Page 1

CeraDiodes

High-speed series

Series/Type:

Date: July 2014

© EPCOS AG 2014. Reproduction, publication and dissemination of this publication, enclosures hereto and the

information contained therein without EPCOS' prior express consent is prohibited.

Page 2

CeraDiodes

High-speed series

Features

Very low capacitance values 0.6 up to 10 pF

ESD protection to IEC 61000-4-2, level 4

Bidirectional ESD protection in one component

No change in ESD protection performance at temperatures

up to 85 °C (temperature derating)

Low parasitic inductance

Low leakage current

Fast response time <0.5 ns

Lead-free nickel barrier terminations suitable for lead-free soldering

RoHS-compatible

Applications

Interfaces, data lines (USB, IEEE 1394, Ethernet, parallel port,

SATA, DisplayPort, etc.), audio lines (digital) and video lines

(analog), DVI, HDMI, ICs and I/O ports

Consumer electronic products (TV, DVD player/recorder, set-top

box, game consoles, MP3 player, digital still/video camera, etc.)

EDP products (desktop and notebook computer, monitor, PDA,

printer, memory card, control unit, head set, speaker, HDD, optical

drive, etc.)

Industrial applications

Mobile phone applications

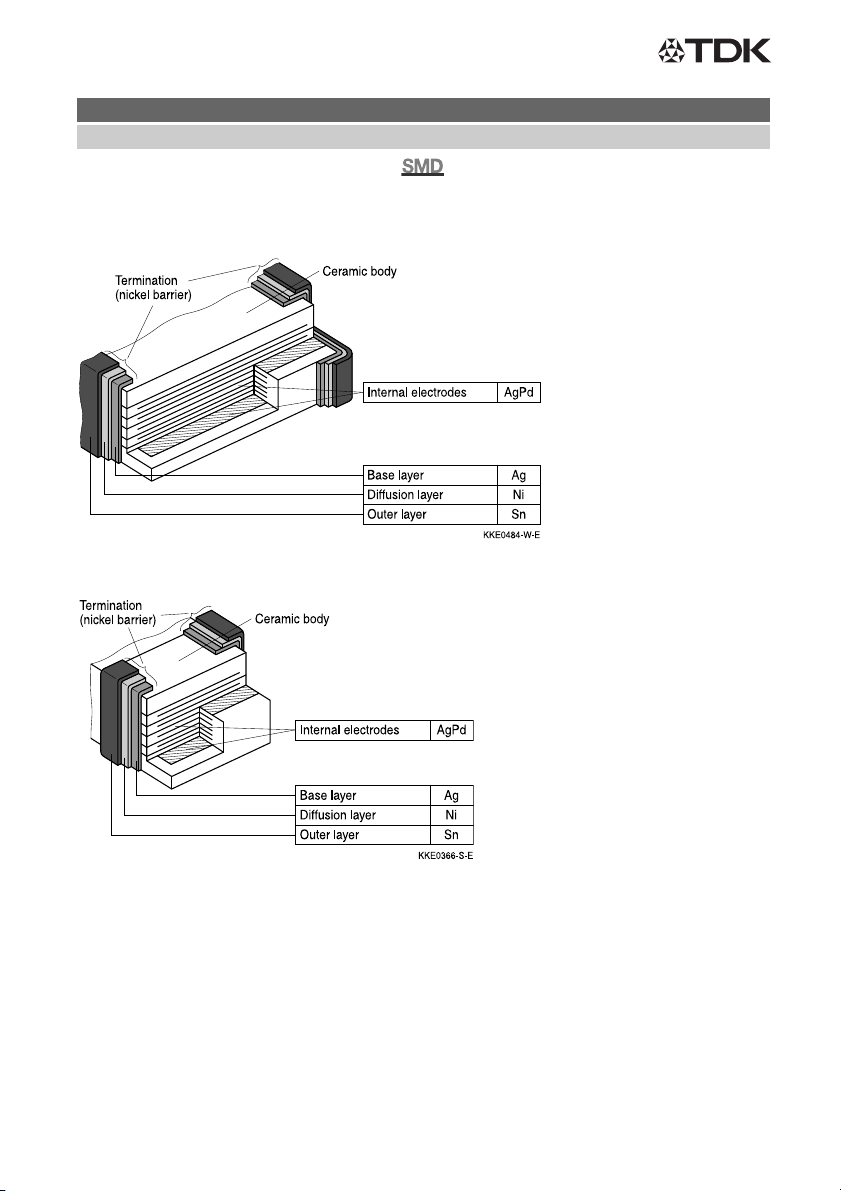

Design

Multilayer technology

Nickel barrier termination (Ag/Ni/Sn) for lead-free soldering

Marking

Due to the symmetrical configuration no marking information is

needed.

Single chip

4-fold array

2/4 data + 1 supply

General technical data

Maximum DC operating voltage V

Typical capacitance C

Air discharge ESD capability to IEC 61000-4-2 V

Contact discharge ESD capability to IEC 61000-4-2 V

Leakage current (V

= 5.6 V) I

leak

Operating temperature T

DC,max

typ

ESD,air

ESD,contact

leak

op

5.5 ... 30 V

0.6 ... 10 pF

15 kV

8 kV

1 µA

40/+85 °C

Storage temperature LCT/UCT 40/+125 °C

Important notes at the end of this document.

