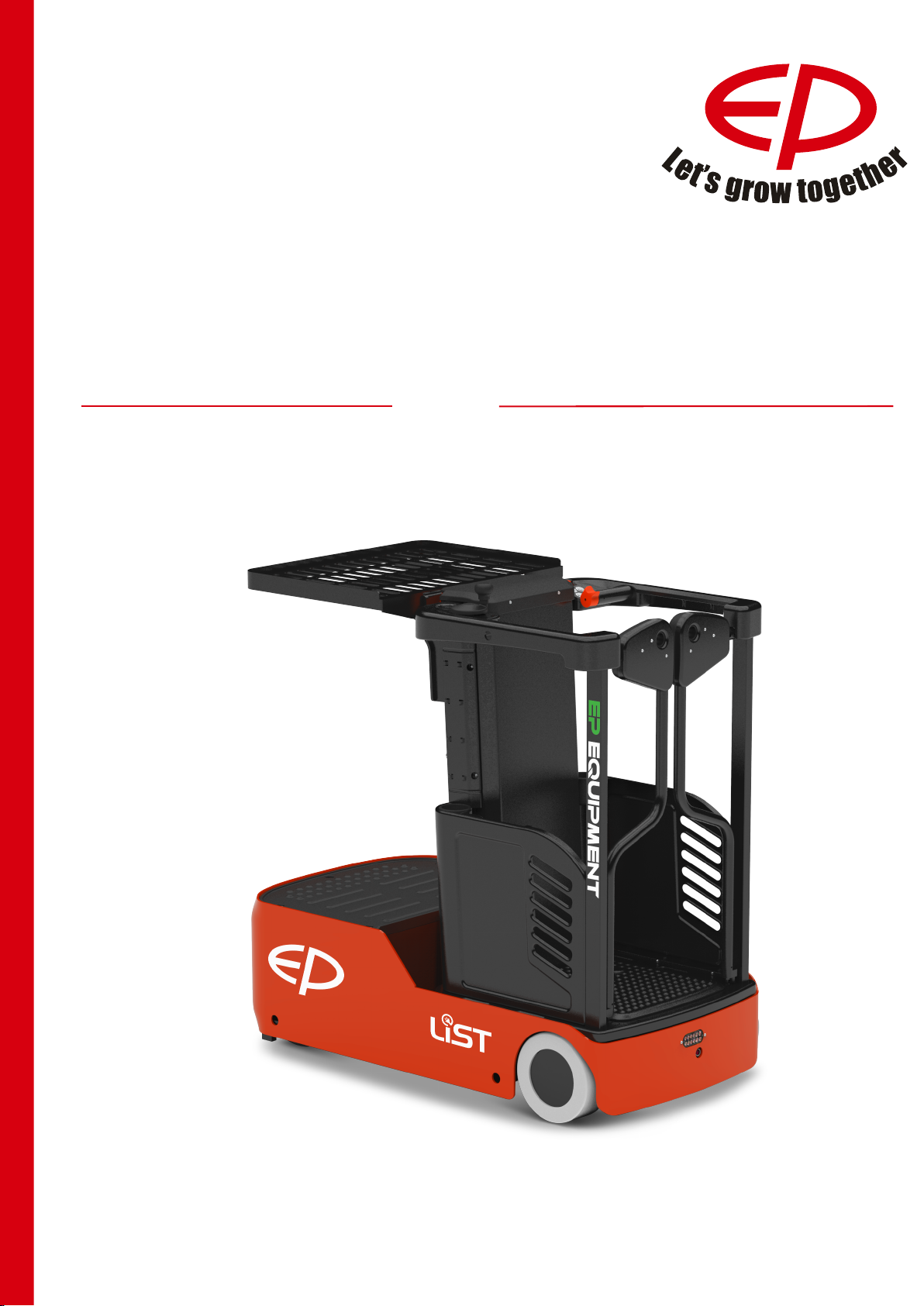

EP Equipment LIST JX0 Operation Manual

Operation Manual

JX0

Part No.1600-504019000002-V1 11/2018Original Instruction

Foreword

The present operation manual are designed to provide sucient instruction for the safe operation

of the industrial truck. The information is provided clearly and concisely.

Our trucks are subject to ongoing development. EP reserves the right to alter the design,

equipment and technical features of the system. No guarantee of particular features of the truck

should therefore be assumed from the present operation manual.

Safety notices and text markups

Safety instructions and important explanations are indicated by the following graphics:

Please strictly adhere to these safety instructions to avoid personal injury or major damage to

equipment.

Please pay attention to the important safety instructions.

Pay attention to Instructions.

i

EP EQUIPMENT CO., LTD

Address: XIAQUAN, DIPU, ANJI, ZHEJIANG, CHINA

Tel: + 86-571-28023920

Website: www.ep-ep.com

Email:

info@ep-care.com

ALL RIGHTS RESERVED

2018.8 1

st

EDITION

Legal requirements for marketing

Declaration

EP EQUIPMENT CO., LTD

Address: XIAQUAN, DIPU, ANJI, ZHEJIANG, CHINA

We declare that the

Industrial truck: according to these operation manual

Type: according to these operation manual

complies with the most recent version of Machinery Directive 2006/42/EC.

Personnel authorised to compile the technical documents:

See EC/EU Declaration of Conformity

EP EQUIPMENT CO., LTD

EC/EU Declaration of Conformity

The manufacturer declares that this industrial truck complies with the EC Machinery Directive

and the provisions of other applicable EC/EU directives eective at the time of sale. This can be

verified by means of the EC/EU Declaration of Conformity and the relevant certification label on the

nameplate.

The industrial truck is supplied with the EC/EU Declaration of Conformity document. This

declaration proves that this truck complies with the requirements of the EC Machinery Directive.

Unauthorized modification or additional installation of equipment to the structure of the industrial

truck may aect its safety, and will therefore invalidate the EC/EU Declaration of Conformity.

The EC/EU Declaration of Conformity must be carefully conserved and kept ready to be presented

to the relevant authorities. If this industrial truck is sold, this declaration document must be handed

over to the new owner.

Table of contents

A Application ............................................................................................................................A1

1.1 Intended use .......................................................................................................................A2

1.2 Improper use .....................................................................................................................A2

B Truck Description ..................................................................................................................B1

1.1 Application ..........................................................................................................................B1

1.2 Functional Description .......................................................................................................B1

1.3 Control elements and displays ...........................................................................................B3

1.3.1 Display .......................................................................................................................... B6

1.4 Standard Version Specifications ....................................................................................... B8

1.4.1Performance data for standard

1.4.2 Dimensions .................................................................................................................... B9

1.5 Identification points ..........................................................................................................B10

1.6 Platform safety ................................................................................................................B13

1.7 Be a safety operator ........................................................................................................B14

1.8 Truck data plate ...............................................................................................................B18

C Safety ...................................................................................................................................C1

1.1 Before Operation ................................................................................................................C1

1.2 Safety regulations for operating mode Drive ......................................................................C1

1.3 Battery Safety .....................................................................................................................C3

1.4 EMC-Electromagnetic compatibility ...................................................................................C3

order pickers

............................................................... B8

Pg.

