查询B82422-T1103供应商

SIMID 1210-T

Size 1210 (EIA) or 3225 (IEC)

Rated inductance 0,010 to 330 µH

Rated current 40 to 450 mA

Construction

■ Ceramic or ferrite core

■ Laser-welded winding

■ Flame-retardant encapsulation

Features

■ High

Q

factor

■ High resonance frequency

■ High

L

value

■ Suitable for reflow (IR and vapor phase)

and wave soldering

Applications

■ Filtering of supply voltages, coupling, decoupling

■ Antenna systems

■ Automotive electronics

■ Telecommunications

B82422-TSMT Inductors, SIMID Series

Terminals

■ Electro-plated

■ 0,4 µm Cu; 1–2 µm Ag; 5–7 µm Sn

■ Base material CuSn6

■ Suitable for soldering and conductive adhesion

■ No leaching during wave soldering

Marking

Marking on component:

Manufacturer and letter »T«,

L

value (in µH) and tolerance ofL value (coded),

date of manufacture (coded)

Minimum data on reel:

Manufacturer, part number, ordering code,

L

value and tolerance ofL value,

quantity, date of packing

Delivery mode

8-mm blister tape, wound on 180-mm or 330-mm ∅ reel

For details on taping, packing and packing units see page 153

110 04/00

SIMID 1210-T

General technical data

B82422-TSMT Inductors, SIMID Series

Rated inductance

Q factor

Q

min

L

R

Measured with impedance analyzer HP 4194A

at frequency

f

L

Measured with impedance analyzer

HP 4194A/HP 4291A at frequency

Rated current

I

R

Maximum permissible dc with

inductance decrease ∆L/

L

0

≤ 10 %

and temperature increase of ≤ 30 K

at rated temperature of 85°C

Self-resonance frequency

DC resistance

R

max

f

res, min

Measured with network analyzer HP 8753

Measured at 20°C ambient temperature,

measuring current <

I

R

Climatic category In accordance with IEC 60068-1

55/125/56 (– 55°C/+ 125°C/56 days damp heat test)

Solderability In accordance with IEC 60062-2-58

(215 ± 3)°C, (3 ± 0,3) s

Wetting of soldering area: ≥ 90 %

Resistance to soldering heat In accordance with IEC 60068-2-20

260°C, 10 s

∆L/L≤ ± 3%

Permissible PCB bending 2 mm (100 mm long standard PCB)

