查询B45196H1226J106供应商

Tantalum Chip Capacitors

B45196H, B45198H

HighCap

Construction

■ Polar tantalum capacitors with solid electrolyte

■ Conventional Ta-MnO

■ Flame-retardant plastic case (UL 94 V-0)

■ Optionally tinned or gold-plated terminals

technology

2

Features

■ Ultra-high volumetric efficiency

■ Excellent solderability

■ Stable temperature and frequency characteristics

■ Low leakage current, low dissipation factor

■ Low self-inductance

■ High resistance to shock and vibration

■ Suitable for use without series resistor

(recommended operating voltage see “General Technical Information”, page 111, 4.4)

Applications

■ Telecommunications (e.g. mobile phones, private branch exchanges)

■ Data processing (e.g. laptops, main frames)

■ Measuring and control engineering (e.g. voltage regulators)

■ Automotive electronics

■ Medical engineering

■ DC/DC converters

Soldering

Suitable for reflow soldering (IR and vapor phase) and wave soldering

Delivery mode

Taped and reeled in accordance with IEC 60286-3

Ordering code structure

B45196 H1226

Passive component

Tantalum capacitor

Series

196 = tinned terminals Sn100

198 = gold-plated terminals

44 10/02

+10

*

Reel diameter

9 = 180 mm, 6 = 330 mm

Case size

10 = A,20 = B, 30 = C, 40 = D, 50 = E

Capacitance tolerance

M =

± 20 %, K = ±10 %, J = ± 5 %

Rated capacitance

First two digits = significant figures

Third digit = exponent

Voltage (code number)