D Transport and Commissioning .............................................................................................D1

1.1 transport .............................................................................................................................D1

1.2 Hoisting the Truck ...............................................................................................................D2

1.3Operating the order picker without its own drive system .....................................................D3

1.4 Using the Truck for the First Time.......................................................................................D4

1.5 Break-in period precautions................................................................................................D4

E Operation .............................................................................................................................E1

1.1 Safety Regulations for the Operation of order pickers........................................................E1

1.2 Run the order picker ...........................................................................................................E1

1.3 Industrial order picker Operation .......................................................................................E2

1.3.1 Safety regulations for order picker operation...................................................................E2

1.3.2 Travel, Steering, Braking .................................................................................................E3

1.4 Picking up, transporting and Placing loads.........................................................................E6

1.5 Parking the order picker securely .......................................................................................E7

1.6 Lifting - Lowering ................................................................................................................E8

1.6.1 Emergency Lowering .......................................................................................................E8

1.6.2 Procedures ......................................................................................................................E8

1.7 Operator daily checklist ......................................................................................................E9

F Battery Maintenance & Charging .........................................................................................F1

1.1 Safety regulations for handling acid batteries ....................................................................F1

1.2 Battery type & dimension....................................................................................................F1

1.3 Charging the battery ...........................................................................................................F2

1.4 Battery removal and installation .........................................................................................F3

1.5 Battery maintenance...........................................................................................................F5

1.6 Battery Disposal .................................................................................................................F5

1.7 Lithium Battery Use and Maintenance Manual ...................................................................F6

1.7.1Battery type & dimension..................................................................................................F7

1.7.2 Instructions .....................................................................................................................F7

1.7.3 Display Instrument ...........................................................................................................F8

1.7.4 Battery Nameplate ...........................................................................................................F9

1.7.5 Charging ..........................................................................................................................F10

1.7.6 Storage ............................................................................................................................F11

Table of contents

1.7.7 Common Problems and Solutions ...................................................................................F12

1.7.8 Maintenance ....................................................................................................................F13

1.7.9 Disposal of Used Battery Packs ......................................................................................F13

G Pallet Truck Maintenance ....................................................................................................G1

1.1 Operational safety and environmental protection ...............................................................G1

1.2 Maintenance Safety Regulations ........................................................................................G1

1.3 Servicing and inspection.....................................................................................................G2

1.3.1Maintenance Checklist .....................................................................................................G3

1.3.2 Lubrication Points ............................................................................................................G4

1.3.3 Maintenance Instructions.................................................................................................G6

1.4 Decommissioning the industrial truck .................................................................................G8

1.4.1 Prior to decommissioning ................................................................................................G8

1.4.2 Restoring the truck to operation after decommissioning .................................................G8

1.5 Safety checks to be performed at regular intervals and following any unusual incidents G9

1.6 Final decommissioning, disposal ........................................................................................G9

1.7 Tire replacement .................................................................................................................G9

H Troubleshooting .......................................................................................................H1

The truck described in the present operator manual is an industrial truck designed for lifting and

transporting load units.

It must be used, operated and maintained according to the information in these operation manual.

Any other uses are outside the design envelope and can lead to injury to persons or damage

to equipment and property. Above all, overloading caused by excessively heavy or unbalanced

loads must be avoided. The max. admissible load to be picked up is indicated on the nameplate

or load diagram label shown on the truck. The truck must not be operated in spaces subject to fire

or explosion hazards, or in spaces where corrosive or very dusty atmospheres prevail.

A Application

Duties of the user

For the purposes of the present operating instructions, the “operating company is defined as any

natural or legal person who either uses the truck himself, or on whose behalf it is used. In special

cases (e. g. leasing or renting). the operating company is considered to be the person who is

to carry out the specified operational duties in accordance with existing contractual agreements

between the owner and. operator of the industrial truck.

The operating company must ensure that the truck is used only for its intended purpose and that

dangers to the health and safety of the operator and third parties are prevented Further more,

accident prevention regulations, safety regulations and operating, servicing and repair guidelines

must be followed. The operating company must ensure that all operators I have read. and

understood these I operating instructions.

Mounting of attachments

The mounting or installation of any attachments which will interfere with, or supplement, the

functions of the truck is permitted only after written approval by the manufacturer has been

obtained. If necessary, the approval of local authorities has to be obtained. Any approval obtained

from local authorities does not, however, make the approval by the manufacturer unnecessary.

Modification

If you want to use the truck for purposes that are not mentioned in the user manual, please

contact dealers accredited by EP Ltd. Any modifcation of your truck, in particular fitting of

equipment or conversion of the truck, is prohibited without the permission of the manufacturer.

1A

REV. 08/2018

1.1

Intended use

The following operations are in accordance with regulations and are permitted:

•

Order picking of goods.

•

Lifting and lowering by the operator on the operator platform

•

Transporting small items on the storage table without pallet

•

Travel with the platform lifted or lowered.

•

Travel in indoor areas without wind forces.

•

Travel on even ground. Travel on negotiating inclines up to 3 degrees is only allowed it the

platform is fully lowered.

•

Light Maintenance work.

•

Operation in areas open to the public like in a store, if the following regulations are observed:

•

The truck must be driven by trained personal only

•

The operator must instruct the public to allow space in order to avoid potential accidents, if

the situation becomes too confusing for the operator because of the presence of the public.

•

If necessary the operator must ask for a marshaller, who should direct people away from the

hazardous area and warn the operator if anyone is still present in the hazardeous area.

•

The truck gives an audible warning when the travel switch is operated to increase the safety

of third persons. In addition can the driver operate a horn.

To protect persons directly under the platform, this area is protected with a sensor with stops

•

lowering of the platform.

If these safety features are not working the truck must be taken out of service until it has been

•

repaired.

If wind forces occur during an indoors application(e. g. if warehouse gates are opened), operation

should be suspended until the wind forces have subsided.

The maximum load and load distance are indicated on the capacity plate and must not be

exceeded.

1.2

Improper use

The operating company or driver, and not the manufacturer, is liable if the truck is used in a

manner that is not permitted. One of the main causes of accidents is the driver ignoring or being

unaware of the basic safe operating practices of the truck.

The following basic safe operating practices must be observed to ensure the safety of operators

and others.Never operate the truck in environments with s potentially explosive atmosphere. The

owing operations are prohibited:

•Lifting and carrying people, with the exception of the driver on the operator platform.

•Pushing or puling of loads.

•Travel on uneven ground.

•Travel in outdoor areas.

REV. 08/2018

2A

•Do not stack loads or turn when driving on a ramp.

•Do not operate the truck on loose or greasy surfaces.

•Do not drive on uneven or obstructed surfaces. Never park the truck in a place that may obstruct

fire extinguishers, fire escapes or aisles.

•Do not dismount from the truck while it is moving.

•Do not dismount from the truck while the platform is not fully lowered

•Do not leave the truck unattended when the load is raised.

•Do not apply horizontal forces in excess of 200 Newton.

•Never leave the vehicle unattended on a ramp. When driving, do not place any part of your body

outside the confines of the truck, lean on the edge of the truck or attempt to jump onto another

truck or object.

•Do not use open ame to check lever, or for leakage of electrolyte and uids or oil. Do not use

open pans of fuel or ammable cleaning uids for cleaning parts.

WARNING

Operation under extreme conditions

Operating the truck under extreme conditions can result in malfunctions and accidents. Special

equipment and authorization are required if the truck is to be used in extreme conditions,

especially in dust-laden or corrosive environments. Operation in explosive atmospheres is not

permitted.

