EPS PS 9080-50 1U, PS 9200-25 1U, PS 9500-10 1U, PS 9750-06 1U, PS 9080-100 1U Operating Manual

...Page 1

Operating Guide

PS 9000 1U

DC Laboratory Power Supply

Stromversorgung

Attention! This document is only

valid for devices with rmware

“KE: 2.07” and “HMI: 2.03”, or

higher. For availability of up-

EPS

dates for your device check our

website or contact us.

Doc ID: PS91UEN

Revision: 05

Date: 08/2016

Page 2

Page 3

TABLE OF CONTENTS

GENERAL

1

1.1 About this document ...................................... 5

1.1.1 Retention and use .......................................... 5

1.1.2 Copyright ........................................................5

1.1.3 Validity ............................................................5

1.1.4 Explanation of symbols .................................. 5

1.2 Warranty .........................................................5

1.3 Limitation of liability ........................................ 5

1.4 Disposal of equipment ...................................6

1.5 Product key ....................................................6

1.6 Intended usage ..............................................6

1.7 Safety .............................................................7

1.7.1 Safety notices ................................................. 7

1.7.2 Responsibility of the user...............................7

1.7.3 Responsibility of the operator ....................... 8

1.7.4 User requirements .........................................8

1.7.5 Alarm signals .................................................. 9

1.8 Technical data ................................................9

1.8.1 Approved operating conditions ...................... 9

1.8.2 General technical data ................................... 9

1.8.3 Specic technical data .................................10

1.8.4 Views ............................................................14

1.9 Construction and function ............................18

1.9.1 General description ......................................18

1.9.2 Block diagram ..............................................18

1.9.3 Scope of delivery .........................................18

1.9.4 The control panel (HMI) ...............................19

1.9.5 Share Bus-Connection ................................20

1.9.6 USB port .......................................................21

1.9.7 Ethernet port ................................................21

1.9.8 Analog interface ...........................................21

1.9.9 Sense connector (remote sensing) .............21

INSTALLATION & COMMISSIONING

2

2.1 Transport and storage .................................22

2.1.1 Transport ......................................................22

2.1.2 Packaging ....................................................22

2.1.3 Storage .........................................................22

2.2 Unpacking and visual check ........................22

2.3 Installation ....................................................22

2.3.1 Safety procedures before installation and

use ................................................................22

2.3.2 Preparation ...................................................22

2.3.3 Installing the device .....................................23

2.3.4 Connection to AC supply .............................23

2.3.5 Connection to DC loads ...............................24

2.3.6 Grounding of the DC output ........................25

2.3.7 Connection of remote sensing ....................25

2.3.8 Connecting the “Share” bus ........................25

2.3.9 Connecting the analog interface .................26

2.3.10 Connecting the USB port ............................. 26

2.3.11 Initial commission .........................................26

2.3.12 Initial network setup .....................................27

PS 9000 1U Series

2.3.13 Commission after a rmware update or a

long period of non-use .................................27

OPERATION AND APPLICATION

3

3.1 Important notes ............................................28

3.1.1 Personal safety ............................................28

3.1.2 General .........................................................28

3.2 Operating modes .........................................28

3.2.1 Voltage regulation / Constant voltage .........28

3.2.2 Current regulation / constant current / current

limiting ..........................................................28

3.2.3 Power regulation / constant power / power

limiting ..........................................................29

3.3 Alarm conditions ..........................................30

3.3.1 Power Fail ...................................................30

3.3.2 Overtemperature ..........................................30

3.3.3 Overvoltage ..................................................30

3.3.4 Overcurrent ..................................................30

3.3.5 Overpower ....................................................30

3.4 Manual operation .........................................31

3.4.1 Switching on the device ...............................31

3.4.2 Switching off the device ...............................31

3.4.3 Conguration in the setup menu .................31

3.4.4 Adjustment limits ..........................................35

3.4.5 Display modes for actual and set values ....36

3.4.6 Manual adjustment of set values .................36

3.4.7 The quick menu ...........................................37

3.4.8 Switching the DC output on or off ................37

3.5 Remote control .............................................38

3.5.1 General .........................................................38

3.5.2 Control locations ..........................................38

3.5.3 Remote control via a digital interface ..........38

3.5.4 Remote control via the analog interface

(AI) ................................................................39

3.6 Alarms and monitoring .................................43

3.6.1 Denition of terms ........................................43

3.6.2 Device alarm handling .................................43

3.7 Control panel (HMI) lock ..............................44

3.8 Loading and saving a user prole ...............45

3.9 Other applications ........................................46

3.9.1 Parallel operation in Share Bus mode ........46

3.9.2 Series connection ........................................47

3.9.3 Operation as battery charger .......................47

3.9.4 Two quadrants operation (2QO) ..................48

SERVICE & MAINTENANCE

4

4.1 Maintenance / cleaning ................................50

4.2 Fault nding / diagnosis / repair...................50

4.2.1 Replacing a defect mains fuse ....................50

4.2.2 Firmware update ..........................................50

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 3

Page 4

PS 9000 1U Series

4.3 Calibration (readjustment) ...........................51

4.3.1 Preface .........................................................51

4.3.2 Preparation ...................................................51

4.3.3 Calibration procedure ..................................51

CONTACT AND SUPPORT

5

5.1 General .........................................................53

5.2 Contact options ............................................53

Page 4

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 5

PS 9000 1U Series

1. General

1.1 About this document

1.1.1 Retention and use

This document is to be kept in the vicinity of the equipment for future reference and explanation of the operation of

the device. This document is to be delivered and kept with the equipment in case of change of location and/or user.

1.1.2 Copyright

Reprinting, copying, also partially, usage for other purposes as foreseen of this manual are forbidden and breach

may lead to legal process.

1.1.3 Validity

This manual is valid for the following equipment including derived variants.

Model Article nr. Model Article nr.

PS 9080-50 1U 06230400 PS 9080-100 1U 06230405

PS 9200-25 1U 06230401 PS 9200-50 1U 06230406

PS 9360-15 1U 06230402 PS 9360-30 1U 06230407

PS 9500-10 1U 06230403 PS 9500-20 1U 06230408

PS 9750-06 1U 06230404 PS 9750-12 1U 06230409

Changes and modications for special models will be listed in a separate document.

1.1.4 Explanation of symbols

Warning and safety notices as well as general notices in this document are shown in a box with a symbol as follows:

Symbol for a life threatening danger

Symbol for general safety notices (instructions and damage protection bans) or important information for operation

Symbol for general notices

1.2 Warranty

EPS Stromversorgung guarantees the functional competence of the applied technology and the stated performance

parameters. The warranty period begins with the delivery of free from defects equipment.

Terms of guarantee are included in the general terms and conditions (TOS) of EPS Stromversorgung.

1.3 Limitation of liability

All statements and instructions in this manual are based on current norms and regulations, up-to-date technology

and our long term knowledge and experience. The manufacturer accepts no liability for losses due to:

• Usage for purposes other than designed

• Use by untrained personnel

• Rebuilding by the customer

• Technical changes

• Use of not authorized spare parts

The actual delivered device(s) may differ from the explanations and diagrams given here due to latest technical

changes or due to customized models with the inclusion of additionally ordered options.

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 5

Page 6

PS 9000 1U Series

1.4 Disposal of equipment

A piece of equipment which is intended for disposal must, according to European laws and regulations (ElektroG,

WEEE) be returned to the manufacturer for scrapping, unless the person operating the piece of equipment or another, delegated person is conducting the disposal. Our equipment falls under these regulations and is accordingly

marked with the following symbol:

1.5 Product key

Decoding of the product description on the label, using an example:

PS 9 080 - 50 1U zzz

Field for identication of installed options and/or special models

S01...S0x = Special models

Construction (not always given)

1U / 2U / 3U = 19" frame with 1 U, 2 U or 3 U

Maximum current of the device in Ampere

Maximum voltage of the device in Volt

Series : 8 = Series 8000 or 800, 9 = Series 9000

Type identication:

PS = Power Supply, usually programmable

PSI = Power Supply Intelligent, always programmable

ELR = Electronic Load with Recovery

Special models are always derived from standard models and can vary in output voltage and

current from those given.

