Enwork XTB4 Installation Manual

1

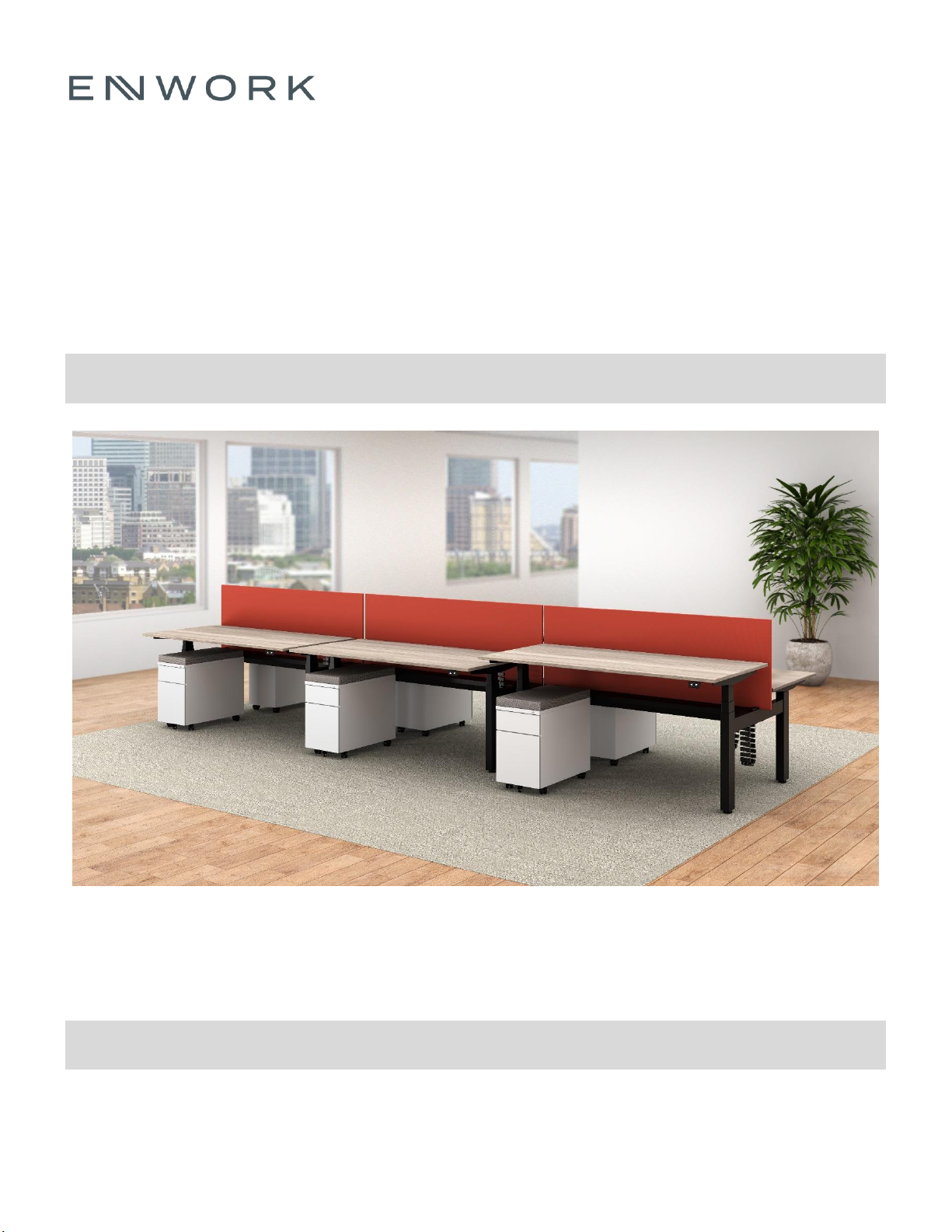

XTB4 LINKED BENCHING

UN0001 Rev. A

Height Adjustable Benching

XTB4 Installation Guide

2

Table of Contents:

i. Parts & Fasteners Included ………………………………………………………………………………3

ii. Tools & Supplies Required ……………………………………………………………………………….6

iii. Rectangular Back-to-Back Benching ……………………………………………………………….7

iv. Optional Additions (Screens/End Panels) ……………………………………………………….12

v. 120 Degree Benching ………………………………………………………………………………………13

vi. Single Sided Benching …………………………………………………………………………………….16

vii. Extended Corner Benching ……………………………………………………………………………..19

viii. Handset Instructions ………………………………………………………………………………………23

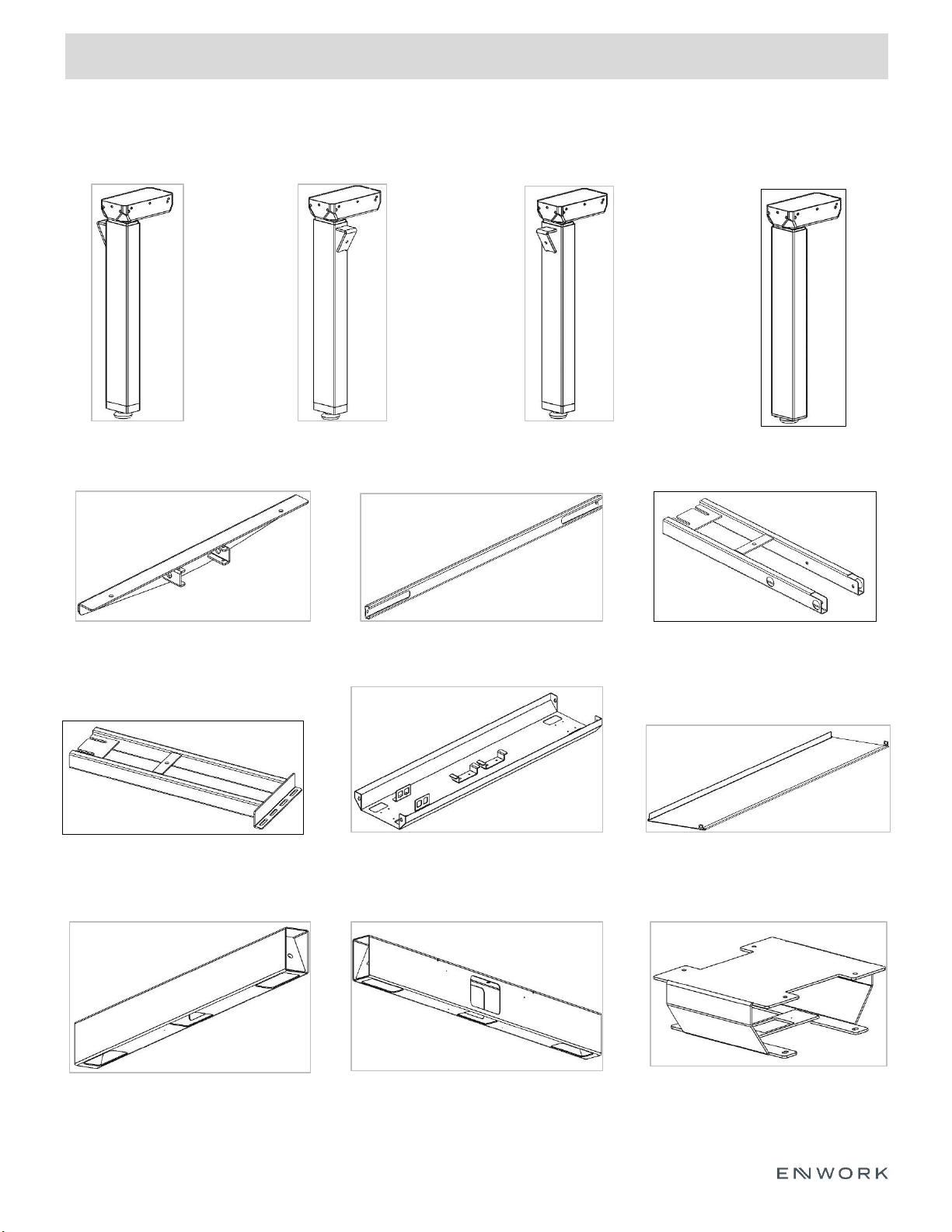

1) Parts and Fasteners Included

INSTALLATION GUIDE

3

Right Leg Column Left Leg Column

*120 Degree - Rear Column

Top Support Bracket Center Rail Support Frame End w/ Control Plate

*Extended Corner Frame Power Trough Trough Cover

Mid Link Connector

End Link Mid Link

*Extended Corner – 3

rd

Leg Column

* - Optional part included with corresponding Single Sided, 120 Degree, or Extended Corner configuration

