Page 1

RESIDENTIAL

Geothermal/Water Source Heat Pumps

• R-410A Refrigerant

• 2, 2.5, 3, 3.5, 4, 5, 6 Ton Single Speed

• 2, 3, 4, 5, 6 Ton Dual Capacity

Installation Information

Water Piping Connections

Desuperheater Connections

Electrical

Startup Procedures

Troubleshooting

Preventive Maintenance

Envision Residential Installation Manual

IM1585 10/07

Page 2

ENVISION RESIDENTIAL INSTALLATION MANUAL

Model Nomenclature

Model Type

N= Envision

Compressor Type

D= Dual Capacity

S= Single Speed

Cabinet Configuration

V= Vertical

H= Horizontal

Unit Capacity

Vintage

A= Current

Voltage

1= 208-230/60/1

N D V 049 A 1 1 1 C T L

Return Air Configuration

L= Left

R= Right

Discharge Air Configuration

B= Bottom

T= Top

S= Side

E= End

Coax Options

C= Copper

N= Cupronickel

Fan Option

0= PSC

1= ECM

2= Oversized ECM Blower Option

(036,038,042,048,049)

3= Oversized PSC Blower Option

(022,030,036,042,048)

Hot Water Option

0= None

1= Hot Water Generation with

factory installed pump

Notes: PSC Motor - Single Speed Only

2

Page 3

ENVISION RESIDENTIAL INSTALLATION MANUAL

T able of Contents

General Installation Information 4-8

Closed Loop Ground Source Systems 9

Open Loop Ground Water Systems 10

Desuperheater Connection & Startup 11-12

Electrical Connections 13-14

Electronic Thermostat Installation 14

Auxiliary Heat Ratings 14

Electrical Data 15

Fan Performance Table 16-17

Setting Fan Speed 16-17

Vertical Dimensional Data 18

Horizontal Dimensional Data 19

Vertical Bottomfl ow Dimensional Data 20

Physical Data 21-22

Wiring Schematics 23-27

Microprocessor Control 28-32

Unit Startup 33

Operation Logic 34

Unit Operating Parameters 35-36

Pressure Drop & Recommended Flow Rates 37

Troubleshooting 38

Preventive Maintenance 39

Replacement Procedures 39

3

Page 4

ENVISION RESIDENTIAL INSTALLATION MANUAL

General Installation Information

Safety Considerations

WARNING: Before performing service or maintenance operations on a system, turn off main

power switches to the indoor unit. If applicable, turn off the accessory heater power switch.

Electrical shock could cause personal injury.

Installing and servicing heating and air conditioning equipment can be hazardous due to system pressure and electrical

components. Only trained and qualifi ed service personnel should install, repair or service heating and air conditioning equip-

ment. Untrained personnel can perform the basic maintenance functions of cleaning coils and cleaning and replacing fi lters.

All other operations should be performed by trained service personnel. When working on heating and air conditioning equipment, observe precautions in the literature, tags and labels attached to the unit and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use a quenching cloth for brazing operations and have a

fi re extinguisher available.

Moving and Storage

Move units in the normal “up” orientation. Horizontal units may be moved and stored per the information on the packaging. Do not stack more than three units in total height. Vertical units may be stored one upon another to a maximum height

of two units. Do not attempt to move units while stacked. When the equipment is received, all items should be carefully

checked against the bill of lading to be sure all crates and cartons have been received. Examine units for shipping damage,

removing the units from the packaging if necessary. Units in question should also be internally inspected. If any damage is

noted, the carrier should make the proper notation on the delivery receipt, acknowledging the damage.

Unit Location

Locate the unit in an indoor area that allows for easy removal of the fi lter and access panels. Location should have

enough space for service personnel to perform maintenance or repair. Provide suffi cient room to make water, electrical

and duct connection(s). If the unit is located in a confi ned space, such as a closet, provisions must be made for return air

to freely enter the space by means of a louvered door, etc. Any access panel screws that would be diffi cult to remove after

the unit is installed should be removed prior to setting the unit. On horizontal units, allow adequate room below the unit for

a condensate drain trap and do not locate the unit above supply piping. Care should be taken when units are located in

unconditioned spaces to prevent damage from frozen water lines and excessive heat that could damage electrical

components.

Installing Vertical Units

Prior to setting the unit in place, remove and discard the compressor hold down

shipping bolt located at the front of the compressor mounting bracket.

Vertical units are available in left or right air return confi gurations. Top air dis-

charge vertical units should be mounted level on a vibration absorbing pad slightly

larger than the base to provide isolation between the unit and the fl oor. It is not

necessary to anchor the unit to the fl oor (see right).

Bottomfl ow units should be mounted level and sealed well to fl oor to prevent air

leakage. Bottomfl ow units require the supply air opening to be cut at least 1/2˝ larger

than the unit’s air outlet. Protect the edges of combustible fl ooring with sheet metal

over-wrap or other non-combustible material.

Figure 1: Vertical Unit Mounting

2” Extruded

Polystyrene

4

Page 5

ENVISION RESIDENTIAL INSTALLATION MANUAL

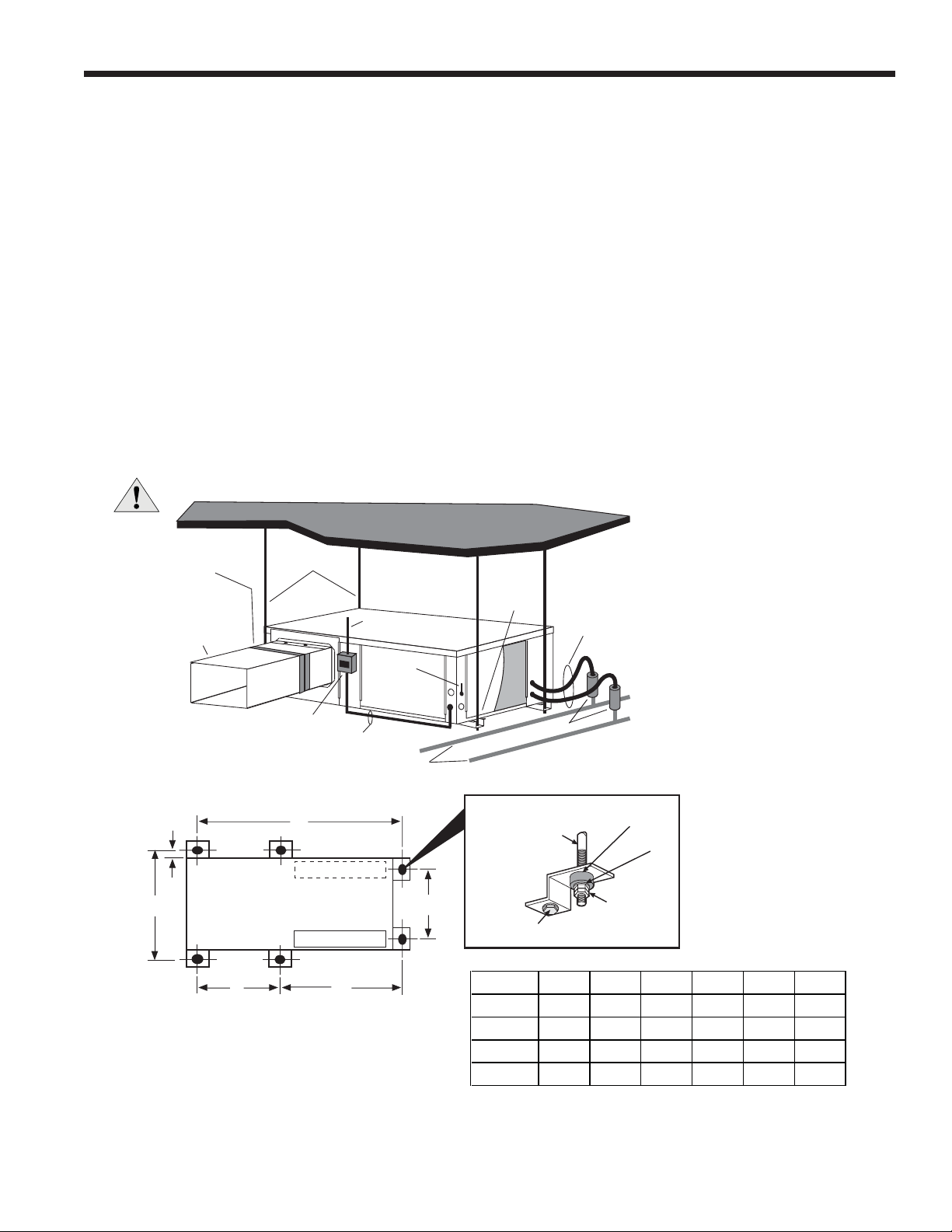

Installing Horizontal Units

Remove and discard the compressor hold down shipping bolt located at the front of the compressor mounting bracket

prior to setting the unit in place. Horizontal units are available with side or end discharge. Horizontal units are normally suspended from a ceiling by six 3/8-inch diameter threaded rods. The rods are usually attached to the unit by hanger bracket

kits furnished with each unit.

Lay out the threaded rods per the dimensions below. Assemble the hangers to the unit as shown. Securely tighten the

brackets to the unit using the weld nuts located on the underside of the bottom panel. When attaching the hanger rods to

the bracket, a double nut is required since vibration could loosen a single nut. To allow fi lter access, one bracket on the fi lter

side should be installed 180° from the position shown in the fi gure below. The unit should be pitched approximately 1/4-inch

towards the drain in both directions to facilitate the removal of condensate. Use only the bolts provided in the kit to attach

hanger brackets. The use of longer bolts could damage internal parts.

Some residential applications require the installation of horizontal units on an attic fl oor. In this case, the unit should

be set in a full size secondary drain pan on top of a vibration absorbing pad. The secondary drain pan prevents possible

condensate overfl ow or water leakage damage to the ceiling. The secondary drain pan is usually placed on a plywood base

isolated from the ceiling joists by additional layers of vibration absorbing material.

CAUTION: Do not use rods smaller than 3/8-inch diameter since they may not be strong enough to

support the unit. The rods must be securely anchored to the ceiling.

Figure 2: Horizontal Unit Mounting

O

Threaded Rods

Electrical

Disconnect

To Line

Power

To

Thermostat

Line Voltage

Building Water Loop

Flexible Duct

Collar

Insulate supply

plenum and use

at least one 90

elbow to

reduce noise

Figure 3: Hanger Location and Assembly

F

A

E

B

Air Coil

Air Coil

D

C

Hanging

Brackets

(Included)

Hose

Kits

Ball Valves

3/8

Threaded Rod

(not supplied)

Bolt and

Lockwasher

Model A B C D E F

022 - 030 24.8

036 - 038 72.4 24.1 43.1

042 - 049 77.4 24.1 48.1

060 - 072 82.4 24.1 53.1

Vibration Isolator

27.8

27.8

27.8

Washer

Hex Nuts

(not supplied)

63.4 21.1 38.1

25.3

29.3

29.3

29.3

1.1

1.1

1.1

1.1

5

Page 6

ENVISION RESIDENTIAL INSTALLATION MANUAL

Duct System

An air outlet collar is provided on vertical top air discharge units and all horizontal units to facilitate a duct connection

(vertical bottomfl ow units have no collar). A fl exible connector is recommended for discharge and return air duct connec-

tions on metal duct systems. Uninsulated duct should be insulated with a minimum of 1-inch duct insulation. Application of

the unit to uninsulated ductwork in an unconditioned space is not recommended as the unit’s performance will be adversely

affected.

If the unit is connected to existing ductwork, check the duct system to ensure that it has the capacity to accommodate

the air required for the unit application. If the duct is too small, as in the replacement of heating only systems, larger ductwork should be installed. All existing ductwork should be checked for leaks and repaired if necessary.

The duct system should be sized to handle the design airfl ow quietly and effi ciently. To maximize sound attenuation of

the unit blower, the supply and return plenums should include an internal duct liner of fi berglass or constructed of ductboard

for the fi rst few feet. On systems employing a sheet metal duct system, canvas connectors should be used between the unit

and the ductwork. If air noise or excessive airfl ow is a problem, the blower speed can be changed.

CAUTION: Be sure to remove the shipping material from the blower discharge before connecting ductwork.

