Epoke SKE8, SKE Series, SKE15, SKE12, SKE20 Instruction Manual

epoke

®

500481

GB-0305.1

Instruction manual

SKE

Valid from ident. no. xxxx0200

If you have technical questions please state ident. no., which is on the machine sign. We recommend that you write this

number here:

Type: ..................................................

Year: .................................................. Ident. no.: .............................................

Valid from ident. no.:

SKE 8 10010200

SKE 12 10030200

SKE 15 10040200

SKE 20 10050200

Published and printed by

Epoke®A/S,

Documentation department

Changes of technical details in relation to specifications and sketches in this instruction are subject

to alteration.

This instruction answers important questions regarding safety, operation, maintenance and technical

data.

1

epoke

®

SKE8-12-15-20

GB-0305.1

Table of contents

1 Identification

1.1 Manufacturer and supplier . . . . . . . . . . . . . . . 2

1.1.1 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.2 Technical documentation . . . . . . . . . . . . . . . . 2

1.1.3 Warranty and liability . . . . . . . . . . . . . . . . . . 2

1.2 Model and type specification . . . . . . . . . . . . . 3

1.3 Start no. and date . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Country of origin . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 CE-mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6 EU certificate of conformity . . . . . . . . . . . . . . . 3

1.6.1 Directives applied . . . . . . . . . . . . . . . . . . . . . . 3

1.6.2 Standards applied . . . . . . . . . . . . . . . . . . . . . . 3

1.9 Quality system certificate . . . . . . . . . . . . . . . . 3

2 Descriptions

2.0.0 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.1 Transport and handling . . . . . . . . . . . . . . . . . . 4

2.0.1.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.1.2 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.1.6 Rules for total weight of towed vehicles . . . . . 4

2.0.2 Information on restrictions on use . . . . . . . . . . 4

2.0.2.1 Normal use . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.2.2 Abnormal use . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.3 Hazards presented by the machine

2.0.3.1 Personal protective measures . . . . . . . . . . . . 4

2.0.3.2 Mechanical hazard . . . . . . . . . . . . . . . . . . . . . 4

2.0.3.3 Electrical hazard . . . . . . . . . . . . . . . . . . . . . . . 4

2.0.3.4 Thermal hazard . . . . . . . . . . . . . . . . . . . . . . . 5

2.0.3.5 Hazard caused by noise . . . . . . . . . . . . . . . . . 5

2.0.3.6 Hazard caused by vibrations . . . . . . . . . . . . . 5

2.0.3.7 Hazard caused by radiation . . . . . . . . . . . . . . 5

2.0.3.8 Hazard caused by materials and substances . . 5

2.1 Safety measures

2.1.1 General safety measures . . . . . . . . . . . . . . . . 5

2.1.2 Reference to permitted total weight . . . . . . . . 5

2.1.3 Reference to safety measures for specific

operating conditions . . . . . . . . . . . . . . . . . . . . 6

2.1.3.1 Safety measuresWork safety . . . . . . . . . . . . . 6

2.1.3.2 Work safety . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3.3 Before driving . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3.4 Safety during cleaning,

repairs and maintenance . . . . . . . . . . . . . . . . 6

2.1.3.5 Suggestions for a user guide . . . . . . . . . . . . . 7

2.1.11 Lubricating grease . . . . . . . . . . . . . . . . . . . . . 7

2.2 Product descriptions

2.2.0.1 Machine overview . . . . . . . . . . . . . . . . . . . . . 8

2.2.1 Product description . . . . . . . . . . . . . . . . . . . . . 8

2.2.4 Dosage system . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Technical data

2.3.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Dimensioned sketch . . . . . . . . . . . . . . . . . . . 12

2.4 Diagrams

2.4.3 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Corrosion protection . . . . . . . . . . . . . . . . . . . . 12