Tantalum Chip Capacitors

B45196H, B45198H

HighCap

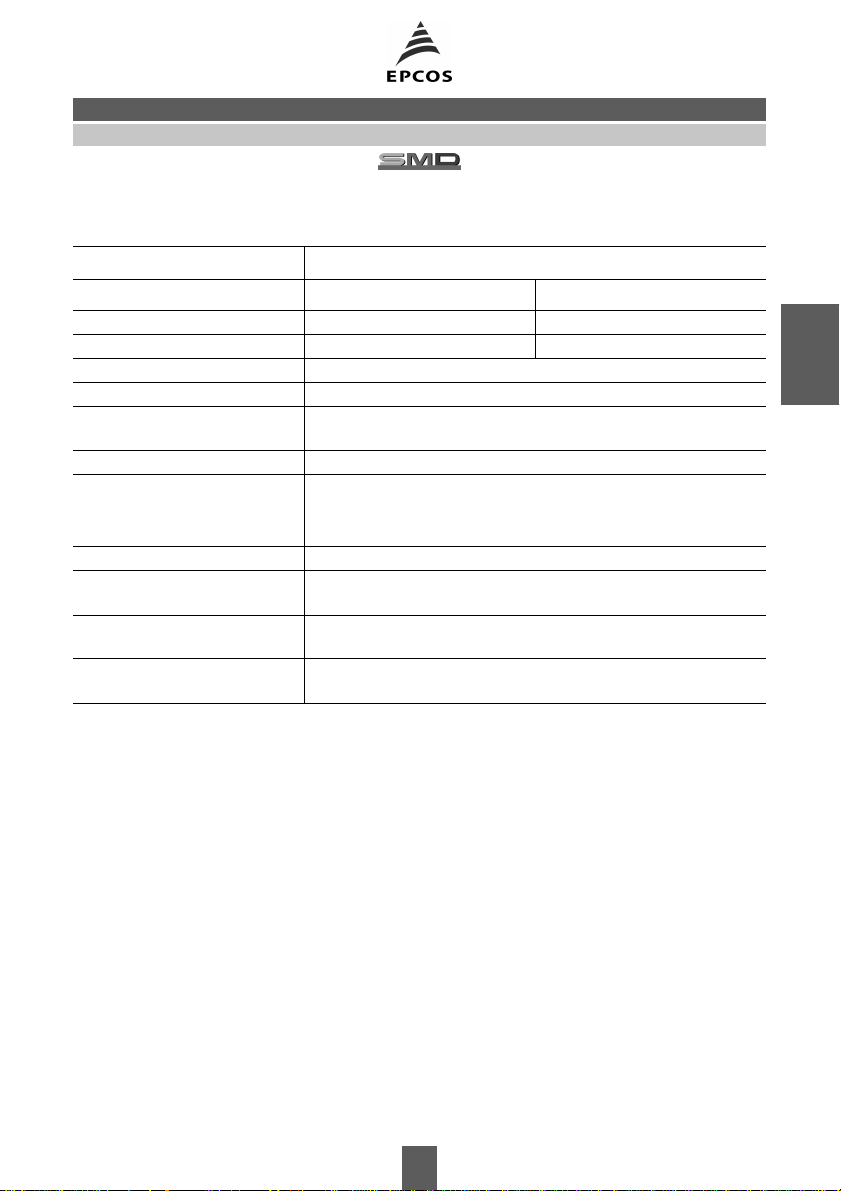

Specifications and characteristics in brief

For characteristic curves see “General Technical Information”, page 107 ff.

HighCap

Series B45196H B45198H

Technology Ta-MnO

2

Ta-MnO

2

Terminals Tinned Gold-plated

Rated voltage V

Rated capacitance C

Capacitance tolerance

(up to 85 °C) 4 … 50 Vdc

R

R

0,15 … 1500 µF

±10%, ± 20%

± 5% (on request)

Operating temperature – 55 … + 125

Failure rate At 40

C

· V

≤ 330 µF · V ≤ 8 fit

R

R

C

· V

> 330 µF · V ≤ 24 fit

R

R

°C

°C; ≤ V

, RS ≥ 3 Ω/V (1 fit = 1 . 10-9 failures/h)

R

Service life > 500 000 h

Leakage current

(V

, 5 min, 20 °C)

R

Detail specification

10 nA/

µC

CECC 30801-802

(tinned terminals)

IEC climatic category To IEC 60068-1

55/125/56 (– 55 /+125

°C; 56 days damp heat test)

