EOS EmoStyle Di, EmoStyle Hi Installation Manual

INNO VATIVE S A U NA TECH N O L OGY

EOS EmoStyle Di | EmoStyle Hi

sauna control unit

Made in Germany

EN

IPx4

Installation and operation manual

Firmware R3.63

Print no. 29344816 en / 06.21

Technical changes reserved

English

Contents

Preface and general information about sauna bathing ............................................................................ 4

General safety precautions .............................................................................................................................. 5-6

Scope of delivery .................................................................................................................................................... 7

Accessories ................................................................................................................................................................ 7

Technical data ....................................................................................................................................................... 8-9

Intended use ............................................................................................................................................................. 9

Installation ........................................................................................................................................................ 10-17

Main electronic unit ............................................................................................................................... 10-11

Control panel - location and cable connection ..................................................................................12

Control panel - ush-mounted installation ...................................................................................13-15

Installation of the temperatur sensor .............................................................................................. 16-17

Electrical connection..................................................................................................................................... 18-22

Sauna heater connection ............................................................................................................................18

Sauna lamp connection ..............................................................................................................................19

Connection of the power extension unit ..............................................................................................19

Installation diagram and terminal layout ...................................................................................... 20-21

Temperature sensor ......................................................................................................................................22

Humidity sensor .............................................................................................................................................22

2nd temperature sensor (bench sensor) ...............................................................................................22

Overview - connection scheme (Model D/Di and H/Hi) .........................................................................23

Vaporizer connection ...........................................................................................................................................24

Humidity sensor installation .............................................................................................................................25

Installation of the optional bench sensor.....................................................................................................26

Setup (commissioning / rst switching) ................................................................................................ 27-28

Operation .......................................................................................................................................................... 29-40

Overview ...........................................................................................................................................................29

Symbol description (main navigation menu) ......................................................................................30

Graphic user interface .................................................................................................................................31

Operation and program settings ...................................................................................................... 32-36

Symbol description (extended settings) ...............................................................................................37

Extended settings ................................................................................................................................... 38-40

2

EN

Manual setting of the lamp ...............................................................................................................................41

Service ................................................................................................................................................................ 42-49

Service- and Setup ........................................................................................................................................ 42

Symbol description .......................................................................................................................................43

Settings ...................................................................................................................................................... 44-49

Troubleshooting (error messages) ..................................................................................................................50

The ”switch-o“ rocker switch .......................................................................................................................... 51

Recycling ..................................................................................................................................................................52

Service Address ......................................................................................................................................................52

General Terms and Conditions of Service .....................................................................................................53

EN

3

Preface

Dear customer,

you have purchased a high-quality electronic

device with which you will enjoy your sauna

& steam bath for many years to come. This

device was designed and inspected according

to the current European safety standards and

manufactured at the factory in accordance with

the quality management standard DIN EN ISO

9001:2015.

This detailed installation and operation manual

has been prepared for your information. Pay

particular attention to the important notes and

the information on electrical connection.

We wish you a restorative and eventful wellness

experience.

General information about

sauna bathing

Please note that an optimal interaction between sauna cabin, sauna heater and sauna

control unit is mandatory for a pleasant sauna

climate in your cabin. With this high-quality

sauna control unit you can “operate“ your sauna system, and thanks to the many individual

programming options, surely you will quickly

nd the setting which suits you best.

Perception in the sauna is very subjective,

therefore, it really requires your own perception or that of your family to nd the most suitable settings.

The control units are supplied with the preset

typical climate values for a classic Finnish sauna

or for models with humidity control, as well as

for a sauna with humidity operation.

The following operating instructions describe

how to pre-select “your“ climate in the cabin.

Read these instructions carefully, so that you

quickly and easily nd your way though the

programming process. Please note the variation in temperatures in the cabin while sauna

bathing. The hottest area is directly below the

cabin ceiling, whereas there is a steady temperature gradient towards the oor of the cabin.

Inversely, the relative humidity is lowest directly below the cabin ceiling and the highest by

the cabin oor.

For safety reasons the temperature sensor with

the overheat safety shutdown is located on the

cabin ceiling above the heater, as this is usually

the hottest area in the cabin.

Thus, there will always be temperature variations between the temperature sensor of the

control unit and the thermometer in the cabin.

For example, when pre-setting the cabin temperature to 100 °C, the thermometer inside the

cabin may show 85 °C - 90 °C. This is in accordance with the typical climate inside the cabin.

Only use sauna-suitable (up to 140 °C temperature-resistant) cabin lights. Always pay attention to hygiene. Always use hand- or bathing

towels to avoid getting perspiration on the

wood.

For control units with vaporizer connection

(optional), we recommend to reheat or dry the

cabin after each humid operation, in order to

protect your cabin from possible damage due

to the humidity mode. In addition, in poorly

ventilated rooms, a ventilation fan can be used

to remove the used moist air.

To avoid drafts, you should avoid using any

ventilation system while sauna bathing. It

should only be used if recommended by the

cabin manufacturer.

4

EN

General safety precautions

• This device may be used by children (age

8 and above) and by persons with reduced

physical, sensory, or mental disabilities, or

inadequate experience and knowledge,

if they are supervised or if they have received adequate instructions in how to

use the device safely and understand the

associated risks.

• Children must be supervised to ensure

they do not play with the unit.

