Page 1

MF1215-01

CMOS 8-BIT SINGLE CHIP MICROCOMPUTER

E0C88832/88862 T

ECHNICAL

M

ANU AL

E0C88832/88862 Technical Hardware

Page 2

NOTICE

No part of this material may be reproduced or duplicated in any form or by any means without the written

permission of Seiko Epson. Seiko Epson reserves the right to make changes to this material without notice.

Seiko Epson does not assume any liability of any kind arising out of any inaccuracies contained in this material

or due to its application or use in any product or circuit and, further, there is no representation that this material

is applicable to products requiring high level reliability, such as medical products. Moreover, no license to any

intellectual property rights is granted by implication or otherwise, and there is no representation or warranty that

anything made in accordance with this material will be free from any patent or copyright infringement of a third

party. This material or portions thereof may contain technology or the subject relating to strategic products under

the control of the Foreign Exchange and Foreign Trade Law of Japan and may require an export license from

the Ministry of International Trade and Industry or other approval from another government agency.

© SEIKO EPSON CORPORATION 2000 All rights reserved.

Page 3

E0C88832/88862 TECHNICAL MANUAL EPSON i

CONTENTS

Contents

1 INTRODUCTION .............................................................................................. 1

1.1 Configuration.....................................................................................................................1

1.2 Features .............................................................................................................................2

1.3 Block Diagram ...................................................................................................................3

1.4 Pin Layout Diagram ..........................................................................................................4

1.5 Mask Option.......................................................................................................................8

2 POWER SUPPLY.............................................................................................. 11

2.1 Operating Voltage.............................................................................................................11

2.2 Internal Power Supply Circuit ..........................................................................................11

2.3 Heavy Load Protection Mode ...........................................................................................12

3 CPU AND MEMORY CONFIGURATION ..................................................... 13

3.1 CPU ..................................................................................................................................13

3.2 Internal Memory ...............................................................................................................13

3.2.1 ROM ........................................................................................................................................13

3.2.2 RAM......................................................................................................................................... 13

3.2.3 I/O memory.............................................................................................................................. 13

3.2.4 Display memory....................................................................................................................... 13

3.3 Exception Processing Vectors ..........................................................................................13

3.4 CC (Customized Condition Flag) .....................................................................................14

4 INITIAL RESET ............................................................................................... 15

4.1 Initial Reset Factors..........................................................................................................15

4.1.1 RESET terminal....................................................................................................................... 15

4.1.2 Simultaneous LOW level input at input port terminals K00–K03...........................................15

4.1.3 Supply voltage detection (SVD) circuit ................................................................................... 16

4.1.4 Initial reset sequence...............................................................................................................16

4.2 Initial Settings After Initial Reset......................................................................................17

5 PERIPHERAL CIRCUITS AND THEIR OPERATION................................ 18

5.1 I/O Memory Map ..............................................................................................................18

5.2 Watchdog Timer................................................................................................................27

5.2.1 Configuration of watchdog timer ............................................................................................ 27

5.2.2 Interrupt function ....................................................................................................................27

5.2.3 Control of watchdog timer ......................................................................................................27

5.2.4 Programming notes .................................................................................................................27

5.3 Oscillation Circuits and Operating Mode ........................................................................28

5.3.1 Configuration of oscillation circuits ....................................................................................... 28

5.3.2 Mask option .............................................................................................................................28

5.3.3 OSC1 oscillation circuit ..........................................................................................................28

5.3.4 OSC3 oscillation circuit ..........................................................................................................29

5.3.5 Operating mode ....................................................................................................................... 29

5.3.6 Switching the CPU clocks ....................................................................................................... 30

5.3.7 Control of oscillation circuit and operating mode.................................................................. 31

5.3.8 Programming notes .................................................................................................................32

5.4 Input Ports (K ports).........................................................................................................33

5.4.1 Configuration of input ports....................................................................................................33

5.4.2 Mask option .............................................................................................................................33

5.4.3 Interrupt function and input comparison register................................................................... 34

Page 4

ii EPSON E0C88832/88862 TECHNICAL MANUAL

CONTENTS

5.4.4 Control of input ports .............................................................................................................. 36

5.4.5 Programming note................................................................................................................... 38

5.5 Output Ports (R ports) ......................................................................................................39

5.5.1 Configuration of output ports.................................................................................................. 39

5.5.2 Mask option ............................................................................................................................. 39

5.5.3 High impedance control .......................................................................................................... 39

5.5.4 DC output ................................................................................................................................39

5.5.5 Special output .......................................................................................................................... 39

5.5.6 Control of output ports ............................................................................................................ 42

5.5.7 Programming notes ................................................................................................................. 45

5.6 I/O Ports (P ports) ............................................................................................................46

5.6.1 Configuration of I/O ports....................................................................................................... 46

5.6.2 Mask option ............................................................................................................................. 46

5.6.3 I/O control registers and I/O mode ......................................................................................... 46

5.6.4 Control of I/O ports.................................................................................................................47

5.6.5 Programming note................................................................................................................... 47

5.7 Serial Interface .................................................................................................................48

5.7.1 Configuration of serial interface.............................................................................................48

5.7.2 Mask option ............................................................................................................................. 49

5.7.3 Transfer modes ........................................................................................................................ 49

5.7.4 Clock source ............................................................................................................................ 50

5.7.5 Transmit-receive control ......................................................................................................... 51

5.7.6 Operation of clock synchronous transfer ................................................................................52

5.7.7 Operation of asynchronous transfer ....................................................................................... 56

5.7.8 Interrupt function ....................................................................................................................60

5.7.9 Control of serial interface .......................................................................................................62

5.7.10 Programming notes ...............................................................................................................66

5.8 Clock Timer.......................................................................................................................67

5.8.1 Configuration of clock timer ................................................................................................... 67

5.8.2 Interrupt function ....................................................................................................................67

5.8.3 Control of clock timer ............................................................................................................. 69

5.8.4 Programming notes ................................................................................................................. 71

5.9 Stopwatch Timer ...............................................................................................................72

5.9.1 Configuration of stopwatch timer ........................................................................................... 72

5.9.2 Count up pattern...................................................................................................................... 72

5.9.3 Interrupt function ....................................................................................................................73

5.9.4 Control of stopwatch timer...................................................................................................... 74

5.9.5 Programming notes ................................................................................................................. 76

5.10 Programmable Timer........................................................................................................77

5.10.1 Configuration of programmable timer .................................................................................. 77

5.10.2 Count operation and setting basic mode...............................................................................77

5.10.3 Setting of input clock ............................................................................................................. 79

5.10.4 Timer mode............................................................................................................................ 79

5.10.5 Event counter mode ............................................................................................................... 80

5.10.6 Pulse width measurement timer mode................................................................................... 80

5.10.7 Interrupt function .................................................................................................................. 81

5.10.8 Setting of TOUT output ......................................................................................................... 81

5.10.9 Transmission rate setting of serial interface.........................................................................82

5.10.10 Control of programmable timer ..........................................................................................83

5.10.11 Programming notes ............................................................................................................. 88

5.11 LCD Controller.................................................................................................................89

5.11.1 Configuration of LCD controller ..........................................................................................89

5.11.2 Mask option ...........................................................................................................................89

5.11.3 LCD power supply................................................................................................................. 90

5.11.4 LCD driver ............................................................................................................................90

5.11.5 Display memory..................................................................................................................... 93

Page 5

E0C88832/88862 TECHNICAL MANUAL EPSON iii

CONTENTS

5.11.6 Display control ..................................................................................................................... 100

5.11.7 Control of LCD controller.................................................................................................... 101

5.11.8 Programming note................................................................................................................ 102

5.12 Sound Generator..............................................................................................................103

5.12.1 Configuration of sound generator........................................................................................ 103

5.12.2 Control of buzzer output.......................................................................................................103

5.12.3 Setting of buzzer frequency and sound level ........................................................................ 104

5.12.4 Digital envelope ................................................................................................................... 105

5.12.5 One-shot output ....................................................................................................................105

5.12.6 Control of sound generator ..................................................................................................106

5.12.7 Programming notes ..............................................................................................................108

5.13 Supply Voltage Detection (SVD) Circuit .........................................................................109

5.13.1 Configuration of SVD circuit ............................................................................................... 109

5.13.2 Operation of SVD circuit...................................................................................................... 109

5.13.3 Control of SVD circuit.......................................................................................................... 111

5.13.4 Programming notes ..............................................................................................................112

