UTILITY SYSTEMS

Generator Condition Monitor (GCM-X)

Installation and Operation Manual

GA0353P02 Rev. B

Contents

Specifications....................................................................................................................................... 5

Application .......................................................................................................................................... 6

Principle of Operation .................................................................................................................... 6

System Description ............................................................................................................................. 7

System Electronics .......................................................................................................................... 7

Display Panel ................................................................................................................................. 7

Input/Output Board......................................................................................................................... 7

Installation........................................................................................................................................... 8

Mounting......................................................................................................................................... 8

System Design Considerations ........................................................................................................... 9

Transit Time Calculations................................................................................................................ 10

Sampling System Components ........................................................................................................ 11

Electrical Connections ...................................................................................................................... 12

Contacts ........................................................................................................................................ 12

Signals .......................................................................................................................................... 12

System Operation ............................................................................................................................. 13

GCM-A Initial Startup .................................................................................................................. 13

Typical Responses to GCM-A Warning & Alarm Indications ..................................................... 14

GCM-A Initialization ....................................................................................................................... 16

GCM-A Menu Displays .................................................................................................................... 17

Navigating the LCD Display ........................................................................................................ 17

LCD Display Menu — Two Modes of Operation ......................................................................... 17

Menu Profile ................................................................................................................................. 17

Menu Navigation Tutorial................................................................................................................ 18

Activating the Menu ...................................................................................................................... 18

Navigating the Menu in Scrolling Mode (GCM-A default) .......................................................... 18

Disabling Scrolling Mode............................................................................................................. 18

Navigating the Menu in Non-Scrolling Mode............................................................................... 18

Function (FN) Menu ..................................................................................................................... 19

Setup Menu ................................................................................................................................... 19

Test Menu ...................................................................................................................................... 20

View Menu .................................................................................................................................... 21

1

GA0383P02 Rev. C

Log Menu ...................................................................................................................................... 22

Procedures ......................................................................................................................................... 23

Draining the Humidifier ............................................................................................................... 23

Adjusting the Ambient Airflow...................................................................................................... 23

Adjusting the Generator Airflow .................................................................................................. 24

Adjusting the Cloud Chamber Airflow ......................................................................................... 25

Setting the Ambient Gain .............................................................................................................. 25

Setting the Ambient Warning Level...............................................................................................25

Setting the Ambient Alarm Level .................................................................................................. 25

Setting the Generator Gain .......................................................................................................... 26

Setting the Generator Warning Level ........................................................................................... 26

Setting the Generator Alarm Level ...............................................................................................26

Setting the Differential Warning Level ......................................................................................... 26

Setting the Differential Alarm Level ............................................................................................. 27

About the Faults Log .................................................................................................................... 27

About the Power Log .................................................................................................................... 28

Modes of Operation .......................................................................................................................... 29

Startup .......................................................................................................................................... 29

Startup Problems .......................................................................................................................... 29

Alternating Operation .................................................................................................................. 30

Ambient Only Operation ............................................................................................................... 30

Generator Only Operation ........................................................................................................... 31

Troubleshooting ................................................................................................................................ 32

Remote Access ................................................................................................................................... 34

Requirements ................................................................................................................................ 34

GCM-A Modem Installation ......................................................................................................... 34

Using a Custom Modem String.....................................................................................................34

Changing the Modem String ......................................................................................................... 35

Establishing a Direct Connection................................................................................................. 35

Establishing a Dialup Connection................................................................................................36

Viewing Output History ................................................................................................................ 36

Configuring the GCM-A for Historical Data Collection ............................................................. 36

Maintenance ...................................................................................................................................... 38

Periodic Maintenance................................................................................................................... 38

Daily ............................................................................................................................................. 38

Weekly ........................................................................................................................................... 38

Monthly ......................................................................................................................................... 38

Quarterly ...................................................................................................................................... 38

Annually ........................................................................................................................................ 38

GA0383P02 Rev. C

2

Figures

Figure 1 - System Overview .............................................................................................................................. 39

Figure 2 - GCM-A Outline ................................................................................................................................ 40

Figure 3 - GCM-A Mounting ............................................................................................................................ 41

Figure 4 - Customer Interface Wiring ............................................................................................................... 42

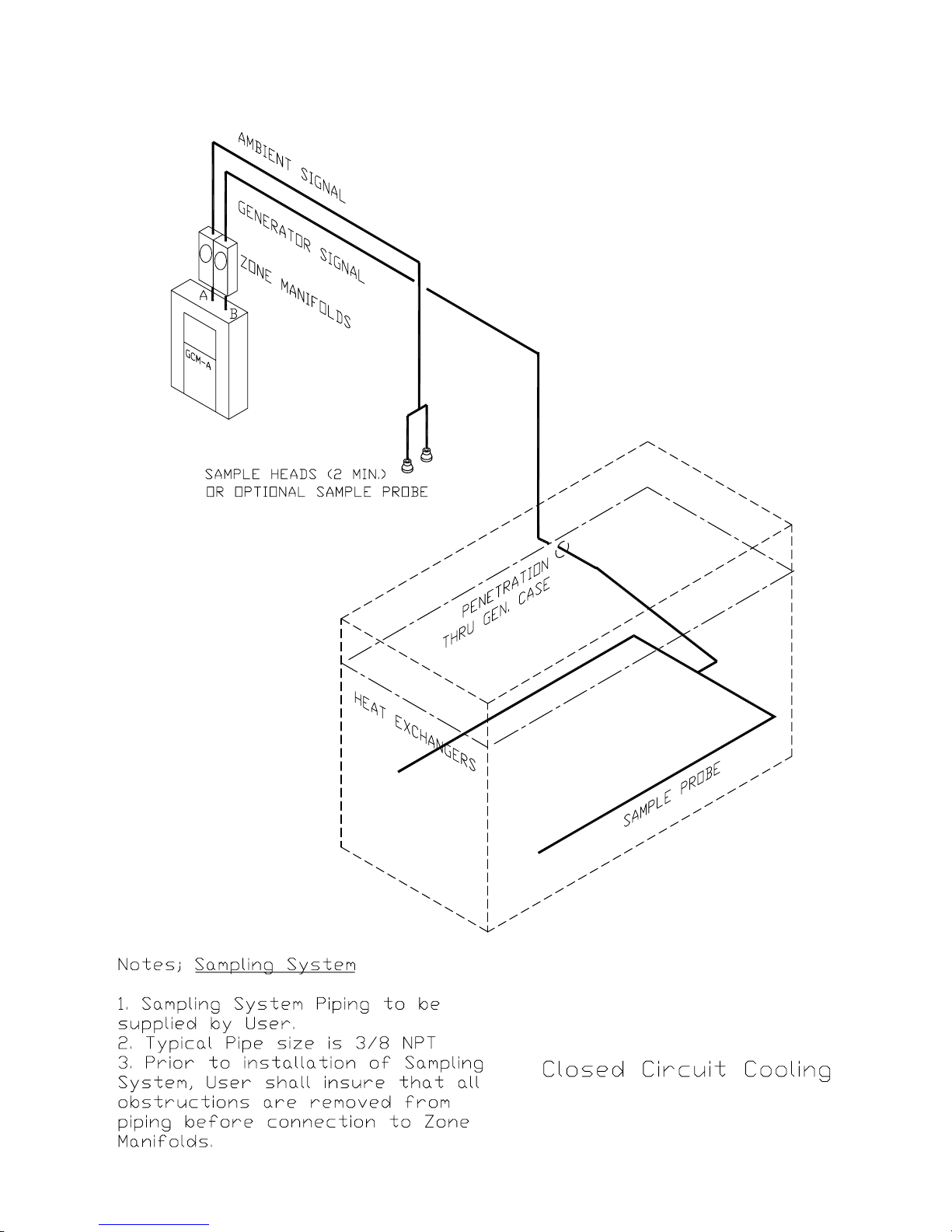

Figure 5 - Closed Circuit “H” Probe ................................................................................................................. 43

Figure 6 - Closed Circuit “U” Probe ................................................................................................................. 44