The truck must be used exclusively in industrial and commercial environments. The truck must be

parked and secured only in indoor areas.

Permissible temperature range +5℃ to +25

Secure parking is only permissible at 5℃ to+25℃.

Maximum air humidity 95% non-condensing.

Do not charge the battery below +5℃.

℃

3A

REV. 08/2018

1.1

Application

The truck is an electric truck.The truck is designed to transport and pick goods on level

ground. Small items can be placed carried on the storage table. The low overall height and

platform height allow it to be driven through doorways. The low net weight means. that it can

travel on lifts.

The rated capacity is indicated on the data plate.

Operation only on paved level ground with sucient load-bearing capacity.

Do not exceed the permissible surface and spot load limits on the travel paths.

Operation only on travel paths that are visible and approved by the operating company.

Do not travel across or at an angle on inclines. Travel with the load facing uphill.

Operation in areas partially open to the public.

1.2

Functional Description

B Truck Description

Safety mechanisms

The order picker geometry with rounded edges ensures safe handling of the truck.

Pressing the Emergency stop switch disconnects all electrical functions in hazardous

situations. Opening the gates will interrupt all driving and lifting / lowering operations

except mechanical emergency lowering of the platform. Before you can drive or lift the

dead man switch must be operated.

If the platform is lifted, the area under the platfom is checked by weight sensitve

switches to prevent any movement if an object or person is detected in that area.

Both hands must be at the control handles for driving and lifting to prevent injury of

hands sticking out. This safety feature can be deactivated by a switch in the control

area, than driving speed is limited to crawl speed.

Drive

The entire drive unit is enclosed in the order picker chassis.

The electronic traction controller ensures the smooth driving operation of the drive

motor and as a result smooth driving, powerful acceleration.

Brake system

The operator can brake gently and wear-free by pulling back the travel control button.

The electromagnetic spring pressure brake acting on the drive motor serves as both

parking and handbrake. Without electric power the springs will engage the brake.

Steering system

The steering controller is monitoring permanently the position of the steering wheel

and the drive wheel. In case of error the truck is stopped immediately. The steering

angle is shown on the display. The maximum steering angle is±90°.

1

B

REV. 08/2018

Controls and Displays

The drive functions are activated via ergonomic thumb movement to ensure fatiguefree operation without stressing the wrists; sens. The display units show all important

driver information such as order picker status reports (e.g. faults), battery capacity

and time etc.

Hydraulic system

All hydraulic operations are controlled by a hydraulic pump.

Electrical system

The electrical system is powered by a 24V battery. Electronic controllers drive the

traction motor (AC), steering and lifting.