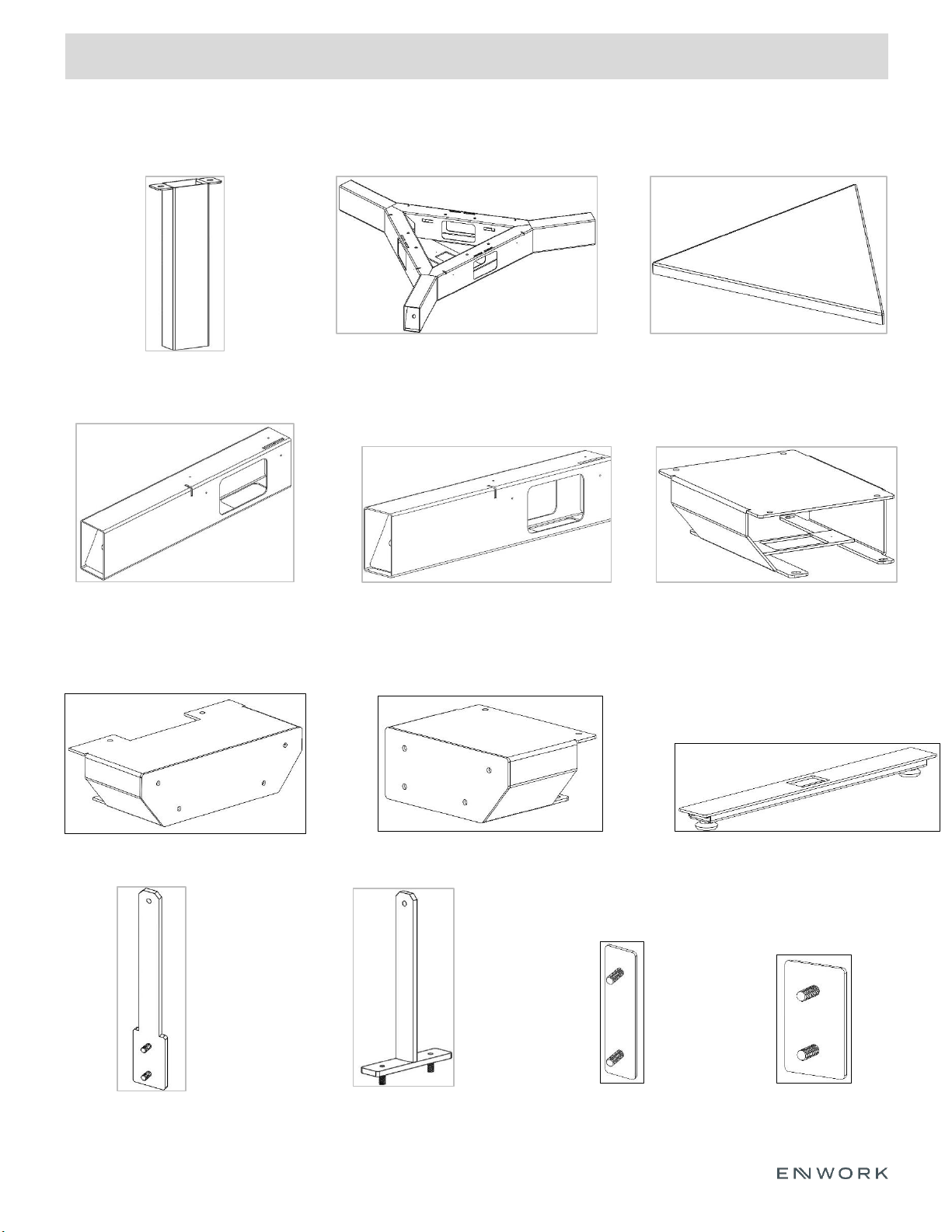

1) Parts and Fasteners Included

INSTALLATION GUIDE

4

In-Feed Leg

*120 Degree Mid Link (120

Degree)

*120 Degree Mid Link Cover

(120 Degree)

*End Link – Single sided *Mid Link – Single Sided

*Foot

*End Panel Bracket - Double Sided

*Screen Bracket -

Double Sided

*Screen Bracket -

Single Sided

*Mid Link Connector – Single Sided

* - Optional part included with corresponding Single Sided, 120 Degree, or Extended Corner configuration