5.14 Interrupt and Standby Status ...........................................................................................113

5.14.1 Interrupt generation conditions ........................................................................................... 114

5.14.2 Interrupt factor flag..............................................................................................................114

5.14.3 Interrupt enable register ...................................................................................................... 115

5.14.4 Interrupt priority register and interrupt priority level......................................................... 115

5.14.5 Exception processing vectors ...............................................................................................116

5.14.6 Control of interrupt .............................................................................................................. 117

5.14.7 Programming notes ..............................................................................................................118

5.15 Notes for Low Current Consumption...............................................................................119

6 BASIC EXTERNAL WIRING DIAGRAM..................................................... 120

7 ELECTRICAL CHARACTERISTICS............................................................ 122

7.1 Absolute Maximum Rating...............................................................................................122

7.2 Recommended Operating Conditions ..............................................................................122

7.3 DC Characteristics ..........................................................................................................123

7.4 Analog Circuit Characteristics ........................................................................................124

7.5 Power Current Consumption ...........................................................................................127

7.6 AC Characteristics...........................................................................................................128

7.7 Oscillation Characteristics ..............................................................................................134

7.8 Characteristics Curves (reference value) ........................................................................135

8 PACKAGE ........................................................................................................ 142

8.1 Plastic Package................................................................................................................142

8.2 Ceramic Package .............................................................................................................144

9 PAD LAYOUT .................................................................................................. 145

9.1 Diagram of Pad Layout ...................................................................................................145

9.2 Pad Coordinates ..............................................................................................................147

10 PRECAUTIONS ON MOUNTING ................................................................. 149

Page 6

Page 7

E0C88832/88862 TECHNICAL MANUAL EPSON 1

1 INTRODUCTION

1 INTRODUCTION

The E0C88832/88862 microcomputer

features the E0C88 (Model 3) CMOS 8-bit core CPU

along with ROM, RAM, three different timers and a

serial interface with optional asynchronization or

clock synchronization.

The E0C88832/88862 fully operable over a wide

range of voltages, and can perform high speed

operations even at low voltage. Like all the

equipment in the E0C Family, these microcomputers have low power consumption.

1.1 Configuration

In this manual, the E0C88832/88862 is associated

with E0C88832 and E0C88862. In these models,

there are differences in built-in ROM capacity,

number of output ports and number of LCD drive

segments, but the other peripheral circuits are

made with the same configuration.

Table 1.1.1 Configuration

Model

E0C88832

E0C88862

Internal ROM

32K bytes

60K bytes

Output port

5 bits

4 bits

LCD segment

*

1

1,632 (Max.)

1,312 (Max.)

*1: Maximum number of drive segments

when the 32 common is selected.

Page 8

2 EPSON E0C88832/88862 TECHNICAL MANUAL

1 INTRODUCTION

1.2 Features

Table 1.2.1 lists the features of the E0C88832/88862.

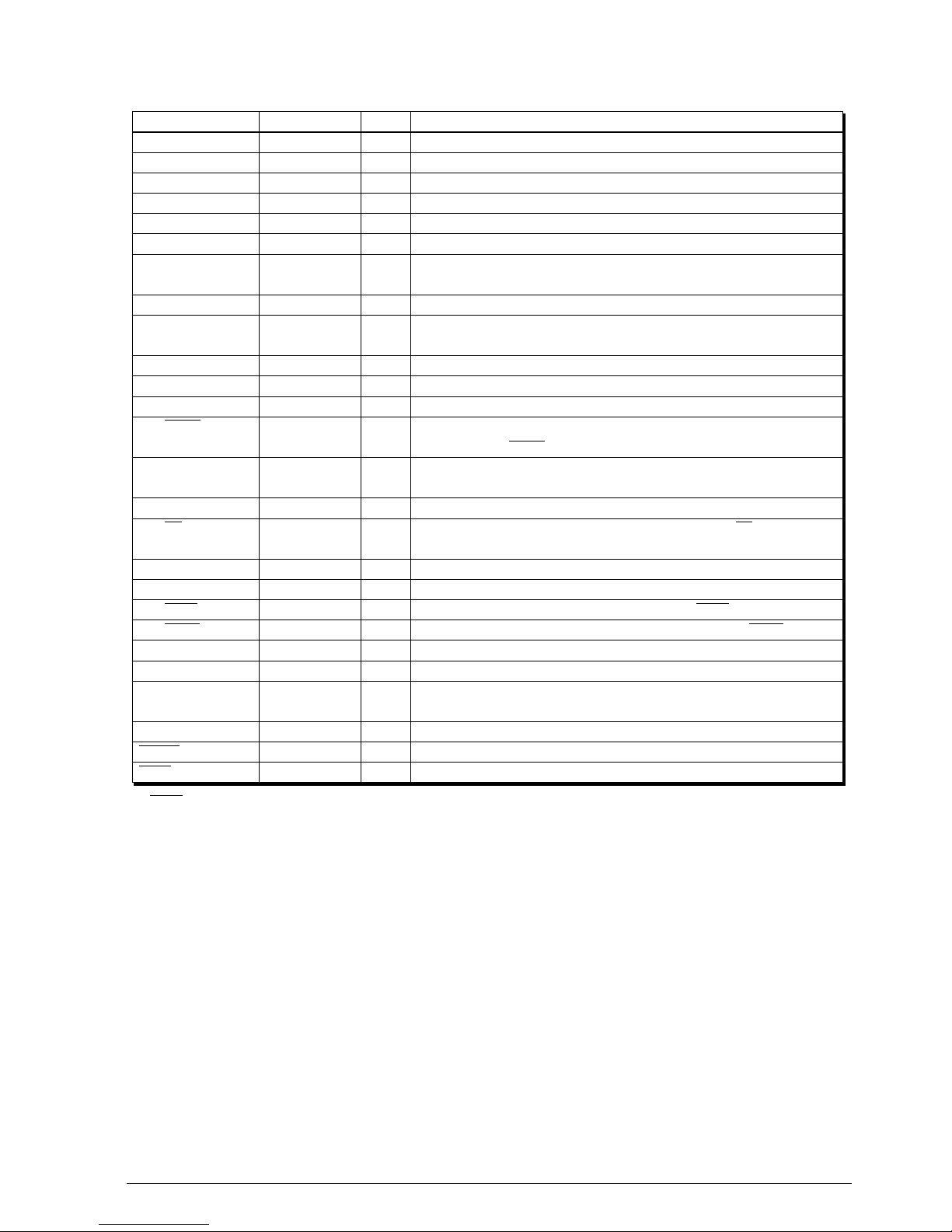

Table 1.2.1 Main features

Model

Core CPU

OSC1 Oscillation circuit

OSC3 Oscillation circuit

Instruction set

Min. instruction execution time

Internal ROM capacity

Internal RAM capacity

Input port

Output port

I/O port

Serial interface

Timer

Power supply circuit to

drive liquid crystals

LCD driver

Sound generator

Watchdog timer

Supply voltage detection

(SVD) circuit

Interrupt

Supply voltage

Consumed

current

Supply form

E0C88 (MODEL3) CMOS 8-bit core CPU

Crystal oscillation circuit/CR oscillation circuit/external clock input 32.768 kHz (Typ.)

Crystal oscillation circuit/ceramic oscillation circuit/CR oscillation circuit/external clock input 8.2 MHz (Max.)

