Page 1

Model 8900 Series Printer

Technical Reference Manual

5321 Buffalo Road • Erie, PA 16510

800-570-4533 • www.fastprinters.com

Page 2

Contents

Preface ............................................................................................... v

1 General Information

Introduction .................................................................................... 1-2

Paper-Handling System .................................................................. 1-2

Printer Features............................................................................... 1-3

Printer Quality ................................................................................ 1-4

Raster Graphics .............................................................................. 1-6

2 Printer Setup

Introduction .................................................................................... 2-3

Model 8900 Series Emulation Modes ............................................ 2-5

Miscellaneous Setup Parameters .................................................. 2-14

Test Features ................................................................................. 2-18

3 Character Sets and Global Commands

Introduction .................................................................................... 3-2

Character Code Table ..................................................................... 3-2

Character Sets................................................................................. 3-3

Control Characters........................................................................ 3-16

Printer Commands ........................................................................ 3-18

Global Command Set.................................................................... 3-19

Global Command Descriptions .................................................... 3-19

4 TI Model 880 Printer Emulation

Introduction .................................................................................... 4-4

Model 880 Printer Emulation Commands ...................................... 4-6

Model 880 Command Descriptions.............................................. 4-10

5 TI Model 855 Printer WP Emulation

Introduction .................................................................................... 5-4

Motion Indexes ............................................................................... 5-5

Model 855 WP Commands............................................................. 5-6

Model 855 WP Command Descriptions......................................... 5-9

ii

Page 3

Contents

6 Tl Model 855 Printer DP Emulation

Introduction .................................................................................... 6-3

Model 855 DP Command Descriptions.......................................... 6-7

7 IBM Proprinter XL Emulation

Introduction .................................................................................... 7-4

IBM Proprinter XL Emulation Commands .................................... 7-5

IBM Proprinter XL Command Descriptions .................................. 7-7

8 Epson FX Printer Emulation

Introduction .................................................................................... 8-5

Epson FX Printer Emulation Commands ....................................... 8-7

Epson FX Emulation Command Descriptions ............................. 8-10

9 Optional Emulation Commands

Introduction .................................................................................... 9-2

DEC LA120 Emulation Commands ............................................... 9-2

Answerback Memory Function ...................................................... 9-5

New Line Mode .............................................................................. 9-5

Auto Wrap ...................................................................................... 9-6

Answerback Memory Message Load ............................................. 9-6

10 Communication Interfaces

Introduction .................................................................................. 10-3

Data-Transfer Operations ............................................................. 10-4

Parallel Communication Interface ................................................ 10-6

Serial Communication Interface................................................. 10-14

Optional Communication Interfaces........................................... 10-21

Appendix

Application Instructions ................................................................ A-1

Index

iii

Page 4

Copyright © 2001 by Lake Erie Systems

All Rights Reserved — Printed In U.S.A.

Model 8900 Series Printers

Technical Reference Manual

Part No. 2557824-0002

Original Issue: August 1989

Revision F: January 2001

Changes may be periodically made to the information in this publication.

Such changes will be incorporated in new editions of this manual.

Record the serial number, purchase date, and firmware revision

number in the spaces provided below. The serial number and firmware

revision are recorded on the label affixed to the rear of the unit. All

correspondence concerning your unit should include the serial

number, firmware revision, and date of purchase.

Serial Number: ____________ Purchase Date: ____________

Firmware Revision: ___________________________________

No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopy,

recording, or otherwise, without the prior written permission of Lake Erie Systems.

This printer, as well as the programs that Lake Erie Systems has created to use with

it, are tools that can help people better manage the information used in their

business: but tools—including Lake Erie Systems products—cannot replace sound

judgment nor make the manager’s business decisions.

Consequently, Lake Erie Systems cannot warrant that its products are suitable for

any specific customer application. The manager must rely on judgment of what is

best for his or her business.

Page Finder, Z-Axis control, and Rapid Print are trademarks of Lake Erie Systems.

Epson is a registered trademark of Seiko Epson Corporation.

IBM is a registered trademark and Proprinter is a trademark of International

Business Machines Corporation.

iv

Page 5

Preface

This manual contains technical information about the Model 8900

Series Printers. This information supplements the information

contained in the Model 8900 Series Printer User’s Manual Part No.

2557785-0002 and is essential to programmers, system managers,

and other technically oriented people.

The information in this manual is presented in individual sections so

you can skip pages with information you already know or that does

not apply to your particular application.

Symbols Used in This Manual

Two international symbols are used throughout this manual to advise

you of important information.

This symbol indicates a Note concerning operating procedures

or information you should know to help you operate your

printer.

This symbol alerts you to a Warning or Caution which

can prevent you from causing a hazard to yourself or to

your printer.

Contents

Chapter 1 — General Information provides a general description

of the Model 8900 Series Printer and brief information about some

of the principals of dot-matrix printing.

Chapter 2 — Printer Setup provides information about printer

configuration. Specifically, this chapter describes the control panel

switch functions and the setup/test menu. This information supplements

the information contained in Chapter 4 of the Model 8900 Series

Printer User’s Manual, Part No. 2557785-0002.

v!vi

Page 6

Chapter 3 — Character Sets and Global Commands provides

general information about character sets and their use in the Model

8900 Series Printer and describes the commands that are valid for all

emulation modes, both standard and optional. These commands

provide control of the basic features of the Model 8900 Series

Printer.

Chapter 4 — Texas Instruments Model 880 Printer Emulation

describes the commands of the Model 880 Printer command set and

provides information about operating the Model 8900 Series Printer

in the Model 880 Printer emulation mode.

Chapter 5 — Texas Instruments Model 855 Printer WP Emulation

describes the commands of the Model 855 Printer WP emulation

command set and provides information about operating the Model

8900 Series Printer in the Model 855 Printer WP emulation mode.

Chapter 6 — Texas Instruments Model 855 Printer DP Emulation

describes the commands of the Model 855 Printer DP emulation

command set and provides information about operating the Model

8900 Series Printer in the Model 855 Printer DP emulation mode.

Chapter 7 — IBM Proprinter XL Emulation describes the

commands of the IBM Proprinter XL command set and provides

information about operating the Model 8900 Series Printer in the

IBM Proprinter XL emulation mode.

Chapter 8 — Epson FX Printer Emulation describes the commands

of an Epson FX printer command set and provides information about

operating the Model 8900 Series Printer in the Epson FX printer

emulation mode.

Chapter 9 — Optional Emulation Commands describes optional

emulation commands available for the Model 8900 Series Printer.

Chapter 10 — Communication Interfaces describes the standard

parallel and serial communication interfaces used with the Model

8900 Series Printer.

Page 7

Appendix — Application Instructions explains how to use the Z-axis

printhead adjustment escape sequence and how to clean the automatic

page finder sensor.

Other Manuals About the Printer

The following manuals are available to help you learn more about

your printer and to help you operate and maintain the printer.

Title Part Number

Model 8900 Series Printer Quick Reference Guide 2557786-0002

Model 8900 Series Printer User’s Manual 2557785-0002

Model 8900 Series Printer Maintenance Manual 2557788-0001

Model 8900 Series Printer Safety Instructions 2557807-0002

Supplies

2551152-001 1 Ribbon Cartridge, Black

2551152-0014 Ribbon Cartridge, Color

You can order the Model 8900 Series Printers, manuals, ribbons and

spare parts from LAKE ERIE SYSTEMS AND SERVICES by

calling toll free: 1-800-570-4533

or online at www.fastprinters.com

Purchase Orders can be sent to:

LAKE ERIE SYSTEMS

5321 Buffalo Road

Erie PA 16510

or may be faxed to: 814-899-1384

vii

Page 8

1

General Information

Introduction .................................................................................... 1-2

Paper-Handling System .................................................................. 1-2

Printer Features............................................................................... 1-3

Print Quality ................................................................................... 1-4

Raster Graphics .............................................................................. 1-6

General Information 1-1

Page 9

Introduction

The Model 8900 Series Printer is one of a family of rugged, highperformance, dot-matrix impact printers, which forms letters,

numbers, and other symbols by printing dot patterns. The printer offers

a variety of common and unique features, such as multiple paper

paths and paper-feed methods, selectable print-quality settings, zero

paper tear-off to prevent waste of paper and forms, and color printing.

This chapter provides general information about the printer.

Paper-Handling System

Both models (8930 and 8920) of the Model 8900 Series Printer can

print heavy-duty multipart continuous forms. In addition, the 8930

can accept hand-inserted cut-sheet paper. Upon completion of a

printing operation, the printer automatically positions the tear-off

perforation even with the tear-off bar to allow removal of the printed

document.

A useful feature of the printer is its ability to park continuous paper

out of the print station area for unloading the paper supply or for

switching to another paper-handling mode. This feature lets you

switch instantly from continuous paper operation to cut-sheet paper

insertion (Model 8930).

Each time you load continuous paper or insert cut-sheet paper, the

printer automatically positions the paper and adjusts the printhead.

The Page Finder

the top, left, and right edges of the paper and sends this information

to the printer electronics. The printer uses this information to adjust

the paper to the top-of-form position and to adjust the printhead to

operate within the left and right boundaries of the paper, regardless

of the paper width. The Z-Axis Control™ motor adjusts the printheadto-paper (z-axis) clearance to its optimum value, regardless of the

thickness of the paper or form set.

™

sensor (located on the printhead carriage) detects

General Information 1-2

Page 10

All paper-handling operations are accessible through the control

panel and via the host computer using global commands.

Printer Features

The Model 8900 Series Printer includes the following features.

q Print quality choices — letter-quality (LQ), text, normal draft,

™

and Rapid Print

draft

q Standard character sets — US ASCII (with 13 international

®

substitution tables), IBM

PC1, IBM PC2, IBM Multinational,

ISO 8859/1 Multinational and Nordic PC

q Character spacing (pitch) — 5.0, 6.0, 7.5, 8.6, 10.0, 12.0, 15.0,

16.7 and 17.1 characters per inch (cpi), depending on the

emulation mode in effect

q Line length — 13.6 inches (345.44 mm) maximum

q Maximum character columns — 136 at 10.0 cpi, 163 at 12.0 cpi,

204 at 15 cpi, and 227 at 16.7 cpi

q Line spacing — 3, 4, 6 and 8 lines per inch (lpi)

q Line feed modes — forward and reverse full or one-half line (for

superscript and subscript characters)

q Print enhancements — bold, emphasized, underlined, and

expanded with true descenders (for lowercase characters such as

g, j, and y)

q Standard fonts — Courier and Gothic

q Optional fonts — Prestige Elite, Presenter, Barcode 3 of 9,

Interleave 2 of 5, OCRA, OCRB and PostNet

General Information 1-3

Page 11

q Graphics capabilities — vertical raster graphics (all points

addressable)

q Color printing — up to seven colors, including black, for both

text and graphics (standard on Model 8930 and optional on

Model 8920)

®

q Resident emulation modes — TI 880, TI 855, Epson

FX and

IBM Proprinter XL

q Standard communication interfaces — serial (RS-232 or RS-423

specified by customer when purchasing the printer) and parallel

q Optional communication interfaces — RS-422 serial and current

loop (TTY)

