EP Equipment EPT20-15ET, EPT20-15ETL Service Manual

Service Manual

Electric Pallet Truck

EPT20-15ETL

EPT20-15ET

Service Manual

Electric Pallet Truck

EPT20-15ETL

EPT20-15ET

Release Date Version No. Changes (Serial number)

2016-09-27 SM-1115 09.16 New Version

This manual applies to:

Model Specifi cations

EPT20-15ET 1,500 kg Capacity

EPT20-15ETL 1,500 kg Capacity, Ultra-low Placement

Some sections of the manual only involve certain model, please refer to the manual

according to the actual confi guration of the vehicle.

*

If there are any changes, revised version will be published once every 12 months;

if there is no change, please follow the most recent version.

*

Please refer to the corresponding version of the service manual against the purchase time

of your vehicle.

*

If you need the latest versions of the manual, please contact our service department or

dealer to obtain.

EP Equipment Co., Ltd.

EP Industrial Park, Xiaquan Village,

Dipu Town, Anji County, Zhejiang Province

www.ep-zl.com

Safety signs and instructions:

Please strictly adhere to these safety instructions to avoid personal injury.

Please pay attention to the important safety instructions.

Instructions.

FOREWORD

This Service Manual can help readers learn more about the truck system components,

maintenance and troubleshooting, and other related information. The operation and

maintenance personnel must read this Manual carefully before using the product. And when

vehicle is in use, be sure to follow the complete operation and maintenance information in

this Manual for vehicle maintenance.

Before using, please check if the pages of the Manual are clear and complete, so as not

to affect your normal use because of incomplete information. If the contents of the Manual

have been illegible or damaged, which may affect reading, please contact our company or

dealer for replacement.

With the constant update and improvement of our products, the equipment you are using

may be slightly different from what has been described in this Manual, therefore, we must

reserve the right to modify the appearance, confi guration and technical specifi cations. If you

have any questions, please contact our sales department or dealer.

i

Copyright

Copyright of Service Manual belongs to

EP Equipment Co., Ltd.

REV. SM-1115 09.16

REV. 09/2016

TABLE OF CONTENTS

TABLE OF CONTENTS

1. INFORMATION & SPECIFICATIONS

..............................

1

1.1 After-sales Service Platform .........................................

3

1.2 Introduction ...................................................................

4

1.3 Common Tools ..............................................................

5

1.4 General Tightening Torques .........................................

6

2. MAINTENANCE

...............................................................

9

2.1 Overview.....................................................................

11

2.2 Maintenance ...............................................................

12

2.2.1 Cleaning ........................................................................12

2.2.2 Inspection ......................................................................12

2.2.3 Lubrication ..................................................................... 16

3. STRUCTURE & FUNCTIONS

........................................

19

3.1 Structure & Functions .................................................

21

3.1.1 Travel Switch .................................................................21

3.1.2 Lifting/Lowering Switch ..................................................21

3.1.3 Emergency Reverse Switch ..........................................21

3.1.4 Horn Switch ...................................................................21

3.1.5 Emergency Stop Switch ................................................22

3.1.6 Key Switch .....................................................................22

3.1.7 Charge Gauge ............................................................... 22

3.1.8 LED Charging Indicator .................................................22

3.1.9 Buzzer ..........................................................................23

3.1.10 Fuse.............................................................................23

3.1.11 Controller .....................................................................23

3.1.12 Charger........................................................................23

3.1.13 Lifting Limit Switch .......................................................24

3.1.14 Interlock Switch ...........................................................24

3.1.15 Pump Motor ................................................................. 24

3.1.16 Gear Pump ..................................................................24

3.1.17 Pump Contactor...........................................................25

3.1.18 Solenoid Valve .............................................................25

4. CHASSIS SYSTEM

........................................................

27

4.1 Load Wheel ................................................................

29

4.1.1 Removal and Installation ...............................................29

4.1.2 Faults and Causes.........................................................30

4.2 Cover ..........................................................................

30

4.2.1 Removal and Installation ...............................................30

SECTION

PAGE

1-5

REV. 09/2016

TABLE OF CONTENTS

4.3 Lifting Mechanism.......................................................

31

4.3.1 Fork Inspection .............................................................. 31

4.3.2 Connecting Rod Adjustment ..........................................31

4.3.3 Removal and Installation ...............................................32

5. DRIVE SYSTEM

.............................................................

33

5.1 Drive Assembly ...........................................................

36

5.1.1 Removal and Installation ...............................................36

5.2 Electromagnetic Brakes..............................................

36

5.2.1 Removal and Installation ...............................................37

5.2.2 Faults and Causes.........................................................37

5.2.3 Checking and Testing ....................................................38

5.2.4 Control Circuit Troubleshooting ..................................... 39

5.3 Drive Wheel ................................................................

40

5.3.1 Removal and Installation ...............................................40

5.3.2 Faults and Causes.........................................................40

5.4 Drive Motor .................................................................

41

5.4.1 Removal and Installation ...............................................41

5.4.2 Faults and Causes.........................................................41

5.4.3 Checking and Testing ....................................................42

5.5 Gearbox ......................................................................

43

5.5.1 Removal and Installation ...............................................43

5.5.2 Faults and Causes.........................................................43

6. OPERATING SYSTEM

...................................................

45

6.1 Control Lever ..............................................................

47

6.2 Button Switch..............................................................

47

6.2.1 Removal and Installation ...............................................47

6.2.2 Faults and Causes.........................................................48

6.2.3 Checking and Testing ....................................................48

6.2.4 Control Circuit Troubleshooting ..................................... 49

6.3 Travel Switch ..............................................................

51

6.3.1 Removal and Installation ...............................................51

6.3.2 Faults and Causes.........................................................51

6.3.3 Checking and Testing ....................................................51

6.3.4 Control Circuit Troubleshooting ..................................... 52

7. HYDRAULIC SYSTEM

...................................................

53

7.1 Overview.....................................................................

55

7.1.1 Hydraulic Schematic Diagram ......................................56

2-5

TABLE OF CONTENTS

SECTION

PAGE

REV. 09/2016

TABLE OF CONTENTS

7.2 Pump and Motor Assembly.........................................

57

7.2.1 Removal and Installation ...............................................57

7.2.2 Component .................................................................... 58

7.3 Pump Motor ................................................................

58

7.3.1 Removal and Installation ...............................................58

7.3.2 Faults and Causes.........................................................59

7.3.3 Checking and Testing ....................................................59

7.4 Pump Contactor..........................................................

60

7.4.1 Faults and Causes.........................................................60

7.4.2 Checking and Testing ....................................................61

7.4.3 Control Circuit Troubleshooting ..................................... 61

7.5 Solenoid Valve ...........................................................

62

7.5.1 Faults and Causes.........................................................62

7.5.2 Checking and Testing ....................................................62

7.5.3 Control Circuit Troubleshooting ..................................... 63

7.6 Reach Cylinder ...........................................................

64

7.6.1 Cylinder Removal Precautions ......................................64

7.6.2 Cylinder Installation Precautions ...................................65

7.6.3 Removal and Installation ...............................................66

7.7 Hydraulic Troubleshooting ..........................................

68

7.8 Hydraulic Symbol........................................................

69

8. ELECTRICAL SYSTEM

.................................................

