epoke

®

500481

GB-0305.1

Instruction manual

SKE

Valid from ident. no. xxxx0200

If you have technical questions please state ident. no., which is on the machine sign. We recommend that you write this

number here:

Type: ..................................................

Year: .................................................. Ident. no.: .............................................

Valid from ident. no.:

SKE 8 10010200

SKE 12 10030200

SKE 15 10040200

SKE 20 10050200

Published and printed by

Epoke®A/S,

Documentation department

Changes of technical details in relation to specifications and sketches in this instruction are subject

to alteration.

This instruction answers important questions regarding safety, operation, maintenance and technical

data.

1

epoke

®

SKE8-12-15-20

GB-0305.1

Table of contents

1 Identification

1.1 Manufacturer and supplier . . . . . . . . . . . . . . . 2

1.1.1 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.2 Technical documentation . . . . . . . . . . . . . . . . 2

1.1.3 Warranty and liability . . . . . . . . . . . . . . . . . . 2

1.2 Model and type specification . . . . . . . . . . . . . 3

1.3 Start no. and date . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Country of origin . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 CE-mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6 EU certificate of conformity . . . . . . . . . . . . . . . 3

1.6.1 Directives applied . . . . . . . . . . . . . . . . . . . . . . 3

1.6.2 Standards applied . . . . . . . . . . . . . . . . . . . . . . 3

1.9 Quality system certificate . . . . . . . . . . . . . . . . 3

2 Descriptions

2.0.0 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.1 Transport and handling . . . . . . . . . . . . . . . . . . 4

2.0.1.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.1.2 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.1.6 Rules for total weight of towed vehicles . . . . . 4

2.0.2 Information on restrictions on use . . . . . . . . . . 4

2.0.2.1 Normal use . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.2.2 Abnormal use . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.3 Hazards presented by the machine

2.0.3.1 Personal protective measures . . . . . . . . . . . . 4

2.0.3.2 Mechanical hazard . . . . . . . . . . . . . . . . . . . . . 4

2.0.3.3 Electrical hazard . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.3.4 Thermal hazard . . . . . . . . . . . . . . . . . . . . . . . 5

2.0.3.5 Hazard caused by noise . . . . . . . . . . . . . . . . . 5

2.0.3.6 Hazard caused by vibrations . . . . . . . . . . . . . 5

2.0.3.7 Hazard caused by radiation . . . . . . . . . . . . . . 5

2.0.3.8 Hazard caused by materials and substances . . 5

2.1 Safety measures

2.1.1 General safety measures . . . . . . . . . . . . . . . . 5

2.1.2 Reference to permitted total weight . . . . . . . . 5

2.1.3 Reference to safety measures for specific

operating conditions . . . . . . . . . . . . . . . . . . . . 6

2.1.3.1 Safety measuresWork safety . . . . . . . . . . . . . 6

2.1.3.2 Work safety . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3.3 Before driving . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3.4 Safety during cleaning,

repairs and maintenance . . . . . . . . . . . . . . . . 6

2.1.3.5 Suggestions for a user guide . . . . . . . . . . . . . 7

2.1.11 Lubricating grease . . . . . . . . . . . . . . . . . . . . . 7

2.2 Product descriptions

2.2.0.1 Machine overview . . . . . . . . . . . . . . . . . . . . . 8

2.2.1 Product description . . . . . . . . . . . . . . . . . . . . . 8

2.2.4 Dosage system . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Technical data

2.3.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Dimensioned sketch . . . . . . . . . . . . . . . . . . . 12

2.4 Diagrams

2.4.3 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Corrosion protection . . . . . . . . . . . . . . . . . . . . 12

3 Demands to the place of mounting

3.1 Demands to the bed plate . . . . . . . . . . . . . . . . 13

3.2 References to dangers which can be

prevented by methods of mounting . . . . . . . . 13

4 Instructions for preparations

4.1.1 Connection with the towing vehicle . . . . . . . . 13

4.1.2 Disconnection . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Operation instructions

5.0.1 Remote control . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.5 Operating levers . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Instructions for Initial Operation

5.2.2 Adjustment of spreading quantity (metering) . . 14

5.4.2 Remote control . . . . . . . . . . . . . . . . . . . . . . . 14

5.4.2.1 Correct installation . . . . . . . . . . . . . . . . . . . . . 14

5.4.2.2 Connection of remote control . . . . . . . . . . . . . 14

5.11 Procedure in case of failure . . . . . . . . . . . . . . . . 15

5.12 Instructions for repair and assembly . . . . . . . 15

6 Maintenance

6.2.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2.3 Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3 Inspection lists and overviews

6.3.1 Inspection list - mechanical . . . . . . . . . . . . . . 16

6.3.4 Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.7 Reference to suitable spare parts . . . . . . . . . . 18

7 Control and test sketch

7.1.2 Steadying wheel . . . . . . . . . . . . . . . . . . . . . . . 19

7.1.6 Dry matter container . . . . . . . . . . . . . . . . . . . . 20

7.1.12 Draw bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.1.20 Tyre list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 Certificates

8.1 EU certificate of conformity . . . . . . . . . . . . . . 23

8.4 Certificate of Quality Management System . . 24

9 Overview of standards . . . . . . . . . . . . . . . . . . 25

20 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

1 Identification

1.1 Manufacturer and supplier

Epoke®A/S

Vejenvej 50

Askov

DK-6600 Vejen

1.1.1 Copyright

The firm of Epoke®A/S, DK-6600 Vejen owns the

copyright to this technical documentation.

Mechanical, photographic or other reproduction or duplication of this technical documentation or parts of it is forbidden. The technical documentation is only intended for

the purchaser and his personnel.

1.1.2 Technical documentation

This technical documentation contains:

• An instruction book

• List of spare parts

These appendices contain basic instructions which must

be followed and read by the fitter / user before assembly

and commissioning. The technical documentation shall

always be available where the spreader is used.