3 Demands to the place of mounting

3.1 Demands to the bed plate . . . . . . . . . . . . . . . . 13

3.2 References to dangers which can be

prevented by methods of mounting . . . . . . . . 13

4 Instructions for preparations

4.1.1 Connection with the towing vehicle . . . . . . . . 13

4.1.2 Disconnection . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Operation instructions

5.0.1 Remote control . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.5 Operating levers . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Instructions for Initial Operation

5.2.2 Adjustment of spreading quantity (metering) . . 14

5.4.2 Remote control . . . . . . . . . . . . . . . . . . . . . . . 14

5.4.2.1 Correct installation . . . . . . . . . . . . . . . . . . . . . 14

5.4.2.2 Connection of remote control . . . . . . . . . . . . . 14

5.11 Procedure in case of failure . . . . . . . . . . . . . . . . 15

5.12 Instructions for repair and assembly . . . . . . . 15

6 Maintenance

6.2.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2.3 Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3 Inspection lists and overviews

6.3.1 Inspection list - mechanical . . . . . . . . . . . . . . 16

6.3.4 Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.7 Reference to suitable spare parts . . . . . . . . . . 18

7 Control and test sketch

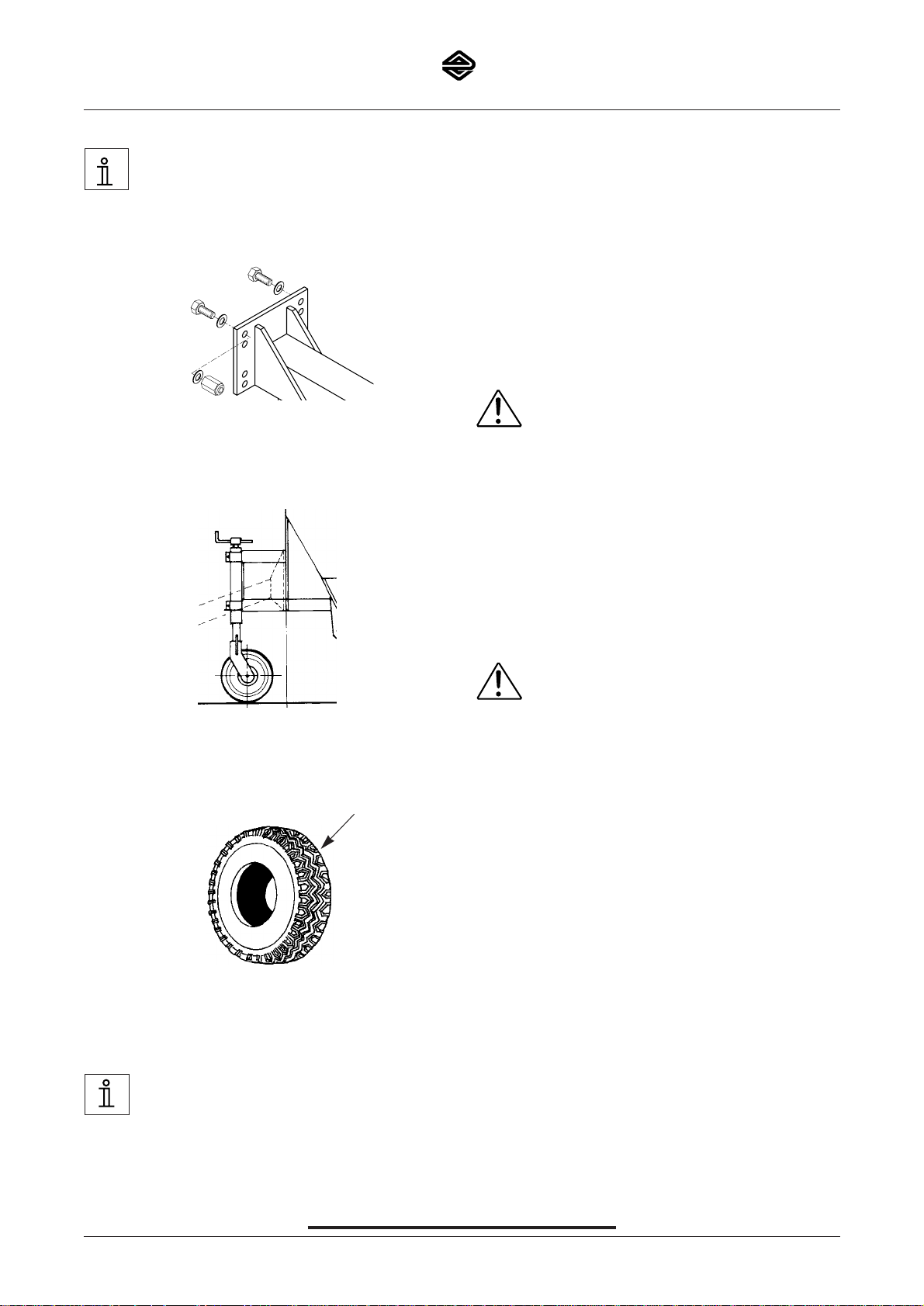

7.1.2 Steadying wheel . . . . . . . . . . . . . . . . . . . . . . . 19

7.1.6 Dry matter container . . . . . . . . . . . . . . . . . . . . 20

7.1.12 Draw bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.1.20 Tyre list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 Certificates

8.1 EU certificate of conformity . . . . . . . . . . . . . . 23

8.4 Certificate of Quality Management System . . 24

9 Overview of standards . . . . . . . . . . . . . . . . . . 25

20 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

1 Identification

1.1 Manufacturer and supplier

Epoke®A/S

Vejenvej 50

Askov

DK-6600 Vejen

1.1.1 Copyright

The firm of Epoke®A/S, DK-6600 Vejen owns the

copyright to this technical documentation.

Mechanical, photographic or other reproduction or duplication of this technical documentation or parts of it is forbidden. The technical documentation is only intended for

the purchaser and his personnel.

1.1.2 Technical documentation

