Page 1

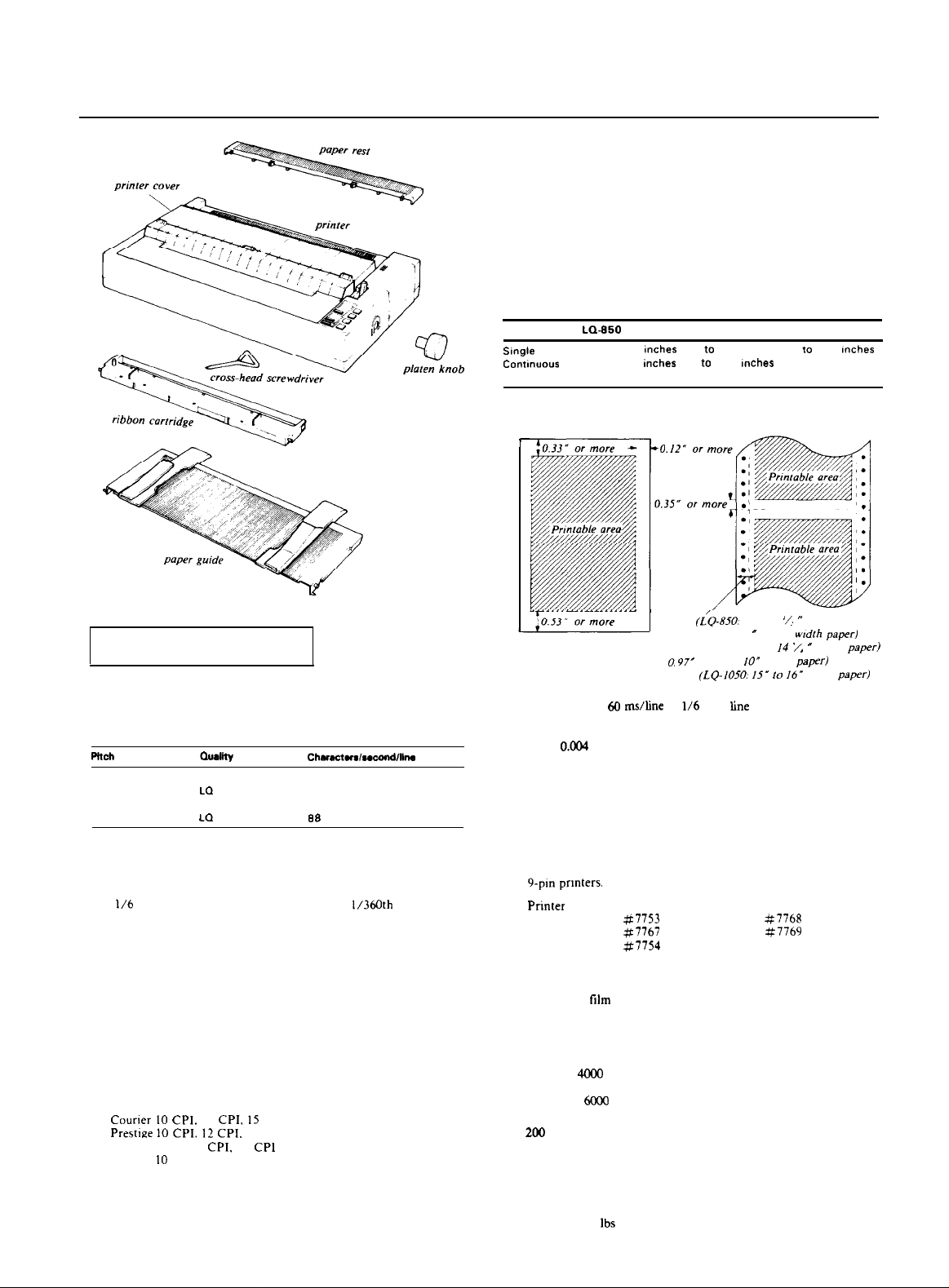

LQ - 850/950/1050 DOT - MATRIX PRINTER

Character tables

96 standard ASCII characters

13 international character sets

Epson Extended Graphics set

Paper

Paper feed methods

Friction

Built-in push feed tractor with paper tension unit

Single-bin or dual-bin cut sheet feeder (optional)

