODUCT DESCRIPTION

CHAPTER

1

Page 9

EPSON Stylus Color 980 Revision A

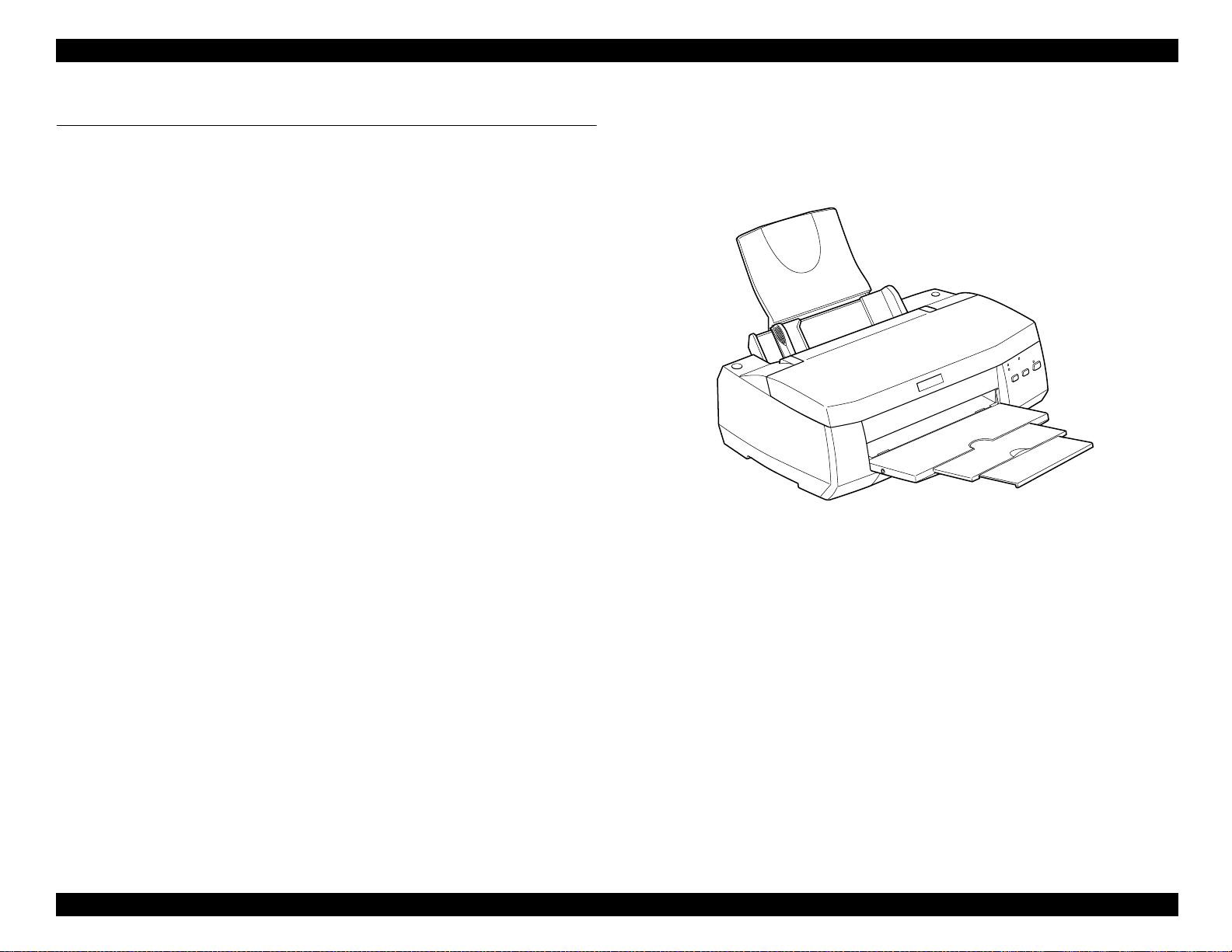

1.1 FEATURES

The Stylus COLOR 980 is the latest in EPSON’s advanced lines of ink

jet printers and offering the following features.

High color print quality:

- 2880 (H) x1440 (V) dpi printing

- Printing with 4 color inks (YMCK)

- Traditional and New Microweave

- Improvement in color rendering using variable dot

Built-in auto sheet feeder:

2

- Holds 100 cut-sheets (64 g/m

- Holds 10 envelopes

- Holds 30 transparency fIlms

Built-in 3 I/F

- Bi-directional parallel I/F (lEEE-1284 level 1 device)

- USB

- Optional Type-B level 2 I/F card slot

)

Figure 1-1. Stylus Color 980

4 scaleable fonts, 5 LQ fonts

13 character tables (Standard version)

37 character tables (NLSP version)

Duplex printing mode

Product Description Features 5

Page 10

EPSON Stylus Color 980 Revision A

1.2 Specifications

Print direction: Bi-direction with logic seeking

Print speed and Printable columns

1.2.1 Printing Specifications

Print method: On demand ink jet

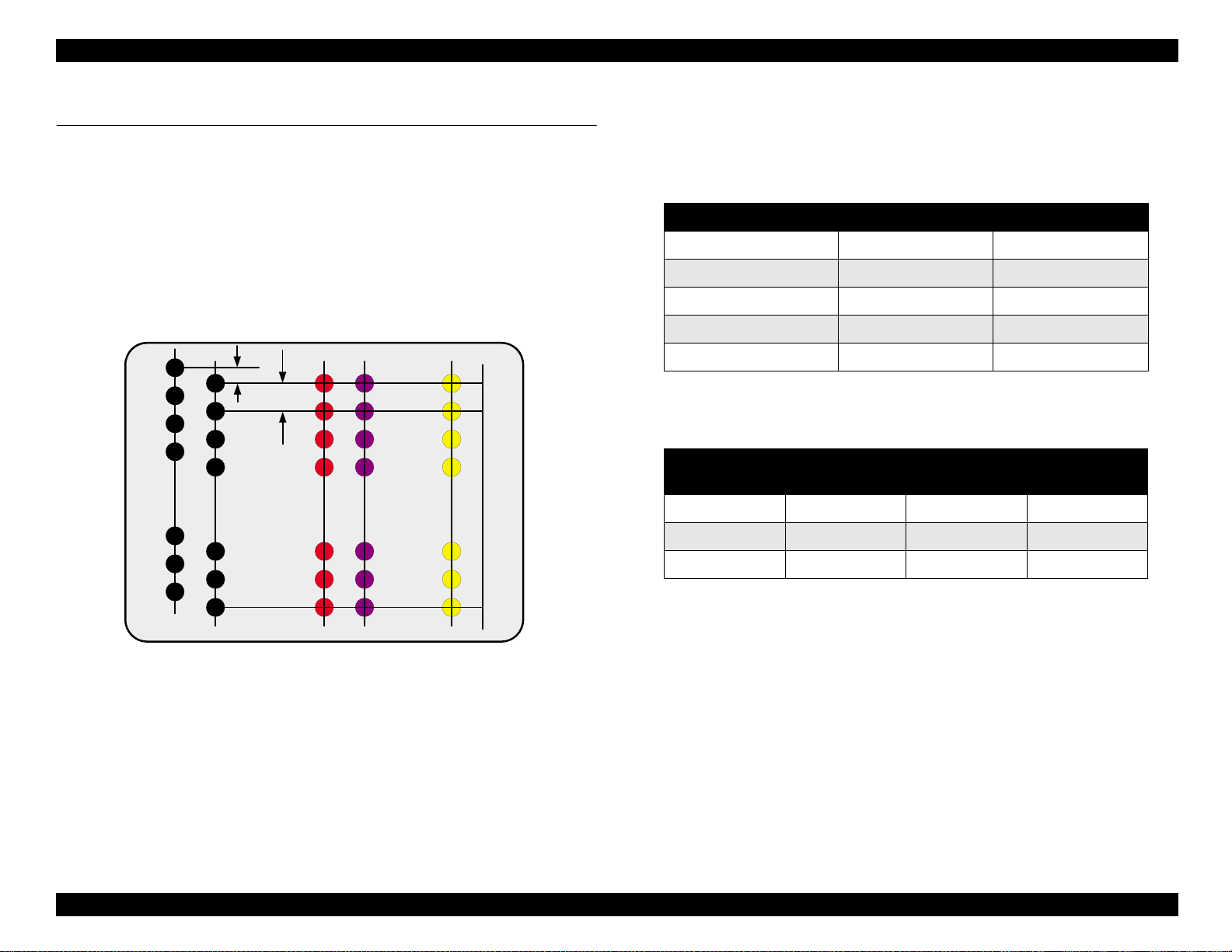

Nozzle configuration: Monochrome=192 nozzles (96 x 2 staggered)

Color=96 nozzles x 3 (Cyan, Magenta,

Yellow)

(See Figure 1-2 for the nozzle configuration.)

#96

#96

#95

#95

#94

#94

#93

#93

#3

#3

#2

#2

#1

#1

R ow A (B lack 1)

R ow B (B lack 2)

Figure 1-2. Nozzle configuration

360 dpi

180 dpi

#96

#95

#94

#93

#3

#2

#1

R ow C (M agenta)

Row D (Cyan)

#96

#95

#94

#93

#3

#2

#1

Row E (Yellow)

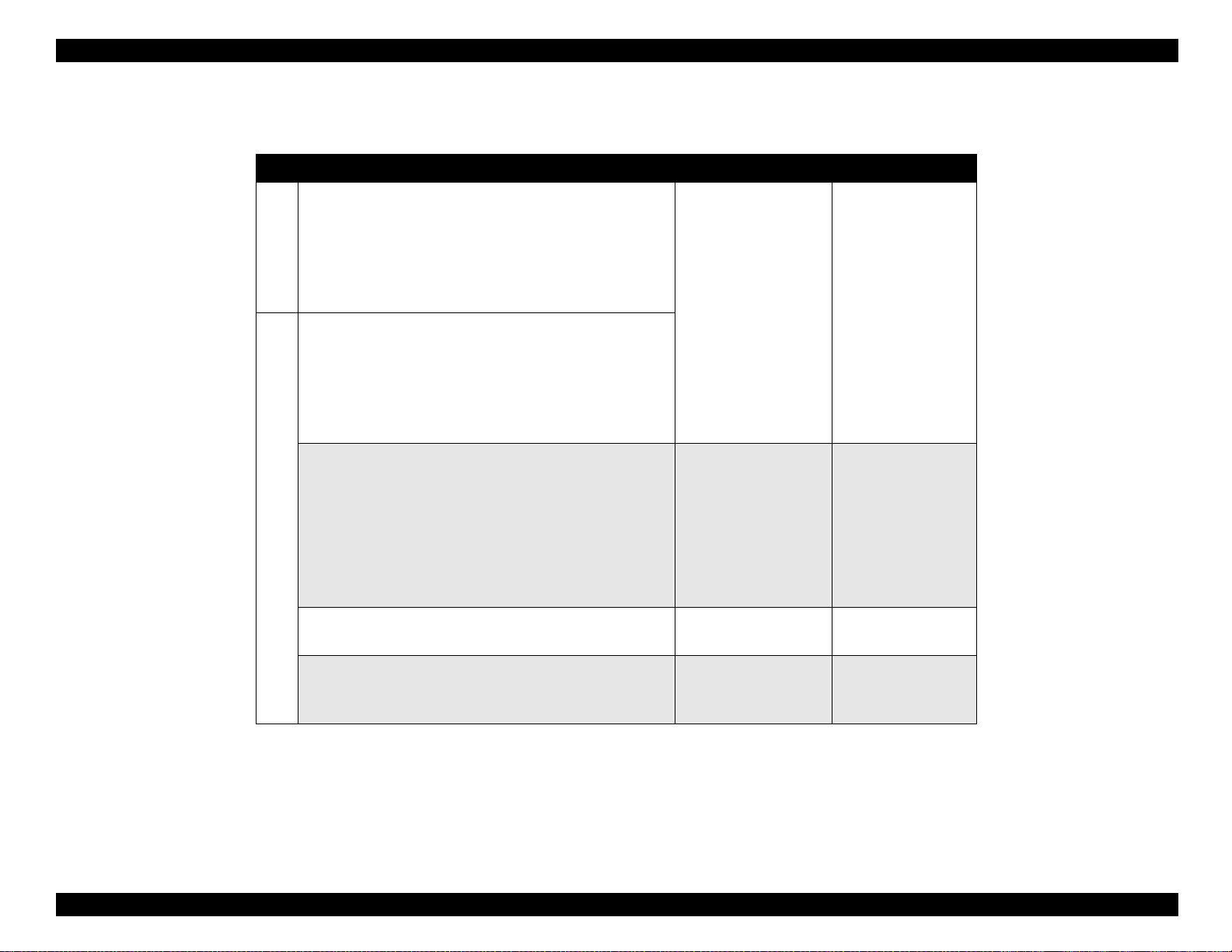

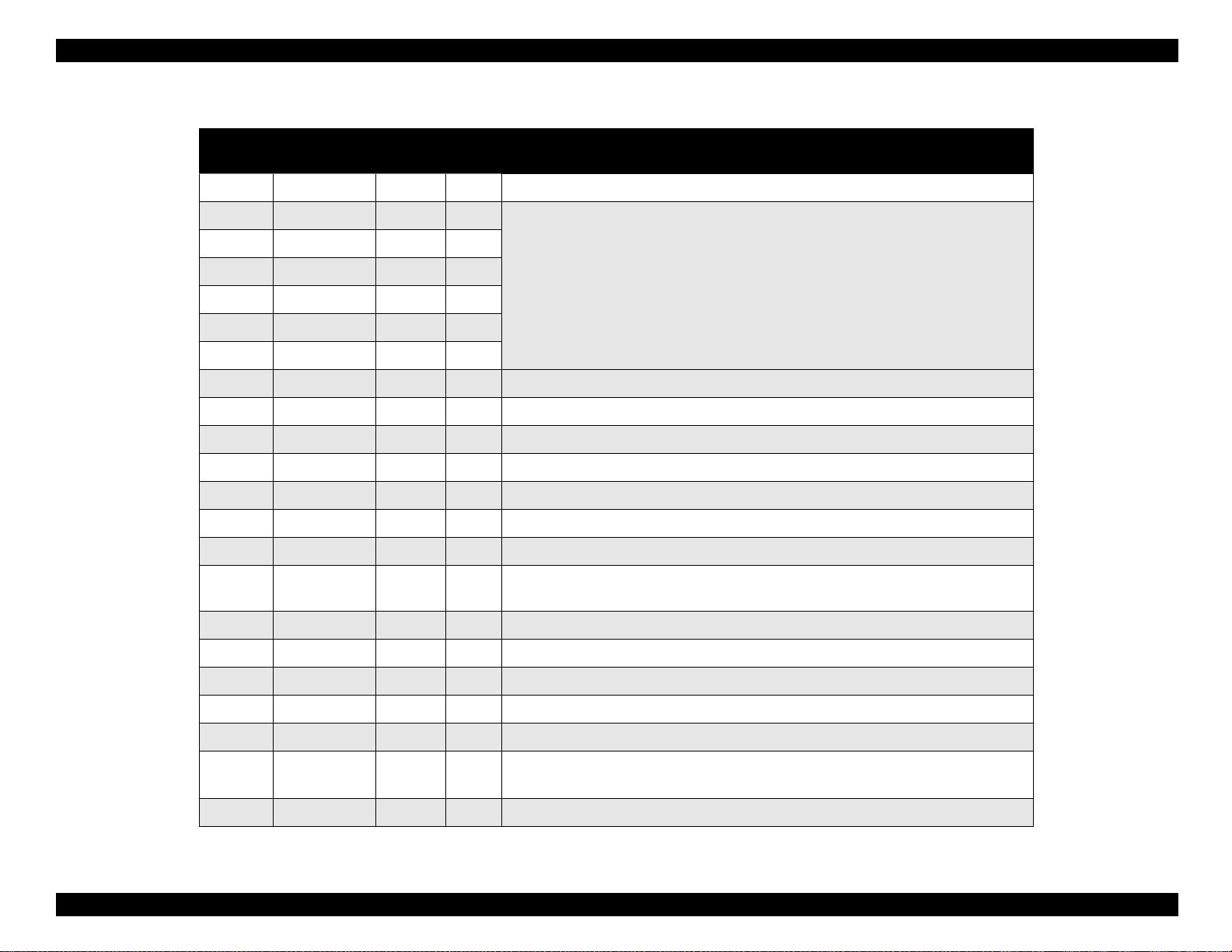

Table 1-1.