71

8.1 Controller ....................................................................

73

8.1.1 Removal and Installation ...............................................73

8.1.2 Controller Interface Function .........................................73

8.2 Fuse............................................................................

75

8.2.1 Location of Fuses ..........................................................75

8.2.2 Checking and Testing ....................................................76

8.3 Key Switch ..................................................................

77

8.3.1 Removal and Installation ...............................................77

8.3.2 Faults and Causes.........................................................77

8.3.3 Checking and Testing ....................................................77

8.3.4 Control Circuit Troubleshooting ..................................... 77

8.4 Charge Gauge ............................................................

78

8.4.1 Removal and Installation ...............................................78

8.4.2 Faults and Causes.........................................................78

8.4.3 Checking and Testing ....................................................78

8.4.4 Control Circuit Troubleshooting ..................................... 78

8.5 LED Charging Indicator ..............................................

79

8.5.1 Removal and Installation ...............................................79

3-5

TABLE OF CONTENTS

SECTION

PAGE

REV. 09/2016

TABLE OF CONTENTS

8.5.2 Faults and Causes.........................................................79

8.5.3 Checking and Testing ....................................................79

8.5.4 Control Circuit Troubleshooting ..................................... 79

8.6 Lifting Limit Switch ......................................................

80

8.6.1 Removal and Installation ...............................................80

8.6.2 Faults and Causes.........................................................80

8.6.3 Checking and Testing ....................................................80

8.6.4 Control Circuit Troubleshooting ..................................... 80

8.7 Interlock Switch ..........................................................

81

8.7.1 Removal and Installation ...............................................81

8.7.2 Faults and Causes.........................................................81

8.7.3 Checking and Testing ....................................................81

8.7.4 Control Circuit Troubleshooting ..................................... 81

8.8 Speed Mode Switch (Optional) ...................................

82

8.8.1 Removal and Installation ...............................................82

8.8.2 Connection Mode ..........................................................82

8.8.3 Faults and Causes.........................................................82

8.8.4 Checking and Testing ....................................................82

8.8.5 Control Circuit Troubleshooting ..................................... 83

8.9 Handheld Unit (Optional) ............................................

84

8.9.1 Handheld Unit Connection.............................................84

8.9.2 Handheld Unit Main Menu .............................................84

8.9.3 Parameter Settings ........................................................85

8.9.4 TESTER Menu ..............................................................87

8.10 Controller Error Message .........................................

88

8.10.1 Traction Controller ....................................................... 88

8.11 Electrical Schematic Diagrams .................................

91

8.12 Cable Wiring Diagrams.............................................

94

8.13 Wiring Harness and Connectors...............................

95

9. TROUBLESHOOTING

...................................................

97

9.1 Preparation Before Troubleshooting ...........................

99

9.1.1 Check the Voltage of Battery .........................................99

9.2 Troubleshooting Solutions of Common Faults ..........

100

APPENDIX

................................................................

103

B SERVICE MANUAL - BATTERY

.................................

105

B1 Lead-acid Battery

......................................................

107

B1-1 Safety and Warnings ..............................................

107

4-5

TABLE OF CONTENTS

SECTION

PAGE

REV. 09/2016

TABLE OF CONTENTS

B1-2 Use of Battery ........................................................

107

B1-2.1 Pre-use Checks ........................................................107

B1-2.2 Discharging ............................................................... 107

B1-2.3 Charging ...................................................................108

B1-2.4 Temperature ..............................................................108

B1-3 Maintenance & Care .............................................

108

B1-3.1 Daily Maintenance ....................................................108

B1-3.2 Weekly Maintenance .................................................108

B1-3.3 Monthly Maintenance ................................................109

B1-3.4 Care ..........................................................................109

B1-4 Storage ..................................................................

110

B1-5 Troubleshooting .....................................................

110

B2 Maintenance-free Battery

.........................................

113

B2-1 Safety and Warnings ..............................................

113

B2-2 Use of Battery ........................................................

113

B2-2.1 Pre-use Checks ........................................................113

B2-2.2 Discharging ............................................................... 113

B2-2.3 Charging ...................................................................114

B2-3 Maintenance & Care ..............................................

114

C SCHEDULE

.................................................................

115

5-5

TABLE OF CONTENTS

SECTION

PAGE

REV. 09/2016

TABLE OF CONTENTS

SAFETY WARNING

For your own safety and that of others, please observe the following safety instructions:

Thorough and normative maintenance is one of the most important prerequisites to ensure

stable and reliable operation of truck. Neglecting regular maintenance could easily lead

to the truck malfunction and failure, and potential threats to staff and operational safety.

Therefore, there must be adequate maintenance equipment, professional maintenance

personnel and a comprehensive maintenance plan in place.

Please perform the maintenance and inspections according to the following provisions:

To strictly enforce the truck maintenance, lubrication and inspection plans.

Truck maintenance, lubrication and inspection personnel must be approved by accredited

certifi cation or evaluation agency.

The following operations shall be performed before you leave the truck:

- No parking on slopes.

- Fully lower the forks.

- Cut off the power supply.

- Turn the switch lock to “STOP” and remove the key.

Prior to truck maintenance:

- Raise the drive wheel off the ground, or cut off the power supply connection.

- Use wooden wedges or other effective fi xtures.

- When performing maintenance underneath the vehicle, make sure that the lifting device

or jack leg is secure.

- Park your vehicle in a safe and secure area.

Never use an open fl ame to check level of electrolyte, other oils or fl uids for leaks.

Keep the parking lot clean, well-ventilated and dry.

Regular checks and maintenance should be conducted to braking, steering, control, warning

and safety devices to keep them in good condition.

All nameplates and safety signs on the truck should be cleaned regularly to make them

clearly visible.

Regular checks and maintenance should be conducted to all the devices of lifting system to

ensure them to be safe for use.

The hydraulic system should be checked regularly based on usage. Hydraulic cylinders,

hydraulic valves and other hydraulic components should be ensured to be without leakage.

Regular checks and maintenance should be conducted to batteries, motors, controllers,

limit switches, protective devices, wires and connectors, and so on. Please pay particular

attention to the electrical insulation.

Park the truck in a clean environment to minimize the risk of fi re.