Weight Approx. 50 mg

f

Q

111 04/00

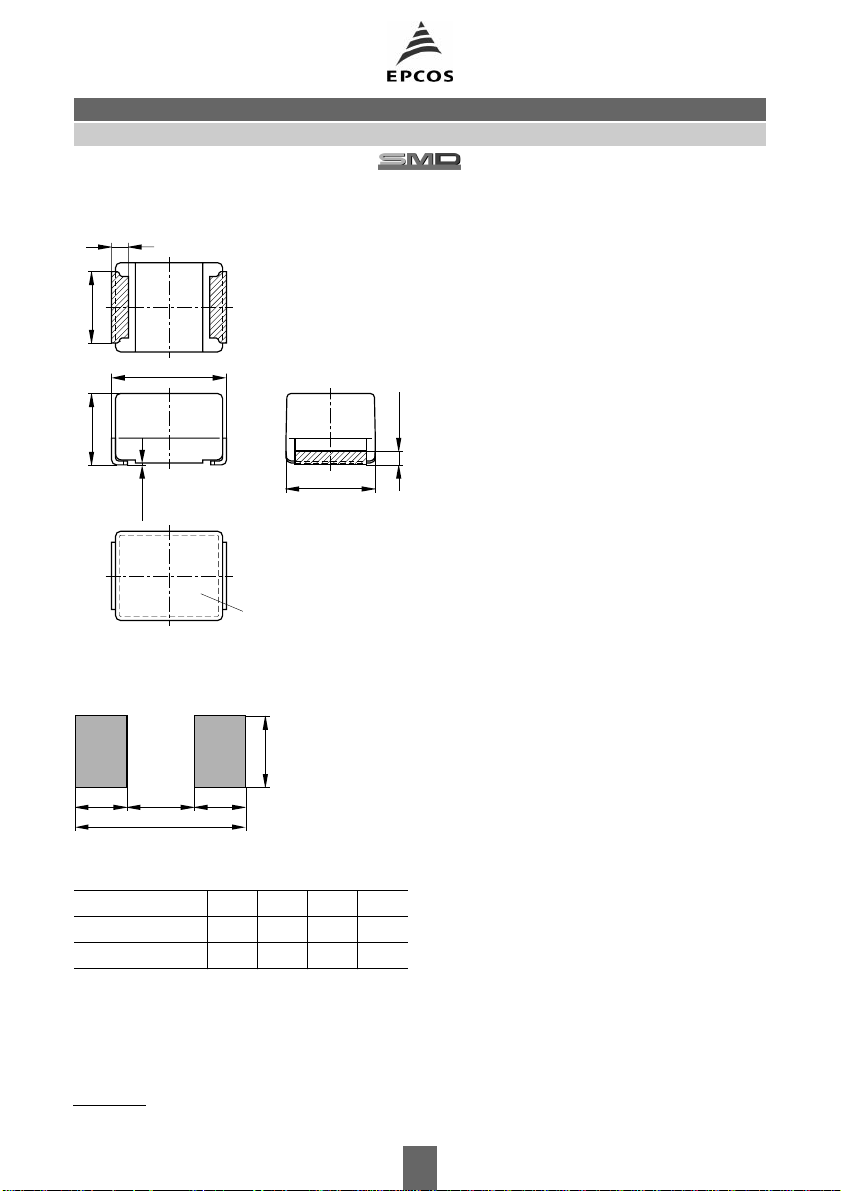

SIMID 1210-T

Dimensional drawing

1)

0,5±0,2

1)

2±0,1

3,2+0,4

B82422-TSMT Inductors, SIMID Series

1)

2,1±0,2

2,5+0,4

0,15 max.

Beschriftung

Marking

SSB1398-U

Layout recommendation

A

B

CB

D

SSB1227-Z

Dimensions (mm)

ABCD

Wave soldering 2,3 1,60 2,1 5,3

Reflow soldering 2,7 1,15 2,1 4,4

0,4 min.

1) Soldering area, tinned

112 04/00

B82422-TSMT Inductors, SIMID Series

SIMID 1210-T

Characteristics and ordering codes

L

µH

R

Tolerance

Q

min

1)

f

;

L

MHz

f

I

Q

R

mA

R

max

Ω

f

res, min

MHz

Ordering code

(∅ 180-mm reel)

2)