Print Speed and Printable Columns for Character Mode

Character pitch Printable columns LQ speed

10 CPI (Pica) 80 285 CPS

12 CPI (Elite) 96 342 CPS

15 CPI 120 428 CPS

17 CPI (Pica condensed) 137 487 CPS

20 CPI (EIite condensed) 160 570 CPS

Table 1-2.

Print Speed and Printable columns for Raster Graphics Mode

Horizontal

resolution

180 dpi 8.26 inch 1488 28.5 IPS

360 dpi 8.26 inch 2976 28.5 IPS

720 dpi 8.26 inch 5952 20 IPS

Control code: ESC/P2 and expanded raster graphics code

Printab le area Available dot CRS

EPSON Remote command

IBM X24E emulation

Product Description Specifications 6

Page 11

EPSON Stylus Color 980 Revision A

Character tables: Legal and 14 international character sets

Standard version: (13 character tables)

Italic table PC 860 (Portuguese)

PC 850 (Multilingual) PC 437(US, Standard Europe)

PC 861 (Icelandic) PC 863(Canadian-French)

PC 865(Nordic) Abicomp

BRASCII Roman 8

ISO Latin 1 PC 858

ISO 8859-15

NLSP version: (36 character tables)

Italic table PC437 PC437 Greek

PC850 PC852 PC853

PC855 PC857 PC860

PC861 PC865 PC866

PC869 MAZOWIA Code MJK

ISO 8859-7 lSO Latin 1T Bulgaria

PC774 Estonia ISO 8859-2

PC866 LAT PC866 UKR PC AR864

PC APTEC PC708 PC720

Hebrew7* Hebrew8* PC862*

Abicomp BRASCII Roman 8

ISO Latin 1 PC 858 lSO 8859-15

Typeface

Bit map LQ font:

EPSON Roman 10 CPI, 12 CPI, 15CPI, Proportional

EPSON Sans Serif 10 CPI, 12 CPI, 15CPI, Proportional

EPSON Courier 10 CPI, 12 CPI, 15CPI

EPSON Prestige 10 CPI, 12 CPI, 15CPI

EPSON Script 10 CPI, 12 CPI, 15CPI

Scaleable font

EPSON Roman 10.5 pt., 8 pt., - 32 pt. (every 2 pt.)

EPSON Sans Serif 10.5 pt., 8 pt., - 32 pt. (every 2 pt.)

EPSON Roman T 10.5 pt., 8 pt., - 32 pt. (every 2 pt.)

EPSON Sans Serif H 10.5 pt., 8 pt., - 32 pt. (every 2 pt.)

* Each Typeface has 4 variation s as the following example of

EPSON Roman.

EPSON Roman normal

EPSON Roman bold

EPSON Roman italic

EPSON Roman bold italic

See Table 1-3 which lists the character tables and available

typefaces.

Feeding method: Friction feed with ASF

* These character tables can not be selected in the Default setting

mode.

Product Description Specifications 7

Line spacing: 1/6 inch, 1/8 inch or programable at 1/360

inch

Paper path: Cut-sheet ASF (Top entry, Front out)

Feed speed: 192/360 inch feed = 116 ms

Continuous feed = 176.3 mm/second

(6.94 inch/second)

Input data buffer: 256 KB

Page 12

EPSON Stylus Color 980 Revision A

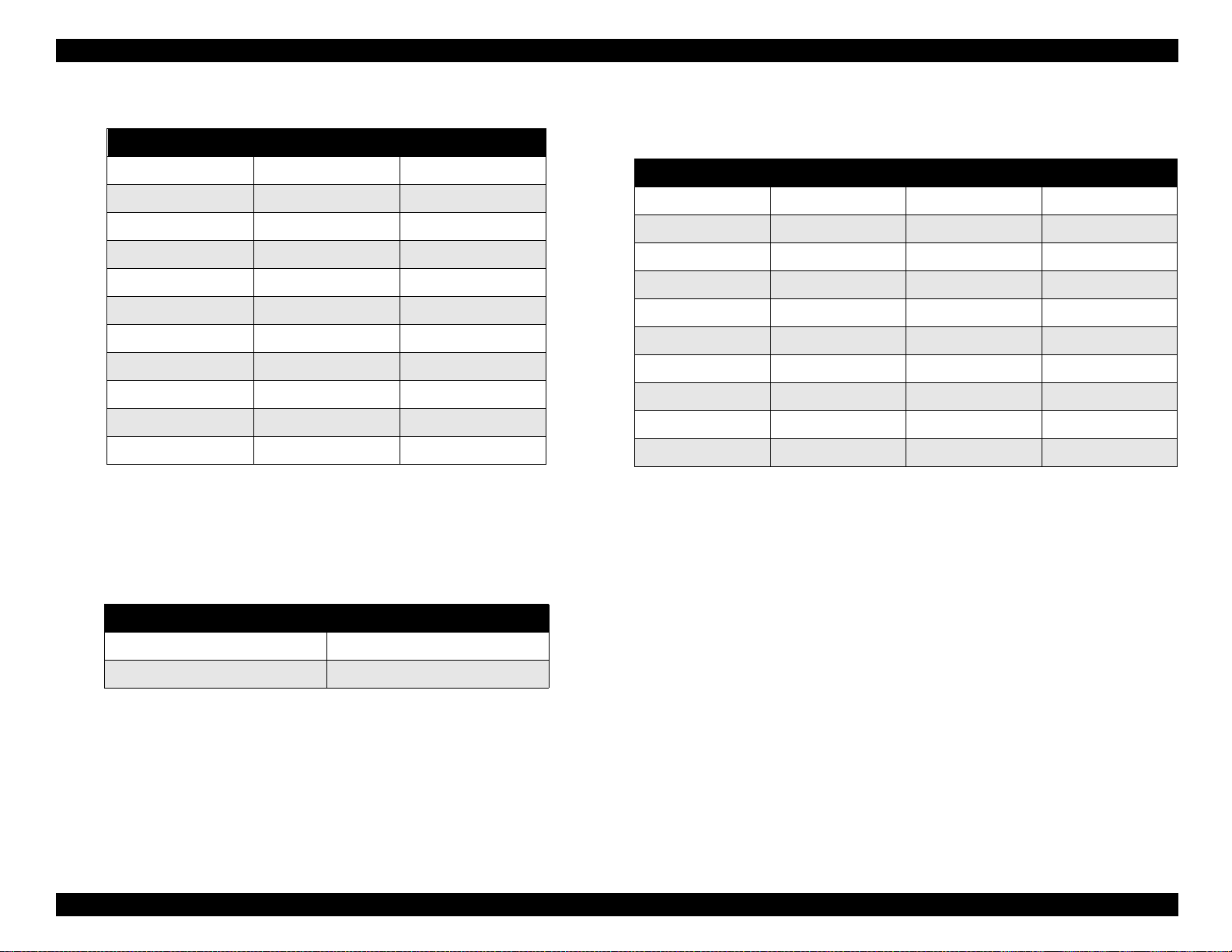

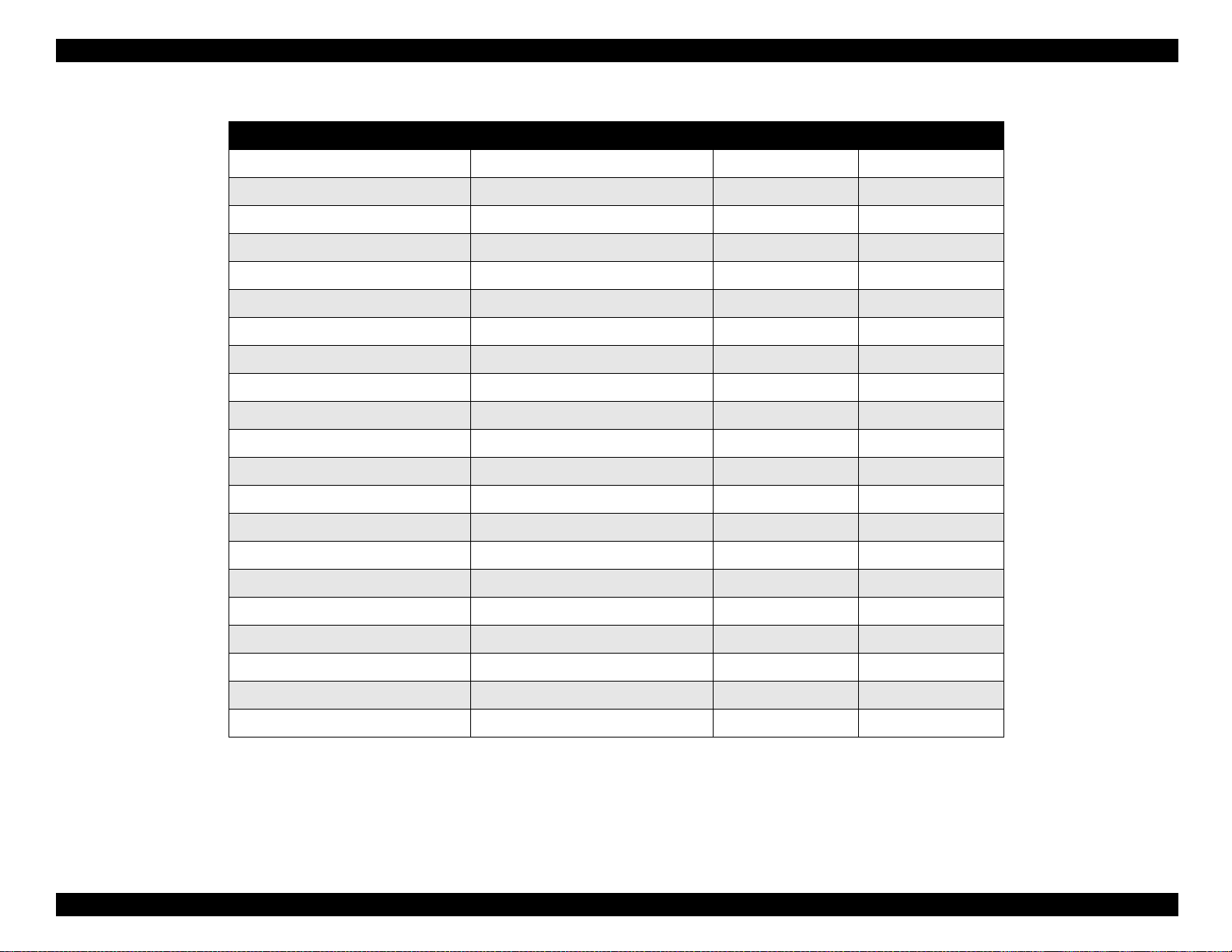

Table 1-3. Character Tables and Available Typefaces

Character Tables Bit map font Scaleable font

Italic table

PC 860 (Portuguese)

PC 861 (Icelandic)

PC 865 (Nordic)

Abicomp

lSO Latin1

Standard version

ISO 8859-15

Italic table

PC 850 (Multilingual)

PC 861 (Icelandic)

Abicomp

lSOLatin1

ISO 8859-15

PC437Greek

PC 853 (Turkish)

PC 857 (Turkish)

PC 869 (Greek)

Code MJK (CSFR)

lSO Latin 1T (Turkish)

NLSP version

PC 774

1SO 8859-2 (lSO Latin 2)

PC 866 UKR

PC APTEC (Arabic)

PC 720 (Arabic)

PC 437 (US Standard Europe)

PC 850 (Multilingual)

PC 863 (Canadian-French)

BRASCII

Roman 8

PC 858

PC 437(US Standard Europe)

PC 860(Portuguese)

PC 865(Nordic)

BRASCIl

Roman8

PC 858

PC 852 (East Europe)

PC 855 (Cyrillic)

PC 866 (Russian)

MAZOWIA (Poland)

lSO 8859-7 (Latin/Greek)

Bulgaria (Bulgarian)

Estonia

PC 866 LAT

PC 708 (Arabic)

PC AR864 (Arabic)

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON Roman

EPSON Sans Serif

EPSON Roman

EPSON Sans Serif

EPSON Roman T

EPSON Sans Serif H

EPSON Roman

EPSON Sans Serif

Not supported

Hebrew7*

Hebrew 8*

PC862 (Hebrew)*

EPSON Roman

EPSON Courier

Not supported

* Not mentioned in the User’s Guide. These character tables can not select in the default setting

mode.