Without the permission of the manufacturer, users are not allowed to change or increase

the capacity of the truck. After having been changed under permission, the nameplates and

safety signs on the truck should also be changed accordingly.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

1

1

1. INFORMATION & SPECIFICATIONS

2

NOTE:

3

REV. 09/2016

INFORMATION & SPECIFICATIONS

1

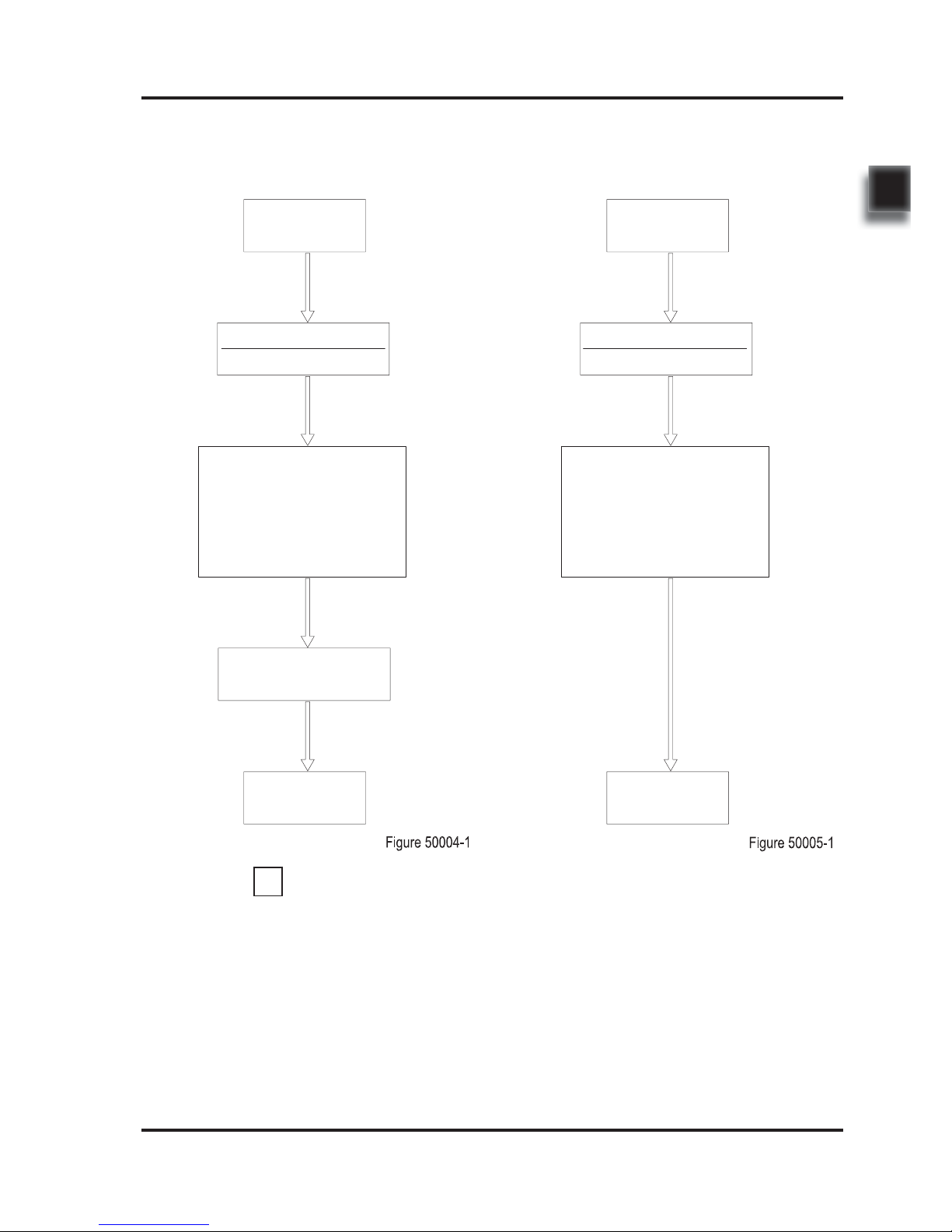

1.1 After-sales Service Platform

Claims/Replacement Parts Service Platform:

In order to provide you with a fast and effi cient

after-sales service, when you claim / order spare

parts or after-sales service upon maintenance,

please provide accurate truck model, vehicle

body serial number and part number.

After-sales Maintenance Service Platform:

Customer

nxsp@ep-zl.com

Customer

Components

Warehouse

Customer service to input

into After-sales System.

After-sale Engineer to

call back to confirm the

accuracy of the information

about the components.

Shipped within

24 hours

Claim Form

Customer service to input

into After-sales System.

After-sale Engineer to call

back to confirm about the

specifi c fault information.

Within two business

days after the maintenance, customer service

will call back and close

the claim.

Maintenance service

specialist will provide

on-site service at the

appointed time.