1.6 Intended usage

The equipment is intended to be used, if a power supply or battery charger, only as a variable voltage and current

source, or, if an electronic load, only as a variable current sink.

Typical application for a power supply is DC supply to any relevant user, for a battery charger the charging of various battery types and for electronic loads the replacement of an ohmic resistor by an adjustable DC current sink

in order to load relevant voltage and current sources of any type.

• Claims of any sort due to damage caused by non-intended usage will not be accepted.

• All damage caused by non-intended usage is solely the responsibility of the operator.

Page 6

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 7

1.7 Safety

1.7.1 Safety notices

Mortal danger - Hazardous voltage

• Electrical equipment operation means that some parts can be under dangerous voltage.

Therefore all parts under voltage must be covered!

• All work on connections must be carried out under zero voltage (output not connected

to load) and may only be performed by qualied and informed persons. Improper actions can cause fatal injury as well as serious material damage!

• Never touch cables or connectors directly after unplugging from mains supply as the

danger of electric shock remains!

• Never touch the contacts on DC output terminal directly after switching off the DC

output, because there still can dangerous voltage present, sinking more or less slowly

depending on the load! There also can be dangerous potential between negative DC

output to PE or positive DC output to PE due to charged X capacitors.

• The equipment must only be used as intended

• The equipment is only approved for use within the connection limits stated on the product label.

• Do not insert any object, particularly metallic, through the ventilator slots

• Avoid any use of liquids near the equipment. Protect the device from wet, damp and conden-

sation.

• For power supplies and battery chargers: do not connect users, particularly low resistance, to

devices under power; sparking may occur which can cause burns as well as damage to the

equipment and to the user.

• For electronic loads: do not connect power sources to equipment under power, sparking may

occur which can cause burns as well as damage to the equipment and to the source.

• ESD regulations must be applied when plugging interface cards or modules into the relative slot

• Interface cards or modules may only be attached or removed after the device is switched off.

It is not necessary to open the device.

• Do not connect external power sources with reversed polarity to DC input or outputs! The

equipment will be damaged.

• For power supply devices: avoid where possible connecting external power sources to the

DC output, and never those that can generate a higher voltage than the nominal voltage of

the device.

• For electronic loads: do not connect a power source to the DC input which can generate a voltage more than 120% of the nominal input voltage of the load. The equipment is not protected

against over voltage and may be irreparably damaged.

• Never insert a network cable which is connected to Ethernet or its components into the masterslave socket on the back side of the device!

• Always congure the various protecting features against overvoltage overpower etc. for sensi-

tive loads to what the currently used application requires

PS 9000 1U Series

1.7.2 Responsibility of the user

The equipment is in industrial operation. Therefore the operators are governed by the legal safety regulations.

Alongside the warning and safety notices in this manual the relevant safety, accident prevention and environmental

regulations must also be applied. In particular the users of the equipment:

• must be informed of the relevant job safety requirements

• must work to the dened responsibilities for operation, maintenance and cleaning of the equipment

• before starting work must have read and understood the operating manual

• must use the designated and recommended safety equipment.

Furthermore, anyone working with the equipment is responsible for ensuring that the device is at all times techni-

cally t for use.

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 7

Page 8

PS 9000 1U Series

1.7.3 Responsibility of the operator

Operator is any natural or legal person who uses the equipment or delegates the usage to a third party, and is

responsible during its usage for the safety of the user, other personnel or third parties.

The equipment is in industrial operation. Therefore the operators are governed by the legal safety regulations.

Alongside the warning and safety notices in this manual the relevant safety, accident prevention and environmental

regulations must also be applied. In particular the operator has to

• be acquainted with the relevant job safety requirements

• identify other possible dangers arising from the specic usage conditions at the work station via a risk assessment

• introduce the necessary steps in the operating procedures for the local conditions

• regularly control that the operating procedures are current

• update the operating procedures where necessary to reect changes in regulation, standards or operating con-

ditions.

• dene clearly and unambiguously the responsibilities for operation, maintenance and cleaning of the equipment.

• ensure that all employees who use the equipment have read and understood the manual. Furthermore the users

are to be regularly schooled in working with the equipment and the possible dangers.

• provide all personnel who work with the equipment with the designated and recommended safety equipment

Furthermore, the operator is responsible for ensuring that the device is at all times technically t for use.

1.7.4 User requirements

Any activity with equipment of this type may only be performed by persons who are able to work correctly and

reliably and satisfy the requirements of the job.

• Persons whose reaction capability is negatively inuenced by e.g. drugs, alcohol or medication may not operate

the equipment.

• Age or job related regulations valid at the operating site must always be applied.

Danger for unqualied users

Improper operation can cause person or object damage. Only persons who have the necessary

training, knowledge and experience may use the equipment.

Delegated persons are those who have been properly and demonstrably instructed in their tasks and the attendant dangers.

Qualied persons are those who are able through training, knowledge and experience as well as knowledge of

the specic details to carry out all the required tasks, identify dangers and avoid personal and other risks.

Page 8

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 9

PS 9000 1U Series

1.7.5 Alarm signals

The equipment offers various possibilities for signalling alarm conditions, however, not for danger situations. The

signals may be optical (on the display as text) acoustic (piezo buzzer) or electronic (pin/status output of an analog

interface). All alarms will cause the device to permanently or temporarily switch off the DC output.

The meaning of the signals is as follows:

Signal OT

(OverTemperature)

• Overheating of the device

• DC output will be switched off temporarily

• Non-critical

Signal OVP

(OverVoltage)

• Overvoltage shutdown of the DC output due to high voltage entering the device or generated by the device itself due to a defect or because the adjusted OVP threshold was

lower than the actual output voltage

• Critical! The device and/or the load could be damaged

Signal OCP

(OverCurrent)

Signal OPP

(OverPower)

Signal PF

(Power Fail)

• Shutdown of the DC output due to excess of the preset limit

• Non-critical, protects the load from excessive current consumption

• Shutdown of the DC output due to excess of the preset limit

• Non-critical, protects the load from excessive power consumption

• DC output shutdown due to AC undervoltage or defect of the AC input circuit

• Critical on overvoltage! AC input circuit could be damaged

1.8 Technical data

1.8.1 Approved operating conditions

• Use only inside dry buildings

• Ambient temperature 0-50°C

• Operational altitude: max. 2000 m above sea level

• Max 80% relative humidity, not condensing

1.8.2 General technical data

Display: Dot matrix, 240pt x 64pt

Controls: 2 rotary knobs with button function, 6 pushbuttons

The nominal values for the device determine the maximum adjustable ranges.