• Children and persons who have not re-

ceived proper instruction must not clean

or service the system.

• ATTENTION: It is forbidden to install

the control box in a closed switch cabinet

or behind a wooden panelling!

• The electrical installation may only be

done by a qualied electrical technician.

• You must comply with the regulations of

your power supply company and applicable VDE regulations (DIN VDE 0100).

• WARNING: Never attempt repairs or

installations yourself, as this could result

in serious injury or death. Only a qualied

technician may remove the housing cover.

• Please note the dimensions in the instal-

lation instructions, especially when installing the temperature sensor. The temperature above the heater is critical for the

temperature setting. The temperature can

be held within operating parameters and

a minimal deviation at the bench level of

the sauna cabin can be achieved only if the

device is installed correctly.

• The device may only be used as intended

as a control unit for sauna heaters up to 9

kW (up to 36 kW when combined with a

power extension unit).

• Completely disconnect the control unit

from the electrical circuit, i.e. ip all circuit

breakers or the main circuit breaker during

each installation or repair.

• Please note the safety and installation

information from the sauna heater manufacturer.

• Make sure to observe the specications

and instructions of the sauna cabin manufacturer.

• ATTENTION: For control units with

remote control functions*, a protection

against switching on if the heater is covered is required. (use the suitable cover

protection rail or another safety device).

*Remote control = setting up, controlling or adjusting a unit by a command that can be given out of

view of the unit by means of transfer media such

as telecommunication, audio technology or bus

systems, this also includes weekly timers. (from EN

60335-1)

EN

5

When designing the sauna cabin, en-

sure that the external exposed glass surfaces

may only reach a maximum temperature of

76 °C. If necessary, protective features need

to be tted.

Inspect the sauna cabin before each

use! In particular, ensure that no objects

have been stored on the sauna heater or the

IR-radiator, if applicable. Risk of re!

Attention!

Dear customer,

according to the valid regulations, the

electrical connection of the sauna heater

and the control box has to be carried out

through the specialist of an authorized

electric shop

We would like to draw your attention that

in case of a warranty claim, you are kindly

requested to present a copy of the invoice

of the executive electric shop.

Attention!

Only the original spare parts may be used.

Any modication of the cables included in

the delivery can lead to malfunctions and

is not permitted.

Any unauthorized technical alteration

makes the product warranty void.

6

EN7EN

Scope of delivery

Check the device for completeness upon receipt. The delivery includes:

1. Main electronic unit (with two-part front cover)

2. Control panel with colour display

3. Voltage regulator

4. Housing base for ush-mounted installation of the control panel

5. De-installation tool (for control panel)

6. Temperature sensor: a) housing, b) sensor board, c) overheat protection fuse, d) 2 mounting

screws 4 x 40 mm, e) connection cable 5 m with RJ10 plug, f) 2-core white cable for overheating protection fuse 5 m

7. Connection cable (control panel - main block) with RJ14 / RJ10 plugs

8. 1 spare overheating protection fuse

9. Plastic bag with 3 mounting screws 4 x 25 mm (for main electronic unit)

10. 8 rubber cable glands

11. 1 installation and operation manual, 1 operation manual (for end users)

3

1

2

4

6

a

f

d

c

b

e

Accessories (optionally available):

nd

2

sensor ..................................Item no. 94.5725

Humidity sensor ........................Item no. 94.5726 (only H-model)

Coloured light control module ...Item no. 94.5996, 94.6007

Sound module...........................Item no. 94.5920, 94.5921

Remote start modul .................. Item no. 94.5782

SBM-WCI-01 web app module ..Item no. 94.5987

7

9

10

5

8

11

KNX-/Modbus-module ..............Item no. 94.7078 / 94.7077

SBM-HOT ...................................Item no. 94.6800

SBM-ECO ...................................Item no. 94.6980

EOSafe. ......................................Item no. 94.7149-7153

Technical data

Voltage (power supply): 400 V 3 N AC 50 Hz

Switching capacity: max. 9 kW resistive load, may be extended with a power

extension unit (LSG)

Fuse 3 x 16 A

Heating time limit: 6 h / 12 h / 18 h / unlimited

Housing: plastic, shatter-resistant

Display: TTFT colour display 55 x 74 mm (3,5“ size)

Operation: 5 capacitive buttons on the control panel

Protection type: IPx4 in accordance with EN 60529, splashproof

Temperature control range: 30° - 115°C (dry sauna mode)

30° - 70°C (humid sauna mode - only H series models)

Humidity control: proportional to time or optionally as per rel. air humidity

(%) with

an optional humidity sensor.

Sensor system: Digital sensor with oveheating protection fuse (STB) 139°C

Control characteristic: Digital two-point control

Connection for fan: min. 5 W, max.150 W (only fans without starting capacitor)

Only use fans suitable for phase control!

Connection for light: • min. 5 W (20 mA)

• resistive loads - max. 100 W,

• dimmable energy saving lamps - max. 35 W

• Lamps at conventional transformers - max. 60 VA.

Attention: only dimmable lamps may be used!

Fan and light output share a common 2AF fuse.

Volt-free output: contact’s resistive load carrying capacity:

Start time pre-selection: up to 24 h in advance

Switching automation: Week timer with 4 switching programs per day

Error display: Clear text error indication on the display

Outputs: 3 x RJ10 jacks for sensor connections

Output S1: maximal load 50 W / 50 VA, no capacitive loads allowed.