Product Description Specifications 8

Page 13

EPSON Stylus Color 980 Revision A

1.2.2 Options and Consumable Products

∗

NOTE:The asterisk (

number, which varies by country.

NOTE:The availability of special media varies by country.

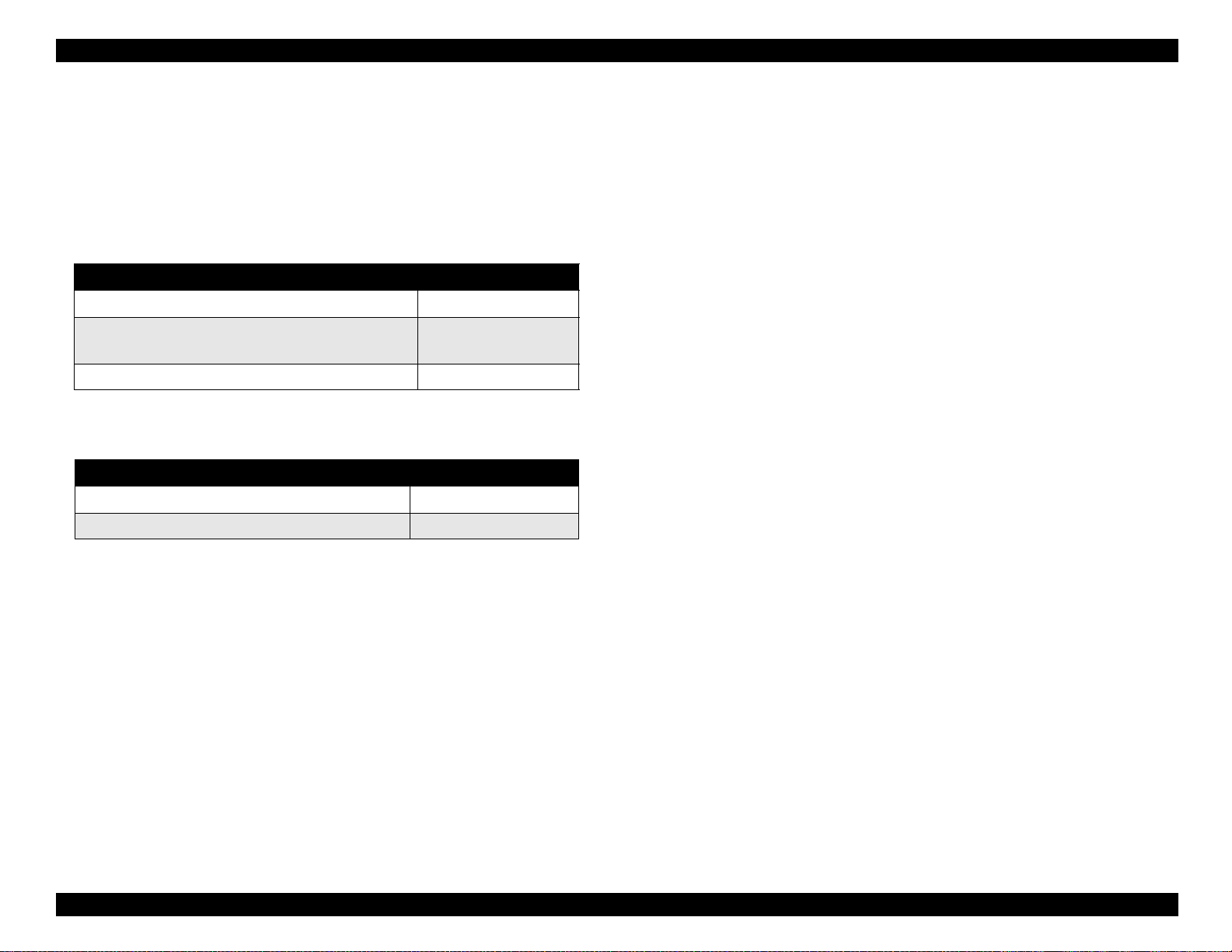

Table 1-4. Options Available for Stylus Color 980

Type B Multi-protocol Ethernet Interface Card C82362

Type B 100BASE-TX Multi-protocol Ethernet

Interface Card

Type B IEEE1394 Interface Card C82372

Table 1-5. Ink Cartridge Available for Stylus Color 980

) is a substitute for the last digit of the product

Items Codes

∗

/C82364

C82363

C82384

∗

∗

∗

Items Codes

Black Ink Cartridge T003

∗

Color Ink Cartridge T005

See Table 1-6 and 1-7 which show the EPSON Special Media.

Product Description Specifications 9

Page 14

EPSON Stylus Color 980 Revision A

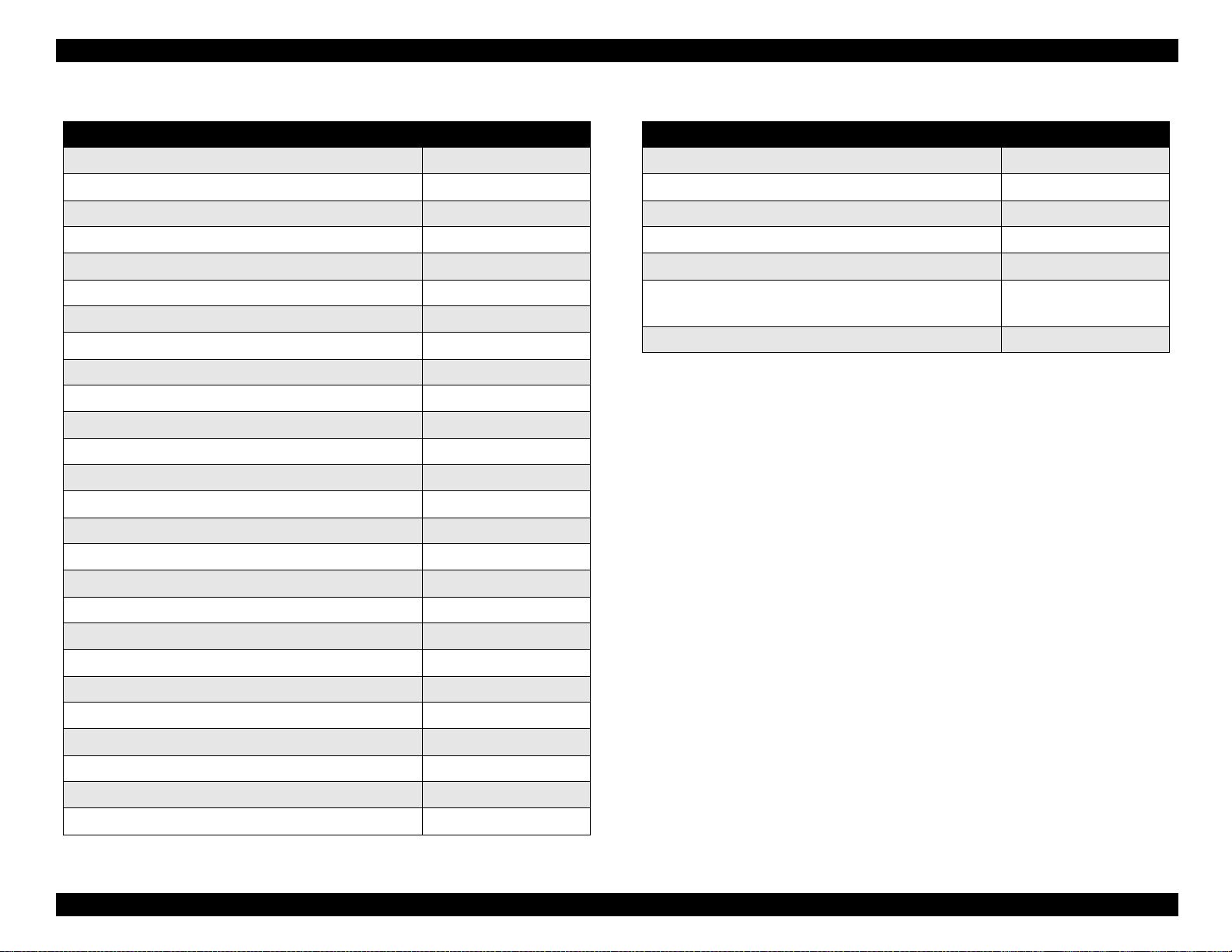

Table 1-6. EPSON Special Media Table 1-7. EPSON Special Media (continued)

Items Codes

Items Codes

EPSON 360 dpi Ink Jet Paper (A4) S041059 / S041025

EPSON 360 dpi Ink Jet Paper (Letter) S041060 / S041028

EPSON Photo Quality Ink Jet Paper (A4) S041061 / S041026

EPSON Photo Quality Ink Jet Paper (Letter) S041062 / S041029

EPSON Photo Quality Ink Jet Paper (Legal) S041067 / S041048

EPSON Photo Quality Ink Jet Card (A6) S041054

EPSON Photo Quality Ink Jet Card (5 x 8”) S041121

EPSON Photo Quality Ink Jet Card (8 x 10”) S041122

EPSON Photo Quality Self Adhesive Sheet (A4) S041106

EPSON Ink Jet Note Card (A6) (with envelopes) S041147

EPSON Ink Jet Greeting Cards (5 x 8”) (with envelopes) S041148

EPSON Ink Jet Greeting Cards (8 x 10”) (with envelopes) S041149

EPSON Photo Quality Glossy Film (A4) S041071

EPSON Photo Quality Glossy Film (Letter) S041072

EPSON Photo Quality Glossy Film (A6) S041107

EPSON Ink Jet Transparencies (A4) S041063

EPSON Ink Jet Transparencies (Letter) S041064

EPSON Photo Paper (A4) S041140

EPSON Photo Paper (100 x 150mm) S041255

EPSON Photo Paper (200 x 300mm) S041254

EPSON Premium Ink Jet Plain Paper (A4) S041214

EPSON Premium Glossy Photo Paper (A4) S041287 / S041297

EPSON Premium Glossy Photo Paper (Letter) SO41286

EPSON Matte Paper-Heavy weight (A4)

EPSON Matte Paper-Heavy weight (Letter) S041257

S041256 / S041258

S041259

EPSON Photo Paper (Letter) S041141

EPSON Photo Paper (4 x 6”) S041134

EPSON Photo Paper Cards (A4) S041177

EPSON Photo Stickers 16 (A6) S041144

EPSON Photo Stickers 4 (A6) S041176

EPSON Panoramic Photo Paper (210 x 594 mm) S041145

EPSON Iron-On Cool Peel Transfer Paper (A4) S041154

EPSON Iron-On Cool Peel Transfer Paper (Letter) S041153 / S041155

Product Description Specifications 10

Page 15

EPSON Stylus Color 980 Revision A

1.2.3 Paper Specifications

This section describes paper specifications including paper handling

and printable area.

Paper Handling: Do not feed paper in reverse more than 9.5 mm

(0.38”).

1.2.3.1 Cut Sheet

Size:

A4: [Width 210 mm (8.3”) x Length 297 mm (11.7”)]

A5: [Width 148 mm (5.8”) x Length 210 mm (8.3”)]

Letter: [Width 216 mm (8.5”) x Length 279 mm (11.0”)]

B5: [Width 182 mm (7.2”) x Length 257 mm (10.1”)]

Legal: [Width 216 mm (8.5”) x Length 356 mm (14.0”)]

Half Letter: [Width 139.7 mm (5.5”) x Length 215.9 mm (8.5”)]

Executive: [Width 184.2 mm (7.25”) x Length 266.7mm(10.5”)]

Thickness: 0.08 mm (0.003”) - 0.11 mm (0.004”)

Weight: 64g/m

Paper Types: Bond paper, Plain paper, EPSON special media

2

(17Ib.) - 90g/m2 (24Ib.)

1.2.3.3 Envelope

Size:

No.10: [Width 241 mm (9 1/2”) x Length 104.8 mm (4 1/8”)]

DL: [Width 220 mm (8.7”) x Length 110 mm (4.3”)]

C6: [Width 162 mm (6.4”) x Length 114 mm (4.5”)]

5 x 8”: [Width 220 mm (8.7”) x Length 132 mm (5.2”)]

Thickness: 0.16 mm (0.006”) - 0.52 mm (0.02”)

Weight: 45g/m

Paper Types: Bond paper, Plain paper, Air mail

NOTES:

1. Print on envelope at normal temperatures only.

2. Place the longer side of the envelope horizontal.

2

(12Ib.) - 75g/m2 (20Ib.)

1.2.3.4 Index Card

Size:

A6 Index card: [Width 105 mm (4.1”) x Length 148 mm (5.8”)]

5 x 8” Index card: [Width 127 mm (5.0”) x Length 203 mm (8.0”)]

10 x 8” Index card:[Width 127 mm (5.0”) x Length 203 mm (8.0”)]

Thickness

1.2.3.2 Transparency, Glossy Fi lm

Size

A4: [Width 210 mm (8.3”) x Length 297 mm (11.7”)]

Letter: [Width 216 mm (8.5”) x Length 279 mm (11.0”)]

A6: [Width 105 mm (4.1”) x Length 148 mm (5.8”)]

Thickness: 0.075 mm (0.003”) - 0.085 mm (0.0033”)

Paper Types: EPSON special media

NOTE:Print on transparency at normal temperatures only.