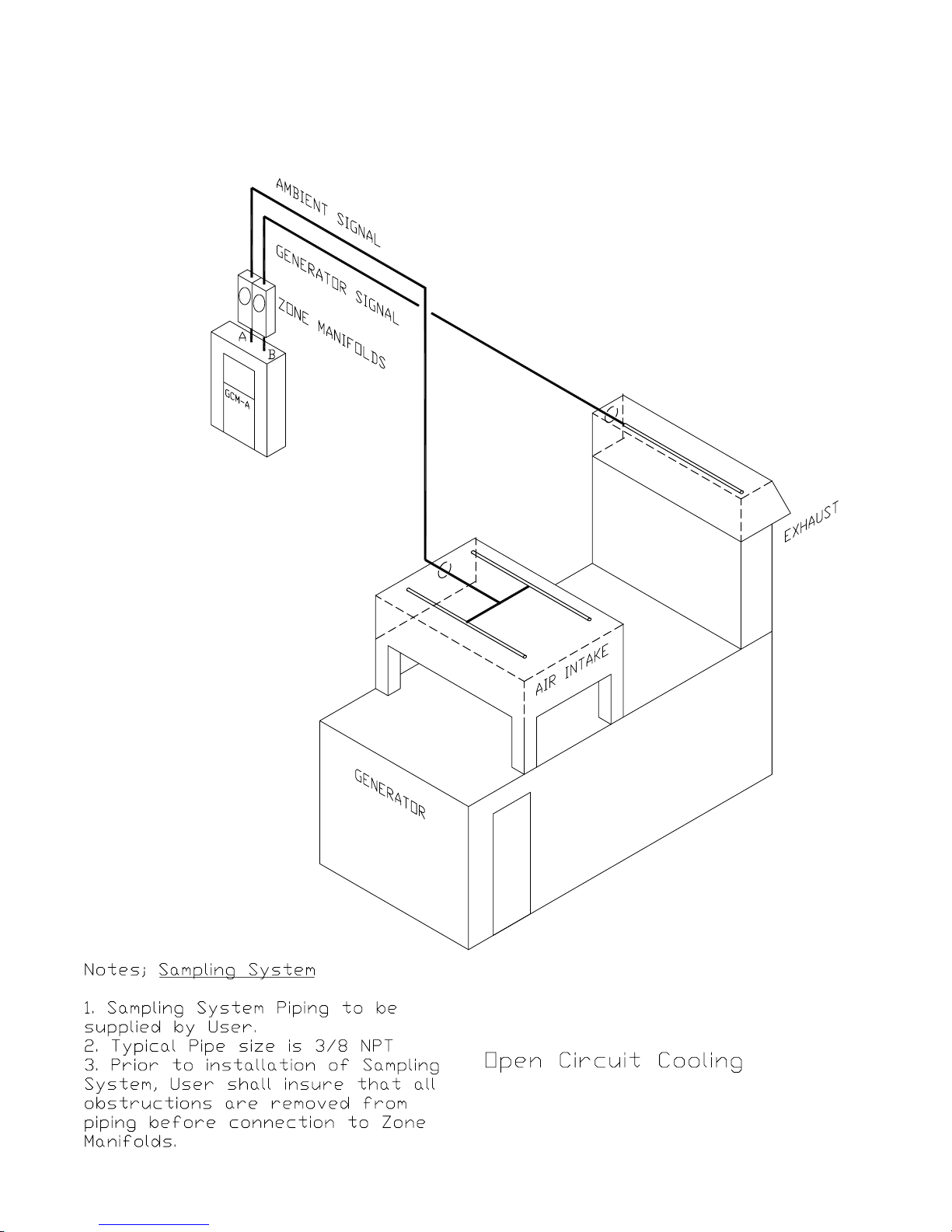

Figure 7 - Open Circuit “Sample Heads” .......................................................................................................... 45

Figure 8 - Open Circuit “Probes” ...................................................................................................................... 46

Figure 9 - Sampling System, 3/8” Typical (PVC) ............................................................................................. 47

Figure 10 - Sampling system, 1/2” Typical (PVC) ............................................................................................ 48

Figure 11 - Sampling System, 1/2” Flange Configuration ................................................................................ 49

Figure 12 - Zone Manifold ................................................................................................................................ 50

Figure 13 - Sample Head ................................................................................................................................... 51

Figure 14 - Sample Probe .................................................................................................................................. 52

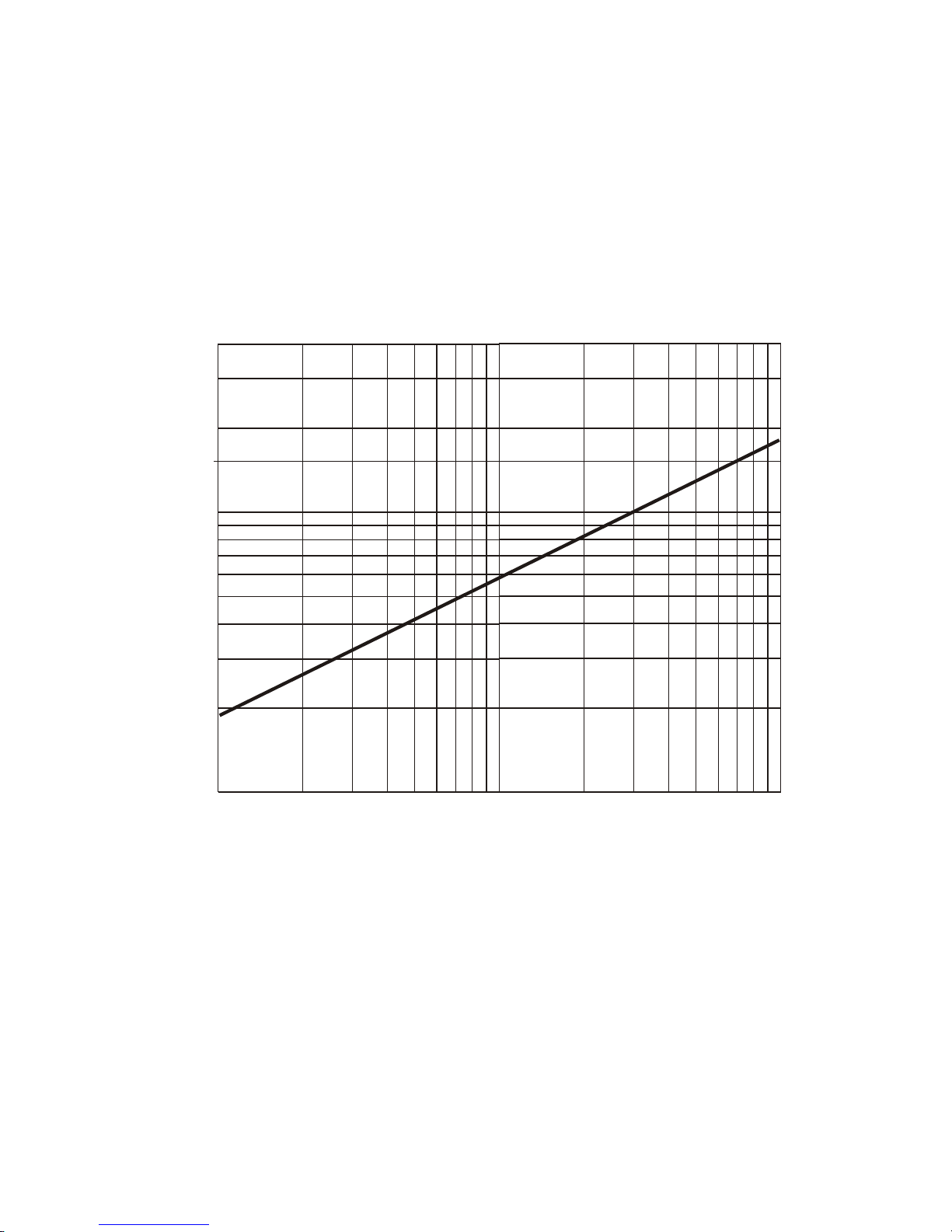

Figure 15 - Zone Manifold Flow, DP mm Water............................................................................................... 53

Figure 16 - Particle Concentration .................................................................................................................... 54

Figure 17 - Control Panel Detail ....................................................................................................................... 55

Figure 18 - Manifold DP Gage .......................................................................................................................... 56

3

GA0383P02 Rev. C

GENERATOR CONDITION MONITOR (GCM-A)

IMPORTANT INFORMATION

THIS EQUIPMENT OPERATES AT VOLTAGE LEVELS THAT CAN BE HAZARDOUS TO

PERSONNEL. THE SECTION ABOUT SAFETY CONSIDERATIONS SHOULD BE READ

BEFORE INSTALLING OR SERVICING.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS

IN EQUIPMENT NOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE

MET IN CONNECTION WITH INSTALLATION, OPERATION OR MAINTENANCE.

SHOULD FURTHER INFORMATION BE DESIRED, OR SHOULD PARTICULAR

PROBLEMS ARISE THAT ARE NOT COVERED SUFFICIENTLY FOR THE

PURCHASER’S PURPOSES, THE MATTER SHOULD BE REFERRED TO

ENVIRONMENT ONE CORPORATION AT +1 518 346 6161 OR WWW.EONE.COM/

DETECTION.

SITE MANAGEMENT IS RESPONSIBLE FOR ASSURING THAT ALL PERSONNEL

WORKING WITH THIS SYSTEM ARE ADEQUATELY TRAINED IN SAFETY

CONSIDERATIONS AND THAT THEY HAVE RECEIVED THE NECESSARY TRAINING TO

PROPERLY OPERATE THE EQUIPMENT.

GENERATOR CONDITION MONITOR (GCM-A)

SAFETY CONSIDERATION

THE SYSTEM ELECTRONICS ENCLOSURE CONTAINS 115 AND/OR 230 VOLTS AC.

