User Manual

Models:

Tracer1206A /Tracer1210A

Tracer2210A/Tracer3210A/Tracer4210A

Tracer A Series

——MPPT Solar Charge Controller

Important Safety Instructions

Please reserve this manual for future review. This manual contains all

instructions of safety, installation and operation for Maximum Power Point

Tracking (MPPT) controller in Tracer A series ("the controller" is referred in this

manual).

General Safety Information

Read carefully all the instructions and warnings in the manual before

installation.

No user serviceable component inside controller. DO NOT disassemble or

attempt to repair the controller.

Mount the controller indoors. Prevent exposure to the elements and do not

allow water to enter the controller.

Install the controller in well ventilated places, the controller‟s heat sink may

become very hot during operation.

Suggested to install appropriate external fuses/breakers.

Make sure switching off all connections with PV array and the fuse/breakers

close to battery before controller installation and adjustment.

Power connections must remain tight to avoid excessive heating from a loose

connection.

Information générales sur la sécurité

Lisez toutes les instructions et précautions dans le manuel avant l'installation.

Il n‟y a aucune pièce utilisable pour l‟utilisateur à l‟intérieur du contrôleur. Ne

démontez pas ou n'essayez pas de réparer le contrôleur.

Montez le contrôleur en intérieur. Évitez l'exposition des éléments et ne laissez

pas d'eau entrer dans le contrôleur.

Installez le contrôleur Tracer dans un endroit bien ventilé, le dissipateur de

chaleur de l'Tracer peut devenir très chaud pendant l'utilisation.

Installez les fusibles / coupe-circuits comme indiqué.

Déconnectez le module solaire, le chargeur et le fusible / coupe-circuit proche

de la batterie avant l'installation ou le réglage du contrôleur.

Les connexions d'alimentation doivent rester à proximité pour évier une

chaleur excessive du fait d'une connexion trop lâche.

Contents

1 General Information .................................................................... 1

1.1 Overview ........................................................................... 1

1.2 Characteristics ................................................................... 2

1.3 Accessories Instructions .................................................... 3

1.4 Maximum Power Point Tracking Technology ...................... 3

1.5 Battery Charging Stage...................................................... 5

2 Installation Instructions ............................................................... 8

2.1 General Installation Notes .................................................. 8

2.2 PV Array Requirements ..................................................... 8

2.3 Wire Size ......................................................................... 10

2.4 Mounting ......................................................................... 11

3 Operation ................................................................................. 13

3.1 Button Function ............................................................... 13

3.2 LCD Display .................................................................... 13

3.3 Parameters setting .......................................................... 15

4 Protections, Troubleshooting and Maintenance ......................... 19

4.1 Protection ........................................................................ 19

4.2 Troubleshooting ............................................................... 20

4.3 Maintenance .................................................................... 20

5 Technical Specifications ........................................................... 22

Annex I Conversion Efficiency Curves ......................................... 24

Annex II Dimensions .................................................................... 29

1 General Information

1.1 Overview

Appreciate you for choosing MPPT solar charge controller, Tracer A series. Based

on common positive design and advanced MPPT control algorithm, with LCD

displaying running status, this product is artistic, economical and practical.

With MPPT control algorithm, in any situation, products of this series can fast and

accurately track out the best maximum power point (MPP) of photovoltaic array, in

order to obtain the maximum solar energy in time, which remarkably improves

energy efficiency. There is dual display function: local LCD panel and remote

meter. With Modbus communication protocol interface, it is convenient for

customers to expand applications and monitor in various fields like

telecommunication base station, household system, street lighting system,

wilderness monitoring system, etc.

All-round electronic fault self-test function and enhanced electronic protection

function could furthest avoid damages on system components resulting from

installation errors or system failures.

Feature:

Advanced Maximum Power Point Tracking (MPPT) technology, with efficiency

no less than 99.5%.

High quality components, perfecting system performance, with maximum

conversion efficiency of 98%.

Ultra-fast tracking speed and guaranteed tracking efficiency.

Accurately recognizing and tracking of multiple power points.

Reliable automatic limit function of maximum PV input power, ensuring no

overload.

Wide MPP operating voltage range.

12/24VDC automatically identifying system voltage.

LCD panel display design, dynamically displaying tool‟s operating data and

working condition.

Multiple load control modes: manual mode, light ON/OFF, light On+Timer and

test mode.

Support 3 charging preprogram options: Sealed, Gel, Flooded.

Battery temperature compensation function.

Real-time energy statistics function.

With RS-485 communication bus interface and Modbus communication

protocol, it is available to meet various communication requirements in different

situations.

