Page 1

Equilibrium Round

EI0005 – Revision A – 8/15/18

Conference/Occasional Table

Installation Instruction

Page 2

12900 Christopher Drive Lowell, MI 49331

800.815.7251 www.enwork.com

Specifications subject to change without notice.

Equilibrium End User Agreement

Enwork Equilibrium table bases must be installed directly onto a four inch

minimum thickness concrete floor using factory provided hardware.

Warning and Indemnity Agreement

Failure to install on four inch thick concrete floor or failure to follow installation

instructions may cause table to function improperly and could lead to personal

injury and or structural damage. Do not, under any circumstance, install on a

concrete floor less than four inches thick.

Equilibrium assembled can weigh in excess of 500 pounds supported in a 0.33

square foot area. It is the responsibility of the dealer to verify that the location

for Equilibrium is suitable and is properly installed. End user agrees that the

installation shall not be modified and the location of the table base shall not be

moved without assistance from an Enwork Dealer.

It is the responsibility of the dealer and end user to adhere to and follow any

local or state building, electrical and accessibility codes.

Enwork is not responsible for any structural failures or personal injuries or

property damage due to improper installation or improper use of product. End

user agrees to defend, indemnify and hold harmless Enwork from any claims of

any nature or type arising out of unauthorized modification or movement of the

table base or any other improper use of the product.

Note: Installation requires at least two people.

