Sliding Top Desk

Sliding Top Desk

AMI0004 - Installation Instruction

Revision A 12/14/2017

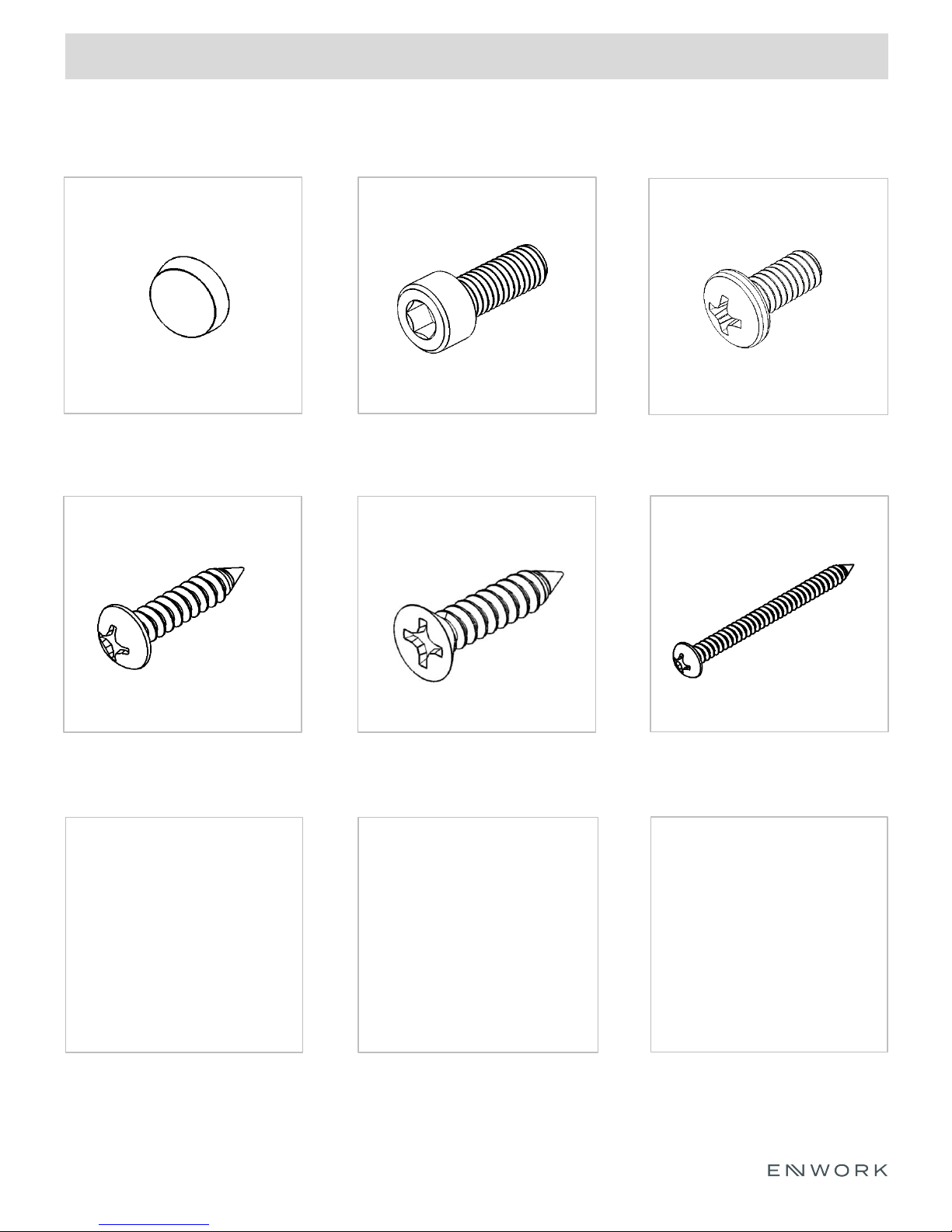

1) Parts and Fasteners Included

INSTALLATION GUIDE

AMM-3030-xx QTY: (1)

