EPA digitax st User Manual

AC variable speed drive

for servo motors

User Guide

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC:

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect installation or

adjustment of the optional operating parameters of the equipment or from mismatching the variable speed drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous

development and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or

the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Drive software version

This product is supplied with the latest software version. If this drive is to be connected to an existing system or machine, all drive

software versions should be verified to confirm the same functionality as drives of the same model already present. This may also

apply to drives returned from an Emerson Industrial Automation Service Centre or Repair Centre. If there is any doubt please contact

the supplier of the product.

The software version of the drive can be checked by looking at Pr 11.29 and Pr 11.34. This takes the form of xx.yy.zz where Pr 11.29

displays xx.yy and Pr 11.34 displays zz. (e.g. for software version 01.01.00, Pr 11.29 = 1.01 and Pr 11.34 displays 0).

Environmental statement

Emerson Industrial Automation is committed to minimising the environmental impacts of its manufacturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is certified to the

International Standard ISO 14001. Further information on the EMS, our Environmental Policy and other relevant information is

available on request, or can be found at:

http://www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/Pages/environment.aspx

The electronic variable-speed drives manufactured by Emerson Industrial Automation have the potential to save energy and (through

increased machine/process efficiency) reduce raw material consumption and scrap throughout their long working lifetime. In typical

applications, these positive environmental effects far outweigh the negative impacts of product manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded but should instead be

recycled by a specialist recycler of electronic equipment. Recyclers will find the products easy to dismantle into their major component

parts for efficient recycling. Many parts snap together and can be separated without the use of tools, while other parts are secured

with conventional fasteners. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller products come

in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these containers can be recycled.

Polythene, used on the protective film and bags for wrapping product, can be recycled in the same way. Emerson Industrial

Automations' packaging strategy prefers easily-recyclable materials of low environmental impact, and regular reviews identify

opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires the supplier

of an article to inform the recipient if it contains more than a specified proportion of any substance which is considered by the European

Chemicals Agency (ECHA) to be a Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for

compulsory authorisation.

For current information on how this requirement applies in relation to specific Emerson Industrial Automations’ products, please

approach your usual contact in the first instance. Emerson Industrial Automations’ position statement can be viewed at:

www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/reachregulation/Pages/reachregulation.aspx.

Copyright © September 2015 Emerson Industrial Automation.

The information contained in this guide is for guidance only and does not form part of any contract. The accuracy cannot be guaranteed

as Emerson have an ongoing process of development and reserve the right to change the specification of their products without notice.

Control Techniques Limited. Registered Office: The Gro, Newtown, Powys SY16 3BE. Registered in England and Wales. Company

Reg. No. 01236886.

Moteurs Leroy-Somer SAS. Headquarters: Bd Marcellin Leroy, CS 10015, 16915 Angoulême Cedex 9, France. Share Capital: 65 800

512 €, RCS Angoulême 338 567 258.

Issue Number: 5

Software: 01.06.00 onwards

For patent and intellectual property related information please go to: www.ctpatents.info.

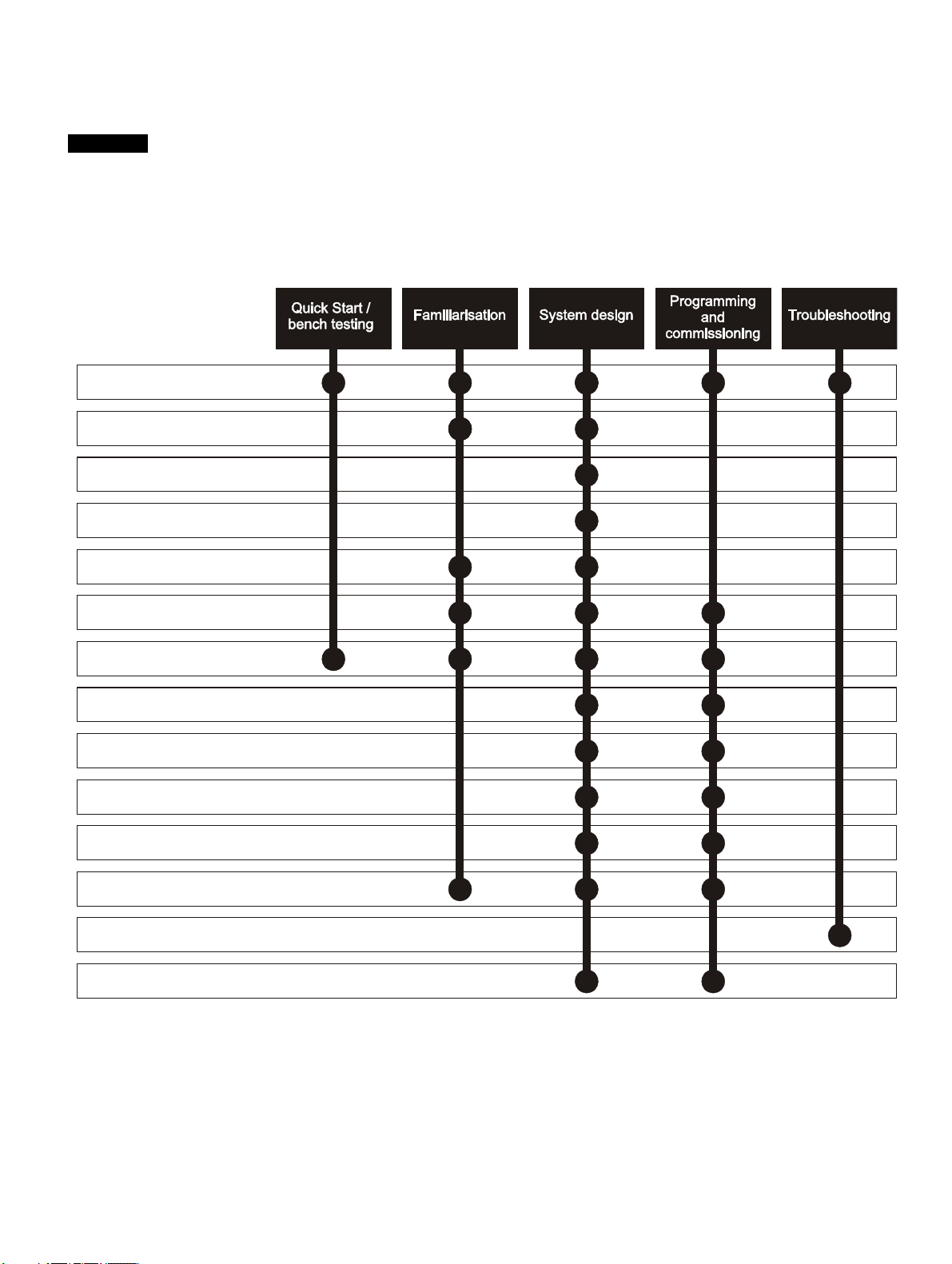

How to use this guide

NOTE

1 Safety information

2 Product information

3 Mechanical installation

4 Electrical installation

5 Getting started

6 Basic parameters

7 Running the motor

8 Optimization

9 SMARTCARD operation

11 Advanced parameters

12 Technical data

13 Diagnostics

14 UL listing information

10 Onboard PLC

This User Guide provides information for operating the drive from start to finish.

The information is in logical order, taking the reader from receiving the drive through to fine tuning the performance.

There are specific safety warnings throughout this guide, located in the relevant sections. In addition, Chapter 1 Safety

Information on page 6 contains general safety information. It is essential that the warnings are observed and the

information considered when working with or designing a system using the drive.

This map of the user guide helps to find the right sections for the task you wish to complete:

Contents

1 Safety Information .................................6

1.1 Warnings, Cautions and Notes .............................6

1.2 Electrical safety - general warning ........................6

1.3 System design and safety of personnel ................6

1.4 Environmental limits ..............................................6

1.5 Access ...................................................................6

1.6 Fire protection .......................................................6

1.7 Compliance with regulations .................................6

1.8 Motor .....................................................................6

1.9 Mechanical brake control ......................................6

1.10 Adjusting parameters ............................................6

1.11 Electrical installation ..............................................6

2 Product information ..............................8

2.1 Introduction ...........................................................8

2.2 Drive ratings ..........................................................8

2.3 Drive model numbers ............................................9

2.4 Drive nameplate description ..................................9

2.5 Features of the drive ...........................................10

2.6 Options ................................................................11

2.7 Items supplied with the drive ...............................14

3 Mechanical installation .......................15

3.1 Safety information ...............................................15

3.2 Planning the installation ......................................15

3.3 Solutions Module / keypad installation / removal 16

3.4 Drive dimensions .................................................17

3.5 External EMC filter rating ....................................18

3.6 Optional braking resistor .....................................19

3.7 Terminal torque settings ......................................20

3.8 Routine maintenance ..........................................20

4 Electrical installation ...........................21

4.1 Power terminal connections ................................22

4.2 Ground connections ............................................23

4.3 AC supply requirements ......................................23

4.4 DC bus design .....................................................24

4.5 DC drive voltage levels .......................................24

4.6 Ratings ................................................................25

4.7 Output circuit and motor protection .....................25

4.8 Braking ................................................................26

4.9 Ground leakage ...................................................27

4.10 EMC (Electromagnetic compatibility) ..................28

4.11 Internal and external conducted emissions

conformity ............................................................30

4.12 Serial communications connections ....................31

4.13 Control connections ............................................32

4.14 Control terminals .................................................34

4.15 Encoder connections ...........................................37

4.16 Encoder terminals ...............................................38

4.17 Safe Torque Off ...................................................42

5 Getting started .................................... 43

5.1 User interfaces ................................................... 43

5.2 CT Soft ............................................................... 43

5.3 SYPTPro (Indexer & Plus only) .......................... 43

5.4 EZMotion PowerTools Pro ................................. 43

5.5 Keypad operation ............................................... 44

5.6 Understanding the display .................................. 44

5.7 Displaying parameters with non-default

values only ......................................................... 47

5.8 Displaying destination parameters only ............. 47

5.9 Communications ................................................ 47

6 Basic parameters ................................ 49

6.1 Single line descriptions ...................................... 49

6.2 Full descriptions ................................................. 54

7 Running the motor .............................. 60

7.1 Quick start Connections ..................................... 60

7.2 Quick Start set-up .............................................. 64

7.3 Setting up a feedback device ............................. 65

7.4 Setting up a buffered encoder output ................. 68

8 Optimization ........................................ 69

8.1 Motor map parameters ....................................... 69

9 EtherCAT interface ............................. 72

9.1 Features ............................................................. 72

9.2 What is EtherCAT? ............................................ 72

9.3 EtherCAT interface information .......................... 72

9.4 EtherCAT interface terminal descriptions ........... 72

9.5 Module grounding .............................................. 72

9.6 Network topology ............................................... 72

9.7 Minimum node-to-node cable length .................. 72

9.8 Quick start guide ................................................ 72

9.9 Quick start flowchart ........................................... 74

9.10 Saving parameters to the drive .......................... 75

9.11 EtherCAT interface Node address ..................... 75

9.12 EtherCAT interface RUN .................................... 75

9.13 Re-initializing the EtherCAT interface ................ 75

9.14 Process Data Objects (PDOs) ........................... 75

9.15 Service Data Object (SDO) parameter access .. 75

9.16 CANopen over EtherCAT (CoE) ........................ 76

9.17 Ethernet over EtherCAT (EoE) ........................... 80

9.18 Drive profile (DSP-402) support ......................... 81

9.19 Interpolated position mode ................................. 87

9.20 vl velocity mode .................................................. 88

9.21 Profile torque mode ............................................ 90

9.22 Homing mode ..................................................... 91

9.23 Cyclic sync position mode .................................. 94

9.24 Advanced features ............................................. 94

9.25 Advanced cyclic data configuration .................... 96

9.26 Internal shortcuts ................................................ 97

9.27 Quick reference .................................................. 98

4 Digitax ST User Guide

Issue: 5

10 SMARTCARD Operation ...................101

10.1 Introduction .......................................................101

10.2 Transferring data ...............................................102

10.3 Data block header information ..........................104

10.4 SMARTCARD parameters ................................104

10.5 SMARTCARD trips ...........................................106

11 Onboard PLC .....................................108

11.1 Onboard PLC and SYPTLite .............................108

11.2 Benefits .............................................................108

11.3 Limitations .........................................................108

11.4 Getting started ..................................................108

11.5 Onboard PLC parameters .................................108

11.6 Onboard PLC trips ............................................109

11.7 Onboard PLC and the SMARTCARD ...............109

14 Diagnostics ........................................183

14.1 Trip indications ..................................................183

14.2 Alarm indications ...............................................198

14.3 Status indications ..............................................199

14.4 EtherCAT Diagnostics .......................................199

14.5 Network configuration objects ...........................200

14.6 Diagnostic parameters ......................................200

14.7 Drive trip display codes .....................................200

14.8 EtherCAT interface temperature .......................201

14.9 EtherCAT interface serial number .....................201

14.10 EtherCAT interface error codes ........................201

14.11 Error handling ...................................................201

14.12 Critical task % free ............................................203

14.13 SDO abort codes ..............................................203

14.14 FLASH file system % free .................................203

12 Advanced parameters .......................110

12.1 Menu 1: Speed reference .................................116

12.2 Menu 2: Ramps .................................................120

12.3 Menu 3: Speed feedback and control ...............124

12.4 Menu 4: Torque and current control ..................127

12.5 Menu 5: Motor control .......................................130

12.6 Menu 6: Sequencer and clock ..........................133

12.7 Menu 7: Analog I/O ...........................................135

12.8 Menu 8: Digital I/O ............................................138

12.9 Menu 9: Programmable logic, motorized

pot, binary sum and timers ................................141

12.10 Menu 10: Status and trips .................................144

12.11 Menu 11: General drive set-up .........................146

12.12 Menu 12: Threshold detectors, variable

selectors and brake control function .................147

12.13 Menu 13: Position control .................................152

12.14 Menu 14: User PID controller ............................156

12.15 Menus 15 and 16: Solutions Module set-up ......159

12.16 Menu 17: Motion processors .............................160

12.17 Menu 18: Application menu 1 ...........................163

12.18 Menu 19: Application menu 2 ...........................163

12.19 Menu 20: Application menu 3 ...........................163

12.20 Menu 21: Second motor parameters ................164

12.21 Menu 22: Additional Menu 0 set-up ..................165

12.22 Advanced features ............................................166

15 UL listing information .......................204

15.1 Common UL information ...................................204

15.2 AC supply specification .....................................204

15.3 Maximum continuous output current .................204

15.4 Common DC bus ..............................................204

15.5 DC Supplied drive .............................................205

15.6 UL listed accessories ........................................205

13 Technical Data ...................................173

13.1 Drive technical data ..........................................173

13.2 Optional external EMC filters ............................182

13.3 Overall EMC filter dimensions ...........................182

Digitax ST User Guide 5

Issue: 5

Safety

WARNING

CAUTION

NOTE

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

1 Safety Information

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for

avoiding a safety hazard.

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of

the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive.

Specific warnings are given at the relevant places in this guide.

1.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into

complete equipment or a system. If installed incorrectly, the drive may

present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control equipment which can cause

injury.

Close attention is required to the electrical installation and the system

design to avoid hazards either in normal operation or in the event of

equipment malfunction. System design, installation, set-up and

maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this

guide carefully.

The STOP and Safe Torque Off functions of the drive do not isolate

dangerous voltages from the output of the drive or from any external

option unit. The supply must be disconnected by an approved electrical

isolation device before gaining access to the electrical connections.

With the sole exception of the Safe Torque Off function, none of the

drive functions must be used to ensure safety of personnel, i.e.

they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which

might result in a hazard, either through their intended behavior or

through incorrect operation due to a fault. In any application where a

malfunction of the drive or its control system could lead to or allow

damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk - for example, an

over-speed protection device in case of failure of the speed control, or a

fail-safe mechanical brake in case of loss of motor braking.

The Safe Torque Off function has been approved by IFA as meeting the

requirements of the following standards, for the prevention of

unexpected starting of the drive:

EN 61800-5-2:2007 SIL 3

EN ISO 13849-1:2006 PL e

EN 954-1:1997 Category 3 (This standard is withdrawn and

should not be used for new designs, information provided for legacy

applications only).

The Safe Torque Off function may be used in a safety-related

application. The system designer is responsible for ensuring that the

complete system is safe and designed correctly according to the

relevant safety standards.

1.4 Environmental limits

Instructions regarding transport, storage, installation and use of the drive

must be complied with, including the specified environmental limits.

Drives must not be subjected to excessive physical force.

1.5 Access

Access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided. For details regarding fire protection please

refer to section 3.2.5 Fire protection on page 15.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses or other protection, and protective ground (earth) connections.

Within the European Union, all machinery in which this product is used

must comply with the following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s

recommendations. Ensure the motor shaft is not exposed.

The values of the motor parameters set in the drive affect the protection

of the motor. The default values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 0.46 motor rated

current. This affects the thermal protection of the motor.

1.9 Mechanical brake control

The brake control functions are provided to allow well co-ordinated

operation of an external brake with the drive. While both hardware and

software are designed to high standards of quality and robustness, they

are not intended for use as safety functions, i.e. where a fault or failure

would result in a risk of injury. In any application where the incorrect

operation of the brake release mechanism could result in injury,

independent protection devices of proven integrity must also be

incorporated.