i

NOTE

Customer

nxsp@ep-zl.com

Claim Form

Customer

REV. 09/2016

INFORMATION & SPECIFICATIONS

1

4

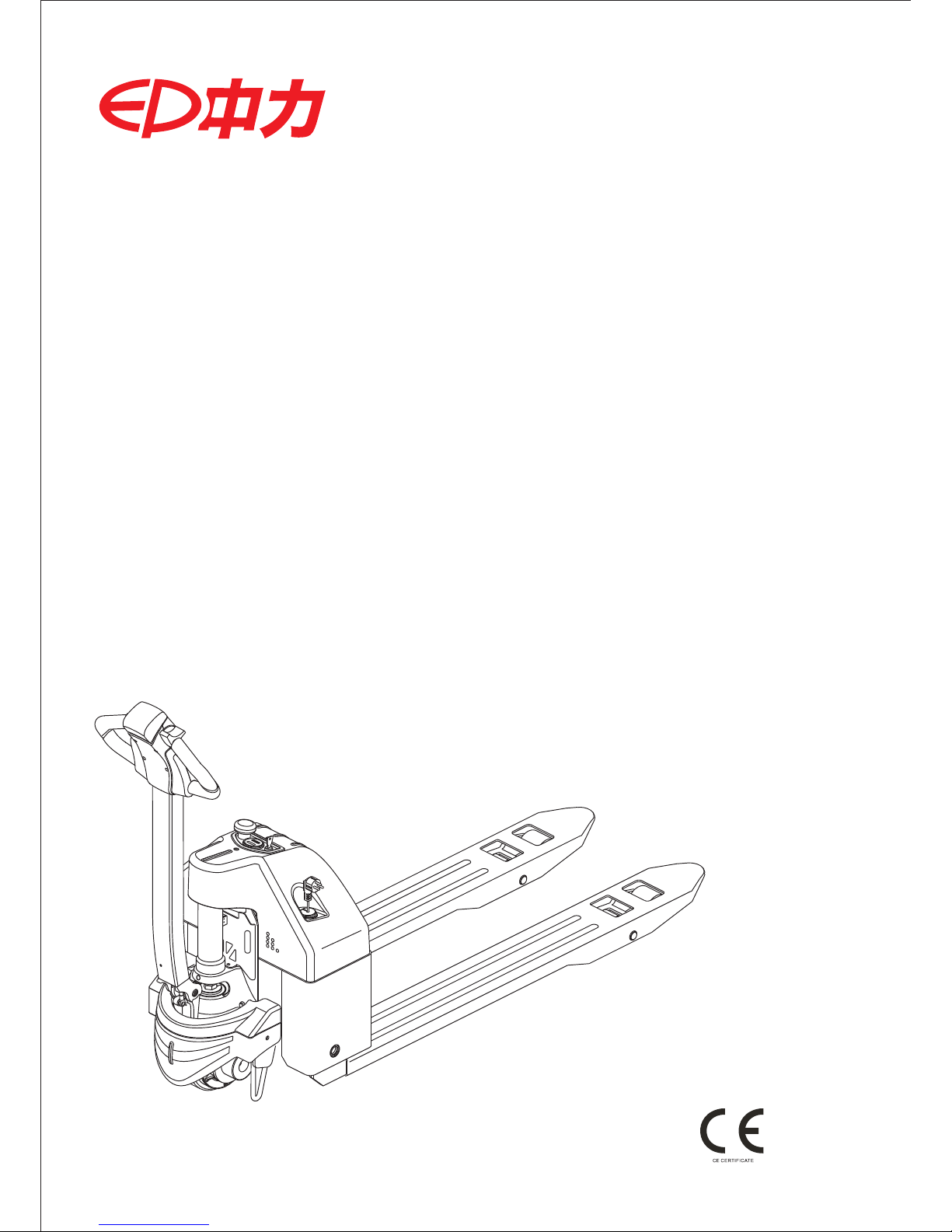

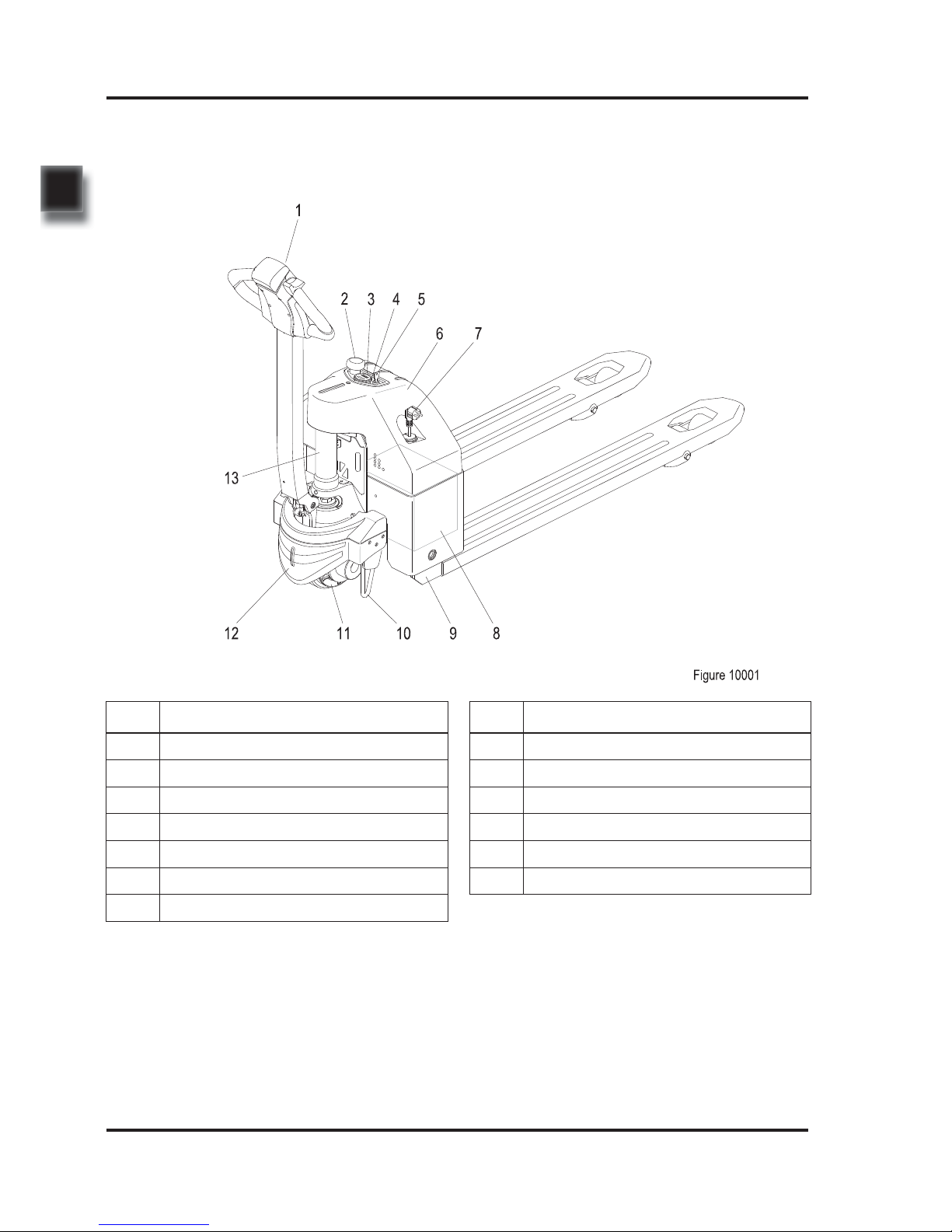

No. Name

1 Control Lever

2 Emergency Stop Switch

3 Charge Gauge

4 LED Charging Indicator

5 Key Switch

6 Upper Cover

7 Charging Plug

No. Name

8 Battery

9 Chassis

10 Balance Stand / Caster Wheel

11 Drive Wheel

12 Lower Cover

13 Lift Cylinder

1.2 Introduction

5

REV. 09/2016

INFORMATION & SPECIFICATIONS

1

This series are electric pallet trucks. Its important structure is as shown in Figure 10001.

-

Please refer to the nameplate for rated load

capacity of the vehicle.

-

The vehicle can only be used on the level gro und indoors, never use it on mezzanine or

balcony area.

WARNING

Truck can only be operated by single operator;

other personnel is forbidden from riding.

1.3 Common Tools

No. Name Remark

1 Hex Wrench 2#~14# One Set

2 Hex Head Socket Wrench 10#~27# One Set

3 Phillips Screwdriver 2# One Piece

4 Slotted Screwdriver 2# One Piece

5 Circlip Pliers One for holes and one for shaft

6 Hammer One Piece

7 Spreader, Crane One Pair

8 Cylinder Wrenches For removal and installation of cylinders

9 Diagonal Pliers One Piece

10 Cylinder Pliers One Piece

11 Grease Gun One Piece

12 Tiger Tooth Wrench 22#/27# One of Each

WARNING

REV. 09/2016

INFORMATION & SPECIFICATIONS

1

6

Table 1.4.1 Screws/Bolts Performance Levels

Performance Level Material Specifi cation (mm)