Pull tractor (optional)

Paper width

Type of paper

Envelopes

LQ-950

7.2 to 10.1 mches 7 2 to 13.0 inches 7.2 to 14.4 Inches

4.0 to 10.0 mches 4.0 to 12.0 Inches 4.0 to 16.0 inches

No. 6, No. 10

No. 6. No. 10 No 6. No. 10

LQ-1050

Printer Specifications

Printing

Printing method

24-pin impact dot matrix

Printing speed

10

10

12

12

Printing direction

Bi-directional with logic-seeking. User can select unidirectional

printing (left to right).

Line

spacing

inch, or programmable in increments of

Buffer

6 Kbytes or 0 Kbytes (DIP switch selectable)

Fonts

Epson New Draft

Epson Roman 10 CPI

Epson Roman 12 CPI

Epson Roman 15 CPI

Epson Roman proportional

Epson Sans Serif 10 CPI

Epson Sans Serif 12 CPI

Epson Sans Serif 15 CPI

Epson Sans Serif proportional

Optional fonts

Script-10 CPI, I2

OCR-A

OCR-B 10 CPI

Orator 10 CPI

Orator-S 10 CPI

24 - Pin Printers

draft

draft

CPI. I2 CPI.

CPI.

CPI

CPI

15 CPI

15 CPl

220

73

264

of an inch

12/12/88

Printable area

Single sheet Continuous paper

0.47”

I

4” to 9 wrdth paper)

(LQ-950: 4

(LQ-1050: 4” to

(LQ-850: IO” wrdth paper)

to 12”

7,

to 16” wrdth paper)

Paper feed speed

Approximately

Paper thickness

Up to

ms/line at

inch

spacing

inches for single sheets; up to 0.0126 inches for

continuous paper

Number of copies

With continuous, multi-part, no-carbon paper only; one original

plus up to three copies, maximum thickness: 0.0126 inches

Mechanical

Ribbon

Cartridge ribbon, available in black only Do not use ribbons for

prmters.

Standard ribbon

Film ribbon

LQ-850

LQ-950

LQ-1050

$7770

Life expectancy (in Letter Quality characters, at 48

dots/character): 2 million for standard ribbon and 0.2

million for

MCBF

For all components excluding print head: 5 million lines.

MTBF

LQ-850:

ribbon

power on hours (at 25% duty)

LQ-950: 5000 power on hours (at 25% duty)

LQ-1050:

power on hours (at 25% duty)

Print head life

million strokes per wire

Dimensions and weight

LQ-850

Height: 5.6 in.

Width: 17.0 in.

Depth: 14.2 in.

Weight: 19.8

LQ-950

Height: 5.6 in.

Width: 20.5 in.

Depth: 14.2 in.

Weight: 22.0 lbs

LQ-1050

Height: 5.6 in.

Width: 23.8 in.

Depth: 14.2 in.

Weight: 26.4 Ibs

LQ - 850/950/1050 - 1

paper)

width

Page 2

LQ - 850/950/1050 DOT - MATRIX PRINTER

Electrical

Voltage

120 VAC, + 10% (USA)

220 VAC,

10% (Europe)

Non-switchable

Power consumption

120 Watts maximum

Frequency

49.5 to 60.5 Hz

Insulation resistance

between AC power line and chassis

Dielectric strength

120 V model can withstand 1.25

line and chassis for 1 minute, or 1.5

Environment

Temperature

Operation: 41” F to 95” F

Storage:

22” F to

C to 35” C)

F

30” C to 65” C)