Product Description Specifications 11

Paper Types: EPSON special media

1.2.3.5 Self Adhesive Sheets

Size

A4: [Width 210 mm (8.3”) x Length 297 mm (11.7”)]

Paper Types: EPSON special media

:

Less than 0.23 mm (0.0091”)

Page 16

EPSON Stylus Color 980 Revision A

1.2.3.6 Photo Paper

Size:

A4: [Width 210 mm (8.3”) x Length 297 mm (11.7”)]

Letter: [Width 216 mm (8.5”) x Length 279 mm (11.0”)]

4 x 6”: [Width 102 mm (4”) x Length 152 mm (6”)]

Panoramic: [Width 210 mm (8.3”) x Length 594 mm (23.4”)]

Paper Types: EPSON special media

1.2.3.7 Photo Stickers

Size:

A6 with 4 or 16 frames:

[Width 105 mm (4.1”) x Length 148 mm (5.8”)]

Paper Types: EPSON special media

Product Description Specifications 12

Page 17

EPSON Stylus Color 980 Revision A

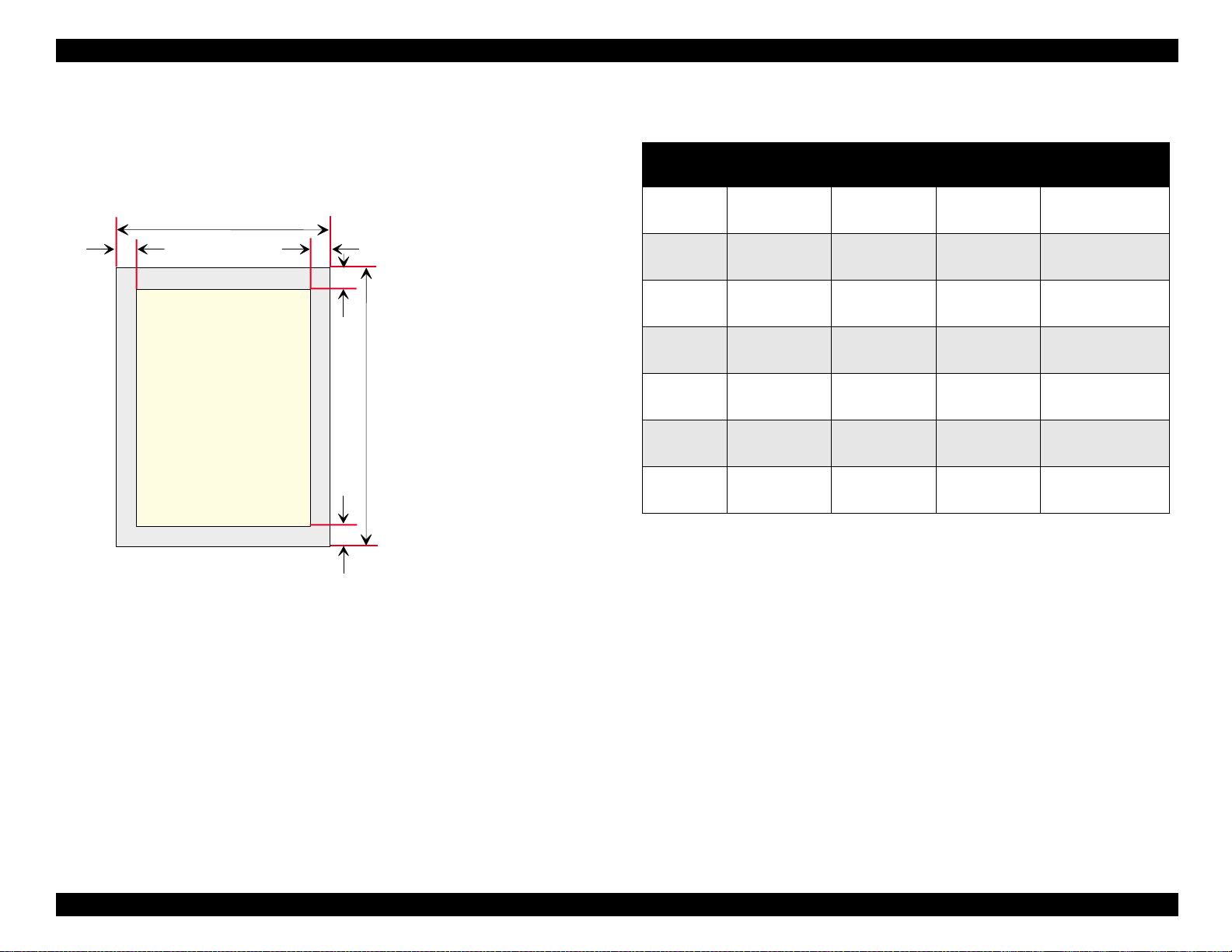

1.2.4 Printable Area

Cut Sheet

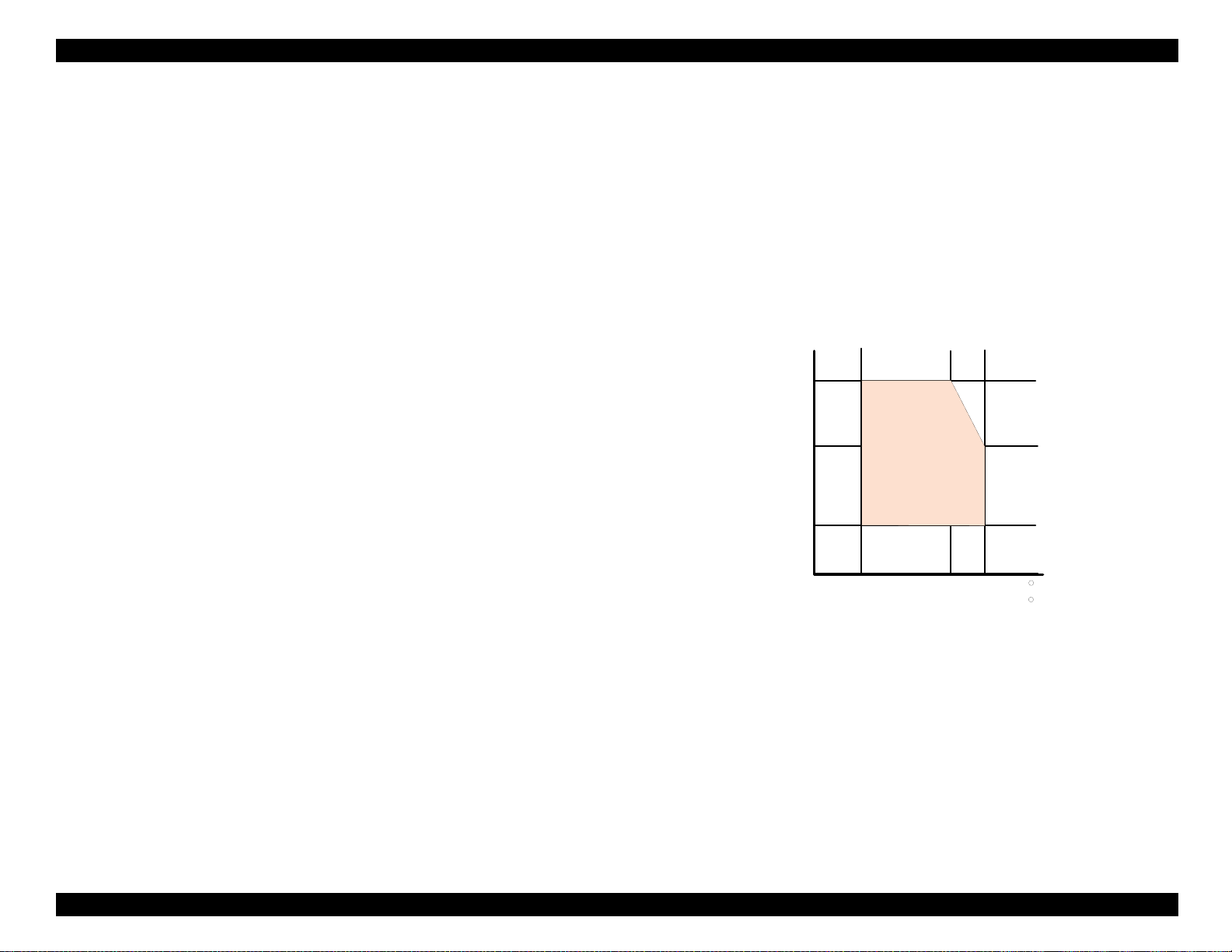

See Figure 1-3 and Table 1-8 for the printable area for cut sheets.

PW

LM

Printable area

Figure 1-3. Printable Area for Cut Sheets

TM

BM

RM

PL

L M : L e ft M a rg in e

R M : R ight M argine

TM : Top M argine

B M : B o tto m M a rg in e

PW : P aper W idth

PL: P aper Length

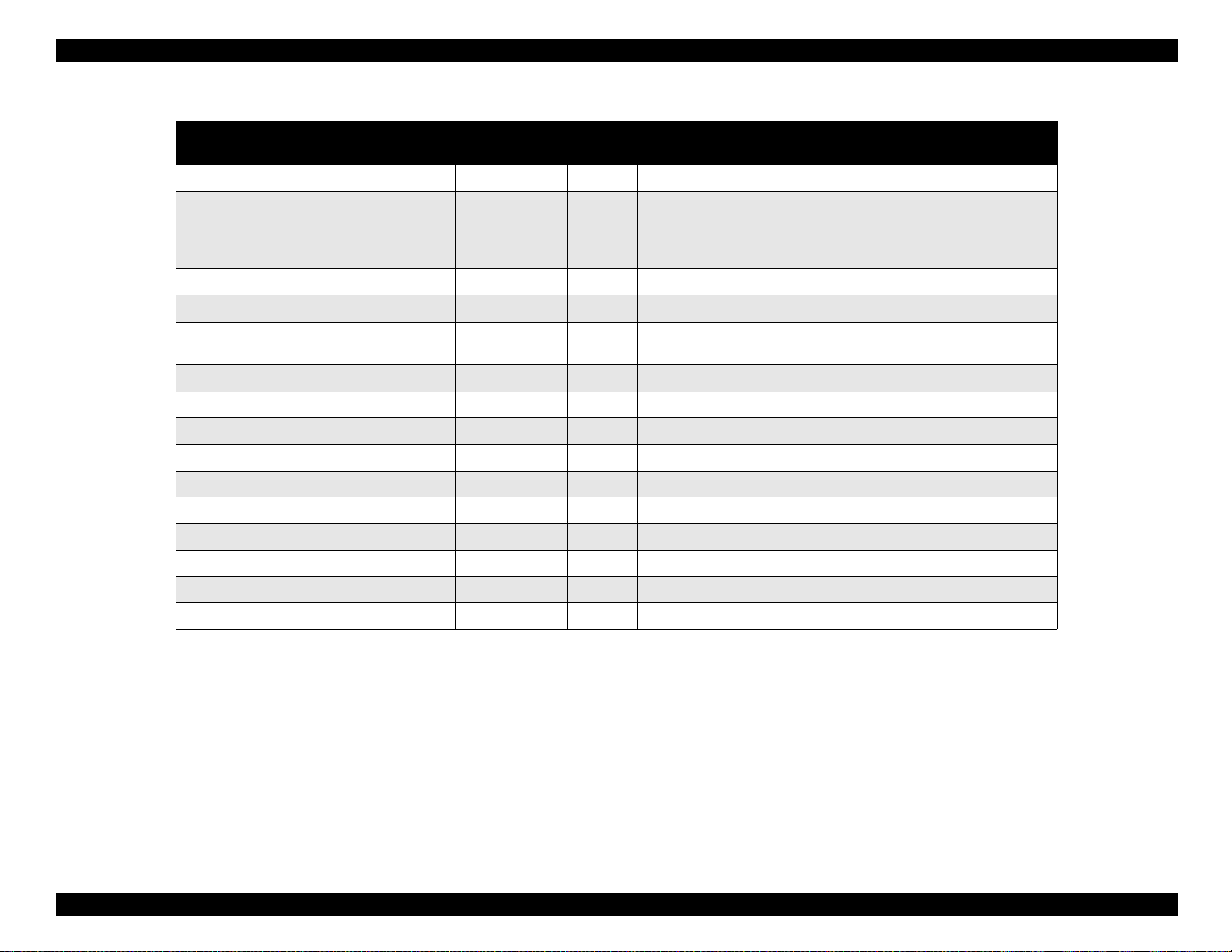

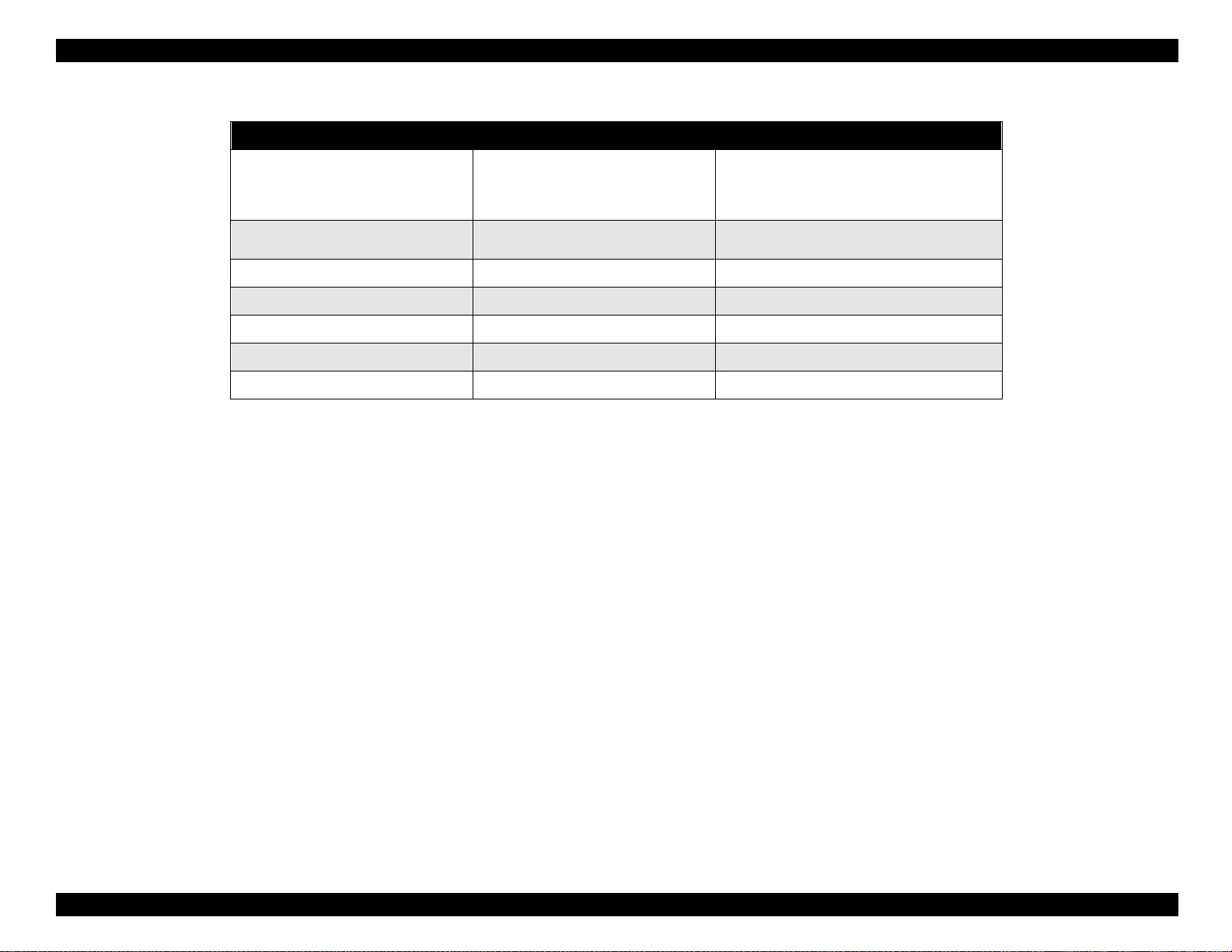

Table 1-8.

