Page 1

FusionPro 32/48

Laser System Manual | Model 16000

Original Instructions

Register your system now for driver update notifications

and FREE files! EPILOGLASER.COM/REGISTER

Technical Support: +1 (303) 215-9171

Knowledge Base: support.epiloglaser.com

System Registration: epiloglaser.com/register

Driver/Firmware: epiloglaser.com/fusionpro-drivers

UPDATED APRIL 2019 | EPILOGLASER.COM/MANUALS

Page 2

Page 3

TABLE OF CONTENTS

FIRE WARNING 1

INTRODUCTION 2

How to Use This Owner’s Manual .............................................................................................................................................. 2

Icons Used in this Manual ............................................................................................................................................................... 2

SECTION 1: SAFETY 3

Laser Safety .............................................................................................................................................................................................. 3

Electrical Safety ..................................................................................................................................................................................... 3

Safety Features and Regulatory Compliance ................................................................................................................. 4

Dos and Don’ts ..................................................................................................................................................................................... 10

SECTION 2: GETTING STARTED 11

1. Unpacking the Laser System ................................................................................................................................................... 12

2. Choose Where to Locate the System ...............................................................................................................................14

3. Connecting the Exhaust ............................................................................................................................................................. 15

4. Connecting Electrical Power...................................................................................................................................................17

5. Connect the Laser to Your Computer .............................................................................................................................. 17

6. Set the Fusion Pro’s IP Address ..............................................................................................................................................18

7. Sign Up for Driver Updates and Register Your System ........................................................................................19

SECTION 3: SOFTWARE INSTALLATION 21

Epilog Job Manager Instructions ............................................................................................................................................. 21

Uninstalling the Previous Job Manager ..............................................................................................................................21

Windows 7: Ethernet Installation .............................................................................................................................................. 23

How to Install the Epilog Job Manager ..............................................................................................................................25

Troubleshooting the Job Manager ......................................................................................................................................... 31

Important Job Manager Notes .................................................................................................................................................32

SECTION 4: THE JOB MANAGER 33

Using the Epilog Job Manager..................................................................................................................................................33

Printing to the Epilog Job Manager ......................................................................................................................................34

Organizing Your Print Jobs ..........................................................................................................................................................34

Previewing Your Job .........................................................................................................................................................................38

Searching for a Job ..........................................................................................................................................................................38

Finding Job History ............................................................................................................................................................................ 39

Vector Sorting ...................................................................................................................................................................................... 40

Material Settings Tab .......................................................................................................................................................................41

Job Settings Tab .................................................................................................................................................................................44

Changing Program Settings ........................................................................................................................................................46

SECTION 5: THE LASER DASHBOARD 47

Setting Up CorelDRAW for the Laser .....................................................................................................................................48

Sending Your First Project .............................................................................................................................................................49

Presetting Your Cut Lines .............................................................................................................................................................. 52

Placing Your Artwork .......................................................................................................................................................................52

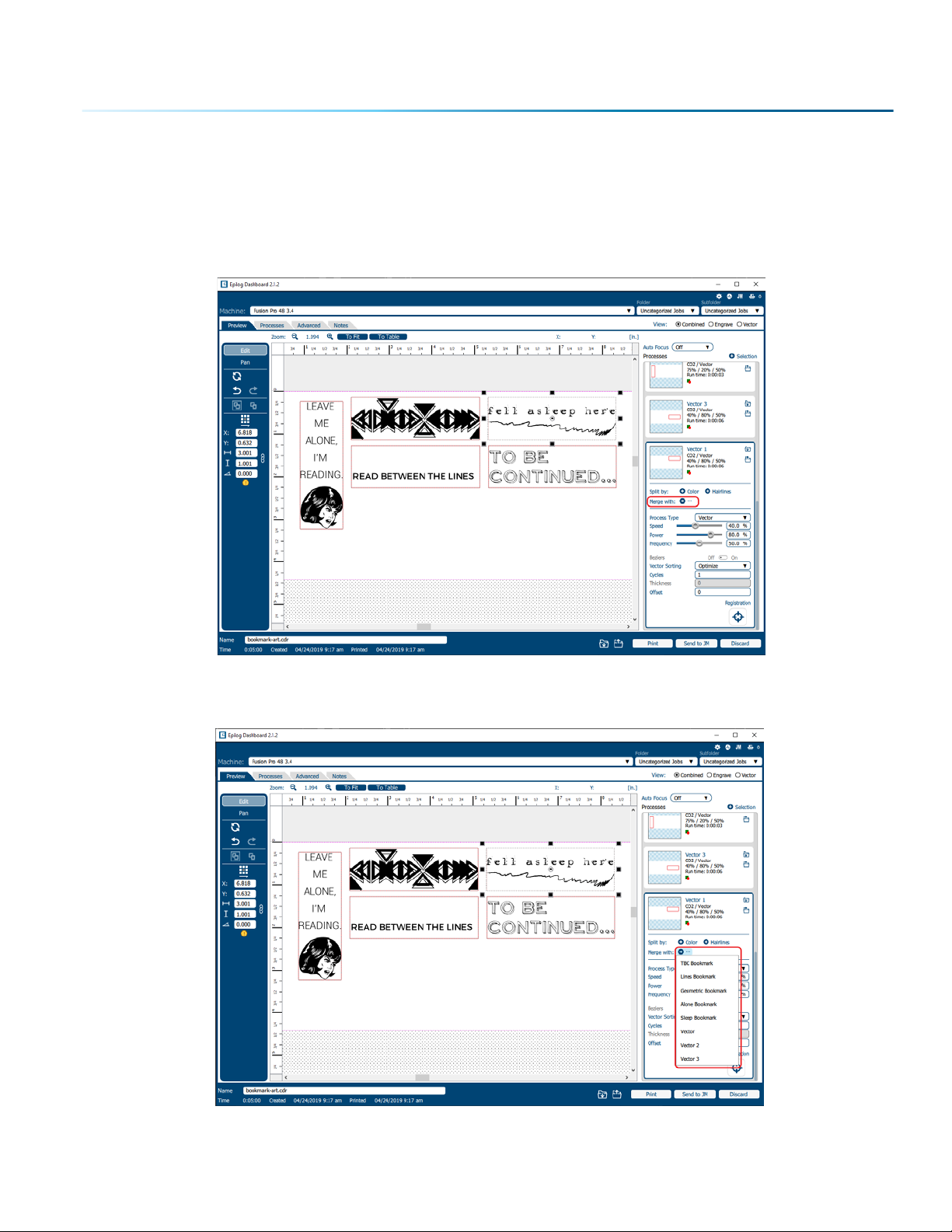

Dividing Your Job Into Processes ............................................................................................................................................ 53

Editing Artwork with Live View ................................................................................................................................................... 59

Saving Your Settings.........................................................................................................................................................................62

File Settings .............................................................................................................................................................................................63

Settings in Detail .................................................................................................................................................................................64

Processes Tab .......................................................................................................................................................................................66

Advanced Tab ...................................................................................................................................................................................... 67

Notes Tab ................................................................................................................................................................................................. 67

File Setup FAQs .....................................................................................................................................................................................68

Additional CorelDRAW Laser Dashboard Features ....................................................................................................68

SECTION 6: CONTROL PANEL 71

Display ......................................................................................................................................................................................................... 71

- i -

Page 4

TABLE OF CONTENTS

Joystick ...................................................................................................................................................................................................... 77

Job Storage ............................................................................................................................................................................................ 77

SECTION 7: QUICK START GUIDE 79

Artwork Setup ........................................................................................................................................................................................ 79

Setting a Vector Cutting Line .................................................................................................................................................... 80

Resolution ..................................................................................................................................................................................................81

Landscape or Portrait .....................................................................................................................................................................83

SECTION 8: SYSTEM FEATURES 85

IRISTM Camera Positioning System ..........................................................................................................................................85

Touch Screen .........................................................................................................................................................................................85

Air Assist ....................................................................................................................................................................................................86

Auto Focus vs Manual Focus ......................................................................................................................................................86

Key Switch ................................................................................................................................................................................................ 87

Image Dithering ...................................................................................................................................................................................87

Color Mapping ......................................................................................................................................................................................89

Using Color Mapping .......................................................................................................................................................................89

Red Dot Pointer ....................................................................................................................................................................................93

Emergency Stop Button .................................................................................................................................................................94

Front Access Door ..............................................................................................................................................................................94

Task Plate/Vacuum Hold-Down Table .................................................................................................................................94

Exhaust Plenum ....................................................................................................................................................................................95

SECTION 9: OPTIONAL FEATURES 97

Vector Cutting Table/Vacuum Hold-Down Table ........................................................................................................ 97

PhotoLaser Plus ....................................................................................................................................................................................98

SECTION 10: ENGRAVING MATERIALS 105

CO2 Laser Materials/Techniques ......................................................................................................................................... 105

SECTION 11: SPECIFICATIONS 115

Fusion Pro Laser Technical Specifications ....................................................................................................................... 115

Compatibility ........................................................................................................................................................................................ 116

Recommended PC ............................................................................................................................................................................ 116

About The CO2 Laser Source ......................................................................................................................................................117

Federal Communications Commission (FCC) Notice ................................................................................................ 118

SECTION 12: TECHNICAL SUPPORT 119

Contacting Technical Support ................................................................................................................................................. 119

Frequently Asked Questions .................................................................................................................................................... 120

Join Epilog Laser’s Online Community ................................................................................................................................122

SECTION 13: MATERIAL SUPPLIERS 123

Industry Material Supplier List ................................................................................................................................................. 123

APPENDIX A: WARRANTY STATEMENT 127

Warranty Statement for the Fusion Pro Laser ...............................................................................................................127

APPENDIX B: MATERIAL SETTINGS 129

Fusion Pro Suggested Material Settings (CO2) ............................................................................................................. 129

APPENDIX C: SYSTEM CALIBRATION 133

Camera Calibration ........................................................................................................................................................................ 136

INDEX 141

- ii -

Page 5

FIRE WARNING

Fire Warning

Your laser system uses a high intensity beam of light that can generate extremely high

temperatures when it comes into contact with the material being engraved, marked or

cut. Some materials are extremely flammable and can easily ignite and burst into open

flame setting the machine afire. This open flame is very dangerous and has the potential to

destroy not only the machine, but the building in which it is housed.

Experience shows that vector cutting with the laser has the most potential to create an open flame.

Many materials are susceptible to igniting, but acrylic, in all its dierent forms, has been shown to be

especially flammable when vector cutting with the laser.

Please read the following warnings and recommendations and follow them closely at all times!

• Stay with the laser. Never operate the laser system while unattended.

• Keep the area clear. Clean around the machine and keep the area free of clutter, combustible

materials, explosives, or volatile solvents such as acetone, alcohol, or gasoline.

• Be prepared with a fire extinguisher. Always keep a properly maintained and inspected fire

extinguisher on hand. Epilog recommends a Halotron fire extinguisher or a multi-purpose dry

chemical fire extinguisher. The Halotron extinguishers are more expensive than a dry chemical, but

oer certain advantages should you ever need to use an extinguisher. The Halotron extinguisher

discharges a clean, easily removable substance that is not harmful to the mechanics or wiring of

the laser system. The dry chemical extinguisher discharges a sticky, corrosive powder that is very

diicult to clean up.

• Use Air Assist. Always use the system’s Air Assist feature when vector cutting.

• Use caution when vector cutting. Many materials have the potential to suddenly burst into flames

when cut with a laser – even materials that may be very familiar to the user. Always monitor the

machine when it is operating.

• Clean the laser. A buildup of cutting and engraving residue and debris is dangerous and can

create a fire hazard in its own right. Keep your laser system clean and free of debris. Regularly clean

underneath the Vector Cutting Table to clean any small pieces that have fallen through the grid.

- 1 -

Page 6

INTRODUCTION

How to Use This Owner’s Manual

Thank you for purchasing an Epilog Fusion Pro Laser system. Your Epilog system has been designed to

be easy to operate, but you will utilize it to its fullest potential by taking some time to read this owner’s

manual prior to use. You will be ready to use the Epilog Laser system as soon as you read the first few

sections. Then you can refer to topics in the remaining sections, as you work.

Icons Used in this Manual

Look for these symbols to help you find valuable information throughout the text:

Helpful notes to keep in mind when running the laser!

This icon signifies advice you can try that will save you significant time.

This icon highlights current contact information for receiving help.

Warnings and cautions to keep in mind when running the laser.

This icon indicates the potential for fire damage when operating the laser.

- 2 -

Page 7

SECTION 1: SAFETY

Laser Safety

The standard reference for laser safety is the American Standard for the Safe Use of Lasers, Z136.1-2000,

developed by the American National Standards Institute (ANSI). This reference is the basis for many of

the federal regulations for laser and laser system manufacturers, and for the Occupational Safety and

Health Administration (OSHA) laser safety guidelines. It contains detailed information concerning proper

installation and use of laser systems.

While the ANSI standard itself does not have the force of law, its recommendations, including warning

signage, training, and the designation of a laser safety oicer, may be compulsory under local workplace

regulations when operating laser systems above Class I. It is the operator’s responsibility to ensure that

the installation and operation of the Epilog Model 16000 Laser System is peormed in accordance with

all applicable laws.

Copies of ANSI Standard Z136.1-2000 are available from Epilog Corporation or from:

Laser Institute of America

12424 Research Parkway, Suite 125

Orlando, FL 32826

(407) 380-1553

Electrical Safety

The AC input power to the Epilog Model 16000 Laser System is potentially lethal and is fully contained

within the cabinet.

• DO NOT open any of the machine’s access panels while the unit is plugged in.

Opening a panel may expose the operator to the unit’s AC input power.

• DO NOT make or break any electrical connections to the system while the unit is

turned on.

Fusion Pro Electrical Specifications

Model Wattage(s) Voltage Amp draw-MAX

Pro 32 50, 60, 80 120 13A

Pro 32 50, 60, 80 240 6.5A

Pro 32 120 240 10A

Pro 48 50, 60, 80 240 6.5A

Pro 48 120 240 10A

- 3 -

Page 8

SECTION 1: SAFETY

Safety Features and Regulatory Compliance

Epilog has incorporated specific safety features into the Model 16000 Laser System in order to meet the

requirements of 21 CFR 1040 and the International Standard IEC 60825-1. These safety features include:

• A safety enclosure (cabinet), which fully encloses the engraving laser and its beam path.

• Dual redundant interlock systems that turn o the engraving laser when the window is opened.

• A visible emission indication when the Laser Diode Pointer (Red Dot Pointer) is operating. There is an

LED indicator on the machine’s front panel.

