Page 1

NVISION

NV3128

RS-422A Machine-Control Data

Routing Switch

Instruction Manual

Manual Part Number: MN3128-00B

Page 2

Printing History

Model NV3128 Manual, Edition 2

Printed in the U.S.A.

Copyright

NVision, Incorporated

January, 2000

July, 1993

All Rights Reserved

No part of this manual may be reproduced in any form by photostat, microfilm,

xerography, or any other means, or incorporated into any information retrieval

system, electronic or mechanical, without the written permission of NVISION, Inc.

Notice

The information contained in this Operations Manual is subject to change without

notice or obligation.

Page 3

Warranty Statement

NVISION, Inc. warrants that the equipment it manufactures shall be free from defects in materials and

workmanship for a period of two (2) years, optionally extendable to five (5) years, from the date of shipment

from the factory. If warranted equipment fails due to such defects, NVISION, Inc. shall, at its option, repair

or provide replacement for the defective part or product.

Equipment that fails after the warranty period, or that which has been operated outside its ratings or

subjected to abuse, shall be repaired for time and material charges at the Buyers expense. All out-ofwarranty repairs are warranted for a period of ninety (90) days from the date of shipment from the factory.

NVISION, Inc. makes no warranties, expressed or implied, of merchantability, fitness for a particular

purpose or otherwise. With respect to the products sold by it, NVISIONs liability for any cause, including

breach of contract, breach of warranty or negligence, is limited to repair or replacement by NVISION, at

its sole discretion. This remedy is exclusive.

In no event shall NVISION be liable for any incidental or consequential damages, including loss of profit.

Year 2000 Warranty Statement

NVISION, Inc. warrants that all of its hardware, firmware, and software products are not date-code sensitive

and that their functionality will not be affected or altered in any way by a 21st century date code.

NVISION cannot warrant that the performance of NVISION products will not be impaired by interaction with

third party equipment and software systems that may not be year 2000 compliant.

NVISION internal operations, manufacturing services, accounting systems and engineering programs

have been determined to be year 2000 compliant and it is not anticipated that a 21st century date will affect

the functionality of our business.

We are investigating our supply channels for components and services to ensure that they will not be

affected by a 21st century date code, but we cannot warrant that our products or services will not be

affected by external services beyond NVISION control.

Disclaimer

NVISION disclaims all responsibility for product or service impairments that may arise due to interaction with

third party products, equipment, or services that are not year 2000 compliant.

Page 4

Technical Support

If you need support of any kind related to your equipment, contact the local representative who sold you

the product, or you may contact NVISION, Inc. directly by any of the following methods.

Telephone Main Telephone: (530)-265-1000

Technical Support: (530) 265-1059

Sales: 800-719-1900 or (530)-265-1000

Facsimile Main FAX Number: (530)-265-1010

Sales: (530)-265-1021

Email Technical Support: support@nvision1.com

Sales: sales@nvision1.com

Postal Addresses Shipping Address: Mailing Address:

NVISION, Inc. NVISION, Inc.

125 Crown Point Court PO Box 1658

Grass Valley, CA 95945 Nevada City, CA 95959

FCC (USA) Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference in which case the user will be

required to correct the interference at their own expense.

European Community (CE) Declaration of Conformance

Some or all of the equipment described in this manual has been designed to conform with the required

safety and emissions standards of the European Community. Products tested and verified to meet these

standards are marked as required by law with the CE mark.

When shipped into member countries of the European Community, this equipment is accompanied by

authentic copies of original Declarations of Conformance on file in NVISION corporate headquarters in

Nevada City, California, USA.

Page 5

Important Safeguards and Notices

The information on the following pages provides important safety guidelines for both operator and service

personnel. Specific warnings and cautions appear throughout the manual where they apply. Please read

and follow this important safety information, especially those instructions related to the risk of electric shock

or injury to persons.

WARNING: Any instructions in this manual that require opening the equipment cover or

enclosure are for use by qualified service personnel only. To reduce the risk of electric shock,

do not perform any servicing other than that contained in the operating instructions unless you

are qualified to do so.

Symbols and Their Meanings

The lightning flash with arrowhead symbol within an equilateral triangle alerts the user to

the presence of dangerous voltages within the products enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to persons.

U

R

The exclamation point within an equilateral triangle alerts the user to the presence of

important operating and maintenance/service instructions. These instructions may include

warnings or cautions advising about the potential for damage to equipment or danger to

personnel.