The personnel who will be involved in operation, servicing,

inspection and assembly shall have the corresponding

qualifications for these areas of work. The area of responsibility, competence and monitoring of personnel must be

defined exactly by the employer. If personnel do not have

the necessary knowledge, they must be trained and

instructed. If necessary, this can be implemented through

the manufacturer/supplier as desired by the

purchaser/user of the spreader. Training abroad is carried

out by the local dealers. Moreover, the employer/user

must ensure that personnel have fully understood the

content of the technical documentation.

1.1.3 Warranty and liability

The general terms of sale and delivery apply unless agreed

otherwise and confirmed in writing upon entering into the

contract. Warranty liability and liability for damages are

excluded for personal injury and material damage if the

injury or damage may be due to one or more of the following reasons:

• Abnormal use of the spreader

• Inexpert assembly, commissioning operation and servicing of the spreader.

• Driving with the spreader with defective safety devices

or incorrectly applied or non-functioning safety and protection devices.

• Non-compliance with the instructions in the technical

documentation with regard to safety, transportation,

storage, assembly, commissioning, operation and maintenance of the spreader.

• Design changes to the spreader which are not performed or approved by the manufacturer.

• Use of non-EPOKE original spare parts

• Inadequate monitoring of parts which are exposed to

wear.

• Inexpertly executed repairs

3

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

1.2 Model and type

Model: Tow-behind spreader

Trade designation: SKE - serie

Type: SKE8

SKE12

SKE15

SKE20

Ident. no.: 1001xxxx (SKE8)

1003xxxx (SKE12)

1004xxxx (SKE15)

1005xxxx (SKE20)

(first 4 digits are type designation, the last 4 digits are

continuous numbering)

Composition of machine sign:

• Type:

• Ident. no.

• Year

• Volume, m

3

• Net weight kg

• Permitted axle load, kg

• Permitted total weight kg

• Permitted support load, kg

• Name and address of manufacturer

The nameplate is located on the spreader’s right side,

near the transmission.

1.3 Start no. and year

Valid from ID no.:

SKE8 - 11010200 - 2000

SKE12 - 10030200 - 2000

SKE15 - 10040200 - 2000

SKE20 - 10050200 - 2000

1.4 Country of origin

Denmark.

1.5 CE-mark

CE-mark is placed on the machine sign.

1.6 EU certificate of conformity

The above spreader has been manufactured in accordance

with the provisions of the COUNCIL DIRECTIVE of 22.

June 1998 on convergence of member states' legislation

on machinery (98/37/EF) with particular reference to

Appendix 1 of the Directive, on material health and safety

standards in connection with the construction and manufacture of machines, see item 8.

1.6.1 Directives applied

(89/392/EEC - 14.06.1989)

(91/368/EEC - 20.06.1991)

(93/44/EEC - 14.06.1993)

(93/68/EEC - 22.07.1993)

98/37/EF - 22.06.1998

1.6.2 Standards applied

EN292-1:1991

EN292-2:1991/A1:1995

EN294:1992

EN349:1993

EN811:1996

EN 953:1997

EN1037:1996

EN 1050:1997

EN1088:1996

prEN13021:1997

see item 9.1.

1.9 Quality system certificate

See item 8.4.

4

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

2 Descriptions

2.0.0 General

Important instructions are highlighted in each section.

Explanations of symbols

Warning (Work safety signal)

Safety should be observed where this sign is

positioned. Pay attention to this safety information sign and follow it be careful. Always follow

the general safety regulations as well.

Information

In the instructions for use, this symbol is placed

next to all important information relating to operation or the equipment’s function.

Later on, these symbols will be used for visual registration

of danger information signs.

2.0.1 Transport and handling

2.0.1.1 Transport

During transport, empty the solids tank and the loosen

spring base adjustment on the spreader.

Danger!

Road-users may be seriously injured, e.g. due

to projec-ting parts, loss of the spreader, etc.!

The spreader should be properly fastened.

Information!

• The spreader should only be put down on a level surface.

• The spreader should be adequately secured on the carrying vehicle.

• Electrical parts should be protected against humidity.

2.0.1.2 Handling

A crane must be used at all times when transporting or using the spreader. The spreader should be raised using the fastening rings.

Note the lifting tackle’s load capacity and the spreader’s

centre of gravity!

People can be seriously injured - e.g. through crushing!

2.0.1.6 Rules for total weight of towed vehicles

The total weight of the towed vehicle must never

exceed the weight limits stated by the manufacturer

of the vehicle/towbar.

In the case of cars, the weight limit may be found on the

manufacturer’s label on the car or in the user manual.

2.0.2 Information on restrictions on use

2.0.2.1 Normal use

Machines for winter service are machines for

removing winter obstacles in traffic areas, and

spreaders are machines for defined spreading

of thawing materials or sand on surfaces car-

rying traffic.

The spreaders must only be used for the purpose for

which they are intended. The spreaders must only be

operated, repaired and maintained by persons who are

fully familiar with these areas. These persons shall also

be informed about the dangers which the spreader can

pose.

Note - Only persons who are physically and psychologically suitable, and who are familiar with the content of the

operating instructions, may use the machine.

The user shall comply with the references in the operating

instructions.

Note - The manufacturer’s liability for any damage that may

occur shall lapse in the event of any form of abnormal use.

2.0.2.2 Abnormal use

Abnormal use

• when the spreaders are not used as spreaders

for winter service, and when the spreader has

not been mounted and connected correctly to

the towing vehicle.

• when the spreader is used for spreading materials which

are not used for combating icy roads.

• when the spreader is towed using an unsuitable vehicle

without taking into account the weight limits imposed by

the manufacturer of the vehicle. (trailer spreader only).

2.0.3 Hazards presented by the machine

2.0.3.1 Personal protective measures

As the design and construction ensure that the

operator's freedom of movement is not reduced,

use of personal protective measures (shoes, glo-

ves etc.) is not required.

2.0.3.2 Mechanical hazard

There is a risk of injury and damage from squashing, cutting and from sharp edges. To the extent

possible, points on machines that present such

hazards are fitted with protective devices.

2.0.3.3 Electrical hazard

• Work on the power supply must only be carried

out by an expert electrician.

• Loose connections and burnt-out cables must

be replaced immediately.

• Use only original fuses.

5

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

2.0.3.4 Thermal hazard

Thermal Hazard - not applicable.

