Page 1

OWNER'S MANUAL FOR EPILOG

Fusion - MODEL 13000

This manual can also be found in electronic format on the

Epilog Dashboard Drivers and Documentation

disk that came with your laser system.

April 17, 2013

16371 Table Mountain Parkway

Golden, CO 80403

Phone (303) 277-1188

Fax (303) 277-9669

Technical Support Direct Line: (303) 215-9171

Email Technical Support: tech@epiloglaser.com

Technical Support Online:

www.epiloglaser.com/service.htm

www.epiloglaser.com/downloads.htm

Page 2

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

ii

Page 3

Contents at a Glance

Fire Warning!.........................................................................................i

Introduction ........................................................................................ xi

Epilog Laser Setup...............................................................................1

Section 1: Safety ............................................................................................................................ 1

Section 2: Dos and Don’ts ........................................................................................................... 13

Section 3: Getting Started .............................................................................................................. 1

Section 4: Installing the ECC (Epilog Control Center) ............................................................... 12

Section 5: Installing the Epilog Dashboard Print Driver ............................................................. 22

Section 6: Using the Epilog Dashboard....................................................................................... 47

Basic Operations................................................................................79

Section 7: Quick Start & Easy Setup ........................................................................................... 81

Section 8: Using the Front Control Panel .................................................................................... 91

Section 9: Using the ECC (Epilog Control Center).................................................................... 101

Section 10: Standard & Optional Machine Features.................................................................. 107

Section 11: Engraving Machine Cleaning ................................................................................. 119

Section 12: Speed and Power Recommendations...................................................................... 131

Section 13: Material Engraving Techniques.............................................................................. 139

Section 14: Material Suppliers................................................................................................... 155

Technical Support, Troubleshooting and Specifications...................161

Section 15: In Case of Difficulty ............................................................................................... 163

Section 16: Specifications.......................................................................................................... 165

Section 17: Upgrading the Operational Firmware ..................................................................... 171

APPENDIX A WARRANTY STATEMENT ...............................................177

APPENDIX B PRINTING FROM AUTOCAD...........................................179

APPENDIX C ADDITIONAL DASHBOARD PRINT DRIVER INSTRUCTIONS

........................................................................................................183

INDEX...............................................................................................195

iii

Page 4

Contents at a Glance

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

iv

Page 5

Table of Contents

Fire Warning!.........................................................................................i

Introduction ........................................................................................ xi

How to Use This Owner’s Manual ........................................................................................ xi

Epilog Laser Setup...............................................................................1

Section 1: Safety ............................................................................................................................ 1

Laser Safety ............................................................................................................................ 1

Electrical Safety ...................................................................................................................... 3

Fire Safety............................................................................................................................... 4

Safety Features and Regulatory Compliance.......................................................................... 5

Section 2: Dos and Don’ts ........................................................................................................... 13

DON’T!................................................................................................................................. 13

DO......................................................................................................................................... 14

Section 3: Getting Started .............................................................................................................. 1

Setting Up Your Laser System ............................................................................................... 1

Connecting the Exhaust ..........................................................................................................7

Connecting Electrical Power................................................................................................... 9

Section 4: Installing the ECC (Epilog Control Center) ............................................................... 12

USB Port ............................................................................................................................... 17

Ethernet Port ......................................................................................................................... 17

Section 5: Installing the Epilog Dashboard Print Driver ............................................................. 22

Installing the Dashboard Driver Using the USB Connection using XP or Vista.................. 23

Installing the Dashboard Driver Using the USB Connection using Windows 7 or 8........... 23

Installing the Dashboard Driver Using an Ethernet Connection and a Crossover Cable ..... 33

Section 6: Using the Epilog Dashboard....................................................................................... 47

Additional Dashboard Driver Features ................................................................................. 75

Changing Dashboard Driver Defaults................................................................................... 77

v

Page 6

Table of Contents

Basic Operations................................................................................79

Section 7: Quick Start & Easy Setup ........................................................................................... 81

Artwork Setup....................................................................................................................... 81

Job Setup............................................................................................................................... 84

Section 8: Using the Front Control Panel .................................................................................... 91

Section 9: Using the ECC (Epilog Control Center).................................................................... 101

Job Tab................................................................................................................................ 101

Configuration Tab............................................................................................................... 105

Section 10: Standard & Optional Machine Features.................................................................. 107

Air Assist ............................................................................................................................ 107

Front Access Door .............................................................................................................. 108

Task Plate............................................................................................................................ 109

Optional Vector Grid/Vacuum Hold-down Table .............................................................. 109

Pin Table ............................................................................................................................. 113

Section 11: Engraving Machine Cleaning ................................................................................. 119

This cleaning section may show photos of other Epilog machines. The cleaning process is

the same so please use these photos as a reference guide................................................... 119

Cleaning - Important!............................................................................................................... i

Fire Warning!...................................................................................................................... 119

Laser Tube .......................................................................................................................... 129

Section 12: Speed and Power Recommendations...................................................................... 131

Engraving Speed ................................................................................................................. 131

Engraving Power................................................................................................................. 131

Recommendations............................................................................................................... 132

Multiple Passes ................................................................................................................... 133

30 Watt................................................................................................................................ 134

40 Watt................................................................................................................................ 135

50 Watt................................................................................................................................ 136

60 Watt................................................................................................................................ 137

75 Watt................................................................................................................................ 138

vi

Page 7

Table of Contents

Section 13: Material Engraving Techniques.............................................................................. 139

Acrylic...................................................................................................................................... i

Fire Warning!...................................................................................................................... 139

Anodized Aluminum........................................................................................................... 142

Brass - Painted .................................................................................................................... 142

Glass.................................................................................................................................... 144

Notary Seals - Delrin .......................................................................................................... 146

Plastic.................................................................................................................................. 147

Rubber Stamps .................................................................................................................... 149

Wood................................................................................................................................... 149

Section 14: Material Suppliers................................................................................................... 155

Technical Support, Troubleshooting and Specifications...................161

Section 15: In Case of Difficulty ............................................................................................... 163

Contacting Technical Support............................................................................................. 163

Section 16: Specifications.......................................................................................................... 165

Epilog Fusion 32 x 20 Specifications ................................................................................. 165

Compatibility ...................................................................................................................... 166

Recommended PC............................................................................................................... 166

Other Computer Hardware Recommendations................................................................... 168

About The Laser ................................................................................................................. 168

Federal Communications Commission (FCC) Notice ........................................................ 169

Section 17: Upgrading the Operational Firmware ..................................................................... 171

Upgrading Your Firmware.................................................................................................. 171

Installing New Firmware onto Your Computer .................................................................. 172

Transferring New Firmware from Your Computer to Your Laser ..................................... 174

APPENDIX A WARRANTY STATEMENT ...............................................177

APPENDIX B PRINTING FROM AUTOCAD...........................................179

APPENDIX C ADDITIONAL DASHBOARD PRINT DRIVER INSTRUCTIONS

........................................................................................................183

Windows 7: Setting up the TCP/IP Address in the Computer........................................... 183

Windows 8: Installing the 64-bit Epilog Dashboard Print Driver in Windows 8.............. 189

vii

Page 8

Table of Contents

INDEX...............................................................................................195

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

viii

Page 9

Fire Warning!

Your laser system uses a high intensity beam of light that can generate extremely

high temperatures when it comes into contact with the material being engraved,

marked or cut. Some materials are extremely flammable and can easily ignite and

burst into open flame setting the machine afire. This open flame is very

dangerous and has the potential to destroy not only the machine, but the building

in which it is housed.

Experience shows that vector cutting with the laser has the most potential to

create an open flame. Many materials are susceptible to igniting, but acrylic, in

all its different forms, has been shown to be especially flammable when vector

cutting with the laser.

Please read the following warnings and recommendations and follow them closely

at all times!

NEVER let the laser system operate if it will be unattended.

KEEP the area around the machine clean and free of clutter, combustible

materials, explosives, or volatile solvents such as acetone, alcohol, or

gasoline.

ALWAYS keep a properly maintained and inspected fire extinguisher on

hand. Epilog recommends a Halotron fire extinguisher or a multi-purpose

dry chemical fire extinguisher. The Halotron extinguishers are more

expensive than a dry chemical, but offer certain advantages should you

ever need to use an extinguisher. The Halotron extinguisher discharges a

clean, easily removable substance that is not harmful to the mechanics or

wiring of the laser system. The dry chemical extinguisher discharges a

sticky, corrosive powder that is very difficult to clean up.