Core material: ceramics

0,010 ± 5 %

^

0,012 17 100 450 0,11 3500 B82422-T3120-+

0,015 19 100 450 0,13 3000 B82422-T3150-+

0,018 21 100 450 0,14 2000 B82422-T3180-+

J

± 10 %

^

K

15 100 450 0,10 4000 B82422-T3100-+

0,022 23 100 450 0,16 2000 B82422-T3220-+

0,027 23 100 450 0,17 1700 B82422-T3270-+

0,033 25 100 450 0,18 1700 B82422-T3330-+

0,039 25 100 450 0,19 1300 B82422-T3390-+

0,047 26 100 450 0,20 1300 B82422-T3470-+

0,056 26 100 450 0,21 1100 B82422-T3560-+

0,068 27 100 450 0,23 1000 B82422-T3680-+

0,082 27 100 450 0,26 1000 B82422-T3820-+

0,10 28 100 450 0,31 900 B82422-T3101-+

Core material: ferrite

0,12 ± 5 %

^

0,15 30 25,2 450 0,18 700 B82422-T1151-+

0,18 30 25,2 450 0,19 500 B82422-T1181-+

0,22 30 25,2 450 0,20 500 B82422-T1221-+

J

± 10 %

^

K

30 25,2 450 0,15 900 B82422-T1121-+

0,27 30 25,2 450 0,21 500 B82422-T1271-+

0,33 30 25,2 450 0,23 500 B82422-T1331-+

0,39 30 25,2 450 0,25 400 B82422-T1391-+

0,47 30 25,2 450 0,30 400 B82422-T1471-+

0,56 30 25,2 450 0,31 300 B82422-T1561-+

0,68 30 25,2 450 0,34 300 B82422-T1681-+

0,82 30 25,2 450 0,38 300 B82422-T1821-+

1,0 30 7,96 400 0,6 300 B82422-T1102-+

1,2 30 7,96 390 0,7 250 B82422-T1122-+

1,5 30 7,96 370 0,7 200 B82422-T1152-+

1,8 30 7,96 350 0,8 140 B82422-T1182-+

2,2 30 7,96 320 0,8 100 B82422-T1222-+

1) Closer tolerances and special versions upon request.

2) Replace the + by the code letter for the required inductance tolerance.

For reel size ∅ 330 mm append code number »8«. Example: B82422-T3100-K8

113 04/00

B82422-TSMT Inductors, SIMID Series

SIMID 1210-T

Characteristics and ordering codes (continued)

L

µH

R

Tolerance

Q

min

1)

f

;

L

MHz

f

I

Q

R

mA

R

max

Ω

f

res, min

MHz

Ordering code

(∅ 180-mm reel)

2)

Core material: ferrite

2,7 ± 5 %

3,3 30 7,96 260 1,2 60 B82422-T1332-+

3,9 30 7,96 250 1,3 60 B82422-T1392-+

4,7 30 7,96 220 1,5 50 B82422-T1472-+

^

± 10 %

^

K

30 7,96 290 0,9 70 B82422-T1272-+

5,6 27 7,96 200 1,6 45 B82422-T1562-+

6,8 27 7,96 180 1,8 40 B82422-T1682-+

8,2 27 7,96 170 2,0 35 B82422-T1822-+

10 27 2,52 150 2,1 30 B82422-T1103-+

12 27 2,52 140 2,5 25 B82422-T1123-+

15 27 2,52 130 2,8 20 B82422-T1153-+

18 27 2,52 120 3,0 20 B82422-T1183-+

22 27 2,52 110 3,5 20 B82422-T1223-+

27 27 2,52 80 4,5 20 B82422-T1273-+

33 27 2,52 70 5,6 17 B82422-T1333-+

39 27 2,52 65 6,4 16 B82422-T1393-+

47 27 2,52 60 7,0 15 B82422-T1473-+

56 27 2,52 60 8,0 12 B82422-T1563-+

68 27 2,52 60 9,0 9 B82422-T1683-+

82 25 2,52 60 10 9 B82422-T1823-+

100 20 0,796 60 11 8 B82422-T1104-+

120 20 0,796 60 12 8 B82422-T1124-+

150 20 0,796 50 17 7 B82422-T1154-+

180 20 0,796 50 18 7 B82422-T1184-+

220 20 0,796 45 22 6 B82422-T1224-+

270 20 0,796 40 28 5 B82422-T1274-+

330 20 0,796 40 34 4 B82422-T1334-+

1) Closer tolerances and special versions upon request.

2) Replace the + by the code letter for the required inductance tolerance.

