Aluminum electrolytic capacitors

Axial-lead and soldering star capacitors

Series/Type: B41692, B41792

Date: December 2006

EPCOS AG 2007. Reproduction, publication and dissemination of this publication, enclosures hereto and the

information contained therein without EPCOS' prior express consent is prohibited.

Axial-lead and soldering star capacitors B41692, B41792

Long useful life, compact up to 140 °C

Applications

Compact design for automotive applications up to 150 °C

Features

Up to 150 °C operating temperature at reduced voltage

applied

Long useful life, 2000 h at up to 140 °C

Very high ripple current capability

Compact design

High vibration resistance

Shelf life up to 15 years at storage temperatures up to 40 °C.

To ensure solderability, the capacitors should be built into the

application within one year of delivery. After a total of two

years' storage, the operating voltage must be applied for one

hour to ensure the specified leakage current.

Construction

Charge/discharge-proof, polar

Aluminum case with insulating sleeve

Negative pole connected to case

Terminals

Axial leads, welded to ensure perfect electrical contact

Also available with soldering stars

Taping and packing

Axial-lead capacitors will be delivered in pallet package.

Capacitors with d × l ≤ 16 × 30 mm are also available taped

on reel.

Soldering star capacitors are packed in cardboard.

Important notes at the end of this document.