ALWAYS use air assist when vector cutting.

BE CAREFUL! when vector cutting. Many materials have the potential

to burst suddenly into flames – even materials that may be very familiar to

the user. Always monitor the machine when it is operating.

KEEP YOUR LASER SYSTEM CLEAN – A build up of cutting and

engraving reside and debris is dangerous and can create a fire hazard in its

own right. Keep your laser system clean and free of debris. Regularly

remove the vector grid to clean any small pieces that have fallen through

the grid.

ix

Page 10

Fire Warning!

SEE PREVIOUS PAGE

x

Page 11

Introduction

How to Use This Owner’s Manual

Thank you for purchasing an Epilog Fusion Laser System. Your Epilog system

has been designed to be easy to operate, but you will utilize it to its fullest

potential by taking some time to read this owner’s manual prior to use. You will

be ready to use the Epilog laser system as soon as you read the first six sections.

Then you can refer to topics in the remaining sections, as you work.

Structure of the Manual

Part I: Setup

Sections 1 through 6 explain how to uncrate and set up your Epilog system,

important safety information you need to know before you use it, the Do’s and

Don’ts of operating the laser, configuring your computer to run the Epilog

Dashboard print driver, configuring CorelDraw, and a brief user’s guide to

running your first job.

Part II: Basic Operations

Sections 7 through 14 explain Using the Epilog Dashboard Print Driver, basic

Epilog laser operations and maintenance, machine features, speed and power

recommendations, material engraving techniques, and material suppliers.

Part III: Troubleshooting, Service and Specifications

Sections 15 through 17 assist with problem troubleshooting, service information;

system specifications and firmware upgrade instructions.

APPENDIX A

Epilog Warranty Information.

APPENDIX B

Printing from AutoCAD.

APPENDIX C

Additional Dashboard Print Driver Instructions.

INDEX

xi

Page 12

Introduction

Icons Used in this Manual

Look for these symbols to help you find valuable information throughout the text:

Sometimes the right perspective on a procedure is essential to success. This icon

Flags a Quick Note regarding the task at hand.

This Icon signifies places to look for additional information to assist with the

topic currently being discussed.

This Icon highlights current contact information for receiving help.

This Icon signifies advice you can try out with your machine right away.

This Icon signifies advice you can try that will save you significant time.

Running into trouble can be detrimental to your success so we’ve marked

Warnings and Cautions with this Icon.

Indicates pages including information regarding connecting your laser system to

your computer using an USB connection.

xii

Page 13

Introduction

Indicates pages including information regarding connecting your laser system to

your computer using an Ethernet connection.

Indicates the potential for fire danger when operating the laser.

xiii

Page 14

Introduction

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

xiv

Page 15

Manual

Epilog Laser Setup

1

Page 16

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

2

Page 17

Section 1: Safety

In This Section

Laser Safety

Electrical Safety

Fire Safety

Safety Features And Regulatory Compliance

Laser Safety

The Epilog Model 13000 Laser System is a Class 2 laser product, as defined in

International Standard IEC 60825-1.

The Epilog Model 13000 complies with 21 CFR 1040.10 and 1040.11, the

Federal Performance Standards for Light-Emitting Products, except for deviations

pursuant to Laser Notice No. 50, dated July 16, 2001. The Center for Devices and

Radiological Health, of the US FDA, issued Laser Notice No. 50 to permit

manufacturers to classify and manufacture their products in accordance with the

International Standard.

The output of the embedded high-power CO2 engraving laser is fully contained.

The laser cabinet has safety interlocks that turn the laser off if the door is opened

during operation, and no special precautions are necessary to operate the highpower laser safely. However, the visible output beam of the Laser Diode Pointer

(Red Dot Pointer) is accessible to the operator. While this device employs the

same technology as the familiar laser pen-pointers, like them it is potentially

hazardous if its beam is directed into the eye.

We have made every effort to make the Laser Diode Pointer (Red Dot Pointer) as

safe as possible. Its beam path is located well inside the cabinet, and under

normal conditions, no hazardous levels of laser radiation can escape.

1

Page 18

Section 1: Safety

The operator of the Epilog Model 13000 should observe the following general

precautions:

DO NOT disassemble the machine or remove any of its protective covers

while the unit is plugged in.

DO NOT attempt to defeat the door interlocks.

DO NOT view directly into the beam of the Laser Diode Pointer (Red Dot

Pointer).

DO NOT operate the Laser Diode Pointer (Red Dot Pointer) without the

machine’s focus lens in place. If the unfocused beam strikes a reflective

surface, it could be directed out of the cabinet.

Caution – Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

* * *

The standard reference for laser safety is the American Standard for the Safe Use

of Lasers, Z136.1-2000, developed by the American National Standards Institute

(ANSI). This reference is the basis for many of the federal regulations for laser

and laser system manufacturers, and for the Occupational Safety and Health

Administration (OSHA) laser safety guidelines. It contains detailed information

concerning proper installation and use of laser systems.

While the ANSI standard itself does not have the force of law, its

recommendations, including warning signage, training, and the designation of a

laser safety officer, may be compulsory under local workplace regulations when

operating laser systems above Class I. It is the operator’s responsibility to ensure

that the installation and operation of the Epilog Model 13000 Laser System is

performed in accordance with all applicable laws.

Copies of ANSI Standard Z136.1-2000 are available from Epilog Corporation or

from:

Laser Institute of America

12424 Research Parkway, Suite 125

Orlando, FL 32826

(407) 380-1553

2

Page 19

Section 1: Safety

Electrical Safety

The AC input power to the Epilog Model 13000 Laser System is potentially lethal

and is fully contained within the cabinet.

DO NOT open any of the machine’s access panels while the unit is

plugged in. Opening a panel may expose the operator to the unit’s AC

input power.

DO NOT make or break any electrical connections to the system while the

unit is turned on.

3

Page 20

Fire Safety

Laser cutting and engraving systems represent a significant fire hazard. Most

engraving materials are inherently combustible, and while the objective of most

cutting and engraving operations is to vaporize material without burning, it is easy

to ignite a flame. Usually this is a simple “flare” of burning gases, issuing from

the focused spot on the work piece, which follows the moving spot and which

extinguishes itself as soon as the laser beam is modulated off. But should the

work piece actually be set on fire, the fire must be extinguished by the operator at

once, or the machine will be seriously damaged or destroyed!

Experience shows that vector cutting with the laser has the most potential to

create an open flame. Many materials are susceptible to igniting, but acrylic, in

all its different forms, has been shown to be especially flammable when vector

cutting with the laser.

Section 1: Safety

Please read the following warnings and recommendations and follow them closely

at all times!

NEVER let the laser system operate if it will be unattended.

KEEP the area around the machine clean and free of unnecessary clutter,

combustible materials, explosives, or volatile solvents such as acetone,

alcohol, or gasoline.

ALWAYS keep a properly maintained and inspected fire extinguisher on

hand. Epilog recommends a Halotron fire extinguisher or a multi-purpose

dry chemical fire extinguisher. The Halotron extinguishers are more

expensive than a dry chemical, but offer certain advantages should you

ever need to use an extinguisher. The Halotron extinguisher discharges a

clean, easily removable substance that is not harmful to the mechanics or

wiring of the laser system. The dry chemical extinguisher discharges a

sticky, corrosive powder that is very difficult to clean up.

ALWAYS use air assist when vector cutting.

BE CAREFUL! When vector cutting. Many materials have the potential

to burst suddenly into flames – even materials that may be very familiar to

the user. Always monitor the machine when it is operating.

KEEP YOUR LASER SYSTEM CLEAN – A build up of cutting and

engraving reside and debris is dangerous and can create a fire hazard in its

own right. Keep your laser system clean and free of debris. Regularly

remove the vector grid to clean any small pieces that have fallen through

the grid.

4

Page 21

Section 1: Safety

Safety Features and Regulatory

Compliance

Epilog has incorporated specific safety features into the Model 13000 Laser

System in order to meet the requirements of 21 CFR 1040 and the International

Standard IEC 60825-1. These safety features include:

A safety enclosure (cabinet), which fully encloses the engraving laser and

its beam path.

Dual redundant interlock systems that turn off the engraving laser when

the window is opened.

A visible emission indication when the Laser Diode Pointer (Red Dot

Pointer) is operating. There is an LED indicator on the machine’s front

panel.