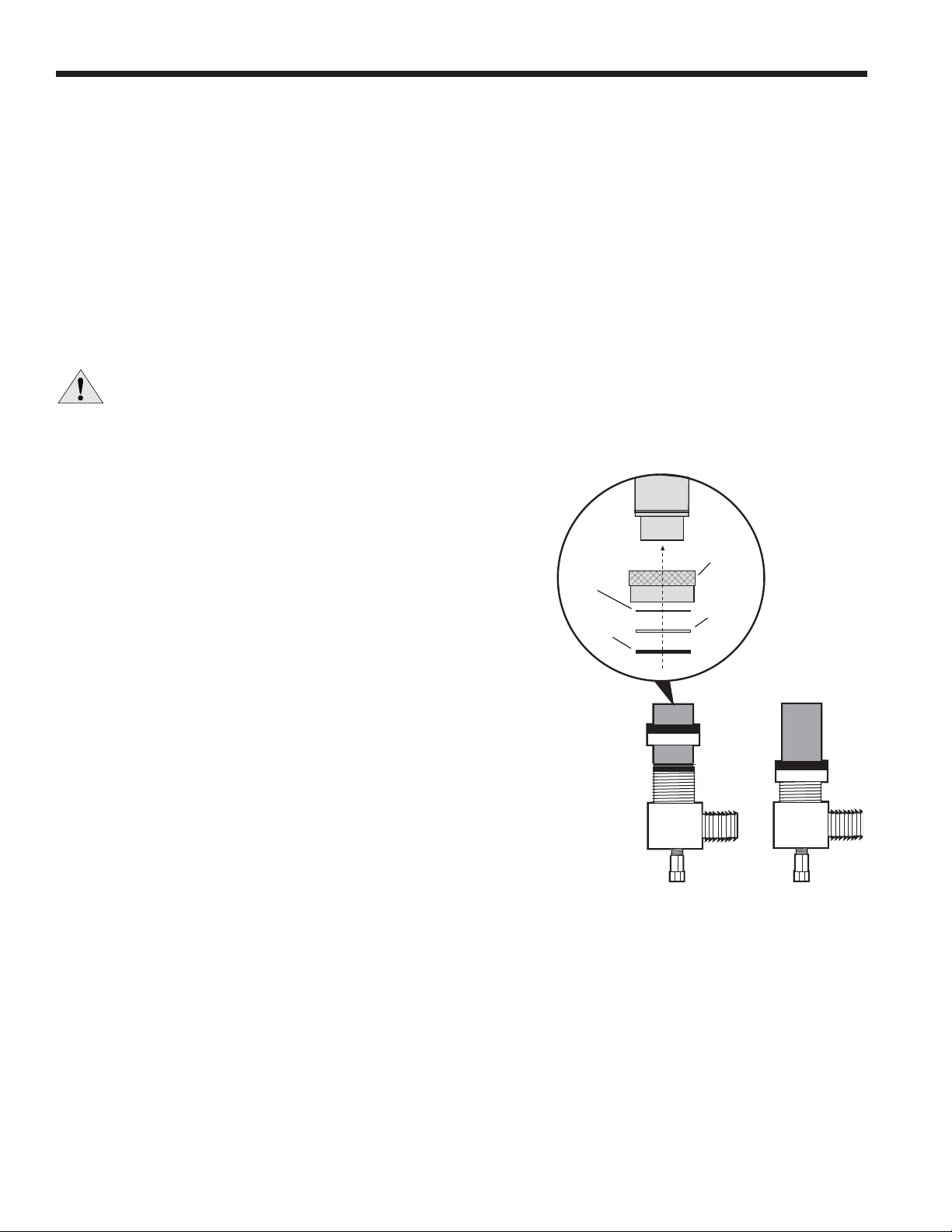

Water Piping

The proper water fl ow must be provided to each unit whenever the

Figure 4: Swivel Connections

(Residential Units)

unit operates. To assure proper fl ow, use pressure/temperature ports

to determine the fl ow rate. These ports should be located at the supply

and return water connections on the unit. The proper fl ow rate cannot

be accurately set without measuring the water pressure drop through

the refrigerant-to-water heat exchanger.

All source water connections on commercial units are fi ttin g s that

accept a male pipe thread (MPT). Insert the connectors by hand, then

tighten the fi tting with a wrench to provide a leakproof joint. When con-

necting to an open loop (groundwater) system, thread any copper MPT

Stainless

Steel

Snap Ring

Gasket

Material

Locking

Ring

Gasket

Support

Sleeve

fi tting into the connector and tighten in the same manner as described

above.

All source water connections on residential units are swivel piping

fi ttings (see Figure 4) that accept a 1-inch male pipe thread (MPT) .

The swivel connector has a rubber gasket seal similar to a rubber hose

gasket, which when mated to the fl ush end of any 1-inch threaded pipe

provides a leak-free seal without the need for thread sealing tape or

compound. Check to ensure that the rubber seal is in the swivel connector prior to attempting any connection. The rubber seals are shipped

attached to the waterline. To make the connection to a ground loop system, mate the brass connector (supplied in CK4L connector kit) against

the rubber gasket in the swivel connector and thread the female locking

ring onto the pipe threads, while maintaining the brass connector in the

desired direction. Tighten the connectors by hand, then gently snug the

fi tting with pliers to provide a leak-proof joint. When connecting to an open loop (ground water) system, thread any 1-inch

MPT fi tting (SCH80 PVC or copper) into the swivel connector and tighten in the same manner as noted above. The open

and closed loop piping system should include pressure/temperature taps for serviceability.

Never use fl exible hoses smaller than 1-inch inside diameter on the unit. Limit hose length to 10 feet per connection.

Check carefully for water leaks.

6

Page 7

ENVISION RESIDENTIAL INSTALLATION MANUAL

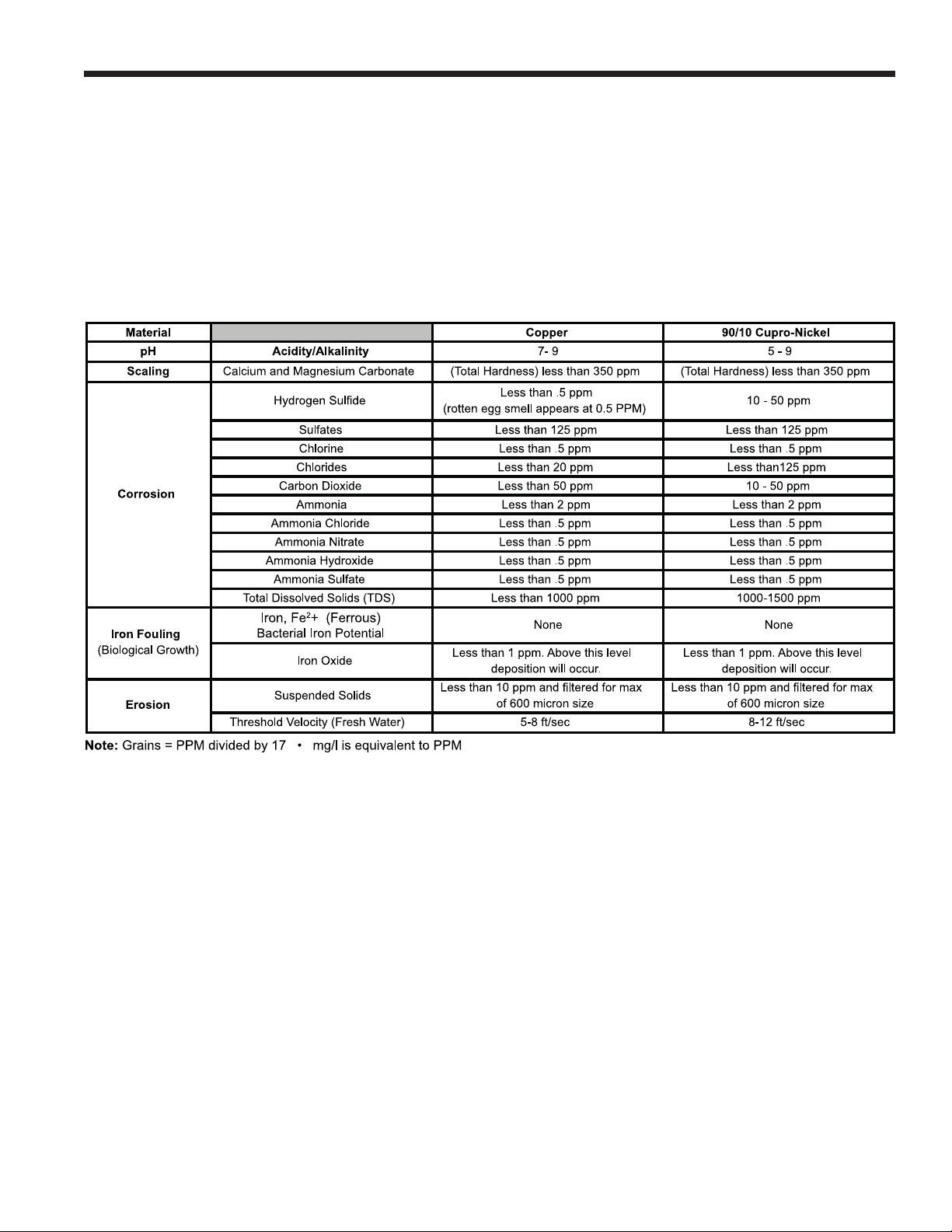

Water Quality

In ground water situations where scaling could be heavy or where biological growth such as iron bacteria will be present, a closed loop system is recommended. The heat exchanger coils in ground water systems may, over a period of time,

lose heat exchange capabilities due to a buildup of mineral deposits inside. These can be cleaned, but only by a qualifi ed

service mechanic, as special solutions and pumping equipment are required. Desuperheater coils can likewise become

scaled and possibly plugged. In areas with extremely hard water, the owner should be informed that the heat exchanger

may require occasional fl ushing.

Units with cupronickel heat exchangers are recommended for open loop applications due to the increased resistance to

build-up and corrosion, along with reduced wear caused by acid cleaning.

7

Page 8

ENVISION RESIDENTIAL INSTALLATION MANUAL

Freeze Protection

Set the freeze sensing switch SW2-2 on the printed circuit board for applications using a closed loop antifreeze solution

to “LOOP”. On applications using an open loop/ground water system (or closed loop no antifreeze), set this dip switch to

“WELL”, the factory default setting. (Refer to the Dip Switch Field Selection table on page 24.)

Condensate Drain

On vertical units, the internal condensate drain assembly consists of a drain tube which is connected to the drain pan, a

3/4-inch PVC female adapter and a fl exible connecting hose. The female adapter may exit either the front or the side of the

cabinet. The adapter should be glued to the fi eld-installed PVC condensate piping. On vertical upfl ow units, a condensate

hose is inside all cabinets as a trapping loop; therefore, an external trap is not necessary.

On horizontal units, a PVC stub is provided for condensate drain piping connection. An external trap is required (see

below). If a vent is necessary, an open stand pipe may be applied to a tee in the fi eld-installed condensate piping.

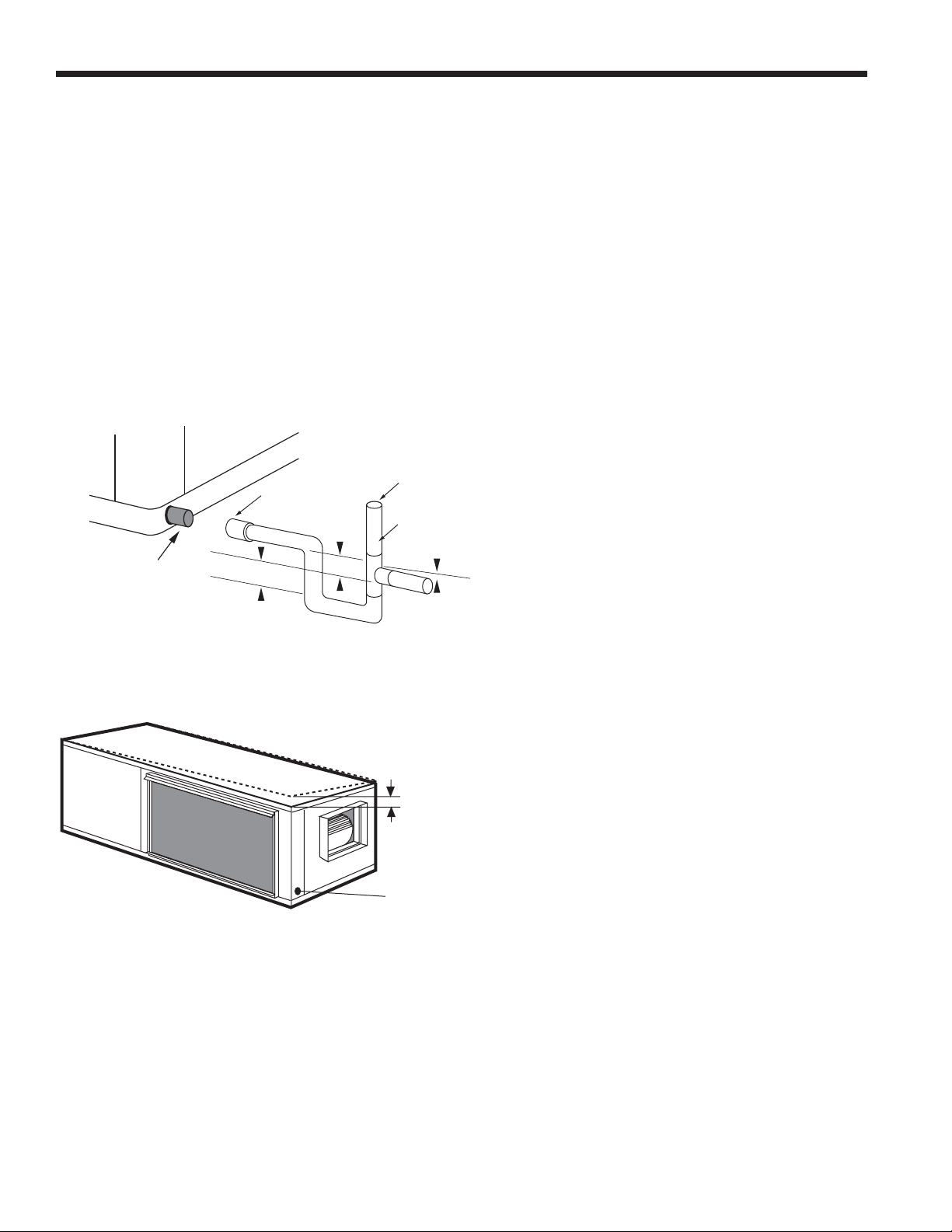

Figure 5: Horizontal Drain Connection

3/4” PVC tube stub

Figure 6: Unit Pitch for Drain

3/4" PVC

Coupling

1.5"

Vent (if needed)

3/4" PVC

1/8" per foot

1.5"

1/2'' Pitch

Drain

8

Page 9

ENVISION RESIDENTIAL INSTALLATION MANUAL

Closed Loop Ground Source Systems

Note: For closed loop systems with antifreeze protection, set SW2-2 to the “loop” position (see table on page 28).

