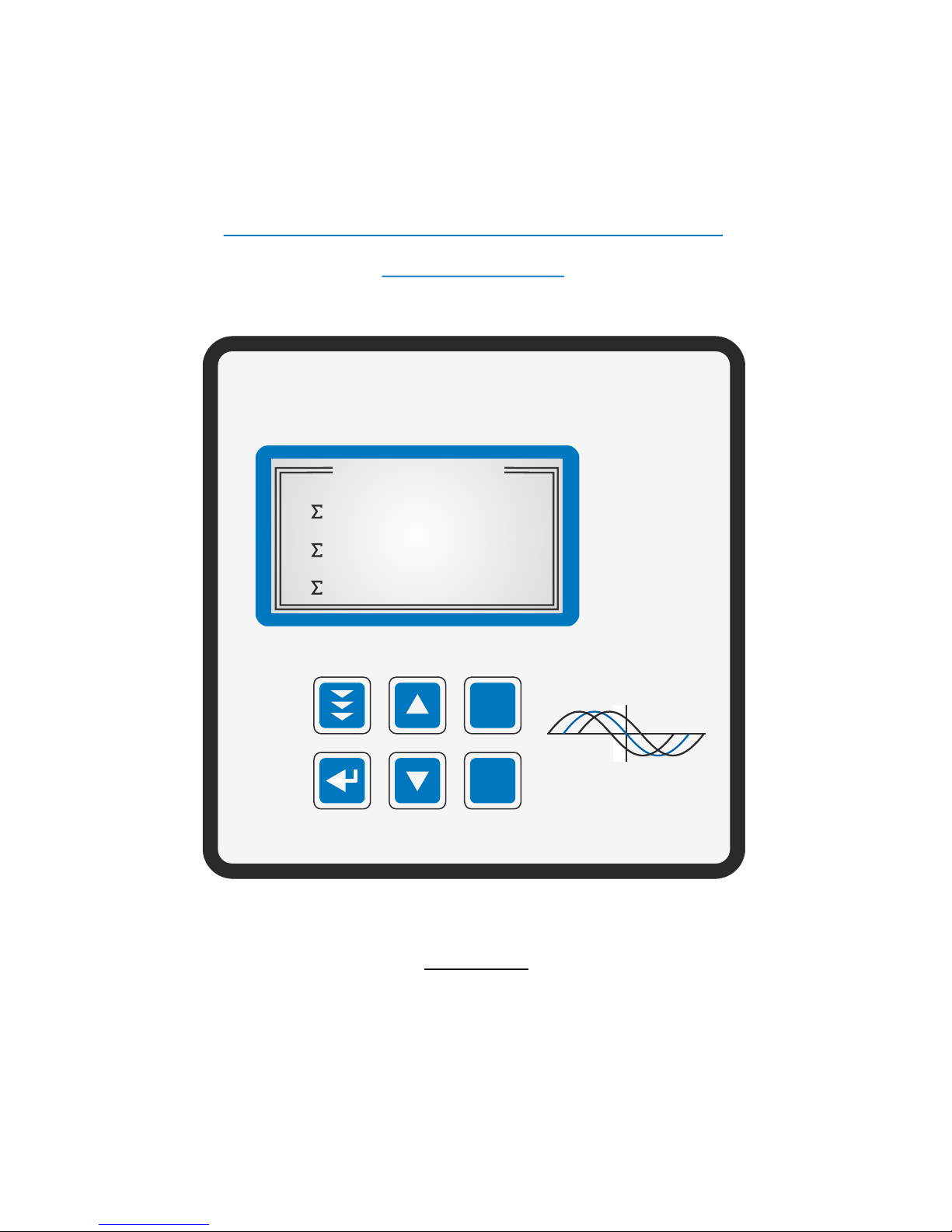

Power Factor Controller

BR 7000

Manual

Version 1.1 E

Power Factor

Controller

BR 7000

Auto

Program

Manual

Service

Enter

OK

Power Quality Solutions

HELP

ESC

AUTO-MODE 2/2

14

137

140

kvar

kW

kVA

Q

P

S

cos

ϕ

!

CAUTIONS:

1. High voltage !

2. BR7000 may only be used indoor !

3. Make sure that the discharge time set in the controller matches

the capacitor discharge time !

CONTENTS

Section 1 General p.3

Section 2 Installation and instructions for usage p.4

Section 3 Connection alternatives measuring voltage p.6

and measuring current

Section 4 Display functions p.8

Section 5 Display of grid parameters p.9

Section 6 PROGRAM-MODE / Manual programming p.11

6.1 Programming lock p.18

6.2 QUICK-Program p.19

Section 7 Automatic initialization p.20

Section 8 Automatic test run p.21

Section 9 HELP-function / actual assignment of outputs p.21

Section 10 MANUAL OPERATION p.23

Section 11 SERVICE MENU / Error storage p.24

Section 12 EXPERT MODE

12.1 Expert-Mode 1 p.25

12.2 Expert-Mode 2 p.27

Section 13 Control principle p.28

Section 14 Interfaces p.29

14.1 ASCII -protocol p.30

14.2 Controller coupling p.30

14.3 Windows-software for PC p.31

Section 15 Alarm relay / Error messages p.32

Section 16 Display-editor p.32

Section 17 OSCI-MODE p.32

Section 18 Maintenance and warranty p.32

Appendixes/ Tables:

Annex 1 Troubleshooting p.33

Annex 2 Technical data p.35

Annex 3 Factory settings p.37

Annex 4 Control series table p.39

Control series editor

Annex 5 Register MODBUS protocol p.40

Annex 6 Operation diagram p.43

- 2 -

Rev.: 04.2013

Section 1: GENERAL

The power factor controller BR7000 is the consequent follow-up development of the well

proven series BR6000.

The main distinctive feature is the new 3-phases measuring system. Due to the 3-phases

recording of voltage and current the device allows a convenient usage as grid measuring

device and as power factor controller.

All measuring values can be edited and may be displayed in big letters for easier

readability.

2 interfaces are standard. By means of the comfortable windows-software that is included

in the delivery and by using one interface for a connection to a PC the execution and

evaluation of grid measurements is possible. The second interface can be used for

customer specific purposes.

Used as PF-controller various control modes are available. They allow not only to control

according to the phase with the highest load or the average demand of the phases, but

also to realize a real single-phase control (balancing) or a mix of balancing and

conventional three-phases-control.

All well proven functions of the BR6000-series are available for the BR7000; for example

the control series editor, the automatic initialization etc. For an easy usage the concept of

graphic menu navigation has mainly been adapted. New are amongst others an

integrated help (HELP-button) and the possibility to jump back in the programming menu

by an additional ESCape-button.

The usage of a fully graphic support display allows an additional Oscilloscope-Mode where

the phases (half waves) of voltage and current can graphically be displayed.

R 3 x 5 free programmable switching outputs

R 1 alarm relay, 1 programmable message relay, 1 relay for the cabinet fan

R Operating voltage: 110 ... 230VAC (+/-15%)

R Measuring voltage: 3 x 30 ... 440 VAC (L-N) / 50...760 V (L-L)

R Measuring current: 3 x 5A / 1A

R Pre-programmed control series and control series editor

R Illuminated graphic display 128 x 64 dot, graphical menu navigation

R 4-quadrant-operation

R Automatic initialization possible

R Measuring of capacitor current possible

R Three-phase display of various grid parameters ( U, I, F, Q, P, S Delta Q ... )

R Switch over to large display possible

R Display up to 31st harmonic of voltage and current

R Simultaneous graphical display 1 period of voltage and current in Osci-mode

R Monitoring of temperature and particular capacitor output

R Storage of maximum grid parameters and switching operations/switch on times of

capacitors with time stamp

R Manual/automatic operation

R Programming of fixed steps or mascing of particular outputs possible

R Control possible as 3-phase, 1-phase or mixed-mode

R Display of different error messages

R Error storage

R Complete 2nd parameter set programmable

R 2 integrated separate interfaces

R Integrated clock, several timers possible

R Integrated help-function/plain text

R Panel-mounted instrument 144 x 144 x 60 mm

- 3 -

- 4 -

Section 2: INSTALLATION AND INSTRUCTIONS FOR USAGE

The BR7000 is designed as panel mounting instrument in PFC-systems. This requires a

cut out of 138 x 138 mm according to DIN 43700 / IEC 61554. The controller has to be

inserted from the front and fixed with the clamps (included in delivery). The device may

only be installed by qualified personnel and may only be operated according the given

safety regulations. In addition the relevant legal and safety instructions have to be

obeyed.