This technical documentation contains:

• An instruction book

• List of spare parts

These appendices contain basic instructions which must

be followed and read by the fitter / user before assembly

and commissioning. The technical documentation shall

always be available where the spreader is used.

The personnel who will be involved in operation, servicing,

inspection and assembly shall have the corresponding

qualifications for these areas of work. The area of responsibility, competence and monitoring of personnel must be

defined exactly by the employer. If personnel do not have

the necessary knowledge, they must be trained and

instructed. If necessary, this can be implemented through

the manufacturer/supplier as desired by the

purchaser/user of the spreader. Training abroad is carried

out by the local dealers. Moreover, the employer/user

must ensure that personnel have fully understood the

content of the technical documentation.

1.1.3 Warranty and liability

The general terms of sale and delivery apply unless agreed

otherwise and confirmed in writing upon entering into the

contract. Warranty liability and liability for damages are

excluded for personal injury and material damage if the

injury or damage may be due to one or more of the following reasons:

• Abnormal use of the spreader

• Inexpert assembly, commissioning operation and servicing of the spreader.

• Driving with the spreader with defective safety devices

or incorrectly applied or non-functioning safety and protection devices.

• Non-compliance with the instructions in the technical

documentation with regard to safety, transportation,

storage, assembly, commissioning, operation and maintenance of the spreader.

• Design changes to the spreader which are not performed or approved by the manufacturer.

• Use of non-EPOKE original spare parts

• Inadequate monitoring of parts which are exposed to

wear.

• Inexpertly executed repairs

3

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

1.2 Model and type

Model: Tow-behind spreader

Trade designation: SKE - serie

Type: SKE8

SKE12

SKE15

SKE20

Ident. no.: 1001xxxx (SKE8)

1003xxxx (SKE12)

1004xxxx (SKE15)

1005xxxx (SKE20)

(first 4 digits are type designation, the last 4 digits are

continuous numbering)

Composition of machine sign:

• Type:

• Ident. no.