Humidity

Operation: 10% to 80% without condensation

Storage: 5% to 85% without condensation

Shock

Operation: Up to

G within 1ms

Storage: Up to 2 G within 1ms

Vibration

Operation: Up to 0.25 G at up to

Storage: Up to 0.5

at up to

Hz

rms applied between AC

rms for

second

Hz

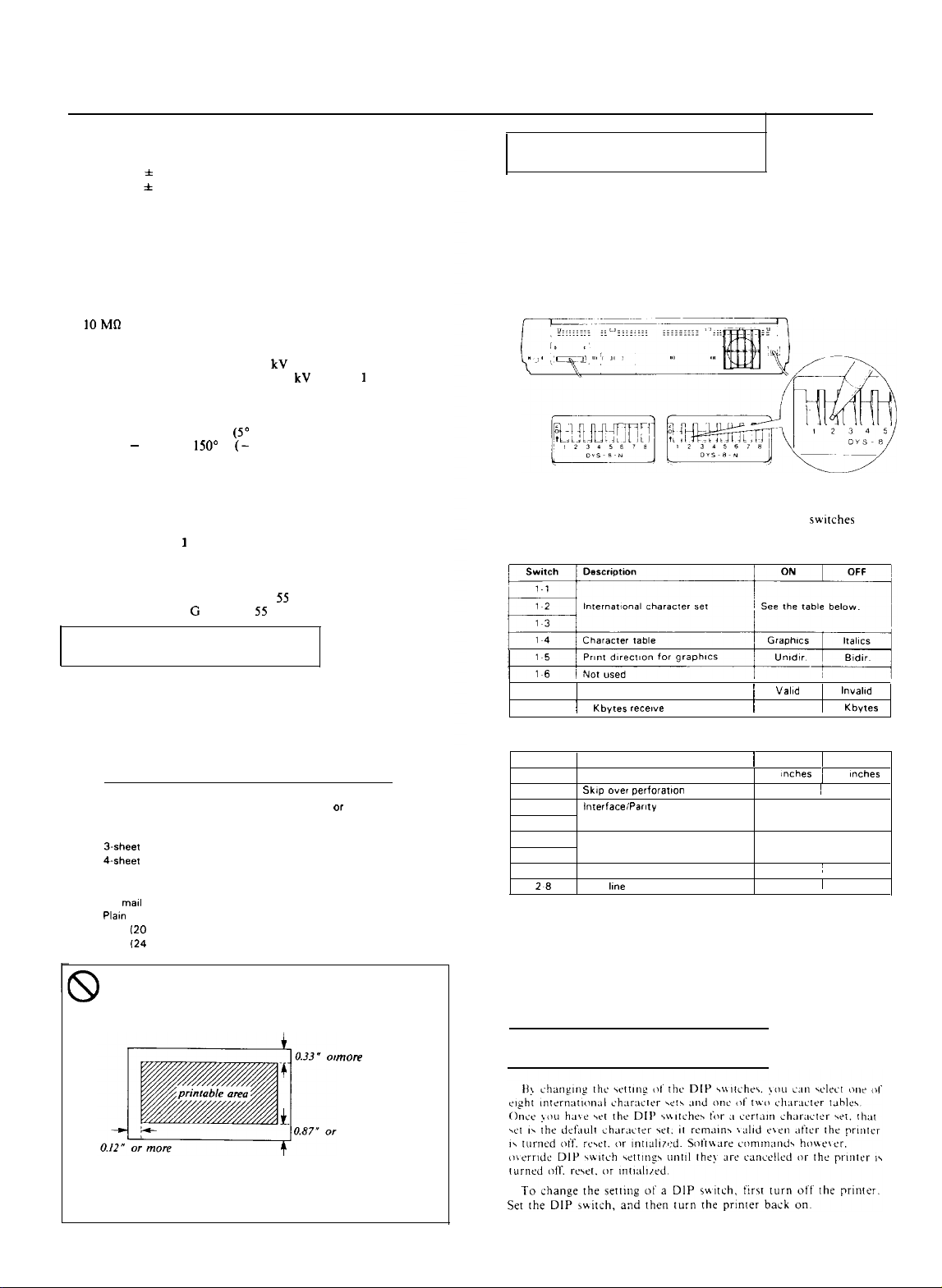

Setting the DIP Switches

By adjusting the settings of the two groups of DIP switches (SW1

and SW2) in the back of the printer, you can control various

features such as character set and page length.