REV. 08/2018

2B

1.3

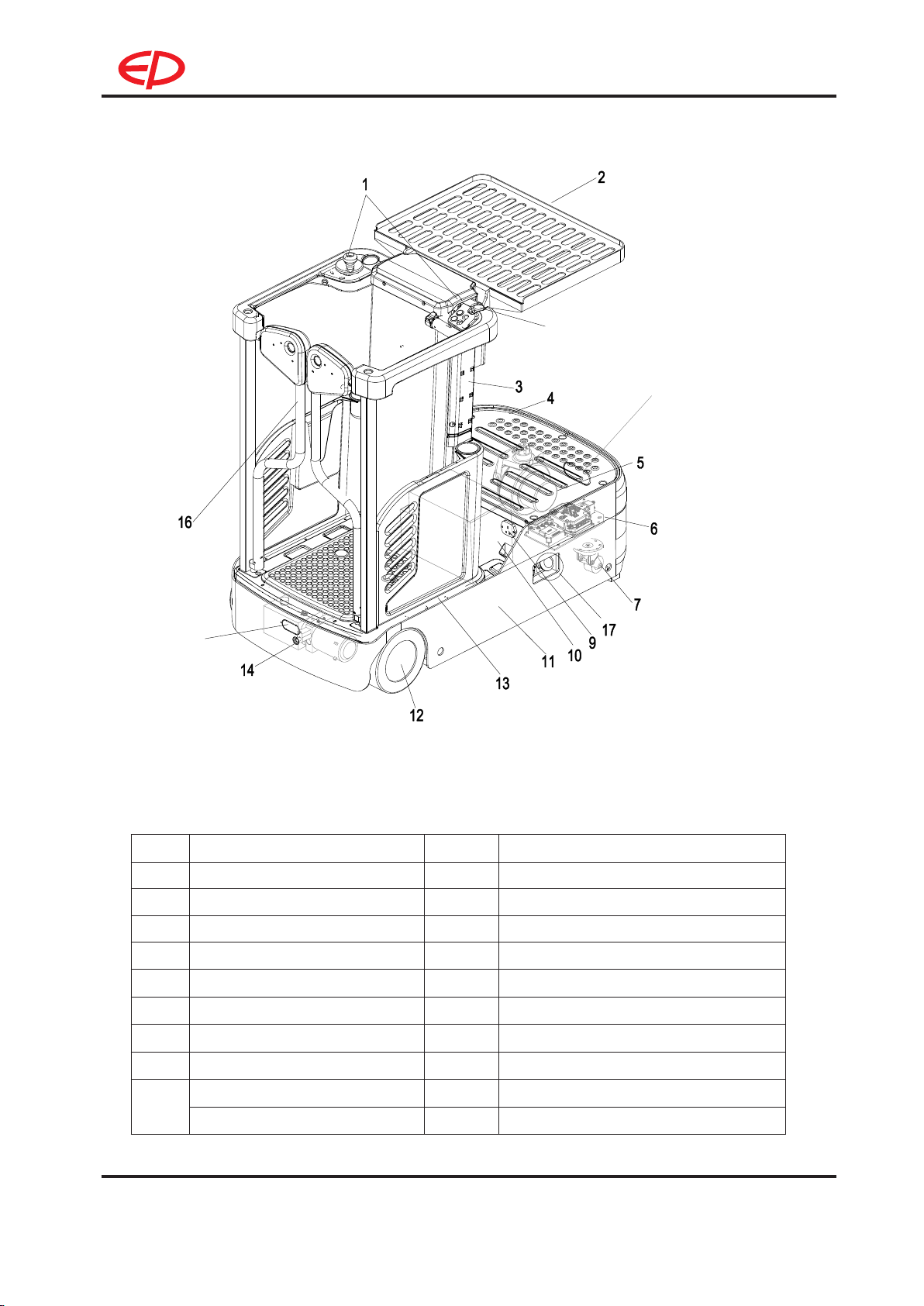

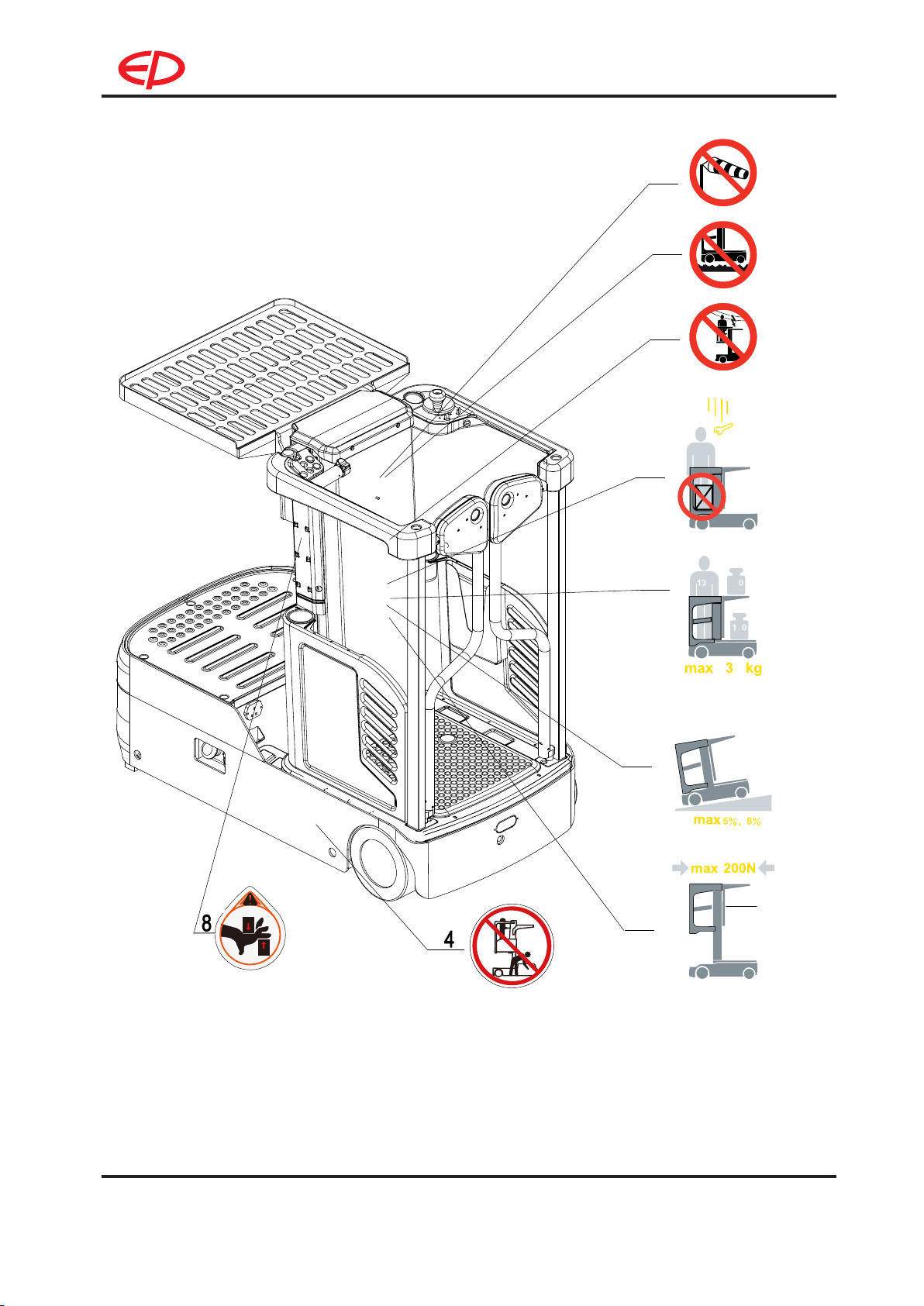

Control elements and displays

8

18

15

1 Control panel 11 Chassis

2 Storage table 12 Load wheels

3 Lift mast 13 Lift platform

4 Additional storage table 14 Hydraulic pump

5 Drive wheel 15 Driving lamp

6 Controller 16 Safety Gates

7 Caster

17 Emergency operation area

8 Emergency stop switch 18 Blue lamp

9 Charger socket

Battery

10

Lithium Battery

(option)

3

B

REV. 08/2018

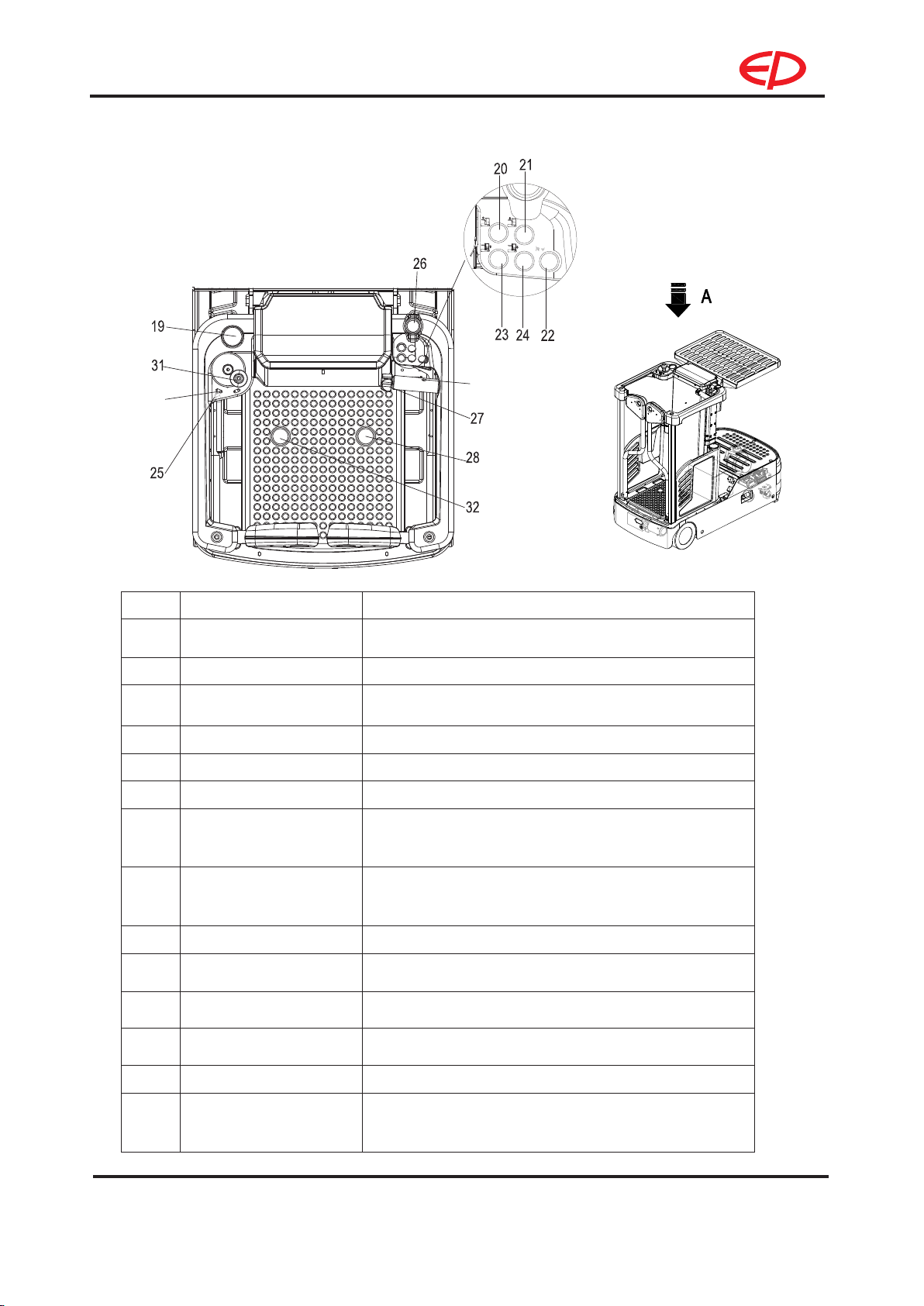

29

30

Item

19 Display unit

Control / Display

Function

Operating information and warning message

display.