Minimum margin for Raster Graphics Mode / Character Mode

Paper

Size

A4 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

A5 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Letter 3 mm (0.12”)

B5 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Legal 3 mm (0.12”)

Half Letter 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Executive 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

*1: For Raster Graphics mode

*2: For Character mode

*3: The minimum bottom margin is reduced to 3 mm when paper dimension is defined

by using the command. Otherwise, the minimum bottom margin remains 14 mm.

Note the extra printing area with the bottom margin of 3 mm is not a guaranteed

area.

Left Margin

(Minimum)

Right Margin

(Minimum)

3 mm (0.12”)*

9 mm (0.35”)*

3 mm (0.12”)*

9 mm (0.35”)*

Top Margin

(Minimum)

1

3 mm (0.12”)

2

1

3 mm (0.12”)

2

Bottom Margin

(Minimum)

14 mm (0.54”)

3 mm (0.12”) *

14 mm (0.54”)

3 mm (0.12”) *

14 mm (0.54”)

3 mm (0.12”) *

14 mm (0.54”)

3 mm (0.12”) *

14 mm (0.54”)

3 mm (0.12”) *

14 mm (0.54”)

3 mm (0.12”) *

14 mm (0.54”)

3 mm (0.12”) *

3

3

3

3

3

3

3

Product Description Specifications 13

Page 18

EPSON Stylus Color 980 Revision A

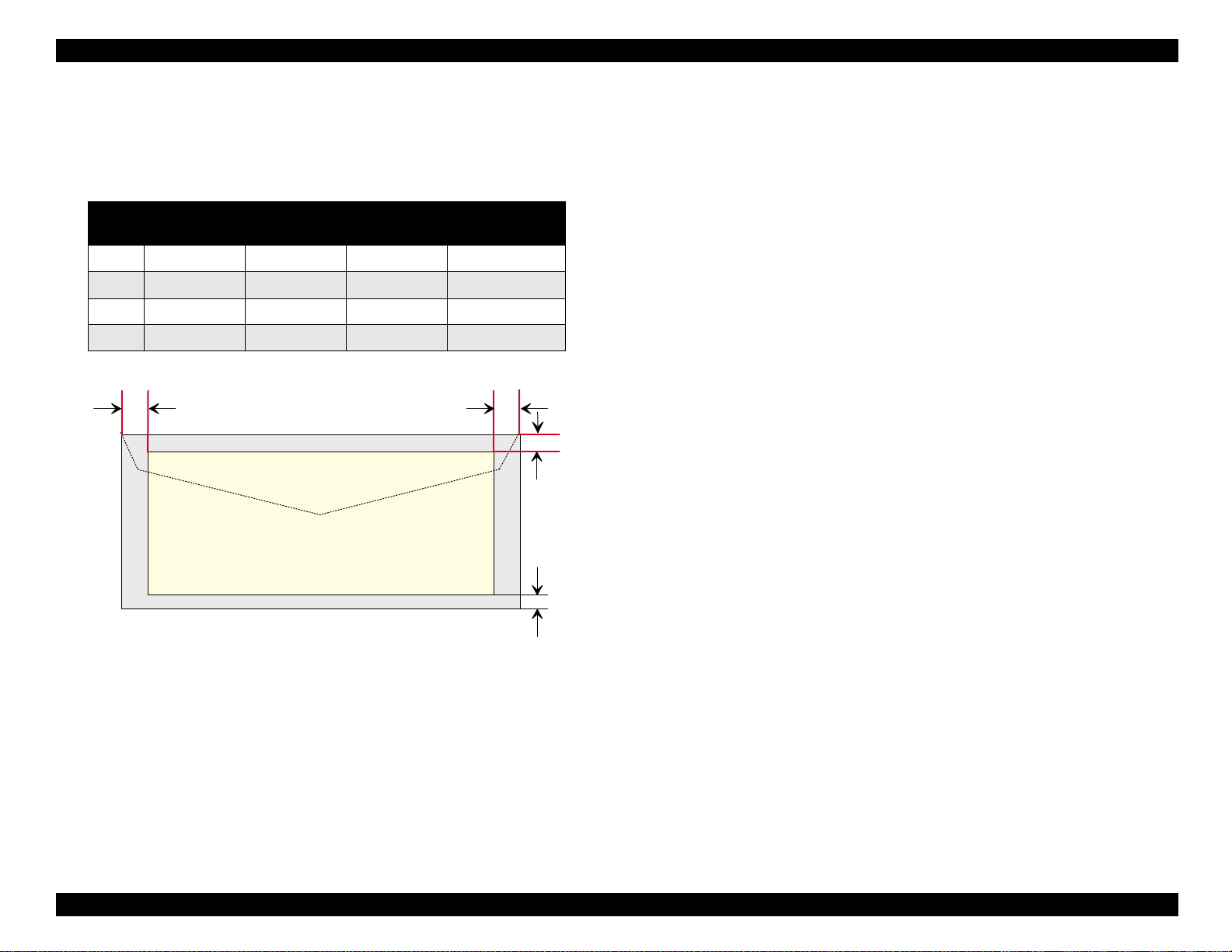

Envelope See Table 1-9 and Figure 1-4 which show the minimum

margin and printable area for envelopes, respectively.

Table 1-9. Minimum Margin for Envelopes

Paper

Size

#10 3 mm (0.12”) 28 mm (1.10”) 3 mm (0.12”) 14 mm (0.54”)

DL 3 mm (0.12”) 7 mm (0.28”) 3 mm (0.12”) 14 mm (0.54”)

C6 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.54”)

5 x 8 3 mm (0.12”) 7 mm (0.28”) 3 mm (0.12”) 14 mm (0.54”)

Left Margin

(Minimum)

Right Margin

(Minimum)

Top Margin

(Minimum)

Bottom Margin

(Minimum)

RMLM

TM

Printable

A re a

BM

Figure 1-4. Printable Area for Envelopes

Product Description Specifications 14

Page 19

EPSON Stylus Color 980 Revision A

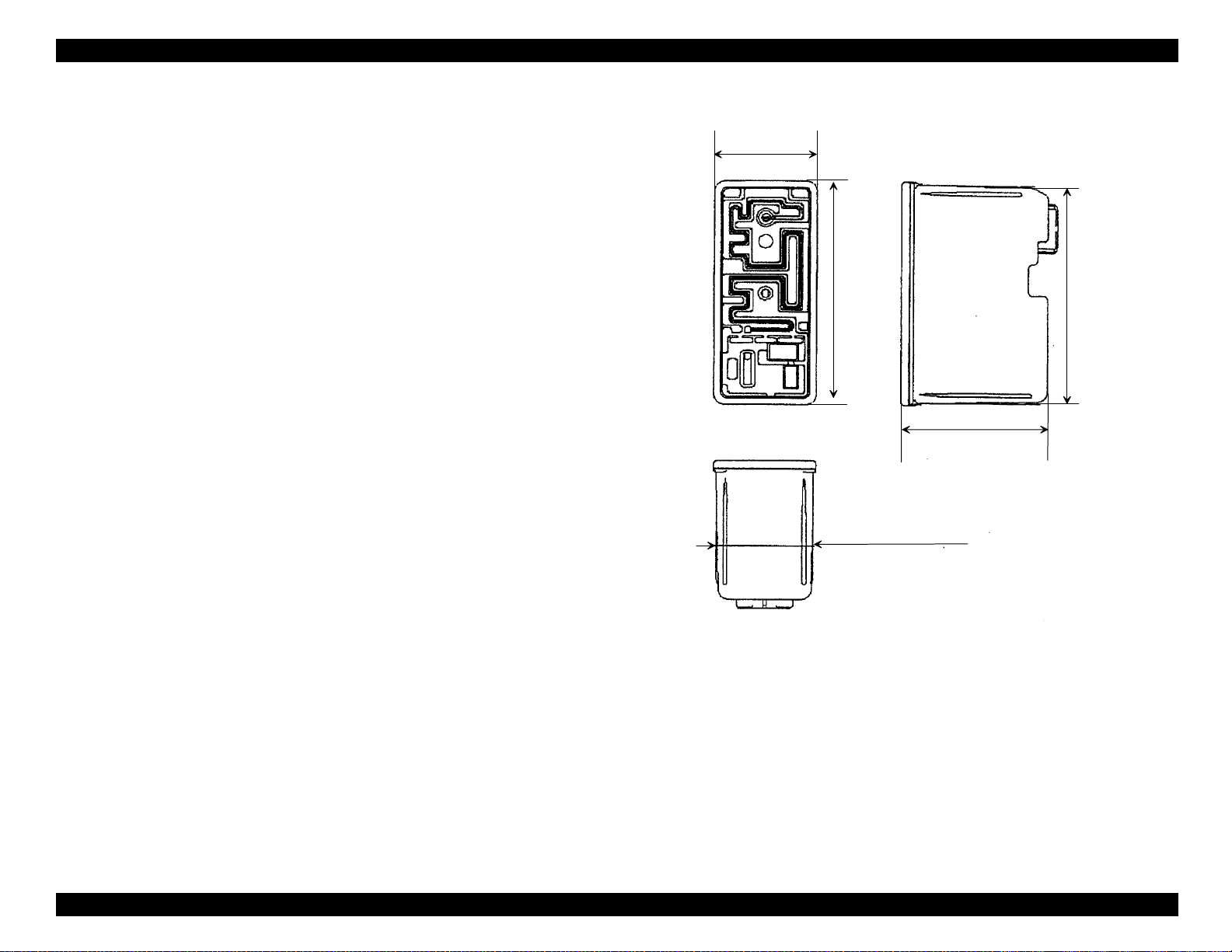

1.2.5 Ink Cartridge Specifications

28.9 m m

1.2.5.1 Black Ink Cartridge

Type: Exclusive ink cartridge

Color: Black

Print Capacity: 1200 pages / A4 (ISO/IEC 10561 Letter

Pattern at 360 dpi)

Ink life: 2 years from indicated production date

Storage temperature:

Storage: -20°C ~ 40°C(within a month at 40 °C)

Packing storage: -30°C ~ 40°C(within a month at 40 °C)

Transit: -30°C ~ 60°C(within 120 hours at 60°C and

within a month at 40°C)

67.4 m m

65.9 m m (R ib area)

Dimensions: 28.9 mm (W) x 67.4 mm (D) x 41.8 mm (H)

41.8 m m

27.4 m m (R ib area)

Figure 1-5. Black Ink Cartridge Appearance

Product Description Specifications 15

Page 20

EPSON Stylus Color 980 Revision A

1.2.5.2 Color Ink Cartridge

Type: Exclusive ink cartridge

Color: Magenta, Cyan, Yellow

Print Capacity: 530 pages / A4 (at 360 dpi, 5% duty each

color)

Ink life: 2 years from indicated production date

Storage temperature:

Storage: -20°C ~ 40°C(within a month at 40 °C)

Packing storage: -30°C ~ 40°C (within a month at 40 °C)

Transit: -30°C ~ 60°C (within 120 hours at 60°C and

within a month at 40°C)

Dimensions: 54.0 mm (W) x 67.4 mm (D) x 41.8 mm (H)

NOTES

1. Do not refill the cartridge. It is a consumable item.

2. Do not used the ink cartridge whose ink life has expired.

°

Ink will be frozen below -4

3.

C. To use ink that is frozen, let it defrost

for at least 3 hours at room temperature.

54 m m

67.4 m m

65.9 m m (R ib area)

41.8 m m

52.5 m m (R ib area)

Figure 1-6. Color Ink Cartridge

Product Description Specifications 16

Page 21

EPSON Stylus Color 980 Revision A

Humidity

(% RH)

80%

55%

20%

10 27

35

50

( C )

80

95

( F )

G uaranteed

A re a

1.2.6 Electrical Specifications

[120V version]

Rated voltage: AC120V

Input voltage range: AC99 ∼132V

Rated frequency range: 50 ∼ 60 Hz

Input frequency range: 49.5 ∼ 60.5 Hz

Rated current: 0.7A (Maximum 1.0A)

Power consumption: Approx.30W (ISO/IEC 10561 Letter pattern)

Energy Star compliant

Insulation Resistance: 10 M ohms min.

(between AC line and chassis, DC 500 V)

Dielectric strength: AC1000 V rms. 1 minute or AC1200 Vrms.

1 second (between AC line and chassis)

[220∼240V version]

Rated voltage: AC220V ∼ 240V

1.2.7 Environmental Condition

Temperature: Operating = 10 to 35 °C (See Figure 1-7.)

Non-operating = -20 to 60 °C *1

1 month at 40 °C

120 hours at 60 °C

Humidity: Operating = 20% ~ 80% RH *1

(See Figure 1-7.)

Non-operating = 5% ~ 85% RH *1 *2

Input voltage range: AC198 ∼ 264V

Rated frequency range: 50 ∼ 60Hz

Input frequency range: 49.5 ∼ 60.5Hz

Rated current: 0.4A (Maximum 0.5A)

Power consumption: Approx.30W (ISO/IEC 10561 Letter pattern)

Energy Star compliant

Insulation Resistance: 10M ohms min.

Product Description Specifications 17

Dielectric strength: AC1500 V rms.

(between AC line and chassis, DC500V)

1 minute (between AC line and chassis)

Resistance to shock: Operating = 1G, within 1 ms

Resistance to vibration: Operating = 0.15G (Operating)

*1: With a shipment container

*2: Without condensation

Figure 1-7. Temperature / Humidity of Range

Non-operating = 2G, within 2 ms *1

Non-operating = 0.50G *1

Page 22

EPSON Stylus Color 980 Revision A

1.2.8 Reliability

Total print volume: 75,000 pages (A4, Letter)

Printhead life: 4000 million dots/nozzle

1.2.9 Safety Approvals

[120V version]

Safety standard: UL1950

CSA22.2 No.950

EMI: FCC part 15 subpart B class B

CSA C108.8 class B

[220∼240V version]

Safety standard: EN 60950 (VDE)

EMI: EN55022 (CISPR Pub.22) class B

AS/NZS 3548 class B

1.2.10 Acoustic Noise

1.2.11 CE Marking (220 ∼ 240 V version)

Low Voltage Directive 73/23/EEC: EN60950

EMC Directive 89/336/EEC: EN55022 Class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

1.2.12 Physical Specifications

Weight: 8.4 Kg

Dimensions: 467 mm (W) x 296 mm (D) x 325 mm (H)

Level: Approximately 47 dB (A) (According to ISO

7779)

Product Description Specifications 18

Page 23

EPSON Stylus Color 980 Revision A

-

1.3 Interface

The EPSON Stylus Color 980 is equipped with USB, Bi-directional 8-bit

parallel interface and a card slot for an optional Type-B interface.

