Page 1

EMC filters

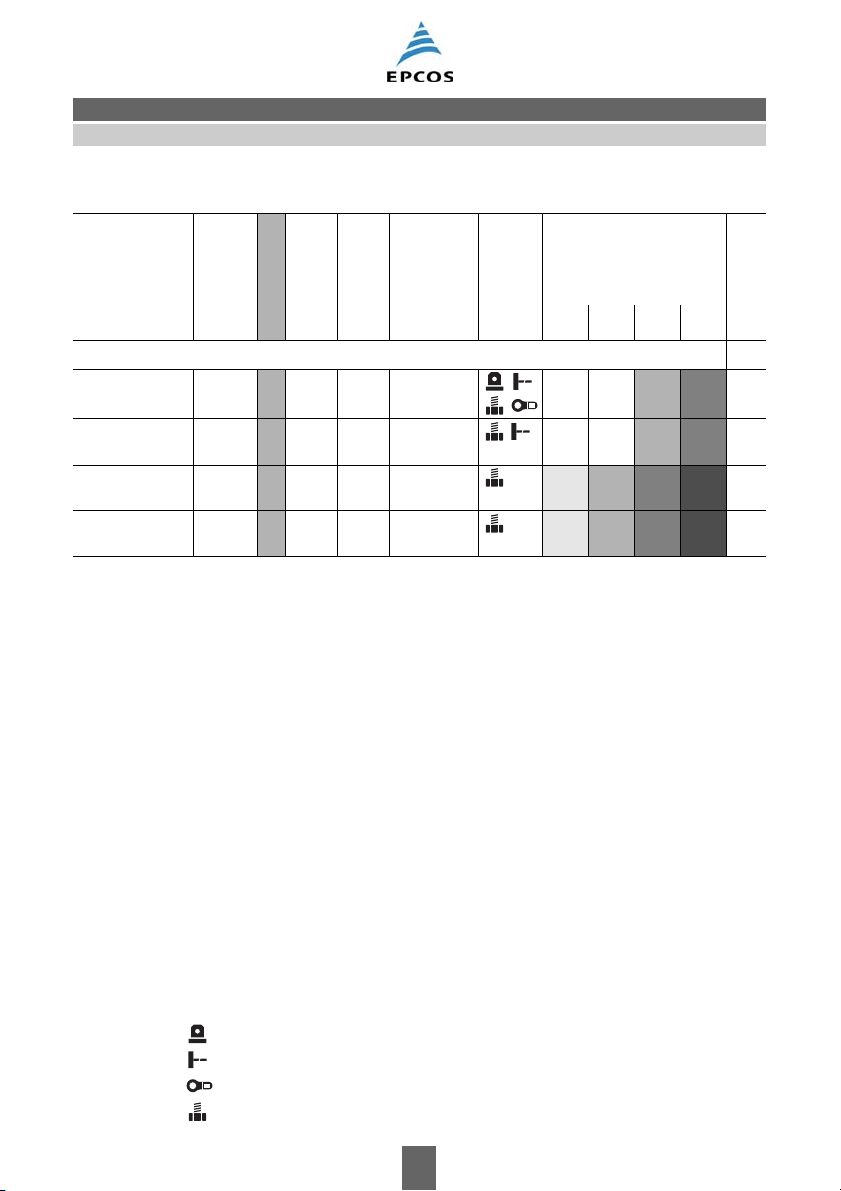

1-line filters

Feedthrough filters

Rated current 16 to 500 A

Series/Type: B85321

Date: January 2006

EPCOS AG 2006. Reproduction, publication and dissemination of this data sheet and the

information contained therein without EPCOS’ prior express consent is prohibited.