Page 2 of 22Please read Cautions and warnings and

Page 3

CeraDiodes

High-speed series

Electrical specifications and ordering codes

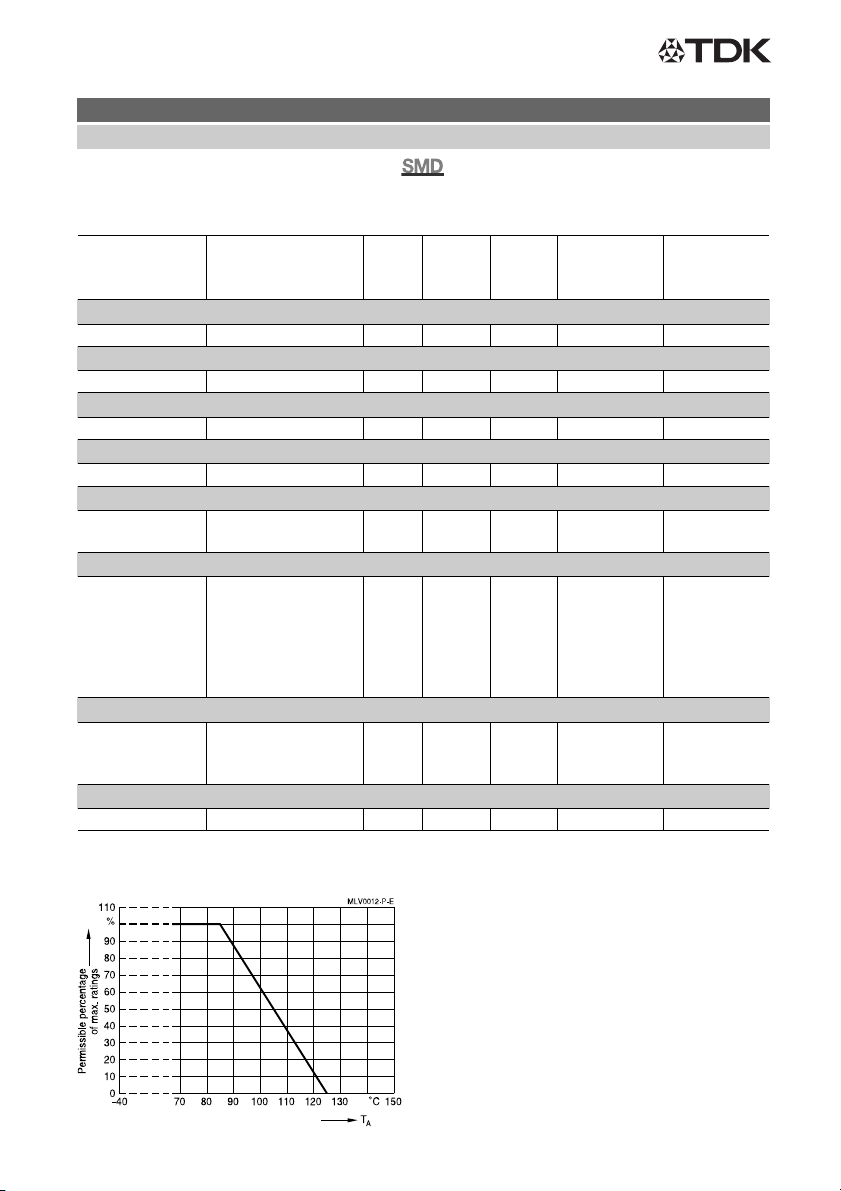

Maximum ratings (T

Type Ordering code

= 85 °C) and characteristics (TA= 25 °C)

op,max

V

V

DC,max

BR,min

(1 mA)

V

V

V

clamp,max

(1 A)

V

C

typ

(1 MHz, 1 V)

pF

C

max

(1 MHz, 1 V)

pF

Array, 2/4 data + 1 supply, 0506, SOT-666

CDA3C05GTH B72755D0050H062 5.6 106 395 2.2 3.5

Array, 2/4 data + 1 supply, 1012, SOT-23 6L

CDA6C05GTH B72735D0050H062 5.6 52 195 7 10

Array, 4-fold, 0508, no semiconductor diode equivalent

CDA4C16GTH B72714D0160H060 16 22 66 10 15

Array, 4-fold, 0612, no semiconductor diode equivalent

CDA5C16GTH B72724D0160H062 16 80 350 3 5

Single, 0201, no semiconductor diode equivalent

CDS1C05GTH1 B72440C0050H160 5.5 17 33 7 -

CDS1C05GTH2 B72440C0050H260 5.5 20 66 3 Single, 0402, SOD-723

CDS2C05HDMI1 B72590D0050H160 5.6 150 - 0.6 0.9

CDS2C05HDMI2 B72590D0050H260 5.6 90 - 0.6 0.9

CDS2C12GTH B72590D0120H060 12 20 66 4.5 CDS2C15GTH B72590D0150H060 15 23 66 10 15

CDS2C16GTH B72590D0160H060 16 65 290 2 3

CDS2C20GTH B72590D0200H060 20 30 80 10 13

Single, 0603, SOD-523

CDS3C05HDMI1 B72500D0050H160 5.6 150 - 0.6 0.9

CDS3C16GTH B72500D0160H060 16 65 290 3 5

CDS3C30GTH B72500D0300H060 30 50 120 10 15

Single, 1003, SOD-323

CDS4C16GTH B72570D0160H060 16 38 146 3 5

Typical characteristics

Important notes at the end of this document.