Print Quality

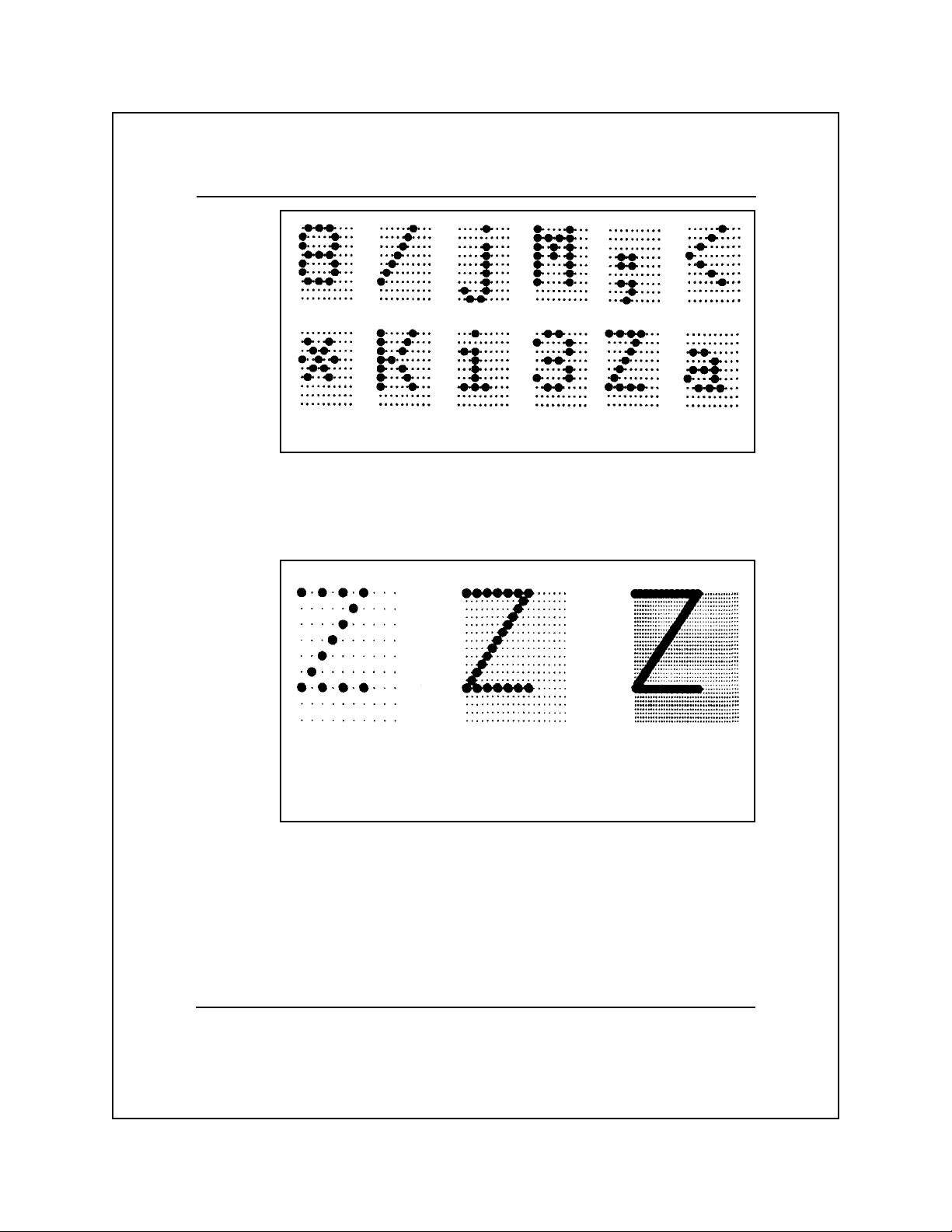

The dot-matrix impact printhead forms a character by printing dots

in a rectangular arrangement of dot cells called a dot matrix.

The following figure shows some examples of dot-matrix characters.

Each character is printed in a 7-dot by 9-dot matrix. Three columns

of blank dots at the right side of each character, the intercharacter

space, provide the proper horizontal spacing between characters.

General Information 1-4

Page 12

typical dot-matrix characters

Quality can be improved by increasing the dot density (resolution),

as shown in the following figure. Dot density is expressed in dots per

inch (dpi).

low-resolution

character

medium-resolution

character

high-resolution

character

effect of increasing dot density

The Model 8900 Series Printer offers four levels of print quality,

based on the dot density and the placement of dots on the matrix.

The increased dot density at higher print-quality levels decreases the

print speed.

General Information 1-5

Page 13

The printer offers the following print-quality levels and speeds.

q Letter quality (LQ) — high-resolution, 32-dot by 18-dot characters

at 100 characters per second (cps).

q Text quality — medium-resolution, 15-dot by 9-dot characters at

240 cps.

q Normal draft quality — low-resolution, 9-dot by 9-dot characters

at 400 cps.

q Rapid Print draft quality — low-resolution, 7-dot by 9-dot

characters. This mode is only valid for character spacings

(pitches) of 12 characters per inch (cpi) and 15 cpi. These

character pitches allow the printer to print at speeds of 480 cps

and 600 cps, respectively.

Raster Graphics

The all-points-addressable raster graphics mode lets you use your

printer to produce pictorial material, such as charts, graphs, special

characters, or almost any design you can devise. Special commands

allow you to design images of any shape by causing the printhead to

print dots in the appropriate places. (See Chapters 4 through 8 for

information about raster graphics commands.)

The best way to print graphics is to use one of the many commercially

available application programs. These programs let you design

images by drawing them on your computer monitor and then issuing

a command to send them to your printer.

General Information 1-6

Page 14

2

Printer Setup

Introduction .................................................................................... 2-3

Model 8900 Series Emulation Modes ............................................ 2-5

TI 880 Emulation....................................................................... 2-6

Execute Commands .............................................................. 2-6

Line Feed and Carriage Return Upon Receipt of LF............ 2-6

Line Feed and Carriage Return Upon Receipt of CR ........... 2-7

Carriage Return Upon Receipt of LF, VT, or DC2............... 2-7

Graphics................................................................................ 2-7

Shift Out Equals Expanded Print.......................................... 2-7

TI 855 Emulation....................................................................... 2-8

Processing Mode................................................................... 2-8

Automatic Line Feed ............................................................ 2-8

IBM Proprinter XL and Epson FX Emulations ......................... 2-8

Automatic Line Feed ............................................................ 2-8

Automatic Carriage Return................................................... 2-9

Slashed Zeros........................................................................ 2-9

Hexadecimal Dump Mode......................................................... 2-9

Interface Parameters ................................................................ 2-10

Port .......................................................................................... 2-10

Buffer Size............................................................................... 2-10

Baud Rate ................................................................................ 2-11

Data Bits .................................................................................. 2-11

Parity ....................................................................................... 2-11

Flow Control............................................................................ 2-11

XON/XOFF (transmit-on/transmit-off)................................... 2-12

Robust XON/XOFF................................................................. 2-12

ETX/ACK (end-of-text/acknowledge) ............................... 2-13

Connection............................................................................... 2-13

DTR (Pin 20) ...................................................................... 2-13

PIN 11 ................................................................................. 2-13

Printer Setup 2-1

Page 15

Miscellaneous Setup Parameters .................................................. 2-14

Character Set ........................................................................... 2-14

Z-Axis Control......................................................................... 2-15

Ribbon Type ............................................................................ 2-15

Ribbon Adjust.......................................................................... 2-15

Idle Delay................................................................................. 2-16

Power-Up Online ..................................................................... 2-16

Paper Pull-Down Warning ....................................................... 2-16

Graphics Printing Mode ......................................................... 2-17

LCD Language......................................................................... 2-17

Paper Out Equals Busy ............................................................ 2-17

Limiting Control Panel Operation ........................................... 2-17

Test Features ................................................................................. 2-18

Printer Setup 2-2

Page 16

Introduction

The Model 8900 Series Printers are compatible with a wide range of

computers and application software. The printer menu structure

enables you to select and alter the fundamental printer operating

parameters to fit the requirements of your computer, its communication

interface, and its application software. You can set these parameters

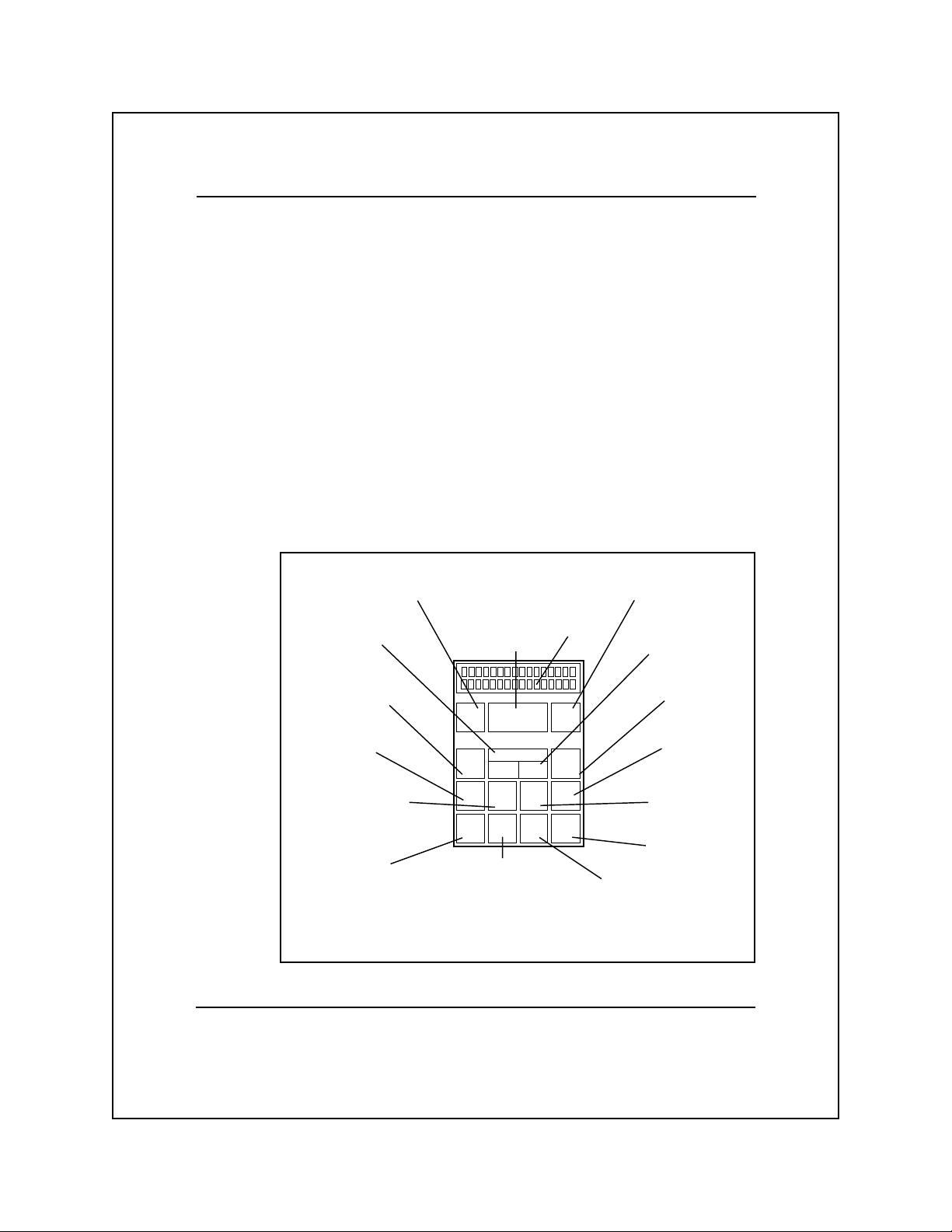

via the operator control panel (see the following figure).