Terminal block area for power

supply and heater connection:

Terminal block area WM, 3, 4,

light, fan:

8

maximum current: 16 A

maximum voltage: 30 V DC / 250VAC

2 x RJ14 jacks for control panel and extension modules

1 x potential free contact (2 terminals)

0.5 – 2.5 mm² rigid or exible crimped wire, two cores with

the same cross section per terminal may be connected

0.34 – 2.5 mm² rigid or exible crimped wire. Please observe

the minimal cross section as per fuse protection of the line!

EN

Card reader: Micro-SD card reader in control panel

Ambient temperatures: -10°C bis +35°C

Storage temperatures: -20°C bis +60°C

Place of installation requirement: Intended for indoor installation only.

Sensors - may not be installed in corrosive or highly salty

environment.

Device - may not be installed in corrosive environment or in

an environment which may cause water condensation.

Dimensions main block: H 270 x W 300 x D 100 mm

Dimensions control panel: H 202 x W 142 x D 42 mm (ush-mounting)

recessed part 37 mm deep

Important note!

The control unit is not suitable for outdoor use!

It may only be used inside buildings and may not be exposed to environmental conditions

such as extreme humidity or moisture with possible condensate formation or corrosive

substances in the ambient air and other weathering. Excessive exposure to cold and intense solar radiation should be avoided as well. If there is an increased risk of mechanical

damage, the control unit must be protected accordingly.

Intended use

This sauna control unit is exclusively intended for the control of the sauna heater in a sauna cabin. Any other use over and above the intended purpose is not considered as appropriate use!

Compliance of the standard operation, maintenance and repair conditions is also an element of

appropriate use.

The manufacturer cannot be held liable for deviating, unauthorized alterations and any resulting

damages: the initiator of these changes bears the full risk.

