Aluminum electrolytic capacitors

Alu-X product lines

Single-ended capacitors

Series/Type: B43081

Data Sheet

Date: August 2008

© EPCOS AG 2008. Reproduction, publication and dissemination of this publication and the infor-

mation contained therein without EPCOS’ prior express consent is prohibited.

Single-ended capacitors B43081

High ripple current – 105 °C

Single-ended capacitors B43081

High ripple current – 105 °C

Long-life grade capacitors for professional applications

Applications

■ Electronic ballast applications

Features

■ RoHS-compatible

■ Very high ripple current

■ High reliability

■ Load life of 3000 h at 105 °C

Construction

■ Radial leads

■ Aluminum case, fully insulated

■ Charge-discharge proof

■ Minus pole marking on the insulating sleeve

■ Case with safety vent from diameter 8 mm

Delivery mode

■ Bulk

■ Taped, Ammo pack

■ Cut

■ Kinked

Please read Cautions and warnings and

Important notes at the end of this document.

2 08/08

Single-ended capacitors B43081

High ripple current – 105 °C

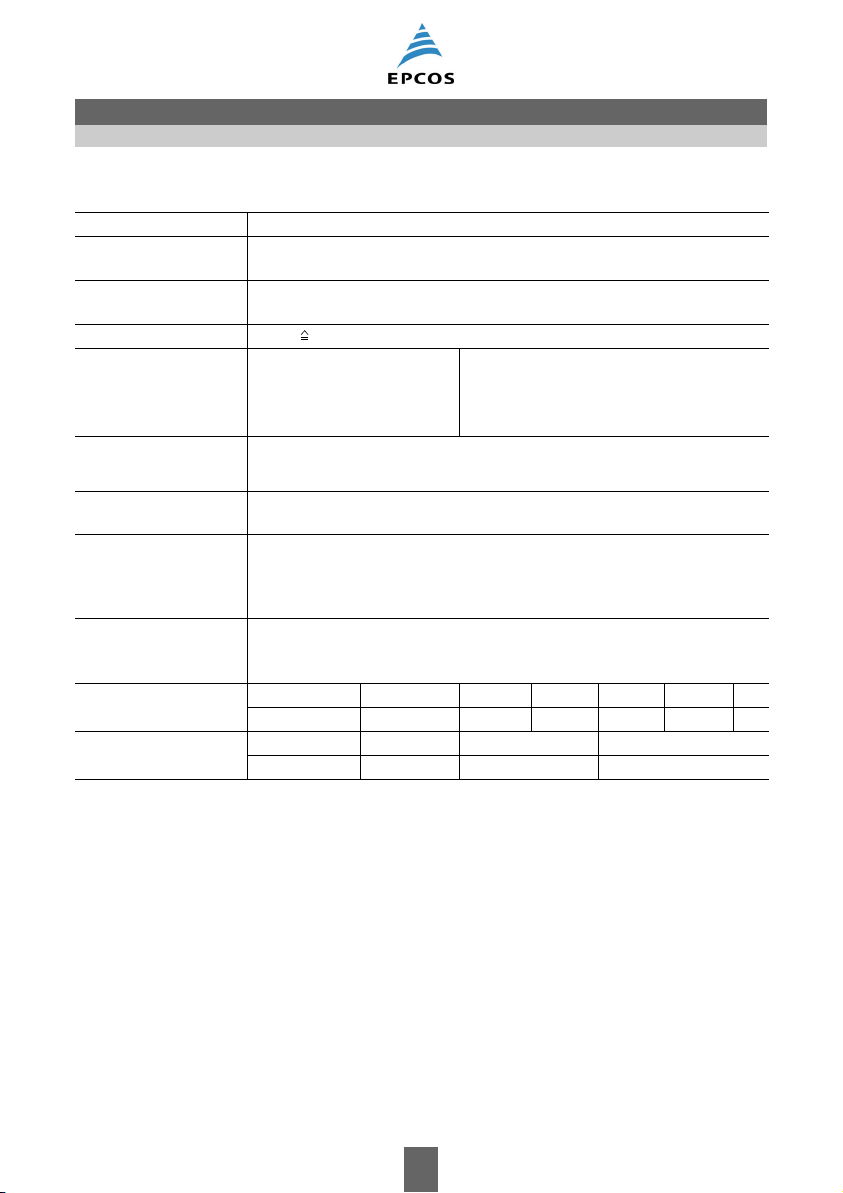

Specifications and characteristics in brief

Rated voltage V

R

Operating temperature

160 ... 400 V DC

–25 °C … +105 °C

range

Rated capacitance C

0.1 … 100 µF

R

(20 °C, 120 Hz)