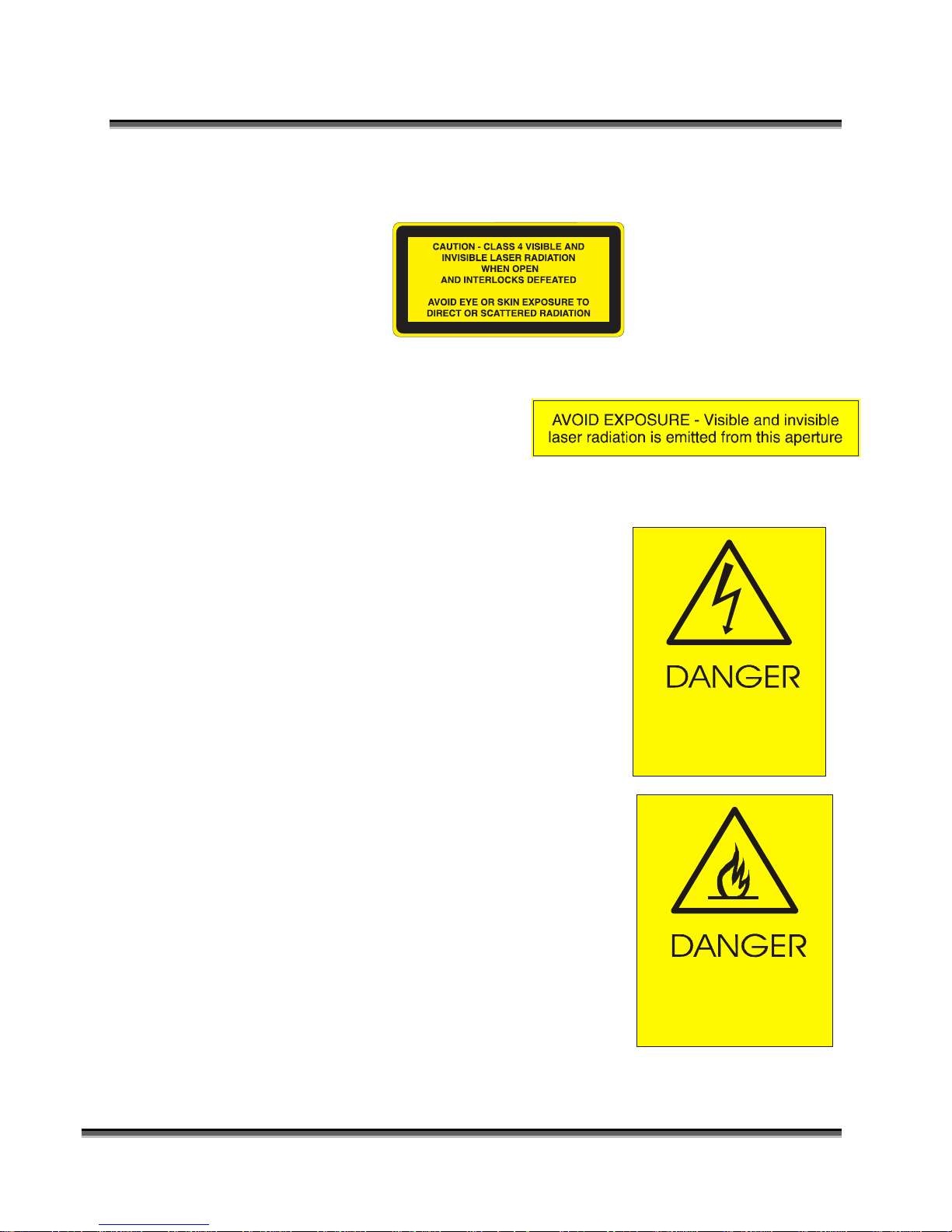

21 CFR 1040 and IEC 60825-1 require that certification, identification, and

warning labels be placed on laser products. Reproductions of labels on the Epilog

Model 13000 Laser System follow, with their locations specified:

1. Certification/Identification Label. This engraved plate is located on the rear

of the machine’s cabinet.

5

Page 22

Section 1: Safety

2. Warning Label. This label is located on the rear of the machine’s cabinet,

below the Certification/Identification Label above.

3. Explanatory Label. This label identifies the classification of the Model

13000 in accordance with IEC 60825-1. It is located on the rear of the

machine’s cabinet, beside the Warning Label above.

LASER RADIAT ION

DO NO T STARE INTO BEAM

CLASS 2 LASE R PRODUCT

1 mW CW M AXIMUM 600-700 nm

4. Non-interlocked Protective Housing Safety Labels (4).

Two of these labels are located on the rear of the machine; beside the edges

of each of the cabinet’s end covers. The other two labels are located on the

cabinet walls under the covers, so that they are visible when the covers have

been removed.

6

Page 23

Section 1: Safety

5. Defeatably-interlocked Protective Housing Safety Label. This label is

located on the machine’s cabinet door, in the upper left-hand corner.

6. Aperture Safety Label.

This label is located on the

steering-mirror cover inside the

machine’s cabinet, beside the

aperture where the laser beams enter the cabinet.

7. Electrical Safety Label.

This label is located on the access panel on

the rear of the machine’s cabinet.

HIGH VOLTAGE INSIDE CABINET

DISCONNECT PO WER

BEFORE OPENING PANEL

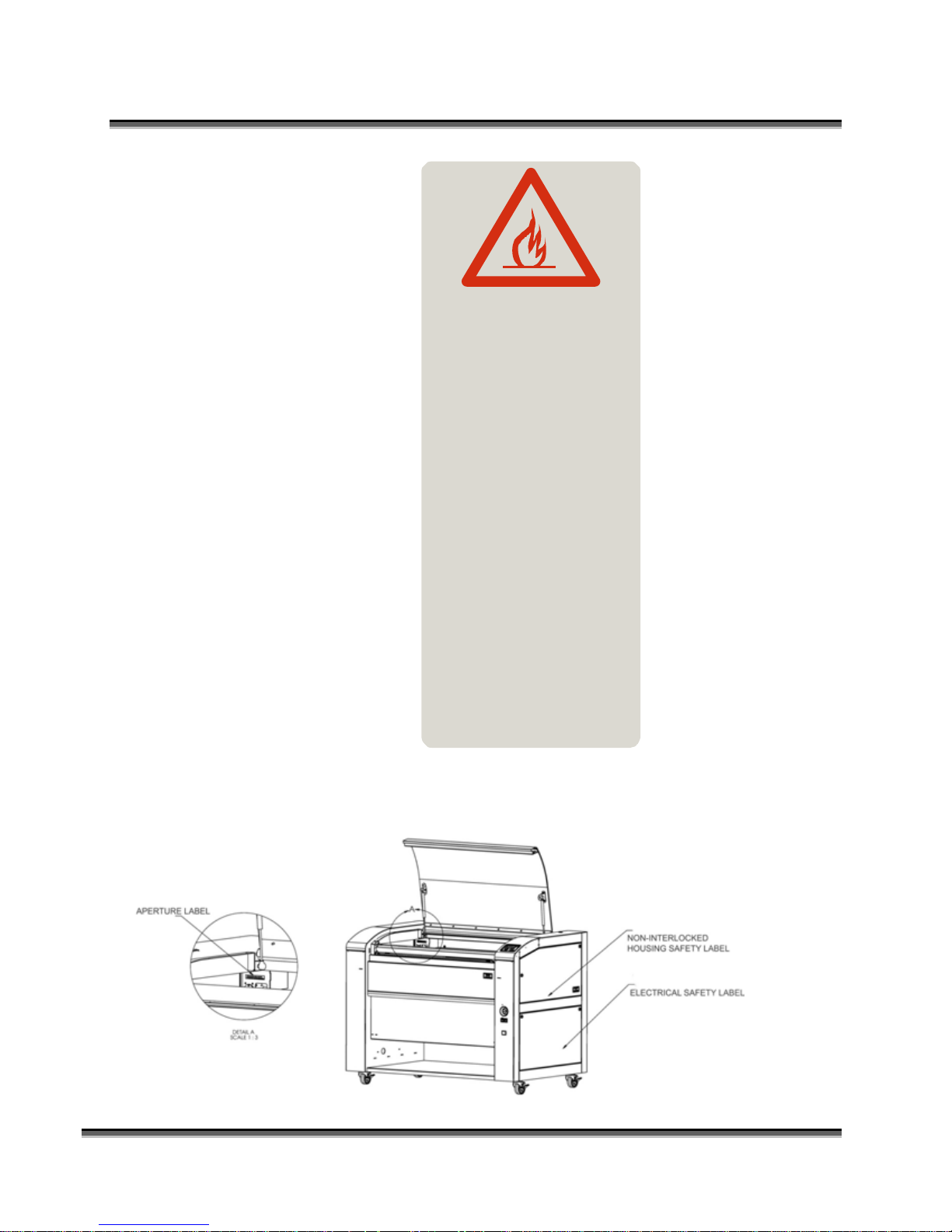

8. Fire Safety Label.

This label is located on the machine’s cabinet

door, in the upper right-hand corner.