THIS VOLTAGE APPEARS AT THE AC POWER STRIP AND VARIOUS OTHER POINTS.

ALL ELECTRICAL CONNECTIONS TO THE SYSTEM ELECTRONICS SHOULD BE

TESTED AND VERIFIED TO BE CORRECT.

ALL WIRING MUST BE IN ACCORDANCE WITH LOCAL CODES AND PROFESSIONAL

PRACTICE.

USE OF THIS EQUIPMENT IN A MANNER NOT SPECIFIED BY ENVIRONMENT ONE

CORPORATION IS STRICTLY PROHIBITED.

GA0383P02 Rev. C

4

Specifications

Measurement Characteristics

Detection principle Submicron particle detector

Air Flow Rate Adjusted by Zone Manifold, nominal 14 LPM

Readout (bar graph) Ambient Air 0% to 100% of scale

Electrical Characteristics

Power Input, grounded power cable 115/230 VAC, 50/60 Hz

Output Relays, general purpose

Ambient Alarm, Generator Alarm,

Differential Alarm, Common Warning,

System Trouble, Flow Trouble 120 VAC/28VDC / 3.0 A

Output Signal (4-20 mA)

Generator Air 0% to 100% of scale

Ambient Air 0% to 100% of scale

Generator Air 0% to 100% of scale

Mechanical Characteristics

Dimensions, overall 24” H x 22” W x 9 1/8” D*

(610 mm x 559 mm x 232** mm)

Weight, approximate 88 lbs. (40 kg)

Connectors, gas inlet 3/8” NPT, female

Temperature, maximum 32-122 F (0-50 C)

Area Classification CE, Non Hazardous

Relative Humidity 0-95%

Controls 5-key membrane switch keypad with liquid

crystal display

* 8”/203 mm for GD0080G02

** 10”/254 mm for GD0080G01

5

GA0383P02 Rev. C

Application

The Generator Condition Monitor for air-cooled machines (GCM-A) is a sensitive real-time

instrument designed to provide early warning indication of overheating (or arcing) in aircooled generators before extensive damage can occur. Tests conducted on operating aircooled generators have shown that the GCM-A can detect thermal decomposition of small

amounts of insulating materials.

Thermal decomposition of organic materials such as epoxy paint, core lamination enamel or

other insulating materials used in the generator results in the production of a large number

of small particles. The onset of particle production, as the material is heated, occurs at a

temperature characteristic of the material (thermal particulation point) and its surrounding

atmosphere. Below this temperature, no particles are created, yet once the critical

temperature is reached (thermal particulation point – TPP), millions of submicron particles

are generated each second for every square centimeter of surface area.

The GCM-A features:

· Microprocessor-based electronics

· Self-diagnostics

· Output indication

· Trouble indication

· Allowance for remote control/display and communication

Principle of Operation

A basic understanding of the GCM-A is necessary to properly utilize the information that the

instrument provides.

Particle detection is by means of a detector utilizing the condensation nuclei principle (cloud

chamber).

In operation, an air sample is delivered to the detector by means of a centrifugal blower

connected to two sets of sampling lines; one line is dedicated to the ambient air and the

second is dedicated to the generator’s cooling circuit. A portion of these air samples is first

diverted into a humidifier and humidified to approximately 100% relative humidity, then

directed to the cloud chamber where it is subjected to a rapid vacuum expansion. The effect

of the vacuum is to cool the air sample and cause water droplets to condense onto particles

that may be present in the air sample.

It is known that particles smaller than the wavelength of visible light occur spontaneously as

material is heated, and in numbers far above those present in a normal ambient

environment. As a result, thermally generated particles cause many droplets to form a cloud

which is then detected by the optical system of the cloud chamber.

GA0383P02 Rev. C

6

System Description

The GCM-A is primarily designed for use on air-cooled generators, although application to

other air-cooled machines is possible. Its main purpose is to provide early warning and

detection of overheating (or arcing) in these machines.

The major components of the GCM-A are the System Electronics and the sampling system.

System Electronics

The System Electronics consist of one display board, one controller board, one input/output

board, two airflow metering boards, one power supply, one vacuum pump, one cloud

chamber, one blower fan and one sampling manifold.

The System Electronics provide calibration, mode selection, alarm contacts, data logging,

system inputs/outputs and diagnostics.

Fail-safe operation of the GCM-A is assured by:

• On power-up the GCM-A must execute and pass qualifying self tests. Failure in any test

results in the suspension of operation and the annunciation of the condition causing the

failure.

• Following power-up and/or system reset, the GCM-A is continuously supervised by an

independent watchdog monitor that serves to reset it should its operation become

erratic.

• The GCM-A is completely self-supervised and continuously checks itself for legal

processor functioning, proper vacuum levels, internal voltages, communication accuracy,

integrity of cabling and relay operation. Any faults are immediately annunciated.

Display Panel

The Control/Display Panel provides control of all functions of the GCM-A as well as

complete annunciation of GCM-A’s status (Figure 17). Functions are accessed by means of

a four-button membrane-switch keypad and 20-character Liquid Crystal Display (LCD).

Generally, pressing the Fn (Function) key causes the LCD to continuously scroll the names

of the available functions. A function may then be accessed by pressing the Enter key when

the function name appears. See “GCM-A Menu Displays” for more information.

The Display Panel provides Light Emitting Diodes (LED’s) to annunciate GCM-A status; they

indicate Warning, Alarm and Trouble conditions. A green LED indicates AC Power.

Since all configuration constants are stored in non-volatile memory, these values will not be

lost should the system be initialized, or should it lose, then regain, AC power.

Input/Output Board

The Input/Output board assembly has terminal strips where all customer connections to the

relay and signal outputs are made. Wire access is provided by the three knockouts at the

top and/or bottom of the Enclosure.

7

GA0383P02 Rev. C

Installation

These instructions provide details to facilitate the equipment installation.

Mounting

The GCM-A (GD0080G01) should be installed indoors. If outdoor installation is necessary, a

protective enclosure should be considered and discussed with Environment One. Locate the

GCM-A out of direct sunlight to prevent the interior ambient temperature from exceeding

50 C (122 F). If a protective enclosure is used, it should also be ventilated.

A GCM-A may be supplied with a protective enclosure. Installation of this variation

(GD0080G02) system begins with installation of the exterior enclosure. This enclosure

should be mounted in accordance with Figure 3.

Please note that both the exterior enclosure and the GCM-A cabinet should be securely

attached to the mounting surface. Securing the GCM-A cabinet only to the exterior

enclosure is not recommended.

GA0383P02 Rev. C

8

System Design Considerations

The GCM-A system consists of the detector unit (the GCM-A itself) and an associated air

sampling system. When designing a system for a particular application, one needs to

consider:

a) The configuration of the generator’s cooling system. In particular, it is important to

know whether the application is a single pass (open) or enclosed (closed) cooling circuit.

This will play a major role in the sampling system design layout. A cooling system

schematic and sectional views of the generator are valuable to this process and should

be provided to Environment One.

b) The mounting location of the GCM-A cabinet. The particular location of the GCM-A

cabinet will play a role in the sampling system design layout and electrical connections

and will also assist in identifying key mechanical installation considerations. For

example, if the GCM-A is to be mounted near or on the generator’s exterior case, the

generator OEM may need to be contacted for information, approval and/or instruction.

Consideration of these and other mechanical factors will facilitate installation.

c) The distance between the GCM-A cabinet and the farthest point the sampling

system will reach. This information is key to the transit time analysis of the sampling

system. Identification of physical obstacles and/or considerations that will impact the

specific piping layout will also be considered. Often, the cooling system schematic

referred to above will provide much of the information sought.

d) The preferred piping material to be used in the sampling system. The GCM-A’s

sampling system can employ a variety of pipe sizes and types. Environment One does

not supply the sampling system’s pipe, but will be interested in learning whether the

power plant has a preference for a particular material – for example, a plant may have a

supply of 1/2-inch conduit left over from electrical service installations throughout the

plant; this material could be viewed as the preferred sampling system pipe. Environment

One will ask the plant whether there is a preference in this regard. Typically, 3/8-inch

NPT is used in a GCM-A sampling system.

9

GA0383P02 Rev. C

Transit Time Calculations

Environment One will utilize information from the customer to develop a sampling system

transit time calculation. The main purpose for this analysis is to verify that the sampling

system will meet minimum system requirements for air flow through the sampling system

and to establish an expectation for the amount of time an overheat signal generated from

within the generator will take to reach the detector unit.

During a typical GCM-A system start-up and commissioning, a 100-watt resistor will be

overheated within the cooling circuit. When this is done, the transit time analysis will be

validated, as there should be a rough correlation between the transit time design

expectation and the actual interval between the resistor being overheated and a response

by the GCM-A.