608 types (usable for multiplication and division instructions)

0.244 µsec/8.2 MHz (2 clock)

32K bytes

1.5K bytes/RAM, 3,216 bits/display memory

9 bits (1 bit can be set for event counter external clock input)

5 bits (can be set for buzzer output, TOUT signal and

FOUT output)

8 bits (4 bits can be set for serial interface input/output)

1ch (Optional clock synchronous system or asynchronous system)

Programmable timer (8 bits):

(1ch can be set as a an event counter or 2ch as a 16 bits programmable timer for 1ch)

Clock timer (8 bits):

Stopwatch timer (8 bits):

Built-in (booster type, 5 potentials/4 potentials)

Dot matrix type (compatible with 5 × 8 or 5 × 5 fonts)

51 segments × 32 common

67 segments × 16 common

67 segments × 8 common

Envelope function, equipped with volume control

Built-in

Can detect up to 16 different voltage levels

External interrupt:

Internal interrupt:

Normal mode:

Low power mode:

High speed mode:

60K bytes

1.5K bytes/RAM, 2,736 bits/display memory

4 bits (can be set for buzzer output and TOUT signal

output)

41 segments × 32 common

57 segments × 16 common

57 segments × 8 common

E0C88832 E0C88862

0.3 µA (Typ./normal mode)

1.5 µA (Typ./normal mode)

9 µA (Typ./normal mode)

1.1 mA (Typ./normal mode)

QFP8-128pin, QFP15-128pin or chip

SLEEP

HALT

In operation

In operation

2ch

1ch

1ch

Input interrupt

Timer interrupt

Serial interface interrupt

2.4 V–5.5 V (Max. 4.2 MHz)

1.8 V–3.5 V (Max. 80 kHz)

3.5 V–5.5 V (Max. 8.2 MHz)

2 systems (3 types)

3 systems (9 types)

1 system (3 types)

(32.768 kHz)

(32.768 kHz)

(4 MHz)

Page 9

E0C88832/88862 TECHNICAL MANUAL EPSON 3

1 INTRODUCTION

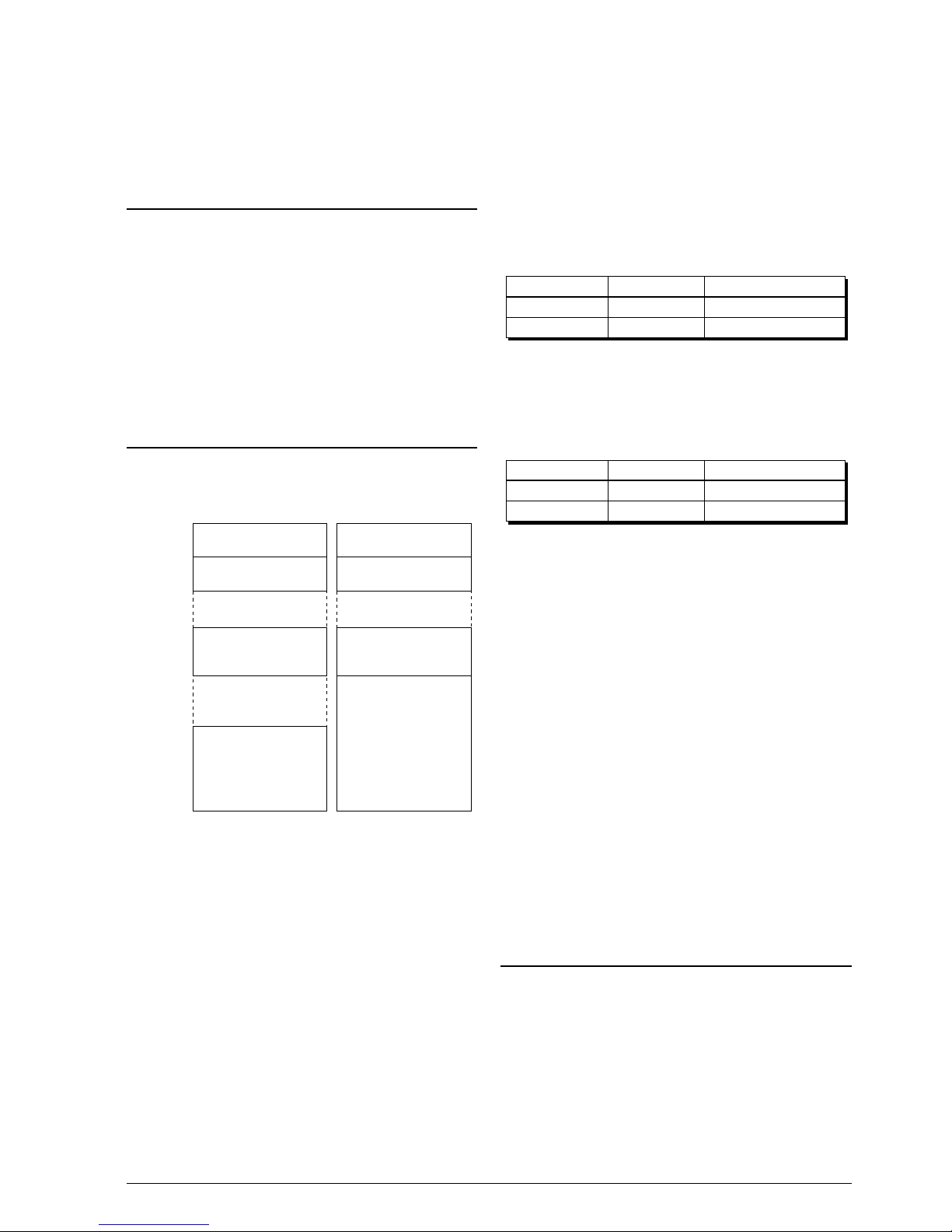

1.3 Block Diagram

Core CPU E0C88

Interrupt Controller

Input Port

Oscillator

OSC1, 2

OSC3, 4

Reset/Test

RESET

TEST

Watchdog Timer

K00–K07

K10 (EVIN)

I/O Port

Serial Interface

Output Port

Programmable Timer

/Event Counter

Clock Timer

Stopwatch Timer

Power Generator

V

DD

V

SS

V

D1

V

OSC

VC1–V

C5

Supply Voltage Detector

RAM

1.5KB

LCD Driver

ROM

60KB

P10 (SIN)

P11 (SOUT)

P12 (SCLK)

P13 (SRDY)

R26 (TOUT *)

R50 (BZ)

R27 (TOUT)

R51 (BZ *)

Sound Generator

SEG0–SEG40

COM16–COM31 (SEG66–SEG51)

COM0–COM15

P14–P17

CA–CG

∗ Selectable by mask option

E0C88832

Fig. 1.3.1 E0C88832 block diagram

E0C88862

Fig. 1.3.2 E0C88862 block diagram

Core CPU E0C88

Interrupt Controller

Input Port

Oscillator

OSC1, 2

OSC3, 4

Reset/Test

Watchdog Timer

K00–K07

K10 (EVIN)

I/O Port

Serial Interface

Output Port

Programmable Timer

/Event Counter

Clock Timer

Stopwatch Timer

Power Generator

Supply Voltage Detector

RAM

1.5KB

LCD Driver

ROM

32KB

P10 (SIN)

P11 (SOUT)

P12 (SCLK)

P13 (SRDY)

Sound Generator

SEG0–SEG50

COM16–COM31 (SEG66–SEG51)

COM0–COM15

P14–P17

R26 (TOUT *)

R34 (FOUT)

R50 (BZ)

R27 (TOUT)

R51 (BZ *)

∗ Selectable by mask option

RESET

TEST

V

DD

V

SS

V

D1

V

OSC

VC1–V

C5

CA–CG

Page 10

4 EPSON E0C88832/88862 TECHNICAL MANUAL

1 INTRODUCTION

1.4 Pin Layout Diagram

Fig. 1.4.1 E0C88832 pin layout

E0C88832

QFP8-128pin QFP15-128pin

6596

33

64

INDEX

321

128

97

6596

33

64

INDEX

321

128

97

Pin No. Pin name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Pin No. Pin name

OSC3

OSC4

V

OSC

V

D1

V

DD

V

SS

OSC1

OSC2

TEST

RESET

K10/EVIN

K07

K06

K05

K04

K03

K02

K01

K00

P17

P16

P15

P14

P13/SRDY

P12/SCLK

P11/SOUT

P10/SIN

R26/TOUT

R27/TOUT

R34/FOUT

R50/BZ

R51/BZ

COM19/SEG63

COM18/SEG64

COM17/SEG65

COM16/SEG66

COM15

COM14

COM13

COM12

COM11

COM10

COM9

COM8

COM7

COM6

COM5

COM4

COM3

COM2

COM1

COM0

CG

CF

CE

CD

CC

CB

CA

V

C5

V

C4

V

C3

V

C2

V

C1

Pin No. Pin name

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

N.C.

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

N.C.: No Connection

Pin No. Pin name

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

SEG31

SEG32

SEG33

SEG34

SEG35

SEG36

SEG37

SEG38

SEG39

SEG40

SEG41

SEG42

SEG43

SEG44

SEG45

SEG46

SEG47

SEG48

SEG49

SEG50

COM31/SEG51

COM30/SEG52

COM29/SEG53

COM28/SEG54

COM27/SEG55

COM26/SEG56

COM25/SEG57

COM24/SEG58

COM23/SEG59

COM22/SEG60

COM21/SEG61

COM20/SEG62

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Page 11

E0C88832/88862 TECHNICAL MANUAL EPSON 5

1 INTRODUCTION

Table 1.4.1 E0C88832 pin description

Pin No.