Capacitance tolerance ±20% M

Load life

(105 °C, V

, I

R

AC,R

Leakage current I

(20 °C, after 5 minutes)

Dissipation factor (max.)

3000 h Requirements:

)

V

leak

I

leak

0.02 µA

C

R

R

⎛⎞

-------

-------

⋅

⋅≤

⎝⎠

µF

V

tan δ ≤ 0.12

∆C/C ≤ ±20% of initial value

tan δ≤ 2 times initial specified limit

I

≤ initial specified limit

leak

(20 °C, 120 Hz)

Low temperature

stability

(impedance ratio)

Z25 °C–()

--------------------------Z +20 °C()

≤ 7

(120 Hz)

Shelf life After storage for 1000 h at 105 °C, the capacitors shall meet the require-

ment of load life test after reforming process. After test: V

to be applied

R

for 30 minutes, 24 to 48 hours before measurement.

Frequency multiplier for

rated ripple current

Temperature multiplier

for rated ripple current

50 Hz 120 Hz 300 Hz 1 kHz 10 kHz 100 kHz

0.3 0.5 0.6 0.8 0.9 1.0

+50 °C +70 °C +85 °C +105 °C

2.1 1.8 1.4 1.0

Please read Cautions and warnings and

Important notes at the end of this document.

3 08/08

Single-ended capacitors B43081

High ripple current – 105 °C

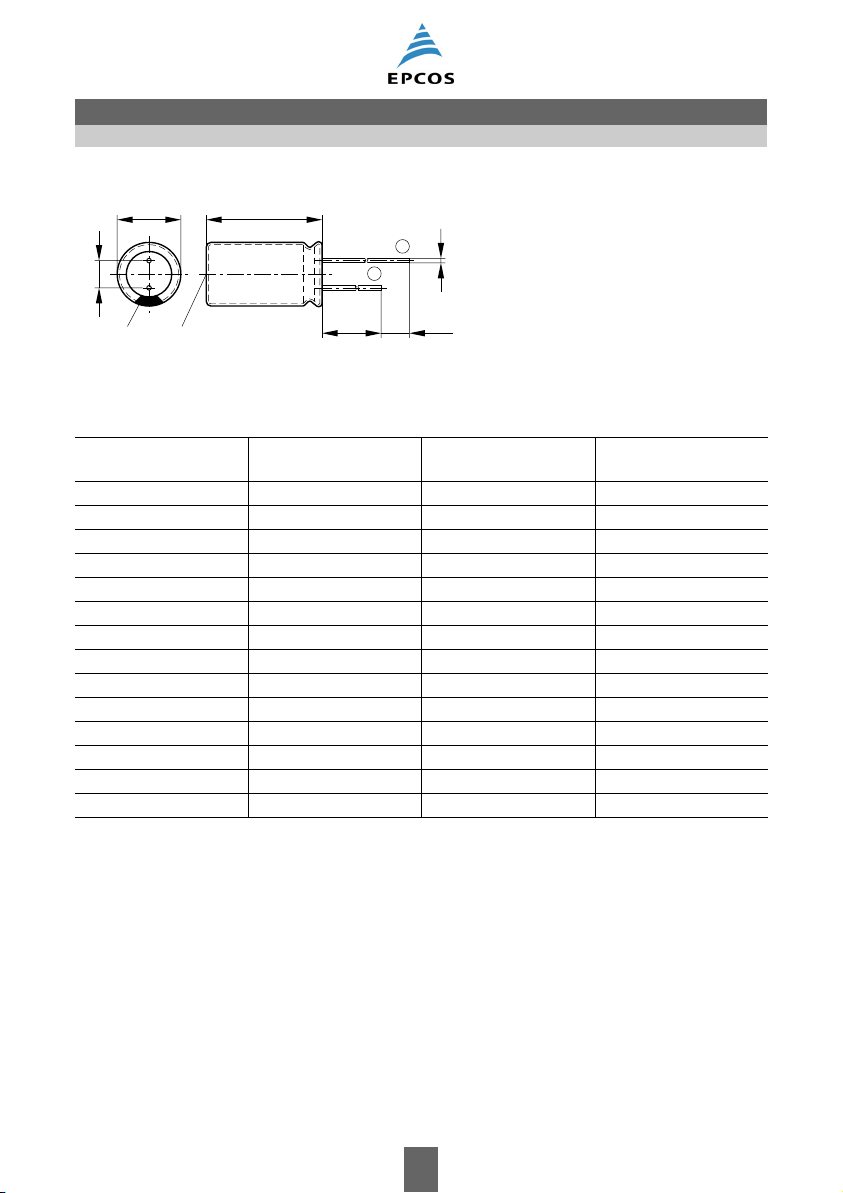

Dimensional drawing

d

a

Minus pole Safety vent

marking

l

+

øb

-

15 min.

5 min.

KAL1080-C-E

Safety vent for diameter ≥ 8 mm.

Case dimensions

d × l

mm

d

max

mm

× I

max

a

mm

6.3 × 11 6.8 × 12.5 2.5 ±0.5 0.5 ±0.1

8 × 11.5 8.5 × 13.0 3.5 ±0.5 0.6 ±0.1

8 × 15 8.5 × 16.5 3.5 ±0.5 0.6 ±0.1

8 × 20 8.5 × 21.5 3.5 ±0.5 0.6 ±0.1

10 × 16 11.0 × 17.5 5.0 ±0.5 0.6 ±0.1

10 × 20 11.0 × 22.0 5.0 ±0.5 0.6 ±0.1

12.5 × 20 13.5 × 22.0 5.0 ±0.5 0.6 ±0.1

12.5 × 25 13.5 × 27.0 5.0 ±0.5 0.6 ±0.1

16 × 20 17.0 × 22.0 7.5 ±0.5 0.8 ±0.1

16 × 25 17.0 × 27.0 7.5 ±0.5 0.8 ±0.1

16 × 31.5 17.0 × 33.5 7.5 ±

0.5 0.8 ±0.1

18 × 20 19.0 × 22.0 7.5 ±0.5 0.8 ±0.1

18 × 25 19.0 × 27.0 7.5 ±0.5 0.8 ±0.1

18 × 31.5 19.0 × 33.5 7.5 ±0.5 0.8 ±0.1

b

mm

Please read Cautions and warnings and

Important notes at the end of this document.