Page 2 of 16Please read Cautions and warnings and

Long useful life, compact up to 140 °C

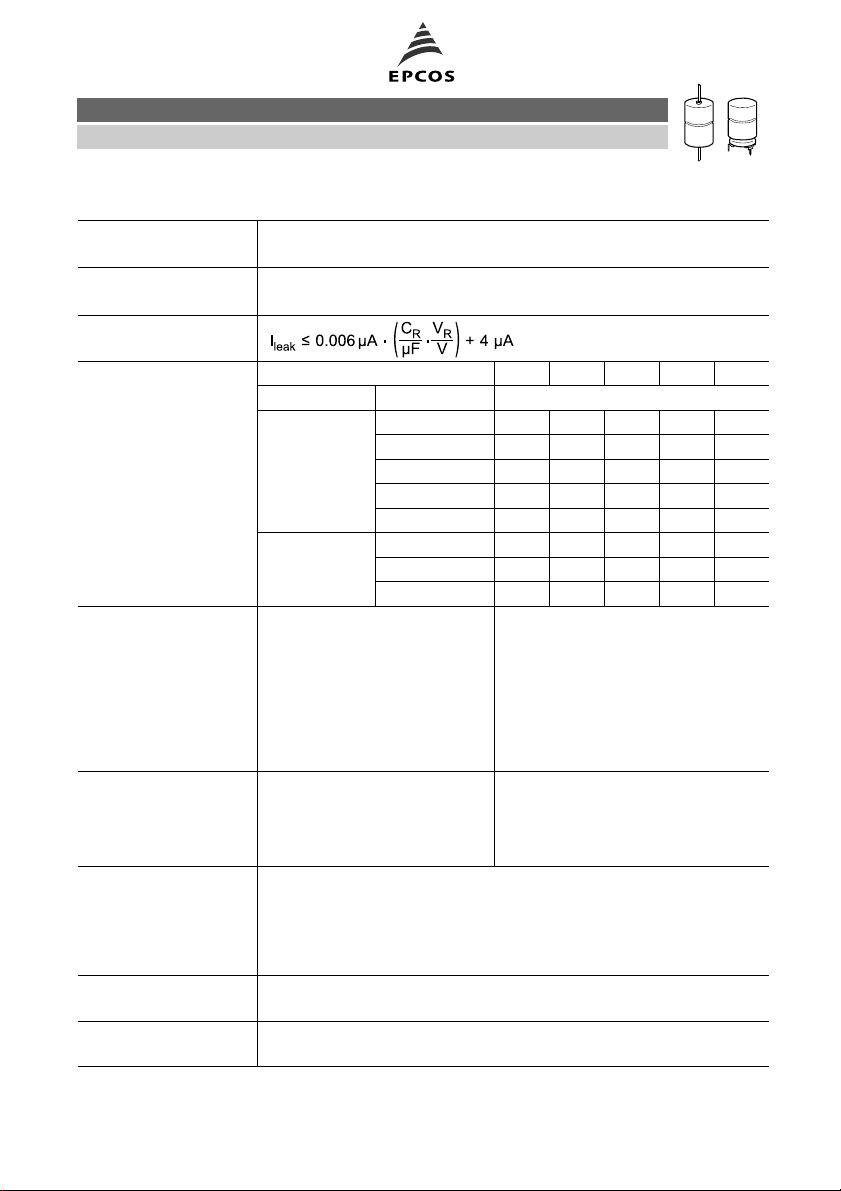

Specifications and characteristics in brief

B41692, B41792

Rated voltage V

Surge voltage V

R

S

25 ... 63 V DC

1.15 V

R

Rated capacitance CR220 ... 6800 µF

Capacitance tolerance 10/+30% Q

Leakage current I

leak

(5 min, 20 °C)

Self-inductance ESL

1)

Diameter d (mm) 12 14 16 18 20/21

Terminals Length l (mm) Approx. ESL (nH)

axial 25 22 26

29 38

30 21 24 29 34

39 33 38 45

49 50

soldering star 25 6 7

30 6 7 8 10

39 9 11

Useful life Requirements:

AC, R

*)

> 2000 h ∆C/C ≤ ±30% of initial value

AC,R

> 2000 h ESR ≤3 times initial specified limit

AC,R

> 5000 h I

≤ initial specified limit

leak

> 15000 h

> 500000 h

150 °C, Vop, 0.5 I

140 °C, VR, 0.6 I

125 °C, VR, I

85 °C, VR,I

AC, R

AC, max

40 °C, VR, 2 I

*)

Vop:see useful life graph

Voltage endurance test Post test requirements:

125 °C, V

R

2000 h ∆C/C ≤ ±10% of initial value

ESR ≤1.3% initial specified limit

I

≤ initial specified limit

leak

Vibration resistance test To IEC 60068-2-6, test Fc:

Displacement amplitude 1.5 mm, at 10 Hz ... 2 kHz,

acceleration max. 20 g, duration 3 × 2 h.

Capacitor mounted by its wire leads at a distance of (6 ±1) mm from

the case and additionally clamped by the case.

IEC climatic category To IEC 60068-1:

55/125/56 (55 °C/+125 °C/56 days damp heat test)

Detail specification

Sectional specification

Similar to CECC 30301-802

IEC 60384-4

1) If optimum circuit design is used, the values are lower by 30%.

Important notes at the end of this document.