Once piping is completed between the unit, pumps and the ground loop (see fi gure below), fi nal purging and charging

of the loop is required. A fl ush cart (or a 1.5 HP pump minimum) is needed to achieve adequate fl ow velocity in the loop

to purge air and dirt particles from the loop itself. Antifreeze solution is used in most areas to prevent freezing. Flush the

system adequately to remove as much air as possible then pressurize the loop to a static pressure of 40-50 PSI (summer)

or 50-75 PSI (winter). This is normally adequate for good system operation. Loop static pressure will fl uctuate with the

seasons. Pressures will be higher in the winter months than during the cooling season. This fl uctuation is normal and should

be considered when initially charging the system.

After pressurization, be sure to open the plug 1 turn in the end of the loop pump motor(s) (if applicable) to allow trapped

air to be discharged and to ensure that the motor housing has been fl ooded. Ensure that the loop pumps provide adequate

fl ow through the unit(s) by checking the pressure drop across the heat exchanger and comparing it to the unit capacity data

in the specifi cation catalog. 2.5 to 3 GPM of fl ow per ton of cooling capacity is recommended in earth loop applications.

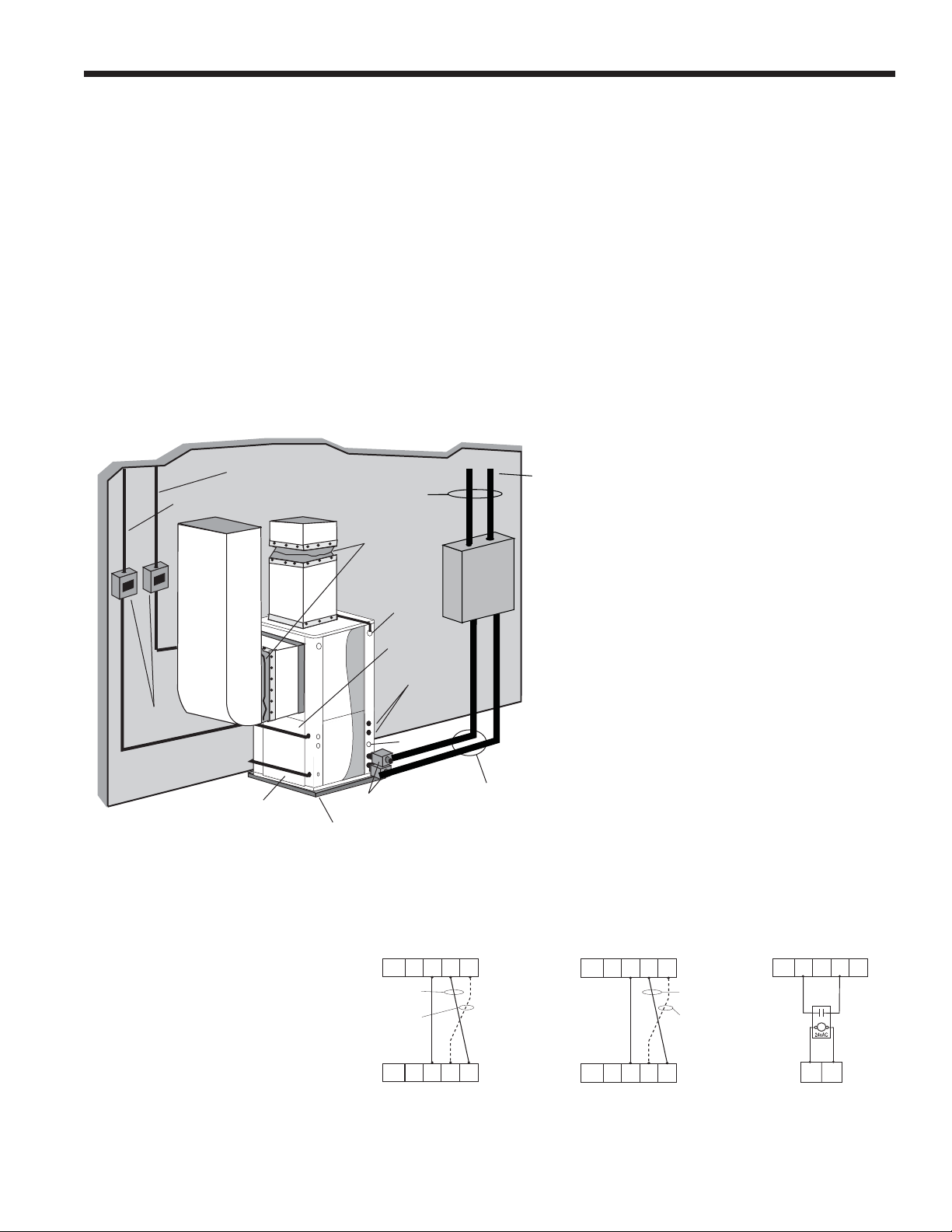

Figure 7: Closed Loop Ground Source Application

Auxiliary Heat

Disconnects

(If Applicable)

Unit Supply

Thermostat

Supply

Low

Voltage to

Vibration Absorbing Pad

Polyethylene w/

P/T Plugs

Multiple Units on

One Flow Center

When two units are connected to

one loop pumping system, pump control is

automatically achieved by connecting the

SL terminals on connector P2 in both units

with 2-wire thermostat wire. These terminals

are polarity dependant (see Figure 8). The

loop pump(s) may be powered from either

unit, whichever is more convenient. If either

unit calls, the loop pump(s) will automatically start. The use of two units on one fl ow

center is generally limited to a total of 20

GPM capacity.

®

GeoLink

®

Armaflex

Insulation

Flexible Duct

Collar

Auxiliary

Heater

Knockout

Unit Power

Desuperheater

Connections

Drain

P/T

Envision to Envision

Microprocessor Units

Dual Capacity

Envision Unit #1

Shut

CC

Down

With pump

wired to Unit 1

With pump

wired to

Unit 2

Shut

CC

Down

Envision Unit #2

Dual Capacity

Link

o

Ge

Flow

nt

e

C

Insulated piping

or hose kit

SL1InSL1

Out

SL1InSL1

Out

TO

LOOP

®

r

e

Note: Additional information can be found

in Flow Center installation manual (IM1961)

and Flush Cart manual (WFS302).

Figure 8: Primary/Secondary Hook-up

Envision to Envision

Microprocessor Units

Single Speed

Envision Unit #1

Shut

Down

Shut

Down

Envision Unit #2

Single Speed

CC

CC

SL1InSL1

Out

SL1InSL1

Out

With pump

wired to Unit 1

With pump

wired to

Unit 2

Envision to

Electromechanical Units

Envision Unit #1

Shut

Down

To Electromechanical Unit

CC

C

SL1InSL1

S

Out

9

Page 10

ENVISION RESIDENTIAL INSTALLATION MANUAL

)

)

)

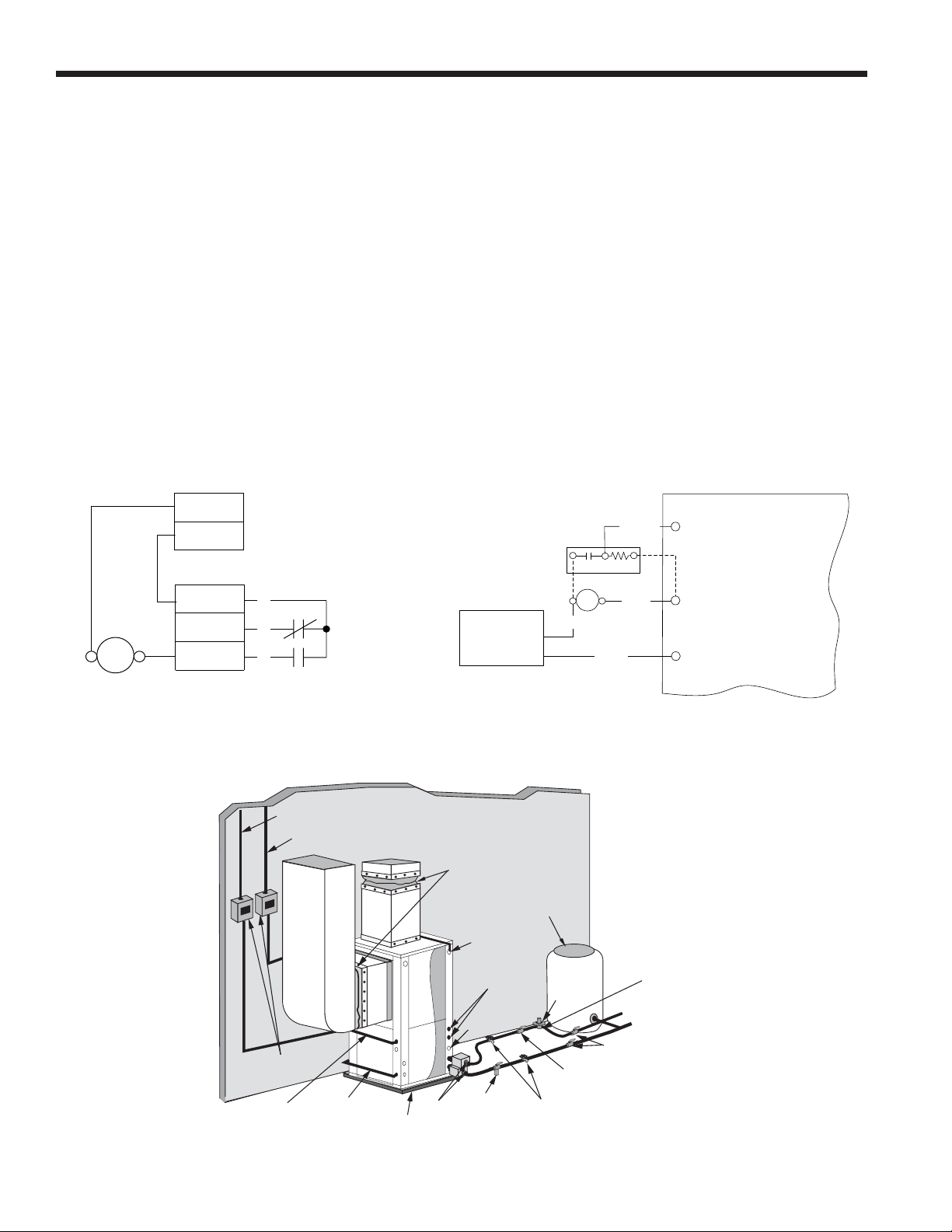

Open Loop Ground Water Systems

Typical open loop piping is shown below. Always maintain water pressure in the heat exchanger by placing water control

valves at the outlet of the unit to prevent mineral precipitation. Use a closed, bladder-type expansion tank to minimize

mineral formation due to air exposure. Insure proper water fl ow through the unit by checking pressure drop across the heat

exchanger and comparing it to the fi gures in unit capacity data tables in the specifi cation catalog. 1.5-2 GPM of fl ow per ton

of cooling capacity is recommended in open loop applications. Due to only minor differences in fl ow rate from low to high,

only one solenoid valve should be used. The valve should be sized for full fl ow .

Discharge water from the unit is not contaminated in any manner and can be disposed of in various ways, depending

on local codes, i.e. recharge well, storm sewer, drain fi eld, adjacent stream or pond, etc. Most local codes forbid the use of

sanitary sewer for disposal. Consult your local building and zoning departments to assure compliance in your area.

Note: For open loop/groundwater systems or systems that do not contain an antifreeze solution, set SW2-Switch #2 to the

“WELL ” position. (Refer to the table on page 28.) Slow opening/closing solenoid valves ( type VM) are recommended to eliminate

water hammer.

Figure 9a: Open Loop Solenoid Valve Connection Option

Typical quick operating external 24V water solenoid valve

(type PPV100 or BPV100) wiring.

C

P1

R

SV

Acc Com

Acc NC

Acc NO

1

2

P3

3

Solenoid

Valve

Note:

SW2-3 should be in the Comp “ON” position.