The measuring input is designed for 1- and 3-phase grids with or without neutral

conductor. The maximum measuring voltage is 440V+ (L-N) / 760V ~ (L-L).

The supply voltage is 110...230 V +/-15%.

Wiring connections must be suitable for the particular voltages. Input leads have to be

protected by over-current-protection devices. The supply voltage must be protected by a

fuse; it must be possible to switch off the supply voltage by a separator.

The BR7000 must not be operated without protective earth contactor connected!

Before connecting the BR7000, it has to be checked that all connections are at zero

potential; current transformers have to be short circuited. Correct phasing of measuring

voltage and measuring current have to be checked. The measuring current circuits must

2

be wired with minimum 2.5 mm Cu.

Terminals may only be plugged when de-energized!

Attention!

During single-phase operation the coil voltage for the capacitor contactors must be drawn

from the same phase as the measuring voltage as only the measuring voltage is

monitored. (Protection against direct re-switching of contactors during a short-term

single-phase voltage drop.)

The controller may only be operated when installed. The complete programming of all

application-specific parameters is done according chapter programming. Then the device

is set to automatic operation by pushing the operation mode button. The controller is now

ready for operation.

Operating the controller without following to these operating instructions may be harmful

and dangerous!

!

!

!

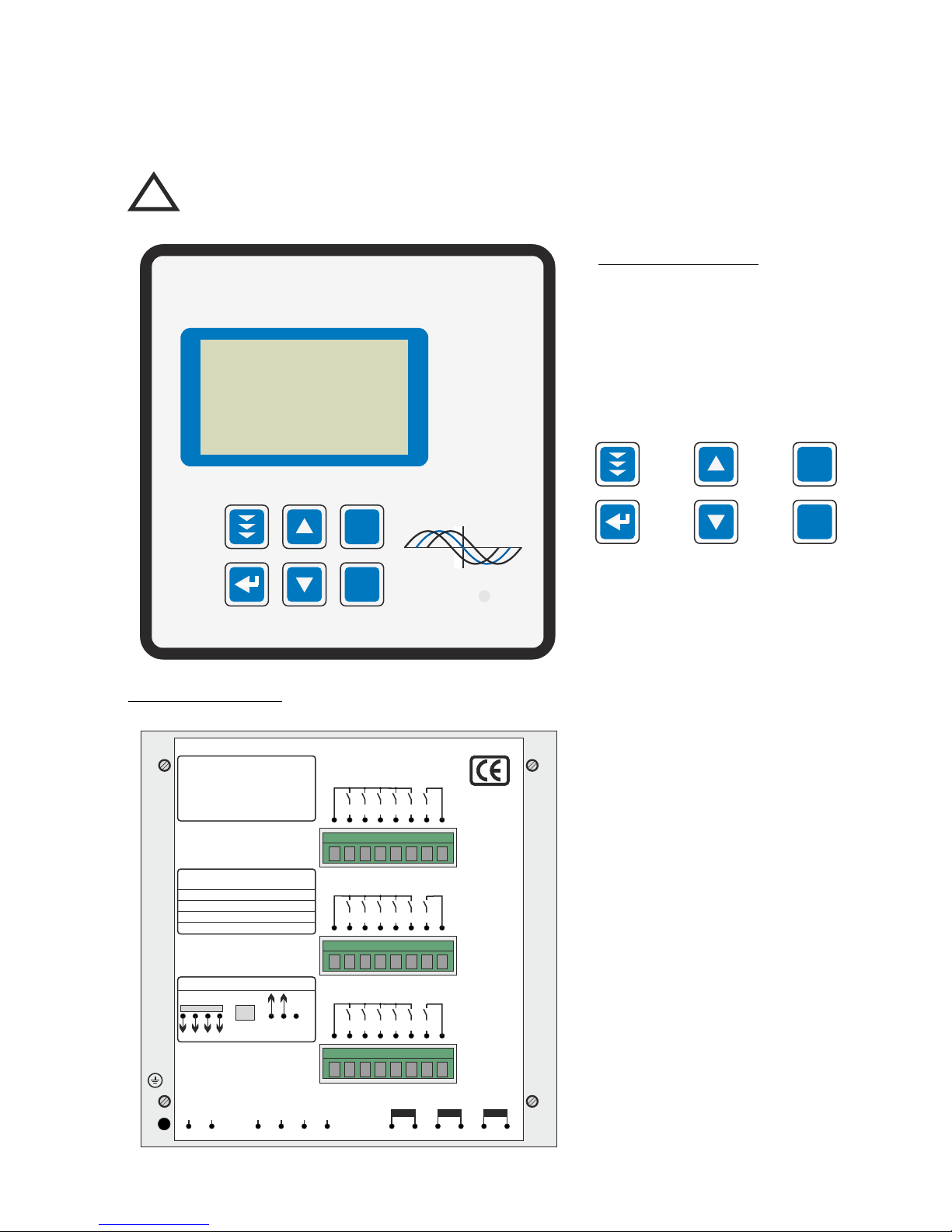

BR 7000 rear view

Operating mode:

- Automatic

- Program.

- Manual oper.

- Service

- Expert Mode

- Osci - Mode

- Display Editor

ENTER/ OK

Confirmation

storage of

values

Increase

selected

parameter

HELP

opens

Help pages

Reduce

selected

parameter

Escape

previous

page/value

in the display

- 5 -

BR 7000 front view

The controller is supplied for a standard operating voltage of 110...230VAC (+/-15%), a

measuring voltage of 30...440 V~ (L-N) resp. 50...760V~ (L-L), 50/60Hz, and a

measuring current of 5A or 1A (programmable). A voltage converter is required for

different operating voltages.

Caution!

Voltages which exceed the allowed voltage range can damage the

device !

!

Power Factor

Controller

BR 7000

Auto

Program

Manual

Service

Enter

OK

Power Quality Solutions

HELP

ESC

HELP

ESC

Power factor controller BR7000

Type: BR7000-R

Meas voltage: 50 - 760VAC 50/60Hz

Supply voltage:110 - 230VAC 50/60Hz

Ser.Nr.: 0815 / 2009

P1

P2

P3

K1

K6

K11

K2

K7

K12

K3

K8

K13

K4

K9

K14

K5

K10

K15

K21

K22

K23

Meas.current

k L1 l

Supply voltage

110...230V~

Measuring voltage

30 ... 440V L-N

Output 11-15

Output 6-10

Output 1-5

Switching outputs:

Fan relay

Message relay

Alarm relay

Meas.current

k L2 l

Meas.current

k L3 l

Interface 1

Contact assignment 2nd terminal at bottom

Interface 2

External input

230V~

GND B A PE

L1 N L1 L2 L3 N

The allocation of switching outputs K1…K15

to the capacitors complies to the selected

connection variant and the desired

CONTROL-MODE

(Programming/point 2)

Especially in ”Mixed Mode“ where some

outputs are used for single phase capacitors,

others for 3-phase-capacitors the proper

connection must be assured!

In the “HELP”-menu the BR7000 directly

displays the actual correct allocation of

outputs (AUTO-MODE: Help-page 7-9).