4 08/08

Single-ended capacitors B43081

High ripple current – 105 °C

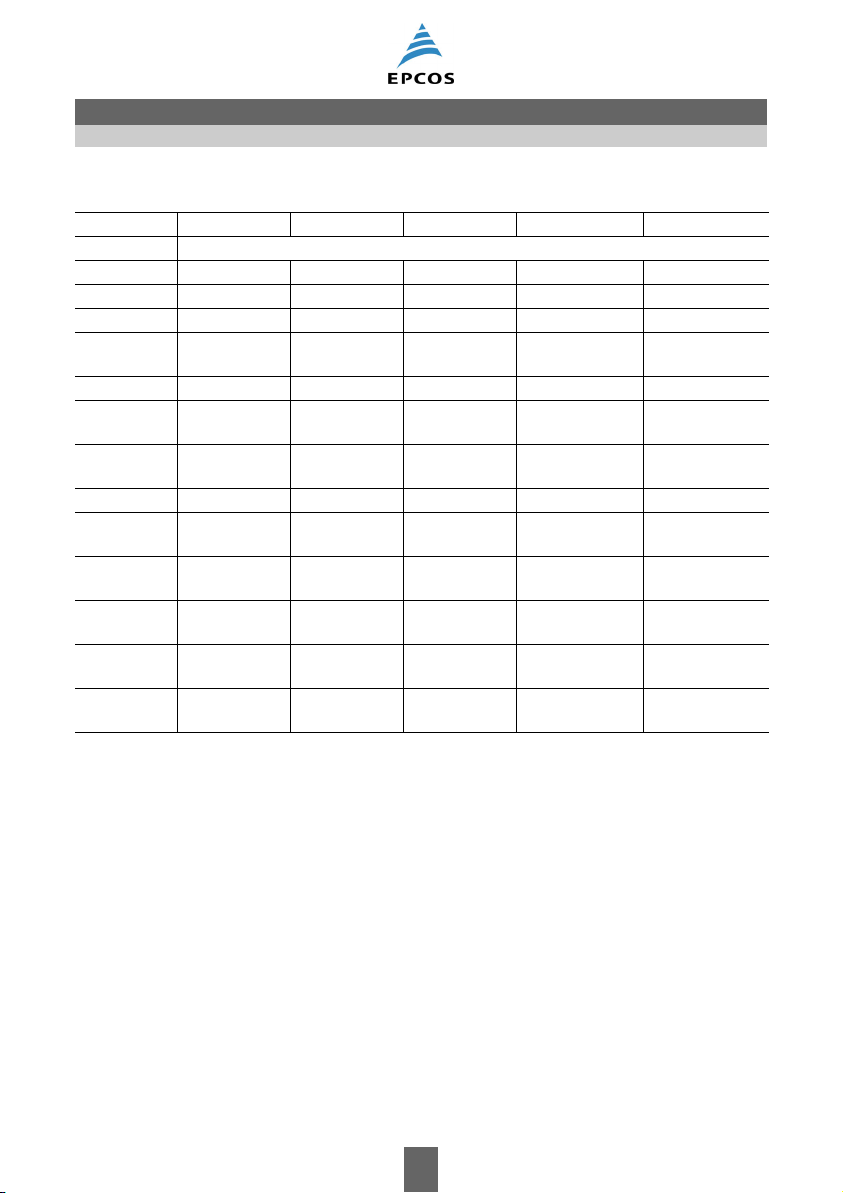

Overview of available types

VR (V DC) 160 200 250 350 400

Case dimensions d × l (mm)

(µF)

C

R

1.0 8 × 11.5 6.3 × 11.5

2.2 8 × 15

3.3 8 × 15

8 × 20

4.7 8 × 11.5 10 × 16 10 × 20

6.8 10 × 16 10 × 16 10 × 20

12.5 × 20

10 10 × 16 10 × 16 10 × 20 10 × 20

12.5 × 20

15 10 × 20 10 × 16 16 × 25

22 10 × 20 10 × 20 10 × 20

12.5 × 20

33 10 × 20 12.5 × 20 12.5 × 20

12.5 × 25

47 12.5 × 20

12.5 × 25

68 12.5 × 25 12.5 × 25

100 16 × 25 16 × 25

12.5 × 20 12.5 × 25

16

16 × 25

16 × 20

18 × 35.5

18 × 25

× 25

12.5 × 20 12.5 × 25

16 × 25

16 × 20 16 × 25

16 × 31.5

16 × 25 16 × 35.5

18 × 25

18 × 25

18 × 20

Please read Cautions and warnings and

Important notes at the end of this document.

5 08/08

Single-ended capacitors B43081

High ripple current – 105 °C

Technical data and ordering codes

V

R

V DC

C

R

120 Hz

20 °C

µF

Case

dimensions

d × l

mm

I

AC,R

100 kHz

105 °C

mA

Ordering code

(composition see

below)

