Page 1

Wide-Format Professional Inkjet Printer

EPSON Stylus Pro 9000

TM-PRO9000

Page 2

Guide to Using This Manual

Before servicing the EPSON Stylus Pro 9000, read the precautions on

CHAPTER 1. Printer Basics

Refer to this chapter for details on control panel operation.

CHAPTER 2. Technical Overview

Read this chapter if you want to know more about how the major systems of this

printer work.

CHAPTER 3. Troubleshooting

Use this chapter to troubleshoot typical printer problems.

CHAPTER 4. Disassembly and Assembly

Follow these step-by-step instructions to disassemble and assemble the printer.

Refer to the “Maintenance” section of this chapter when you need to replace the

Waste Ink Pads and other consumable parts.

CHAPTER 5. Adjustments

When you remove or replace parts, read the beginning of this chapter to find out

which adjustments are required and how to perform them.

CHAPTER 6. Maintenance

Follow these routine inspection and maintenance pro ced ures each time you

service the printer.

page 5

. Then turn to one of these chapters:

CHAPTER 7 Appendix

Provides the following additional informati on for reference :

• Setup instru ctions

• Detailed product specifications

• Parts list

• Exploded di agrams

• Electrical circuit boards schematics

Page 3

COPYRIGHT NOTICE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the written permission of Epson America, Inc. No patent liability is assumed with respect to use of the information

contained herein. Neither is any liability assumed for damages resulting from the use of the information contained herein. While every precaution has been taken in

the preparation of this book, Epson America, Inc., assumes no responsibility for errors and omissions.

Neither Epson Americ a, Inc ., nor its affilia tes sh all be liable to the purchaser of this product or third partie s for damages, losses, costs, or expenses incurred by

purchaser or third parties as a result of: accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product.

Epson America, Inc., shall not be liable against any damages or problems arising from the use of any options or any consumable products other than those

designated as Original EPSON Products or EPSON-Approved Products by Seiko Epson Corporation.

TRADEMARKS

EPSON and ESC/P are registered trademarks and ESC/P 2, EPSON Stylus COLOR 900, and EPSON Sylus COLOR 900N are trademarks of Seiko Epson

Corporation. Epson Connection is a service mark of Epson America, Inc.

General Notice:

any and all rights in those marks.

Copyright © 1999 Epson America, Inc.

20770 Madrona Avenue

Torrance, CA 90509-2842

Other product names used herein are for identification purposes only and may be trademarks of their respective compani es. EPSON disclaims

July 1999

Page 4

FCC COMPLIANCE STATEMENT

g

q

q

FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and c an radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful interference to radio and television reception. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause interference to radio and television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate th e receivin

Increase t he separation between the e

Connect the e

Consult th e dealer or an ex perience d radio/TV t ec hnician fo r help.

WARNING

The connection of a non-shielded equipment interface cable to this equipment will invalidate the FCC Certification of this device and may cause interference levels

that exceed the limits established by the FCC for this equipment. It is the responsibility of the user to obtain and use a shielded equipment interface cable with this

device. If this equipment has more than one interface connector, do not leave cables connected to unused interfaces.

Changes or modifications not expressly approved by the manufacturer could void the user's authority to operate the printer.

FOR CANADIAN USERS

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le materiel brouilleur du Canada.

uipment int o an outlet on a circuit diff erent from that to which t he receiver is co nnected .

antenna.

uipment and receiver.

Page 5

PRECAUTIONS

g

y

Precautionary notes throughout the text are categorized with respect to: (1) personal injury and (2) damage to equipment.

W ARNING

CAUTION

Always observe the precautions listed below when performing repair and maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing a procedure

preceded by a WARNING.

Signals a precaution which, if ignored, could result in damage to equipment.

WARNING

1. Always disconnect the product from both the power source and the host computer before performing any maintenance or repair procedure.

2. No work sh ould be perfo rm ed on the un it by persons u nf am iliar with bas ic s af ety measure s dic t at ed for all elect ronics technicians in th eir line of

work.

3. In performin

must be co nnected, use extreme ca ut ion in working on the pow er s upply and other electronic c om ponents.

testing describe d in this manu al, do not connec t t he unit to a pow er s ource until instructe d t o do so. When th e power supply cable

CAUTION

1. Repairs o n EPSON pr oducts should be perfo m ed only by an EPSO N -c ertified repair technic ian.

2. Make certain that the source voltage is the same as the rated voltage listed on the serial number/rating plate. If the EPSON product has a primary

AC rating different from the available power source, do not connect it to the power source.

3. Always verify that the EPSON prod uc t has been disconnected f rom t he power source bef ore removing or replacing printed circuit boards or

individual chips.

4. To protect se ns it iv e microproc essors an d ot he circuitr

components.

5. Replace malfunctioning components only with those components recommended by the manufacturer; introduct ion of second- sour ce ICs or other

nonappr ov ed components may damage the product and void any applicable EPSON w arranty.

, use static discharge equipment, such as anti-static wrist straps, when accessing internal

Page 6

EPSON Stylus Pro 9000 Revision A

Contents

1 Printer Basics

Features ...................................................................................................... 11

Control Panel Operations ......................................................................... 12

Control Panel Buttons ............................................................................ 12

Operation in Normal Mode .................................. .......... ....... .. .......... .. 12

Operation at Power On ....................................................................... 13

SelecType Mode .................................................................................... 13

Control Panel Operation in SelecType Mode ..................................... 13

Main Menu Options in SelecType Mode ............................................ 13

Printer Setting Menu........................................................................ 14

Test Print Menu............................................................................... 15

Printer Status Menu......................................................................... 15

Paper Configuration Menu. .............................................................. 16

Cutter Replace Menu....................................................................... 16

Head Alignment Menu..................................................................... 16

Service-Related Modes .......................................................................... 17

Maintenance Mode . ............................................................................ 17

Maintenance Mode 2 .......................................................................... 17

LED Indicators and Error Messages ........................................................ 18

LED Indicators ........................................................................................ 18

LCD Display ........................................................................................... 19

Options and Consumables ....................................................................... 20

2 Technical Overview

Location of Com ponents .......................................................................... 22

Carriage Mechanism ....................................................................... 22

Paper Feed Mechanism .................................................................. 22

Ink System ....................................................................................... 23

Circuit Boards.................................................................................. 23

Operation ................................................................................................... 24

Carriage Mechanism .............................................................................. 24

Carriage (CR) Guide Rail ................................................................ 24

Platen Gap (PG) Mechanism........................................................... 24

Paper Width Sensor........................................................................ 25

Carriage Motor and Position Control............................................... 26

Cutter Mechanism .................................................... .......... .. ....... .... 27

Printheads ....................................................................................... 27

Paper Feed Mechanism ......................................................................... 28

Paper Feed Motor and Rollers . . ...................................................... 28

Paper Feed Sensors ....................................................................... 29

Paper Suction Fan........................................................................... 30

Paper Width Determination (Left and Right edge Detection) . ......... 31

Paper size Determination (Detection of Top edge) ......................... 32

Paper Loading Errors ...................................................................... 33

Carriage Lock Mechanism ..................................................................... 33

Ink Supply Mechanism ........................................................................... 34

Ink-Related Sensors........................................................................ 35

Cover Open Sensor ............................................................................... 36

Control Circuit ........................................................................................ 37

3 Troubleshooting

Overview .................................................................................................... 39

Troubleshooting Usin g LCD Error Messa ges ......................................... 39

LCD Error Messages .................................. ....... ....... ....... ..... ....... ....... .... 40

Errors that require a service technician .................................................. 41

General Errors ........................................................................................ 45

Ink Low............................................................................................ 45

Paper Out........................................................................................ 45

Load xxx Paper ............................................................................... 45

Load Paper...................................................................................... 45

Paper Jam....................................................................................... 46

Cover Open..................................................................................... 46

6

Page 7

EPSON Stylus Pro 9000 Revision A

Paper Not Cut . ................................................................................. 46

Paper Not Straight. .......................................................................... 46

Reload Paper................................................................................... 47

Push Lever Down............................................................................ 47

Compartment Open......................................................................... 47

Ink Out............................................................................................. 48

No Ink Cartridge .............................................................................. 48

Remove Paper................................................................................. 48

Option I/F Error................................................................................ 48

Print Quality Troubleshooting .................................................................. 49

Missing Dots or Lines...................................................................... 49

No Ink Output from One or Both Printheads.................................... 50

Uneven Printing or Poor Resolution................................................ 50

Smudged or Marred Printout (Front) ............................................... 51

Smudged or Marred Printout (Reverse side)................................... 51

White or Black Banding ................................................................... 51

Connector-Related Errors ......................................................................... 52

4 Disassembly & Assembly

Overview ..................................................................................................... 55

Precautions ............................................................................................ 55

Tools ....................................................................................................... 56

Screw List ............................................................................................... 56

Order of Disassembly ............................................................................. 57

Housing Parts ......................................................................................... 58

Housing Removal ...................................................................................... 58

Maintenance Cover Removal .......................................................... 58

Top Cover Removal......................................................................... 59

Left and Right Side Cover Removal................................................ 60

Front Cover Removal...................................................................... 61

Roll Cover Removal......................................................................... 62

Lower Paper Guide Removal ................................................... ....... 63

Upper Paper Guide Removal ................................................... ....... 64

Circuit Board Removal .............................................................................. 65

Power Supply Board Removal......................................................... 65

Main Board Removal....................................................................... 66

Maintenance Procedures .......................................................................... 67

Replacing the Waste Ink Pads........................................................ 67

Maintenance Assembly Removal & Disassembly........................... 69

Printer Mechanism Disassembly ............................................................. 71

Replacing the Printheads................................................................ 71

Removing the Carriage Motor Assembly......................................... 75

Removing the PF Motor Assembly.................................................. 76

Removing the Platen Gap Adjustment motor.................................. 78

Removing the Platen Gap Home Position Sensor........................... 78

Removing the Cover open Sensors................................................. 79

Removing the Paper Thickness Sensor.......................................... 80

Removing the Rear Paper Sensor................................................... 80

Removing the Front Paper Sensor.................................................. 81

Removing the Paper Release Sensor............................................. 81

Removing the Carriage Home Position Sensor and Encoder ......... 82

Ink Holder Disassembly ............................................................................ 84

Removing the I/C Holder Assembly ....................................................... 84

Disassembling the I/C Holder ................................................................. 91

Removing the Ink Tubes ........................................................................... 92

Preparation...................................................................................... 92

Removing the Ink Pipe Covers........................................................ 92

Separating the ink pipes and ink tubes ........................................... 92

Removing the CR circuit board........................................................ 93

Disconnecting the ink dampers....................................................... 93

Removing the cable connection plate.............................................. 94

Ink Tubing Reassembly .......................................................................... 95

Installing the new cable connec t ion plate........................................ 95

Positioning the tube guides and FFCs............................................. 95

Connecting the ink tubes to the ink pipes........................................ 96

Securing the the ink tubes and ink pipes......................................... 96

Securing the tube guides on the CR side........................................ 96

Checking the ink tubes.................................................................... 97

Attaching the CR circuit board......................................................... 97

Connecting the carriage FFCs......................................................... 97

Connecting the ink tubes and dampers. .......................................... 98

Confirming the tube guide assembly position.................................. 99

Connecting the carriage FFCs to the relay circuit board. .............. 100

Resetting the printer...................................................................... 100

7

Page 8

EPSON Stylus Pro 9000 Revision A

5 Adjustments

Overview ......... ....... ..................... ...................... ..................... ................... 102

Precautio n s ............................ ...................... ..................... ................... 102

Adjustment Tools .................................................................................. 102

Required Adjustments ......................................................... ....... .......... 103

ROM Backup and Updating ........... ..................... ...................... .............. 105

Requirements for Backup.............................................................. 105

Backup Procedure......................................................................... 105

Download Proce d ure............ ............................ ...................... ....... 106

Possible Errors During Backup or Downloading............................ 106

Firmware Update ... ............................................................................... 106

Updating From a PC...................................................................... 106

Updating From a Memory Card..................................................... 107

Self-Diagnostics ........................... ..................... ..................... ................. 107

Using the Self-Diagnostic Mode . .......................................................... 108

Self-Diagnostic Menus ......................................................................... 109

Test Menu ............................................................................................ 110

Version................................... ...................... ............................ ..... 111

Control Panel ................................................................................. 111

Sensors................ ..................... ..................... ..................... .......... 112

Encoder ......................................................................................... 113

Fan ................................ ..................... ...................... ..................... 113

Elec. (Maintenance Records) ........................................................ 113

Adjustment Menu ................................................................................. 115

Cap Position Adjustment............................................................... 116

Check Skew.......................... ..................... ...................... .............. 117

Input Rank (Printhead ID) Adjustment........................................... 117

Check Nozzle....................... ..................... ...................... .............. 118

B Head Slant/C Head Slant Adjustment (Head Angle).................. 119

BC Head Slant Adjustment (Head Height) .................................... 120

Bi-D Adjus tmen t............... ...................... ..................... ................... 121

Head LR Adjustment (Head Gap Timing).... .................................. 123

Flush Point Right and Left Adjustment.......................................... 124

Feed Adjustmen t............. ............................. ..................... ............ 124

Top & Bottom (Margin) Adjustment............................................... 125

Rear Sensor Position Adjustment.................................................. 126

Test Print....................................................................................... 127

Clean Head (Drain Ink).................................................................. 127

Counter Clear ................................................................................ 128

Cleaning menu ...................... ....... .. ....... .......... ....... .. ....... .......... .. ....... .. 128

Print menu ............................................................................................ 128

Parameter menu .................................................... .. ....... .......... .. ....... .. 129

Initialize......................................................................................... 129

Update........................................................................................... 129

Mechanical Adjustments ........................................................................ 130

Carriage Cover Height Adjustment..................................... .. ....... .. 130

Cutter Position Adjustment............................................................ 131

Carriage Belt Tension Adjustment................................................. 132

PF Belt Tension Adjustment.......................................................... 132

Platen Gap Gear Backlash Adjustment......................................... 133

I/H Lever Position Adjustment ....................................................... 133

Paper Thickness Sensor Adjustment............................................ 134

Cover Open Sensor Assembly (Right and left).............................. 135

Sensor Trimmer Adjustment.......................................................... 136

6 Maintenance

Overview .................................................................................................. 138

Physical Inspection and Cleaning ......................................................... 138

Lubrication ............................................................................................... 139

Checking and Clearing Counters ........................................................... 139

Checking Maintenance Counters ......................................................... 140

Clearing Maintenance Counters ........................................................... 140

Service Error Code s and Rep laceabl e Part s ........................................ 143

The Difference Between a ‘Maintenance Call’ and a ‘Service Call’ ...... 143

Ink Cartridge Replacement ..................................................................... 144

Cutter Blade Replacement ...................................................................... 144

8

Page 9

EPSON Stylus Pro 9000 Revision A

7 Appendix

Unpacking and Transporting the Printer .......................................... ..... 146

The Packagin g ......... ..................... ...................... ............................ ..... 146

Before Opening the Large & Medium boxes................................. 146

Contents of the Packaging ................................................................... 146

Medium-size b ox.......................................... ..................... ............ 146

Large box....................................................................................... 147

Unpacking and Assembly ..................................................................... 147

From unpacking to assembling the Stand..................................... 147

Assembling the Printer body.......................................................... 151

Repacking and Transporting the Printer ............................................... 155

Before Shipping............................................................................. 155

After Shi ppi n g....... .............. ..................... ............................ .......... 155

Specifications ............ ....... ............................ ...................... ..................... 156

Mechanical .................................... ...................... ..................... ............ 156

Safety Appr ov a ls ................................ ..................... ...................... ....... 157