20 "Lifting" button Lift the storage table.

21 "Lowering" button Lower the storage table.

22 "Horn" button Activates the horn.

23 "Lifting" button Lift the lift platform.

24 "Lowering" button Lower the lift platform.

Switches control current on and o. Removing the

25 Key switch

key prevents the order picker from being switched

on by unauthorized personnel.

26

27

28

29

30

Emergency stop

switch

Travel switch

Right dead man

switch

Sensor switch of

steering wheel

Sensor switch of

accelerator

31 Steering wheel

32

Left dead man

switch(option)

Disconnects the supply current, deactivates all

electrical functions, causing the order picker to

brake automatically.

Select the required driving direction.

Apply the right drive pedal to start up the order

picker.

The left hand must be placed in the position of the

sensor switch to operate the order picker.

The right hand must be placed in the position of the

sensor switch to drive the

Steers the order picker in the required direction.

order picker to move

If you choose this function, you need to step

down the right drive pedal at the same time to

start the order picker .

.

REV. 08/2018

4B

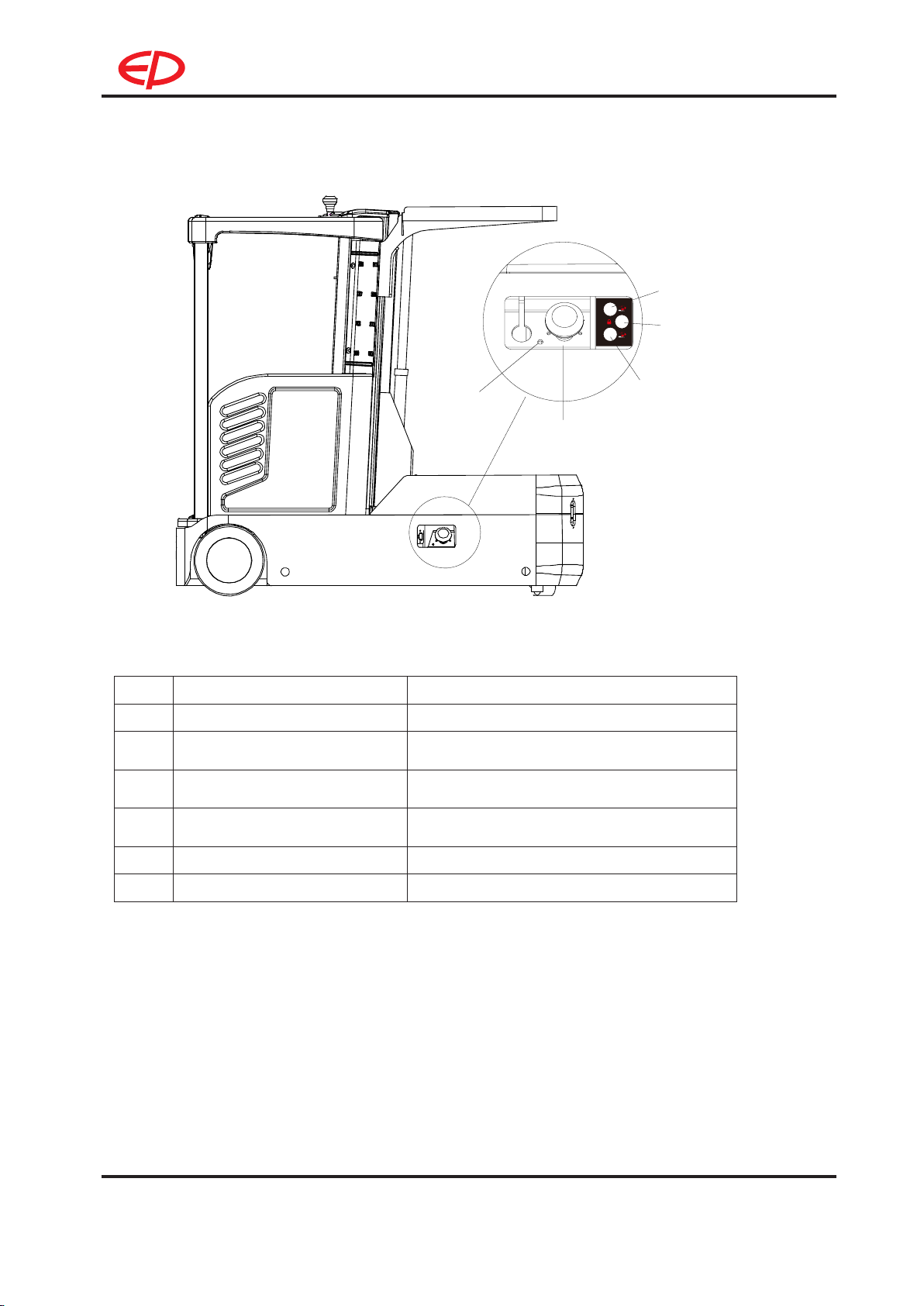

37

36

33

34

35

Item Control / Display Function

33 LED Lamp

34 Emergency stop switch

Disconnects the circuit, all electrical

Display charging status

functions are deactivated.

35 "Lowering" button Lower the lift platform.

36 Low control Cooperate with the lift and lower button

37 "Lifting" button Lift the lift platform.