V

DD

VSS

VD1

VOSC

VC1–VC5

CA–CG

OSC1

OSC2

OSC3

OSC4

K00–K07

K10/EVIN

R26/TOUT

R27/TOUT

R34/FOUT

R50/BZ

R51/BZ

P10/SIN

P11/SOUT

P12/SCLK

P13/SRDY

P14–P17

COM0–COM15

COM16–COM31

/SEG66–SEG51

SEG0–SEG50

RESET

TEST

∗1

Pin name In/out Function

37

38

36

35

32–28

27–21

39

40

33

34

51–44

43

60

61

62

63

64

59

58

57

56

55–52

20–5

4–1, 128–117

66–116

42

41

–

–

–

–

O

–

I

O

I

O

I

I

O

O

O

O

O

I/O

I/O

I/O

I/O

I/O

O

O

O

I

I

Power supply (+) terminal

Power supply (GND) terminal

Regulated voltage for internal circuit

Regulated voltage for OSC1 oscillation circuit

LCD drive voltage output terminals

Voltage boost/reduce-capacitor connection terminals for LCD

OSC1 oscillation input terminal

(select crystal oscillation/CR oscillation/external clock input with mask option)

OSC1 oscillation output terminal

OSC3 oscillation input terminal

(select crystal/ceramic/CR oscillation/external clock input with mask option)

OSC3 oscillation output terminal

Input terminals (K00–K07)

Input terminal (K10) or event counter external clock input terminal (EVIN)

Output terminal (R26) or programmable timer underflow signal inverted

output terminal (TOUT) (selectable by mask option)

Output terminal (R27)

or programmable timer underflow signal output terminal (TOUT)

Output terminal (R34) or clock output terminal (FOUT)

Output terminal (R50) or buzzer output terminal (BZ)

Output terminal (R51) or buzzer inverted output terminal (BZ)

(selectable by mask option)

I/O terminal (P10) or serial I/F data input terminal (SIN)

I/O terminal (P11) or serial I/F data output terminal (SOUT)

I/O terminal (P12) or serial I/F clock I/O terminal (SCLK)

I/O terminal (P13) or serial I/F ready signal output terminal (SRDY)

I/O terminals (P14–P17)

LCD common output terminals

LCD common output terminals (when 1/32 duty is selected)

or LCD segment output terminal (when 1/16 or 1/8 duty is selected)

LCD segment output terminals

Initial reset input terminal

Test input terminal

∗1 TEST is the terminal used for shipping inspection of the IC. For normal operation be sure it is connected to VDD.

Page 12

6 EPSON E0C88832/88862 TECHNICAL MANUAL

1 INTRODUCTION

6596

33

64

INDEX

321

128

97

6596

33

64

INDEX

321

128

97

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

N.C.

COM15

COM14

COM13

COM12

COM11

COM10

COM9

COM8

COM7

COM6

COM5

COM4

COM3

COM2

COM1

COM0

CG

CF

CE

CD

CC

CB

CA

V

C5

V

C4

V

C3

V

C2

V

C1

OSC3

OSC4

N.C.

N.C.

N.C.

N.C.

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

SEG36

SEG37

SEG38

SEG39

SEG40

COM31/SEG51

COM30/SEG52

COM29/SEG53

COM28/SEG54

COM27/SEG55

COM26/SEG56

COM25/SEG57

COM24/SEG58

COM23/SEG59

COM22/SEG60

COM21/SEG61

COM20/SEG62

COM19/SEG63

COM18/SEG64

COM17/SEG65

COM16/SEG66

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

N.C.

V

OSC

V

D1

V

DD

V

SS

OSC1

OSC2

TEST

RESET

K10/EVIN

K07

K06

K05

K04

K03

K02

K01

K00

P17

P16

P15

P14

P13/SRDY

P12/SCLK

P11/SOUT

P10/SIN

R26/TOUT

R27/TOUT

R50/BZ

R51/BZ

N.C.

N.C.

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

N.C.

N.C.

N.C.

N.C.

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

N.C.: No Connection

Pin No. Pin name Pin No. Pin name Pin No. Pin name Pin No. Pin name

E0C88862

QFP8-128pin QFP15-128pin

Fig. 1.4.2 E0C88862 pin layout

Page 13

E0C88832/88862 TECHNICAL MANUAL EPSON 7

1 INTRODUCTION

Pin No.

V

DD

VSS

VD1

VOSC

VC1–VC5

CA–CG

OSC1

OSC2

OSC3

OSC4

K00–K07

K10/EVIN

R26/TOUT

R27/TOUT

R50/BZ

R51/BZ

P10/SIN

P11/SOUT

P12/SCLK

P13/SRDY

P14–P17

COM0–COM15

COM16–COM31

/SEG66–SEG51

SEG0–SEG40

RESET

TEST

∗1

Pin name In/out Function

68

69

67

66

61–57

56–50

70

71

62

63

82–75

74

91

92

93

94

90

89

88

87

86–83

49–34

32–17

101–128, 4–16

73

72

–

–

–

–

O

–

I

O

I

O

I

I

O

O

O

O

I/O

I/O

I/O

I/O

I/O

O

O

O

I

I

Power supply (+) terminal

Power supply (GND) terminal

Regulated voltage for internal circuit

Regulated voltage for OSC1 oscillation circuit

LCD drive voltage output terminals

Voltage boost/reduce-capacitor connection terminals for LCD

OSC1 oscillation input terminal

(select crystal oscillation/CR oscillation/external clock input with mask option)

OSC1 oscillation output terminal

OSC3 oscillation input terminal

(select crystal/ceramic/CR oscillation/external clock input with mask option)

OSC3 oscillation output terminal

Input terminals (K00–K07)

Input terminal (K10) or event counter external clock input terminal (EVIN)

Output terminal (R26) or programmable timer underflow signal inverted

output terminal (TOUT) (selectable by mask option)

Output terminal (R27)

or programmable timer underflow signal output terminal (TOUT)

Output terminal (R50) or buzzer output terminal (BZ)

Output terminal (R51) or buzzer inverted output terminal (BZ)

(selectable by mask option)

I/O terminal (P10) or serial I/F data input terminal (SIN)

I/O terminal (P11) or serial I/F data output terminal (SOUT)

I/O terminal (P12) or serial I/F clock I/O terminal (SCLK)

I/O terminal (P13) or serial I/F ready signal output terminal (SRDY)

I/O terminals (P14–P17)

LCD common output terminals

LCD common output terminals (when 1/32 duty is selected)

or LCD segment output terminal (when 1/16 or 1/8 duty is selected)

LCD segment output terminals

Initial reset input terminal

Test input terminal

Table 1.4.2 E0C88862 pin description

∗1 TEST is the terminal used for shipping inspection of the IC. For normal operation be sure it is connected to VDD.

Page 14

8 EPSON E0C88832/88862 TECHNICAL MANUAL

1 INTRODUCTION

1.5 Mask Option

Mask options shown below are provided for the

E0C88832/88862. Several hardware specifications

are prepared in each mask option, and one of them

can be selected according to the application. The

function option generator WINFOG, that has been

prepared as the development software tool of the

E0C88832/88862, is used for this selection. Mask

pattern of the IC is finally generated based on the

data created by the WINFOG. Refer to the "E0C88

Family Development Tool Manual" for details on

the WINFOG.

Functions selectable with E0C88832/88862 mask options

(1)RESET terminal pull-up resistor

This mask option can select whether the pull-up

resistor for the RESET terminal is used or not.

(2)External reset by simultaneous LOW

input to the input port (K00–K03)

This function resets the IC when several keys

are pressed simultaneously. The mask option is

used to select whether this function is used or

not. Further when the function is used, a

combination of the input ports (K00–K03),

which are connected to the keys to be pressed

simultaneously, can be selected. Refer to Section

4.1.2, "Simultaneous LOW level input at input

port terminals K00–K03", for details.

(3)OSC1 oscillation circuit

The specification of the OSC1 oscillation circuit

can be selected from among four types: "Crystal

oscillation", "CR oscillation", "Crystal oscillation

(gate capacitor built-in)" and "External clock

input". Refer to Section 5.3.3, "OSC1 oscillation

circuit", for details.