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 9

Page 10

PS 9000 1U Series

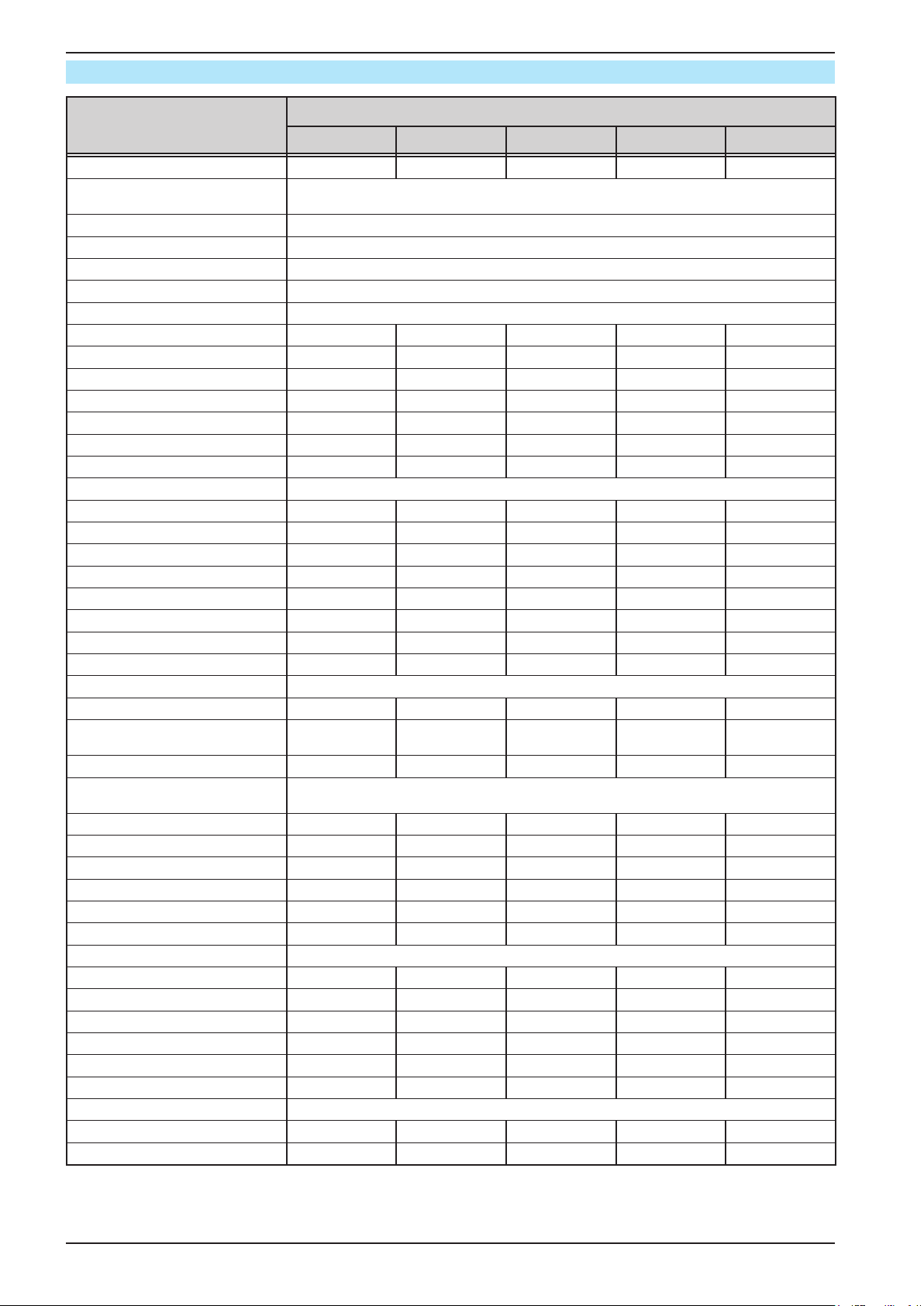

1.8.3 Specic technical data

Model 1U

1500 W

AC Input

Input voltage / frequency

Input connection 1ph (L, N, PE)

Input fuse (internal) T16 A

Leak current < 3.5 mA

Power factor ~ 0.99

Idle mode power consumption ~ 70 W

DC Output

Max. output voltage U

Max. output current I

Max. output power P

Overvoltage protection range 0...88 V 0...220 V 0...396 V 0...550 V 0...825 V

Overcurrent protection range 0...55 A 0...27,5 A 0...17,6 A 0...11 A 0...6,6 A

Overpower protection range 0…1650 W 0…1650 W 0…1650 W 0…1650 W 0…1650 W

Temperature coefcient Voltage / current: 100 ppm/K

Output capacitance (approx.) 5640 μF 1000 μF 470 μF 105 μF 49 μF

Voltage regulation

Adjustment range 0...81.6 V 0...204 V 0...367.2 V 0...510 V 0...765 V

Accuracy

(1

(at 23 ± 5°C) < 0.1% U

Line regulation at ±10% ΔU

Load regulation at 0...100% load < 0.05% U

Rise time 10...90% ΔU Max. 15 ms Max. 15 ms Max. 15 ms Max. 15 ms Max. 15 ms

Transient time after load step < 1.7 ms < 1.4 ms < 2.2 ms < 2 ms < 2 ms

Display: Resolution See section „1.9.4.4. Resolution of the displayed values“

Display: Accuracy

(2

Ripple

Remote sensing compensation Max. 5% U

Fall time (at no load) after

switching DC output off

Current regulation

Adjustment range 0...51 A 0...25.5 A 0...15.3 A 0...10.2 A 0...6.12 A

Accuracy

(1

(at 23 ± 5°C) < 0.2% I

Line regulation at ±10% ΔU

Load regulation at 0...100% ΔU

(2

Ripple

Display: Resolution See section „1.9.4.4. Resolution of the displayed values“

Display: Accuracy

Power regulation

Adjustment range 0…1530 W 0…1530 W 0…1530 W 0…1530 W 0…1530 W

Accuracy

(1

(at 23 ± 5°C) < 1% P

Line regulation at ±10% ΔU

Load regulation at 10-90% ΔU*ΔI < 0.75% P

Display: Resolution See section „1.9.4.4. Resolution of the displayed values“

Efciency at 100% U

Efciency at 100% I

(1 Related to the nominal values, the accuracy denes the maximum deviation between an adjusted values and the true (actual) value.

Example: a 80 V model has min. 0.1% voltage accuracy, that is 80 mV. When adjusting the voltage to 5 V, the actual value is allowed to differ max. 80 mV, which

means it might be between 4.92 V and 5.08 V.

(2 RMS value: LF 0...300 kHz, PP value: HF 0...20MHz

(3 The display error adds to the error of the related actual value on the DC output

Max

Max

Max

(3

(3

DC

DC

PS 9080-50 PS 9200-25 PS 9360-15 PS 9500-10 PS 9750-06

Without derating: 150...264 V AC, 50/60 Hz

With derating to 1000 W: 100...150 V AC

80 V 200 V 360 V 500 V 750 V

50 A 25 A 15 A 10 A 6 A

1500 W 1500 W 1500 W 1500 W 1500 W

AC

Nenn

< 0.02% U

≤ 0.2% U

Nom

< 100 mVPP

< 5.2 mV

RMS

Nenn

Nenn

Nenn

< 0.1% U

Nenn

< 0.02% U

< 0.05% U

≤ 0.2% U

Nom

< 293 mVPP

< 51 mV

RMS

Max. 5% U

Down from 100% to <60 V: less than 10 s

Nom

Nom

< 0.2% I

Nom

< 0.05% I

< 0.15% I

< 29 mA

≤ 0.2% I

< 1% P

PP

Nom

Nom

< 0.05% P

< 0.75% P

Nom

Nom

AC

AC

< 0.05% I

< 0.15% I

OUT

< 75 mA

≤ 0.2% I

< 0.05% P

Nom

Nom

Nom

PP

Nom

Nom

~ 91% ~ 93% ~ 94% ~ 94% ~ 95%

~ 89% ~ 90% ~ 92% ~ 92% ~ 94%

Nenn

Nenn

Nenn

Nom

Nom

< 0.1% U

Nenn

< 0.02% U

< 0.05% U

≤ 0.2% U

Nom

< 195 mVPP

< 33 mV

RMS

Max. 5% U

< 0.2% I

< 0.05% I

< 0.15% I

< 10 mA

≤ 0.2% I

< 1% P

Nom

Nom

Nom

PP

Nom

Nom

< 0.05% P

< 0.75% P

Nenn

Nenn

Nenn

Nom

Nom

< 0.1% U

Nenn

< 0.02% U

< 0.05% U

≤ 0.2% U

Nom

< 293 mVPP

< 63 mV

RMS

Max. 5% U

< 0.2% I

< 0.05% I

< 0.15% I

< 9.2 mA

≤ 0.2% I

< 1% P

Nom

Nom

Nom

PP

Nom

Nom

< 0.05% P

< 0.75% P

Nenn

Nenn

Nenn

Nom

Nom

< 0.1% U

Nenn

< 0.02% U

< 0.05% U

≤ 0.2% U

Nom

< 260 mVPP

< 40 mV

RMS

Max. 5% U

< 0.2% I

< 0.05% I

< 0.15% I

< 4.1 mA

≤ 0.2% I

< 1% P

Nom

Nom

Nom

PP

Nom

Nom

< 0.05% P

< 0.75% P

Nenn

Nenn

Nenn

Nom

Nom

Page 10

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 11

PS 9000 1U Series

Model 1U

1500 W

Analog interface

Type Sub-D, 15 pole, female

Set value inputs U, I, P

Actual value output U, I

Control signals DC on/off, Remote on/off

Status signals CV, OVP, OT

Galvanic isolation to the device Max. 1500 V DC

Sample rate of inputs & outputs 500 Hz

Insulation Allowed oat (potential shift) on the DC output:

Negative terminal to PE Max. ±400 V DC ±400 V DC ±400 V DC ±400 V DC ±400 V DC

Positive terminal to PE Max. ±480 V DC ±600 V DC ±760 V DC ±900 V DC ±1150 V DC

Miscellaneous

Cooling Temperature controlled fans, front inlet, rear exhaust

Ambient temperature 0..50°C

Storage temperature -20...70°C

Humidity < 80%, not condensing

Standards EN 61010, EN 61326

Overvoltage category 2

Protection class 1

Pollution degree 2

Operational altitude < 2000 m

Digital interfaces

Featured 1x USB-B, 1x Ethernet

Galvanic isolation from device Max. 1500 V DC

USB specication USB 2.0, socket type B, VCOM driver

USB response time SCPI: max. 5 ms, ModBus: max. 5 ms

Ethernet specication RJ45, 10/100Mbit, TCP/IP, ICMP, HTTP, DHCP

Ethernet response time SCPI: max. 7 ms, ModBus: 9-17 ms

Terminals

Rear side Share Bus, DC output, AC input, remote sensing, analog interface, USB-B, Ethernet

Dimensions

Enclosure (WxHxD) 19“ x 1U x 500 mm

Total (WxHxD) 483 x 44 x min. 565 mm

Weight ~ 10.5 kg ~ 10.5 kg ~ 10.5 kg ~ 10.5 kg ~ 10.5 kg

Article number 06230400 06230401 06230402 06230403 06230404

(1

PS 9080-50 PS 9200-25 PS 9360-15 PS 9500-10 PS 9750-06

(1 For technical specications of the analog interface see „3.5.4.4 Analog interface specication“ on page 40

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 11

Page 12

PS 9000 1U Series

Model 1U

3000 W

AC Input

Input voltage / frequency

Input connection 1ph (L, N, PE)

Input fuse (internal) T16 A

Leak current < 3.5 mA

Power factor ~ 0.99

Idle mode power consumption ~ 70 W

DC Output

Max. output voltage U

Max. output current I

Max. output power P

Overvoltage protection range 0...88 V 0...220 V 0...396 V 0...550 V 0...825 V

Overcurrent protection range 0...110 A 0...55 A 0...33 A 0...22 A 0...13,2 A

Overpower protection range 0…3300 W 0…3300 W 0…3300 W 0…3300 W 0…3300 W

Temperature coefcient Voltage / current: 100 ppm/K

Output capacitance (approx.) 8930 μF 1500 μF 705 μF 150 μF 70 μF

Voltage regulation

Adjustment range 0...81.6 V 0...204 V 0...367.2 V 0...510 V 0...765 V

Accuracy

(1

(at 23 ± 5°C) < 0.1% U

Line regulation at ±10% ΔU

Load regulation at 0...100% load < 0.05% U

Rise time 10...90% ΔU Max. 15 ms Max. 15 ms Max. 15 ms Max. 15 ms Max. 15 ms

Transient time after load step < 1.7 ms < 1.4 ms < 2.2 ms < 2 ms < 2 ms

Display: Resolution See section „1.9.4.4. Resolution of the displayed values“

Display: Accuracy

(2

Ripple

Remote sensing compensation Max. 5% U

Fall time (at no load) after

switching DC output off

Current regulation

Adjustment range 0...102 A 0...51 A 0...30.6 A 0...20.4 A 0...12.24 A

Accuracy

(1

(at 23 ± 5°C) < 0.2% I

Line regulation at ±10% ΔU

Load regulation at 0...100% ΔU

(2

Ripple

Display: Resolution See section „1.9.4.4. Resolution of the displayed values“

Display: Accuracy

Power regulation

Adjustment range 0...3060 W 0...3060 W 0...3060 W 0...3060 W 0...3060 W

Accuracy

(1

(at 23 ± 5°C) < 1% P

Line regulation at ±10% ΔU

Load regulation at 10-90% ΔU*ΔI < 0.75% P

Display: Resolution See section „1.9.4.4. Resolution of the displayed values“

Efciency at 100% U

Efciency at 100% I

Max

Max

Max

(3

(3

DC

DC

PS 9080-100 PS 9200-50 PS 9360-30 PS 9500-20 PS 9750-12

Without derating: 207...264 V AC, 45...66 Hz

With derating to 2500 W: 180...207 V AC

80 V 200 V 360 V 500 V 750 V

100 A 50 A 30 A 20 A 12 A

3000 W 3000 W 3000 W 3000 W 3000 W

AC

< 0.02% U

≤ 0.2% U

< 76 mVPP

< 4.2 mV

Nenn

Nom

RMS

Nenn

Nenn

Nom

< 0.1% U

Nenn

< 0.02% U

< 0.05% U

≤ 0.2% U

Nom

< 234 mVPP

< 40 mV

RMS

Max. 5% U

Down from 100% to <60 V: less than 10 s

Nenn

Nenn

< 0.2% I

Nenn

< 0.05% I

< 0.15% I

< 29 mA

≤ 0.2% I

< 1% P

PP

Nom

Nenn

< 0.05% P

< 0.75% P

Nenn

Nenn

AC

AC

< 0.05% I

< 0.15% I

OUT

< 114 mA

≤ 0.2% I

< 0.05% P

Nenn

Nenn

Nenn

PP

Nom

Nenn

~ 91% ~ 93% ~ 94% ~ 94% ~ 95%

~ 89% ~ 90% ~ 92% ~ 92% ~ 94%

Nenn

Nenn

Nom

Nenn

Nenn

< 0.1% U

Nenn

< 0.02% U

< 0.05% U

≤ 0.2% U

Nom

< 156 mVPP

< 26 mV

RMS

Max. 5% U

< 0.2% I

< 0.05% I

< 0.15% I

< 10 mA

≤ 0.2% I

< 1% P

Nenn

Nenn

Nenn

PP

Nom

Nenn

< 0.05% P

< 0.75% P

Nenn

Nenn

Nom

Nenn

Nenn

< 0.1% U

Nenn

< 0.02% U

< 0.05% U

< 234 mVPP

< 50 mV

RMS

Max. 5% U

< 0.2% I

< 0.05% I

< 0.15% I

< 9.2 mA

≤ 0.2% I

< 1% P

Nenn

Nenn

Nenn

PP

Nom

Nenn

< 0.05% P

< 0.75% P

Nenn

Nenn

Nom

Nenn

Nenn

< 0.1% U

< 0.02% U

< 0.05% U

< 260 mVPP

< 40 mV

Max. 5% U

< 0.2% I

< 0.05% I

< 0.15% I

< 4.1 mA

≤ 0.2% I

< 1% P

< 0.05% P

< 0.75% P

Nenn

Nenn

Nenn

RMS

Nom

Nenn

Nenn

Nenn

PP

Nom

Nenn

Nenn

Nenn

(1 Related to the nominal values, the accuracy denes the maximum deviation between an adjusted values and the true (actual) value.

Example: a 80 V model has min. 0.1% voltage accuracy, that is 80 mV. When adjusting the voltage to 5 V, the actual value is allowed to differ max. 80 mV, which

means it might be between 4.92 V and 5.08 V.