160 22 10 × 20 500 B43081A1226M***

33 10 × 20 500 B43081A1336M***

47 12.5 × 20 600 B43081A1476M***

47 12.5 × 25 670 B43081B1476M***

68 12.5 × 25 750 B43081A1686M***

100 16 × 25 1100 B43081A1107M***

200 4.7 8 × 11.5 158 B43081A2475M***

6.8 10 × 16 230 B43081A2685M***

10 10 × 16 310 B43081A2106M***

15 10 × 20 400 B43081A2156M***

22 10 × 20 500 B43081A2226M***

33 12.5 × 20 600 B43081A2336M***

47 12.5 × 20 600 B43081A2476M***

68 12.5 × 25 750 B43081A2686M***

68 16 × 20 750 B43081B2686M***

100 16 × 25 1100 B43081A2107M***

100 18 × 20 1100 B43081B2107M***

250 1.0 8 × 11.5 18 B43081F2105M***

4.7 10 × 16 200 B43081F2475M***

6.8 10 × 16 240 B43081F2685M***

10 10 × 16 300 B43081F2106M***

15 10 × 16 380 B43081F2156M***

22 10 × 20 500 B43081F2226M***

22 12.5 × 20 600 B43081G2226M***

33 12.5 × 20 600 B43081F2336M***

33 12.5 × 25 670 B43081G2336M***

47 12.5 × 25 700 B43081F2476M***

47 16 × 25 780 B43081G2476M***

68 16 × 25 1000 B43081F2686M***

68 18 × 35.5 1200 B43081G2686M***

100 18 × 25 1200 B43081F2107M***

350 10 10 × 20 250 B43081A4106M***

22 12.5 × 20 350 B43081A4226M***

33 16 × 20 500 B43081A4336M***

47 16 × 25 650 B43081A4476M***

68 18 × 25 800 B43081A4686M***

*** = Version

000 = for standard leads, bulk

001 = for kinked leads, bulk

002 = for cut leads, bulk

007 = for taped leads, Ammo pack, lead spacing a = 2.5 mm

006 = for taped leads, Ammo pack, lead spacing a = 3.5 mm

008 = for taped leads, Ammo pack, lead spacing a = 5.0 mm

Please read Cautions and warnings and

Important notes at the end of this document.

6 08/08

Single-ended capacitors B43081

High ripple current – 105 °C

Technical data and ordering codes

V

R

V DC

C

R

120 Hz

20 °C

µF

Case

dimensions

d × l

mm

I

AC,R

100 kHz

105 °C

mA

Ordering code

(composition see

below)

400 1.0 6.3 × 11.5 18 B43081A9105M***

2.2 8 × 15 108 B43081A9225M***

3.3 8 × 15 108 B43081A9335M***

3.3 8 × 20 121 B43081B9335M***

4.7 10 × 20 180 B43081A9475M***

6.8 10 × 20 220 B43081A9685M***

6.8 12.5 × 20 240 B43081B9685M***

10 10 × 20 250 B43081A9106M***

10 12.5 × 20 270 B43081B9106M***

15 16 × 25 400 B43081A9156M***

22 12.5 × 25 400 B43081A9226M***

22 16 × 25 500 B43081B9226M***

33 16 × 25 600 B43081A9336M***

33 16 × 31.5 670 B43081B9336M***

47 16 × 35.5 750 B43081A9476M***

47 18 × 25 750 B43081B9476M***

*** = Version

000 = for standard leads, bulk

001 = for kinked leads, bulk

002 = for cut leads, bulk

007 = for taped leads, Ammo pack, lead spacing a = 2.5 mm

006 = for taped leads, Ammo pack, lead spacing a = 3.5 mm

008 = for taped leads, Ammo pack, lead spacing a = 5.0 mm

Please read Cautions and warnings and

Important notes at the end of this document.

7 08/08

Single-ended capacitors B43081

Single-ended capacitors B43081

Taping, packing and lead configurations

Taping, packing and lead configurations

Taping, packing and lead configurations of single-ended capacitors

Single-ended capacitors are available taped in Ammo pack from diameter 4 to 10 mm as follows:

Lead spacing 2.0 mm (∅ d = 4 ... 5 mm)

Last 3 digits of ordering code: 016

ød

P

P

0

h∆h ∆

D

2

0

H

H

0

W

1

W

0

W

W

1 max.

View B

t

1

Base tape

Adhesive tape

F

P

B

1

l

KAL1138-D-E

Dimensions in mm

∅ dF H W W

0

W1W2PP0P1l

t ∆hD

1

4 ... 5 2.0 18.5 18.0 7.0 9.0 3.0 12.7 12.7 5.10 1.0 0.7 1 4.0

–0.2 ±0.75 ±0.5 min. ±0.5 max. ±1.0 ± 0.3 ±0.7 max. ±0.2 ±1.0 ±0.2

0

Please read Cautions and warnings and

Important notes at the end of this document.