• Year

• Volume, m

3

• Net weight kg

• Permitted axle load, kg

• Permitted total weight kg

• Permitted support load, kg

• Name and address of manufacturer

The nameplate is located on the spreader’s right side,

near the transmission.

1.3 Start no. and year

Valid from ID no.:

SKE8 - 11010200 - 2000

SKE12 - 10030200 - 2000

SKE15 - 10040200 - 2000

SKE20 - 10050200 - 2000

1.4 Country of origin

Denmark.

1.5 CE-mark

CE-mark is placed on the machine sign.

1.6 EU certificate of conformity

The above spreader has been manufactured in accordance

with the provisions of the COUNCIL DIRECTIVE of 22.

June 1998 on convergence of member states' legislation

on machinery (98/37/EF) with particular reference to

Appendix 1 of the Directive, on material health and safety

standards in connection with the construction and manufacture of machines, see item 8.

1.6.1 Directives applied

(89/392/EEC - 14.06.1989)

(91/368/EEC - 20.06.1991)

(93/44/EEC - 14.06.1993)

(93/68/EEC - 22.07.1993)

98/37/EF - 22.06.1998

1.6.2 Standards applied

EN292-1:1991

EN292-2:1991/A1:1995

EN294:1992

EN349:1993

EN811:1996

EN 953:1997

EN1037:1996

EN 1050:1997

EN1088:1996

prEN13021:1997

see item 9.1.

1.9 Quality system certificate

See item 8.4.

4

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

2 Descriptions

2.0.0 General

Important instructions are highlighted in each section.

Explanations of symbols

Warning (Work safety signal)

Safety should be observed where this sign is

positioned. Pay attention to this safety information sign and follow it be careful. Always follow

the general safety regulations as well.

Information

In the instructions for use, this symbol is placed

next to all important information relating to operation or the equipment’s function.

Later on, these symbols will be used for visual registration

of danger information signs.

2.0.1 Transport and handling

2.0.1.1 Transport

During transport, empty the solids tank and the loosen

spring base adjustment on the spreader.

Danger!

Road-users may be seriously injured, e.g. due

to projec-ting parts, loss of the spreader, etc.!

The spreader should be properly fastened.

Information!

• The spreader should only be put down on a level surface.

• The spreader should be adequately secured on the carrying vehicle.

• Electrical parts should be protected against humidity.

2.0.1.2 Handling

A crane must be used at all times when transporting or using the spreader. The spreader should be raised using the fastening rings.

Note the lifting tackle’s load capacity and the spreader’s

centre of gravity!

People can be seriously injured - e.g. through crushing!

2.0.1.6 Rules for total weight of towed vehicles

The total weight of the towed vehicle must never

exceed the weight limits stated by the manufacturer

of the vehicle/towbar.

In the case of cars, the weight limit may be found on the

manufacturer’s label on the car or in the user manual.

2.0.2 Information on restrictions on use

2.0.2.1 Normal use

Machines for winter service are machines for

removing winter obstacles in traffic areas, and

spreaders are machines for defined spreading

of thawing materials or sand on surfaces car-

rying traffic.

The spreaders must only be used for the purpose for

which they are intended. The spreaders must only be

operated, repaired and maintained by persons who are

fully familiar with these areas. These persons shall also

be informed about the dangers which the spreader can

pose.

Note - Only persons who are physically and psychologically suitable, and who are familiar with the content of the

operating instructions, may use the machine.

The user shall comply with the references in the operating

instructions.

Note - The manufacturer’s liability for any damage that may

occur shall lapse in the event of any form of abnormal use.

2.0.2.2 Abnormal use

Abnormal use

• when the spreaders are not used as spreaders

for winter service, and when the spreader has

not been mounted and connected correctly to

the towing vehicle.

• when the spreader is used for spreading materials which

are not used for combating icy roads.