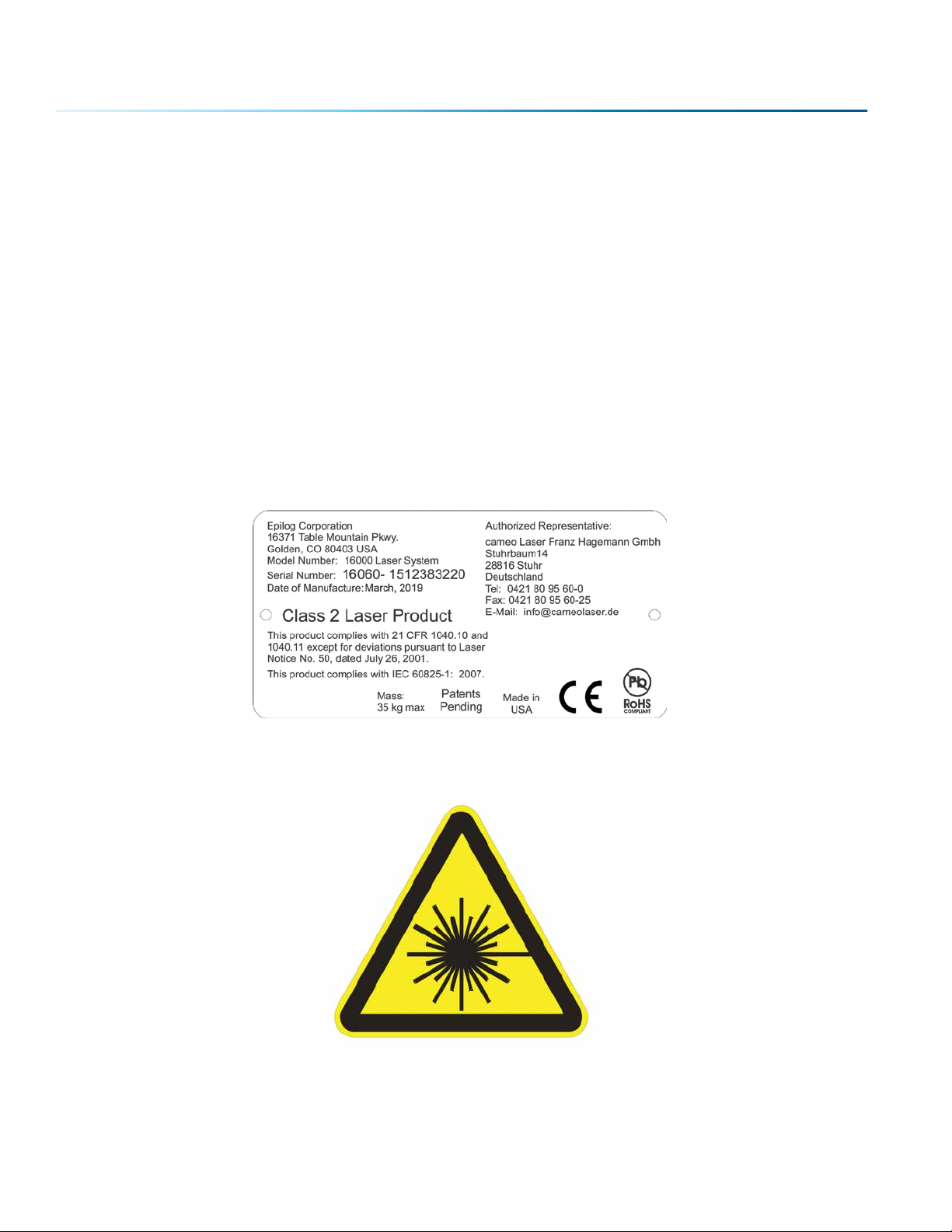

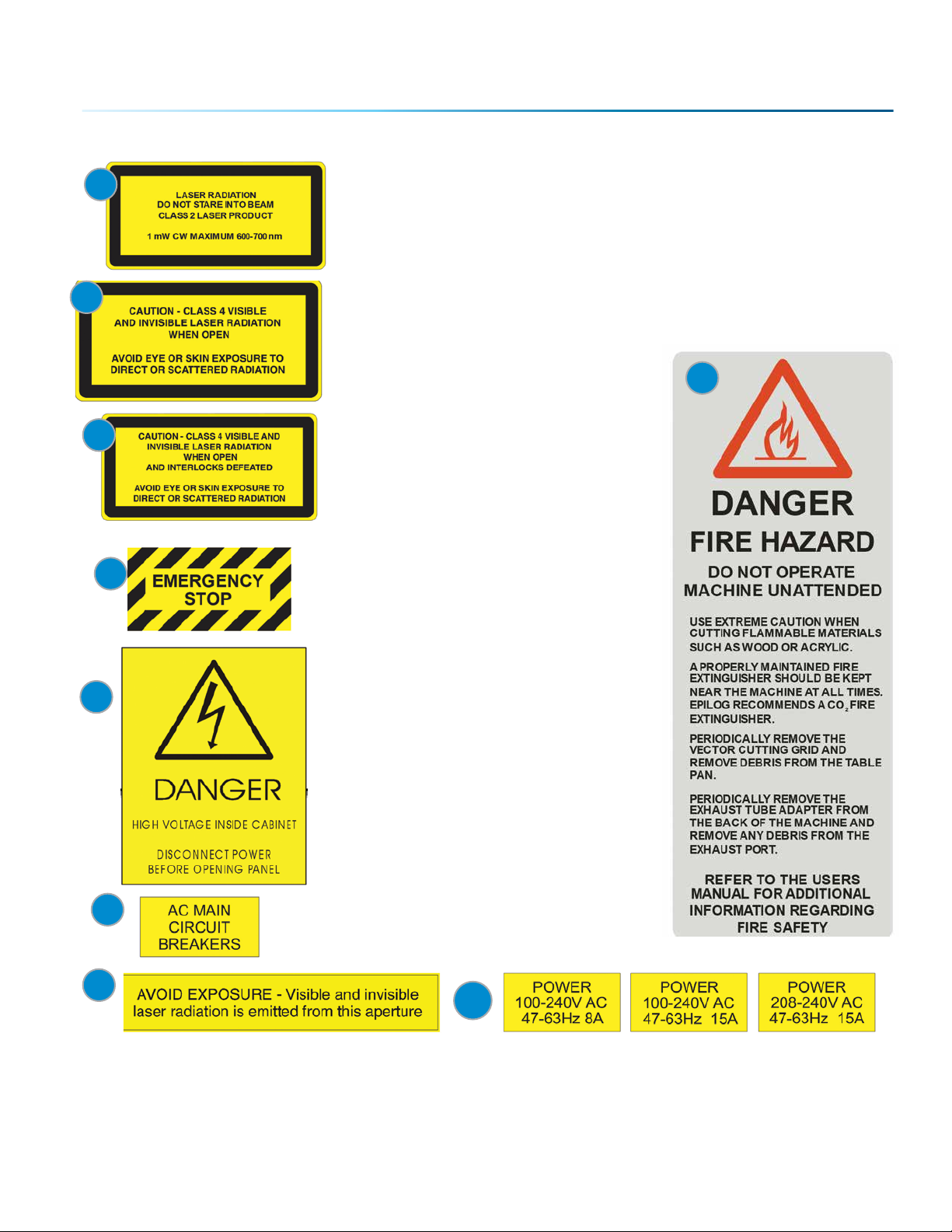

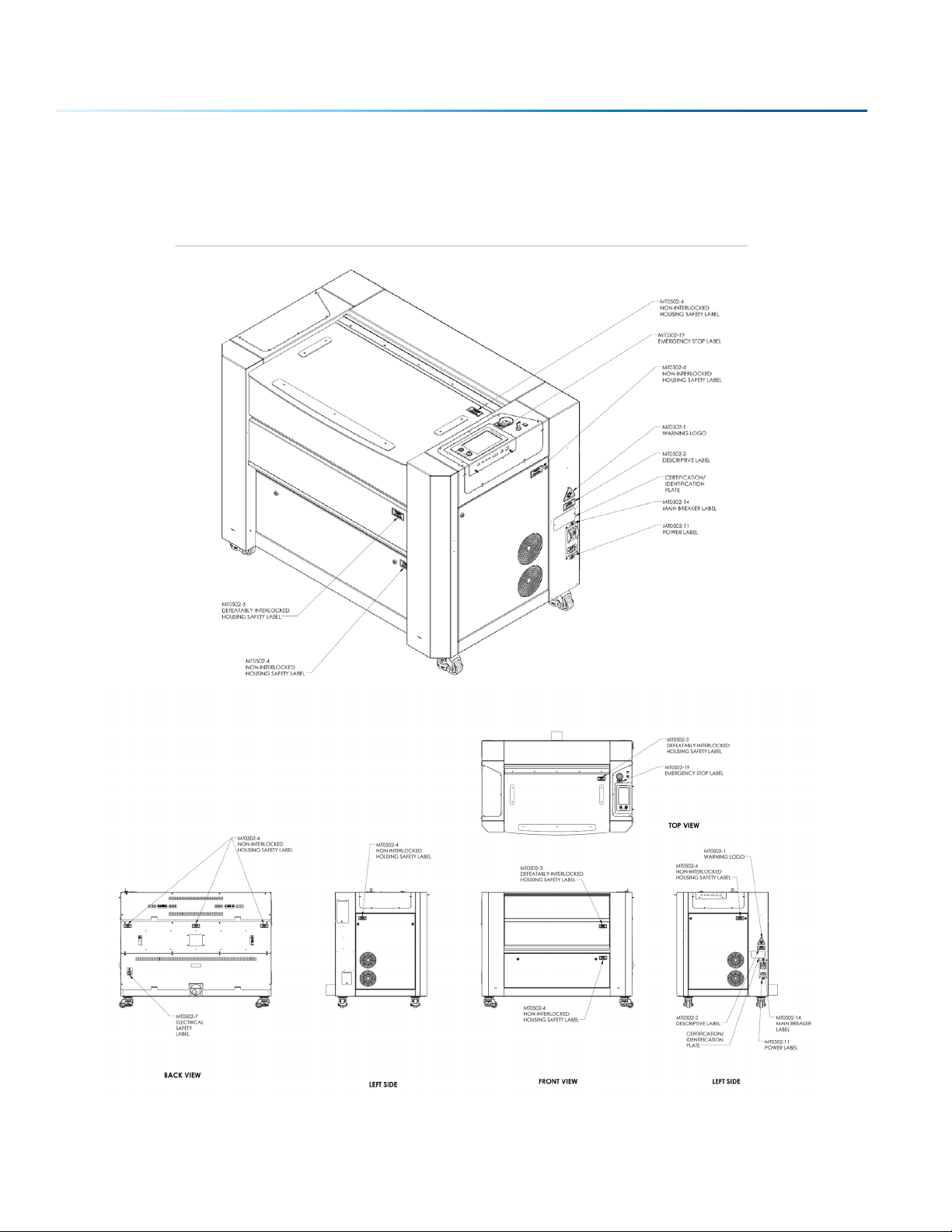

21 CFR 1040 and IEC 60825-1 require that certification, identification, and warning labels be placed on laser

products. Reproductions of labels on the Epilog Model 16000 Laser System follow, with their locations

specified:

1. Certification/Identification Plate: This engraved plate is located on the right side of the machine’s

cabinet.

2. Warning Logotype: This label is located on the right side of the machine’s cabinet, above the

Certification/Identification plate.

- 4 -

Page 9

SECTION 1: SAFETY

3. Descriptive Label: This label identifies the classification of the

3

4

5

Model 16000 in accordance with 21 CFR 1040.10 and IEC 60825-1. It is

located on the right side of the machine’s cabinet, below the Warning

Logotype.

4. Non-interlocked Protective Housing Safety Labels: These labels

are located on, or adjacent to, removable access covers on the

machine’s cabinet as shown in the diagrams to follow. Where a label

is located on a removable cover, there is an additional label under

the cover so that it will be visible when the cover has been removed.

5. Defeatably-interlocked Protective

Housing Safety Labels: There is one

label on each of the machine’s cabinet

doors; one on the front door and one

on the top door.

6. Emergency Stop Label: This label is

located below the red Emergency Stop

switch on the top right side of the

machine.

11

7. Electrical Safety Label: This label is

6

7

8

9

located on the back of the machine in

the lower le hand corner.

8. Main Breaker Label: This label is

located on or above the power module

panel at the right side of the machine’s

cabinet.

9. Aperture Safety Label: This label is

located above the aperture, inside the

cabinet, where laser beams enter the

machine’s engraving area.

10. Power Labels: The appropriate label

for the machine is located on or below

the power module panel at the right

side of the machine’s cabinet.

11. Fire Warning Label: There are two

labels on top of the machine’s cabinet;

one to the le and one to the right of

the top cabinet door.

10

- 5 -

Page 10

SECTION 1: SAFETY

The following diagrams show the location of each specific label.

Fusion Pro 32:

- 6 -

Page 11

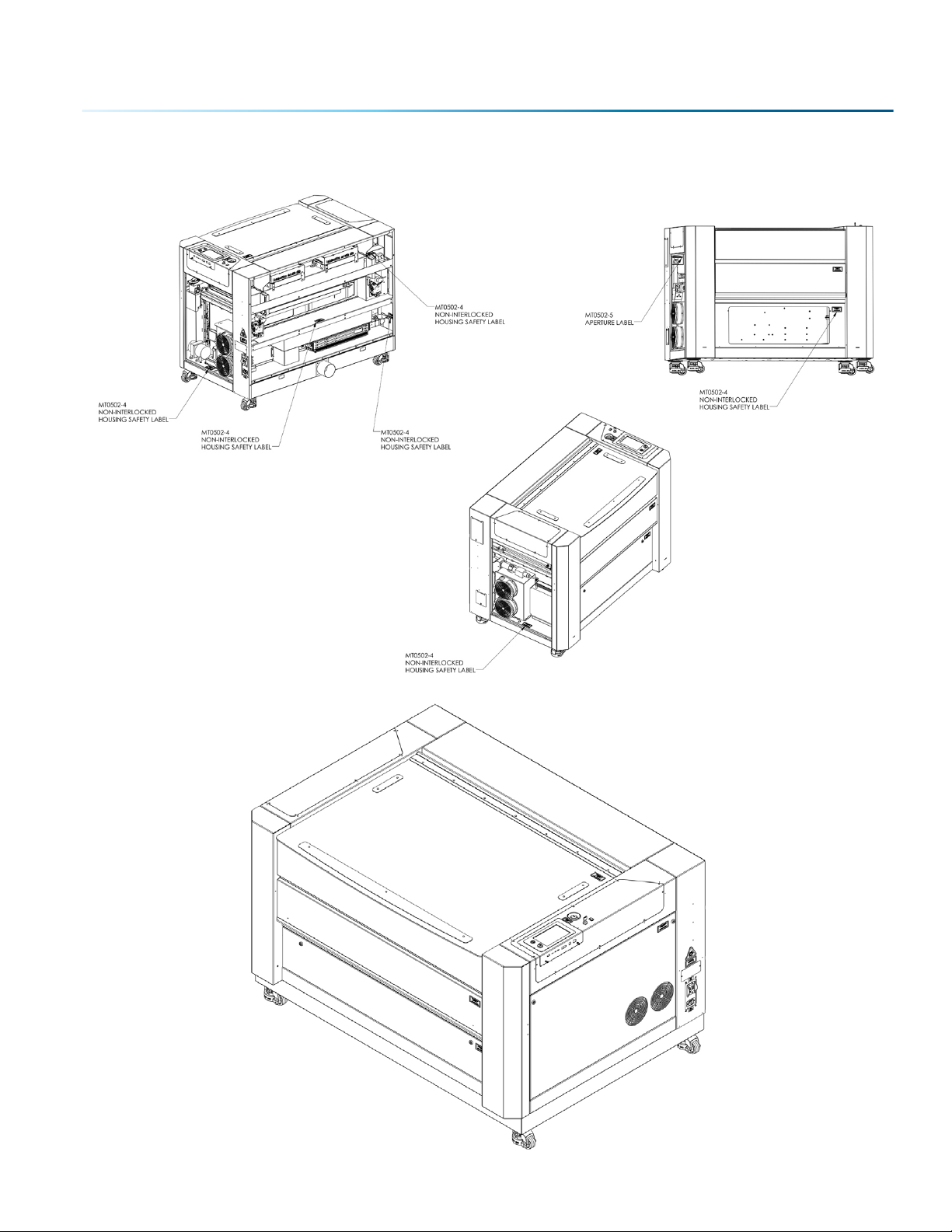

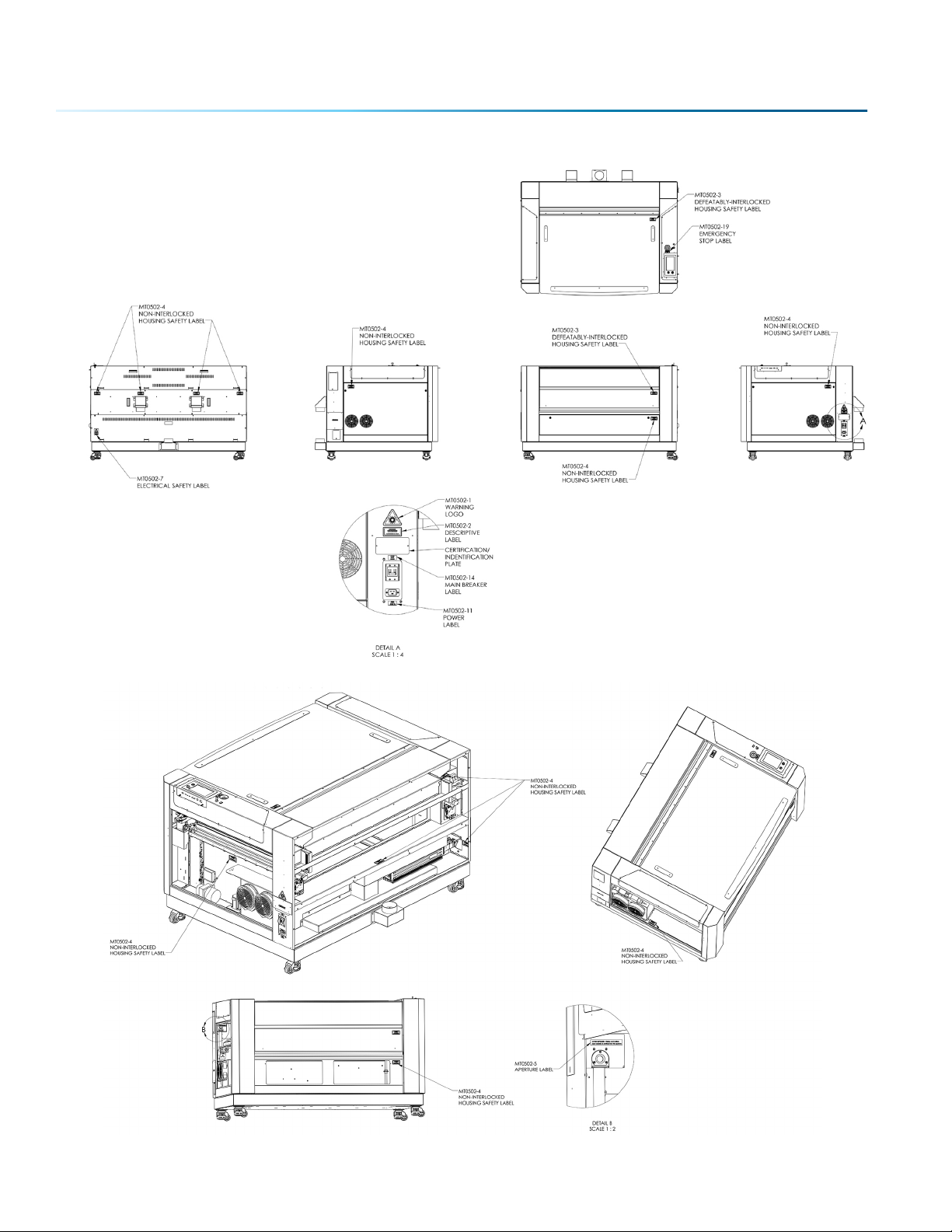

SECTION 1: SAFETY

Fusion Pro 48:

- 7 -

Page 12

SECTION 1: SAFETY

- 8 -

Page 13

SECTION 1: SAFETY

FCC:

Supplier’s Declaration of Conformity

47 CFR Paragraph 2.1077 Compliance Information

Laser Materials Processing System Model 16000

Epilog Laser Corporation

16371 Table Mountain Parkway

Golden, CO 80403

Telephone: (303) 277-1188

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including

interference that may cause undesired operation..