Should the approximated transit time not be validated during the commissioning of the

system, air flow through the Zone Manifolds would be validated using an external DP gage

to verify proper flow rates and adjustments to flow would be made to meet system

requirements and customer expectations.

GA0383P02 Rev. C

10

Sampling System Components

As noted, the GCM-A’s sampling system is composed of a pipe network that delivers an air

sample to the GCM-A. The individual components of a GCM-A sampling system may differ

from installation to installation (see isometric views Figures 5 though 8 of an open and

closed circuit application). In most instances, the following components are used (see

Figures 9 through 14 for component details):

• Zone Manifold – Two Zone Manifolds are used in the GCM-A system; one for the

Ambient signal, the other for the Generator signal. These components are typically

installed close to the GCM-A and are used to adjust airflow from each segment of the

sampling system network. Each Zone Manifold will be supplied with pipe unions to ease

removal of these components from the sampling system should the need arise.

Communication between Environment One and the power plant customer will confirm

the particular configuration of the pipe unions. A Zone Manifold also contains a

replaceable filter that helps guard against dirt and insects from entering the inlet manifold

of the GCM-A system (possibly obstructing flow).

• Sampling pipe — This material is supplied by the site. Communication between

Environment One and the power plant customer will determine necessary lengths. It is

the responsibility of site management to assure that sampling system piping is installed

in accordance with sampling system design parameters, local codes and professional

practice.

• Sample Heads — Sample Heads may be used as part of the sampling system, and

particularly for the Ambient signal. Sample Heads have a fixed orifice and contain a

replaceable filter that helps guard against dirt and insects from entering the sampling

system (possibly obstructing flow); see Figure 13.

• Sample Probes — Sample Probes are sections of sampling system pipe that have

holes drilled in them at particular spacing and with particular diameters. They are used as

an alternative to Sample Heads and are often preferred for the Generator signal portion of

the sampling system because of their inherent flexibility. Communication between

Environment One and the power plant customer will determine whether Sample Probes

will be used in a GCM-A sampling system; see Figure 14.

• DP Gage — The DP Gage is an external metering component used to confirm the air

flow across a Zone Manifold. The default GCM-A system design parameter for air flow is

14 LPM for each sample line. The DP Gage will be utilized during system commissioning

and at maintenance intervals to validate sampling system operation; see Figure 18.

11

GA0383P02 Rev. C

Electrical Connections

Electrical connections are made through three knockouts provided at the top and bottom of

the GCM-A cabinet (Figure 4). The system power requirement is 115/230 VAC (+/- 10%),

50/60 Hz. The source of AC power should be reliable and not subject to severe transients.

Wiring and wire routing should be in accordance with Figure 4 so that noise generated from

the AC power and contacts does not interfere with the signals. If a circuit breaker is used, it

should be 10 amps. The ground wire should be 12 AWG with 25-amp capacity.

ALL WIRING MUST BE IN ACCORDANCE WITH LOCAL CODES AND PROFESSIONAL

PRACTICE.

Contacts

As shown in Figure 4, the GCM-A provides these relay contacts:

· Ambient Alarm Relay. Both a normally open and a normally closed contact (single pole,

double throw configuration) is provided and an alarm is signaled by an energized relay.

· Generator Alarm Relay. Both a normally open and a normally closed contact (single

pole, double throw configuration) is provided and an alarm is signaled by an energized

relay.

· Differential Alarm Relay. Both a normally open and a normally closed contact (single

pole, double throw configuration) is provided and an alarm is signaled by an energized

relay.

· Warning Relay. Both a normally open and a normally closed contact (single pole,

double throw configuration) is provided and a warning is signaled by an energized relay.

· Flow Trouble Relay. Both a normally open and a normally closed contact (single pole,

double throw configuration) is provided a flow rate problem is signaled by an energized

relay.

· System Trouble Relay. Both a normally open and a normally closed contact (single

pole, double throw configuration) is provided, and Trouble is signaled by a de-energized

relay.

Signals

· Ambient Output Level Signal. 4 to 20 mA signal (transmitter)

· Generator Output Level Signal. 4 to 20 mA signal (transmitter)

GA0383P02 Rev. C

12

System Operation

GCM-A Initial Startup

The GCM-A leaves the factory without any water in the water bottle or in the humidifier to

prevent damage during shipping. Before starting the GCM-A, fill the water bottle with

distilled water. (WARNING: The use of anything other than distilled water will damage

the GCM-A and will void the warranty.)

To fill the GCM-A water bottle:

• Open the outer door.

• Remove the six screws from the GCM-A subdoor.

• Remove the water bottle from the water bottle shelf.

• Remove the cap from the water bottle and fill it with distilled water.

• Secure the cap on the water bottle and return the bottle to the water bottle shelf.

• Secure the GCM-A subdoor and outer door.

The humidifier is filled during the boot process (see the section GCM-A Initialization for

details of the boot process). At the point in the boot process where the GCM-A normally

indicates “WATER OK,” it will instead indicate “WATER=0”. After one second, “WATER=0”

will be followed by “WATER=1,” and so on until “WATER=15” is reached. At this point the

GCM-A will flash the prompt “CONTINUE FILLING?”. Press the enter key to continue filling.

The humidifier will be filled to capacity at or about “WATER=17”.

The GCM-A may detect that the Zone Manifolds need to be adjusted during the initial boot.

If it detects that the flow rates are out of specification, it will stop the boot process and flash

the out of specification reading on the display. It will flash “AMB FLO = N.N LPM” if the

ambient air flow rate is out of specification and/or “GEN FLO = N.N LPM” if the generator

airflow rate is out of specification. Adjust the appropriate Zone Manifold to a nominal 14 LPM

correct the problem and validate the air flow through the Zone Manifold using the DP Gage.

The two zone manifolds are adjusted with an allen head set screw located on their lower

right hand side (see Figure 12). Turn the set screw in a clockwise direction to decrease the

airflow or in a counterclockwise direction to increase the airflow. The GCM-A requires

that the airflow be between 7 and 21 LPM (nominal 14 liters per minute) for initial startup.

After the GCM-A has started successfully, adjust the airflow and clear the event logs.

You may want to run the tutorial called “Menu Navigation Tutorial” to familiarize yourself with

menu navigation before proceeding with these steps.

See the procedures titled “Adjusting the Ambient Airflow” and “Adjusting the Generator

Airflow” to adjust the airflow. See the sections “CLEAR FAULTS LOG” and “CLEAR POWER

LOG” under the heading “Log Menu” to clear the event logs.

13

GA0383P02 Rev. C

Typical Responses to GCM-A Warning & Alarm Indications

This section addresses what a power plant may consider as reasonable actions in response

to particular GCM-A indications. It does not purport to cover all instances.

The GCM-A provides information for plant personnel to use in making operational decisions.

The information provided is often validated by other I&CS. Plant management is encouraged

to consider the relationship of the GCM-A to other systems installed on site. By considering

these relationships, plant management will be in the best position to maximize the utility of

the GCM-A to the plant’s efficient operation.

In the event of:

GCM-A System Trouble — Select SHOW FAULTS LOG from the <LOG MENU>. If no

faults are indicated, then the operator may have disabled monitoring. If faults are indicated,

see the section “About the Faults Log” for interpretation.

Ambient Warning and Alarm — The Warning point is typically selected based on an initial

examination of the normal, or typical, background particle level at the site. Standard practice

is to allow a GCM-A run for several days to determine the highest nominal background

particle level at the site and then select a Warning point that is marginally above that. The

Alarm set point is similarly arrived at; the Alarm point must always higher than the Warning.

When Ambient particle levels rise above the Warning and possibly to the Alarm threshold, it

is reasonable to ask whether this is a short-term condition or whether the nominal

background particle level has changed due to the introduction of another environmental

factor.

In the event of an Ambient Warning or Alarm, examine the operating environment for the

presence of particle generation sources that are not common to the normal operating

environment (excessive exhaust or a fire is a good example of an extraneous source). If

there is such a temporary extraneous event, site personnel should consider whether it

can/should be eliminated/anticipated in the future and make adjustments to Warning and

“Alarm” set points as necessary.

If additional equipment has been installed at the plant site since the GCM-A’s installation

date, an Ambient Warning or Alarm may result from that equipment’s impact on nominal

background particle levels. In such an instance, site personnel may need to consider

increasing the Warning point to a level that is above the highest anticipated nominal particle

level. Essentially, the GCM-A is an environmental monitor; therefore, if the nominal

background particle level has changed because of the introduction of a sustained particle

generating source, reassessment of Warning and Alarm points is required.

Generator Warning and Alarm — The Generator Warning and Alarm points are selected

similarly to the Ambient points (see above). Therefore, a change in the nominal Ambient

particle level could be expected to cause a similar particle level increase in the Generator

signal, insofar as the Ambient air represents the same air as the air contained within the

generator’s cooling circuit.