Page 3

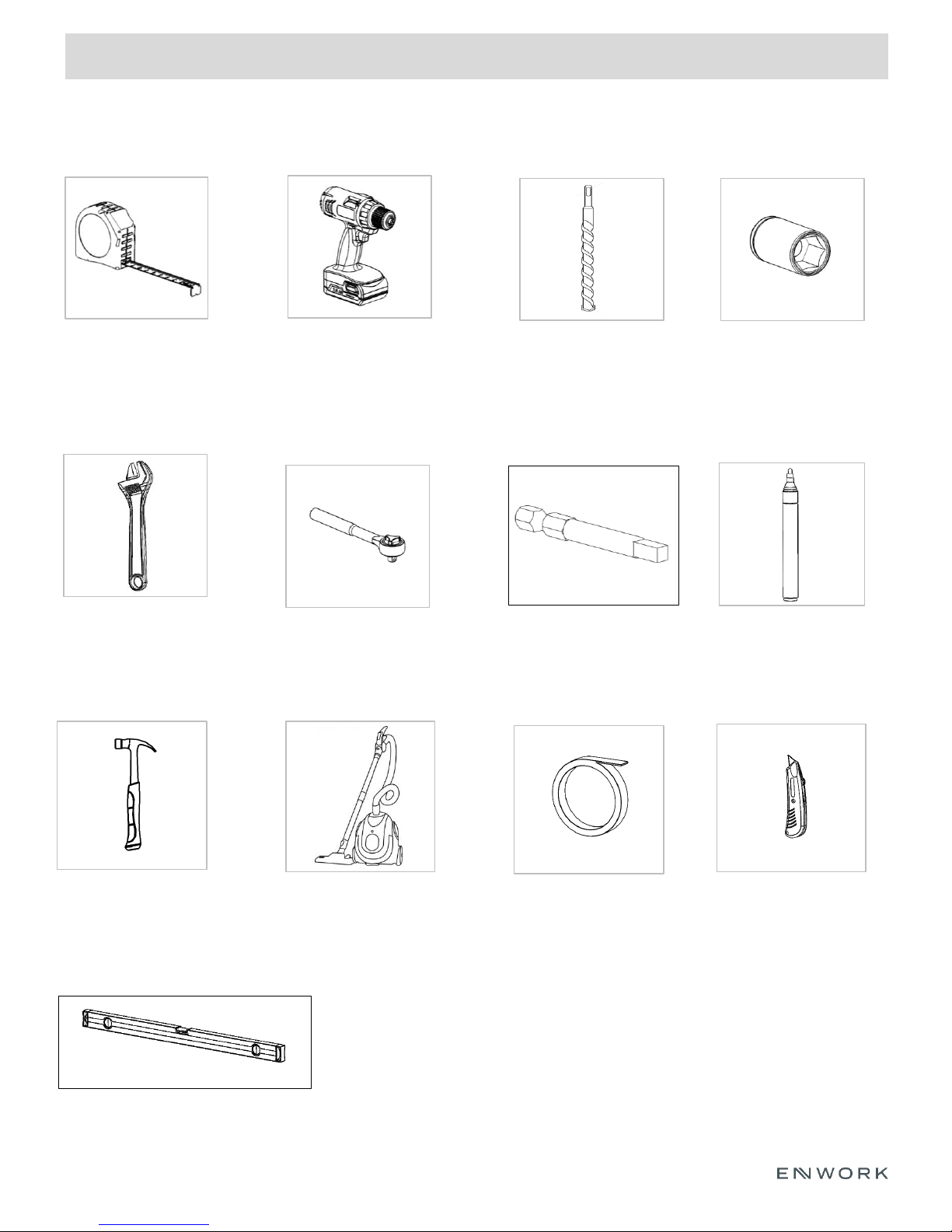

1) Tools and Supplies Required

INSTALLATION GUIDE

Hammer or Mallet

Tape Measure

Drill / Hammer Drill

½” Diameter

Masonry Drill Bit

Adjustable Wrench

Socket Wrench

9/16” Socket

3/4” Socket

Level

Square Drive

Utility Knife

Marker

Roll of Tape

Vacuum

Page 4

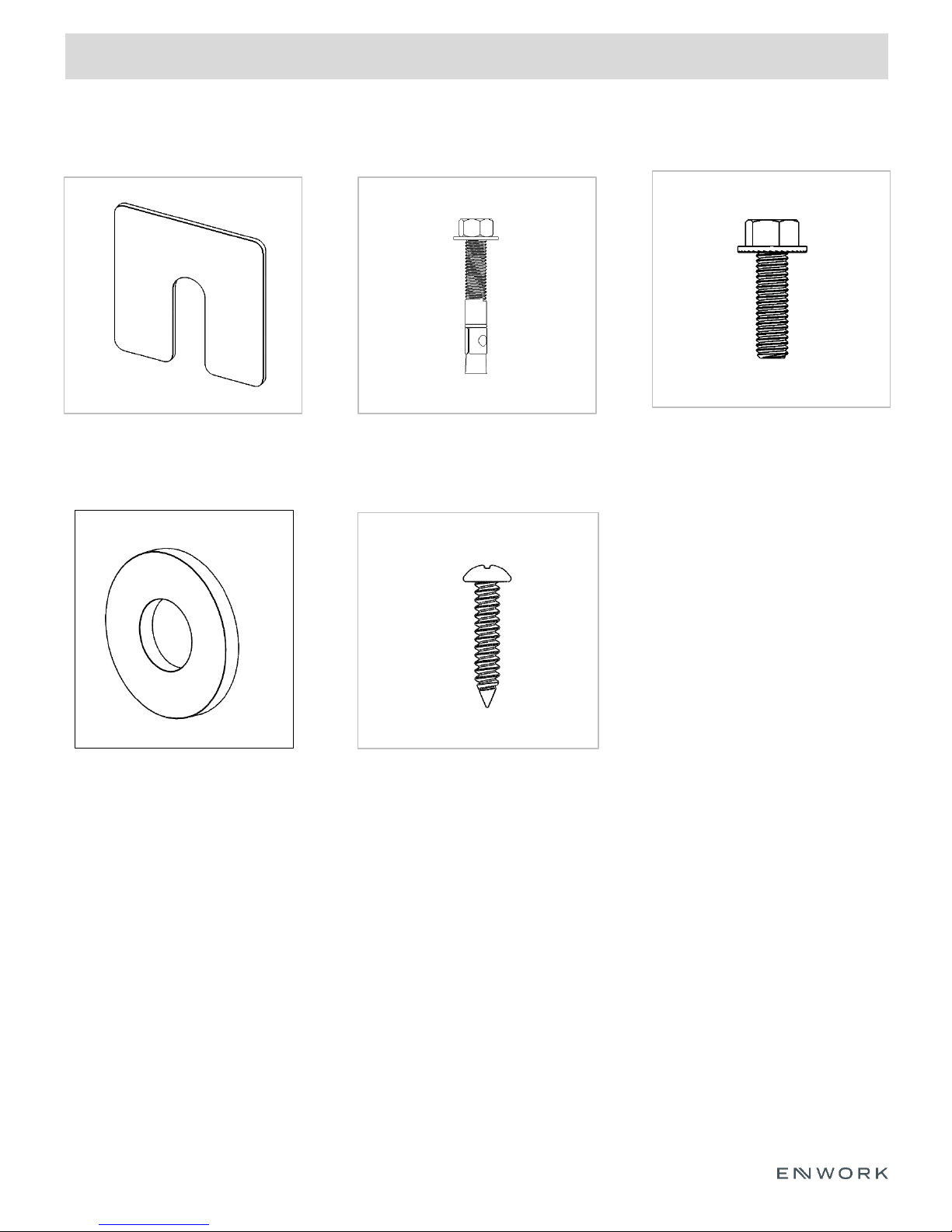

2) Parts and Fasteners Included

INSTALLATION GUIDE

Aluminum Shim (Pack) ½” x 3 ¾” Concrete Stud

3/8” – 16 x 1 1/2” Flange Hex

Bolt

Screw 1 (Black)