NOTE: This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equpment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

This product contains a Certified transmitter module (wireless network

interface), FCC ID: Z64-WL18DBMOD

- 9 -

Page 14

SECTION 1: SAFETY

Dos and Don’ts

Don’ts

Do Not Run the Laser Unvented: Never operate the machine without a properly operating vent to the

outside or to a filtration unit! Most material will only produce an irritating smoke when engraved.

Some materials, including but not limited to paint, varnish, composition board and plastics, produce

compounds that can be harmful if concentrated. A properly installed vent is the only way to ensure that

problems do not occur.

Do Not Engrave or Cut PVC: Never engrave or cut any material containing PVC or vinyl. When engraved,

a corrosive agent is produced that will destroy your machine. Your warranty will be void if your machine

is damaged by corrosion from engraving or cutting PVC or Vinyl.

Do Not Operate Machine While Unattended: Never operate your machine without someone watching

the system. There is a significant risk of fire if the machine is set improperly, or if the machine should

experience a mechanical or electrical failure while operating.

Do Not Vector Cut While Machine is Unattended: Never laser cut any material with the laser without

someone watching the system. Because vector cutting moves relatively slowly compared to raster

engraving, a tremendous amount of heat is applied to the material being cut. This buildup of heat can

cause significant fire risk and the machine should always be monitored. Additionally, the Air Assist should

always be turned on when vector cutting to reduce the risk of fire.

Do Not Operate The System While Doors are Open: Never operate with any of the covers or enclosures

removed, and never modify the enclosure. The laser beam is invisible and is very dangerous!

Dos

Clean the System: Please allow a few minutes a week for cleaning your machine. Just a small amount of

eort at the end of the week will pay o with years of trouble free operation of your machine.

- 10 -

Page 15

SECTION 2: GETTING STARTED

Setting up your Epilog Laser System is easy to do! If you’ve ever installed a paper printer, this is only

slightly more diicult. The following information will help you understand the entire system and how it

works.

Your Fusion Pro laser system consists of the following components:

1. Fusion Pro Laser System

2. Epilog Driver Disc

3. USB and Ethernet Cables

You will also need:

1. A computer or laptop.

2. An exhaust fan: The exhaust fan is mandatory and is used to remove smoke and debris from the

Fusion Pro work area. The exhaust air can be ported to the outside or into a filter box.

Follow these steps to setup your Fusion Pro Laser system:

1. Unpack the laser system.

2. Choose where to locate the system.

3. Connect the exhaust system to your laser.

4. Connect the electrical power.

5. Connect the laser to your computer through USB or Ethernet connection.

6. Sign up for driver updates and register your system at www.epiloglaser.com/register.

- 11 -

Page 16

SECTION 2: GETTING STARTED

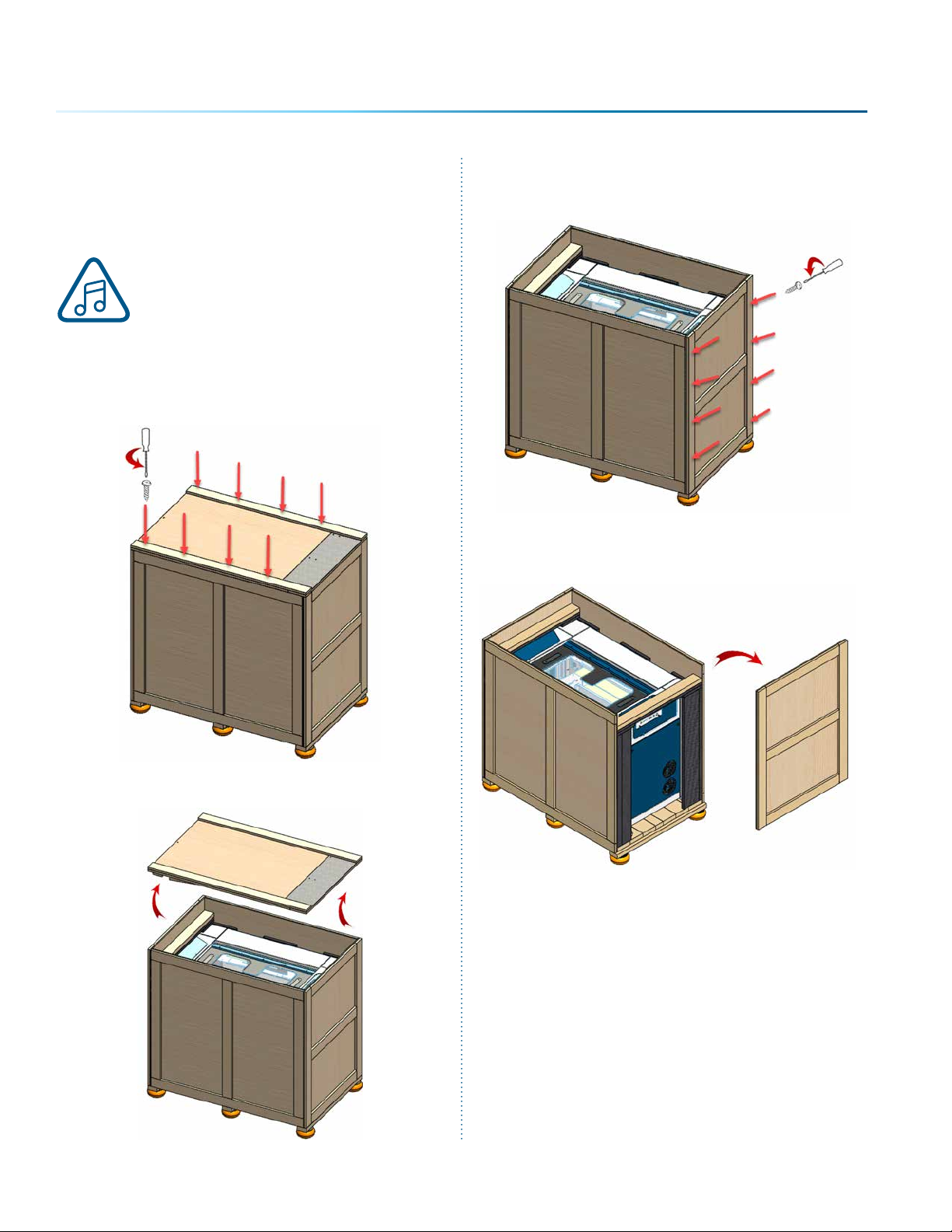

1. Unpacking the Laser System

Unpack the laser system from the crate

provided by Epilog. Please be sure to

hold on to all packing materials and

crating in case you need to move the

system in the future.

1. First, remove the screws securing the top lid

using a screwdriver.

3. Remove the screws securing the front panel.

4. Slide the front panel out of the box.

2. Remove the top lid and set it to the side.

- 12 -

Page 17

SECTION 2: GETTING STARTED

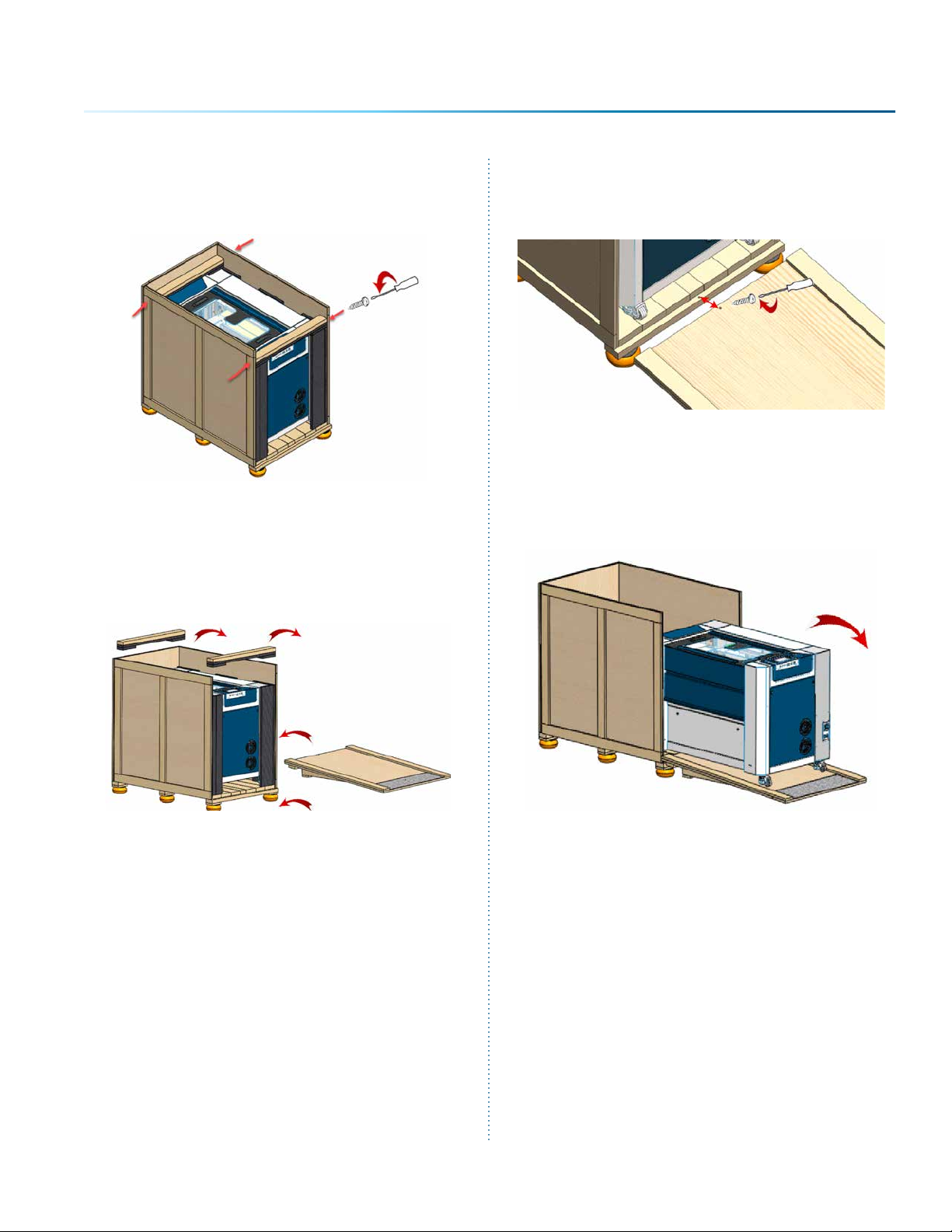

5. Remove the outer screws holding up the two

braces.

6. Remove the braces as well as any foam

pieces around the machine.

7. Using the top panel you removed at the

beginning, align its corners with the ledge on

the bottom of the box, making a ramp.

Secure the ramp with a screw.

8. Roll the machine down the ramp slowly and

carefully until it is out of the box and on level

ground.

- 13 -

Page 18

SECTION 2: GETTING STARTED

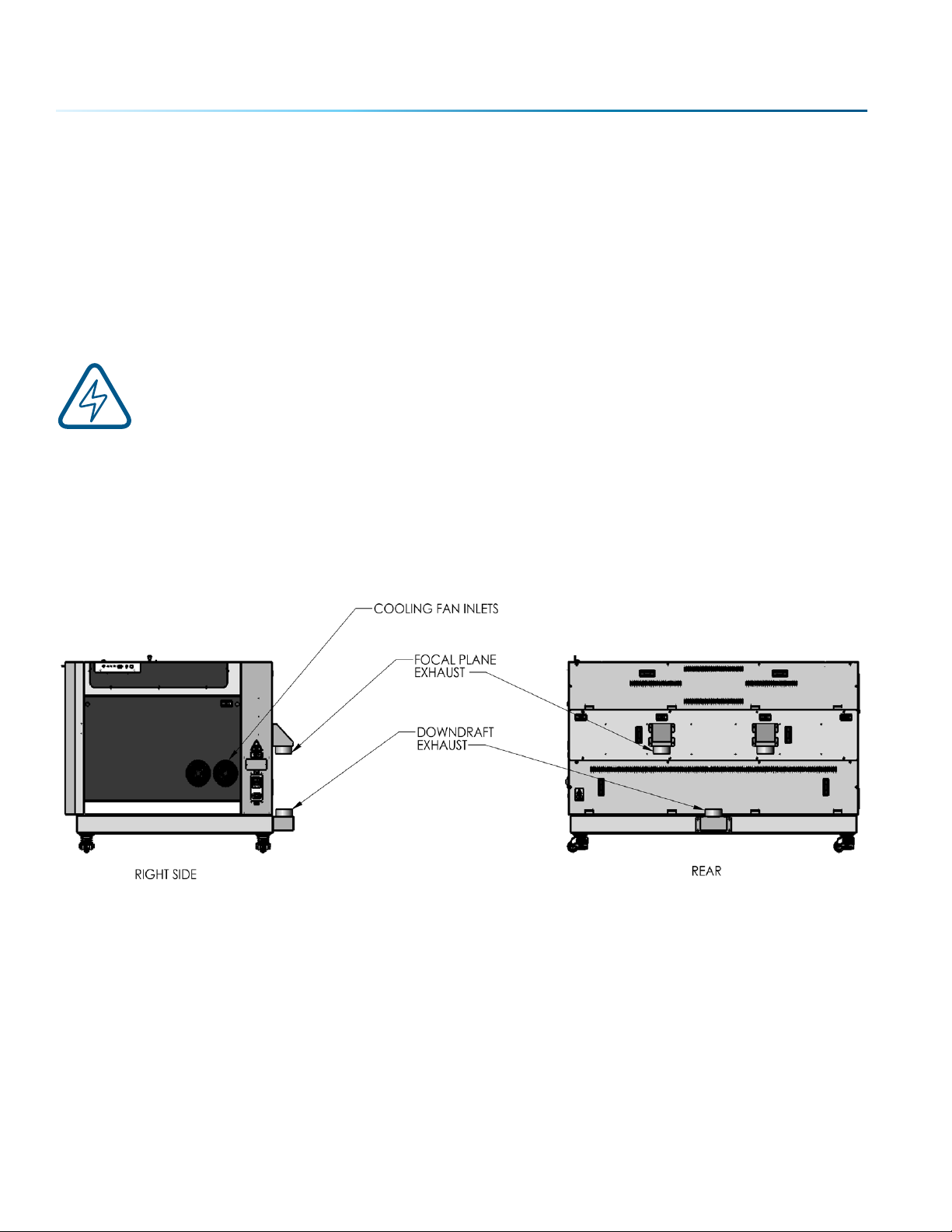

2. Choose Where to Locate the System

Cooling Requirements and Operating Temperatures

All Epilog Laser systems use air-cooled laser tubes. Laser technology is such that the laser tubes generate

a lot of excess heat and the tubes must be cooled for proper operation. There are cooling fans located

on both sides of the laser. The fans and vents should always be clear of restrictions and should never be

covered.