Figure 10: Open System - Groundwater Application

Unit Supply

Aux. HeatSupply

Figure 9b: Open Loop Solenoid Valve Connection Option

Typical slow operating external 24V water solenoid valve

(type VM) wiring.

CC

CC-GND

CCHI

Logic Board

Comfort

Alert

Flexible

Duct Collar

Violet(2

VM valve

CC

Blk(1

Violet(3

Y1

Y2

Wht(4)

Rubber Bladder

Expansion Tank

Auxiliary

Disconnects

(IfApplicable)

Compressor

Line Voltage

Low Voltage

to Thermostat

and Valve

P/T Plugs

Vibration

Absorbing Pad

Heater

Knockout

Desuperheater

Connections

Drain

Strainer

Solenoid

Valve

valve whileacid flushing)

Boiler Drains

For HXFlushing

(to isolatesolenoid

Flow Control

(on outletof

Solenoid Valve)

Water Out

Shut OffValves

Shut OffValves

Valve

Water In

10

Page 11

ENVISION RESIDENTIAL INSTALLATION MANUAL

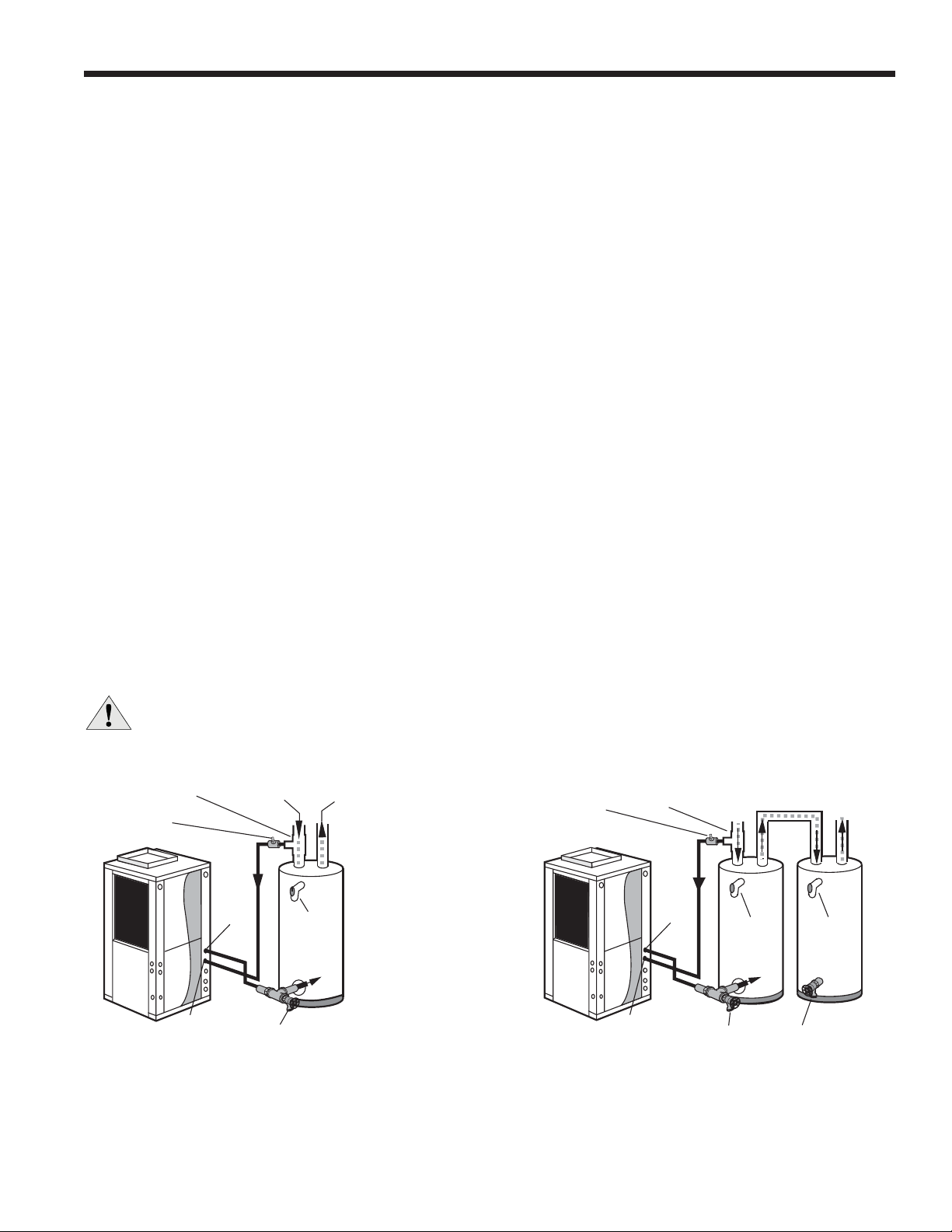

Desuperheater Connections

To m a x i m i ze t h e b e n e fi ts of the desuperheater a minimum 50- gallon water heater is recommended. For higher

demand applications, use an 80 -gallon water heater or two 50 -gallon water heaters connec ted in a series as shown

below. Electric water heaters are recommended. Make sure all local electrical and plumbing codes are met for installing

a desuperheater.

Note: Under certain conditions, Envision dual capacity units operate with very low refrigerant discharge temperatures,

producing little or no water heating capability. This scenario occurs when the unit is operating with cold entering source

water (loop or well). Allowing the desuperheater pump to operate during these conditions actually removes heat from the

DHW circulating through the unit. To overcome this, En vision unit microprocessors have been programmed to disengage

the desuperheater pump during such conditions. (Dur ing low capac ity c ooling oper ation, the pump will operate only if

the DHW temperature entering the unit is less than the liquid line temperature plus 35º F. During high capacity cooling

operation, the pump will operate only if the DHW temperature is less than the l i quid line t emperature plus 60º F.) Using

a preheat tank, as shown in Figure 12, will maximize desuperheater capabilities.

Water Tank Preparation

To install a unit with desuperheater, follow these installation guidelines.

Turn off the power to the water heater.

1.

Attach a water hose to the water tank drain connection and run the other end of the hose to an open drain or

2.

outdoors.

Close the cold water inlet valve to the water heater tank.

3.

Drain the tank by opening the valve on the bottom of the tank, then open the pressure relief valve or hot water

4.

faucet.

Flush the tank by opening the cold water inlet valve to the water heater to free the tank of sediments. Close when

5.

draining water is clear.

Disconnect the garden hose and remove the drain valve from the water heater.

6.

Refer to Plumbing Installation and Desuperheater Startup on page 12.

7.

Residential units with desuperheaters contain an internal circulator and fi ttings.

CAUTION: Elements will burn out if energized dry.

Figure 11: Typical Desuperheater Installation

3/4 x 3/4 x 1/2 tee

Venting Waste

Valve or Vent

Coupling

DHW

Water In

DHW

Water Out

Cold

Water In

P/T Relief

Drain Valve

Valve

Water Out

In

Hot

Figure 12: Desuperheater Installation In Preheat Tank

Venting Waste Valve

or Vent Coupling

Note: This confi guration maximizes desuperheater capability.

3/4" x 3/4" x 1/2"

tee

DHW

Water In

DHW

Water Out

Cold

Water In

P/T Relief

Valve

In

Drain ValveDrain Valve

Hot

Water Out

P/T Relief

Valve

11

Page 12

ENVISION RESIDENTIAL INSTALLATION MANUAL

Plumbing Installation

1. Inspect the dip tube in the water heater cold inlet for a check valve. If a check valve is present it must be removed

or damage to the desuperheater circulator will occur.

2. Remove drain valve and fi tti n g .

3. Thread the 3/4-inch NPT x 3-1/2-inch brass nipple into the water heater drain port.

4. Attach the center port of the 3/4-inch FPT tee to the opposite end of the brass nipple.

5. Attach the 1/2-inch copper to 3/4-inch NPT adaptor to the side of the tee closest to the unit.

6. Install the drain valve on the tee opposite the adaptor.

7. Run interconnecting tubing from the tee to DHW water out.

8. Cut the cold water “IN” line going to the water heater.

9. Insert the reducing solder tee in line with cold water “IN” line as shown.

10. Run interconnecting copper tubing between the unit DHW water “IN” and the tee (1/2-inch nominal).

The recommended maximum distance is 50 feet.

11. To prevent air entrapment in the system, install a vent coupling at the highest point of the interconnecting lines.

12. Insulate all exposed surfaces of both connecting water lines with 3/8-inch wall closed cell insulation.

Note: All plumbing and piping connections must comply with local plumbing codes

.

Desuperheater Startup

1. Close the drain valve to the water heater.

2. Open the cold water supply to the tank.

3. Open a hot water faucet in the building to bleed air from the system. Close when full.

4. Open the pressure relief valve to bleed any remaining air from the tank, then close.

5. If so equipped, unscrew the indicator plug 1 turn on the motor end of the pump until all air is purged from the pump,

then tighten the plug. Use vent couplings to bleed air from the lines.

6. Carefully inspect all plumbing for water leaks and correct as required.

7. Before restoring electrical supply to the water heater, adjust the temperature setting on the tank.

• On tanks with both upper and lower elements, the lower element should be turned down to the lowest setting,

approximately 100°F. The upper element should be adjusted to 120°F to 130°F. Depending upon the specifi c

needs of the customer, you may want to adjust the upper element differently.

• On tanks with a single element, lower the thermostat setting to 120°F.

8. After the thermostat(s) is adjusted, replace the access cover and restore electrical supply to the water heater.

9. Make sure that any valves in the desuperheater water circulating circuit are open.

10. Turn on the unit to fi rst stage heating.

11. The DHW pump should be running. When the pump is fi rst started, open the inspection port 1 turn (if equipped) until

water dribbles out, then replace. Allow the pump to run for at least fi ve minutes to ensure that water has fi lled the

circulator properly. Be sure the switch for the DHW pump (SW4) is “ON”. The DHW “OFF” LED on the unit should not

be illuminated.

12. The temperature difference between the water entering and leaving the desuperheater should be 5°F to 15°F. The

water fl ow should be approximately 0.4 GPM per ton of nominal cooling.

13. Allow the unit to heat water for 15 to 20 minutes to be sure operation is normal.

CAUTION: Never operate the DHW circulating pump while dry. If the unit is placed in operation

before the desuperheater piping is connected, be sure that the pump switch is set to the OFF

position.

12

Page 13

ENVISION RESIDENTIAL INSTALLATION MANUAL

Electrical Connections

General

Be sure the available power is the same voltage and phase as that shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the National Electric Code, whichever is applicable.

Unit Power Connection

Connect the incoming line voltage wires to L1 and L2 of the contactor as shown in Figure 13C for single-phase unit. Consult

the Unit Electrical Data in the Specifi cation Catalog for correct fuse sizes.

Open lower front access panel. Remove ground fastener from bottom of control box (Figure 13B). Swing open control box

(Figure 13A). Insert power wires through knockouts on lower left side of cabinet. Route wires through left side of control box

and connect to contactor and ground (Figure 13C). Close control box and replace grounding fastener before unit start-up.

Figure 13A:

Wire access (control box open)

Location

Figure 13B:

Wire access (control box closed)

Ground FastenerWire Insert

Figure 13C:

Line Voltage 208-230/60/1 control box

L2

L1

Accessory Relay

A set of “dry” contacts has been provided to control accessory devices, such as water solenoid valves on open loop installations, electronic air cleaners, humidifi ers, etc. This relay contact should be used only with 24 volt signals and not line voltage

power. The relay has both normally open and normally closed contacts and can operate with either the fan or the compressor.

Use DIP switch SW2-3 to cycle the relay with fan or compressor. The relay contacts are available on terminals #2 and #3 of

P3.

208 Volt Operation

All Envision 208/230 units are factory wired for 230 volt operation. For 208 volt operation, the red and blue transformer

wires must be switched on terminal strip PS.

13

Page 14

ENVISION RESIDENTIAL INSTALLATION MANUAL

Electrical Connections (cont.)

Pump Wiring

Figure 14: Pump Wiring 208-230/60/1

See Figure 14 for electrical connections

from control box to pumps.

Electronic Thermostat

Position the thermostat subbase against the wall so that it is level and the

thermostat wires protrude through the middle of the subbase. Mark the position

of the subbase mounting holes and drill holes with a 3/16-inch bit. Install supplied

anchors and secure base to the wall. Thermostat wire must be 8-conductor, 18AWG wire. Strip the wires back 1/4-inch (longer strip lengths may cause shorts)

and insert the thermostat wires into the connector as shown. Tighten the screws

to insure secure connections. The thermostat has the same type connectors,

requiring the same wiring. See instructions enclosed in the thermostat for detailed

installation and operation information.

Figure 15: Thermostat Wiring

Microprocessor Controlle

r

R

C

Y1

Y2

W

O

G

24VAC (Hot)

24VAC (Common)

Compressor (1st Stage)

Compressor (2nd Stage)

Aux. Heat

Reversing Valve

Blower Relay

L

System Monitor

Thermostat Connection

Note: DIP switch SW2-8 is required to be in the “OFF” position for the control to

operate with FaultFlash or ComforTalk thermostats. SW2-8 in the “ON” position confi gures the control to operate with typical

thermostats (continuous lockout signal). There must be a wire connecting Y2 on the microprocessor controller to 2nd stage

compressor on the thermostat for proper operation.