(4)OSC3 oscillation circuit

The specification of the OSC3 oscillation circuit

can be selected from among four types: "Crystal

oscillation", "Ceramic oscillation", "CR

oscillation" and "External clock input". Refer to

Section 5.3.4, "OSC3 oscillation circuit", for

details.

(5)Input port pull-up resistor

This mask option can select whether the pull-up

resistor for the input port terminal is used or

not. It is possible to select for each bit of the

input ports. Refer to Section 5.4, "Input Ports (K

ports)", for details.

(6)R26, R51 output port specifications

The R26 port can be configured as a generalpurpose output port or as the TOUT output

port (TOUT inverted output).

The R51 port can be configured as a generalpurpose output port or as the BZ output port

(BZ inverted output). Refer to Section 5.5,

"Output Ports (R ports)", for details.

(7)I/O port pull-up resistor

This mask option can select whether the pull-up

resistor for the I/O port terminal (it works

during input mode) is used or not. It is possible

to select for each bit of the I/O ports. Refer to

Section 5.6, "I/O Ports (P ports)", for details.

Since P10 to P13 are shared with the serial

interface I/O terminals, the selected P10 and

P12 terminal configuration is applied to the

serial input (SIN) terminal and serial clock input

terminal (SCLK in clock synchronous mode)

when the serial interface is used. Refer to

Section 5.7, "Serial Interface", for details.

(8)LCD drive duty

The drive duty for the built-in LCD driver can

be selected whether it will be 1/32 and 1/16

software-switched or fixed at 1/8. Refer to

Section 5.11, "LCD Controller", for details.

(9)LCD power supply

Either the internal power supply or an external

power supply can be selected as the LCD

system power source. Furthermore, when using

the internal power supply, the LCD drive

voltage can be set for a 4.5 V panel or a 5.5 V

panel and the drive bias to 1/5 or 1/4. Refer to

Section 5.11, "LCD Controller", for details.

(10) Initial reset by SVD circuit

The SVD circuit has a function that generates an

initial reset signal when the supply voltage

drops to level 0 or less. The mask option is used

to select whether this function is used or not.

Refer to Section 5.13, "Supply Voltage Detection

(SVD) Circuit", for details.

Page 15

E0C88832/88862 TECHNICAL MANUAL EPSON 9

1 INTRODUCTION

Option list

The following options can be set for the E0C88832/88862. Multiple specifications are available in each

option item as indicated in the Option List. Select the specifications that meet the target system and check

the appropriate box.

The option selection is done interactively on the screen during WINFOG execution, using this option list as

reference.

E0C88832/88862 mask option list (1/2)

1 OSC1 SYSTEM CLOCK

■■ 1. Crystal

■■ 2. External Clock

■■ 3. CR

■■ 4. Crystal (with Gate Capacity)

2 OSC3 SYSTEM CLOCK

■■ 1. Crystal

■■ 2. Ceramic

■■ 3. CR

■■ 4. External Clock

3 MULTIPLE KEY ENTRY RESET

• Combination ... ■■ 1. Not Use

■■ 2. Use K00, K01

■■ 3. Use K00, K01, K02

■■ 4. Use K00, K01, K02, K03

4 SVD RESET

■■ 1. Not Use

■■ 2. Use

5 INPUT PORT PULL UP RESISTOR

• K00 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K01 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K02 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K03 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K04 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K05 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K06 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K07 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K10 ................... ■■ 1. With Resistor ■■ 2. Gate Direct

• RESET .............. ■■ 1. With Resistor ■■ 2. Gate Direct

6 I/O PORT PULL UP RESISTOR

• P10 .................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P11 .................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P12 .................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P13 .................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P14 .................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P15 .................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P16 .................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P17 .................... ■■ 1. With Resistor ■■ 2. Gate Direct

Page 16

10 EPSON E0C88832/88862 TECHNICAL MANUAL

1 INTRODUCTION

E0C88832/88862 mask option list (2/2)

7 LCD DRIVE DUTY

■■ 1. 1/32 & 1/16 Duty

■■ 2. 1/8 Duty

8 LCD POWER SUPPLY

■■ 1. Internal TYPE A (V

C2 Standard, 1/5 Bias, 4.5 V)

■■ 2. External

■■ 3. Internal TYPE B (VC2 Standard, 1/5 Bias, 5.5 V)

■■ 4. Internal TYPE C (VC2 Standard, 1/4 Bias, 4.5 V)

■■ 5. Internal TYPE D (VC1 Standard, 1/4 Bias, 4.5 V)

9 R51 OUTPUT PORT SPECIFICATION

■■ 1. With BZ (Use)

■■ 2. Without BZ (Not Use)

10 R26 OUTPUT PORT SPECIFICATION

■■ 1. With TOUT (Use)

■■ 2. Without TOUT (Not Use)

Page 17

E0C88832/88862 TECHNICAL MANUAL EPSON 11

2 POWER SUPPLY

2 POWER SUPPLY

In this section, we will explain the operating

voltage and the configuration of the internal power

supply circuit of the E0C88832/88862.

2.1 Operating Voltage

The E0C88832/88862 operating power voltage is as

follows:

Normal mode: 2.4 V to 5.5 V

Low power mode: 1.8 V to 3.5 V

High speed mode: 3.5 V to 5.5 V

If supply voltage drops below level 0 (see Chapter

7, "ELECTRICAL CHARACTERISTICS"), the

system is automatically reset by a supply voltage

detection (SVD) circuit described in the latter. This

function can be selected by mask option.

2.2 Internal Power Supply Circuit

The E0C88832/88862 incorporates the power supply

circuit shown in Figure 2.2.1. When voltage within

the range described above is supplied to VDD (+) and

VSS (GND), all the voltages needed for the internal

circuit are generated internally in the IC.

Roughly speaking, the power supply circuit is

divided into three sections.

The internal logic voltage regulator generates the

operating voltage <VD1> for driving the internal

logic circuits and the OSC3 oscillation circuit. The

VD1 voltage can be selected from the following

three types: 1.3 V for low-power mode, 2.2 V for

normal mode and 3.3 V for high-speed mode.

It should be selected by a program to switch

according to the supply voltage and oscillation

frequency.

See Section 5.3, "Oscillation Circuits and Operating

Mode", for the switching of operating mode.

The oscillation system voltage regulator generates

the operating voltage <VOSC> for the OSC1

oscillation circuit.

The LCD system power supply circuit generates the

LCD drive voltages <VC1> to <VC5>. In 1/5 bias

mode, VC1 is generated by halving VC2 output from

the LCD system voltage regulator and VC3 to VC5 are

generated by boosting VC2. These five voltages can

be supplied from outside the IC by mask option.

Furthermore, 1/4 bias drive can be selected by

mask option. In this case, the VC2 voltage level

becomes equal to the VC3 voltage level. When using

with 1/4 bias configuration, the mask option also

allows selection of VC1 standard mode that

generates VC2 to VC5 by boosting VC1.

See Chapter 7, "ELECTRICAL CHARACTERISTICS" for the voltage values.

In the E0C88832/88862, the LCD drive voltage is

supplied to the built-in LCD driver which drives

the LCD panel connected to the SEG and COM

terminals.

Note: Do not use the VC1–VC5 outputs for driving

external circuits.

Fig. 2.2.1 Configuration of power supply circuit

V

DD

V

V

OSC

D1

V

C1

V

C3

V

C4

V

C5

CA

CB

CC

CD

CE

CF

CG

V

SS

LCD system

power supply

circuit

LCD driver

V

D1

VC1–V

C5

V

OSC

V

C2

External

power

supply

OSC3, OSC4

OSC1, OSC2

Regulator

Booster/reducer

Internal logic

voltage regulator

OSC3

oscillation circuit

Internal voltage

setting circuit

Oscillation system

voltage regulator

Internal circuit

OSC1

oscillation circuit

COM0~COM15

COM16~COM31/SEG66~SEG51

SEG0~SEG50

COM0~COM15

COM16~COM31/SEG66~SEG51

SEG0~SEG40

E0C88832

E0C88862

Page 18

12 EPSON E0C88832/88862 TECHNICAL MANUAL

2 POWER SUPPLY

2.3 Heavy Load Protection Mode

The E0C88832/88862 has a heavy load protection

function for stable operation even when the supply

voltage fluctuates by driving a heavy load. The

heavy load protection mode becomes valid when

the peripheral circuits are in the following status:

(1) The OSC3 oscillation circuit is switched ON

(OSCC = "1" and not in SLEEP)

(2) The buzzer output is switched ON

(BZON = "1" or BZSHT = "1")

SLEEP status

Heavy load

protection mode

OSCC

BZON

BZSHT

Fig. 2.3.1 Configuration of heavy load protection mode

control circuit

For details of the OSC3 oscillation circuit and

buzzer output, see "5.3 Oscillation Circuits and

Operating Mode" and "5.12 Sound Generator",

respectively.