The Ground symbol represents a protective grounding terminal. Such a terminal must be

connected to earth ground prior to making any other connections to the equipment.

The fuse symbol indicates that the fuse referenced in the text must be replaced with one

having the ratings indicated.

The presence of the UL symbol in or on NVISION equipment means that it has been

designed, tested and certified as complying with applicable Underwriters Laboratory

(USA) regulations and recommendations.

The presence of the CE symbol in or on NVISION equipment means that it has been

designed, tested and certified as essentially complying with all applicable European Union

(CE) regulations and recommendations.

Page 6

Warnings

A warning indicates a possible hazard to personnel which may cause injury or death. Observe the following

general warnings when using or working on this equipment.

- Heed all warnings on the unit and in the operating instructions.

- Do not use this equipment in or near water.

- This equipment is grounded through the grounding conductor of the power cord. To avoid electrical shock,

plug the power cord into a properly wired receptacle before connecting the equipment inputs or outputs.

- Route power cords and other cables so they are not likely to be damaged.

- Disconnect power before cleaning the equipment. Do not use liquid or aerosol cleaners; use only a damp

cloth.

- Dangerous voltages may exist at several points in this equipment. To avoid personal injury, do not touch

exposed connections and components while power is on.

- Do not wear rings or wristwatches when troubleshooting high current circuits such as the power supplies.

- During installation, grasp the chassis of the equipment firmly and lift with your legs; do not bend over at

the waist to lift heavy items. Moreover, do not rely on door handles or front panels to lift the equipment

as they are not intended for this purpose.

- To avoid fire hazard, use only the specified fuse(s) with the correct type number, voltage and current

ratings as referenced in the appropriate locations in the service instructions or on the equipment. Always

refer fuse replacements to qualified service personnel.

- To avoid explosion, do not operate this equipment in an explosive atmosphere.

- Have qualified service personnel perform safety checks after any completed service.

- If equipped with redundant power supplies, the equipment has two power cords. To reduce the risk of

electric shock, disconnect both power supply cords before servicing the unit.

Page 7

Cautions

A caution indicates a possible hazard to equipment that could result in equipment damage. Observe

the following general cautions when operating or working on this equipment.

- When installing this equipment, do not attach the power cord to building surfaces.

- To prevent damage to equipment when replacing fuses, locate and correct the problem that caused

the fuse to blow before re-applying power.

- Verify that all power supply lights are off before removing the power supply or servicing the equipment.

- Use only the specified replacement parts.

- Follow static precautions at all times when handling this equipment.

- This product should only be powered as described in the manual. To prevent equipment damage,

select the proper line voltage at the AC input connector (if applicable) as described in the installation

documentation.

- To prevent damage to the equipment, read the instructions in the equipment manual for proper input

voltage range selection.

- To maximize protection against unwanted power loss, ensure that the power cords for redundant

power supplies are plugged into separate branch circuits.

Page 8

North American Power Supply Cords

The power cords supplied with this equipment have a molded grounding plug (NEMA 5-15P) at one

end and molded grounding receptacle (IEC 320-C13) at the other end. Conductors are CEE colorcoded: Light blue (neutral), Brown (line) and Green or Green/Yellow (ground).

Operation of this equipment at voltages exceeding 130 VAC will require power supply cords which

comply with NEMA configurations.

Brown

Blue

Green or Green

with Yellow Stripe

Line

Neutral

Ground (Earth)

International Power Supply Cords

The power cords supplied with this equipment have a molded grounding receptacle (IEC 320-C13) at

one end and stripped conductors (50/5 mm) at the other end. Conductors are CEE color-coded: Light

blue (neutral), Brown (line) and Green/Yellow (ground). Other IEC 320-C13 type power supply cords

can be used if they comply with the safety regulations of the country in which they are installed.