BOLTED FRAME ASSEMBLY

AMM-1424-xx QTY: (1)

TROUGH

LVTER QTY: (2)

LEG COLUMN ASSEMBLY

AMM-1425-2 QTY: (1)

WIRE MANAGEMENT COVER

EM-2162-3 QTY: (2)

FOOT WELDMENT

AMM-1433-2 QTY: (4)

SLIDING/STOP BRACKET

FOOT ATTACHMENT QTY: (2)

SPACER

AML-1354-xx QTY: (1)

WORK SURFACE BACK PIECE

AML-1355-xx QTY: (1)

WORK SURFACE FRONT PIECE

1) Parts and Fasteners Included

INSTALLATION GUIDE

3M BUMPON ADHESIVE

BACKED RUBBER BUMPER

QTY: (2)

#8 x 0.75” PAN HEAD WOOD SCREW

QTY: (12)

M6 X 16mm SHCS

QTY: (20)

#8x 0.75” FLAT HEAD WOOD SCREW

QTY: (4)

#8-32 x .375” MACHINE SCREW

QTY: (11)

#10 x 2.25” WOOD SCREW

QTY: (6)

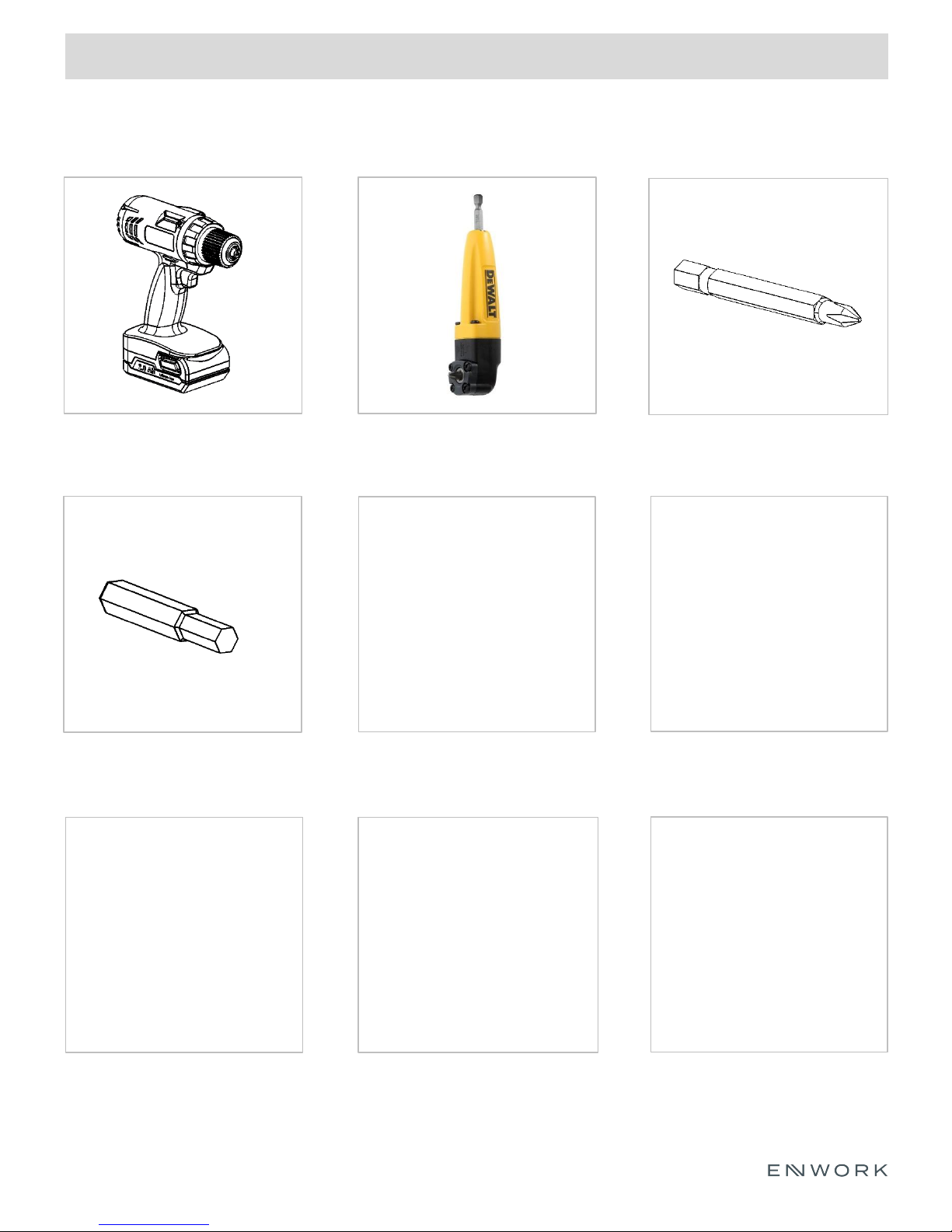

2) Tools and Supplies Required

INSTALLATION GUIDE

DRILL / DRIVER

5mm HEX BIT

RIGHT ANGLE DRILL ADAPTER

#2 PHILLIPS DRIVER BIT

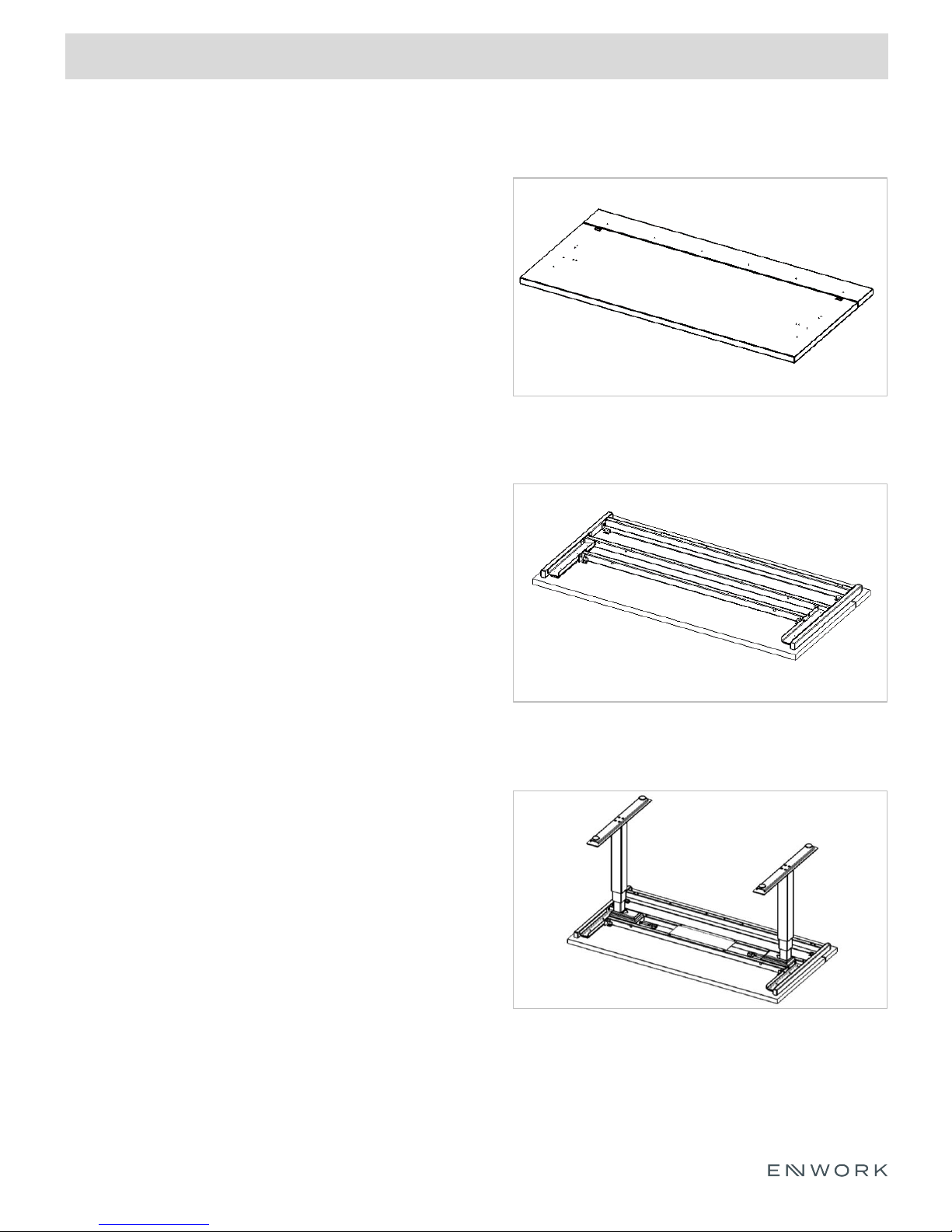

3) Assembly Overview

1. Surface preparation

2. Bolted frame attachment

3. Leg column attachment

4. Slide-stop bracket attachment

INSTALLATION GUIDE

5. Trough attachment