FIRE HAZARD

7

DO NOT OPERATE

MACHINE UNATTENDED

Page 24

Section 1: Safety

9. Emergency Stop

EMERGENCY

STOP

10. Power Labels

11. Main Breaker Labels

12. Air Assist Label

AIR ASSIST

30 PSI MAX

200 kPa MA X

12. Fire Warning Label

This fire hazard label is located on the left and right sides of the top access

door of your laser system:

8

Page 25

Section 1: Safety

DANGER

FIRE HAZARD

DO NOT OPERATE

MACHINE UNATTENDED

USE EXTREME CAUTION WHEN

CUTTING FLAMMABLE MATERIALS

SUCH AS WOOD OR ACRYLI C.

A PROPERLY MAIN TAINED FIRE

EX TINGU ISHER SHOULD BE KEPT

NEAR THE MACHINE AT ALL TIMES.

EPILO G RECOMME NDS A CO FIRE

EXTINGUISHER.

PERIODICALLY REMOVE THE

VECTOR C UTTING GR ID AND

REMOVE DEBRIS FROM THE TABLE

PAN.

PERIODICALLY REMOVE THE

EXH AUST TUBE ADA PTER FRO M

TH E BACK OF THE MACHINE AND

REMO VE ANY DEBRIS FROM THE

EX HAUST PORT.

2

REFER TO THE USERS

MANUAL FO R ADDITIONAL

IN F ORM ATI O N RE GARDI N G

FIRE SAFETY

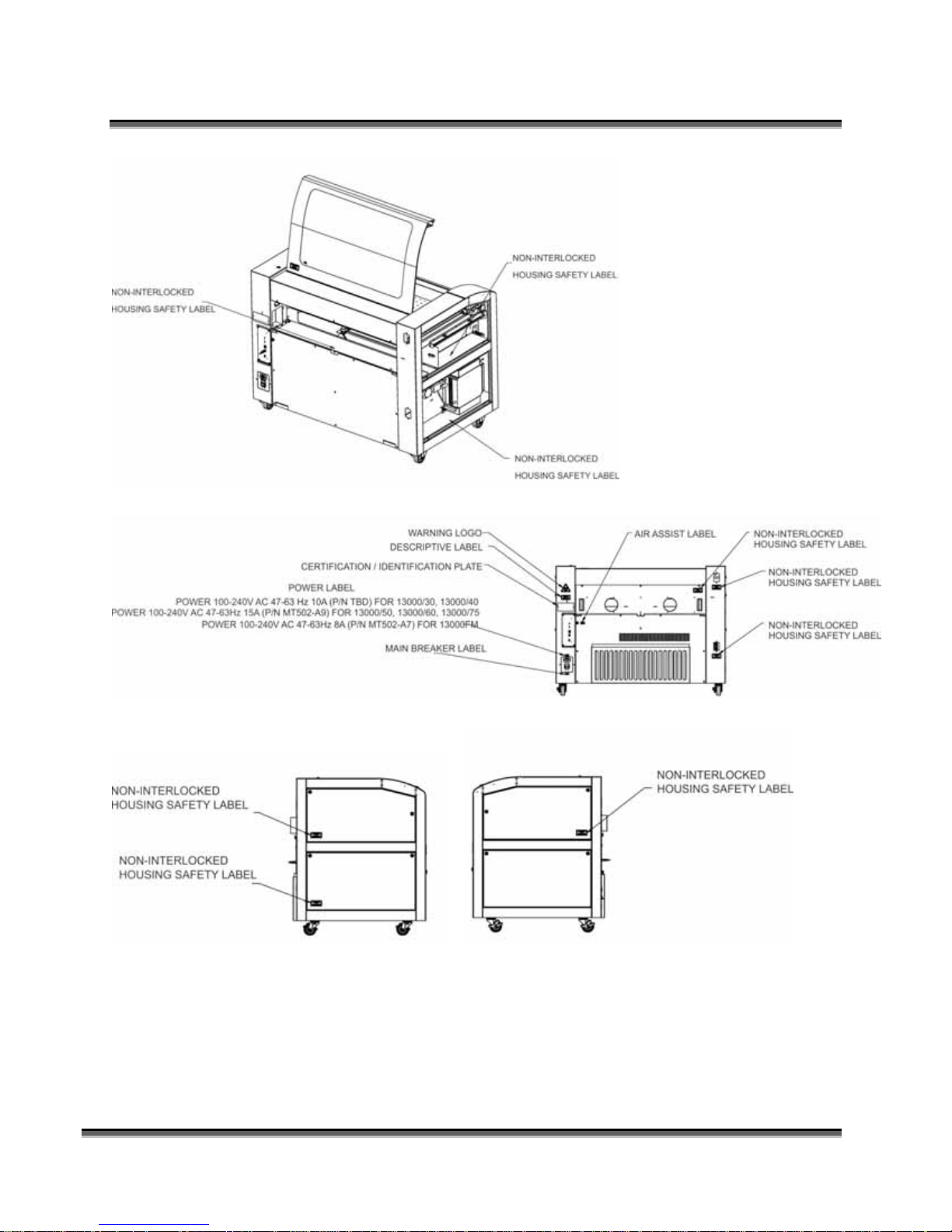

The following diagrams show the location of each specific label described above.

9

Page 26

Section 1: Safety

10

Page 27

Section 1: Safety

11

Page 28

Section 1: Safety

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

12

Page 29

Section 2: Dos and Don’ts

In This Section

Operating Dos and Don’ts

DON’T!

NEVER operate the machine without a properly operating vent to the outside!

Most material will only produce an irritating smoke when engraved. Some

materials, including but not limited to paint, varnish, composition board and

plastics, produce compounds that can be harmful if concentrated. A properly

installed vent is the only way to ensure that problems do not occur.

NEVER engrave or cut any material containing PVC or vinyl. When engraved, a

corrosive agent is produced that will destroy your machine. Your warranty will

be void if your machine is damaged by corrosion from engraving or cutting

PVC or Vinyl.

NEVER operate your machine unattended. There is a significant risk of fire if the

machine is set improperly, or if the machine should experience a mechanical or

electrical failure while operating.

NEVER vector cut any material while the machine is unattended. Because vector

cutting moves relatively slowly compared to raster engraving, a tremendous

amount of heat is applied to the material being cut. This buildup of heat can

cause significant fire risk and the machine should always be monitored.

Additionally, the air assist should always be turned on when vector cutting to

reduce the risk of fire.

NEVER operate with any of the covers or enclosures removed, and never modify

the enclosure. The laser beam is invisible!

13

Page 30

DO

Section 2: Dos and Don’ts

Please allow a few minutes a week for cleaning your machine. Just a small

amount of effort at the end of the week will pay off with years of trouble free

operation of your machine.

See the Engraving Machine Cleaning section of this manual for specifics.

14

Page 31

Section 3: Getting Started

In This Section

Setting Up Your Laser System

Connecting The Exhaust

Connecting The Electrical Power

Laser Cooling Requirements And Operating Temperatures

Installing the ECC (Epilog Control Panel)

Installing the Dashboard Print Driver

Setting Up Your Laser System

Setting up your Epilog Laser System is easy to do! If you’ve ever installed a

paper printer, this is only slightly more difficult. The following information will

help you understand the entire system and how it works.

Your Fusion laser system consists of the following components:

1) Fusion laser system:

2) Computer and a graphics software package.

1

Page 32

Section 3: Getting Started

3) Epilog software and connection options:

Epilog provides two pieces of software for the Fusion:

1) The ECC (Epilog Control Panel).

2) The Dashboard print driver.