*End Panel Bracket - Single Sided

*Cover – Double

Sided

*Cover – Single

Sided

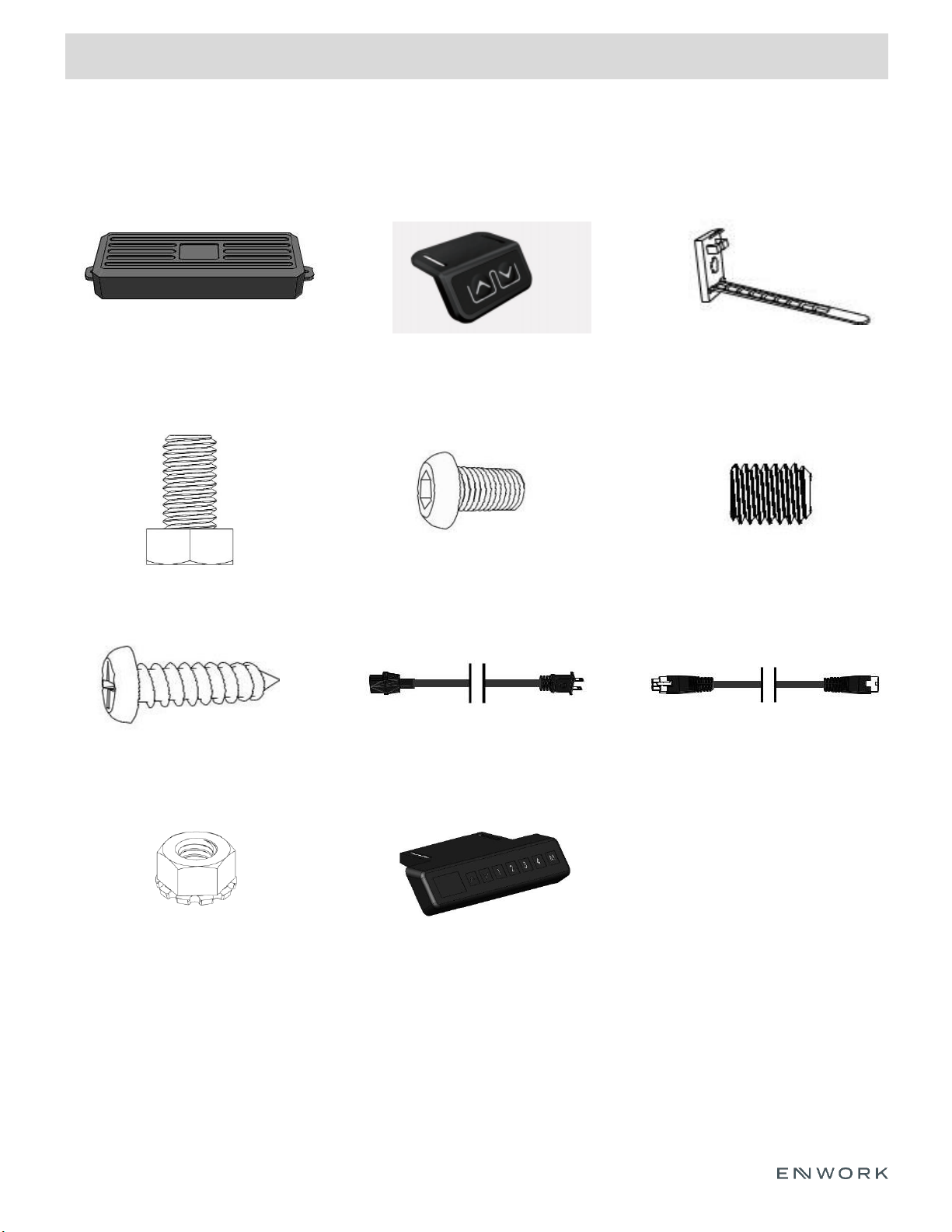

1) Parts and Fasteners Included

INSTALLATION GUIDE

5

Control Box

Handset Cable ties

M6 x 1.0 Button Head

Hex Screw

Set Screw (pre-installed)