CE Marking ...... ....... ..................... ..................... ...................... .............. 157

Electrical ............................. ..................... ..................... ...................... .. 158

Environmen ta l ...................... ..................... ...................... ..................... 158

Ink Cartridge ......................................................................................... 158

Controll e r .............................. ..................... ...................... ..................... 159

Cutter .................................................................................................... 159

Paper .................................................................................................... 160

Paper Release Lever ............................................................................ 162

Interface ........................ ..................... ..................... ...................... ....... 162

Paralle l i nt e r fa ce .................... ..................... ..................... ................. 164

Nibble Mode ..................... ..................... ...................... ..................... 166

ECP Mode ........................................................................................ 166

Type-B Interface (Optional) .............................................................. 168

Interface se le ction ............ .............. ..................... ...................... ....... 168

Initialization ........... .............. ............................. ..................... ................... 169

Jumper and DIP Switch Settings ............ ....... ..................... ................... 170

Connector Summary ...... ....... ..................... ............................ ................. 171

Parts List ... ...................... ..................... ..................... ..................... .......... 173

Exploded D ia gram s ..... ....... ...................... ..................... .......................... 179

Main Board Component Layout .................. ...................... ..................... 194

Circuit Diagrams ......................................... ..................... ...................... .. 196

9

Page 10

PRINTER BASICS

Page 11

EPSON Stylus Pro 9000

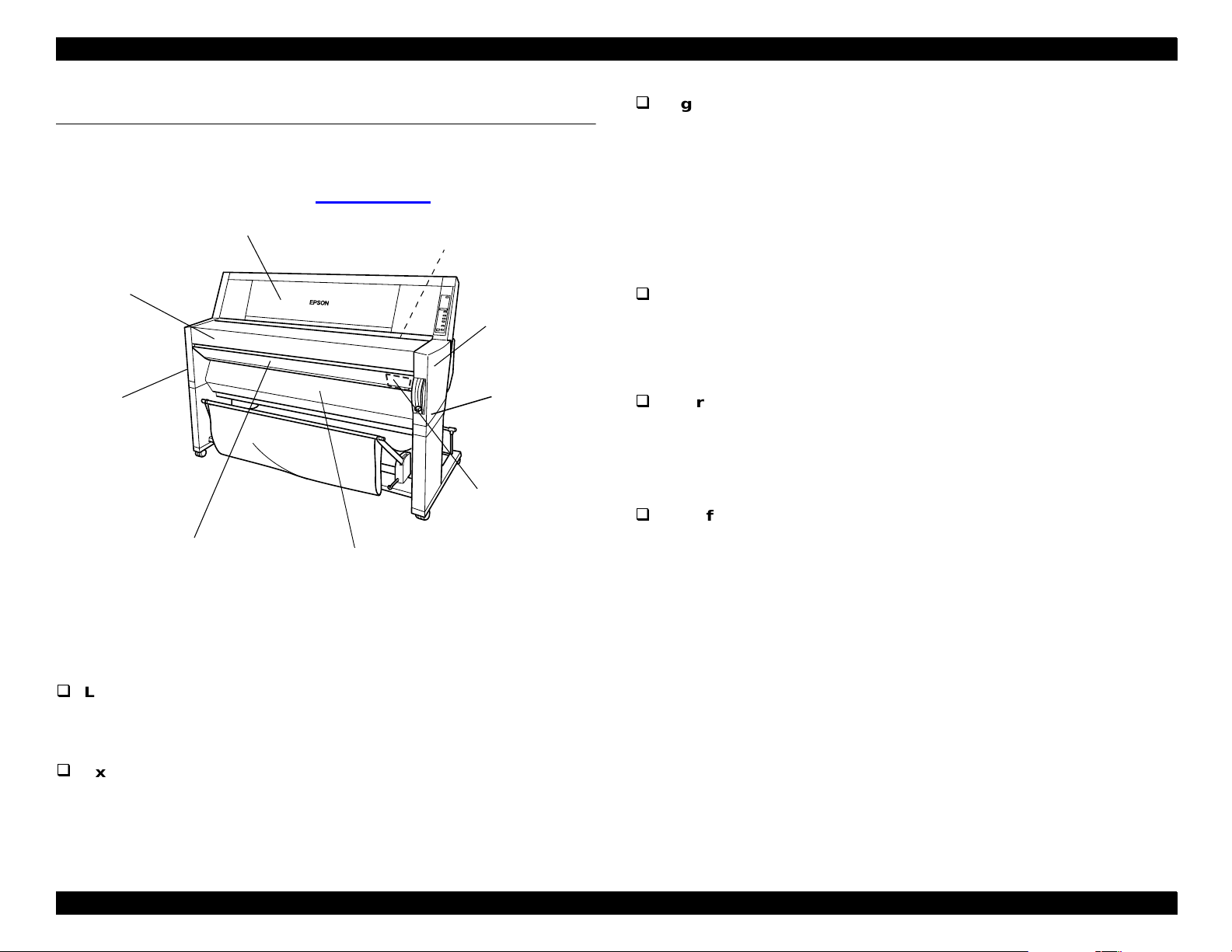

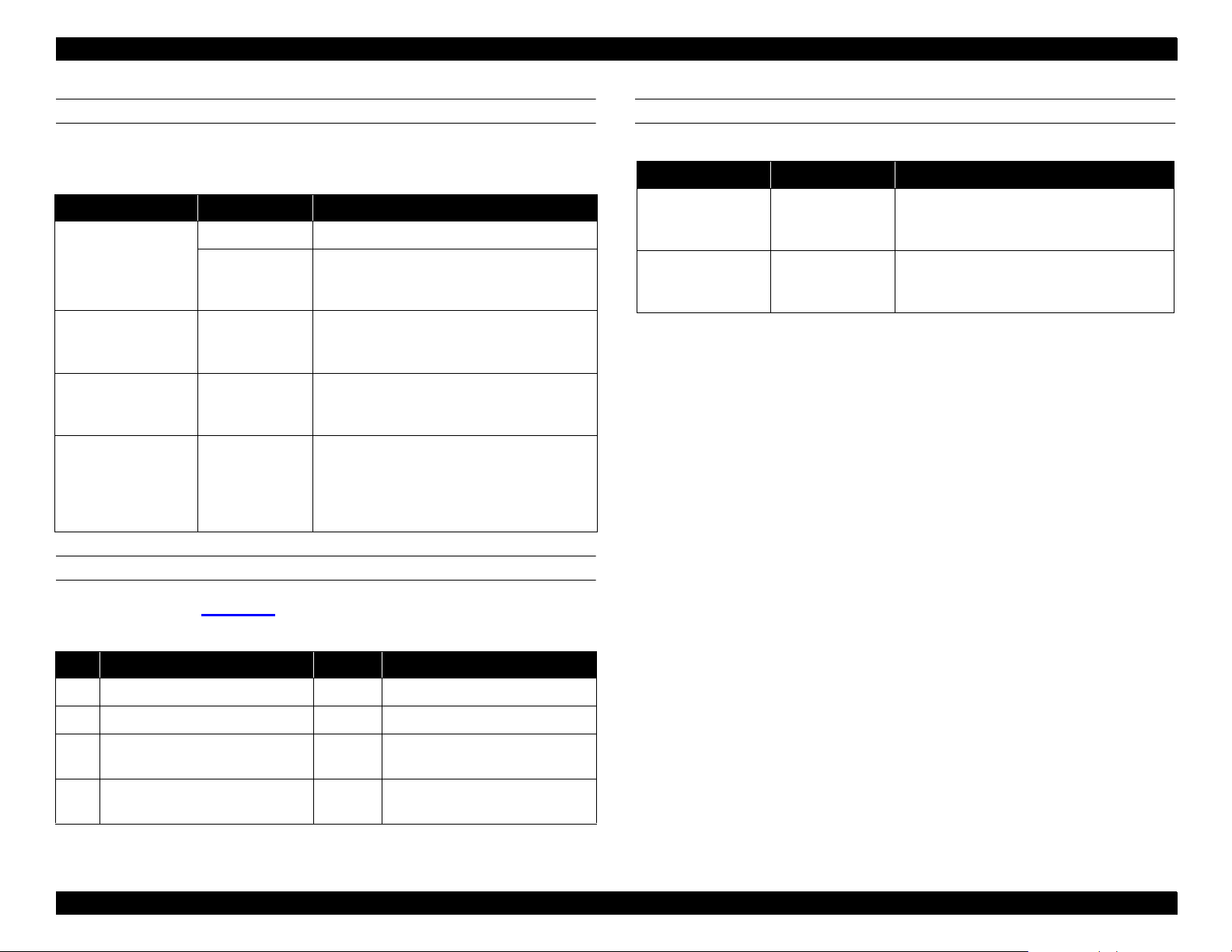

1.1 Features

The EPSON Stylus Pro 9000 is an ultra-wide, 6-color ink jet printer with

professional color o ut put. It provid es t he c olor printin g f eatures listed

below. (For addition al details, see

Roll Cover

Top Cover

Specifications

on page 156.)

Upper P aper Guide

(behind Top Cov er)

Right Side

Cover

High-speed printing

64 nozz les per color

RISC-CPU and high-speed color raster ASIC quickly process

detailed print data

approx. 10 minutes (360

approx. 30 minutes (720

approx. 55 minutes (1440

Low operating costs

× 360 dpi/speed) on A0/normal paper

× 720 dpi/quality) on A0/glossy paper

× 720 dpi/superfine) on A0/glossy paper

6 separate ink cartridges so only the empty ink cartridge is replaced

Auto Rotate feature saves paper by automatically rotating an image

if the widt h is s horter than th e height

Left Side

Cover

Front Cover

Lower Paper Gui de

Figure 1-1. Exterior View of the EPSON Stylus Pro 9000

Large printing

Up to B0-wide paper (44 inches [1,118 mm]), including print

registration marks

Excellent photo-quality printing

1440 (H)

× 720 (V) dpi co m bined with EPSON’s M ic rodot printing

Right Joint

Cover

Main tenance

Cover

Alternative interface compatibility

IEEE-1284 bidirectional parallel interface (supports ECP mode)

Macintosh serial int erface (approximat ely 1. 8 Mbps)

Type-B ex pansion slot f or an optiona l int erface

User friendly

2 roll hold ers f or easily swit c hing between paper types

Standard roll paper cutter

Optional roll paper take-up reel for automatically winding up your

long prin t outs

Printer Basics 11

Page 12

EPSON Stylus Pro 9000

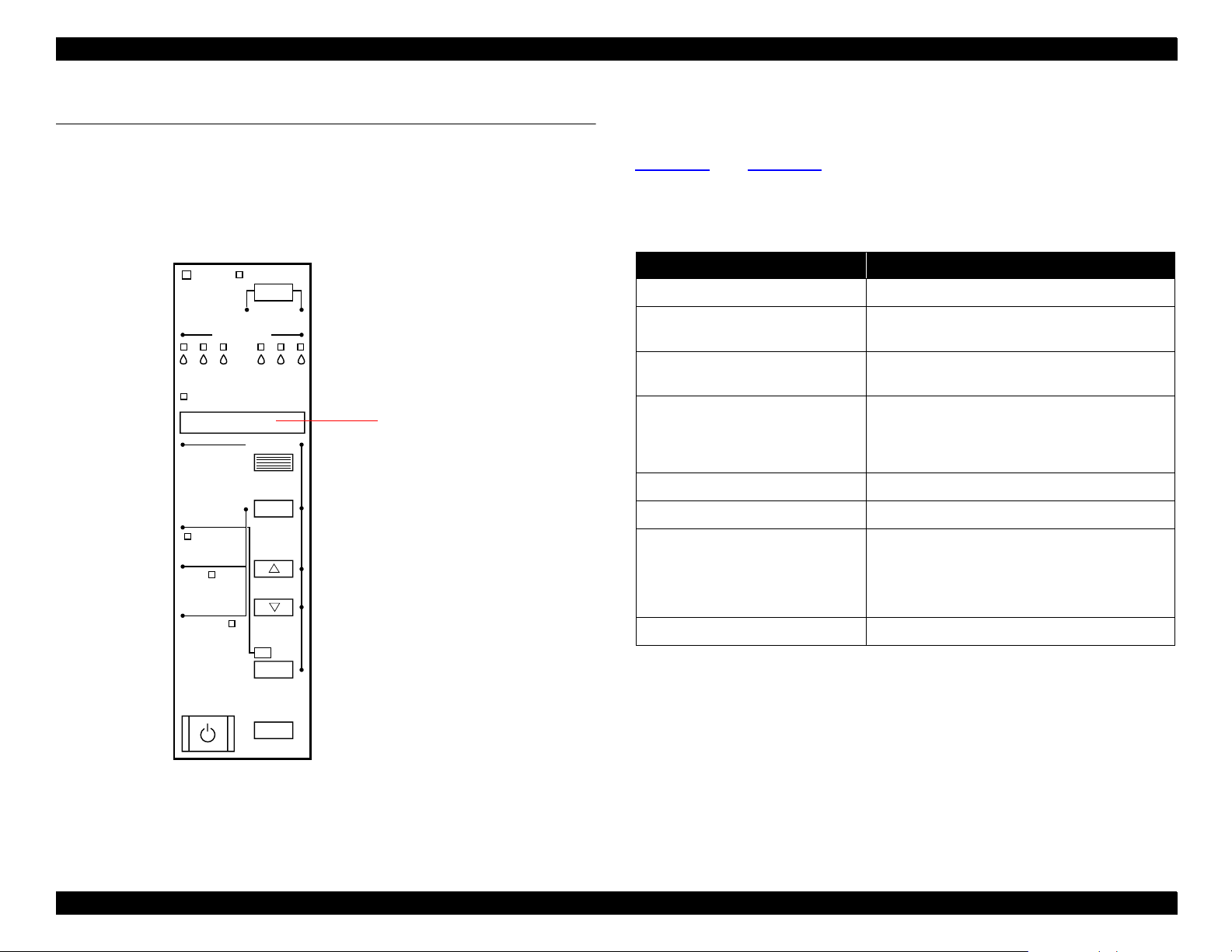

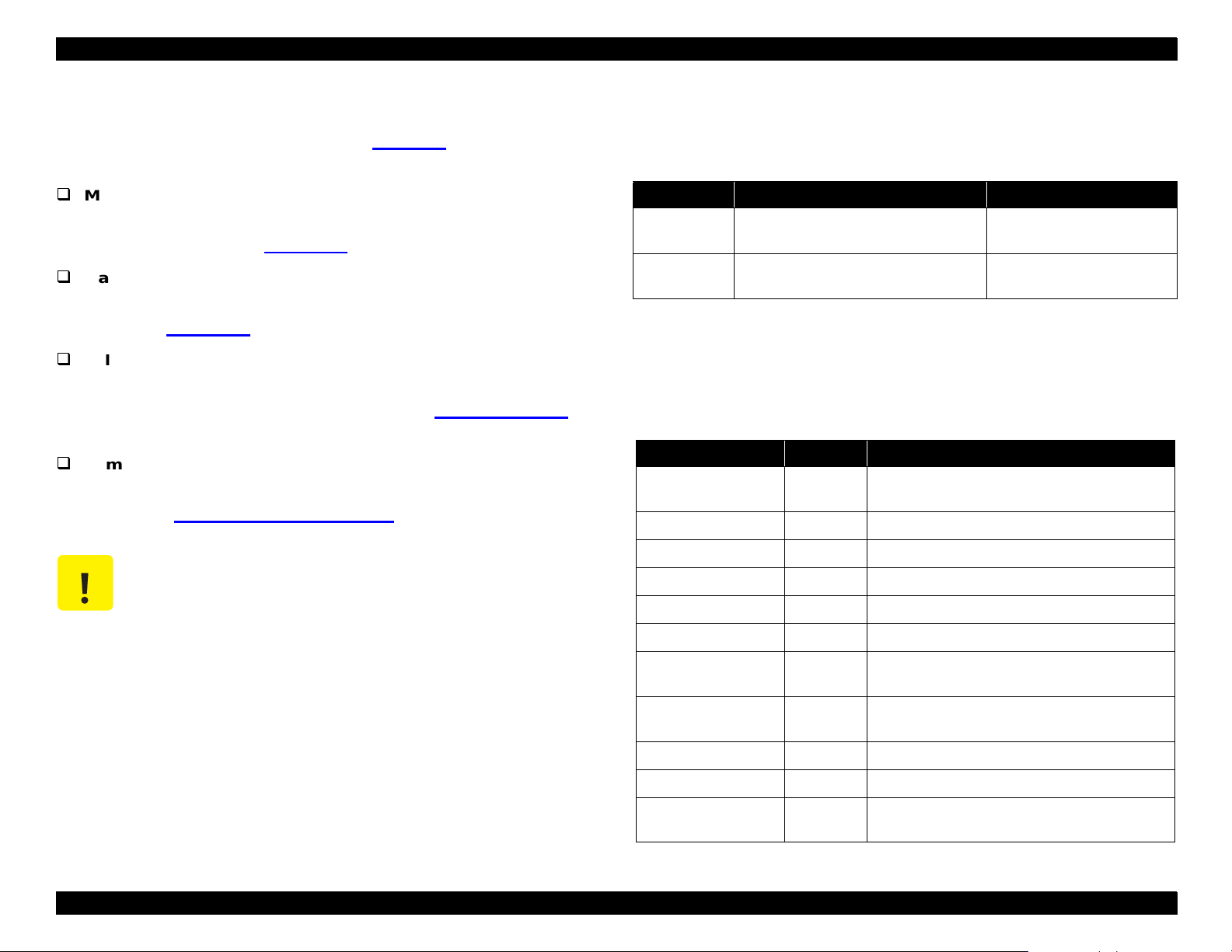

1.2 Control Panel Operations

The EPSON Stylus Pro 9000 co nt rol panel dis plays status and error

messages , and the lights indicate wh en a problem oc c urs or if any ink

cartridge is low or runs out. This section provides inf ormatio n on the

control panel buttons, LEDs, and liquid crystal display (LCD).