To set up the printer, you set the various printer parameters to meet

the requirements of your computer system. (Refer to your computer

operator’s manual for more information.) After you set the parameters

to the required values, the printer stores these settings in its nonvolatile

random-access memory (NVRAM). Because the NVRAM retains

information even when the printer is without power, the printer

retains these settings until you change them.

function switch associated with messages

and symbols shown at the left end of the

display (loads form on 8930)

selects one of ten preset

form formats or forms

settings report

allows you to select the

primary paper path or an

alternate paper path

selects one of four

character spacing

choices

selects one of three print

quality choices

allows you to get a report

of current printer settings,

test basic printer

functions, and change

printer features

F1

Paper

Path

Pitch

Setup/

Test

causes the display to

show a brief summary

of printer status and

current printer settings

operator control panel

select items

shown on the

display (loads

form on 8920)

Form

Config.

Select

Quality Font Clear

Status Form

Align

function switch associated with

messages and symbols shown at the

display

F2Select

On Line

Error

Form

Feed

which lets you move the paper up

right end of the display

allows you to change

form format values

selects online or

offline operation

clears error messages

from the display

selects one of the

standard fonts or an

optional font

advances paper to the

top of the next form

invokes the form align screen

or down in the print station

Printer Setup 2-3

Page 17

Note: The Model 8900 Series Printers User’s Manual (Part No.

2557785-0002) explains the basic use of the operator control panel

and its associated menu structure.

The Setup/Test switch on the control panel lets you enter the setup/

test menu. This menu consists of the following submenus containing

most of the printer setup parameters and test features.

q Emulation mode — The emulation mode submenu lets you

select an emulation mode and set its parameters. This submenu

also lets you select the hexadecimal dump mode.

q Interface parameters — The interface parameters submenu lets

you set the serial communication parameters to the values

required by the host computer and by the communication interface.

q Miscellaneous parameters — The miscellaneous parameters

submenu lets you select various printer features, both standard

and optional.

q Test mode — The test mode submenu lets you select the printer

test features.

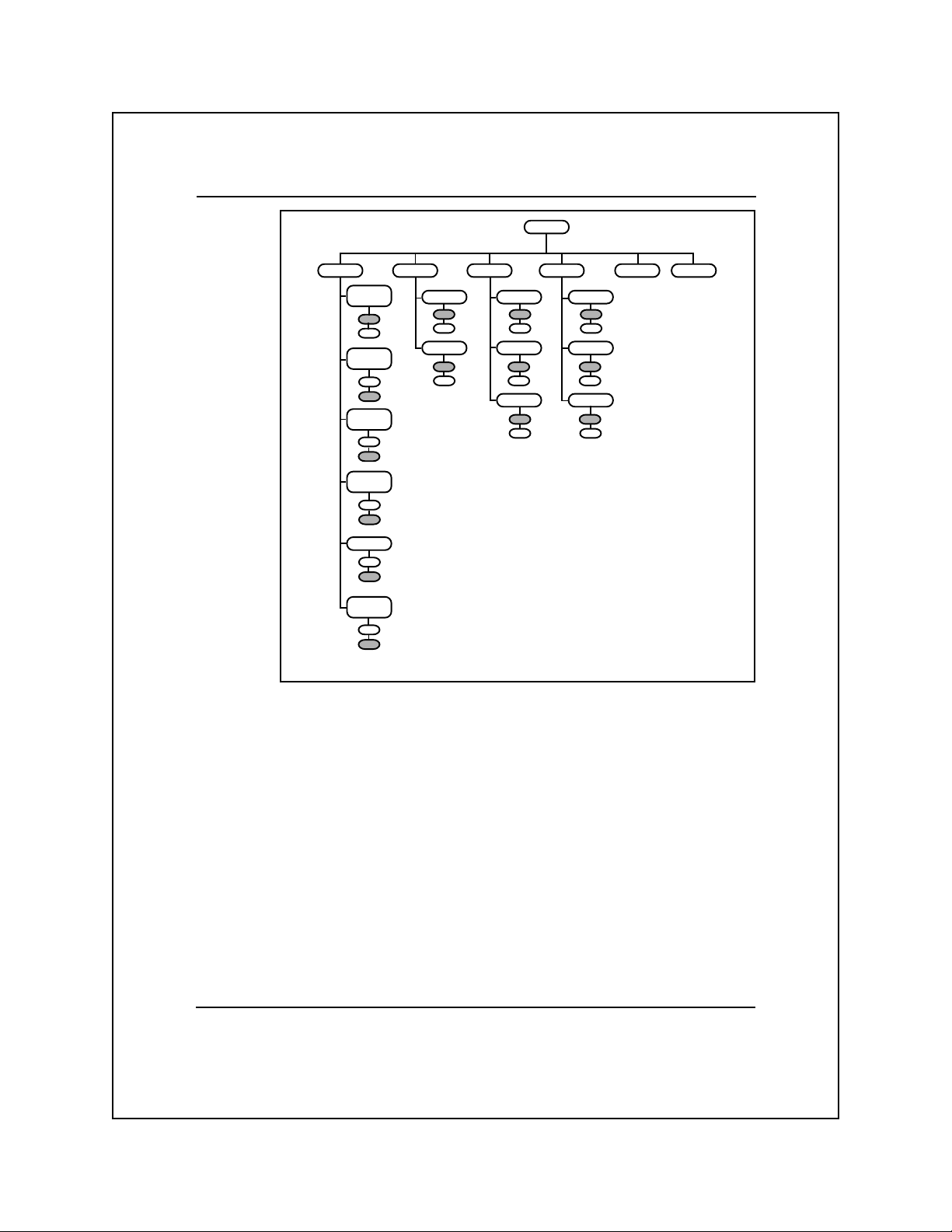

The following figure shows the setup/test menu and the following

paragraphs describe the setup/test submenus.

Setup/

Test

Emulation

setup/test menu

Interface Misc Test Mode

Printer Setup 2-4

Page 18

Model 8900 Series Emulation Modes

The emulation mode determines how the printer responds to commands

from the host computer and determines the specific set of commands

to which the printer responds. For example, if you select the TI 880

emulation mode, the printer emulates the functions of the TI Model

880 Printer and responds to the set of commands designed for that

printer.

The emulation mode submenu lets you choose one of the following

emulation modes or select the hexadecimal dump mode.

q TI Model 880 printer (default)

q TI Model 855 printer

q IBM Proprinter XL

q Epson FX printer

q Optional

q Hexadecimal dump

Chapters 4 through 8 of this manual describe these emulation modes

and their functions. The emulation mode you choose must be

compatible with the host computer and its currently installed software.

The following figure shows the emulation mode submenu and the

following paragraphs describe the emulation mode setup parameters.

Printer Setup 2-5

Page 19

Execute

Commands

ON

OFF

LF/CR

ON LF

OFF

OFF

LF/CR

ON CR

ON

OFF

CR W/LF

VT DC2

ON

OFF

Graphics

ON

OFF

SO=

Expand

ON

OFF

Proc Mode Auto LF Auto LF

DP

WP

Auto LF Auto CR

NO

YES

emulation mode submenu

Emulation

ProPrinterTI855TI880 Epson optional Hexdump

NO

YES

NO

YES

Slashed 0’s

NO NO

YES

NO

YES

Auto CR

NO

YES

Slashed 0’s

YES

TI 880 Emulation

The TI 880 emulation submenu contains a group of setup parameters

that can be set to either on or off. These parameters determine how

your printer responds to certain commands from the host computer.

Execute Commands

When on, this parameter enables the printer to respond to escape

sequence commands from the host computer. The default setting is ON.

Line Feed and Carriage Return Upon Receipt of LF

When on, this parameter causes the printer to perform both a line

feed (LF) operation and a carriage return (CR) operation upon

receiving an LF command from the host computer. The default

setting is OFF.

Printer Setup 2-6

Page 20

Line Feed and Carriage Return Upon Receipt of CR

When on, this parameter causes the printer to perform both an LF

operation and a CR operation upon receiving a CR command from

the host computer. The default setting is OFF.

Carriage Return Upon Receipt of LF, VT, or DC2

When on, this parameter causes the printer to perform a CR operation

upon receiving any of the following commands.

q Line feed (LF) — The printer moves the printhead down to the

next print line and returns the carriage to the left margin.

q Vertical tabulation (VT) — The printer prints the remainder of

the current print line, moves the printhead down to the next

vertical tab stop, and returns the carriage to the left margin.

q Device control 2 (DC2) — The printer moves the printhead

down to the print line specified by the DC2 n (Move to Line n)

command and returns the printhead to the left margin.

The default setting for the parameter CR W/LF VT DC2 is OFF.

Graphics

When on, this parameter enables the raster graphics escape sequences

described in Chapter 4. The default setting is OFF.

Shift Out Equals Expanded Print

When on, this parameter causes the printer to print one line of

expanded print after receiving a shift out (SO) command. When this

parameter is off, the printer invokes the G1 character set into the GL

area of the character table upon receiving SO. The default setting is

OFF.

Printer Setup 2-7

Page 21

TI 855 Emulation

The TI 855 emulation submenu contains the processing mode (WP/DP)

parameter and the automatic line feed parameter, both of which can

be set to match the requirements of your computer. The following

paragraphs describe these parameters.

Processing Mode

The Tl 855 emulation mode lets you choose either of the following

processing modes.

q DP mode — uses commands (described in Chapter 6) similar to

those used by a dot-matrix-type printer.

q WP mode — uses commands (described in Chapter 5) similar to

those used by a daisy-wheel printer.

The default setting for the processing mode parameter is DP.

Automatic Line Feed

Some software programs send both a CR command and an LF command

at the end of each print line, while others send only a CR command.

For software that sends only a CR command at the end of each print

line, the printer needs to perform an LF operation automatically. The

default setting for the automatic LF parameter is NO.

IBM Proprinter XL and Epson FX Emulations

The IBM Proprinter XL and Epson FX emulation submenus contain

the same following parameters.

Automatic Line Feed

This parameter is identical to the automatic LF parameter described

for the TI 855 emulation mode. The default setting is NO.

Printer Setup 2-8

Page 22

Automatic Carriage Return

This parameter is similar to the automatic LF parameter but is turned

on for software that does not send a CR command at the end of each

print line. If the printer advances from print line to print line but fails

to perform a carriage return operation, you need to turn on the

automatic CR parameter. The default setting is NO.

Slashed Zeros

When on, this parameter causes the printer to print slashes over all

zeros to distinguish them from the letter O. The default setting is NO.

Hexadecimal Dump Mode

The hexadecimal dump (HEXDUMP) mode causes the printer to

print the ASCII (hexadecimal) codes for all text characters, control

characters, and escape-sequence commands it receives. The resulting

printout can be useful as a troubleshooting device or in analyzing a

block of data and commands sent from the host computer.

The printer does not respond to any control characters or commands

except when the printer is using the serial or option port and FLOW

CONTROL is set to ETX/ACK; in such a case, the printer interprets

and responds to an ETX control character as an end-of-text command.

The ETX character is also included as part of the hex dump.

Note: Chapter 3 describes ASCII codes and control characters;

Chapters 5 and 6 describe the escape-sequence commands for the

TI 855 emulation mode.