1.10 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

1.11 Electrical installation

1.11.1 Electric shock risk

The voltages present in the following locations can cause severe electric

shock and may be lethal:

• AC supply cables and connections

• DC bus, dynamic brake cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and

must not be touched.

1.11.2 Isolation device

The AC supply must be disconnected from the drive using an approved

isolation device before any cover is removed from the drive or before

any servicing work is performed.

1.11.3 STOP function

The STOP function does not remove dangerous voltages from the drive,

the motor or any external option units.

6 Digitax ST User Guide

Issue: 5

Safety

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

1.11.4 Stored charge

The drive contains capacitors that remain charged to a potentially lethal

voltage after the AC supply has been disconnected. If the drive has been

energized, the AC supply must be isolated at least ten minutes before

work may continue.

Normally, the capacitors are discharged by an internal resistor. Under

certain, unusual fault conditions, it is possible that the capacitors may fail

to discharge, or be prevented from being discharged by a voltage

applied to the output terminals. If the drive has failed in a manner that

causes the display to go blank immediately, it is possible the capacitors

will not be discharged. In this case, consult Emerson Industrial

Automation or their authorized distributor.

1.11.5 Equipment supplied by plug and socket

Special attention must be given if the drive is installed in equipment

which is connected to the AC supply by a plug and socket. The AC

supply terminals of the drive are connected to the internal capacitors

through rectifier diodes which are not intended to give safety isolation. If

the plug terminals can be touched when the plug is disconnected from

the socket, a means of automatically isolating the plug from the drive

must be used (e.g. a latching relay).

1.11.6 Permanent magnet motors

Permanent magnet motors generate electrical power if they are rotated,

even when the supply to the drive is disconnected. If that happens then

the drive will become energized through its motor terminals.

If the motor load is capable of rotating the motor when the supply is

disconnected, then the motor must be isolated from the drive before

gaining access to any live parts.

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

Digitax ST User Guide 7

Issue: 5

Safety

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

2 Product information

2.1 Introduction

The Digitax ST family of servo drives are available with five levels of

intelligence:

• Digitax ST Base

• Digitax ST Indexer

• Digitax ST Plus

• Digitax ST EZMotion

• Digitax ST EtherCAT

The Digitax ST Base drive operates in velocity or torque modes and is

designed to operate with a centralized motion controller or as a

standalone drive.

The Digitax ST Indexer drive performs point-to-point motion profiling

including relative, absolute, rotary plus, rotary minus, registration and

homing motion. The Digitax ST Indexer will operate as a single

standalone system controller. Alternatively, the Digitax ST Indexer can

form part of a distributed system where commands are sent over a

fieldbus or through digital input/output signals. The Digitax ST Indexer

drive is commissioned using a simple and easy to use indexing tool that

resides within CTSoft, a set-up tool for Emerson Industrial Automation

products.

The Digitax ST plus drive offers all the features available o the Digitax

ST Indexer drive with the addition of performing complex motion as a

single axis or synchronized to a reference axis. This offers digital lock

and electronic camming via a virtual master reference. The Digitax ST

Plus drive is commissioned using a simple and easy to use indexing tool

that resides within CT Soft, a set-up tool for Emerson Industrial

Automation products.

For more complex systems using the Digitax ST Indexer and Digitax ST

Plus drives, an export feature is available that allows the user to import

applications into SYPTPro for further development.

The Digitax ST EZMotion drive is part of the Motion Made Easy family of

servo drives and allows the user to create programs to sequence

motion, I/O control, and other machine operations in one environment.

Digitax ST EZMotion also supports advanced functions such as a

Position Capture Object, Multiple Profile Summation, Queuing, and

Program Multitasking.

The Digitax ST EtherCAT drive offers onboard EtherCAT allowing the

product to be connected to an EtherCAT network as a slave device. It

can be used in a variety of applications, including those requiring

accurate synchronization and precise motion control.

All variants provide a Safe Torque Off function.

Four documentation guides are available for Digitax ST, these cover all

variants:

All guides are available for download at:

http://www.emersonindustrial.com/en-EN/controltechniques/downloads/

userguidesandsoftware/Pages/downloads.aspx

or

www.emersonindustrial.com/en-EN/leroy-somer-motors-drives/

downloads/Pages/manuals.aspx

Installation Guide (packed with product)

• Designed to be used by an "Electrician/Wireman" installing the drive

(FIGS Available).

Technical Data Guide

• Designed as a reference guide for experienced drive users (FIGS

Available).

User Guide

• Designed as a step by step guide to help the user become familiar

with the product, and as a reference guide for experienced drive

users (FIGS Available).

Advanced User Guide

• In-depth parameter descriptions.

2.2 Drive ratings

The drive rating is limited by numerous systems which protect the power

stage hardware. (Rectifier, DC bus, inverter)

These systems come into operation under various extremes of operating

conditions. (I.e. ambient, supply imbalance, output power.)

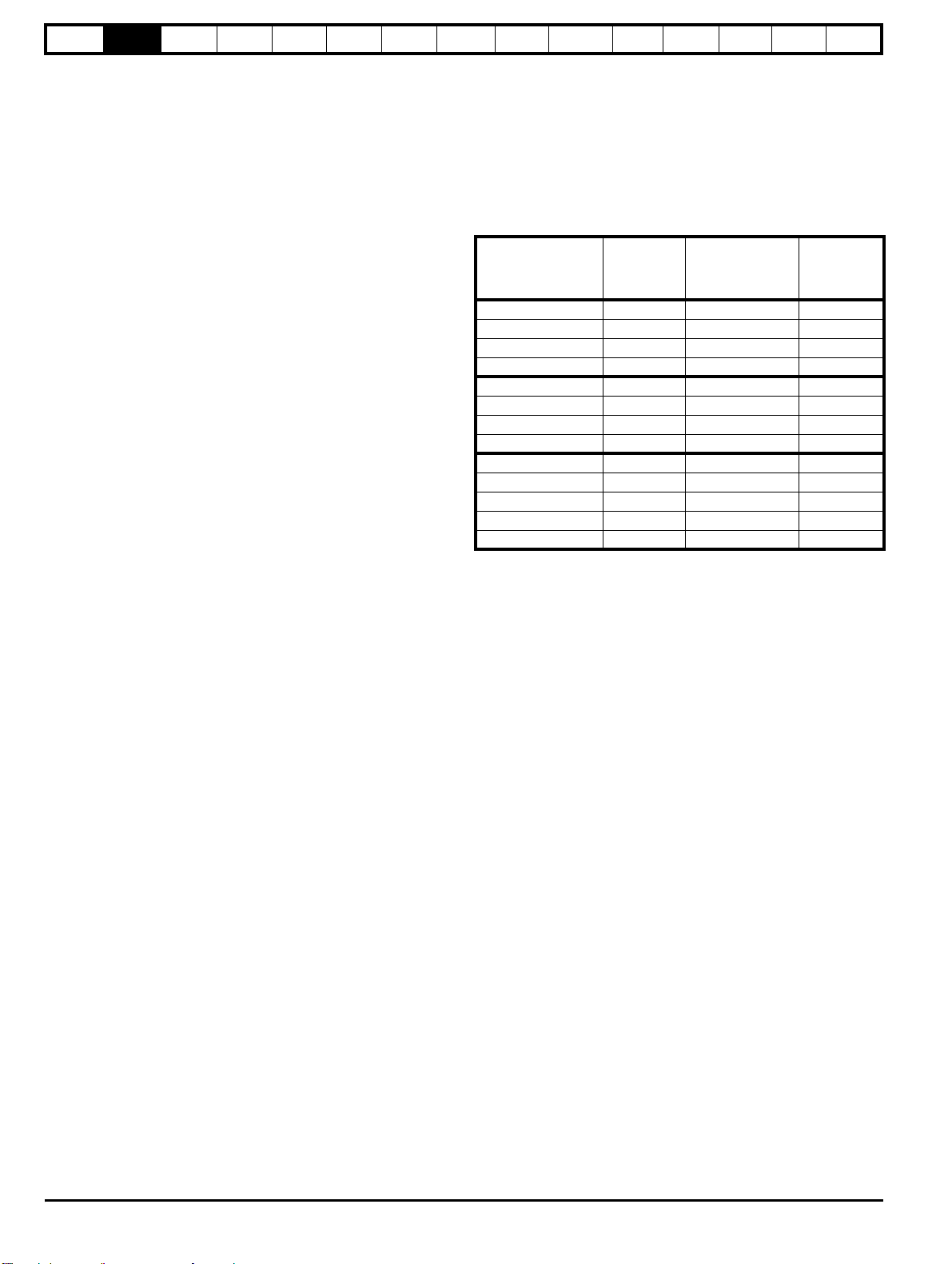

2.2.1 Maximum ratings

Table 2-1 Maximum ratings

Nominal current

I

n

AA

Model

No of input

phases

DST1201 1 1.1* 2.2

DST1202 1 2.4* 4.8

DST1203 1 2.9* 5.8

DST1204 1 4.7* 9.4

DST1201 3 1.7 5.1

DST1202 3 3.8 11.4

DST1203 3 5.4 16.2

DST1204 3 7.6 22.8

DST1401 3 1.5 4.5

DST1402 3 2.7 8.1

DST1403 3 4.0 12.0

DST1404 3 5.9 17.7

DST1405 3 8.0 24.0

*The maximum rating information, in Table 2-1 above, for the 200 V

single phase supply, illustrates a 200 % overload capability. When the

Digitax ST 120x is used with a single phase supply it is possible to

achieve the three phase nominal current rating as long as the single

phase peak current rating is observed.

The rating information shown in section 2.3 Drive model numbers on

page 9 is based on the limitations of the drive output stage only.

The ratings are based on the following operating conditions:

• Ambient temperature = 40 °C

• Altitude = 1000 m

• Not exceeding power ratings

• DC bus voltage = 565 V for DST140X

• DC bus voltage = 325 V for DST120X

The sizing tool should be used to select a drive for a profile or condition

that is not given as an example in section 13.1.2 Typical pulse duty on

page 173.

Peak current

I

MAX

8 Digitax ST User Guide

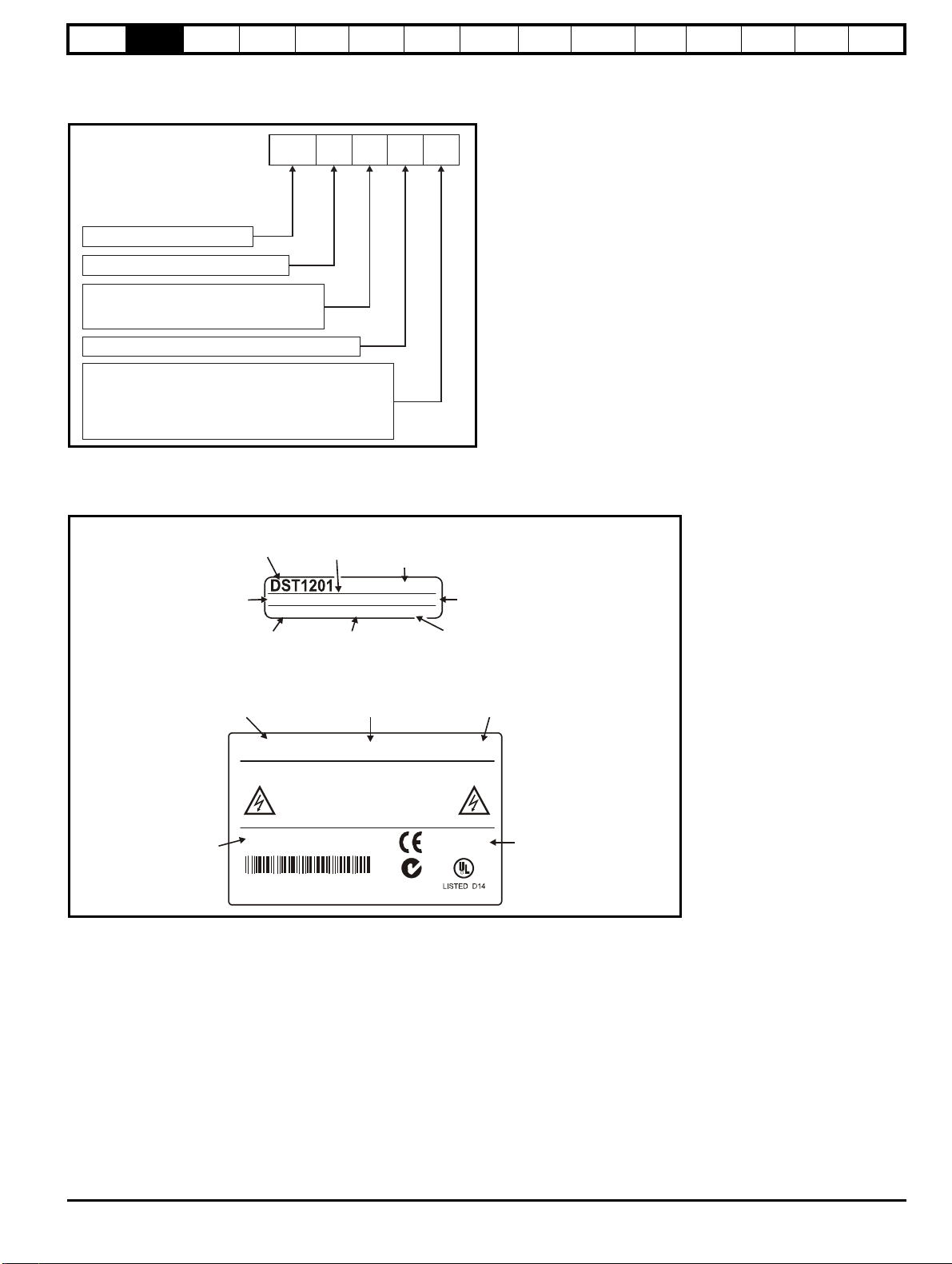

Issue: 5

Safety

Model: Digitax ST

Frame size

Voltage rating

2:4:200V to 240V

380V to 480V

Current rating step

Variant

DST 1 2 01 B

B:

I:

P:

Z:

E:

Base

Indexer

Plus

EZMotion

EtherCAT

Model

3098-0010

2.2/5.1Apk 250ms

S/N: 3000005001

Serial

number

Rating

Please read the manual before connecting

Electric Shock Risk: Wait 10 mins

between disconnecting supply

and accessing terminals

UL file: E171230

Approvals

Approvals label

Designed in the U.K. Made in China

IND. CONTROL

EQUIPMENT

R

RoHS

Compliant

I/P 200-240V 50-60Hz 1/3ph 4.0/3.1A

O/P 0-240V 2.2/5.1Apk

Input

voltage

CT Model type

Serial

number

Single/three phase

peak output current

Output voltage

ST 1.1A M/TL 3ph

Rating label

S/N: 3000005001

Single/three

phase input

current

Frequency

LS Model

type

CUS

8

R10

Date code

N1652

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

2.3 Drive model numbers

Each drive variant and rating has a unique model number.

Figure 2-1 Model code explanation

2.4 Drive nameplate description

The drive rating label provides the user with various details relating to the drive variant and rating.