To change the setting of a DIP switch, first turn off the printer.

Using a pencil, pen, or other pointed instrument, change the setting

as shown below. Then, turn the printer back on.

SW 1

The tables below describe the functions of the DIP switches

DIP Switch 1

SW 2

Printing on Special Paper

For printing on special types of paper, see the table below. When

the paper thickness lever is set to position 4 or higher, the MULTI-

PART light comes on and the printing speed is reduced.

The following table gives you general guidelines for selecting the

right paper thickness lever position to match your paper:

Paper Type

Paper (single sheets or continuous)

Thin paper

Multi-part paper

P-sheet

Labels

Envelopes

Air mall

Bond

lb.1

Bond

lb.1

When printing on envelopes, be sure that your application

program settings keep the printing entirely within the

printable area of the envelopes as shown below.

Lever Position

2

2

1

3

4

5

4

4

4 or 5

6

6

7

17 Cut sheet feeder mode

1.8

DIP Switch

Switch

21

22

23

2-4

25

26

27

6

2

Description

Page length

Baud rate

Short tear-off mode

Auto

buffer

feed

Valid

0 bytes 1 6 Kbytes

ON 1

I

12

ON

See the table below

See the table below

OFF

ON

ON

OFF

11

OFF

OFF

represents the DIP switch settings that have been preset at

the factory.

The factory settings for International character sets (DIP switches

1-1 to 1-3), the Character table (DIP switch 1-4). and Page length

(DIP switch 2-1) vary depending on the country, and are not

shown in the tables above.