Page 2

1-line filters

Feedthrough components

Overview of available types

Type Dia-

meter

mm

Feedthrough filters

B85321A*+160 16

B85321A*+160 20

B85321A*A250

30

B85321A*A750

B85321A*A630,

55

A101 … A501

Insertion loss in the

frequeny range (Hz)

7

New

Rated current

(A)

Rated voltage

(VAC)

Rated

capacitance

105 106 10

(µF)

Terminal type

● 16 250 2 × 0.0025 6

● 25 250,

2 × 0.0025 8

500

● 25,

● 63 …

250 2 × 0.1 …

75

250 2 × 0.5 …

500

2 × 1.0

10

11

2 × 4.7

Page

5

Legend

Terminal type: Tab connectors

Axial leads

Soldering tags

Threaded studs

Please read Cautions and warnings and

Important notes at the end of this document.

01/06 2

Page 3

1-line filters

Feedthrough components

General

Feedthrough components from EPCOS are used for EMI suppression of all electrical installations

and equipment. This new type series is also outstandingly well suited for telephone exchanges and

base stations. Thanks to broadband EMI suppression up to the GHz range, it prevents external interference pulses being transmitted to the inside of the equipment via the supply network and viceversa.

The essential features of this new type series are its modular design and the solder-free contacting

technology developed by EPCOS with the aid of mesh contact.

Mesh contact technology permits uniform concentric contacting of the MKP capacitor winding and

avoids the thermal stress associated with soldering. The result is an even higher insertion loss, a

high insulation resistance and a particularly compact case.

The modular system used in this new technology for feedthrough capacitors and filters allows the

cost-effective implementation of a wide range of standard types. Other capacitance values can also

be supplied for special applications upon request.

Feedthrough components fitted

into a shielding wall.

In feedthrough capacitors, the conductor carrying the operating current is connected concentrically

to one electrode and is run centrally through the capacitor. The other electrode is contacted concentrically to the capacitor case.

Feedthrough capacitors are dimensioned so that they perform well from low frequencies to far above

300 MHz. The capacitor element with low inductance contacted securely on the face side is

incorporated in a metal case provided with a screw thread.

The feedthrough filters are constructed in a π-circuit. They consist of two identical capacitative

transverse elements and an inductive longitudinal element. The concentric layout of the components allows high insertion loss values to be attained in a frequency range to above 1 GHz.

Safety note

Feedthrough components with high capacitances require the implementation of safety measures in

line with the applicable specifications! (See also Chapter “Mounting instructions”.)

Please read Cautions and warnings and

Important notes at the end of this document.

01/06 3

Page 4

1-line filters

Feedthrough components

Mounting instructions

To fully utilize their RF properties, the feedthrough components must be mounted directly into shielding walls. The case must be contacted seamlessly (sealed against RF signals) to the shielding

wall. This can be best done by screwing it into a threaded hole or bushing so that contact is made

via the threads.

Alternatively, the feedthrough components may be screwed into feed-through holes on the shielding

wall by means of attachment nuts. The contact between case and the shielding wall is then set up

via the contact surface of the thread.

Caution

Contacts with rigid copper busbars are not permitted in view of mechanical stresses of the

bushings due to impacts and vibrations.

For types with screw connections, the connecting cable must be secured between two nuts

to exclude a torque on the feedthrough pins. The use of two flat wrenches is recommended.