EN

9

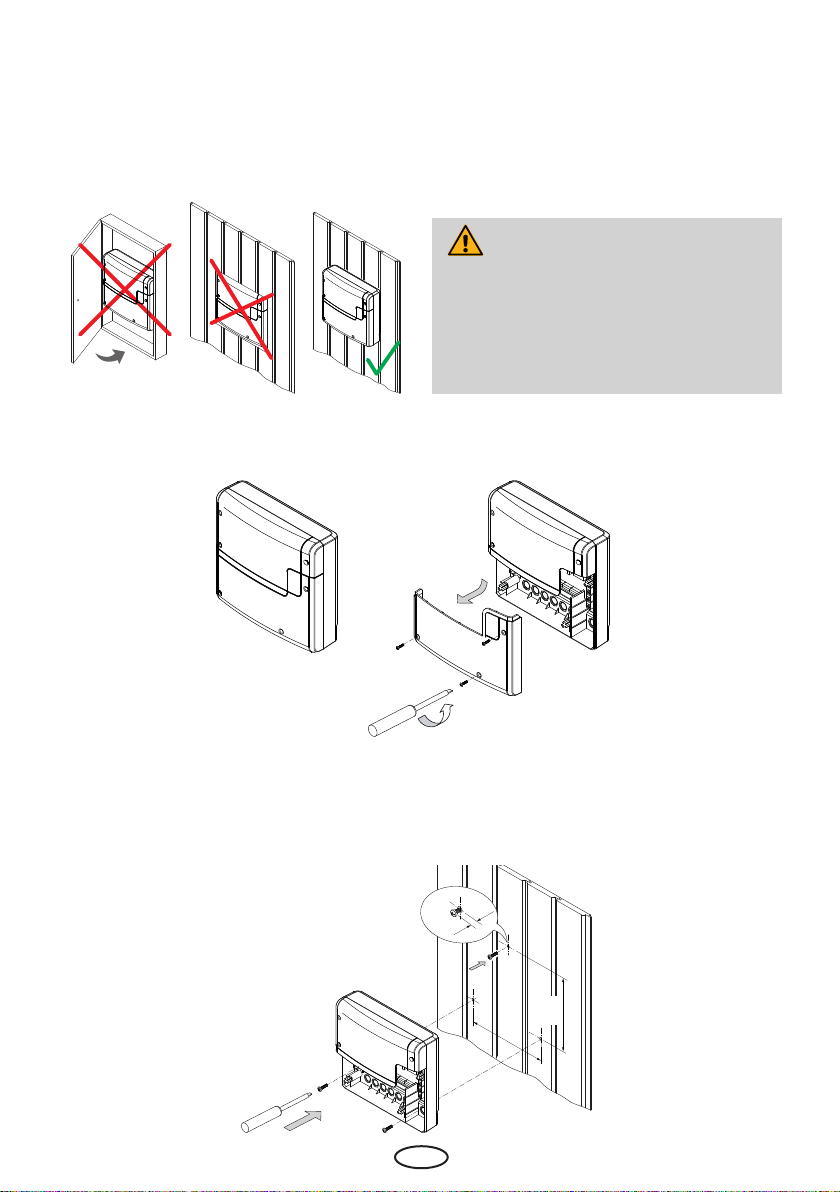

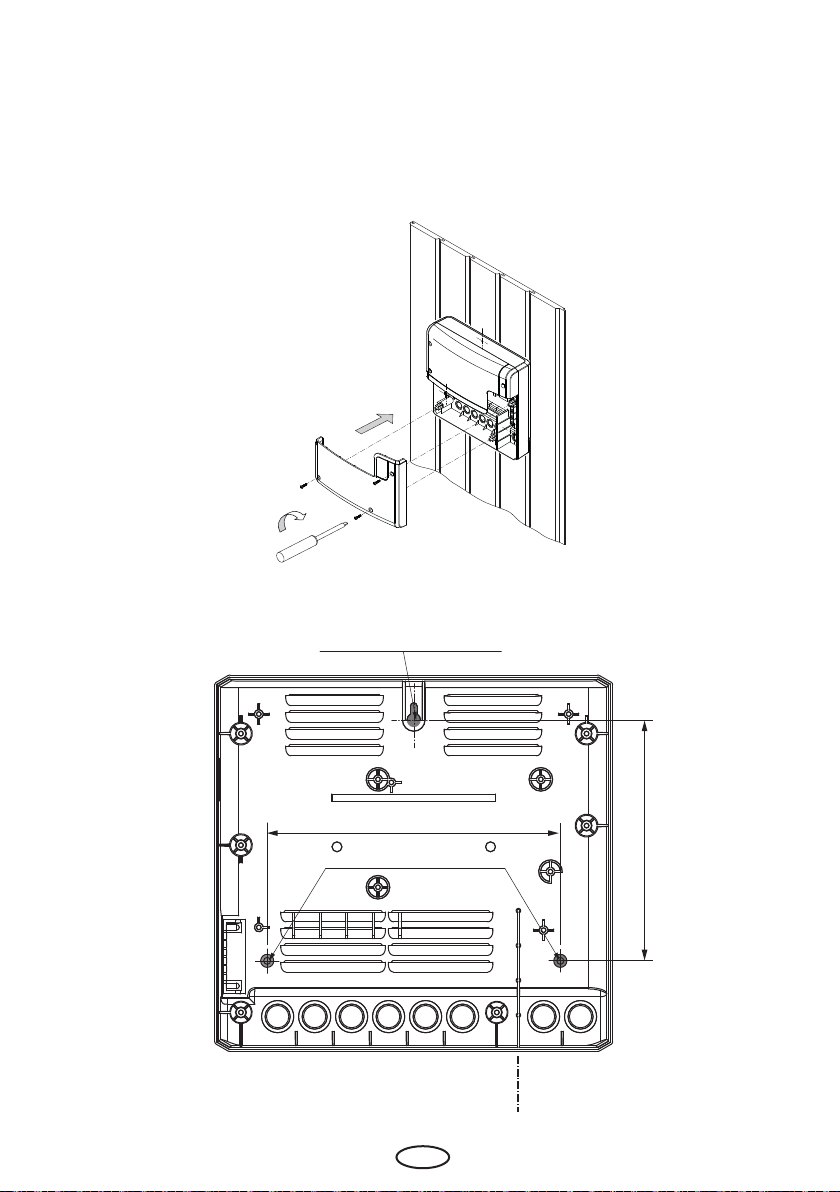

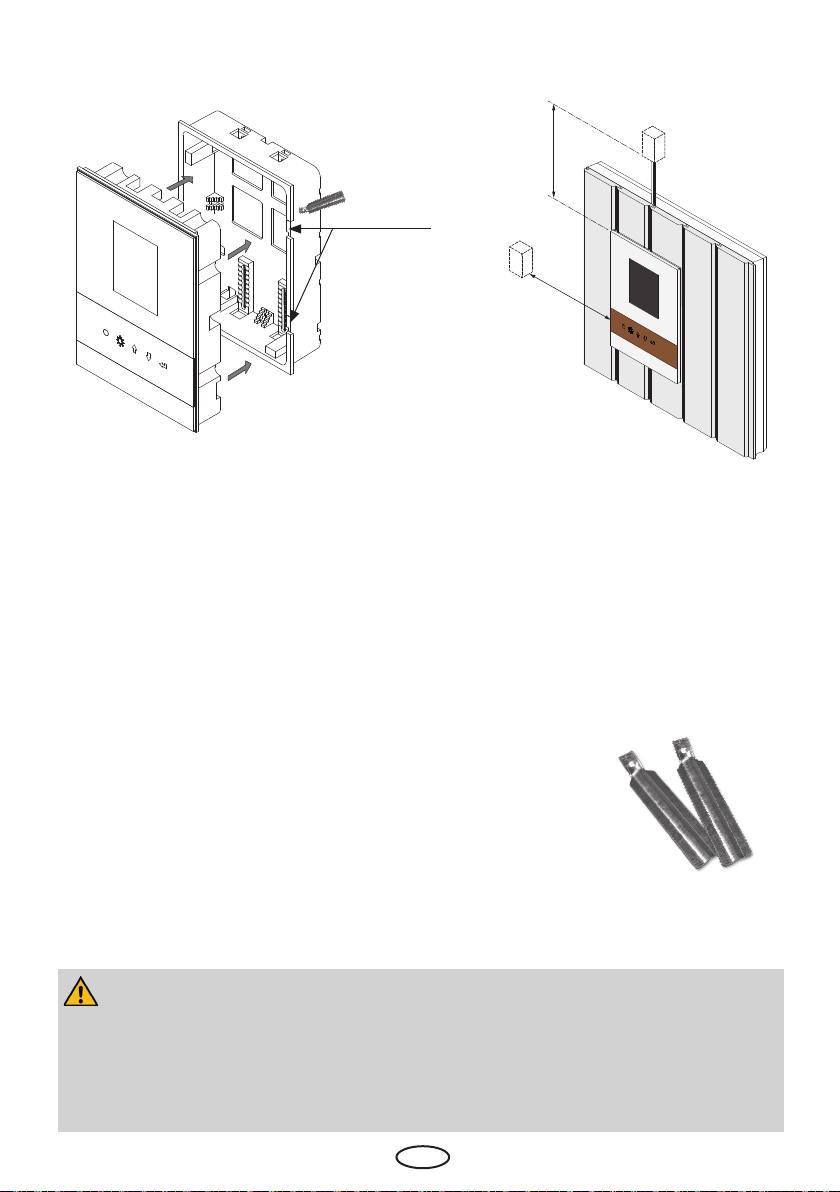

Installation of the main electronic unit

1.

2.

210

180

3

The main electronic unit (relay box) may be installed only outside the cabin. The recommended

places of installation are the outer cabin wall or the engineering room (plant room). If empty ducts

for connection cables are already available, then they usually predetermine the installation position. The installation shall be carried out as follows:

Attention: The relay box may not

be installed in a closed switch cabinet

or behind a wooden panelling!

Risk of overheating! Fire hazard!

1. Remove the lower cover from the relay box. Unscrew the 3 xation screws, then slightly pull

the lower housing cover down and take it o. See g. 1 for details.

Fig. 1

The holes for the provided 4 x 25 mm screws are to be installed according to the dimensions

shown in Fig. 2.

2. Use the upper central screw to hang the relay box. Make sure that this screw stands out approx. 3 mm (detail in Fig. 2).

Fig. 2

10

EN

180 mm

210 mm

3. Hang the housing on the upper central screw in the upper central mounting hole.

Insert the supplied rubber cable glands into the openings of the bottom of the housing (from

below or from behind, as desired) and then guide the connection cables through these openings.

Screw the lower part of the housing rmly to the cabin wall in the two lower mounting holes

(Fig. 3).

Fig. 3

upper central mounting hole

Lower mounting holes

Knock-out openinigs for connection cables

for heater, vaporizer, fan, lamp.

Knock-out openings

for sensor cables

Fig. 4

EN

11

189 mm

128 mm

max.