For examples also see chapter 9.

cos

ϕ

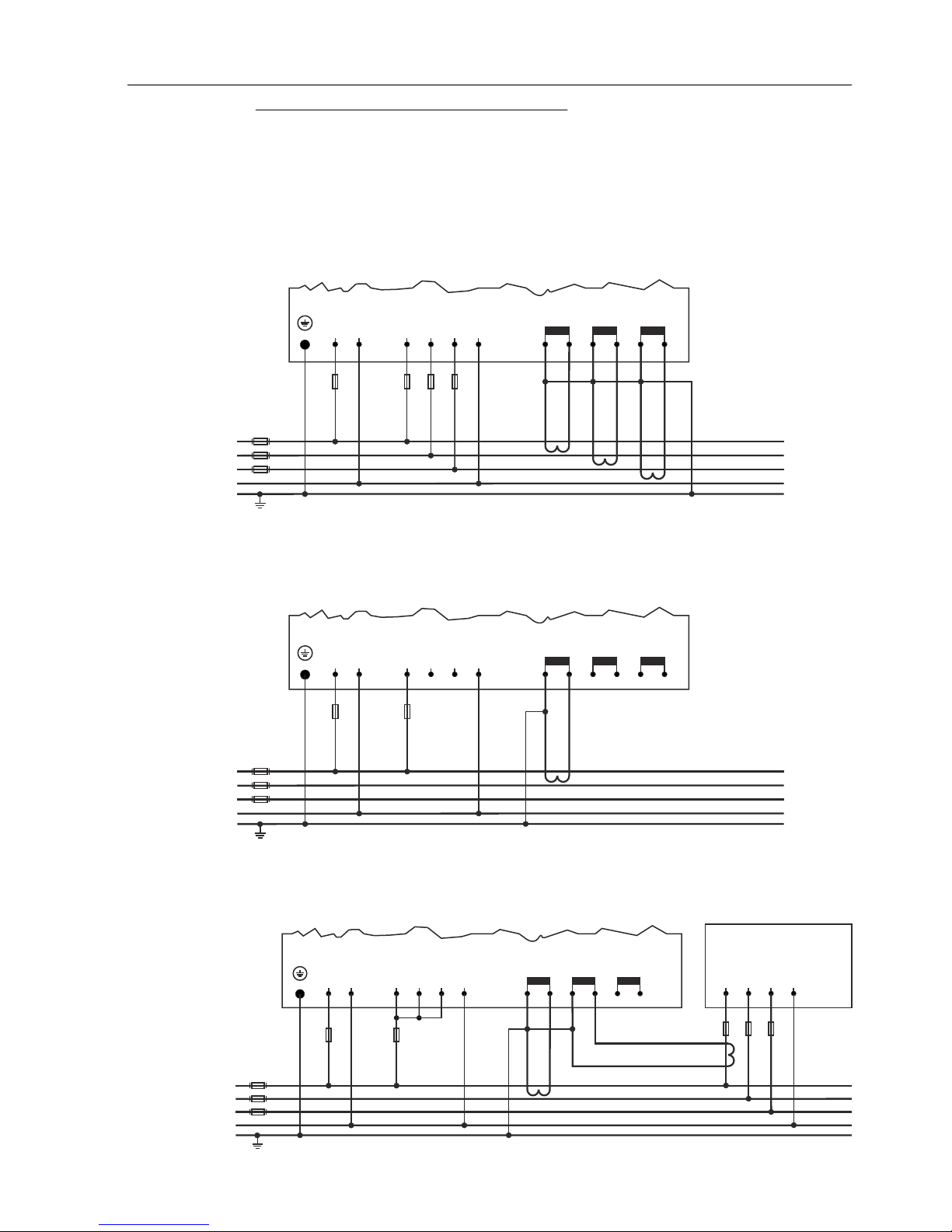

Section 3: CONNECTION ALTERNATIVES MEASURING VOLTAGE

AND MEASURING CURRENT

According to the existing grid and the desired operating mode (CONTROL-MODE

Programming) the BR7000 has to be connected accord. one of the following alternatives.

In grids without neutral conductor the connector N(PE) from meas.voltage at

the controller has to be connect with the PE of the grid !

Alternative 1: measuring performed in each phase - 3 current transformers needed

Use: CONTROL-MODE: 1 - 4 (control modes see page 11)

BR7000

Alternative 2: single-phase measuring via current transformer in L1 Values extrapolated (balance assumed).

Measuring complies with conventional measuring for switching of three-phase capacitors.

Use: CONTROL-MODE 5

BR7000

Alternative 3: single-phase measuring as alternative 2 , but with capacitor current measuring in the compensation

system for collection of real capacitor currents.

Use: CONTROL-MODE 6

BR7000

Reserve

PE

N

L2 (S)

L3 (T)

L1 (R)

( L1) ( N )

L1 L2 L3 N(PE)*

Supply voltage

110-230V~

Measuring voltage Um

Meas.current

L3

Meas.current

L2

Meas.current

L1

Load site

( L1) ( N )

L1 L2 L3 N(PE)*

Supply voltage

110-230V~

Measuring voltage Um

Meas.current

L3

Meas.current

L2

Meas.current

L1

L1 (R)

L2 (S)

L3 (T)

PE

N

Load site

- 6 -

( L1) ( N )

L1 L2 L3 N(PE)*

Supply voltage

110-230V~

Measuring voltage Um

Meas.current

L3

Meas.current

L2

Meas.current

L1

L1 (R)

L2 (S)

L3 (T)

PE

N

L1 L2 L3 N

P F C- system

- 7 -

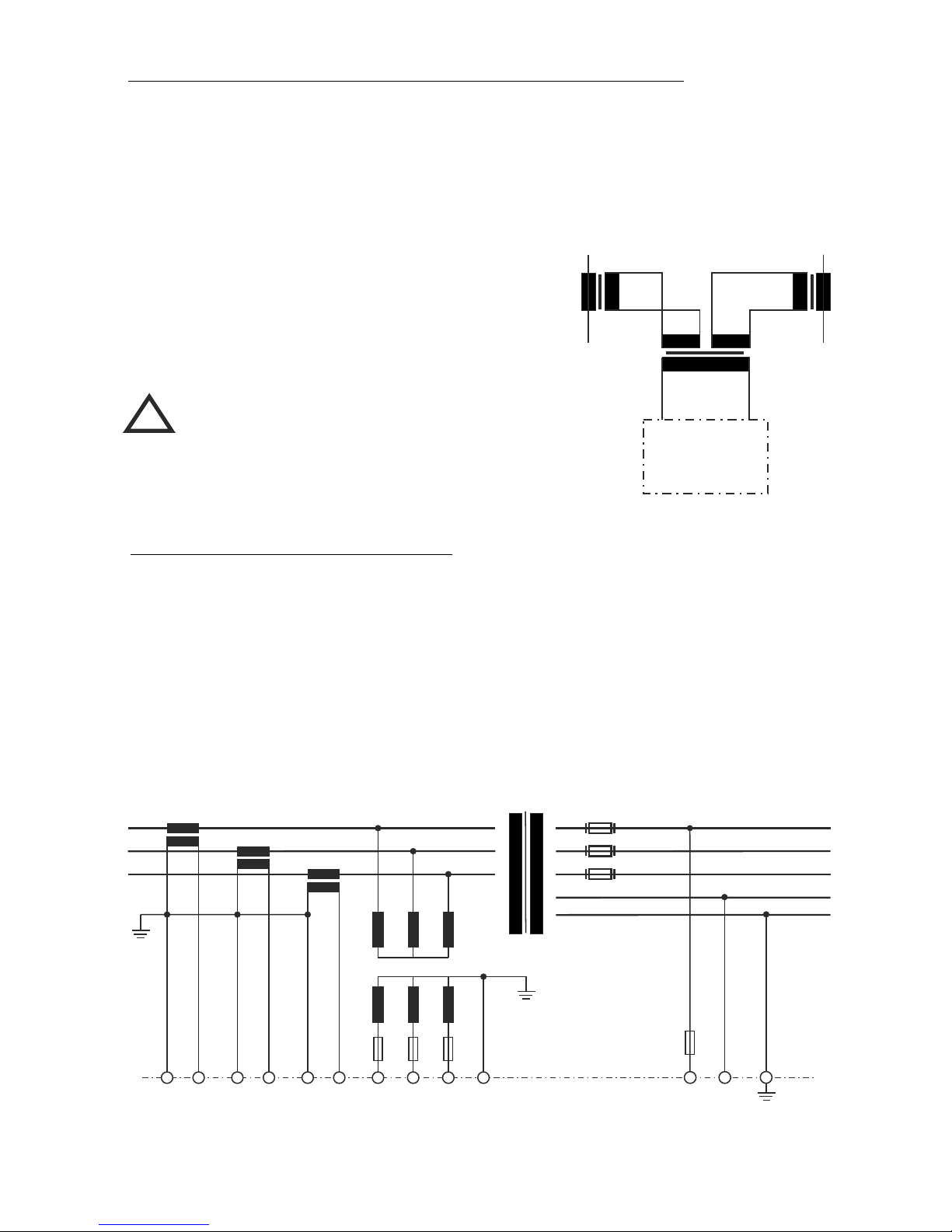

kK k K

lL l L

Feed 1 Feed 2

K L K L

Measurement via sum current converter

P.F.Controller

Current

measurement

k l

k l

Example:

C.converter 1: 1000/5A

C.converter 2: 1000/5A

Sum-current converter: 5A+5A / 5A

C.converter ratio is: 2000 /5A

Connection of current transformer / sum current transformer

When installing the current converter, care should be taken to ensure that the load

current flows through it. The outputs of the compensation network must be installed

behind the current converter (in the direction of current flow). If the is connected

up via sum-current converters, the overall conversion ratio is entered.