45 10/02

Tantalum Chip Capacitors

HighCap

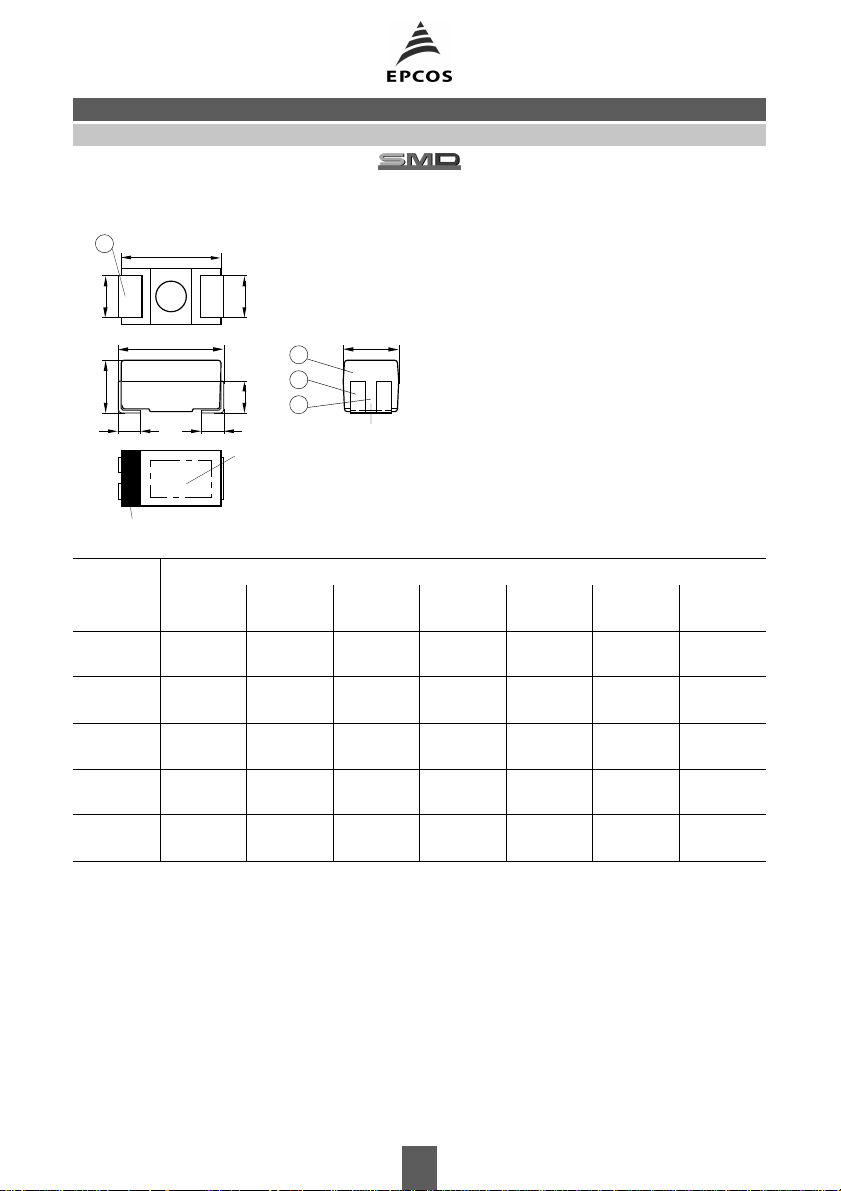

Dimensional drawing

B45196H, B45198H

3

2

W

H

L

2

2

W

L

PP

Positive pole marking

2

H

Marking

1

2

3

Positive pole marking

Case size Dimensions in mm (inches)

LW

A (10) 3,2

(,126

B (20) 3,5

(,138

C (30) 6,0

(,236

D (40) 7,3

(,287

E (50) 7,3

(,287

± 0,2

±,008)

± 0,2

±,008)

± 0,3

±,012)

± 0,3

±,012)

± 0,3

±,012)

H L

± 0,2

1,6

(,063

2,8

(,110

3,2

(,126

4,3

(,169

4,3

(,169

± 0,2

± 0,3

± 0,3

± 0,3

±,008)

±,008)

±,012)

±,012)

±,012)

1,6

(,063

1,9

(,075

2,5

(,098

2,8

(,110

4,1

(,157

W

KTA0254-9-E

± 0,2

±,008)

± 0,2

±,008)

± 0,3

±,012)

± 0,3

±,012)

± 0,3

±,012)

typ. W

2

3,0

(,118)

3,3

(,130)

5,8

(,228)

7,1

(,280)

7,1

(,280)

Encapsulation: molded epoxy resin

➀

NiFe; tinned surface Sn100 or

➁

gold-plated

Reduced slot length for case size A

➂

± 0,1

2

±(,004)

1,2

(,047)

2,2

(,087)

2,2

(,087)

2,4

(,094)

2,4

(,094)

typ. p ± 0,3

H

2

1,0

(,039)

1,2

(,047)

1,5

(,059)

1,6

(,062)

1,6

(,062)

±(,012)

0,8

(,031)

0,8

(,031)

1,3

(,051)

1,3

(,051)

1,3

(,051)