Ink Out

Paper Source

Pause

Reset

3 sec.

SelecType

Item

+

Paper Feed

_

Cut /Eject

Enter

Cleaning

3 sec.

LCD Display

Operate

KC LCMLMY

Paper Out

Roll

Auto Cut

Roll

Cutter Off

Sheet

Power

1.2.1 Control Panel Buttons

Pressing a control panel button executes the functions listed in

and

Table 1-1

Table 1-2

1.2.1.1 Operation in Normal Mode

Table 1-1. Operation in Normal Mode

Button (Second function) Function

Power Power ON and OFF

Pause (Reset) Switches between onl ine and offline.

SelecType Enters SelecType mode (when printer is in

Cut/Eject (Enter)*

Paper Feed

Paper Feed

Paper Source (Item) Selects paper source:

Cleaning Cleans both heads if pressed for 3 seconds

* Int errupts the ink-drying time, if taking place.

** 1.27 cm/second paper feed for 2 seconds after key is pressed.

7.62 cm/second paper feed if pressed for over 2 seconds.

Maximum feed of 20 cm when the button is pressed once.

***1.27 cm/second paper feed for 2 seconds after key is pressed.

7.62 cm/second paper feed if pressed for over 2 seconds.

U

D

.

Resets the printer i f pressed for 3 seconds.

Standby)

• Cuts and ejects paper if Roll Aut o Cut is

selected

• Ejects paper if Roll Cutter Off or Sheet is

selected

Feeds paper backward**

Feeds paper forward***

•Roll Auto Cut

• Roll Cutter Off

• Sheet

Figure 1-2. EPSON Stylus Pro 9000 Control Panel

Printer Basics 12

Page 13

EPSON Stylus Pro 9000

1.2.1.2 Operation at Power On

Pressing th es e buttons a t po w er on puts the printer in one of th e

following service-related modes. See

Service-Related Modes

page 17 for d et ails .

Table 1-2. Operation at Power On

Button (Second function) Function

Power —

Pause (Reset) Maintenance Mode

See

Maintenance Mode

SelecType

Cut/Eject (Enter)

Paper Feed

Paper Feed

Paper Source (Item)

Cleaning

Paper Source, Paper Feed

Paper Source, Cut/Eject, Cleaning Firmware Update Mode

Paper Feed

U

D

, Cut/Eject Maintenance Mode 2

D

See

Maintenance Mode 2

See

ROM Backup and Updating

, Cut/Eject, Cleaning Self-Diagnostic Mode

D

See

Self-Diagnostics

—

page 105

on

on page 17

on page 17

on page 107

on

1.2.2 SelecT ype Mode

The SelecType menus allows y ou to configu re printer set t ings and

perform c ert ain maintenance op erations fro m th e c ontrol pane l. To

access these menus, press th e SelecType button while the printer is not

printing. The printer enters the SelecType mode and cannot print.

1.2.2.1 Control Panel Operation in SelecType Mode

The con tr ol panel buttons have th e f ollowing func t ions in this mode:

Table 1-3. Operation in SelecType Mode

Button (Second function) Function

Power

Pause (Reset)

SelecType Selects menu

Cut/Eject (Enter) Confirms and saves value

Paper Feed

Paper Feed

Paper Source (Item) Selects item within a menu

Cleaning —

U

D

Increases a value

Dec re ases a value

1.2.2.2 Main Menu Options in SelecType Mode

Table 1-4

lists the menus and where to find additional in fo rm ation.

—

Table 1-4. SelecType Menus

Menu Description For more

information

Printer Setting Configure the printer

Test Print Print a nozzle check or status check

Printer Status Check ink levels and component life

page 14

page 15

page 15

Printer Basics 13

Page 14

EPSON Stylus Pro 9000

Table 1-4. SelecType Menus (continued)

Menu Description For more

Paper Configuration Register pape r thi ckne ss and dr ying t ime,

and select registered configurations

Cutter Replacement Replace the pap er cut ter blade

Head Alignment Align the printhe ad

information

page 16

page 16

page 16

PRINTER SETTING MENU

The bold it em is the default setting.

Table 1-5. Printer Setting Menu

Message Item Explanation

PLATEN GAP

PAGE LINE

INTERFACE

PARA. I/F

CODE PAGE

AUTO

THICK

ON

OFF

AUTO

PARALLEL

MAC

OPTION

COMPAT*

ECP

PC437

PC850

Adjusts the platen gap. Normally leave

set to AUTO.

When AUTO CUT OFF is selected on

the control panel, this setting

determines whether a li ne for ma nual

cutting is printed

Determines which interface the print er

checks for data. AUTO cont inuously

checks all interfaces and is good for

normal use. MA C is the serial interface.

Determines the data t ran sfer r ate when

using this interface. Normally leave set

to COMPAT*.

Character code setting. PC437 is for

expanded graphics. PC850 is for multilingual.

ROLL MARG

INIT. PANEL EXEC. Initialize control panel setup values

* The printed image is t he sam e size as the printed image using the 0.12 inch (3 mm)

setting. However , t he printer adds 0.47 inch ( 12 mm) of paper clearance (for a total

margin of 0.59 inch [15 mm] ) to t he top and bottom edges to make paper feeding

more stable and to preven t the paper from rubbing the printheads.

T/B15MM*

15MM All margins are 0.59 in. (15 m m).

3MM All margins are 0.12 in. (3 mm).

Top and bottom margins are 0. 59 in.

(15 mm). The left and right margins ar e

0.12 in. (3 mm).

Printer Basics 14

Page 15

EPSON Stylus Pro 9000

TEST PRINT MENU

Table 1-6. Test Print Menu

Message Item Explanation

NOZZLE CHECK PRINT Check the printo ut. Any missing lines mean the

nozzle(s) ar e clogged.

STATUS CHECK PRINT Prints the amount of ink lef t or the component life as

follows:

• E*****F = full (or full life remaining)

• E ****F = ¾ full (or ¾ life remaining)

• E ***F = ½ full (or ½ life remaining)

• E **F = ¼ full (or ¼ life re maining)

• E *F = nearly empty (or service life near end)

• E F = empty (or service life ended)

PRINTER STATUS MENU

Use this menu to view the printer status on the contr ol panel display

without printing a sta tu s ch eck. While in this m enu, press th e I tem

button to view the messages in Table 1-7

.

Table 1-7. Printer Status Menu

Table 1-7. Printer Status Menu (continued)

Message Explanation

WASTE INK Ink pad maintenance information

CR MOTOR Carriage motor maintenance information

PF MOTOR Paper feed motor mainten ance information

HEAD UNIT Printhead maintenance information

CLEANER Maintenance information

Contin ue pressing t he Item button to display the am ount remaining for

each of the 6 inks or se rv ic e lif e remainin g f or t he part. The indicator

reads as fo llows:

E*****F = full (or full life remaining)

E **** F = ¾ full (or ¾ lif e remaining )

E ***F = ½ full (or ½ life remaining)

E **F = ¼ full (or ¼ life remaining)

E *F = nearly empty (or service life ne ar end)

E F = empty (or se rv ic e lif e ended)

Message Explanation

VERSION <number> Shows the firmware version

INK LEFT-C Amount of cyan ink remaining

INK LEFT-M Amount of magenta ink remaining

INK LEFT-LC Amount of light cyan ink remaining

INK LEFT-LM Amount of light magen ta ink remaining

INK LEFT-Y Amount of yellow in k remaining

INK LEFT-K Amount of black ink r em aining

CUTTER LIFE Useful life of the cutter remaining

TOTAL PRINTS Total num ber of printed documents

Printer Basics 15

Page 16

EPSON Stylus Pro 9000

PAPER CONFIGURATION MENU

The bold ite m is th e default sett ing.

Table 1-8. Paper Configuration Menu

Message Item Explanation

PAPER NUMBER

THICK. PAT PRINT Prints a pattern t o detec t the paper

PAPER THICK 1 If PAPER NUMBER is set to STD, the

DRYING TIME 0MIN De termines the length of time th e pri nter

STD*

1 Select the appropriate number for thick

Select STD for Epson specia l paper

paper. Use the

registered number up to 4.

thickness. If PAPER NUMBER is set to

STD, the message does not appear.

message does not app ear. Use the

select the reg istered number up to 17.

allows the ink to dry. When printing on roll

paper, the print er will wai t the specif ied ti me

after printing. Use the

registered number up to 30MIN.

or − to select the

+

or − to select the

+

or − to

+

HEAD ALIGNMENT MENU

Table 1-10. Head Alignment Menu

Messages Item Explanation

ADJUST. PATT

PAPER THICK STD Leave on STD for EPSON paper. For other

ALL

Prints a full series of patterns. To print a

single pattern, use the

registered pattern appears.

media, use the

thickness in 0.1-m m increments.

+

and − until the

+

and − to select the

CUTTER REPLACE MENU

Follow the order in Table 1-9

to replace the cutter.

Table 1-9. C u tter R eplacement Menu

Step Message Item Explanation

1 CUT. REPLACE EXEC. Prepare a replacement cutter

2 OPEN LOWER COVER — Open the front cover

3 REPLACE CUTTER — Remove the old cutter and instal l

a new one

4 CLOSER LOWER COVER — Close the front cover. READY

appears on the display.

Printer Basics 16

Page 17

EPSON Stylus Pro 9000

1.2.3 Service-Related Modes

Press and hold down the buttons li sted in

enter one of t hes e service- related modes:

Maintenance Mode

Lets you print a hex dum p or change th e language us ed for LCD

display messages . S ee

Maintenance Mode 2

Table 1-11

Lets you clear maintenance counters after replacing consumable

parts. See

Self-Diagnostic Mode

Table 1-12

on this pag e.

Lets you adjust printer settings, check and reset certain counters,

make test prints, a n d cle an th e pri nt head. S ee

page 107.

Firmware Update Mode

Lets you update the printer’s firmw are after replacing the Main

Board. See

CAUTIO N

ROM Backup and Updating

The operations described in this section a re for s ervic e

and support only. Avoid sharing this information with

the end us er .

Table 1-2

on this page.

Self-Diagnostics

on page 105.

at power on to

on

1.2.3.1 Maintenance Mode

Press the

Message Menu Item Explanation

HEX DUMP PRINT Pr int data printed in

LANGUAGE ENGLISH, PORTUGUESE, SPANISH,

Pause

button while turning on the printer.

Table 1-11. Maintenance Mode Menu

GERMAN, ITALIAN, FRENCH

hexadecimal form

Determines language used

for LCD display messages

1.2.3.2 Maintenance Mode 2

Press the

Paper Source, Cut/Eject,

turning on the printer.

Table 1-12. Maintenance Mode 2 Menu

Message Menu Item Explanation

INIT. ALL EXEC. Initializes NVRAM, Timer, life counters, and

mechanical coun ters

INIT. NVRAM EXEC. Initializes NVRAM

INIT. TIMER EXEC. Initializes timer

INIT CR MOTOR EXEC. Initialize s CR motor (after r eplacing ink tubes)

INIT. PF MOTOR EXEC. Initializes PF motor

Paper Feed

and

D buttons while

INIT. HEAD UNIT EXEC. Initializes head unit

NOTE: In Main te nanc e M ode an d Main te nanc e M ode 2, pre ss t he

Paper Source button to select a menu item, and press

Enter save a setting.

INIT CLEANING

UNIT

INIT. TOTAL

PRINTING

INIT. INK EXEC. Initializes ink counter

INIT. WASTE INK EXEC. Initializes waste ink counter

DETECT INK LABEL ON

EXEC. Initializes cleaning unit

EXEC. Initializes total print counter

Determines whether the Ink ID sensor checks

OFF

the ink ID label on the ink cartridge.

Printer Basics 17

Page 18

EPSON Stylus Pro 9000

1.3 LED Indicators and Error Messages

The printe r dis plays stat us m es s ages and e rror codes us ing its LED

indicators and LCD panel. Interpret these messages using the tables on

the following pages .

Ink Out

Paper Source

Pause

Reset

3 sec.

SelecType

Item

+

Paper Feed

_

Cut /Eject

Enter

Cleaning

3 sec.

LCD Display

LED Indicators

Operate

KC LCMLMY

Paper Out

Roll

Auto Cut

Roll

Cutter Off

Sheet

Power

1.3.1 LED Indicators

Table 1-13. LED Indicators

LED Status Explanation

Operate On Power on

Flashing Receiving data or perfor m ing power-down sequence

Paper Out On No paper loaded

Flashing Paper jam

Pause On Printer ready

Flashing Performing head cleaning. Printer is in ink- drying

phase. Performing ink- charging operation.

Ink Out Y On Ink out (also occurs if no or wrong cartridge is installed)

Flashing Ink low

Ink Out LM O n Ink out (also occurs if no or wrong cartridge is installed)

Flashing Ink low

Ink Out LC On Ink out (also occurs if no or wrong cartridge is installed)

Flashing Ink low

Ink Out M On Ink out (also occurs if no or wrong cartridge is installed)

Flashing Ink low

Ink Out C O n Ink out (also occurs if no or wrong cartridge is installed)

Flashing Ink low

Ink Out K On Ink out (also occurs if no or wrong cartridge is installed)

Flashing Ink low

Paper Source

(Auto C u t)

On Roll paper will automa ti ca ll y b e cut

Paper Type

(Cut Off)

On Roll paper will not be cut (sel ect th is sett ing when usi ng

the optional take-up Roller)

Figure 1-3. Control Panel Indicators and LCD Display

Paper Type

(Sing le Sh ee t)

On Single sheet printi ng m ode

Printer Basics 18

Page 19

EPSON Stylus Pro 9000

1.3.2 LCD Display

Table 1-14. LCD Display Messages

Message Explanation

COVER OPEN Lower cover is open

INK COMPART. OPEN Replacing ink cartridge when the ink compartment

cover is open

INK DRY FOR <number>

MIN*

INK LOW Ink cartridge(s) are n early empty. Pri nting continues.