5.8 grade Low carbon steel M6 ~ M48

8.8 grade

Quenched and tempered medium

carbon steel

M6 ~ M48

10.9 grade

Quenched and tempered medium

carbon alloy steel

M6 ~ M48

12.9 grade

Quenched and tempered medium

carbon alloy steel

M6 ~ M48

12.9

10.9

8.8

5.8

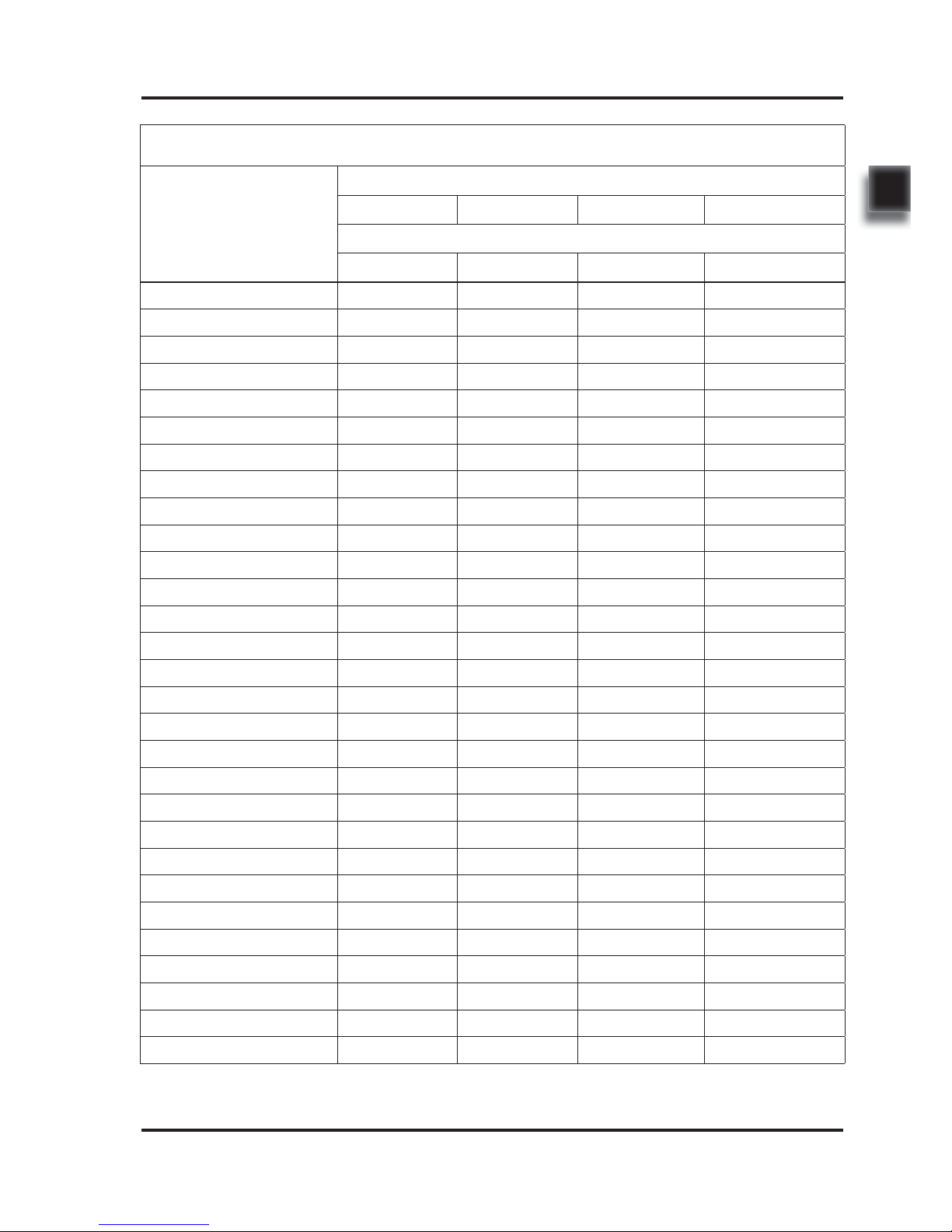

1.4 General Tightening Torques

Screws or bolts used on the truck are of 8.8

grade or higher performance level.

When you are conducting truck maintenance,

you can refer to Table 1.4.1 and Table 1.4.2 to

select the suitable screws or bolts for replacement.

-

-

CAUTION

The performance levels of screws or bolts are

marked on the heads of the screws or bolts.

If you fi nd the screws or bolts used on certain

position are not marked with performance

level, please select spare parts with performance level of at least 8.8 grade or higher level

forreplacement.

7

REV. 09/2016

INFORMATION & SPECIFICATIONS

1

Table 1.4.2 Metric Screws/Bolts Tightening Torque Table (n•m)

Nominal Diameter

(mm)

Performance Level

5.8 8.8 10.9 12.9

Proof Stress (MPa)

380 600 830 970

M6 7~8 10~12 14~17 17~20

M8 16~18 25~30 34~41 41~48

M8×1 17~20 27~32 37~43 43~52

M10 31~36 49~59 68~81 81~96

M10×1 35~41 55~66 76~90 90~106

M12 55~64 86~103 119~141 141~167

M12×1.5 57~67 90~108 124~147 147~174

M14 87~103 137~164 189~224 224~265

M14×1.5 144~170 149~179 206~243 243~289

M16 136~160 214~256 295~350 350~414

M16×1.5 144~170 228~273 314~372 372~441

M18 186~219 294~353 406~481 481~570

M18×1.5 210~247 331~397 457~541 541~641

M20 264~312 417~500 576~683 683~808

M20×1.5 294~345 463~555 640~758 758~897

M22 360~431 568~680 786~941 918~1099

M22×1.5 395~473 624~747 803~1034 1009~1208

M24 457~547 722~864 998~1195 1167~1397

M24×2 497~595 785~940 1086~1300 1269~1520

M27 669~801 1056~1264 1461~1749 1707~2044

M27×2 723~865 1141~1366 1578~1890 1845~2208

M30 908~1087 1437~1717 1984~2375 2318~2775

M30×2 1005~1203 1587~1900 2196~2629 2566~3072

M36 1587~1900 2506~3000 3466~4150 4051~4850

M36×3 1680~2011 2653~3176 3670~4394 4289~5135

M42 2538~3039 4088~4798 5544~6637 6479~7757

M42×3 2731~3269 4312~5162 5965~7141 6921~8345

M48 3813~4564 6020~7207 8327~9969 9732~11651

M48×3 4152~4970 6556~7848 9069~10857 10598~12688

REV. 09/2016

INFORMATION & SPECIFICATIONS

1

8

9

2

2. MAINTENANCE

10

NOTE:

11

REV. 09/2016

MAINTENANCE

2

-

-

-

Working conditions:

-

-

-

2.1 Overview

Only by performing regular vehicle maintenance

and repair, can ensure the continuous and

reliable use of the truck.

Only specially trained and qualified personnel

are capable of maintenance and repair

operations of the equipment. If you want to

perform the maintenance and repair on your

own, it is recommended that on-site training

should be conducted to your maintenance

personnel by the service representative of the

vendor.

When lifting load components or during the

operations under the cabin, sufficiently strong

chains or safety device must be used to secure

the vehicle.

Truck must be parked on the level ground

reserved for maintenance (such area needs

to be clean and with less dust), block the

wheels with wooden wedges, disconnect

the key switch and disconnect the battery

connections.

When lifting the truck, the lifting tools can

only be installed on the fixed positions as

specifi ed.

When jacking up the truck, appropriate tools,

such as wedge blocks, wooden blocks, and

so on, must be used to secure the truck to prevent the occurrence of accidental rolling or

tipping over.

Without the supplier's consent, it is strictly

forbidden to make modifi cations to truck, espe-

cially to the safety devices. It is strictly forbidden

to change the various working speeds of the

truck.