Printer Setup 2-9

Page 23

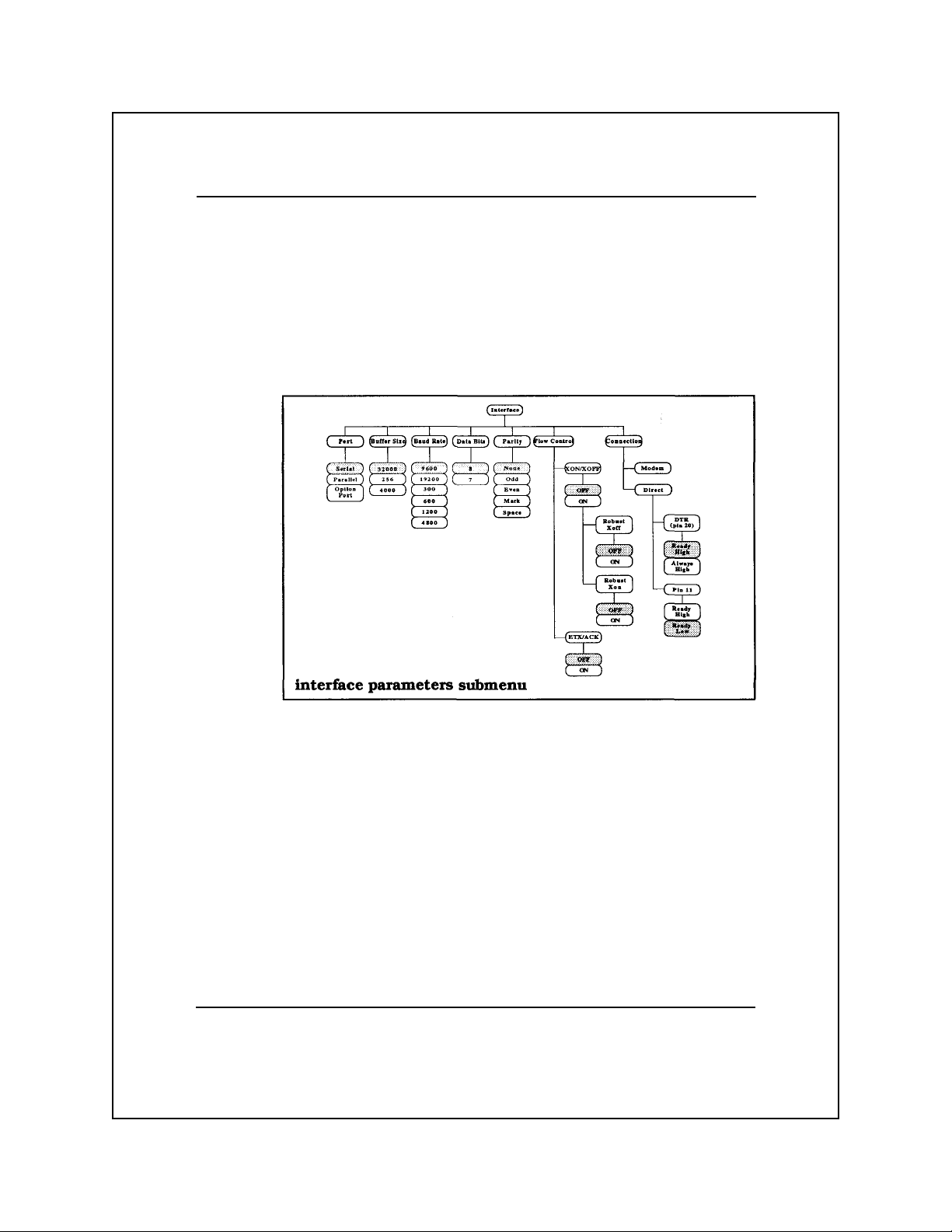

Interface Parameters

The interface parameters are values associated with serial communication interfaces. When using a serial interface, these parameters

must be set to correspond to the capabilities of the host computer and

the interface.

The following figure shows the interface submenu and the following

paragraphs describe the interface setup parameters.

Port

The port submenu lets you choose the correct communication

interface port, depending on whether you are using a serial, parallel,

or optional interface. The default setting is SERIAL.

Buffer Size

The buffer size specifies the number of data bytes that the printer’s

receive buffer can store. The buffer size parameter can be set to 256,

4000, or 32,000 bytes. The default setting is 32,000.

Printer Setup 2-10

Page 24

Baud Rate

The baud rate is the rate (in bits per second) at which the interface

transfers data. This parameters are 300, 600, 1200, 2400, 4800, 9600,

or 19,200 bits per second. The default setting is 9600.

Note: Data transferred over a serial interface consists of either 7- or

8-bit data bytes, each of which is accompanied by a start bit, a stop

bit, and a parity bit. The values chosen for the data bits and parity

parameters depend upon the requirements of the host. (See Chapters

3 and 10.)

Data Bits

The data bits parameter specifies whether the printer is to print 7- or

8-bit character codes. The default setting is 8. (Refer to Chapters 3

and 10 for information about 7- and 8-bit data.)

Parity

Parity checking (often called simply parity) is a method of verifying

that data is not changed in the transfer process. This parameters are

None, Odd, Even, Mark, or Space, depending upon the requirements

and capabilities of your computer. The default setting is NONE. If

the parity bit is selected, it is in addition to the 7 or 8 data bits.

Flow Control

To ensure the orderly flow of data between the host and printer, the

host computer establishes a set of rules commonly known as the

ready/busy protocol. This protocol allows the printer to notify the

host that it is either ready to receive data or that it is busy and cannot

receive data. The following paragraphs describe the flow-control

parameters.

Printer Setup 2-11

Page 25

XON/XOFF (transmit-on/transmit-off)

For this busy-handling protocol, the printer sends a single XON (a

DC1 control character) to indicate that it is ready to receive data and

a single XOFF (a DC3 control character) to indicate that it is busy.

The default setting is OFF.

Robust XON/XOFF

For the robust XON/XOFF protocol, the printer sends an XON (DC1

control character) approximately every 5 seconds to indicate that it is

ready to receive data until either data is received or another busy

condition occurs. The printer sends an XOFF (DC3 control character)

when the initial busy condition occurs (buffer overflow) to indicate

that it is busy. If the host continues to send data, the printer sends an

XOFF approximately every 20 ms until the hosts stops sending data.

The default setting is OFF.

The following table lists the ready and busy points using the

XON/XOFF protocol.

LCD Display of Busy Point Ready Point

Buffer Size From Empty After Busy

32,000 @ 32,000 Bytes @ 31,250 Bytes

4,000 @ 4,000 Bytes @ 3,250 Bytes

256 @ 256 Bytes @ 128 Bytes

Note: Actual buffer size is 32,768 bytes; overflow error status only

occurs after 32,768 bytes.

Printer Setup 2-12

Page 26

ETX/ACK (end-of-text/acknowledge)

For this busy-handling protocol, the host sends an ETX control

character at the end of each data transmission, and the printer

responds with an ACK control character to indicate that it is ready to

receive additional data. If the printer is busy when it receives the

ETX control character, it delays sending the ACK control character

until the busy condition is cleared. The default setting is OFF.

Connection

This feature provides selections for use when connecting the printer

directly to the host computer or indirectly via a modem. When you

connect the printer to a modem, set the connection parameter to

MODEM. When you connect the printer directly to the host computer

or a terminal, select DIRECT and set the busy-handling parameters

to conform to the requirements of the computer. The default setting

is DIRECT. The following paragraphs describe the direct connection,

ready/busy protocol.

DTR (Pin 20)

For this parameter you can choose either READY HIGH or AL WAYS

HIGH. For the READY HIGH setting, the printer sets interface pin

20 high to indicate that it is ready to receive data and low to indicate

that it is busy. For the ALWAYS HIGH setting, pin 20 is not used for

busy notification; one of the other busy-handling options must be

chosen. The default setting is READY HIGH.

PIN 11

For this parameter, you can choose either READY HIGH or READY

LOW. For the READY HIGH setting, the printer sets interface pin 11

high to indicate that it is ready to receive data and low to indicate

that it is busy. For the READY LOW setting the printer sets interface

pin 11 low to indicate that it is ready to receive data and high to

indicate that it is busy. The default setting is READY LOW.

Printer Setup 2-13

Page 27

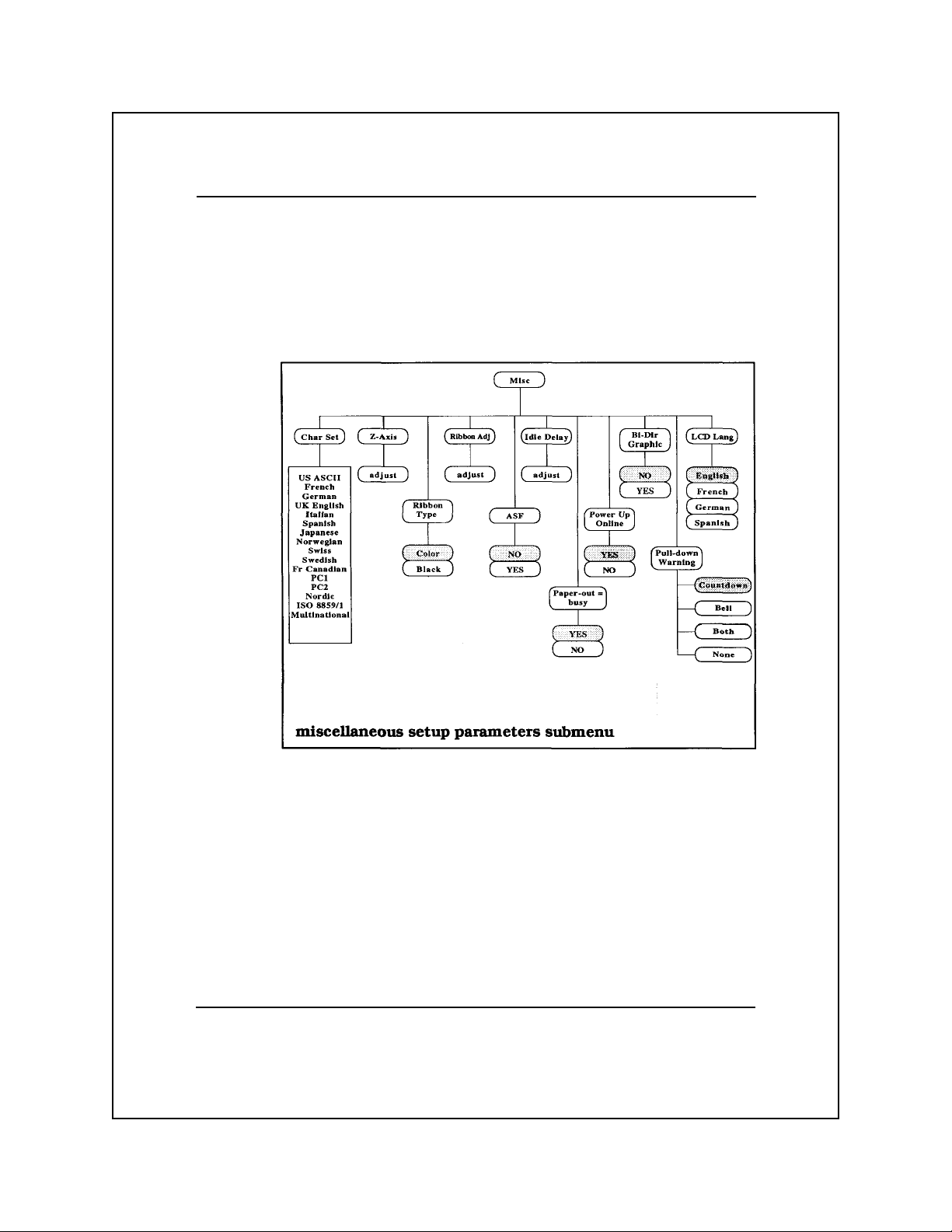

Miscellaneous Setup Parameters

The miscellaneous setup parameters are mechanical and operational

features that do not fit logically into the other setup categories.