Page 3 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

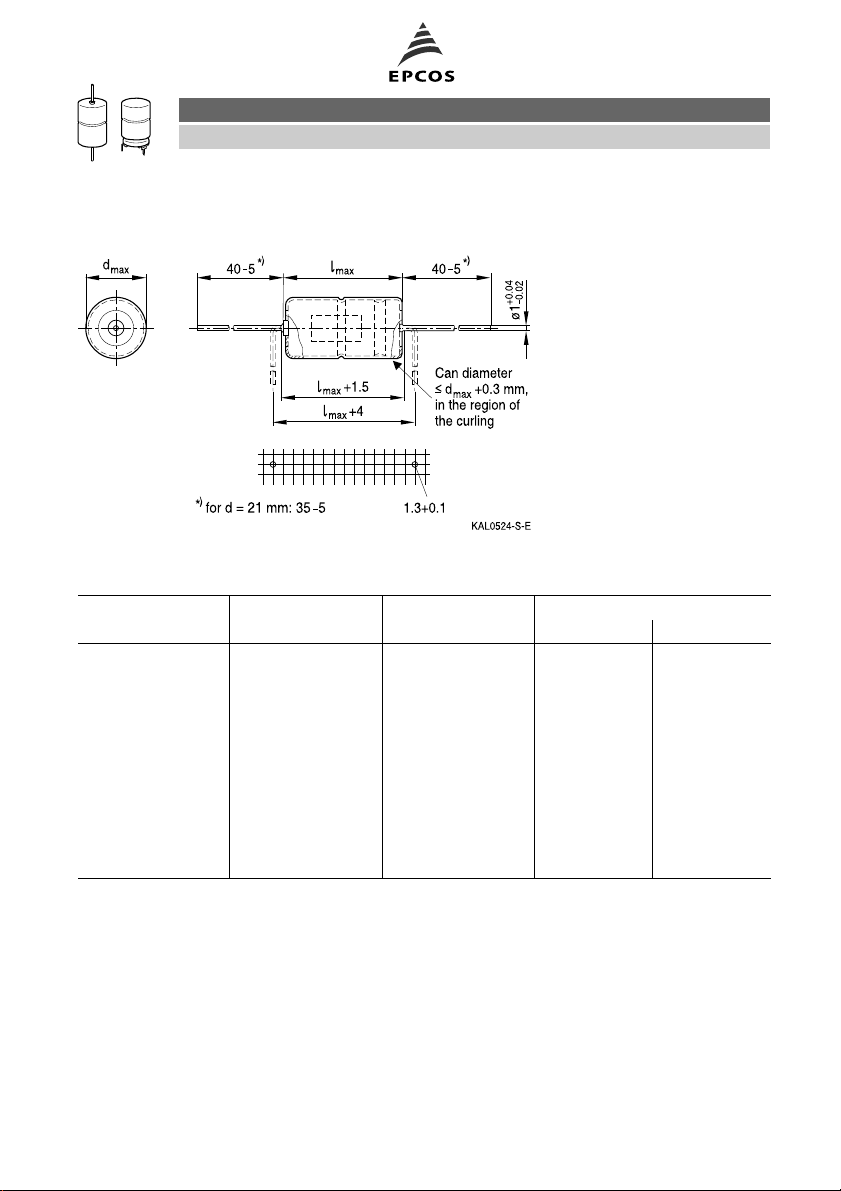

Axial-lead capacitors

Dimensional drawing

Dimensions, weights and packing units

d × l d

max

× I

max

Approx. weight Packing units (pcs.)

mm mm g Pallet Reel

12 × 30 12.5 × 30.5 5.1 288 450

14 × 25 14.5 × 25.5 5.7 200 350

14 × 30 14.5 × 30.5 6.8 200 350

16 × 30 16.5 × 30.5 8.9 180 250

16 × 39 16.5 × 40 11.7 180

18 × 30 18.5 × 30.5 11.1 160

18 × 39 18.5 × 40 14.7 160

20 × 29 20.5 × 29.5 13.5 140

21 × 39 21.5 × 40 20.0 140

21 × 49 21.5 × 50 25.0 110

Important notes at the end of this document.