Current converter clamps should be grounded on one side!

Caution!

Current converter clamps should

be grounded on one side !

The secondary clamps of the CT

have to be short circuited before

current leads are iterrupted !

BR7000

!

BR7000 in High Voltage Application

The example shows the connection of BR7000 in HV-application.

The measuring current is taken off primary via X/1A transformer. Measuring voltage

produced via transformer 20000/100 V. In this case, the BR7000 has to be programmed

as follows:

4 I-CONVERTER sek: X / 1A

14 MEASUR.VOLTAGE: 100 V

15 V-CONVERTER: 20kV / 100 V

L1 (R)

L1 (R)

L2 (S)

L2 (S)

L3 (T)

L3 (T)

N

Meas.current

Im (X/1A)

supply

voltage

Ub

Meas voltage

Um

BR 7000

PE

Meas.current Meas. voltage Um

Supply voltage Ub

L1 L2 L3

L1 L2 L3 N

L1 N

HIGH VOLTAGE LOW VOLTAGE

20 kV / 400 V

20000

100

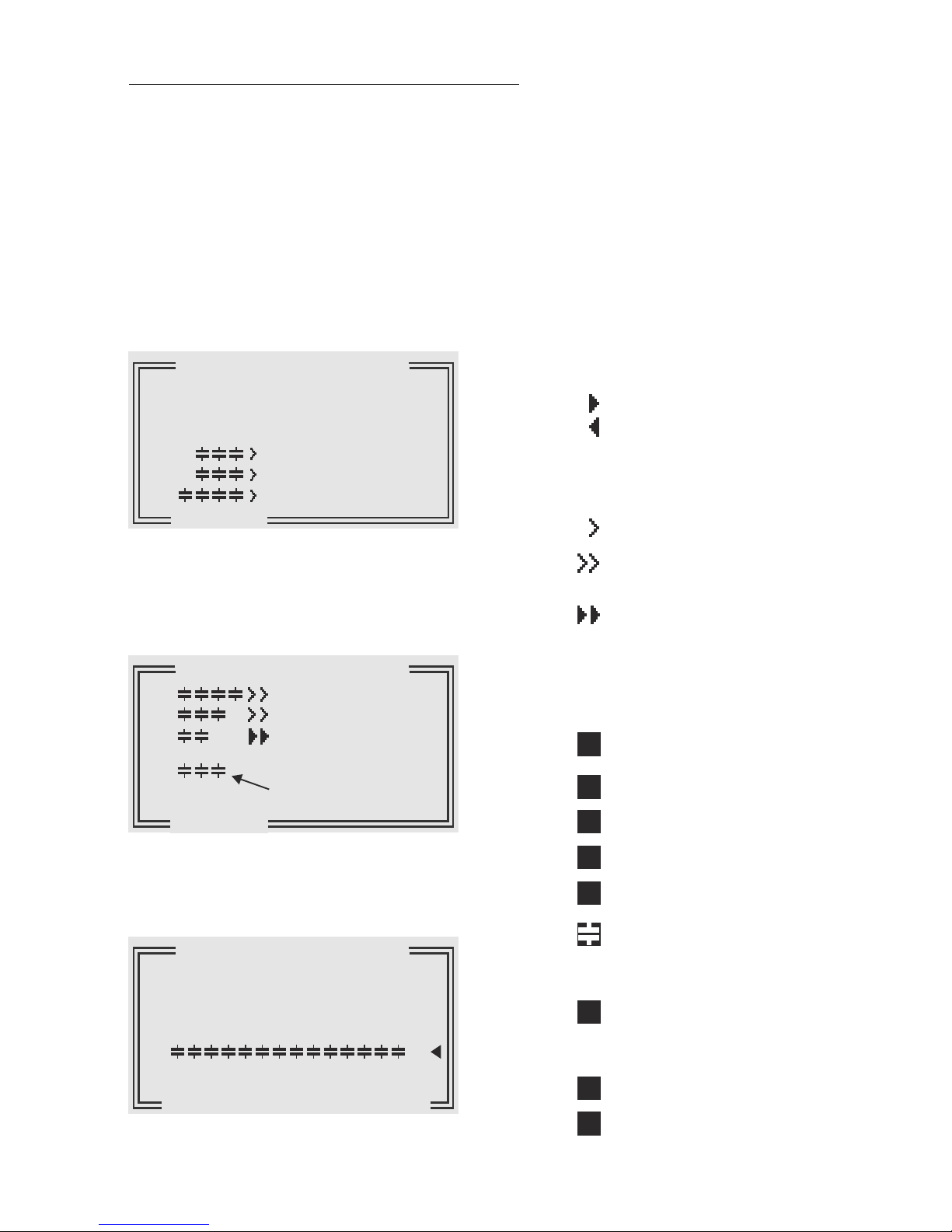

Section 4: DISPLAY - FUNCTIONS

After the operating voltage has been switched on, the BR7000 briefly indicates with

description and software-version before changing to automatic operation.

Actual values and symbols of the particular operation state are shown in the display.

In the automatic operation (standard) capacitor steps are automatically switched on or

off to reach the pre-set target cos-phi. This happens when the required reactive power is

higher than the value of the smallest capacitor step.