Wood Screw Power Cable

Leg Cable

M8 x 1.25 Hex Head Bolt

M6 x 1.0 Locknut w/ external tooth

lock washer

*Programmable Handset

* - Optional part

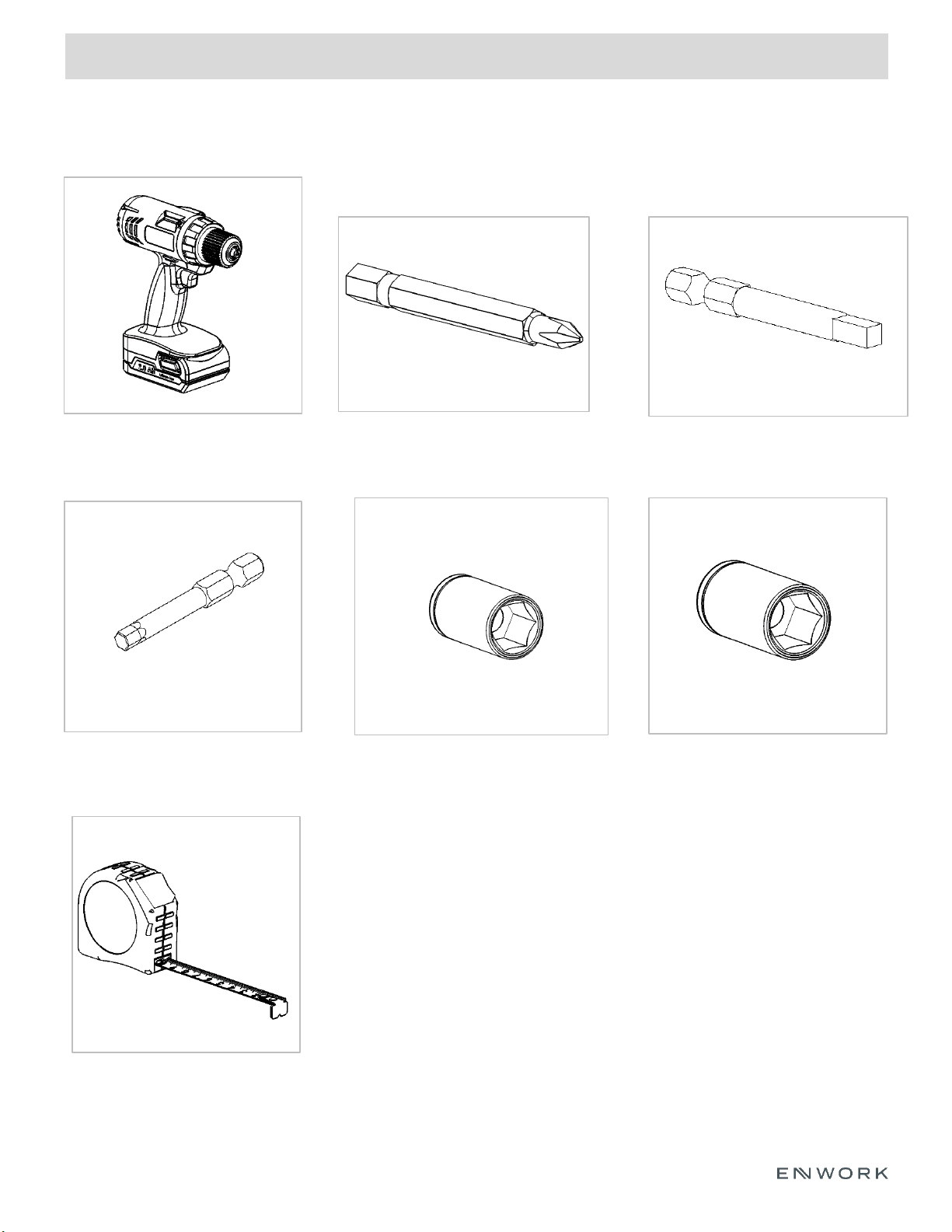

2) Tools and Supplies Required

INSTALLATION GUIDE

6

4mm Hex Bit

10mm Socket

Drill

Phillips Bit

Square Bit

13mm Socket

Tape Measure

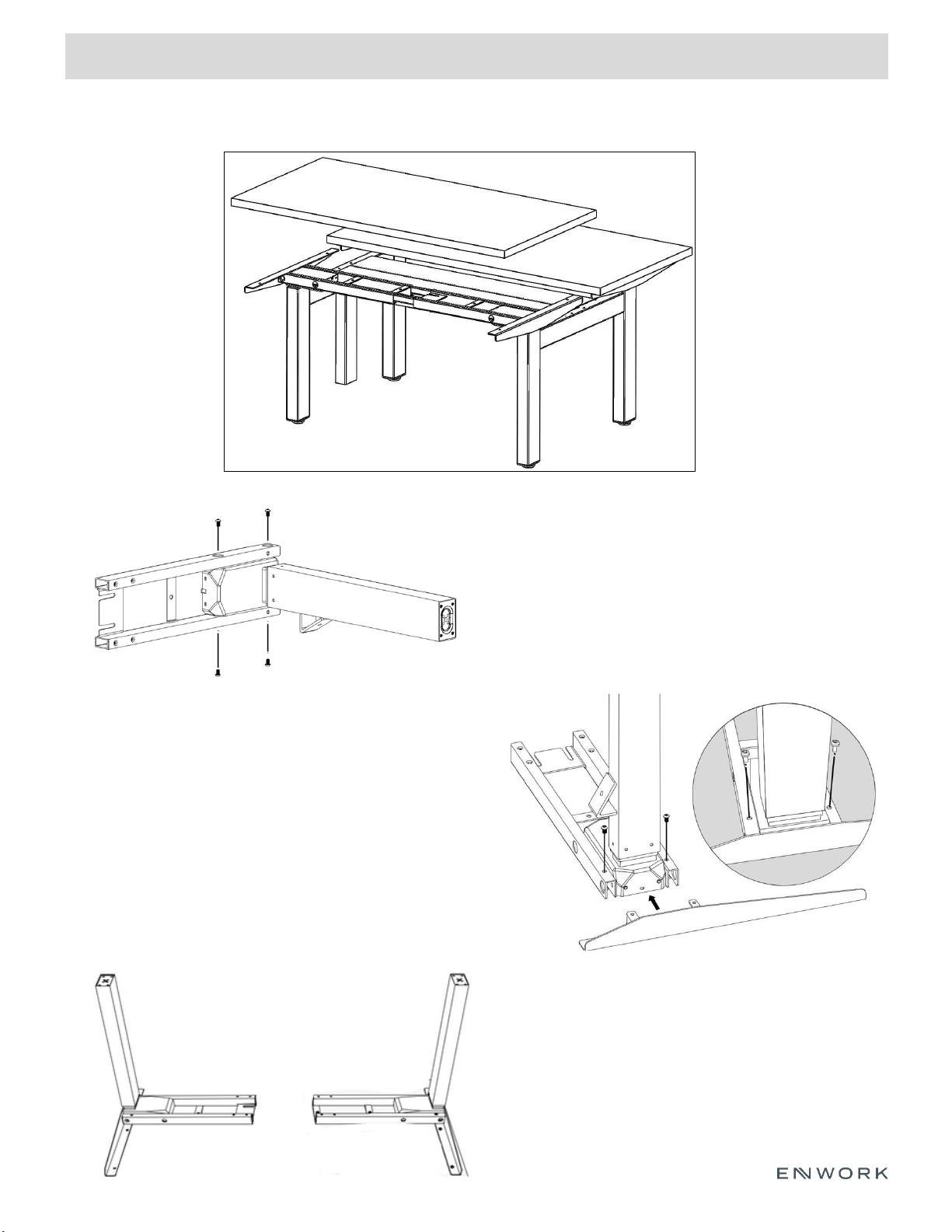

3) Assembly:

INSTALLATION GUIDE

7

3.1.1) Insert a Right Leg Column into a Frame

End w/ Control Plate using (4) M6 x 1.0 Button

head hex screws. Do not fully tighten at this

time.

3.2.1) Attach a Top Support Arm using (2) M6 x 1.0

Button head hex screws. Do not full tighten.

3.2.2) Once Frame and Arm are in place together,

tighten all screws completely.

**Note** The two tabs on the support arm will slot

into the frame end, surrounding the leg column.

3.3.1) Repeat previous steps to assemble

remaining leg columns, frame ends, and top

support brackets.