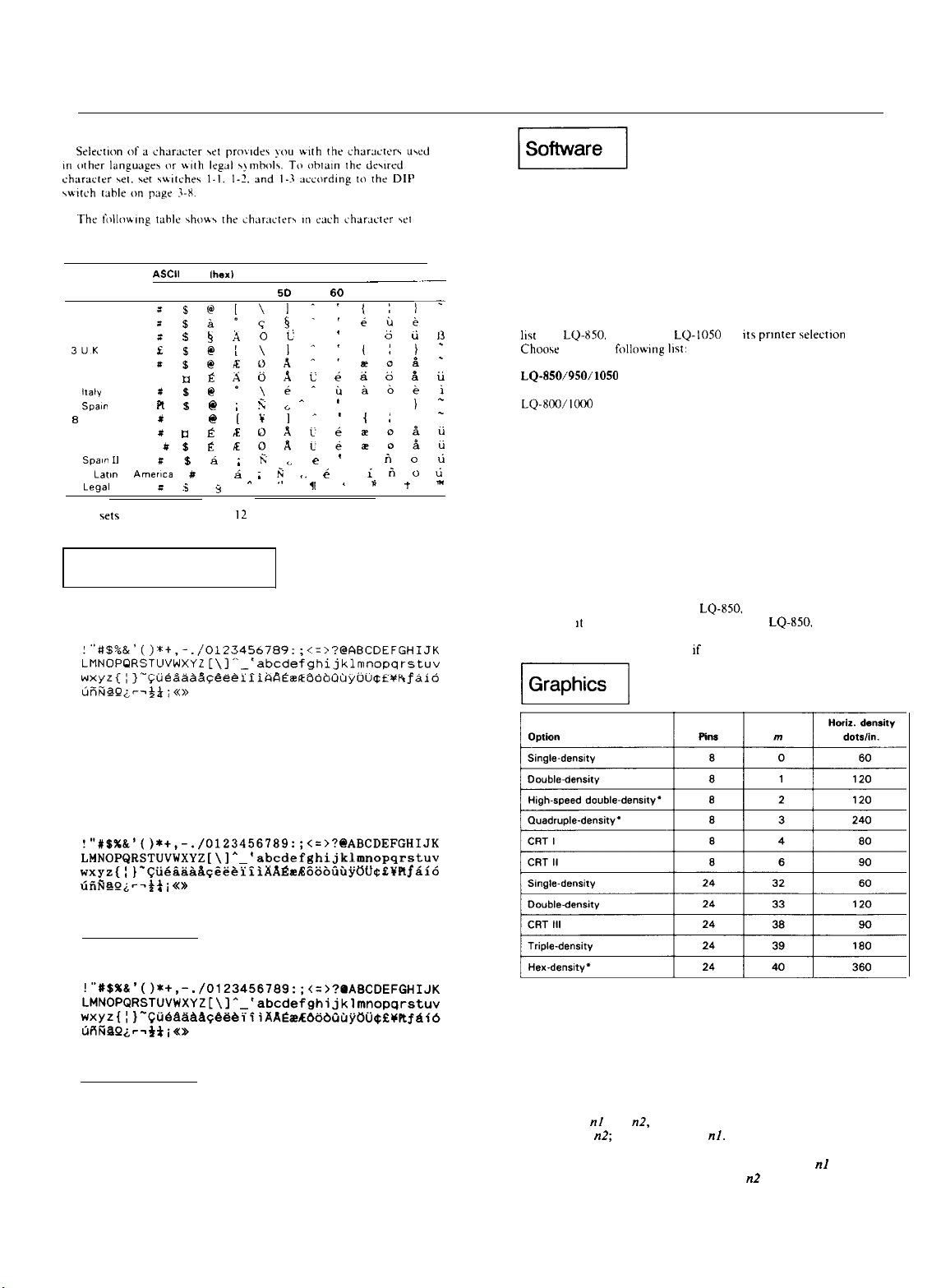

Selecting Character Sets

more

To make sure that the printing fits within this area, always

perform a sample printing test using a normal single sheet

of paper before printing on envelopes.

LQ - 850/950/1050 - 2

12/12/88

24 - Pin Printers

Page 3

Choosing a character set

Character sets

Country

23 24 40 50 5C

OUSA

1 France

2 Germany

4 Denmark I

5 Sweden A A

6

7

I

Japan

3 Norway

10 Denmark II

11

12 Latm

64 Legal

The

numbered 8 through

$

$

g &

$

5E

.

t

70 7C 70 7E

a d ti

i

ii

&

Ii

and 64 are available only through

a software command. See page 9-3 I.

Selecting Typestyles

Draft mode uses fewer dots per character for high-speed printing.

DRAFT

LQ - 850/950/1050 DOT - MATRIX PRINTER

Now that you have set up and tested the LQ, you should make

sure that it works with the application programs you want to use.

Most application programs let you specify the type of printer you

are using so that the program can take full advantage of the

printer’s features. Many of these programs provide an installation

or setup section that presents a list of printers from which to

choose.

Choosing from a menu

Because the family of Epson printers shares a great many

commands, you can use an application program even if it does not

the

LQ-2500

LQ-1500

If none of these printers is listed, select the first one available on

the following list.

EX

FX

LX

RX

MX

Epson printer

Standard printer

Draft printer

To use all the features of the

however,

LQ-1050 on its menu. If your program does not list these printers.

contact the manufacturer to see

LQ-950. or

from the

is best to use a program with the

an update is available.

on

prmter

LQ-950, and LQ-1050.

menu.

LQ-950, or

We’ve just seen your excellent ad for

miniature zebras in a recent back issue of

Trader’s Times. What is the price schedule

for quantities over one gross?

The Roman and Sans Serif Letter Quality (LQ) fonts use a larger

number of dots for higher print quality at a lower speed.

ROMAN

.

We’ve just seen your excellent ad for

miniature zebras in a recent back issue of

Trader’s Times.

for quantities over one gross?

SANS

SERIF

We’ve just seen your excellent ad for

miniature zebras in a recent back issue of

Trader’s Times.

for quantities over one gross?

What is the price schedule

What is the price schedule

. . .

. . .

‘Adjacent dots cannot be printed in this mode.