5

B

REV. 08/2018

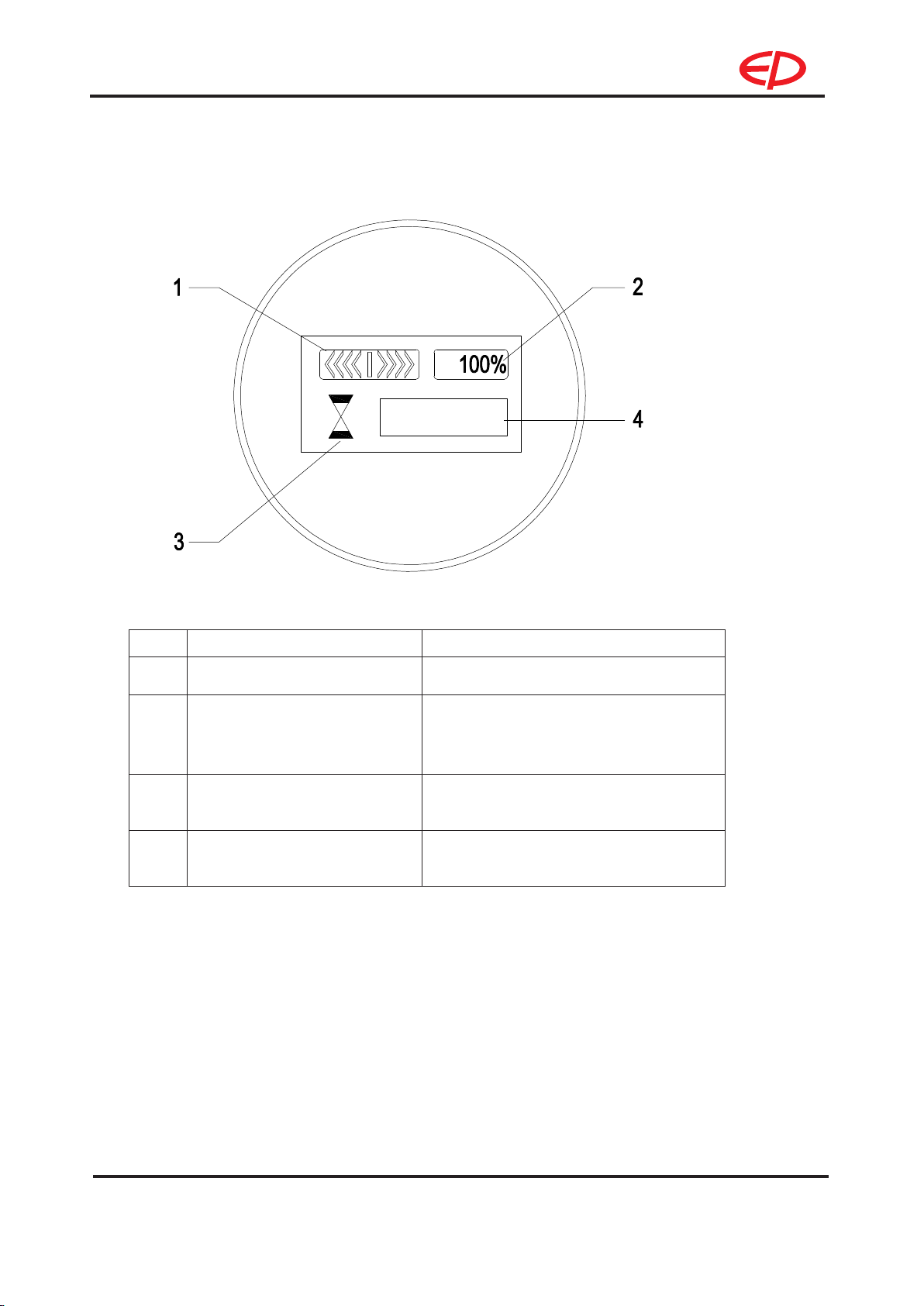

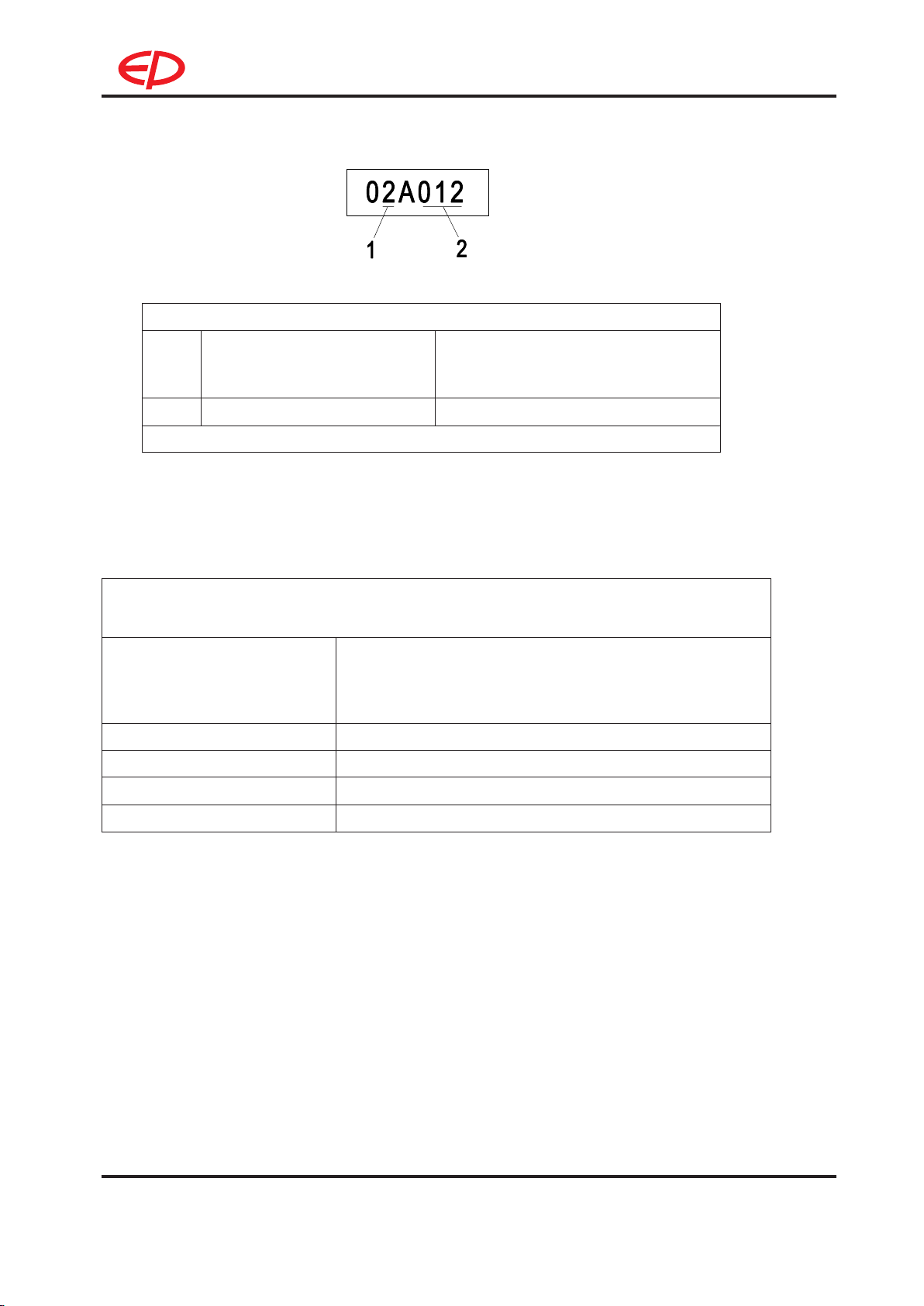

Display for JX01.3.2

Item Component Function

1

Steering signal

The position of the drive wheel is

shown here.

When the electricity is less than10%,

2

Battery discharge indicator

the lamp will illuminate.Must prevent

the battery from over discharging,

please charge.

•Always on, dead man switch opened.

3

4

Working status signal

Information display area

• Flashing, dead man switch closed,

start timing.

• Normally displays the total working

hours.

• If fault, displays the error code.

REV. 08/2018

6B

Error Code

1

2

Controller number

Error code note

2 = Traction controller

6 = Steering controller

Note: Consult the service manual

When the lift platform rises to 2000 mm the vehicle automatically operates with

crawl speed.

Driving speed

Lift platform height ( mm ) Speed

0 - 500

500 - 1000

1000- 2000

6.5

3

2

Unit: Km/h

2000 - MAX.