(2 RMS value: LF 0...300 kHz, PP value: HF 0...20MHz

(3 The display error adds to the error of the related actual value on the DC output

Page 12

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 13

PS 9000 1U Series

Model 1U

3000 W

Analog interface

Type Sub-D, 15 pole, female

Set value inputs U, I, P

Actual value output U, I

Control signals DC on/off, Remote on/off

Status signals CV, OVP, OT

Galvanic isolation to the device Max. 1500 V DC

Sample rate of inputs & outputs 500 Hz

Insulation Allowed oat (potential shift) on the DC output:

Negative terminal to PE Max. ±400 V DC ±400 V DC ±400 V DC ±400 V DC ±400 V DC

Positive terminal to PE Max. ±480 V DC ±600 V DC ±760 V DC ±900 V DC ±1150 V DC

Miscellaneous

Cooling Temperature controlled fans, front inlet, rear exhaust

Ambient temperature 0..50°C

Storage temperature -20...70°C

Humidity < 80%, not condensing

Standards EN 61010, EN 61326

Overvoltage category 2

Protection class 1

Pollution degree 2

Operational altitude < 2000 m

Digital interfaces

Featured 1x USB-B, 1x Ethernet

Galvanic isolation from device Max. 1500 V DC

USB specication USB 2.0, socket type B, VCOM driver

USB response time SCPI: max. 5 ms, ModBus: max. 5 ms

Ethernet specication RJ45, 10/100Mbit, TCP/IP, ICMP, HTTP, DHCP

Ethernet response time SCPI: max. 7 ms, ModBus: 9-17 ms

Terminals

Rear side Share Bus, DC output, AC input, remote sensing, analog interface, USB-B, Ethernet

Dimensions

Enclosure (WxHxD) 19“ x 1U x 500 mm

Total (WxHxD) 483 x 44 x min. 565 mm

Weight ~ 11 kg ~ 11 kg ~ 11 kg ~ 11 kg ~ 11 kg

Article number 06230405 06230406 06230407 06230408 06230409

(1

PS 9080-100 PS 9200-50 PS 9360-30 PS 9500-20 PS 9750-12

(1 For technical specications of the analog interface see „3.5.4.4 Analog interface specication“ on page 40

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 13

Page 14

PS 9000 1U Series

1.8.4 Views

Page 14

Figure 1 - Front side

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Figure 2 - Rear side

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

A - Mains switch D - Exhausts G - AC input connector

B - Control panel E - Share Bus and remote sensing connectors

www.eps-germany.de

info@eps-germany.de

C - Control interfaces (digital, analog) F - DC output

Page 15

PS 9000 1U Series

Figure 3 - Left hand side view with DC cover

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

Figure 4 - Right hand side view without DC cover

www.eps-germany.de

info@eps-germany.de

Page 15

Page 16

PS 9000 1U Series

Figure 5 - Top view

Page 16

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 17

Figure 6 - Control Panel

Overview of the elements of the operating panel

For a detailed description see section „1.9.4. The control panel (HMI)“.

Display

(1)

Used for indication of set values, menus, conditions, actual values and status.

Left hand rotary knob, with pushbutton function

(2)

Turn: adjusts various set values which are related to the DC output voltage.

Push: selects the decimal position of a value to be changed (cursor)

Button bank

PS 9000 1U Series

Button : Activates the setup menu for various device settings (see „3.4.3. Conguration in the setup

menu“)

Button : Navigates through menus, submenus and parameters (direction: up / left) or changes

view mode

(3)

Button : Navigates through menus, submenus and parameters (direction: down / right) or changes

view mode

Button : Submits altered parameters or set values in submenus, as well enters submenus. Can

also be used to acknowledge alarms.

Button : Cancels changes of parameters in the setup menu or leaves submenus

Right hand rotary knob, with pushbutton function

Turn: adjusts various set values which are related to the DC output current, the DC output power. Also

(4)

adjusts parameters in the setup menu.

Push: selects the decimal position of a value to be changed (cursor)

On/Off Button for DC output

(5)

Used to toggle the DC output between on and off, also used to acknowledge alarms. The LED indicates

the state of the DC output, no matter if the device is manually controlled or remotely (LED on = output on).

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 17

Page 18

PS 9000 1U Series

1.9 Construction and function

1.9.1 General description

The electronic high performance power supplies of the PS 9000 1U series are especially suitable for test systems

and industrial controls due to their compact construction in a 19” enclosure with 2 height units (2U).

For remote control using a PC or PLC the devices are provided as standard with a USB-B slot and an Ethernet

port on the back side as well as a galvanically isolated analog interface. All interfaces are galvanically isolated up

to 1500 V DC.

In addition, the devices offer as standard the possibility for parallel connection in Share bus operation for constant

current sharing. Operating in this way allows up to 10 units to be combined to a single system with a total power

of up to 30 kW.

All models are controlled by microprocessors. These enable an exact and fast measurement and display of actual

values.

1.9.2 Block diagram

The block diagram illustrates the main components inside the device and their relationships.

There are digital, microprocessor controlled components (KE, DR, BE), which can be target of rmware updates.

Share &

Sense

Power stage

DC

AC

=

≈

PS 9000 1U

Block diagram

1.9.3 Scope of delivery

1 x Power supply device

1 x AC cord (IEC type plug, 250 V, 16 A)

1 x USB stick with documentation and software

1 x Share Bus plug

1 x Remote sensing plug

1 x 1.8 m USB cable

ETH

Controller

(DR)

Commu-

nication

(KE)

USB

Ana

log

HMI (BE)

Page 18

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 19

PS 9000 1U Series

1.9.4 The control panel (HMI)

The HMI (Human Machine Interface) consists of a display, two rotary knobs with pushbutton function and six

pushbuttons.

1.9.4.1 Display

The graphic display is divided into a number of areas. In normal operation the left upper half is used to show actual

values and the lower half is used to display status information and set values:

Actual values

U/I or U/P

Regulation mode

Alarms

Set value of voltage Status: control location / panel lock Set value of current or

Set value of power

• Actual values area (upper half)

In normal operation the DC output values (large numbers) of voltage and current resp. of power are displayed,

depending on the selected view mode. The display format of values is according to what’s listed in 1.9.4.4.

Furthermore, the actual regulation mode CV, CC or CP (see „3.2. Operating modes“) is displayed here, as well as

alarms with abbreviations (OT, OVP, OCP, PF, OPP). For details refer to „3.3. Alarm conditions“.

• Set values area (lower half, left and right side)

The set values of voltage and current (mode: U/I) resp. of voltage and power (mode: U/P) are displayed here and

are adjustable with the left hand and right hand rotary knobs when operating the device manually. While doing

so, the digit to adjust can be selected by pushing the corresponding rotary knob, in order to move the cursor. The

left hand rotary knob is always assigned to the DC output voltage and related parameters like OVP or U-max,

whereas the right hand rotary knobs is either assigned to the DC output current and related parameters or to the

DC output power. In remote control condition, no matter if analog or digital, the set values given from remote are

displayed here.

Logically, the values are increased by clockwise turning and decreased by anti-clockwise turning, unless they are

somehow limited by a maximum value or an adjustment limit (see „3.4.4. Adjustment limits“).

General display and settings ranges:

Display Unit Range Description

Actual voltage V 0-125% U

Set value voltage V 0-102% U

Actual current A 0.2-125% I

Set value current A 0-102% I

Nom

Actual power W 0-125% P

Set value power W 0-102% P

Nom

Nom

Nom

Nom

Nom

Actual values of DC output voltage

Set value for limiting the DC output voltage

Actual value of DC output current

Set value for limiting the DC output current

Actual value of output power, P = U * I

Set value for limiting DC output power

Adjustment limits A, V, kW 0-102% Nominal val. U-max, I-min etc., related to the physical units

Protection settings A, V, kW 0-110% Nominal val. OVP, OCP etc., related to the physical units

• Status area (lower half, middle)

This area shows the control location mode (see „3.5.2. Control locations“) or another status (see table below). In

case pushbutton is activated while the output is on, the quick menu (see „3.4.7. The quick menu“) will be

displayed:

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 19

Page 20

PS 9000 1U Series

This area furthermore displays various status texts:

Display Description

Locked The HMI is locked

Remote The device is under remote control from...

Analog ...the built-in analog interface

USB ...the built-in USB port or a plug in interface module

Ethernet ...the built-in Ethernet/LAN port

Local The device has been locked by the user explicitly against remote control

1.9.4.2 Rotary knobs

As long as the device is in manual operation, the two rotary knobs are used to adjust set values, as well

as setting the parameters in the settings menu. For a detailed description of the individual functions see

section „3.4 Manual operation“ on page 31.