1500 mm

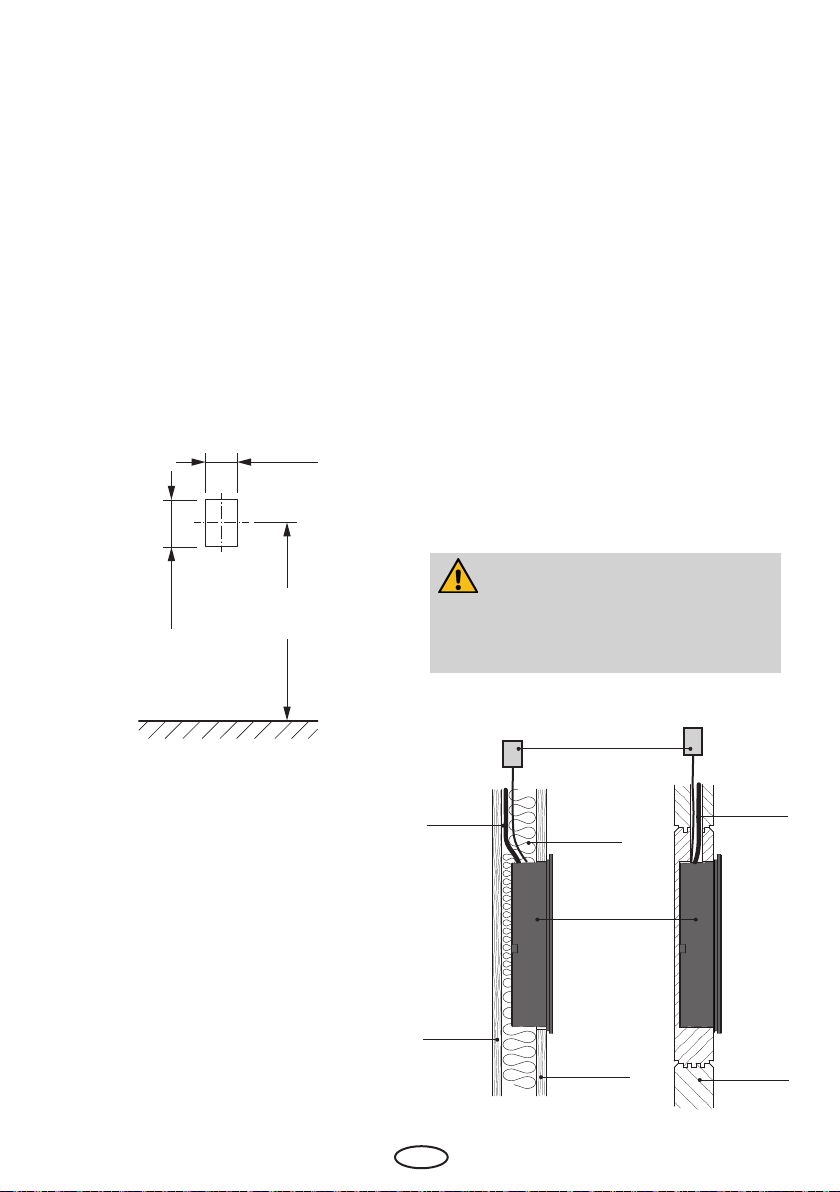

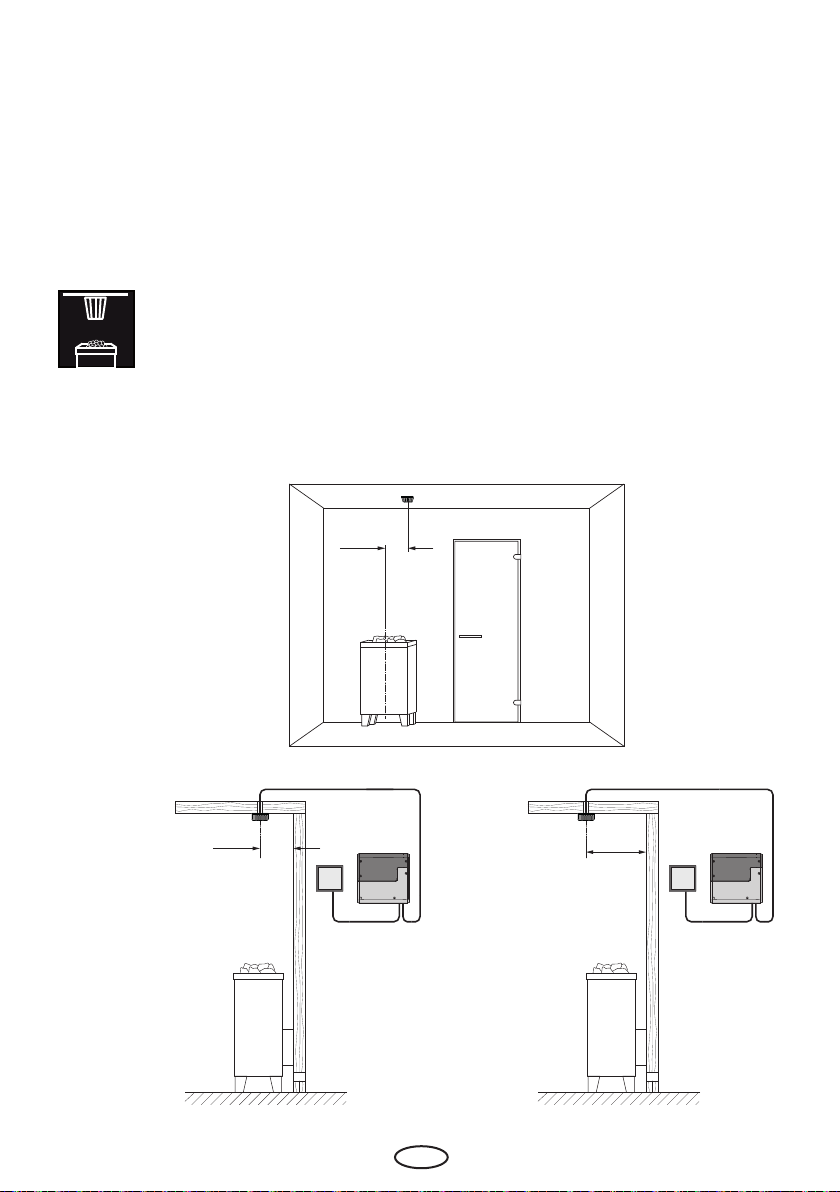

Control panel

Location

The control panel may be mounted inside the

sauna cabin on the sauna wall. If ductwork is already provided for electrical installations then

the position of the control panel is predetermined by that.

The control panel is designed for ush-mounted installation into the sauna wall. The installation shall be carried out as follows.

First of all determine the location.

Make an installation cut-out in the wall with the

size 189 mm height x 128 mm depth (g. 5).

Cable connection

Lay the connection cable from the relay box to

the control panel.

The connection cable may be laid only between the outer sauna wall and insulation layer

to prevent overheating (g. 6).

The insulation should ensure that the temperature at the outer sauna wall may not exceed

65 °C.

Make sure that the cable with the smaller plug

(RJ10) is routed to the control panel.

Use the supplied 5 m connection cable with

RJ10 plug (control panel side) and RJ14 plug

(relay box side).

If necessary, this connection line may be extended to approx. 100 m length. The extension

should occur on the relay box side. For this purpose, a coupling (RJ14 / RJ14) and an extension

cable with RJ14 connector are required (available from specialist dealers).

Important notice:

Maximum cable length between control

panel and main unit is 100 m.