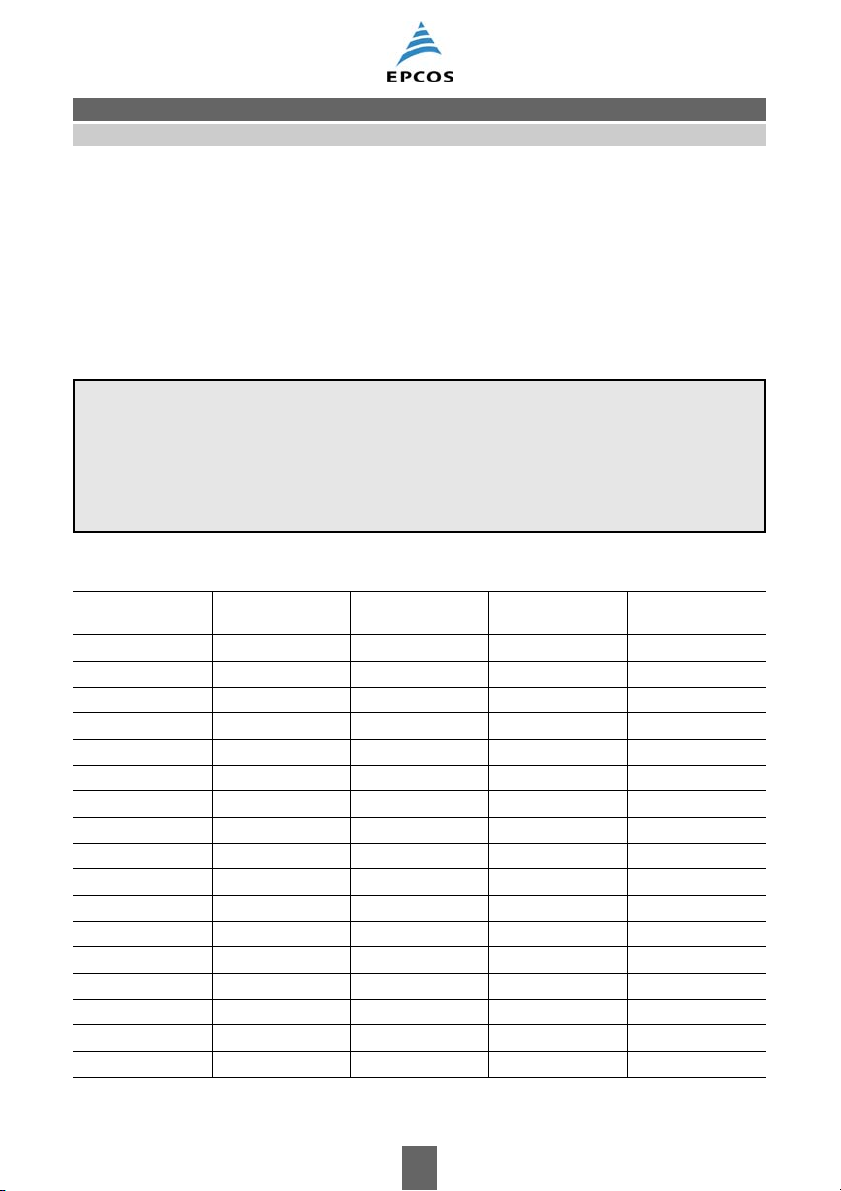

Recommended tightening torques for feedthrough components (capacitors, filters)

Thread

dimensions

Tightening

torque (Nm)

Tolerance (Nm) Terminal Thread base

attachment

M2 0.2 +0.05 ×

M3 0.6 +0.1 ×

M4 1.2 +0.1 ×

M5 2 +0.5 ×

M6 3 +0.5 ×

M8 5 +0.5 ×

M10 8 +2 ×

M12 12 +2 ×

M16 28 +2 ×

M18 35 +2 ×

M10 × 0.75 3 +0.5 ×

M12 × 0.75 4 +0.5 ×

M20 × 1 0 +1 ×

1

M24 × 1.5 12 +1.5 ×

M27 × 1.5 16 +2 ×

M32 × 1.5 24 +2.5 ×

Please read Cautions and warnings and

Important notes at the end of this document.