8 08/08

Single-ended capacitors B43081

Taping, packing and lead configurations

Lead spacing 2.5 mm (∅ d = 4 ... 6.3 mm)

Last 3 digits of ordering code: 007

ød

P

P

0

h∆h ∆

0

H

H

Base tape

Adhesive tape

2

W

1

0

W

W

W

F

P

1

D

0

1

B

l

1 max.

View B

t

KAL1074-3-E

Dimensions in mm

∅ dFHH

WW0W1W2PP0P1l

0

t ∆hD

1

0

4 ... 6.3 2.5 18.5 16.0 18.0 7.0 9.0 3.0 12.7 12.7 5.10 1.0 0.7 0 4.0

To le r a nc e – 0 . 2 ±0.75 ±0.5 ±0.5 min. ±0.5 max. ±1.0 ±0.3 ±0.7 max. ±0.2 ±1.0 ±0.2

Lead spacing 3.5 mm (∅ d = 8 mm)

Last 3 digits of ordering code: 006

ød

P

P

0

D

2

0

H

H

0

W

1

W

0

W

W

h∆h ∆

1 max.

View B

t

1

Base tape

Adhesive tape

F

P

B

1

l

KAL1138-D-E

Dimensions in mm

∅ dFHWW

0W1W2

PP0P1l

t ∆hD

1

0

8 3.5 18.5 18.0 10 9.0 3.0 12.7 12.7 5.10 1.0 0.7 1 4.0

To le r a nc e ±0.5 ±0.75 ±0.5 min. ±0.5 max. ±1.0 ± 0.3 ± 0.7 max. ±0.2 max. ±0.2

Please read Cautions and warnings and

Important notes at the end of this document.

9 08/08

Single-ended capacitors B43081

Taping, packing and lead configurations

Lead spacing 5.0 mm (∅ d = 4 ... 8 mm)

Last 3 digits of ordering code: 008

ød

P

P

0

h∆ h∆

2

H

0

H

W

1

W

0

W

W

1 max.

View B

t

Base tape

Adhesive tape

F

P

1

D

0

B

1

l

KAL1075-B-E

Lead spacing 5.0 mm (∅ d = 10 mm)

Last 3 digits of ordering code: 008

ød

P

P

0

2

H

W

0

W

1

W

h∆ h∆

1 max.

View B

W

t

Base tape

Adhesive tape

F

P

1

D

0

B

1

l

KAL1076-J-E

Dimensions in mm

∅ dFHH

WW0W1W2PP0P1L1t ∆hD

0

0

4 ... 6.3 5.0 18.5 16 18.0 7.0 9.0 3.0 12.7 12.7 3.85 1.0 0.6 2.0 4.0

8 5.0 18.5 16 18.0 10 9.0 3.0 12.7 12.7 3.85 1.0 0.6 2.0 4.0

10 5.0 18.5 – 18.0 12.5 9.0 3.0 12.7 12.7 3.85 1.0 0.6 2.0 4.0

Tolerance +0.6

±0.75 ±0.5 +1.0

–0.2

+1.0–0±0.5 max. ±0.5 ±0.3 ± 0.7 max. +0.3

–0.5

max. ±0.2

–0.2

Taping is available up to dimensions d × l = 10 × 20 mm. For ∅ 12.5, 16 and 18 mm taping is not

available.

Please read Cautions and warnings and

Important notes at the end of this document.

10 08/08

Single-ended capacitors B43081

Taping, packing and lead configurations

Kinked or cut leads

Single-ended capacitors are available with kinked or cut leads. Other lead configurations also available on request.