0.8-1

7

B

REV. 08/2018

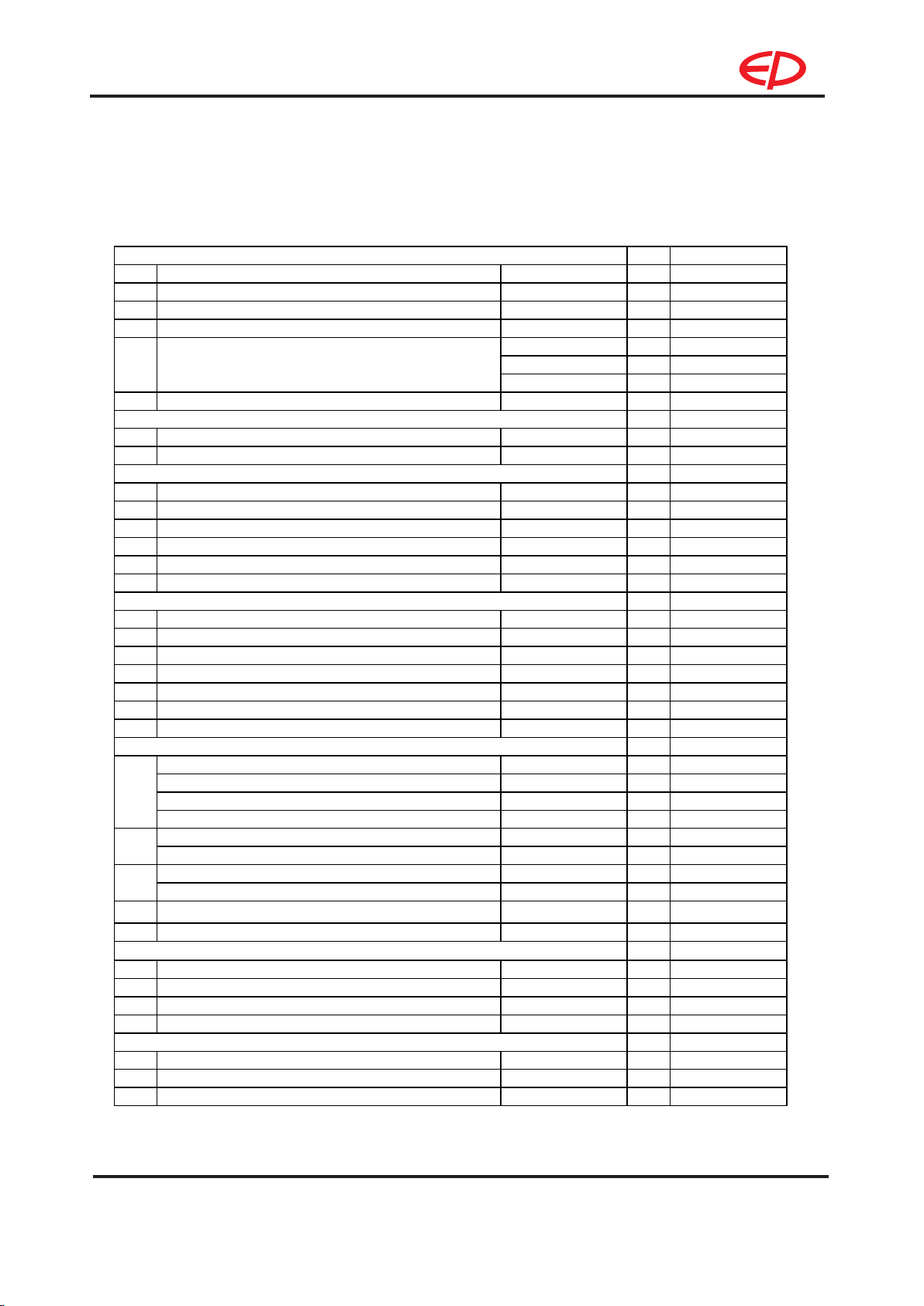

1.4 Standard Version Specifications

Distinguishing mark

b10

b11

h3

h

7

h

12

l1

b1/ b2

m2

Technical specification details in accordance with VDI2198. Technical modifications and additions

reserved.

