www.DataSheet4U.com

P 11 × 7

B65531Core

■ In accordance with IEC 60133

■ Pot cores are supplied in sets

Magnetic characteristics (per set)

Σl/A

l

e

A

e

A

min

V

e

with

center hole

1,0

15,9

15,9

—

252,0

without

center hole

0,92

16,30

17,70

14,90

289,00

Approx. weight (per set)

m 1,7 1,8 g

Gapped

Material A

value

L

s

approx.

nH

K1 25

40

M33 40

63

N48 100

160

250

400

± 3 % 1,00 20 B65531-D25-A1

± 3 % 0,41 32 B65531-D40-A1

± 3 % 0,64 32 B65531-D40-A33

± 3 % 0,38 50 B65531-D63-A33

± 3 % 0,20 80 B65531-D100-A48

± 3 % 0,10 127 B65531-+160-A48

± 3 % 0,06 199 B65531-+250-A48

± 5 % 0,03 318 B65531-D400-J48

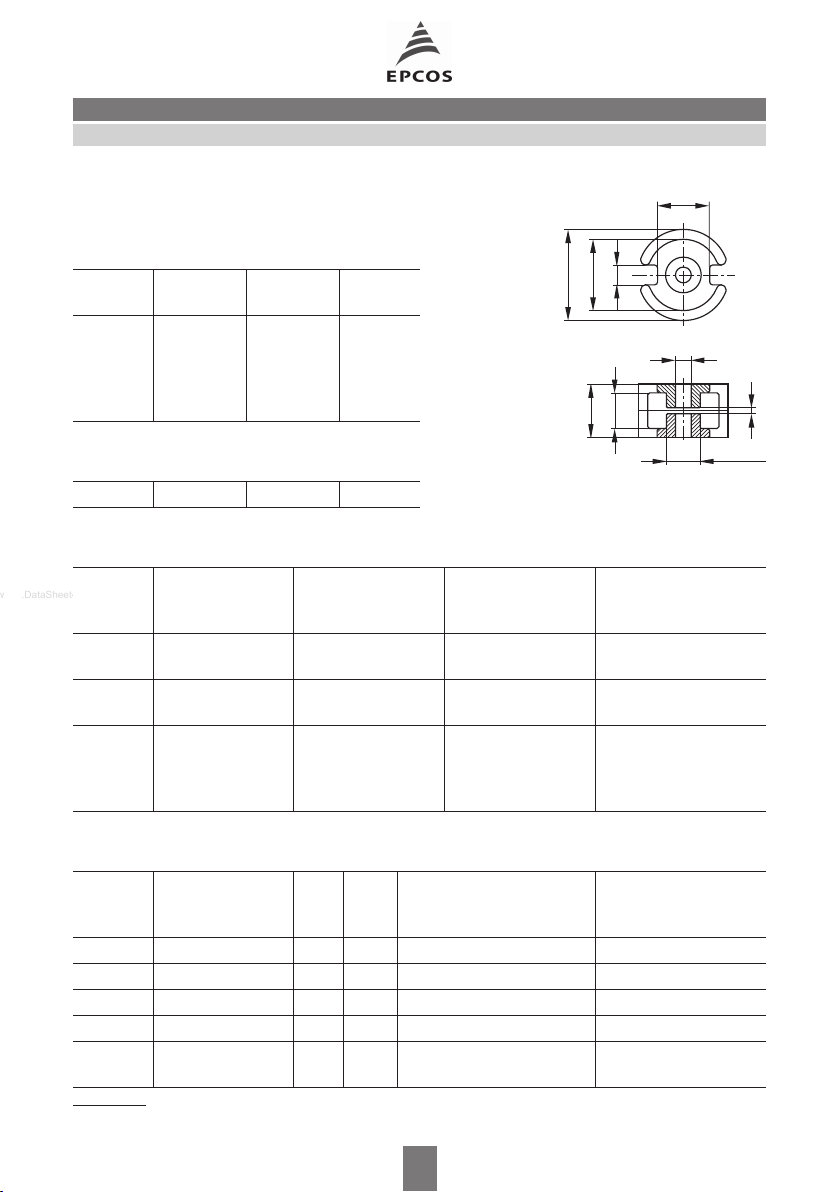

mm

mm

mm

mm

mm

mm

_

6,95 0,45

_

9+0,4

2,3+0,4

11,3 0,4

–1

4,4+0,3

ø2+0,1

ø4,7 0,2

FPK0069-T

1)

s

_

2

2

3

µ

e

0,26,6

_

Ordering code

-D with center hole

-T with threaded sleeve

Ungapped

Material A

M33 780 + 30/– 20 % 620 B65531-D-R33

N26 1800 + 30/– 20 % 1430 B65531-D-R26

N30 3500 + 30/– 20 % 2560 B65531-W-R30

T38 7000 + 40/– 30 % 5120 B65531-W-Y38

N87 2000 + 30/– 20 % 1460 1250 < 0,12

1) Replace the + by the code letter ”D“ or ”T“ for the required version.