1

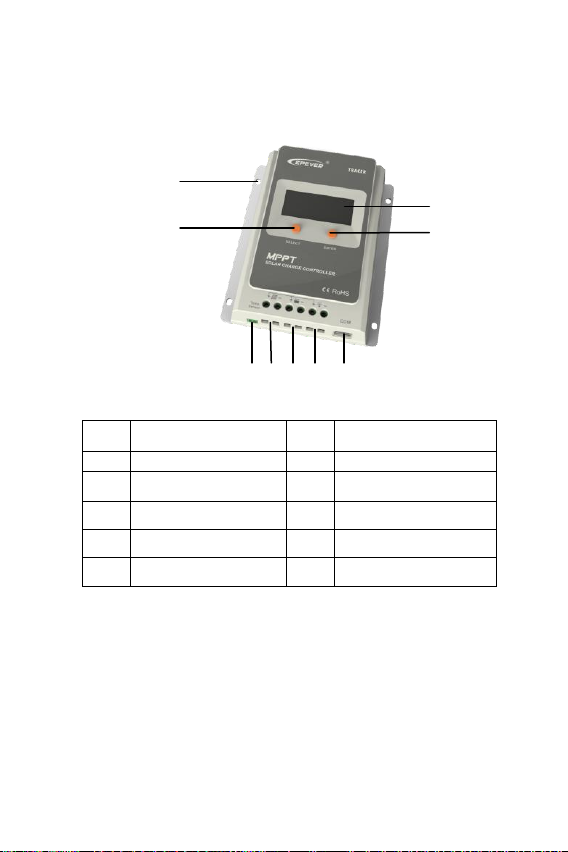

Item

Name

Item

Name

①

Mounting hole sizeΦ5

⑥

Load Terminals

②

Select Button

⑦

RS-485 Port②

③

RTS Port①

⑧

Enter Button

④

PV Terminals

⑨

LCD

⑤

Battery Terminals

Figure 1-1 Tracer-A Series Characteristics

⑨

② ① ⑧ ③ ④ ⑤ ⑥

⑦

Available for PC monitoring and external display unit connecting like MT50 and

so on, realizing real-time data checking and parameters setting.

Support software upgrade.

1.2 Characteristics

Explanations:

① Connection for a RTS (Remote Temperature Sensor) to remotely detect

battery temperature.

② Monitor controller by PC, remote meter MT50 or APP and update controller

software via RS485 (RJ45 interface).

2

Input power (PPV)= Output power (P

Bat

)

Input voltage (V

Mpp

) *input current (IPV) =Battery voltage (V

Bat

) *battery current (I

Bat

)

1.3 Accessories Instructions

1) Remote Temperature Sensor (Model: RTS300R47K3.81A)

Acquisition of battery temperature for undertaking temperature compensation of

control parameters, the standard length of the cable is 3m (length can be

customized). The RTS300R47K3.81A connects to the port (3th) on the controller.

NOTE: Unplug the RTS, the temperature of battery will be set to a fixed value

25ºC.

2) Remote Meter (Model:MT50)

The digital remote meter displays system operating information, error indications,

parameters setting and self-diagnostics.

3) Super Parameter Programmer (Model: SPP-02)

The SPP-02 can realize one-button setting operation which is suitable for bulk

quantity products setting in the projects.

4) USB To RS-485 converter (Model: CC-USB-RS485-150U)

USB To RS-485 converter is used to monitor each controller on the network using

Solar Station PC software. The length of cable is 1.5m. TheCC-USB-RS485-150U

connects to the RS-485 Port on the controller.

1.4 Maximum Power Point Tracking Technology

Due to the nonlinear characteristics of solar array, there is a maximum energy

output point (Max Power Point) on its curve. Traditional controllers, with switch

charging technology and PWM charging technology, can‟t charge the battery at

the maximum power point, so can‟t harvest the maximum energy available from

PV array, but the solar charge controller with Maximum Power Point Tracking

(MPPT) Technology can lock on the point to harvest the maximum energy and

deliver it to the battery.

The MPPT algorithm of our company continuously compares and adjusts the

operating points to attempt to locate the maximum power point of the array. The

tracking process is fully automatic and does not need user adjustment.

As the Figure 1-2, the curve is also the characteristic curve of the array, the

MPPT technology will „boost‟ the battery charge current through tracking the MPP.

Assuming 100% conversion efficiency of the solar system, in that way, the

following formula is established:

Normally, the V

is always higher than V

Mpp

, Due to the principle of conservation

Bat

3

of energy, the I

V

Mpp &VBat,

discrepancy between array and battery, the bigger reduction of the conversion

efficiency of the system, thus the controller‟s conversion efficiency is particularly

important in the PV system.

Figure 1-2 is the maximum power point curve, the shaded area is charging range

of traditional solar charge controller (PWM Charging Mode), it can obviously

diagnose that the MPPT mode can improve the usage of the solar energy

resource. According to our test, the MPPT controller can raise 20%-30%

efficiency compared to the PWM controller. (Value may be fluctuant due to the

influence of the ambient circumstance and energy loss.)

is always higher than IPV. The greater the discrepancy between

Bat

the greater the discrepancy between IPV& I

. The greater the

Bat

Figure 1-2 Maximum Power Point Curve

In actual application, as shading from cloud, tree and snow, the panel maybe

appear Multi-MPP, but in actually there is only one real Maximum Power Point. As

the below Figure 1-3 shows:

Figure 1-3 Mutil-MPP Curve

4

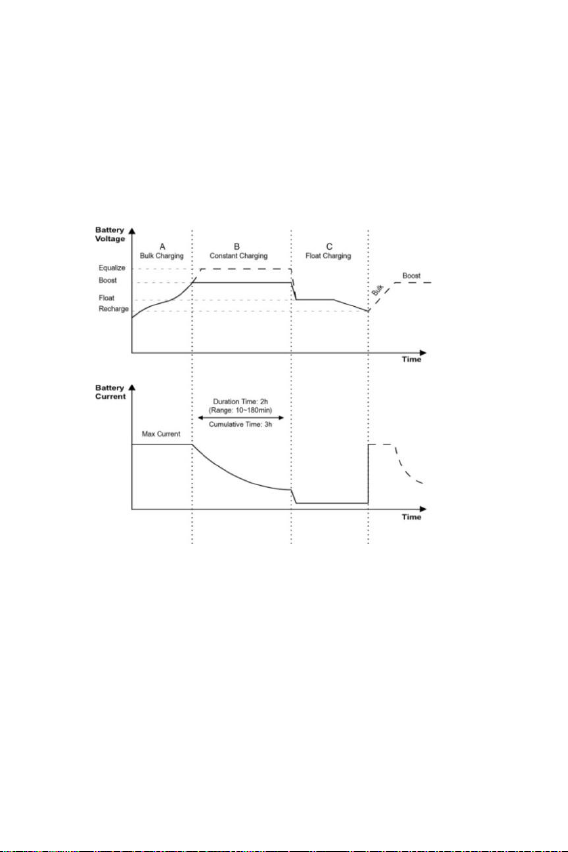

Figure 1-4 Battery changing stage Curve

If the program works improperly after appearing Multi-MPP, the system will not

work on the real max power point, which may waste most solar energy resources

and seriously affect the normal operation of the system. The typical MPPT

algorithm, designed by our company, can track the real MPP quickly and

accurately, improve the utilization rate of the array and avoid the waste of

resources.

1.5 Battery Charging Stage

The controller has a 3 stages battery charging algorithm (Bulk Charging, Constant

Charging and Float Charging) for rapid, efficient, and safe battery charging.

A) Bulk Charging

In this stage, the battery voltage has not yet reached constant voltage (Equalize or

Boost Voltage), the controller operates in constant current mode, delivering its

maximum current to the batteries (MPPT Charging).

B) Constant Charging

When the battery voltage reaches the constant voltage setpoint, the controller will

start to operate in constant charging mode, this process is no longer MPPT

charging, and in the meantime the charging current will drop gradually, the

process is not the MPPT charging. The Constant Charging has 2 stages,

equalize and boost. These two stages are not carried out constantly in a full

charge process to avoid too much gas precipitation or overheating of battery.

5

Boost Charging

The Boost stage maintain 2 hours in default, user can adjust the constant time and

preset value of boost voltage according to demand.

The stage is used to prevent heating and excessive battery gassing.

Equalize Charging

WARNING: Explosive Risk!

Equalizing flooded battery would produce explosive gases, so well

ventilation of battery box is recommended.

CAUTION: Equipment damage!

Equalization may increase battery voltage to the level that

damages sensitive DC loads. Verify that all load allowable input

voltages are 11% greater than the equalizing charging set point

voltage.

CAUTION: Equipment damage!

Over-charging and excessive gas precipitation may damage the

battery plates and activate material shedding on them. Too high

an equalizing charge or for too long may cause damage.

Please carefully review the specific requirements of the battery

used in the system.

AVERTISSEMENT: Risque d‟explosion!

l'égalisation de batteries noyées peut produire des gaz explosifs,

donc il est recommandé de bien ventiler le boitier de la batterie.

ATTENTION: Dégât sur l'équipement!

L'égalisation peut augmenter la tension de la batterie jusqu'à un

niveau nuisible pour les charges CC sensibles. Vérifiez que la

tension d'entrée autorisées de toutes les charges disponibles sont

supérieures à 11% à la tension du point d'installation de

chargement d'égalisation.

ATTENTION: Dégât sur l'équipement!

Un chargement excessif et une précipitation de gaz peut

endommager les plaques de la batterie et la formation de matières

actives dessus. Un chargement trop fort ou une égalisation

prolongée peut causer des dégâts. Inspectez soigneusement les

conditions spécifiques de la batterie utilisée dans le système.

Some types of batteries benefit from equalizing charge on a regular basis, which

is able to stir electrolyte, balance battery voltage and accomplish chemical

reaction. Equalizing charge increases battery voltage, higher than the standard

complement voltage, which gasifies the battery electrolyte.

6

The controller will equalize the battery on 28th each month. The constant

equalization period is 0~180 minutes. If the equalization isn‟t accomplished in

one-time, the equalization recharge time will be accumulated until the set time is

finished. Equalize charge and boost charge are not carried out constantly in a full

charge process to avoid too much gas precipitation or overheating of battery.

NOTE:

1) Due to the influence of ambient circumstance or load working, the battery

voltage can’t be steady in constant voltage, controller will accumulate and

calculate the time of constant voltage working. When the accumulated time

reach to 3 hours, the charging mode will turn to Float Charging.

2) If the controller time is not adjusted, the controller will equalize charge

battery once every month following the inner time.

C) Float Charging

After the Constant voltage stage, the controller will reduce charging current to

Float Voltage setpoint. This stage will have no more chemical reactions and all

the charge current transforms into heat and gas at this time. Then the controller

reduces the voltage to the floating stage, charging with a smaller voltage and

current. It will reduce the temperature of the battery and prevent the gassing and

charging the battery slightly at the same time. The purpose of Float stage is to

offset the power consumption caused by self consumption and small loads in the

whole system, while maintaining full battery storage capacity.

In Float charging stage, loads are able to obtain almost all power from solar panel.

If loads exceed the power, the controller will no longer be able to maintain battery

voltage in Float charging stage. If the battery voltage remains below the Recharge

Voltage, the system will leave Float charging stage and return to Bulk charging

stage.

7

2 Installation Instructions

2.1 General Installation Notes

Before installation, please read through the entire installation instructions to

get familiar with the installation steps.