1.9.4.3 Pushbutton function of the rotary knobs

The rotary knobs also have a pushbutton function which is used in all menu options for value adjustment to move

the cursor by rotation as shown:

1.9.4.4 Resolution of the displayed values

In the display, set values can be adjusted in xed increments. The number of decimal places depends on the

device model. The values have 4 or 5 digits, while actual and set values related to the same physical unit always

have the same number of digits.

Adjustment resolution and number of digits of set values in the display:

Nominal

Voltage,

OVP, U-min, U-max

Min. increment Nominal

Digits

Current,

OCP, I-min, I-max

Min. increment Nominal

Digits

Power,

OPP, P-max

Min. increment

Digits

80 V 4 0.01 V 6 A 4 0.001 A 1500 W 4 1 W

200 V 5 0.01 V 10 A / 12 A 5 0.001 A 3000 W 4 1 W

360 V / 500 V 4 0.1 V 15 A / 20 A 5 0.001 A

750 V 4 0.1 V 25 A 5 0.001 A

30 A / 50 A 4 0.01 A

100 A 5 0.01 A

In manual operation every set value can be set in the increments given above. In this case

the actual output values set by the device will lie within percentage tolerances as shown in the

technical data sheets. These will inuence the actual values.

1.9.5 Share Bus-Connection

The 2 pole WAGO socket (“Share”) on the back side of the device is provided for

connection to equally named sockets on compatible power supplies series to achieve

a balanced load current distribution during parallel connection of up to 10 units. It is

furthermore use Following power supply series are compatible:

• PSI 9000 2U

• PSI 9000 3U

• ELR 9000

• PSE 9000

• PS 9000 2U *

• PS 9000 3U *

• EL 9000 B

* From hardware revision 2, see type label (in case it does not show “Revision” on type label, it is revision 1)

Page 20

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 21

PS 9000 1U Series

1.9.6 USB port

The USB-B port on the back side of the device is provided

for communication with the device and for rmware updates.

The included USB cable can be used to connect the device

to a PC (USB 2.0, USB 3.0). The driver is delivered on the

included USB stick or is available as download and installs

a virtual COM port. Details for remote control can be found

in external documentation, a general programming guide,

on the web site of the manufacturer or on the included USB

stick.

The device can be addressed via the USB port either using the international standard ModBus protocol or by SCPI

language. The device recognises the message protocol used automatically.

If remote control is in operation the USB port has no priority over either the analog interface or the Ethernet interface

and can, therefore, only be used alternatively to these. However, monitoring is always available.

1.9.7 Ethernet port

The Ethernet port on the back side of the device (standard

version of device only) is provided for communication with

the device in terms of remote control or monitoring. The user

has basically two options of access:

1. A website (HTTP, port 80) which is accessible in a standard

browser under the IP or the host name given for the device.

This website offers to conguration page for network parameters, as well as a input box for SCPI commands.

2. TCP/IP access via a freely selectable port (except 80 and other reserved ports). The standard port for this device

is 5025, default IP is 192.168.0.2. Via TCP/IP and this port, communication to the device can be established in

most of the common programming languages.

Using the Ethernet port, the device can either be controlled by commands from SCPI or ModBus protocol, while

automatically detecting the type of message.

The network setup can be done manually or by DHCP. The transmission speed is set to “Auto negotiation” and

means it can use 10MBit/s or 100MBit/s. 1GB/s is not supported. Duplex mode is always full duplex.

If remote control is in operation the Ethernet port has no priority over either the analog interface or the USB interface

and can, therefore, only be used alternatively to these. However, monitoring is always available.

1.9.8 Analog interface

This 15 pole Sub-D socket on the back side of the device is

provided for remote control of the device via analog signals

or switching conditions.

If remote control is in operation this analog interface can

only be used alternately to the digital interface. However,

monitoring is always available.

The input voltage range of the set values and the output voltage range of the monitor values, as well as reference

voltage level can be switched in the settings menu of the device between 0-5 V and 0-10 V, in each case for 0-100%.

1.9.9 Sense connector (remote sensing)

During constant voltage operation (CV) and in case the adjusted output voltage has

to be held constant on the load and not on the power supply’s DC output, remote

sensing can be used in order to compensate for the voltage drop on cables up to

a certain limit. The maximum possible compensation is given in the technical data.

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 21

Page 22

PS 9000 1U Series

2. Installation & commissioning

2.1 Transport and storage

2.1.1 Transport

• The handles on the front side of the device are not for carrying!

• Do not transport when switched on or connected!

• When relocating the equipment use of the original packing is recommended

• The device should always be carried and mounted horizontally

• Use suitable safety clothing, especially safety shoes, when carrying the equipment, as due to

its weight a fall can have serious consequences.

2.1.2 Packaging

It is recommended to keep the complete transport packaging for the lifetime of the device for relocation or return

to the manufacturer for repair. Otherwise the packaging should be disposed of in an environmentally friendly way.

2.1.3 Storage

In case of long term storage of the equipment it is recommended to use the original packaging or similar. Storage

must be in dry rooms, if possible in sealed packaging, to avoid corrosion, especially internal, through humidity.

2.2 Unpacking and visual check

After every transport, with or without packaging, or before commissioning, the equipment should be visually

inspected for damage and completeness using the delivery note and/or parts list (see section „1.9.3. Scope of

delivery“). An obviously damaged device (e.g. loose parts inside, damage outside) must under no circumstances

be put in operation.

2.3 Installation

2.3.1 Safety procedures before installation and use

• When using a 19” rack, rails suitable for the width of the housing and the weight of the device

are to be used. (see „1.8.3. Specic technical data“)

• Before connecting to the mains ensure that the connection is as shown on the product label.

Overvoltage on the AC supply can cause equipment damage.

2.3.2 Preparation

Mains connection for a PS 9000 1U series device is done via the included 2 meters long 3 pole mains cord. In case

a different AC wiring is required, make sure that the other cable has a minimum cross section of 1.5 mm² (AWG 12).

Dimensioning of the DC wiring to the load/consumer has to reect the following:

• The cable cross section should always be specied for at least the maximum input current of

the device.

• Continuous operation at the approved limit generates heat which must be removed, as well as

voltage loss which depends on cable length and heating. To compensate for these the cable

cross section should be increased and the cable length reduced.

Page 22

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 23

PS 9000 1U Series

2.3.3 Installing the device

• Select the location for the device so that the connection to the load is as short as possible!

• Leave sufcient space behind the equipment, minimum 30cm, for ventilation!

• The device is not stackable!

• Do not put anything with a total weight of more than 1kg on top of the device!

A device in a 19” housing will usually be mounted on suitable rails and installed in 19” racks or cabinets. The depth

of the device and its weight must be taken into account. The handles on the front are for sliding in and out of the

cabinet. Slots on the front plate are provided for xing the device (xing screws not included).

Acceptable and inacceptable installation positions:

Standing surface

2.3.4 Connection to AC supply

• The device can be connected to any wall socket or multi-socket outlet, as long as those feature

a safety contact (PE) and are capable for 16 A.

• When connecting the device to a multi-socket outlet, along with other electric devices, it is

important to consider the total power consumption of all devices on the outlet, so that the maxi-

mum current (power ÷ minimum voltage) does not exceed the denition for the wall socket,

the multi-socket outlet and/or main distribution

• Before plugging in the input plug ensure that the device is switched off by its mains switch!

The device is delivered with a 3 wire mains cord (L, N, PE). If the device is going to be connected to a standard

2-phase or 3-phase supply, following phases are required:

Nominal power Phases Supply type

1.5 kW / 3 kW L1 or L2 or L3, N, PE At least wall socket 16 A

The default input values of all models in this series are: 230 V, 16 A, 50 Hz. It is internally fused with 16 A. The 16

A input denition is due to the AC input current depending on the higher intake at low AC voltage (for minimum

input voltage see technical specs).