Page 19

E0C88832/88862 TECHNICAL MANUAL EPSON 13

3 CPU AND MEMORY CONFIGURATION

3 CPU AND MEMORY CONFIGURATION

In this section, we will explain the CPU and memory configuration.

3.1 CPU

The E0C88832/88862 utilize the E0C88 8-bit core

CPU whose resistor configuration, command set,

etc. are virtually identical to other units in the

family of processors incorporating the E0C88.

See the "E0C88 Core CPU Manual" for the E0C88.

The E0C88832/88862 supports Model 3/minimum

mode of the E0C88 CPU which allows accessing of

the internal memory mapped within the physical

space from 000000H to 00FFFFH.

3.2 Internal Memory

The E0C88832/88862 is equipped with internal

ROM and RAM as shown in Figure 3.2.1.

3.2.1 ROM

The internal ROM capacity is shown in Table

3.2.1.1.

Table 3.2.1.1 Internal ROM capacity

Fig. 3.2.1 Internal memory map

I/O memory

Display memory

Unused area

RAM

(1.5K bytes)

ROM

(60K bytes)

E0C88832 E0C88862

00FFFFH

00FF00H

00FD42H

00F800H

00F7FFH

00F600H

00F5FFH

00F000H

00EFFFH

008000H

007FFFH

000000H

I/O memory

Display memory

Unused area

RAM

(1.5K bytes)

Unused area

ROM

(32K bytes)

Model

E0C88832

E0C88862

ROM capacity

32K bytes

60K bytes

Address

000000H–007FFFH

000000H–00EFFFH

3.2.2 RAM

The internal ROM capacity is shown in Table

3.2.2.1.

Table 3.2.2.1 Internal ROM capacity

Model

E0C88832

E0C88862

RAM capacity

1.5K bytes

1.5K bytes

Address

00F000H–00F5FFH

00F000H–00F5FFH

3.2.3 I/O memory

A memory mapped I/O method is employed in the

E0C88832/88862 for interfacing with internal

peripheral circuit. Peripheral circuit control bits and

data register are arranged in data memory space.

Control and data exchange are conducted via

normal memory access. The I/O memory is

arranged from address 00FF00H to address

00FFFFH. See Section 5.1, "I/O Memory Map", for

details of the I/O memory.

3.2.4 Display memory

The E0C88832/88862 is equipped with an internal

display memory which stores a display data for

LCD driver.

The display memory is arranged from address

00F800H to address 00FD42H (including the

unused area). See Section 5.11, "LCD Controller",

for details of the display memory.

3.3 Exception Processing Vectors

Address 000000H to address 000023H in the

program area of the E0C88832/88862 is assigned as

exception processing vectors. Furthermore, from

address 000026H to address 0000FFH, software

interrupt vectors are assignable to any two bytes

which begin with an even address.

Table 3.3.1 lists the vector addresses and the

exception processing factors to which they

correspond.

Page 20

14 EPSON E0C88832/88862 TECHNICAL MANUAL

3 CPU AND MEMORY CONFIGURATION

Table 3.3.1 Vector addresses and

exception processing factors

3.4 CC (Customized Condition Flag)

The E0C88832/88862 does not use the customized

condition flag (CC) in the core CPU. Accordingly, it

cannot be used as a branching condition for the

conditional branching instruction (JRS, CARS).

Vector

address

000000H

000002H

000004H

000006H

000008H

00000AH

00000CH

00000EH

000010H

000012H

000014H

000016H

000018H

00001AH

00001CH

00001EH

000020H

000022H

000024H

000026H

:

0000FEH

Priority

High

↑

↓

Low

No

priority

rating

Exception processing factor

Reset

Zero division

Watchdog timer (NMI)

Programmable timer 1 interrupt

Programmable timer 0 interrupt

K10 input interrupt

K04–K07 input interrupt

K00–K03 input interrupt

Serial I/F error interrupt

Serial I/F receiving complete interrupt

Serial I/F transmitting complete interrupt

Stopwatch timer 100 Hz interrupt

Stopwatch timer 10 Hz interrupt

Stopwatch timer 1 Hz interrupt

Clock timer 32 Hz interrupt

Clock timer 8 Hz interrupt

Clock timer 2 Hz interrupt

Clock timer 1 Hz interrupt

System reserved (cannot be used)

Software interrupt

For each vector address and the address after it, the

start address of the exception processing routine is

written into the subordinate and super ordinate

sequence. When an exception processing factor is

generated, the exception processing routine is

executed starting from the recorded address.

When multiple exception processing factors are

generated at the same time, execution starts with

the highest priority item.

The priority sequence shown in Table 3.3.1 assumes

that the interrupt priority levels are all the same.

The interrupt priority levels can be set by software

in each system. (See Section 5.14 "Interrupt and

Standby Status".)

Note: For exception processing other than reset,

SC (system condition flag) and PC (program

counter) are evacuated to the stack and

branches to the exception processing

routines. Consequently, when returning to

the main routine from exception processing

routines, please use the RETE instruction.

See the "E0C88 Core CPU Manual" for information

on CPU operations when an exception processing

factor is generated.

Page 21

E0C88832/88862 TECHNICAL MANUAL EPSON 15

4 INITIAL RESET

4.1.1 RESET terminal

Initial reset can be done by executed externally

inputting a LOW level to the RESET terminal.

Be sure to maintain the RESET terminal at LOW

level for the regulation time after the power on to

assure the initial reset.

In addition, be sure to use the RESET terminal for

the first initial reset after the power is turned on.

The RESET terminal is equipped with a pull-up

resistor. You can select whether or not to use by

mask option.

4.1.2 Simultaneous LOW level input at

input port terminals K00–K03

Another way of executing initial reset externally is to

input a LOW level simultaneously to the input ports

(K00–K03) selected by mask option.

Since there is a built-in time authorize circuit, be

sure to maintain the designated input port terminal

at LOW level for two seconds (when the oscillation

frequency fOSC1 = 32.768 kHz) or more to perform

the initial reset by means of this function.

However, the time authorize circuit is bypassed

during the SLEEP (standby) status and oscillation

stabilization waiting period, and initial reset is

executed immediately after the simultaneous LOW

level input to the designated input ports.

The combination of input ports (K00–K03) that can

be selected by mask option are as follows:

(1) Not use

(2) K00 & K01

(3) K00 & K01 & K02

(4) K00 & K01 & K02 & K03

For instance, if mask option (4) "K00 & K01 & K02

& K03" is selected, initial reset will take place when

the input level at input ports K00–K03 is simultaneously LOW.

When using this function, make sure that the

designated input ports do not simultaneously

switch to LOW level while the system is in normal

operation.

4 INITIAL RESET

Initial reset in the E0C88832/88862 is required in order to initialize circuits. This chapter describes

initial reset factors and the initial settings for internal registers.

4.1 Initial Reset Factors

There are three initial reset factors for the

E0C88832/88862 as shown below.

(1) RESET terminal

(2) Simultaneous LOW level input at input port

terminals K00–K03.

(3) Supply voltage detection (SVD) circuit

Figure 4.1.1 shows the configuration of the initial

reset circuit.

The CPU and peripheral circuits are initialized by

means of initial reset factors. When the factor is

canceled, the CPU commences reset exception

processing. (See "E0C88 Core CPU Manual".)

When this occurs, reset exception processing

vectors, Bank 0, 000000H–000001H from program

memory are read out and the program (initialization routine) which begins at the readout address is

executed.

K00

Input port K00

K01

Input port K01

K02

Input port K02

K03

Input port K03

V

DD

RESET

V

DD

V

DD

SLEEP status

Time authorize

circuit

Oscillation stability waiting signal

Internal initial reset

Mask option

Supply voltage detection

(SVD) circuit

Fig. 4.1.1 Configuration of initial reset circuit

Page 22

16 EPSON E0C88832/88862 TECHNICAL MANUAL

4 INITIAL RESET

4.1.3 Supply voltage detection (SVD) circuit

When the SVD circuit detects that supply voltage

has dropped below level 0 four successive times

(see Chapter 7, "ELECTRICAL CHARACTERISTICS"), it outputs an initial reset signal until the

supply voltage has been restored to level 2.