12

Fig. 5

Connection cable

Outer sauna

wall

EN

Voltage regulator

Insulation

Innercontrol panel

Inner sauna

wall

Connection cable

Installation

on wooden

planks

Fig. 6

1,5 m

0,7 m

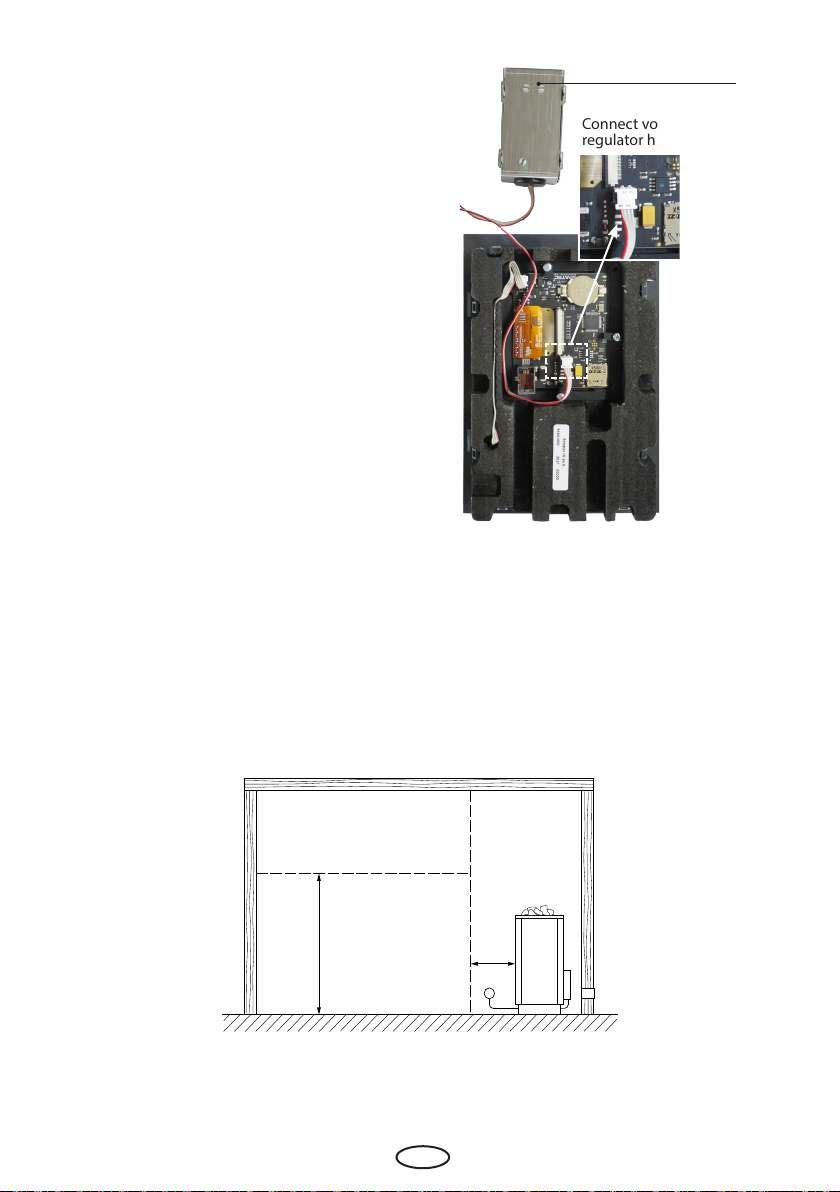

Voltage regulator

Voltage regulator

The control panel is equipped with an external

voltage regulator. This component is located

in a small separate metal housing and is con-

Connect voltage

regulator here

nected to the control panel by cable.

The voltage regulator may be placed e.g. on

the sauna roof. Guide the connection cable of

the voltage regulator to the control panel and

insert the plug into the corresponding small

socket on the circuit board before inserting the

control panel into the lower part (see g. 7).

The voltage regulator must not be exposed to

elevated temperatures. Therefore, the installation in the sauna wall is not permitted. The voltage regulator may be placed e.g. on the sauna

roof.

Control panel interior

Notes on mounting the control panel in sauna cabins

Can be used in sauna cabins in areas up to 110 °C (area 2).

Never directly above or in the surrounding area of the sauna heater (area 1),

or in the direct radiation range of short-wave infrared radiators.

.

Fig. 7

Area 3

Area 1

Area 2

ATTENTION!

When installing the control panel, ensure the tightness in the inside of the cabin. Excessively high temperatu-

res inside the control panel can lead to errors with the electronic components.