Fig 3.1

Fig 3.2

Fig 3.3

Standard Benching

2-Pack Rectangular Bench Shown

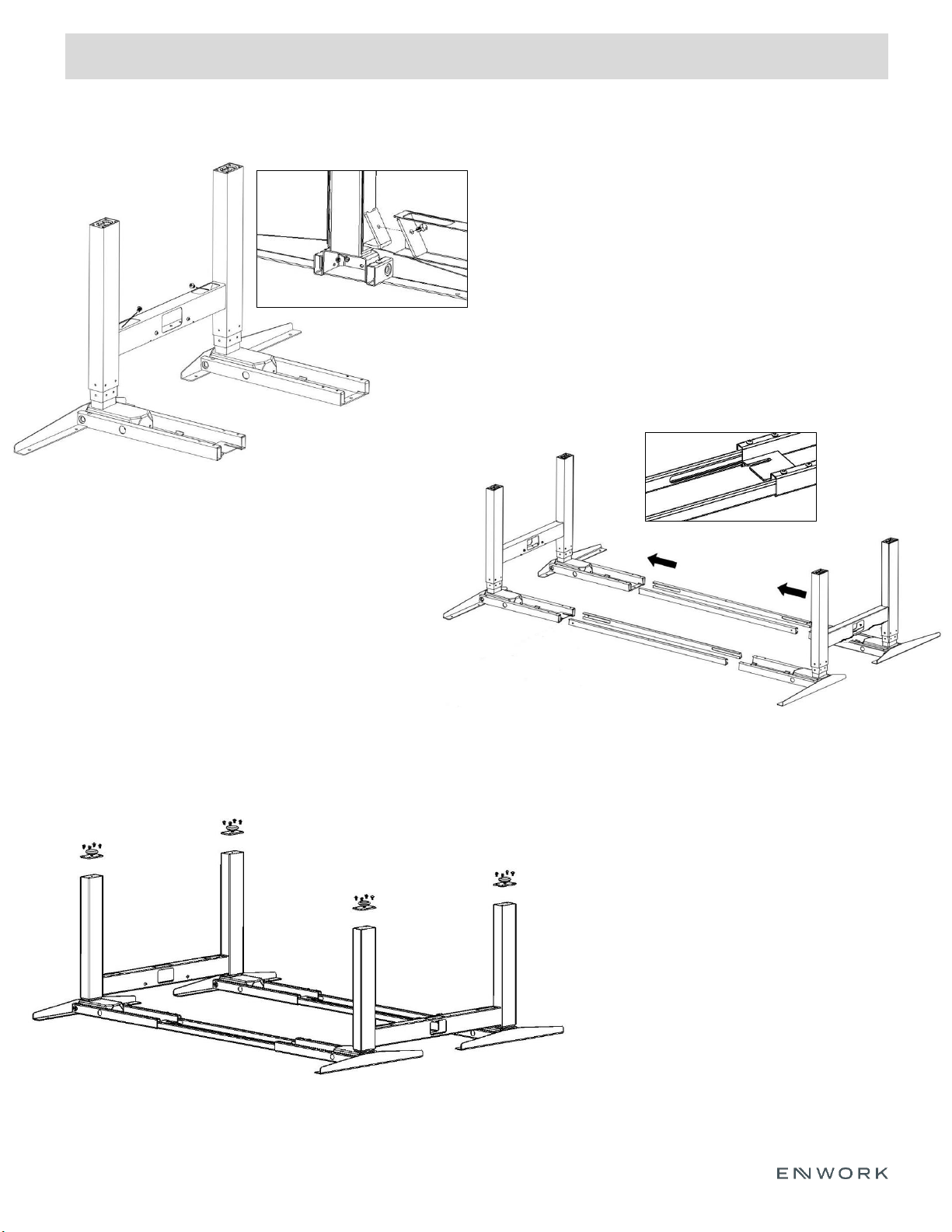

3) Assembly:

INSTALLATION GUIDE

8

3.5.1) Slide center rail supports into leg assemblies

so that the midpoint mark is facing up and the slot-

cuts are facing inwards. Do not fully tighten set

screws at this step.

**Note** Orientation of center rail supports

3.4.1) Connect one Right leg assembly and one

Left leg assembly together using an End link and

(2) M8 x 1.25 Hex Head bolts. *See section detail

for alignment

3.4.2) Repeat previous step on left leg assembly

using a Mid link.

**Note** Mid-Link has a pass thru-hole. End-Link

will have one closed vertical face. Use the Mid-link

when additional desk pairs are needed. Use the

End-links where no additional desks will be used.

Fig 3.5

Fig 3.6

Fig 3.4

3.6.1) If not already, attach each stand-off

using (4) M6 x 1.0 Button head hex screws

3.6.2) Insert levelers if not already in place.

Standard Benching Cont.