Figure 2-2 Typical drive label

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

Digitax ST User Guide 9

Issue: 5

Safety

Solutions

Module

slot 2

cover

Solutions

Module

slot 1

cover

Buffered

encoder output

Encoder In

connection

Motor

connections

Line to

ground

varistor

screw

AC supply

48V connection

(for low voltage

DC operation)

Braking

resistor

connections

SMARTCARD

slot

Serial port

connector

Control

terminals

Relay

terminal

Keypad

connection

EMC bracket

Ground

screw

EMC bracket

Ground

screw

Status LED

Marker tag

location

*

Internal

EMC

filter

screw

Rating

label

Approvals

label

Brake

resistor slot

Reset

button

**

Fan

Control cable

strain relief

Product

identifier

NOTE

NOTE

WARNING

CAUTION

Information

Product

information

Mechanical

installation

Electrical

installation

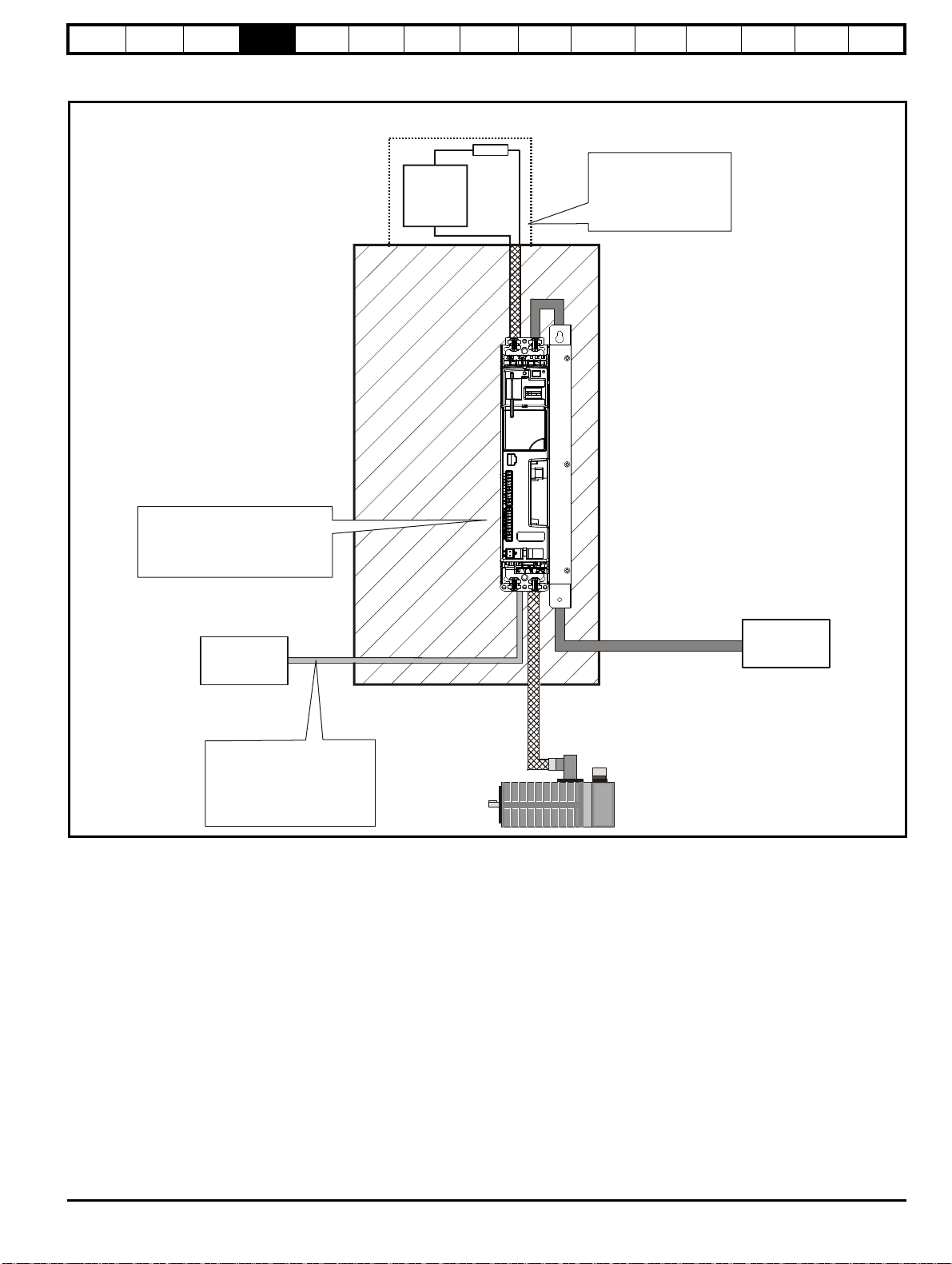

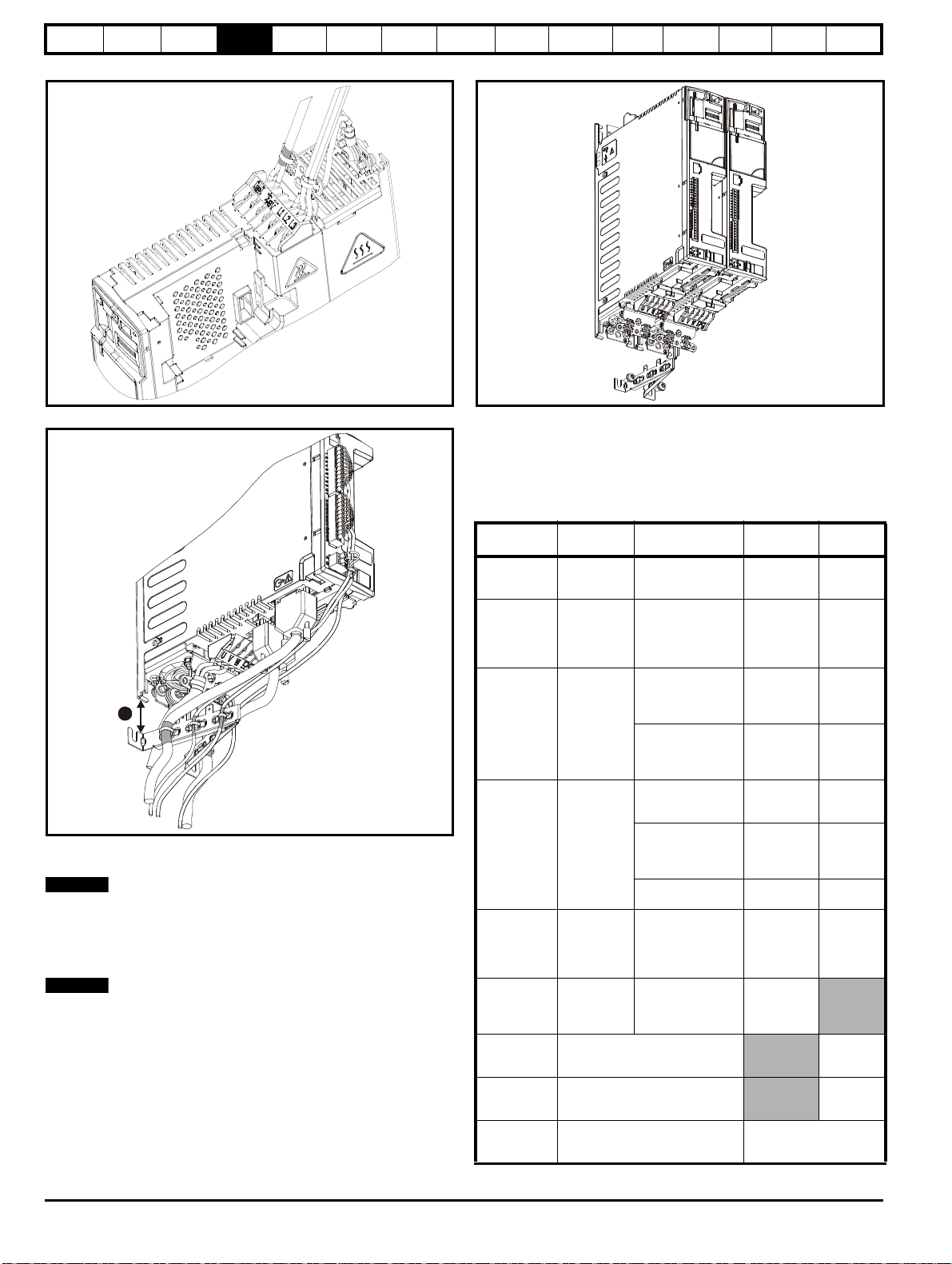

2.5 Features of the drive

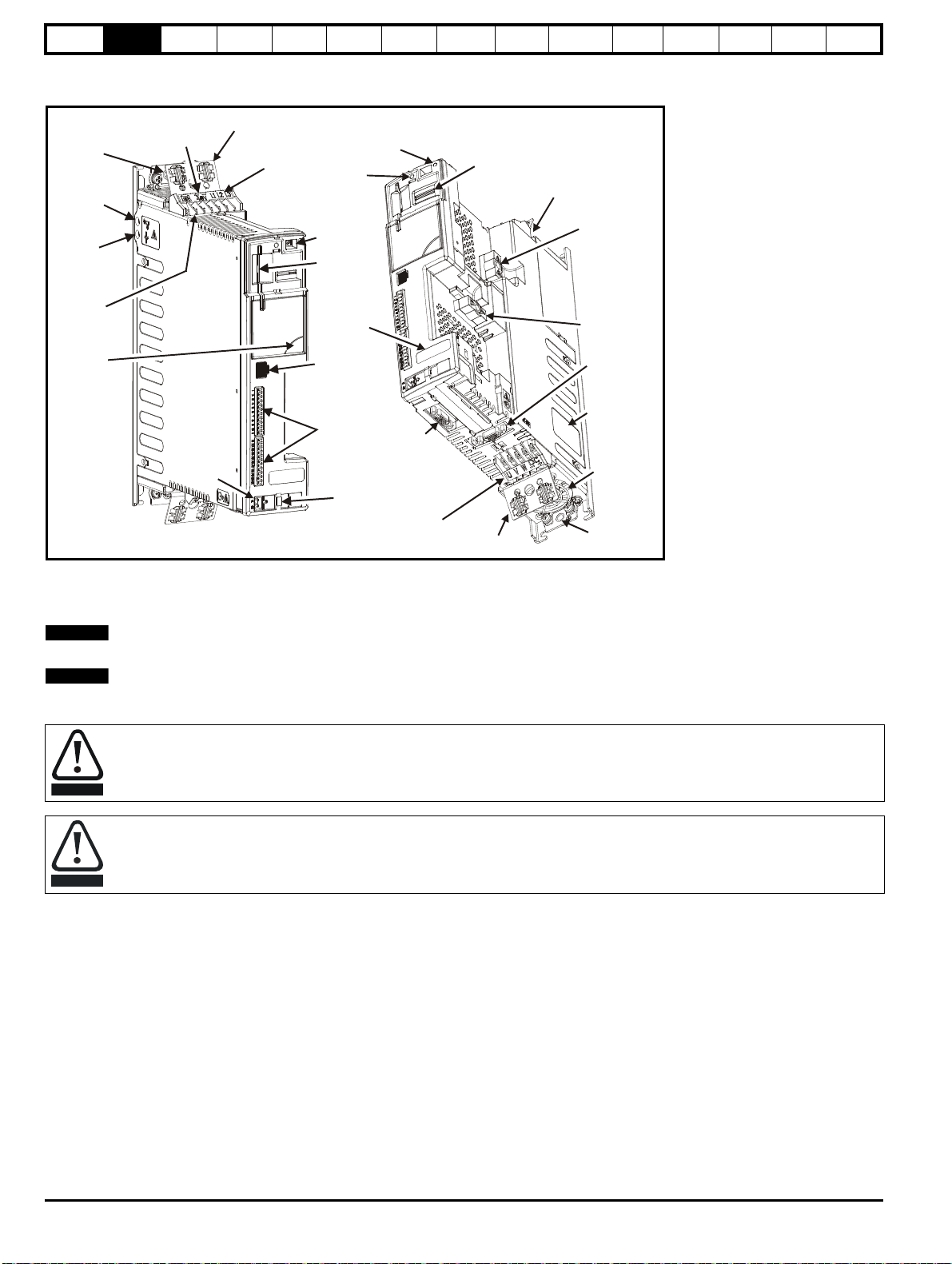

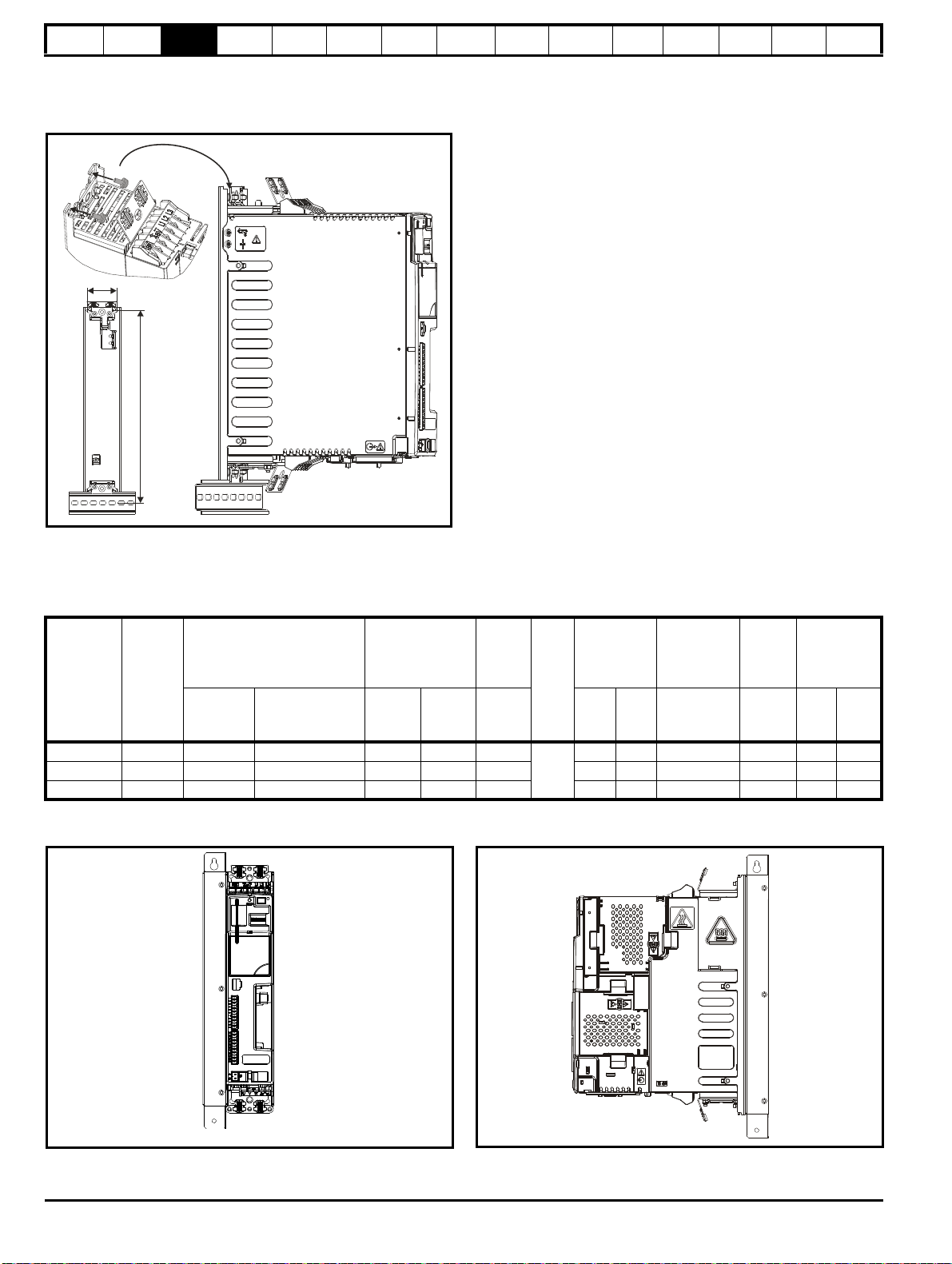

Figure 2-3 Features of the drive

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

*

The Marker Tag (as shown in Figure 2-3 above), is where markers can be placed to identify a particular drive which can prove beneficial where several Digitax

ST drives are located in the same panel.

** A drive reset can be performed even when a keypad is not installed, by pressing the recessed reset button.

If the embedded interface is removed, the warranty for the drive will be void.

The drive is supplied with a SMARTCARD installed. Do not remove until after first power-up, as defaults are stored on the SMARTCARD.

Be aware of possible live terminals when inserting the SMARTCARD.

Static precautions must be taken when removing the Solutions Module slot covers.

10 Digitax ST User Guide

Issue: 5

Safety

SM-Keypad Plus

SMARTCARD*

DST Keypad

CT Comms

cable

External footprint/

bookcase EMC

filter

Internal

braking

resistor

Grounding

bracket

15-way

D-type

converter

I/O Expansion

Applications

Automation

Fieldbus

Feedback

S

l

o

t

2

S

l

o

t

1

*

Inputs Outputs

• Incremental encoders • Quadrature

• SinCos encoders • Frequency and direction

• SSI encoders • SSI simulated outputs

• EnDat encoders

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

2.6 Options

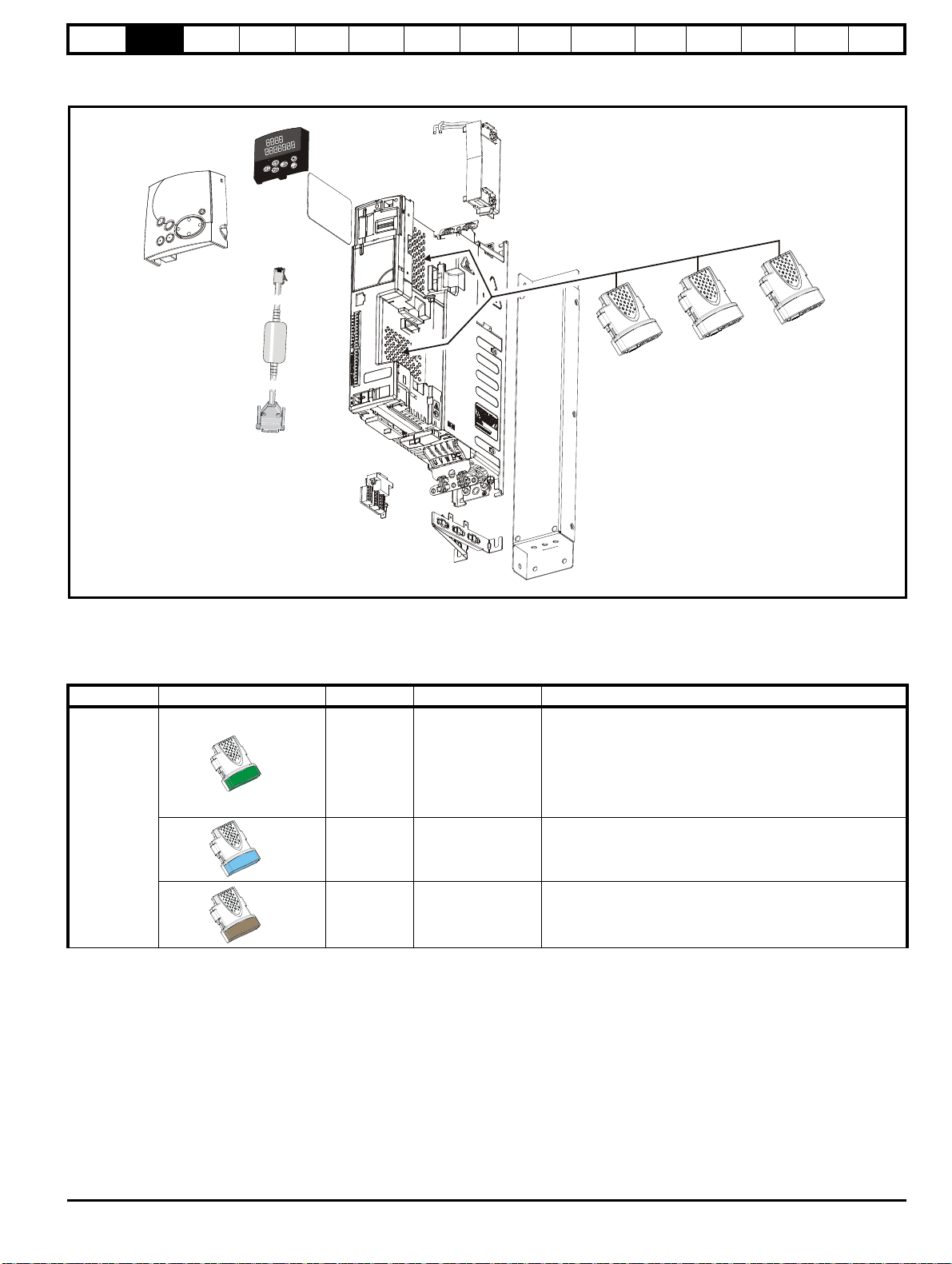

Figure 2-4 Options available with Digitax ST

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

* A SMARTCARD is provided as standard. For further information refer to Chapter 10 SMARTCARD Operation on page 101.