Epilog also provides two different methods of connection the Fusion to your

computer:

1) USB

2) Ethernet

The software and the connection methods are associated because the connection

method affects which software can be used. The following shows how software

and connection methods work:

Connection Method Software Compatibility

USB Dashboard Driver & ECC

Ethernet Dashboard Driver Only

As you can see, the USB provides the most versatility.

The most popular choice is to use the USB for both printing and accessing the

ECC. This choice is the simplest and the most versatile.

One advantage of having two connection options that is not immediately obvious

is that you can use both connections, or just one of them. If you choose, you can

print using the Ethernet connection while using the USB connection for the ECC.

Both the USB and the Ethernet cable can be plugged into the Fusion at the same

time. This method is a little more complicated, but is just as versatile as the USB

only connection.

The last choice is to use only the Ethernet connection. Most users will not choose

this method because the ECC is not available through the Ethernet connection.

2

Page 33

Section 3: Getting Started

4) ECC (Epilog Control Center)

The ECC is the software program that provides job management capabilities to

keep track of print jobs, laser settings and other job management tasks after the

job has been sent to the laser from the Dashboard driver.

The ECC is not required in order to operate your Fusion laser, but is a very

useful job management tool that users find quite valuable.

It is useful to install the ECC prior to installing the print driver.

The ECC ONLY works through the USB

connection. The ECC cannot be accessed

through the Ethernet connection.

3

Page 34

Section 3: Getting Started

5) The Fusion Dashboard print driver.

The print driver is the primary interface between the computer and the laser

and sends all jobs and laser parameters to the laser. Your Fusion laser system

cannot run without the Dashboard driver.

The print driver can be used with either the

USB or Ethernet connection.

Most users will want to install the print driver

on the USB port because they will also want to

use the ECC. The ECC ONLY

works through

the USB connection.

The simplest setup is to install the print driver

using the USB connection. This method allows

you to also use the same USB connection for

the ECC.

4

Page 35

n

Section 3: Getting Started

6) Connection cables that allow your computer and laser to talk to each other.

The Fusion has both Ethernet and USB connections.

7) Exhaust fan. The exhaust fan is mandatory and is used to remove smoke and

debris from the Fusion work area. The exhaust air can be ported to the outside

or into a filter box.

The following drawing represents a typical setup:

5

air flow

exhaust fan

From Fusio

Page 36

Section 3: Getting Started

ETHERNET

USB

Electrical

Connection

(110/220V - 50/60 Hz)

Follow these steps to set up your Fusion laser system:

Remove it from the crate

Connect the exhaust system to your laser

Connect electrical power

Install the ECC (Epilog Control Panel)

Install the Epilog Dashboard Print Driver –

Connect both the USB and Ethernet cables from your computer to your

laser system.

6

Page 37

Section 3: Getting Started

Connecting the Exhaust

It is mandatory that an exhaust blower is installed and operating whenever your

laser system is running a job. The exhaust blower removes the dust, debris and

smell from the engraving cavity and exhausts it to the outside of the building.

You should never operate your laser system without a properly working exhaust.

Prior to the installation of the laser system, a contractor should install the exhaust

system. The blower should be mounted outside your building for noise

considerations. Ideally, the blower should not be more than twenty feet (6

meters) from the laser. You should provide a metal duct (flexible aluminum or

galvanized sheet metal) from the blower to the laser. All Epilog model 13000

laser systems require an exhaust fan that is rated at a minimum of 650 CFM.

Note: Remember to put the blower switch for the laser system in an obvious and

accessible place so it can be routinely switched on prior to using the engraver.

Please connect the exhaust blower to the laser as shown below and on the

following pages.

You may need a contractor to install the exhaust. This must be done PRIOR to

installation of the laser system.

Warning: It’s important that either rigid or flexible metal ducting be used for

all connections leading to and from the laser system and the exhaust fan. Vinyl,

plastic, or any type of “soft” ducting is potentially flammable and should NEVER

be used.

7

Page 38

Section 3: Getting Started

Epilog Exhaust Blower Connections

There are two 4” (100 mm) ports attached to the back of the laser system. Attach your

ducting to the machine as shown above.

Check your exhaust system for leaks. Most small leaks can be remedied with

duct tape.

DO NOT OPERATE your laser with inadequate or leaking exhaust.

The drawings below show the typical exhaust setup. The top drawing shows the

exhaust on the roof and the bottom drawing shows the exhaust fan near the

machine. Where the exhaust fan is placed is a choice of personal preference.

Some users like the exhaust fan outside because of noise considerations.

8

Page 39

Section 3: Getting Started

Exhaust Blower

Connecting Electrical Power

Roof or exterior wall

All Epilog laser systems have an auto-switching power supply that detects the

incoming voltage and automatically switches itself to operate properly at any

single-phase voltage between 100 and 240 VAC. The power supply will also

automatically compensate for either 50 or 60 Hz. Epilog supplies the appropriate

power cord for all of our equipment. The electrical cord is found in the accessory

package with your machine. It is recommended that a dedicated 15 amp circuit be

used if available, but it is not required.

The 60 watt and 75 watt machines draw more current than the lower wattage

lasers. These two systems can operate on 110 volts, but most users find that a 200

V connection is more efficient.

4” (100 mm) flex ible aluminum duct

or rigid galvanized sheet

metal (Do not use vinyl,

plastic or “soft” flexible duct).

The electrical connection is found at the lower back of the machine.

Electrical

Connection

(110/220V - 50/60 Hz)

9

Page 40

Section 3: Getting Started

Laser Cooling Requirements and

Operating Temperatures

All Epilog laser systems use air-cooled laser tubes. Laser technology is such that

the laser tubes generate a lot of excess heat and the tubes must be cooled for

proper operation. There are cooling fans located at the back of the laser. The fans

and vents should always be clear of restrictions and should never be covered.

Warning: The cooling fans and vents are located at the back of the Fusion and

should never be covered or blocked in any way. Lasers that overheat will not

operate properly and may begin to produce erratic laser output or possibly

complete failure.

Ambient air temperature where the laser system is operating should not exceed 90 degrees F (32

C). Operating in an environment where the ambient air temperature is above 90 degrees F (32 C)

will void the Epilog warranty.

10

Page 41

Section 3: Getting Started

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

11

Page 42

Section 4: Installing the ECC

(Epilog Control Center)

In This Section

Installing the ECC

The ECC (Epilog Control Center) provides Job Management features as well as laser control and

laser machine configuration options. The ECC is not required to operate the laser, but it provides

many user features that make operating your Fusion easy.

To install the ECC, insert the Epilog install disk into your computer’s disk drive. It should AutoStart and the following window should appear:

12

Page 43

Section 4: Installing the ECC

If the following screen appears, click on Run fusion_driver.exe and then the

install screen will appear.

Click on Epilog Control Center Installation. You will need to choose between the

32-bit and 64-bit driver based on your computer’s operating system.

13

Page 44

Section 4: Installing the ECC

14

Page 45

Click on Install.

The next screen will prompt you to allow Windows to install the software. Click

Yes.

Select Repair and then Next

Section 4: Installing the ECC

Click on Finish

15

Page 46

Section 4: Installing the ECC

After installing the ECC connect your computer to the laser using either the USB connection or

the Ethernet connection. The following combinations can be used.

USB only connection – Both the print driver and the ECC operate simultaneously through the

USB connection.

Ethernet only connection – The Print driver can be used with the Ethernet connection, but the

Job Management portion of the ECC does not work with the Ethernet connection. However, the

Control tab and the Configuration tab in the ECC are operational and very useful with the

Ethernet connection.

Combination Ethernet and USB – If you choose, you can connect both the USB and Ethernet

connections. This allows you to print through the Ethernet connection and use the ECC through

the USB connection.

16

Page 47

Section 4: Installing the ECC

To install the ECC use the following instructions:

Insert the Epilog install disk into your computer’s disk drive.

USB Port

A USB cable is included in the accessory kit. The USB port is located at the rear

of the machine. USB cables have different connectors on each end. Turn the laser

Off, then connect this end to the laser and connect the other end into any available

USB port at the back of your computer. After connecting the USB cable, turn the

laser back on.

Ethernet Port

The Ethernet Port is a standard 10BaseT connection. A crossover cable (included in the

accessories kit) is used. The Ethernet port is located at the back of the machine. Your

Epilog laser has all of the versatility of a Network capable peripheral. As such, there are

many different ways that the laser can be connected to a computer or a network. A direct

connection using a crossover cable is the only method that will be described in this

manual. Plug the cable into the Ethernet port on the laser and then plug the other end into

the Ethernet port on the back of your computer.