3/8” x 1” Flat Washer

Page 5

2) Parts and Fasteners Included

INSTALLATION GUIDE

BASE COLUMN, 60”-84”

EQM-2225-xx

BASE COLUMN, 36”-54”

EQM-2246-xx

TOP WELDMENT, 60”-84”

EQM-2226-1

REMOVABLE TOP COVER

EQM-1557-x

TOP WELDMENT, 36”-54”

EQM-2255-1

REMOVABLE BASE COVER

EQM-1558-x

Page 6

3) Assembly: Installing the Base Column

INSTALLATION GUIDE

Front

Page 7

3) Assembly:

INSTALLATION GUIDE

Fig. 3.1

Fig. 3.2

Fig. 3.3

3.1.1) Locate final location of base

3.1.2) Set base in desired location and using marker,

trace hole location and mark perimeter for carpet

removal if needed

3.2.1) Set base over marked hole locations.

Note: Check that base is oriented as desired

3.2.2) Using a utility knife, cut away any carpet around

the base location

3.2.3) With carpet removed, double-check hole

locations and if not already there, re-mark hole

locations if needed.

Note: Hold the marker vertically and

spin the marker around the hole to get

the best result.

3.3.1) Measure 2 ¾” from the bottom of the ½”

diameter concrete drill bit and wrap drill bit with

tape creating a visual depth gauge.

Page 8

3) Assembly:

INSTALLATION GUIDE

Fig. 3.4

Fig. 3.5

Fig. 3.6

3.4.1) Drill marked hole locations to 2 ¾” deep.

3.4.2) Vacuum out the drilled holes to remove

dust that may prevent anchor from seating

properly.

3.5.1) Place one washer and one hex nut onto

provided concrete anchor so that the hex nut is

flush with the top of the anchor.

3.5.2) Insert anchor with washer and nut into the

the drilled floor hole. Using a hammer or

mallet pound anchors into drilled holes

until there is 1” - 1-1/2” protruding from

the floor.

3.5.3) Use ¾” socket to tighten anchor hex nuts

3.5.4) Once all bolts has been tightened, loosen

and remove the washers and nuts.

3.6.1) Take the base column and set into place,

aligning holes over bolts.

3.6.2) With base now in place, use washer and hex

nut and tighten to base.

Page 9

3) Assembly:

INSTALLATION GUIDE

Fig. 4

Page 10

3) Assembly:

INSTALLATION GUIDE

Fig. 4.1

4.1.1) Place top support onto base column

Fig. 4.3

4.3.1) Check that the top support is level

4.3.2) If the top support is not level, slightly

loosen the bolts and use the aluminum

shims under the top support

Installing Top Support continued

Fig. 4.2

4.2.1) Align holes on base column with slots

on top support

4.2.2) Using 3/8”-16 x 1-1/2” flange hex bolts

and 3/8” x 1” flat washer, assemble top

support to base column

Note: Do not fully tighten hardware yet

Fig. 4.4

4.4.1) Once shims are in place, tighten the bolts

for the top support. Double check that

top support is now level.

Page 11

3) Assembly:

INSTALLATION GUIDE

5.1.1) Center surface on base. For multi-piece

tops attach tight joint fasteners. Orient seam as

desired.

Note: It may be easier to access all tight joint

fasteners while surface it still on the ground.

5.1.2) Secure surface to base using included

Screw 1

x

x

5.2.1) Power/Data routes thru base top plate

cutout

Fig. 5.1

Fig. 5.2

Page 12

3) Assembly:

INSTALLATION GUIDE

Installing leg covers

6.1.1) Fig 6.1 is base with removable covers

installed

6.2.1) Install the leg cover by attaching it to

pre-installed magnets

6.2.2) Fig. 6.2 shows power routing hole down

for power infeed access outside of base

6.2.3) If no power routing is needed, flip the

column cover so that routing hole is up

Fig. 6.1

Fig. 6.2

6.3.1) For top support cover, angle the cover

and lift the entire piece into the gap

between cantilevers

6.3.2) Once cover is inside the cantilevers, it can

be laid down and will rest on the side

tabs and rear flange touching the top

support of the base

Fig. 6.3

Page 13

12900 Christopher Drive Lowell, MI 49331

800.815.7251 www.enwork.com

Specifications subject to change without notice.

Loading...

Loading...