All Solutions Modules are color-coded in order to make identification easy. The following table shows the color-code key and gives further details on

their function.

Table 2-2 Solutions Module identification

Type Solutions Module Color Name Further Details

Universal Feedback interface

Feedback interface for the following devices:

SM-Universal

Encoder Plus

Resolver interface

Feedback interface for resolvers.

Simulated quadrature encoder outputs

Feedback

Light Green

Light Blue SM-Resolver

Incremental encoder interface

Brown SM-Encoder Plus

Feedback interface for incremental encoders without

commutation signals.

No simulated encoder outputs available

Digitax ST User Guide 11

Issue: 5

Safety

• Digital inputs x 3

• Analog output (voltage) x 1

• Digital I/O x 3 • Relay x 2

• Analog inputs (voltage) x 2

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

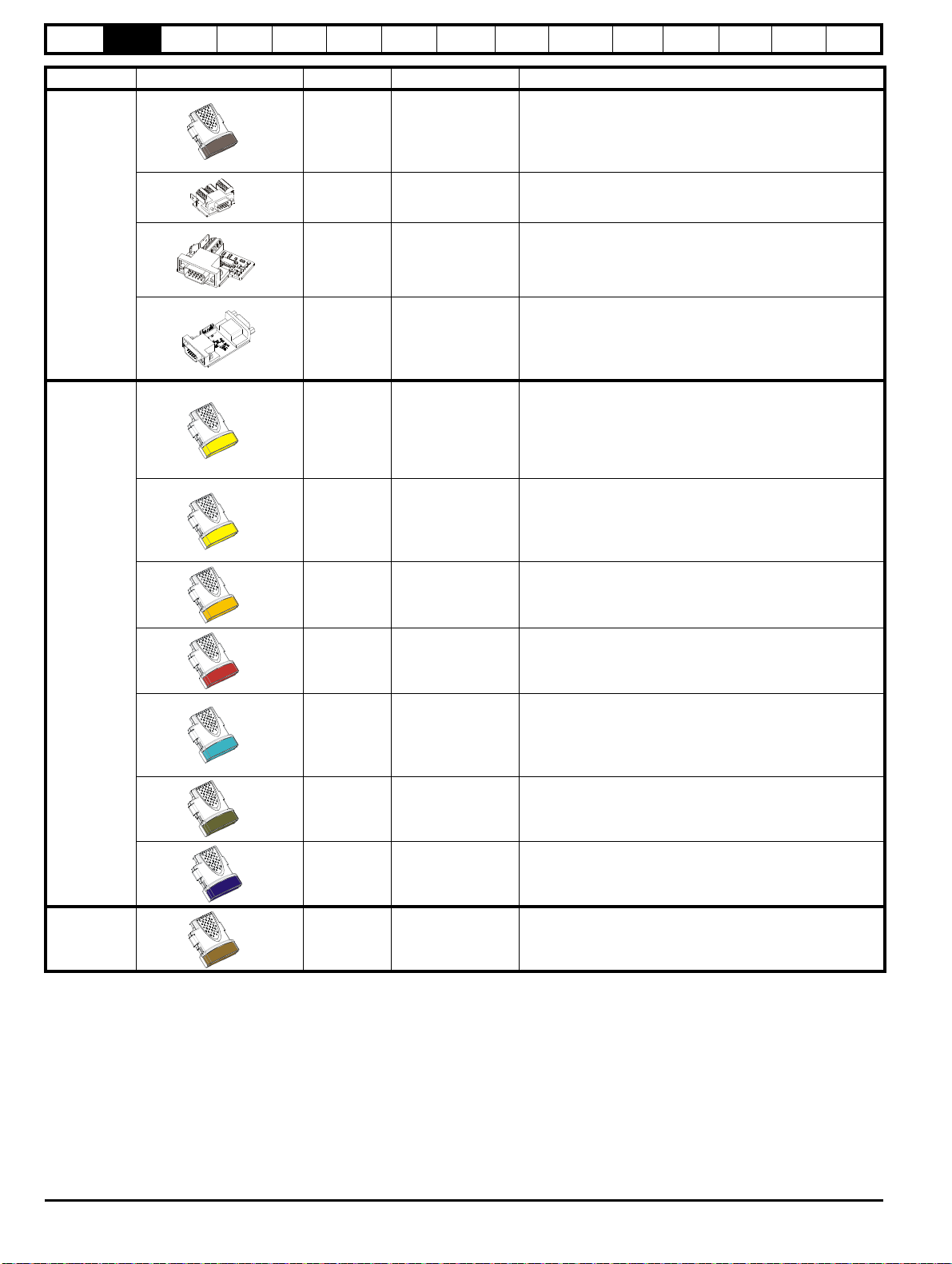

Type Solutions Module Color Name Further Details

Incremental encoder interface

Feedback interface for incremental encoders without

commutation signals.

Simulated encoder output for quadrature, frequency and

Dark Brown

SM-Encoder Output

Plus

direction signals

Drive encoder input converter

Provides screw terminal interface for encoder wiring and spade

terminal for shield

Single ended encoder interface

Provides an interface for single ended ABZ or UVW encoder

signals, such as those from hall effect sensors. 15 V and 24 V

versions are available.

Feedback

N/A

N/A

15-way D-type

converter

Single ended

encoder interface

(15 V or 24 V)

ERN1387 Encoder Interface Board

Provides an interface for Heidenhain ERN1387 and ERN487

SinCos encoder which use a single SinCos cycle per revolution

commutation track. A SM-Universal Encoder Plus module is

N/A

ERN1387 Encoder

Interface Board

required to use this interface board.

Extended I/O interface

Increases the I/O capability by adding the following to the

Yellow SM-I/O Plus

existing I/O in the drive:

Extended I/O interface

Increase the I/O capability by adding the following to the

Yellow SM-I/O 32

existing I/O in the drive:

• High speed digital I/O x 32

• +24 V output

Additional I/O

1 x Analog input (±10 V bi-polar or current modes)

1 x Analog output (0-10 V or current modes)

3 x Digital input and 1 x Relay

Additional I/O with real time clock

As per SM-I/O Lite but with the addition of a Real Time Clock

Automation

(I/O

Expansion)

Dark Yellow SM-I/O Lite

Dark Red SM-I/O Timer

for scheduling drive running

Isolated I/O to NAMUR NE37 specifications

For chemical industry applications

Turquoise SM-I/O PELV

1 x Analog input (current modes)

2 x Analog outputs (current modes)

4 x Digital input / outputs, 1 x Digital input, 2 x Relay outputs

Technical

Data

Diagnostics

UL listing

information

Olive SM-I/O 120V

Cobalt Blue

Automation

(Applications)

12 Digitax ST User Guide

Golden

brown

SM-I/O 24V

Protected

SM-Register

Additional I/O conforming to IEC 61131-2 120 Vac

6 digital inputs and 2 relay outputs rated for 120 Vac operation

Additional I/O with overvoltage protection up to 48 V

2 x Analog outputs (current modes)

4 x Digital input / outputs, 3 x Digital inputs, 2 x Relay outputs

Applications Processor

nd

2

processor for running position capture functionality with

CTNet support.

Issue: 5

Safety

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

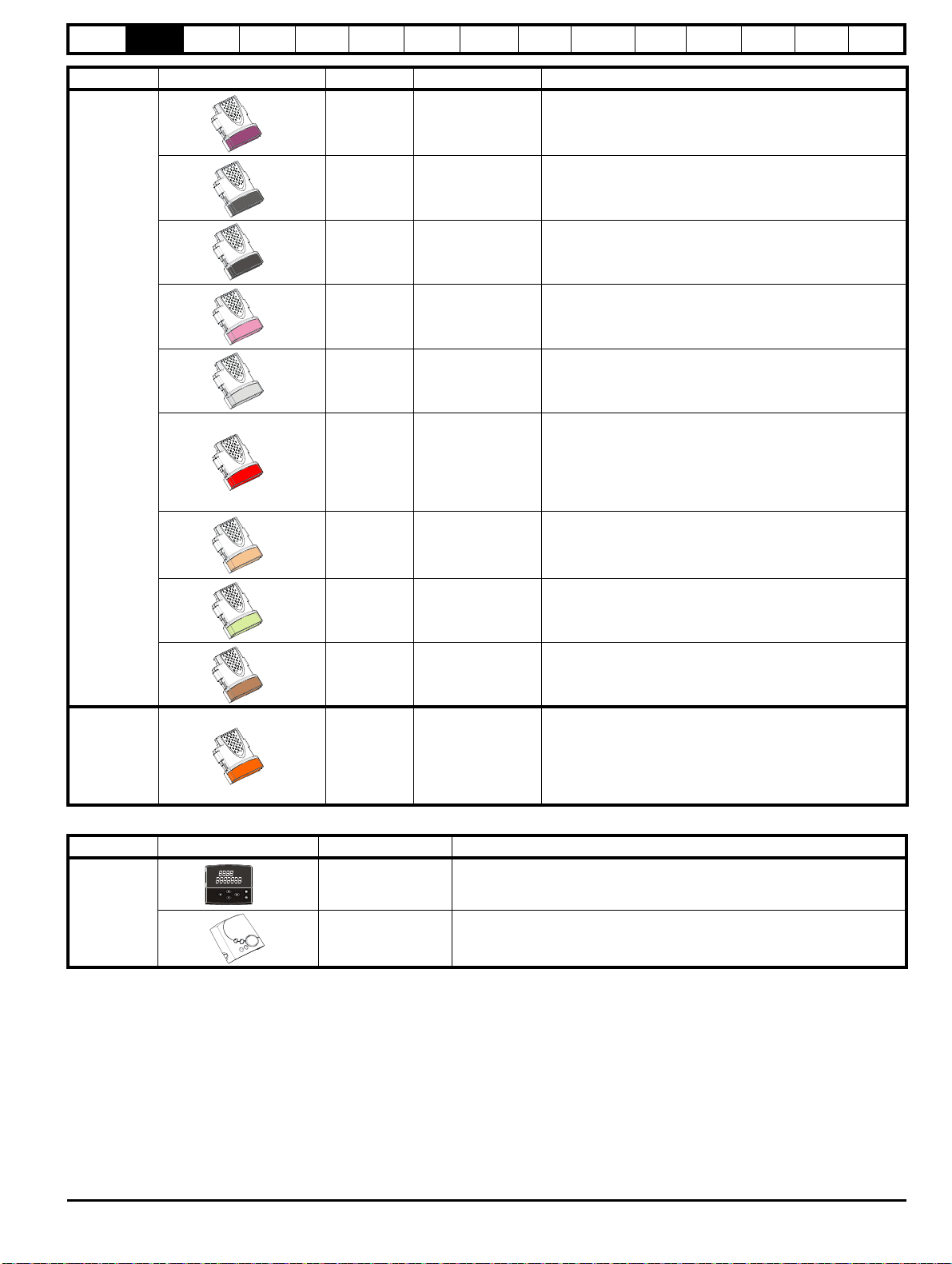

Type Solutions Module Color Name Further Details

Technical

Data

Diagnostics

UL listing

information

Fieldbus

Purple

SM-PROFIBUS-DP-V1Profibus option

Medium Grey SM-DeviceNet

Dark Grey SM-INTERBUS

Pink SM-CAN

Light Grey SM-CANopen

Red SM-SERCOS

Beige SM-Ethernet

PROFIBUS DP adapter for communications with the drive

DeviceNet option

Devicenet adapter for communications with the drive

Interbus option

Interbus adapter for communications with the drive

CAN option

CAN adapter for communications with the drive

CANopen option

CANopen adapter for communications with the drive

SERCOS option

Class B compliant. Torque velocity and position control modes

supported with data rates (bit/sec): 2 MB, 4 MB, 8 MB and 16

MB.

Minimum 250 μsec network cycle time. Two digital high speed

probe inputs 1 μsec for position capture

Ethernet option

10 base-T / 100 base-T; Supports web pages, SMTP mail and

multiple protocols: DHCP IP addressing; Standard RJ45

connection

Pale Green SM-LON

Brown Red SM-EtherCAT

LonWorks option

LonWorks adapter for communications with the drive

EtherCAT option

EtherCAT adapter for communications with the drive

SLM interface

The SM-SLM allows SLM feedback to be connected directly to

SLM Orange SM-SLM

the Digitax ST drive and allows operation in either of the

following modes:

• Encoder only mode

• Host mode

Table 2-3 Keypad identification

Type Keypad Name Further Details

Digitax ST Keypad

LED keypad option

Keypad with a LED display

Keypad

SM-Keypad Plus

Remote keypad option

Keypad with an alpha-numeric LCD display with Help function

Digitax ST User Guide 13

Issue: 5

Safety

Control

connectors

Relay

connector

Ground

screws

Cable

guides

Grounding

bracket

Ground

screws

Digitax ST

Plus

additional

connectors

123

Digitax ST

EtherCAT

additional

connector

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Table 2-4 Other options

Type Option Name Further details

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

EMC EMC Filters

CT Comms cable

Communications

CTSoft

SyPTLite

These additional filters are designed to operate together with the drive’s own

integral EMC filter in areas of sensitive equipment

Cable with isolation RS232 to RS485 converter. For connecting PC/Laptop to

the drive when using the various interface software (e.g. CTSoft)

Software for PC or Laptop which allows the user to commission and store

parameter settings.

Software for PC or Laptop which allows the user to program PLC functions

within the drive.