Be very careful when installing the batteries, especially flooded lead-acid

battery. Please wear eye protection, and have fresh water available to wash

and clean any contact with battery acid.

Keep the battery away from any metal objects, which may cause short circuit of

the battery.

Explosive battery gases may come out from the battery during charging, so

make sure ventilation condition is good.

Gel, Sealed or Flooded batteries are recommended, other kinds please refer to

the battery manufacturer.

Ventilation is highly recommended if mounted in an enclosure. Never install the

controller in a sealed enclosure with flooded batteries! Battery fumes from

vented batteries will corrode and destroy the controller circuits.

Loose power connections and corroded wires may result in high heat that can

melt wire insulation, burn surrounding materials, or even cause fire. Ensure

tight connections and use cable clamps to secure cables and prevent them from

swaying in mobile applications.

Battery connection may be wired to one battery or a bank of batteries. The

following instructions refer to a singular battery, but it is implied that the battery

connection can be made to either one battery or a group of batteries in a battery

bank.

Multiple same models of controllers can be installed in parallel on the same

battery bank to achieve higher charging current. Each controller must have its

own solar module(s).

Select the system cables according to 5A/mm2 or less current density in

accordance with Article 690 of the National Electrical Code, NFPA 70.

2.2 PV Array Requirements

Serial connection (string) of PV modules

As the core component of PV system, controller could be suitable for various

types of PV modules and maximize converting solar energy into electrical energy.

According to the open circuit voltage (Voc) and the maximum power point voltage

(V

) of the MPPT controller, the series number of different types PV modules

Mpp

can be calculated. The below table is for reference only.

8

System

voltage

36cell

Voc<23V

48cell

Voc<31V

54cell

Voc<34V

60cell

Voc<38V

MAX.

Best

MAX.

Best

MAX.

Best

MAX.

Best

12V 2 2 1 1 1 1 1 1

24V 2 2 - - - - - -

System

voltage

72cell Voc<46V

96cell Voc<62V

Thin-Film Module

Voc>80V

MAX.

Best

MAX.

Best

12V 1 1 - - - 24V 1 1 - -

-

System

voltage

36cell

Voc<23V

48cell

Voc<31V

54cell

Voc<34V

60cell

Voc<38V

MAX.

Best

MAX.

Best

MAX.

Best

MAX.

Best

12V 4 2 2 1 2 1 2 1

24V 4 3 2 2 2 2 2 2

System

voltage

72cell

Voc<46V

96cell

Voc<62V

Thin-Film Module

Voc>80V

MAX.

Best

MAX.

Best

12V 2 1 1 1 1 24V 2 1 1 1

1

Tracer1206A:

Tracer1210A/Tracer2210A/Tracer3210A/Tracer4210A:

NOTE: The above parameter values are calculated under standard test

conditions (STC (Standard Test Condition):Irradiance 1000W/m2,Module

Temperature 25℃,Air Mass1.5.)

PV array maximum power

This MPPT controller has a limiting function of charging current, the charging

current will be limited within rated range, therefore, the controller will charge the

battery with the rated charging power even if the input power at the PV exceeds.

The actual operation power of the PV array conforms to the conditions below:

1) PV array actual power ≤ controller rated charge power, the controller charge

battery at actual maximum power point.

2) PV array actual power > controller rated charge power, the controller charge

battery at rated power.

9

Model

Rated Charge

Current

Rated Charge

Power

Max. PV Array

Power

Max. PV open circuit

voltage

Tracer1206A

10A

130W/12V

260W/24V

390W/12V

780W/24V

46V

①

60V

②

Tracer1210A

10A

130W/12V

260W/24V

390W/12V

780W/24V

92V

①

100V②

Tracer2210A

20A

260W/12V

520W/24V

780W/12V

1560W/24V

Tracer3210A

30A

390W/12V

780W/24V

1170W/12V

2340W/24V

Tracer4210A

40A

520W/12V

1040W/24V

1560W/12V

3120W/24V

Model

Max. PV input current

Max. PV wire size(mm2/AWG)

Tracer1206A

Tracer1210A

10A

4/12

Tracer2210A

20A

6/10

Tracer3210A

30A

10/8

Tracer4210A

40A

16/6

If the PV array higher than rated power, the charging time at rated power to

battery will be longer, more energy to battery yields.

When the PV array straight polarity, the actual operation of the PV array must

NOT exceed three times of rated charge power;When the PV array reverse

polarity, the actual operation must NOT exceed 1.5 times. For real application

please refer to the table below:

①At 25℃ environment temperature

②At minimum operating environment temperature

2.3 Wire Size

The wiring and installation methods must conform to all national and local

electrical code requirements.

PV Wire Size

Since PV array output can vary due to the PV module size, connection method or

sunlight angle, the minimum wire size can be calculated by the Isc of PV array.

Please refer to the value of Isc in PV module specification. When the PV modules

connect in series, the Isc is equal to the PV module‟s Isc. When the PV modules

connect in parallel, the Isc is equal to the sum of PV module‟s Isc. The Isc of PV

array must not exceed the maximum PV input current, please refer to the table as

below:

WARNING: Controller will be damaged when the PV array straight

polarity and the actual operation power of the PV array is three times

greater than the rated charge power!

WARNING: Controller will be damaged when the PV array reverse

polarity and the actual operation power of the PV array is 1.5 times

greater than the rated charge power!