Kinked leads

Last 3 digits of ordering code: 001

3.2±0.1

l

2.1±0.1

1.2±0.1

KAL1137-5

l

ød

ød

4.5±0.5

a

KAL1084-A

Case size d × l (mm) a (mm) Case size d × l (mm) a (mm)

4 × 7 1.5 12.5 × 16 5.0

5 × 7 2.0 12.5 × 20 5.0

5 × 11 2.0 12.5 × 25 5.0

6.3 × 7 2.5 12.5 × 31.5 5.0

6.3 × 11 2.5 12.5 × 35.5 5.0

6.3 × 15 2.5 12.5 × 40 5.0

8 × 7 3.5 16 × 20 7.5

8 × 11.5 3.5 16 × 25 7.5

8 × 15 3.5 16 × 31.5 7.5

8 × 20 3.5 16 × 35.5 7.5

10 × 12.5 5.0 16 × 40 7.5

10 × 16 5.0 18 × 20 7.5

10 × 20 5.0 18 × 25 7.5

10 × 25 5.0 18 × 31.5 7.5

10 × 31.5 5.0 18 × 35.5 7.5

18 × 40 7.5

Please read Cautions and warnings and

Important notes at the end of this document.

11 08/08

Single-ended capacitors B43081

Taping, packing and lead configurations

Cut leads

Last 3 digits of ordering code: 002

l

ød

4.5±0.5

a

KAL1086-R

Case size d × l (mm) a (mm) Case size d × l (mm) a (mm)

4 × 7 1.5 12.5 × 16 5.0

5 × 7 2.0 12.5 × 20 5.0

5 × 11 2.0 12.5 × 25 5.0

6.3 × 7 2.5 12.5 × 31.5 5.0

6.3 × 11 2.5 12.5 × 35.5 5.0

6.3 × 15 2.5 12.5 × 40 5.0

8 × 7 3.5 16 × 20 7.5

8 × 11.5 3.5 16 × 25 7.5

8 × 15 3.5 16 × 31.5 7.5

8 × 20 5.0 16 × 35.5 7.5

10 × 12.5 5.0 16 × 40 7.5

10 × 16 5.0 18 × 20 7.5

10 × 20 5.0 18 × 25 7.5

10 × 25 5.0 18 × 31.5 7.5

10 × 31.5 5.0 18 × 35.5 7.5

18 × 40 7.5

Please read Cautions and warnings and

Important notes at the end of this document.

12 08/08

Cautions and warnings

General

Also see “Important notes” on page 15.

1 Aluminum electrolytic capacitors have a bi-polar structure. This is marked on the body of the

capacitor. A capacitor must not be mounted with reversed polarity. The application of an AC

or reverse voltage may cause a short circuit or damage the capacitor. Bi-polar capacitors

must not be used in AC applications, where the polarity may be reversed in the circuits or is

unknown.

2 The DC voltage applied to the capacitor terminal must not exceed its rated operating voltage,

as this will result in a rapid increase of the leakage current and may damage the capacitor. It

is recommended to operate the capacitor at 70–80% of its rated voltage to optimize its service life.

3 The ripple current applied to the capacitor must be within the permitted range. An excessive

ripple current leads to impaired electrical properties and may damage the capacitor. Note that

the sum of the peak values of the ripple voltage and the DC operating voltage must not exceed the rated DC voltage.

4 Capacitors must be used within their permitted range of operating temperature. Operation at

room temperature optimizes their service life.

5 Capacitors with case diameter ≥8 mm are equipped with a safety vent. In capacitors fitted

with a lead or soldering lug, the safety vent is usually located at the base of the case. It needs

sufficient space around it to operate optimally. The following dimensions are recommended:

for case diameter d = 8 to 16 mm, more than 2 mm; for d =18 to 35 mm, more than 3 mm;

and for d = 42 mm or more, more than 5 mm.

6 Capacitors should not be mounted with the safety vent face down on the board. Do not locate

any wire or copper trace near the safety vent. Do not reverse the voltage, as this may result

in excess pressure and the leakage of electrolyte.

7 Gas is released through the safety vent when the pressure inside the capacitor is too high. A

gaseous liquid around the safety vent does not indicate a leakage of electrolyte.

8 The capacitor should be stored under conditions of normal temperature and in a non-acid,

non-alkali environment of normal humidity. Exposure to high temperatures, for example under direct sunlight, will reduce its operating life. If the capacitor is stored in an environment

containing acids or alkalis, the solderability of the leads may be affected.