6. Foot attachment

7. Handset Attachment

8. Wire Management

9. Completed Table

FIGURE 3.1

WORKSURFACE

FIGURE 3.3

BOLTED FRAME ATTACHMENT

FIGURE 3.6

LEG AND FOOT ATTACHMENT

INSTALLATION GUIDE

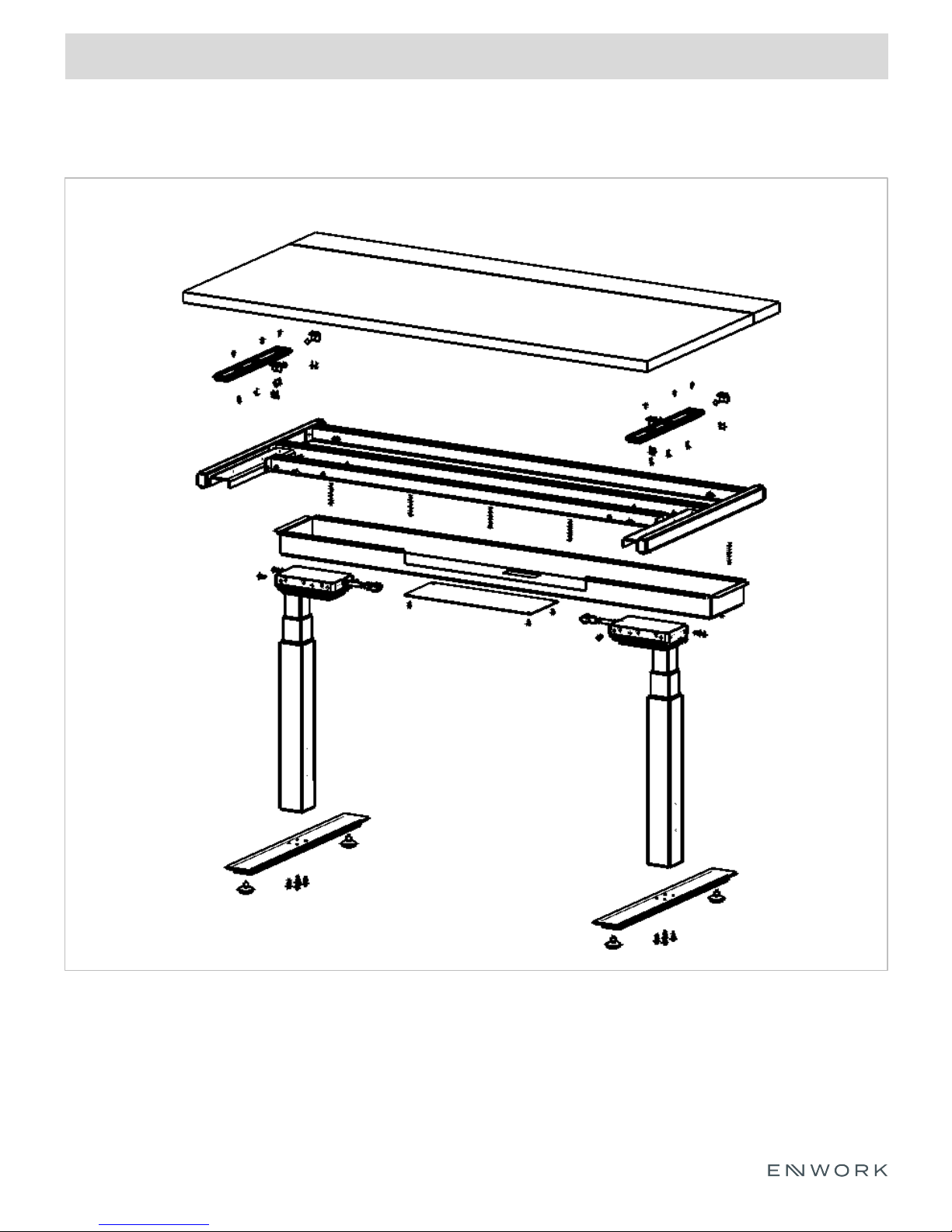

4) Assembly:

Exploded View

FIGURE 4.0.1

EXPLODED ASSEMBLY VIEW

INSTALLATION GUIDE

4) Assembly:

FIGURE 4.1.1

Work-surface preparation

Place both work-surface pieces (AML-1354-xx

and AML-1355-xx) down on a padded

workbench or similar non-marring surface.

Bolted Frame Attachment

Figure 4.2.1

Bolted frame attachment

Line up the predrills of the work-surface back

piece (AML-1354-xx) to the through holes of

the Bolted Frame Assembly (AMM-3030-xx).

Attach the Bolted Frame Assembly (AMM3030-xx) to the work-surface (AML-1354-xx)

using (6) #10 x 2.25” wood screws.

FIGURE 4.2.2

Top view of work surface and bolted frame

shown.

FIGURE 4.2.3

Detailed view of figure 4.2.2 shown.

After AMM-3030-xx is attached, confirm that