1.4.1 Performance data for standard order pickers

1.1 Manufacturer EP

1.2 Model designation JX0

1.3 Drive unit E

1.4 Operator type standing

rated capacity

1.5

1.9 Wheelbase y mm 1095

Weight

2.1 Service weight (include battery) kg 800

2.3 Axle loading, unladen driving side/loading side kg 370/430

Types,Chassis

Tyre type, Driving wheels/Loading wheels polyurethane

3.1

3.2 Tyre size, driving wheels(Diameter×Width) mm Ф210×70

3.3 Tyre size, loading wheels(Diameter×Width) mm Ф250×100

3.5 Wheels, number driving,caster/loading (x=drive wheels) mm 1x,2/2

3.6 Track width, front,driving side

3.7 Track width,rear,loading side

Dimensions

4.4 Lift height)

4.8 Seat height/standing height)

4.14 Stand height, elevated

4.19 Overall length

4.21 Overall width

4.32 Ground clearance, center of wheelbase

4.35 Turning radius Wa mm 1260

Performance data

Travel speed, laden/ unladen (H:0-500mm) km/ h 6/6.5

Travel speed, laden/ unladen (H:500-1000mm) km/ h 3

5.1

Travel speed, laden/ unladen (H:1000-2000mm) km/ h 2

Travel speed, laden/ unladen (H:2000-3000mm) km/ h 1

Lifting speed, laden/ unladen(Q3) m/ s 0.213/0.225

5.2

Lifting speed, laden/ unladen(Q1) m/ s 0.023/0.028

Lowering speed, laden/ unladen)(Q3) m/ s 0.230/0.2

5.3

Lowering speed, laden/ unladen)(Q1) m/ s 0.030/0.029

not lifting

5.8 Max. gradeability, laden/unladen % 5\8

5.10 Service brake type Electromagnetic

Electric-engine

6.1 Drive motor rating S2 60 min kW 0.65

6.2 Lift motor rating at S3 15% kW 2.2

6.4 Battery voltage/nominal capacity K5 V/ Ah 12x2/120

6.5 Battery weight kg 30X2

Addition data

8.1 Type of drive unit DC

10.5 Steering type Electronic

10.7 Sound pressure level at the driver’s ear dB

,

Q 1 kg 90

Q 2 kg 110

Q 3 kg 136

mm 545

mm 640

mm 3620

mm 275

mm 3000

mm 1440

mm 750

mm 35

(A) 74

33

REV. 08/2018

8B

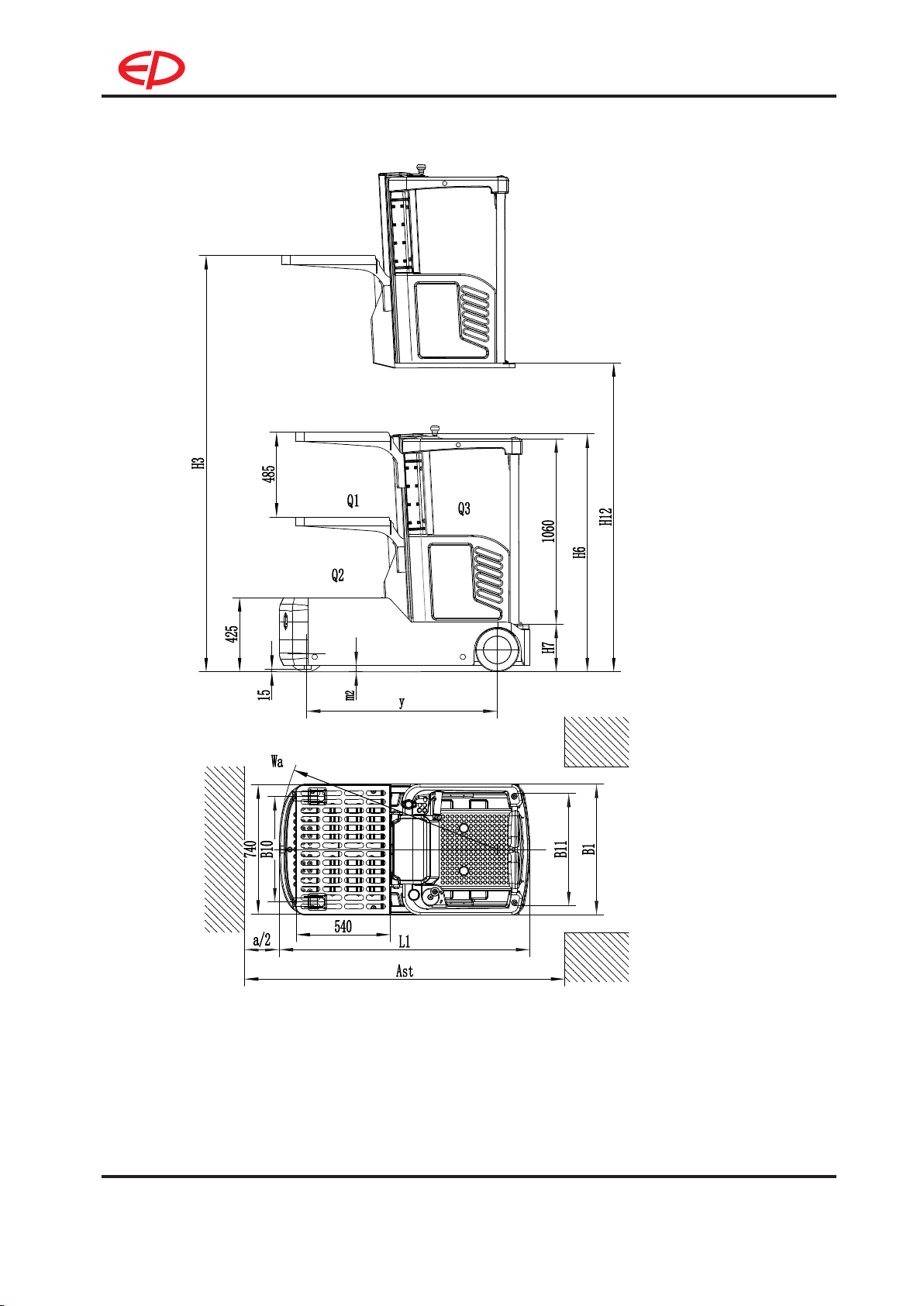

1.4.2 Dimensions

9

B

REV. 08/2018

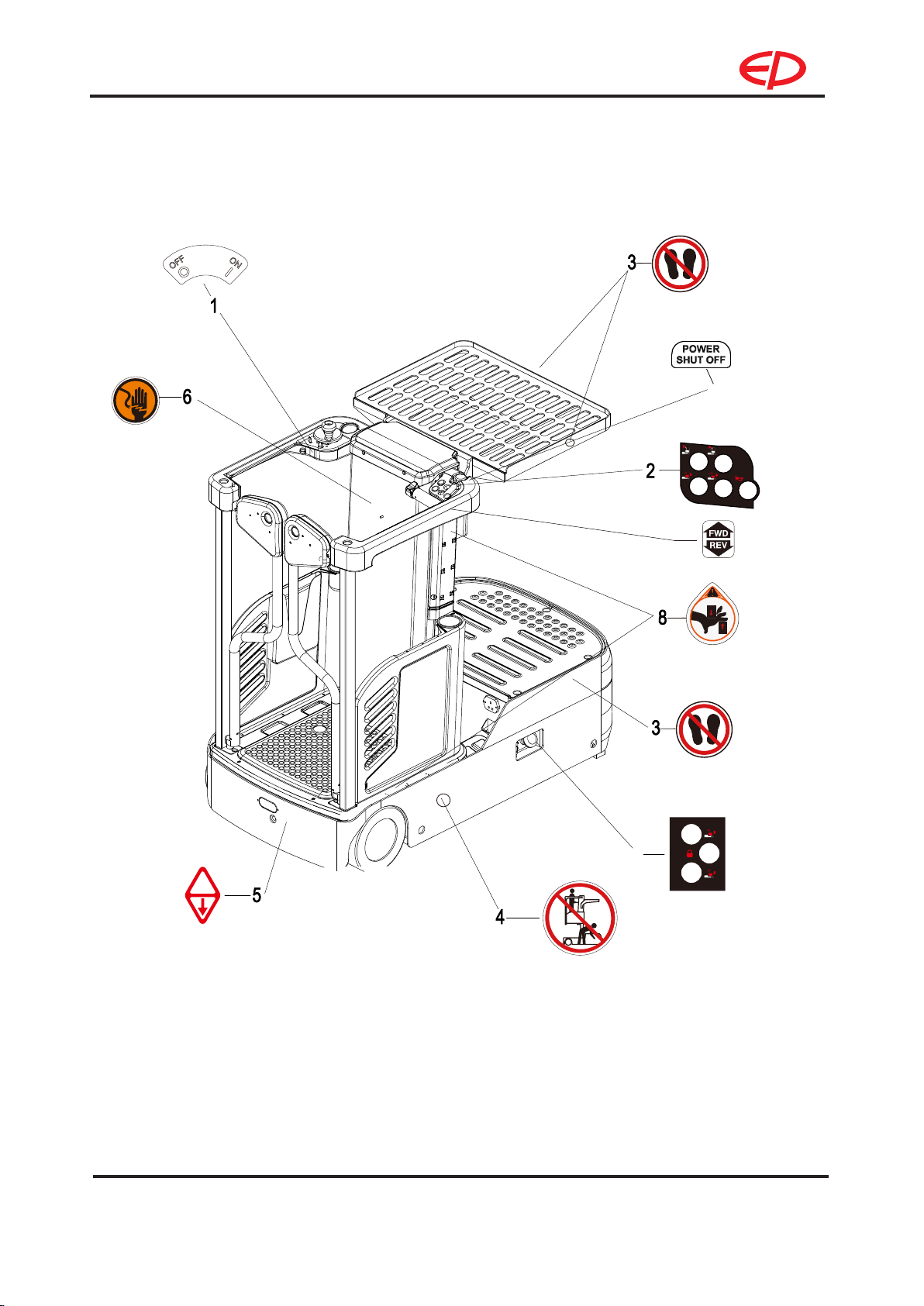

1.5 Data plate and Identification points

9

10

REV. 08/2018

7

!

10B

12

15

13

14

17

11

16

6 9

3

5%,8%

1

6

11

B

REV. 08/2018

Item Description

Key Switch

1

Lifting button, Lowering button, horn button

2

Information sign "Never standing

3

Information sign "Never stand under the platform

4

5

Emergency Lowering

"

"

6 Information sign

7 Emergency operation area

8 Risk of trapping

9 Power shut o

10 Forward travel Reverse

11 Lifting button, Lowering button, horn button

12

No operation permitted in wind

13

No operation permitted on uneven ground.

Maintain clearance to the ceiling.

14

-No operation permit under power lines.

This platform is not insulatied

"

Carrying loose objects :

-No loose objects may be carried on the operator

15

platform.

-Secure objects against falling.

Maximum load :

-Maximum operator weight.

16

-Maximum load on the storage table.

-Maximum load on the addtional storage table.

-Maxmum incline with no lifing and laden is 5

17

-Maxmum incline with no lifing and unladen is 8

18

Maximum manual force

"

%.

% .

19

Danger of crushing by platform

REV. 08/2018

12B

Loading...

Loading...