Page 3 of 22Please read Cautions and warnings and

Page 4

CeraDiodes

High-speed series

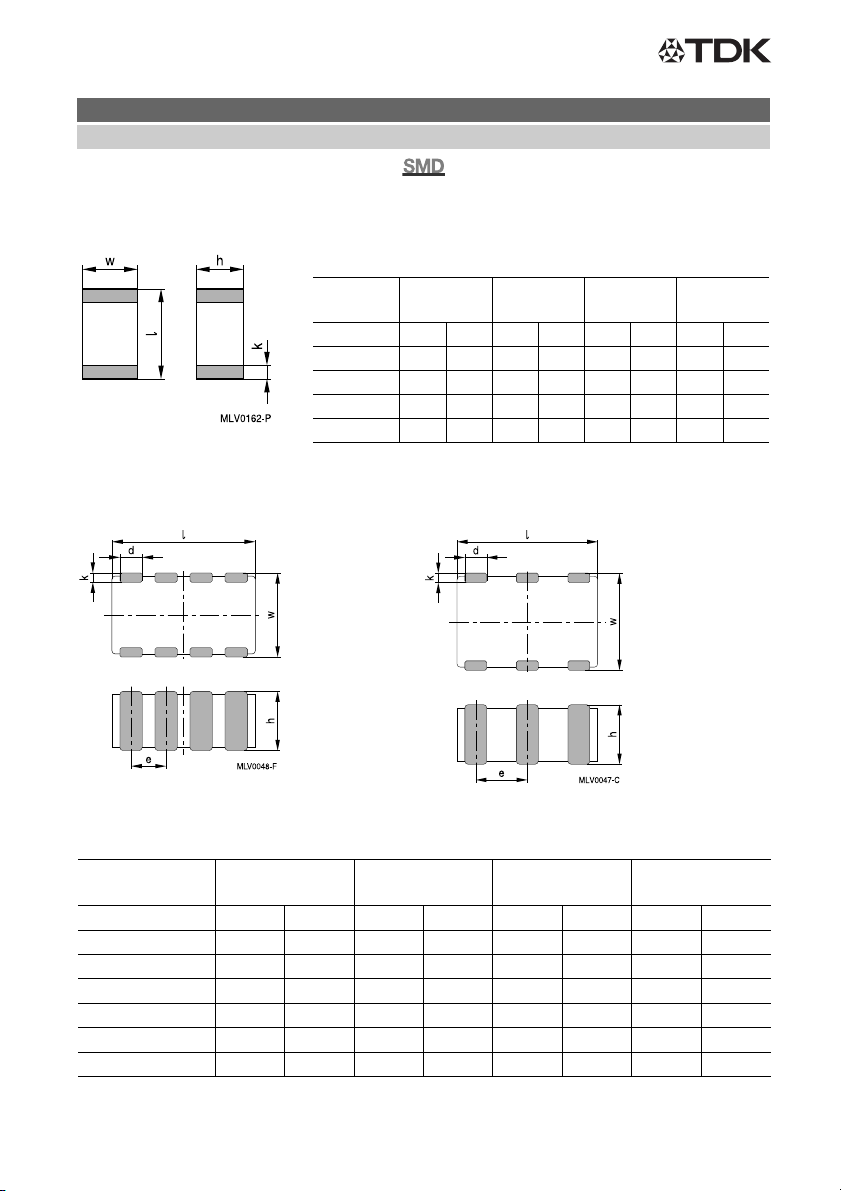

Dimensional drawings

Single device

Dimensions in mm

Case

(inch)

size

(mm)

0201

0603

0402

1005

Min. Max. Min. Max. Min. Max. Min. Max.

l 0.57 0.63 0.85 1.15 1.45 1.75 2.34 2.74

w 0.27 0.33 0.4 0.6 0.7 0.9 0.7 0.9

h 0.27 0.33 0.4 0.6 0.7 0.9 0.7 0.9

k 0.1 0.2 0.1 0.3 0.1 0.4 0.13 0.75

Array devices

4-fold array 2/4 data + 1 supply

0603

1608

1003

2508

Dimension in mm

Case size (inch)

(mm)

0506

1216

0508

1220

0612

1632

1012

2532

Min. Max. Min. Max. Min. Max. Min. Max.

l 1.50 1.70 1.8 2.2 3.0 3.4 2.90 3.50

w 1.20 1.40 1.05 1.45 1.45 1.75 2.25 2.75

h - 0.6 - 0.9 - 0.9 - 1.2

d 0.2 0.4 0.2 0.4 0.25 0.55 0.35 0.65

e 0.4 0.6 0.4 0.6 0.61 0.91 0.8 1.1

k - 0.35 - 0.35 - 0.35 - 0.45

Important notes at the end of this document.