Page 4 of 16Please read Cautions and warnings and

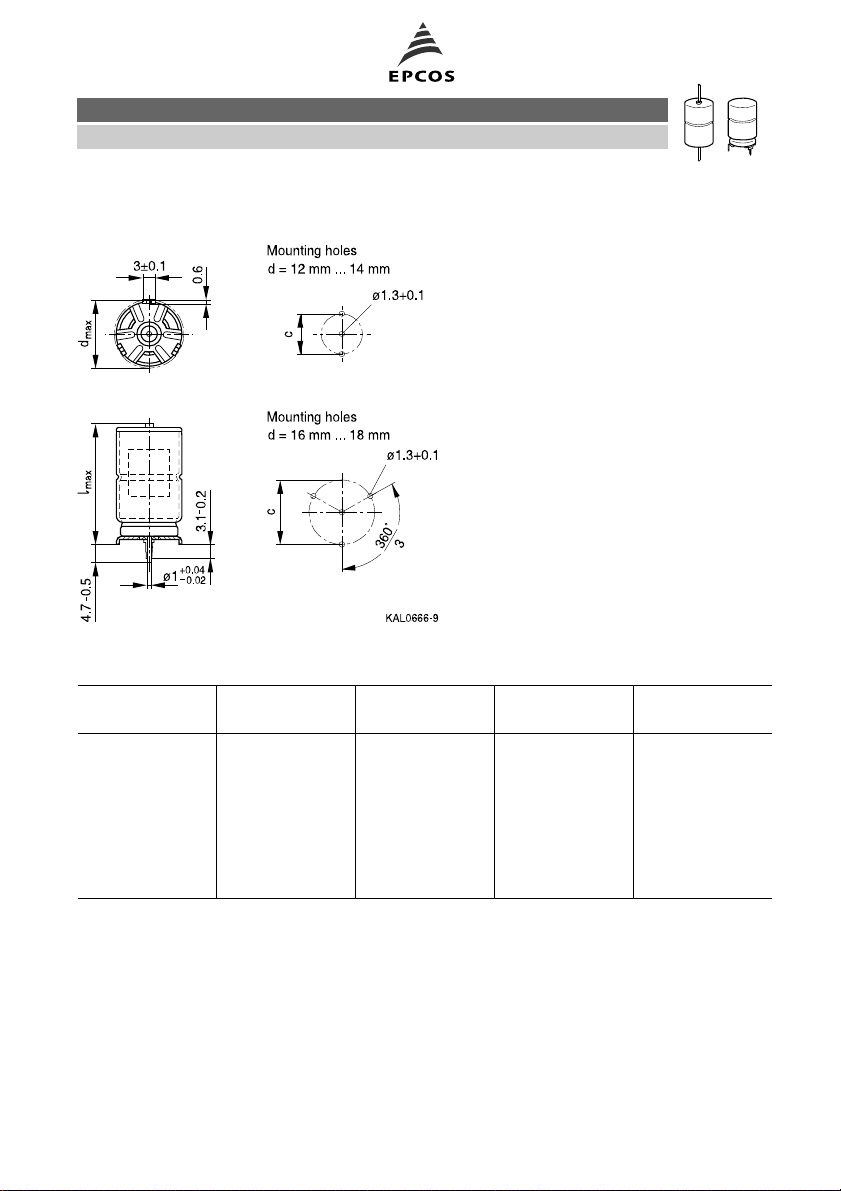

Long useful life, compact up to 140 °C

Soldering star capacitors

Dimensional drawing

Dimensions, weights and packing units

B41692, B41792

d × l d

max

× I

max

c ±0.1 Approx. weight Packing units

mm mm mm g pcs.

12 × 30 13.5 × 32 12.5 5.4 480

14 × 25 15.5 × 27 14.5 6.1 480

14 × 30 15.5 × 32 14.5 7.2 480

16 × 30 17.5 × 32 16.5 9.4 300

16 × 39 17.5 × 41.5 16.5 12.2 200

18 × 30 19.5 × 32 18.5 11.8 300

18 × 39 19.5 × 41.5 18.5 15.4 200

Important notes at the end of this document.

Page 5 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Overview of available types

VR(V DC) 25 40 63

Case dimensions d × l (mm)

CR(µF)

220 12 × 30

330 14 × 30

470 12 × 30 16 × 30

680 12 × 30 14 × 30 16 × 39

18 × 30

1000 14 × 25 16 × 30 18 × 39

1100 20 × 29

1500 14 × 30 16 × 39

18 × 30

1800 21 × 39

2200 16 × 39

18 × 30

3300 18 × 39

18 × 39

20 × 29

21 × 39

21 × 49

20 × 29

4400 21 × 49

5000 21 × 39

6800 21 × 49

Important notes at the end of this document.

Page 6 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Case dimensions and ordering codes