10

Model

Rated

charge

current

Rated

discharge

current

Battery wire

size

(mm2/AWG)

Load wire

size

(mm2/AWG)

Tracer1206A

Tracer1210A

10A

10A

4/12

4/12

Tracer2210A

20A

20A

6/10

6/10

Tracer3210A

30A

30A

10/8

10/8

Tracer4210A

40A

40A

16/6

16/6

NOTE: When the PV modules connect in series, the open circuit voltage of the

PV array must not exceed46V(for Tracer1206A) or 92V(for Tracer**10A) (25℃)

Battery and Load Wire Size

The battery and load wire size must conform to the rated current, the reference

size as below:

NOTE: The wire size is only for reference. If there is a long distance between the

PV array and the controller or between the controller and the battery, larger wires

can be used to reduce the voltage drop and improve performance.

2.4 Mounting

CAUTION: The controller requires at least 150mm of clearance

above and below for proper air flow. Ventilation is highly

recommended if mounted in an enclosure.

WARNING: Risk of explosion! Never install the controller in a

sealed enclose with flooded batteries! Do not install in a confined

area where battery gas can accumulate.

WARNING: Risk of electric shock!

Exercise caution when handling solar wiring. The solar PV array

can produce open-circuit voltages in excess of 100V when in

sunlight. Pay more attention to it.

ATTENTION: Le contrôleur Tracer nécessite au moins un espace

libre de 150mm au dessus et en dessous pour une circulation

correcte de l'air. Une ventilation est hautement recommandée en

cas d'installation dans un boitier.

AVERTISSEMENT: Risque d‟explosion ! N'installez jamais le

Tracer dans un boitier fermé avec des batteries noyées! N'installez

pas dans un espace confiné où des gaz de batterie peuvent

s'accumuler.

AVERTISSEMENT: Risque d'électrochoc!

Faites attention lors de la manipulation des connexions solaires.

La matrice PV solaire peut produire des tensions supérieures à

100V, à la lumière du soleil. Soyez particulièrement attentif à cela.

11

Figure 2-1 Mounting

1) Connect components to the charge controller in the sequence as shown above

and pay much attention to the “+” and “-”. Please don‟t turn on the fuse during the

installation. When disconnecting the system, the order will be reserved.

2) After installation, power the controller and check the LCD on. If it‟s not on,

please refer to chapter 4. Always connect the battery first, in order to allow the

controller to recognize the system voltage.

3) The battery fuse should be installed as close to battery as possible. The

suggested distance is within 150mm.

4) The Tracer A series is a positive ground controller. Any positive connection of

solar, load or battery can be earth grounded as required.

CAUTION: Unplug the RTS, the temperature of battery will be set to a

fixed value 25 ºC.

CAUTION: Please connect the inverter to the battery rather than to the

controller, if the inverter is necessary.

12

3 Operation

Button

Function

SELECT button

Browse interface

Setting parameter

ENTER button

Load ON/OFF

Clear error

Enter into Set Mode

Save data

Item

Icon

Status

PV array

Day Night No charging

Charging

PV Voltage, Current, Power

Battery

Battery capacity, In Charging

Battery Voltage, Current, Temperature

Battery Type

Load

Load ON

Load OFF

Load Voltage, Current, Load mode

Figure 3-1 LCD

3.1 Button Function

3.2 LCD Display

Status Description

13

Status

Icon

Description

Battery over

discharged

Battery level shows empty, battery frame

blink, fault icon blink

Battery over

voltage

Battery level shows full, battery frame blink,

fault icon blink

Battery over

temperature

Battery level shows current value, battery

frame blink, fault icon blink

Load failure

Load overload① ,Load short circuit

Fault Indication

①When load current reaches1.02-1.05 times 1.05-1.25 times, 1.25-1.35 times and 1.35-1.5

times more than nominal value, controller will automatically turn off loads in 50s, 30s,10s and 2s

respectively.

Browse interface

NOTE:

1) When no operation, the interface will be automatic cycle, but the follow two

interfaces not be display.

2) Accumulative power zero clearing: Under PV power interface, press

ENTER button and hold on 5s then the value blink, press ENTER button

again to clear the value.

3) Setting temperature unit: Under battery temperature interface, press

ENTER button and hold on 5s to switch.

14

Time 1

Time 2

Light ON/OFF

Disabled

Load will be on for 1 hour

since sunset

Load will be on for 1 hour

before sunrise

Load will be on for 2 hours

since sunset

Load will be on for 2 hours

before sunrise

~

Load will be on for 3~13 hours

since sunset

~

Load will be on for 3~13

hours before sunrise

Load will be on for 14 hours

since sunset

Load will be on for 14

hours before sunrise

Load will be on for 15 hours

since sunset

Load will be on for 15

hours before sunrise

Test mode

Disabled

Manual mode(Default load

ON)

Disabled

Figure 3-2 Setting operation

3.3 Parameters setting

Load mode setting

Set Load modes under below interface.

Operating Steps:

Under load mode setting interface, press ENTER button and hold on 5s till the

number begin flashing, then press SELECT button to set the parameter, press

ENTER button to confirm.

NOTE: Please set Light ON/OFF, Test mode and Manual mode via Timer1.

Timer2 will be disabled and display " ".

Parameters setting

15

Pins

Define

1

Power supply output +5V

2

Power supply output +5V

3

RS-485-B

4

RS-485-B

5

RS-485-A

6

RS-485-A

7

Ground

8

Ground

Four methods to configure the controller:

1) Remote meter, MT50 (Use standard twisted net cable, model:

CC-RS485-RS485-200U-MT).