Auxiliary Heat Ratings

KW BTU/HR Min Envision Series Compatibility

Model 208V 230V Stages 208V 230V CFM 022 026 - 030 036 - 049 060 - 072

EAM(H)5 3.6 4.8 1 12,300 16,300 450

EAM(H)8 5.7 7.6 2 19,400 25,900 550

EAM(H)10 7.2 9.6 2 24,600 32,700 650

EAL(H)10 7.2 9.6 2 24,600 32,700 1100

EAL(H)15 10.8 14.4 3 36,900 49,100 1250

EAL(H)15-3 10.8 14.4 3 36,900 49,100 1250

EAL(H)20 14.4 19.2 4 49,200 65,500 1500

14

••

••

•

••

••

••

•

Page 15

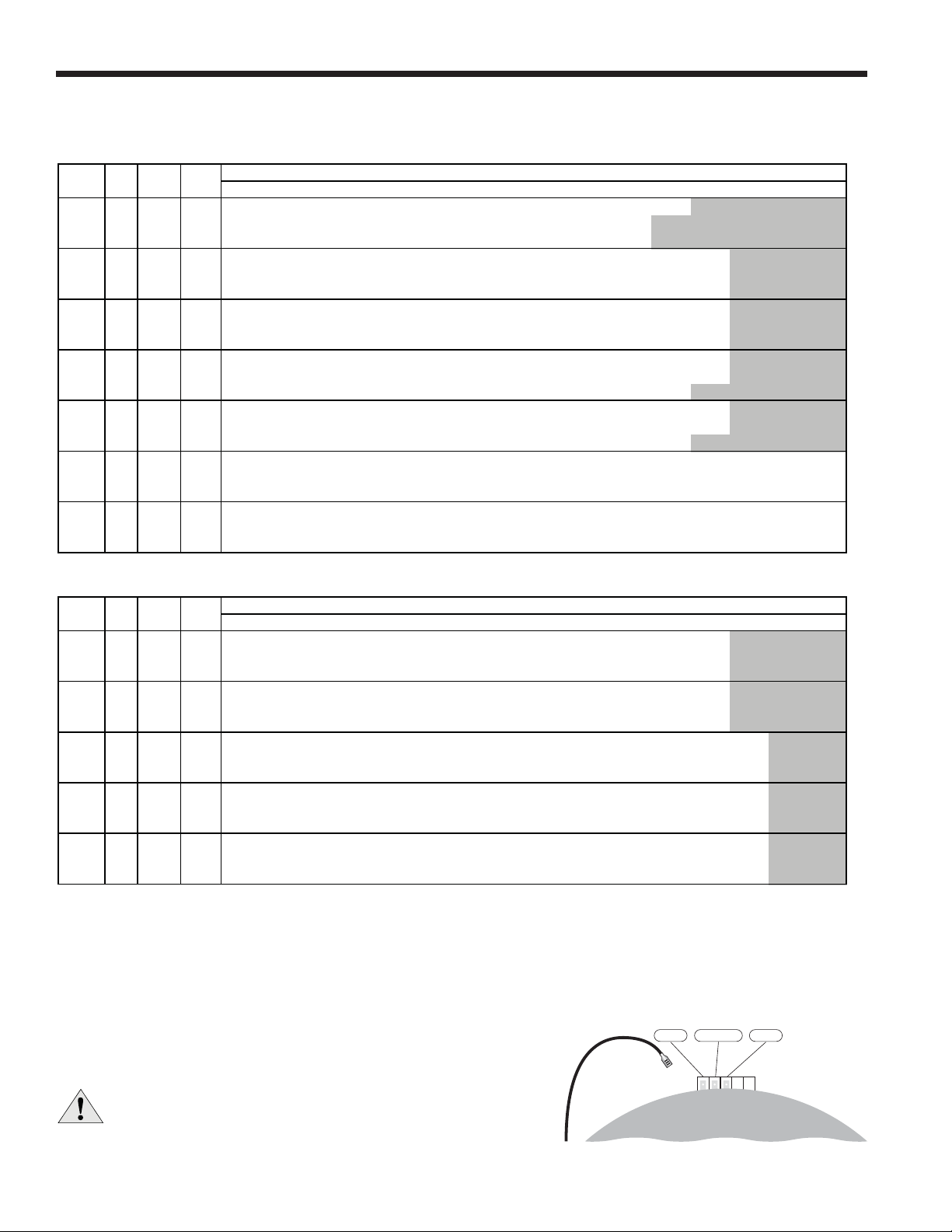

Unit Electrical Data

Single speed with ECM motor

Model

022

030

036

036*

042

042*

048

048*

060

070

*With optional 1 HP ECM2 motor

Rated

Voltage

208-230/60/1 197/253

Voltage

MIN/MAX

Single speed with PSC Motor

Model

022

022*

030

030*

036

036*

042

042*

048

048*

060

070

*With optional over-sized blower

Rated Voltage

Voltage Min/Max

208-230/60/1 197/253

Compressor

MCC RLA LRA FLA FLA FLA FLA Amp HACR

14.0 9.0 48.0 0.4 5.4 4.0 18.8 21.0 30

20.0 12.8 58.3 0.4 5.4 4.0 22.6 25.8 35

22.0 14.1 73.0 0.4 5.4 4.0 23.9 27.4 40

22.0 14.1 73.0 0.4 5.4 7.0 26.9 30.4 40

26.0 16.6 79.0 0.4 5.4 4.0 26.4 30.6 45

26.0 16.6 79.0 0.4 5.4 7.0 29.4 33.6 50

31.0 19.8 109.0 0.4 5.4 4.0 29.6 34.6 50

31.0 19.8 109.0 0.4 5.4 7.0 32.6 37.6 50

41.2 26.4 134.0 0.4 5.4 7.0 39.2 45.8 70

47.0 30.1 158.0 0.4 5.4 7.0 42.9 50.4 80

Compressor

MCC RLA LRA FLA FLA FLA FLA Amp HACR

14.0 9.0 48.0 0.4 5.4 1.2 16.0 18.2 25

14.0 9.0 48.0 0.4 5.4 1.5 16.3 18.5 25

20.0 12.8 58.3 0.4 5.4 1.5 20.1 23.3 35

20.0 12.8 58.3 0.4 5.4 2.2 20.8 24.0 35

22.0 14.1 73.0 0.4 5.4 2.8 22.7 26.2 40

22.0 14.1 73.0 0.4 5.4 3.5 23.4 26.9 40

26.0 16.6 79.0 0.4 5.4 3.5 25.9 30.1 45

26.0 16.6 79.0 0.4 5.4 4.6 27.0 31.2 45

31.0 19.8 109.0 0.4 5.4 3.5 29.1 34.1 50

31.0 19.8 109.0 0.4 5.4 4.6 30.2 35.2 50

41.2 26.4 134.0 0.4 5.4 5.9 38.1 44.7 70

47.0 30.1 158.0 0.4 5.4 5.9 41.8 49.3 70

ENVISION RESIDENTIAL INSTALLATION MANUAL

HWG Ext Fan Total Min Max

Pump Loop Motor Unit Circ Fuse/

HWG Ext Fan Total Min Max

Pump Loop Motor Unit Circ Fuse/

2/20/07

Dual Capacity

Model

026

038

038*

049

049*

064

072

*With optional 1 HP ECM2 motor

NOTE: HACR circuit breaker in USA only. All fuses Class RK-5

Rated

Voltage

208-230/60/1 197/253

Voltage

MIN/MAX

Compressor

MCC RLA LRA FLA FLA FLA FLA Amp HACR

16.0 10.2 52.0 0.4 5.4 4.0 20.0 22.6 30

26.0 16.6 82.0 0.4 5.4 4.0 26.4 30.6 45

26.0 16.6 82.0 0.4 5.4 7.0 29.4 33.6 50

33.0 21.1 96.0 0.4 5.4 4.0 30.9 36.2 50

33.0 21.1 96.0 0.4 5.4 7.0 33.9 39.2 60

40.0 25.6 118.0 0.4 5.4 7.0 38.4 44.8 70

42.5 27.2 150.0 0.4 5.4 7.0 40.0 46.8 70

HWG Ext Fan Total Min Max

Pump Loop Motor Unit Circ Fuse/

5/30/06

15

Page 16

ENVISION RESIDENTIAL INSTALLATION MANUAL

Fan Blower Motor Airflow (cfm) at External Static Pressure (in. wg)

Model Spd Size HP 0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00

H 1110 1095 1080 1065 1045 1020 995 970 945 915 880 810 ---M 9 x 71/5850845835825815805795775755735715----L 750745740735725715700685670650630----H 1290 1270 1245 1220 1190 1160 1125 1090 1055 1020 985 880 760 - - M 9 x 7 1/3 1100 1090 1075 1060 1045 1020 995 970 940 910 875 785 625 - - L 910 905 900 895 885 875 865 850 835 810 780 710 560 - - H 1665 1640 1610 1580 1550 1515 1480 1450 1415 1315 1215 1090 980 - - M 9 x 7 1/2 1465 1445 1425 1400 1375 1350 1325 1260 1190 1140 1090 990 890 - - L 1130 1115 1100 1090 1075 1035 995 965 930 895 860 795 730 - - H 2010 1975 1940 1905 1870 1825 1780 1735 1690 1640 1590 1470 1210 - - M 10 x 10 1/2 1670 1650 1630 1610 1590 1560 1530 1495 1460 1425 1390 1190 1080 - - L 1220 1215 1210 1295 1200 1180 1160 1130 1100 1060 1020 930 ---H 2010 1975 1940 1905 1870 1825 1780 1735 1690 1640 1590 1470 1210 - M 10 x 10 1/2 1670 1650 1630 1610 1590 1560 1530 1495 1460 1425 1390 1190 1080 - - L 1220 1215 1210 1295 1200 1180 1160 1130 1100 1060 1020 930 ---H 2430 2400 2365 2330 2290 2255 2215 2180 2140 2095 2045 1945 1835 1715 1510 1330

M 11 x 10 1 2265 2235 2205 2175 2145 2110 2070 2035 2000 1960 1915 1825 1730 1605 1440 1260

L 2075 2050 2020 1995 1965 1940 1915 1885 1850 1820 1785 1720 1610 1505 1335 1175

H 2430 2400 2365 2330 2290 2255 2215 2180 2140 2095 2045 1945 1835 1715 1510 1330

M 11 x 10 1 2265 2235 2205 2175 2145 2110 2070 2035 2000 1960 1915 1825 1730 1605 1440 1260

L 2075 2050 2020 1995 1965 1940 1915 1885 1850 1820 1785 1720 1610 1505 1335 1175

Fan Blower Motor Airflow (cfm) at External Static Pressure (in. wg)

Model Spd Size HP 0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00

H 1290 1270 1245 1220 1190 1160 1125 1090 1055 1020 985 880 760 - - M 9 x 7 1/3 1100 1090 1075 1060 1045 1020 995 970 940 910 875 785 625 - - L 910 905 900 895 885 875 865 850 835 810 780 710 560 - - H 1365 1340 1325 1305 1280 1250 1215 1180 1140 1100 1055 960 850 - - M 9 x 7 1/2 1040 1040 1035 1030 1020 1005 990 970 945 915 885 810 735 - - L 880 880 880 880 875 870 860 840 820 800 775 730 480 - - H 1930 1905 1875 1840 1805 1765 1725 1680 1635 1530 1425 1270 1150 1025 - M 9 x 7 1/2 1635 1620 1600 1580 1555 1530 1505 1465 1425 1335 1240 1135 1035 775 - L 1230 1230 1225 1215 1200 1165 1130 1095 1060 1035 1005 935 795 675 - H 2115 2075 2035 1980 1920 1900 1880 1840 1795 1730 1660 1390 1225 1070

1070

-M 10 x 10 3/4 2005 1980 1950 1910 1865 1815 1765 1725 1685 1585 1485 1315 1140 1025 - L 1860 1835 1805 1780 1750 1715 1675 1635 1590 1540 1490 1260 1115 980 - H 2115 2075 2035 1980 1920 1900 1880 1840 1795 1730 1660 1390 1225 - M 10 x 10 3/4 2005 1980 1950 1910 1865 1815 1765 1725 1685 1585 1485 1315 1140 1025 - L 1860 1835 1805 1780 1750 1715 1675 1635 1590 1540 1490 1260 1115 980 - -

Factory settings are in Bold

High-Static option not available for 060 and 070

Air flow values are with dry coil and standard filter

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, 400 fpm by 0.12in. wg.

and 500 fpm by 0.16 in. wg.

022

030

036

042

048

060

070

022

030

036

042

048

Fan Performance Data - PSC

Standard PSC Motor

Optional High Static PSC Motor

Setting Fan Speed - PSC

CAUTION: Disconnect all power before

performing this operation.