Column reservation numbers

The graphics command requires more than one number to specify

how many columns to reserve because one line can use thousands of

columns, but the LQ does not use numbers larger than 255

(decimal). Therefore, the graphics mode command uses two

numbers for reserving columns.

To figure

The result is

and n2, divide the total number of columns by 256.

the remainder is

Since the command is set up

for two numbers, you must supply two even if you need only one.

When you need fewer than 256 columns, just make

the number

of columns you are reserving and make n2 a zero.

24 - Pin Printers

12/12/88

LQ - 850/950/1050 - 3

Page 4

LQ - 850/950/1050 DOT- MATRIX PRINTER

The Cut Sheet Feeder

The following

proper operation of your cut sheet feeder. Not all software is

the

you

a

you may find that a

best equivalent settings to use.

example of a software setup reqmred for

of experimentation

up

required

After checking to see that you have all of the parts shown in the

figure above, remove the foam packaging from between the paper

rests and rollers. Keep the packing materials in the original box in

case you need to store or transport the cut sheet feeder.

In

To

Change Page

Length from

Change Top

Margin from

Change

Bottom

Margin from

Many word processors and other software

change these \ettmgs’

l

l You can change the program’s default settings so that every time

If your program has additional features, such as headers and

footers, you have to compensate accordingly.

Control panel operation

All of the functions from the control panel are

feeder mode.

off. the loading

the

per page. You may need

The optional cut sheet feeders

handling of

paper can be fed automatically into the printer without reloading.

These

Printer

LQ-850

LQ-950

LQ-

The dlustratlons

LQ-1050. but the others work in the same way. For the dual bin

feeders, see the manual that comes with them for assembly

instructions. You can select the second bin with a software command

(ESC EM) or the control panel.

54 prmted

form \ettmgs

You can change the settings in each individual file you print or;

you use the program, these new settings are in effect.

after loading a sheet using the LOAD/EJECT button and

the ON LINE button.

for as long as the power remams on. If the power IS turned

for thts new page length.

sheet paper Up to 150 sheets of standard bond

can also automatically feed envelopes.

Single bin

per page:

Cut sheet

feeder settmgs

61

4

6

adjustment of the

returned to the factory

with micro adjustment affects the number of lines

change your software margin settings

this chapter show the

to

you

you easier and more efficient

paper support

sets a new sheet loading

Dual bin

bin feeder for the

3

ways to

cut sheet

Changing

paper feeder rests

I I

The optlonal pull tractor (A731

LQ-950. or q7312 for the LQ-1050) provides optimum contmuous

paper handling. The pull tractor IS especially

multi-part forms and labels. For best results, use the pull tractor

along with the budt-in push tractor. as described in this section.

After making sure that you have both parts of the

option as shown below, remove the packing material and save it in

case you need to ship the unit later.

The short tear-off function cannot be used with the pull

tractor. Before you start printing with the pull tractor,

!

make sure that DIP switch 2-7 is set to off. (See the

section on setting DIP switches in Chapter 3.)

The Multi

The optional Multi-Font Module (#7631) gives you seven

additional fonts for your LQ printer. Once you install it in either slot

A or slot B, the following fonts are available: Courier, Prestige,

Script, OCR-A, OCR-B, Orator, and Orator-S.

The Multi-Font Module is installed in one of the slots (A or B)

the printer. See the manual that comes with the module for full

information on using the font module.

Using the Multi-Font Module

To install a font module, follow these steps:

1. Make sure the printer is turned off.

2. Open the font compartment cover. Inside the compartment are

two connectors labelled A and

Font Module

for the LQ-850, #7313 for the

continuous

tractor

pull tractor cover

LQ - 850/950/1050 - 4

front stacker suporis

12/12/88

24 - Pin Printers

Page 5

LQ - 850/950/1050 DOT-MATRIX PRINTER

3.

Insert the font module securely into SLOT A or

so that the

arrow symbols on the font module and the slot are facing each

other. If you install only one font module, be sure to insert it

into SLOT A.