If you are going to print to the Fusion through the Ethernet connection you will want to set the IP

Address in the Fusion using the Configuration tab of the ECC. This part was described in the

previous section of this manual so you do not need to perform this function again if you have

already completed this step. To set the IP Address in the Fusion make sure your Fusion is

powered on then go to your computer and open the ECC to the Configuration tab.

You can also set the IP Address from the Fusion keyboard. Instructions are provided in the

section “Using the Front Control Panel” later in this manual.

17

Page 48

Section 4: Installing the ECC

Type the IP Address you want to

use along with the Subnet Mask.

The Gateway can remain blank.

Click “ Set” to change the setting

in the Fusion.

With the IP Address setting established you are ready to print to the Fusion from the Dashboard

print driver:

The next step is to set up and print a test job:

18

Page 49

Section 4: Installing the ECC

Use Ctrl P, or go to File | Print to print to the laser.

Choose the Fusion driver, and then click on Preferences:

19

Page 50

Section 4: Installing the ECC

Set your laser parameters for the test job and then press Okay. For this test job the laser

parameters are not overly important. We are just making sure the computer and laser are talking

to each other and that a job can be sent and will start running.

20

Page 51

Section 4: Installing the ECC

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

21

Page 52

Section 5: Installing the

Epilog Dashboard Print Driver

In This Section

Installing the Dashboard Print Driver Using an USB Connection

Installing the Dashboard Print Driver Using an Ethernet Connection

The Epilog Dashboard is the print driver that allows your computer to talk to your

Epilog laser system when either the USB or Ethernet Crossover cables are

connected. The driver is included in the accessories kit on a CD-ROM or on our

web site - www.epiloglaser.com. Install the Dashboard by following the

procedures on the following pages.

There are two ways of installing the Epilog Dashboard.

Most users will want to install the driver with using the USB connection.

1. USB connection.

a) The process for Windows XP or Vista is easy and straightforward.

b) The process for Windows 7 or 8 takes additional steps.

2. Ethernet connection.

The Fusion offers both 32-bit and 64-bit drivers. Windows XP, Vista, Windows 7 and Windows

8 can be used.

22

Page 53

Section 5: Installing the Epilog Dashboard

Print Driver

Installing the Dashboard Driver

Using the USB Connection using XP

or Vista

To install the Dashboard print driver using the USB connections with Windows

XP or Vista, follow these instructions:

1. Connect your laser system to your computer using the USB cable that came

with your machine.

2. Power up your Fusion system.

3. Insert the Epilog driver disk into your computer’s hard drive.

4. Your computer will prompt you to install the driver.

5. Follow the prompts.

Installing the Dashboard Driver

Using the USB Connection using

Windows 7 or 8

The process of installing a USB printer when using Windows 7 or 8 is more

complicated than when using XP or Vista. Windows 7 and 8 will not

automatically walk you through the installation process so it is important to

follow the instructions below.

Please follow these instructions closely! Using a

different process to install the Dashboard driver

using a different process is likely to fail if you

are using Windows 7 or 8.

23

Page 54

Section 5: Installing the Epilog Dashboard

Print Driver

1) Insert the Epilog driver install disk into your computer. One of the following

screens will appear. For the USB installation, you will want to close then. We

do not want the computer to automatically try and install the driver. Manually

installing the driver will be much more successful.

2) Connect the USB cable to your computer and your Fusion.

3) After closing the Window above and connecting the USB cable, power on

your Fusion laser system. It will take about a minute for the Fusion to

initialize. After it initializes it will start the process of installing the driver.

You will see activity on the USB icon in your system tray (lower right corner

of your computer screen).

The activity will show a small window in the lower right corner that indicates

installation was successful. This is only partially true.

After a short wait you will see another small window that indicates the

installation was not successful. This is what we hope to see and will lead us to

the next step in the process.

24

Page 55

Section 5: Installing the Epilog Dashboard

Print Driver

If your computer is connected to the Internet, it will take a few minutes for

your computer to display these windows. Please be patient during this process

and let the computer finish trying to install the drivers. Interrupting the

computer at this point will require us to restart the process.

4) After the failure notification, go to the Windows start button (lower left corner

of your computer screen). Click on Devices and Printers.

5) First, right click on the Fusion icon. Then click on Properties.

25

Page 56

Section 5: Installing the Epilog Dashboard

Print Driver

6) Select the Hardware tab.

7) Select the device EpilogEngraverFusion. Then click on Properties.

26

Page 57

Section 5: Installing the Epilog Dashboard

Print Driver

8) Click on Change Settings.

9) Click on the Driver tab.

27

Page 58

Section 5: Installing the Epilog Dashboard

Print Driver

10) Click on Update Driver

28

Page 59

Section 5: Installing the Epilog Dashboard

Print Driver

11) Click on Browse my Computer for driver software

12) Use the Browse button to direct your computer to your disk drive that contains

the Epilog driver disk that you inserted earlier in this process.

For this document we show the DVD RW drive as the drive where the disk is

located.

29

Page 60

Section 5: Installing the Epilog Dashboard

Print Driver

Once you have the proper disk drive showing click on the Next button.

The progress window will appear.

30

Page 61

Section 5: Installing the Epilog Dashboard

Print Driver

13) You will then be asked if you want to install this driver: Click on Install this

Driver Anyway

14) Your Epilog Fusion Dashboard print driver has been successfully installed on

the USB port.

15) Click on Close in the next window and then Close again.

31

Page 62

Section 5: Installing the Epilog Dashboard

Print Driver

You will then see your Fusion driver in the Devices and Printers page. Click

on the red X in the upper right corner of this page.

16) That’s it! You are ready to print to your Fusion.

32

Page 63

Section 5: Installing the Epilog Dashboard

Print Driver

Installing the Dashboard Driver

Using an Ethernet Connection and a

Crossover Cable

If you using an Ethernet connection to print to the Fusion the first steps will show

how to set up your computer to talk to the Fusion before the driver is installed.

The process includes the following steps:

1. Setting the Ethernet IP Address on the laser,

2. Setting up the computer’s TCP/IP Address, and

3. Dashboard Driver Installation.

Note: The following instructions work only for a direct connection from the

computer to the Epilog laser using a Crossover cable. This procedure does not

work with a hub or a server. For Ethernet connections that require a hub, server,

or multiple machines/computers, please consult with your network administrator.

Hardware Requirements

A 10Base-T or 10/100Base T Ethernet network card installed in your

computer. All brand name computers that have been built in the last

couple of years should have come standard with an Ethernet card installed.

A crossover cable connecting your computer to the laser (included in your

accessories kit).

33

Page 64

Section 5: Installing the Epilog Dashboard

Print Driver

Step 1: Setting the Ethernet IP Address on

the Laser

The easiest way to set the IP Address on the Fusion is to first install the ECC and

make the change from the Configuration tab.

You can set the IP Address from the Fusion keyboard on the front of the machine,

however it is more convenient to use the ECC. See the section on “Using the

Front Control Panel” for keyboard instructions.

Type the IP Address you want to

use – we have used 192.168.3.4.

Type in the Subnet Mask of

255.255.255.000. The Gateway

can remain blank.

Clicking “ Set” will enable these

setting in the Fusion electronics.

34

Page 65

Section 5: Installing the Epilog Dashboard

Print Driver

Step 2: Setting up the Computer’s TCP/IP Address

Once you have set the IP Address on the laser you will need to set the TCP/IP

Address in your computer.

1. From the Start menu at the bottom of your computer monitor screen select

Start | Control Panel | Network Connections.

2. There are additional instructions for different Windows versions in the

Appendix at the back of this manual if your Windows version is different

than the one shown below.

Right mouse click on the

Local Area Connections

icon, then click on

Properties.

3. Highlight the Internet Protocol

(TCP/IP) V4.

4. Then click on Properties.

35

Page 66

Section 5: Installing the Epilog Dashboard

Print Driver

5. The window below will appear. Select Use the following IP address radio

button.

6. Type in the following (leave everything else blank on this page).

IP Address 192 168 3 3

Subnet Mask 255 255 255 0

Default Gateway Leave blank

7. Click the OK button in this window and then click on the Close button in

the next window.

8. Your computer is now set to print through a crossover cable to the Ethernet

port on the laser.