1.3.1 Parallel Interface (Forward Channel)

Transmission mode: 8 bit parallel, IEEE-1284 compatibility mode

Synchronization: By /STROBE pulse

Handshaking: BY BUSY and /ACKLG signal

Signal level: TTL compatible level

Adaptable connector: 57-30360 (amphenol) or equivalent

The BUSY signal is set high before setting either/ERROR low or PE

high, and held high until all these signals return to their inactive state.

The BUSY signal is HIGH:

During data entry (see Data transmission timing)

When the input data buffer is full

During/INIT signal is at LOW level or during hardware

initialization.

The ERROR signal is LOW when one of the following error has

occurred:

Printer hardware error (fatal error)

Paper Out error

Paper Jam error

Ink Out error

The PE signal is at a high level during Paper Out error.

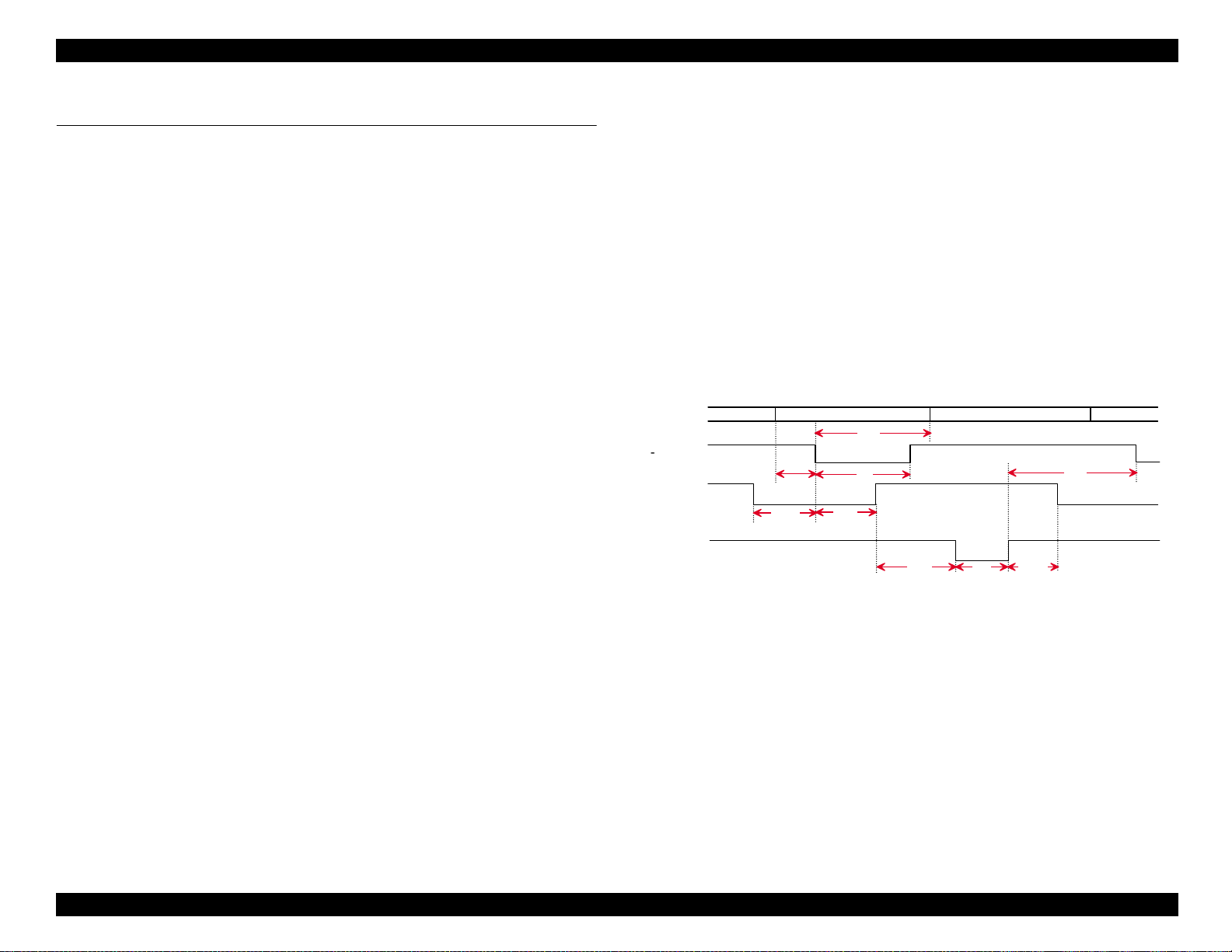

See Figure 1-8 and Table 1-10 which show the data transmission

timing.

DATA

STROBE

BUSY

-ACKNLG

tsetup

tready

data byte n

thold

ts tb

tbusy

treply ta c k

tnbusy

data byte n+1

tnext

Figure 1-8. Data Transmission Timing

During a printer error condition (See /ERROR signal).

When the parallel interface is not selected.

Product Description Interface 19

Page 24

EPSON Stylus Color 980 Revision A

Table 1-10. Data Transmission Timing

Parameter Minimum Maximum

tsetup 500ns ---

thold 500ns ---

tstb 500ns ---

tready 0 ---

tbusy --- 500ns

tt-out* --- 120ns

tt-in** --- 200ns

treply 0 ---

tack 500ns 10us

tnbusy 0 ---

tnext 0 ---

NOTE:tt-out shows the rise and fall time of every output signal.

tt-in shows the rise and fall time of every input signal.

Typical time of tack is shown in Table 1-11.

Table 1-11. Typical Time of Tack

Table 1-12. Signal level for TTL Compatible

(IEEE-1284 level 1 device)

Parameters Minimum Maximum Condition

VOH* --- 5.5V

VOL* -0.5V ---

IOH* --- 0.32mA VOH = 2.4V

IOL --- 12mA VOL = 0.4V

CO --- 50pF

VIH --- 2.0V

VIL 0.8V ---

IIH --- 0.32mA VIH = 2.0V

IIL --- 12mA VIL = 0.8V

CI --- 50pF

* A LOW logic level on the Logic H signal is as follows:

2.0 V or less when the printer is turned off.

3.0 V or more when the printer is turned on.

The receiver provides an impedance equivalent to 7.5 K

ground.

Ω

to

Parallel Interface Mode Typical Time of Tack

High speed 1 us

Normal speed 3 us

See Table 1-13 which shows the connector pin assignment and signals

for the forward channel of the parallel interface.

Product Description Interface 20

Page 25

EPSON Stylus Color 980 Revision A

Table 1-13. Parallel I/F Forward Channel

Pin No. Signal Name

1 /STROBE 19 I The strobe pulse. Read-in of data is performed at the falling edge of this pulse.

2 DATA0 20 I

3DATA1 21

4 DATA2 22

5DATA3 23

6 DATA4 24

7DATA5 25

8 DATA6 26

9DATA7 27

10 /ACKNLG 28 O This signal is a negative pulse indicating that the printer can again accept data.

11 BUSY 29 O A high signal indicates that the printer cannot receive data.

12 PE 28 O A high signal indicates paper-out error.

13 SLCT 28 O Always at high level when the printer is powered on.

14 /AFXT 30 I Not used.

31 /INIT 30 I

Return

GND Pin

In/Out Functional Description

The DATA0 through DATA7 signals represent data bits 0 to 7, respectively. Each

signal is at high level when data is logical 1 and low level when data is logical 0.

The falling edge of a negative pulse or a low signal on this line causes the printer to

initialize. Minimum 50 us pulse is necessary.

32 /ERROR 29 O A low signal indicates printer error condition.

36 /SLIN 30 I Not used.

18 Logic H ---- O Pulled up to +5V via 3.9K ohm resistor.

35 +5V ---- O Pulled up to +5V via 3.9K ohm resistor.

17 Chassis GND ---- --- Chassis GND.

16,33,

19-30

15,34 NC ---- --- Not connected.

*: In and Out refers to the direction of the signal as viewed from the printer.

GND ---- --- Signal GND.

Product Description Interface 21

Page 26

EPSON Stylus Color 980 Revision A

1.3.2 Parallel Interface (Reverse Channel)

Transmission mode: IEEE-1284 nibble mode

Adaptable connector: See the forward channel.

Synchronization: Refer to the IEEE-1284 specification

Handshaking: Refer to the IEEE-1284 specification

Data trans. timing: Refer to the IEEE-1284 specification

Signal level: IEEE-1284 level 1 device

(See forward channel.)

Extensibility request:

The printer responds affirmatively when the extensibility request

values are 00H or 04H,as follows;

00H:Request Nibble Mode Reverse Channel Transfer.

04H:Request device ID using Nibble Mode Rev Channel

Transfer.

Device ID:

The printer sends following device ID string upon request.

When IEEE1284.4 is disabled;

[00H] [5DH]

MFG:EPSON;

CMD:ESCPL2,PRPXL,BDC;

MDL:Stylus[SP]COLOR[SP]980;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]COLOR[SP]980;

NOTES:

1. [00H] denotes a hexadecimal value of zero.

2. MDL value and DES value depend on the EEPROM setting.

3. CMD value depends on the IEEE1284.4 setting.

See Table 1-14 which shows pin assignment for reverse channel

When IEEE1284.4 is enabled;

[00H] [60H]

MFG:EPSON;

CMD:ESCPL2,PRPXL,BDC,D4;

MDL:Stylus[SP]COLOR[SP]980;

CLS:PRINTER;

DES:EPSON[SP]Stylus[SP]COLOR[SP]980;

Product Description Interface 22

Page 27

EPSON Stylus Color 980 Revision A

Table 1-14. Pin Assignment For Reverse Channel

Pin No. Signal Name

1 HostClk 19 I Host clock signal.

2-9 Data0-7 20-27 I

10 PrtClk 28 O Printer clock signal.

11 PtrBusy, Data Bit-3,7 29 O Printer busy signal and reverse channel transfer data bit 3 or 7.

Return GND

Pin

In/Out Functional Description

The DATA0 through DATA7 signals represent data bits 0 to7,

respectively. Each signal is at high level when data is logical 1 and

low level when data is logical 0. These signals are used to transfer

the 1284 extensibility request values to the printer.

12 AckData Req, DataBit-2,6 28 O

13 Xflag, DataBit-1,5 28 O X-flag signal and reverse channel transfer data bit 1 or 5.

14 HostBusy 30 I Host busy signal.

31 /INIT 30 I Not used.

32 /DataAvail, DataBit-0,4 29 O Data available signal and reverse channel transfer data bit 0 or 4.

36 1284-Active 30 I 1284 Active Signal

18 Logic-H ---- O Pulled up to +5V via 3.9K ohm resister.

35 +5V ---- O Pulled up to +5V via 3.3K ohm resister.

17 Chassis GND ---- --- Chassis GND.

16,33, 19-30 GND ---- --- Signal GND.

15,34 NC ---- --- Not connected.

* In/Out refers to the direction of signal flow from the printer’s point of view.

Acknowledge data request signal and reverse channel transfer

data bit 2 or 6.

Product Description Interface 23

Page 28

EPSON Stylus Color 980 Revision A

1.3.3 USB Interface

Standard: Based on the following:

Universal Serial Bus Specifications Rev. 1.0

Universal Serial Bus Device Class Definition

for Printing Device Version 1.0

Bit Rate: 12 M bps

Data Encoding: NRZI

Adaptable Connector:USB Series B

Recommended Cable Length:2 meters

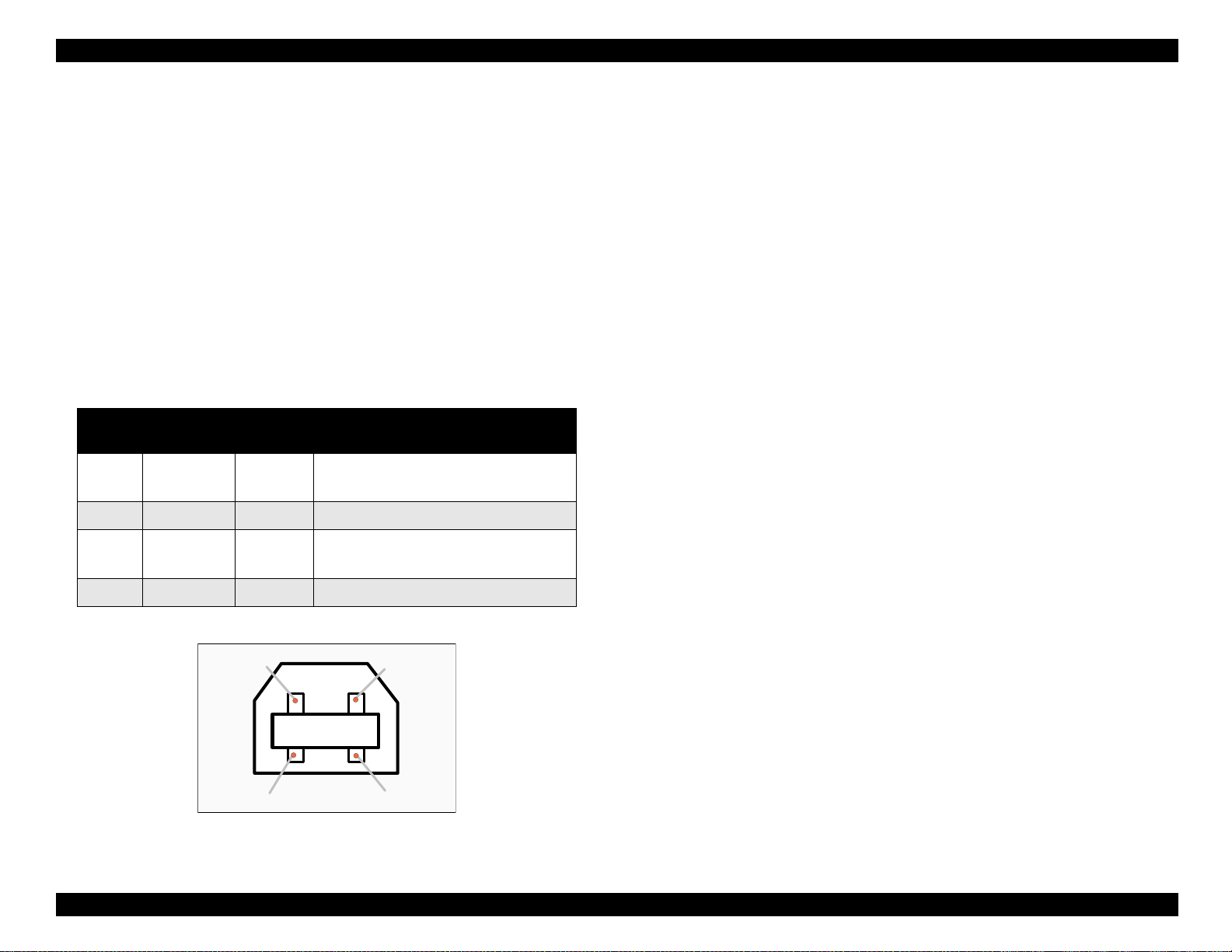

Table 1-15. Pin Assignment and Signal of the USB I/F

Pin No.