01/06 4

Page 5

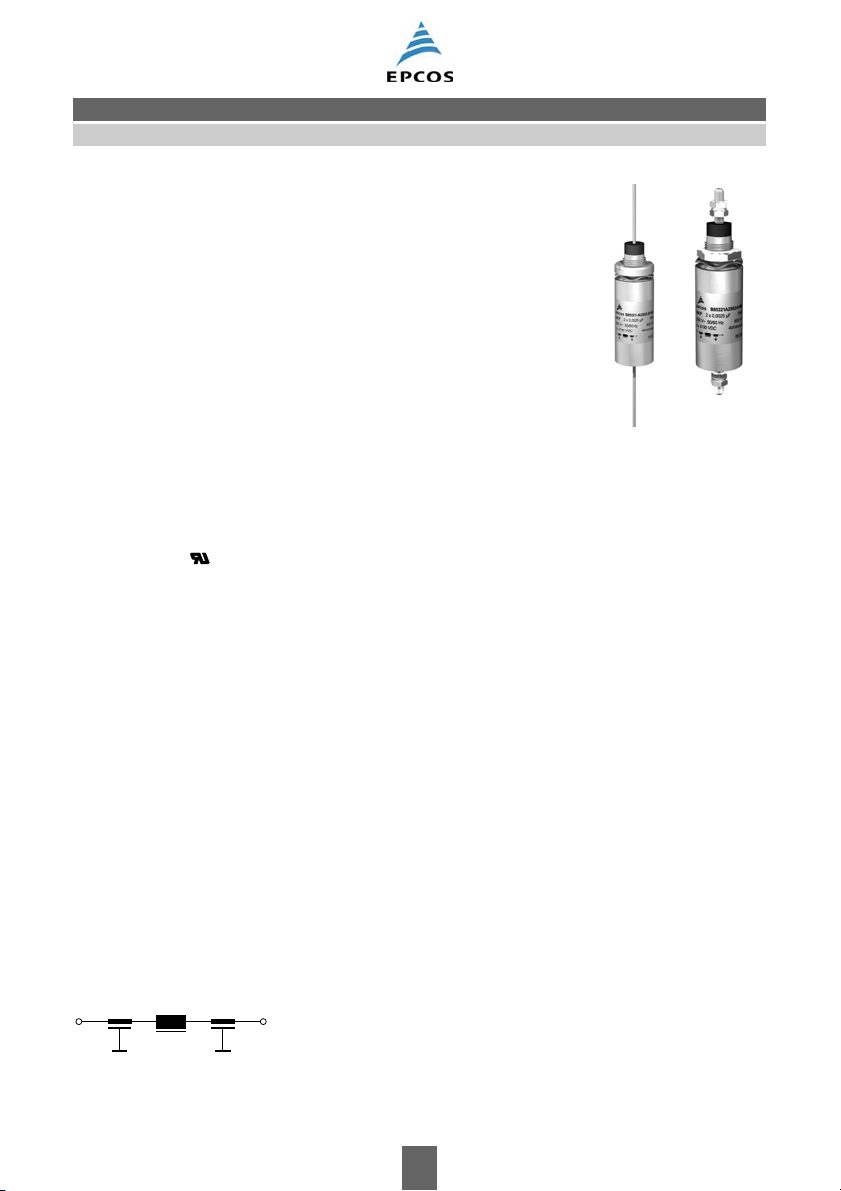

1-line filters B85321

Feedthrough filters

Rated voltage 250 V AC

Rated current 16 to 500 A

Rated capacitance 2 × 0.0025 to 2 × 4.7 µF

Construction

■ Building-block system

■ MKP technology (dry, self-healing)

Dielectric: polypropylene, metallized

■ Metal case, polyurethane potting (UL 94 V-0)

■ For central screw fixing

Features

■ Compact dimensions

■ Versions with rated voltage 440 V AC available on request

■ High insertion loss

■ Easy to install

■ High contact reliability thanks to central screw fixing

■ Comply with EN 133200

■ UL approval

Applications

Broadband interference suppression

for AC/DC supply lines, e. g. in

■ shielded rooms

■ telephone exchanges, base stations

■ electrical machines and systems

■ power supplies

Terminals

■ Threaded studs

■ Axial leads

■ Soldering tag

■ Tab connector

Marking

Manufacturer, ordering code, rated capacitance,

rated voltage, rated current, climatic category,

circuit diagram, date of manufacture (MM.YY), approvals

Circuit diagram

SSB1274-B

Please read Cautions and warnings and

Important notes at the end of this document.