36

This number is not an error -the last digit of the IP address

in this window must be

different than the IP address

set in the Fusion.

Page 67

Section 5: Installing the Epilog Dashboard

Print Driver

Step 3: Installing the Dashboard Driver for an

Ethernet Connection

Insert the Epilog Laser CD into your computer’s disk device. It should Auto-Start

and the following window should appear:

If the following screen appears, click on Run fusion_driver.exe and then the

install screen will appear.

:

Click on Dashboard Driver Install.

37

Page 68

Section 5: Installing the Epilog Dashboard

Print Driver

Click on Add Local Printer:

38

Page 69

Section 5: Installing the Epilog Dashboard

Print Driver

Click on Create New Port and then click on the dropdown menu and select

Standard TCP/IP Port

Enter the IP Address you want to use. Most Epilog users will use 192.168.3.4 that

is what we use in this document. Whatever number you use, it must be the same

number you assigned to the IP Address in the Fusion laser.

After typing in the IP Address, click on Next.

39

Page 70

Section 5: Installing the Epilog Dashboard

Print Driver

Wait while the computer identifies the port.

Select Custom and then Settings, then click on Next

40

Page 71

Section 5: Installing the Epilog Dashboard

Print Driver

Select LPR and type in Laser into the Queue Name. Then, Click on OK.

Set Protocol to

LPR. This is a very

important step.

Your download

time will be greatly

increased if LPR is

not selected.

After clicking OK above you will return to the window below. Click on Next.

41

Page 72

Section 5: Installing the Epilog Dashboard

Print Driver

Click on Have Disk

Click on Browse

Find the disk drive with the Epilog install disk and click on Open

Select the driver folder and then click on Open

42

Page 73

Section 5: Installing the Epilog Dashboard

Print Driver

Click on the EpilogWinALLFusion file and then click on Open

43

Page 74

Section 5: Installing the Epilog Dashboard

Print Driver

Click on OK

Click on Next

You can rename your printer here. We have not changed it for this document. We have not

changed it for this document, but many users like to associate the driver name with the IP

Address they are using. Especially if there is more than one laser connected to a single computer.

Click on Next.

44

Page 75

Section 5: Installing the Epilog Dashboard

Print Driver

Click on Finish and the driver has been installed! You are ready to print.

45

Page 76

Section 5: Installing the Epilog Dashboard

Print Driver

THIS PAGE WAS

INTENTIONALLY LEFT BLANK

46

Page 77

Section 6: Using the Epilog

Dashboard

In This Section

General Tab

Advanced Tab

Color Mapping Tab

Additional Dashboard Features

Changing Dashboard Defaults

The Epilog Dashboard is the print driver that sends your artwork and laser

parameters from the computer to the laser.

The Dashboard is shown below and can be installed from the driver CD that came

in your accessories kit. It can also be downloaded from the Epilog web site –

www.epiloglaser.com. If you are just getting started and are in a hurry to engrave

a job, you can do so by setting just a couple of parameters in the Dashboard

without having a detailed understanding of what different choices are available to

you.

To get started with a simple engraving job, type your name in CorelDraw, press

the Ctrl and P keys to print, select the Dashboard as the Destination to your

printer and go into Properties. Set the following parameters:

47

Page 78

Section 6: Using the Epilog Dashboard

Now that you have printed a simple job, you are ready to gain a better

understanding of the different printing options available from the Dashboard.

Most engraving and cutting jobs can be accomplished by using only the General

tab. Advanced features for more complex jobs can be found under the Advanced

and Color Mapping tabs.

Note! – When using the slider bars, there are several different ways to get the

desired setting. These different methods all follow standard Windows protocol,

so they will work in other Windows software applications too.

You can move the settings in increments of one by using the + and – icons.

You can move the slider in increments of ten by clicking close to, but not on,

the slider. Holding down the Alt key on your computer keyboard while

clicking close to the slider will bring up the dotted box outlining the slider and

will allow a little better control of moving in increments of ten. Clicking

directly on the slider control (the little box in the center) will also bring up the

dashed outline.

48

Page 79

Section 6: Using the Epilog Dashboard

You can move the little slider box by clicking down, holding and then moving

to the desired number before releasing your mouse.

You can type the setting into the number box.

The following sections provide detailed explanations of the different features in

the Print Driver. Most engraving and cutting jobs can be accomplished by using

only the General tab of the Print Driver. Advanced features for more complex

jobs can be found under the Advanced tab.

NOTE: The Fusion driver is used for both CO2 laser and the Fiber laser sources.

There are a few functions in the driver that only apply to one laser type or the

other. Most functions apply to both, but if a function does not apply to the laser

type installed in your machine that function will be “grayed out”. For instance, in

the image below we have selected Laser Type as CO2. Notice that the Freq

function under Raster Setting is Grayed out. This setting is only used with the

Fiber laser so it is not necessary to try and set it with the CO2 laser.

49

Page 80

Section 6: Using the Epilog Dashboard

General Tab

Job Type

One of the first things new users want to know is how the laser system knows

when to engrave and when to cut. The decision is based on several variables:

1) Line weight (or Stroke) as defined in your graphic image from Corel,

Illustrator, etc. The line weight of your object will determine if it will

engrave or cut.

2) The Resolution as set in the DashBoard driver will also have an effect

on which lines will engrave and which will cut.

3) The Job Type as set in the DashBoard driver - Raster, Vector or

Combined.

To make things easy on themselves, most users set their lines for vector

processing as a Hairline (0.003”) and make the lines red. This provides

a very clear indicator that there is a vector line in the artwork.

Raster Mode – This mode will only engrave. Vector lines will not be processed

from this mode.

Vector Mode – This mode will only vector. Raster images will not be processed

from this mode.

Combined Mode – By properly setting up your artwork you can both engrave

and cut from this mode.

50

Page 81

Section 6: Using the Epilog Dashboard

Select the Job Type

here.

Raster

Raster mode is used for marking or engraving materials. Typical uses would be

reproducing clipart, scanned images, photos, text and graphic images. The Raster

Speed and Raster Power boxes will be enabled when you have selected Raster

under Job Type. Set the Speed and Power boxes to the appropriate settings for

the material that you are engraving. For speed and power guidelines, see the

Speed and Power Recommendations section of this manual.

Note – Very thin lines will not raster engrave, and the definition of “thin” varies

depending on the Resolution being used. Most users use a Hairline or 0.003” line

to designate vector lines.

Example: The rectangle below has a line weight of 0.003 inch. It will not raster

engrave at any resolution. If you send just this box to the laser in Raster mode

and try to run the job, the laser will beep once and be finished because the line is

too small to be recognized as an engraving line.

Line weight = 0.003 inch.

51

Page 82

Section 6: Using the Epilog Dashboard

Vector

Vector mode is used for thin line marking as well as cutting applications. The

Vector Speed, Power and Frequency bars will be enabled when you have selected

Vector or Combined under Job Type.

Note - Artwork, such as scanned images, photos, JPEGs, etc. will not vector cut

because they do not contain thin lines of any kind.

Note: When you are cutting in Vector or Combined mode be aware that your best

results are typically produced at slower speeds. The highest speeds are

specifically designed for draft mode or less demanding applications where speed

is much more important than quality.

Note – Very thin lines are used to define Vector cutting and the definition of

“thin” varies depending on the Resolution being used. As a general rule, most

users set their vector line weights to Hairline or 0.003 inch.

Example: The rectangle below has a line weight of 0.003 inch. It will vector at

any resolution.

Line weight = 0.003 inch.

52

Page 83

Section 6: Using the Epilog Dashboard

When using vector mode, it is necessary to design your job to give the intended

result. Objects and text should be unfilled and drawn with the thinnest possible

outline (other than zero), as shown below. A .001 inch (.025 mm) is

recommended.

CORRECT Vector setup INCORRECT Vector setup

Combined

Combined mode is used when you want to incorporate both Raster and Vector

functions in the same job setup. When you are in Combined mode, all Raster

operations will be performed first, with the Vector operations second.

Note on Vectors: If you are in Vector or Combined mode, all thin lines will be

vector cut! This can be disconcerting because even if the lines are not visible in

your artwork they will still cut. Usually, this happens when incorporating a

clipart image that has hidden lines that are not readily apparent. Please refer to

the Quick Start & Easy Setup section of this manual for an illustrated explanation

of how this can affect your work.