2.0.3.5 Hazard caused by noise

A noise measurement has not been carried out as the noise pollution depends on the used vehicle.

2.0.3.6 Hazard caused by vibrations

Vibration measurement is omitted - not relevant.

2.0.3.7 Hazard caused by radiation

Radiation measurement is omitted - not relevant.

2.0.3.8 Hazard caused by materials and substances

Demounting (scrapping): Is to be carried out by a environmental acknowledged scrap merchant.

2.1 Safety measures

2.1.1 General safety measures

All EPOKE spreaders and equipment can be

operated by one person. Spread is controlled

entirely from the driver’s cab.

Instruction - The owner of the carrying vehicle undertakes

to ensure that the spreader is used only by people who:

• know the basic safety regulations and are thoroughly

familiar with the operation of the spreader

• have read and understood the section on safety and the

warnings in the technical documentation.

Instruction - Everyone who is authorised to work with the

spreader undertakes:

• to familiarise themselves with the basic safety regulations.

• to read and understand the section on safety and the

warnings in the technical documentation.

Instruction - only trained and instructed personnel are

permitted to work with the spreader:

• The authorisation of the personnel for starting, operating,

maintenance and repair must be clearly defined.

• Personnel in training may only work with the spreader

under the supervision of an experienced person.

Instruction - The spreader is designed with the safety

regulations in mind. Even so, the life of the driver may be

at risk while the machine is in use.

The spreader may only be used for its intended purpose

and in the proper condition as regards safety equipment.

Out of consideration for safety, the following is to be

observed:

Before operation the operator is to check whether devices

for control, safety and protection are correctly fitted and ok.

If defects are noted on safety devices or when other defects are noted which have influence on the safe

operation of the machine, there cannot be any operation

until these defects have been repaired.

Correction of flaws, maintenance and repairs are only to

be carried out, when the machine is not in operation.

After maintenance or repairs, the safety devices are to be

correctly placed.

2.1.2 Reference to permitted total weight

SKE8

Permitted total weight . . . . . . . . . . . . . . . . . . . . . 1200 kg

Permitted axle load . . . . . . . . . . . . . . . . . . . . . . . 1000 kg

Supporting load on draweye . . . . . . . . . . . . . . . . .200 kg

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400 kg

SKE12

Permitted total weight . . . . . . . . . . . . . . . . . . . . 1500 kg

Permitted axle load . . . . . . . . . . . . . . . . . . . . . . . 1200 kg

Supporting load on draweye . . . . . . . . . . . . . . . . 300 kg

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 kg

SKE15

Permitted total weight . . . . . . . . . . . . . . . . . . . . . 2660 kg

Permitted axle load . . . . . . . . . . . . . . . . . . . . . . . 1210 kg

Supporting load on draweye . . . . . . . . . . . . . . . . . 560 kg

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 kg

SKE20

Permitted total weight . . . . . . . . . . . . . . . . . . . . 3500 kg

Permitted axle load . . . . . . . . . . . . . . . . . . . . . . 2800 kg

Supporting load on draweye . . . . . . . . . . . . . . . . 750 kg

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 720 kg

2.1.3 Reference to safety measures for specific

operating conditions

2.1.3.1 Safety measures

• The tow plate of the spreader must be vertical when the

vehicle is loaded.

• The draw bar is adjustable for height as well as length.

Important: When adjusting height, self-locking nuts (A)

must only be used once, i.e. always use new selflocking nuts. Nut (M14 DIN 985 A2) torque must be

120 Nm.

• The stabiliser/supporting leg facilitates

connection/disconnection of the spreader. Before driving, the driver must check that the stabiliser/supporting

leg has been lifted.

• The depth of the tyre tread pattern must be min. 1.6 mm.

For information on air pressure in the road tyres.

2.1.3.2 Work safety

• Protection devices: The equipment must not be

operated without protection devices.

• The drawbar position must not be above hori-

zontal position due to the risk of tipping.

See section 2.1.2 Total weight reference – support load.

• Driving gear: The warranty and liability become void if

changes are made to the driving gear.

• Oblique position: The road may have a maximum incli-

nation of 10%.

• The spreader must only be subjected to repair work

when the motor of the towing vehicle has been stopped.

• Following repair work, all safety devices must be connected to the spreader.

• Unauthorised persons are to be turned away from the

danger zone.

• Persons must not be in the immediate proximity of the

machine (1 m to the side of the machine) when the

machine is operating.

• Notice! - Only spare parts recommended by the manufacturer must be used.

2.1.3.3 Before driving

Before starting, the driver should check that:

• the tow plate of the spreader must be vertical

when the vehicle is loaded.

• the spreader’s towbar is correctly positioned and secured to the tow-bar on the vehicle.

• the stabilizers have been raised.

• the safety devices are functioning.

• electrical connections and power supply have been con-

nected.

• the lights are functioning.

• the operating device has been fitted.

• the air pressure in the tyres is correct.

Remember to check adjustments.

2.1.3.4 Safety during cleaning, repairs and main-

tenance

• When cleaning, repairs, maintenance and similar

work is performed on the spreader, the motor of

the towing vehicle must be stopped.

• Intervals of maintenance are divided into operating

hours and apply to normal operating terms.

• Please observe the specified intervals of maintenance.

• See the maintenance and inspection list.

• Only the spare parts approved and recommended by

the manufacturer must be used.

Please use the original Epoke-spare parts only.

• After repair, safety devices must be correctly fitted

again.

• It is not allowed to drive without safety devices.

6

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

7

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

2.1.3.5 Suggestions for a user guide

For a safe operation, the employer has to make

a user´s guide.

Employer is required to equip the tool with various devices

and make all necessary arrangements which correspond

to the applicable safety instruction, technical and medical

regulations.

The employer has to instruct the users of the dangers,

which may arise from operation with the tool and

precautions which must be made, and thereafter the

instruction must be repeated at regular intervals, at least

once a year.

The employer can fulfill this requirement by providing a

user´s guide. Please be aware of the legislation concerning the safety area.

You may pass on the following instructions/information of

the operation to your staff e.g.:

• Normal/permitted usage

• Abnormal usage

• Safety in public traffic

• The user must be aware of, that his/her presence in the

danger zone (working area) is forbidden.