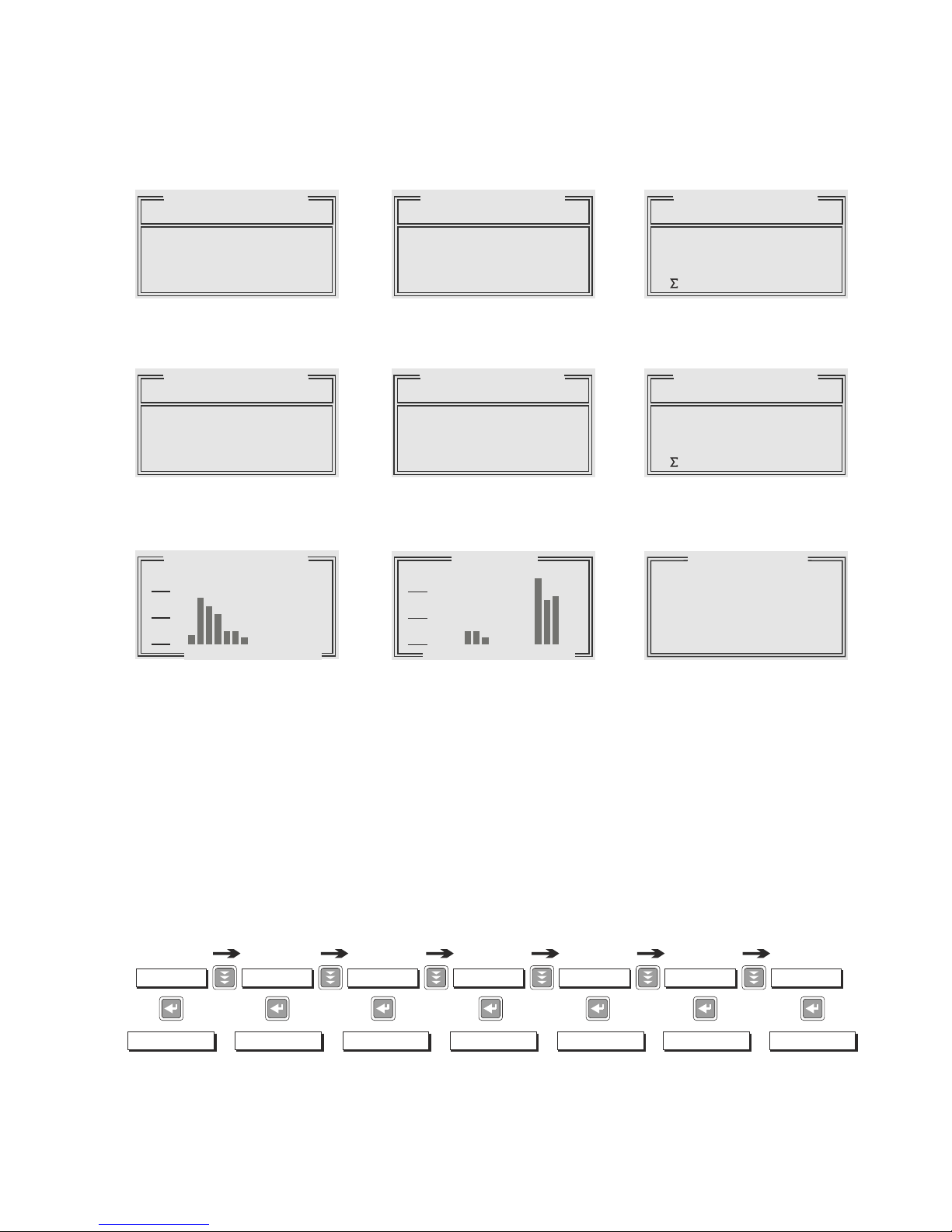

Example 1: Automatic operation

L1...L3: Individual compensation by single-phase capacitors

- 8 -

Number of switching outputs until end stop.

Here: 15 three-phase capacitors, end-stop: 15

Control direction is symbolized by a

compact arrow:

Connecting-in

Connecting-out

The connecting-in arrow is always

located after the maximum possible

number of stages (end stop)

An open arrow indicates that the

required blocking time (Discharge time)

is running before an impending

switching step

A double arrow symbolizes switching of

several branches

The sigma-sign indicates the threephase-value (mean-value) resp.

activated three-phase-capacitors

Alarm relay activated

(declines in case of error)

Message relay activated: “SUPPLY”

Message relay activated:“Undercurrent”

Message relay aktivated: “Harmonics”

FAN-relay: ON

The particular capacitor outputs are

permanently monitored. Inverse display

= capacitor out of range

Display of 2nd parameter-set

Supply display (i.e.generator operation)

nd

2 Target-cos phi activated by timer

nd

2 Target-cos phi activated by supply

S

A

U

H

F

2

T

é

é

Example 2: Automatic operation (Mixed Mode)

L1...L3: phase wise compensation by

single phase capacitors

Σ: Three-phase capacitors activated

Example 3: Automatic operation

Measuring in one phase

Controlling of 15 three-phase-capacitors

Σ

AUTO-MODE 1/2

cosϕ 0.869 IND

cosϕ 0.869 IND

cosϕ 0.869 IND

cosϕ 0.917 CAP

L1

L1

L2

L2

L3

L3

1 2 3 4

Σ

Σ

Σ

AUTO-MODE 1/3

AUTO-MODE 1/2

L1

L2

L3

1 2 3 4

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15

control direction

(here: connected-in)

active capacitor

branches

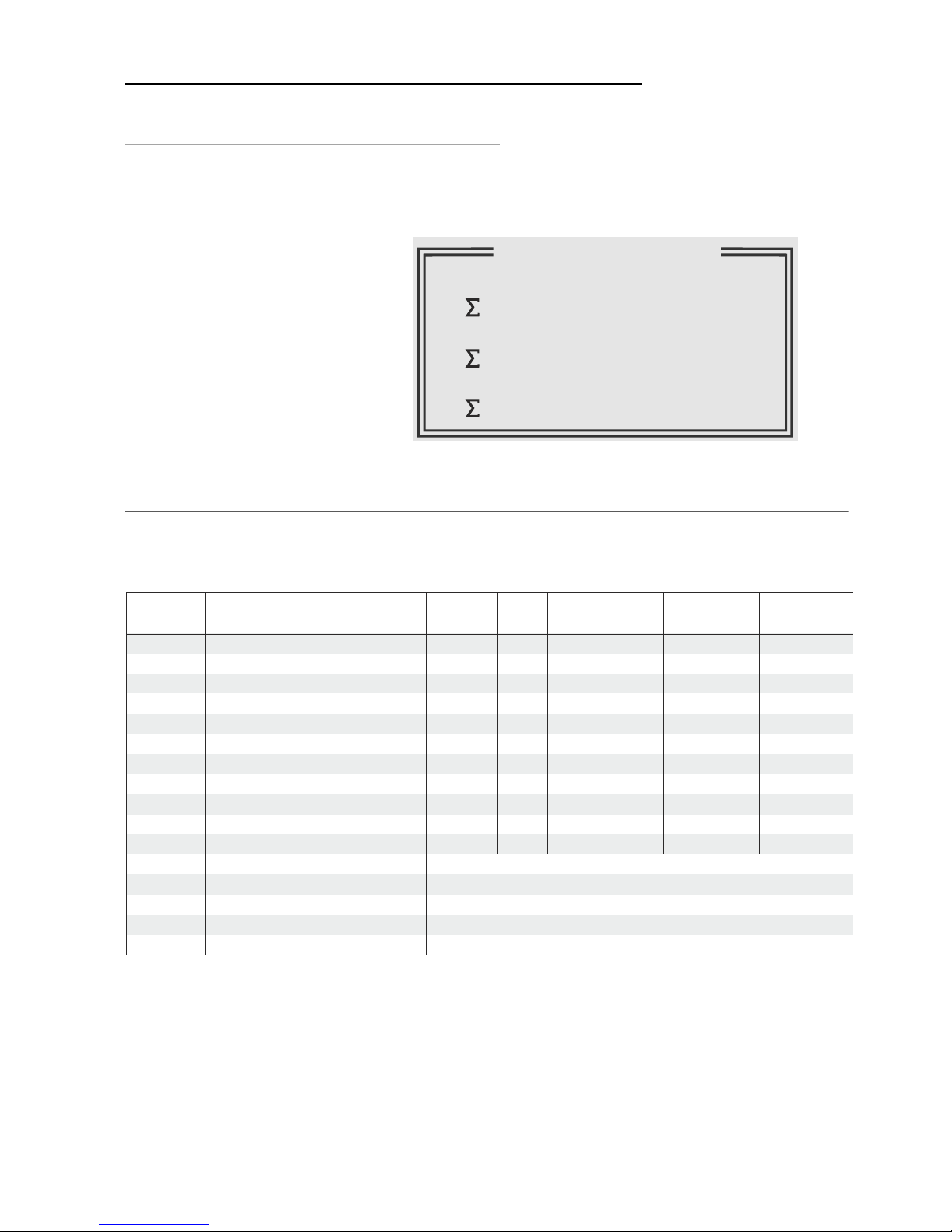

Section 5: DISPLAY OF GRID PARAMETERS

5.1 Display of 3 selected grid parameters

In Auto-Mode, button é leads to display mode 1. Here 3 (free selectable) grid parameters

are displayed in large letters. The selection and storage of these values is done in the

Display- Editor.

Example: Display mode 1:

Desired values selected in the

Display Editor (see section 16 )

5.2 Display of particular grid parameters (from AUTO-MODE by pressing ENTER)

By repeated activation of the “ENTER”-button (in automatic operation) several grid

parameters can be displayed (s. table below):

Action Display Unit in% large display Bargraph 3-phase

possible possible

ENTER 1 LINE VOLTAGE V x x

ENTER 2 APPARENT CURRENT A x x x

ENTER 3 REACTIVE POWER kvar x x x

ENTER 4 ACTIVE POWER kW x x x

ENTER 5 APPARENT POWER kVA x x x

ENTER 6 DIFF. kvar to target kvar x x x

ENTER 7 FREQUENCY Hz x x

ENTER 8 TEMPERATURE °C / °F x

ENTER 9 3.-31. HARMONICS V/ I x x x

ENTER 10 HARMONICS THD-V/I x x x

ENTER 11 Comp.- power (only at real capacitor current measurement)

ENTER 12 ENERGY kvarh / kWh

ENTER 13 TIME / DATE é / ê change the date format

ENTER 14 Software version

ENTER return to: 1

Buttons é / ê change the display format:

The values can be displayed in their unit, in % or as large display resp. bar chart.