If a Generator Warning or Alarm occurs and it is not accompanied by an Ambient Warning

or Alarm, site personnel are advised to consider that overheating may be occurring within

GA0383P02 Rev. C

14

(Typical Responses, cont’d)

the generator cooling circuit. In this instance, other site instrumentation should be reviewed

for corroborating indications of generator overheating.

Differential Warning and Alarm — A Differential Warning or Alarm occurs as a result of a

difference existing between Ambient and Generator particle levels. It is an expression of

“Generator less Ambient” and its value cannot equal less than zero.

The Differential Warning and Alarm set points are adjustable, with the factor default being a

30 percent difference for Warning and a 50 percent difference for Alarm. These settings are

adjustable.

In the event of a Differential Warning or Alarm, other site instrumentation should be

reviewed for corroborating indications of generator overheating. The GCM-A’s indication of a

Differential Warning, and particularly a Differential Alarm, is the most serious indication of a

thermal particulation event occurring within the generator’s cooling circuit. Site personnel

are advised to immediately initiate internal procedures for dealing with an acute problem that

could lead to generator failure.

Environment One is sometimes asked whether a GCM-A Differential Alarm should be used

to “trip” a generator off-line. This is not a question that Environment One is in a position to

respond to, as decisions relating to taking a generator off-line involve significant economic

considerations/repercussions and are solely the responsibility of site management.

Environment One can only advise GCM-A end-users that our experience has been that

operators typically reduce load upon a verified alarm in one of our overheat monitoring

instruments. They typically evaluate whether a reduced load changes the alarm condition

and then act in accordance with their established internal procedures. In the event that plant

operators choose to use a GCM-A to trip a generator, the “Differential Alarm” is the only

indication that should be used.

15

GA0383P02 Rev. C

GCM-A Initialization

Apply system power to the GCM-A. The GCM-A DISPLAY PANEL will respond with (a) all

discrete LED’s lit; (b) all segments of the AMBIENT and GENERATOR bar graphs lit; and (c)

all pixels of the LCD display on.

After a delay of two seconds, (a) all discrete LED’s, except the AC POWER, SYSTEM

TROUBLE and FLOW LED’s, will turn off; (b) all segments of the AMBIENT and

GENERATOR displays will turn off; and (c) the display will echo the results of cold start

initialization:

· “GCM-A Ver 1.7B-8”

· “CHECKSUM OK”

· “POWER OK”

· “RELAY TEST …”

· “… PASSED”

· “STARTING …” will flash for two seconds;

· “ROTARY VALVE …”

· “… PASSED”

· “VACUUM OK”

· “SAMPLE LINE ...”

· “… PASSED”

· “GEN SOLENOID ...”

· “… PASSED”

· “AMB SOLENOID ...”

· “… PASSED”

· “AMB FLO=14.0 LPM”

· “GEN FLO=14.0 LPM”

· “WATER OK”

· “END DIAGNOSTICS”

“NORMAL OPERATION” will flash for two seconds; the GCM-A will begin normal operation

and the display will read “GCM-A by E/One.”

GA0383P02 Rev. C

16

GCM-A Menu Displays

The following sections provide definitions and user information regarding the various menus

that are accessible via the GCM-A’s LCD display. It is strongly recommended that users

familiarize themselves with this section. Additional questions can be forwarded to

Environment One at +1 518 346-6161 or www.eone.com/detection.

Navigating the LCD Display

Four keys are used to control menu operation. The keys are FN, ENTER, UP ARROW and

DOWN ARROW.

· The FN key activates the menu and exits the menu.

· The ENTER key selects an item from the menu.

The UP ARROW and DOWN ARROW keys change the selection displayed.

LCD Display Menu — Two Modes of Operation

The menu has two modes of operation. The modes are scrolling and non-scrolling.

· In scrolling mode the selection shown on the LCD changes automatically every two

seconds.

· In non-scrolling mode the UP ARROW and DOWN ARROW keys must be used to

change the selection.

Scrolling is the default mode. Users can change modes by reviewing the SETUP MENU

section in the following pages.

Menu Profile

Five menus are available: the Function menu, the Log menu, the Setup menu, the View

menu and the Test menu. The Function menu is the top-level menu; all of the other menus

are accessed through this menu.

Function

· Log

· Setup

· View

· Test

17

GA0383P02 Rev. C

Menu Navigation Tutorial

Activating the Menu

Press FN to start the menu. The LCD should display the prompt <FUNCTION MENU>.

Press FN again to turn it off.

Navigating the Menu in Scrolling Mode (GCM-A default)

1. Press FN to start the menu. The LCD should display the prompt <FUNCTION MENU>.

After two seconds the prompt should change to GO REMOTE.

2. Wait until the prompt GO TO VIEW MENU and press the ENTER key. The LCD should

display the prompt <VIEW MENU>.

3. Wait until the prompt VIEW LEVEL and press the ENTER key. The display should show

GENERATOR=N.N% (or AMBIENT=N.N%) where N.N is the present value of the cloud

chamber response. Press the FN key; the prompt will be restored to VIEW LEVEL.

4. Press FN again. The prompt will be restored to GO TO VIEW MENU.

5. Press FN a third time. The LCD will display “GCM-A by E/One” as the menu is

deactivated.

Disabling Scrolling Mode

1. Press FN to start the menu.

2. Wait until the prompt GO TO SETUP MENU and press ENTER.

3. Wait until the prompt SET SCROLL OFF and press ENTER.

4. The prompt will flash SET SCROLL OFF.

5. Press FN to return to the beginning of the menu.

Navigating the Menu in Non-Scrolling Mode

1. The LCD should display the prompt <FUNCTION MENU>. Press the DOWN ARROW

key until the prompt GO TO VIEW MENU and press the ENTER key.

2. The LCD should display the prompt <VIEW MENU>. Press the DOWN ARROW key until

the prompt VIEW LEVEL and press the ENTER key. The display should read

GENERATOR=N.N% (or AMBIENT=N.N%) where N.N is the present value of the cloud

chamber response.

3. Press the FN key. The prompt will be restored to VIEW LEVEL.

4. Press FN again. The prompt will be restored to GO TO VIEW MENU.

5. Press FN a third time. The LCD will display “GCM-A by E/One.”

GA0383P02 Rev. C

18

Function (FN) Menu

· GO REMOTE Select this item to transfer control to an active remote control software

session. The GO REMOTE prompt will flash for two seconds after it is selected. If the

FN key is pressed while GO REMOTE is still flashing, transfer will be canceled. If the

GCM-A cannot detect an active remote control software session, the transfer will be

canceled and the GCM-A will remain in local mode.

· GO LOCAL Select this item to transfer control to the display panel located on the front

of the GCM-A cabinet (only shown if control was previously transferred to an active

GCM-A Remote Control Software session). The GO LOCAL prompt will flash for two

seconds after it is selected. If the FN key is pressed while GO LOCAL is still flashing,

transfer will be canceled.

· GO TO LOG MENU Select this item to enter the LOG MENU. The log menu contains

selections to view and clear the fault and power logs. The log menu also includes a

selection to view the software version number.

· GO TO SETUP MENU Select this item to enter the SETUP MENU. The setup menu

includes selections for setup and configuration.

· GO TO TEST MENU Select this item to enter the TEST MENU. The test menu contains

selections to test the power supplies, the keypad, the relays, the vacuum pump, the

cloud chamber, the bar graphs and the four- to 20-milliamp (4-20 mA) outputs.

· GO TO VIEW MENU Select this item to enter the VIEW MENU. The view menu contains

selections to view the water usage, the LED current, the cloud chamber output, the

vacuum, the air flow and the cloud chamber period.

Setup Menu

· AMBIENT GAIN Select this item to change the ambient gain. See Setting the Ambient

Gain for more information.

· GENERATOR GAIN Select this item to change the generator gain. See Setting the

Generator Gain for more information.

· AMBIENT FLOW ADJ Select this item to change the ambient flow limits. See Adjusting

the Ambient Airflow for more information.

· GENERATOR FLOW ADJ Select this item to change the generator flow limits. See

Adjusting the Generator Airflow for more information.

· AMBIENT WARN Select this item to change the ambient warning level. See Setting the

Ambient Warning Level for more information.

· GENERATOR WARN Select this item to change the generator warning level. See

Setting the Generator Warning Level for more information.

· DIFFERENCE WARN Select this item to change the difference warning level. See

Setting the Difference Warning Level for more information.

19

GA0383P02 Rev. C

(Setup Menu, cont’d)

· AMBIENT ALARM Select this item to change the ambient alarm level. See Setting the

Ambient Alarm Level for more information.

· GENERATOR ALARM Select this item to change the generator alarm level. See Setting

the Generator Alarm Level for more information.

· DIFFERENCE ALARM Select this item to change the difference alarm level. See Setting

the Difference Alarm Level for more information.

· DRAIN WATER This item is to be used for decommissioning the instrument. Select this

item to drain the humidifier. See Draining the Humidifier for more information.

· CHAMBER FLOW ADJ Select this item to adjust the chamber airflow. See Adjusting

Chamber Airflow for more information.