• when the spreader is towed using an unsuitable vehicle

without taking into account the weight limits imposed by

the manufacturer of the vehicle. (trailer spreader only).

2.0.3 Hazards presented by the machine

2.0.3.1 Personal protective measures

As the design and construction ensure that the

operator's freedom of movement is not reduced,

use of personal protective measures (shoes, glo-

ves etc.) is not required.

2.0.3.2 Mechanical hazard

There is a risk of injury and damage from squashing, cutting and from sharp edges. To the extent

possible, points on machines that present such

hazards are fitted with protective devices.

2.0.3.3 Electrical hazard

• Work on the power supply must only be carried

out by an expert electrician.

• Loose connections and burnt-out cables must

be replaced immediately.

• Use only original fuses.

5

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

2.0.3.4 Thermal hazard

Thermal Hazard - not applicable.

2.0.3.5 Hazard caused by noise

A noise measurement has not been carried out as the noise pollution depends on the used vehicle.

2.0.3.6 Hazard caused by vibrations

Vibration measurement is omitted - not relevant.

2.0.3.7 Hazard caused by radiation

Radiation measurement is omitted - not relevant.

2.0.3.8 Hazard caused by materials and substances

Demounting (scrapping): Is to be carried out by a environmental acknowledged scrap merchant.

2.1 Safety measures

2.1.1 General safety measures

All EPOKE spreaders and equipment can be

operated by one person. Spread is controlled

entirely from the driver’s cab.

Instruction - The owner of the carrying vehicle undertakes

to ensure that the spreader is used only by people who:

• know the basic safety regulations and are thoroughly

familiar with the operation of the spreader

• have read and understood the section on safety and the

warnings in the technical documentation.

Instruction - Everyone who is authorised to work with the

spreader undertakes:

• to familiarise themselves with the basic safety regulations.

• to read and understand the section on safety and the

warnings in the technical documentation.

Instruction - only trained and instructed personnel are

permitted to work with the spreader:

• The authorisation of the personnel for starting, operating,

maintenance and repair must be clearly defined.

• Personnel in training may only work with the spreader

under the supervision of an experienced person.

Instruction - The spreader is designed with the safety

regulations in mind. Even so, the life of the driver may be

at risk while the machine is in use.

The spreader may only be used for its intended purpose

and in the proper condition as regards safety equipment.

Out of consideration for safety, the following is to be

observed:

Before operation the operator is to check whether devices

for control, safety and protection are correctly fitted and ok.

If defects are noted on safety devices or when other defects are noted which have influence on the safe

operation of the machine, there cannot be any operation

until these defects have been repaired.

Correction of flaws, maintenance and repairs are only to

be carried out, when the machine is not in operation.

After maintenance or repairs, the safety devices are to be

correctly placed.

2.1.2 Reference to permitted total weight

SKE8

Permitted total weight . . . . . . . . . . . . . . . . . . . . . 1200 kg

Permitted axle load . . . . . . . . . . . . . . . . . . . . . . . 1000 kg

Supporting load on draweye . . . . . . . . . . . . . . . . .200 kg

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400 kg

SKE12

Permitted total weight . . . . . . . . . . . . . . . . . . . . 1500 kg

Permitted axle load . . . . . . . . . . . . . . . . . . . . . . . 1200 kg

Supporting load on draweye . . . . . . . . . . . . . . . . 300 kg

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 kg

SKE15

Permitted total weight . . . . . . . . . . . . . . . . . . . . . 2660 kg

Permitted axle load . . . . . . . . . . . . . . . . . . . . . . . 1210 kg

Supporting load on draweye . . . . . . . . . . . . . . . . . 560 kg

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 kg

SKE20

Permitted total weight . . . . . . . . . . . . . . . . . . . . 3500 kg

Permitted axle load . . . . . . . . . . . . . . . . . . . . . . 2800 kg

Supporting load on draweye . . . . . . . . . . . . . . . . 750 kg

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 720 kg

2.1.3 Reference to safety measures for specific

operating conditions

2.1.3.1 Safety measures

• The tow plate of the spreader must be vertical when the

vehicle is loaded.