Page 4 of 22Please read Cautions and warnings and

Page 5

CeraDiodes

High-speed series

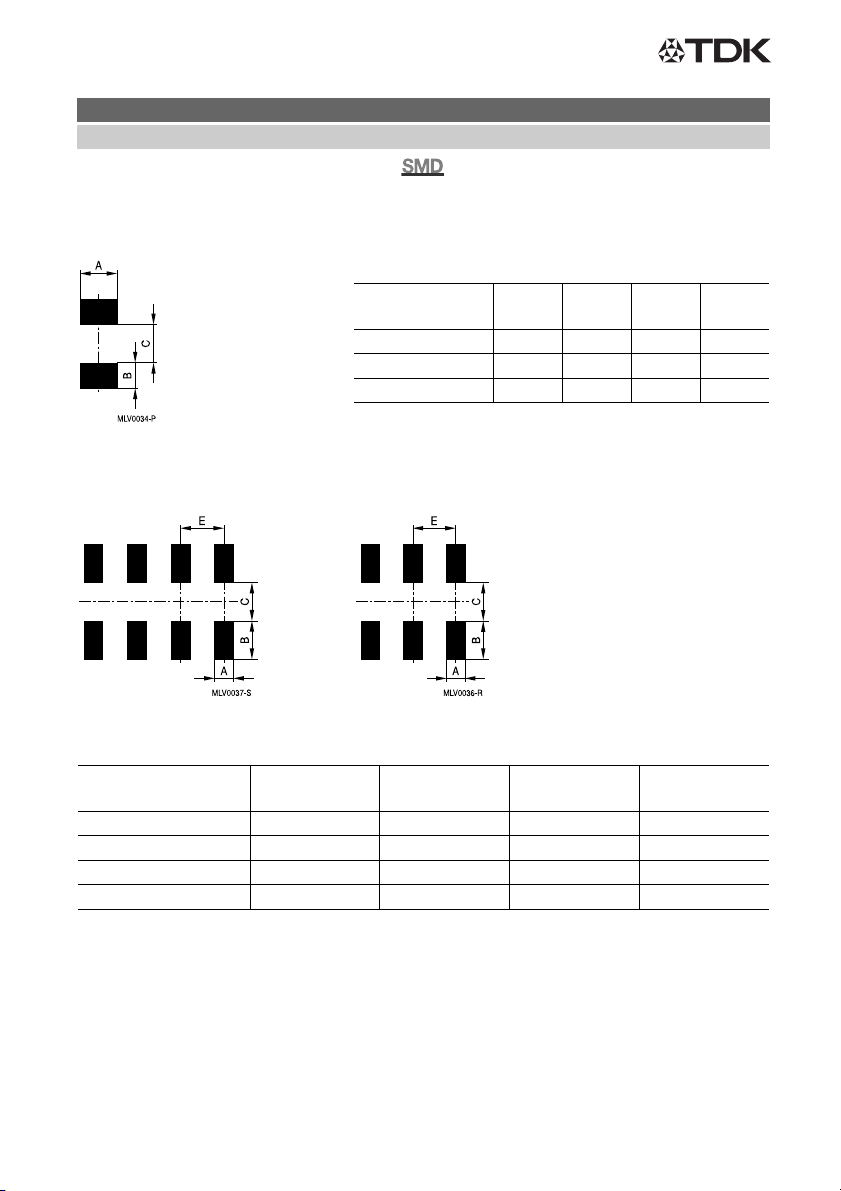

Recommended solder pads

Single device

Dimensions in mm

Case size (inch)

(mm)

A 0.3 0.6 1.0 0.8

B 0.25 0.6 1.0 0.8

C 0.3 0.5 1.0 1.45

Array devices

4-fold array 2/4 data + 1 supply

0201

0603

0402

1005

0603

1608

1003

2508

Dimensions in mm

Case size (inch)

(mm)

A

B

C

E

Important notes at the end of this document.

0506

1216

0.36 0.35 0.5 0.7

0.84 0.9 0.7 1.0

0.62 0.4 1.2 1.4

0.50 0.5 0.76 0.95

0508

1220

Page 5 of 22Please read Cautions and warnings and

0612

1632

1012

2532

Page 6

CeraDiodes

High-speed series

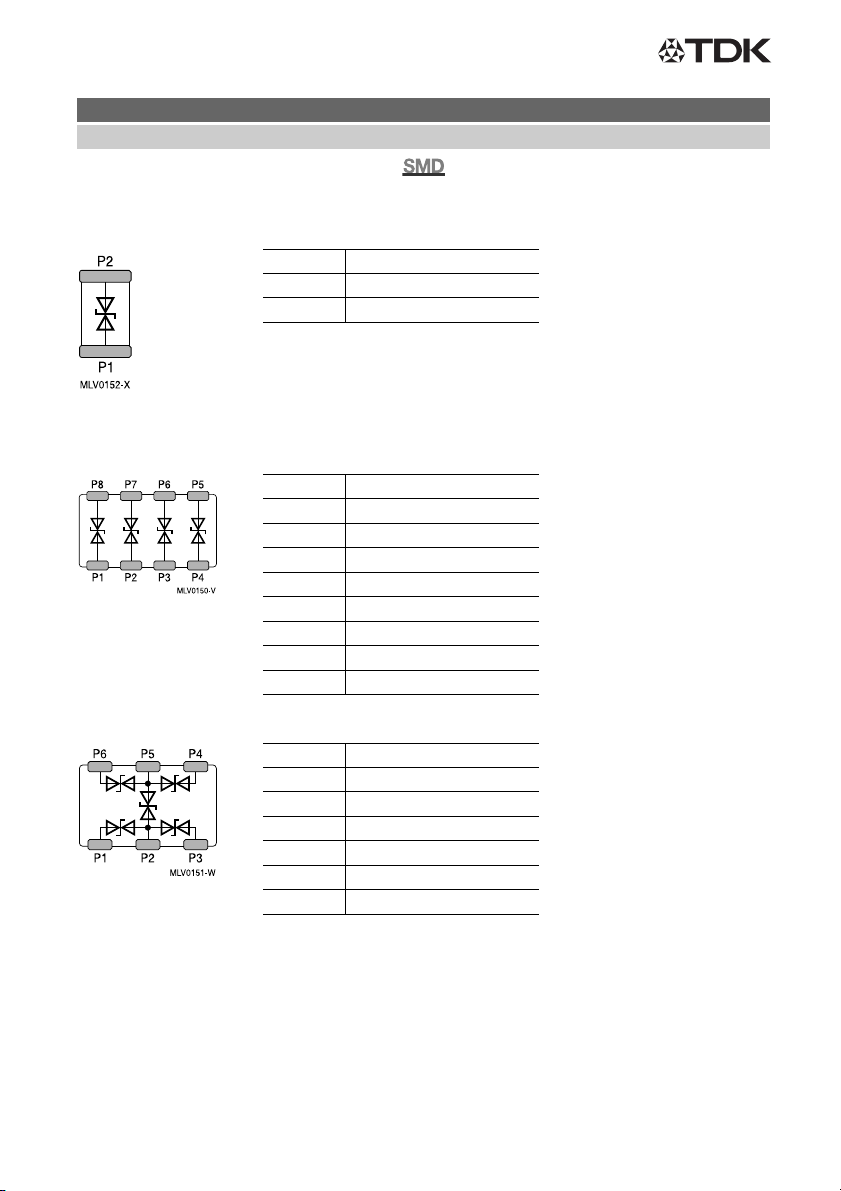

Pin configurations

Single device

Array devices

4-fold array

Pin Description

P1 GND

P2 I/O line

Pin Description

P1 GND

P2 GND

P3 GND

P4 GND

P5 I/O line 1

P6 I/O line 2

P7 I/O line 3

P8 I/O line 4

2/4 data + 1 supply

Pin Description

P1 I/O line 1

P2 GND

P3 I/O line 2

P4 I/O line 3

P5 V

P6 I/O line 4

Important notes at the end of this document.

DC

Page 6 of 22Please read Cautions and warnings and

Page 7

CeraDiodes

High-speed series

Termination

Single device

Array device

Important notes at the end of this document.

Page 7 of 22Please read Cautions and warnings and

Page 8

CeraDiodes

High-speed series

Delivery mode

EIA case size Taping Reel sizemmPacking unit

Type Ordering code

pcs.

