Page 1

B1PF Actuator

3 Port Motorised Valve Actuator

CAUTION! Installation and connection

should only be carried out by a qualied person

and in accordance with wiring regulations.

Do not open the products. There are no serviceable

or adjustable parts inside. The system must be fused

to no more than 3 Amps.

Important: Keep this document

The B1PF range of actuators c/w auxiliary switch are specically

designed for use in domestic applications only.

They are not designed for use in commercial or industrial

applications such as schools, nursing homes or hotels where large

commercial pump sets are tted.

Warranty will be void If a valve is tted in any application other

than domestic.

Please note we have a full range of commercial and industrial valves

to suit every application.

TECHNICAL SPECIFICATION

ACTUATOR MANUFACTURER MODEL SIZE & TYPE MAX. CLOSE OFF PRESSURE

EPH B322P(F) 22mm Compression 1.0 Bar

B1PF

replacement

for

EPH B328P(F) 28mm Compression 0.6 Bar

Honeywell V4073A 22mm Compression 1.0 Bar

Honeywell V4044C 28mm Compression 0.6 Bar

Horstmann 2322 22mm Compression 1.0 Bar

Isolate mains supply before installation commences.

Isolate mains supply before attaching cable to

actuator.

Isolate mains supply before detaching cable from

actuator.

If this equipment is installed or used in a way not

specied by the manufacturer, its safety may be

impaired.

ACTUATOR

Motor supply voltage 230V Impedance protected motor

Rated impulse voltage 2500V Max. ambient temperature 50˚C

Power consumption 5W Protection rating IP20

LEAD SUPPLIED

ACTUATOR OPERATION

MANUAL OVERRIDE

1.2 metre cable. Earth Connection required.

230V Power to open - Spring return to close.

This is not a fail safe, a no fail or a safety product.

This control is designated Type 1. AA. C in accordance with EN60730.

Type of action is multi position. Type of movement is rotary.

Valve may be manually opened for lling or draining the system.

In normal operation, the lever must be in the Auto position

If the mains power is disconnected, the valve will automatically spring

return to the closed position (Port A)

Page 1

Page 2

INSTALLATION & OPERATING INSTRUCTIONS

1. Valve positioning

Install the valve so the actuator head is not below the horizontal level of the pipework. The open vent and

cold feed must not be isolated. The ow must be in the direction of the arrow. (from the centre port to either

Port A or Port B).

2. Fitting the valve body to the pipework

Fit the valve body using the nuts and olives provided. When tightening the compression nuts ensure that

only the valve body is used for grip. Take care not to overtighten.

3. Removal of actuator from the valve body

To remove the actuator head from the valve body ensure that the manual override lever is in the manual

position. Remove the two screws that x the actuator cover to the base. Remove the actuator cover. Remove

the two screws that x the base to the valve body. Remove the base of the actuator.

4. Fitting of actuator to the valve body

Before tting the actuator, please ensure that the maual override lever is in the raised manual position and

the xing screw is loosened. The actuator is mounted by aligning the 4mm at spindle on the valve body to

the identically sized slot on the actuator. Tighten the two xing screws on the base of the actuator. Fit the

actuator cover and tighten the two screws to hold the cover in place.

Once the valve is tted, place the manual override lever in the raised manual position. It is now possible

to ush and drain the system to remove any foreign matter. The system can now be relled and corrosion

inhibitor may be added if required.

5. Wiring Connections

5.1 The 1.2 metre cable can be connectd as follows:

WIRE COLOUR DESCRIPTION

Blue Neutral supply

Orange

Grey Hot Water OFF from cylinder stat or OFF from programmer

White Central Heating ON from room stat or ON from programmer

Yellow / Green Earth connection

Hot Water ON from cylinder stat or ON from programmer

Also connect to boiler and pump live.

CAUTION!

Ensure that no more than a 3A fuse is used to supply all controls.

It is not permissible to use any voltage other than 230V on the auxiliary switch.

Electrical installation must conform with current I.E.E. regulations.

Page 2

Page 3

5.2 For use as a Diverting Valve, see table below:

ELECTRICAL CONNECTION CABLE CONNECTION VALVE POSITION

Not connected Not connected Hot Water “Port B” open.

230V connected to Orange core Hot Water “Port B” open.

230V connected to Grey core Hot Water “Port B” open.

230V connected to White core Mid position “Port A” and “Port B” open.

230V connected to Grey & White cores Central Heating “Port A” open.

6. Commissioning

Once the system has been lled and vented, ensure the manual override lever is in the auto position.

7. For Hot Water only

Switch the Central Heating ‘OFF” at the programmer or set the room thermostat to the minimum. Switch the

Hot Water “ON” at the programmer and set the cylinder thermostat to the maximum. Port “B” should open on

the valve. The boiler should re and the pump should run. The pipe connected to Port “B” should get hot.

8. For Central Heating only

Switch the Hot Water “OFF” at the programmer or set the cylinder thermostat to the minimum. Switch the

Central Heating “ON” at the programmer and set the room thermostat to the maximum. Port “A” should open

on the valve. The boiler should re and the pump should run. The pipe connected to Port “A” should get hot.