Warning: The cooling fans and vents are located on both sides of the Fusion Pro and should

never be covered or blocked in any way. Lasers that overheat will not operate properly and

may begin to produce erratic laser output or possibly complete failure.

Ambient air temperature where the laser system is operating should not exceed 90 degrees F (32 C).

Operating in an environment where the ambient air temperature is above 90 degrees F (32 C) will void the

Epilog warranty. For more information, see the “Warranty Statement for the Fusion Pro Laser” on page

127.

- 14 -

Page 19

SECTION 2: GETTING STARTED

3. Connecting the Exhaust

In this manual, the term “exhaust” refers to either an exhaust fan or a filter unit and the term “exhaust”

is used for simplicity. The important point is that it is mandatory that an exhaust unit or filter system is

incorporated as part of your laser system. Never operate your laser system without a properly functioning

exhaust. The exhaust removes the dust, debris and smell from the engraving cavity and exhausts it to

the outside of the building or to the filter unit. Prior to the installation of the laser system, you may need

a contractor to install the exhaust system. The blower should be mounted outside your building for noise

considerations. Ideally, the blower should not be more than twenty feet (6 meters) from the laser. You

should provide a metal duct (flexible aluminum or galvanized sheet metal) from the blower to the laser.

All Epilog model 16000 laser systems require an exhaust fan that is rated at a minimum of 800 CFM for

external exhaust.

The exhaust requirements for the Fusion Pro 32 and 48 are the same:

• The Fusion Pro 32 model requires 400 CFM for the primary exhaust port (upper port) and 400 CFM for

the downdra exhaust port (lower port) totaling 800 CFM.

• The Fusion Pro 48 model also requires a total of 400 CFM for the two primary exhaust ports (200 CFM

per upper port) and 400 CFM for the downdra port (lower port) totaling 800 CFM.

Epilog provides recommended exhaust flow rates (CFM) only for direct ventilation exhaust systems

that are ported to the outside. Please note that this is also a recommendation and not a requirement,

because factors such as length and type of tubing from the Epilog laser to the exhaust fan and from the

exhaust fan to the outside of the building can produce significant losses on the true amount of air that

is drawn from the Epilog laser.

Exhaust flow rates (CFM) for filter systems are not specified in this document. However, exhaust flow rates

for filtration units will be lower than a direct ventilation exhaust systems because filters are designed to

be placed directly adjacent to the laser system and do not exhibit the air-flow losses that are typically

found with direct exhaust fans. Epilog has worked with most major filter manufacturers to recommend a

specific filter system for each model of Epilog laser. Please contact your Epilog distributor to match a

filter to the Epilog laser system you are using.

Note: Remember to put the blower switch for the laser system in an obvious and accessible

place so it can be routinely switched on prior to using the engraver. Please connect the

exhaust blower to the laser as shown below and on the following pages.

Remember, you may need a contractor to install

the exhaust. This must be done PRIOR to

installation of the laser system.

Warning: It’s important that either

rigid or flexible metal ducting be

used for all connections leading to

and from the laser system and the

exhaust fan. Vinyl, plastic, or any

type of “so” ducting is potentially flammable

and should not be used unless provided by the

filtration system manufacturer and made from

fire-proof materials.

- 15 -

Page 20

SECTION 2: GETTING STARTED

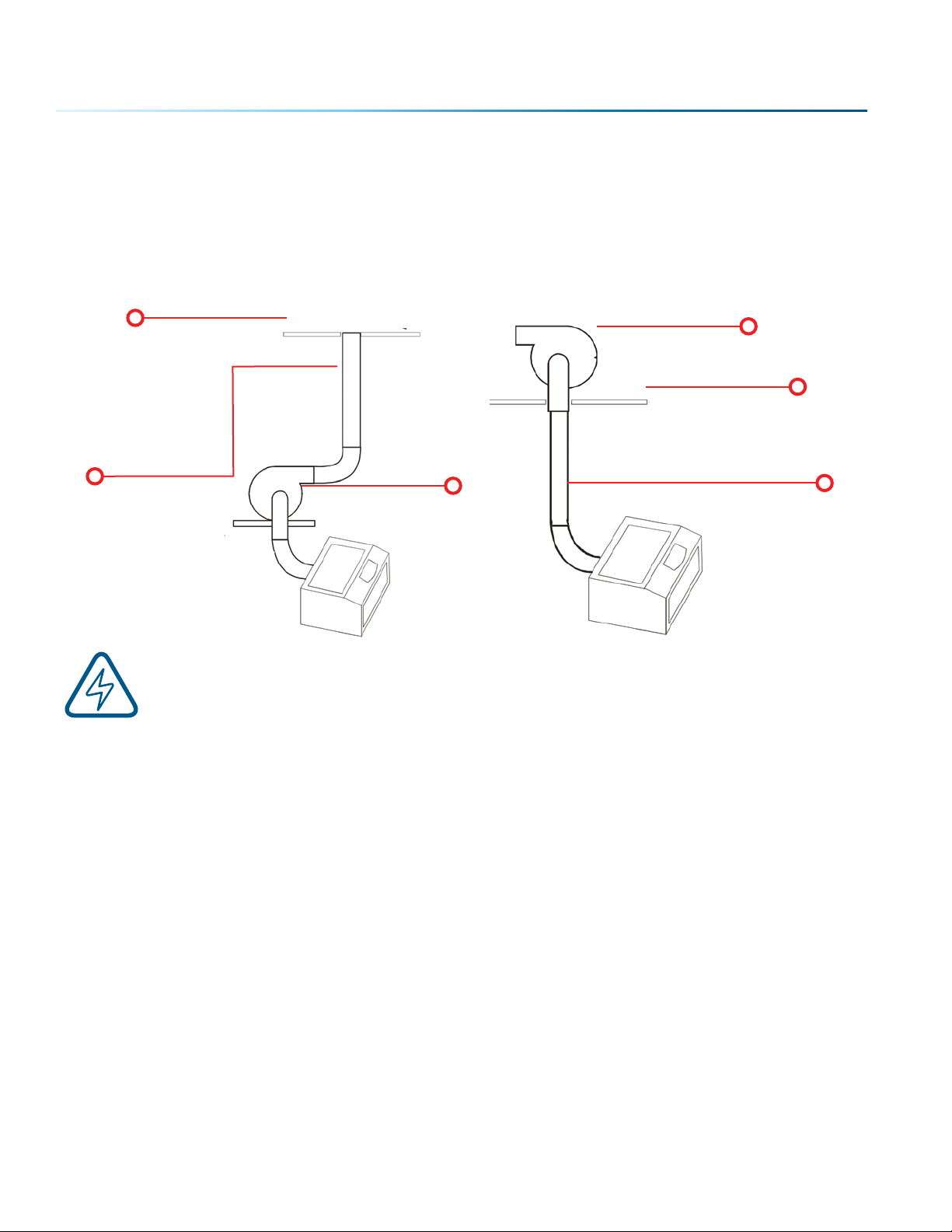

Epilog Exhaust/Filter Connections

There are two 4” (102 mm) ports attached to the back of the Fusion Pro 32 laser system, and three 4” (102

mm) ports attached to the back of the Fusion Pro 48 laser system. Attach your ducting to the machine as

shown in the diagram.

Roof or Exterior Wall

4” (102 mm) flexible

aluminum duct or

rigid galvanized

sheet metal (do

not use vinyl,

plastic or “so”

flexible duct).

Check your exhaust system for leaks. Most small leaks can be remedied with duct tape.

DO NOT OPERATE your laser with inadequate or leaking exhaust.

The drawings above show the typical exhaust setup. The le drawing shows the exhaust near the

machine and the right drawing shows the exhaust fan on the roof. Where the exhaust fan is placed is a

choice of personal preference. Some users like the exhaust fan outside because of noise considerations.

Exhaust Blower

Exhaust Blower

Roof or Exterior Wall

4” (102 mm) flexible aluminum

duct or rigid galvanized sheet

metal (do not use vinyl, plastic

or “so” flexible duct).

- 16 -

Page 21

SECTION 2: GETTING STARTED

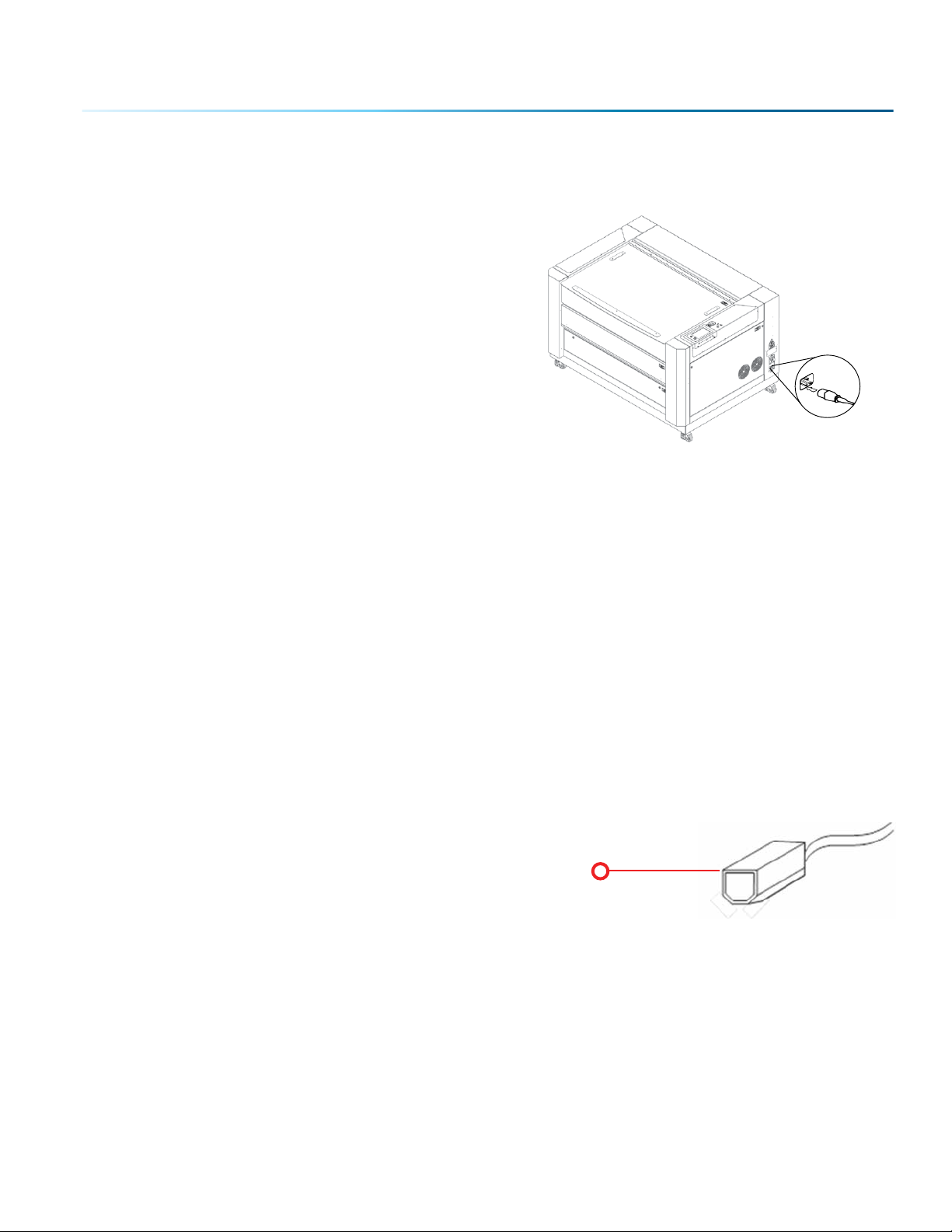

4. Connecting Electrical Power

Epilog supplies the appropriate power cord

for the system you ordered. The power cord

is found in the accessory package with your

machine. The power cord for the laser plugs

into the power receptacle located on the le

side of the machine in the rear corner. It is

recommended that a dedicated 15 amp circuit

be used if available, but it is not required.

The Fusion Pro 48 laser system requires

208/220/240 volt electrical power. This system

will not operate on 120 volt power. The Fusion

Pro 48 power cord comes with a male plug

type NEMA L6-15R (which is a Hubble HBL4570C

equivalent).

We recommend using 208/220/240 volt electrical power on all systems to achieve maximum peormance.

For more information, see “Fusion Pro Electrical Specifications” on page 3.

Electrical Connection

220 V-50/60 Hz

5. Connect the Laser to Your Computer

You are now ready to connect your computer to the laser. The following connections can be used:

1. USB only connection: You can use the USB port for connecting to the Epilog Job Manager. Multiple

laser systems cannot be operated from a single computer through the USB connections. If you are

using the USB connection, you will need one computer for each laser system.

2. Ethernet only connection: With an Ethernet connection you can print from the Laser Dashboard

and use the Epilog Job Manager.

USB Connection

A USB cable is included in the accessory kit. The USB port is

located on the right hand side of the machine. USB cables have

dierent connectors on each end. The USB connection will

behave similarly to an Ethernet cable when communicating

with the laser. Both the computer and machine should

recognize the USB without any need to reboot.

Connect to the laser

- 17 -

Page 22

SECTION 2: GETTING STARTED

Ethernet Connection

The Ethernet Port is a standard 10BaseT connection. Your Epilog Laser has all of the versatility of a

network capable peripheral. As such, there are many dierent ways that the laser can be connected

to a computer or a network. A direct connection using an Ethernet cable is the only method that will be

described in this manual. Connect the Ethernet cable (included in the accessories kit) to the Ethernet

port, located on the right hand side of the machine. Plug the cable into the Ethernet port on the laser,

then plug the other end into the Ethernet port on your computer.

The Epilog Dashboard is the print driver that allows your computer to talk to your Epilog Laser system

when either the USB or Ethernet cables are connected. The driver is included in the accessories kit on a

CD-ROM or on our website at www.epiloglaser.com. To see detailed instructions on installing the print

driver, see “SECTION 3: SOFTWARE INSTALLATION” on page 21.