The following figure shows the miscellaneous setup parameters

submenu and the following paragraphs describe these parameters.

Character Set

The Model 8900 Series Printers character set repertoire includes 6

standard character sets and 11 international language versions. The

default character set is IBM PC1 and the default international

language version is U.S. English.

Printer Setup 2-14

Page 28

Z

-Axis Control

The printer adjusts the printhead-to-paper clearance (z-axis) automatically when you load paper into the printer. In addition, the Z-AXIS

parameter provides a manual z-axis adjustment. This selection

invokes a display that lets you adjust the printhead in or out.

You also can adjust the z-axis using an escape sequence described in

the Appendix to this manual.

Ribbon T ype

The RIBBON TYPE parameter lets you choose between color

printing and black printing. The default setting is COLOR.

Ribbon Adjust

If the printer appears to be printing mixed colors or missing the upper

or lower parts of the characters, the ribbon may need adjustment.

The RIBBON ADJ parameter invokes a display that lets you adjust

the ribbon up or down.

Printer Setup 2-15

Page 29

Idle Delay

At the end of a printing operation, if the paper is at top of form, the

printer waits for more data and then, after a short delay (idle delay),

moves the paper to the tear-off position. The IDLE DELAY parameter

invokes a display that lets you adjust the idle delay to a value in the

range of 300 milliseconds to 90 seconds.

You can disable the idle delay feature by selecting a value above 90

seconds, in which case the LCD displays DISABLE. When you

disable this feature, the printhead “relaxes” (moves away from the

paper) after 91 seconds of idle time and the paper is not moved to the

tear-off position.

Power-Up Online

The PWRUP ONLINE parameter lets you set the printer to power-up

in either its online or offline condition. The default setting is YES

(power-up online).

Paper Pull-Down Warning

This parameter lets you select the type of warning that occurs when

the printer is about to pull down tractor-fed paper from its tear-off

position to the normal printing position.

The COUNTDOWN option (factory default) causes the printer LCD

to display the numerals 9, 8, 7... down to 1, visually warning that

paper pull-down is imminent. The pull-down time delay is increased

about 3 to 4 seconds.

The BELL option causes a series of nine beeps of increasing duration

to indicate paper pull-down. The pull-down time delay is increased

about 3 to 4 seconds.

The BOTH option causes the COUNTDOWN and BELL options to

occur simultaneously.

The NONE option turns off the pull-down warning.

Printer Setup 2-16

Page 30

Graphics Printing Mode

The BI-DIR GRAPHIC parameter lets you choose whether the

printer prints graphics bidirectionally or from left to right only. The

default setting is NO (print graphics from left to right only).

LCD Language

The LCD LANG parameter lets you set the control panel LCD to

display its messages in English, French, German, or Spanish. The

default setting is ENGLISH.

Paper Out Equals Busy

The PAPER OUT = BUSY parameter, when set to YES, lets the

printer send a busy condition signal to the communication interface

when the printer runs out of paper. The default setting is YES.

Limiting Control Panel Operation

This parameter enables you to select three levels of control panel

functioning, intended to limit operator access to certain printer

function. This effectively prevents operator error resulting from

incorrect control panel operation. The menu offers four choices from

Level 0 (factory default) to Level 3.

Level 0 is conventional, full control panel operation.

Level 1 permits full offline control panel operation, but when the

printer is online only the Online and Clear Error keys function.

Level 2 limits online operation to the Online and Clear Error keys

and, when offline, disables the Form Config, Pitch, Quality, Font,

and Setup/Test keys.

Level 3 limits online operation to the Online and Clear Error keys

and, when offline, disables the Form Select, Form Config, Pitch,

Quality, Font, and Setup/Test, and Form Feed keys.

Printer Setup 2-17

Page 31

Access the menu to select the four available options as follows.

1. Press and hold the Clear Error switch, then press and hold the

Status switch.

2. Release the Clear Error switch, continue to hold the Status

switch, then press and hold the Setup/Test switch.

3. Release the Status switch, continue to hold the Setup/Test

switch. The LCD displays Key Access.

4. Press the F2 switch until the level you want is displayed, then

press the On Line switch to return the printer to its previous

mode.

Test Features

The test mode submenu lets you use the built-in printer test

features. The Model 8900 Series Printers User’s Manual, Part No.

2557785-0001, describes the status report and the barberpole test.

Clear

Error

press & hold press & hold

▲

Status

limiting control panel operation menu

▲

Setup/

Test

Key

Access

Level 0

Level 1

Level 2

Level 3

Printer Setup 2-18

Page 32

3

Character Sets and Global Commands

Introduction .................................................................................... 3-2

Character Code Table ..................................................................... 3-2

Character Sets................................................................................. 3-3

The US ASCII Character Set..................................................... 3-3

International ASCII Character Sets ........................................... 3-5

The IBM PC1 Character Set...................................................... 3-6

The IBM PC2 Character Set...................................................... 3-8

The Nordic PC Character Set .................................................. 3-10

ISO 8859/1 Multinational Character Set ................................. 3-12

IBM Multinational Character Set ............................................ 3-14

Control Characters........................................................................ 3-16

Printer Commands ........................................................................ 3-19

Global Command Set.................................................................... 3-20

Global Command Descriptions .................................................... 3-20

Barcode Operations ................................................................. 3-21

Set Barcode Parameters ...................................................... 3-21

Print Barcode Text .............................................................. 3-22

Oversize Characters Feature.................................................... 3-22

Set Oversize Character Scale Factor .................................. 3-22

Print Oversize Character..................................................... 3-22

Color Printing .......................................................................... 3-23

Selecting an Automatic Sheet Feeder Bin ............................... 3-24

Selecting a Form Format ......................................................... 3-24

Defining Raster Graphics ........................................................ 3-25

Selecting a Font’s HMI............................................................ 3-25

Selecting Characters Per Inch (cpi) ......................................... 3-26

Selecting Print Quality ............................................................ 3-26

Selecting an International Character Set ................................. 3-27

Selecting an Emulator.............................................................. 3-28

Adjusting the Printhead Z-Axis Position................................. 3-29

Writing to the Printer Display ................................................. 3-29

Paper-Handling Operations ..................................................... 3-29

Character Sets and Global Commands 3-1

Page 33

Introduction

This chapter describes the standard character sets and provides

information about their use in the Model 8900 Series Printers.

The printer can use any of several standard or optional character sets

that can be selected via the operator control panel switches or via the

host computer. These character sets provide all control characters

and graphic characters necessary to implement the various printer

emulation modes.

The standard character sets reside in the printer read-only memory

(ROM), and the optional character sets can be plugged into one of

the option ROM sockets on the printer logic board.

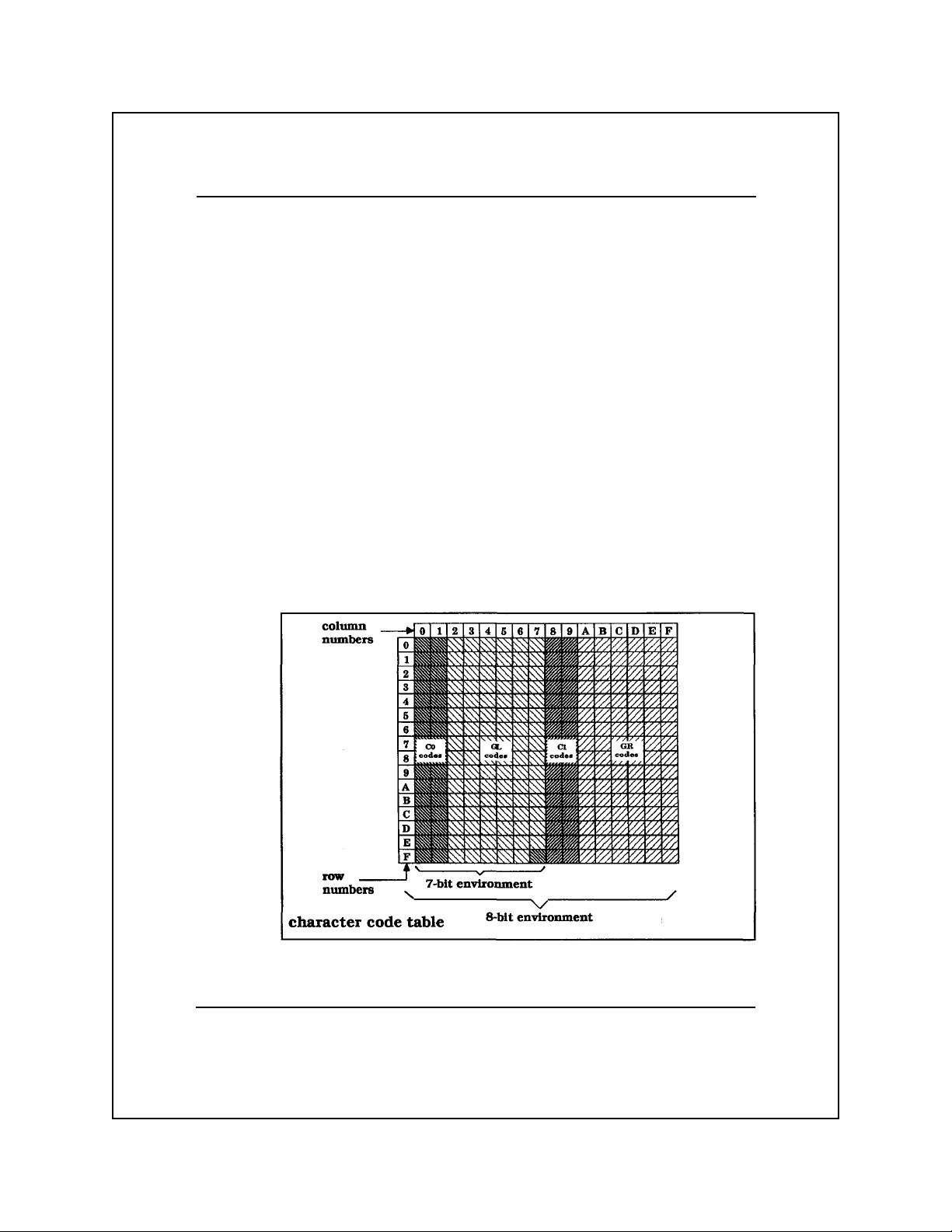

Character Code Table

The following figure shows the printer character code table. The

character code table is an area in the printer memory in which one

8-bit character set or two 7-bit character sets reside.

Character Sets and Global Commands 3-2

Page 34

Character Sets

Your printer can use any of the following character sets.

q US ASCII (default character set)

q IBM PC1

q IBM PC2

q Nordic PC

q ISO 8859/1 Multinational

q IBM Multinational

Note: The option ROM sockets on the printer logic board let you

install additional character sets.