In addition to speed, power and frequency, there are two additional parameters for

vector mode:

Slow Cutting:

Slow Cutting reduces all speed settings by ½. For example, a speed setting of 10

without Slow Cutting select will move twice as fast as a setting of 10 with Slow

Cutting selected. In essence, Slow Cutting provides an alternative set of speed

parameters that are ½ the speed as the standard settings. Slow Cutting mode will

most often be used for very slow cutting applications when the standard settings

are too fast. Most users will rarely use Slow Cutting mode, but it adds an

additional mode of operation for unusual or demanding applications.

53

Page 84

Section 6: Using the Epilog Dashboard

Power Comp:

Power Comp (Compensation) adds another dimension to Vector Cutting

settings. Selecting Power Comp is especially useful for vector cutting jobs that

incorporate a large number of curves. Power Comp slows the lens carriage and

automatically reduces the laser power to compensate for the change of speed as

the carriage moves through a curve. This has the effect of producing unparalleled

edge quality when cutting curves. Straight lines are cut more quickly and

efficiently with Power Comp deselected, but many users find that while selecting

Power Comp may sacrifice a little speed for straight line cutting, the better edge

quality in curves is worth it. For most applications, we suggest selecting Power

Comp.

Resolution

Print quality is commonly referred to as Resolution, and is one of the variables

that determine image quality. Resolution is expressed in dots-per-inch (DPI) and

is determined by the number of lines or dots that are engraved for every inch of

movement. Each horizontal line is referred to as a raster line. The higher the

resolution setting, the finer the detail that can be achieved. Keep in mind that

engraving resolution is only one factor in determining image quality. The quality

of the artwork being sent to the laser can have a bigger influence on the look of

the final product than the resolution. If low quality artwork is being used, even

the highest resolution will not improve it. Also keep in mind that image quality is

subjective. 300 DPI may be just fine for some images and some customers, while

600 DPI is the absolute minimum for others.

54

Resolution (Print

Quality) is set in the

Dashboard prior to

sending the job to the

laser.

Higher resolution

produces better image

quality.

Page 85

Section 6: Using the Epilog Dashboard

Speed and Power settings are dependent on resolution setting. For example, there

is greater overlap of each raster line at 600 DPI than there is at 300 DPI. The

additional overlap at 600 DPI has the effect of lasering over more of each line

twice. This means that on material like wood, you will notice a greater depth of

engraving at 600 DPI than you will at 300 DPI if you use the same Speed and

Power settings.

Resolution Settings

Uses for different resolution settings:

75 – 150 DPI

These resolution values are typically used for non-production purposes where you

want to experiment with image location, or if you want to quickly produce a

rough draft.

200 DPI

Some users like 200 DPI for engraving photographs that have been processed

through PhotoGrav or other photo editing software designed for the laser. Other

users prefer 300 DPI for this style of photographs.

300 DPI

This resolution can be good for production work where image quality needs to be

good, but not great. Many users will use 300 DPI on plastic and other materials

that don’t require a lot of power in combination with large block lettering.

Attempting to produce really fine detail with 300 DPI is not recommended.

400 DPI

This resolution value is ideal for many applications. It combines very good image

quality with fast engraving times. Many users like 400 DPI for all of their work.

600 DPI

When really fine detail or overall excellent results are required, most users choose

600 DPI.

1200 DPI

This resolution is used for projects that require the best engraving quality

possible, although it’s seldom used because under normal circumstances most

people cannot visually discern the difference between 1200 and 600 DPI. There

55

Page 86

Section 6: Using the Epilog Dashboard

are however some users that appreciate this high level of quality and are willing to

take twice as long to produce an image at 1200 DPI as it would take them at 600

DPI.

The diagram below shows the concept of raster lines and dots-per-inch (DPI).

The arrows show the change in direction of the carriage between raster lines. The

difference in dot density between 300 DPI and 600 DPI resolution is shown.

600 DPI300 DPI

Helpful Hints

1. There are four times as many dots engraved at 600 DPI than there are at 300

DPI - twice as many horizontally and twice as many vertically.

2. The gap between the dots is very small at 600 DPI. At 300 DPI the lesser

overlap is responsible for the jagged edges that are visible when engraving

at lower resolutions. It’s important to remember that while resolution plays

a part in producing good image quality, the artwork that is sent to be

engraved is just as important. If the artwork that is sent to the laser is poor

quality, trying to engrave it at 600 DPI will not improve it. It’s always best

to start with high resolution images. Poor artwork will probably always

look poor at any resolution, while good artwork will look good at any

resolution.

3. Twice as many dots and twice as many lines at 600 DPI produces a much

deeper burn into materials like wood than you would see engraving the

same thing at 300 DPI. This is important to understand because depth of

burn is closely associated with engraving resolution – the higher the

resolution, the greater the depth of burn for a given speed. The relationship

between resolution, depth of engraving and Speed and Power setting is

something that most people figure out with just a little experience. The

Speed and Power Recommendations section of this manual helps to make

this easy to understand by providing different Speed and Power settings for

300, 400, and 600 DPI engraving for each different material listed.

56

Page 87

Section 6: Using the Epilog Dashboard

The photos below show a CorelDraw clipart image engraved at 300 DPI (top) and

at 600 DPI (bottom). This clipart image is full of different shades of gray and

you can see that the dot spacing is spread out more on the 300 DPI than it is on

the 600 DPI. Just changing the resolution to 600 DPI produces so much dot

overlap that the fill patterns tend to blend together. It’s a matter of personal

preference as to which resolution looks better, but these photos show the dramatic

difference resolution can make, especially when engraving with grayscale images.

300 DPI

600 DPI

57

Page 88

Section 6: Using the Epilog Dashboard

Piece Size

Many users like to create their artwork on a page size in CorelDraw or other

software program that matches the size of the piece that is to be lasered.

Compensating for beveled edges or placing an image in an exact location is easy

when there is a one-for-one relationship between the material and the page size of

the artwork. If this method works for you, set the Piece Size dimensions to match

the page size you have set in your graphics software.

On the other hand, many users do not want to change the Piece Size dimensions

every time they print something new. They prefer to use a standard page size in

Corel that matches the table size (32” x 20” for example) and place their artwork

into the upper left corner of the page prior to printing.

Both methods are effective and it is a matter of personal preference which method

is used.

58

Set the Piece Size in the

driver to match the page size

from your Corel file.

Page 89

Section 6: Using the Epilog Dashboard

Auto Focus

Most users prefer to use the Auto Focus capability when focusing because it is so quick

and easy to use.

To use auto focus first measure the thickness of the material you are using. Click on Auto

Focus and the input the material thickness using decimal units into the Thickness box.

The table will move up or down so that the top of your material is 2” below the bottom of

the focus lens.

If there the Auto Focus box is not selected, Auto focus will be disabled and the

table will not move up or down when the job starts.

When the Vector Grid is installed and you want to use Auto Focus, click both the

Auto Focus box and the Vector Grid box. This tells the laser system that the

vector grid is installed and it will automatically calculate the appropriate focal

distance based on this information. Please note – The material thickness is still

required when using the vector grid. If a thickness is not specified the system will

auto focus to the top of the vector grid, not to the top of your material.

Use a pair of calipers for an accurate measurement of your material thickness and

enter this value in the “Thickness” box in the driver.

WARNING: If you are using Auto Focus and you know there is not enough

clearance between the lens carriage and your material, you will need to lower the

table before you insert your material and start the job. To lower the table, use the

59

Page 90

Section 6: Using the Epilog Dashboard

Note: Please be careful when auto focusing on irregularly shaped items. The

crash bar and air assist tube must clear all edges of the work piece in this

situation also.

Crash bar

60

Page 91

Section 6: Using the Epilog Dashboard

Engrave Direction

This feature applies to Raster engraving only and allows you to engrave your

project either from the top down, or the bottom up. This is very helpful for some

materials like plastic or rubber stamps. In standard top-down engraving there can

be a large amount of engraving debris generated. As the debris moves towards

the exhaust plenum, some of it collects in the area that has just been engraved.

Bottom-Up engraving prevents the debris from collecting in the freshly engraved

spaces.

Top-down engraving starts from the

top and works its way down.

Bottom-Up engraving starts from the

bottom and works its way up.

61

Page 92

Section 6: Using the Epilog Dashboard

Raster Settings

Speed

The Speed setting determines the travel speed of the carriage in Raster mode and