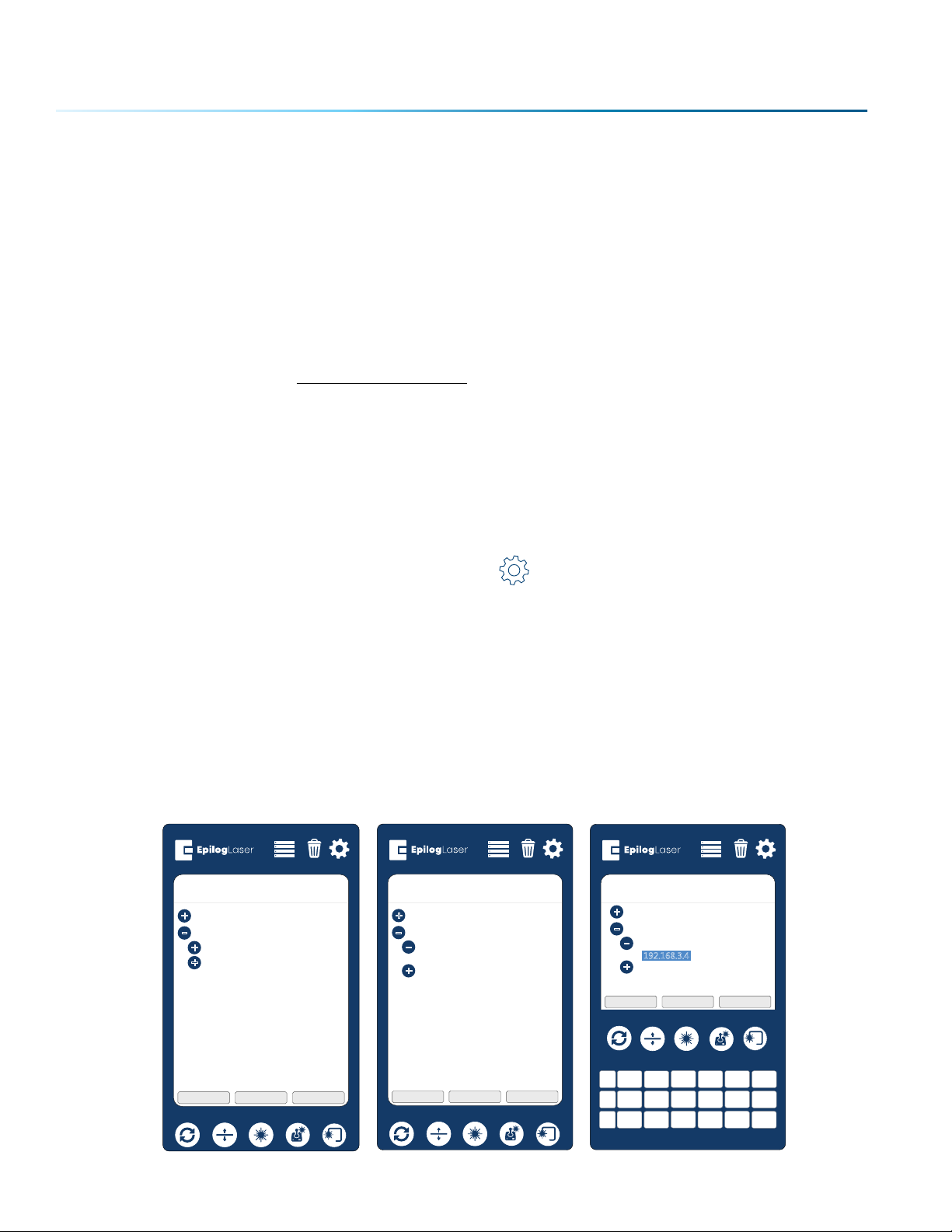

6. Set the Fusion Pro’s IP Address

Ethernet Cable Setup

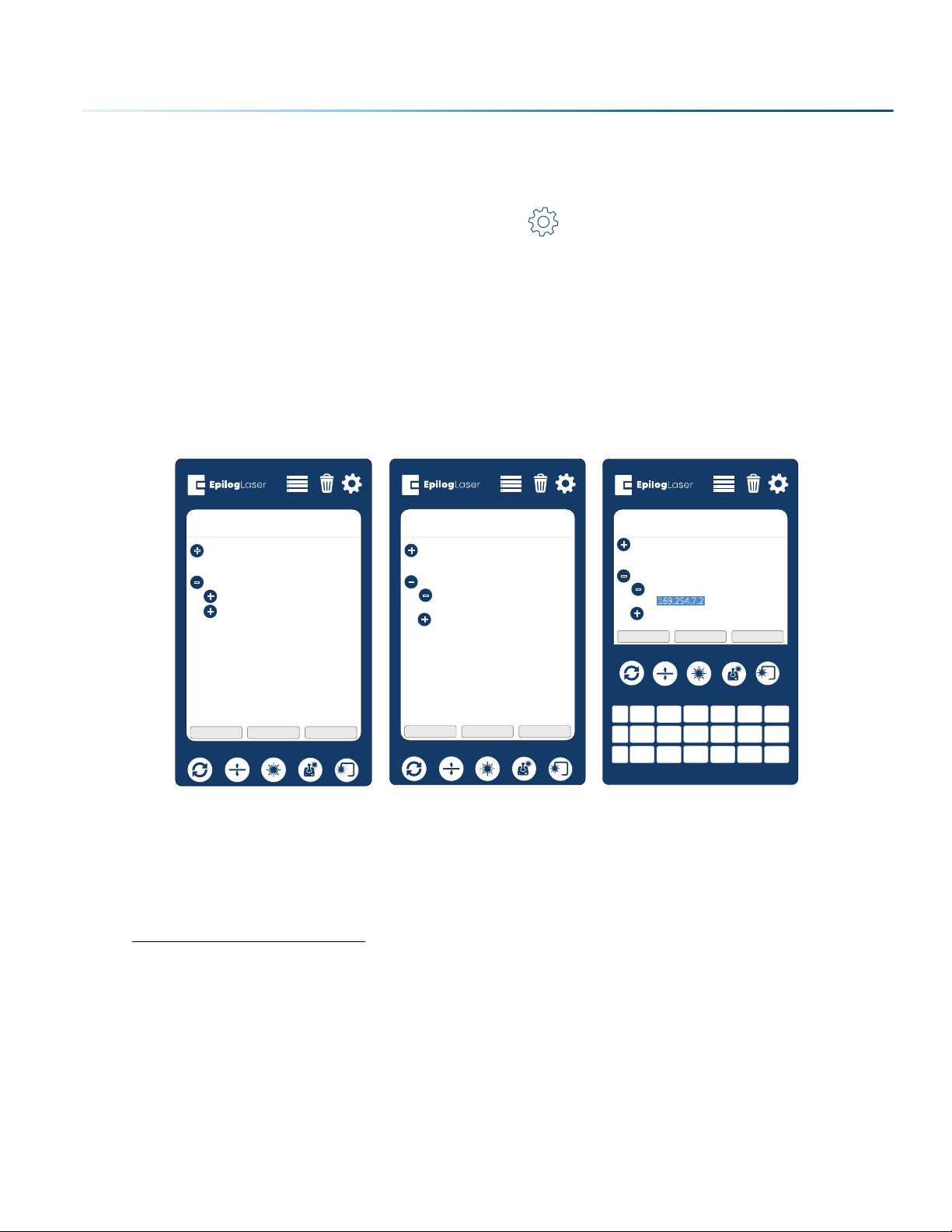

1. Once your machine is booted up, select the Settings button in the upper right corner of the

touchpad.

2. Select Network in the settings list.

3. Under Network you will see “IP Address” and “Netmask”, press “IP Address” and then press the

numbers that appear next to them. A keyboard should show up at the bottom of the screen.

4. Press the “123” Button in the bottom le corner of the keyboard to access the numerical keypad.

5. Type in whichever IP Address you prefer to use. Most Epilog users will use the IP Address of 192.168.3.4

which is what we use in this manual.

6. Press the Close key to close the keyboard, then press the Job Menu Button to return to the main

screen and your settings should be saved.

+

System

Network

-

+

+

Settings

IP

Address

Netmask

+

System

Network

-

-

+

Settings

IP

Address

192.168.3.4

Netmask

Idle

Settings

+

System

Network

-

Address

IP

-

192.168.3.4

Netmask

+

Park Axis Home Axis Home Table

Park Axis Home Axis Home Table

Idle

Park Axis Home Axis Home Table

Idle

- 18 -

+

7 8 9 ,

-

4 5 6

1

SP 2 3 0

.

“

< >

ABC Del

Enter Close

Page 23

SECTION 2: GETTING STARTED

USB Cable Setup

1. Once your machine is booted up, select the Settings button in the upper right corner of the

touchpad.

2. Select USB in the settings list.

3. Under USB you will see “IP Address” and “Netmask”, press “IP Address” and then press the numbers

that appear next to them. A keyboard should show up at the bottom of the screen.

4. Press the “123” Button in the bottom le corner of the keyboard to access the numerical keypad.

5. Type in whichever IP Address you prefer to use. In this case we used 169.254.7.2

6. Press the Close key to close the keyboard, then press the Job Menu Button to return to the main

screen and your settings should be saved.

Settings

+

System

Network

USB

-

IP

Address

+

Netmask

+

Park Axis Home Axis Home Table

Idle

Settings

+

System

Network

USB

-

IP

Address

-

169.254.7.2

Netmask

+

Park Axis Home Axis Home Table

Idle

Idle

+

-

SP 2 3 0

Settings

+

System

Network

USB

-

IP

Address

-

169.254.7.2

Netmask

+

Park Axis Home Axis Home Table

7 8 9 ,

4 5 6

1

.

ABC Del

Enter Close

“

< >

7. Sign Up for Driver Updates and Register Your

System

Go to www.epiloglaser.com/register and register your system. You can also sign up for our monthly

e-newsletter, quarterly customer printed newsletter, and sign up for driver update notifications.

- 19 -

Page 24

Page 25

SECTION 3: SOFTWARE INSTALLATION

Epilog Job Manager Instructions

The Epilog Job Manager is a poweul new tool that will quickly become one of your favorite features

on your laser system. From one piece of soware, you can access any job you have sent to the laser,

view the settings you used on any past job, re-run projects, access your material database, and much

more. It’s a great addition to the Epilog Laser product features, and we look forward to seeing how our

customers use this soware!

• Windows 7/8/10 is required to use the Epilog Job Manager.

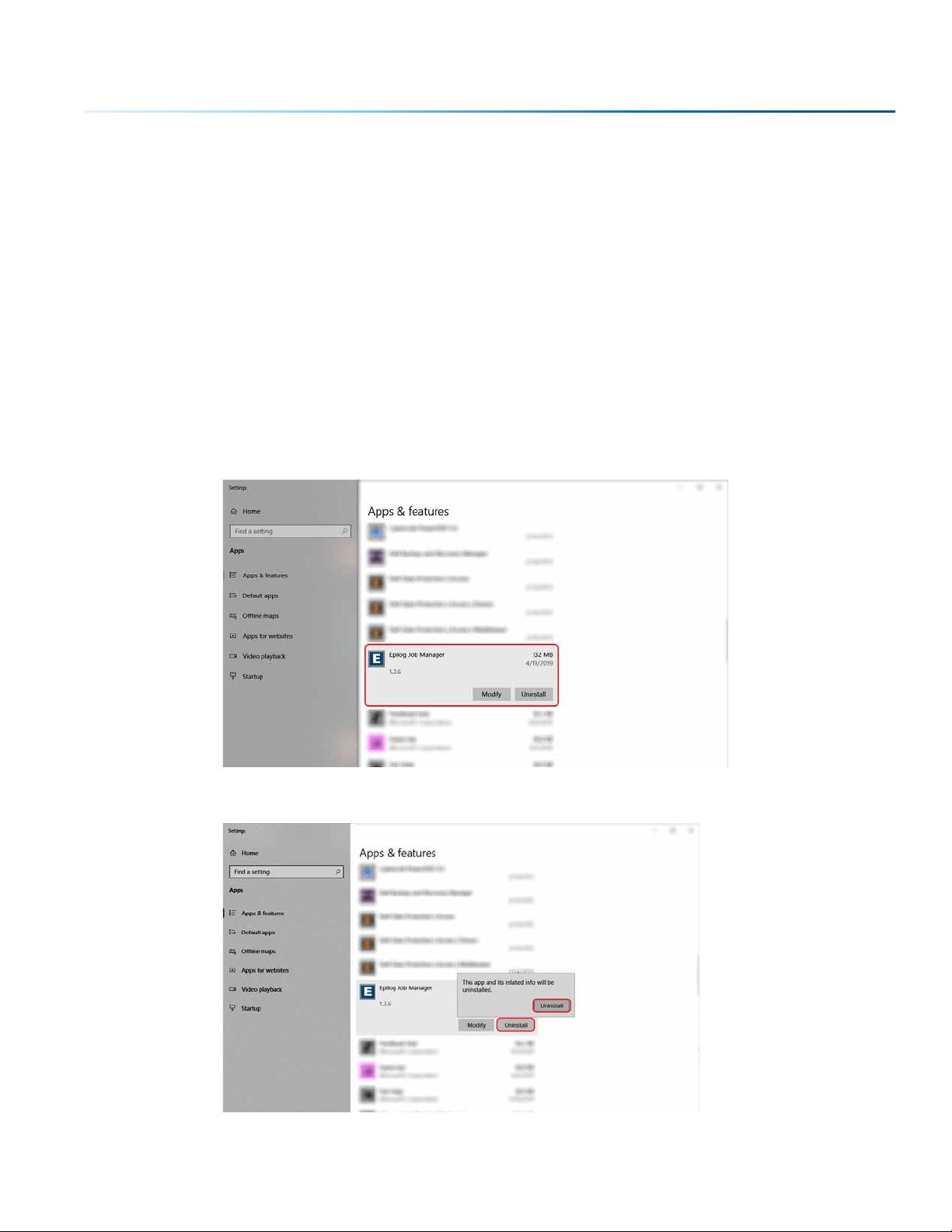

Uninstalling the Previous Job Manager

If you have installed a previous version of the Job Manager on your computer, you must uninstall it first

before you continue.