Commands in Numerical Order

The following list shows control codes and ESC sequences (with

their decimal and hexadecimal values), and the page number where

the complete command can be found.

ASCII Dec.

BEL

BS

HT

LF

VT

CR

so

DC1

DC2

DC3

DC4

CAN

DEL

127

ESC SO

ESC

ESC EM

ESC

ESC !

ESC

ESC

ESC

ESC

ESC IESC

ESC +

ESC

ESC I

ESC 0

ESC 2

ESC 3

ESC 4

ESC 5

ESC 6

ESC 7

ESC :

ESC

ESC =

ESC

ESC

ESC

ESC A

ESC B

ESC C

ESC C 0

ESC D

ESC E

ESC F

ESC G

ESC H

ESC J

ESC K

ESC L

64

65

66

67

67

68

69

70

71

72

74

75

76

10

11

12

13

14

15

17

18

19

20

24

14

15

25

32

33

35

36

37

38

40

42

43

45

47

48

50

51

52

53

54

55

58

60

61

62

63

9

Description

Hex

07

Beeper

Backspace

08

09

Tab Horizontally

OA

Line Feed

OB

Tab Vertically

OC

Form Feed

OD

Carriage Return

OE

Select Double-wide Mode (one line)

OF

Select Condensed Mode

11

Select Printer

12

Cancel Condensed Mode

13

Deselect Printer

14

Cancel Double-wide Mode (one

18 9-13

Cancel Line

7F

Delete Character

OE

Select Double-wide Mode (one

OF

Select Condensed Mode

19 9-11

Turn Cut Sheet Feeder Mode

20 9-31

Set Intercharacter Space

21

Master Select

23 9-12

Cancel MSB Control

24

Set Absolute Print Position

25

Select User-defined Set

26

Define User-defined Characters

28 9-29

Select /Cancel Score

2A

Select Graphics Mode

2B

Select n/360-inch Line Spacing

2D

2F

30

32

33

34

35

36

37

3A

3c

3D

3E

3F

40

41

42

43

43

44

45

46

47

48

4A

4B

4c

Underlining On/Off

Select Vertical Tab Channel

Select l/&inch Line Spacing

Select

Line Spacing

Select n/l8@inch Line Spacing

Select Italic Mode

Cancel Italic Mode

Enable Printable Characters

Enable Upper Control Codes

Copy ROM into RAM

Select Unidirectional Mode (one line)