INK OUT Ink cartridge(s) are empty. Printing stops.

LOAD PAPER Wrong paper is loaded or the paper set lever is up

LOAD ROLL PAPER Paper source set ting i n pri nt options is dif feren t fro m

LOAD SHEET PAPER

MAINTENANCE REQ. 0100 Waste Ink Pads are nearly ful l. See

NO INK CARTRIDGE Ink cartridge(s) not installed

OPTION I/F ERROR Wrong interface card is installed

PAPER JAM Paper is jammed inside printer.

PAPER NOT CUT Roll pa per was not cut completely ( when Auto Cut is

PAPER NOT STRAIGHT Paper slipped and fed into the printer at an angle.

PAPER OUT No paper is loaded or paper has run out

PAUSE Pause state

Printer is paused for minutes shown to let ink dry

while loading paper

control panel

LCD Error

Messages

selected)

Printing stops.

Cut paper did not fall off

The paper detect sensor may have dust or grime

blocking its operation

on page 40.

Table 1-14. LCD Display Messages (continued)

Message Explanation

PRINTING* Printer is receiving data

PUSH LEVER DOWN Paper release lever is in the release position

READY* Printer is ready to print

RELOAD PAPER Pap er could not be reversed into the pri nti ng

position

Paper is set out of the printable area or out of the

horizontal cutting area

Paper is not fully ejected

PAPER NOT CUT error was not cleared

REMOVE PAPER Paper is too thick for head cl eaning

RESET Printer is resetting

SERVICE REQ. <error

number>

SWITCHING POWER OFF Preparing to shut down

TURN PWR OFF AND ON Tried to print a test patter n while in an error

WAIT* Resett ing timer IC

WRONG CARTRIDGE Wrong ink cartridge(s) install ed

* If the pl aten gap setting is set to Thic k, a “W” appears in the last space on the

LCD display.

A fatal error has occurred. See

Messages

condition or the ink compartment cove r was open

Clearing NVRAM

Performing res et operation

Performing in k sequence operation

Initializing the printer

Dealing with initi al paper operation

on page 40.

LCD Error

PRESS PAUSE BUTTON Press Pause to continue

For a listing of LCD error m essages and how to read them, see

Error Messages

on page40.

LCD

Printer Basics 19

Page 20

EPSON Stylus Pro 9000

1.4 Options and Consumables

The table below li sts the co nsumable it ems and options available for the

EPSON St y lus Pro 9000 .

Table 1-15. Optional Items

Item Part Number Description

Paper cutter blade C815131 Consumable item

Roll feed spindle 2 in ch C811021* 2 in. diameter roll paper

Roll feed spindle 3 in ch C811031** 3 in. diameter roll paper

Auto take-up reel unit C81508* Pr inted roll paper option

C815091

(core only)

Glossy photo paper S041225 36 in. (914 mm) wide

68.9 ft (21 m) long

S041224 44 in. (1 ,118 mm) wide

68.9 ft (21 m) long

Semigloss photo ro ll paper S041222 36 in. (914 mm) wide

16.4 ft (5 m) long

S041223 44 in. (1 ,118 mm) wide

82 ft (25 m) long

Matte roll paper S041221 36 in. (914 mm) wide

82 ft (25 m) long

S041220 44 in. (1 ,118 mm) wide

82 ft (25 m) long

Photo quality ink j et paper S041079 A2

S041068/S041045 A3

S041069/S041043 A3 Wide/B

S041070/S041044 B

Table 1-15. Optional Items (continued)

Item Part Number Description

Photo paper S041142 A3

S041143 A3 Wide/B

S041156 B

Photo quality glossy film S041073 A3

S041074 A3 Wide/B

S041075 B

Rip Station 5100 PS

Server Series

Multi-protocol Ethernet

interface card

100 Mbps multiprotoc ol

Ethernet interface card

* Two rolls can be installed at the same time.

** Can be installed only in the upper spindle hold er.

EAI - C850092

Other - C850093

C823622 Type-B 10BaseT

C823632 Type-B 100BaseT

Fiery Adobe

®

PostScript® 3™ Server

Table 1-16. Consumables

Item Part Number Description

Ink cartridge T407011 Black ink

T410011 Cyan ink

T409011 Magenta ink

T408011 Yellow ink

T412011 Light Cyan ink

T411011 Light Magenta ink

Printer Basics 20

Page 21

TECHNICAL OVERVIEW

Page 22

EPSON Stylus Pro 9000

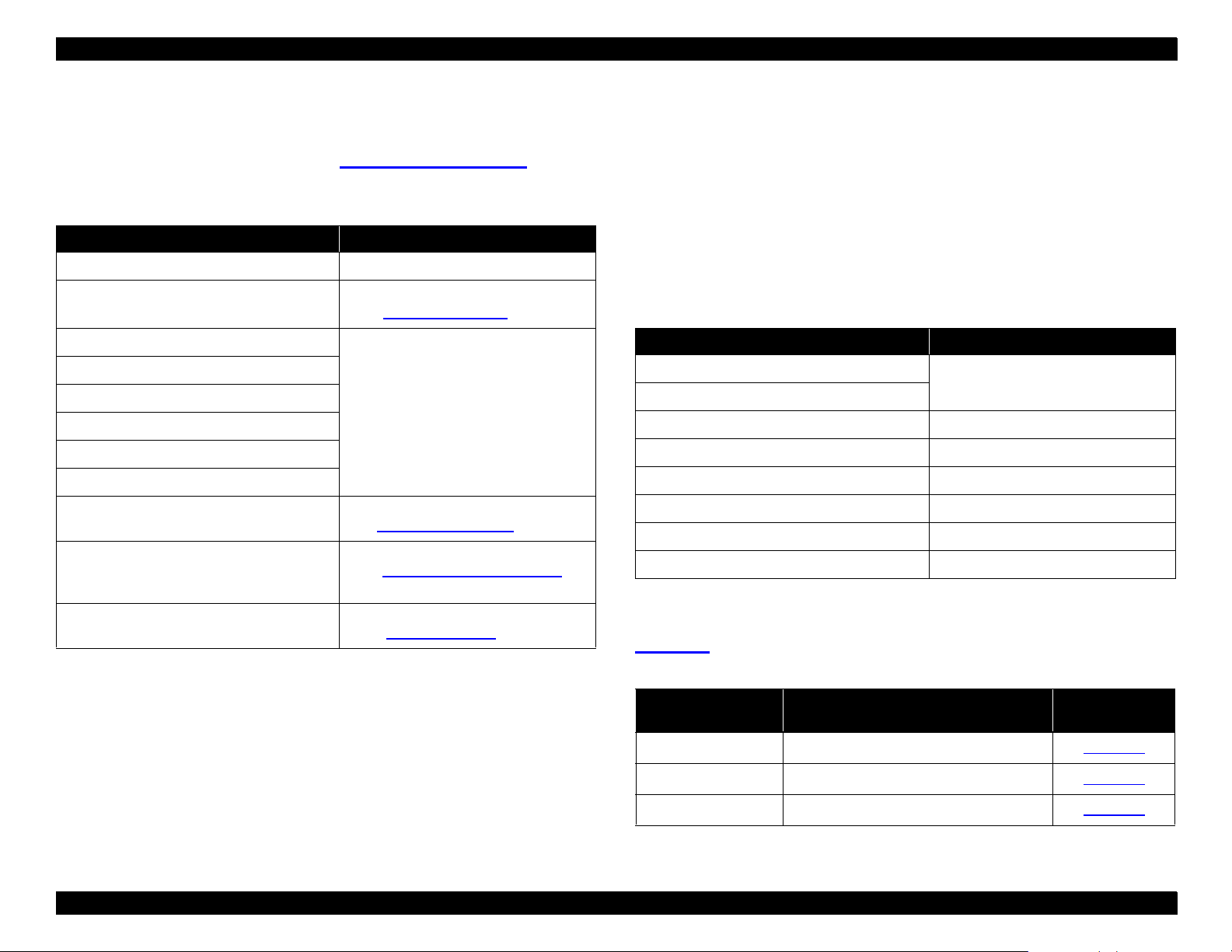

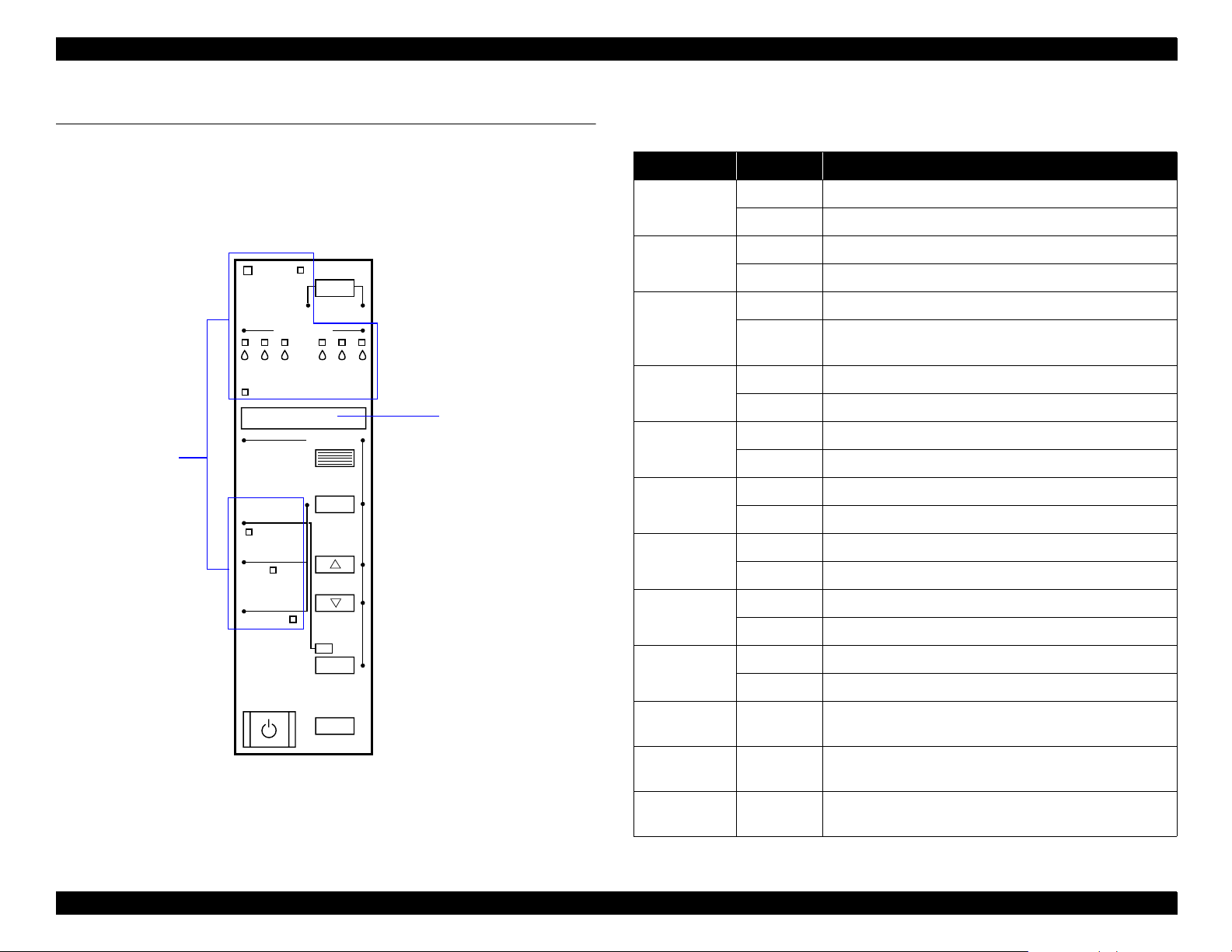

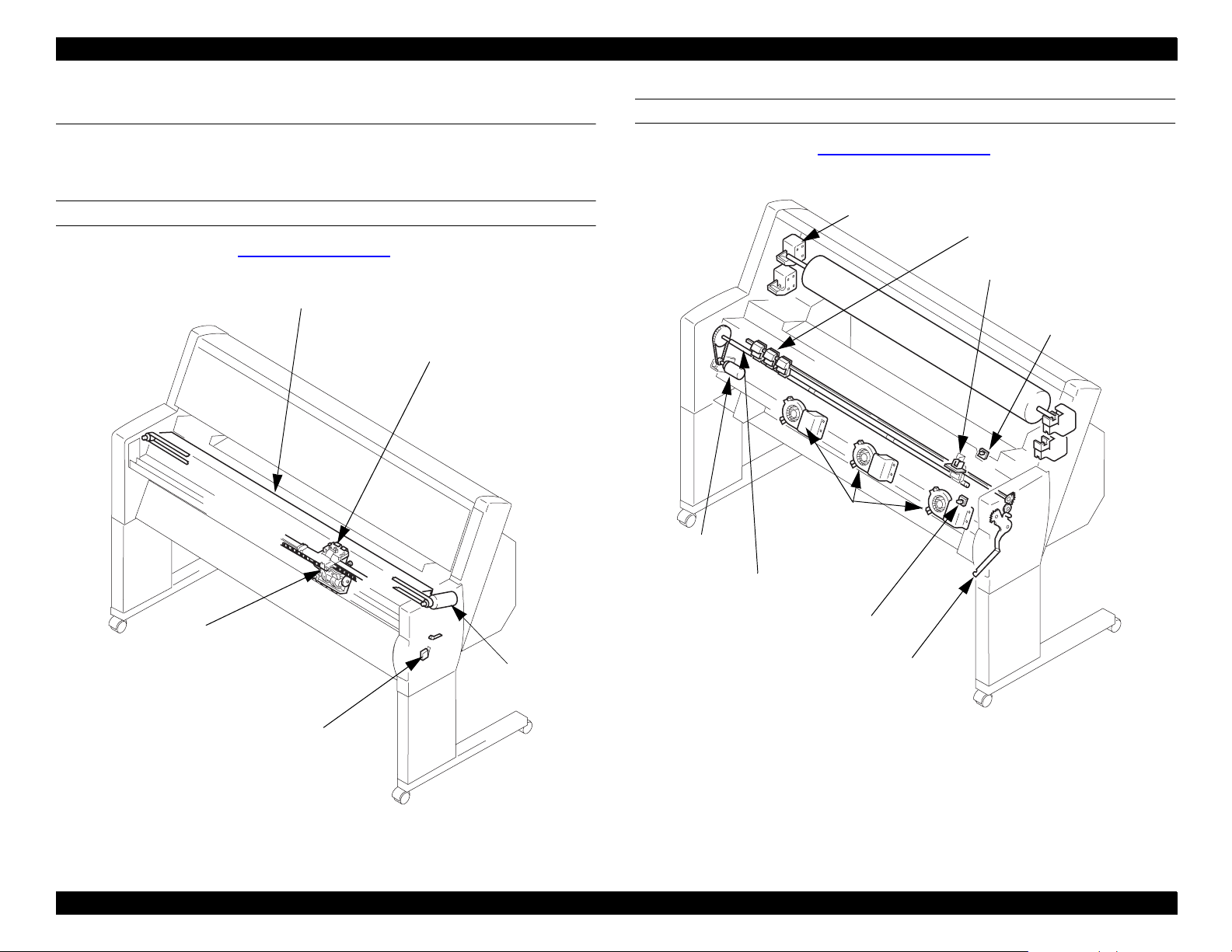

2.1 Location of Components

The following figures show the main components of the EPSON Stylus Pro

9000.