2) Super parameter programmer, SPP-02(Use standard twisted net cable,

model: CC-RS485-RS485-200U). One-button easily configure and apply to

batch setting.

3) PC monitoring setting software “Solar Station Monitor”(Use USB to RS485

converter cable: CC-USB-RS485-150U).

WARNING: DO NOT communicate with the PC using the Ethernet

cable, otherwise the components of controller will be damaged.

The RJ45 interface pin define is shown below:

WARNING: The RJ45 interface is only allowed to connect with our

company products or operated by qualified engineer. (The RJ45

interface Voltage is 5V and the current is 50mA)

4) Mobile APP (Use USB to RS485 converter cable: CC-USB-RS485-150U and

OTG cable: OTG-12CM)

16

Battery charging setting

Sealed

Gel

Flooded

User

Over Voltage Disconnect

Voltage

16.0V

16.0V

16.0V

9~17V

Charging Limit Voltage

15.0V

15.0V

15.0V

9~17V

Over Voltage Reconnect

Voltage

15.0V

15.0V

15.0V

9~17V

Equalize Charging

Voltage

14.6V

——

14.8V

9~17V

Boost Charging Voltage

14.4V

14.2V

14.6V

9~17V

Float Charging Voltage

13.8V

13.8V

13.8V

9~17V

Boost Reconnect

Charging Voltage

13.2V

13.2V

13.2V

9~17V

Low Voltage Reconnect

Voltage

12.6V

12.6V

12.6V

9~17V

Under Voltage Warning

Reconnect Voltage

12.2V

12.2V

12.2V

9~17V

Under Volt. Warning Volt.

12.0V

12.0V

12.0V

9~17V

Low Volt. Disconnect Volt.

11.1V

11.1V

11.1V

9~17V

Discharging Limit Voltage

10.6V

10.6V

10.6V

9~17V

Equalize Duration (min.)

120

——

120

0~180

Boost Duration (min.)

120

120

120

10~180

3.4 Battery Type

Operating Steps

Under Battery Voltage interface, long press ENTER button enter into the

interface of Battery type setting. After choosing the battery type by pressing

SELECT button, waiting for 5 seconds or pressing ENTER button again to modify

successfully.

Battery Type

①Sealed (Default) ②Gel ③Flooded

④ User(Apply to “MT50” and “PC software “Solar Station Monitor”)

Battery Voltage Parameters (parameters is in 12V system at 25℃, please

use double value in 24V.)

NOTE:

1) When the battery type is sealed, gel, flooded, the adjusting range of equalize

duration is 0 to180min and boost duration is 10 to180min.

17

2) The following rules must be observed when modifying the parameters value in

user battery type (factory default value is the same as sealed type):

a. Over Voltage Disconnect Voltage > Charging Limit Voltage ≥ Equalize

Charging Voltage ≥ Boost Charging Voltage ≥ Float Charging Voltage > Boost

Reconnect Charging Voltage.

b. Over Voltage Disconnect Voltage > Over Voltage Reconnect Voltage

c. Low Voltage Reconnect Voltage > Low Voltage Disconnect Voltage ≥

Discharging Limit Voltage.

d. Under Voltage Warning Reconnect Voltage > Under Voltage Warning Voltage

≥ Discharging Limit Voltage.

e. Boost Reconnect Charging voltage > Low Voltage Disconnect Voltage.

CAUTION: Please refer to user guide or contact with the sales for the

detail of setting operation.

18

4 Protections, Troubleshooting and Maintenance

4.1 Protection

PV Over Current

The controller will limit charge power in rated charge power. An over-sized PV

array will not operate at maximum power point.

PV Short Circuit

When PV short circuit occurs, the controller will stop charging. Clear it to resume

normal operation.

PV Reverse Polarity

Fully protection against PV reverse polarity, no damage to the controller will

result. Correct the miswire to resume normal operation.

WARNING: Controller will be damaged when the PV array reverse

polarity and the actual operation power of the PV array is 1.5 times

greater than the rated charge power!

Battery Reverse Polarity

Fully protection against battery reverse polarity, no damage to the controller will

result. Correct the miswire to resume normal operation.

Battery Over voltage

When battery voltage reach to the voltage set point of Over Voltage Disconnect,

the controller will stop charging the battery to protect the battery overcharge to

break down.

Battery Over discharge

When battery voltage reach to the voltage set point of Low Voltage Disconnect ,

the controller will stop discharging the battery to protect the battery over

discharged to break down.

Battery Overheating

The controller detect the battery temperature through the external temperature

sensor. If the battery temperature exceeds 65ºC, the controller will automatically

start the overheating protection to stop working and recover below 55 ºC.

Load Overload

If the load current exceeds the maximum load current rating 1.05 times, the

controller will disconnect the load. Overloading must be cleared up through

reducing the load and restarting controller.

Load Short Circuit

Fully protected against load wiring short-circuit. Once the load shorts (more than

quadruple rate current), the load short protection will start automatically. After five

automatic load reconnect attempts, the fault must be cleared by restarting

controller.

Damaged Remote Temperature Sensor

If the temperature sensor is short-circuited or damaged, the controller will be

charging or discharging at the default temperature 25℃ to prevent the battery

damaged from overcharging or over discharged.