01/06 5

Page 6

1-line filters B85321A*+160

Feedthrough filters

∅ 16 mm, 16 A

Feedthrough filters ∅ 16 mm

Technical data and measuring conditions

Rated voltage V

R

250 V AC, 50/60 Hz

600 V DC

Rated current I

R

Referred to 40 °C ambient temperature

Reduced current values at 400 Hz

Capacitance tolerance ± 20%

Climatic category (IEC 60068-1) 40/085/56 (–40 °C/+85 °C/56 days damp heat test)

Screw cap fixing M10 × 0.75

Approvals UL 1283, 250 V

Characteristics and ordering codes

C

I

R

R

A

µF

V

R

V AC

V

R

V DC

V

Terminal Fig. Ordering code Approvals

test

V DC

16 2 × 0.0025 250 600 2700 M2 1 B85321A2502X160 ×

2 × 0.0025 250 600 2700 Soldering tag 2 B85321A2502Y160 ×

2 × 0.0025 250 600 2700 Leads ∅ 2 mm 3 B85321A2502Z160 ×

2 × 0.0025 250 600 2700 Tab connector

4 B85321A2502W160 ×

6.3 mm

× = approval granted

Insertion loss (dB); typical values at 50 Ω

C

(µF) 10 kHz 100 kHz 1 MHz 10 MHz 100 MHz 1 GHz

R

2 × 0.0025 – – – 25 > 80 > 80

Dimensional drawings

Figure 1, B85321A2502X160

1...3

ø16

Please read Cautions and warnings and

Important notes at the end of this document.

Marking

45+2

60+2

80+2

ø10.5+0.3

5

10 4

_

SSB2018-T

M2

M10 x 0.75

01/06 6

Thread Tightening torque

M2 0.2 +0.05 Nm

M10 × 0.75 3 +0.5 Nm

Page 7

1-line filters B85321A*+160

Feedthrough filters

∅ 16 mm, 16 A

Figure 2, B85321A2502Y160

Soldering tag,

size 3 mm

1...3

M2

ø16

Marking

45+2

60+2

80+2

ø10.5+0.3

5

_

4 10

SSB2019-2-E

M10 x 0.75

Thread Tightening torque

M2 0.2 +0.05 Nm

M10 × 0.75 3 +0.5 Nm

Figure 3, B85321A2502Z160

1...3

ø16

ø2

Marking

ø10.5+0.3

45+2

60+2

_

3155

Figure 4, B85321A2502W160

Tab connector,

size 6.3 mm

1...3

ø16

Marking

ø10.5+0.3

45+2

62+2 13+1

90±2

Please read Cautions and warnings and

Important notes at the end of this document.

5

45±3

M10 x 0.75

SSB2020-5

M10 x 0.75

SSB2031-K-E

01/06 7

Tightening torque: 3 +0.5 Nm

Tightening torque: 3 +0.5 Nm

Page 8

1-line filters B85321A*+160

Feedthrough filters

∅ 20 mm, 25 A

Feedthrough filters ∅ 20 mm

Technical data and measuring conditions

Rated voltage V

R

250 and 500 V AC, 50/60 Hz

600 and 700 V DC

Rated current I

R

Referred to 40 °C ambient temperature

Reduced current values at 400 Hz

Capacitance tolerance ± 20%

Climatic category (IEC 60068-1) 40/085/56 (–40 °C/+85 °C/56 days damp heat test)

Screw cap fixing M12 × 0.75

Approvals UL 1283, 250 V

Characteristics and ordering codes

C

I

R

R

A

µF

V

R

V AC

V

R

V DC

V

Terminal Figure Ordering code Approvals

test

V DC

25 2 × 0.0025 250 600 2700 M4 1 B85321A2502A160 ×

2 × 0.0025 250 600 2700 Leads

2 × 0.0025 500 700 3000 B85321A4502C160 ×

∅ 2 mm

2 B85321A2502B160 ×

× = approval granted

Insertion loss (dB); typical values at 50 Ω

CR (µF) 10 kHz 100 kHz 1 MHz 10 MHz 100 MHz 1 GHz

2 × 0.0025 – – – 25 > 80 > 80

Please read Cautions and warnings and

Important notes at the end of this document.