9. For Hot Water and Central Heating

Switch both the Hot Water and the Central Heating “ON” at the programmer. Set both the room thermostat

and the cylinder thermostat to the maximum. The valve should go to the mid position with both Port “A” and

Port “B” open. The boiler should re and the pump should run. The pipes connected to Port “A” and Port “B”

should get hot.

Once satised with the valve operation, reset the programmer and the thermostats to normal control

settings.

WARNING!

Under no circumstances should the actuator be insulated or covered by any other material.

Lack of ventilation will cause the actuator to heat up beyond the maximum permissible ambient temperature

of 50˚C.

Page 3

Page 4

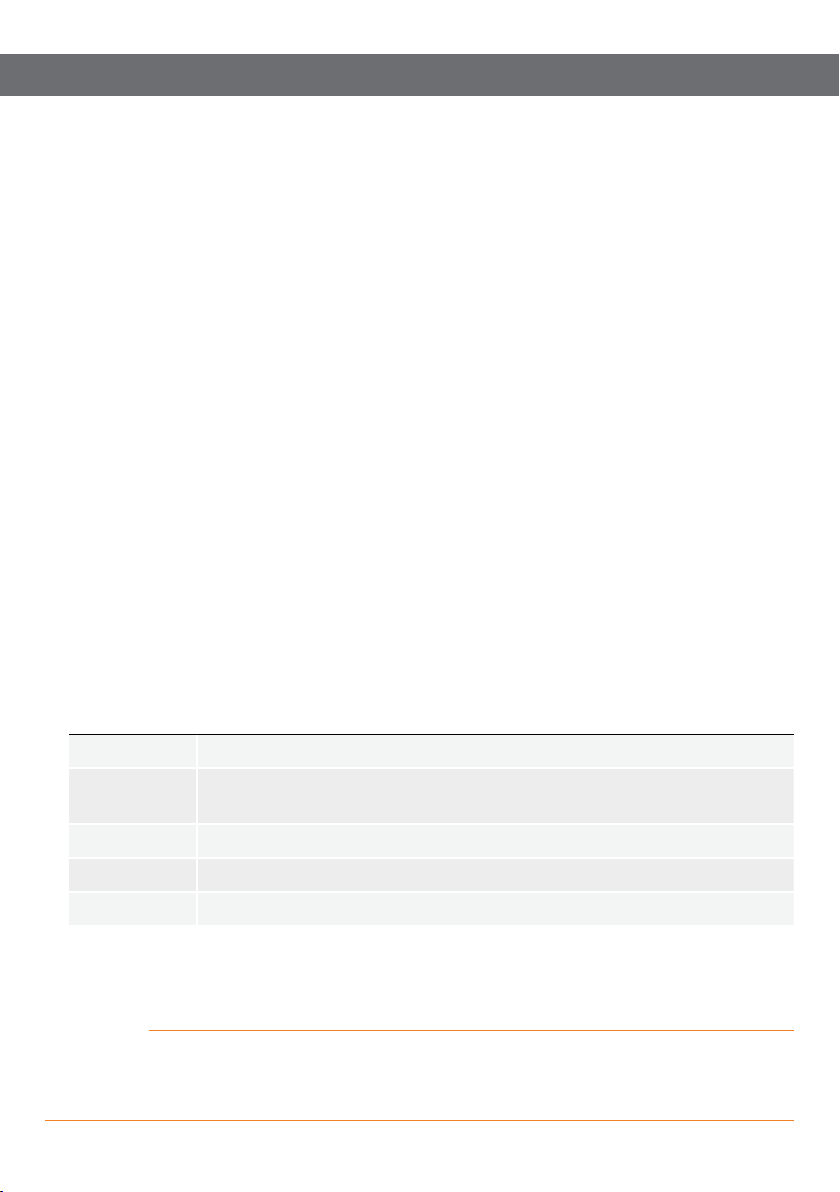

Product Drawing

A

VALVE TYPE A B C

B1PF 70 93 68

B C

WARNING!

Under no circumstances should the actuator be insulated or covered by any other material.

Lack of ventilation will cause the actuator to heat up beyond the maximum permissible ambient temperature of 50˚C.

The crossed out wheelie bin symbol on this product indicates that this product must not be disposed of in your general waste. It can

be taken to your Local Authority Civic Amenity site for free or returned to your retailer for free when you are buying a replacement.

Inappropriate waste handling could lead to negative eects on the environment and human health. With your cooperation you

contribute to the correct disposal, reuse, recycling and recovery of the components of this product and the protection of the

environment.

EPH Controls IE

T 021 434 6238

sales@ephcontrols.com

www.ephcontrols.com

Page 4

EPH Controls UK

T 01933 626 396

sales@ephcontrols.co.uk

www.ephcontrols.co.uk

20170711_AW1077_B1PF_DS_JW

Loading...

Loading...