· MONITORING MODE This item is to be used for troubleshooting. When selected, the

GCM-A will display its operation mode. The GCM-A can operate in one of four modes:

Normal Operation, Alternating Operation, Ambient Only and Generator Only. Use the

arrow keys to scroll through the choices and press the ENTER key to select one. See

Normal Operation, Alternating Operation, Ambient Only Operation or Generator Only

Operation for more information.

· START MONITORING This item is displayed when the monitoring is currently turned off.

Select it to turn monitoring on. When selected, the START MONITORING prompt will

flash STARTING for two seconds before monitoring begins. If the FN key is pressed

while it is still flashing, the command will be canceled. See Normal Operation for more

information.

· SET SCROLL OFF This item is displayed when the scrolling is currently turned on.

Select it to turn scrolling off. When scrolling is inactive, the displayed menu items will not

change until a menu key (UP ARROW, DOWN ARROW, FN or ENTER) is pressed.

· SET SCROLL ON This item is displayed when the scrolling is currently turned off. Select

it to turn scrolling on. When scrolling is active, the displayed menu items will change

once every two seconds.

Test Menu

· CONTACT TEST Select this item to start an interactive test of the relay contacts. The

GCM-A will place all relays except one in a de-energized condition. The LCD will display

the name of the single relay that is still energized. Use the arrow keys to change which

relay is energized. Press the FN or ENTER keys to terminate the test.

· KEYPAD TEST Select this item to start an interactive test of the keypad. The LCD will

display the prompt PRESS ANY KEY at the start of the test. Test the keypad by

pressing, one at a time, all of the keys on the keypad, reserving the FN key for last. The

LCD will echo the name of each key as it is pressed. The test will terminate when the FN

key is pressed.

· OUTPUT TEST Select this item to start an interactive test of the bar graphs and four- to

20-milliamp (4-20 mA) outputs. The GCM-A will clear the bar graphs, set the four- to 20milliamp outputs to four milliamps and display CURRENT=4mA on the LCD display at

the start of the test. Use the arrow keys to increase or decrease the current in one

GA0383P02 Rev. C

20

(Test Menu, cont’d)

milliamp steps. The bar graphs will track the current outputs with four milliamps equal to

zero percent and 20 milliamps equal to 100 percent. Press FN or ENTER to terminate

the test.

· POWER TEST Select this item to test the power supplies. When POWER TEST is

selected, the GCM-A will display the voltage for each power supply in the format

<nominal value>=<present value>. An example for the 5-volt power supply would be

+5 VOLTS =5.1. The GCM-A will scroll through all five power supply voltages. The

voltages are displayed for two seconds apiece.

· RELAY TEST Select this item to test all of the relays. The LCD will display RELAY TEST;

the system will cause each relay to be energized. If no errors are detected, the LCD will

display RELAYS PASS. If an error is detected, the LCD will display the failure mode and

then list the names of the malfunctioning relays. The failure modes are STUCK ON,

STUCK OFF and MISSING.

· SYSTEM TEST Select this item to test the submicron particle detection subsystem. The

submicron particle detection subsystem consists of the inlet manifold, the ambient and

generator airflow meters, the cloud chamber detector, the vacuum pump and the water

level sensors. The GCM-A will annunciate any problems it detects.

· VACUUM PUMP TEST Select this item to start an interactive test of the vacuum pump.

The GCM-A will position the rotary valve to achieve the maximum vacuum for a given

duty cycle at the start of the test. The vacuum can be increased or decreased by

changing the duty cycle. Press the UP key to increase the duty cycle or the DOWN key

to decrease it. The LCD will display the vacuum and duty cycle. Press the FN or ENTER

keys to terminate the test.

· LED RESPONSE TEST Select this item to check the dynamic response of the cloud

chamber optical system. The CPU will pulse the cloud chamber LED to simulate a cloud

obscuration and measure the response. It will display the response in the format

NN@M.M where NN is the response of the electronics and M.M is the LED current in

milliamps. Press the FN key to terminate the test.

View Menu

· VIEW WATER USAGE Select this item to display the GCM-A’s water meter. The water

meter indicates the number of seconds the GCM-A has spent filling the humidifier. The

water meter is cleared by restarting the GCM-A.

· VIEW PHOTOCELL Select this item to display the current through the cloud chamber

LED in milliamperes.

· VIEW PERIOD Select this item to display the cloud chamber sampling state and cycle

count. This is an advanced diagnostic intended for factory use only.

· VIEW LEVEL Select this item to display the output of the cloud chamber and the zone

being sampled at a once/second update rate.

· VIEW VACUUM Select this item to display the vacuum level and vacuum pump duty

cycle. Three numbers are displayed: the peak vacuum present during the expansion

process, the minimum vacuum present during the fill/flush process and the vacuum

pump duty cycle required to maintain these vacuum levels.

21

GA0383P02 Rev. C

(View Menu, cont’d)

· VIEW FLOW Select this item to display the ambient or generator airflow in liters per

minute. Press the up or down arrow keys to toggle between the ambient airflow and the

generator airflow.

Log Menu

· SHOW FAULTS LOG Select this item to view the faults log. See About the Fault Log for

more information.

· CLEAR FAULTS LOG Select this item to clear the faults log. When selected, the

CLEAR FAULTS LOG prompt will flash for two seconds before clearing the faults log. If

the FN key is pressed while it is still flashing clearing of the log will be canceled. See

About the Fault Log for more information.

· SHOW POWER LOG Select this item to view the power log. See About the Power Log

for more information.

· CLEAR POWER LOG Select this item to clear the power log. When selected the

CLEAR POWER LOG prompt will flash for two seconds before clearing the power log. If

the FN key is pressed while it is still flashing, clearing of the log will be canceled. See

About the Power Log for more information.

· SHOW PROGRAM ID Select this item to display the program identification and revision

level in the format GCM-A Rev X.X. This manual was written for software version 1.7A-

8.

GA0383P02 Rev. C

22

Procedures

Some maintenance procedures and most troubleshooting/repair activities will involve gaining

access to the GCM-A’s internal assemblies. In each instance where internal components of

the GCM-A are to be accessed, site management should consider whether power

should be removed from the unit. If the unit remains powered, site management is

responsible for proper safety procedures being used.

To access internal GCM-A components,

· Open the GCM-A’s outer door.

· Remove the six (6) screws from the GCM-A’s subdoor (do not lose the screws).

· Open the subdoor to gain access to the GCM-A’s internal components.

· If internal electronics (PCB’s) will be handled, an electrostatic protective wrist strap

should be worn.

Draining the Humidifier

The Humidifier must be drained before moving the GCM-A. Once the Humidifier has been

drained, the GCM-A should be powered down.

When DRAIN HUMIDIFIER is selected, the GCM-A will stop monitoring particulate levels and

the SYSTEM TROUBLE LED will illuminate. The prompt VALVE OPEN will be displayed on

the LCD display. Disconnect the water line from the water bottle and connect it to a syringe

(E/One Part # 0823-023). Draw back on the plunger of the syringe to draw the water out of

the Humidifier. Disconnect the syringe from the water line and press the syringe plunger to

discharge the water it contains. Repeat this process until all of the water in the Humidifier

has been removed. It has a 15 cubic centimeter capacity. Remove power from the GCM-A.

Adjusting the Ambient Airflow

Allow the flow meters to stabilize by letting the GCM-A warm up for at least 15 minutes prior

to making this adjustment.

IMPORTANT! It is important to note that the GCM-A system addresses flow monitoring in

two ways: the first is by using an external instrument (DP Gauge) to validate flow through the

zone manifold; the second method is by way of internal air flow sensors located within the

inlet manifold of the GCM-A. For the purposes of system design parameters and validation,

the DP Gauge is designated as the authoritative source of information regarding flow across

the zone manifold. The GCM-A’s internal flow sensor indication, while accurate, may differ

slightly from the DP Gauge. So long as the difference is minor, the end-user need not be

concerned. Should the difference between the GCM-A’s internal indicator and the GP Gauge

exceed 25 percent, contact Environment One at +1 518 346-6161 or www.eone.com/

detection, for technical support.

Locate the zone manifold that supplies ambient air to the GCM-A. Connect a differential

pressure gauge to the taps on the zone manifold (see Figure 12). Loosen or tighten the allen

head flow adjustment screw until the differential pressure gauge reads 6 inches of water

23

GA0383P02 Rev. C

(Adjusting the Ambient Airflow, cont’d)

(turn the screw clockwise to decrease the flow and reduce the differential pressure).

The GCM-A monitors the airflow through the zone manifold and generates a warning

indication if it drifts significantly from its nominal value. The GCM-A detects significant drift by

comparing the airflow against two software adjustable airflow limits. These flow limits should

be reset after adjusting the airflow through the zone manifold.