1. Go to Control Panel > Programs and Features and click on Epilog Job Manager

2. Click “Uninstall” and confirm if asked again.

- 21 -

Page 26

SECTION 3: SOFTWARE INSTALLATION

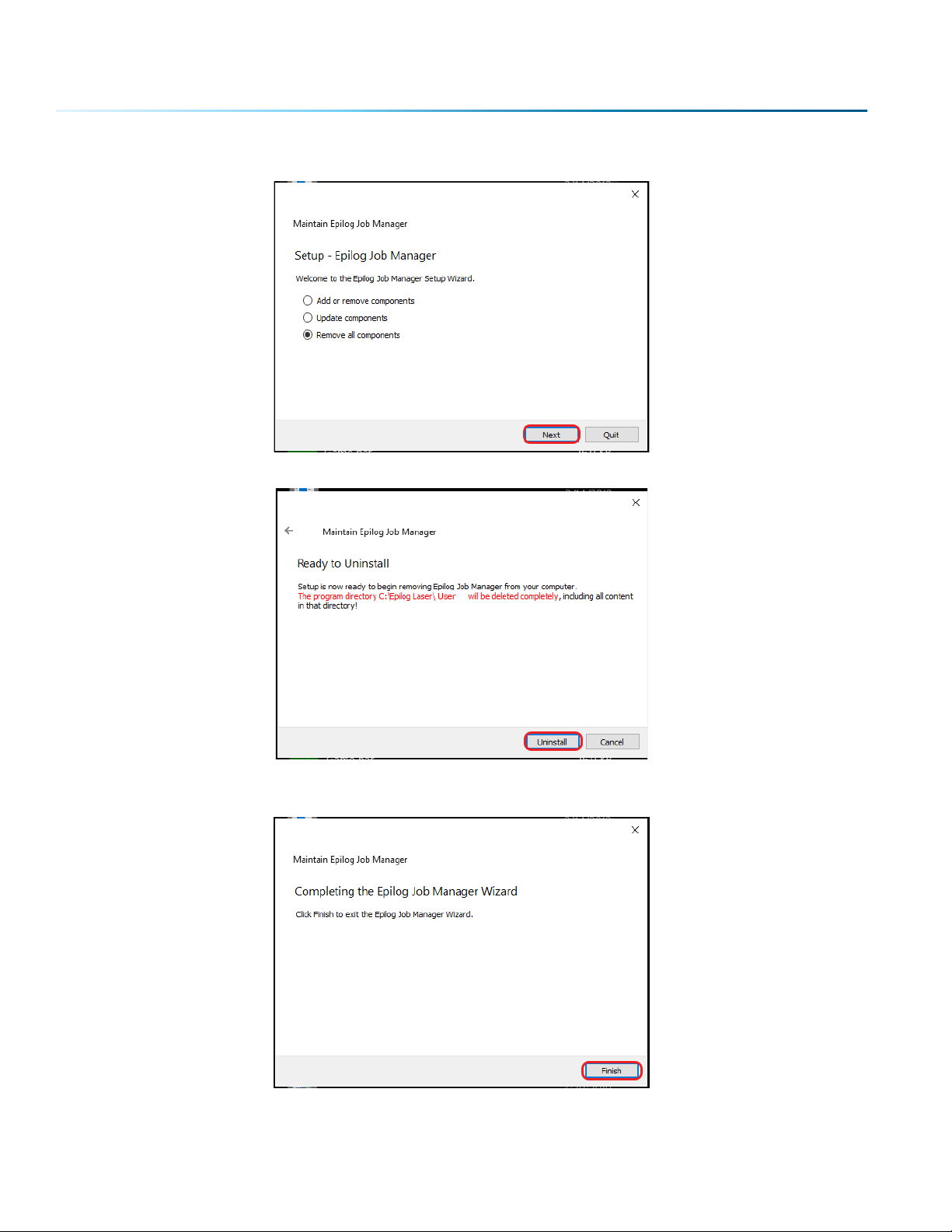

3. Select “Remove all components” and then click “Next”.

4. Click “Uninstall”.

5. Click Finish to complete the uninstallation of the previous Job Manager.

- 22 -

Page 27

SECTION 3: SOFTWARE INSTALLATION

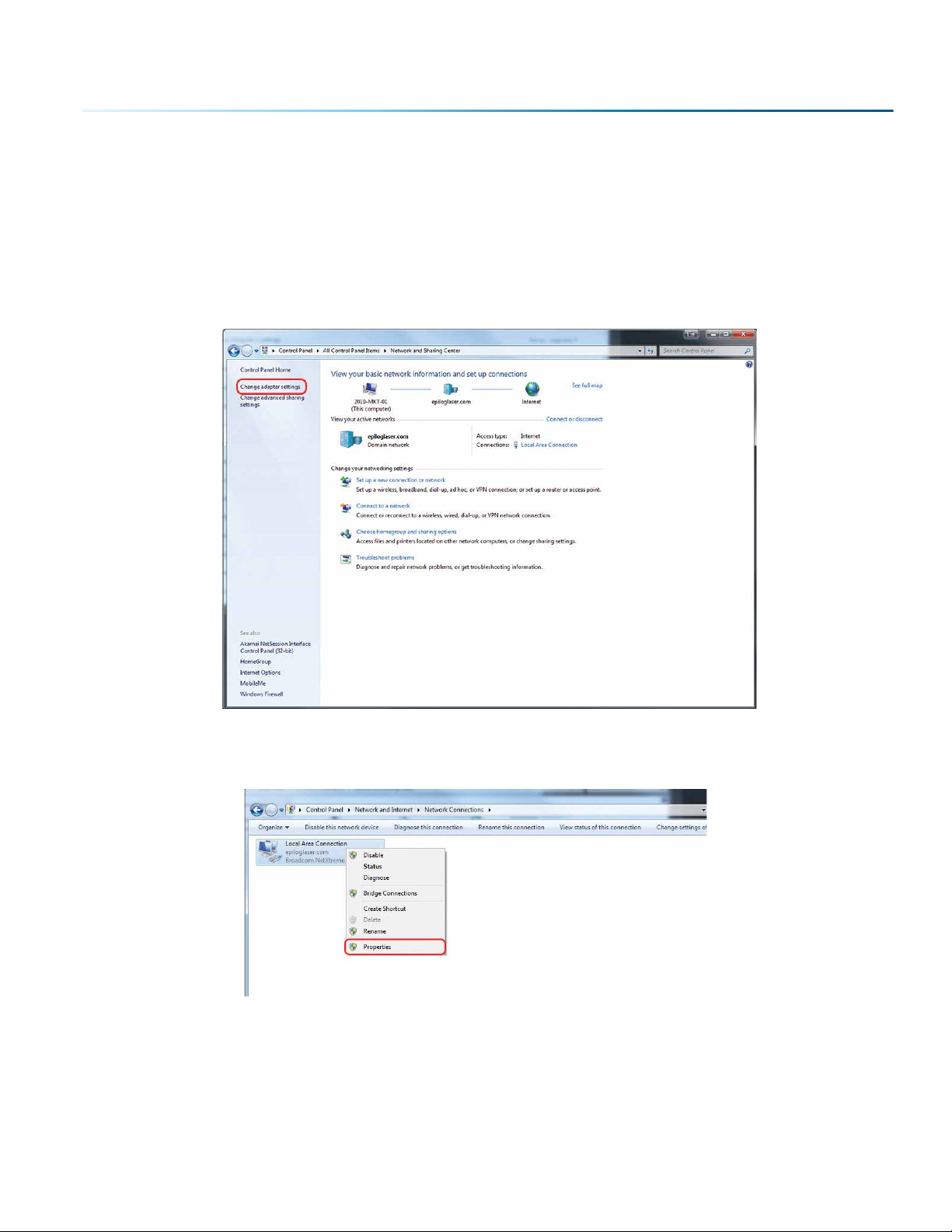

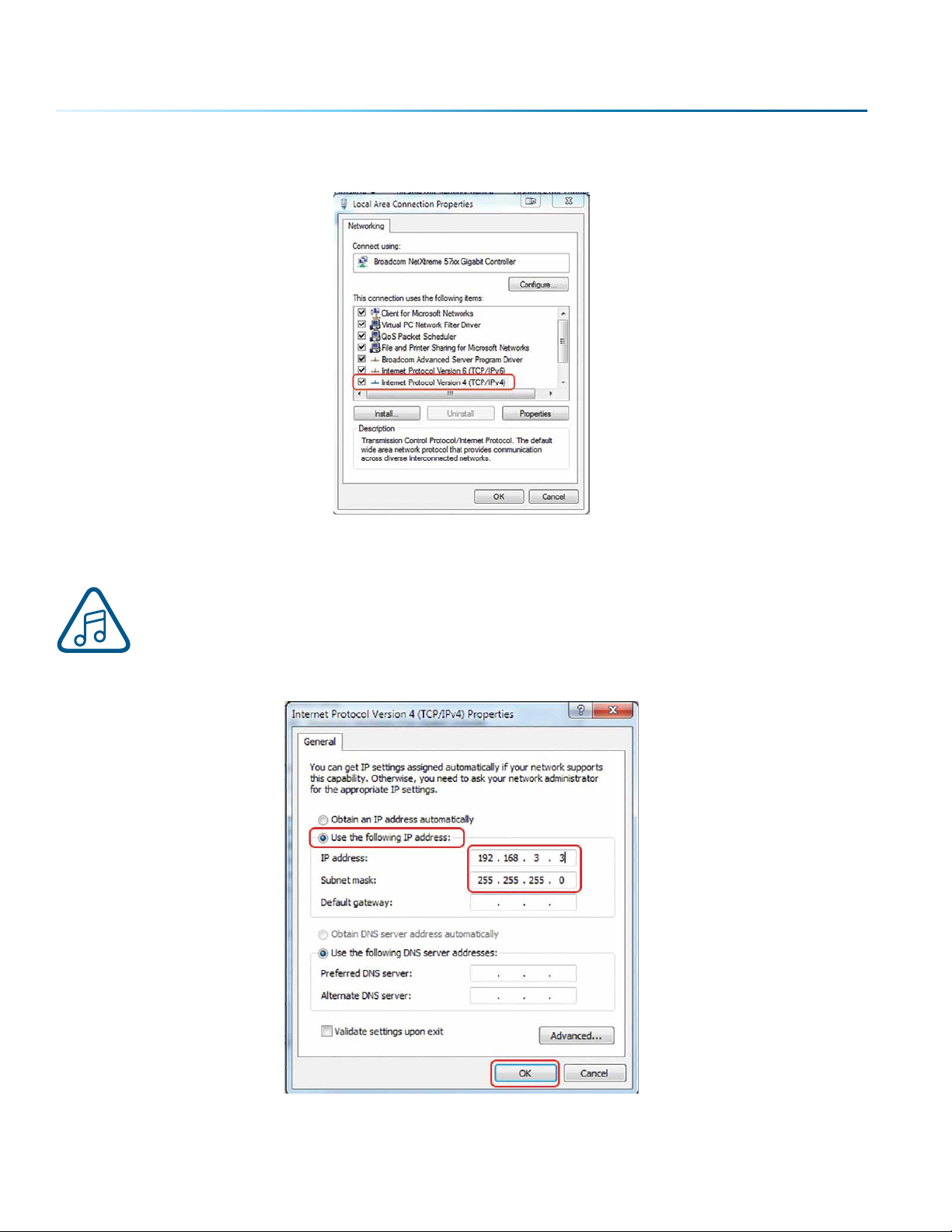

Windows 7: Ethernet Installation

Set Up TCP/IP Address in the Computer

Go to your Network and Sharing Center in your computer’s Control Panel.

1. Click Change Adapter Settings.

2. Right click Local Area Connection, then click Properties.

- 23 -

Page 28

SECTION 3: SOFTWARE INSTALLATION

3. Select Internet Protocol Version 4 (TCP/IP). Make sure you do not select Version 6.

4. Select Use the following IP Address. Type in the following IP Address: 192.168.3.3.

This number is not an error; the last digit of the IP address in this window must be dierent

than the IP address you set in the laser.

Type in a Subnet Mask of 255.255.255.0, then click OK.

- 24 -

Page 29

SECTION 3: SOFTWARE INSTALLATION

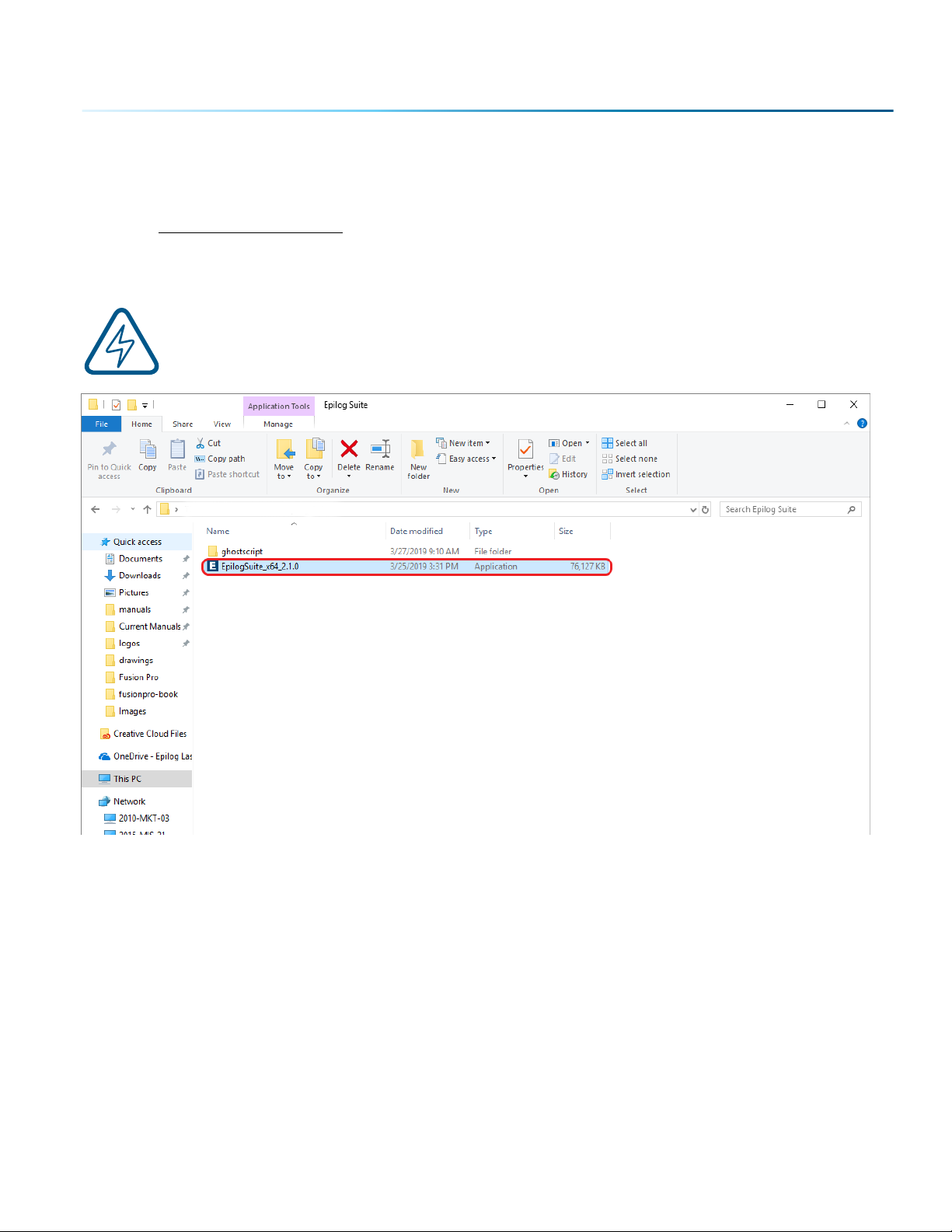

How to Install the Epilog Job Manager

1. Go to epiloglaser.com/drivers and select the Epilog Fusion Pro. Then click on the Epilog Soware

Suite to download the installation file.

2. The installation file will download as a .zip folder that will need to be extracted. Right click the

folder and click “Extract All”. Once finished, double click on the EpilogSuite file.

Note: Make sure that the “Ghostscript” folder included in the download is always in the same

location as your Epilog Suite installation file, or the installation will not be able to complete.

- 25 -

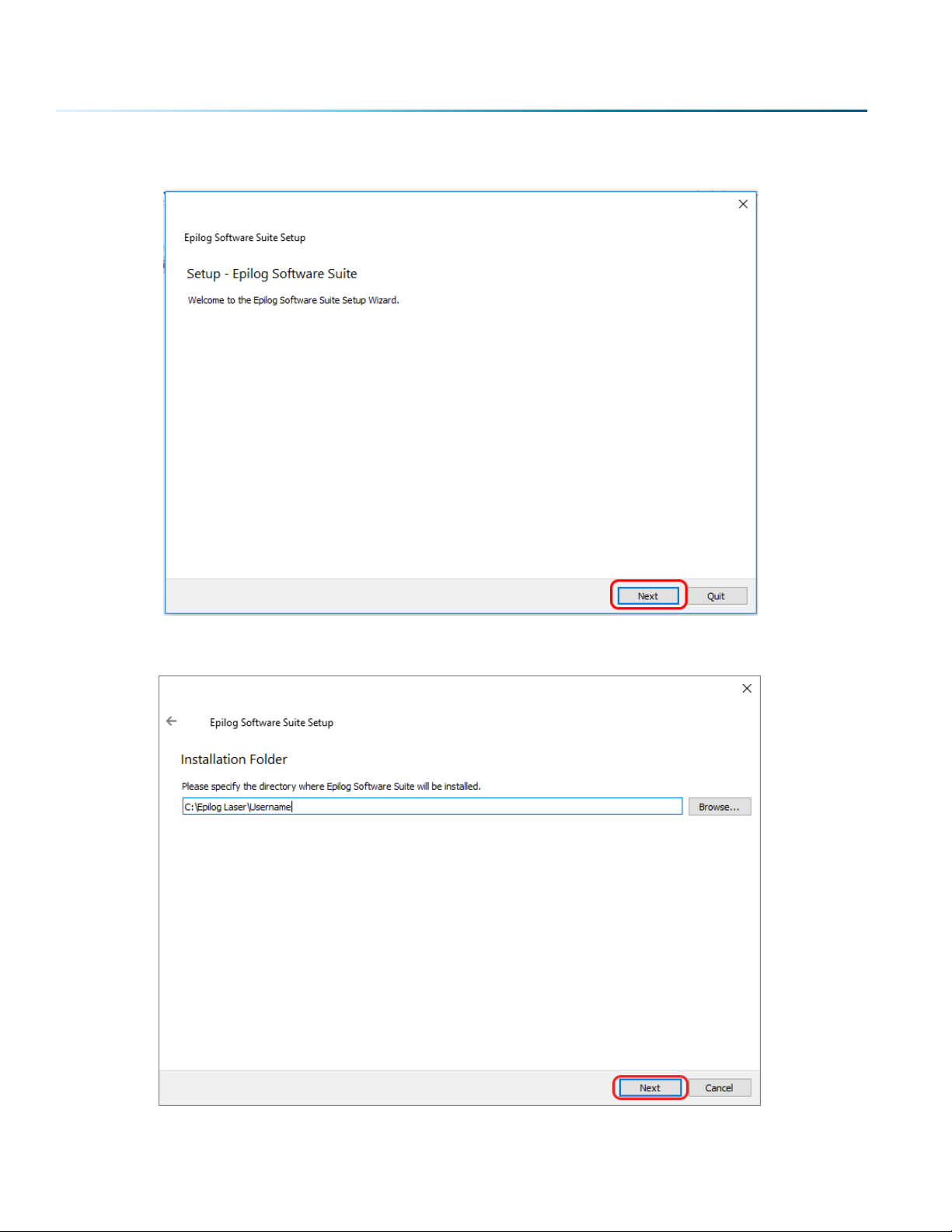

Page 30

SECTION 3: SOFTWARE INSTALLATION

3. A welcome screen appears, click Next.

4. Select a directory location for the installation file and click Next.

- 26 -

Page 31

SECTION 3: SOFTWARE INSTALLATION

5. Read and accept the license agreements and click Next.

6. Click Next to use the default start menu, or choose a start menu name of your choice.

- 27 -

Page 32

SECTION 3: SOFTWARE INSTALLATION

7. Click Install to begin the installation.

8. The Epilog Soware Suite will begin installing, during the installation a dialog box will pop up to

also install the AGPL Ghostscript Package, click Next.

- 28 -

Page 33

SECTION 3: SOFTWARE INSTALLATION

9. Read and accept the AGPL Ghostscript License Agreement, then click Next.

10. Click Finish to complete the AGPL Ghostscript installation and resume the Epilog Soware Suite

installation.