V

R

V DC

C

R

100 Hz

20 °C

µF

Case

dimensions

d × l

mm

Ordering code

Axial pallet

Ordering code

Axial reel

Ordering code

Soldering star

25 680 12 × 30 B41692A5687Q007 B41692A5687Q009 B41792A5687Q000

1000 14 × 25 B41692A5108Q007 B41692A5108Q009 B41792A5108Q000

1500 14 × 30 B41692A5158Q007 B41692A5158Q009 B41792A5158Q000

2200 16 × 39 B41692A5228Q007 B41792A5228Q000

2200 ∇ 18 × 30 B41692B5228Q007 B41792B5228Q000

3300 18 × 39 B41692A5338Q007 B41792A5338Q000

3300 ∇ 20 × 29 B41692B5338Q007

5000 21 × 39 B41692A5508Q007

6800 21 × 49 B41692A5688Q007

40 470 12 × 30 B41692A7477Q007 B41692A7477Q009 B41792A7477Q000

680 14 × 30 B41692A7687Q007 B41692A7687Q009 B41792A7687Q000

1000 16 × 30 B41692A7108Q007 B41692A7108Q009 B41792A7108Q000

1500 16 × 39 B41692A7158Q007 B41792A7158Q000

1500 ∇ 18 × 30 B41692B7158Q007 B41792B7158Q000

2200 18 × 39 B41692A7228Q007 B41792A7228Q000

2200 ∇ 20 × 29 B41692B7228Q007

3300 21 × 39 B41692A7338Q007

4400 21 × 49 B41692A7448Q007

63 220 12 × 30 B41692A8227Q007 B41692A8227Q009 B41792A8227Q000

330 14 × 30 B41692A8337Q007 B41692A8337Q009 B41792A8337Q000

470 16 × 30 B41692A8477Q007 B41692A8477Q009 B41792A8477Q000

680 16 × 39 B41692A8687Q007 B41792A8687Q000

680 ∇ 18 × 30 B41692B8687Q007 B41792B8687Q000

1000 18 × 39 B41692A8108Q007 B41792A8108Q000

1100 20 × 29 B41692A8118Q007

1800 21 × 39 B41692A8188Q007

2200 21 × 49 B41692A8228Q007

∇ Variant with different case dimensions

Important notes at the end of this document.

Page 7 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Technical data

C

100 Hz

20 °C

µF

ESR

R

100 Hz

20 °C

mΩ

typ

ESR

max

100 Hz

20 °C

mΩ

ESR

max

100 Hz

40 °C

mΩ

ESR

max

10 kHz

20 °C

mΩ

Z

max

100 kHz

20 °C

mΩ

I

AC,max

10 kHz

85 °C

A

I

AC,max

10 kHz

105 °C

A

I

AC,max

10 kHz

125 °C

A

I

AC,R

10 kHz

125 °C

A

I

AC,max

10 kHz

140 °C

A

VR= 25 V DC

680 150 250 1600 165 155 4.5 3.8 2.85 1.95 1.25

1000 100 170 1200 120 112 4.8 4.1 3.1 2.1 1.4

1500 70 120 800 82 77 6.2 5.3 4.0 2.75 1.8

2200 50 82 550 55 50 9.2 7.9 5.9 4.05 2.6

2200 ∇ 48 79 550 52 48 9.1 7.8 5.8 4.0 2.6

3300 32 53 360 35 33 12.7 10.8 8.1 5.5 3.6

3300 ∇ 33 55 360 38 36 10.6 9.1 6.8 4.6 3.0

5000 22 37 240 27 27 15.0 12.9 9.6 6.6 4.3

6800 17 28 180 20 20 19.0 16.3 12.1 8.3 5.4

VR= 40 V DC

470 145 240 1400 135 128 4.9 4.2 3.1 2.15 1.4

680 105 170 1000 95 90 6.0 5.1 3.8 2.6 1.7

1000 73 120 660 70 67 6.9 5.9 4.4 3.0 2.0

1500 49 80 450 50 48 9.6 8.2 6.1 4.2 2.7

1500 ∇ 46 77 450 45 43 9.7 8.3 6.1 4.2 2.7

2200 32 53 300 30 29 13.3 11.4 8.5 5.8 3.8

2200 ∇ 34 55 300 33 32 10.9 9.3 6.9 4.8 3.1

3300 23 39 200 23 23 15.4 13.1 9.8 6.7 4.4

4400 18 30 160 18 18 19.4 16.6 12.3 8.5 5.5

VR= 63 V DC

220 210 350 1600 145 138 4.7 4.0 3.0 2.05 1.35

330 140 240 1100 100 95 5.9 5.0 3.7 2.55 1.7

470 105 170 750 75 72 6.8 5.8 4.3 3.0 2.0

680 71 120 500 55 53 9.4 8.0 6.0 4.1 2.7

680 ∇ 69 114 500 50 48 9.4 8.0 6.0 4.1 2.7

1000 50 78 350 35 34 13.0 11.1 8.2 5.7 3.7

1100 48 75 330 36 35 10.9 9.3 6.9 4.8 3.1

1800 30 47 220 23 23 15.5 13.2 9.8 6.7 4.4

2200 25 38 175 19 19 19.3 16.5 12.3 8.5 5.5

∇ Variant with different case dimensions

Important notes at the end of this document.