Both CTSoft and SyPTLite can be downloaded at: http://www.emersonindustrial.com/en-EN/

controltechniques/downloads/userguidesandsoftware/Pages/digitaxst.aspx

Internal braking

resistor

SMARTCARD SMARTCARD

Braking resistor Optional braking resistor 70R 50 W

Standard feature that enables simple configuration of parameters in a variety of

ways

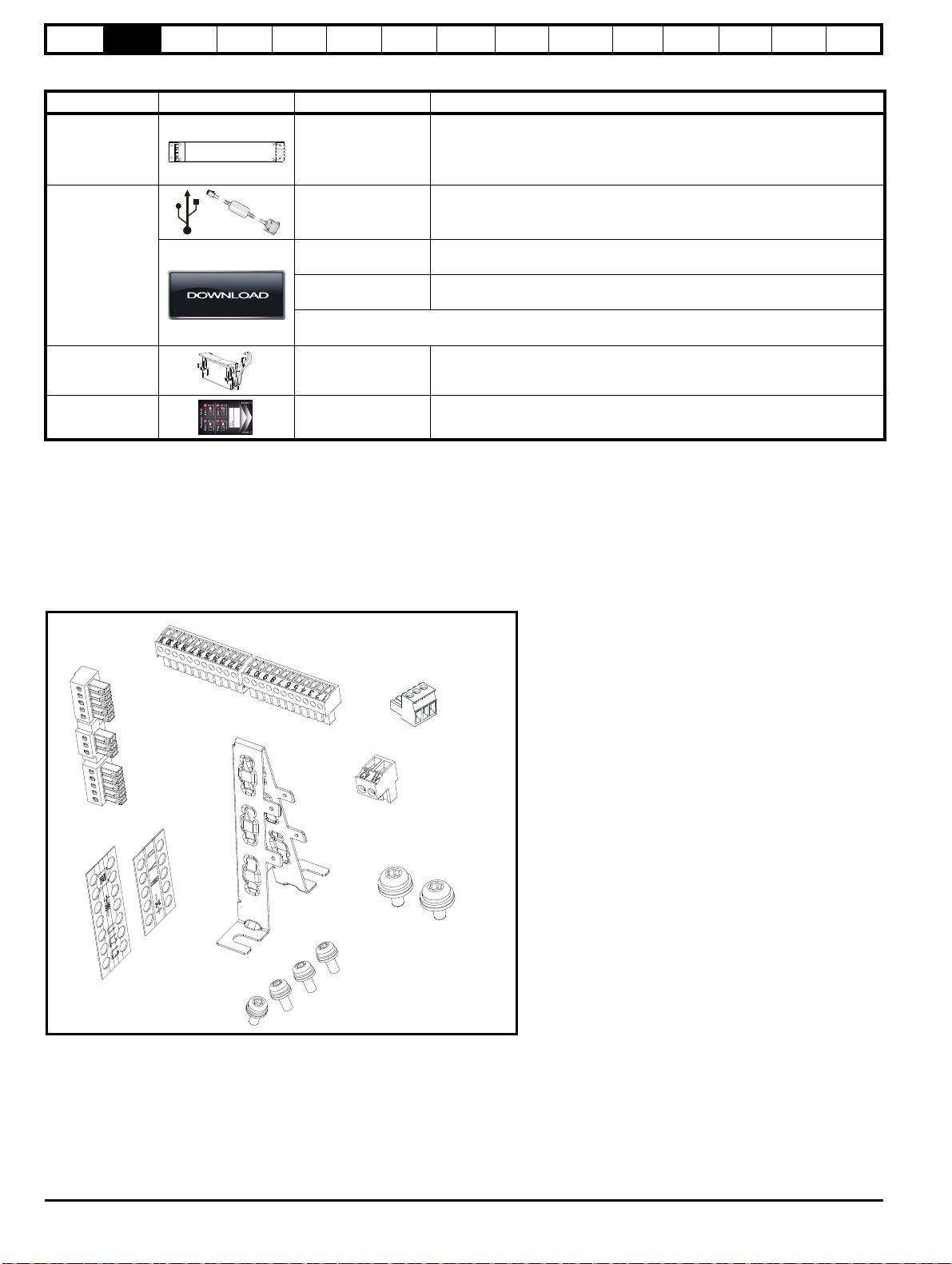

2.7 Items supplied with the drive

The drive is supplied with the following items:

• Installation Guide

•SMARTCARD

• Safety Information booklet

• Certificate of Quality

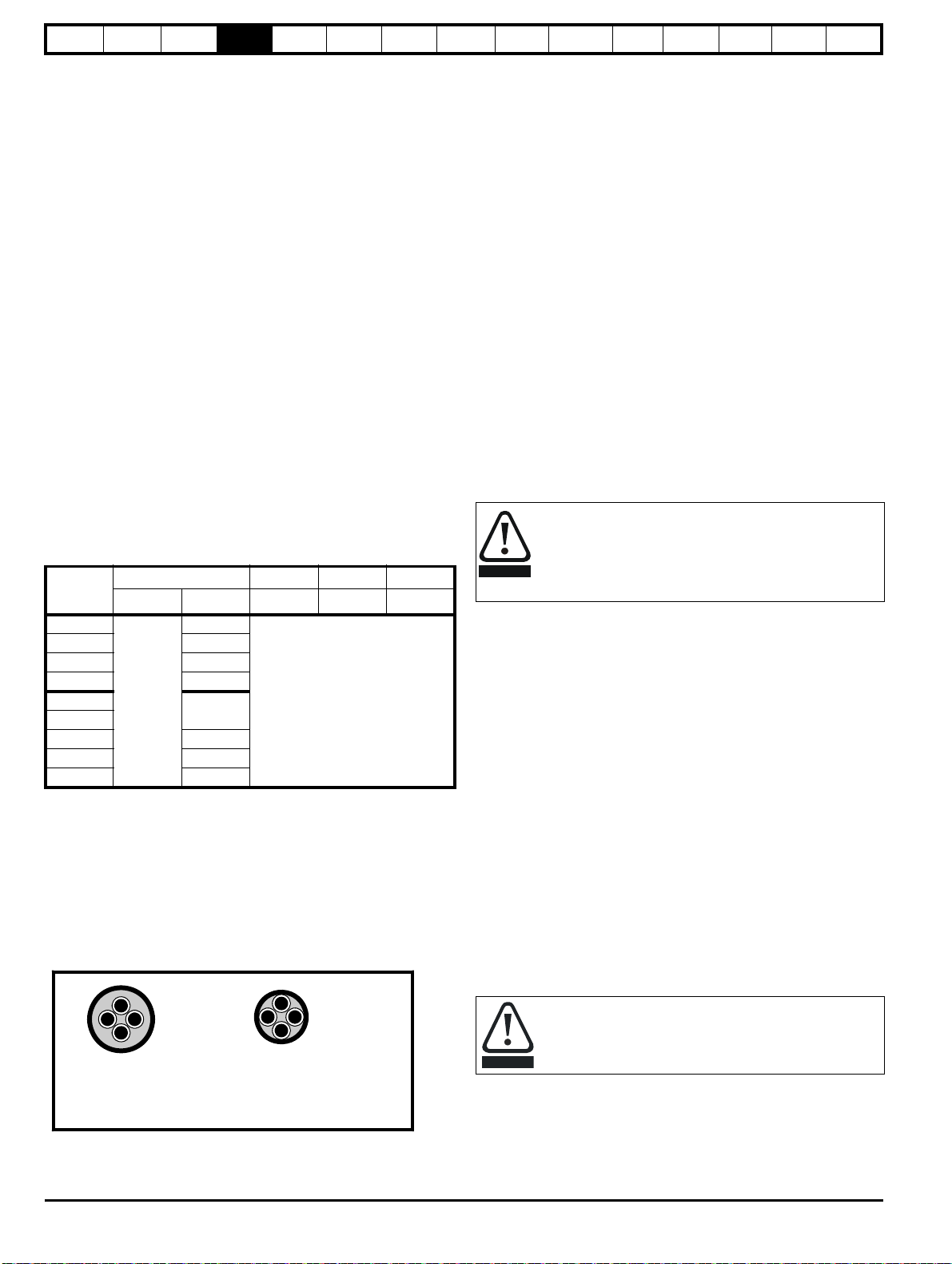

An accessory box containing the items illustrated in Figure 2-5 is also provided.

Figure 2-5 Accessory box contents

Issue: 5

14 Digitax ST User Guide

Safety

WARNING

WARNING

WARNING

WARNING

NOTE

Drive

5

o

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

3 Mechanical installation

This chapter describes how to use all mechanical details to install the

drive. The drive is intended to be installed in an enclosure. Key features

of this chapter include:

• Through-hole mounting

• IP54 as standard or through-panel mounting

• Enclosure sizing and layout

• Solutions Module installing

• Terminal location and torque settings

3.1 Safety information

Follow the instructions

The mechanical and electrical installation instructions must

be adhered to. Any questions or doubt should be referred to

the supplier of the equipment. It is the responsibility of the

owner or user to ensure that the installation of the drive and

any external option unit, and the way in which they are

operated and maintained, comply with the requirements of

the Health and Safety at Work Act in the United Kingdom or

applicable legislation and regulations and codes of practice in

the country in which the equipment is used.

Stored charge

The drive contains capacitors that remain charged to a

potentially lethal voltage after the AC supply has been

disconnected. If the drive has been energized, the AC

supply must be isolated at least ten minutes before work

may continue. Normally, the capacitors are discharged by an

internal resistor. Under certain, unusual fault conditions, it is

possible that the capacitors may fail to discharge, or be

prevented from being discharged by a voltage applied to the

output terminals. If the drive has failed in a manner that

causes the display to go blank immediately, it is possible the

capacitors will not be discharged. In this case, consult

Emerson Industrial Automation or their authorized

distributor.

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

• corrosive gasses

During installation it is recommended that the vents on the drive are

covered to prevent debris (e.g. wire off-cuts) from entering the drive.

3.2.3 Cooling

The heat produced by the drive must be removed without its specified

operating temperature being exceeded. Note that a sealed enclosure

gives much reduced cooling compared with a ventilated one, and may

need to be larger and/or use internal air circulating fans.

3.2.4 Electrical safety

The installation must be safe under normal and fault conditions.

Electrical installation instructions are given in Chapter 4 Electrical

installation on page 21.

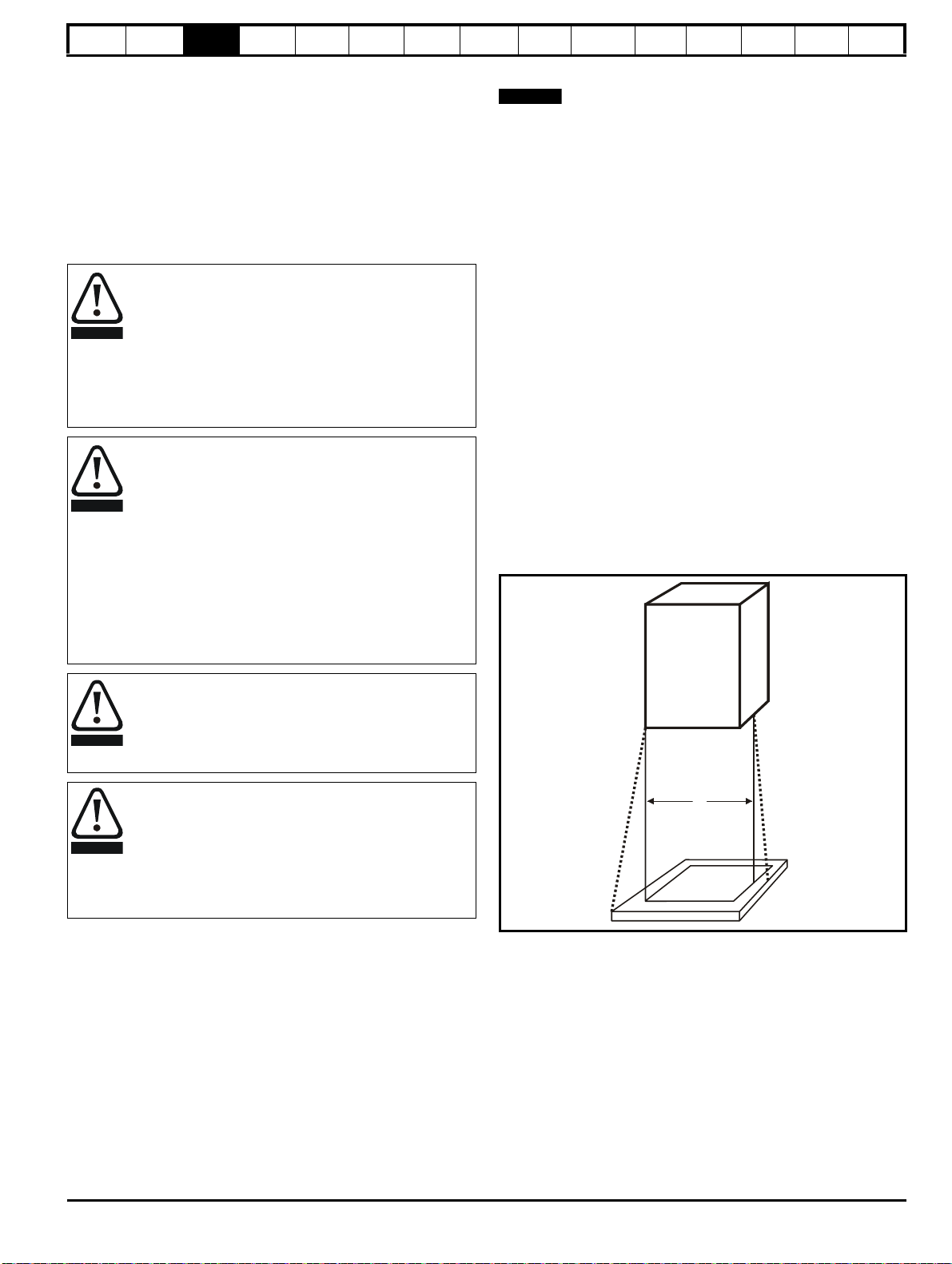

3.2.5 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided.

For installation in the USA, a NEMA 12 enclosure is suitable.

For installation outside the USA, the following (based on IEC 62109-1,

standard for PV inverters) is recommended.

Enclosure can be metal and/or polymeric, polymer must meet

requirements which can be summarized for larger enclosures as using

materials meeting at least UL 94 class 5VB at the point of minimum

thickness.

Air filter assemblies to be at least class V-2.

The location and size of the bottom shall cover the area shown in Figure

3-1. Any part of the side which is within the area traced out by the 5°

angle is also considered to be part of the bottom of the fire enclosure.

Figure 3-1 Fire enclosure bottom layout

Competence of the installer

The drive must be installed by professional assemblers who

are familiar with the requirements for safety and EMC. The

assembler is responsible for ensuring that the end product or

system complies with all the relevant laws in the country

where it is to be used.

Enclosure

The drive is intended to be mounted in an enclosure which

prevents access except by trained and authorized

personnel, and which prevents the ingress of contamination.

It is designed for use in an environment classified as

pollution degree 2 in accordance with IEC 60664-1. This

means that only dry, non-conducting contamination is

acceptable.

3.2 Planning the installation

The following considerations must be made when planning the installation:

3.2.1 Access

Access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

3.2.2 Environmental protection

The drive must be protected from:

• moisture, including dripping water or spraying water and

condensation. An anti-condensation heater may be required, which

must be switched off when the drive is running.

• contamination with electrically conductive material

• contamination with any form of dust which may restrict the fan, or

impair airflow over various components

• temperature beyond the specified operating and storage ranges

The bottom, including the part of the side considered to be part of the

bottom, must be designed to prevent escape of burning material - either

by having no openings or by having a baffle construction. This means

that openings for cables etc. must be sealed with materials meeting the

5VB requirement, or else have a baffle above. See Figure 3-2 for

acceptable baffle construction. This does not apply for mounting in an

enclosed electrical operating area (restricted access) with concrete floor.

Digitax ST User Guide 15

Issue: 5

Safety

Notless

than 2X

Ba ffle plates (m ay be

above orbelow bottom

ofenclosure)

X

Bo ttom of fire

enclosure

Not less

than 2

times ‘X’

Baffle plates (may be above or

below bottom of enclosure)

Bottom of fire enclosure

X

CAUTION

NOTE

WARNING

Information

information

Product

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

Figure 3-2 Fire enclosure baffle construction

3.2.6 Electromagnetic compatibility

Variable speed drives are powerful electronic circuits which can cause

electromagnetic interference if not installed correctly with careful

attention to the layout of the wiring.

Some simple routine precautions can prevent disturbance to typical

industrial control equipment.

If it is necessary to meet strict emission limits, or if it is known that

electromagnetically sensitive equipment is located nearby, then full

precautions must be observed. In-built into the drive, is an internal EMC

filter, which reduces emissions under certain conditions. If these

conditions are exceeded, then the use of an external EMC filter may be

required at the drive inputs, which must be located very close to the

drives. Space must be made available for the filters and allowance made

for carefully segregated wiring. Both levels of precautions are covered in

section 4.10 EMC (Electromagnetic compatibility) on page 28.

3.2.7 Hazardous areas

The drive must not be located in a classified hazardous area unless it is

installed in an approved enclosure and the installation is certified.