16

HIGH

E

R

I

W

D

E

E

P

S

N

A

F

PSC FAN MOTOR BODY

LOWMEDIUM

Page 17

ENVISION RESIDENTIAL INSTALLATION MANUAL

Fan Performance Data - ECM

ECM2

Single Speed

MODEL

022 0.50

030 0.50

036 0.50

036

w/1hp*

042 0.50

042

w/1hp* L M

048 0.50

048

w/1hp*

060 0.75

070 0.75

Factory settings are at recommended L-M-H DIP switch locations CFM is controlled within ±5% up to the maximum ESP

M-H settings MUST be located within boldface CFM range Max ESP includes allowance for wet coil and standard filter

Lowest and Highest DIP switch settings are assumed to be L and H respectively

MAX AIR FLOW DIP SWITCH SETTINGS

ESP123456789101112

650 750 850 1000 1100 1200

0.75

0.75

0.75

800 1000 1100 1300 1500 1600

650

800

650

800

800

800

400 500 600 700

400 500 600 700

L MH

800 900 1050 1150 1250 1350 1450 1550

900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

800 900 1050 1150 1250 1350 1450 1550

900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

950 1100 1300 1500 1750 1950 2100 2300

950 1100 1300 1500 1750 1950 2100 2300

L M

L M

L

L

L

L MH

L

L

MH

MH

H

MH

800 900 1000 1100 1200

H

800 900 1000 1100 1200

MH

H

1300 1400 1500

1800

MH

5/30/06

Dual Capacity

MODEL

026 0.50

038 0.50

038

w/1hp*

049 0.50

049

w/1hp*

064 0.75

072 0.75

Factory settings are at recommended L-M-H DIP switch locations CFM is controlled within ±5% up to the maximum ESP

M-H settings MUST be located within boldface CFM range Max ESP includes allowance for wet coil and standard filter

Lowest and Highest DIP switch settings are assumed to be L and H respectively

A 12-position DIP switch package on the control allows the airfl ow levels to be set for low, medium, and high

speed when using the ECM2 blower motor. Only three of the DIP switches can be in the "on" position.

The example to the right shows SW1 on the control board confi gured for the following NS042 airfl ow settings.

MAX AIR FLOW DIP SWITCH SETTINGS

ESP123456789101112

650 750 850 1000 1100 1200

0.75

0.75

The fi rst "on" switch (the lowest position number) determines the low speed fan setting.

•

The second "on" switch determines the medium speed fan setting.

•

The third "on" switch determines the high speed fan setting.

•

Low Speed Fan: 900 CFM

•

Medium Speed Fan: 1150 CFM

•

High Speed Fan: 1450 CFM

•

800 1000 1100 1300 1500 1600

L MH

650

800

L

800

800

400 500 600 700

L

800 900 1050 1150 1250 1350 1450 1550

L

900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

950 1100 1300 1500 1750 1950 2100 2300

L M

950 1100 1300 1500 1750 1950 2100 2300

L M

MH

MH

L

800 900 1000 1100 1200

MH

H

1300 1400 1500

1800

MH

H

5/30/06

SW1

OnOff

1

2

3

4

5

6

7

8

9

10

11

12

Setting Fan Speed - ECM

ECM2 fan motors have a 12-speed selector dip switch on the logic board (SW1) and are factory set for optimum performance. To change speeds, select the appropriate speeds on dip switch SW1. Consult the ECM2 fan performance table

below for specifi c airfl ow and switch information.

CAUTION: Disconnect all power before performing this operation.

17

Page 18

ENVISION RESIDENTIAL INSTALLATION MANUAL

LEFT RETURN RIGHT RETURN

FRONT

TOP

2ft [61cm ]

Primary Service Access

TOP

A

DEHFKJ I G

1.9in

[4.8cm]

1.9in

[4.8cm]

M

R

Q

N

O

L

R

N

O

L

P

Q

RIGHT SIDE

B

C

B

LEFT SIDE

STS

T

C

Vertical Dimensional Data

T op Air Discharge

Overall Cabinet

Vertical

Models

in. 22.5 26.5 48.5 2.0 7.0 13.5 16.5 10.2

022-030

cm. 57.2 67.2 123.2 5.0 17.7 34.2 41.8 26.0 21.6 26.4 29.8 15.5 2.1 35.6 35.6 11.1 4.2 56.3 66.0 4.4

in. 25.6 31.6 50.4 2.3 7.3 15.9 18.9 10.6

036-038

cm. 65.0 80.2 128.0 5.7 18.4 40.3 47.9 26.8 20.3 28.6 32.4 17.5 2.8 45.7 45.7 9.6 4.4 71.2 66.0 4.3

in. 25.6 31.6 54.4 2.3 7.3 15.9 18.9 10.6

042-049

cm. 65.0 80.2 138.2 5.7 18.4 40.3 47.9 26.8 20.3 28.6 32.4 17.5 2.8 45.7 45.7 9.6 4.4 71.2 76.2 4.3

in. 25.6 31.6 58.4 2.3 7.3 15.9 18.9 10.6

060-072

cm. 65.0 80.2 148.3 5.7 18.4 40.3 47.9 26.8 20.3 28.6 32.4 17.5 2.8 45.7 45.7 9.6 4.4 71.2 86.4 4.3

Condensate is 3/4" PVC female glue socket and is switchable from side to front

Vertical unit shipped with deluxe 2" (field adjustable to 1") duct collar/filter rack extending from unit 3.25" and is suitable for duct connection.

Discharge flange is field installed and extends 1" [25.4 mm] from cabinet

Decorative molding and water connections extend 1.2" [30.5mm] beyond front of cabinet.

IJK

AB CDE F G H

Width Depth Height* In Out HWG In

Water Connections Electrical Knockouts

HWG

Out

Cond-

ensate

Loop

Water FPT HWG FPT

1" Swivel 1" Swivel

1" Swivel 1" Swivel

1" Swivel 1" Swivel

1" Swivel 1" Swivel

1/2" cond 1/2" cond 3/4" cond LMNOPQRST

Low

Voltage

8.5 10.4 11.8 6.1 0.8 14.0 14.0 4.4 1.7 22.2 26.0 1.7

8.0 11.3 12.8 6.9 1.1 18.0 18.0 3.8 1.7 28.1 26.0 1.7

8.0 11.3 12.8 6.9 1.1 18.0 18.0 3.8 1.7 28.1 30.0 1.7

8.0 11.3 12.8 6.9 1.1 18.0 18.0 3.8 1.7 28.1 34.0 1.7

Ext Pump

Discharge Connection

duct flange installed (±0.10 in)

Power

Supply

Supply

Width

Supply

Depth

Return Connection

using std deluxe filter rack (±0.10 in)

Return

Return

Depth

Height

Rev.: 07/19/06 B

18

Page 19

ENVISION RESIDENTIAL INSTALLATION MANUAL

S

S

Horizontal Dimensional Data

TOP VIEW

2ft [61cm ]

Primary Service Access

Q

P

2.1in [5.4cm ]

MOUNT (2) HANGER BRACKET

AS SHOWN TO ALLOW ACCES

TO FILTER

SIDE DISHCARGE VIEW

B

END VIEW

L

L

O

N

M

C

H

1.9in

[4.8cm]

KJ I

FRONT VIEW

A

S

DE F G

AS SHOWN LR UNIT (RR UNIT ON OPPOSITE SIDE—SAME DIMENSIONS)

Overall Cabinet

Horizontal

Models

in. 22.5 63.0 19.3 2.0 7.0 13.5 16.5 0.8

022-030

cm. 57.2 160.0 49.0 5.0 17.7 34.2 41.8 2.1 22.2 24.0 30.0 5.8 26.5 23.8 14.7 7.0 77.3 42.9 3.3

in. 25.6 72.0 21.3 2.3 7.3 15.9 18.9 0.8

036-038

cm. 65.0 182.9 54.1 5.7 18.4 40.3 47.9 2.1 22.2 24.0 30.0 34.6 33.5 7.0 90.0 47.9 3.3

in. 25.6 77.0 21.3 2.3 7.3 15.9 18.9 0.8

042-049

cm. 65.0 195.6 54.1 5.7 18.4 40.3 47.9 2.1 22.2 24.0 30.0 34.6 33.5 7.0 102.5 47.9 3.3

in. 25.6 82.0 21.3 2.3 7.3 15.9 18.9 0.8

060-072

cm. 65.0 208.3 54.1 5.7 18.4 40.3 47.9 2.1 22.2 24.0 30.0 34.6 33.5 7.0 115.2 47.9 3.3

Right Return End Discharge

Right Return Side Discharge

Left Return End Discharge

Left Return Side Discharge

AB C

Width Depth Height* In Out HWG In

DE F G H

LUnits Not Shown Above O

in. 2.8 4.6

cm. 7.1 11.8

in. 4.9 6.9

cm. 12.4 17.5

in. 4.9 7.6

cm. 12.4 19.4

in. 2.8 6.9

cm. 7.1 17.5

Water Connections Electrical Knockouts

IJK

HWG

Out

Cond-

ensate

Loop

Water FPT HWG FPT

1" Swivel 1" Swivel

1" Swivel 1" Swivel

1" Swivel 1" Swivel

1" Swivel 1" Swivel

1/2" cond 1/2" cond 3/4" cond LMNOPQRS

Low

Ext Pump

Voltage

8.8 9.4 11.8 2.3 10.5 9.4 5.8 2.8 30.5 16.9 1.3

8.8 9.4 11.8

8.8 9.4 11.8 13.6 13.2 2.8 40.4 18.9 1.3

8.8 9.4 11.8 13.6 13.2 2.8 45.4 18.9 1.3

Power

Supply

Discharge Connection

duct flange installed (±0.10 in)

Supply

Supply

Height

Depth

13.6 13.2 2.8 35.5 18.9 1.3

SEE

CHART

SEE

CHART

SEE

CHART

SEE

CHART

SEE

CHART

SEE

CHART

using std deluxe filter rack (±0.10 in)

Return Connection

Return

Depth

Return

Height

O

Rev.: 07/18/06 B

S

R

Condensate is 3/4" PVC female glue socket and is switchable from side to front

Horizontal unit shipped with deluxe 2" (field adjustable to 1") duct collar/filter rack extending from unit 2.88" and is suitable for duct connection.

Discharge flange is field installed and extends 1" [25.4 mm] from cabinet

Decorative molding and water connections extend 1.2" [30.5mm] beyond front of cabinet.

19

Page 20

ENVISION RESIDENTIAL INSTALLATION MANUAL

Vertical Dimensional Data

Bottomfl ow

LEFT RETURN

RIGHT RETURN

1.70

4

(4.3 cm)

C

S

S

T

T

B

LEFT SIDE

R

L

2ft [61cm]

Primary Service Access

Bottomflow

Models

022-030 .66.81.546.349.146.37.947.642.043.535.255.625.22.ni 0 9.3 10.5 1.0 2.2 22.2 26.0 5.6

036-072 .41.92.258.059.846.30.060.754.844.345.265.135.52.ni 8 13.4 13.6 1.5 1.8 28.1 34.0 5.6

Condensateis 3/4" PVC femaleglue socketand is switchable from side tofront

Verticalbottomflow unitshippedwithdeluxe 2" (fieldadjustableto1") duct collar/filter r ack extendingfromunit3.25" and issuitable for ductconnection.

Decorative moldingand w ater connectionsex tend 1.2" (30.5mm)beyond frontofcabinet.

ABCDEFG H

Width Depth Height In Out HWG In HWG Out Condensate Water FPT

O

M

LEFT BOTTOM DISCHARGE

2017.984.3313.762.75.mc

N

FLOOR FOOT PRINT

4321

19.2212.0118.8510.088.46.mc 2.6 23.1 12.2 34.0 34.5 3.8 4.6 71.4 86.4 14.2

snoitcennoCretaWtenibaCllarevO

5

1" Swivel

.92.6216.8111.

