Epcos B 65855 Service Manual

www.DataSheet4U.com

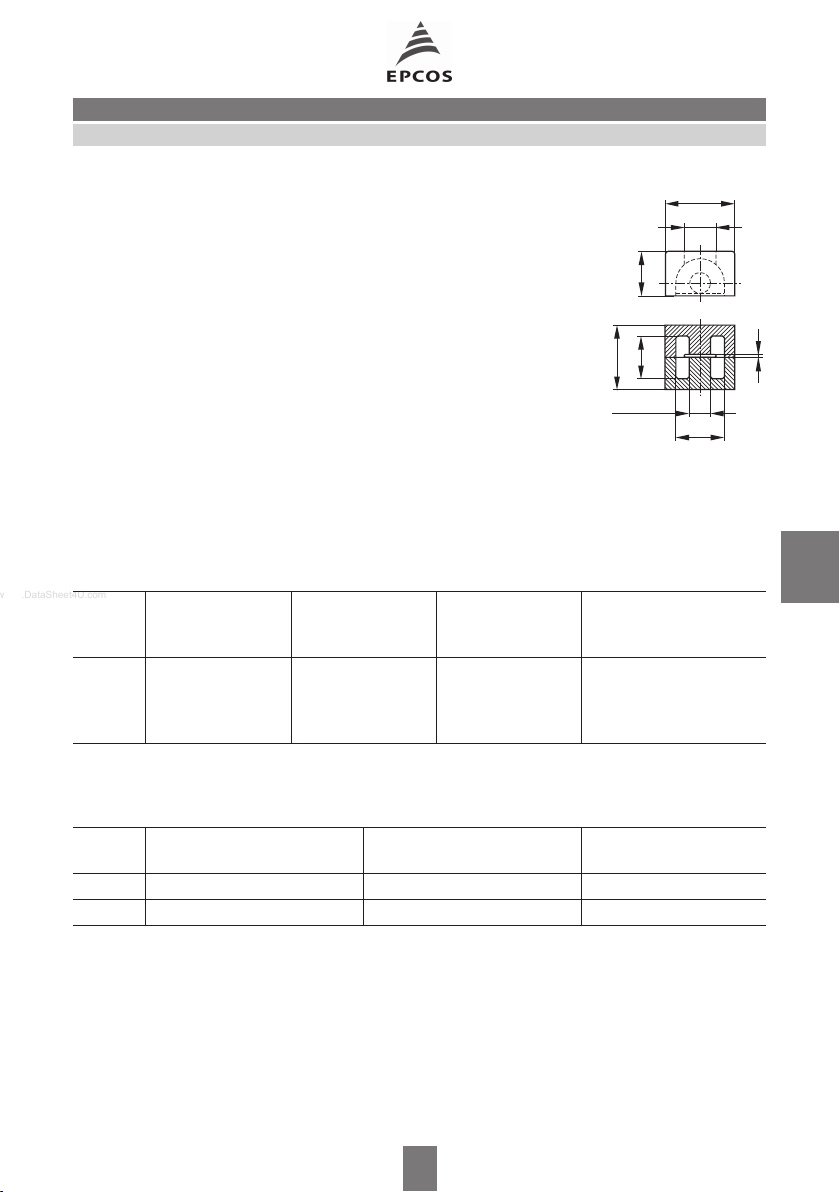

EP 5

Core

EP 5 through EP 20

■ For small interface transformers and filter chokes

■ Suitable for high precise feed-through gapping

■ Same footprint as EE5

■ A

value increases about 40 % against EE5

L

■ Winding area larger than EE5

■ EP cores are supplied in sets

Magnetic characteristics (per set)

Σl/A = 3,154 mm

–1

le= 9,73 mm

= 3,09 mm

A

e

A

= 2,34 mm

min

Ve= 30 mm

2

2

3

Approx. weight 0,5 g/set

Gapped

B65855

_

6,15 0,3

2,8

_

3,9 0,25

_

3,8+0,4

5,7 0,2

_

ø1,8 0,15

4,3+0,25

)

∗

gapped (one-sided)

)

∗

FEP0002-E

s

Material A

T38 16

Ungapped

Material A

T38 2000 + 40/– 30 % 5100 B65855-A-Y38

T42 2200 + 40/– 30 % 5500 B65855-A-Y42

value

L

µ

e

s

Ordering code

approx.