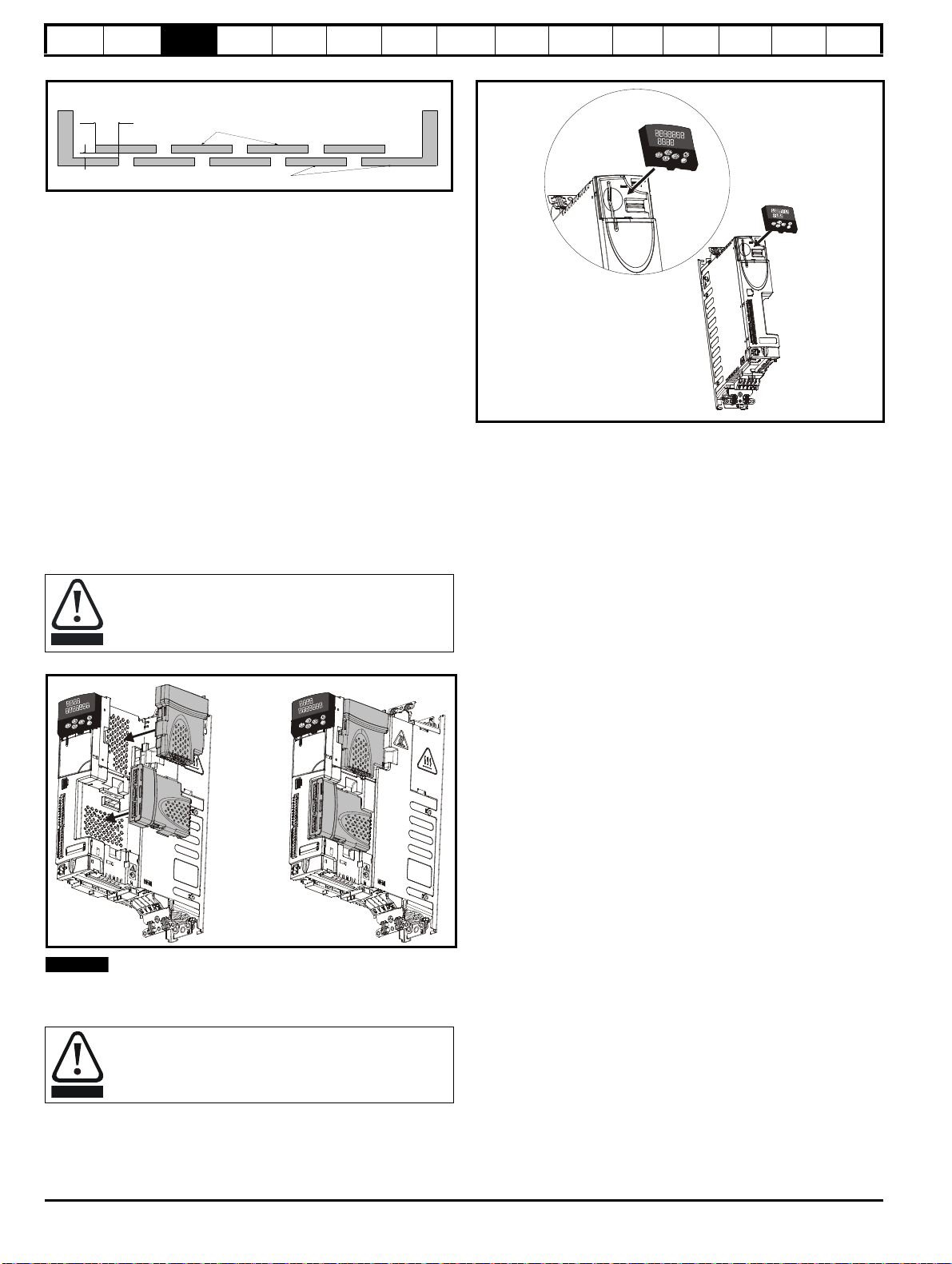

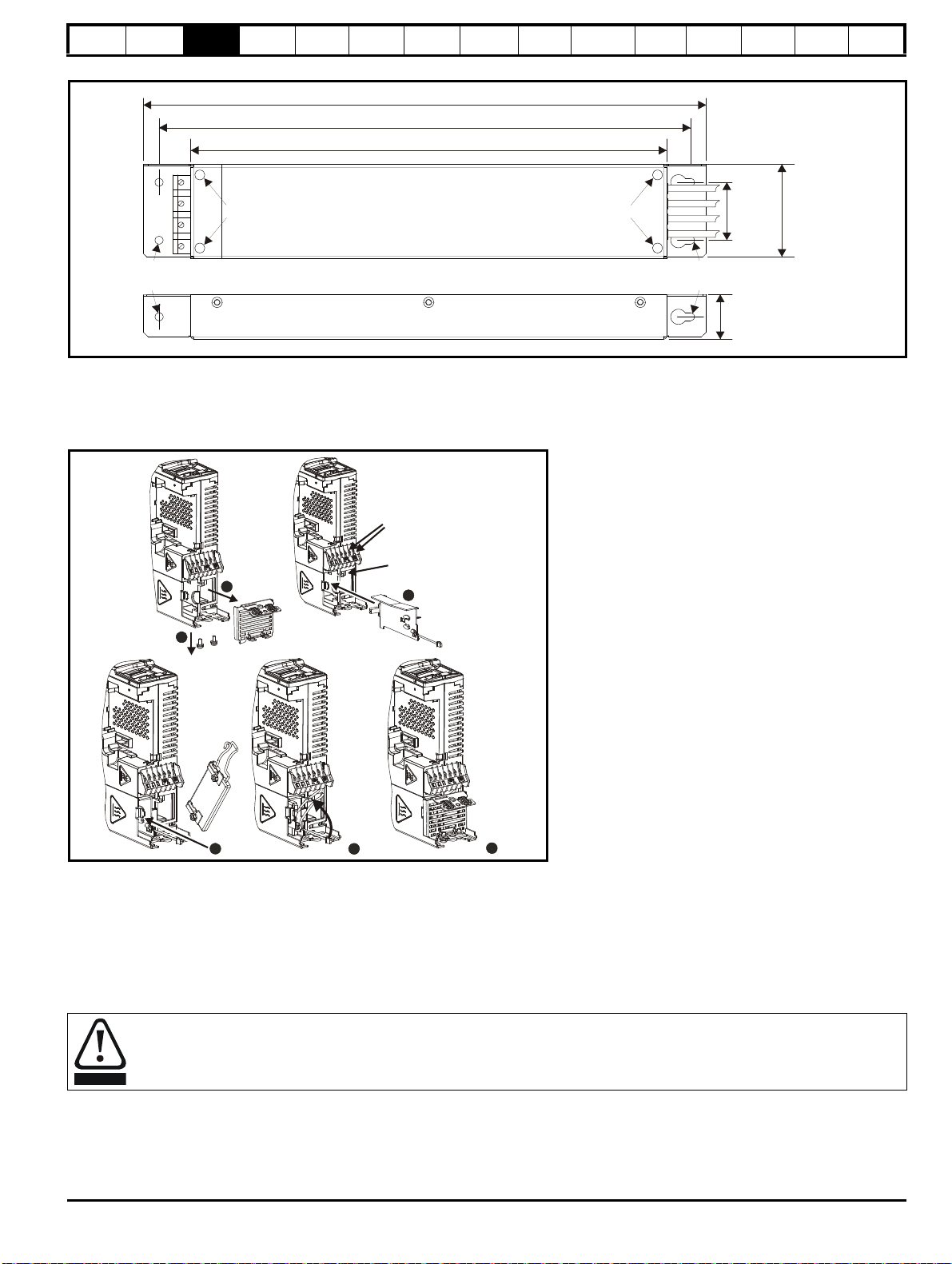

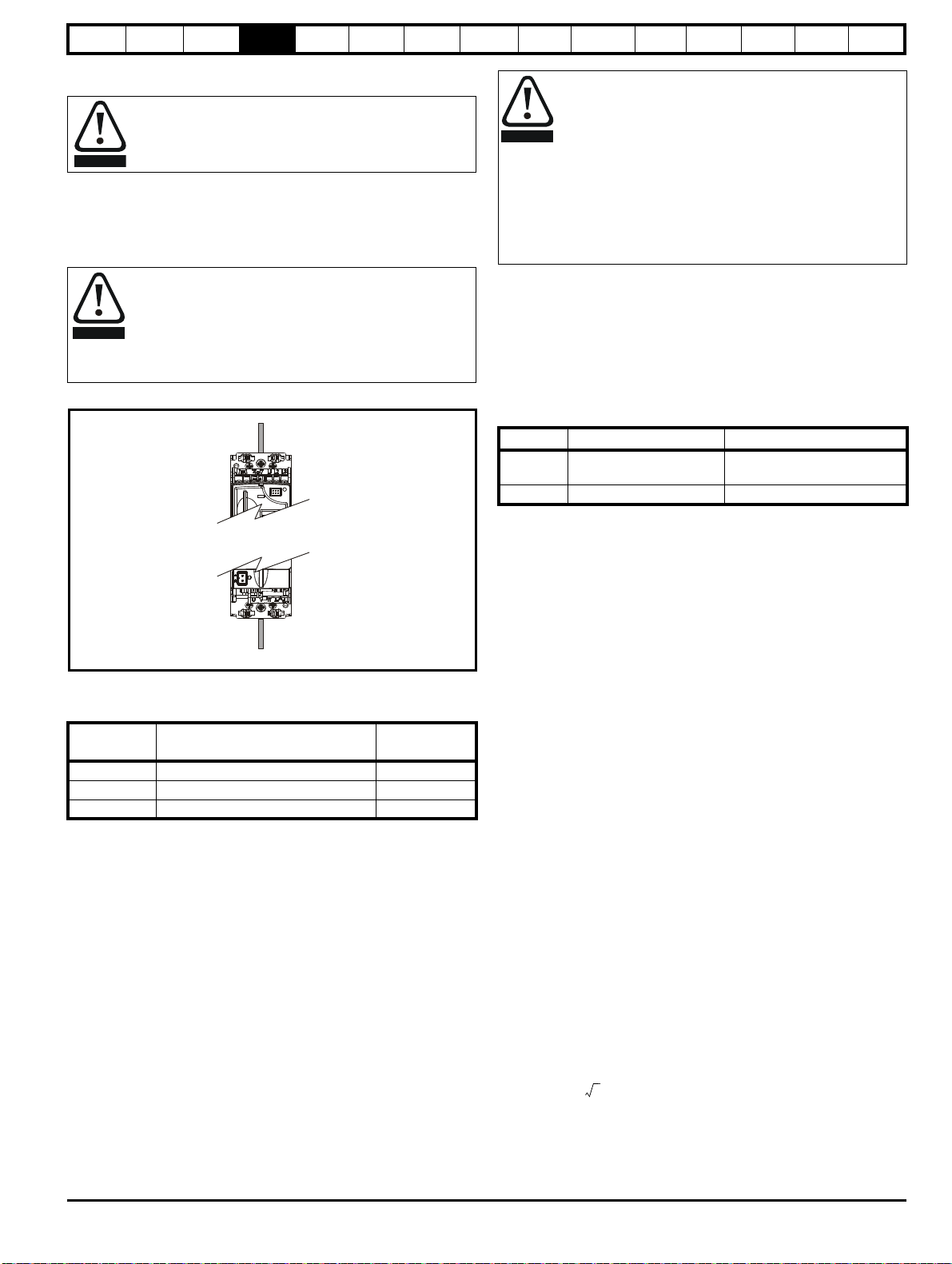

3.3 Solutions Module / keypad installation

/ removal

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

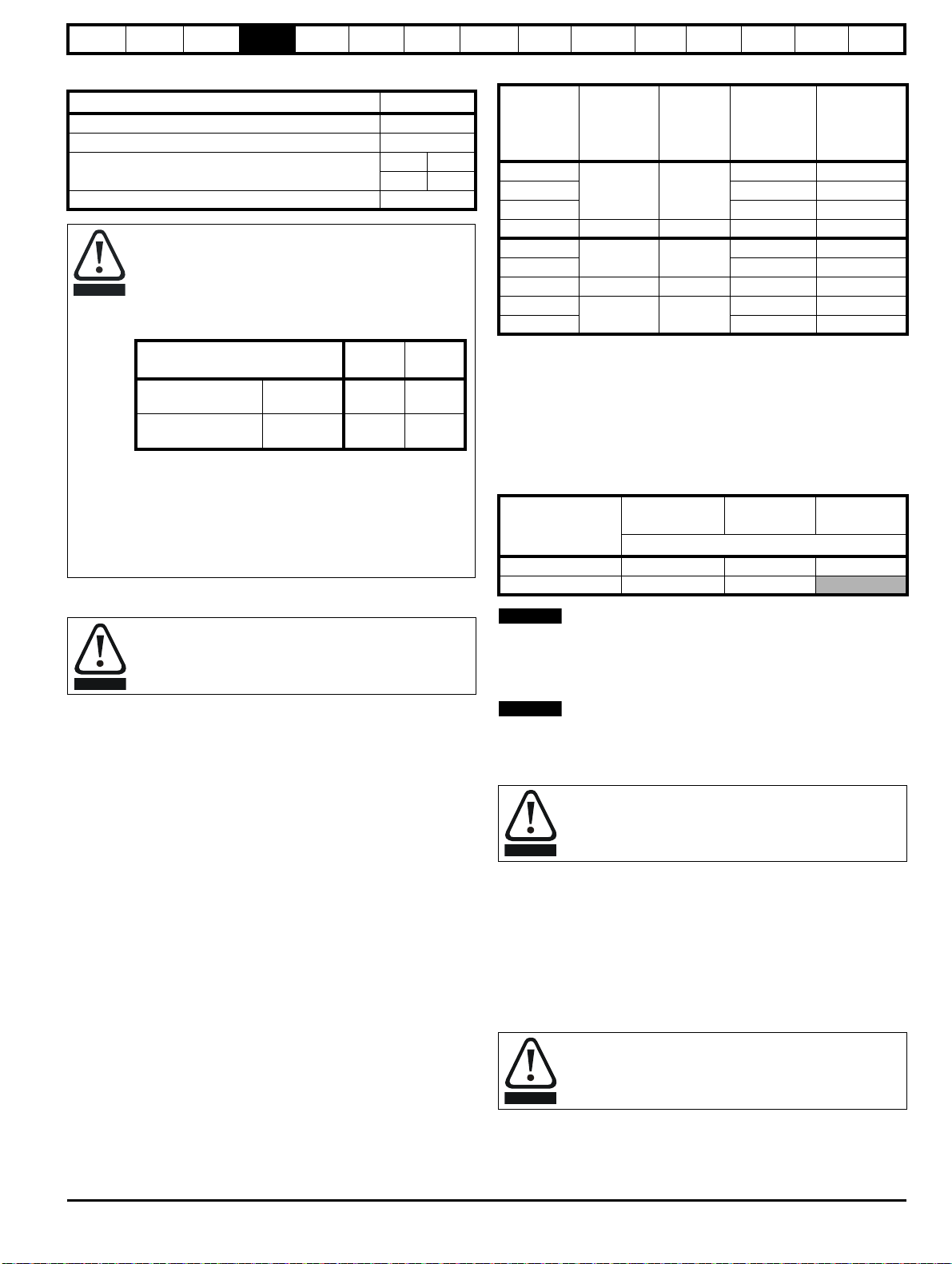

Figure 3-4 Installation of a keypad

Technical

Data

Diagnostics

UL listing

information

Power down the drive before installing / removing the

Solutions Module. Failure to do so may result in damage to

the product.

Figure 3-3 Installation of a Solutions Module

The protective tab from the Solutions Module slot must be removed

before attempting to install a Solutions Module.

Be aware of possible live terminals when installing the

keypad.

16 Digitax ST User Guide

Issue: 5

Safety

WARNING

62mm

(2.44in)

249.7mm

(9.83in)

220mm (8.66in)

47mm

(1.85in)

7.5mm

(0.3in)

304mm

(11.96in)

292mm

(11.49in)

6mm

(0.24in)

∅

5.4mm (0.21in)

M5

322mm

(12.68in)

226mm (8.9in)

226mm (8.9in)

229mm (9.02in)

Ingress protective labels

NOTE

100mm (4in)

100mm (4in)

*2mm (0.08in)