EN

13

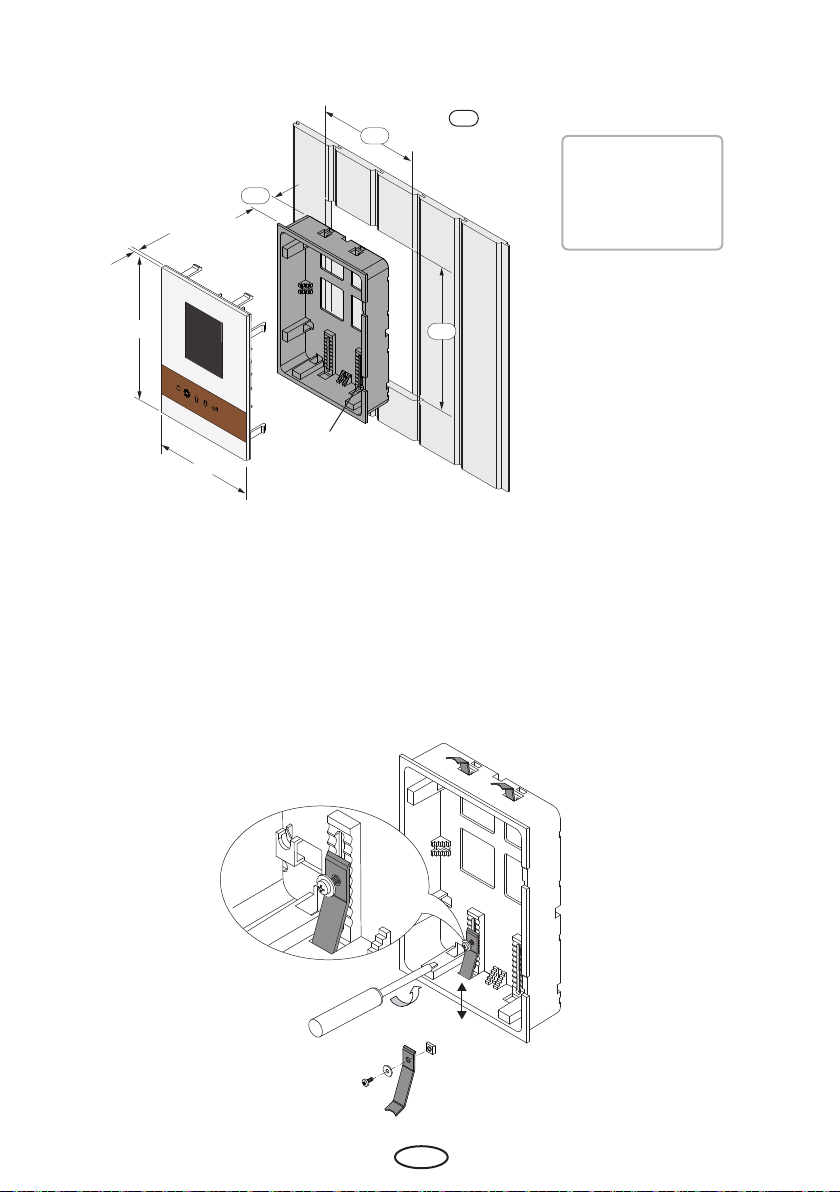

Flush-mounted installation (wall-mounting)

128

Wall aperture:

37

3

alle Maße in mm

Hight: 189 mm

Width: 128 mm

Depth: min. 37 mm

Notice:

Please pay attention to the

correct orientation of the

bottom housing. The con-

202

37

189

nection cable duct must be

at the bottom side (see g.

8).

Cable duct position

142

Fig. 8

Änderungen vorbehalten

Installation of the housing base

First install the housing base (see g. 8).

1. Loosen 4 screws on the fastening brackets

2. Pull the connection cable and the voltage regulator cable through the cable duct in the housing base.

3. Insert the housing base into the wall opening.

4. Adjust the brackets by moving them on the fastening brackets of the housing part to the designated wall panelling thickness.

5. Clamp the brackets (by tightening the screw clockwise)

= Dimensions must be strictly adhered to

Minimum wall depth:

37 mm

14

4x

4x

4x

4x

4x

Fig. 9

EN

Installation of the housing upper part (control panel with display)

Voltage regulator

ca. 3 m

use tool

here

ca. 3 m

The voltage regulator must be mounted

within a radius of approx. 3 m (cable length)

away from the control

panel.

Bauteil

Fig. 10

Fig. 11

Place the control panel directly in front of the housing base and pay attention to the correct orientation. Plug in the connection cable with the RJ10 plug to the control panel. Now press the control

panel carefully into the housing base until the fastening tabs lock securely. Make sure the control

panel sits reliably in the base part.

Notice: When you lay the connection cable do not pull it too tight, allow some extra length around

the base, so that later you can easily take the control panel out of the base while still having it

connected.

How to remove the display panel

In order to remove the display panel, use the included removal tool or a

similar suitable tool like a at headed screwdriver.

Insert the two tools into the grooves on the side edge of the control panel (between control panel and wall housing) and lever the control panel

from the wall surface, then pull it out of the wall housing. Make sure that

the connection cable can also be removed from the wall housing.

Remove the connection cable from the RJ-plug on the control panel. For

this purpose, carefully press on the small securing tab of the plug and pull it out of the connector.

Important note:

For the removal, use the tools exclusively for the provided grooves in the control panel.

Under no circumstances may the tools be used elsewhere! This can damage the glass of the

control panel. In this case, the warranty is void!

EN

15

20 cm

Connection of sensor cables

Do not lay sensor and power supply lines together, or lead them through the same duct. This can

lead to interferences in the electronics, such as “uttering” in the relays. Connect the cable shielding (if present) to ground in the control unit.

Please observe that the following dimensions relate to the values stipulated during the unit inspection acc. EN 60335-2-53. The heater sensor must always be installed at the point where the

highest temperatures are to be expected. Fig. 12-14 provide you an overview of the mounting

point of the sensor.

Installation of the temperature sensor

Make sure that there is no deviating mounting position of the sensor, specic to

the sauna heater (check the installation guide of the sauna heater).

1. Mount the heater sensor in cabins up to 2 x 2 m according to g. 13, in larger cabins according

to g. 14.

2. Drill a hole to lead the cable through, preferably through the middle of one of the wooden

planks.

16

< 2 x 2 m

19 cm

heater heater

sensor line

Sauna control

unit. Display

panel design

may vary.

Fig. 13 Fig. 14

EN

> 2 x 2 m

Fig. 12

sensor line

35 cm

Sauna control

unit. Display

panel design

may vary.

Loading...

Loading...