nH

mm

± 3 % 40 0,24 B65855-A16-A38

± 3 % 63 0,15 B65855-A25-A38

25

± 5 % 100 0,10 B65855-A40-J38

40

± 8 % 160 0,06 B65855-A63-D38

63

nH

value

L

µ

e

Ordering code

275 08/01

EP 5

Preliminary data

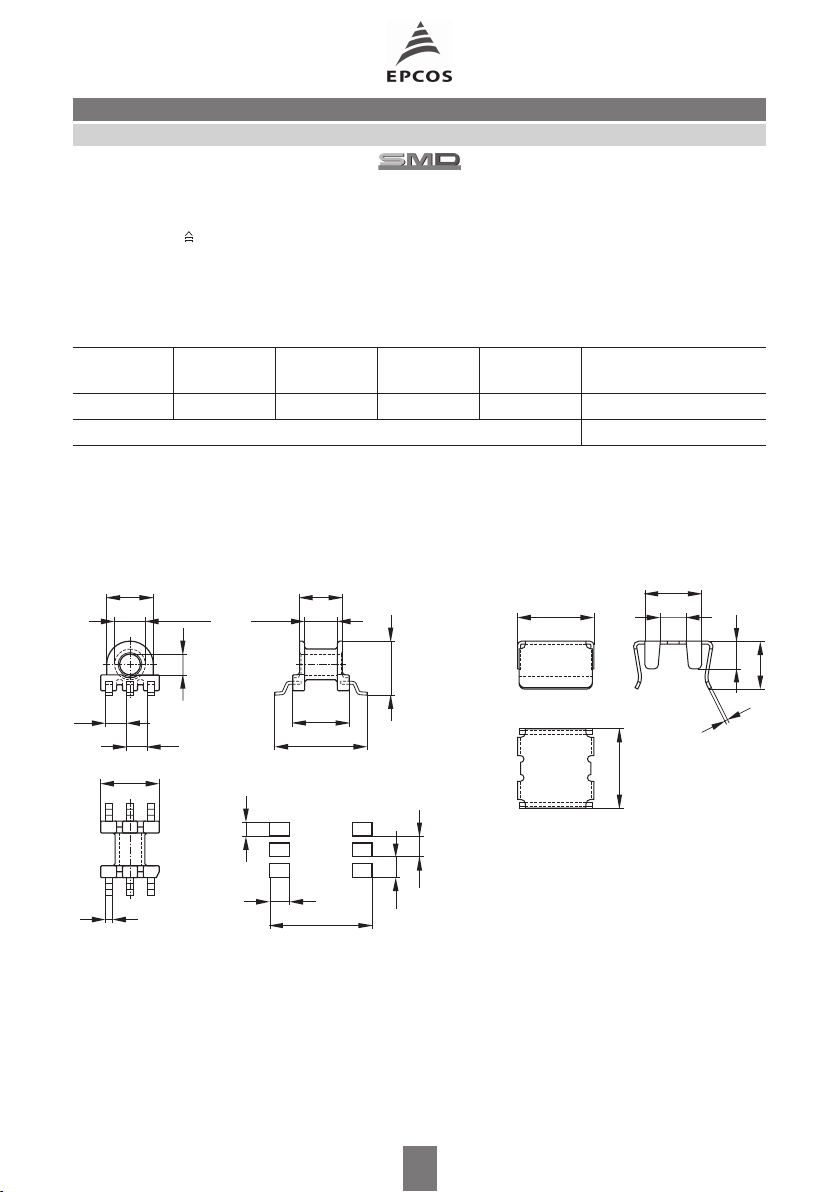

SMD coil former with gullwing terminals

Material: GFR liquid crystal polymer (UL 94 V-0, insulation class to IEC 60085:

F max. operating temperature 155

Solderability: to IEC 60068-2-20, test Ta, method 1 (aging 3): 350

Resistance to soldering heat: to IEC 60068-2-20, test Tb, method 1B: 350

°C), color code black

°C, 1 s

°C, 3,5 s

permissible soldering temperature for wire-wrap connection on coil former: 400

Winding: see “Processing Notes”, page 156

B65856Accessories

°C, 1 s

Sections A

mm

N

2

l

N

mm

A

valueµΩTerminals Ordering code

R

1 2,1 10,4 168 6 B65856-A1006-T1

Cap yoke B65856-C2000

Coil former and cape yoke on request.

Coil former Cap yoke

1,85

0,6

_

0,14,1

5,2 max.

2,6±0,05

1,9

1,85

2,9+0,1

1,1

_

0,13,7

4,9 max.

8,0 max.

Recommended

PCB layout

1,5

8,6

4,6 max.

1,85

1,85

FEP0003-R

6,6+04

5

2,2

6,8 max.

2,4

4 max.

0,2

FEP0037-Z

276 08/01

Loading...

Loading...