nH

value

L

A

L1min

P

V

µ

e

Ordering code

-D with center hole

nH

W/set

-W w/o center hole

B65531-W-R87

(200 mT, 100 kHz, 100 °C)

324 08/01

www.DataSheet4U.com

P 11 × 7

B65532Accessories

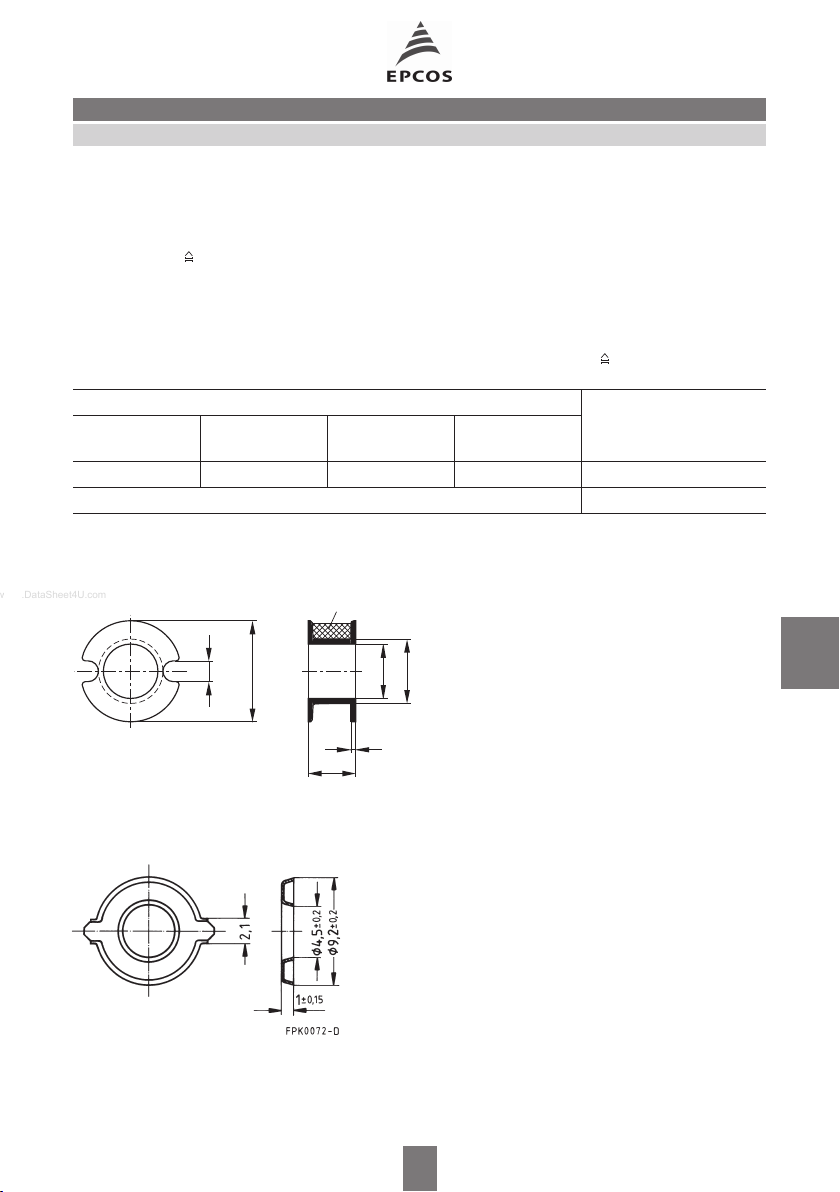

Coil former

Standard: to IEC 60133

Material: GFR polyterephthalate (UL 94 V-0, insulation class to IEC 60085:

F max. operating temperature 155 °C), color code black

Winding: see “Processing Notes”, page 155

Insulating washer 1 between core and coil former

■ For tolerance compensation and for insulation

■ Polycarbonate spring washer (UL 94 V-0, insulation class to IEC 60085: E 120°C), 0,04 m m thick

Coil former Ordering code

Sections A

mm

N

2

l

N

mm

A

µΩ

value

R

1 4,2 22 180 B65532-B-T1

Insulating washer 1 (reel packing, PU = 1 reel) B65532-A5000

Coil former

A

N

Insulating washer 1

0,2

_

1,8+0,4

8,9

4,2_0,1

ø4,8+0,1

0,4

FPK0266-G

0,1

_

ø5,7

325 08/01

Loading...

Loading...