Brown

Blue

Green with

Yellow Stripe

Line

Neutral

Ground (Earth)

Page 9

TABLE OF CONTENTS

1. GENERAL INFORMATION ........................................................................................ 1-1

1.1 General .................................................................................................... 1-3

1.2 Architecture .............................................................................................. 1-4

1.3 I/O .......................................................................................................... 1-12

1.4 Physical .................................................................................................. 1-12

1.5 Ancillary Equipment ................................................................................ 1-13

1.6 Specifications ......................................................................................... 1-14

2. INSTALLATION .......................................................................................................... 2-1

2.1 HARDWARE INSTALLATION .................................................................... 2-3

2.2 CONFIGURATION .................................................................................... 2-6

2.3 CABLING ................................................................................................ 2-14

2.4 ADDING A REDUNDANT CONTROLLER ............................................... 2-18

2.5 IMPLEMENTING HOT CHANGEOVER ................................................... 2-18

2.6 PC DIAGNOSTIC INTERFACE ................................................................ 2-19

3. OPERATION ............................................................................................................... 3-1

3.1 CONNECTION NOTES ............................................................................. 3-3

3.2 COMPUTER UTILITIES ............................................................................. 3-5

4. THEORY OF OPERATION ........................................................................................ 4-1

4.1 System ...................................................................................................... 4-3

4.2 Circuit Operation ...................................................................................... 4-5

5. MAINTENANCE AND TROUBLESHOOTING.......................................................... 5-1

5.1 Customer Support .................................................................................... 5-3

5.2 Scheduled Maintenance ........................................................................... 5-3

5.3 Reliability .................................................................................................. 5-3

5.4 Troubleshooting ........................................................................................ 5-4

GLOSSARY ................................................................................................................... G-1

INDEX...................................................................................................................... Index-1

Page 10

Page 11

CHAPTER 1: GENERAL INFORMATION

NV3128 RS-422A Machine-Control Data Switch 1-1

Page 12

NV3128 RS-422A Machine-Control Data Switch 1-2

Page 13

CHAPTER 1 - GENERAL INFORMATION

1.1 GENERAL

The NV3128 is a serial digital switch for routing RS-422A machine-control

data in a video or audio broadcast or production facility. Table 1.1 at the end

of this section lists its performance specifications.

Requiring only eight units of a 19" EIA rack for a bi-directional, 128-machine

array, the NV3128 achieves a 10:1 space reduction over traditional analog or

relay routers. Its non-blocking matrix architecture and unique dynamic portconfiguration capability combine to vastly simplify the cumbersome routing

of duplex machine-control signals. The system is capable of multidrop

RS422-A chains without bus contention.

At the heart of the NV3128 is the Control Card/Command Interpreter, which

parses the command strings from any of a large number of commonly available

router-control systems into physical from and to crosspoint addresses. Further,

the Interpreter gleans from those commands the information it needs to

configure the I/O ports. Transparently, the Interpreter allows the NV3128 to

be steered by the same routing-control system that drives a plants program

and other auxiliary data switching.

The NV3128 can be synchronized to a video black burst signal or it can free

run. Takes occur during the vertical retrace interval of the video reference, or

during a calculated recreation of that interval if video is not present.

Router control systems typically communicate over serial RS-422A lines,

and this is what the new Universal Control Card uses. The obsolete Command

Interpreter card used in older models additionally supported RS-232 and a

parallel RS-422A implementation for such hardware interfaces as the Horizon

control protocol.

PC-compatible software furnished with the unit provides extensive

configuration, query and diagnostic utilities. Finally, should it prove undesirable

to merge the machine data route-control system into the program control, the

NV3128 comes with a simple, easy-to-use PC-based control system.

To enhance system reliability, the NV3128 frame houses an optional, fully

redundant 80-watt power supply. The outputs of the first and second supplies

share the load equally, but in the event of a failure, either can handily power

the system solo. Sensing circuitry activates an alarm relay on each power

supply, with contacts brought out for operating an external alarm. In the event

of a power failure, a one farad capacitor charge maintains power on a backup

SRAM bank, keeping the mapping of the switch intact for no less than 3 days.

NV3128 RS-422A Machine-Control Data Switch 1-3

Page 14

For very high reliability applications, a redundant controller can also be added

to the frame, with circuitry provided for automatic changeover.

With its duplex complexity, RS-422A has long been a troublesome method of

plant signal routing. The NV3128 untangles the problems unique to this data

type to offer an innovative, low-cost solution that merges easily into a facilitys

over-all routing plan.

A scaled-down version of the switch, with 64 of the 128 ports enabled, is

available as model NV3128-64.