1

1" Swivel 1" Swiv el

Loop

Q

RIGHT BOTTOM DISCHARGE

HWG

FPT

1" Swiv el

B

RIGHT SIDE

RQ

O

FLOOR FOOT PRINT

Electrical Knockouts

I

J

1/2" cond 1/2" cond 3/4" cond

Low

Voltage

ExtPump

Power

Supply

C

K

J

I

LN

P

DischargeConnection

K

.6 21.8 15.2 23.6 26.7 2.5 5.6 56.4 66.0 14.2

4117.0114.601

310.9212.4211.94.2518.44

duct flange installed (±0.10 in)

LMNOPQRST

Supply

Width

Supply

Depth

3

2

1

1.90

(4.7 cm)

5

A

FRONT

using std deluxe filter rack (± 0.10 in)

D

H

Return Connection

Return

Return

Height

Depth

E

Rev.: 09/27/07

G

F

20

Page 21

ENVISION RESIDENTIAL INSTALLATION MANUAL

Physical Data (Single Speed)

Model

Compressor (1 each)

Factory Charge R410a, oz [kg] Vertical 62 [1.76] 62 [1.76] 82 [2.32] 82 [2.32] 98 [2.78] 110 [3.12] 146 [4.14]

Factory Charge R410a, oz [kg] Horizontal 60 [1.70] 66 [1.87] 82 [2.32] 82 [2.32] 98 [2.78] 94 [2.67] 122 [3.46]

022 030 036 042 048 060 070

Copeland Scroll

Fan Motor & Blower

SINGLE SPEED

Fan Motor Type/Speeds

Fan Motor- hp [W]

Blower Wheel Size (Dia x W), in. [mm]

ECM

PSC

ECM 1/2 [373] 1/2 [373] 1/2 [373] 1/2 [373] 1/2 [373] 1 [746] 1 [746]

PSC 1/5 [149] 1/3 [249] 1/2 [373] 1/2 [373] 1/2 [373] 1 [746] 1 [746]

ECM

PSC

9 x 7

[229 x 178]

9 x 7

[229 x 178]

9 x 7

[229 x 178]

9 x 7

[229 x 178]

ECM Variable Speed

PSC 3 Speeds

11 x 10

[279 x 254]

10 x 10

[254 x 254]

[279 x 254]

[254 x 254]

11 x 10

10 x 10

11 x 10

[279 x 254]

10 x 10

[254 x 254]

11 x 10

[279 x 254]

11 x 10

[279 x 254]

Coax and Water Piping

Water Connections Size - Swivel - in [mm] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4]

HWG Connection Size - Swivel - in [mm] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4]

Coax & Piping Water Volume - gal [l] 0.7 [2.6] 1.0 [3.8] 1.3 [4.9] 1.3 [4.9] 1.6 [6.1] 1.6 [6.1] 2.3 [8.7]

Vertical

Air Coil Dimensions (H x W), in. [mm]

Air Coil Total Face Area, ft2 [m2] 3.9 [0.362] 3.9 [0.362] 4.9 [0.451] 5.6 [0.570] 5.6 [0.570] 6.3 [0.641] 6.3 [0.641]

Air Coil Tube Size, in [mm] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5]

Air Coil Number of rows 3 3 3 3 3 4 4

Filter Standard - 2" [51mm] Pleated

MERV11 Throwaway, in [mm]

Weight - Operating, lb [kg] 305 [138] 320 [145] 365 [166] 380 [172] 420 [190] 455 [206] 480 [218]

Weight - Packaged, lb [kg] 315 [143] 330 [150] 375 [170] 390 [177] 430 [195] 465 [211] 490 [222]

28 x 20

[711 x 542]

28 x 24

[712 x 610]

28 x 20

[711 x 542]

28 x 24

[712 x 610]

28 x 25

[711 x 635]

28 x 30

[712 x 762]

32 x 25

[813 x 635]

32 x 30

[813 x 762]

32 x 25

[813 x 635]

32 x 30

[813 x 762]

36 x 25

[914 x 635]

36 x 30

[914 x 762]

Horizontal

Air Coil Dimensions (H x W), in. [mm]

Air Coil Total Face Area, ft2 [m2] 3.9 [0.362] 3.9 [0.362] 4.9 [0.451] 5.6 [0.570] 5.6 [0.570] 6.3 [0.641] 6.3 [0.641]

Air Coil Tube Size, in [mm] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5]

Air Coil Number of rows 3 3 3 3 3 3 3

Filter Standard - 2" [51mm] Pleated

MERV11 Throwaway, in [mm]

Weight - Operating, lb [kg] 307 [139] 322 [146] 370 [168] 385 [175] 425 [193] 460 [209] 485 [220]

Weight - Packaged, lb [kg] 322 [146] 337 [153] 385 [175] 400 [181] 440 [200] 475 [215] 500 [227]

18 x 30

[457 x 762]

1 - 18 x 32

[457 x 813]

18 x 30

[457 x 762]

1 - 18 x 32

[457 x 813]

20 x 35

[508 x 889]

1 - 20 x 37

[686 x 940]

20 x 40

[508 x 1016]

1 - 20 x 20

[508 x 508]

1 - 20 x 22

[508 x 559]

20 x 40

[508 x 1016]

1 - 20 x 20

[508 x 508]

1 - 20 x 22

[508 x 559]

20 x 45

[508 x 1143]

1 - 20 x 25

[508 x 635]

1 - 20 x 22

[508 x 559]

Notes: Sizes 036, 042, 048 available with 1HP blower motor. (ICM only)

11 x 10

[279 x 254]

11 x 10

[279 x 254]

36 x 25

[914 x 635]

36 x 30

[914 x 762]

20 x 45

[508 x 1143]

1 - 20 x 25

[508 x 635]

1 - 20 x 22

[508 x 559]

4/9/07

21

Page 22

ENVISION RESIDENTIAL INSTALLATION MANUAL

Physical Data (Dual Capacity)

Model

Compressor (1 each) Copeland 2-speed Scroll, UltraTech

Factory Charge R410a, oz [kg] Vertical 62 [1.76] 78 [2.21] 89 [2.52] 122 [3.46] 140 [3.97]

Factory Charge R410a, oz [kg] Horizontal 60 [1.70] 76 [2.16] 89 [2.52] 124 [3.52] 160 [4.54]

026 038 049 064 072

DUAL CAPACITY

ECM Fan Motor & Blower

Fan Motor Type/Speeds ECM Variable Speed

Fan Motor- hp [W] 1/2 [373] 1/2 [373] 1/2 [373] 1 [746] 1 [746]

Blower Wheel Size (Dia x W), in. [mm]

9 x 7

[229 x 178]

11 x 10

[279 x 254]

11 x 10

[279 x 254]

11 x 10

[279 x 254]

11 x 10

[279 x 254]

Coax and Water Piping

Water Connections Size - Swivel - in [mm] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4]

HWG Connection Size - Swivel - in [mm] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4] 1" [25.4]

Coax & Piping Water Volume - gal [l] 0.7 [2.6] 1.3 [4.9] 1.6 [6.1] 1.6 [6.1] 2.3 [8.7]

Vertical

Air Coil Dimensions (H x W), in. [mm]

Air Coil Total Face Area, ft2 [m2] 3.9 [0.362] 4.9 [0.451] 5.6 [0.570] 6.3 [0.641] 6.3 [0.641]

Air Coil Tube Size, in [mm] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5]

Air Coil Number of rows 3 3344

Filter Standard - 2" [51mm] Pleated

MERV11 Throwaway, in [mm]

Weight - Operating, lb [kg] 305 [138] 370 [168] 420 [190] 465 [211] 480 [218]

Weight - Packaged, lb [kg] 315 [143] 380 [172] 430 [195] 475 [215] 490 [222]

28 x 20

[711 x 542]

28 x 24

[712 x 610]

28 x 25

[711 x 635]

28 x 30

[712 x 762]

32 x 25

[813 x 635]

32 x 30

[813 x 762]

36 x 25

[914 x 635]

36 x 30

[914 x 762]

36 x 25

[914 x 635]

36 x 30

[914 x 762]

Horizontal

Air Coil Dimensions (H x W), in. [mm]

Air Coil Total Face Area, ft2 [m2] 3.9 [0.362] 4.9 [0.451] 5.6 [0.570] 6.3 [0.641] 6.3 [0.641]

Air Coil Tube Size, in [mm] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5] 3/8 [9.5]

Air Coil Number of rows 3 3344

Filter Standard - 2" [51mm] Pleated

MERV11 Throwaway, in [mm]

Weight - Operating, lb [kg] 307 [139] 375 [170] 425 [193] 470 [213] 485 [220]

Weight - Packaged, lb [kg] 322 [146] 390 [177] 440 [200] 485 [220] 500 [227]

18 x 30

[457 x 762]

1 - 18 x 32

[457 x 813]

20 x 35

[508 x 889]

1 - 20 x 37

[686 x 940]

20 x 40

[508 x 1016]

1 - 20 x 20

[508 x 508]

1 - 20 x 22

[508 x 559]

20 x 45

[508 x 1143]

1 - 20 x 25

[508 x 635]

1 - 20 x 22

[508 x 559]

20 x 45

[508 x 1143]

1 - 20 x 25

[508 x 635]

1 - 20 x 22

[508 x 559]

4/9/07

Notes: Sizes 038, 049 available with 1HP blower motor (ICM only).

22

Page 23

ENVISION RESIDENTIAL INSTALLATION MANUAL

C

HWL

HP

Thermostat

CO

R

CY1O

L1

Y2

NOTE4

G

LP

PS

FP

W

Brn(15)

Org(14)

123

P10

4

5

Envision - SingleSpeed Wiring Schematic - 208-230/60/1

97P774-06 9/27/06

PB2

Auxiliary Electric Heat Power

208-230/60/1

With optional ' EA' Series

Auxiliary ElectricHeat

Typical schematic shown

2

3

HE1 TS1

HE2 TS2

HE3 TS3

HE4 TS4

P7

L4 L2

L2 NOTE5

Pink

Yel

Blk

Gray

Pink

Yel

Blk

Gray

Gray

Blk

Yel

Pink

Gray

Pink

Blk

Yel

Pink

Yel

Blk

Gray

Pink

Yel

Blk

Gray

Grn

F2

P9

ER1

ER2

ER3

ER4

L1

L1 L3

NO

NO

NO

NO

Org

Brn

Brn

Org

Brn

Or

5

4

Pink

Orange

White

Tan

Blue

NOTE2

Red

6

EASeries PCB

Blk/Wht(11)

Gry/Wht(10)

SL1 In

SL1Out

Optional

RemoteUnit

Without

LoopPump

Foldandmatearrows

Foldand mate arrows

Foldand mate arrows

Foldand mate arrows

L1 L2

Single Disconnect Power

208-230/60/1

AuxElect Power

208-230/60/1

L1 L2 L1 L2

Unit Power

208-230/60/1

CSAinstalled units only

Localcodes may require asingle

sourceof power supply

Breakerbox

furnishedby

installer

E-SeriesLogic Board - Physical Layout

NOTE9

1

123

P10

456

P2

1

StatusLED PCB

SW4

RRRRR

GYR

T

T

G G

432

1

P8

123

4

123

1

P4

OnOff

SW1

240V- L2

240V- L1

Fused L2

Fused L2

Fused L2

F1

F1

R

R

Microprocessor

Premier2LogicBoard

CR2- Loop

Pump

N.O.

240V- L2

240V- L1

C

C

1

2345678

9

10111213141516

P6

1234567

8

9

1011121314

P5

Fused L2

Fused L1

CR1- DHW

Pump

N.O.

CC

CC-GND

CCLO

CCHI

123

P3

234

5

678

9

101112

1

OnOff

SW2

2

3

4

5

678

1

OnOff

SW3

234

5

P1

1234567 8

2

345

P2

671

RCY1Y2 GOWL

Shut

Down

ACC

NO

ACC

NC

ACC

COM

CC

SL1

IN

SL1

Out

SL2

IN

SL2

Out

CircuitBreakers

CC

Blk(1)

Transformer

NOTE1

24V

Red

208V

Blu

240V

Blk

Blk/WhYel

Gry(9)

N.O.

CR4-

Com

N.O.

CR3-

Com

N.C.

Unit Power

208-230/60/1

G

L2 L1

CC

NOTE6

DHW

Pump

Blu

3A

Fuse

Optional

Electronic

Air-Filter

NOTE10

240V L2

240VL1

240VL 2

P6

Premier 2

Microprocessor

Logic Control

(DC Voltage)

P1

Fused L2

R

C

CC-GND

NO

CR2

COM

F1-10A240 V

Fused L2

NO

CR1

COM

Pink

1234567

8

123

P4

Pink

Black

Violet

Yellow

Black

Blue

Blue

Orange

Orange

Pink

Yellow

Yellow

Pink

Orange

White

Tan

Blue

NotUsed

123C

P2

Down

C

1234567

Shut

SL1 In

Not

SL1Out

Used

NOTE3

AccCom

AccNC

AccNO

123

P3

NotUsed

NotUsed

Brown

Gray

123

MainLogic PCB

F1-10A

240V

Tan

NotUsed

Red

6

5

487

P5

12

129

10

349

11

2

10

8

1125

3

13

14

15

16

11

GWO

R

C

Y1

Y2

LO

On

SW1

123456789

101112

ECM2

AirFlow

Settings

Black

Blue

14

13

6

7

CC

NO

NC

CR4

COM

NO

NC

CR3

COM

Blk(7)

Blu(17)

Violet(2)

RV

Ext Pump

1/2 hp Total

208-230/60/1

Pump Pump

G

2

1

PB1

1

2

Yel(8)

Comfort

Alert

R

Y

C

CCHI

NotUsed

NotUsed

Violet(3)

Blk(5)

Yel(6)

L

ComfortAlert

15

10

16

3

P12

P11

2

345

1

8

Pink(13)

FieldSelection Dips - #1 On, #6On, #7 On

Drainpan overflow Lockout

FPthermistor (loop<15 °F,well<30°F) Lockout

HighPressure > 600 PSI Lockout

Low Pressure < 40 PSI Lockout

ECM2RPM < 100 rpm Lockout

Microprocessormalf unction*

HWLthermi stor> 130°F

DHWpump switch off

Drain

WaterFlow

HighPress

LowPress / Comp

AirFlow

Status

DHWLim it

DHWoff

LED Normal Display Mode

#1Off, #6 On,#7 On

Drainpan overflow

FPthermistor (loop< 15°F,well<30° F)

HighPressure > 600 PSI

Low Pressure < 40 PSI

ECM2RPM < 100 rpm

NotUsed

HWLthermistor > 130°F

DHWpump switch off

Current Fault Status

#6Off, #7 On

Y1

Y2

OGW

SL1

SL2

--

Inputs

#6On, #7 Off

CompressorLo

CompressorHi

RV

FAN

DHWPump

LoopPump 1

LoopPump 2

--

Outputs

#6Of f,#7 Off

BlowerLo

BlowerMed

BlowerHi

AuxHeat #1

AuxHeat #2

AuxHeat #3

AuxHeat #4

--

Outputs2

Diagnostic Modes

*GreenLED not flashing

NOTE11

C

S

R

Run

Capacitor

132

Red Black

Blue

Tan

(16)

Comfort Alert

LED Flash Code Description

Green Solid Module Has Power

Red Solid Y1 Present But Compressor Not Running

Code 1 Long Run Time

Code2 System PressureTrip

Code 3 S hort Cycling

Code 4 Loc ked Rotor

Code 5 Open Circ uit

Code 6 Open S tart Circuit

Code 7 Open Run Circ uit

Code 8 W elded Contactor

Code 9 Low V oltage

Yellow

Comfort Alert Status

Notes:

1– Switch Blueand Redwires for 208V operation.