For reel size ∅ 330 mm append code number »8«. Example: B82422-T1272-K8

114 04/00

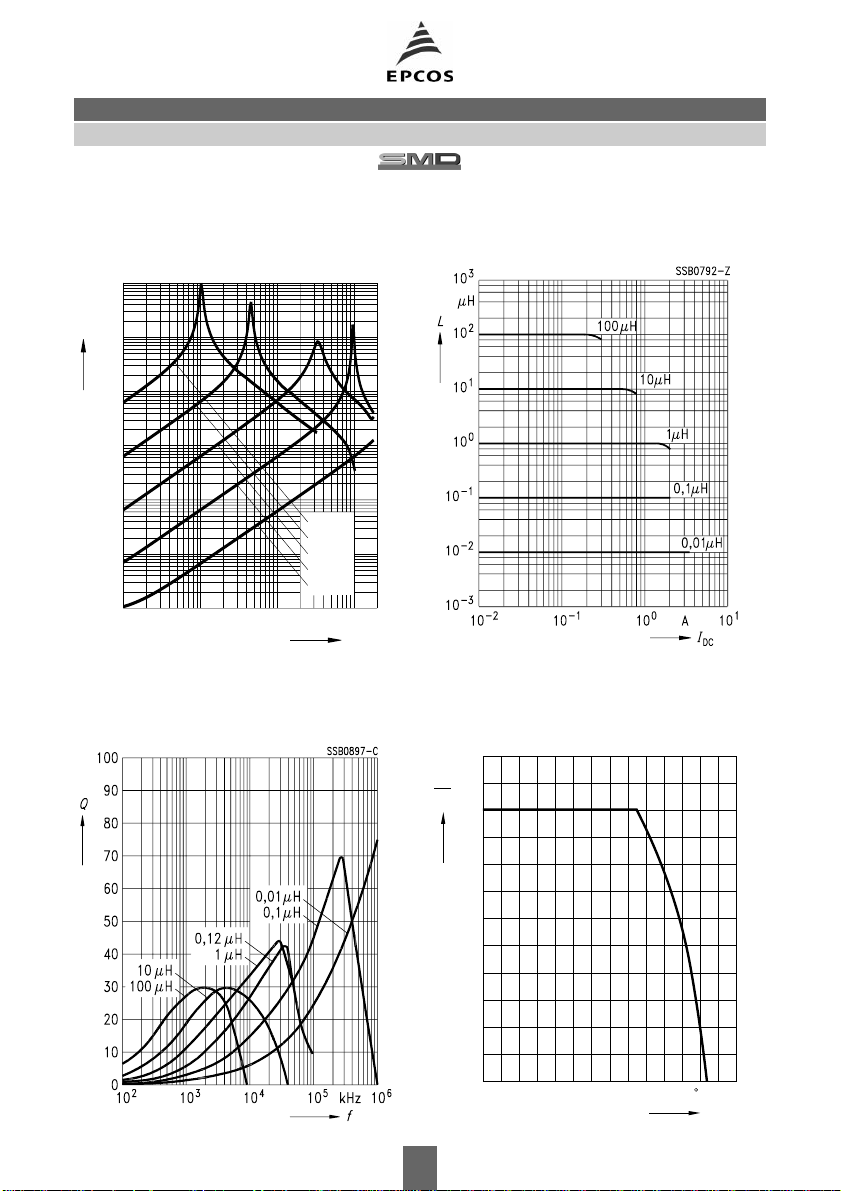

SIMID 1210-T

B82422-TSMT Inductors, SIMID Series

Impedance |Z|

versus frequency

f

measured with impedance analyzer

HP 4291A

5

10

Ω

|Z|

4

10

3

10

2

10

1

10

0

10

_

1

10

3

10

Q

factor versus frequency

10

4

5

f

measured with impedance analyzer

HP 4194A / HP 4291A

SSB1540-A

100

µ

H

10

µ

H

µ

1H

100 nH

10 nH

kHz10

Inductance

versus dc load current

L

I

DC

measured with LCR meter

HP 4275A

6

10

f

Current derating

versus ambient temperature

1,2

I

Ι

op

B

I

Ι

R

R

1,0

I

/

I

op

R

T

A

SSB0893-E

0,8

0,6

0,4

0,2

115 04/00

0

0

20 40 60 80 100 140C

T

A

Loading...

Loading...