Page 1

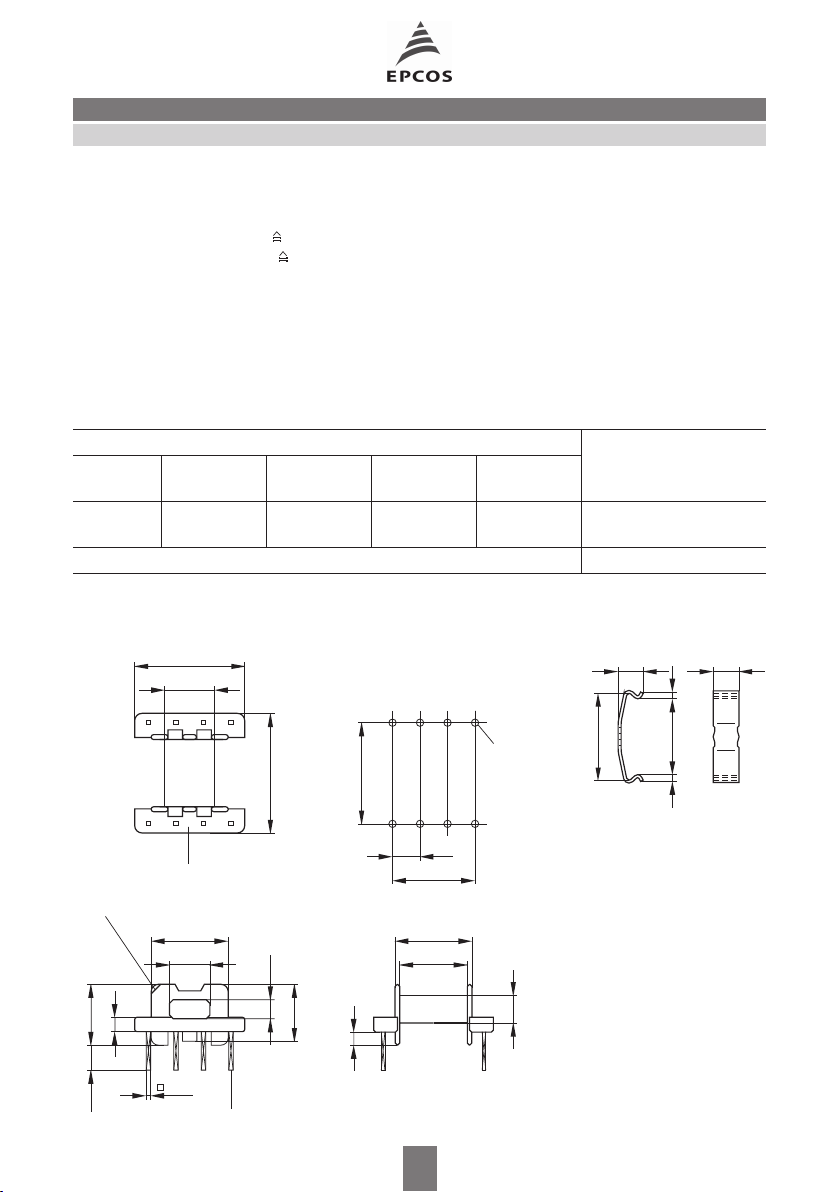

EFD 15/8/5

B66413Core

■ E core with flattened, lower center leg

for especially flat transformer design

■ For DC/DC converters

■ EFD cores are supplied as single units

Magnetic characteristics (per set)

Σl/A = 2,27 mm

–1

le= 34 mm

= 15 mm

A

e

A

= 12,2 mm

min

Ve= 510 mm

2

2

3

Approx. weight 2,8 g/set

Ungapped

Material A

nH

value

L

µ

e

A

nH

L1min

P

V

W/set

N49 600 + 30/– 20 % 1080 330 < 0,11

(50 mT, 500 kHz, 100 °C)

N87 780 + 30/– 20 % 1400 560 < 0,28

(200 mT, 100 kHz, 100 °C)

Gapped

Material A

value

L

µ

e

nH

N87 100

± 10 % 180 0,17 B66413-U100-K187

± 15 % 288 0,08 B66413-U160-L187

160

g

approx. mm

g

4,65±0,15

Ordering code

B66413-G-X149

B66413-G-X187

Ordering code

15±0,4

5,3±0,15

11±0,35

5,5±0,2

0,2±0,1

FEK0417-2

7,5±0,15

2,4±0,1

The A

value in the table applies to a core set comprising one ungapped core (dimension g = 0) and

L

one gapped core (dimension g > 0).