0201 Cardboard 180 15000 CDS1C05GTH1 B72440C0050H160

0201 Cardboard 180 15000 CDS1C05GTH2 B72440C0050H260

0402 Cardboard 180 10000 CDS2C05HDMI1 B72590D0050H160

0402 Cardboard 180 10000 CDS2C05HDMI2 B72590D0050H260

0402 Cardboard 180 10000 CDS2C12GTH B72590D0120H060

0402 Cardboard 180 10000 CDS2C15GTH B72590D0150H060

0402 Cardboard 180 10000 CDS2C16GTH B72590D0160H060

0402 Cardboard 180 10000 CDS2C20GTH B72590D0200H060

0506 Blister 180 3000 CDA3C05GTH B72755D0050H062

0508 Cardboard 180 4000 CDA4C16GTH B72714D0160H060

0603 Cardboard 180 4000 CDS3C05HDMI1 B72500D0050H160

0603 Cardboard 180 4000 CDS3C16GTH B72500D0160H060

0603 Cardboard 180 4000 CDS3C30GTH B72500D0300H060

0612 Blister 180 3000 CDA5C16GTH B72724D0160H062

1003 Cardboard 180 4000 CDS4C16GTH B72570D0160H060

1012 Blister 180 2000 CDA6C05GTH B72735D0050H062

Important notes at the end of this document.

Page 8 of 22Please read Cautions and warnings and

Page 9

CeraDiodes

High-speed series

1 Taping and packing for chip and array CeraDiodes

1.1 Cardboard tape (taping to IEC 60286-3)

Dimensions in mm

Case size (inch) 0201

(mm)

0603 1005 1608 2508 1220

0402 0603 1003 0508 Tolerance

Compartment width A00.38 ±0.05 0.6 0.95 1.0 1.6 ±0.2

Compartment length B00.68 ±0.05 1.15 1.8 2.85 2.4 ±0.2

Sprocket hole diameter D01.5 ±0.1 1.5 1.5 1.5 1.5 +0.1/ 0

Sprocket hole pitch P04.0 ±0.11)4.0 4.0 4.0 4.0 ±0.1

Distance center hole to center

P22.0 ±0.05 2.0 2.0 2.0 2.0 ±0.05

1)

compartment

Pitch of component compartments P12.0 ±0.05 2.0 4.0 4.0 4.0 ±0.1

Tape width W 8.0 ±0.3 8.0 8.0 8.0 8.0 ±0.3

Distance edge to center of hole E 1.75 ±0.1 1.75 1.75 1.75 1.75 ±0.1

Distance center hole to center

F 3.5 ±0.05 3.5 3.5 3.5 3.5 ±0.05

compartment

Distance compartment to edge G 1.35 min. 0.75 0.75 0.75 0.75 min.

Thickness tape T 0.35 ±0.02 0.6 0.9 1.0 0.95 max.

Overall thickness T20.4 min. 0.7 1.1 1.1 1.12 max.

1)

≤ ±0.2 mm over 10 sprocket holes

Important notes at the end of this document.

Page 9 of 22Please read Cautions and warnings and

Page 10

CeraDiodes

High-speed series

1.2 Blister tape (taping to IEC 60286-3)

Dimensions in mm

Case size (inch)

(mm)

0506

1216

0612

1632

1012

2532

Tolerance

Compartment width A01.5 1.9 2.8 ±0.2

Compartment length B01.8 3.5 3.5 ±0.2

Compartment height K00.8 1.8 1.8 max.

Sprocket hole diameter D01.5 1.5 1.5 +0.1/ 0

Compartment hole diameter D11.0 1.0 1.0 min.

Sprocket hole pitch P04.0 4.0 4.0 ±0.1

Distance center hole to center

P22.0 2.0 2.0 ±0.05

1)

compartment

Pitch of component compartments P14.0 4.0 4.0 ±0.1

Tape width W 8.0 8.0 8.0 ±0.3

Distance edge to center of hole E 1.75 1.75 1.75 ±0.1

Distance center hole to center

F 3.5 3.5 3.5 ±0.05

compartment

Distance compartment to edge G 0.75 0.75 0.75 min.

Thickness tape T 0.3 0.3 0.3 max.

Overall thickness T21.3 2.5 2.5 max.

1)

≤ ±0.2 mm over 10 sprocket holes

Important notes at the end of this document.

Page 10 of 22Please read Cautions and warnings and

Page 11

CeraDiodes

High-speed series

1.3 Reel packing

Dimensions in mm

Dimensions Tolerance Dimensions Tolerance

Reel diameter A 180 +0/ –3 330 ±2

Reel width (inside) W

Reel width (outside) W

8.4 +1.5/ –0 8.4 +1.5/ –0

1

14.4 max. 14.4 max.

2

Package: 8-mm tape

Reel material: Plastic

1.4 Packing units

Case size

(inch) / (mm)

∅ 180-mm reel

pieces

∅ 330-mm reel

pieces

Tape

0201 / 0603 15000 - cardboard

0402 / 1005 10000 50000 cardboard

0603 / 1608 4000 16000 cardboard

1003 / 2508 4000 16000 cardboard

0506 / 1216 3000 12000 blister

0508 / 1220 4000 16000 cardboard

0612 / 1632 3000 12000 blister

1012 / 2532 2000 8000 blister

Important notes at the end of this document.

Page 11 of 22Please read Cautions and warnings and

Page 12

CeraDiodes

High-speed series

Soldering directions

1 Reflow soldering temperature profile

Recommended temperature characteristic for reflow soldering following

JEDEC J-STD-020D

Profile feature Sn-Pb eutectic assembly Pb-free assembly

Preheat and soak

- Temperature min T

- Temperature max T

- Time t

Average ramp-up rate T

Liquidous temperature T

Time at liquidous t

Peak package body temperature T

smin

L

smin

smax

smax

L

1)

p

to t

Time (tP)3)within 5 °C of specified

classification temperature (Tc)

Average ramp-down rate Tpto T

100 °C 150 °C

150 °C 200 °C

60 ... 120 s 60 ... 180 s

smax

to Tp3 °C/ s max. 3 °C/ s max.