Page 8 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Useful life

depending on ambient temperature TAunder ripple current operating conditions at V

Useful life

depending on case temperature TCunder ripple current operating conditions at V

R

1)

R

1)

1) Refer to chapter "General technical information, 5.3 Calculation of useful life" for an explanation on how to interpret the useful life

graphs.

Important notes at the end of this document.

Page 9 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Useful life

depending on ambient temperature TAunder ripple current operating conditions at V

VR= 25 V: Vop≤ 20 V;

VR= 40 V: Vop≤ 35 V;

VR= 63 V: Vop≤ 55 V

Useful life

depending on case temperature TCunder ripple current operating conditions at V

op

VR= 25 V: Vop≤ 20 V;

VR= 40 V: Vop≤ 35 V;

VR= 63 V: Vop≤ 55 V

2)

op

2)

2) Refer to chapter "General technical information, 5.3 Calculation of useful life" for an explanation on how to interpret the useful life

graphs.

Important notes at the end of this document.

Page 10 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Important notes at the end of this document.

Page 11 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Frequency factor of permissible ripple

current IACversus frequency f

Equivalent series resistance ESR

versus frequency f

Typical behavior for 2200 µF/25 V

Frequency characteristics of ESR

Typical behavior

Impedance Z

versus frequency f

Typical behavior for 2200 µF/25 V

Important notes at the end of this document.

Page 12 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Cautions and warnings

Personal safety

The electrolytes used by EPCOS have not only been optimized with a view to the intended

application, but also with regard to health and environmental compatibility. They do not contain

any solvents that are detrimental to health, e.g. dimethyl formamide (DMF) or dimethyl acetamide

(DMAC).

Furthermore, part of the high-voltage electrolytes used by EPCOS are self-extinguishing. They

contain flame-retarding substances which will quickly extinguish any flame that may have been

ignited.

As far as possible, EPCOS does not use any dangerous chemicals or compounds to produce

operating electrolytes. However, in exceptional cases, such materials must be used in order to

achieve specific physical and electrical properties because no safe substitute materials are

currently known. However, the amount of dangerous materials used in our products has been

limited to an absolute minimum. Nevertheless, the following rules should be observed when

handling Al electrolytic capacitors:

Any escaping electrolyte should not come into contact with eyes or skin.

If electrolyte does come into contact with the skin, wash the affected parts immediately with

running water. If the eyes are affected, rinse them for 10 minutes with plenty of water. If

symptoms persist, seek medical treatment.

Avoid breathing in electrolyte vapor or mists. Workplaces and other affected areas should be

well ventilated. Clothing that has been contaminated by electrolyte must be changed and

rinsed in water.

Important notes at the end of this document.

Page 13 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Product safety

The table below summarize the safety instructions that must be observed without fail. A detailed

description can be found in the relevant sections of chapter "General technical information".

Topic Safety information Reference

Chapter "General

technical information"

Polarity Make sure that polar capacitors are connected

with the right polarity.

1

"Basic construction of

aluminum electrolytic

capacitors"

Reverse voltage Voltages polarity classes should be prevented by

connecting a diode.

Upper category

Do not exceed the upper category temperatur. 7.2

temperature

3.1.6

"Reverse voltage"

"Maximum permissible

operating temperature"

Maintenance Make periodic inspections of the capacitors.

Before the inspection, make sure that the power

10

"Maintenance"

supply is turned off and carefully discharge the

electricity of the capacitors.

Do not apply any mechanical stress to the

capacitor terminals.

Mounting

position of screw

terminal capacitors

Do not mount the capacitor with the terminals

(safety vent) upside down.

11.1.

"Mounting positions of

capacitors with screw

terminals"

Mounting of

single-ended

capacitors

The internal structure of single-ended capacitors

might be damaged if excessive force is applied to

the lead wires.