- 29 -

Page 34

SECTION 3: SOFTWARE INSTALLATION

11. Select whether or not you want to run the program now. Click Finish to complete the installation.

12. An icon for the Job Manager will be automatically added to your Desktop. You are now ready to

use the Job Manager.

- 30 -

Page 35

SECTION 3: SOFTWARE INSTALLATION

Troubleshooting the Job Manager

If you were unable to install the Job Manager, it’s possible that your Anti-Virus soware is blocking

installation.

To disable Symantec Anti-Virus soware, choose Options. Other anti-virus packages should have

something similar to Symantec.

Disable all Virus and Spyware Protection Features. Aer the Job Manager has been installed go back

into your Anti-Virus soware and re-enable the setting that was disabled.

- 31 -

Page 36

SECTION 3: SOFTWARE INSTALLATION

Important Job Manager Notes

• Warning: Before activating your laser, install the newest version of the driver to properly

associate the correct machine with the Job Manager.

• We suggest a minimum of 1 GB of free RAM space when managing very large raster and vector jobs.

- 32 -

Page 37

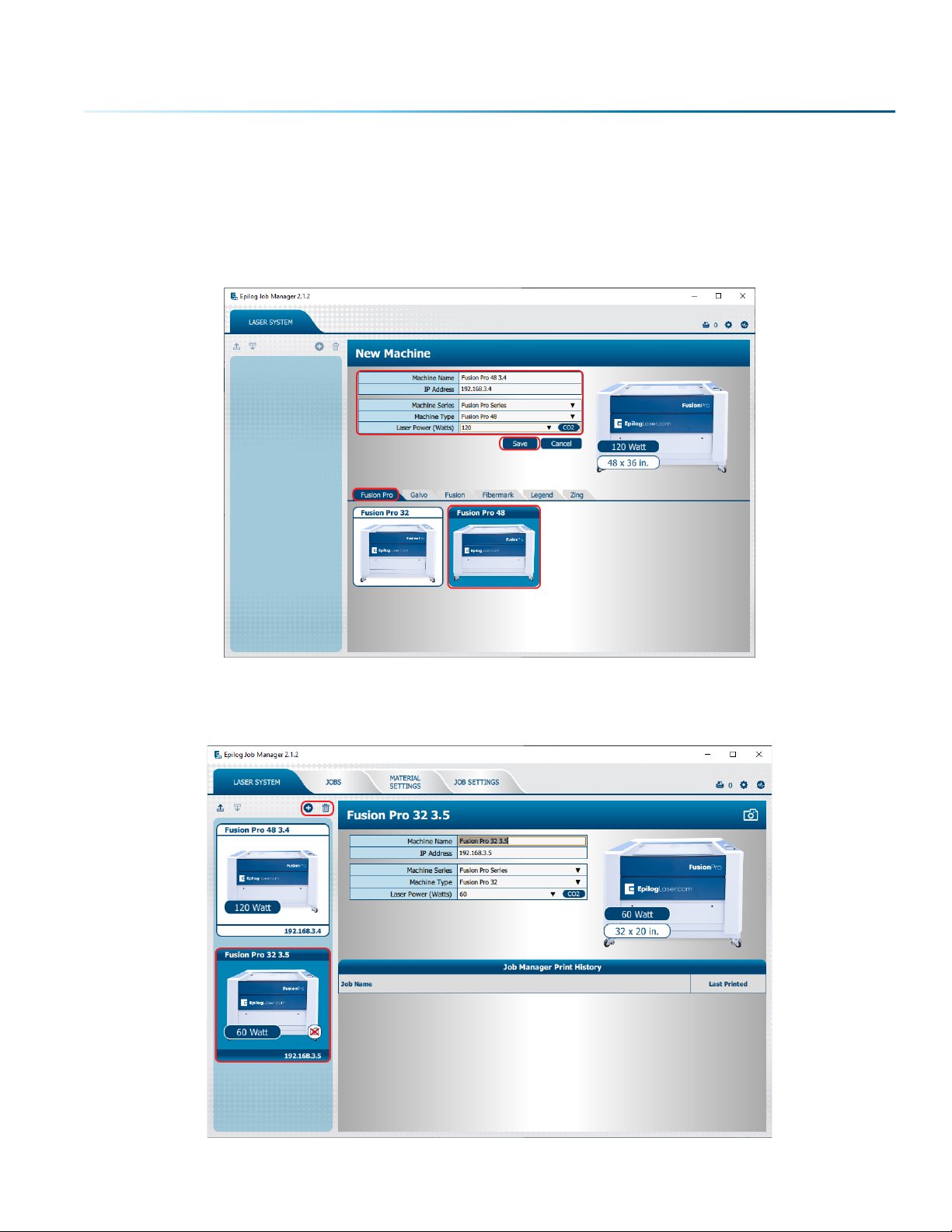

SECTION 4: THE JOB MANAGER

Using the Epilog Job Manager

1. The first time you open the Job Manager you’ll see a tab for each of the machine models. Begin by

selecting the correct model, naming your machine, setting the IP Address, and selecting the correct

laser wattage, then click Save.

2. Your new laser has been activated in the Job Manager and now appears in the le panel. It is now

ready to accept jobs from the print driver. Use the Add or Delete buttons to add or remove

additional machines. Below you can see we have installed an additional Fusion Pro 32 laser system.

- 33 -

Page 38

SECTION 4: THE JOB MANAGER

Printing to the Epilog Job Manager

Create a file in your graphic soware and select Print. When the print dialog opens up, make sure you

select Epilog Engraver as your printer and set the Page to Match Orientation and Size. Once your desired

settings are selected, click Print again.

Organizing Your Print Jobs

Click the Jobs tab. All print jobs will be displayed in the Uncategorized folder. Click on your job to highlight

it. You can now Print, Edit, Preview or Delete this job using the available icons.

- 34 -

Page 39

SECTION 4: THE JOB MANAGER

Create and Delete Job Folders

Click the Add Job Folders icon to add folders. You can add as many folders as you’d like.

Type in the folder name and click the check mark to create your new folder.

- 35 -

Page 40

SECTION 4: THE JOB MANAGER

Move an Uncategorized File to a Folder

When you highlight a folder you will see From Uncategorized on the right side of the folder. Click From

Uncategorized to move a job from the Uncategorized folder to this subfolder. Select the job you want to

move and click OK.

Create Subfolders

First, highlight the folder in the le panel where you want to add a subfolder. Below we have highlighted

the Betty’s Electronics folder. Click the Add Subfolder icon. Type the subfolder name in the Add Subfolder

field, then click the check mark to create the subfolder.

- 36 -

Page 41

SECTION 4: THE JOB MANAGER

Move a Job Between Folders

You can also move any job to another folder or subfolder by clicking and dragging it up or down between

folders. An arrow will indicate where you are placing the job. Once you see the arrow selecting the correct

folder, let go of the job file to place it in that folder.

Switch Machine Selection

By clicking on the machine photo in the upper le corner, you can quickly change which machine model

you want to have active.

- 37 -

Page 42

SECTION 4: THE JOB MANAGER

Previewing Your Job

To view a preview of the job, double click on one in the Jobs Tab. A Preview Tab will open and you can

preview the combined raster vector job, just the raster components, or just the vector components. We

have selected vector to show only the vector components of this job. The preview mode is very useful in

identifying unwanted vector components in a job. For more information, see “Presetting Your Cut Lines”

on page 52.

Searching for a Job

The Job Manager has a poweul search function. Type in part of a file name and press enter to find all

files related to that name. You can organize files by Standard, Created, Last Printed, or Alphabetically to

find a specific file.

- 38 -

Page 43

SECTION 4: THE JOB MANAGER

Notice that the jobs are displayed dierently if you change the search category to Alphabetical. Your

jobs are now displayed in alphabetical order. Once the search is finished, most users revert back to the

default selection of Standard.

Finding Job History

You can find the Job Manager Print History under the Laser System tab to see a full print history of a

machine, including settings you used in each print. Clicking on each job will expand it and reveal its

settings. Clicking on each machine’s icon will only reveal the print history on the selected machine.

Under the Jobs tab you can modify, print or save jobs from this window using the listed settings or with

new settings. The new settings will be saved as the next print job complete with time stamp and date.

You’ll see which machine it was printed to, when it was first printed (Initial Print), all subsequent prints,

and all laser parameters used. To access this, double-click on the job, then select History. To view the

laser parameters of this job, click on the print version. In this example we have clicked on the Initial Print.

- 39 -

Page 44

SECTION 4: THE JOB MANAGER

Vector Sorting

You can determine the cutting order of vector lines directly from the Epilog Job Manager.

You can choose from three dierent vector sorting options:

1. None: Vector line cutting order is determined by the order they were created.

2. Inside/Out: All internal vector paths in the file will be process prior to the external vector paths. For

example, if cutting the letter O, the inner oval will be cut before the outer oval.

3. Optimized: The laser will process the vector lines looking for the next closest node for quicker

vectoring.

- 40 -

Page 45

SECTION 4: THE JOB MANAGER

Material Settings Tab

The Material Settings Tab allows you to save and import settings for individual processes. If you frequently

use the same settings for engraving or cutting, this feature allows you to import those settings into a

single process quickly.

Saving Material Settings

1. To save a process setting, first you need to create a folder in the Job Manager under the Material

Settings Tab by clicking the “Add Subfolder” button.

2. Name the folder and click the check mark to save it.

- 41 -

Page 46

SECTION 4: THE JOB MANAGER

3. Now go to the Epilog Dashboard and set up the file to your preferred settings. Click on the process

that has settings you want to save. In this example we have clicked on CMYK Blue. The Process box

should open, then click the “Export Settings to Material” button.

4. A box will appear asking you to name the Material Setting and select a folder to save it in. Fill out

this information and then click “Save”.

- 42 -

Page 47

SECTION 4: THE JOB MANAGER

Importing Material Settings

1. To import previously saved settings to a new job, click on the process you want to apply the

settings to. Then click the “Import Material Settings” button.

2. A box will appear asking you to select the settings you want to load into this process. Select your

settings and click “Import”.

3. The material settings should load on to that process and be ready to print to the laser.

- 43 -

Page 48

SECTION 4: THE JOB MANAGER

Job Settings Tab

The Job Settings Tab allows you to store all the information that is in a job, except for the artwork, as a file

you may import into future jobs. If you have a project you run frequently that requires the same settings

every time, this feature allows you to import those settings quickly.

Saving a Job’s Settings

1. To save a job’s settings, first open the job in the Epilog Dashboard and set up the file as you

normally would to print. Once your settings are ready to save, click the Export Job Settings button

at the bottom of the screen.

2. A box will appear asking you to name the Job Settings file and select a folder to save it in. Fill out

this information and then click “Save”.

- 44 -

Page 49

SECTION 4: THE JOB MANAGER

Importing Job Settings

1. To import previously saved settings to a new job, click the Import Job Settings button at the bottom

of the screen.

2. A box will appear asking you to select the settings you want to load into this job. Select your

settings and click “Import”.

3. The job settings should load into the file, ready for printing to the laser.

Note: You may also create Job and Material settings from scratch in their respective Job

Manager tabs.

- 45 -

Page 50

SECTION 4: THE JOB MANAGER

Changing Program Settings

You can access the Program Settings by clicking on the gear at the top right of the page.

On this screen you can set several dierent system settings, including:

Display Tab:

• Language: Choose from several languages.

• Default Length Units: Choose from inches, centimeters, or millimeters.

Dashboard Tab:

• New Job Settings: Uses the Epilog Default, Previous Settings, Split by Color, Split by Hairlines, or Split

by Color and Hairlines. For more information see “Dividing Your Job Into Processes” on page 53.

• Open Job Manager Automatically: When “Send to JM” is clicked, and this option is On, the Job

Manager will automatically be opened.

• Discard Aer Printing: When “Print” is clicked, and this option is On, the job will be discarded.

Alerts Tab:

Choose when the program asks for confirmation when you delete machines, folders, subfolders, or jobs

and materials.

Database Tab:

• Backup Database: Save a backup of all files, material settings, etc.

• Restore Database: Reload settings from a previous backup.

• Clear Entire Database: Delete all settings, machines and jobs from the database.

• Clear All Jobs: Delete all jobs in the database.

• Clear Uncategorized: Clear out all uncategorized jobs in the database.

• Clear Dashboard Jobs: Delete all queued jobs in the database.

We will be adding new features to the soware oen, so sign up for the Driver Update

Notification list at www.epiloglaser.com/tech-support/epilog-drivers.htm.

- 46 -

Page 51

SECTION 5: THE LASER DASHBOARD

The Epilog Dashboard is your portal between your graphic file and the laser. Install your Dashboard at

epiloglaser.com/drivers. There are four main areas we’ll cover to get you started:

1. Sending Your First Project

2. Presetting Your Cut Lines

3. Placing Artwork

4. Dividing Your Job into Processes

If you have worked with Epilog’s previous print driver, you’ll see some new ways that the

Dashboard lets you interact with your file. It may seem dierent at first, but you’ll quickly find

that you can still use your traditional methods of printing to the laser, or use several new ones

that make file setup quicker and easier!

- 47 -

Page 52

SECTION 5: THE LASER DASHBOARD

Setting Up CorelDRAW for the Laser

If you are using CorelDRAW, first make this quick, one time change to the settings.

1. Go to Tools > Options > Global > Printing > Driver Compatibility.

2. Select Epilog Engraver from the drop-down list.

3. Select “Printer can match document page sizes”, and click OK. You’re ready to go!

- 48 -

Page 53

SECTION 5: THE LASER DASHBOARD

Sending Your First Project

1. When you have your file designed, print it to the laser. Choose the Epilog Engraver as your printer

and set the Page to Match Orientation and Size.

2. Click on the Color tab and select Output colors as RGB. Then click Print.

- 49 -

Page 54

SECTION 5: THE LASER DASHBOARD

3. Your file will open in the Laser Dashboard. Select “To Fit” to zoom in on your object.

4. On the right side of the screen you can see two processes in the process list: Engrave and Vector.

These layers automatically separated because we set the line width of cut lines to .003”

(0.077 mm) or thinner). You can set the Dashboard to automatically separate vector lines

by line thickness, color, or no action. For more information, see “Presetting Your Cut Lines”

on page 52.

- 50 -

Page 55

SECTION 5: THE LASER DASHBOARD

5. With the Engrave process selected, we can now adjust the settings for this process.

• Process Name: Click on the process name (“Selection” in this

example) to rename the process.

• Run Time: Each process will show an estimated run time, which

depends on the size of the artwork, the Speed settings and the

Resolution settings.

• Split By: Select either “Color” to move every color in the graphic

to separate processes (useful for color mapping), or “Hairlines”

to manually move .003” (0.077 mm) or thinner vector lines to a

separate process.

• Merge With: Merge the current process with another process

layer. For more details, see “Merging Processes” on page 57.

• Process Type: Choose if you want the process to be “O”

(ignored by the laser), “Engrave”, or “Vector”.

Setting the process to Engrave will engrave all graphics and

lines, regardless of line width.

Setting the process to Vector will ignore any raster graphics and

only cut all vector lines in the process, regardless of line width.

• Resolution can be set anywhere between 75-1200 DPI. For more information about resolution, see

“Resolution” on page 81.

• Set your Speed and Power. Frequency will only be active when the process type is set to Vector.

For more information, see “Frequency” on page 65.

• Dithering / Vector Sort: The dithering drop-down will appear for Engrave processes, and Vector

Sort for Vector processes.

For more information on Dithering settings, see “Image Dithering” on page 87.

For more information on Vector Sorting, see “Vector Sorting” on page 40.

• Cycles: How many times to repeat this process.

• Laser: This will only appear if you are working with a Dual Source machine. Choose between the

CO2 and Fiber laser for each process.

• Thickness: This feature will be available soon.

• Oset: Only activated if Auto Focus is turned on. Set the oset you would like. For more

information, see “Oset” on page 65.

• Registration: Feature coming soon.

• Direction: Choose whether you want the engraving to start at the bottom of your piece or the

top. For more information, see “Engrave Direction” on page 64.

- 51 -

Page 56

SECTION 5: THE LASER DASHBOARD

6. Repeat this set up with the Vector process layer.

7. Print the file to the laser.

Presetting Your Cut Lines

Although you can select any vector line in the Dashboard

and set it as a cut line, there are several ways in the

Dashboard to preset your cut lines to save you time.

Click the settings icon in the Dashboard and go to the

Dashboard tab. Choose between New Job Settings:

1. Epilog Default: No automatic separation of processes

when a new job is sent to the Dashboard.

2. Previous Settings: Use the settings from the last job

sent to the laser.