• Information of safety devices.

• If a fault/defect arises in the equipment in the equipment

which may present a risk/danger to the insured parties,

the equipment must be stopped.

• First aid instructions

• Operational safety

• Reference to faults and their rectification

• Instructions regarding the warning instructions

• Permissible operating data

• Environmental protection

• Supervision during use

• Servicing

• Maintenance

• Repair work on load-bearing and other technical parts

relating to safety.

2.1.11 Lubricating grease

Long-term or repeated contact with the skin can entail irritation or serious skin problems. Wash thoroughly with

soap and water. Avoid inhalation of grease fumes. Avoid

wearing clothing wetted with grease.

8

epoke

®

SKE8-12-15-20

GB-0305.1

2.2 Product descriptions

2.2.0.1 Machine overview

1

.1 SKE spreaders

2.2 Stabiliser

2.3 Stabiliser spindle

2.4 Pull device

3.1 Impellor shaft

3.2 Delivery roller

3.3 Rubber base

3.4.1 Spring base

3.4.2 Spring base stop

3.6 Spring base adjustment

3.7.1 Transmission from drive wheel, over downward

gearing to delivery drum

3.7.2 Transmission from delivery drum to mixer

3.8 Handle for manual operation of connection and

disconnection of spreading

5.5 Holder for transmission exposure

5.6 Rubber bonnet for transmission exposure

2.2.1 Product description

The Epoke SKE towed spreader is a surface-dependent

drum spreader for spreading salt, sand and grit.

The SKE spreaders are fitted with the Epoke dosing

system where the delivery drum and mixer are pulled from

the spreader drive wheel via mechanical gearing.

The SKE may be equipped with different gearings

(SKE8/SKE12 - 11%, 24%, 36%, 76% and SKE15/SKE20

- 24%, 38%) in the delivery drum in relation to the wheels.

Operation: The wheels supply all the energy needed for

operation of the spreader, which is thus completely surfacedependent.

Dosing system: The material tank and the supporting

frame are welded together. The tank is fitted with a mixer

shaft and a dosing unit. The mixer shaft prevents the

spreading material from building up, thus grinding and

distributing the spreading material over the entire length of

the tank.

The dosing unit is situated under the mixer shaft, consists

of the spring-supported rubber base and the delivery

drum, whose function is to dose the material to the road

surface. The drop, i.e. the distance between the road and

the dosing drum, is relatively small, thus making the spreaders practically insensitive to side winds and turbulence.

As a result, the spreading material is delivered where it is

needed, i.e. on the road surface.

Material volume: The indicated material volume is delivered surface-dependently at any speed of driving, as the

dosing unit speed depends on the vehicle speed. Set the

material volume (at input) by adjusting the spring base.

Stabiliser: The SKE features an ungraduated adjustable

stabiliser.

5.5

3.3

3.2

3.1

3.3

3.4.1

2.2

2.3

3.6

3.8

3.4.2

1.1

2.4

5.6

3.7.1

3.7.2

9

epoke

®

SKE8-12-15-20

GB-0305.1

2.2.4

6

7

8

9

10

1

2

3

4

5

C

B

A

C

D

10

epoke

®

SKE8-12-15-20

GB-0305.1

2.2.4 Metering system

1 The Epoke principle

A - Impellor shaft with springs

B - Delivery roller with cams

C - Rubber base

D - Spring base

2 The impellor shaft pulverizes all lumps, distributes the

spreading material in the whole length of the hopper,

and ensures constant supply to the delivery roller.

Impellor springs: When replacing defect impellor

springs, the flat side is to point to the front in working

direction and be placed in two spirals, which start in

the centre, whereby the material is lead towards the

centre. Start with no. 1 in the middle. Turn the tube

1/4 turn forward in the working direction, mount pair

no. 2 equally on each side of no. 1. Turn 1/4 turn in

the working direction, mount pair no. 3 equally on

each side of the previously mounted pair etc.

3 Possibility for demounting defect impellor springs.

4 The delivery roller is provided with cams (A) which

bring the material through the spring adjusted rubber

base. The cams are available in different designs for

all types of material and dosages.

Great and many cams: Great amount (sand etc).

Small and less cams: Small amount (salt).

5 The delivery cams: If the cams are worn, they are to

be replaced. If the screws are rustbound, the cams

can be blasted with a hammer, and the screws be

loosened with tongs. To ease a replacement of cams

later, it is recommended to fill in approx. 1/4 l waste

oil into the delivery roller. This has not been done

from the works out of regard for the oil waste during

shipment.

6 The rubber bases are jammed under the clamping iron

and can be turned and worn on all edges provided that

they are turned in time, see also description of the

spring base.

7 The spring base presses the bottom rubber base

against the cams of the delivery roller, regulated by

the spring base adjustment. Defect springs by wearing are to be replaced. When the spring base is

open, all points of the springs are to be in line.

The spring base stop is adjustable and placed in

order to stop the movement of the spring base for

max. material quantity.

8 Spring base adjustment: The adjustment is obtained

by the pressure of the bottom rubber base with different strength against the delivery roller by means of

the spring base. The pressure is varied by the adjustment handle at the rear of the spreader.

11

epoke

®

SKE8-12-15-20

GB-0305.1

2.3.1 Technical data

Model SKE8 SKE12 SKE15 SKE20

Hopper capacity, m

3

0,725 0,9 1,25 1,65

Total width, mm 1285 1665 1665 2195

Track gauge, mm 790 1160 1000 1530

Spreading width - min., mm 1008 1390 1390 1918

Rim size 4.00 E x 9 4.00 E x 9 5.50F x 10 5.50F x 10

Tyre size, 10PR 6.00 - 9 6.00 - 9 7.50 - 10 7.50 - 10

Tyre size, 12PR 6.00 - 9 6.00 - 9 7.50 - 10 7.50 - 10

Tyre size, 14PR ----- ----- 7.50 - 10 7.50 - 10

Net weight, kg 400 500 600 720

Permitted total weight, kg 1200 1500 2660 3500

Permitted shaft load capacity, kg 1000 1200 2100 2800

Supporting load on draweye, kg 200 300 560 750

Speed, km/h 30 30 30 30

12

epoke

®

SKE8-12-15-20

GB-0305.1

2.3.2 Dimensioned sketch

SKE15, SKE20

SKE8, SKE12

2.4 Diagrams

2.4.3 Electrical diagram

Electrical diagram, see spare parts manual.