183 °C 217 °C

60 ... 150 s 60 ... 150 s

220 °C ... 235 °C

3)

20 s

6 °C/ s max. 6 °C/ s max.

smax

2)

245 °C ... 260 °C

3)

30 s

2)

Time 25 °C to peak temperature maximum 6 min maximum 8 min

1) Tolerance for peak profile temperature (TP) is defined as a supplier minimum and a user maximum.

2) Depending on package thickness. For details please refer to JEDEC J-STD-020D.

3) Tolerance for time at peak profile temperature (tP) is defined as a supplier minimum and a user maximum.

Note: All temperatures refer to topside of the package, measured on the package body surface.

Number of reflow cycles: 3

Important notes at the end of this document.

Page 12 of 22Please read Cautions and warnings and

Page 13

CeraDiodes

High-speed series

2 Soldering guidelines

The use of mild, non-activated fluxes for soldering is recommended, as well as proper cleaning of

the PCB.

The components are suitable for reflow soldering to JEDEC J-STD-020D.

3 Solder joint profiles / solder quantity

3.1 Cement quantity

The component is fixed onto the circuit board with cement prior to soldering. It must still be able

to move slightly. When the board is placed into the reflow oven, excessively rigid fixing can lead

to high forces acting on the component and thus to a break. In addition, too much cement can

lead to unsymmetrical stressing and thus to mechanical fracture of the component. The cement

must also be so soft during mounting that no mechanical stressing occurs.

3.2 Mounting the components on the board

It is best to mount the components on the board before soldering so that one termination does not

enter the oven first and the second termination is soldered subsequently. The ideal case is simultaneous wetting of both terminations.

3.3 Solder joint profiles

If the meniscus height is too low, that means the solder quantity is too low, the solder joint may

break, i.e. the component becomes detached from the joint. This problem is sometimes interpreted as leaching of the external terminations.

If the solder meniscus is too high, i.e. the solder quantity is too large, the vise effect may occur.

As the solder cools down, the solder contracts in the direction of the component. If there is too

much solder on the component, it has no leeway to evade the stress and may break, as in a vise.

Important notes at the end of this document.

Page 13 of 22Please read Cautions and warnings and

Page 14

CeraDiodes

High-speed series

3.3.1 Solder joint profiles for nickel barrier termination

Good and poor solder joints caused by amount of solder in infrared reflow soldering

Important notes at the end of this document.

Page 14 of 22Please read Cautions and warnings and

Page 15

CeraDiodes

High-speed series

4 Solderability tests

Test Standard Test conditions /

Sn-Pb soldering

Wettability IEC

60068-2-58

Immersion in

60/40 SnPb solder

using non-activated

flux at 215 ±3 °C for

3 ±0.3 s

Test conditions /

Pb-free soldering

Immersion in

Sn96.5Ag3.0Cu0.5

solder using non- or

low activated flux

at 245 ±5 °C

Criteria / test results

Covering of 95%

of end termination,

checked by visual

inspection

for 3 ±0.3 s

Leaching

resistance

Tests of

resistance to

soldering heat

IEC

60068-2-58

IEC

60068-2-58

Immersion in

60/40 SnPb

solder using

mildly activated flux

without preheating

at 255 ±5 °C

for 10 ±1 s

Immersion in

60/40 SnPb for 10 s

at 260 °C

Immersion in

Sn96.5Ag3.0Cu0.5

solder using non- or

low activated flux

without preheating

at 255 ±5 °C

for 10 ±1 s

Immersion in

Sn96.5Ag3.0Cu0.5

for 10 s at 260 °C

No leaching of

contacts

Capacitance change:

15% ≤∆C ≤15%

for SMDs

Note:

Leaching of the termination

Effective area at the termination might be lost if the soldering temperature and/or immersion time

are not kept within the recommended conditions. Leaching of the outer electrode should not exceed 25% of the chip end area (full length of the edge A-B-C-D) and 25% of the length A-B,

shown below as mounted on the substrate.

As single chip As mounted on substrate

Important notes at the end of this document.

Page 15 of 22Please read Cautions and warnings and

Page 16

CeraDiodes

High-speed series

5 Notes for proper soldering

5.1 Preheating and cooling

The average ramp-up rate must not exceed 3 °C/s.

The cooling rate must not exceed 8 °C/s.

5.2 Repair / rework

Manual soldering with a soldering iron must be avoided, hot-air methods are recommended for

making repairs.

5.3 Cleaning

All environmentally compatible agents are suitable for cleaning. Select the appropriate cleaning

solution according to the type of flux used. The temperature difference between the components

and cleaning liquid must not be greater than 100 °C. Ultrasonic cleaning should be carried out

with the utmost caution. Too high ultrasonic power can impair the adhesive strength of the metallized surfaces. Insufficient or excessive cleaning can be detrimental to CeraDiode performance.

5.4 Solder paste printing (reflow soldering)

An excessive application of solder paste results in too high a solder fillet, thus making the chip

more susceptible to mechanical and thermal stress. This will lead to the formation of cracks. Too

little solder paste reduces the adhesive strength on the outer electrodes and thus weakens the

bonding to the PCB. The solder should be applied smoothly to the end surface to a height of

min. 0.2 mm.

5.5 Selection of flux

Used flux should have less than or equal to 0.1 wt % of halogenated content, since flux residue

after soldering could lead to corrosion of the termination and/or increased leakage current on the

surface of the CeraDiode. Strong acidic flux must not be used. The amount of flux applied should

be carefully controlled, since an excess may generate flux gas, which in turn is detrimental to solderability.

5.6 Storage

Solderability is guaranteed for one year from date of delivery, provided that components are

stored in their original packages.