• The draw bar is adjustable for height as well as length.

Important: When adjusting height, self-locking nuts (A)

must only be used once, i.e. always use new selflocking nuts. Nut (M14 DIN 985 A2) torque must be

120 Nm.

• The stabiliser/supporting leg facilitates

connection/disconnection of the spreader. Before driving, the driver must check that the stabiliser/supporting

leg has been lifted.

• The depth of the tyre tread pattern must be min. 1.6 mm.

For information on air pressure in the road tyres.

2.1.3.2 Work safety

• Protection devices: The equipment must not be

operated without protection devices.

• The drawbar position must not be above hori-

zontal position due to the risk of tipping.

See section 2.1.2 Total weight reference – support load.

• Driving gear: The warranty and liability become void if

changes are made to the driving gear.

• Oblique position: The road may have a maximum incli-

nation of 10%.

• The spreader must only be subjected to repair work

when the motor of the towing vehicle has been stopped.

• Following repair work, all safety devices must be connected to the spreader.

• Unauthorised persons are to be turned away from the

danger zone.

• Persons must not be in the immediate proximity of the

machine (1 m to the side of the machine) when the

machine is operating.

• Notice! - Only spare parts recommended by the manufacturer must be used.

2.1.3.3 Before driving

Before starting, the driver should check that:

• the tow plate of the spreader must be vertical

when the vehicle is loaded.

• the spreader’s towbar is correctly positioned and secured to the tow-bar on the vehicle.

• the stabilizers have been raised.

• the safety devices are functioning.

• electrical connections and power supply have been con-

nected.

• the lights are functioning.

• the operating device has been fitted.

• the air pressure in the tyres is correct.

Remember to check adjustments.

2.1.3.4 Safety during cleaning, repairs and main-

tenance

• When cleaning, repairs, maintenance and similar

work is performed on the spreader, the motor of

the towing vehicle must be stopped.

• Intervals of maintenance are divided into operating

hours and apply to normal operating terms.

• Please observe the specified intervals of maintenance.

• See the maintenance and inspection list.

• Only the spare parts approved and recommended by

the manufacturer must be used.

Please use the original Epoke-spare parts only.

• After repair, safety devices must be correctly fitted

again.

• It is not allowed to drive without safety devices.

6

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

7

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

2.1.3.5 Suggestions for a user guide

For a safe operation, the employer has to make

a user´s guide.

Employer is required to equip the tool with various devices

and make all necessary arrangements which correspond

to the applicable safety instruction, technical and medical

regulations.

The employer has to instruct the users of the dangers,

which may arise from operation with the tool and

precautions which must be made, and thereafter the

instruction must be repeated at regular intervals, at least

once a year.

The employer can fulfill this requirement by providing a

user´s guide. Please be aware of the legislation concerning the safety area.

You may pass on the following instructions/information of

the operation to your staff e.g.:

• Normal/permitted usage

• Abnormal usage

• Safety in public traffic

• The user must be aware of, that his/her presence in the

danger zone (working area) is forbidden.

• Information of safety devices.

• If a fault/defect arises in the equipment in the equipment

which may present a risk/danger to the insured parties,

the equipment must be stopped.

• First aid instructions

• Operational safety

• Reference to faults and their rectification

• Instructions regarding the warning instructions

• Permissible operating data

• Environmental protection

• Supervision during use

• Servicing

• Maintenance

• Repair work on load-bearing and other technical parts

relating to safety.

2.1.11 Lubricating grease

Long-term or repeated contact with the skin can entail irritation or serious skin problems. Wash thoroughly with

soap and water. Avoid inhalation of grease fumes. Avoid

wearing clothing wetted with grease.

Loading...

Loading...