You can select whether or not to use the initial reset

according to the SVD circuit by mask option. If you

use it, the supply voltage must be at least level 2 for

the first sampling of the SVD circuit, when the

power is turned on. At this time, if the power

voltage level is less than level 2, the initial reset

status will not be canceled and instead the SVD

circuit will continue sampling until the supply

voltage reaches level 2 or more.

For more information, see "5.13 Supply Voltage

Detection (SVD) Circuit" in this Manual.

4.1.4 Initial reset sequence

After cancellation of the LOW level input to the

RESET terminal, when the power is turned on, the

start-up of the CPU is held back until the oscillation

stabilization waiting time (8,192/fOSC1 sec.) has

elapsed. When the initial reset by the SVD circuit

has been used, an initial sampling time (248/fOSC1

sec.) is added as additional waiting time.

Figure 4.1.4.1 shows the operating sequence

following initial reset release.

Also, when using the initial reset by simultaneous

LOW level input into the input port, you should be

careful of the following points.

(1) During SLEEP status, since the time authoriza-

tion circuit is bypassed, an initial reset is

triggered immediately after a LOW level

simultaneous input value. In this case, the CPU

starts after waiting the oscillation stabilization

time and the SVD circuit initial sampling time

(when used with the mask option), following

cancellation of the LOW level simultaneous

input.

(2) Other than during SLEEP status, an initial reset

will be triggered 1–2 seconds after a LOW level

simultaneous input. In this case, since a reset

differential pulse (64/f

OSC1 sec.) is generated

within the E0C88832/88862, the CPU will start

even if the LOW level simultaneous input status

is not canceled.

PC PC PC 00-0000

Dummy Dummy VECL

f

OSC1

RESET

Internal initial reset

Internal address bus

Internal data bus

Internal read signal

8192/f

OSC1

[sec]

Oscillation stable waiting time

248/f

OSC1

[sec]

First SVD sampling time * Dummy cycle Reset exception processing

∗

When the initial reset by the SVD circuit with the mask option has been used, this cycle is inserted as the waiting time.

Fig. 4.1.4.1 Initial reset sequence

Page 23

E0C88832/88862 TECHNICAL MANUAL EPSON 17

4 INITIAL RESET

Register name

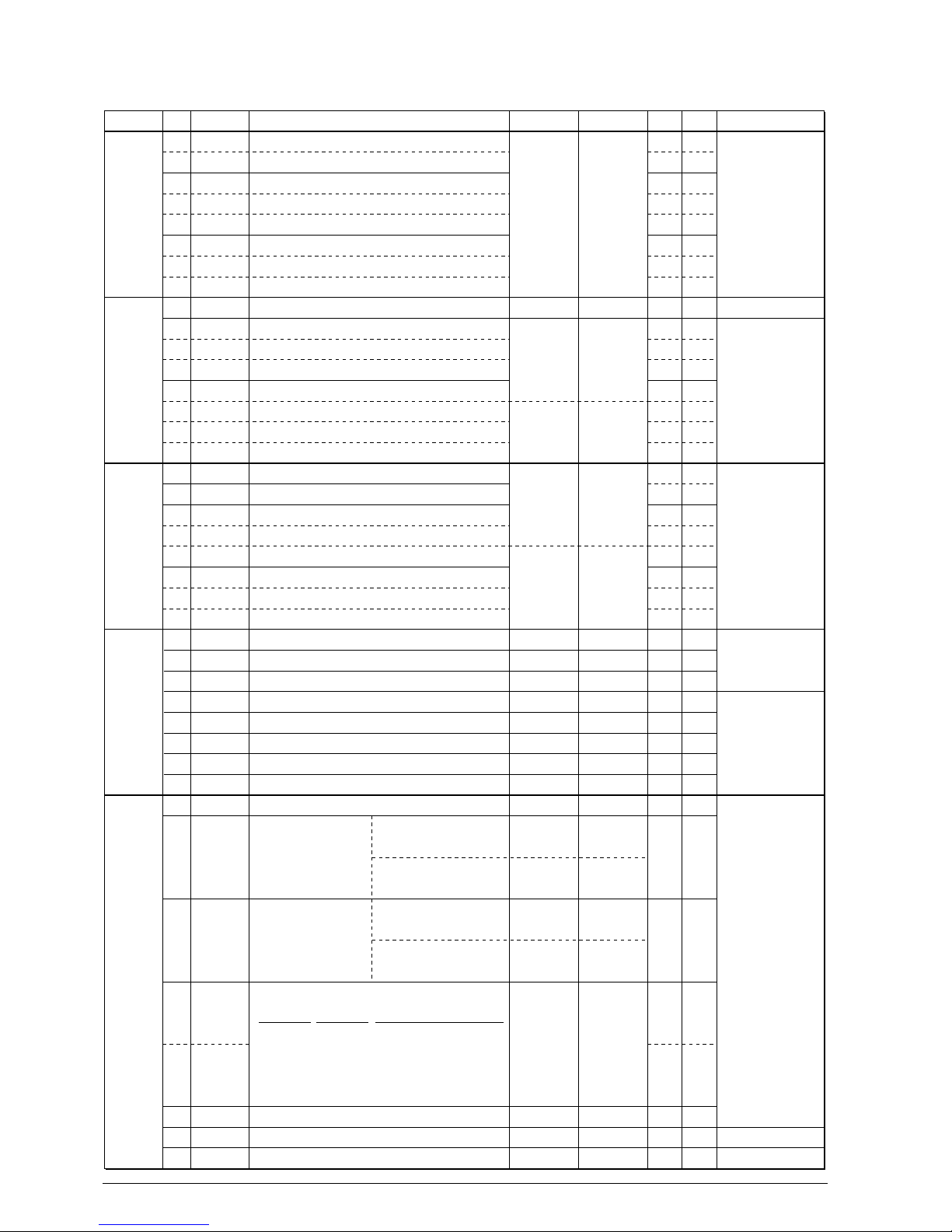

Code Setting value

Data register A

Data register B

Index (data) register L

Index (data) register H

Index register IX

Index register IY

Program counter

Stack pointer

Base register

Zero flag

Carry flag

Overflow flag

Negative flag

Decimal flag

Unpack flag

Interrupt flag 0

Interrupt flag 1

New code bank register

Code bank register

Expand page register

Expand page register for IX

Expand page register for IY

A

B

L

H

IX

IY

PC

SP

BR

Z

C

V

N

D

U

I0

I1

NB

CB

EP

XP

YP

Undefined

Undefined

Undefined

Undefined

Undefined

Undefined

Undefined

Undefined

Undefined

0

0

0

0

0

0

1

1

01H

Undefined

00H

00H

00H

Bit length

8

8

8

8

16

16

16

16

8

1

1

1

1

1

1

1

1

8

8

8

8

8

*

*

4.2 Initial Settings After Initial Reset

The CPU internal registers are initialized as follows

during initial reset.

Table 4.2.1 Initial settings

* Reset exception processing loads the preset

values stored in 0 bank, 000000H–000001H into

the PC. At the same time, 01H of the NB initial

value is loaded into CB.

Initialize the registers which are not initialized at

initial reset using software.

Since the internal RAM and display memory are

not initialized at initial reset, be sure to initialize

using software.

The respectively stipulated initializations are done

for internal peripheral circuits. If necessary, the

initialization should be done using software.

For initial value at initial reset, see the sections on

the I/O memory map and peripheral circuit

descriptions in the following chapter of this

Manual.

Page 24

18 EPSON E0C88832/88862 TECHNICAL MANUAL

5 PERIPHERAL CIRCUITS AND THEIR OPERATION (I/O Memory Map)

5 PERIPHERAL CIRCUITS AND

THEIR OPERATION

The peripheral circuits of the E0C88832/88862 is interfaced with the CPU by means of the memory

mapped I/O method. For this reason, just as with other memory access operations, peripheral circuits can

be controlled by manipulating I/O memory. Below is a description of the operation and control method for

each individual peripheral circuit.