the product matches the picture shown in

Figure 4.2.3.

INSTALLATION GUIDE

4) Assembly:

Figure 4.2.4

Bolted Frame Attachment Cont.

Open the drawer slides (6500B 14) and line up the

predrills to the circular holes in the drawer slide.

Attach the drawer slides to the work-surface sliding

piece (AML-1355-xx) using (8) #8 x 0.75” Pan head

wood screws.

Detailed view of slide attachment.

Note: The center attachment point may be covered by

the middle slide rail. Adjust the slide accordingly to

access this attachment point.

Figure 4.2.5

Figure 4.2.6

Once the slides are attached, slide the desk back to

the closed position.

Once the drawer slides are attached to the work

surface sliding piece, slide the top into the closed

position.

INSTALLATION GUIDE

4) Assembly:

Leg Column Attachment

Figure 4.3.1

To attach the leg columns to the bolted frame, insert (2) M6 x 16mm socket head cap screws into the

threaded holes in the back of the leg column. Do not fully drive these screws in, simply get them started into

the threaded holes.

Then, lower the leg column down onto the bolted frame so that the partially inserted screws rest on the

open notches of the bolted frame assembly.

INSTALLATION GUIDE

4) Assembly:

Figure 4.3.2

Leg Column Attachment Cont.

Detailed view of previous step shown.

The bolts will rest in the open slot cuts of the Bolted

Frame assembly.

Line up the clearance holes in the bolted frame with

the threaded holes in the side of the leg column.

Attach the leg column to the bolted frame with (4) M6

x 16mm socket head caps screws.

Figure 4.3.3

Figure 4.3.4

NOTE: If the front crossbar of the Bolted frame

assembly does not line up to the leg column, loosen

the 1/4-20 Phillips pan head screw that holds the front

crossbar to the slide plate. This will allow the Leg

column to seat flush to the front crossbar. Tighten the

¼-20 pan head screw when finished.

Fully tighten the (2) M6 bolts from Figure 4.3.1

Repeat steps from Figure 4.3.1 through 4.3.4 for the

second leg column.