Examples, see next page.

- 9 -

AUTO-MODE 2/2

14

137

140

kvar

kW

kVA

Q

P

S

=== DISPLAY ===

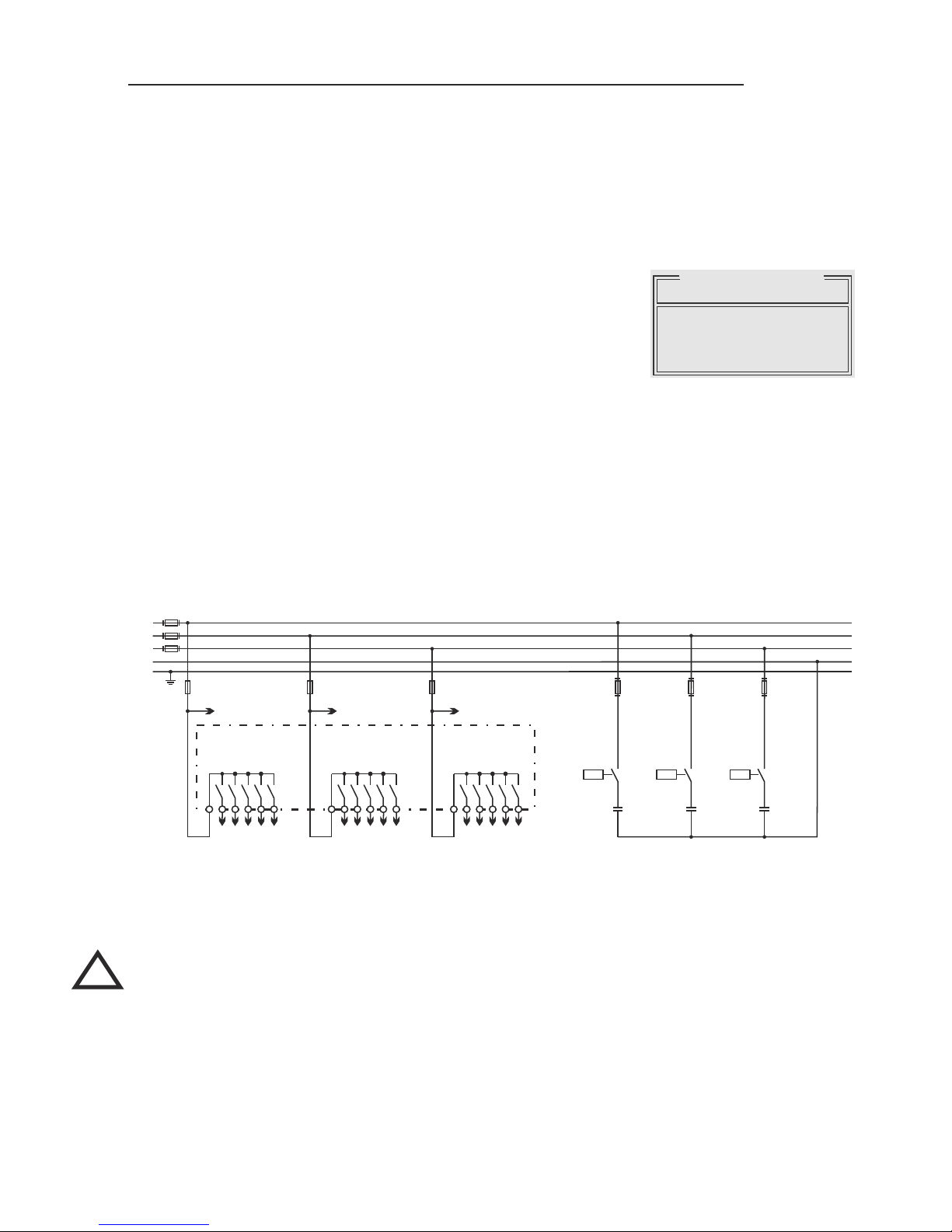

Examples of different displays:

VOLTAGE 3-phas. CURRENT: 3-phas. REACTIVE PWR 3-phas.

HARMONICS in % TEMPERATURE °C REACTIVE PWR in %

LARGE LETTERS

HARMONICS diagram THD V/I as bar diagram REACTIVE POWER

LARGE LETTERS

- 10 -

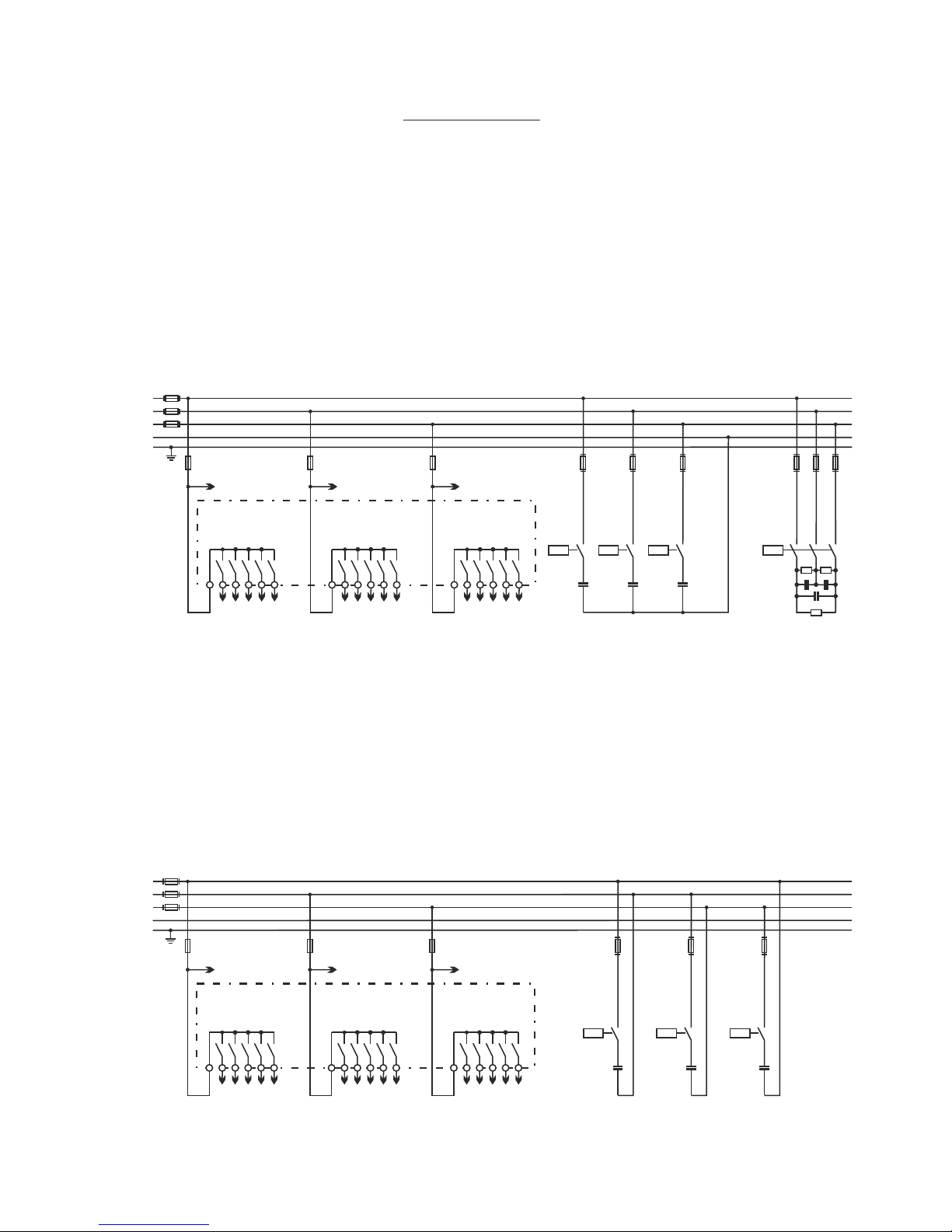

Repeated pressing of the "Operating Mode” key activates the various menus in sequence:

Automatic operation - Programming - Manual (manual operation)- Service - Expert

mode - OsciMode - DisplayEditor and back to Auto.