Under harsh working conditions: such as, the

external temperature is too high or too low,

dusty, or implementing multiple shifts per day,

the maintenance and care interval should be

shortened.

Prior to lubrications, replacement of fi lters or

operating the hydraulic system, please clean

the external parts carefully and use a clean

container.

Only compliant lubricants can be used See

Table 2.2 Lubricants.

WARNING

CAUTION

i

NOTE

12

REV. 09/2016

MAINTENANCE

2

-

-

-

-

2.2 Maintenance

2.2.1 Cleaning

Do not use flammable liquids to clean the

truck.

Before starting to clean, all necessary

security measures must be taken to prevent

sparking (short circuit) during operation. If the

truck is powered by battery, battery plug must

be pulled out.

When cleaning electrical and electronic components, you should use low-intensity suction

gas or compressed dry air. Meanwhile, clean

the dust on the surface of components with

non-conductive and antistatic brush.

Do not use vapor steam to clean the equipment.

2.2.2 Inspection

Regular inspection and maintenance under

normal conditions of use:

Operating

Hours (h)

Requirements

50 At least once per 7 days

250 At least once per 60 days

500 At least once per 90 days

1000 At least once every 6 months

2000 At least once per year

When the truck is at running-in phase (after

approximately 100 hours of operation), the

equipment user must check the fastening of

wheel nuts and bolts and re-tighten them if

necessary.

Regular inspection and maintenance under

harsh conditions of use:

Under harsh working conditions, especially:

-

Dusty environment

-

Corrosive environment

-

Cold storage environment

The maintenance intervals should be shortened

by half.

CAUTION

13

REV. 09/2016

MAINTENANCE

2

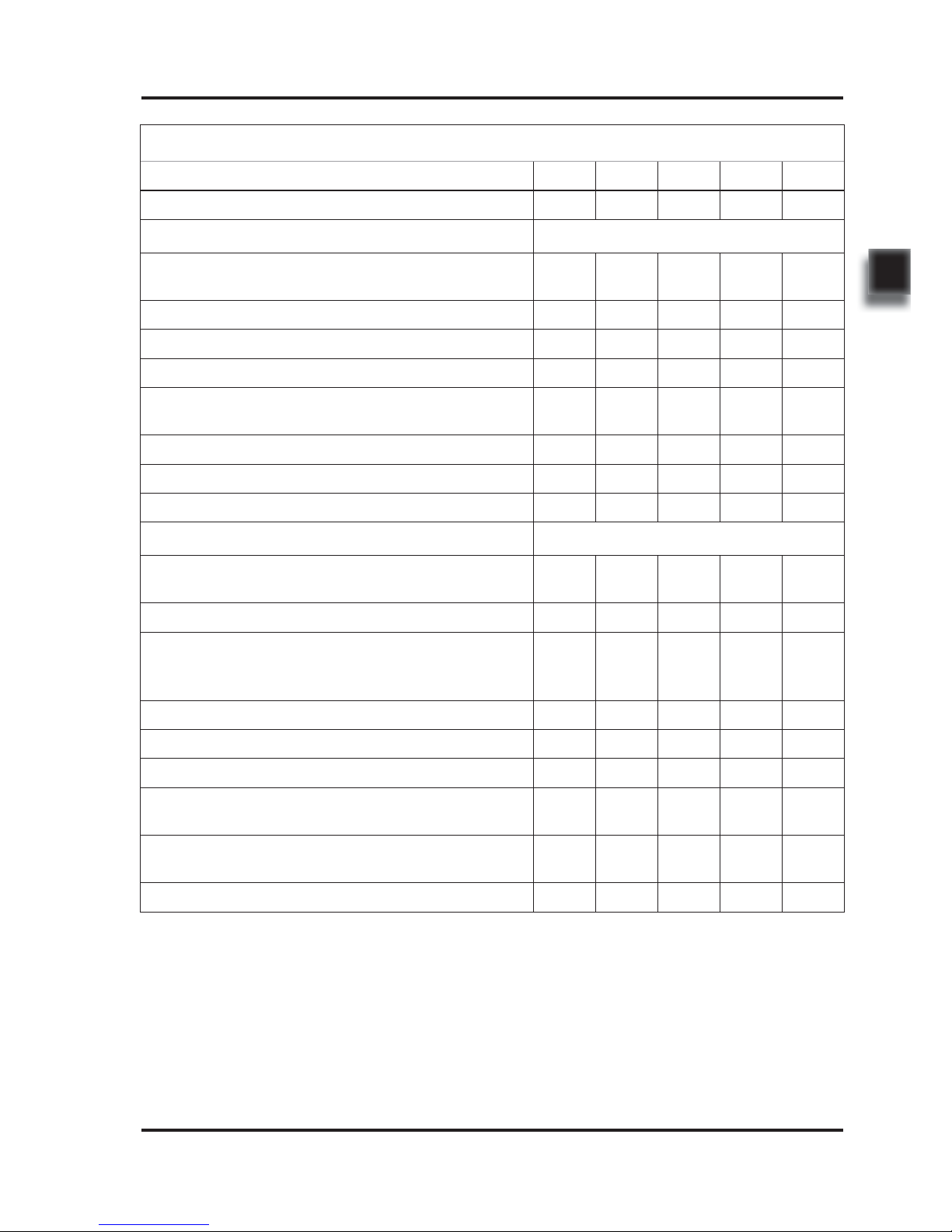

Table 2.1 Inspection & Maintenance List

Interval in days/months/years 7 d 60 d 90 d 6 m 1y

Interval in hours 50 250 500 1000 2000

Functions and Control

Check the functions of the operation switches and

display

A

Check alarm system functions A

Check interlock switch functions A

Check the emergency switch functions A

Check the cables for damage and if the terminals are

secure

A

Check the lifting limit switch functions A

Check and tighten the controllers and contactors A

Check fault information records and operating hours A

Power Supply & Drive System

Check the battery cables for damage and replace if

necessary

A

Check the battery charge connector A

Check if the cable connections between battery monomers are secure, apply some grease to electrodes if

necessary

A

Check the position of various bearings for noise A

Clean or add the gear grease A / L

Check the gearbox for abnormal noise or leaks A

Check and lubricate the bearings between drive motor

and gearbox

A / L

Check the drive wheel and load wheel for worn or

damage

A

Check the wheel bearings and fi xation A

A = Check / Adjust

Please refer to Inspection & Maintenance List

for regular inspection and maintenance of the

vehicles.

L = Lubrication

Under harsh conditions, the lubrication intervals

should be shortened by half.