Character Sets and Global Commands 3-3

Page 35

The US ASCII Character Set

The following table shows the U.S.A. Standard Code for Information

Interchange (US ASCII) character set. This 7-bit character set is

defined by the American National Standards Institute document

ANSI X3.4 and is a variant of the ISO 646 character set.

US ASCII Character Set

Character Sets and Global Commands 3-4

Page 36

International ASCII Character Sets

With a few exceptions, the international versions of the ASCII

character set are identical to the US ASCII character set. These

international versions can be selected via the operator control panel

or via the host computer. The following table lists the variations

between the US ASCII character set and the international versions.

Variations Between US ASCII and International ASCII

Character Sets and Global Commands 3-5

Page 37

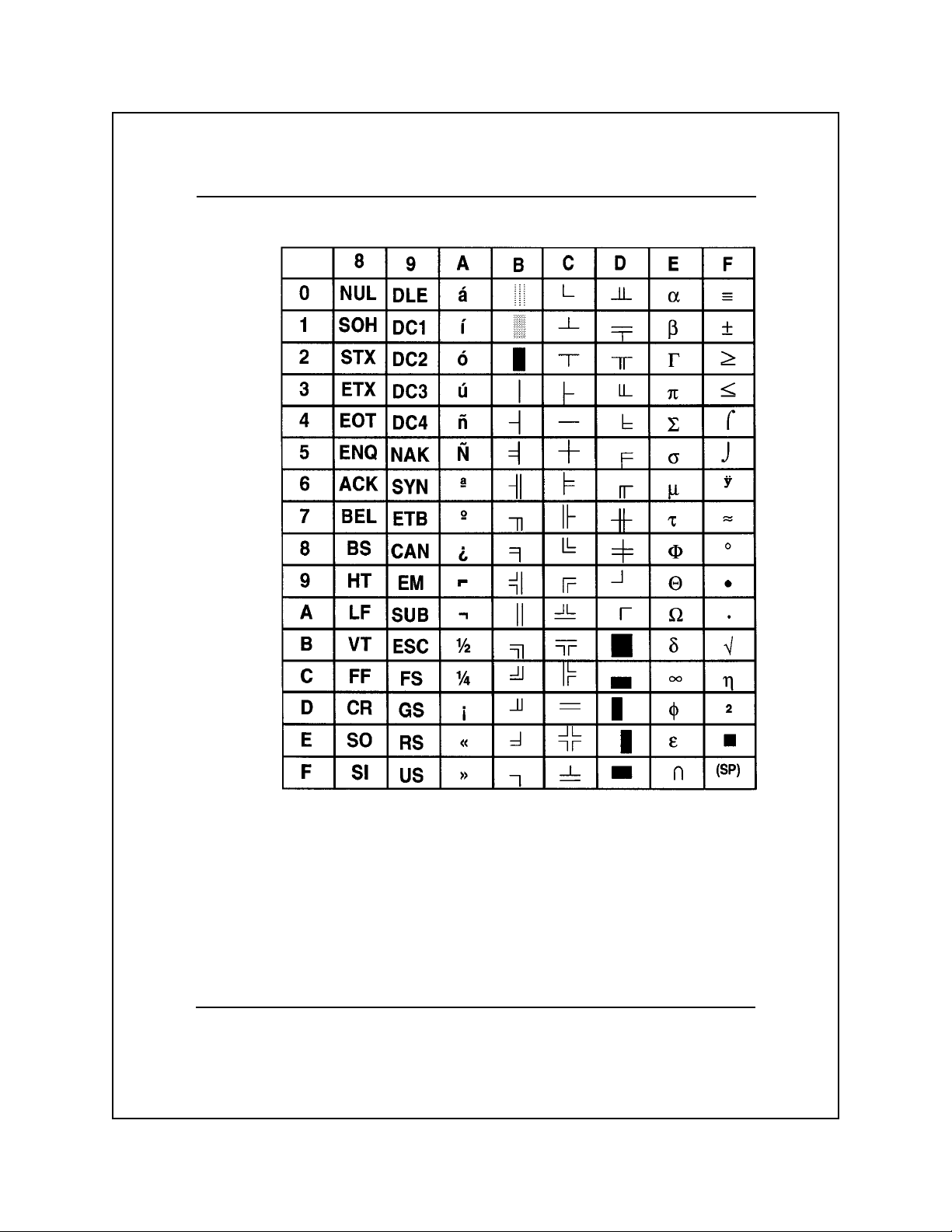

The IBM PC1 Character Set

The following two tables show, respectively, the left half and right

half of the the IBM PC 1 character set.

IBM PC1 Character Set, Left Half

Character Sets and Global Commands 3-6

Page 38

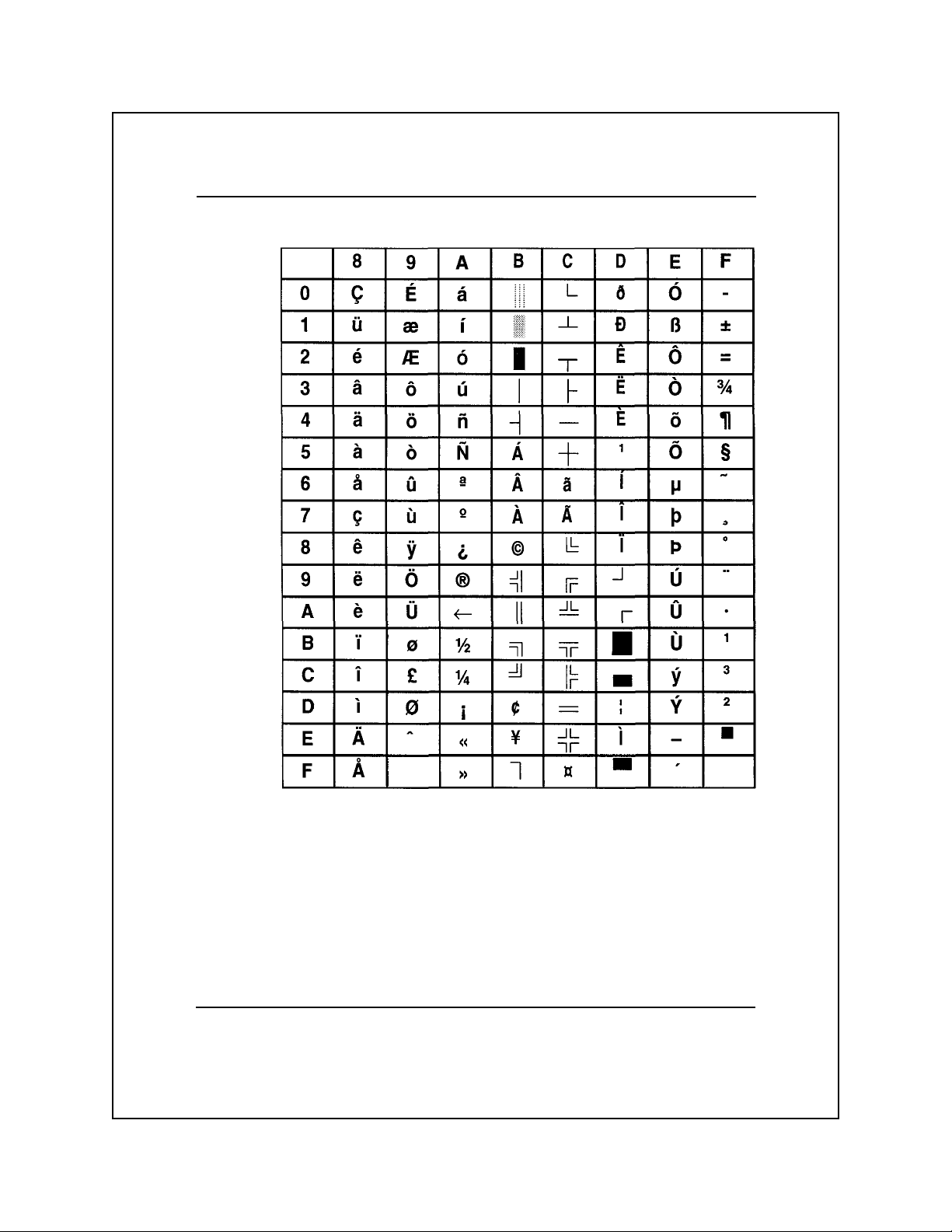

IBM PC1 Character Set, Right Half

Character Sets and Global Commands 3-7

Page 39

The IBM PC2 Character Set

The following two tables show, respectively, the left half and the

right half of the IBM PC2 character set.

IBM PC2 Character Set, Left Half

Character Sets and Global Commands 3-8

Page 40

IBM PC2 Character Set, Right Half

Character Sets and Global Commands 3-9

Page 41

The Nordic PC Character Set

The following two tables show, respectively, the left half and right

half of the Nordic PC character set.

Nordic PC Character Set, Left Half

Character Sets and Global Commands 3-10

Page 42

Nordic PC Character Set, Right Half

Character Sets and Global Commands 3-11

Page 43

ISO 8859/1 Multinational Character Set

The following two tables show, respectively, the left half and right

half of the ISO 8859/1 Multinational character set. The shaded

character positions (128-159) represent the Cl control characters

which are not implemented in the Model 8900 Series Printers.

ISO 8859/1 Multinational Character Set, Left Half

Character Sets and Global Commands 3-12

Page 44

ISO 8859/1 Multinational Character Set, Right Half

Character Sets and Global Commands 3-13

Page 45

IBM Multinational Character Set

The following two tables show, respectively, the left half and right

half of the IBM Multinational character set.

IBM Multinational Character Set, Left Half

Character Sets and Global Commands 3-14

Page 46

IBM Multinational Character Set, Right Half

Character Sets and Global Commands 3-15

Page 47

Control Characters

Any character that causes the printer to perform a function is classified

as a control character. Note that, although the Cl control characters are

available in one of the standard character sets (ISO 8859/Multinational),

your printer does not implement them.

American National Standard ANSI X3.4 and International Standard

ISO 646 define the C0 control characters based on the specific

function performed by the character. The C0 control characters are

divided into the following categories.

q Communication controls - Control characters intended to control

or enable data transmissions over communication networks.

q Format effectors - Control characters that control the layout or

position of information on the printed page.

q Information separators - Control characters that separate and

qualify information in a logical sense.

q Miscellaneous control characters - Control characters whose

definitions preclude their inclusion in the preceding categories.

The following table lists and defines the original use of the C0

control characters.

Note: The functions of the control characters can vary from one

emulation mode to another. Therefore, these descriptions are included

in Chapters 4 through 9.

Character Sets and Global Commands 3-16

Page 48

C0 Control Characters

Char Code Definition

Communication controls:

SOH 01 Start of header

STX 02 Start of text

ETX 03 End of text

EOT 04 End of transmission

ENQ 05 Enquiry

ACK 06 Acknowledge

DLE 10 Data link escape

NAK 15 Negative acknowledge

SYN 16 Synchronous idle

ETB 17 End of transmission block

Format effectors:

BS 08 Backspace

HT 09 Horizontal tabulation

LF 0A Line feed

VT 0B Vertical tabulation

FF 0C Form feed

CR 0D Carriage return

FS 1C File Separator

Information separators:

GS 1D Group separator

RS 1E Record separator

US 1F Unit separator

Miscellaneous controls:

NUL 00 Null

BEL 07 Bell

SO 0E Shift out

SI 0F Shift in

DC1 11 Device control 1

DC2 12 Device control 2

DC3 13 Device control 3

DC4 14 Device control 4

CAN 18 Cancel

EM 19 End of medium

SUB 1A Substitute

ESC 1B Escape

DEL 7F Delete

Hexadecimal

Character Sets and Global Commands 3-17

Page 49

Printer Commands

The Model 8900 Series Printers receive commands from the host

computer in the form of ASCII control character codes and escapesequence codes. In response to these commands, the printer performs

one or more operations defined by the command set of the currently

selected emulation mode. Chapters 4 through 8 describe the standard

emulation modes.