2.5 Corrosion protection

All Epoke-products were sandblasted with steel balls, zinc

dusted with 1-component epoxyester (does not apply to

non-corrosion-resistant components), first coated with 2component polyurethan and varnished with 2-component

polyurethan varnish.

13

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

3 Demands to the place of mounting

3.1 Demands to the bed plate

Important! The spreader is to be loaded off onto

a solid, horizontal bed capable of bearing.

3.2 References to dangers which can be prevented by methods of mounting

Demands to the off-loading: The spreader is to be placed

with adequate space around itself in order to carry out

maintenance, lubrication, cleaning etc. comfortably and

safely. The distance from the spreader to a stationary

building must be at least 0.7 m, and between several

spreaders the distance must be at least 1.1 m.

4 Instructions for preparations

4.1.1 Connection with the towing vehicle

1. Make sure that the spreader cannot roll backwards.

Break blocks must be used on an even or very uneven

surface or on a slope.

2. Adjust the stabiliser or supporting leg so that the

towing vehicle hits the middle or just above the lowest

part of the coupling on the vehicle.

3. There must be no persons between the spreader and

the vehicle.

4. Coupling of spreader and vehicle. Replace the vehicle.

5. Once the coupling has been completed, check to

make sure that it is correct.

6. Connect the supply cables (electricity).

7. Turn op the stabiliser/supporting leg.

8. Remove brake blocks.

9 Check spreader light.

4.1.2 Disconnection

1. Secure the spreader by using

break blocks on an even or very uneven surface or on

a slope.

2. Lower the stabiliser/supporting leg.

3. Disconnect supply cables (electricity).

4. Disconnect the spreader.

5. There must be no persons between the spreader and

the vehicle.

6. Remove the vehicle from the spreader.

5 Operation instructions

5.0.1 Remote control

1. Spreading stop

2. Spreading - start

3. Material level indicator

4. Voltage control

5.1.5 Operating levers

As standard the spreader is supplied with manual remote

control of clutch for delivery roller and impellor.

The handle is placed onto the left transmission box of the

spreader.

Quantity control: The quantity control is done in differring

the pressure of the spring base against the delivery roller.

The pressure is varied through the handle at the rear of

the spreader.

1

2

3

4

14

epoke

®

SKE8-12-15-20

GB-0305.1

5.2 Instructions for Initial Operation

5.2.2 Adjustment of spreading quantity (metering)

At metering or check of quantity per m2you must be aware

that the width of the spread is 136% of the width of the

delivery roller when the road speed is 20 km/h or above.

The measuring tray corresponding to a width of spread of

1 metre must therefore be 1:1.36=0.735 m.

10 g/m2= 10 kg per driven km in measuring tray 0.735 m

20 g/m2= 20 kg per driven km in measuring tray 0.735 m

30 g/m2= 30 kg per driven km in measuring tray 0.735 m

40 g/m2= 40 kg per driven km in measuring tray 0.735 m

You may either hang the measuring tray up below the

delivery roller and drive exactly 1 km. Or you may activate

the wheel of the spreader and count the turns. In the latter

case the following calculation must be made:

Turns of wheel per km =

1000

D x π

D

Ex.: D = 0,540 m

= 589 turns per km

1000

0,540 x 3,14

5.4.2 Remote control

5.4.2.1 Correct installation

Direct current requirements for the electric control system

of the spreader: 11V - 32V.

When switching between 12V and 24V vehicles, working

lamp and rotating beacon must be switched accordingly.

5.4.2.2 Connection of remote control

• The electric remote control is connected to the spreader

by means of the multipoled plug on the remote control

cable, and connect it to the socket on the spreader.

• Plug the power supplying cable into the universal plug

on the vehicle (the lighter).

The remote control can be fastened in the cab using

mounting hardware (optional equipment), which is the

most suitable positioning for the remote control.

The remote control must be protected against the weather

when the spreader and thus the remote control are not in

use.

Gritting

Do not drive with engaged delivery roller without material in

the hopper in order to prevent unnecessary wear of the

rubber base.

If you wish to keep the marked width of spread the speed

should not exceed 25 - 30 km/h. At greater speeds the

width is increased through the wind, and widths of more

than 6,0 m may be acheived.

15

epoke

®

SKE8-12-15-20

GB-0305.1

5.12 Instructions for repair and assembly

Replacement of delivery roller and impellor

The shafts are drawn sidewards out of the rear plates of the

hopper. The holes are big enough to let through the delivery

roller and the impellor mounted with cams and springs.

Remember to loosen both allan screws in the flange bearings when the delivery roller and the impellor are dismounted. When mounting the delivery roller and the impellor the

tallow string tightenings are to be connected carefully and

the shaft ends to be wiped and greased. The chain wheels

must also flush.

6 Maintenance

6.2.1 Cleaning

All Epoke spreaders have been sandblasted, zinc dust

primed and primed before being painted with laquer, and

they are therefore extremely well-protected against rust.

However it is recommended - espescially after spreading

salt and if there are longer pauses between operations that the spreader is washed down with water after use.

Regular control extends the lifetime of the spreader and

guarantees a safer function.

6.2.2 Maintenance

Cleaning remote control.

Clean the remote control with a slightly moistened cloth

and wipe with a dry cloth.

Maintaining remote control.

Connectors and strain reliefs should be checked at regular intervals or at least every 100 operating hours. Defect

connectors must be replaced.

All moving transmission parts and bearings should be

lubricated with grease, see inspection list - mechanical

item 6.3.1.

The driving shafts are suspended in spherical roller bearings with tightenings and in flange bearings. They should

be greased only once a year. Over-greasing may spoil the

tightenings. Likewise too much grease may cause the

bearings to overheat.