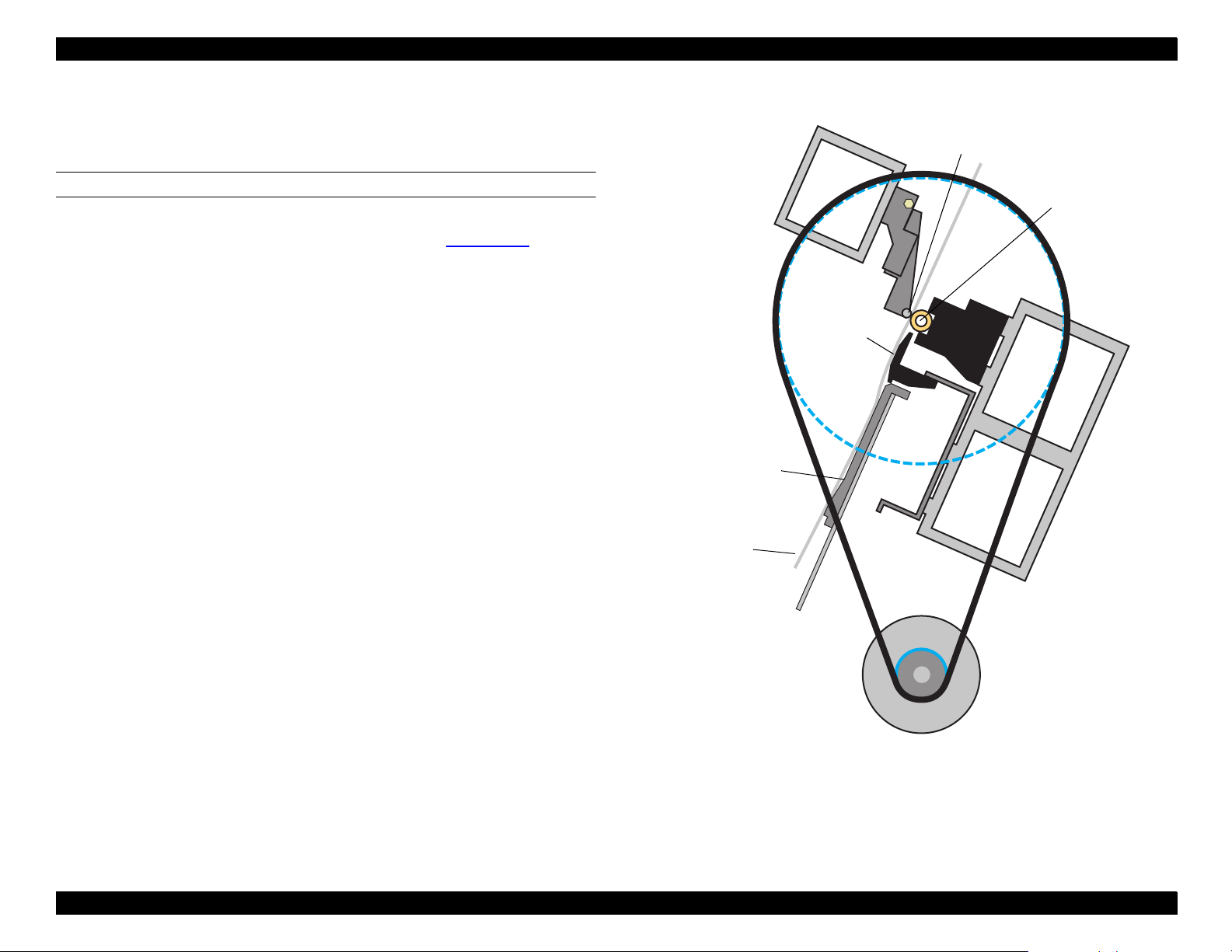

CARRIAGE MECHANISM

For more information, see

Car ria ge Mechanism

Guide Rail

on page 24.

HP Sensor/

Encoder

PAPER FEED MECHANISM

For more information, see

PF Motor

Paper Feed Mechanism

Roll Paper

Holders

Paper

Suction

Fans

on page 28.

Paper Pressure Rollers

Paper

ThicknessSensor

Rear Paper

Sensor

Paper Feed

Roller

Carriage

CR Motor

Cover Open Sensor

(interlock switch)

Front P a per Sens or

Paper Release Lever

Figure 2-2. Paper Feed Mechanism

Figure 2-1. Carriage Mechanism

Technical Overview 22

Page 23

EPSON Stylus Pro 9000

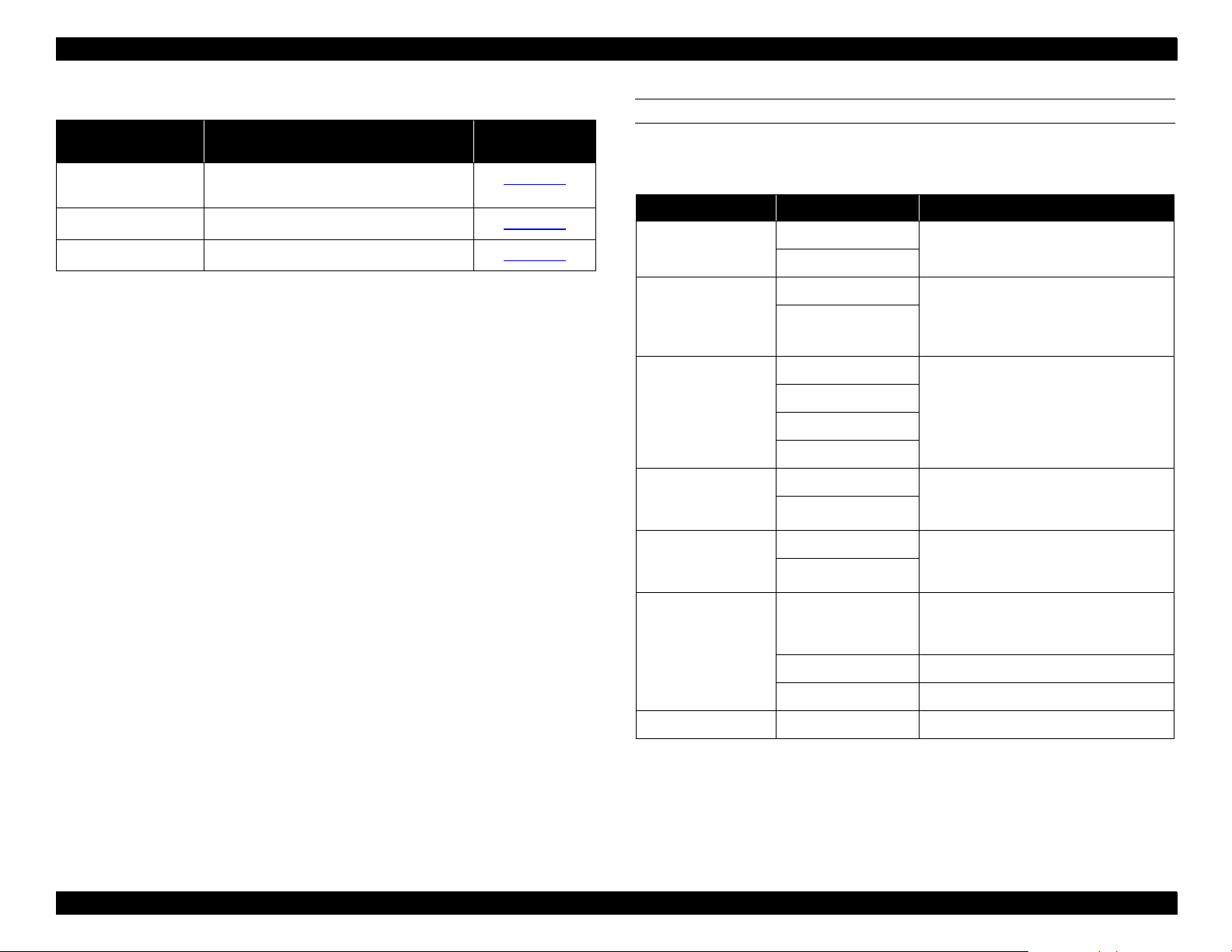

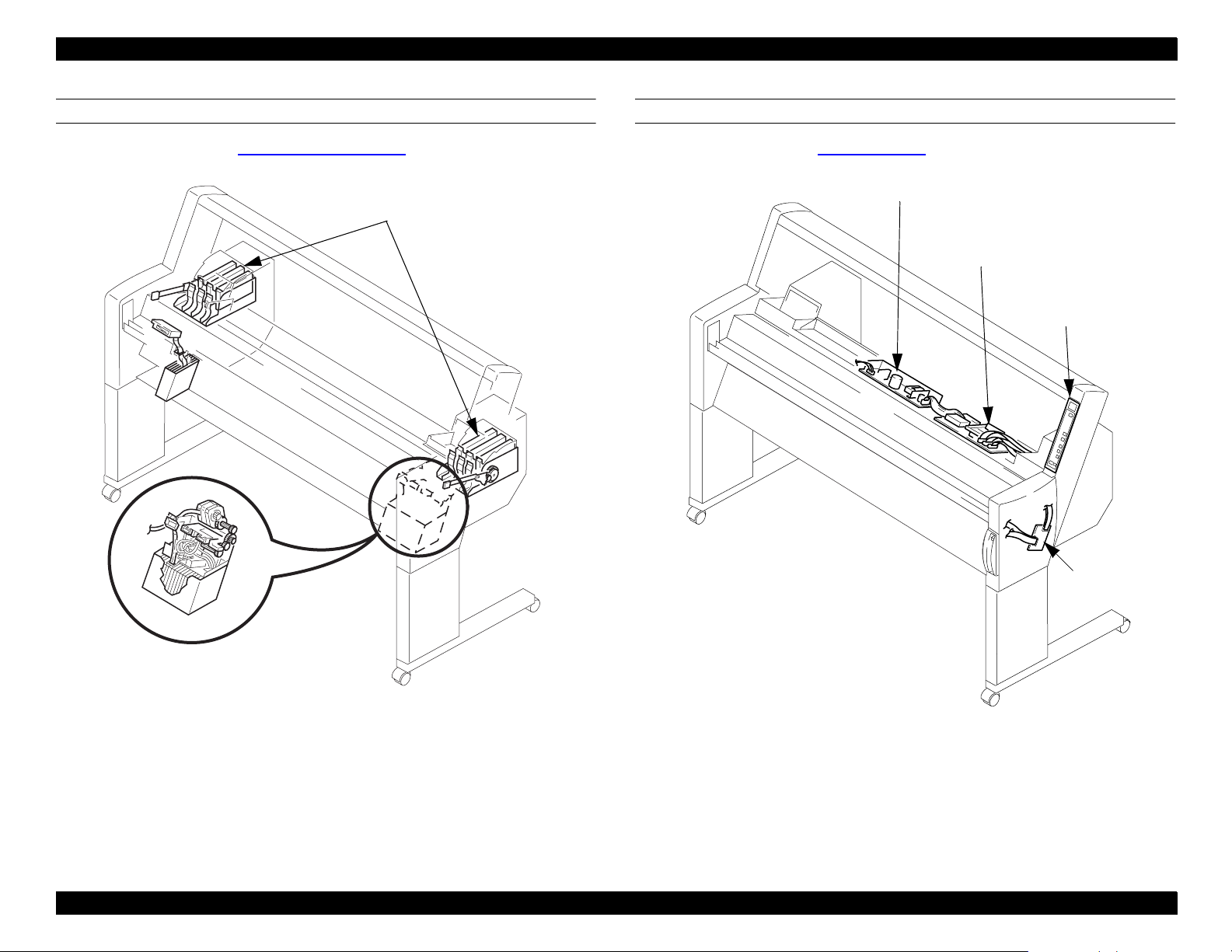

INK SYST EM

For more information, see

Flushing Box (L)

Waste Ink Pads

Ink Supply Mechanism

I/H Assembly

Pump Assembly

Wiper/Clea ner B l ade

Cap Assembly

CR Lock

Flush i ng Box (R)

Waste Ink Pads (R)

on page 34.

CIRCUIT BOARDS

For more information, see

Control Circuit

Power Supply Board

on page 37.

Main Board

(C277MAIN)

Control Panel

Relay

Board

Figure 2-3. Ink System

Figure 2-4. Circuit Boards

Technical Overview 23

Page 24

EPSON Stylus Pro 9000

2.2 Operation

The following sections describe how the printer’s main components operate .

2.2.1 Carriage Mechanism

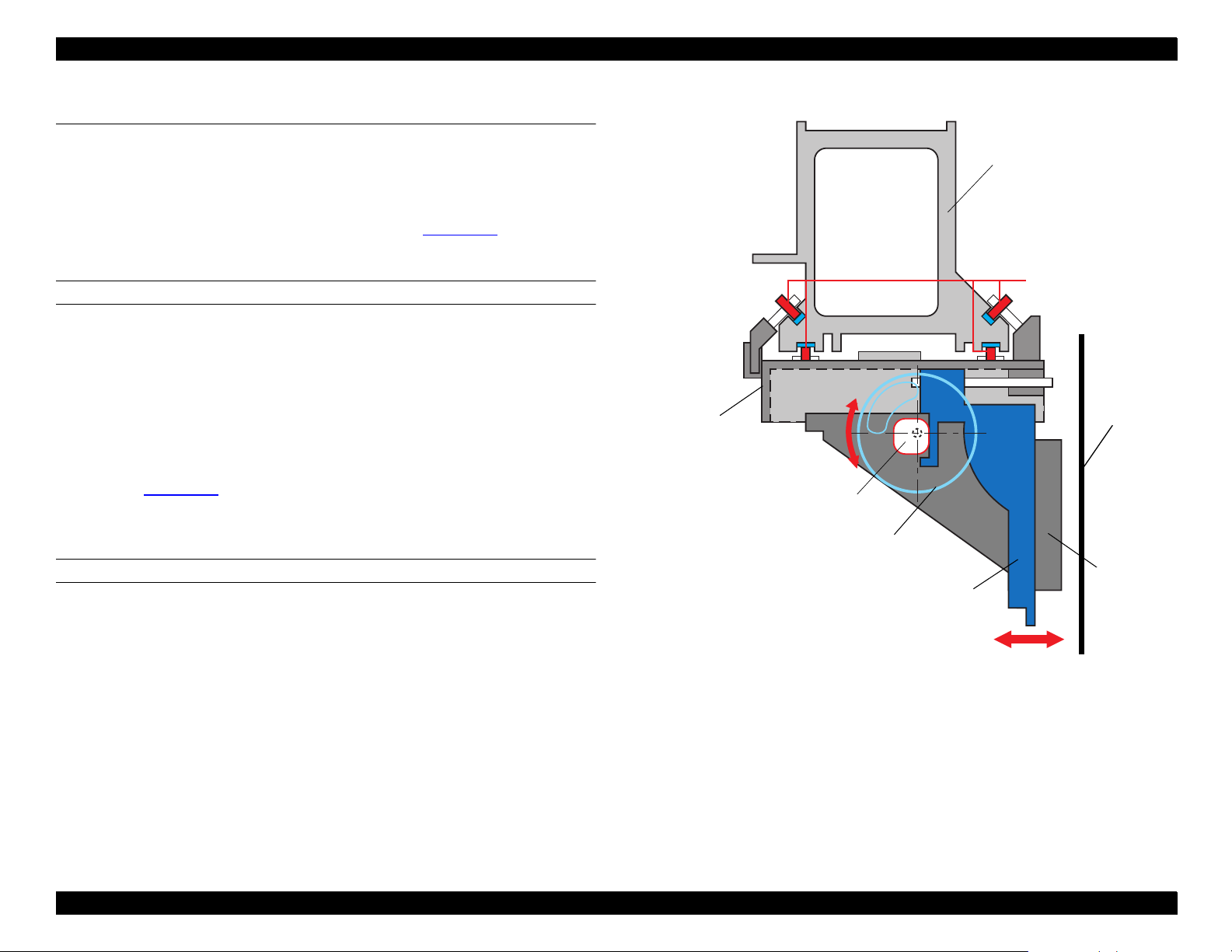

The carriage mechanism includes the parts shown in

operation is described below.