2- Connection ofremote unitthat does nothave aloop pumpfor slaveoperation .

3- 24VAccessory relay(see SW2 -3 fordescription ofoperation )

4- The blk/whand gray/wh wiresar eremoved whenAux Heat isinstalled .

6- DHW pumponly in models withhot water generationoption .

5- Buss lugsL1 and L2can be removedand dualpow erwire setsconnected directlyto boxlugs L 1,L2 ,

andL3, L4.

10- When optionalelectronic air-filter is installed, powerfor the electronicair-f ilteris provided byP2-2 and

24VAC.

8– SW3-4 shouldbe in theOFF positionwhen using the 17P501A01 electricheat board and

shouldbe ON whenusing the 17P514A01 electricheat board .

11-Comfort Alert faultoutput toPremier Control Board

9– SW2-8 mustb ein theO FFposition for pulsed“L” lockout signaland inthe ON positionfor constant

“L”lockout signal.

7– This Sw itchallows theunit todown stagewith thet -stat whenOFF andfinish on secondstagewhen

ON. Finish second stagered ucesstage changing inrecip dualcapacity compressors andshould

beON for unzonedDual CapE -Series orPremier 2 speedunits.

On

SW3

On

SW2

1

2345678

NoHtg 3/ Htg3

Dehum /Norm

Fan/ Comp

Loop/ Well

Test/ Norm

Outputs/ Norm

Inputs / Norm

2Speed / 1 Speed

Normal /Finish on 2

nd

(Note 7)

NoRPM / RPM

ElectricHeat / Normal (Note 8)

Envision /E Series or Premier

1

234

5

PulseL / Constant L (NOTE 9)

Y

L

R

C

DC

Sol

Data

Port

ComfortAl ert

PhysicalLayout

POWER

ALERT

TRIP

Brn

Wht

Grn

P13

H M L

PSC

FanMotor

Cap

Blk

Wht

Thermistor

Light emitting diode - Green

Relaycoil

Capacitorw /bleed resistor

Switch -Condensate overflow

Switch -High pressure

Switch -Low pressure

Switch-Hot Water On/Off

Polarizedconnector

FactoryLow voltage wiring

FactoryLine voltage wiring

Fieldlow voltage wiring

Fieldline voltage wiring

Optionalblock

DCVoltage PCB traces

Internaljunction

Quickconnect terminal

Wirenut

Fieldwirelug

Ground

Fuse

CC-

CO-

CR1-

CR2-

CR3-

CR4-

F1and F2 -

FP-

HE-

HP-

LP-

PB1, PB2-

PS-

RV-

SW1 -

SW2 -

SW3 -

SW4 -

TS-

CompressorContactor

Condensateoverflow sensor

DHWpump relay

Looppump relay

Fuses

Freezeprotection sensor

Heaterelement

Highpressure switch

Low pressure switch

Powerblocks

Powerstrip

ReversingValve coil

DIPpackage 12 position

DIPpackage 8 position

DIPpackage 5 position

Hotwater pump enable switch

Thermallimit switch

Legend

RelayContacts -

N.O., N.C.

G

T

132

P

L1

PSCFan Speed Relay

PSCFan Power Relay

ER1to ER4 - Aux heatstage relays

HWL-

Hotwater limit sensor

SC-

StartContactor

StartRelay

SR-

CS- Compressor Solenoid

CA-

ComfortAl ert

Wiring Schematics

Envision - Single Speed Wiring Schematic - 208-230/60/1 - PSC

23

Page 24

C

HWL

HP

Thermostat

CO

R

C

Y1

O

L1

Y2

NOTE 4

G

LP

PS

FP

W

Brn(15)

Org(14)

1

2

3

P10

4

5

97P774-01 6/29/06

Org

Brn

NOTE 2

6

Blk/Wht(11)

Gry/Wht(10)

SL1 In

SL1 Out

Optional

Remote Unit

Without

Loop Pump

StatusLED PCB

SW4

R

R

R

R

R

G

Y

R

T

T

CC

Blk(1)

Transformer

NOTE 1

24V

Red

208V

Blu

240V

Blk

Blk/WhYel

Gry(9)

Unit Power

208-230/60/1

G

L2 L1

CC

NOTE 6

DHW

Pump

Blu

3A

Fuse

Optional

Electronic

Air-Filter

NOTE 10

240V L2

240V L1

240V L2

P6

Premier 2

Microprocessor

Logic Control

(DC Voltage)

P1

Fused L2

R

C

CC-GND

NO

CR2

COM

F1-10A 240V

Fused L2

NO

CR1

COM

Pink

1

2

3

4

5

6

7

8

1

2

3

P4

Pink

Black

Violet

Yellow

Black

Blue

Blue

Orange

Orange

Pink

Yellow

Yellow

Pink

Orange

White

Tan

Blue

Not Used

1

2

3C

P2

DownC1

2

3

4

5

6

7

Shut

SL1 In

Not

SL1 Out

Used

NOTE 3

Acc Com

Acc NC

Acc NO

1

2

3

P3

Not Used

Not Used

Brown

Gray

123

F1-10A

240V

Tan

Not Used

Red

6

5

4

8

7

P5

12

1

2

9

10

3

4

9

11

2

10

8

1

12

5

3

13

14

15

16

11

G

W

O

R

C

Y1

Y2

LO

On

SW1

1

2

3

4

5

6

7

8

9

10

11

12

On

SW2

1

2

3

4

5

6

7

8

No Htg3 / Htg3

Dehum / Norm

Fan / Comp

Loop / Well

Test / Norm

Outputs / Norm

Inputs / Norm

ECM2

Air Flow

Settings

NOTE 7

Black

Blue

14

13

6

7

CC

NO

NC

CR4 COM

NO

NC

CR3 COM

Fused L1

Blk(7)

Blu(17)

Violet(2)

RV

Ext Pump

1/2 hp Total

208-230/60/1

Pump Pump

G

2

1

PB1

1

2

Yel(8)

Comfort

Alert

R

Y

C

CCHI

Not Used

Not Used

Violet(3)

Blk(5)

Yel(6)

L

Comfort Alert

Pulse L / Constant L

(See Note 9)

ECM2

Fan Motor

Grn

15 10163

On/Off

PWM

RPM

C2

RPMgrnd

P12

P112 3 4 51

8

Pink(13)

NOTE11

C

S

R

Run

Capacitor

1

3

2

Red Black

Blue

Tan

(16)

Comfort Alert

Field Selection Dips - #1 On, #6 On, #7 On

Drain pan overflow Lockout

FP thermistor (loop<15°F,well<30°F) Lockout

High Pressure > 600 PSI Lockout

Low Pressure < 40 PSI Lockout / CA

ECM2 RPM < 100 rpm Lockout

Microprocessor malfunction*

HWL thermistor > 130°F

DHW pump switch off

Drain

WaterFlow

High Press

Low Press/Comp

Air Flow

Status

DHW Limit

DHW off

LED Normal Display Mode

#1Off, #6 On,#7 On

Drain pan overflow

FP thermistor (loop<15°F, well<30°F)

High Pressure > 600 PSI

Low Pressure < 40 PSI / CA

ECM2 RPM < 100 rpm

Not Used

HWL thermistor > 130°F

DHW pump switch off

Current Fault Status

#6 Off, #7 On

Y1

Y2

O

G

W

SL1

--

--

Inputs

#6On, #7 Off

Compressor Lo

Compressor Hi

RV

FAN

DHW Pump

Loop Pump(s)

--

--

Outputs

#6 Off, #7 Off

Blower Lo

Blower Med

Blower Hi

Aux Heat #1

Aux Heat #2

AuxHeat #3

Aux Heat #4

--

Outputs2

Diagnostic Modes

*Green LED not flashing

LED Flash Code Description

Green Solid Module Has Power

Red Solid Compressor Overload Trip

Code 1 Long Run Time

Code 2 System Pressure Trip

Code 3 Short Cycling

Code 4 Locked Rotor

Code 5 Open Circuit

Code 6 Open Start Circuit

Code 7 Open Run Circuit

Code 8 Welded Contactor

Code 9 Low Voltage

Yellow

Comfort Alert Status

PN - 17P513-07

On

SW3

2 Speed / 1 Speed

Normal / Finish on 2

nd

(Note 12)

No RPM / RPM

OldEH& ECM/ Normal(Note8)

Envision / E Series or Premier

1

2

3

4

5

ENVISION RESIDENTIAL INSTALLATION MANUAL

Wiring Schematics

Envision - Single Speed Wiring Schematic - 208-230/60/1 - ECM

24

Page 25

ENVISION RESIDENTIAL INSTALLATION MANUAL

PB2

Auxiliary Electric Heat Power

208-230/60/1

Violet

Blu

With optional ' EA' Series

Auxiliary ElectricHeat

Typical schematic shown

2

3

HE1 TS1

HE2 TS2

HE3 TS3

HE4 TS4

P7

L4 L2

L2 NOTE 5

Pink

Yel

Blk

Gray

Pink

Yel

Blk

Gray

Gray

Blk

Yel

Pink

Gray

Pink

Blk

Yel

Pink

Yel

Blk

Gray

Pink

Yel

Blk

Gray

Grn

F2

P9

ER1

ER2

ER3

ER4

L1

L1 L3

NO

NO

NO

NO

Brn

Org

Brn

Or

5

4

Pink

Orange

White

Tan

Blue

Violet

Blue

Yellow

Black

Gray

Red

EA Series PCB

E-Series Logic Board - Physical Layout

1

123

P10

456

P2

1

G G

4

3

2

1

P8

1

2

3

4

123

1

P4

OnOff

SW1

240V- L2

240V- L1

Fused L2

Fused L2

Fused L2

F1

F1

R

R

Microprocessor

E-SeriesLogic Board

CR2- Loop

Pump

N.O.

240V- L2

240V- L1

C

C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

P6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

P5

Fused L2

Fused L1

CR1- DHW

Pump

N.O.

CC

CC-GND

CCLO

CCHI

123

P3

2

3

4

5

6

7

8

9

10

11

12

1

OnOff

SW2

2

3

4

5

6

7

8

1

OnOff

SW3

2

3

4

5

P1

1234567 8

2

345P2671

RCY1Y2 GOWL

Shut

Down

ACCNOACC

NC

ACC

COM

CC

SL1INSL1

Out

SL2INSL2

Out

L1 L2

Single Disconnect Power

208-230/60/1

Aux Elect Power

208-230/60/1

L1 L2 L1 L2

Unit Power

208-230/60/1

CSA installed units only

Local codes may require a single

source of power supply

Breaker box

furnished by

installer

Circuit Breakers

N.O.

CR4-

Com

N.O.

CR3-

Com

N.C.

ECM2

Fan Motor

Grn

15 10163

On/Off

PWM

RPM

C2

RPMgrnd

P12

P112 3 4 51

8

1. Switch Blue and Red wires for 208V operation.

2. Connection of remote unitthat does not have a loop pump for slave operation.

3. 24V Accessory relay (see SW2 -3 for description of operation).

4. The blk/wh and gray/wh wires are removed when Aux Heat is installed.

5. Buss lugs L1 and L2 canbe removedand dual power wire sets connecteddirectly to boxlugs L1, L2, andL3, L4.

6. DHW pump only in models with hot water generation option.

7. Air Flow Configuration Example: SW1 configured for dip 1 as low, dip 3 as medium, and dip5 as high speed ECM2 fan.

8. SW3-4 should be in the OFF position when using ECM motor and 17P501A01 electric heat board and should be ON when

using ECM2 with 17P514A01 electric heat board.

9. SW2-8 must be in the OFF position for pulsed “L” lockout signal and in the ON position for constant “L” lockoutsignal.

10. When optional electroni c air-filter is installed, power for the electronic air-filter is provided by P2-2and 24 VAC.

11. Comfort Alert fault output to Premier Control Board.

12. This switch allows the unit to down stage with the t-stat when off and finish with second stage when on. Finish on second

stage reduces stage changing in recip dual capacity compressors and should be ON for unzoned Dual Cap E Series or

Premier 2 Speed.

NOTES

Thermistor

Light emitting diode - Green