Delivery roller and impellore are suspended in flange

bearings by a laminated tightening. The bearings are greased at the factory and do not need much greasing, but

for the sake of the tallow tightenings mounted behind a

frquent greasing is recommended, at least after each 25

hours ‘ operating.

Spring base adjustment is lubricated through the lubrication nipple with grease, see inspection list - mechanical

item 6.3.1

Defect cams are to be replaced. If the screws are rustbound, the cams can be blasted with a hammer, and the

screws can be loosened with tongs. In order to avoid this,

it is recommended, before use to loosen a cam and fill in

approx. 1/4 litre waste oil in the delivery roller.

Impellors: Defect springs are to be replaced, see metering system item 2.2.4.

Spring base: Defect springs are to be replaced. When

the spring base is wide open, the points of the springs

must be in line.

Rubber base: The rubber bases are wedged in under

clamping iron and can be turned and worn on all 4 edges,

provided that they are turned in time.

Roller chains: Control that they are tightened. They shall

be tightened in such a way that they by means tightening

them totally.

Clutch: Free function is checked. Otherwise clean and grease all parts. When the spreader is engaged is engaged the

pawl chamber, the pawl retainer and the pawl must turn free

without touching the stripper. When the spreader is disengaged the pawl must be combletely in bottom.

6.2.3 Storing

After the winter season it is recommended that the spreader is cleaned, protected against corrosion, lubricated and

has damages in the laquer repaired.

The spreader must be stored with an open (completely

open) spring base.

Storing remote control

When not in use, the remote control should be stored in a

dry place.

5.11 Procedure in case of failure

Problems Cause Remedy

1. Electric remote control out of order 1a. No power 1a. Connect power

1b. Fuse blown 1b. Replace the fuse

2. The spreader does not start 2a. No power on the system 2a. See item 1.

when using the remote control 2b. Bad connection in the 4-poled plug 2b. Clean/replace the plug

2c. Engine defective 2c. Replace engine

3. The spreader does not start manually 3a. Scraper does not move/ 3a. Check connections to start/stop

eccentric does not turn handle/axle (tailstock screw has

come loose – tighten)

3b. Chain broken 3b. Mount a new chain

4. Defective light/indicator 4a. No power 4a. Check connections

4b. Bad connection in the 7-poled plug 4b. Clean/replace the plug

4c. Bulb broken 4c. Replace bulb

16

epoke

®

SKE8-12-15-20

GB-0305.1

Date:

Signed:

1 Flanged bearings:

At the delivery roller and

the impellor shaft Ball bearing grease 25 h

2Tallow string packing:

At the delivery roller and

the impellor shaft 25 h ***

3 Delivery roller:

Cams 50 h Visual inspection. Worn

cams to be replaced.

4 Impellor springs 50 h Worn springs to be replaced

5 Rubber bases 50 h The rubber bases are wed-

ged in under the clamping

iron and can be turned and

worn on all edges - provided

that they are turned in time.

6 Spring base 50 h Visual inspection. When

the spring base is wide

open, the points of the

springs must be in line.

Worn springs to be replaced

7 Chain transmission:

Roller chains 50 h Check that the chains are

tight. The chains must not,

however, be firmly tightened.

Rolling chain - lubrication Wynn's Viscotene 50 h Silicone spray grease

8 Wheel nuts *140 Nm(14,0 kpm) 50 h *Tightening moment

9 Air pressure see tyre list 50 h

10 Spring base adjustment Grease 100 h

*** The tallow string packing consists of a rubber collar in which the tallow string of 2 1/2 windings is pressed in between

flange bearing and covering plate. When the flange bearing is mounted, the space between tallow string and flange

bearing is filled withe grease, which supports the tightening effect of the tallow string. Lubrication is carried out with

intervals of 25 hours of operation. If the grease penetrates into the hopper through the tallow string packing when lubricating, the tallow string should be replaced.

To be checked

Pos.

Machine:

Inspection list - mechanical

Measure size

and test size.

Operational

means and consumption means

Interval Result of

inspection

Comment

6.3.1.

17

epoke

®

SKE8-12-15-20

GB-0305.1

Date:

Signed:

11 Coupling 100 h Check that the ratchet is

working freely, alternatively

clean and grease all parts.

When the spreader is connected, the ratchet chamber, ratchet holder and ratchet must move freely

without touching the scraper. When the speeder is

disengaged, the ratchet

must be fully compressed.

12 Pawl for clutch Lubricating oil 100 h

13 Strickler Lubricating oil 100 h

14 Clutch lever Lubricating oil 100 h

15 Eccentric Lubricating oil 100 h

16 Stabiliser and support leg Lubricating oil 100 h

17 Nuts for drawbar *120 Nm (12,0 kpm) Before *Torque moment

each season

18 Greasing bearing Ball bearing grease Before

(drive wheel axle) each season

19 Salt spreading During longer It is recommended that the

pauses in spreader be flushed with

spreading water.

To be checked

Pos.

Machine:

Inspection list - mechanical

Measure size

and test size.

Operational

means and consumption means

Interval Result of

inspection

Comment

6.3.1.

18

epoke

®

SKE8-12-15-20

GB-0309.2

6.3.4 Grease

Grease:

Spreaders have been lubricated using Texaco products,

either mineral lubricating grease or biological lubricating

grease.

Mineral lubricating

grease: Texaco Texando CX EP 2.

Biological lubricating

grease: Texaco Biostar Grease LC EP 2.

6.7 Reference to suitable spare parts

Rubber base 8x210 (A), 12x210 (B) - See spare parts

manual.

Cams - See spare parts manual.

Impellor springs - See spare parts manual.

Tyres - See spare parts manual.

A

B

19

epoke

®

SKE8-12-15-20

GB-0305.1

Tested

Inspection

Steadying wheel

Control at use (Visual inspection)

Date Signed Result Date Signed

7.1.2

20

epoke

®

SKE8-12-15-20

GB-0305.1

Tested

Inspection

Dry matter container

Control at use (Visual inspection)

Date Signed Result Date Signed

• Visual checks should include checks for exterior damage, deformities, wear and tear and corrosion.

• Implementing safety devices.