An example of a control character command common to all character

sets and all emulation modes is the line feed (LF) character. This

control character (designated by hexadecimal code 0A or decimal

code 10) causes the printer to advance the paper or form to the next

print line. To invoke the line feed operation, the host computer sends

the 8-bit code (00001010) identified as the LF character.

An escape-sequence command is a sequence of two or more characters

that always begins with the ASCII escape (ESC) control character

designated by hexadecimal code 1B. The ESC control character

signals the printer that one or more succeeding characters are an

escape-sequence command.

An example of an escape-sequence command common to all standard

emulation modes is the Set Form Length command ESC C n. This

command contains the following elements.

q ESC — the ASCII control character that signals the start of an

escape sequence

q C — an ASCII character that identifies the escape sequence as a

form length command

q n — a decimal variable that can be set to a range of values to

specify the form length in number lines

Note: Decimal values of variables are designated by lowercase italic

letters. ASCII characters and number values of variables are

designated by uppercase italic letters.

Character Sets and Global Commands 3-18

Page 50

Some escape sequence commands, valid for all emulation modes, are

called global commands. These are special commands that select or

control some basic or specially defined printer operation.

Global Command Set

The following table lists the global commands for the Model 8900

Series Printers. These commands are characterized by an intermediate

control character DLE following the ESC character.

Model 8900 Series Printers Global Commands

Command Command Name

ESC DLE B P t r s ETX Set Barcode Parameters

ESC DLE B C text ETX Print Barcode Text

ESC DLE C C text ETX Print Oversize Characters

ESC DLE C P p1 p2 ETX Set Oversize Characters Scale Factor

ESC DLE c n Select Color Printing

ESC DLE E text ETX Select Emulator

ESC DLE EM n Select Automatic Sheet Feeder Bin

ESC DLE F x Select Form Format

ESC DLE G d1 d2 n1 n2 data Define Raster Graphics

ESC DLE f n Select font

ESC DLE H Select Font HMI

ESC DLE P n Select Characters Per Inch (cpi)

ESC DLE p 0 Load from Current Paper Path

ESC DLE p 1 Park Continuous Paper

ESC DLE p 2 Load Cut-Sheet Paper from Front

ESC DLE p 3 Load Continuous Paper

ESC DLE p 4 Load Cut-Sheet Paper from Top

ESC DLE Q n Select Print Quality

ESC DLE R n Select International Character Set

ESC DLE STX text ETX Write to Printer Display

ESC DLE z S NN Adjust Printhead Z-axis Position

Global Command Descriptions

The following paragraphs describe the Model 8900 Series Printers

global commands.

Character Sets and Global Commands 3-19

Page 51

Barcode Operations

The barcode commands let you select a barcode font, set its

parameters, and print any specified character in the equivalent

barcode font.

Note: If the barcode option is not installed, using this ESC sequence

causes an ESC SEQ error.

Set Barcode Parameters

Escape sequence: ESC DLE B P trsETX

Hexadecimal: 1B 10 42 50 trs03

This command, where t = type, r = readability, and s = size, lets you

select a barcode font and set its associated parameters. The following

values are valid for the command variables.

q Type:

0 — Barcode 3 of 9 (default)

1 — Interleaved 2 of 5

3 — Codabar

q Readability:

0 — Not human readable (default)

1 — Human readable characters on top

2 — Human readable characters on bottom

3 — Human readable characters on top and bottom

q Size:

Vertical height in 8/72 inch increments (default 8/72")

Note: PostNet barcode is available as a font; see “Selecting a Font.”

Character Sets and Global Commands 3-20

Page 52

Print Barcode Text

Escape sequence: ESC DLE B C text ETX

Hexadecimal: 1B 10 42 43 text 03

This command lets you print a character or string of characters

specified by the variable text. For example, to print the barcode

equivalents of the numerals 0, 1, and 2 from the barcode font set

selected by the Set Barcode Parameters command, enter the sequence

ESC DLE B C 0 1 2 ETX.

Oversize Characters Feature

Using this feature, you can increase the size of your selected font

from 1 times to 127 times the original size. One global command

determines the character size; a second global command prints the

oversize characters.

Set Oversize Character Scale Factor

Escape sequence: ESC DLE C P p1 p2 ETX

Hexadecimal: 1B 10 43 50 p1 p2 03

This command defines the horizontal and vertical scale factors which

determine the size of the characters printed by the Print Oversize

Character command.

The p1 variable is the vertical scale factor (1 byte), from 1 to 127;

the default is 2. The p2 variable is the horizontal scale factor (1 byte),

from 1 to 127; the default is 2. If either variable is set to less than 1

or more than 127, the value defaults to 2.

Character Sets and Global Commands 3-21

Page 53

Print Oversize Character

Escape sequence: ESC DLE C C text ETX

Hexadecimal: 1B 10 43 43 text 03

This command prints the text contained within the command using

the horizontal and vertical scale factors selected by the Set Oversize

Characters command. The text variable is the character string to be

printed in oversize characters.

You can use a maximum of 200 characters in a text string; excess

characters are treated as normal characters, and the command is

limited to printing from the logical start position to the logical end

position of a single line of text. Text extending beyond the end of the

line is truncated at the logical end position.

Because the ETX control character is used as the command sequence

delimiter, if your text string requires an ETX character you must use

two consecutive ETX characters within the text string to be recognized.

The printer uses the bit patterns dictated by the print quality selected;

draft quality bit patterns in draft mode, text quality bit patterns in

text and quality modes.

Color Printing

Escape sequence: ESC DLE c n

Hexadecimal: 1B 10 63 n

The Model 8900 Series Printers can print up to seven different colors

(including black). This feature is standard on the Model 8930 and

optional on the Model 8920.

This command selects the color specified by the variable n, where n

can be any of the following values.

0 — black 4 — green

1 — cyan 5 — purple

2 — magenta 6 — orange

3 — yellow

Character Sets and Global Commands 3-22

Page 54

Selecting an Automatic Sheet Feeder Bin

Escape sequence: ESC DLE EM n

Hexadecimal: 1B 10 19 n

This command selects the ASF bin designated by the variable n,

where n can range from 30 through 33 hex as follows:

0 (30H) = Load from current bin

1 (31H) = Select & load from bin 1

2 (32H) = Select & load from bin 2

3 (33H) = Load from current bin

If the command is received with paper loaded from a friction feed

path, the currently loaded form is ejected, and a form is loaded as

defined by this command. If the command is received with paper

loaded from the tractor feed path, this command is accepted but

ignored.

The ASF option on the Miscellaneous Menu of the printer control

panel must be set to “YES” for this function to operate.

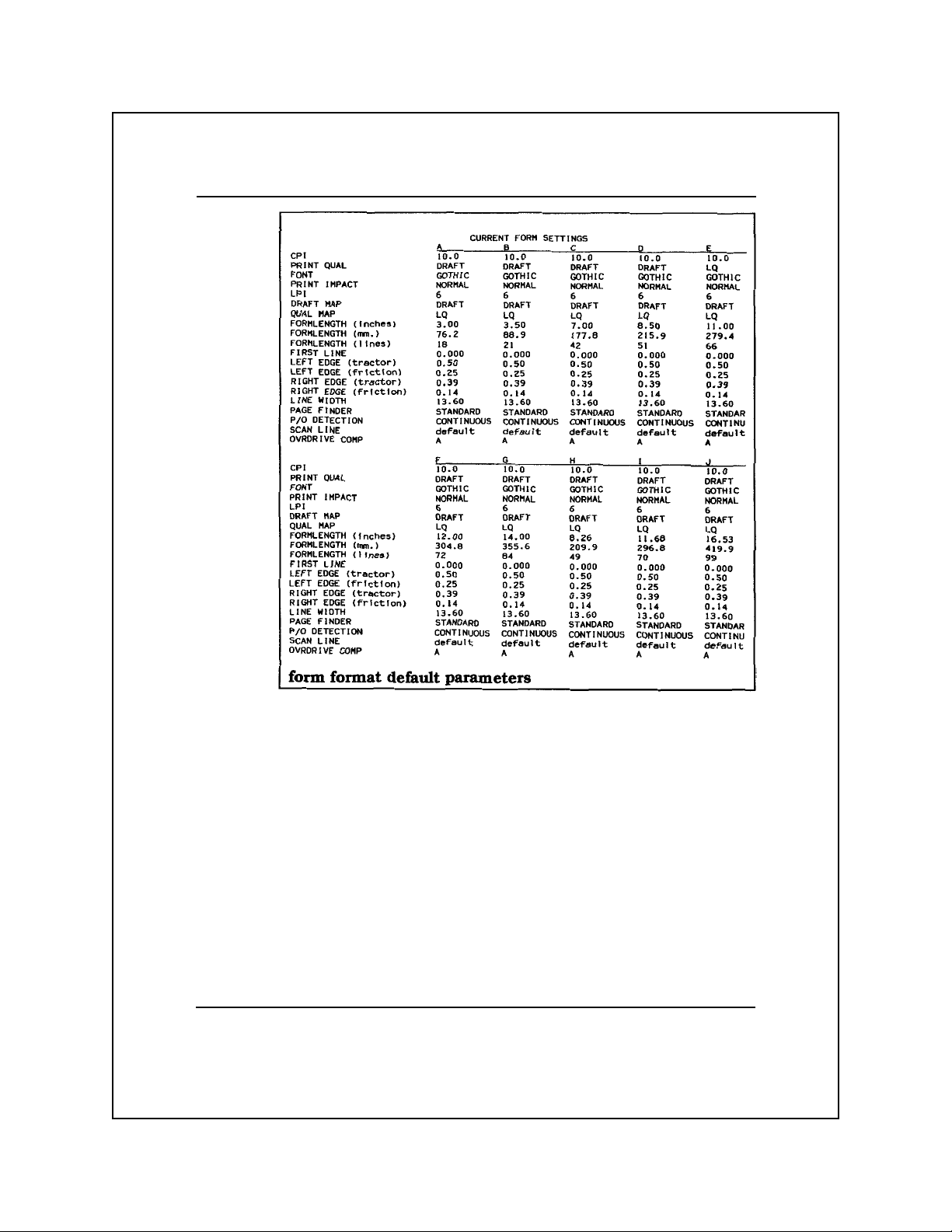

Selecting a Form Format

Escape sequence: ESC DLE F x

Hexadecimal: 1B 10 46 x

The Model 8900 Series Printers offer a set of ten predefined form

formats. Each of these form formats, designated as A through J, has an

associated set of values that defines the parameters of the form. Although

these form format parameters are preset at the factory to their default

values, the user can select any of the form formats and alter its

parameters to fit any specific application. The Model 8900 Series

Printers User’s Manual, Part No. 2557785-0002, describes the preset

form format parameters and explains how to select and change them.

The Select Form Format command selects the form format designated

by the variable x, where the value of x can be any of the ten predefined

form formats A through J.