The procedure that resets the airflow limits is accessed through the SETUP menu. Select

SETUP from the main menu then AMBIENT FLOW ADJ from the SETUP menu. The GCM-A

will display the ambient airflow in liters per minute. Press the ENTER key to set the limits.

The GCM-A will respond by flashing SETTING LIMITS for two seconds while it sets the

ambient low flow limit and the ambient high flow limit. The ambient low flow limit is set to 50

percent of the indicated airflow reading, and the ambient high flow limit is set to 150 percent

of the indicated airflow reading.

Disconnect the differential pressure gauge and replace the sealing caps on the zone

manifold taps.

Adjusting the Generator Airflow

Allow the flow meters to stabilize by letting the GCM-A warm up for at least 15 minutes prior

to making this adjustment.

IMPORTANT! It is important to note that the GCM-A system addresses flow monitoring in

two ways; the first is by using an external instrument (DP Gage) to validate flow through the

zone manifold. The second method is by way of internal air flow sensors located within the

inlet manifold of the GCM-A. For the purposes of system design parameters and validation,

the DP Gage is designated as the authoritative source of information regarding flow across

the zone manifold. The GCM-A’s internal flow sensor indication, while accurate, may differ

slightly from the DP Gage. So long as the difference is minor, the end-user need not be

concerned. Should the difference between the GCM-A’s internal indicator and the GP Gage

exceed 25 percent, contact Environment One at +1 518 346-6161 or www.eone.com/

detection, for technical support.

Locate the zone manifold that supplies generator air to the GCM-A. Connect a differential

pressure gauge to the taps on the zone manifold (see Figure 12). Loosen or tighten the allen

head flow adjustment screw until the differential pressure gauge reads 6 inches of water

(turn the screw clockwise to decrease the flow and reduce the differential pressure).

The GCM-A monitors the airflow through the zone manifold and generates a warning

indication if it drifts significantly from its nominal value. The GCM-A detects significant drift by

comparing the airflow against two software adjustable airflow limits. These flow limits should

be reset after adjusting the airflow through the zone manifold.

The procedure that resets the airflow limits is accessed through the SETUP menu. Select

SETUP from the main menu then GENERATOR FLOW ADJ from the SETUP menu. The

GCM-A will display the ambient airflow in liters per minute. Press the ENTER key to set the

limits. The GCM-A will respond by flashing SETTING LIMITS for two seconds while it sets the

generator low flow limit and the generator high flow limit. The generator low flow limit is set to

50 percent of the indicated airflow reading and the generator high flow limit is set to 150

percent of the indicated airflow reading.

GA0383P02 Rev. C

24

(Adjusting the Generator Airflow, cont’d)

Disconnect the differential pressure gauge and replace the sealing caps on the zone

manifold taps.

Adjusting the Cloud Chamber Airflow

When CHAMBER FLOW ADJ is selected, the GCM-A will stop monitoring particulate levels

and the SYSTEM TROUBLE LED will illuminate. The prompt CONNECT FLOWMETER will

be displayed on the LCD display for reference. Press the FN key to return to the SETUP

MENU.

To check and or adjust the cloud chamber flow disconnect the air sample line from the quick

disconnect fitting on the manifold and insert it into the cloud chamber flow meter (Part #

FA0263G01). Adjust the air flow to 1.1 LPM by adjusting the Chamber Flow Adjust screw (1/

16 allen screw) located on the Chamber/Humidifier assembly on the bottom front side of the

cloud chamber. Remove the air flow meter and reconnect the air sample line to the Inlet

Manifold fitting. Press the FN key to return to normal functioning.

Setting the Ambient Gain

The ambient gain determines the sensitivity of the submicron particle detector. The higher

the ambient gain setting, the more sensitive the detector. The factory default value for the

ambient gain is 1. The ambient gain can be changed by selecting AMBIENT GAIN from the

SETUP MENU.

When AMBIENT GAIN is selected, the ambient gain will be displayed on the LCD display.

Press the UP ARROW key to increase it. Press the DOWN ARROW key to decrease it. It

cannot be decreased below 1 or increased beyond 9.9. Press the ENTER key to save your

changes and return to the SETUP MENU. Press the FN key to discard the changes and

return to the SETUP MENU.

Setting the Ambient Warning Level

The ambient warning level determines what electrical output from the cloud chamber

detector will trigger a WARNING indication The ambient warning level is expressed as a

percentage of full scale. A WARNING indication is given when the output of the cloud

chamber detector exceeds the value of ambient warning level. The factory default value for

the ambient warning level is 50 percent. The ambient warning level can be changed by

selecting AMBIENT WARNING from the SETUP MENU.

When AMBIENT WARNING is selected, the ambient warning level will be displayed on the

LCD display. Press the UP ARROW key to increase it. Press the DOWN ARROW key to

decrease it. It cannot be decreased below one or increased beyond the ambient alarm level.

Press the ENTER key to save your changes and return to the SETUP MENU. Press the FN

key to discard the changes and return to the SETUP MENU.

Setting the Ambient Alarm Level

The ambient alarm level determines what electrical output from the cloud chamber detector

will trigger an ALARM indication. The ambient alarm level is expressed as a percentage of full

scale. An ALARM indication is given when the output of the cloud chamber detector exceeds

the value of ambient alarm level. The factory default value for the ambient alarm level is 80

percent. The ambient alarm level can be changed by selecting AMBIENT ALARM from the

SETUP MENU.

25

GA0383P02 Rev. C

(Setting the Ambient Alarm Level, cont’d)

When AMBIENT ALARM is selected, the ambient alarm level will be displayed on the LCD

display. Press the UP ARROW key to increase it. Press the DOWN ARROW key to

decrease it. It cannot be decreased below the ambient warning level or increased beyond 99

percent. Press the ENTER key to save your changes and return to the SETUP MENU. Press

the FN key to discard the changes and return to the SETUP MENU.

Setting the Generator Gain

The generator gain determines the sensitivity of the submicron particle detector. The higher

the generator gain setting, the more sensitive the detector. The factory default value for the

generator gain is one. The generator gain can be changed by selecting GENERATOR GAIN

from the SETUP MENU.

When GENERATOR GAIN is selected, the generator gain will be displayed on the LCD

display. Press the UP ARROW key to increase the value; press the DOWN ARROW key to

decrease the value. The value cannot be decreased below one or increased beyond 9.9.

Press the ENTER key to save chances and return to the SETUP MENU; press the FN key to

discard the changes and return to the SETUP MENU.

Setting the Generator Warning Level

The generator warning level determines what electrical output from the cloud chamber

detector will trigger a WARNING indication. The generator warning level is expressed as a

percentage of full scale. A WARNING indication is given when the output of the cloud

chamber detector exceeds the value of generator warning level. The factory default is 50

percent; select GENERATOR WARNING from the SETUP MENU to change the default.

When GENERATOR WARNING is selected, the generator warning level is displayed on the

LCD display. Press the UP ARROW key to increase the level; press the DOWN ARROW to

decrease the level. The level cannot below one or increased beyond the generator alarm

level. Press the ENTER key to save changes and return to the SETUP MENU; press the FN

key to discard changes and return to the SETUP MENU.

Setting the Generator Alarm Level

The generator alarm level determines what electrical output from the cloud chamber detector

will trigger an ALARM indication. The generator alarm level is expressed as a percentage of

full scale. An ALARM indication is given when the output of the cloud chamber detector

exceeds the value of the generator alarm level. The factory default is 80 percent; the default

can be changed by selecting GENERATOR ALARM from the SETUP MENU.

Setting the Differential Warning Level

The differential warning level determines what electrical output from the cloud chamber

detector will trigger a WARNING indication. The differential warning level is expressed as a

percentage of full scale. A WARNING indication is given when the output of the cloud

chamber detector exceeds the value of the differential warning level. The factory default value

is 30 percent; the value can be changed by selecting DIFFERENTIAL WARNING from the

SETUP MENU.

When DIFFERENTIAL WARNING is selected, the differential warning level will be displayed

on the LCD display. Press the UP ARROW key to increase the value; press the DOWN

ARROW key to decrease the value. The value cannot be decreased below one or increased

GA0383P02 Rev. C

26

(Setting the Differential Warning Level, cont’d)

beyond the differential alarm level. Press the ENTER key to save your changes and return to

the SETUP MENU. Press the FN key to discard changes and return to the SETUP MENU.

Setting the Differential Alarm Level

The differential alarm level determines what electrical output from the cloud chamber

detector will trigger an ALARM indication. The differential alarm level is expressed as a

percentage of full scale. An ALARM indication is given when the generator output level

exceeds the ambient output level by a value greater than the differential alarm level. The

factory default value is 50 percent. The differential alarm level can be changed by selecting

DIFFERENTIAL ALARM from the SETUP MENU.

When DIFFERENTIAL ALARM is selected, the differential alarm level is displayed on the

LCD display. Press the UP ARROW key to increase the value; press the DOWN ARROW

key to decrease the value. The value cannot be decreased below the differential warning

level or increased beyond 99 percent. Press the ENTER key to save changes and return to

the SETUP MENU; press the FN key to discard changes and return to the SETUP MENU.