46 10/02

Tantalum Chip Capacitors

HighCap

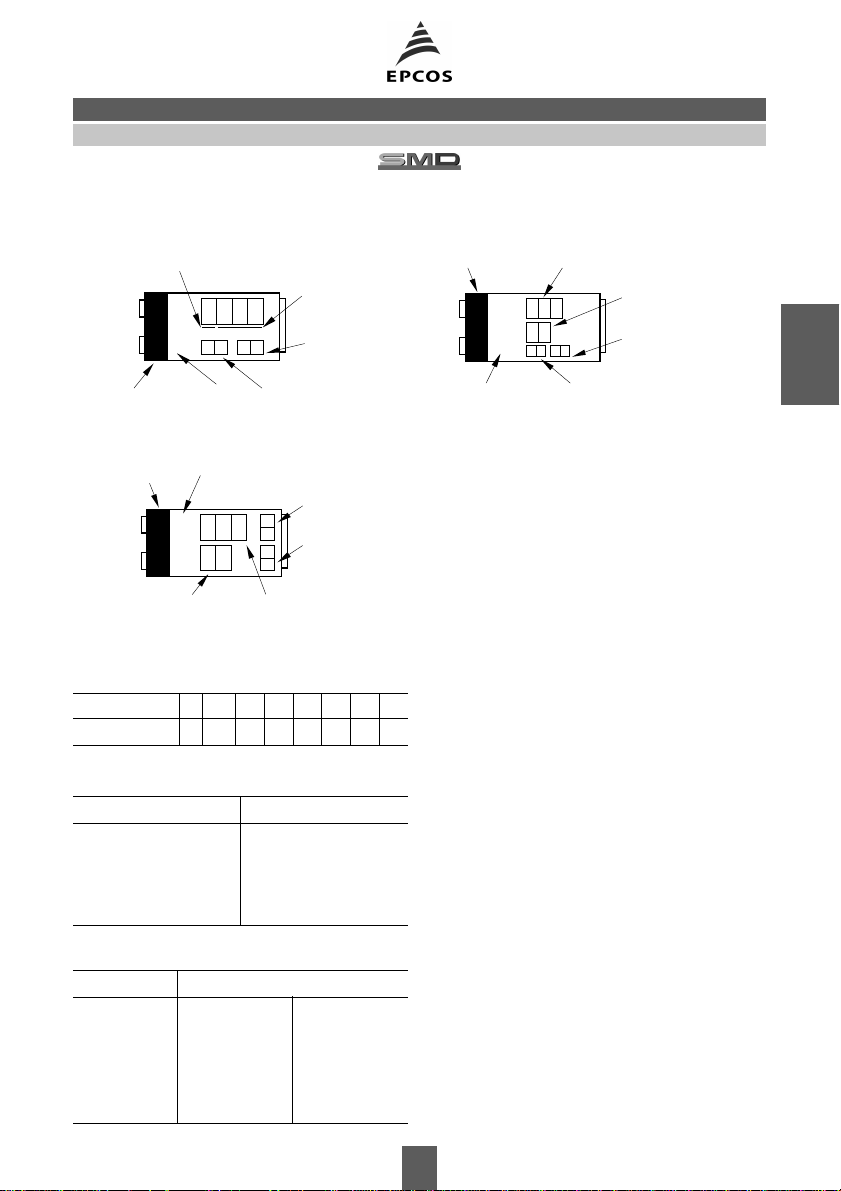

Marking

Case size A Case size B

Positive

pole (bar)

Manufacturer’s

logo

Positive

pole (bar)

Rated voltage

(in coded form)

EPCOS

Manufacturer’s

logo

Capacitance

(in coded form)

Internal code

for production

(2 to 3 figures)

Date code

KTA0245-A-E

Capacitance

(in coded form)

V

EPCOS

Date code

B45196H, B45198H

Rated voltage, (not

V

coded) = 6,3 V

R

is abbreviated as 6.

Internal code

for production

(2 to 3 figures)

KTA0246-I-E

Positive

pole (bar)

Rated voltage, (not

V

coded)

is abbreviated as 6.

= 6,3 V

R

Manufacturer’s

logo

V

EPCOS

Capacitance

(in coded form)

Internal code for

production equipment

(2 to 3 figures)

Date code

KTA0244-2-E

Case sizes C, D, E

Voltage coding for case size A

Rated voltage 4 6,3 10 16 20 25 35 50

Code letter G J A C D E V T

Capacitance coding

1st and 2nd digit Capacitance in pF

3rd digit Multiplier: 4 = 10

Date coding

5 = 10

6 = 10

7 = 10

8 = 10

4

5

6

7

8

pF

pF

pF

pF

pF

Year Month

M = 2000 1 = January 7 = July In addition to the year and month of manufac-

N = 2001 2 = February 8 = August

P = 2002 3 = March 9 = September

R = 2003 4 = April O = October

ture, the stamp includes another two or three

figures which internally allow us an assign-

ment to production equipment.

S = 2004 5 = May N = November

T = 2005 6 = June D = December

47 10/02

Loading...

Loading...