1 Vcc ----

2 -Data Bi-D Data

3+DataBi-D

4 Ground ---- Cable Ground

Signal

Name

I/O Description

Cable power, Maxi. power consumption

is 100 mA

Data, pull up to +3.3 V via 1.5 K ohms

resistor

Pin #2

Pin #1

1.3.4 Optional interface

Type-B level 2 optional interfaces are available.

Reply message:

ESC/P2 is selected

Min-Type:MTP48p, PW80 cl 10 cpi, PRG (Wxxxxx)rev,

AP800ma, SPDO fast

Product-Name: Stylus COLOR 980

Emulation-Type: ESCPL2-00

Entity-Type: EPSONLQ2

X24E is selected

Main-Type:MTP48p, PW80cl10cpi, PRG(Wxxxxx)rev,

AP800ma, SPDO fast

Product-Name: Stylus COLOR 980

Emulation-Type: PRPXL24-00

Entity-Type: EPSONPRPXL24

Emergency command

0x00 :Get device ID

0x01 :Get all status

Sending BDC-ST through DBIN register

When State-Reply is set “ON” by ST from Type-B I/F, sending BDCST through DBIN register is started. When State-Reply is started,

“Start” and “End” of BDC-ST characters are announced by sending

the Main command 0Eh.

See Table 1-16 which shows Reply for option command.

See Table 1-17 which shows Supported main command and sending

timing

Pin #3

Pin #4

Figure 1-9. USB Pin Assignment

Product Description Interface 24

Page 29

EPSON Stylus Color 980 Revision A

Table 1-16. Reply for Option Command

Option command number Command name Reply-A Reply-B

00h No-operation None None

01h Start Hardware Reset Accept Execute OK

02h Start Software Reset Reject None

03h Send Main System Type Accept Execute OK

04h Send Name Data Reject None

05h Inquire Name Data Accept Execute OK

06h Send Product Name Accept Execute OK

07h Send Software Emulation Type Accept Execute OK

08h Complete Buffered Data Accept Check Condition

09h Stop Procedure Reject None

0Ah Return Buffered Data Reject None

0Bh Send Entity Type Accept Execute OK

0Ch Send Status Accept Execute OK

0Dh Quit Procedure Reject None

0Eh Inquire ASCII Message Reject None

0Fh Send ASCII Message Accept Execute OK

10h - 13h (Reserved) Unknown None

14h Inquire Emergency Message Accept Execute OK

15h Send Emergency Message Accept Execute OK

16h - 1Fh (Reserved) Unknown None

20h - FFh (Reserved) Unknown None

Product Description Interface 25

Page 30

EPSON Stylus Color 980 Revision A

Table 1-17. Supported main command and sending timing

Main command number Command name Sending timing

Start Software Reset

01h

02h

04h Send Name Data

Send Option Type

-INIT signal on the std. parallel I/F

Type-B I/F option command : 01h

Cold start

Deciding the level of Type-B I/F after

powered on

Type-B I/F option command : 05h

07h Inquire Software Emulation Name

0Eh Inquire ASCII Message

14h Inquire Emergency Reply

15h Send Emergency Message

Changing Software Emulation Type

Writing to DBIN register

Reply for Emergency command

Receive Emergency command

Product Description Interface 26

Page 31

EPSON Stylus Color 980 Revision A

1.3.5 Printer Language and Emulation

Printer language: ESC/P2

IBM X24E emulation

EPSON Remote

Interface state and interface selection

When the parallel interface is not selected, the interface goes

into the BUSY state.

NOTE:An interrupt signal, such as /I NIT, on the parallel interface is

not effective while that interface is not selected.

1.3.6 Prevention Hosts from Data Transfer time-out

Generally, hosts abandon data transfer to peripherals when a peripheral

is in the busy state for dozens of seconds continuously. To prevent

hosts from this kind of time-out, the printer receives data very slowly,

several bytes per minute, even if the printer is in busy state. This

slowdown is started when the rest of the input buffer becomes several

hundreds of bytes. Finally, the printer is in the busy state continuously

when the input buffer is full.

USB and IEEE1284.4 on the parallel interface do not require this function.

1.3.7 Auto Interface Selection

The EPSON Stylus Color 980 has three types of interfaces: USB,

parallel interface and optional Type-B interface. Each interface can be

selected manually in default setting mode or automatically.

Manual Selection:

One of three interfaces can be selected in default setting mode.

Automatic Selection:

The automatic interface selection is enabled by the default setting

mode. In this automatic interface selection mode, the printer is

initialized to the idle state scanning for which interface is to receive

data when it is powered on. The interface that receives data first is

selected. When the host stops data transfer and the printer is in the

stand-by state for a number of seconds, the printer returns to the

idle state. As long as the host sends data or the printer interface is

busy state, the selected interface is let as it is. The changes to other

interface are prohibited during duplex printing.

Product Description Interface 27

Page 32

EPSON Stylus Color 980 Revision A

1.3.7.1 IEEE 1284 .4 Protocol

The packet protocol described by IEEE1284.4 standard allows a device

to carry on multiple exchanges or conversations which contain data

and/or control information with another device at the same time across

a single point-to-point link. The protocol is not, however, a device

control language. It does provide basic transport-level flow control and

multiplexing services. The multiplexed logical channels are independent

of each other and blocking of one has no effect on the others. The

protocol operates over IEEE1284.

Automatic selection:

An initial state is compatible interface and starts IEEE1284.4

communication when magic strings (1284.4 synchronous

commands) are received.

ON:

IEEE1284.4 is enabled as initial state. Data sent before the magic

string (1284.4 synchronous commands) is discarded.

OFF:

IEEE1284.4 is disabled and IEEE1284.4 synchronous commands

are ignored. Compatible interface is the initial state.

Product Description Interface 28

Page 33

EPSON Stylus Color 980 Revision A

n

1.4 Control Panel Operation

The control panel of the EPSON Stylus Color 980 is composed of the 2

non-lock type push-buttons, 1 lock-type push-button, and 4 LEDs, as

shown below:

Paper O ut LED

In k O u t

(Black) LED

In k O u t

(Color) LED

C leaning

B u tto n

Power LED

Power Button

Load/E ject B utto

1.4.1 Indicators (LEDs)

1. Power

Lights when the operate switch is “ON”, and AC power is supplied.

2. Paper out

Lights during the paper-out condition, and blinks during the paperjam condition.

3. Ink Out (Black)

Lights during no Black ink condition, and blinks during the Black

ink low condition.

4. Ink Out (Color)

Lights during no Color ink condition, and blinks during the Color ink

low condition.

Figure 1-10. Control Panel

Product Description Control Panel Operation 29

Page 34

EPSON Stylus Color 980 Revision A

1.4.2 Panel Functions

Panel function: Refer to Table 1-18.

Table 1-18. Panel Functions

Button Function

• Loads or ejects paper.

Load/Eject

(within 2 seconds) *1

Load/Eject

(for 2 seconds) *1

Cleaning

(for 2 seconds) *1

Cleaning

(within 2 seconds) *1

*1: 3 seconds is specified in the Users Gu ide.

*2: This operation is not effective in printing status.

Panel function with power on:Refer to Table 1-19.

• When the carriage is in the I/C replacement position,

pressing this button returns the carriage to the capping

position.

• In the condition of “Double Feed Error” returning from

error condition printing is restarted

• Starts the I/C replacement sequence. *2

• Move the carriage to the I/C replacement position.

• Starts the printhead cleaning sequence.

• Starts the I/C replacement sequence when the printer

is in one of the following conditions:

“Ink Low”, “Ink Out”, No Ink Cartridge” *2

• When the carriage is in the I/C replacement position,

returns the carriage to the capping position.

1.4.2.1 Printer Setting Mode

While turning the printer on, press the Cleaning button, and the Paper

Out LED starts blinking. This operation must be followed by pressing

the specified button while the Paper Out LED is still blinking to enter the

Default setting mode or Printhead alignment mode, as described in

Table 1-20.

Table 1-20. Printer Setting Mode

Button Function / Operation

While the Paper Out LED is blinking, pressing

Cleaning or no button

Load/Eject

(Press it within 10 seconds.)

Load/Eject

(Hold it down for 10 seconds.)

*1: Leaving the Paper Out LED blinking wit hout pressi ng any butto n also gene rates

the Default setting mode.

*2: Not intended for users. This function is used only for troubleshooting.

the Cleaning or no button generates the

Default setting mode. *1

While the Paper Out LED is blinking, pressing

the Load/Eject button generates the Printhead

alignment mode.

Changes the default for the parallel I/F

communication protocol. *2

Table 1-19. Panel Function with Power On

Button Function

Load/Eject 1) Starts the status print. *1

Enters the printer setting mode. (The Paper Out LED starts

Cleaning

Load/Eject

+

Cleaning

*1: The status print includes firmware version, ink counter, and nozzle check

pattern.

blinking.) *2

Specified button must be then pressed while the LED is

blinking to activate each mode. (See Section 1.4.2.1.)

Enters the special setting mode. (Factory use only)

Specified button must be then pressed while the Paper Out

LED is blinking to activate each mode. (See Section

1.4.2.2.)

See the following pages for detailed information on the default setting

mode and the Printhead alignment mode.

Product Description Control Panel Operation 30

Page 35

EPSON Stylus Color 980 Revision A

Default setting mode

Some printer setting parameters can be changed by users and will

be referred at the time of printer initialization. The setting method is

as shown below:

1. Enter the Default setting mode.

2. Select the desirable language for “Usage of this mode” by pressing

the Cleaning button.

3. Press Load/Eject button. The current setting and the “Usage of this

mode” in the selected language is printed.

4. Select the menu by pressing the Cleaning button.

5. Press the Load/Eject button to enter the value selection phase of

the selected menu.

6. Select the value by pressing the Load/Eject button.

7. Press the Cleaning button. The printer memorizes the selected

setting value, and returns the indication to the main menu.

8. Repeat the steps from 4 to 7. The menu selection will return to the

first menu after the last menu selection is over.

9. Turn the printer off. The new settings are stored in the non-volatile

memory.

Table 1-22. Default Setting Menu (continued)

Menu Setting

I/F mode Auto, Parallel, USB, Optional

Auto I/F wait mode 10 seconds, 30 seconds

This mode is for the network environment only.

Network I/F mode

Parallel I/F transfer rate Fast, Normal

Software ESC/P2, IBM X24E

Auto CR (IBM mode only) On, Off

A.G.M (IBM mode only) On, Off

Auto line feed On, Off

0 slash 0, 0

Character tables

<Standard version>

Character tables In addition to the Standard version:

Off:

Used in a usual environment.

On: Used in the network environment.

Italic USA

Italic UK

Italic Italy

PC 850

PC865

Abicomp

PC 858

Italic France

Italic Denmark

Italic spain 1

PC 860

PC 861

Roman 8

ISO 8859-15

Italic Germany

Italic Sweden

PC 437

PC 863

BRASCII

ISO Latin 1

Table 1-21. Default Setting Menu

Menu Setting

Font

Pitch 10 cpi, 12 cpi, 15 cpi, 17.1 cpi, 20 cpi, Proportional

Print direction Auto, Bi-D, Uni-D

Loading Position 3 mm, 8.5 mm, Others

Roman, Sans Serif, Courier

T, Sans Serif H, Draft

, Prestige, Script, Roman

<NLSP version >

*: Underlined values are the defaults for the EEPROM reset.

PC437 Greek

PC852

PC869

ISO 8859-7

PC 774

PC 866 LAT

PC 708

PC 437

PC 853

PC 857

MAZOWIA

ISO Latin 1T

Estonia

PC 866 UKR

PC 720

PC 855

PC 866

Code MJK

Bulgaria

ISO 8859-2

PC APTEC

PC AR864

Product Description Control Panel Operation 31

Page 36

EPSON Stylus Color 980 Revision A

Printhead alignment mode

1.4.2.2 Special Setting Mode

Alignment method is as described below:

1. While holding down both Load/Eject and Cleaning (Black) buttons,

turn the printer on.

2. Printer prints an instruction sheet that shows how to adjust the

printer and current alignment.

3. Referring to the current alignment, press the Cleaning button until

the LED indicate the appropriate test number.

4. Press the Load/Eject button. The printer prints the test pattern.

5. Referring to the test patterns on the new printout, select the most

closely aligned pattern by pressing the Load/Eject button.

6. Press the Cleaning button.

7. Repeat the steps from 3 to 6 until all test patterns are properly

aligned.

8. Turn the printer off.

While turning the printer on, pressing the both Load/Eject and Cleaning

buttons generates the Special setting mode. While the Paper Out LED

is blinking, activate each function by pressing the specified button(s) in

the method described in Table 1-23.

Table 1-23. Special Setting Mode

Switch Function

While the Paper Out LED is blinking, pressing

Load/Eject

Cleaning

(Hold it down for 10 seconds)

the Load/Eject button initializes the EEPROM

and resets the timer IC. (Refer to EEPROM

Address Map in Appendix.)

While the Paper Out LED is blinking, pressing

the Cleaning button for 10 seconds resets the

waste ink counter in the EEPROM. (Refer to

EEPROM Address Map in Appendix.)