Figure 2-5

CARRIAGE (CR) GUIDE RAIL

To print on paper as wide as B0, the printhead carriage must be more stable

and must travel further than the usual carriage. To make the printheads more

stable, EPSON added the CR Guide Rail to the Stylus Pro 9000.

Every EPSON ink jet printer until now has used a carriage guide shaft to

stabilize the carriage during printing and horizontal movement. The

Stylus Pro 9000 does away with the carriage guide shaft and relies on the

printer frame for its stability.

As shown in

bearings, and the carriage in turn holds the subcarriage. The subcarriage holds

the printheads.

Figure 2-5

, the Carriage attaches to the CR Guide Rail with eight

. Their

Carriage

CR Guide Rail

Bearings

Platen

PG Cam

PG Gear

PLATEN GAP (PG) MECHANISM

Unlike previous models, the Stylus Pro 9000 uses a special system to ensure

that the distance between the printhead nozzles and paper remains the same

for all supported paper thicknesses. The subcarriage can be moved using the

PG Cam which is driven by the PG Gear; this causes the subcarriage and all its

components to move slightly nearer to or farther from the platen. The

subcarriage moves because the PG Cam is mounted off-center, so one side of

the cam pushes the subcarriage closer to the platen than the other side.

Subcarriage

Figure 2-5. CR Guide Rail and PG Mechanism (side view)

Printhead

Technical Overview 24

Page 25

EPSON Stylus Pro 9000

To maintain a constant distance between the printhead nozzles and the paper,

the printer measures the thickness of the paper and adjusts the height of the

carriage accordingly. The printhead has three platen gap (height) settings, as

described in the table below.

Table 2-1. Platen Gap Settings

Platen Gap Setting Gap Distance

PG “Small” 1.3mm

PG “Medium” 2.2mm

PG “Large” 2.7mm

The actual platen gap position used during printing depends on both the

detected paper thickness and the user’s paper thickness setting on the control

panel.

Table 2-2. Platen Gap Setting Determination

Control Panel Setting Paper Thickness Sensor Platen Gap Position

Wide Wide PG “Large”

Standard PG “Medium”

Auto Wide PG “Large”

Standard PG “Small”

PG Sensor

This light-reflecting sensor detects whether the subcarriage is in the thick

paper position or normal paper position. The PG Gear rotates with the PG

Cam, and the PG Sensor determines the subcarriage’s position from the

position of the PG Gear, using the hole in the gear’s side as a reference.

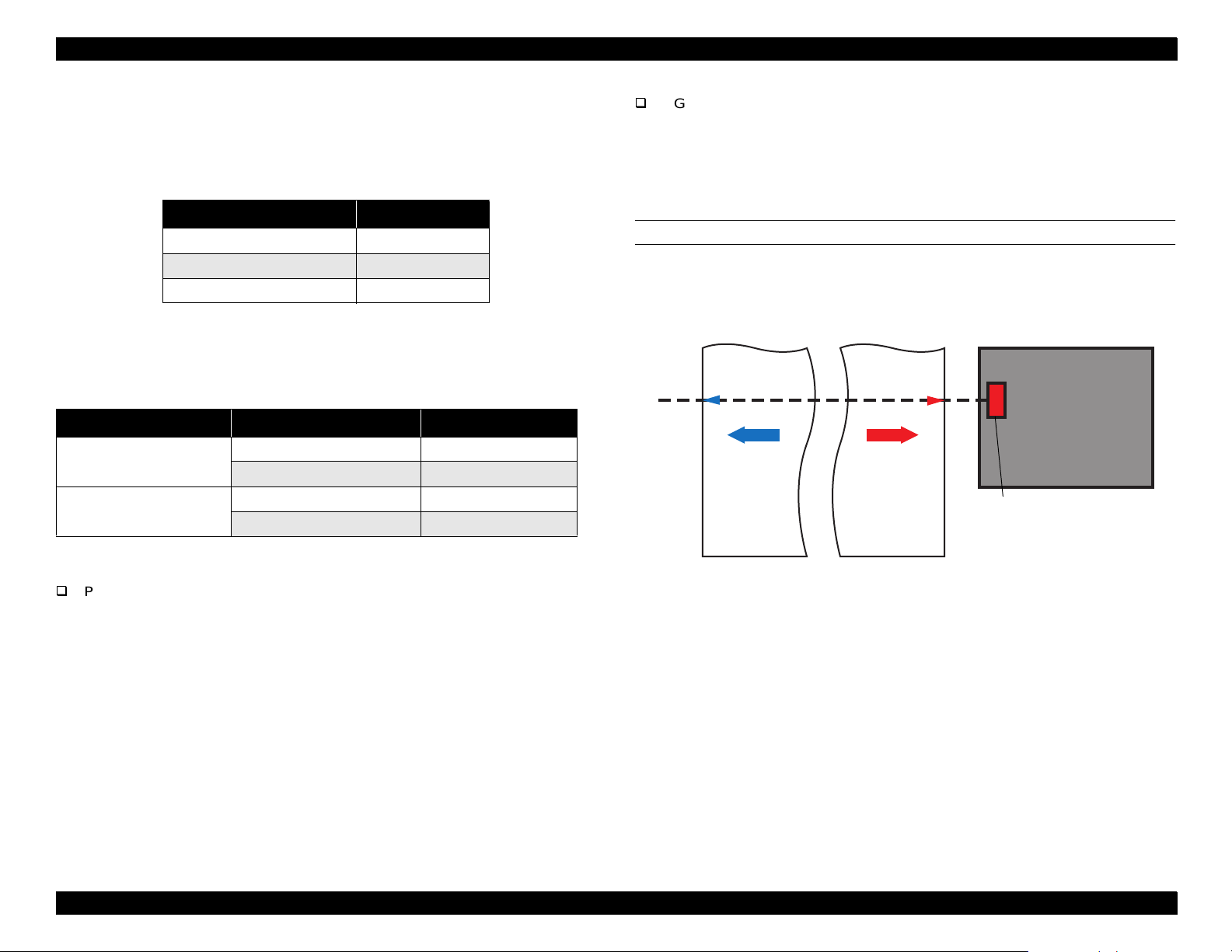

PAPER WIDTH SENSOR

This sensor locates the right and left edges of the paper. The light emitted from

the sensor is reflected back to the sensor where paper exists. In this way the

sensor determines where the paper’s edge is and how wide the paper is.

Carriage

Left

edge

Right

edge

Paper Width

sensor

HP side

The printer uses two sensors in setting the platen gap:

Paper Thickness Sensor

This sensor physically gauges whether the paper falls into the normal/thin

Paper

Figure 2-6. Paper Width Sensor

category or the thick category. The Pressure Roller unit closest to home

position has a thin metal flag on top. When the Paper Release Lever is in

the Lock position and thin paper is loaded, this flag pivots into the space

between the sensor’s light emitter and receiver. However, when thick

paper is loaded, the flag is forced forward out of the sensor area.

Sensor signal = ON at 0.7 V or less: Normal or thin paper

Sensor signal = OFF at 2.4 V or more:Thick paper

Technical Overview 25

Page 26

EPSON Stylus Pro 9000

CARRIAGE MOTOR AND POSITION CONTROL

For the greatest possible print accuracy and to minimize vibration, the printer

uses a DC motor to move the carriage. Because a rubber timing belt would

stretch over the long distance the carriage must travel during printing, the

Stylus Pro 9000’s timing belt is made from steel.

The following sensors are located on the carriage and control the carriage’s

position (see

HP Sensor

Figure 2-7

This optical sensor activates when the CR Guide Rail flag enters the space

between the sensor’s light emitter and the light receiver. The flag is located

just above home position, and the HP sensor sends an ON signal when the

carriage is in home position.

Linear Encoder Sensor

This sensor determines the position of the carriage by counting bands on

the timing fence (timing strip) while the carriage is in motion. The bands

have a distance equal to 180 dpi. For every band the Linear Encoder

passes over, it sends a print timing pulse to the software servo system.

The software servo forms a closed-loop with the CR motor and Encoder

Sensor. It receives feedback from the Encoder Sensor and adjusts the

current to the CR motor to maintain constant carriage speed.

):

CR Motor Motion Failure

During operation, the encoder measures the distance the carriage travels. If

the CR speed as determined by the encoder varies too much from the speed

set by the Software Servo, a fatal error occurs (Service Call 00010005).

CR Guide Rail flag (projected

Carriage

area)

HP Sensor

No HP signal

HP signa l

Linear

Encoder

Timing Strip

Carriage Speed and Acceleration

Carriage Speed

Carriage

The carriage speed during printing is described below.

Table 2-3. Carriage Speed

Figure 2-7. Carriage Mechanism Sensors

Print Mode Carriage Speed

720 dpi & Normal M/W 200 cps

4 Pass FOL printing 300 cps

Unidirectional 400 cps

Carriage Acceleration

Due to the carriage’s quick acceleration, even after the heads reach and

maintain normal speed, they are not stable enough to print for the next 10 mm.

Technical Overview 26

Page 27

EPSON Stylus Pro 9000

CUTTER MECHANISM

To make a paper cut, the cutter solenoid plunges the cutter blade into the

paper. To cut the paper evenly, the following method is used:

1)The cutter cuts from the left of center (when facing the printer) to the left

edge.

2)The cutter cuts from several centimeters inside the right edge to the right

edge.

3)The cutter cuts the remaining center portion, from right to left.

Cutter

Carriage

solenoid

PRINTHEADS

The printheads are the same type used in the EPSON Stylus Pro 5000, and

are installed in the same way. Three levers are provided to make sure the

heads are lined up vertically and that neither head leans one way or the other.

Cutter

Blade

Paper

Figure 2-8. Cutter Mechanism

Technical Overview 27

Page 28

EPSON Stylus Pro 9000

2.2.2 Paper Feed Mechanism

The main components of the paper feed mechanism are described below.

PAPER FEED MOTOR AND ROLLERS

When paper is loaded, it’s held against the Paper Feed Roller by the Paper

Pressure Rollers. Raising the Paper Release Lever (see

the Paper Pressure Rollers away from the Paper Feed Roller, and releases

any loaded paper. The Paper Feed Roller Assembly is made up of three equal

lengths of rollers and their coupling.

Figure 2-10

) moves

CR Guide

Rail

Speed-

Reduction

Gear

Paper Pressu r e

Roller

Paper Fe ed

Roller

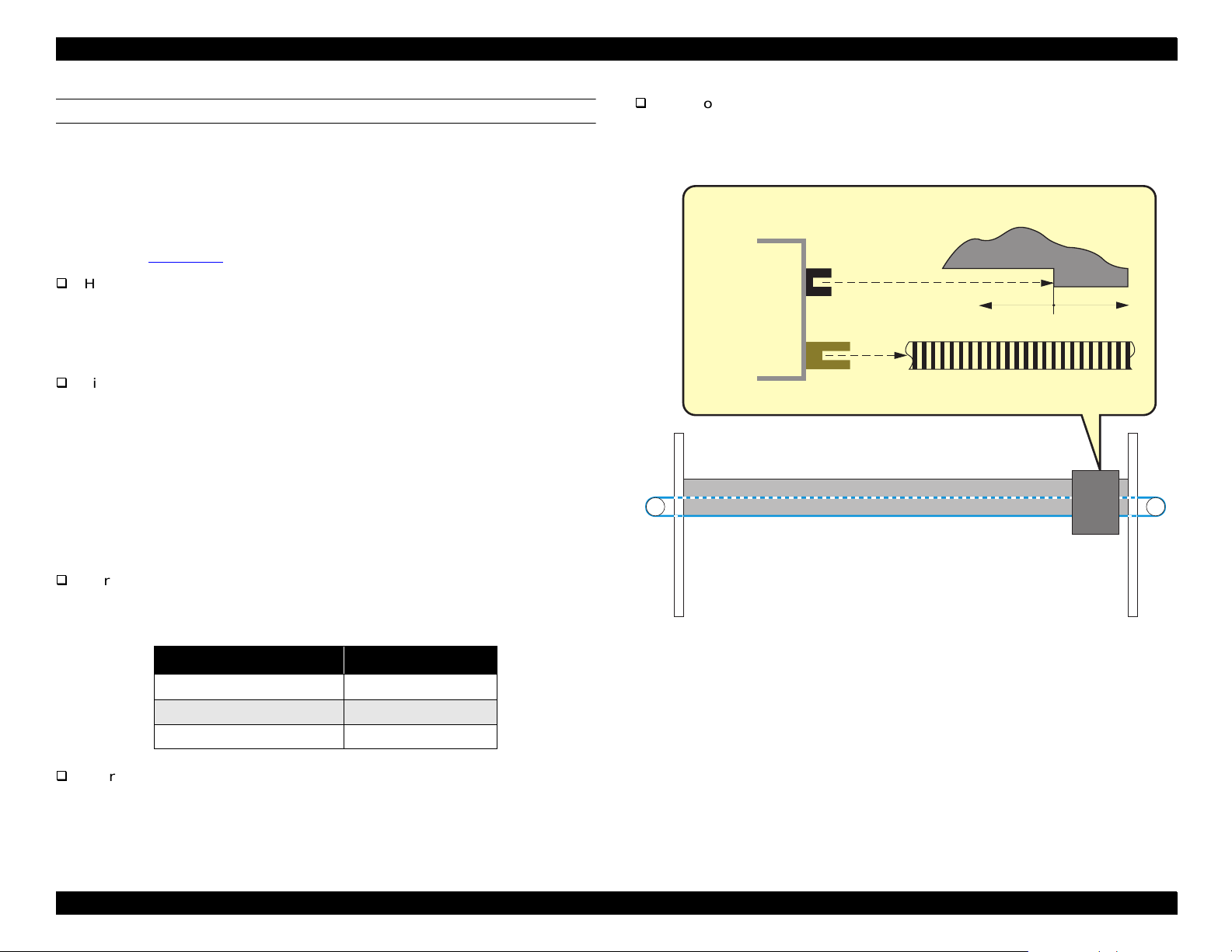

The PF Motor uses a DC motor, which has a built-in optical rotary encoder. The

encoder sends signals to the software servo system, which regulates the

speed of the motor. Motion is transferred through a timing belt to the SpeedReduction Gear, which improves the accuracy of paper feeding.

Platen

Subplaten

Paper

PF Motor

Figure 2-9. Paper Feed Mechanism

Technical Overview 28

Page 29

EPSON Stylus Pro 9000

PAPER FEED SENSORS

The printer relies on the following sensors for paper feeding:

Front Paper Sensor

This optical sensor is attached to the back side of the Lower Paper Guide,

and detects the front edge (top or leading edge) of the paper.

Rear Paper Sensor

This optical sensor is attached to the back side of the Lower Paper Guide,

and detects the rear edge (bottom or trailing edge) of the paper.

Paper Release Lever Position Sensor

The Paper Release Lever is located on the right side of the pri nter, and the

sensor attaches to the bottom of the lever, inside the right-side frame. This

sensor’s signal is ON when the lever is in down, which allows the printer to

print.