01/06 8

Page 9

1-line filters B85321A*+160

Feedthrough filters

∅ 20 mm, 25 A

Dimensional drawings

Figure 1, B85321A2502A160

1...3

M4

ø20

Marking

45+2

60+2

93+2

ø12.5+0.3

M12 x 0.75

5

_

17 2

SSB2022-L

Thread Tightening torque

M4 1.2 +0.1 Nm

M12 × 0.75 4.0 +0.5 Nm

Figure 2, B85321A2502B160, B85321A4502C160

1...3

ø2

ø20

Please read Cautions and warnings and

Important notes at the end of this document.

Marking

45+2

60+2

155 3

ø12.5+0.3

_

5

45±3

M12 x 0.75

SSB2023-U

01/06 9

Tightening torque: 4 +0.5 Nm

Page 10

1-line filters B85321A*A250, A750

Feedthrough filters

∅ 30 mm, 25 A, 75 A

Feedthrough filters ∅ 30 mm

Technical data and measuring conditions

Rated voltage V

R

250 V AC, 50/60 Hz

500 and 600 V DC

Rated current I

R

Referred to 40 °C ambient temperature

Reduced current values at 400 Hz

Capacitance tolerance ± 20%

Climatic category (IEC 60068-1) 40/085/56 (–40 °C/+85 °C/56 days damp heat test)

Screw cap fixing M20 × 1

Approvals UL 1283, 250 V

Characteristics and ordering codes

I

R

A

25 × 0.1 250 600 3000 M6 B85321A2204A250 ×

C

µF

2

V

R

V AC

V

R

R

V DC

V

test

V DC

Terminal Ordering code Approvals

2 × 0.5 250 600 2000 M6 B85321A2105A250 ×

2 × 1.0 250 500 1700 M6 B85321A2205A250 ×

75 × 0.1 250 600 3000 M6 B85321A2204A750 ×

2

2 × 0.5 250 600 2000 M6 B85321A2105A750 –

2 × 1.0 250 500 1700 M6 B85321A2205A750 ×

× = approval granted

Insertion loss (dB); typical values at 50 Ω

C

(µF) 10 kHz 100 kHz 1 MHz 10 MHz 100 MHz 1 GHz

R

2 × 0.1 2 10 25 70 > 100 > 100

2 × 0.5 5 25 45 80 > 100 > 100

2 × 1.0 10 30 60 90 > 100 > 100

Dimensional drawing

M6

M20 x 1

5

Please read Cautions and warnings and

Important notes at the end of this document.

Marking

130 1

81+1

_

M6

ø30

Thread Tightening

torque

M6 3 +0.5 Nm

SSB2085-J

M20 × 1 10 +1 Nm

01/06 10

Page 11

1-line filters B85321A*A630, A101 … A501

Feedthrough filters

∅ 55 mm, 63 … 500 A

Feedthrough filters ∅ 55 mm

Technical data and measuring conditions

Rated voltage V

R

250 V AC, 50/60 Hz

350 and 600 V DC

Rated current I

R

Referred to 40 °C ambient temperature

Reduced current values at 400 Hz

Capacitance tolerance ±20%

Climatic category (IEC 60068-1) 40/085/56 (–40 °C/+85 °C/56 days damp heat test)