14

REV. 09/2016

MAINTENANCE

2

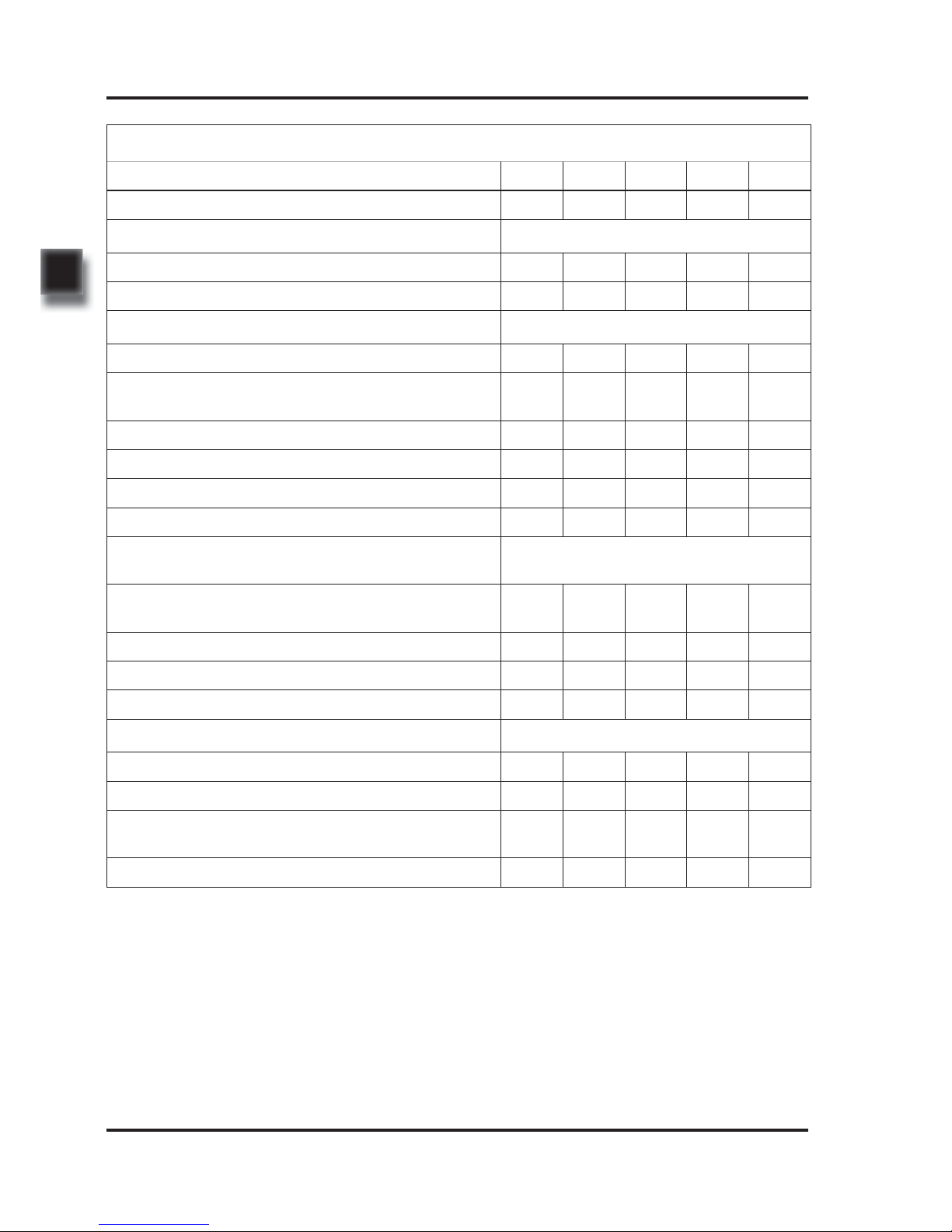

Table 2.1 Inspection & Maintenance List (Continued)

Interval in days/months/years 7 d 60 d 90 d 6 m 1y

Interval in hours 50 250 500 1000 2000

Power Supply & Drive System

Check the bearing bridge for damage or crack A

Check the travel speed A

Hydraulic System

Check the functions of hydraulic system A

Check if the hoses, pipes and interfaces are fastened

or sealed securely, and check if there is damage

A

Check the cylinders for leaks A

Check the cylinders for damages and check the fi xation A

Check the oil tank fi xation and check for leaks A

Check the hydraulic oil level A

Clean or replace the hydraulic oil

Replace after 100 hours of early operation.

Then replace once every 2000 hours

Check the function of emergency pressure relief

valve

A

Check and clean oil tank air fi lter A

Replace the oil tank air fi lter and fi lter A

Check the relief pressure A

Breking System

Check the braking functions of electromagnetic brake A

Check the air gap of electromagnetic brake A

Check the installation and connection of electromagnetic brake

A

Check the braking distance of electromagnetic brake A

A = Check / Adjust

Please refer to Inspection & Maintenance List

for regular inspection and maintenance of the

vehicles.

L = Lubrication

Under harsh conditions, the lubrication intervals

should be shortened by half.

15

REV. 09/2016

MAINTENANCE

2

Table 2.1 Inspection & Maintenance List (Continued)

Interval in days/months/years 7 d 60 d 90 d 6 m 1y

Interval in hours 50 250 500 1000 2000

Lifting Mechanism

Check the connecting rod mechanism for wear or

damage

A

Check whether the pin shaft is fi xed securely A

Check and lubricate the moving parts of connecting

rod mechanism

A / L

Check the lifting and lowering speed A

Other

Check if the signs are clear and complete A

Check the chassis for cracks or damages A

Check the connections of bolts and nuts A

Checking covering parts for damages A

Check if the optional features are functioning properly A

A = Check / Adjust

Please refer to Inspection & Maintenance List

for regular inspection and maintenance of the

vehicles.

L = Lubrication

Under harsh conditions, the lubrication intervals

should be shortened by half.

16

REV. 09/2016

MAINTENANCE

2

-

-

2.2.3 Lubrication

Improper operations may constitute hazards

to the operator's health and life, as well as to

the surrounding environment.

When storing or adding lubricant, use clean

containers. It is strictly forbidden to mix

different types and specifi cations of lubricants

with each other (except for those can be

mixed under clear statement).

The use and disposal of lubricants must be

carried out in strict accordance with the manufacturer's regulations.

Lubricant

Please see Table 2.2 for the lubricants used in

this truck.