Rear Paper

Sensor

Paper Thickness

Sensor

Paper Release

Lever

Front Paper

Sensor

Paper Release Lever

Position Sensor

Figure 2-10. Paper Feed Sensors

Technical Overview 29

Page 30

EPSON Stylus Pro 9000

PAPER SUCTION FAN

The Paper Suction Fans are located behind the lower paper guide and suck air

through the holes in the guide. This keeps the paper from bulging as it feeds

through the printer and prevents ink smears. The table below relates fan speed

to various printer states and user actions.

Table 2-4. Fan Speeds

Fan speed User action Printer action Sensor state LCD message

Level 1 (low) User begins to load paper —

Level 2 (medium) User continues loading paper —

Rear Paper Sensor ON

Front Paper Sensor OFF

Rear Paper Sensor ON

Front Paper Sensor ON

“Load Paper” if Paper

Release Lever UP

“Paper Out” if Paper Release

Lever DOWN

“Load Paper” if Paper

Release Lever UP

“Press Pause Button” if Paper

Release Lever DOWN

Fan goes from

Level 3 (high) to

Off, and then

back to Level 3

(high) during

paper setting

sequence

Off —

Level 3 (high) User sends print data Printing

User lowers Paper Release

Lever and presses Pause, or

user allows several seconds

to pass after lowering Paper

Release Lever and prin ter

automatically ends “Pause”

state

Printer sets paper

Paper loaded and

printer waiting for

print data

Depends on paper’s location

while being set

Rear Paper Sensor ON

Front Paper Sensor ON

Depends on paper’s location

while printing

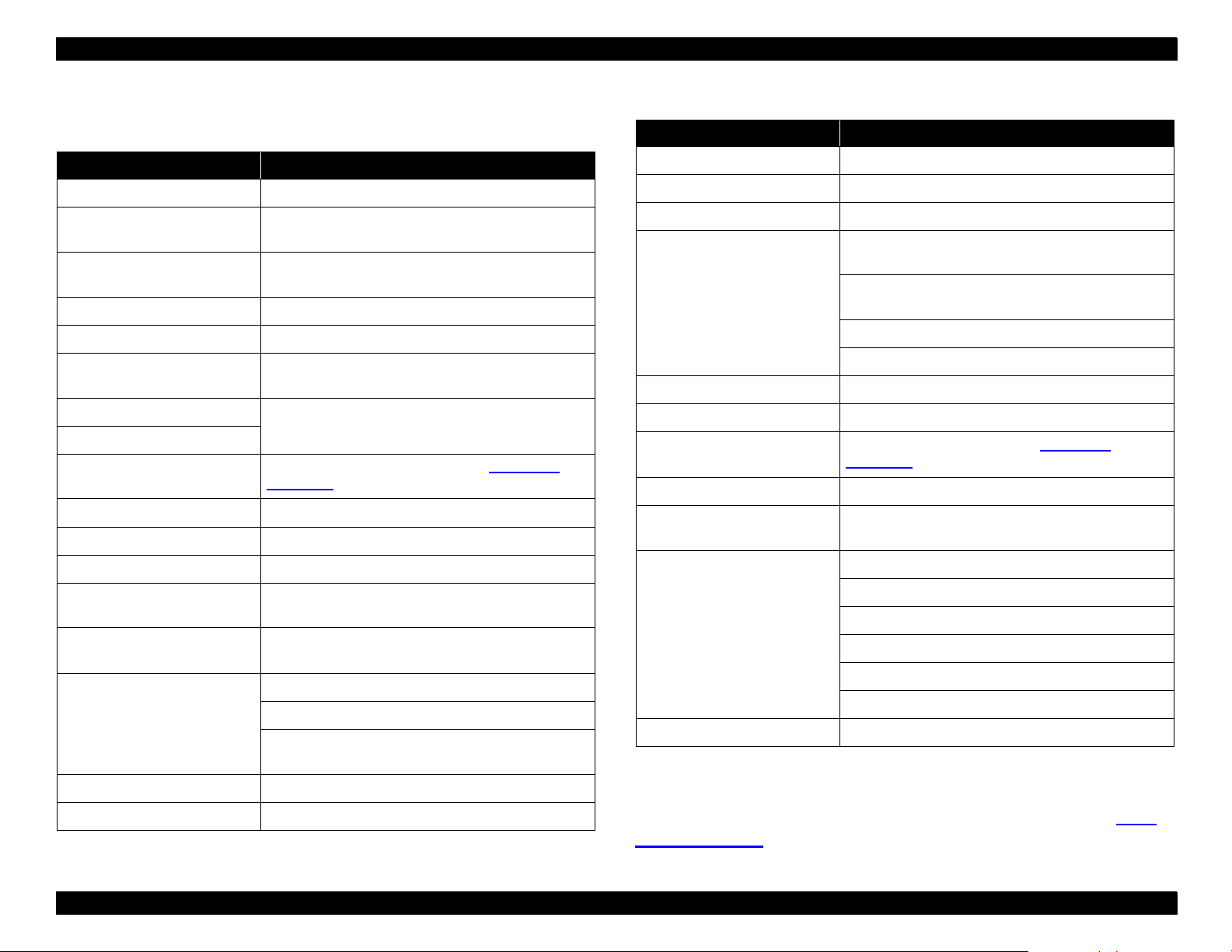

“Wait”

“Ready”

“Printing”

Technical Overview 30

Page 31

EPSON Stylus Pro 9000

PAPER WIDTH DETERMINATION (LEFT AND RIGHT EDGE DETECTION)

Before printing, the printer sets the platen gap and then flushes the printheads

to make sure no ink smears the paper. The printer then detects the left and

right edges of the paper. Note how “left” and “right” are defined below:

Right Paper Edge

Left Paper Edge

Printable Area

To detect the left and right edges, the printer performs the following steps:

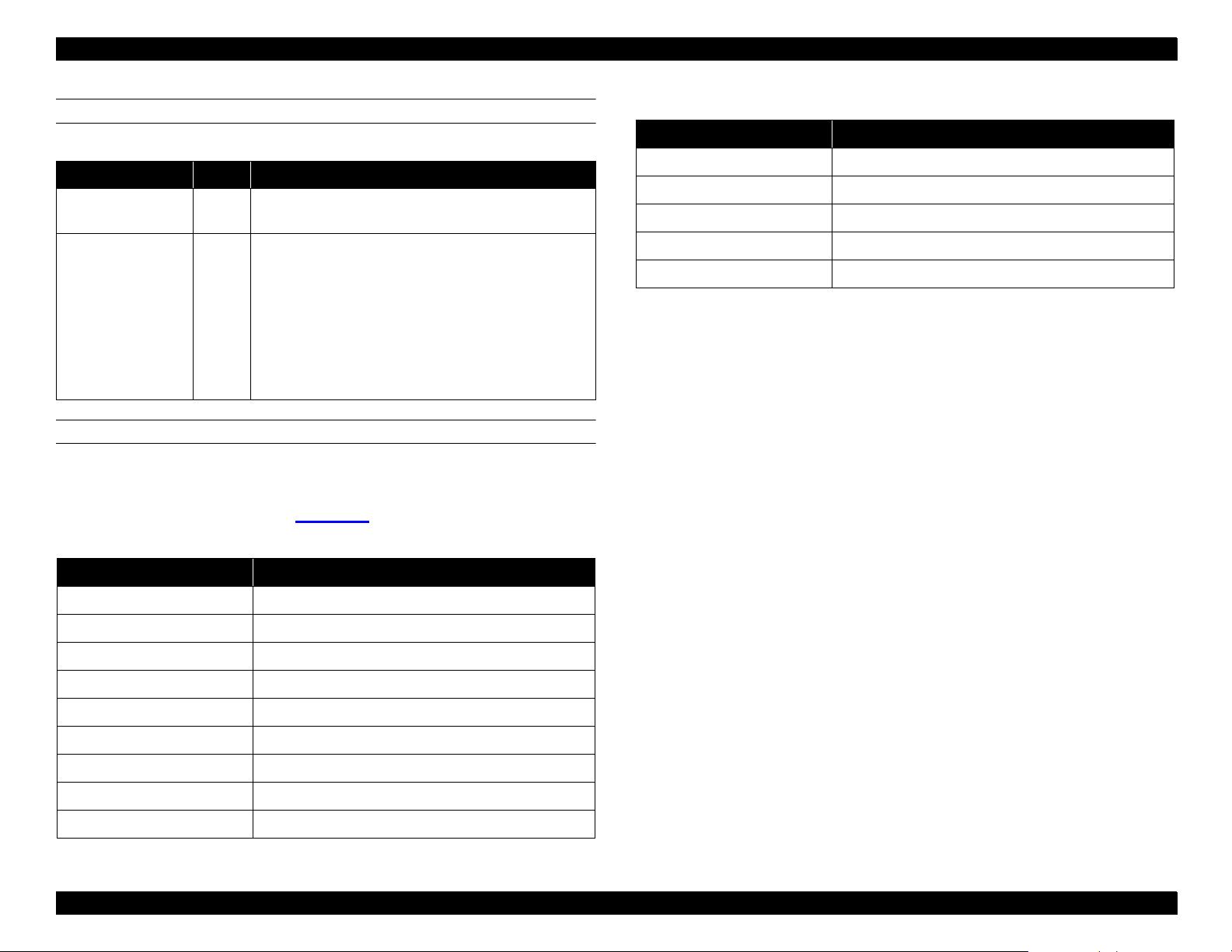

Table 2-5. Left and Right Edge Detection

Purpose Step Action

To make sure

paper is

loaded

correctly

The carriage moves just to t he inside of where the left edge

1

should be, if the paper is loaded correctly.

The Paper Width Sensor checks for paper. If paper is

2

detected, go to step 3; otherwise report “Reload Paper” error.

Table 2-5. Left and Right Edge Detection (continued)

Purpose Step Action

To determine

position of lef t

edge

To determine

position of

right edge

To verify left

edge position

and determine

paper width

The carriage move s to the left paper edge and regi sters its

7

position.

8 The carriage moves to the right edge of the paper.

The Paper Width Sensor checks for paper. If paper is not

9

detected, go to step10; otherwise, report “Reload Paper”

error.

The printer registers the position of the right edge of the

10

paper.

11 The carriage returns to th e lef t paper edge.

The Paper Width Sensor checks for paper. If paper is not

12

detected, go to step13; otherwise, report “Reload Paper”

error.

The printer verifies the edge position and registers the

13

distance from one edge of the paper to the other.

To establish

sensor signal

level

To make sure

paper is

loaded

correctly

To establish

sensor signal

level

The printer registers the sensor’s “paper present” (ON) signal

3

level.

The carriage moves just to t he outside of where the left edge

4

should be, if the paper is loaded correctly.

The Paper Width Sensor checks for paper. If paper is not

5

detected, go to step 6; otherwise report “Reload Paper” error.

The printer registers the sensor’s “no paper” (OFF) signal

6

level.

Technical Overview 31

Page 32

EPSON Stylus Pro 9000

PAPER SIZE DETERMINATION (DETECTION OF TOP EDGE)

If the printer is in Roll Auto Cut or (Cut) Sheet mode, it determines the location

of the top (leading) edge of the paper before printing. Note that the printer skips

this procedure if Roll Cutter Off is selected.

The “top-left” and “top-right” edges are as shown below. Note that the top edge

may not be straight across.

Printable Area

Top-R i ght Pape r Edge

After determining the position of the left and right edges of the paper (see

Paper Width Determination (Left and Right edge Detection)

the printer performs the following steps to locate the top edge and correctly

position the paper for printing:

Top-Left Paper Edge

on page 31),

Table 2-6. Top Edge Detection and Positioning

Purpose Step Action

Printer reverse feeds (pulls paper back up) a maximum

To make sure

paper is

loaded

correctly

To determine

top-left edge

position

To determine

top-right edge

position

To ready

carriage for

printing

1

distance of 200mm.

The Front Paper Sensor checks for paper. If, during rever se

2

feeding, it detects the top edge of the paper, go to step 3;

otherwise, report “Reload Paper” error.

Carriage moves from home posit ion to 30 mm inside lef t edge

3

of paper.

4 Printer reverse feeds 200 mm max.

The Paper Width Sensor checks for paper. If, duri ng reverse

5

feeding, it detects the top edge of the paper, go to step 6;

otherwise, report “Reload Paper” error.

6 Printer registers top-left edge position.

7 Carriage moves to 30 mm inside right edge.

The Paper Width Sensor checks for paper. If it det ects paper,

the printer reverse feeds paper until Paper Width Sensor

8

detects top-right edge. If paper n ot detected, printer advances

paper until Paper Width Sensor detects top-right edge.

9 Carriage returns to home position.

To set paper

for printing

Printer advanc es paper so that the shorter of the two edges

10

(top-left or top-right ) aligns with a position approx imately 1 cm

below the level of the Fr ont Paper Sensor.

Technical Overview 32

Page 33

EPSON Stylus Pro 9000

PAPER LOADING ERRORS

“Reload Paper” Error

After paper is loaded in the printer, the printer performs the left, right, and

leading edge detection operations described above. If the operations fail at

any point, a “Reload Paper” error occurs.

“Paper Not Straight” Error

To avoid printing on paper that is skewed or fed at a slant too far to the

right or left, the printer detects the right and left edges at the leading edge

of each page. If the printer determines that the paper is skewed 3 mm or

more from the position previously detected, a “Paper Not Straight” error

occurs.

To avoid paper loading errors, make sure the paper’s left edge (near HP) is

lined up with the vertical line of holes in the Lower Paper Guide. Paper loaded

within 10 mm of the center of the vertical line of holes in the Lower Paper Guide

is considered in the printable zone; however, paper loaded outside that 10 mm

zone causes an error.

2.2.3 C arriage Lock Mechanism

The printer uses an electromagnetic solenoid to release the carriage lock.

When the carriage lock does not receive any signal, the actuator rises into the

opening at the bottom of the subcarriage, restricting carriage movement. To

release the carriage for printing, the printer signals the actuator which then

moves down, releasing the carriage.

Carriage Cover

Locking Actuator

CR Lock

Release

Lever

Figure 2-11. Carriage Lock Mechanism

Technical Overview 33

Page 34

EPSON Stylus Pro 9000

2.2.4 Ink Supply Mechanism

The two ink cartridge holders each hold three cartridges, K, C, and M on one

side and Lc, Lm, and Y on the other side. The design of the holders makes it

quite easy to install and replace ink cartridges from the front of the printer. The

I/H Lever opens and closes the I/H door, and at the same time it changes the

angle of the Ink Cartridge Holder Assembly as shown in

page 34. To prevent users from accidently installing a color ink cartridge in the

wrong slot, the cartridges have slightly different designs.

Another important feature of the ink cartridge holders is the ink valve, which is

located on the outer sides of the ink cartridge holders. It can be used to shut off

the flow of ink during printer transportation. The valve is closed when:

the user turns the valve to the “CLOSE” position

the I/H lever is lifted to install cartridges

When the valves are open, the ink flows out of the ink cartridges, through the

stainless steel pipes, through the ink tubes, and finally into the printheads.

Figure 2-12

on

I/H Lever

Ink Cartridge

Holder Assembly

Figure 2-12. Ink Supply Mechanism

Technical Overview 34

Page 35

EPSON Stylus Pro 9000

INK-RELATED SENSORS

The following sensors are located in the I/H compartment:

I/H Assembly sensor

This optical sensor detects the whether the door is open and the I/H

Assembly is in the install position or the door is closed and the I/H

Assembly is in the print position.

When the I/H door is open, the signal = ON

When the I/H door is closed, the signal = OFF

Ink Cartridge sensor

This mechanical sensor (microswitch) is built in all six ink cartridge slots.