Screw cap fixing Standard M32 × 1.5

Special fixing M27 × 1.5 for filters up to 300 A on request

Approvals UL 1283, 250 V

Characteristics and ordering codes

C

V

V

V

I

R

R

R

R

A

µF

V AC

V DC

Terminal Dimensions (mm) Ordering code Approvals

test

V DC

l +1 l1 –1 l2 –3

63 2 × 0.5 250 600 3000 M6 100 166 45 B85321A2105A630 ×

2 × 1.0 250 600 2500 M6 100 166 45 B85321A2205A630 ×

2 × 2.0 250 600 2500 M6 100 166 45 B85321A2405A630 ×

2 × 4.7 250 350 1700 M6 100 166 45 B85321A2945A630 ×

100 2 × 0.5 250 600 3000 M8 100 180 52 B85321A2105A101 ×

2 × 1.0 250 600 2500 M8 100 180 52 B85321A2205A101 ×

2 × 2.0 250 600 2500 M8 100 180 52 B85321A2405A101 ×

2 × 4.7 250 350 1700 M8 100 180 52 B85321A2945A101 ×

200 2 × 0.5 250 600 3000 M10 100 185 55 B85321A2105A201 ×

2 × 1.0 250 600 2500 M10 100 185 55 B85321A2205A201 ×

2 × 2.0 250 600 2500 M10 100 185 55 B85321A2405A201 ×

2 × 4.7 250 350 1700 M10 100 185 55 B85321A2945A201 ×

300 2 × 0.5 250 600 3000 M12 100 195 60 B85321A2105A301 ×

2 × 1.0 250 600 2500 M12 100 195 60 B85321A2205A301 ×

2 × 2.0 250 600 2500 M12 100 195 60 B85321A2405A301 –

2 × 4.7 250 350 1700 M12 100 195 60 B85321A2945A301 ×

400 2 × 0.5 250 600 3000 M16 130 245 72 B85321A2105A401 –

2 × 1.0 250 600 2500 M16 130 245 72 B85321A2205A401 –

2 × 2.0 250 600 2500 M16 130 245 72 B85321A2405A401 –

2 × 4.7 250 350 1650 M16 130 245 72 B85321A2945A401 –

× = approval granted

Please read Cautions and warnings and

Important notes at the end of this document.

01/06 11

Page 12

1-line filters B85321A*A

Feedthrough filters

∅ 55 mm, 63 … 500 A

Characteristics and ordering codes

I

C

V

V

V

R

R

R

R

A

µF

V AC

V DC

Terminal Dimensions (mm) Ordering code Approvals

test

V DC

l +1 l1 –1 l2 –3

500 2 × 0.5 250 600 3000 M18 130 250 75 B85321A2105A501 –

2 × 1.0 250 600 2500 M18 130 250 75 B85321A2205A501 –

2 × 2.0 250 600 2500 M18 130 250 75 B85321A2405A501 –

2 × 4.7 250 350 1650 M18 130 250 75 B85321A2945A501 –

× = approval granted

Insertion loss (dB); typical values at 50 Ω

(µF) 10 kHz 100 kHz 1 MHz 10 MHz 100 MHz 1 GHz

C

R

2 × 0.5 5 25 45 80 > 100 > 100

2 × 1.0 10 30 60 > 100 > 100 > 100

2 × 2.0 15 35 70 > 100 > 100 > 100

2 × 4.7 25 40 90 > 100 > 100 > 100

Dimensional drawing

A/F 41

A/F 10

55±1

Thread Tightening torque

M6 3 +0.5 Nm

M8 5 +0.5 Nm

M10 8 +2 Nm

M12 12 +2 Nm

M16 28 +2 Nm

M18 35 +2 Nm

Please read Cautions and warnings and

Important notes at the end of this document.

Marking

8

15+1

2

1

M

M32 x 1.5

SSB1273-3-E

Thread Tightening torque

M27 × 1.5 16 +2 Nm

M32 × 1.5 24 +2.5 Nm

01/06 12

Page 13

EMC filters

Cautions and warnings

Important information

Please read all safety and warning notes carefully before installing the EMC filter and putting it into

operation (see

). The same applies to the warning signs on the filter. Please ensure that the signs

are not removed nor their legibility impaired by external influences.