Avoid any compressive, tensile or flexural stress.

11.4

"Mounting

considerations for

single-ended capacitors"

Do not move the capacitor after soldering to PC

board.

Do not pick up the PC board by the soldered

capacitor.

Do not insert the capacitor on the PC board with a

hole space different to the lead space specified.

Robustness of

terminals

The following maximum tightening torques must

not be exceeded when connecting screw

11.3

"Mounting torques"

terminals:

M5: 2 Nm

M6: 2.5 Nm

Soldering Do not exceed the specified time or temperature

limits during soldering.

11.5

"Soldering"

Important notes at the end of this document.

Page 14 of 16Please read Cautions and warnings and

B41692, B41792

Long useful life, compact up to 140 °C

Topic Safety information Reference

Chapter "General

technical information"

Soldering,

cleaning agents

Passive

flammability

Active

flammability

Do not allow halogenated hydrocarbons to come

into contact with aluminum electrolytic capacitors.

11.6

"Cleaning agents"

Avoid external energy, such as fire or electricity. 8.1

"Passive flammability"

Avoid overload of the capacitors. 8.2

"Active flammability"

Reference

Chapter "Capacitors

with screw terminals"

Breakdown strength

of insulating

Do not damage the insulating sleeve, especially

when ring clips are used for mounting.

"Screw terminals -

accessories"

sleeves

Important notes at the end of this document.

Page 15 of 16Please read Cautions and warnings and

Important notes

The following applies to all products named in this publication:

1. Some parts of this publication contain statements about the suitability of our products for

certain areas of application. These statements are based on our knowledge of typical re-

quirements that are often placed on our products in the areas of application concerned. We

nevertheless expressly point out that such statements cannot be regarded as binding

statements about the suitability of our products for a particular customer application.

As a rule, EPCOS is either unfamiliar with individual customer applications or less familiar

with them than the customers themselves. For these reasons, it is always ultimately incumbent on the customer to check and decide whether an EPCOS product with the properties described in the product specification is suitable for use in a particular customer application.

2. We also point out that in individual cases, a malfunction of passive electronic compon-

ents or failure before the end of their usual service life cannot be completely ruled out

in the current state of the art, even if they are operated as specified. In customer applica-

tions requiring a very high level of operational safety and especially in customer applications

in which the malfunction or failure of a passive electronic component could endanger human

life or health (e.g. in accident prevention or life-saving systems), it must therefore be ensured

by means of suitable design of the customer application or other action taken by the customer

(e.g. installation of protective circuitry or redundancy) that no injury or damage is sustained by

third parties in the event of malfunction or failure of a passive electronic component.

3. The warnings, cautions and product-specific notes must be observed.

4. In order to satisfy certain technical requirements, some of the products described in this

publication may contain substances subject to restrictions in certain jurisdictions (e.g.

because they are classed as “hazardous”). Useful information on this will be found in our

Material Data Sheets on the Internet (www.epcos.com/material). Should you have any more

detailed questions, please contact our sales offices.

5. We constantly strive to improve our products. Consequently, the products described in this

publication may change from time to time. The same is true of the corresponding product

specifications. Please check therefore to what extent product descriptions and specifications

contained in this publication are still applicable before or when you place an order. We also

reserve the right to discontinue production and delivery of products. Consequently, we

cannot guarantee that all products named in this publication will always be available.

6. Unless otherwise agreed in individual contracts, all orders are subject to the current ver-

sion of the “General Terms of Delivery for Products and Services in the Electrical Industry” published by the German Electrical and Electronics Industry Association

(ZVEI).

7. The trade names EPCOS, EPCOS-JONES, BAOKE, Alu-X, CeraDiode, CSSP, MLSC,

PhaseCap, PhaseMod, SIFERRIT, SIFI, SIKOREL, SilverCap, SIMID, SIOV, SIP5D, SIP5K,

UltraCap, WindCap are trademarks registered or pending in Europe and in other countries.

Further information will be found on the Internet at www.epcos.com/trademarks.

Page 16 of 16

Loading...

Loading...