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 23

Page 24

PS 9000 1U Series

2.3.5 Connection to DC loads

• In the case of a device with a high nominal current and hence a thick and heavy DC

connection cable it is necessary to take account of the weight of the cable and the

strain imposed on the DC connection. Especially when mounted in a 19” cabinet or

similar, where the cable hangs on the DC output, a strain reliever should be used.

• Connection to and operation with transformerless DC-AC inverters (for example solar inverters) is restricted, because the inverter can shift the potential of negative

output (DC-) against PE (ground), which is generally limited to max. ±400 V DC.

The DC load output is on the rear side of the device and is not protected by a fuse. The cross section of the connection cable is determined by the current consumption, cable length and ambient temperature.

For cables up to 1.5 m and average ambient temperature up to 50°C, we recommend:

up to 10 A: 0,75 mm² (AWG18) up to 15 A: 1,5 mm² (AWG14)

up to 30 A: 4 mm² (AWG10) up to 40 A: 6 mm² (AWG8)

up to 60 A: 16 mm² (AWG4) up to 100 A: 25 mm² (AWG2)

per lead (multi-conductor, insulated, openly suspended). Single cables of, for example, 70 mm² may be replaced

by e.g. 2x35 mm² etc. If the cables are long then the cross section must be increased to avoid voltage loss and

overheating.

2.3.5.1 DC terminal

The table below shows an overview of the various DC terminals. It is recommended that connection of load cables

always utilises exible cables with ring lugs.

M6 bolt on a nickel plated copper bar

Recommendation: Ring lugs with a 6 mm hole

2.3.5.2 Cable lead and plastic cover

A plastic cover for contact protection is included for the DC terminal. It should always be installed.

Page 24

The connection angle and the required bending radius for the DC cable must be taken into

account when planning the depth of the complete device, especially when installing in a 19”

cabinet or similar. In case, the plastic DC cover is going to be used, only horizontal lead of the

cables is possible.

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 25

PS 9000 1U Series

2.3.6 Grounding of the DC output

Individually operated devices can always be grounded from the DC minus pole, i.e. can be directly connected to

PE. The DC plus pole, however, if it is to be grounded, may only be so for output voltages up to 400 V, unless

stated otherwise in the technical specications.

For this reason, for all models which can provide an output voltage of more than 400 V, earthing of the DC plus

pole is not recommended, because it will shift the potential of the DC minus pole in negative direction, up to the

maximum output voltage. If the output voltage is not adjusted higher than 400 V, grounding the DC plus pole is

allowed with restrictions.

• Grounding of the DC-plus pole for any model with >400 V nominal voltage only at one’s own

risk! Risk of damaging the device! Risk of voiding warranty!

• Digital and analog interface are galvanically isolated from the DC output and should never be

grounded, but under no circumstances if any of the DC output poles is grounded too, because

this will cancel the galvanic isolation

• If grounding one of the DC output poles check if any pole of the load is already grounded. This

could lead to a short circuit!

2.3.7 Connection of remote sensing

In order to compensate, to a certain degree, the voltage loss in a DC cable, the device provides the possibility to

connect the remote sensing input “Sense” to the load. The device recognizes the remote sensing mode automatically and regulates the output voltage (only in CV operation) at the load rather than at its own DC output.

In the technical specications (see section „1.8.3. Specic technical data“) the level of maximum possible com-

pensation is given. If that is insufcient, the cable cross section must be increased.

Both pins „NC“ of the Sense connector must not be wired!

• The cross section of the sense cables is noncritical. However, it should be increased with

increasing cable length. Recommendation: for cables up to 5 m use at least 0.5 mm²

• Sense cables should be twisted and laid close to the DC cables to damp oscillation. If neces-

sary, an additional capacitor should be installed at the load/consumer to eliminate oscillation

• The sense cables must be connected + to + and - to - at the load, otherwise both systems

may be damaged

Figure 7 - Example for remote sensing wiring

2.3.8 Connecting the “Share” bus

The “Share” connector on the back side is intended to balance the current of multiple units in parallel operation,

especially when using the integrated function generator of the master unit. For further information about this mode

of operation can be found in section „3.9.1. Parallel operation in Share Bus mode“ .

For the connection of the share bus the following must be paid attention to:

• Connection is only permitted between compatible devices (see „1.9.5. Share Bus-Connection“

for details) and between a max. of 10 units

• The Share bus is referenced to DC minus output and thus affected by potential shifts. The

potential of the DC minus has to considered when connecting the Share bus to other devices!

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 25

Page 26

PS 9000 1U Series

2.3.9 Connecting the analog interface

The 15 pole connector (Type: Sub-D, D-Sub) on the rear side is an analog interface. To connect this to a controlling hardware (PC, electronic circuit), a standard plug is necessary (not included in the scope of delivery). It is

generally advisable to switch the device completely off before connecting or disconnecting this connector, but at

least the DC output.

The analog interface is galvanically isolated from the device internally. Therefore do not

connect any ground of the analog interface (AGND) to the DC minus output as this will

cancel the galvanic isolation.

2.3.10 Connecting the USB port

In order to remotely control the device via this port, connect the device with a PC using the included USB cable

and switch the device on.

2.3.10.1 Driver installation (Windows)

On the initial connection with a PC the operating system will identify the device as new hardware and will try to

install a driver. The required driver is for a Communications Device Class (CDC) device and is usually integrated in

current operating systems such as Windows 7 or 10. But it is strongly recommended to use and install the included

driver installer (on USB stick) to gain maximum compatibility of the device to our softwares.

2.3.10.2 Driver installation (Linux, MacOS)

We cannot provide drivers or installation instructions for these operating systems. Whether a suitable driver is

available is best carried out by searching the Internet.

2.3.10.3 Alternative drivers

In case the CDC drivers described above are not available on your system, or for some reason do not function

correctly, commercial suppliers can help. Search the Internet for suppliers using the keywords “cdc driver windows“

or “cdc driver linux“ or “cdc driver macos“.

2.3.11 Initial commission

For the rst start-up after purchasing and installing the device, the following procedures have to be executed:

• Conrm that the connection cables to be used are of a satisfactory cross section

• Check that the default settings for set values, safety and monitoring functions and communication are suitable

for your application and change them where necessary, as described in the manual

• In case of remote control via PC, read the additional documentation for interfaces and software

• In case of remote control via the analog interface, read the section in this manual concerning analog interfaces

and, where needed, other appropriate documentation especially concerning the use of such interfaces

Page 26

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 27

PS 9000 1U Series

2.3.12 Initial network setup

The device is delivered with default network parameters (see „3.4.3.6. Menu “Communication”“). The Ethernet/

LAN port is immediately ready for use after the initial commission. Default parameters:

IP: 192.168.0.2

Subnet mask: 255.255.255.0

Gateway: 192.168.0.1

Port: 5025

DHCP: off

For wiring, i.e. the hardware connection to a network, contact and ask your IT manager or any similar responsible

person. Network cable of common type (CAT5 or better) can be used.

In order to set up the network parameter to your needs, you have three options: the setup menu or the device’s

website or the software „EPS Power Control“, which is available since April 2015 as download or included with

your device. For the conguration in the setup menu please refer to „3.4.3.6. Menu “Communication”“.

For the conguration via the device’s website or EPS Power Control, you need the device to be connected to a

network or directly to a PC which can access the default IP 192.168.0.2.

► How to do the network setup on the device website

1. In case the device display is in any kind of menu, lave menu to main display.

2. Open the device website in a browser by entering the default IP (http://192.168.0.2) or the default host name

(http://Client, only possible if there is a running DNS in the network) into the URL box.

3. After the website has been completely loaded, check the status eld item “Access” to show the status “free”.

In case it shows different, the device is either already in remote control (rem) or blocked from remote control

(local). If it shows “local”, rst remove the block. Refer to section „3.5.2. Control locations“ to do that.

4. If it says “rem” in the “Access” item, skip to step 4. Else enter command syst:lock on (attention! space

before on) into the SCPI command box and send with return key. Check if item “Access” in status eld

changes to “rem-eth” (means: remote Ethernet).