NOTE

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

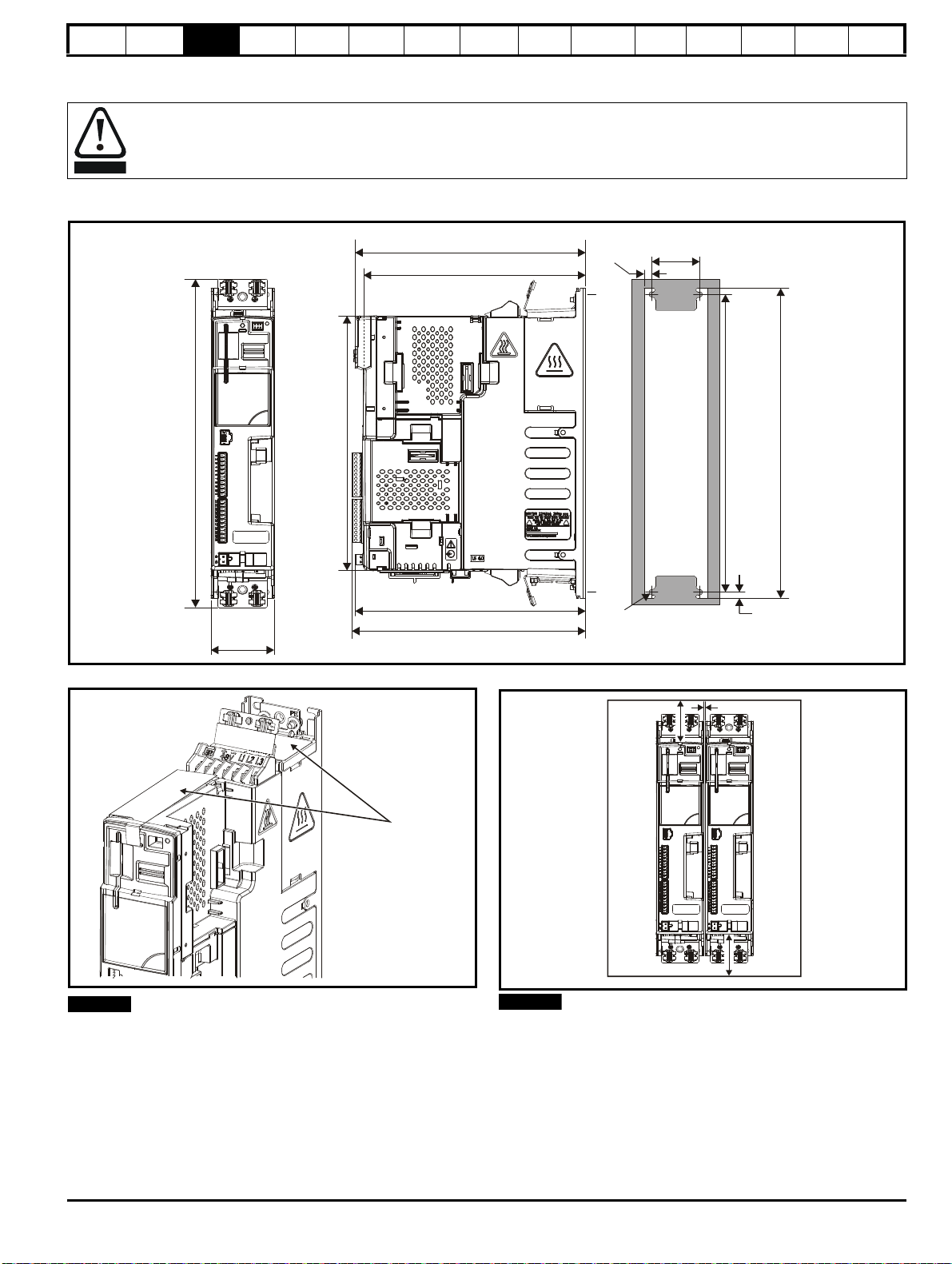

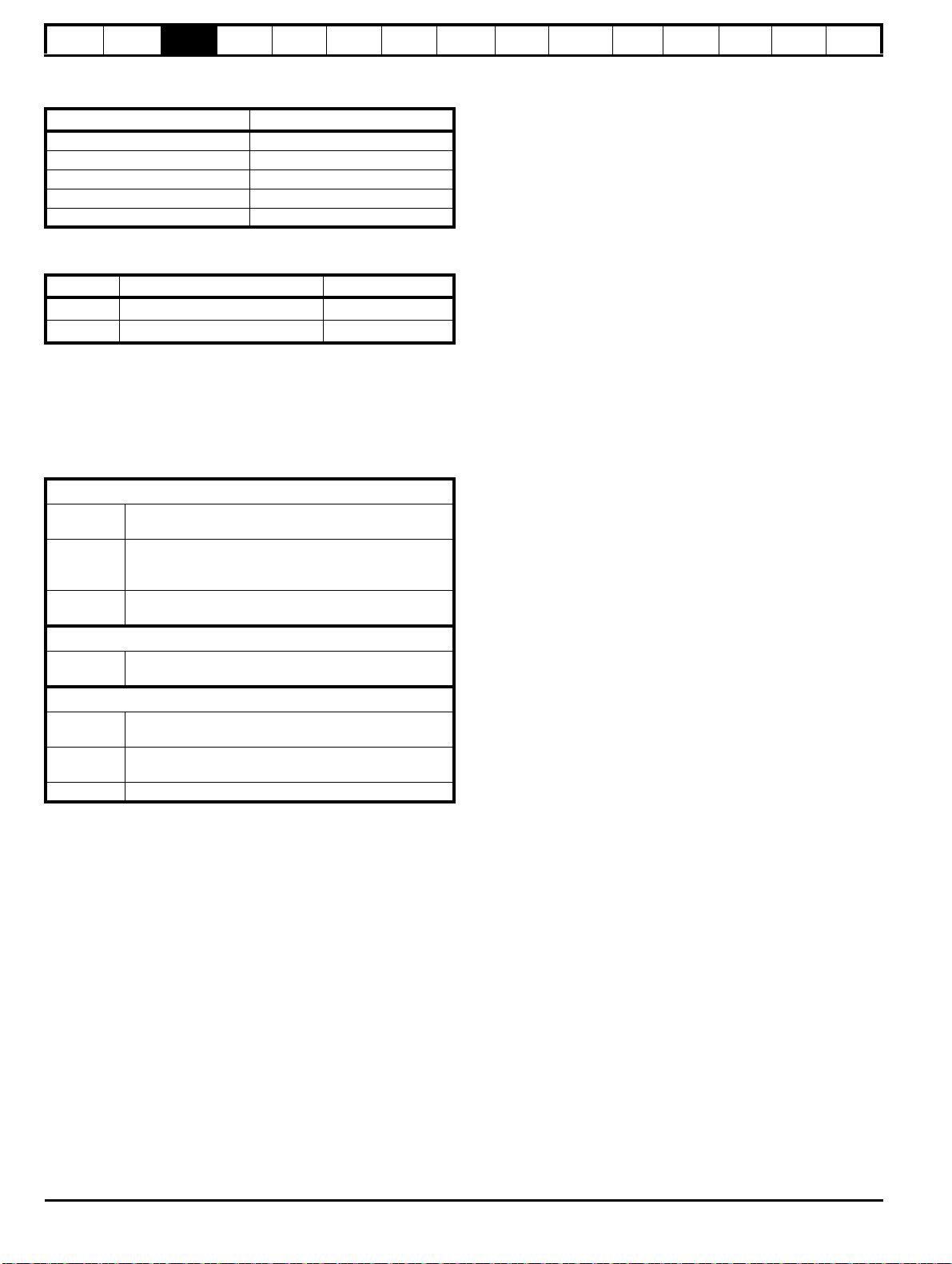

3.4 Drive dimensions

Enclosure

The drive is intended to be mounted in an enclosure which prevents access except by trained and authorized personnel, and which

prevents the ingress of contamination. It is designed for use in an environment classified as pollution degree 2 in accordance with IEC

60664-1. This means that only dry, non-conducting contamination is acceptable.

The drive complies with the requirements of IP20 as standard.

Figure 3-5 Dimensions

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

Figure 3-6 Ingress protective label

The ingress protective labels (shown on Figure 3-6 above) should

remain in place while the drive is mounted, and until all the electrical

wires have been connected. The labels should be removed before first

power up.

Figure 3-7 Minimum mounting clearances

*2 mm clearance between drives to allow for mechanical tolerance.

If Solutions Modules are installed, a larger clearance between drives will

be required if access to the modules is needed without removing the

drive.

Digitax ST User Guide 17

Issue: 5

Safety

47mm (1.85in)

312.7mm

(12.31in)

Information

information

Product

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

Digitax ST can be mounted using a DIN rail, either fixed at the top or the

bottom of the drive (as illustrated in Figure ). Two screws are required to

fix the drive to the backplate at the opposite end to the DIN rail.

Figure 3-8 DIN rail mounting

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

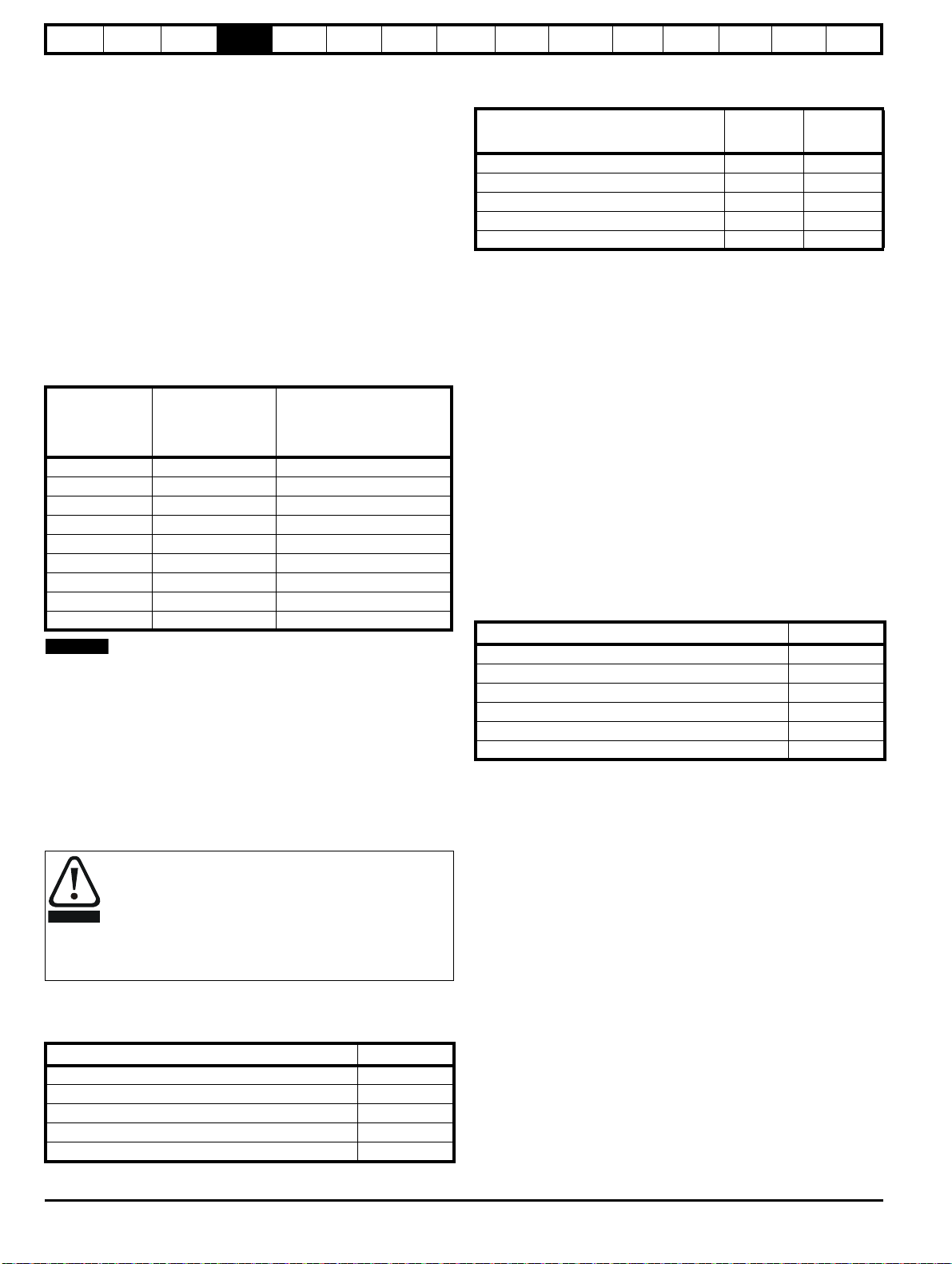

3.5 External EMC filter rating

Filter details for each drive rating are provided in the tables below.

Table 3-1 External EMC filter ratings

Worst

case

leakage

current

Used with

Number

of

phases

Filter part number

CT Schaffner

Maximum

continuous

current

@40°C

(104°F)

@50°C

Power

losses

at rated

current

Weight

IP

rating

Operational

leakage

current

(122°F)AWKglbmAmANmlb ft

A

DST120X 1 4200-6000 FS23072-19-07 19 17.3 11

DST120X 3 4200-6001 FS23073-17-07 17 15.5 13 1.2 2.64 8 50 0.8 0.6

1.2 2.64 29.5 56.9 0.8 0.6

20

DST140X 3 4200-6002 FS23074-11-07 11 10 10 1.2 2.64 16 90 0.8 0.6

The external EMC filters can be footprint or bookcase mounted, see Figure 3-9 and Figure 3-10.

Figure 3-9 Bookcase mounting Figure 3-10 Footprint mounting

Filter

terminal

tightening

torque

18 Digitax ST User Guide

Issue: 5

Safety

29mm (1.14in)

359mm (14.13in)

339mm (13.35in)

304mm (11.97in)

38mm

(1.50in)

61mm

(2.40in)

M5 M5

Torque settings of connector = 0.8 N m

∅

5.3mm (M5)

(0.21in)

∅

5.3mm (M5)

(0.21in)

4

2

1

Brake

connections

Thermistor

connection

3

5

6

WARNING

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

Figure 3-11 External EMC filter dimensions

Figure 3-11 shows a 3 phase filter. For a single phase filter, there are only 3 input terminals (L1, N, ground) and 3 output cables (L1, N, ground).

3.6 Optional braking resistor

3.6.1 Optional internal braking resistor

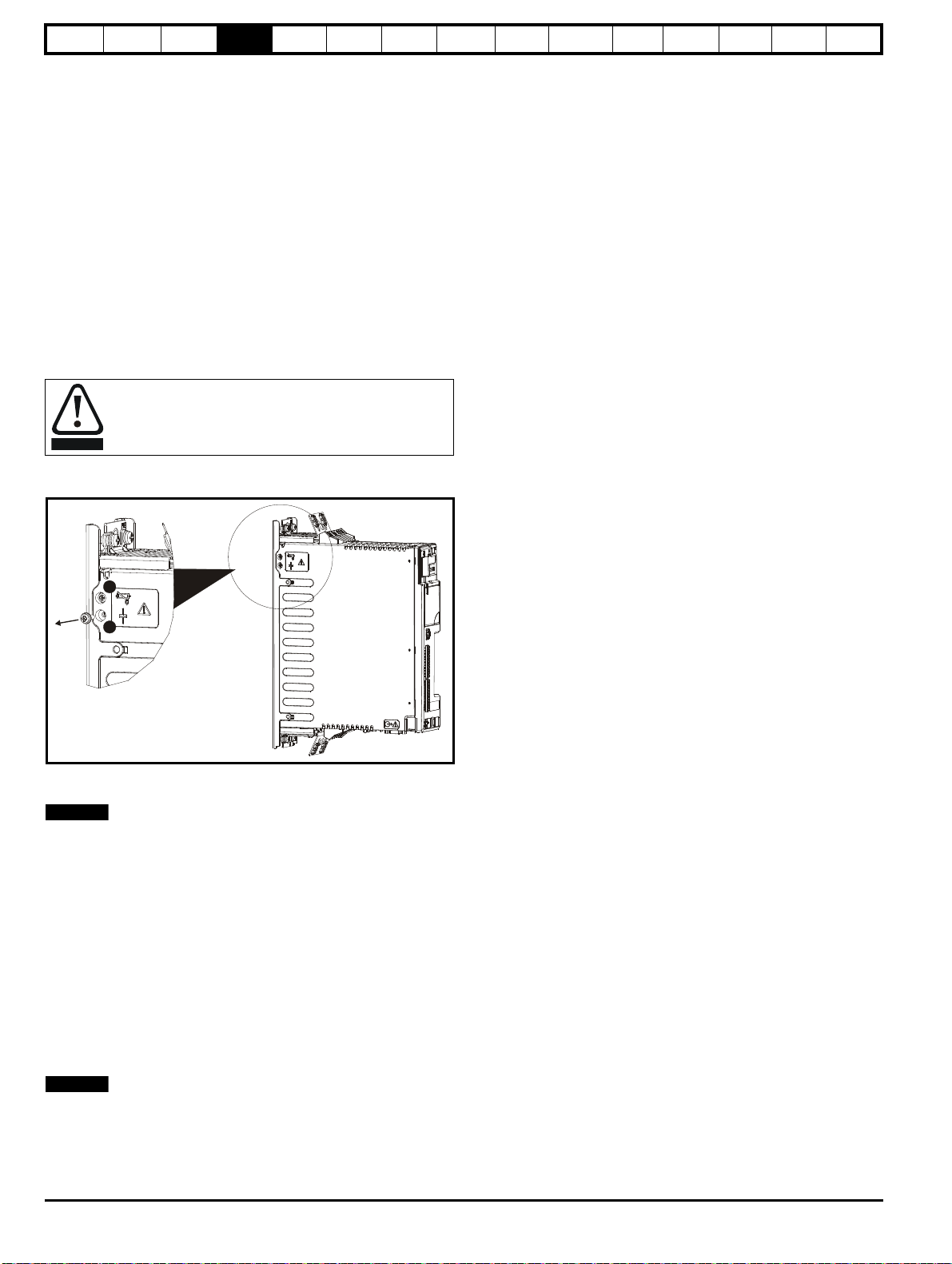

Figure 3-12 Installing an optional internal braking resistor (top view of drive)

1. Remove screws.

2. Remove grill.

3. Install the braking resistor shield.

4. Install the optional internal braking resistor in the slot provided (note the angle).

5. Electrically connect the braking resistor and thermistor (connections shown in Figure 4-1 Power terminal connections on page 22).

6. Re-install the grill and mounting screws by reversing the procedure in points 1 and 2.

3.6.2 Optional external braking resistor

If using an external braking resistor, the following Warning must be adhered to:

Digitax ST User Guide 19

Issue: 5

Braking resistor: High temperatures and overload protection

Braking resistors can reach high temperatures. Locate braking resistors so that damage cannot result. Use cable having insulation capable

of withstanding the high temperatures.

Safety

Information

information

Product

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

3.7 Terminal torque settings

Table 3-2 Torque settings

Terminals Torque setting*

Power terminals 1.0 N m (12.1 lb in)

Control terminals 0.2 N m (1.7 lb in)

Status relay terminals 0.5 N m (4.5 lb in)

Ground terminals 4 N m (35 lb in)

Small ground terminal screws 2 N m (17.7 lb in)

*Torque tolerance = 10 %

Table 3-3 Plug-in terminal block maximum cable sizes

Model size Terminal block description Max cable size

All 11 way control connectors

All 2 way relay connector

1.5 mm

2.5 mm

2

(16 AWG)

2

(12 AWG)

3.8 Routine maintenance

The drive should be installed in a cool, clean, well ventilated location.

Contact of moisture and dust with the drive should be prevented.

Regular checks of the following should be carried out to ensure drive /

installation reliability are maximized:

Environment

Ambient

temperature

Dust

Moisture

Enclosure

Enclosure

door filters

Electrical

Screw

connections

Crimp

terminals

Cables Check all cables for signs of damage

Ensure the enclosure temperature remains at or below

maximum specified

Ensure the drive remains dust free – check that the

heatsink and drive fan are not gathering dust. The

lifetime of the fan is reduced in dusty environments.