Set MSB to 0

Set MSB to 1

Reassign Graphics Mode

Initialize Printer

Select

Line Spacing

Set Vertical Tabs

Select Page Length in Lines

Select Page Length in Inches

Set Horizontal Tabs

Select

Mode

Cancel Emphasized Mode

Select Double-strike Mode

Cancel Double-strike Mode

Perform n/l8@inch Line Feed

Select Single-density Graphics Mode

Select Double-density Graphics Mode

Page

9-12

9-21

9-15

9-17

9-13

9-25

9-24

9-a

9-25

9-9

9-26

9-9

9-25

9-25

9-23

9-20

9-34

9-33

9-36

9-16

9-28

9-15

B-16

9-16

9-32

9-32

9-34

9-10

9-11

9-12

9-37

9-a

b-16

9-17

9-14

9-14

9-21

9-26

9-27

9-27

9-27

9-35

9-35

Commands

ASCII

ESC M 77

ESC N 78

ESC 0

ESC

ESC Q

ESC R 82

ESC SO 83

ESC

ESC T

ESC

ESC W 87

ESC

ESC 2 90

ESC

ESC a 97

ESC b 98

ESC g

ESC k

ESC

ESC

ESCq113

ESCt116

ESC

ESC x

in

1

83

85

89

92

103

107

108

p 112

119

120

Order

Select 12 Pitch

4D

Set Skip Over Perforation 9-14

4E

Cancel Skip Over Perforation 9-15

4F

Select 10 Pitch

50

Set Right Margin

51

52

53

53

54

5.5

57

59

5A

61

62

67

a Character Set

Select Superscript Mode 9-27

Select Subscript Mode 9-28

Cancel Superscript/Subscript 9-28

Turn Unidirectional Mode On/Off 9-10

Turn Double-wide Mode On/Off 9-26

Select

Select Quadruple-density Graphics

Set Relative Position

Select Justification

Set Vertical Tabs in Channels 9-18

Select 15 Pitch

Select Typestyle Family 9-22

Set Left

70 Turn

71

74

77

78

Proportional Mode On/Off 9-24

Select Character Style 9-30

Select Character Table

Select Double High

Select Letter Quality or Draft 9-22

9-23

9-19

9-33

Graphics 9-35

9-31

9-24

9-18

9-25

Page

9-23

9-36

Interface Boards

Compatible interfaces

The following is a list of Epson interfaces that are compatible

your LQ prmter.

interface number

$8148

All Epson Interfaces have the EPSON name printed on them. If

the board has an Identification code prmted on it. be a four

digit number

8, and should correspond

numbers listed in the table above.

one of the

24 - Pin

Printers

12/12/88

LQ - 850/950/1050 - 5

Page 6

LQ - 850/950/1050 DOT - MATRIX PRINTER

Installation/Support Tips

Short Tear Off

To activate the short tear-off feature on the printer, first turn

DIP switch 2-7 to the on position. To control it through the

software, send a form feed command at the end of each

page. After sending a form feed, do not send it any more

data for a 3-second interval. To activate the tear -off

feature manually, take the printer off line and press the FF

button. When it is put back on line, the print position will

go right back to the top of the page, ready for the next

print job.

Single - Sheet Loading

When loading single sheets, make sure that the paper lever

is set to single sheets, not tractor paper. The paper can be

loaded manually or via the auto load button. Before

attempting to load in the paper, wait for the platen to lock in

place after changing the paper lever.

Setting up the Page Length

The page length has to be adjusted for using single sheets

and for using tractor paper. When your software you asks

you to set up the number of lines/page, single sheets

require a shorter page length than does tractor paper. Set

the page length to 61 lines for single sheets (also when

using the cut -sheet feeder) and 66 lines for tractor paper.

Software

The type of printer installed on your system must be

identified for each software package. This is usually done

through a setup menu.

in the software package, any Epson 24-pin driver will be

compatible. (Preferably, choose the LQ-800/1000.)

If the LQ-850/950/1050 is not listed

DIP Switch Settings

The default settings will usually work for most applications,

but they should be checked before using the printer. This

will avoid unexpected results.

LQ - 850/950/1050 - 6

12/12/88

24 - Pin Printers

Page 7

LQ - 850/950/1050 DOT - MATRIX PRINTER

Information Reference List

Engineering Change Notices

LQ - 850 - 007/

LQ-1050-007

LQ - 850 - 006/

LQ-1050-006

LQ - 850 - 003

LQ - 850 - 002

7340-001

LQ-850-004

LQ - 850 - 005

8/12/88

7/28/88

2/2/88

6/29/88

1/14/88

2/1/88

Version M82982 to Version M80483

LQ-850 PROM upgrade: to increase graphics accuracy in 24-pin

bidirectional mode.

Version M8307A to Version M82982

PROM upgrade: to correct and improve paper handling and and print

quality.

Version M81777 to Version M82778

PROM upgrade: to correct and improve print quality.

Version M81179 to Version M8217A

PROM upgrade: CSF eject/15-cpi print in unidirectional mode.

Improved paper-holding spring

Base plate and lower case modification

Change of printer cover B

Product Support Bulletins

P - 0020

5/6/88 Paper thickness lever

Related Documentation

M-TM-LQ8/9/10

Y45499114000

Technical Information Bulletins

LQ - 850 - 001

LQ-1050-001

5/6/88 MONMA carriage width selection

24 - Pin Printers

LQ -850/950/1050 Technical Manual

LQ -850/950/1050 User’s Manual

12/12/88

LQ - 850/950/1050 - 7

Loading...

Loading...