3. Split by Color: Automatically split all processes by

colors. This is helpful when using color mapping to set

dierent settings to dierent colors in your artwork, or

if you always set your cut lines to a specific color.

4. Split by Hairlines: Automatically split all thin vector lines (line thickness set to .003” (0.077 mm) or

less).

5. Split by Color and Hairlines: Automatically split files by both color and line thickness.

By using the same process to identify your cut lines every time you are setting up a file, you

will find the process to be quick and easy to have your processes set up whenever you print

a new job to the Dashboard!

Placing Your Artwork

With the Laser Dashboard, you can move your image anywhere on the page to

line up with your material on the table. There is no need to precisely place your

artwork in your design soware, because you can align it with your material

using the live camera system on the Fusion Pro.

For the most accurate results, we recommend placing your material

as close to the center of the camera as possible.

• Edit: You can click on the file and move it wherever you would like on the

table.

• Pan: Change to Pan mode to move around the table without moving the

graphic’s position on the table. You may also center-click and drag, or hold

down the space bar to activate Pan mode.

- 52 -

Page 57

SECTION 5: THE LASER DASHBOARD

• Reset: Reset the entire file back to its original status when printed to the Dashboard. This will also

reset all laser parameters such as speed and power settings.

• Undo / Redo: Undo one change, or redo one change.

• Group / Ungroup: The file will initially appear grouped. If you want to move individual sections of

the file, with the graphic selected click the ungroup icon several times until all items are ungrouped.

• Boundary: This is the working boundary the laser will recognize. It will ignore any graphics outside

this boundary area.

Dividing Your Job Into Processes

When you have your job in the Dashboard, there are several ways to split your project into separate

processes.

Split by Color (Color Mapping)

When you set several items to dierent colors in your design file, you can color map them to their own

processes and define their speed and power settings individually. There are two ways to separate each

color into a dierent process:

1. In your Dashboard settings, select “Split by Color” to automatically process. For more information

“Presetting Your Cut Lines” on page 52.

2. When the file appears, select “Split by Color” in the single process on the right side of the screen.

(See below).

3. Now all of your colors have been separated into dierent processes and you can assign settings to

each process separately. Processes are labeled by the name of each color.

- 53 -

Page 58

SECTION 5: THE LASER DASHBOARD

Split by Hairline

When you print your file to the laser, you can manually select to split your processes by hairline.

1. Click on the process and select “Split by Hairline”.

2. All hairline vector lines will be grouped into a separate process.

- 54 -

Page 59

SECTION 5: THE LASER DASHBOARD

Split by Selection

Aer you have ungrouped your artwork, select a portion of your artwork you want to separate into its

own process and select “+ Selection”. In this example we have moved the text into a separate process

from the other graphics, letting us adjust the speed and power settings for just that portion of the

engraving.

- 55 -

Page 60

SECTION 5: THE LASER DASHBOARD

Ordering Processes

In the Processes section of the Dashboard, you may rearrange the order in which each process runs on

the laser. The order of the processes in the list is the order that they will be completed by the laser. You

can change the order of the processes by clicking and dragging them up and down in the list. In this

example we are engraving and cutting leather bookmarks. The top most process will engrave first, and

the job will finish with the lemost outline being cut.

The process order will always begin with any engraving processes, then follow with your vector processes.

If you attempt to move a vector process above an engraving process, it will automatically go back to its

previous position below all the engraving processes. This is to ensure that the engraving processes are

completed while the piece is as flat as possible. Once cut through, pieces may shi as they are cut out

of the item, providing a misaligned engraving.

- 56 -

Page 61

SECTION 5: THE LASER DASHBOARD

Merging Processes

If you want certain proccesses to be engraved at the same time with the same settings, you may merge

them into one process. Click on the process you want to merge with other processes, then click on the

icon next to “Merge with”.

A list of processes will drop down, select a process to merge with by clicking on it.

- 57 -

Page 62

SECTION 5: THE LASER DASHBOARD

If you want to merge multiple processes all at once, hold down “ctrl” before clicking on multiple processes

in the list.

Once you let go of the “ctrl” button, all of the processes should be merged together as one process.

- 58 -

Page 63

SECTION 5: THE LASER DASHBOARD

Editing Artwork with Live View

Occasionally you may want to edit your engraving artwork to fit a uniquely shaped object. With the IRIS™

Camera on the Fusion Pro, you can copy the live preview image of your engraving piece and open it up

in your preferred graphic soware. From there you may adjust your graphic accordingly to the shape

of your engraving piece. In this example we will create a custom curve for text to follow, for engraving a

quote onto a clothes hanger.

1. First, place the object you want to engrave on the engraving table, then close the top door of the

machine.

2. Once the live preview of the table appears in the Dashboard, click on the “Copy Background

Image” button.

3. Open up your preferred graphic soware and paste the image into a new document, with the

table size as the dimensions of your document. In this example we used Corel Draw with the Fusion

Pro 32, so our document size is 32” x 20”.

Note: In CorelDraw you can lock the background image into place by right clicking on the

image and selecting “Lock Object”.

- 59 -

Page 64

SECTION 5: THE LASER DASHBOARD

4. To make our quote follow the shape of the hanger, we will need to trace the area we want to place

the text with the Freehand tool.

5. Once the tracing is finished, select the Text tool and move the mouse over the traced line until you

see a curved line icon appear. Click on the traced line when this icon appears.

- 60 -

Page 65

SECTION 5: THE LASER DASHBOARD

6. The text box will appear and anything typed out will automatically follow the path of the line.

Adjust your font face and size as needed.

7. Once your text is ready, select the line you used to curve the text with the Shape tool

8. Then click on the Pick tool

9. Select the text, go to File > Print and change the Print Range to “Selection”, then print to the Epilog

Engraver.

and hit “Delete” on your keyboard to remove the line.

- 61 -

Page 66

SECTION 5: THE LASER DASHBOARD

10. The text should now fit the shape of your engraving piece and be ready to print with your preferred

settings.

Saving Your Settings

You have two ways you can save settings for your jobs - by material and by job.

1. Settings by Material: Next to each process you will see a

small upload and download folder icon. These settings

will only aect the currently selected process.

• Import current material settings by clicking the folder

with the down arrow. Select between the Engrave and

Vector tabs, then choose your material from the list.

• Export your new material settings by clicking the folder

with the up arrow. Add a settings name and add it to an

existing folder.

• For step by step instructions see “Material Settings

Tab” on page 41.

2. Settings by Job: Your settings for the entire job can be saved by clicking on the folder icons at the

bottom of the Dashboard.

• Click the folder with the down arrow to import saved job settings.

• Click the folder with the up arrow to export your current job settings.

- 62 -

Page 67

SECTION 5: THE LASER DASHBOARD

• When is this helpful? When you have a series of processes you use frequently. For example, you

oen use a specific two-ply plastic for creating signs. You can save both your engraving and

vector processes.

• For step by step instructions, see “Job Settings Tab” on page 44.

File Settings

At the top of the Dashboard, you will see several file-related settings:

• Machine: Choose which laser you are sending the file to. This will show any lasers you have installed

in the Job Manager.

• Folder / Subfolder: Which folder and subfolder you want to save the file to in the Job Manager.

• View: This will change what portions of the graphic are shown in the preview. Choose to show all

processes (Combined), or just your Engrave or Vector processes. This is a good way to preview your

job and make sure you have set all of the lines you want to cut rather than engrave.

At the bottom of the page you’ll see several additional file settings:

• Name: Set your file name.

• Time: Displays the estimated time the project will take to run at the laser.

• Created / Printed: Displays the date and time the file was created and last printed.

• Print: Press the print button to send the job to the laser.

• Send to JM: Press this button to send the job to the Job Manager.

• Discard: Delete the file from the Dashboard.

- 63 -

Page 68

SECTION 5: THE LASER DASHBOARD

Settings in Detail

Resolution

Set your print resolution anywhere from 75 to 1200 DPI. For the best engraving results, use a resolution

equal to the resolution in the raster images within your project setup. We recommend using a resolution

of 400-500 for most standard engraving jobs. Use 600 DPI for jobs requiring finer detail. The resolution

setting in the print driver will aect the engraving time (there are twice as many engraved lines at 600 DPI

as at 300 DPI) and the quality. For a detailed discussion on Resolution, visit “Resolution” on page 81.

Engrave Direction

This feature applies to engraving only and allows you to engrave your project either from the top-down

or the bottom-up direction. In standard top-down engraving there can be a large amount of engraving

debris generated, especially on materials such as plastic, wood and rubber. As the debris moves toward

the exhaust plenum, some of it collects in the area that has just been engraved. Bottom-up engraving

prevents the debris from collecting in the freshly engraved spaces.

Process Type

Choose between the three modes of operation.

• O: This setting will tell the laser to ignore any items within this process.

• Engrave Mode: Used for engraving or marking materials. Typical uses include engraving clipart,

scanned images, photos, text and graphic images.

• Vector Mode: Selected when you are running only cut lines or for use with the Red Dot Pointer for

previewing the job processing area.

Speed

Determines the travel speed of the carriage and is adjustable in 1% increments from 1 to 100%. The slower

the speed, the deeper the engraving or cutting. Speed settings are heavily dependent on the hardness

and the thickness of the material being engraved or cut, with harder materials requiring slower speeds

for deeper engraving/cutting. Please refer to “APPENDIX B: MATERIAL SETTINGS” on page 129 in this

manual.

Power

Determines the amount of laser energy that is delivered to the piece being cut and is adjustable in

increments from 1 to 100%. The higher the power, the deeper the engraving/cutting. Please refer to

“APPENDIX B: MATERIAL SETTINGS” on page 129 in the manual.

- 64 -

Page 69

SECTION 5: THE LASER DASHBOARD

Frequency

The frequency setting is only active on vector processes, and controls the number of laser pulses that

the laser fires per inch of travel. The frequency is set in the dashboard and can be adjusted from 1 to

100%. A lower frequency number will have the eect of less heat because fewer pulses are being used to

cut the material. Lower frequency rates are helpful for products like wood, where charring is evident at

higher frequencies. High frequencies are useful on materials like acrylic where a large amount of heat is

desirable to melt or flame polish the edges.

Dithering

Dithering is used only for Raster engraving and has no eect on vector cut lines. This setting defines how

the dot patterns will be engraved in raster images that contain grayscale images, blends, or color. The

Dashboard oers six dierent dithering patterns to enhance your engraving projects. The default mode

is Standard. This mode can be used for all images including photographs, but some images improve

when engraved with other dithering patterns. For more information, go to “Image Dithering” on page

87.

Oset

Oset allows you to focus at any point above or below the suace of your material. When engraving

acrylic, many users like to focus above the suace to produce a “soer” finish to the engraving.

Conversely, when cutting acrylic, many users like to focus about half way into the acrylic. Oset allows

you to do this automatically. A positive value will move the table away from the focus lens. A negative

value, such as -.095, will move the table closer the focus lens.

- 65 -

Page 70

SECTION 5: THE LASER DASHBOARD

Processes Tab

The Processes tab is an alternative view of the various processes within your file. You can see each

process with the settings located next to the process without the video view of the table.

- 66 -

Page 71

SECTION 5: THE LASER DASHBOARD

Advanced Tab

On the Advanced tab, you can change settings that will aect the entire job. More features will be added

to this tab in the near future.

• Copies: Set the number of times you would like to rerun the job. If you have 2 processes, the laser

will complete each of the two processes, then run the two processes a second time. If you have a

process with more than one cycle (process 1: cycles 1, process 2: cycles: 2) and set the copies to 2, it

will run process 1 once, process 2 twice, then process 1 once again, and process 2 twice more. This is

useful when using the fiber laser with the system.

Notes Tab

Use the Notes tab to keep notes on running your file. This can include suggestions for artwork placement,

speed and power notes, or anything else a laser operator may find helpful when running that project.

- 67 -

Page 72

SECTION 5: THE LASER DASHBOARD

File Setup FAQs

I have a file with only cut lines, but they came in as an “Engrave” process.

How do I change it to a cut process?

Select the process and change the Process Type to “Vector”.

I merged two of my layers, but now it lost pa of the graphic.

Change the Process Type to “Engrave” and see if they show up now. It may have changed your process

to Vector and hidden any non-vector parts of your image.

I want to set up the Dashboard to automatically process all files I print to

the laser with hairlines as cut lines. How do I do this?

Go to the Settings icon and in the Dashboard tab, change your New Job Settings to “Split by Hairlines”.

I forgot to remove pa of the awork I don’t want to engrave. How do I get

rid of that pa of the file?

There are two ways to do this. Either ungroup your image, select the item and delete it, or separate it by

selection and turn that process to O.

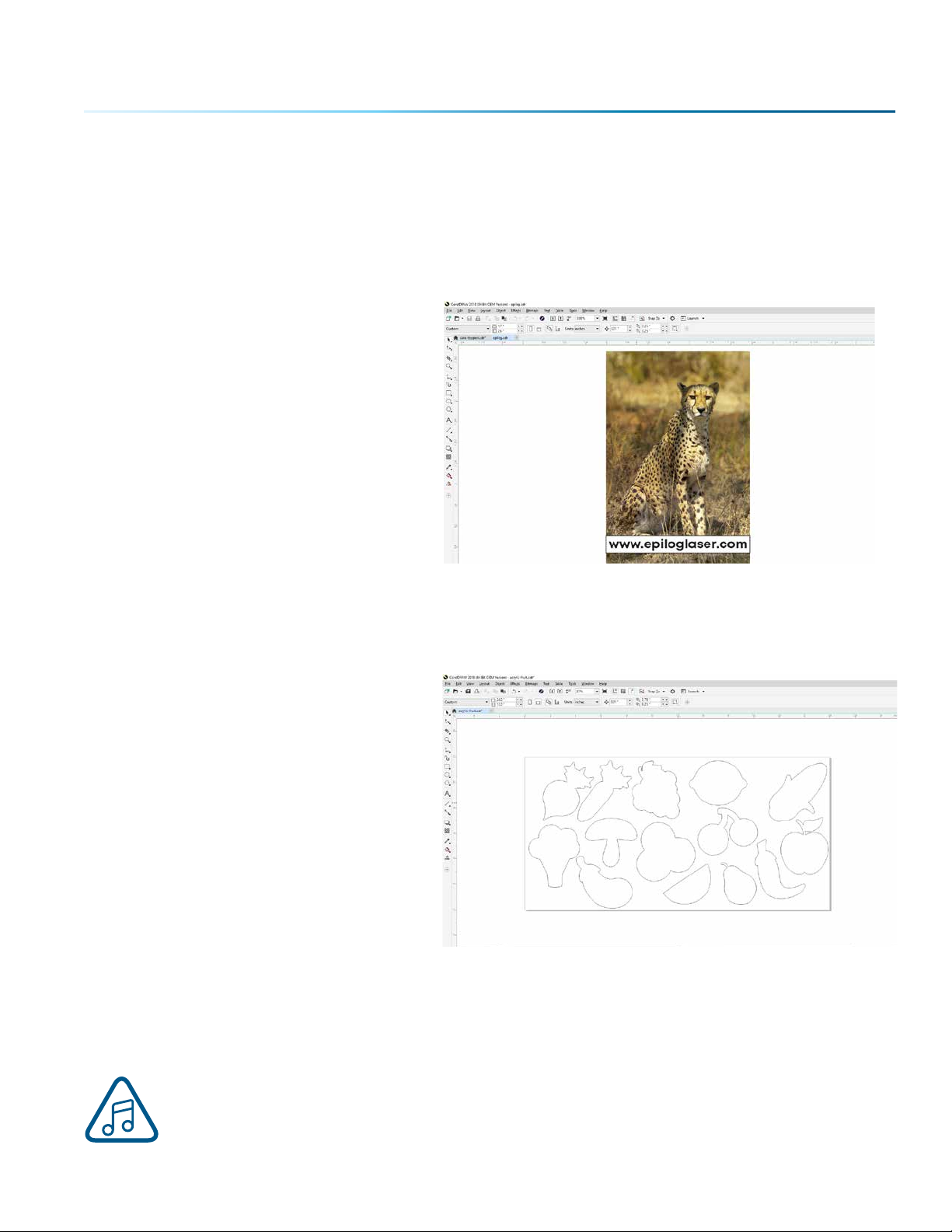

Additional CorelDRAW Laser Dashboard Features

Each program you use will provide dierent ways to manage these functions. CorelDRAW oers a very

straight forward way to access each of these features.

Multiple Passes

You can automatically engrave or cut a job multiple times by setting the Number of Copies to the number