9 The leakage current of an aluminum electrolytic capacitor may increase after a long period

of storage. After such storage, the capacitor must be aged by applying the rated operating

voltage for 6–8 hours before use.

10 Manual soldering:

a Soldering must be performed within the specified conditions.

Bit temperature: 350 °C; application time of soldering iron: 3 seconds.

b Ensure that the soldering iron does not touch any part of the capacitor body.

Please read Cautions and warnings and

Important notes at the end of this document.

13 08/08

Cautions and warnings

11 Do not apply excessive force to the leads and terminals. Do not move the capacitor after sol-

dering it onto the PC board and do not carry the PC board by gripping the capacitor. Observe

the following rules to prevent undue stress to the capacitor:

a Do not tilt or bend the capacitor after soldering.

b Ensure that the terminal spacing matches the corresponding hole spacing on the PC

board.

12 The aluminum case is not insulated from the cathode. Do not place a conductor under the

aluminum capacitors on the PC board as this may cause a short circuit. The case and top of

capacitors used in switched mode power supplies have a high-voltage-resistant heat shrink

sleeve to ensure safe usage.

13 The leads of capacitors with a case diameter exceeding 14 mm cannot be used for fixing.

Please read Cautions and warnings and

Important notes at the end of this document.

14 08/08

Important notes

Important notes

The following applies to all products named in this publication:

1. Some parts of this publication contain statements about the suitability of our products for

certain areas of application. These statements are based on our knowledge of typical

requirements that are often placed on our products in the areas of application concerned. We

nevertheless expressly point out that such statements cannot be regarded as binding

statements about the suitability of our products for a particular customer application. As

a rule, EPCOS is either unfamiliar with individual customer applications or less familiar with them

than the customers themselves. For these reasons, it is always ultimately incumbent on the

customer to check and decide whether an EPCOS product with the properties described in the

product specification is suitable for use in a particular customer application.

2. We also point out that in individual cases, a malfunction of electronic components or failure

before the end of their usual service life cannot be completely ruled out in the current state

of the art, even if they are operated as specified. In customer applications requiring a very

high level of operational safety and especially in customer applications in which the malfunction

or failure of an electronic component could endanger human life or health (e.g. in accident

prevention or life-saving systems), it must therefore be ensured by means of suitable design of

the customer application or other action taken by the customer (e.g. installation of protective

circuitry or redundancy) that no injury or damage is sustained by third parties in the event of

malfunction or failure of an electronic component.

3. The warnings, cautions and product-specific notes must be observed.

4. In order to satisfy certain technical requirements, some of the products described in this

publication may contain substances subject to restrictions in certain jurisdictions (e.g.

because they are classed as hazardous). Useful information on this will be found in our

Material Data Sheets on the Internet (www.epcos.com/material). Should you have any more

detailed questions, please contact our sales offices.

5. We constantly strive to improve our products. Consequently, the products described in this

publication may change from time to time. The same is true of the corresponding product

specifications. Please check therefore to what extent product descriptions and specifications

contained in this publication are still applicable before or when you place an order.

We also reserve the right to discontinue production and d elivery of products. Consequently,

we cannot guarantee that all products named in this publication will always be available. The

aforementioned does not apply in case of individual agreements deviating from the foregoing for

customer-specific products.

6. Unless otherwise agreed in individual contracts, all orders are subject to the current version

of the “General Terms of Delivery for Products and Services in the Electrical Industry”

published by the German Electrical and Electronics Industry Association (ZVEI).

7. The trade names EPCOS, BAOKE, Alu-X, CeraDiode, CSSP, CTVS, DSSP, MiniBlue, MKK,

MLSC, MotorCap, PCC, PhaseCap, PhaseMod, SIFERRIT, SIFI, SIKOREL, SilverCap,

SIMDAD, SIMID, SineFormer, SIOV, SIP5D, SIP5K, ThermoFuse, WindCap are trademarks

registered or pending in Europe and in other countries. Further information will be found on

the Internet at www.epcos.com/trademarks.

15 08/08

Loading...

Loading...