AUTO-MODE

to display operation to programming to manual operation to value buffer special functions to graphic. mode display-functions

PROGRAMMING

MANUAL-MODE

SERVICE EXPERT-MODE OSZI - MODE

DISPLAY-EDITOR

DISPLAY 7/9

8 HARMONICS [3.]

L1 V 0.4% I 0.5%

L2 V 1.4% I 0.8%

L3 V 1.4% I 0.7%

DISPLAY 3/4

TEMPERATURE

25 °C

DISPLAY 1/3

1 LINE VOLTAGE

L1-N 233 V

L2-N 233 V

L3-N 233 V

24VDC 24 V

DISPLAY 3/3

25

25

25

kvar

kvar

kvar

Q1

Q2

Q3

ANZEIGE 1/3

2 APPAR.CURRENT

L1 235 A

L2 133 A

L3 133 A

DISPLAY 1/2

3 REACTIVE POWER

L1 71 kvar

L2 23 kvar

L3 22 kvar

116 kvar

DISPLAY 2/3

3 REACTIVE POWER

L1 31 %

L2 10 %

L3 10 %

17 %

HARMONICS [V-1]

1.0%

0.5%

0%

35 79

11 13 15 17 19 21 23 25 27 29 31

THD 1/2

20%

10%

0%

THD V 1 2 3 THD I 1 2 3

DISPLAY 1/3

Section 6: PROGRAM-MODE (manual programming)

Pressing the button “Operation Mode“ one time switches from automatic operation to the

program mode.

The upper part of the display always shows the parameter, the adjustable values are

shown in the lower part. Editable values are generally given in square brackets. Changes

of these values can be done by the buttons é / ê. By pressing the “ENTER-button” the

value is stored. Pressing the “ESC”-button allows to go one step back (without storing).

1 LANGUAGE

This selects the language of the operating menu

[GERMAN, ENGLISH, SPANISH, RUSSIAN, TURKISH]

2 CONTROL-MODE [1...6]

CONTROL-MODE [1]:

3-phase measuring / max. 3x5 single phase capacitors L-N

(3 current transformers needed), values displayed and calculated per phase.

Connection of measuring current and measuring voltage (refer to page 6).

Controlling is done with max. 5 outputs per phase in case of switching of singlephase capacitors L-N.

Allocation of switching outputs K1…K15 to the capacitors according to the selected

connection variant and the desired CONTROL-MODE.

Especially in ”Mixed Mode“ where some outputs are used for single phase

capacitors, and others for 3-phase-capacitors the proper connection must be

assured!

In the HELP-function the BR7000 directly displays the correct allocation of outputs

(AUTO-MODE: Help-page 7-9).

!

- 11 -

Example :

3x 5 single-phase capacitors (L-N)

Output assignment

L1 (R)

L2 (S)

L3 (T)

P1 1 2 3 4 5 P2 6 7 8 9 10 P3 11 12 13 14 15

Output 1-5 Output 6-10 Output 11-15

meas.voltage L1 meas.voltage L2 meas.voltage L3

PE

N

F1: 6,3AT F1: 6,3AT F1: 6,3AT

C1.1 (C1 at L1-N)

C1.2 (C1 at L2-N)

C1.3 (C1 at L3-N)

C2.1 (C2 at L1-N)

C2.2 (C2 at L2-N)

C2.3 (C2 at L3-N)

C3.1 (C3 at L1-N)

C4.1 (C4 at L1-N)

C5.1 (C5 at L1-N)

C3.2 (C3 at L2-N)

C4.2 (C4 at L2-N)

C5.2 (C5 at L2-N)

C3.3 (C3 at L3-N)

C4.3 (C4 at L3-N)

C5.3 (C5 at L3-N)

K1

(K2)

(K3)

(K4)

(K5)

K6

(K7)

(K8)

(K9)

(K10)

K11

(K12)

(K13)

(K14)

(K15)

C1.1

(C2.1)

(C3.1)

(C4.1)

(C5.1)

C1.2

(C2.2)

(C3.2)

(C4.2)

(C5.2)

C1.3

(C2.3)

(C3.3)

(C4.3)

(C5.3)

PROGRAM-MODE

1 LANGUAGE [1]

[ ENGLISH ]

=== PROGRAM-MODE ===

CONTROL-MODE [2]: MIXED-MODE 3-phasige measuring

3 current transformers required. Values displayed and calculated per phase. Connection of

measuring current and measuring voltage see page 6.

Controlling done with max. 4 outputs per phase for switching of single phase capacitors L-N.

The rest of the outputs (min. 3, max. 12) are used for switching of three-phase capacitors

to control the base load.

Partitioning into single-phase / three-phase capacitors is done at

Programming: 4 ENDSTOP!

The allocation of the switching outputs to the particular capacitors can be retrieved in AUTOMODE on HELP-pages 7…9.

CONTROL-MODE [3]:

3-phase measuring / max. 3x5 single-phase capacitores L-L

3 current transformers required. Values displayed and calculated per phase.

Controlling done with max. 5 outputs per phase, switching of single phase capacitors L-L

L1 (R)

L2 (S)

L3 (T)

Example:

3x 4 single-phase-capacitors +

3 standard 3-phase capacitors

Output assignment

3 x 4 Single-phase steps

3 Three-phase-

capacitors

P1 1 2 3 4 5 P2 6 7 8 9 10 P3 11 12 13 14 15

Output 1-5 Output 6-10 Output 11-15

meas.voltage L1 meas.voltage L2 meas.voltage L3

PE

N

K 5

(K10)

(K15)

F1: 6,3AT F1: 6,3AT F1: 6,3AT

C1.1 (C1 at L1-N)

C1.2 (C1 at L2-N)

C1.3 (C1 at L3-N)

C2.1 (C2 at L1-N)

C2.2 (C2 at L2-N)

C2.3 (C2 at L3-N)

C3.1 (C3 at L1-N)

C4.1 (C4 at L1-N)

C3.2 (C3 at L2-N)

C4.2 (C4 at L2-N)

C3.3 (C3 at L3-N)

C4.3 (C4 at L3-N)

C1Σ (C1 3-phas.)

C2Σ (C2 3-phas.)

C3Σ (C3 3-phas.)

C1Σ

( C2Σ )

( C3Σ )

K1

(K2)

(K3)

(K4)

K6

(K7)

(K8)

(K9)

K11

(K12)

(K13)

(K14)

C1.1

(C2.1)

(C3.1)

(C4.1)

C1.2

(C2.2)

(C3.2)

(C4.2)

C1.3

(C2.3)

(C3.3)

(C4.3)

L1 (R)

L2 (S)

L3 (T)

Example:

3x 5 single-phase capacitors (L-L)

Output assignment

P1 1 2 3 4 5 P2 6 7 8 9 10 P3 11 12 13 14 15

Output 1-5 Output 6-10 Output 11-15

meas.voltage L1 meas.voltage L2 meas.voltage L3

PE

N

F1: 6,3AT F1: 6,3AT F1: 6,3AT

C1.1 (C1 at L1-L2)

C1.2 (C1 at L2-L3)

C1.3 (C1 at L3-L1)

C2.1 (C2 at L1-L2)

C2.2 (C2 at L2-L3)

C2.3 (C2 at L3-L1)

C3.1 (C3 at L1-L2)

C4.1 (C4 at L1-L2)

C5.1 (C5 at L1-L2)

C3.2 (C3 at L2-L3)

C4.2 (C4 at L2-L3)

C5.2 (C5 at L2-L3)

C3.3 (C3 at L3-L1)

C4.3 (C4 at L3-L1)

C5.3 (C5 at L3-L1)

K1

(K2)

(K3)

(K4)

(K5)

K6

(K7)

(K8)

(K9)

(K10)

K11

(K12)

(K13)

(K14)

(K15)

C1.1

(C2.1)

(C3.1)

(C4.1)

(C5.1)

C1.2

(C2.2)

(C3.2)

(C4.2)

(C5.2)

C1.3

(C2.3)

(C3.3)

(C4.3)

(C5.3)