About the Faults Log

· The Faults log traps these error conditions: I/O Read Error, I/O Write Error, COM1 RX

Overflow, COM1 Tx Overflow, Bad Command Checksum, Received Unknown

Command, Alarm Relay Fault, Trouble Relay Fault, Ambient Flow Fault, Generator Flow

Fault, Vacuum Fault, Photocell Fault, Cycle Fault, Water Fault and Power Fault.

· An I/O READ ERROR is logged when a read error is detected in the communication

channel that connects the processor and I/O board.

· An I/O WRITE ERROR is logged when a write error is detected in the communication

channel that connects the processor and I/O board.

· A COM1 RX OVERFLOW is logged when the remote computer sends data faster than

the GCM-A can process it. It usually indicates a problem with the flow control setting on

the remote computer.

· A COM1 TX OVERFLOW is logged when the GCM-A sends data faster than the remote

computer can process it.

· A BAD CMD CHECKSUM is logged when the GCM-A receives a command that was

corrupted during transmission.

· A RCVD UNKNOWN CMD is logged when the GCM-A receives a command from the

remote computer that it does not understand. It usually indicates that the software

version of the remote control software is newer than that of the GCM-A.

· A POWER FAULT is logged when the measured voltage of one or more of the power

supplies is out of specification.

· An ALARM RELAY FAULT is logged when one of the three alarm relays is not

functioning properly.

· A TROUBLE RELAY FAULT is logged when there is a problem with the warning, flow

trouble or system trouble relays.

27

GA0383P02 Rev. C

(About the Faults Log, cont’d)

· An AMBIENT FLOW FAULT is logged when flow rate through the ambient air intake falls

below the ambient low flow limit or climbs above the ambient high flow limit.

· A GENERATOR FLOW FAULT is logged when flow rate through the generator air intake

falls below the generator low flow limit or climbs above the generator high flow limit.

· A VACUUM FAULT is logged when the Vacuum level or the duty cycle of the Vacuum

pump deviates from its normal range.

· A PHOTOCELL FAULT is logged when the LED current deviates from its normal range.

The normal range of LED current is from 4 mA to 16 mA.

· A CYCLE FAULT is logged when the timing of the vacuum pulse varies by more than 2

percent.

· A WATER FAULT is logged when the GCM-A is low on water or when it uses an unusual

amount of water. An unusual amount is defined as filling for more than 15 continuous

seconds or going without water for more than 24 hours.

About the Power Log

· The Power log records the minimum and maximum voltage of each power supply. The

voltage is sampled once every two seconds.

· When SHOW POWER LOG is selected, the GCM-A will display the minimum and

maximum for each power supply in the format <nominal value>=<minimum

value>,<maximum value>. An example for the 5-volt power supply is +5V=4.9,5.2. Use

the UP ARROW key or DOWN ARROW key to scroll through the five power supply

voltages. Press the FN key to return to the LOG MENU.

GA0383P02 Rev. C

28

Modes of Operation

Startup

The GCM-A initializes the display mode to local and all relays to the de-energized position.

The GCM-A executes a “power-on self test” (POST) to verify its proper operation. It verifies

its software by checksum testing the contents of its read-only memory (ROM). It tests all of

its power supplies and all of its relays. It verifies the sampler system, vacuum pump and

rotary valve. It checks the water system and the ambient and generator airflow rates.

The POST will take about 30 seconds to complete if no errors are encountered. At the

conclusion of the POST, the GCM-A display panel will flash STARTING CHAMBER for two

seconds before beginning normal operation. If the FN key is pressed while it is still flashing,

normal operation will be canceled and the GCM-A will enter suspended operation instead.

Startup Problems

The GCM-A verifies its software by checksum testing the contents of its read only memory

(ROM). If it finds a problem it will stop the POST process and flash BAD CHECKSUM on the

LCD. The FN key may be pressed to allow the GCM-A to continue the POST process.

However, proper operation cannot be guaranteed if this error is present.

The GCM-A will annunciate any problems it finds with the power supplies or relays. The

presence of one or more of these faults will not stop the POST process. However, they

should be corrected as soon as possible because they indicate a hardware problem.

· +5 VOLTS=N.N a flashing 5-volt power supply voltage indicates that the 5-volt power

supply is out of specification.

· +6 VOLTS=N.N a flashing 6-volt power supply voltage indicates that the 6-volt power

supply is out of specification.

· +15 VOLTS=N.N a flashing 15-volt power supply voltage indicates that the 15-volt power

supply is out of specification.

· -15 VOLTS=N.N a flashing -15 volt power supply voltage indicates that the -15 volt

power supply is out of specification.

· The GCM-A will annunciate any problems it finds with the submicron particle detector.

The GCM-A will pause on each error and wait for the operator to acknowledge the error

by pressing the FN key.

· BAD ROTARY VALVE indicates a problem with the cloud chamber rotary valve or optical

interrupter.

· BAD VACUUM indicates that the vacuum pump could not provide at least 8 inches of

vacuum to the cloud chamber.

· PLUGGED SAMPLE LINE indicates a loose rotary valve or a plugged sample line.

· AMB FLO=N.N LPM a flashing airflow indicates that the airflow indicated is less than the

29

GA0383P02 Rev. C

(Startup Problems, Cont’d.)

ambient low flow limit or greater than ambient high flow limit. This error indicates that the

airflow needs to be adjusted according to the procedure “Adjusting the Ambient Airflow.”

· GEN FLO=N.N LPM a flashing airflow indicates that the airflow indicated is less than the

generator low flow limit or greater than generator high flow limit. This error indicates that

the airflow needs to be adjusted according to the procedure “Adjusting the Generator

Airflow.”

· LEAKING SAMPLE LINE indicates that the sample line running from the inlet manifold to

the cloud chamber may be leaking.

· BAD SOLENOID (AMB) indicates that the intake manifold solenoid that controls the

ambient air intake has failed.

· BAD SOLENOID (GEN) indicates that the intake manifold solenoid that controls the

generator air intake has failed.

· FILL WATER BOTTLE indicates that the water bottle is empty.

· CONTINUE FILLING? Indicates that the humidifier is using an unusually large quantity of

water. It may indicate that the water level sensor has failed. Press ENTER to continue

filling.

Alternating Operation

· When the GCM-A is in alternating operation, it will monitor the particulate level but it will

not generate any alarms or warnings.

· The SYSTEM TROUBLE LED will be illuminated whenever the GCM-A is in this mode of

operation.

· The GCM-A monitors the flow rate with a flow sensor. It monitors the particulate level

with a cloud chamber detector.

· The GCM-A will display the particulate level of the generator and ambient air on the LED

bar graphs. The particulate level of the generator and ambient air are also available

through two four- to 20-milliamp (4-20 mA) outputs.

· The particulate level of the generator and ambient air is updated once every 32 seconds.

Ambient Only Operation

· When the GCM-A is in ambient only operation, it will monitor the ambient particulate level,

but it will not generate any alarms or warnings.

· The SYSTEM TROUBLE LED will be illuminated whenever the GCM-A is in this mode of

operation.

• The GCM-A monitors the flow rate with a flow sensor. It monitors the particulate level

with a cloud chamber detector.

· The GCM-A will display the particulate level of the ambient air on the LED bar graph

labeled “AMB”; the bar graph labeled GEN will read zero. The particulate level of the

generator air will not be checked. The particulate level of the ambient air is also

GA0383P02 Rev. C

30

(Ambient Only Operation, cont’d)

available through two four- to 20-milliamp (4-20mA) outputs.

· The particulate level of the generator and ambient air is updated every second.

Generator Only Operation

• When the GCM-A is in suspended operation, it will monitor the generator particulate level,

but it will not generate any alarms or warnings.

• The SYSTEM TROUBLE LED will be illuminated whenever the GCM-A is in this mode of

operation.

• The GCM-A monitors the flow rate with a flow sensor. It monitors the particulate level

with a cloud chamber detector.

• The GCM-A will display the particulate level of the generator air on the LED bar graph

labeled “GEN”; the bar graph labeled “AMB” will read zero. The particulate level of the

ambient air will not be checked. The particulate level of the generator air is also available

through its four- to 20-milliamp (4-20mA) output.

• The particulate level of the generator air is updated every second.

31

GA0383P02 Rev. C

Troubleshooting

Table 1 (Customer Contacts)

Contact

Ambient Alarm

Generator Alarm

Energized when an ambient alarm occurs, can only be cleared by

pressing reset.

Energized when a generator alarm occurs, can only be cleared by

pressing reset.

Difference Alarm

Flow Trouble

System Trouble

Common Warning

1

Applicable line in Table 4 (GCM-A Status)

Energized when a difference alarm occurs, can only be cleared by

pressing reset.

Energized whenever the airflow through the ambient or generator

sampling system is out of specification.