Storage temperature: 25 °C to +45 °C

Relative humidity: ≤75% annual average, ≤95% on 30 days a year

The solderability of the external electrodes may deteriorate if SMDs are stored where they are exposed to high humidity, dust or harmful gas (hydrogen chloride, sulfurous acid gas or hydrogen

sulfide).

Do not store SMDs where they are exposed to heat or direct sunlight. Otherwise the packing material may be deformed or SMDs may stick together, causing problems during mounting.

After opening the factory seals, such as polyvinyl-sealed packages, it is recommended to use the

SMDs as soon as possible.

Important notes at the end of this document.

Page 16 of 22Please read Cautions and warnings and

Page 17

CeraDiodes

High-speed series

5.7 Placement of components on circuit board

It is of advantage to place the components on the board before soldering so that their two terminals do not enter the solder oven at different times. Ideally, both terminals should be wetted simultaneously.

5.8 Soldering caution

Sudden heating or cooling of the component results in thermal destruction by cracks.

An excessively long soldering time or high soldering temperature results in leaching of the outer electrodes, causing poor adhesion due to loss of contact between electrodes and termination.

Avoid manual soldering with a soldering iron.

Wave soldering must not be applied for CeraDiodes designated for reflow soldering only.

Keep to the recommended down-cooling rate.

5.9 Standards

CECC 00802

IEC 60068-2-58

IEC 60068-2-20

JEDEC J-STD-020D

Important notes at the end of this document.

Page 17 of 22Please read Cautions and warnings and

Page 18

CeraDiodes

High-speed series

Symbols and terms

CeraDiode Semiconductor diode

C

max

C

typ

I

BR

I

leak

I

PP

P

PP

IR, I

I

RM

IP, I

P

T

PP

PP

Maximum capacitance

Typical capacitance

(Reverse) current @ breakdown voltage

(Reverse) leakage current

Current @ clamping voltage, peak pulse

current

Peak pulse power

T

op

T

stg

V

BR

V

BR,min

V

clamp

V

clamp,max

V

DC

V

BR

V

cl,VC

VRM, V

RWM

, VWM, V

DC

Operating temperature

Storage temperature

(Reverse) breakdown voltage

Minimum breakdown voltage

Clamping voltage

Maximum clamping voltage

(Reverse) stand-off voltage, working

voltage, operating voltage

V

DC,max

V

ESD,air

V

ESD,contact

V

leak

- *) I

VRM, V

F

- *) IRM, I

, VWM, V

RWM

RM,max@VRM

DC

Maximum DC operating voltage

Air discharge ESD capability

Contact discharge ESD capability

(Reverse) voltage @ leakage current

Current @ forward voltage

(Reverse) current @ maximum reverse

stand-off voltage, working voltage,

operating voltage

- *) V

F

Forward voltage

*) Not applicable due to bidirectional characteristics of CeraDiodes

Important notes at the end of this document.

Page 18 of 22Please read Cautions and warnings and

Page 19

CeraDiodes

High-speed series

Cautions and warnings

General

Some parts of this publication contain statements about the suitability of our CeraDiodes for certain areas of application, including recommendations about incorporation/design-in of these products into customer applications. The statements are based on our knowledge of typical requirements often made of our CeraDiodes in the particular areas. We nevertheless expressly point out

that such statements cannot be regarded as binding statements about the suitability of our

CeraDiodes for a particular customer application. As a rule, EPCOS is either unfamiliar with individual customer applications or less familiar with them than the customers themselves. For these

reasons, it is always incumbent on the customer to check and decide whether the CeraDiodes

with the properties described in the product specification are suitable for use in a particular customer application.

Do not use EPCOS CeraDiodes for purposes not identified in our specifications, application

notes and data books.

Ensure the suitability of a CeraDiode in particular by testing it for reliability during design-in. Always evaluate a CeraDiode under worst-case conditions.

Pay special attention to the reliability of CeraDiodes intended for use in safety-critical applications (e.g. medical equipment, automotive, spacecraft, nuclear power plant).

Design notes

Always connect a CeraDiode in parallel with the electronic circuit to be protected.

Consider maximum rated power dissipation if a CeraDiode has insufficient time to cool down

between a number of pulses occurring within a specified isolated time period. Ensure that electrical characteristics do not degrade.

Consider derating at higher operating temperatures. Choose the highest voltage class compatible with derating at higher temperatures.

Surge currents beyond specified values will puncture a CeraDiode. In extreme cases a

CeraDiode will burst.

If steep surge current edges are to be expected, make sure your design is as low-inductance

as possible.

In some cases the malfunctioning of passive electronic components or failure before the end of

their service life cannot be completely ruled out in the current state of the art, even if they are

operated as specified. Do not use CeraDiodes in applications requiring a very high level of operational safety and especially when the malfunction or failure of a passive electronic component could endanger human life or health (e.g. in accident prevention, life-saving systems, or

automotive battery line applications such as clamp 30), ensure by suitable design of the application or other measures (e.g. installation of protective circuitry or redundancy) that no injury or

damage is sustained by third parties in the event of such a malfunction or failure.

Specified values only apply to CeraDiodes that have not been subject to prior electrical, mechanical or thermal damage. The use of CeraDiodes in line-to-ground applications is therefore

not advisable, and it is only allowed together with safety countermeasures like thermal fuses.

Important notes at the end of this document.

Page 19 of 22Please read Cautions and warnings and

Page 20

CeraDiodes

High-speed series

Storage

Only store CeraDiodes in their original packaging. Do not open the package before storage.

Storage conditions in original packaging: temperature -25 to +45°C, relative humidity ≤75% annual average, maximum 95%, dew precipitation is inadmissible.

Do not store CeraDiodes where they are exposed to heat or direct sunlight. Otherwise the

packaging material may be deformed or CeraDiodes may stick together, causing problems during mounting.

Avoid contamination of the CeraDiode surface during storage, handling and processing.

Avoid storing CeraDiodes in harmful environments where they are exposed to corrosive gases

for example (SOx, Cl).