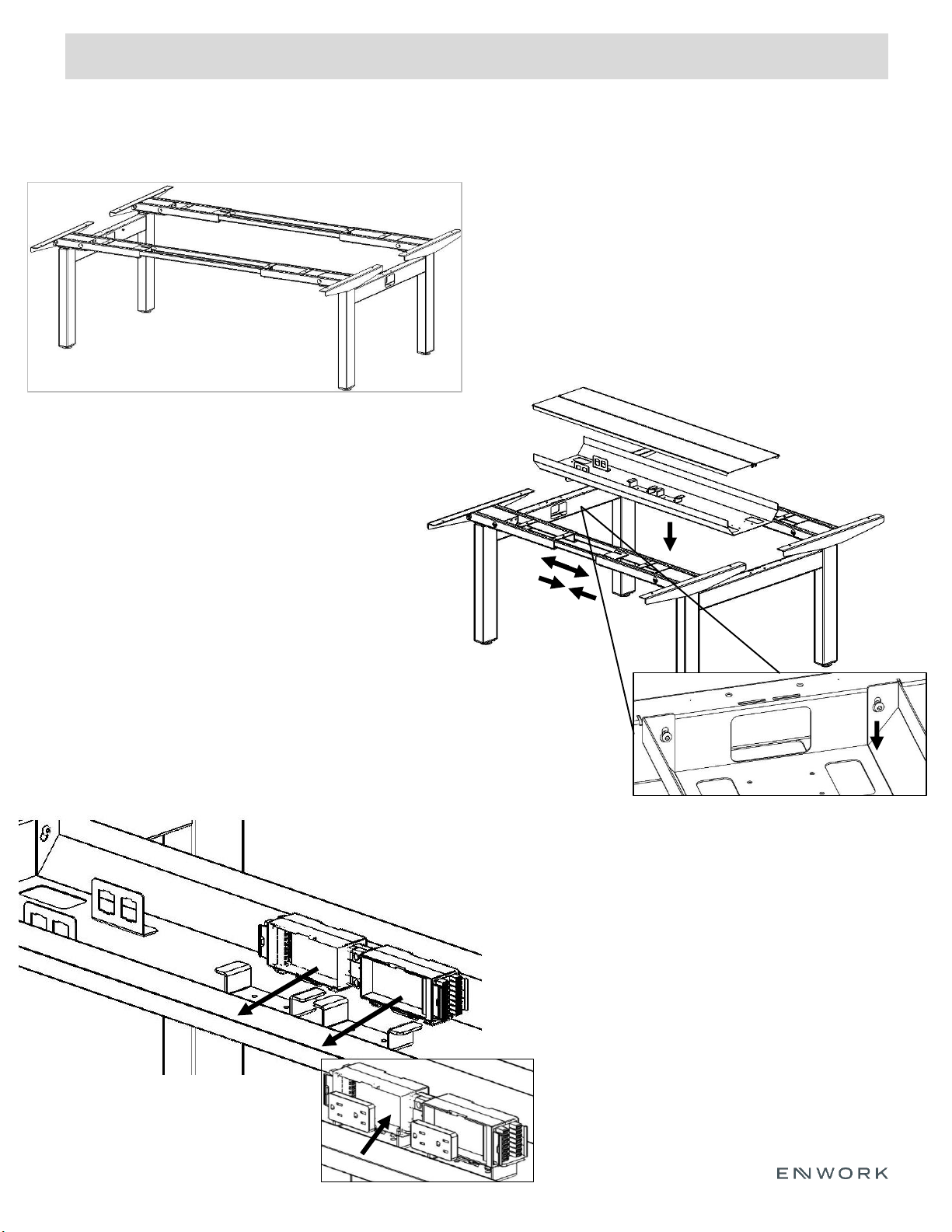

3) Assembly:

INSTALLATION GUIDE

9

3.7.1) Double check that legs, frame, and links are tight.

**Note** Center rails to still be loose at this time.

3.7.2) With (at least) one other person, carefully flip

frame. Please note that the center rails will slide freely.

Fig 3.8

Fig 3.7

3.9.1) Attach power block to pre-installed brackets

as shown. Brackets should click into place.

3.9.2) Once power block is installed, insert the

outlets into place.

**Note** If wiring diagrams are needed, refer to

instructions from electrical components.

3.8.1) Loosely install (4) M6 x 1.0 Button head hex

screws into end and mid-links.

3.8.2) Lower power trough into place using

keyslots onto machine screws. Once it is in place,

secure all screws.

**Note** Center rails may need to slide to

accommodate for trough width.

3.8.3) After trough is in place, tighten all set

screws on the bottom of the frames to secure the

Center rails.

Standard Benching Cont.

Fig 3.9

Loading...

Loading...