INSTALLATION GUIDE

4) Assembly:

Figure 4.4.1

Slide-Stop Bracket Attachment

Locate the two slide stop brackets (AMM-1433-2) that

do not have magnets attached to them.

Locate (4) #8 x 0.75” flat head wood screws.

Attach the slide stop bracket to the designated

pockets routed into the front work surface using (2) #8

x 0.75” flat head wood screws.

Verify that the bracket is orientated correctly as seen in

figure 4.4.2.

Figure 4.4.2

Figure 4.4.3

Locate the 3M Bumpon adhesive bumper.

Peel the bumper off of the backer paper and attach it

to the front of the slide-stop bracket. Center the

bumper over the small hole in the bracket.

Complete the above steps for the second bracket.

INSTALLATION GUIDE

4) Assembly:

Figure 4.4.4

Slide-Stop Bracket Attachment Cont.

Locate (2) Slide-stop brackets with the magnets

attached and (4) #8 x 0.75” Pan head wood screws.

Confirm that the sliding top is in the closed position.

Place the Slide-stop bracket on the work surface and

align the clearance slots with the pre-drilled holes in

the work surface.

Allow the magnet to attach to the front crossbar of the

Bolted Frame assembly. Verify that the clearance slots

still line up with the pre-drilled holes.

Figure 4.4.5

Figure 4.4.6

Attach the Slide-stop bracket to the work surface using

(2) #8 x 0.75” Pan head wood screws.

Complete the above steps for the second Slide-stop

bracket.

INSTALLATION GUIDE

4) Assembly:

Trough Attachment

Figure 4.5.1

Locate the wire management trough (AMM-1424-xx).

Align the clearance holes in the trough with the threaded holes in the Bolted Frame assembly. The larger

clearance holes will also align with the heads of the screws from Figure 4.2.2

Attach the Trough with (7) 8-32 x 0.375” Pan head machine screws.

INSTALLATION GUIDE

4) Assembly:

Foot Weldment Attachment

Locate the Foot Attachment Spacer.

Place the Foot Attachment Spacer on the bottom of the Leg column. Align the 4 holes in the Foot Spacer

with the tapped holes in the Leg column.

Locate the Foot Weldment (EM-2162-3) Align the clearance holes in the Foot Weldment to the clearance

holes in the Attachment Spacer.

Attach the Foot Weldment to the leg column using (4) M6 x 16mm socket head cap screws.

Repeat these steps for the second Attachment Spacer and Foot Weldment.

Figure 4.6.1

INSTALLATION GUIDE

4) Assembly:

Figure 4.7.1

Handset Attachment

Locate the electronics included with the Leg columns

(LVTER).

Refer to the assembly instructions included in the Leg

Column box for information on assembling the

electronics of the base.

Once the electronics are properly assembled, place the

power supply block in between the crossbars of the

Bolted Frame assembly.

NOTE: Do not attach the power supply block to the

work surface with screws as this will cause the sliding

work surface to malfunction.

Figure 4.7.2

Figure 4.7.3

Attach the included handset to the front edge of the

sliding work surface.

Be sure to leave enough slack in the handset cord to

allow the top to travel back and forth.

INSTALLATION GUIDE

4) Assembly:

Figure 4.8.1

Wire Management Cover Attachment

Locate the Wire Management Cover (AMM-1424-x)

and (4) 8-32 x 0.375” pan head machine screws.

Align the clearance holes in the Wire Management

Cover with the tapped holes in the Bolted Frame

assembly

Attach the Wire Management Cover with (4) 8-32 x

0.375” pan head machine screws.

Figure 4.8.2

Verify that no wires are pinched between the Power

Supply Cover and the work surface.

INSTALLATION GUIDE

4) Assembly:

Completed Table

Carefully flip the desk over onto the feet. Adjust the glides as needed to level the desk.

FIGURE 4.9.1

12900 Christopher Drive Lowell, MI 49331

800.815.7251 www.enwork.com

Specifications subject to change without notice.

Loading...

Loading...