Use CeraDiodes as soon as possible after opening factory seals such as polyvinyl-sealed packages.

Solder CeraDiodes after shipment from EPCOS within the time specified: 12 months.

Handling

Do not drop CeraDiodes and allow them to be chipped.

Do not touch CeraDiodes with your bare hands - gloves are recommended.

Avoid contamination of the CeraDiode surface during handling.

Washing processes may damage the product due to the possible static or cyclic mechanical

loads (e.g. ultrasonic cleaning). They may cause cracks to develop on the product and its parts,

which might lead to reduced reliability or lifetime.

Mounting

When CeraDiodes are encapsulated with sealing material or overmolded with plastic material,

be aware that potting, sealing or adhesive compounds can produce chemical reactions in the

CeraDiode ceramic that will degrade its electrical characteristics and reduce its lifetime.

Make sure an electrode is not scratched before, during or after the mounting process.

Make sure contacts and housings used for assembly with CeraDiodes are clean before mounting.

The surface temperature of an operating CeraDiode can be higher. Ensure that adjacent components are placed at a sufficient distance from a CeraDiode to allow proper cooling.

Avoid contamination of the CeraDiode surface during processing.

Only CeraDiodes with an Ni barrier termination are approved for lead-free soldering.

Soldering

Complete removal of flux is recommended to avoid surface contamination that can result in an

instable and/or high leakage current.

Use resin-type or non-activated flux.

Bear in mind that insufficient preheating may cause ceramic cracks.

Rapid cooling by dipping in solvent is not recommended, otherwise a component may crack.

Important notes at the end of this document.

Page 20 of 22Please read Cautions and warnings and

Page 21

CeraDiodes

High-speed series

Operation

Use CeraDiodes only within the specified operating temperature range.

Use CeraDiodes only within specified voltage and current ranges.

Environmental conditions must not harm a CeraDiode. Only use them in normal atmospheric

conditions. Reducing the atmosphere (e.g. hydrogen or nitrogen atmosphere) is prohibited.

Prevent a CeraDiode from contacting liquids and solvents. Make sure that no water enters a

CeraDiode (e.g. through plug terminals).

Avoid dewing and condensation.

EPCOS CeraDiodes are designed for encased applications. Under all circumstances avoid exposure to:

direct sunlight

rain or condensation

steam, saline spray

corrosive gases

atmosphere with reduced oxygen content

EPCOS CeraDiodes are not suitable for switching applications or voltage stabilization where

static power dissipation is required.

This listing does not claim to be complete, it merely reflects the experience of EPCOS AG.

Display of ordering codes for EPCOS products

The ordering code for one and the same EPCOS product can be represented differently in data

sheets, data books, other publications, on the EPCOS website, or in order-related documents

such as shipping notes, order confirmations and product labels. The varying representations of

the ordering codes are due to different processes employed and do not affect the

specifications of the respective products. Detailed information can be found on the Internet

under www.epcos.com/orderingcodes

Important notes at the end of this document.

Page 21 of 22Please read Cautions and warnings and

Page 22

Important notes

The following applies to all products named in this publication:

1. Some parts of this publication contain statements about the suitability of our products for

certain areas of application. These statements are based on our knowledge of typical re-

quirements that are often placed on our products in the areas of application concerned. We

nevertheless expressly point out that such statements cannot be regarded as binding

statements about the suitability of our products for a particular customer application.

As a rule, EPCOS is either unfamiliar with individual customer applications or less familiar

with them than the customers themselves. For these reasons, it is always ultimately incumbent on the customer to check and decide whether an EPCOS product with the properties described in the product specification is suitable for use in a particular customer application.

2. We also point out that in individual cases, a malfunction of electronic components or

failure before the end of their usual service life cannot be completely ruled out in the

current state of the art, even if they are operated as specified. In customer applications

requiring a very high level of operational safety and especially in customer applications in

which the malfunction or failure of an electronic component could endanger human life or

health (e.g. in accident prevention or lifesaving systems), it must therefore be ensured by

means of suitable design of the customer application or other action taken by the customer

(e.g. installation of protective circuitry or redundancy) that no injury or damage is sustained by

third parties in the event of malfunction or failure of an electronic component.

3. The warnings, cautions and product-specific notes must be observed.

4. In order to satisfy certain technical requirements, some of the products described in this

publication may contain substances subject to restrictions in certain jurisdictions (e.g.

because they are classed as hazardous). Useful information on this will be found in our Ma-

terial Data Sheets on the Internet (www.epcos.com/material). Should you have any more detailed questions, please contact our sales offices.

5. We constantly strive to improve our products. Consequently, the products described in this

publication may change from time to time. The same is true of the corresponding product

specifications. Please check therefore to what extent product descriptions and specifications

contained in this publication are still applicable before or when you place an order. We also

reserve the right to discontinue production and delivery of products. Consequently, we

cannot guarantee that all products named in this publication will always be available. The

aforementioned does not apply in the case of individual agreements deviating from the foregoing for customer-specific products.

6. Unless otherwise agreed in individual contracts, all orders are subject to the current ver-

sion of the "General Terms of Delivery for Products and Services in the Electrical Industry" published by the German Electrical and Electronics Industry Association

(ZVEI).

7. The trade names EPCOS, Alu-X, CeraDiode, CeraLink, CeraPlas, CSMP, CSSP, CTVS,

DeltaCap, DigiSiMic, DSSP, FilterCap, FormFit, MiniBlue, MiniCell, MKD, MKK, MLSC,

MotorCap, PCC, PhaseCap, PhaseCube, PhaseMod, PhiCap, PQSine, SIFERRIT, SIFI,

SIKOREL, SilverCap, SIMDAD, SiMic, SIMID, SineFormer, SIOV, SIP5D, SIP5K, TFAP,

ThermoFuse, WindCap are trademarks registered or pending in Europe and in other countries. Further information will be found on the Internet at www.epcos.com/trademarks.

Page 22 of 22

Loading...

Loading...