7.1.6

21

epoke

®

SKE8-12-15-20

GB-0305.1

Tested

Inspection

Draw bar

Control at use (Visual inspection)

Date

Signed

Result Date Signed

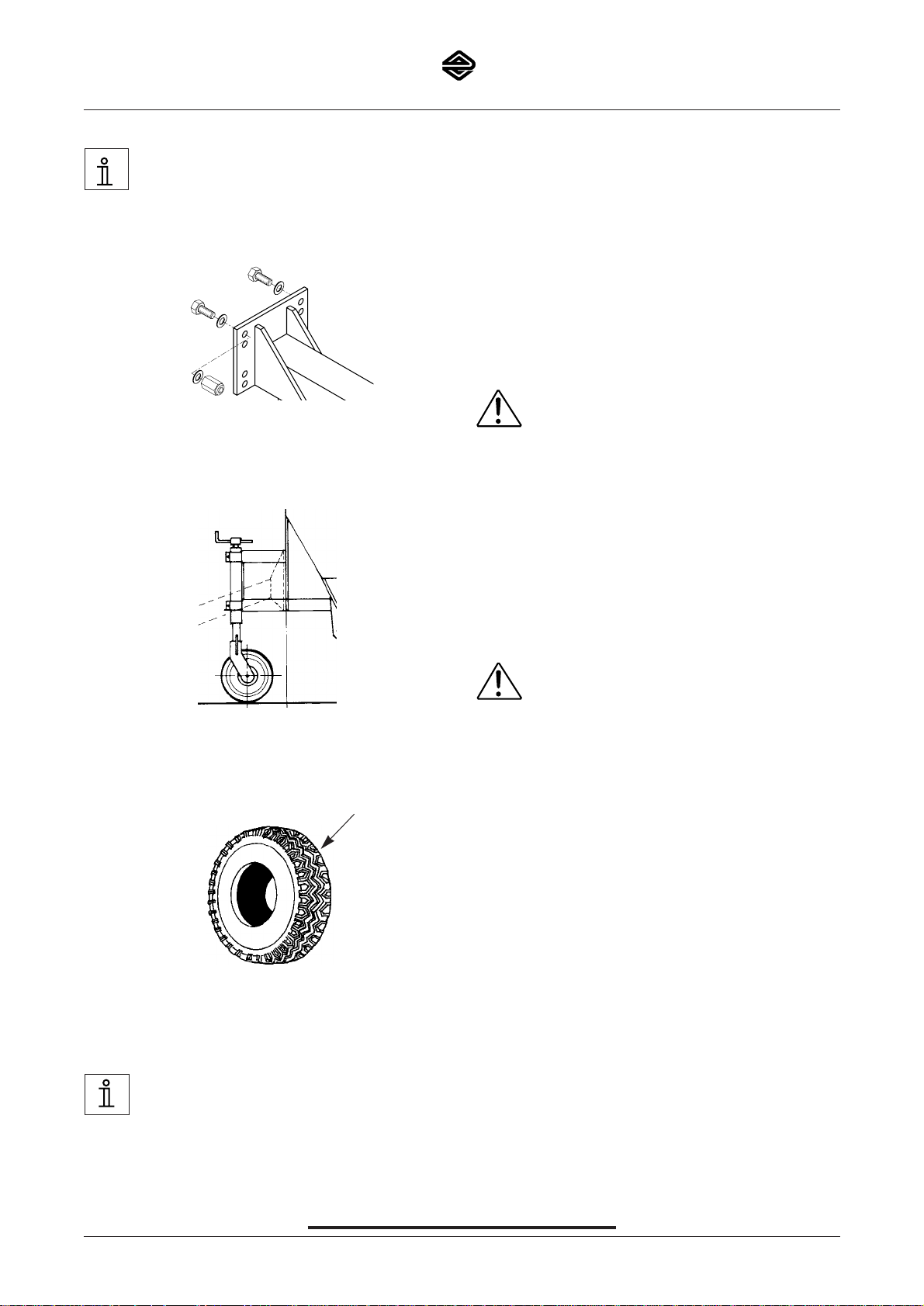

• TThe drawbar is adjustable in height.

Important: When adjusting height, self-locking nuts must only be used once, i.e. always use new self-locking nuts. Nut

(M14 DIN 985 A2) torque is 120 Nm.

• Do not perform subsequent changes on the drawbar, e.g. welding repairs.

• Check the driving gear for wear at regular intervals.

• Replace the bush at the “eye”. The bush may be replaced by rolling or pressing it in. Do not insert a bush by welding

or tacking.

7.1.12

22

epoke

®

SKE8-12-15-20

GB-0305.1

7.1.20 Tyre list

I

Mashine Ident. Torque moment

type no: kpm Size of tyre Ply Profile Epoke no:

TKG12 1101

TKB9-280 1107 3.00-4" 6 T-991 impl. 82251314 7 101,5

TK12E 1210 14 6.00-9" 10 T-523 82251114 8,5 123,25

TK12E-275 1211 14 6.00-9" 12 T-523 HS 82251505 10 145

TKEB12 1301 14 6.00-9" 12 T-523 Steel-Belt 82253612 8,1 117,45

TKEB9-275 1306

TMK10 1400 14 6.00-9" 10 T-523 82251114 8,5 123,25

TMK10-275 1405 14 6.00-9" 12 T-523 HS 82251505 10 145

TMK7 1404 14 6.00-9" 12 T-523 Steel-Belt 82253612 8,1 117,45

TMK7GT 1406

TT10H2 1610 3.00-4" 6 T-991 impl. 82251314 7 101,5

TT10H6 1611 14 6.00-9" 10 T-523 82251114 8,5 123,25

TT10H2-275 1612 14 6.00-9" 12 T-523 HS 82251505 10 145

TT10H6-275 1613 14 6.00-9" 12 T-523 Steel-Belt 82253612 8,1 117,45

SW2000 2425 3.00-4" 6 T-991 impl. 82251314 7 101,5

14 6.00-9" 6 T-523 82251002 2,2 31,9

CS1000 1507 14 6.00-9" 10 T-523 82251114 8,5 123,25

CS1000 MKII 1510 14 6.00-9" 12 T-523 HS 82251505 10 145

CS1000 MKII

1511 14 6.00-9" 12 T-523 Steel-Belt 82253612 8,1 117,45

Air pressure at

50 km/h

bar psi

SKE8 1001 14 6.00-9" 10 T-523 82251114 8,5 123,25

SKE12 1003 14 6.00-9" 12 T-523HS 82251505 10 145

14 6.00-9" 12 T-523Steel belt 82253612 8,1 117,45

SKE15 1004 4.00-4" 6 T-991 82251435 7 101,5

SKE20 1005 14 7,50-10" 10 T-523 82251071 6,5 94,25

14 7,50-10" 14 T-523HS 82251501 9 130,5

14 6.00-9" 6 T-523 82251002 4,3 62,35

14 6.00-9" 12 T-523HS 82251505 10 145

ITM35 1501 4.00-8" 6 T-49 HS 82251278 5,2 75,4

ITM45 1502 155/70R-13" 75 Q M+S 82250006 2,2 31,9

ITM60 1503

Epomini 5 2.00-16" VM 100 82256258 2,5 36,25

Epomini 20 2.75-17" VM 100 82256299 2,75 39,875

IGLO S2400 2490 18x8.0-10 82250008 6 87

2491 185-R14" 8 P75 82250001 4,5 65,25

2492 185-R14" 8 P75 82250001 4,5 65,25

2493 18x8.0-10 82250008 6 87

2494 185-R14" 8 P75 82250001 4,5 65,25

2495 185-R14" 8 P75 82250001 4,5 65,25

TS1000 1551 9 185QR-14" P75 82252279 3 43,5

9 185-R14" 8 P75 82250001 3 43,5

TS1000 1552 9 215/75R-17,5" L71 82250005 8,5 123,25

PW803H 3105 10,5 155/70R-13" 75 Q M+S 82250006 1,5 21,75

PW23H 3130

SWxxxx 14 185R-14" MS PLUS 3 Q 82252279 1,5 21,75

EpoJet

PWV87

23

epoke

®

SKE8-12-15-20

GB-0305.1

8.1

24

epoke

®

SKE8-12-15-20

GB-0305.1

8.4 Certificate of Quality Management System (ISO 9001)

This quality management system is a very important requirement in order to assert oneself in international trade and frequently also in order to participate in open tenders.

The company has held the certificate since April 21, 1993, and it is applicable to the Epoke product range, including grass

mowers, spreaders, sweepers, snow ploughs, which have all been subject to ISO 9001 testing.

25

epoke

®

SKE8-12-15-20

GB-0305.1

9 Overview of standards

EUROPEAN STANDARD

EN 292-1 : 1991

Safety of machinery - Basic concepts - General principles for design - Part 1: Basic terminology, methodology.

EN 292-2 : 1991/A1 : 1995

Safety of machinery - Basic concepts, general principles for design - Part 2: Technical principles and specifications.

EN 294 : 1992

Safety of machinery - Safety distances to prevent danger zones being reached by the upper limbs.

EN 349 : 1993

Safety of machinery - Minimum gaps to avoid crushing of parts of the human body.

EN 418 : 1993

Safety of machinery - Emergency stop equipment, functional aspects - Principles for design.

EN 811 : 1996

Safety of machinery - Safety distances to prevent danger zones being reached by the lower limbs.

EN 953 : 1997

Safety of machinery - Guards - General requirements for the design and construction of fixed and movable guards.

EN 1037 : 1996

Safety of machinery - Prevention of unexpected start-up.

EN 1050 : 1997

Safety of machinery - Principles for risk assessment.

EN 1088 : 1996

Safety of machinery - Interlocking devices associated with guards - Principles for design and selection.

EN 60204-1 : 1998

Safety of machinery - Electrical equipment of machines - Part 1: General requirements.

26

epoke

®

SKE8-12-15-20

GB-0305.1

20 Index

A

Abnormal use, 4

Adjustment of spreading quantity (metering), 14

Before driving, 6

C

CE-mark, 3

Certificate of Quality Management System, 24

Certificates, 23

Cleaning, 15

Connection of remote control, 14

Connection with the towing vehicle, 13

Control and test sketch, 19

Copyright, 2

Correct installation, 14

Corrosion protection, 12

Country of origin, 3

D

Demands to the bed plate, 13

Demands to the place of mounting, 13

Descriptions, 4

Diagrams, 12

Dimensioned sketch, 12

Directives applied, 3

Disconnection, 13

Dosage system, 9

Draw bar, 21

Dry matter container, 20

E

Electrical diagram, 12

Electrical hazard, 4

EU certificate of conformity, 3, 23

G

General safety measures, 5

General, 4

Grease, 18

H

Handling, 4

Hazard caused by materials and substances, 5

Hazard caused by noise, 5

Hazard caused by radiation, 5

Hazard caused by vibrations, 5

Hazards presented by the machine, 4

I

Identification, 2

Information on restrictions on use, 4

Inspection list – mechanical, 16

Inspection lists and overviews, 16

Instructions for Initial Operation, 14

Instructions for repair and assembly, 15

L

Lubricating grease, 7

M

Machine overview, 8

Maintenance, 15

Manufacturer and supplier, 2

Mechanical hazard, 4

Model and type specification, 3

N

Normal use, 4

O

Operating levers, 13

Operation instructions, 13

Overview of standards, 25

P

Personal protective measures, 4

Procedure in case of failure, 15

Product description, 8

Q

Quality system certificate, 3

R

Reference to permitted total weight, 5

Reference to safety measures for specific operating conditions, 6

Reference to suitable spare parts, 18

References to dangers which can be prevented by methods of mounting, 13

Remote control, 13, 14

Rules for total weight of towed vehicles, 4

S

Safety measures, 5

Safety measuresWork safety, 6

Sikkerhed ved rengøring, reparation og vedligeholdelse, 6

Standards applied, 3

Start no. and date, 3

Steadying wheel, 19

Storing, 15

Suggestions for a user guide, 7

T

Technical data, 11

Technical documentation, 2

Thermal hazard, 5

Transport and handling, 4

Tyre list, 22

W

Warranty and liability, 2

Work

Loading...

Loading...