19

Faults

Possible reasons

Troubleshooting

The LCD is off

during daytime

when sunshine falls

on PV modules

properly

PV array

disconnection

Confirm that PV and battery

wire connections are correct

and tight

Wire connection is

correct, LCD not

display

Battery voltage is

lower than 9V

Please check the voltage of

battery. At least 9V voltage to

activate the controller

Interface

blink

Battery voltage

higher than over

voltage disconnect

voltage(OVD)

Check if the battery voltage is

too high, and disconnect the

solar module

Interface

blink

Battery under

voltage

Load output is normal,

charging LED indicator will

return to green automatically

when fully charged

Interface

blink

Battery low voltage

disconnect

The controller will cut off the

output automatically, LED

indicator will return to green

automatically when fully

charged

Interface

blink

Over load or Short

circuit

Remove or reduce the load

and press the button, the

controller will resume to work

after 3 seconds

Controller Overheating

If the temperature of the controller heat sinks exceeds 85℃, the controller will

automatically start the overheating protection and recover below 75℃.

High Voltage Transients

PV is protected against small high voltage surge. In lightning prone areas,

additional external suppression is recommended.

4.2 Troubleshooting

4.3 Maintenance

The following inspections and maintenance tasks are recommended at least two

times per year for best performance.

Make sure controller firmly installed in a clean and dry ambient.

20

Make sure no block on air-flow around the controller. Clear up any dirt and

fragments on radiator.

Check all the naked wires to make sure insulation is not damaged for serious

solarization, frictional wear, dryness, insects or rats etc. Repair or replace some

wires if necessary.

Tighten all the terminals. Inspect for loose, broken, or burnt wire connections.

Check and confirm that LCD is consistent with required. Pay attention to any

troubleshooting or error indication .Take corrective action if necessary.

Confirm that all the system components are ground connected tightly and

correctly.

Confirm that all the terminals have no corrosion, insulation damaged, high

temperature or burnt/discolored sign, tighten terminal screws to the suggested

torque.

Check for dirt, nesting insects and corrosion. If so, clear up in time.

Check and confirm that lightning arrester is in good condition. Replace a new

one in time to avoid damaging of the controller and even other equipments.

WARNING:Risk of electric shock!

Make sure that all the power is turned off before above operations,

and then follow the corresponding inspections and operations.

21

Item

Tracer

1206A

Tracer

1210A

Tracer

2210A

Tracer

3210A

Tracer

4210A

Nominal system

voltage

12/24VDC Auto

Rated charge

current

10A

10A

20A

30A

40A

Rated discharge

current

10A

10A

20A

30A

40A

Battery input

voltage range

8V~32V

Max. PV open

circuit voltage

60V(Tracer1206A)

100V(Tracer**10A)

at minimum operating environment temperature

46V(Tracer1206A)

92V(Tracer**10A)

at 25℃ environment temperature

MPP Voltage

range

V

BAT

+2V~36V(Tracer1206A)

V

BAT

+2V~72V(Tracer**10A)

Max. PV input

power

130W/12V

260W/24V

130W/12V

260W/24V

260W/12V

520W/24V

390W/12V

780W/24V

520W/12V

1040W/24V

Self-consumption

≤20mA(12V); ≤16mA(24V)

Discharge

circuit voltage

drop

≤0.18V

Temperature

compensate

coefficient

-3mV/ºC/2V(Default)

Communication

RS485(RJ45 interface)

Grounding

Common positive

Environmental

Parameter

LCD temperature range

-20℃~+70℃

Working environment

temperature range*

-25℃~+45℃

Storage temperature range

-35℃~+80℃

Humidity range

≤95% (N.C.)

Enclosure

IP30

5 Technical Specifications

Electrical Parameters

Environmental Parameters

* Please operate controller at permitted ambient temperature. If over permissible

range, please derate capacity in service.

22

Mechanical

Tracer1206A

Tracer1210A

Tracer2210A

Dimension

172mmx139mmx44mm

220mm x154mm x 52mm

Mounting dimension

130mmx130mm

170mmx145mm

Mounting hole size

Φ5

Power Terminals

12AWG(4mm2)

6AWG(16mm2)

Weight

0.6kg

1.1kg

Mechanical

Tracer3210A

Tracer4210A

Dimension

228mmx164mmx55mm

252mmx180mmx63mm

Mounting dimension

170mmx164mm

210mmx171mm

Mounting hole size

Φ5

Power Terminals

6AWG(16mm2)

6AWG(16mm2)

Weight

1.2kg

1.9kg

Mechanical Parameters

Mechanical Parameters

23

84.00%

86.00%

88.00%

90.00%

92.00%

94.00%

96.00%

98.00%

100.00%

20W

50W

100W

130W

Conversion Efficency(η%)

Charging Power (W)

12V Conversion Efficency Curves

17V

34V

84.00%

86.00%

88.00%

90.00%

92.00%

94.00%

96.00%

98.00%

100.00%

20W

50W

100W

150W

200W

250W

300W

Conversion Efficency(η%)

Charging Power (W)

24V Conversion Efficency Curves

34V

Annex I Conversion Efficiency Curves

Illumination Intensity: 1000W/m

Model: Tracer1206A

1. Solar Module MPP Voltage(17V, 34V) / Nominal System Voltage(12V)

2

Temp: 25ºC

2. Solar Module MPP Voltage(34V) / Nominal System Voltage(24V)

84.00%

86.00%

88.00%

90.00%

92.00%

94.00%

96.00%

98.00%

100.00%

20W

50W

100W

130W

Conversion Efficency(η%)

Charging Power (W)