Ensure the drive enclosure shows no signs of

condensation

Ensure filters are not blocked and that air is free to flow

Ensure all screw terminals remain tight

Ensure all crimp terminals remains tight – check for any

discoloration which could indicate overheating

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

20 Digitax ST User Guide

Issue: 5

Safety

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

4 Electrical installation

Many cable management features have been incorporated into the

product and accessories, this chapter shows how to optimize them. Key

features include:

• Safe Torque Off function

• Internal EMC filter

• EMC compliance with shielding / grounding accessories

• Product rating, fusing and cabling information

• Brake resistor details (selection / ratings)

Electric shock risk

The voltages present in the following locations can cause

severe electric shock and may be lethal:

• AC supply cables and connections

• DC and brake cables, and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single

insulated and must not be touched.

Isolation device

The AC supply must be disconnected from the drive using

an approved isolation device before any cover is removed

from the drive or before any servicing work is performed.

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

STOP function

The STOP function does not remove dangerous voltages

from the drive, the motor or any external option units.

Safe Torque Off function

The Safe Torque Off function does not remove dangerous

voltages from the drive, the motor or any external option

units.

Stored charge

The drive contains capacitors that remain charged to a

potentially lethal voltage after the AC supply has been

disconnected. If the drive has been energized, the AC

supply must be isolated at least ten minutes before work

may continue.

Normally, the capacitors are discharged by an internal

resistor. Under certain, unusual fault conditions, it is possible

that the capacitors may fail to discharge, or be prevented

from being discharged by a voltage applied to the output

terminals. If the drive has failed in a manner that causes the

display to go blank immediately, it is possible the capacitors

will not be discharged. In this case, consult Emerson

Industrial Automation or their authorized distributor.

Equipment supplied by plug and socket

Special attention must be given if the drive is installed in

equipment which is connected to the AC supply by a plug

and socket. The AC supply terminals of the drive are

connected to the internal capacitors through rectifier diodes

which are not intended to give safety isolation. If the plug

terminals can be touched when the plug is disconnected

from the socket, a means of automatically isolating the plug

from the drive must be used (e.g. a latching relay).

Permanent magnet motors

Permanent magnet motors generate electrical power if they

are rotated, even when the supply to the drive is

disconnected. If that happens then the drive will become

energized through its motor terminals.

If the motor load is capable of rotating the motor when the

supply is disconnected, then the motor must be isolated from

the drive before gaining access to any live parts.

Digitax ST User Guide 21

Issue: 5

Safety

L1*L2

*

L2L1L3/N

UVW

Optional EMC

filter

Optional

line reactor

Fuses

L3

*

Mains

supply

Supply

ground

AC

connections

_

+

DC

DC

High current

-DC connections

+

_

Low voltage

DC (48V)

DST12XX = 200 to 240V 10%

DST14XX = 380 to 480V 10%

±

±

Connectors specification:

Maximum size of power cable

= 4.0mm (10AWG)

Torque setting = 1 N m

2

PE

It is essential that the braking

resistor be protected against

overload caused by a failure

of the brake control. Unless

the resistor has in-built

protection, a circuit like those

shown in Figure 4-1 should

be used, where the thermal

protection device

disconnects the AC supply to

the drive. Do not use AC

relay contacts directly in

series with the braking

resistor circuit, because it

carries DC.

WARNING

Terminals Torque setting

Power terminals

1.0 N m

(12.1 lb in)

Control terminals

0.2 N m

(1.7 lb in)

Status relay

terminals

0.5 N m

(4.5 lb in)

Ground terminal

screws

4 N m

(35 lb in)

Small ground

terminal screws

2 Nm

(17.7 Ib in)

* *Torque tolerance = 10%

NOTE

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

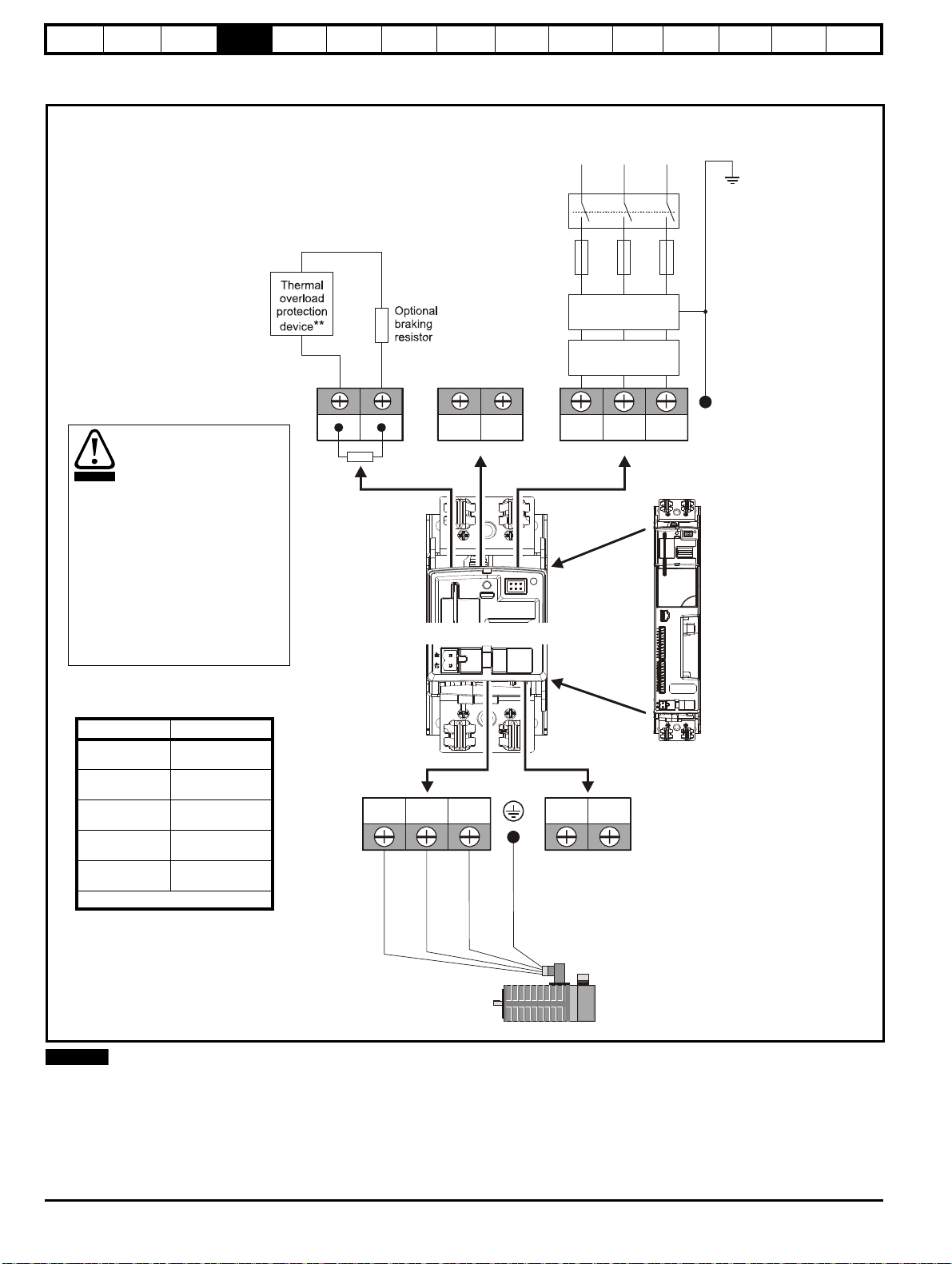

4.1 Power terminal connections

Figure 4-1 Power terminal connections

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

* When using a 200 V drive on a single phase supply, the live and neutral conductors can be connected to any of the AC connections on the drive.

** This is not required if the optional internal braking resistor is used.

22 Digitax ST User Guide

Issue: 5

Safety

WARNING

WARNING

Supply

ground

Motor

ground

WARNING

L

Y

100

----------

V

3

-------

×

1

2π f I

------------

×=

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

4.2 Ground connections

Electrochemical corrosion of grounding terminals

Ensure that grounding terminals are protected against

corrosion i.e. as could be caused by condensation.

The drive must be connected to the system ground of the AC supply. The

ground wiring must conform to local regulations and codes of practice.

The supply and motor ground connections are made using the M6

threaded hole in the metal back plate of the drive located at the top and

bottom of the drive. See Figure 4-2 for details.

The ground loop impedance must conform to the

requirements of local safety regulations.

The drive must be grounded by a connection capable of

carrying the prospective fault current until the protective

device (fuse, etc.) disconnects the AC supply.

The ground connections must be inspected and tested at

appropriate intervals.

Figure 4-2 Ground connection

4.3 AC supply requirements

Table 4-1 Supply requirements

Model Voltage

DST120X 200 V to 240 V ±10 % single phase 48 Hz to 65 Hz

DST120X 200 V to 240 V ±10 % three phase* 48 Hz to 65 Hz

DST140X 380 V to 480 V ±10 % three phase* 48 Hz to 65 Hz

*Maximum supply in-balance: 2 % negative phase sequence (equivalent

to 3 % voltage in-balance between phases).

For UL compliance only, the maximum supply symmetrical fault current

must be limited to 100 kA.

4.3.1 Supply types

All drives are suitable for use on any supply type i.e TN-S, TN-C-S, TT

and IT.

• Supplies with voltage up to 600 V may have grounding at any

potential, i.e. neutral, centre or corner (“grounded delta”)

• Supplies with voltage above 600 V may not have corner grounding

Drives are suitable for use on supplies of installation category III and

lower, according to IEC60664-1. This means they may be connected

permanently to the supply at its origin in a building, but for outdoor

installation additional over-voltage suppression (transient voltage surge

suppression) must be provided to reduce category IV to category III.

Frequency

range

Operation with IT (ungrounded) supplies:

Special attention is required when using internal or external

EMC filters with ungrounded supplies, because in the event

of a ground (earth) fault in the motor circuit the drive may not

trip and the filter could be over-stressed. In this case, either

the filter must not be used (removed) or additional

independent motor ground fault protection must be provided.

Refer to Table 4-2.

For instructions on removal, refer to Figure 4-4 Removing

the internal EMC filter and line to ground varistors on

page 28. For details of ground fault protection contact the

supplier of the drive.

A ground fault in the supply has no effect in any case. If the motor must

continue to run with a ground fault in its own circuit then an input

isolating transformer must be provided and if an EMC filter is required it

must be located in the primary circuit.

Unusual hazards can occur on ungrounded supplies with more than one

source, for example on ships. Contact the supplier of the drive for more

information.

Table 4-2 Behavior of the drive in the event of a motor circuit

ground (earth) fault with an IT supply

Drive size Internal filter only External filter (with internal)

0 (200 V)

May not trip – precautions

required

Drive trips on fault

0 (400 V) Drive trips on fault Drive trips on fault

4.3.2 Line reactors

Input line reactors reduce the risk of damage to the drive resulting from

poor phase balance or severe disturbances on the supply network.

Where line reactors are to be used, reactance values of approximately 2

% are recommended. Higher values may be used if necessary, but may

result in a loss of drive output (reduced torque at high speed) because of

the voltage drop.

For all drive ratings, 2 % line reactors permit drives to be used with a

supply imbalance of up to 3.5 % negative phase sequence (equivalent to

5 % voltage imbalance between phases).

Severe disturbances may be caused by the following factors, for

example:

• Power factor correction equipment connected close to the drive

• Large DC drives having no or inadequate line reactors connected to

the supply

• Direct-on-line started motor(s) connected to the supply such that

when any of these motors are started, the voltage dip exceeds 20 %

Such disturbances may cause excessive peak currents to flow in the

input power circuit of the drive. This may cause nuisance tripping, or in

extreme cases, failure of the drive.

Drives of low power rating may also be susceptible to disturbance when

connected to supplies with a high rated capacity.

When required, each drive must have its own reactor(s). Three individual

reactors or a single three-phase reactor should be used.

Reactor current ratings

Continuous current:

Not less than the continuous input current rating of the drive.

Repetitive peak current:

Not less than three times the continuous input current rating of the drive.

4.3.3 Input inductor calculation

To calculate the inductance required (at Y%), use the following equation:

Where:

I = drive rated input current (A)

L = inductance (H)

f = supply frequency (Hz)

V = voltage between lines

Digitax ST User Guide 23

Issue: 5

Safety

NOTE

WARNING

Information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

EtherCAT

interface

SMARTCARD

Operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL listing

information

4.4 DC bus design

4.4.1 DC bus design

Parallel connections

The power limit of the rectifier must be adhered to for all combinations of

drives in parallel. In addition to this If the total rated bus power required

exceeds the capability of 1 x Digitax ST rectifier then two or more Digitax

ST's can be connected with the AC & DC in parallel. If the AC supply is

connected to more than one drive in a parallel DC bus application,

balancing of the current in the input stage of each drive must be

considered.

Using DC bus chokes makes the current in the rectifier diodes of each

drive the same, so providing a solution to sharing.

There are many possible combinations for paralleling drives through the

DC bus connections. Table 4-3 gives details of the internal capacitance

for each drive and the additional capacitance which can be powered

from the drive. The capacitance must incorporate its own soft-start

circuit. All Digitax ST drives incorporate this feature.

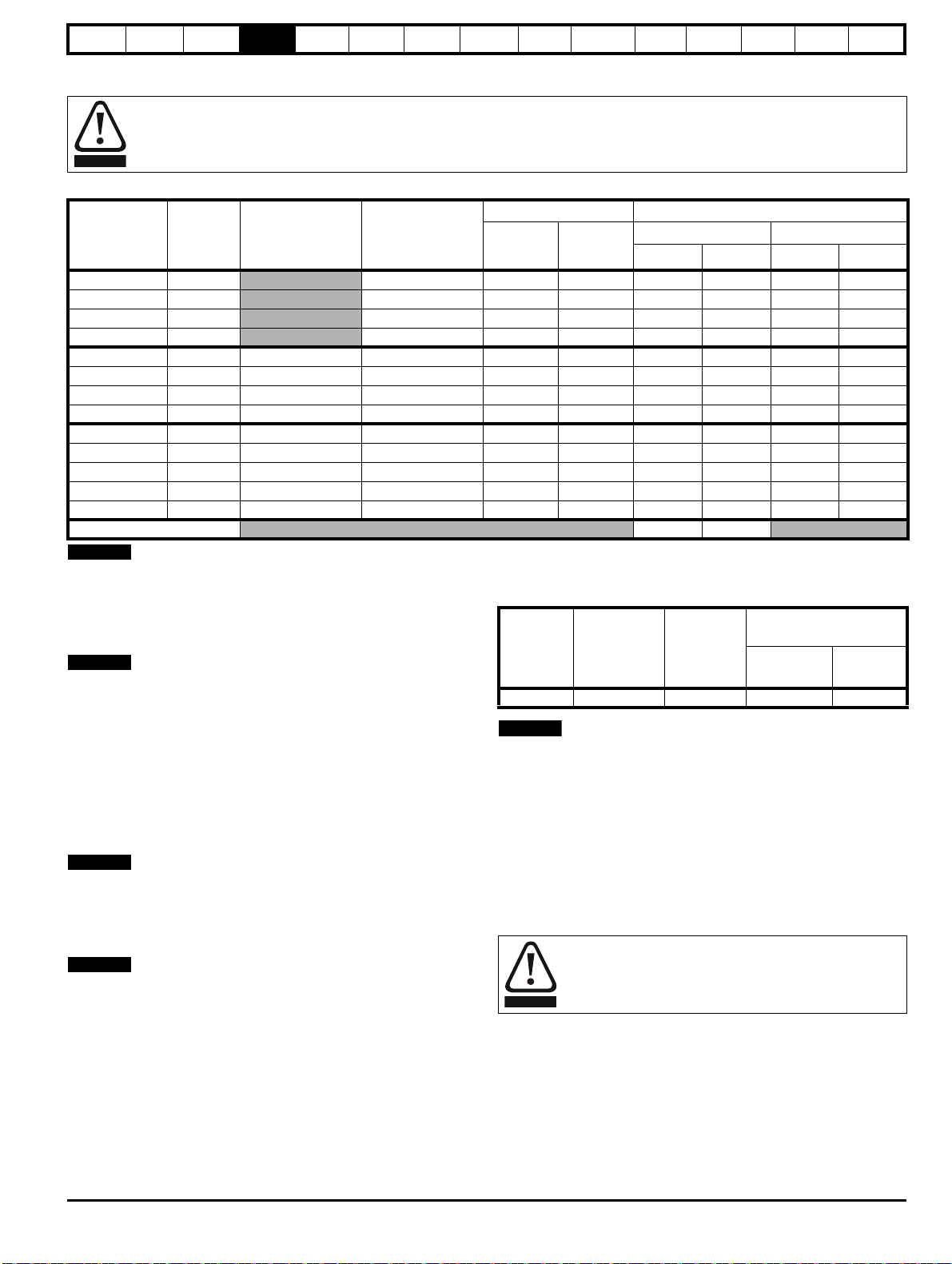

Table 4-3 DC bus data

Internal DC bus

Drive

capacitance

(μF)

DST1201 440 1760

DST1202 880 1320

DST1203 880 1320

DST1204 1320 880

DST1401 220 660