Calculation factors (for formulas, see “E cores: general information”, page 382)

Material Relationship between

air gap – A

value

L

Calculation of saturation current

K1 (25 °C) K2 (25 °C) K3 (25 °C) K4 (25 °C) K3 (100 °C) K4 (100 °C)

N87 29,7 – 0,676 44,2 – 0,796 33,2 – 0,873

Validity range: K1, K2: 0,10 mm < s < 1,00 mm

K3, K4: 30 nH < A

< 280 nH

L

507 08/01

Page 2

EFD 15/8/5

B66414Accessories

Coil former

Material: GFR thermosetting plastic; UL 94 V-0, insulation class to IEC 60085:

B66414-B: F max.operating temperature 155 °C; color code green

B66414-W: H max.operating temperature 180 °C; color code black

Solderability: to IEC 60068-2-20, test Ta, method 1 (aging 3): 235 °C, 2 s

Resistance to soldering heat: to IEC 60068-2-20, test Tb, method 1B: 350 °C, 3,5 s

Winding: see “Processing Notes”, page 157

Squared pins

Yoke

Material: Stainless spring steel (0,25 mm)

Coil former Ordering code

Sections A

mm

N

2

l

N

mm

A

µΩ

value

R

Pins

1 15,5 35,9 79,7 8 B66414-B1008-D1

B66414-W1008-D1

Yoke (ordering code per piece, 2 are required) B66414-B2000

Coil former Yoke

1

8

Duroplast

Marking of pin 1

10,55

5,55+0,15

1,7

8,3 max.3,5±0,2

15±0,2

_

0,1

6,95

2

7

6

_

0,15

0,45

CuSn6, tinned

43

5

16,5±0,2

2,55

0,2

_

7,5

_

13,75

0,151,6

Mounting holes

8

1

3,75

11,25

_

0,2

10,4

8,85 min.

508 08/01

5

ø1+0,1

4

4

FEK0418-A

15,6

4,4

13,6 min. 1

1

4,8 max.

FEK0271-J

Page 3

EFD 15/8/5

SMD coil former with J terminals

Material: GFR liquid crystal polymer (UL 94 V-0, insulation class to IEC 60085:

F max. operating temperature 155 °C), color code black

Solderability: to IEC 60068-2-20, test Ta, method 1 (aging 3): 350 °C, 1 s

Resistance to soldering heat: to IEC 60068-2-20, test Tb, method 1B: 350 °C, 3,5 s

permissible soldering temperature for wire-wrap connection on coil former: 400 °C, 1 s

Winding: see “Processing Notes”, page 160

Yoke

Material: Stainless spring steel (0,25 mm)

Mounting: Preferred assembly direction from the top

Cover plate

For marking and improved processing on assembly machines.

See under coil former for material and resistance to soldering heat.

B66414Accessories

Sections A

mm

N

2

l

N

mm

A

µΩ

value

R

Terminals Ordering code

1 18,1 35,1 66,7 8 B66414-B6008-T1

2 17,1 35,1 70,5 8 B66414-B6008-T2

Yoke (ordering code per piece, 2 are required) B66414-B2000

Cover plate B66414-A7000

Coil former Yoke

_

0,2515

_

0,2

10,4

0,5±0,05

0,5±0,05

_

0,3

20,8

0,6±0,05

0,2

_

6,4

2

3

4

0,55±0,05

Center flange omitted for one-section version

0,2

_

3,45

81

7

6

3,75

11,25

5

10,6 0,2

5,5+0,2

7,7±0,15

16 0,2

Recommended

Empfehlung für das

Leiterplattenlayout

PCB layout

1,2

2,5

17,7

_

_

7,3 0,1

2,6+0,15

_

3,75

11,25

FEK0329-J

4,4

15,6

Cover plate

Abdeckplatte

0,5 max.

12,8±0,1

13,6 min. 1

1

FEK0187-Y

4,8 max.

FEK0271-J

1,8±0,1

6,6±0,1

509 08/01

Page 4

Herausgegeben von EPCOS AG

Marketing Kommunikation, Postfach 80 17 09, 81617 München, DEUTSCHLAND

EPCOS AG 2000. Alle Rechte vorbehalten. Vervielfältigung, Veröffentlichung, Verbreitung und

Verwertung dieser Broschüre und ihres Inhalts ohne ausdrückliche Genehmigung der EPCOS AG

nicht gestattet.

Mit den Angaben in dieser Broschüre werden die Bauelemente spezifiziert, keine Eigenschaften

zugesichert. Bestellungen unterliegen den vom ZVEI empfohlenen Allgemeinen Lieferbedingungen

für Erzeugnisse und Leistungen der Elektroindustrie, soweit nichts anderes vereinbart wird.

Diese Broschüre ersetzt die vorige Ausgabe.

Fragen über Technik, Preise und Liefermöglichkeiten richten Sie bitte an den Ihnen nächstgele-

genen Vertrieb der EPCOS AG oder an unsere Vertriebsgesellschaften im Ausland.

Bauelemente können aufgrund technischer Erfordernisse Gefahrstoffe enthalten. Auskünfte

darüber bitten wir unter Angabe des betreffenden Typs ebenfalls über die zuständige Vertriebsgesellschaft einzuholen.

Published by EPCOS AG

Marketing Communications, P.O. Box 80 17 09, 81617 Munich, GERMANY

EPCOS AG 2000. All Rights Reserved. Reproduction, publication and dissemination of this brochure and the information contained therein without EPCOS’ prior express consent is prohibited.

The information contained in this brochure describes the type of component and shall not be considered as guaranteed characteristics. Purchase orders are subject to the General Conditions for

the Supply of Products and Services of the Electrical and Electronics Industry recommended by the

ZVEI (German Electrical and Electronic Manufacturers’ Association), unless otherwise agreed.

This brochure replaces the previous edition.

For questions on technology, prices and delivery please contact the Sales Offices of EPCOS AG or

the international Representatives.

Due to technical requirements components may contain dangerous substances. For information on

the type in question please also contact one of our Sales Offices.

1

Loading...

Loading...