Product Description Control Panel Operation 32

Page 37

EPSON Stylus Color 980 Revision A

1.4.3 Printer Condition and Panel Status

Table 1-24 shows printer condition and panel status. Since the table

shows various error status and also indicates printer status, it enables

you to find appropriate repair ways.

Table 1-24. Printer Condition and Panel Status

Indicators

Printer Status

Power

Power on condition On --- --- --- 9

Ink Sequence mode Blink --- --- --- 6

I/C replacement mode Blink --- --- --- 5

Data processing Blink --- --- --- 8

Paper Out --- --- --- On 4

Double Feed --- --- --- On 4

Ink Out

(Black)

Ink Out

(CMY)

Paper Out

Priority

Paper Jam --- Off Off Blink 3

No I/C, Ink Out (Black) --- On --- --- 7

Ink level low (Black) --- Blink --- --- 7

No I/C, Ink Out (CMY) --- --- On --- 7

Ink level low (CMY) --- --- Blink --- 7

Enters the EEPROM and

Timer IC Reset

Maintenance Request Blink Blink Blink Blink 2

Fatal Error Blink On On Blink 1

--- ON (for 1 second only) ---

Product Description Control Panel Operation 33

Page 38

EPSON Stylus Color 980 Revision A

1.5 Error Status

When any of the following status occurs, the printer goes in the error

status and stops receiving data, setting the /ERROR signal in the

interface to “Low”, and Busy signal to “High”. During this condition, the

printer is in non-printable status. Refer to Section 1.4.3 for detailed LED

Panel indicator status and corresponding error types.

1.5.1 Ink Out

When the printer has run out the most of the ink of any color, it warns of

Ink Low condition and keeps printing. When the printer runs out the

whole ink of any color, it stops printing and indicates the Ink Out error.

User is required to install a new ink-cartridge in this state. Note if an inkcartridge has been taken out, it should never be used again.

Reinstalling the used cartridge (not fully filled with ink) upsets the ink

level detection and may cause a serious problem in the printhead as a

result.

CAUTIO N

Never use an ink cartridge that has been removed.

1.5.4 No Ink Cartridge

When the printer detects that the ink cartridge has come off, it goes into

the No ink cartridge error.

1.5.5 Maintenance Request

When the total quantity of ink wasted through the cleanings and flushing

has reached the limit, printer indicates this error and stops printing. The

absorber in the printer needs to be replaced with a new one by a service

person.

1.5.6 Fatal Errors

When the printer detects the carriage control error or CG access error, it

enters the fatal error condition.

1.5.7 Double Feed Errors

When the printer fails to load a sheet, it goes Double feed error

condition.

1.5.2 Paper Out

When the printer fails to load a sheet, it goes into the Paper Out error

condition.

1.5.3 Paper Jam

When the printer fails to eject a sheet, it goes into the Paper Jam error

condition.

Product Description Error Status 34

Page 39

EPSON Stylus Color 980 Revision A

1.6 Printer Initialization

The EPSON Stylus Color 980 is equipped with three types of

initialization methods.

Power-on initialization

The printer is initialized when it is turned on or recognizes the coldreset command (remote RS command). When the printer is

initialized, it performs the following:

(a) Initializes the printer mechanism.

(b) Clears the input data buffer.

(c) Clears the print buffer.

(d) Sets the default values.

Operator initialization

This printer is initialized when it is turned on again within 10 seconds

after last power off or recognizes the /INIT signal (negative pulse) of

the parallel interface. When printer is initialized, it performs the

following:

(a) Caps the printhead.

(b) Ejects a paper.

(c) Clears the input data buffer.

(d) Clears the print buffer.

(e) Sets the default values.

Software initialization

The ESC@ command also initializes the printer. When the printer is

initialized, it performs the following:

(a) Clears the print buffer.

(b) Sets the default values.

Product Description Printer Initialization 35

Page 40

EPSON Stylus Color 980 Revision A

1.7 Component Layout

The main components of the Stylus Color 980 are as follows:

1) Printer mechanism

2) C380 Main board

3) C265 PSB/PSE board

4) C265 panel board

5) C265 relay board

1.7.1 Printer Mechanism

The printer mechanism of the Stylus Color 980 has black and color

heads united in one unit which drives larger amount of nozzles (180

nozzles in total) than ever. Also, for a new ink jet printer feature, the

printer has succeeded in printing in the acceleration/deceleration areas

by reading the slits on the linear scale to improve the throughput. This

improvement in throughput mostly depends on the Pump/ASF switching

mechanism. In other printers, the gear trains are switched when the

trigger lever hits the mechanism along with the carriage’s movement. In

Stylus Color 980, however, the exclusive solenoid is directly attached to

the mechanism instead. With the solenoid which switches drive at a

higher speed, the printer can control high-speed paper ejection system:

the printer bring the leading edge of the second sheet to the printing

position just before ejecting the first sheet.

The motors equipped with the printer are CR motor, PF motor, and the

Pump/ASF Motor, same as for the Stylus Color 900.

Product Description Component Layout 36

Page 41

EPSON Stylus Color 980 Revision A

1.7.2 C380 Main Board

The main features of the C380 Main board are as follows.

1. IEEE1284 compliant

ECP mode is available

Type-B I/F is available

2. USB full-speed is available (at 12 M bps without the hub).

3. All motors (CR motor, Pump/ASF motor, and PF motor) are

controlled with the micro step system (using up to 4W1-2 phase

excitation mode) and current attenuation mode (First, Slow, Mixed,

and Decay).

4. Intensive temperature control of the new type of the printhead:

operates the cooling fan using the thermistors and the abnormal

temperature detection circuit on the printhead board.

C90A09CA, a CPU which is the hub of the C380 Main board, has an

internal flash memory with the size of 128 KB. Since the CPU runs with

24 MHz, it can send print data efficiently for a high throughput. The

C380 Main board has two independent exclusive ASICs, ASIC1 and

ASIC2. The former controls all interfaces but the USB I/F and sensors,

while the latter controls the printhead, motors, encoder, and USB I/F.

The combined IC (IC8) which has a normal timer IC and EERPOM in

one chip also features the printer. Since the EEPROM counts ink

consumption at the valuable printing

*1

, its size has increased to 2 K bit.

to fire three different sizes of dots in one raster, and ink-jet specific

adverse conditions such as uneven printing and white banding are

improved as a result.

The C380 Main board is also equipped with a CG-ROM which deals

with DOS users. The CG ROM attachment condition and size are as

shown in Table 1-25.

Table 1-25. Relation between P-ROM and CG ROM

Destination P-ROM CG-ROM

Standard version 16 M (TFU00X) Not installed.

NLSP version 16 M (TFU00X) 16M (M160B16XA)

NOTE:The “X” in the table represents the version.

*1: The valuable dot system, or many-valued dot system, enables the

printer to freely fire three different sizes of dots (normal, middle, and

small dots) in one raster. In other printers, if the super micro dot

mode is once selected through the printer driver, the printers prints

only in the selected mode until the current print data is completed.

However, the valuable dot system of this printer enables the printer

Product Description Component Layout 37

Page 42

EPSON Stylus Color 980 Revision A

p

IC5(D-RAM)

IC4(One-time PROM)

CN15

IC3(E05B60)

CN1

CN2

IC2(E05B59)

CN4

CN5

IC1(CPU:H8S)

CN6

(IC11) PF Motor Driver

(IC12) CR Motor Driver

Thermistor (detects temperature

CN13

CN10

CN-

11

CN-

16

CN-

12

CN14

Heat Sink

of the heat sink)

Q5 (upper), Q6 (low er)

Charging/Discharging driver

for driving the black nozzles

CN9

Q3 (upper), Q4 (lower)

Charging/Discharging driver

for driving the color nozzles

CN8

Thermistor (detects temperature

on the printhead board)

IC16 (upper), IC15 (lower)

Head

re-driver

IC8(Timer & EEPROM)

Lithium Battery

IC13 (upper),

IC14 (lower)

ASF Motor Driver

Figure 1-11. C380 Main Board

Product Description Component Layout 38

Page 43

EPSON Stylus Color 980 Revision A

(

)

1.7.3 C265 PSB/PSE Board

There are two types of the C265 power supply board as listed below.

C265 PSB board:For America, Japan, part of South east Asia

C265 PSE board:The rest of all regions

W ARNING

Never touch the heat sink (radiation plate) on the Q1

with your bare hands as it is not insulated. Otherwise,

you will get an electrical shock.

The C265 PSB/PSE board uses the switching regulator system. Since

the C265 PSB/PSE board uses the power switch on the secondary side,

it keeps applying voltage to the primary side across the T1. Especially,

the heat sink to which the Q1 is attached can not be insulated due to the

circuit’s formation. Therefore, to avoid an electrical shock, be careful not

to touch the heat sink and other metallic parts simultaneously while

troubleshooting.

IC 51(+5V regulator)

D 51(D iode)

CN3

CN2

CN1

F1(Fuse)

C 1(N oise cut capacitor)

T1(Trans)

D 55(D iode)

L1

N ose cut reactance

Danger!

Q 1(FET)

C 11(for sm oothing)

Figure 1-12. C265 PSB/PSE Board

Product Description Component Layout 39

Page 44

EPSON Stylus Color 980 Revision A

1.7.4 C265 PNL Board

The C265 panel board is composed of the three switches and four

LEDs.

LED 3

LED 1

SW 2 SW 1

LED 2

CN1

1

Figure 1-13. C265 PNL Board

LED 0

SW 0

12

1.7.5 C265 Relay Board

The C265 relay board is installed to relay the following with connectors:

Power for driving motors and sensors

Control signals

If any of the connectors is connected to a wrong position during

assembly, the printer shows a fatal error at power on.

Carriage home position (CRHP) sensor

Carriage (CR) Motor

CRH PE ASF

M/C

RED

WHT

M/C

BLK

Pump/ASF Motor

Paper Feed (PF) Motor

Connector from the CN11

on the C380 Main Board

Connector from the CN12

on the C380 Main Board

Connector from the CN10

on the C380 Main Board

Connector from the CN16

on the C380 Main Board

M/C

Control Panel

ASF Sensor

PE Sensor

Solenoid (Switches ASF/PUMP

mechanism)

Connector from the CN15

on the C380 Main Board

Figure 1-14. C265 Relay Board

Product Description Component Layout 40

Page 45

OPERATING PRINCIPLES

CHAPTER

2

Page 46

EPSON Stylus Color 980 Revision A

2.1 Overview

This chapter describes the operating principles of the printer

mechanism and electrical circuits.

2.2 Printer Mechanism Operating Principles

The EPSON Stylus Color 980 has black and color heads united in one

unit which includes a total of 480 nozzles: 192 nozzles for black (96

nozzles x 2) and 96 nozzles for each color. This printhead enables the

printer to print 3 lines by one pass at 10-cpi printing. Also, new ASF/

pump switching mechanism offers higher throughput with quick feeding

motion at continuous printing by combining the trigger solenoid and

independent pump/ASF motor. Production of PTS signal using the

encoder belt also enables the printer to improve printing accuracy,

detect paper jam in the CR operational range, and print during

acceleration/deceleration (on normal paper / 360 x 360 dpi only).

See Figure 2-1 for the printer mechanism block diagram.

Operating Principles Overview 42

Page 47

EPSON Stylus Color 980 Revision A

PF drive gear (high-precision gear)

H igh-precision pinion

PF m otor

Flashing position (the 80th colum n side)

PTS encoder

Paper eject sub roller

Black I/C detection lever

C olor I/C detection lever

C R unit

U nited printhead for black and color

Tim ing belt

Cap

V a lv e fo r c a p p in g

AS F sensor (for phase detection)

ASF cam

A S F d riv e s h a ft

P a p e r lo a d r o lle r s

PE (Paper End) sensor

Pum p/ASF m otor

AS F solenoid (for switching the

AS F, pum p gear trains)

Pum p

C R H P sensor

PF roller (pow dery-coated roller)

C R guide shaft

Encoder belt

C R m otor

Figure 2-1. The Stylus Color 980 Printer Mechanism Block Diagram

Operating Principles Printer Mechanism Operati ng Principles 43

Page 48

EPSON Stylus Color 980 Revision A

2.2.1 Carriage Mechanism

As shown in Figure 2-1, the carriage unit with the printhead on it moves

right and left, depending on the rotational direction of the CR (Carriage)

motor. Table 2-1 shows the CR motor specifications.

Table 2-1. CR Motor Specifications

No. Item Specifications

1 Motor Type 4-phase / 200-pole / HB-type stepping motor

2 Drive voltage 42 VDC

3 Coil resistance 5.8

4 Drive mode Bipolar constant current drive

The CR unit position is always memorized and controlled by the CRHP

(Carriage Home Position) sensor. This sensor confirms the CR position

to renew the memory at the following timing:

When power is turned on / off

When a head cleaning operation, including initial ink charge, is

performed.

When the printer returns to a ready status because the printer

has executed print job or receives no data for one second or

more.

See Table 2-2 and Table 2-3 which show the CRHP sensor

specifications and CRHP sensor switch mode, respectively.

±

5% (Applied to the driver)

Ω

±

10%

Table 2-2. CRHP Sensor Specifications

No. Item Specifications

1Type

2 Drive voltage 5 V ± 5%

3 Collector resistance 30 VDC or less

Photo-electrically transfer system

(SHARP GP1S73P2)

Table 2-3. CRHP Sensor Switch Mode

CR Position Switch mode Sensor output

Within the CRHP

range

Off the CRHP range Close 2.4 VDC or more

Open 0.7 VDC or less

If this sensor is defective or does not work, it does not detect the

carriage while the carriage is in the home position seek mode. In this

case, the printer cuts off electricity to the CR motor and shows a fatal

error.

Like the Stylus color 900, the Stylus color 980 also uses a linear

encoder to obtain secure carriage movement and accurate print timing.

The linear encoder reads slits on the encoder belt (linear scale) above

the timing belt to control the carriage. See Table 2-4 for the linear

encoder specifications.

Operating Principles Printer Mechanism Operati ng Principles 44

Page 49

EPSON Stylus Color 980 Revision A

Table 2-4. Linear Encoder Specifications

No.

1 Type Radiative Incremental encoder module

2 Drive voltage 5 VDC ± 5%

3

4 Minimum step 1/180 inch (increment of the lines on the linear scale)

5

Item Specifications

Output

waveform

Response

frequency

Phase A/B 2-channel digital output (TTL level)

20 KHz