When the I/C is installed, switch = closed

When the I/C is not installed, switch = open

Ink Low sensor

This mechanical sensor (microswitch) is at the bottom of all six ink

cartridge slots and detects when ink is running out.

When the I/C is nearly empty, the switch = open

When the I/C is not low (normal), the switch = closed

Ink ID sensor

This optical sensor is located on the side of all six ink cartridge slots and

detects which market the cartridge is for. Although not currently

implemented, the sensor can also detect the type of ink (presently dye

only) and any special color (if new colors are introduced in the future).

The Ink ID sensor looks for the following marks on the ink cartridge.

Ink Cartridge

Figure 2-13. Ink Cartridge Holder Sensors

Ink ID Sensor

Ink Low Sensor

Ink Cartridge Sensor

Market: No mark, white = Overseas/Global

Ink type: No mark, white = dye-based ink

Special color: No mark, white = N/A (may be available in future)

Technical Overview 35

Page 36

EPSON Stylus Pro 9000

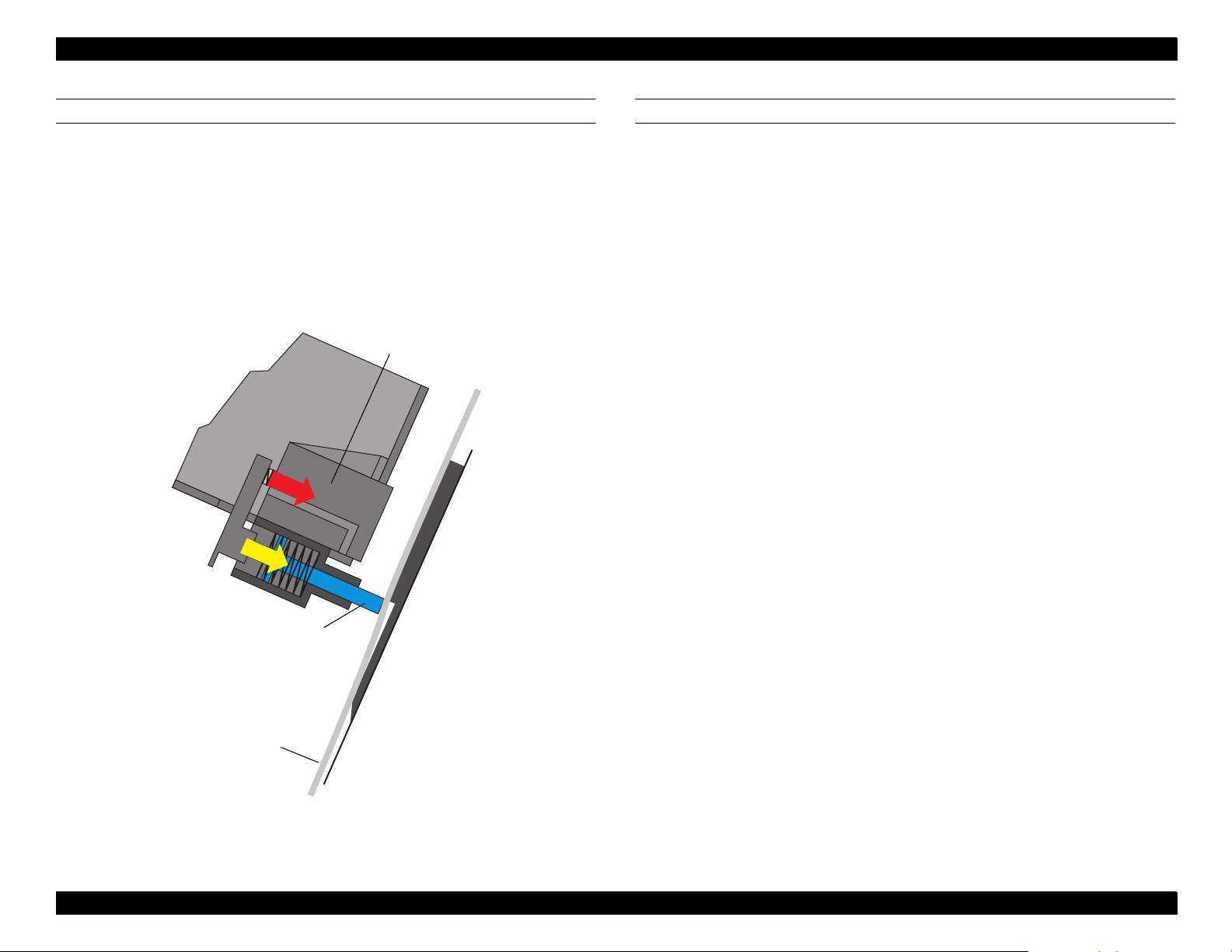

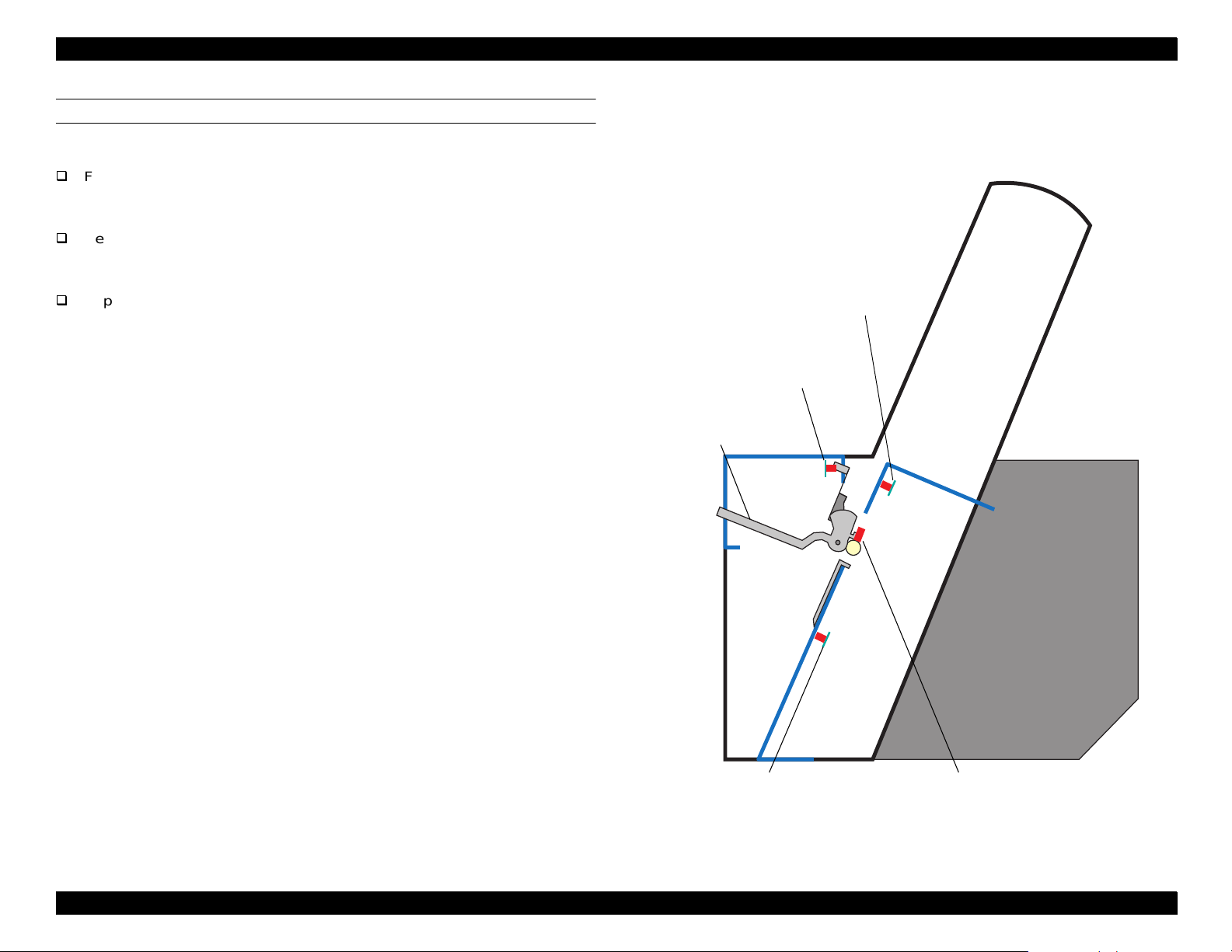

2.2.5 Cover Ope n Se ns or

There are two cover open sensors, or safety interlock switches, one on each

side of the printer, that detect when the cover is open. When the cover is open,

relays that control current to the CR motor and PF motor cut off the flow of

current. As shown in

from damaging drivers and other circuitry when the relays shut off.

Figure 2-15

Front

Cover

, a bypass capacitor prevents current spikes

CR

Motor

PF

Motor

Driver

Front Co v er

open

Cover Open

Sensor

Figure 2-14. Cover Open Sensor

Driver

C126/127

Figure 2-15. Relay Circuit Between Cover Open Sensors and

Printer Motors

Technical Overview 36

Page 37

EPSON Stylus Pro 9000

2.2.6 Control Circuit

This section summarizes the functions of the (C277MAIN) Main Board.

Motor

drivers

Printer

mechanism

IC8

CPU/C90A08CA

(SH7043)

IC13

ASIC/E05B61AA

IC32

ASIC/uPD65802

IC33

Motor

CR

IC35

PF

Motor

IC20

ASIC/TE7751

IC30

PG

Motor

CN7

Control Panel

IC31

Pump

Motor

IC39

SRAM/8KB

IC18/19

DRAM/2MB

CN19

RAM-SIMM/16MB

IC1/2

Flash mem./1MB

CN20

PC Card connector

Head data & control signals

IC37

DAC/M65530FP

B head C head

Head-drive voltage

common driver

Printheads (B/C)

CN2

Type-B Slot

CN3

Mac Serial I/F

CN1

Parallel I/F

Fixed

-Firmware

-Setting parameters

Head-drive wave

generation

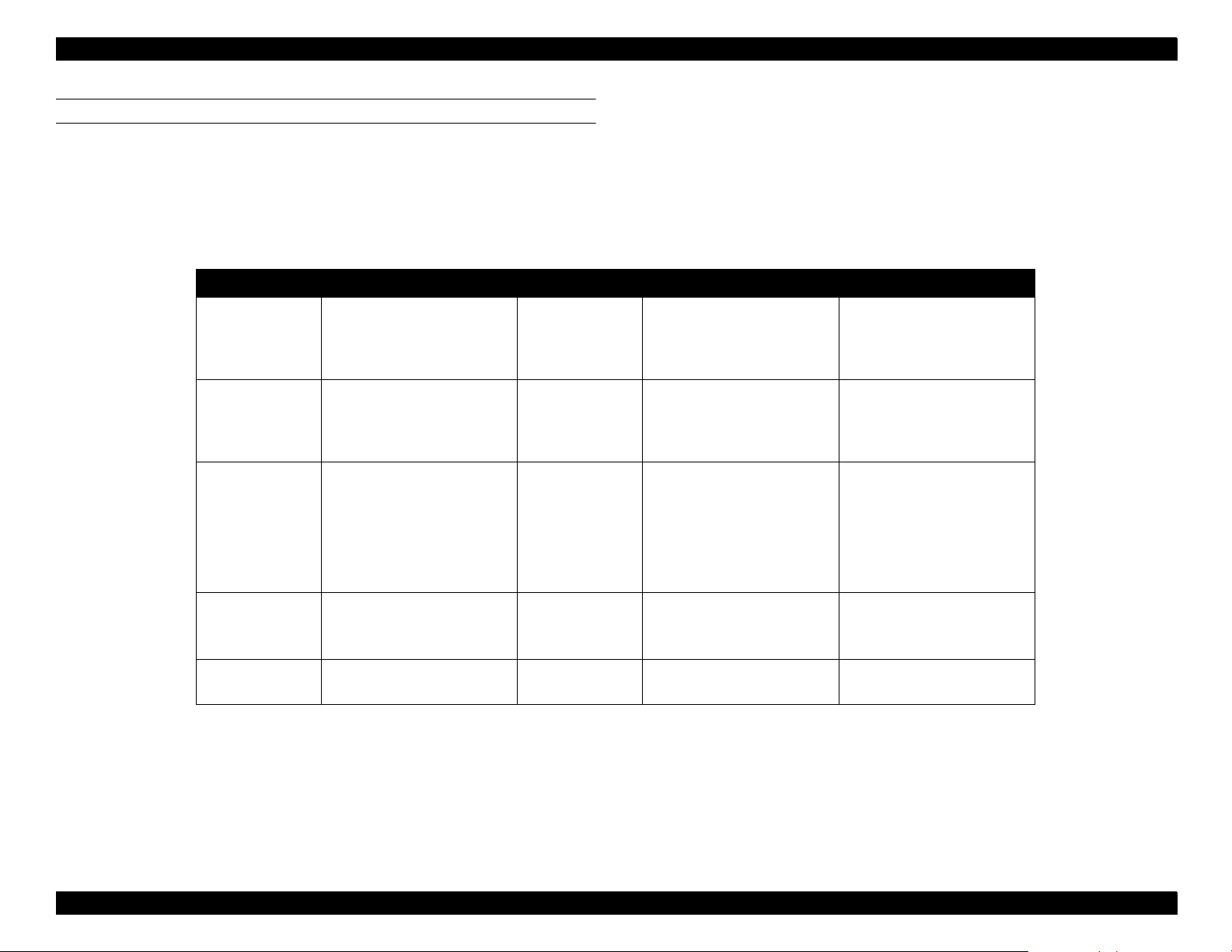

Table 2-7. C277MAIN Board Main Components

Name/Code Location Function

CPU (C90A08CA)

SH7043

IC8

ASIC (E05B61AA) IC13

ASIC (TE7751) IC20

ASIC (uP D65802) IC32

DAC (M65530FP) IC37

Flash Memory

(MBM29F400TC)

IC1/2

DRAM (EDO) IC18/19

SRAM (LC3564SM-

10)

IC39

Driver IC (L6203) IC33/35 CR/PF Motor Driver

Driver IC (LB1845) IC30/31 PG/Pump Motor Driver

32 bit RISC-CPU

Clock speed = 33M H z

128KB PROM internal

Regulates print data

Command handling

Rasterizer (image da ta handling)

Head drive regulation (DAC)

Print timing regulation

Memory (DRAM /SR AM)

I/F Circuit Control

Parallel interface (IEEE1284)

Macint osh Serial interface

Type-B

Regulates Motor

Pump Motor

PG Motor (PG setting)

Fan (PS, Paper Suction)

Regulates motor (PWM regul ation)

CR Motor

PF Motor

3 channel 10 bit DA converter

head-drive voltage control

Fla sh Me mory (1Mbyte)

Save firmware

Register setting parameters

EDO RAM

2Mbyte

16Mbtye (CN19 mounted SIMM)

64Kbit SRAM

External da ta ring buffer type

Figure 2-16. C277MAIN Board-Circuit Block Diagram

Technical Overview 37

Page 38

TROUBLESHOOTING

Page 39

EPSON Stylus Pro 9000

3.1 Overview

To troubleshoot printer problems, turn to one of these sections:

If the LCD display shows an error message, see

LCD Error Messages

Since an LED or LCD error message may indicate a loose cable connector,

see also

If you notice problems with print quality such as missing dots or lines,

misaligned vertical lines, or banding (faint white lines), see

Troubleshooting

Connector-Related Errors

on page 39.

on page 52.

on page 49.

Trouble shooting Usi ng

Print Quality

3.2 Troubleshooting Using LCD Error Messages

The EPSON Stylus Pro 9000 performs self-diagnostic tests using the data