12V Conversion Efficency Curves

17V

34V

68V

84.00%

86.00%

88.00%

90.00%

92.00%

94.00%

96.00%

98.00%

100.00%

20W

50W

100W

150W

200W

250W

300W

Conversion Efficency(η%)

Charging Power (W)

24V Conversion Efficency Curves

34V

68V

Model: Tracer1210A

Solar Module MPP Voltage(17V, 34V, 68V) / Nominal System Voltage(12V)

1. Solar Module MPP Voltage(34V, 68V) / Nominal System Voltage(24V)

85.00%

87.00%

89.00%

91.00%

93.00%

95.00%

97.00%

99.00%

20W

50W

100W

150W

200W

250W

Conversion Efficency(η%)

Charging Power (W)

12V Conversion Efficency Curves

17

34V

68V

85.00%

87.00%

89.00%

91.00%

93.00%

95.00%

97.00%

99.00%

20W

50W

100W

150W

200W

250W

300W

350W

400W

450W

500W

550W

Conversion Efficency(η%)

Charging Power (W)

24V Conversion Efficency Curves

34V

68V

Model: Tracer2210A

Solar Module MPP Voltage(17V, 34V, 68V) / Nominal System Voltage(12V)

1. Solar Module MPP Voltage(33V, 68) / Nominal System Voltage(24V)

90.00%

91.00%

92.00%

93.00%

94.00%

95.00%

96.00%

97.00%

98.00%

99.00%

100.00%

50W

100W

150W

200W

250W

300W

350W

400W

Conversion Efficency(η%)

Charging Power (W)

12V Conversion Efficency Curves

17V

34V

68V

90.00%

91.00%

92.00%

93.00%

94.00%

95.00%

96.00%

97.00%

98.00%

99.00%

100.00%

50W

100W

150W

200W

250W

300W

350W

400W

450W

500W

550W

600W

650W

700W

750W

800W

Conversion Efficency(η%)

Charging Power (W)

24V Conversion Efficency Curves

34V

68V

Model: Tracer3210A

Solar Module MPP Voltage(17V, 34V, 68V)/ Nominal System Voltage(12V)

1. Solar Module MPP Voltage(34V, 68V) / Nominal System Voltage(24V)

87.00%

88.00%

89.00%

90.00%

91.00%

92.00%

93.00%

94.00%

95.00%

96.00%

97.00%

98.00%

50W

100W

150W

200W

250W

300W

350W

400W

450W

500W

550W

Conversion Efficency(η%)

Charging Power (W)

12V Conversion Efficency Curves

17V

34V

68V

87.00%

88.00%

89.00%

90.00%

91.00%

92.00%

93.00%

94.00%

95.00%

96.00%

97.00%

98.00%

99.00%

50W

100W

150W

200W

250W

300W

350W

400W

450W

500W

550W

600W

650W

700W

750W

800W

850W

900W

950W

1000W

Conversion Efficency(η%)

Charging Power (W)

24V Conversion Efficency Curves

34V

68V

Model: Tracer4210A

1. Solar Module MPP Voltage(17V, 34V, 68V) / Nominal System Voltage(12V)

2. Solar Module MPP Voltage(34V, 68V) Nominal System Voltage(24V)

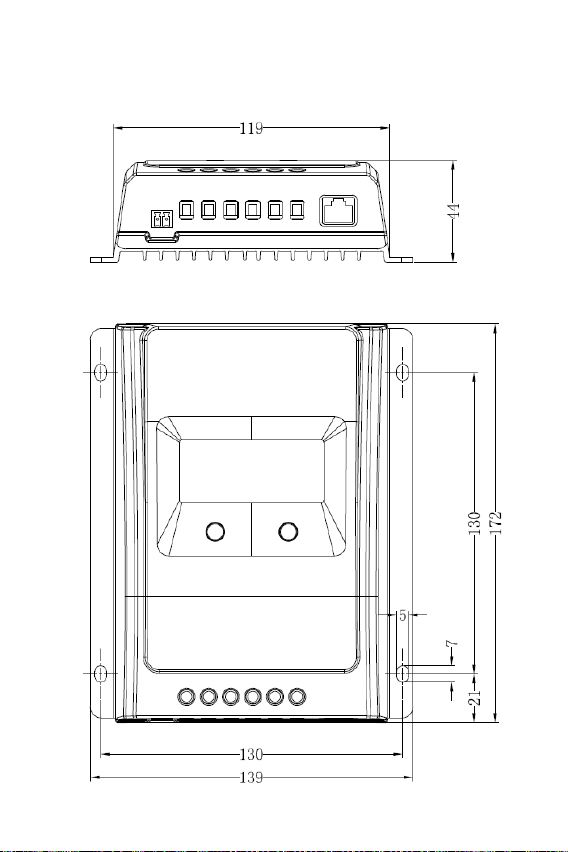

Annex II Dimensions

Tracer1206A/Tracer1210A Dimensions in Millimeters

Tracer2210A Dimensions in Millimeters

Tracer3210A Dimensions in Millimeters

Tracer4210A Dimensions in Millimeters

Final interpretation right of the manual belongs to EPsolar. Any changes

without prior notice!

Version number: V1.4

BEIJING EPSOLAR TECHNOLOGY CO., LTD.

Tel: +86-10-82894112 / 82894962

Fax: +86-10-82894882

E-mail:info@epsolarpv.com

Website: http://www.epsolarpv.com/

http://www.epever.com/

Loading...

Loading...