Death, serious bodily injury and substantial material damage to equipment may occur if the appropriate safety measures are not carried out or the warnings in the text are not observed.

Using according to the terms

The EMC filters may be used only for their intended application within the specified values in lowvoltage networks in compliance with the instructions given in the data sheets and the data book.

The conditions at the place of application must comply with all specifications for the filter used.

Warnings

■ It shall be ensured that only qualified persons (electricity specialists) are engaged on work such

as planning, assembly, installation, operation, repair and maintenance. They must be provided

with the corresponding documentation.

■ Danger of electric shock. EMC filters contain components that store an electric charge. Danger-

ous voltages can continue to exist at the filter terminals for longer than five minutes even after

the power has been switched off.

■ The protective earth connections shall be the first to be made when the EMC filter is installed and

the last to be disconnected. Depending on the magnitude of the leakage currents, the particular

specifications for making the protective-earth connection must be observed.

■ Impermissible overloading of the EMC filter, such as impermissible voltages at higher frequen-

cies that may cause resonances etc. can lead to destruction of the filter housing.

■ EMC filters must be protected in the application against impermissible exceeding of the rated

currents by suitable overcurrent protective.

13 01/06

Page 14

EMC filters

Important notes

The following applies to all products named in this publication:

1. Some parts of this publication contain statements about the suitability of our products for

certain areas of application. These statements are based on our knowledge of typical

requirements that are often placed on our products in the areas of application concerned. We

nevertheless expressly point out that such statements cannot be regarded as binding

statements about the suitability of our products for a particular customer application. As

a rule, EPCOS is either unfamiliar with individual customer applications or less familiar with them

than the customers themselves. For these reasons, it is always ultimately incumbent on the

customer to check and decide whether an EPCOS product with the properties described in the

product specification is suitable for use in a particular customer application.

2. We also point out that in individual cases, a malfunction of passive electronic components

or failure before the end of their usual service life cannot be completely ruled out in the

current state of the art, even if they are operated as specified. In customer applications

requiring a very high level of operational safety and especially in customer applications in which

the malfunction or failure of a passive electronic component could endanger human life or health

(e.g. in accident prevention or life-saving systems), it must therefore be ensured by means of

suitable design of the customer application or other action taken by the customer (e.g.

installation of protective circuitry or redundancy) that no injury or damage is sustained by third

parties in the event of malfunction or failure of a passive electronic component.

3. The warnings, cautions and product-specific notes must be observed.

4. In order to satisfy certain technical requirements, some of the products described in this

publication may contain substances subject to restrictions in certain jurisdictions (e.g.

because they are classed as “hazardous”). Useful information on this will be found in our

Material Data Sheets on the Internet (www.epcos.com/material). Should you have any more

detailed questions, please contact our sales offices.

5. We constantly strive to improve our products. Consequently, the products described in this

publication may change from time to time. The same is true of the corresponding product

specifications. Please check therefore to what extent product descriptions and specifications

contained in this publication are still applicable before or when you place an order.

We also reserve the right to discontinue production and delivery of products.

Consequently, we cannot guarantee that all products named in this publication will always be

available.

6. Unless otherwise agreed in individual contracts, all orders are subject to the current version

of the “General Terms of Delivery for Products and Services in the Electrical Industry”

published by the German Electrical and Electronics Industry Association (ZVEI).

7. The trade names EPCOS, EPCOS-Jones, Baoke, CeraDiode, CSSP, MLSC, PhaseCap,

PhaseMod, SIFI, SIKOREL, SilverCap, SIMID, SIOV, SIP5D, SIP5K, UltraCap, WindCap are

trademarks registered or pending in Europe and in other countries. Further information will be

found on the Internet at www.epcos.com/trademarks.

14 01/06

Loading...

Loading...