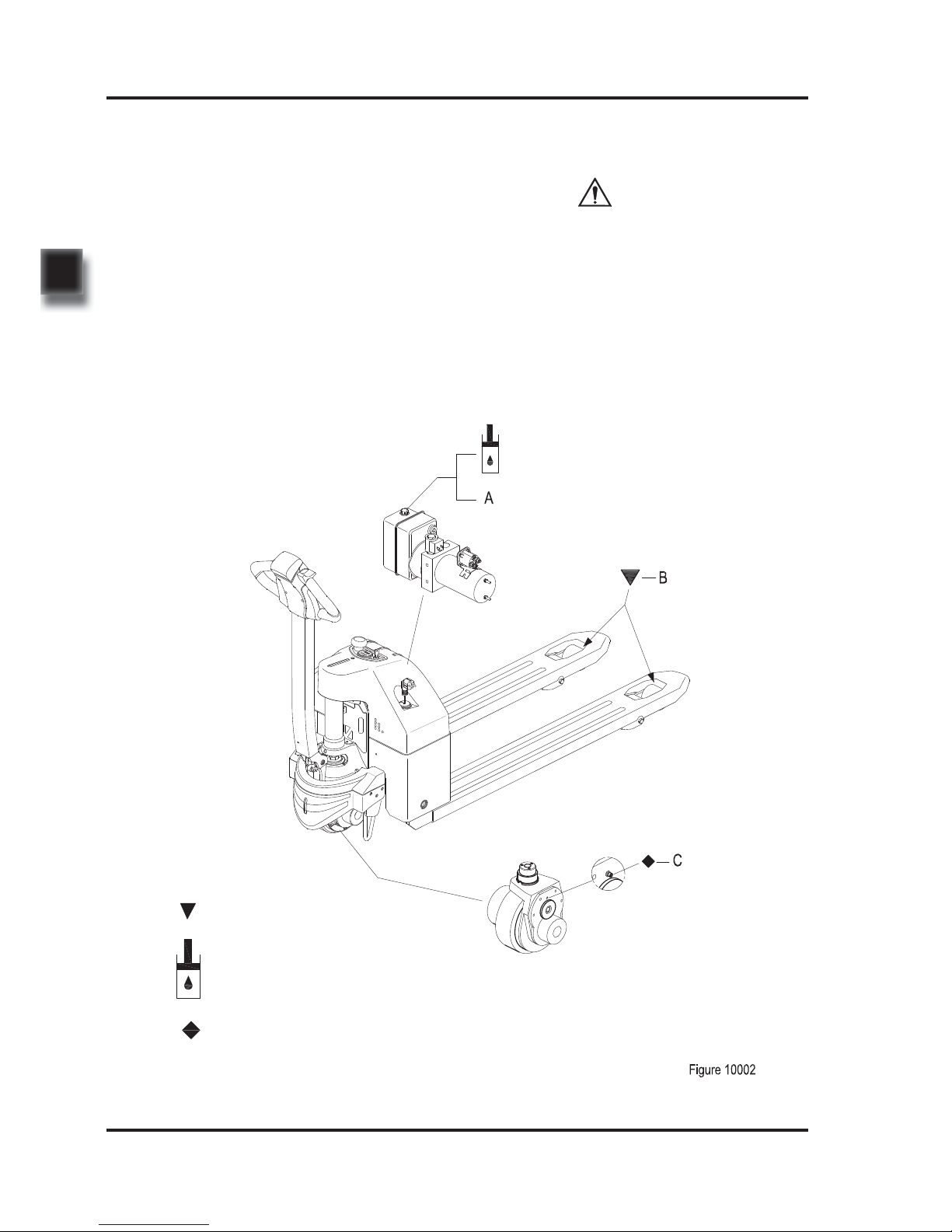

Sliding surface

Hydraulic oil injection nozzle

Gear oil injection nozzle

CAUTION

17

REV. 09/2016

MAINTENANCE

2

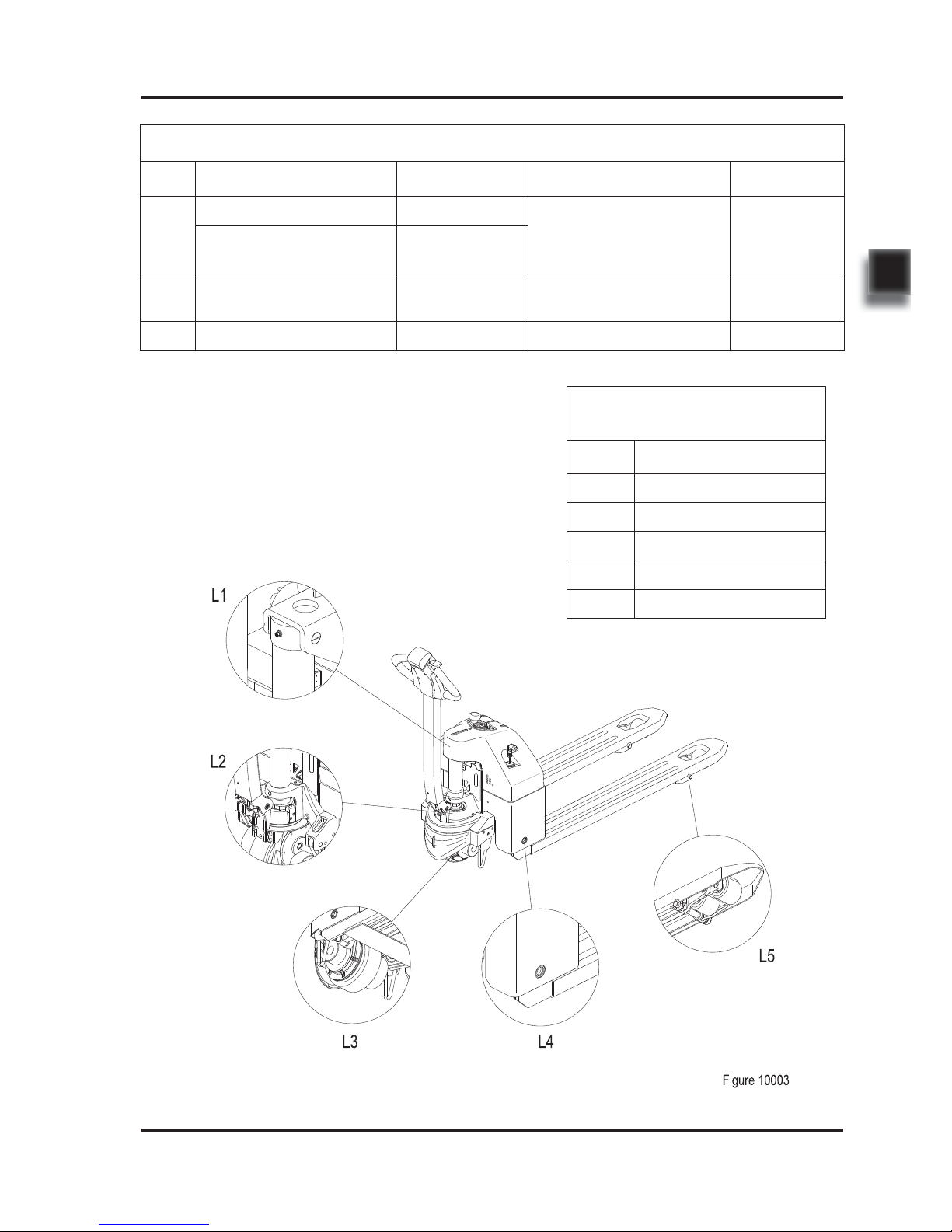

Table 2.2 Lubricants

Code Type Specifi cation Amount Position

A

Anti-wear hydraulic oil L-HM46

0.65 L

Hydraulic

System

Low temperature anti-wear

hydraulic oil (cold storage)

L-HV32

B

Multi-purpose grease Polylub GA352P Appropriate amount

Sliding surface

(See Table 2.3)

C

Grease (MoS2) - 100 grams Gearbox

Table 2.3 Sliding Surface

Lubrication Table

Code Position

L1 Mounting Shaft

L2 Steering Bearing

L3 Drive Wheel

L4 Long Shaft

L5 Load Wheel

18

REV. 09/2016

MAINTENANCE

2

19

3

3. STRUCTURE & FUNCTIONS

Loading...

Loading...