5. Switch to page CONFIGURATION (upper left corner) and set up the network parameters as well as the port

here resp. activate DHCP and submit the change with SUBMIT button.

6. Wait a few seconds before testing the new IP by entering it in the browser’s URL box. Opening the website

again by using the host name is only possible after the device has restarted, because only then the new IP

is reported to the DNS.

2.3.13 Commission after a rmware update or a long period of non-use

In case of a rmware update, return of the equipment following repair or a location or conguration change, similar

measures should be taken to those of initial start up. Refer to „2.3.11. Initial commission“.

Only after successful checking of the device as listed may it be operated as usual.

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 27

Page 28

PS 9000 1U Series

3. Operation and application

3.1 Important notes

3.1.1 Personal safety

• In order to guarantee safety when using the device, it is essential that only persons operate

the device who are fully acquainted and trained in the required safety measures to be taken

when working with dangerous electrical voltages

• For models which can generate a voltage which is dangerous by contact, or is connected to

such, the included DC terminal cover, or an equivalent, must always be used

• Whenever the load and DC output are being re-congured, the device should be disconnected

from the mains, not only the DC output switched off!

3.1.2 General

• Operation of a power supply without any load or a very small load (<0.5% of INom) is not

considered as a normal operation mode

• Technical specications can probably not be guaranteed when running a power supply without

a load

• It is recommended to run a power supply always with at least 10% voltage and current load

3.2 Operating modes

A power supply is internally controlled by different control or regulation circuits, which shall bring voltage, current

and power to the adjusted values and hold them constant, if possible. These circuits follow typical laws of control

systems engineering, resulting in different operating modes. Every operating mode has its own characteristics

which is explained below in short form.

3.2.1 Voltage regulation / Constant voltage

Voltage regulation is also called constant voltage operation (CV).

The DC output voltage of a power supply is held constant on the adjusted value, unless the output current or the

output power according to P = U

will automatically change to constant current or constant power operation, whatever occurs rst. Then the output

voltage can not be held constant anymore and will sink to a value resulting from Ohm’s law.

While the DC output is switched on and constant voltage mode is active, then the condition “CV mode active”

will be indicated on the display by the abbreviation CV and this message will be passed as a signal to the analog

interface, as well stored as status which can also be read as a status message via digital interface.

3.2.2 Current regulation / constant current / current limiting

Current regulation is also known as current limitation or constant current mode (CC).

The DC output current is held constant by the power supply, once the output current to the load reaches the adjusted

limit. Then the power supply automatically switches The current owing from the power supply is determined by the

output voltage and the load’s true resistance. As long as the output current is lower than the adjusted current limit,

the device will be either in constant voltage or constant power mode. If, however, the power consumption reaches

the set maximum power value, the device will switch automatically to power limiting and sets the output current

according to I

by the user, is always an upper limit only.

While the DC output is switched on and constant current mode is active, then the condition “CC mode active” will

be indicated on the display by the abbreviation CC and this message will be passed as a signal to the analog

interface, as well stored as status which can also be read as a status message via digital interface.

MAX

= P

/ UIN , even if the maximum current value is higher. The current set value, as determined

SET

OUT

* I

reaches the adjusted current or power limit. In both cases the device

OUT

Page 28

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 29

PS 9000 1U Series

3.2.3 Power regulation / constant power / power limiting

Power regulation, also known as power limiting or constant power (CP), keeps the

DC output power of a power supply constant if the current owing to the load in

relation to the output voltage and the resistance of the load reaches the adjusted

power value according to P = U * I resp. P = U² / R. The power limitation then regulates the output current according to I = sqr(P / R), where R is the load’s resistance.

Power limiting operates according to the auto-range principle such that at lower

output voltages higher current ows and vice versa in order to maintain constant

power within the range P

Constant power operation primarily impacts the output current. This means, the

adjusted maximum output current can not be achieved if the maximum power value

limits the output current according to I = P / U. The adjustable set value of current,

as indicated in the display, is always only an upper limit.

While the DC output is switched on and constant power mode is active, then the condition “CP mode active” will

be shown on the display by the abbreviation CP and can also be read as a status message via digital interface.

3.2.3.1 Power derating

The power supplies of series PS 9000 1U offer an extended AC supply voltage range, but are dedicated for the

use at typical 230 VAC, ±10%. Below a certain supply voltage, all models will automatically start to derate, i.e.

reduce the maximum available output power. The derating happens on the AC input side and thus the device will

not indicate the derating condition as “CP” (constant power resp. power limitation).

Depending on the nominal power of the particular model, the derating acts at different supply voltages:

• 3 kW models

▪ Below approx. 207 VAC: Derating to max. 2500 W output power

▪ Below approx. 180 VAC: Shutdown of the DC output

(see diagram to the right)

N

• 1.5 kW models

▪ Below approx. 150 VAC: Derating to max. 1000 W output power

▪ Below approx. 90 VAC: Shutdown of the DC output

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 29

Page 30

PS 9000 1U Series

3.3 Alarm conditions

This section only gives an overview about device alarms. What to do in case your device indicates an alarm condition is described in section „3.6. Alarms and monitoring“.

As a basic principle, all alarm conditions are signalled optically (Text + message in the display), acoustically (if

activated) and as a readable status via the digital interface. With any alarm occurring, the DC output of the device

is switched off. In addition, the alarms OT and OVP are reported as signals on the analogue interface.

3.3.1 Power Fail

Power Fail (PF) indicates an alarm condition which may have various causes:

• AC input voltage too high (mains overvoltage) or too low (mains undervoltage, mains failure)

• Defect in the input circuit (PFC)

Switching off the device by the mains switch can not be distinguished from a mains blackout

and thus the device will signalise a PF alarm every time the device is switched off. This can

be ignored.

3.3.2 Overtemperature

An overtemperature alarm (OT) can occur if

• an excess temperature inside the device causes to switch off the DC output.

Internal overtemperature and subsequent temporary shutdown is usually caused by insufcient cooling (excess

ambient temperature, fans and air inlets polluted). The fans will still cool down the unit until it can automatically

switch on again to continue operation.

3.3.3 Overvoltage

An overvoltage alarm (OVP) will switch off the DC output and can occur if

• the power supply itself, as a voltage source, generates an output voltage higher than set for the overvoltage

alarm threshold (OVP, 0...110% U

) or the connected load somehow returns voltage higher than set for the

Nom

overvoltage alarm threshold

• the OV threshold has been adjusted too close above the output voltage. If the device is in CC mode and if it

then experiences a negative load step, it will make the voltage rise quickly, resulting in an voltage overshoot for

a short moment which can already trigger the OVP

This function serves to warn the user of the power supply acoustically or optically that the device probably has

generated an excessive voltage which could damage the connected load application.

The device is not tted with protection from external overvoltage. Overvoltage can

damage parts inside!

3.3.4 Overcurrent

An overcurrent alarm (OCP) will switch off the DC output and can occur if

• the output current in the DC output reaches the adjusted OCP limit.

This function serves to protect the connected load application so that this is not overloaded and possibly damaged

due to an excessive current.

3.3.5 Overpower

An overpower alarm (OPP) will switch off the DC output and can occur if:

• the product of the output voltage and output current in the DC output reaches the adjusted OPP limit.

This function serves to protect the connected load application so that this is not overloaded and possibly damaged

due to an excessive power consumption.

Page 30

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

Page 31

PS 9000 1U Series

3.4 Manual operation

3.4.1 Switching on the device

The device should, as far as possible, always be switched on using the rotary switch on the front of the device.

Alternatively this can take place using an external cutout (contactor, circuit breaker) of suitable current capacity.

After switching on, the display will show the manufacturers logo for a few seconds, plus some information like

device model, rmware version(s), serial number and item number and will then be ready for use. In setup (see

section „3.4.3. Conguration in the setup menu“) in the second level menu “General” is an option “DC output

after power ON” in which the user can determine the condition of the DC output after power-up. Factory setting

here is “OFF”, meaning that the DC output on power-up is always switched off. Selection “Restore” means that

the last condition of the DC output will be restored, either on or off. All set values are always saved and restored.

3.4.2 Switching off the device