5.1 I/O Memory Map

Table 5.1.1(a) I/O Memory map (00FF00H–00FF10H)

Address Bit Name

00FF00 D7

D6

D5

D4

D3

D2

D1

D0

BSMD1

BSMD0

CEMD1

CEMD0

CE3

CE2

CE1

CE0

SR R/WFunction Comment

General-purpose register

General-purpose register

General-purpose register

General-purpose register

General-purpose register

General-purpose register

General-purpose register

General-purpose register

Reserved register

(Note)

10

0

0

1

1

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

1 0

00FF01 D7

D6

D5

D4

D3

D2

D1

D0

SPP7

SPP6

SPP5

SPP4

SPP3

SPP2

SPP1

SPP0

General-purpose register

General-purpose register

General-purpose register

General-purpose register

General-purpose register

General-purpose register

General-purpose register

General-purpose register

Reserved register

(Note)

0

0

0

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

10

00FF02 D7

D6

D5

D4

D3

D2

D1

D0

EBR

WT2

WT1

WT0

CLKCHG

OSCC

VDC1

VDC0

General-purpose register

General-purpose register

General-purpose register

General-purpose register

CPU operating clock switch

OSC3 oscillation On/Off control

Operating mode selection

0

0

0

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

1

OSC3

On

0

OSC1

Off

VDC1

1

0

0

VDC0

×

1

0

High speed (VD1=3.3V)

Low power (V

D1

=1.3V)

Normal (V

D1

=2.2V)

Operating mode

00FF10 D7

D6

D5

D4

D3

D2

D1

D0

–

–

–

LCCLK

LCFRM

DTFNT

LDUTY

SGOUT

–

–

–

General-purpose register

General-purpose register

LCD dot font selection

LCD drive duty selection

General-purpose register

Constantry "0" when

being read

Reserved register

–

–

–

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

–

–

–

1

5 x 5 dots

1/16 duty

1

–

–

–

0

5 x 8 dots

1/32 duty

0

*1

Reserved register

*1 When 1/8 duty has been selected by mask option, setting of this register becomes invalid.

Note) When debugging using the E0C88 Family debugging tools ICE88R (ICE88) and PRC88348,

all the interrupts including NMI are disabled until values are written to addresses "00FF00H"

and "00FF01H".

Reserved register

Page 25

E0C88832/88862 TECHNICAL MANUAL EPSON 19

5 PERIPHERAL CIRCUITS AND THEIR OPERATION (I/O Memory Map)

Table 5.1.1(b) I/O Memory map (00FF11H–00FF22H)

Address Bit Name SR R/WFunction Comment10

00FF11 D7

D6

D5

D4

D3

D2

D1

D0

–

DSPAR

LCDC1

LCDC0

LC3

LC2

LC1

LC0

–

LCD display memory area selection

LCD display control

LCD contrast adjustment

"0" when being read

These bits are reset

to (0, 0) when

SLP instruction

is executed.

–

0

0

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

–

Display area 1–Display area 0

LCDC1

1

1

0

0

LCDC0

1

0

1

0

LCD display

All LCDs lit

All LCDs out

Normal display

Drive off

LC3

1

1

:

0

LC2

1

1

:

0

LC1

1

1

:

0

LC0

1

0

:

0

Contrast

Dark

:

:

Light

00FF12 D7

D6

D5

D4

D3

D2

D1

D0

–

–

SVDSP

SVDON

SVD3

SVD2

SVD1

SVD0

–

–

SVD auto-sampling control

SVD continuous sampling control/status

SVD detection level

Constantry "0" when

being read

These registers are

reset to "0" when

SLP instruction

is executed.

*2

–

–

0

1→0*1

0

X

X

X

X

R/W

R/W

R

R

R

R

–

–

On

Busy

On

–

–

Off

Ready

Off

R

W

SVD3

1

1

:

0

SVD2

1

1

:

0

SVD1

1

1

:

0

SVD0

1

0

:

0

Detection level

Level 15

Level 14

:

Level 0

*1 After initial reset, this status is set "1" until conclusion of hardware first sampling.

*2 Initial values are set according to the supply voltage detected at first sampling by hardware.

Until conclusion of first sampling, SVD0–SVD3 data are undefined.

00FF20 D7

D6

D5

D4

D3

D2

D1

D0

PK01

PK00

PSIF1

PSIF0

PSW1

PSW0

PTM1

PTM0

K00–K07 interrupt priority register

Serial interface interrupt priority register

Stopwatch timer interrupt priority register

Clock timer interrupt priority register

0

0

0

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

PK01

PSIF1

PSW1

PTM1

1

1

0

0

PK00

PSIF0

PSW0

PTM0

1

0

1

0

Priority

level

Level 3

Level 2

Level 1

Level 0

00FF21 D7

D6

D5

D4

D3

D2

D1

D0

–

–

–

–

PPT1

PPT0

PK11

PK10

–

–

–

–

Programmable timer interrupt priority register

K10 interrupt priority register

Constantly "0" when

being read

–

–

–

–

0

0

0

0

R/W

R/W

R/W

R/W

–

–

–

–

–

–

–

–

PPT1

PK11

1

1

0

0

PPT0

PK10

1

0

1

0

Priority

level

Level 3

Level 2

Level 1

Level 0

00FF22 D7

D6

D5

D4

D3

D2

D1

D0

–

ESW100

ESW10

ESW1

ETM32

ETM8

ETM2

ETM1

–

Stopwatch timer 100 Hz interrupt enable register

Stopwatch timer 10 Hz interrupt enable register

Stopwatch timer 1 Hz interrupt enable register

Clock timer 32 Hz interrupt enable register

Clock timer 8 Hz interrupt enable register

Clock timer 2 Hz interrupt enable register

Clock timer 1 Hz interrupt enable register

"0" when being read

–

0

0

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

–

Interrupt

enable

–

Interrupt

disable

Page 26

20 EPSON E0C88832/88862 TECHNICAL MANUAL

5 PERIPHERAL CIRCUITS AND THEIR OPERATION (I/O Memory Map)

Table 5.1.1(c) I/O Memory map (00FF23H–00FF31H)

Address Bit Name SR R/WFunction Comment10

D7

D6

D5

D4

D3

D2

D1

D0

00FF24 D7

D6

D5

D4

D3

D2

D1

D0

–

FSW100

FSW10

FSW1

FTM32

FTM8

FTM2

FTM1

–

Stopwatch timer 100 Hz interrupt factor flag

Stopwatch timer 10 Hz interrupt factor flag

Stopwatch timer 1 Hz interrupt factor flag

Clock timer 32 Hz interrupt factor flag

Clock timer 8 Hz interrupt factor flag

Clock timer 2 Hz interrupt factor flag

Clock timer 1 Hz interrupt factor flag

"0" when being read

–

0

0

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

–

(R)

Interrupt

factor is

generated

(W)

Reset

–

(R)

No interrupt

factor is

generated

(W)

No operation

00FF25 D7

D6

D5

D4

D3

D2

D1

D0

FPT1

FPT0

FK1

FK0H

FK0L

FSERR

FSREC

FSTRA

Programmable timer 1 interrupt factor flag

Programmable timer 0 interrupt factor flag

K10 interrupt factor flag

K04–K07 interrupt factor flag

K00–K03 interrupt factor flag

Serial I/F (error) interrupt factor flag

Serial I/F (receiving) interrupt factor flag

Serial I/F (transmitting) interrupt factor flag

0

0

0

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

(R)

Interrupt

factor is

generated

(W)

Reset

(R)

No interrupt

factor is

generated

(W)

No operation

00FF23 EPT1

EPT0

EK1

EK0H

EK0L

ESERR

ESREC

ESTRA

Programmable timer 1 interrupt enable register

Programmable timer 0 interrupt enable register

K10 interrupt enable register

K04–K07 interrupt enable register

K00–K03 interrupt enable register

Serial I/F (error) interrupt enable register

Serial I/F (receiving) interrupt enable register

Serial I/F (transmitting) interrupt enable register

0

0

0

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Interrupt

enable

Interrupt

disable

00FF30 D7

D6

D5

D4

D3

D2

D1

D0

–

–

–

MODE16

CHSEL

PTOUT

CKSEL1

CKSEL0

–

–

–

8/16-bit mode selection

TOUT output channel selection

TOUT output control

Prescaler 1 source clock selection

Prescaler 0 source clock selection

Constantry "0" when

being read

–

–

–

0

0

0

0

0

R/W

R/W

R/W

R/W

R/W

–

–

–

16-bit x 1

Timer 1

On

f

OSC3

f

OSC3

–

–

–

8-bit x 2

Timer 0

Off

f

OSC1

f

OSC1

00FF31 D7

D6

D5

D4

D3

D2

D1

D0

EVCNT

FCSEL

PLPOL

PSC01

PSC00

CONT0