Character Sets and Global Commands 3-23

Page 55

Defining Raster Graphics

Escape sequence: ESC DLE G d1 d2 n1 n2 data

Hexadecimal: 1B 10 47 d1 d2 n1 n2 data

This command defines the dots-per-inch (DPI) density, the byte

count of bit-image data, and bit-image data of those emulations that

currently support raster graphics.

The variable d1 d2 is DPI density, where d1 is LSB and d2 is MSB.

The variable nl n2 is the byte count, where n1 is the LSB and n2 is

the MSB. And data is bit-image data. All variables can range from 0

through 255.

DPI density defines the horizontal dots per inch at which the bit

image data is printed. Valid DPI values are 60, 72, 80, 90, 100, 120,

135, 144, 150, 180, 200, 240, and 300 dots per inch. Any other value

causes an escape sequence error. The DPI density format is d1 + (d2

* 256) = DPI.

The byte count variable indicates the number of bit-image data bytes

to follow. The byte count format is n1 + (n2 * 256) = byte count.

A bit-image data byte defines a column of 8-pin raster graphics. The

bits of each byte have valid values of 1, 2, 4, 8, 16, 32, 64, and 128.

In a vertical column of dots, the dots are arranged so that the MSB

(bit value = 128) is at the top, and the LSB (bit value = 1) is at the

bottom.

Character Sets and Global Commands 3-24

Page 56

Selecting a Font

Escape Sequence: ESC DLE f n

Hexadecimal: 1B 10 66 n

This command allows you to access type styles not specifically

supported by an emulation.

This command selects the font designated by the variable n, where n

can range from 0 through 254 decimal as follows:

Font ID No.

Courier 0

Prestige Elite 1

OCR A 3

OCR B 4

Gothic 5

Presentor 6

PostNet 7

Note: Using any value other than the valid font ID number for n,

causes the printer to accept and ignore the command, and cause a

FONT NOT AVAILABLE ERROR.

Selecting a Font’s HMI

Escape sequence: ESC DLE H

Hexadecimal: 1B 10 48

This command enables you to access natural pitches of a font that may

not be specifically supported by an emulation. The command sets

horizontal motion index (HMI) to the currently selected font’s HMI.

The command cancels the double-width print mode, but does not

cancel the oversize-character (scalable characters) command. This

command resets the Epson variable spacing to zero.

Character Sets and Global Commands 3-25

Page 57

Selecting Characters Per Inch (cpi)

Escape sequence: ESC DLE P n

Hexadecimal: 1B 10 50 n

This command enables you to access natural pitches of a font that

may not be specifically supported by an emulation. The command

sets pitch according to the variable n, which can range from 30

through 33 hex.

Unless specified otherwise, the emulation’s default HMI is used.

Character pitch commands are effective immediately upon receipt,

thus causing a pitch change within a line.

This command cancels double-wide print mode and compressed print

mode. The values of n for cpi selection are listed in the following

table.

Value of n Hex Value Pitch*

13010

23112

33215

4 33 16.7

*for standard fonts and emulations

Selecting Print Quality

Escape sequence: ESC DLE Q n

Hexadecimal: 1B 10 51 n

This command enables you to access print quality modes not

specifically supported by an emulation. The command selects the

print quality mode according the the variable n, which can range

from 30 through 33 hex.

This command does not affect the forms configuration draft/rapiddraft setting. However, the fast draft mode setting is valid only in 12

and 15 cpi. If 10 cpi is set, draft mode is selected.

Character Sets and Global Commands 3-26

Page 58

The values of n for print mode selection are listed in the following table.

Mode Hex Value

Draft 30

Text 31

Letter 32

Fast Draft 33

Selecting an International Character Set

Escape sequence: ESC DLE R n

Hexadecimal: 1B 10 52 n

The ASCII character set contains the C0 control codes, the uppercase

and lowercase elements of the Latin alphabet, punctuation symbols,

and other commonly used symbols. The international versions of the

ASCII character set are identical to the standard US ASCII version

with a few exceptions. (See the paragraph entitled “International

ASCII Character Sets” in Chapter 3.)

This command selects the international ASCII character set designated

by the variable n, where the value of n can be any of the hexadecimal

values shown in the following table.

Character Set Hex Character Set Hex

United States English 00 not used 0C

French 01 PC No. l, LH 0D

German 02 PC No. 1, RH 0E

United Kingdom English 03 PC No. 2, LH 0F

Italian 04 PC No. 2, RH 10

Spanish 05 Multinational LH 11

Japanese 06 Multinational RH 12

Norwegian 07 Nordic No. 2, LH 13

Swiss 08 Nordic No. 2, RH 14

Swedish 09 ISO 8859/1 LH 15

French Canadian 0A ISO 8859/1 RH 16

All Characters 0B

Character Sets and Global Commands 3-27

Page 59

A character set is defined as 128 character positions. If more than

128 character positions are required, the set is divided in two and is

designated left half (LH) for positions 1 through 127 and right half

(RH) for positions 128 through 255. The MSB determines if the

character set is placed in the left half (0 through 7F) or the right half

(80 through FF) of the 8-bit character set table. An MSB of zero

places the character set in the left half, MSB of one, in the right half.

Note: The hex value 1B (left half) is reserved for use as the ASCII

escape control character (ESC). Any graphic defined at this location

is not printed.

The error message FONT NOT AVAILABLE occurs if the value of n

is not specified or is out of range.

Selecting an Emulator

Escape sequence: ESC DLE E text ETX

Hexadecimal: 1B 10 45 text 03

The Select Emulator command selects the emulation mode specified

by the variable text. To use this command, substitute the name of the

emulator for text that appears on the control panel display. If the

name does not exactly match one of the following resident emulation

modes (or an installed optional emulation mode), the printer ignores

this command.

q TI880

q TI855

q PROPRINTER

q EPSON

q HEXDUMP

Note: When the printer is in the hexadecimal dump mode, the Select

Emulator command is not functional.

Character Sets and Global Commands 3-28

Page 60

Adjusting the Print head Z-Axis Position

Escape sequence: ESC DLE zSNN

Hexadecimal: 1B 10 7A SNN

The Adjust Printhead Z-Axis Position command adjusts the

printhead in or out by the number of steps specified by the variable

NN, which is a two-digit ASCII value ranging from 00 through 99.

See Appendix A for Application Instructions.

Writing to the Printer Display

Escape sequence: ESC DLE STX text ETX

Hexadecimal: 1B 10 02 text 03

The Write to Printer Display command lets you write a message of

up to 16 characters to the second line of the printer display. For

example, to write THIS IS TEXT to the display, enter the sequence

ESC DLE STX THIS IS TEXT ETX. The display then shows the

message THIS IS TEXT on the second line. A message is terminated

by either ETX or upon reaching the sixteenth character.

Paper-Handling Operations

Escape sequence: ESC DLE p n

Hexadecimal: 1B 10 70 n

The paper-handling commands enable you to clear the current paper

path or select various paper-loading options, where n is a value

ranging from 30 through 33 hex. The value of n selects the following

paper-handling options:

0 (30H) = Load from current paper path

1 (31H) = Clear current paper path

2 (32H) = Load from front friction-feed path

3 (33H) = Load from tractor-feed path

4 (34H) = Load from top friction-feed path

Character Sets and Global Commands 3-29

Page 61

If the paper is not at the top-of-form position when the printer

receives the clear current path command, the printer executes a form

feed operation before attempting to park tractor-fed paper and

displays a prompt to PLEASE TEAR paper.

If the PAPEROUT=BUSY option in the Setup/Test menu is set to

YES, clearing (parking) the paper causes the printer to send a BUSY

signal to the host, which may suspend communication.

The clear-current-paper-path command (n = 1) is executed as follows:

q With tractor-fed paper loaded, the printer parks the paper.

q With friction-fed paper loaded, the printer ejects any cut sheets.

q With no paper loaded, the printer accepts but ignores the command.

If tractor-fed paper is currently loaded, only the clear/park command

(n = 1) is executed; any other paper path command is ignored.

If friction-fed paper (cut sheet) is currently selected and loaded, the

command functions as follows:

q Any command option to select another paper path causes ejection

of the current paper before execution of the command.

q A friction-feed command for the currently selected paper path is

accepted but ignored.

q A clear/park command (n = 1) causes ejection of the cut sheet.

Character Sets and Global Commands 3-30

Page 62

4

Texas Instruments Model 880

Printer Emulation

Introduction .................................................................................... 4-4

TI 880 Answer Message Function............................................. 4-5

TI 880 Response Format Selection............................................ 4-5

Model 880 Printer Emulation Commands ...................................... 4-6

Model 880 Command Descriptions.............................................. 4-10

The Variables N and n.............................................................. 4-10

Printer Operation Commands .................................................. 4-11

Sound Bell .......................................................................... 4-11

Transmit Configuration Report........................................... 4-11

Transmit Status Report ....................................................... 4-13

Select Unidirectional Printing ............................................ 4-14

Cancel Unidirectional Printing ........................................... 4-14

Form Format Selection Commands ......................................... 4-14

Set Form Length to N Lines................................................ 4-14

Set Form Length to n Lines ................................................ 4-15

Load Default Form Parameters........................................... 4-15

Margin Control Commands ..................................................... 4-17

Set Top Margin at Line N ................................................... 4-17

Set Bottom Margin at Line N.............................................. 4-17

Set Top and Bottom Margins at Lines N1 and N2 .............. 4-17

Set Left Margin at Column N ............................................. 4-18

Set Right Margin at Column N ........................................... 4-18

Set Left and Right Margins at Columns N1 and N2 ........... 4-18

Set Line Width to n Columns ............................................. 4-18

Restore Default Line Width................................................ 4-18

Horizontal Motion Commands ................................................ 4-19

Backspace ........................................................................... 4-19

Tab Horizontally ................................................................. 4-19

TI Model 880 Printer Emulation 4-1

Page 63

Move to Column n .............................................................. 4-19

Carriage Return................................................................... 4-19

Tab Right to Column N....................................................... 4-20

Tab Right N Columns ......................................................... 4-20

Set Horizontal Tab Stops .................................................... 4-20

Clear All Horizontal Tab Stops .......................................... 4-20

Set Horizontal Tab Stop at Current Position ...................... 4-21

Clear Horizontal Tab Stop at Current Position ................... 4-21

Vertical Motion Commands..................................................... 4-21

Line Feed ............................................................................ 4-21

Form Feed ........................................................................... 4-21

Tab Vertically...................................................................... 4-22

Move to Line n.................................................................... 4-22

Tab Vertically to Line N...................................................... 4-22

Tab Vertically N Lines ........................................................ 4-22

Set Vertical Tab Stops......................................................... 4-23

Set Vertical Tab Stop at Current Position ........................... 4-23

Clear All Vertical Tab Stops ............................................... 4-23

Clear Vertical Tab Stop at Current Position ....................... 4-23

Character Pitch Commands ..................................................... 4-23

Set Character Pitch to 5 cpi ................................................ 4-23

Set Character Pitch to 8.3 cpi ............................................. 4-23

Set Character Pitch to 10 cpi .............................................. 4-24

Set Character Pitch to 12 cpi .............................................. 4-24

Set Character Pitch to 16.7 cpi ........................................... 4-24

Line Spacing Commands ......................................................... 4-24

Set Line Spacing to 3 lpi..................................................... 4-24

Set Line Spacing to 4 lpi..................................................... 4-24

Set Line Spacing to 6 lpi..................................................... 4-24