=== PROGRAMM-MODE ===

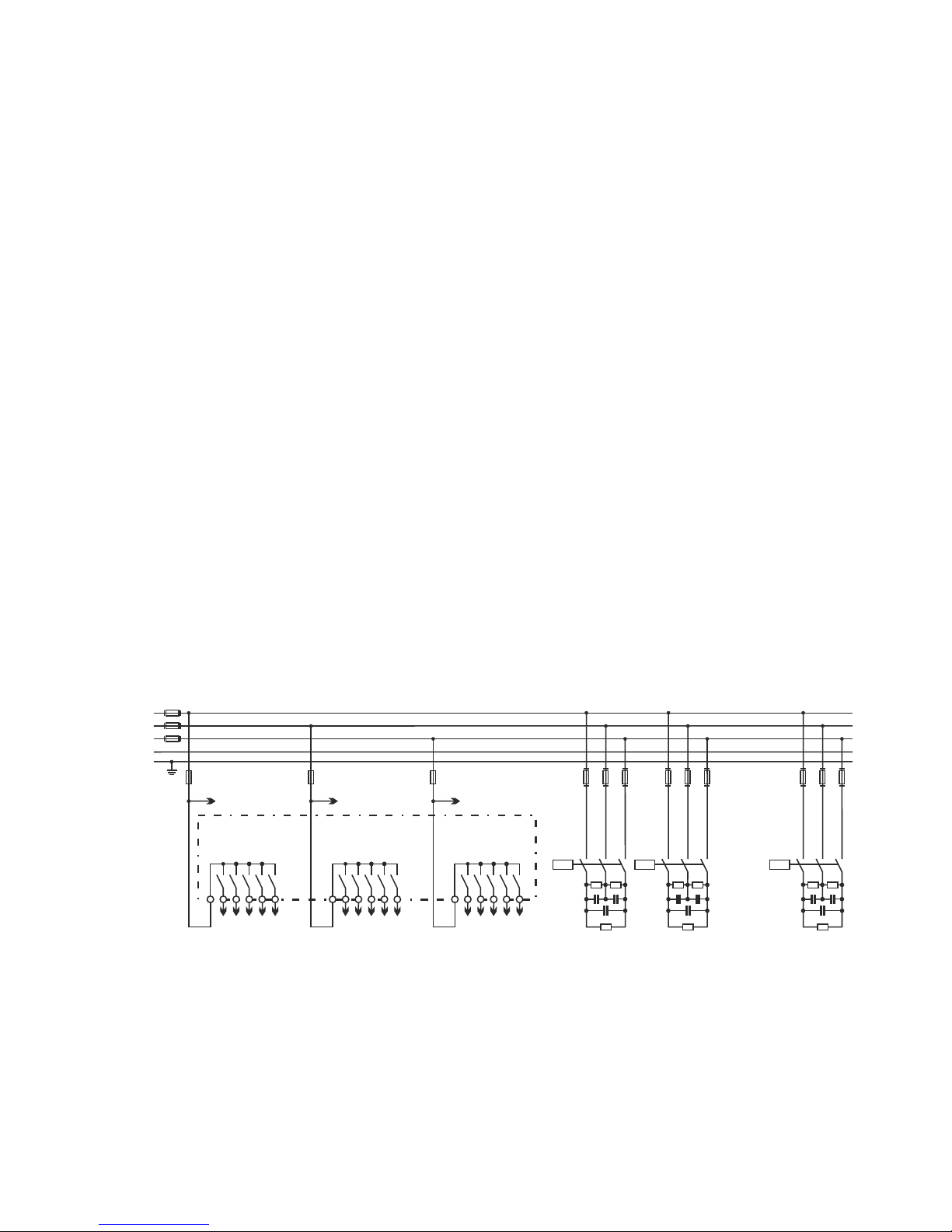

CONTROL-MODE [4]:

3-phase measuring / max. 15 three-phase capacitors

3 current transformers required. Connection of measuring current and measuring voltage

refer to page 6.

Values displayed and calculated per phase.

Controlling done with max. 15 outputs according to maximum or mean-value of the reactive

power

CONTROL-MODE [5]:

1-phase measuring / max. 15 three-phase capacitors

Only 2 current transformer in L1 required

Connection of measuring current and measuring voltage see page 6

Values extrapolated to all phases (balance assumed)

Measuring complies with conventional measuring for switching of three-phase capacitors.

CONTROL-MODE [6]:

1-phase measuring / max. 15 three-phase capacitors

with capacitor current measurement

According variant 5, but the free current inputs (L2 or L3) are used for capacitor current

measurement for real monitoring of capacitors.

Connection of measuring current and measuring voltage see page 6!

- 13 -

L1 (R)

L2 (S)

L3 (T)

Example:

15 standard 3-phase capacitors

P1 1 2 3 4 5 P2 6 7 8 9 10 P3 11 12 13 14 15

Output 1-5 Output 6-10 Output 11-15

meas.voltage L1 meas.voltage L2 meas.voltage L3

PE

N

K1 K2 K15

F1: 6,3AT F1: 6,3AT F1: 6,3AT

C1 ( 3-phase)

C6 ( 3-phase)

C11 ( 3-phase)

C2 ( 3-phase)

C7 ( 3-phase)

C12 ( 3-phase)

C3 ( 3-phase)

C8 ( 3-phase)

C13 ( 3-phase)

C4 ( 3-phase)

C9 ( 3-phase)

C14 ( 3-phase)

C5 ( 3-phase)

C10 ( 3-phase)

C15 ( 3-phase)

C1 C2 C15

....

=== PROGRAMM-MODE ===

3 I-CONVERTER PRIM [1000 ] A / X ( 5 ... 13000) A

Selects the primary current of the current converter.

Sequential adjustment of L1...L3.

via the é / ê keys. Save and continue with ENTER

4 I-CONVERTER SEC 1000 A /[ 5 ]A ( 1 / 5 A )

This sets the secondary current of the current converter.

Selection via é / ê. Save and continue with ENTER

5 END STOPP

Programming of the maximum number of active

capacitor branches.

Depending on the selected operation mode the

maximum number of connected capacitors at the output

groups L1…L3 and (if available) for the output groups Σ

(three-phase capacitors) are set.

The visible symbols of the capacitors correspond to the

connected outputs.

Input via é / ê. Save and continue with ENTER

6 CONTROL SERIES [1] ( 1...20 + ED )

The ratio of the capacitor branch powers determines the

control series, the power of the first capacitor always

being assigned the value 1.

Selection of desired control series consecutively for

L1…L3 and for Σ (three-phase outputs).

If the required control series should not be present, the

user may define a special one in control series “ED” ( see

Annex 4: Control-series editor )

7 CONTROL PRINCIPLE

The control preference may be selected here:

SEQUENTIAL connection

LOOP connection

INTELLIGENT loop connection (default setting)

COMBINED CHOKE

See Section 13 for an explanation of the control modes.

Selection with é / ê keys.

Save and continue with ENTER

8 POWER 1st STAGE [0.01 ... 255.99] / [10...2550] kvar

To determine the controller's response sensitivity, the

dimensions of the smallest capacitor (stage 1) must be

known. They are entered in two steps in kvar. The

integral kvar values (before the comma) are initially

selected via the é / ê keys and saved with ENTER.

The positions after the comma are then selected, again

via the é / ê keys.

If the capacitor value is below the response sensitivity, a

warning will occur ( indication of “!” in the display )

- 14 -

PROGRAM-MODE

7 CONTR.PRINC. 3]

[ INTELLIGENT ]

PROGRAM-MODE

3 I-CONVERTER PRIM

[ 1000]A / 5 A

1000]A / 5 A

1000]A / 5 A

L1

L2

L3

PROGRAM-MODE

8 POWER 1.STAGE

[ 25].00 kvar

25 .00 kvar

25 .00 kvar

L1-N

L2-N

L3-N

PROGRAM-MODE

6 CONT.SERIES L1-N

12333

12333

12333

[ 3]

3

3

L1-N

L2-N

L3-N

1 2 3 4 5

PROGRAM-MODE

5 END STOP L1-N

[ 5]

5

5

L1-N

L2-N

L3-N

1 2 3 4 5

Loading...

Loading...