1.2 ARCHITECTURE

BACKGROUND:

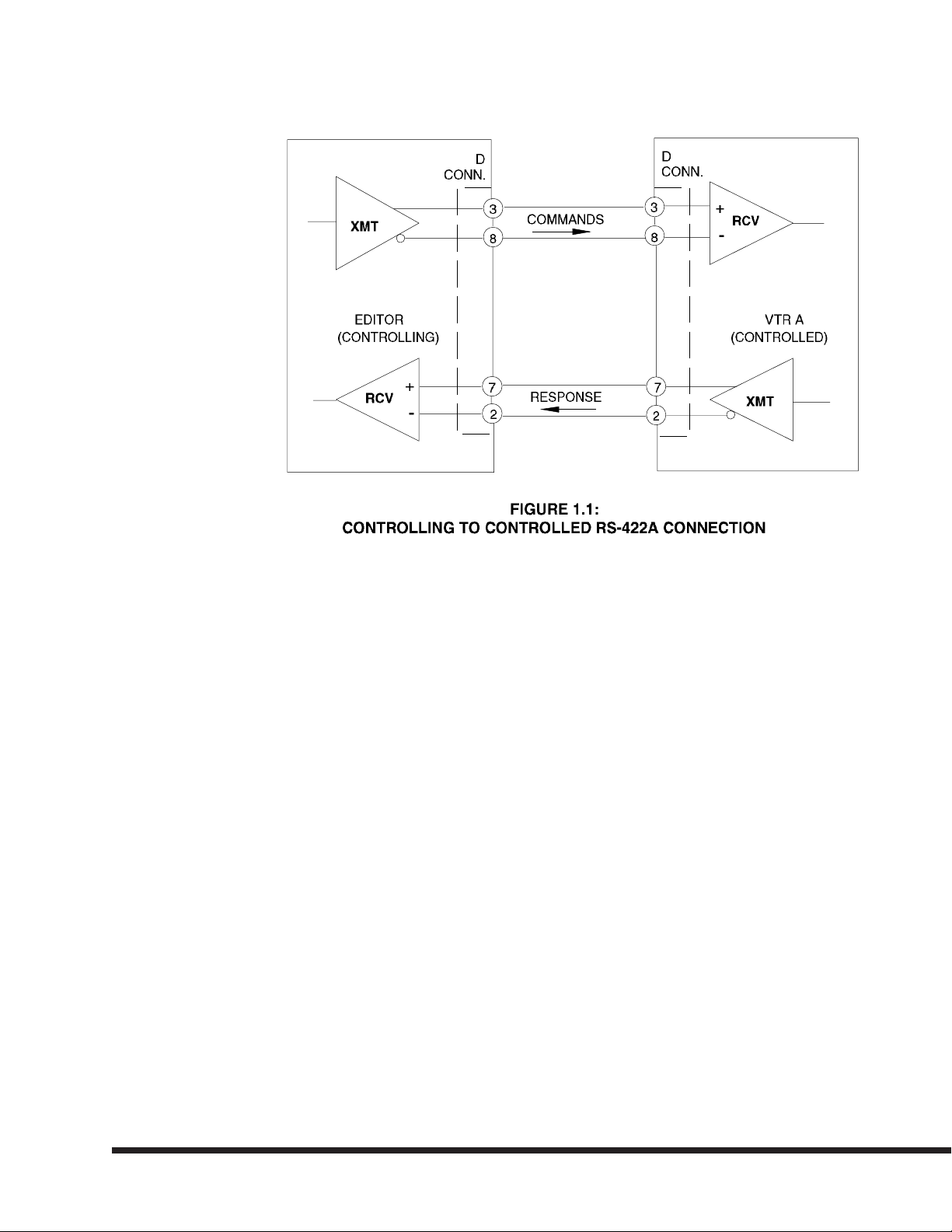

The duplex nature of RS-422A communication creates its own level of

complexity. The Electronic Industry Associates RS-422A, is a balanced,

serial, 4-wire transmission technique with a line driver and receiver at either

end of the link. In the typical video or audio production-machine hookup, one

machine is master, and one or more machines are slaved. The master is

referred to as a controlling device, the slave as a controlled device. The

controlling device issues commands to the controlled device via a D connector

over pin pair 3/8. The controlled device receives the commands over the same

pin pair, 3/8, and transmits status, acknowledgement and diagnostic data

back over pin pair 2/7. The controlling device receives this feedback over pin

pair 2/7. Fig. 1.1 illustrates this fundamental connection.

NV3128 RS-422A Machine-Control Data Switch 1-4

Page 15

NV3128 RS-422A Machine-Control Data Switch 1-5

Page 16

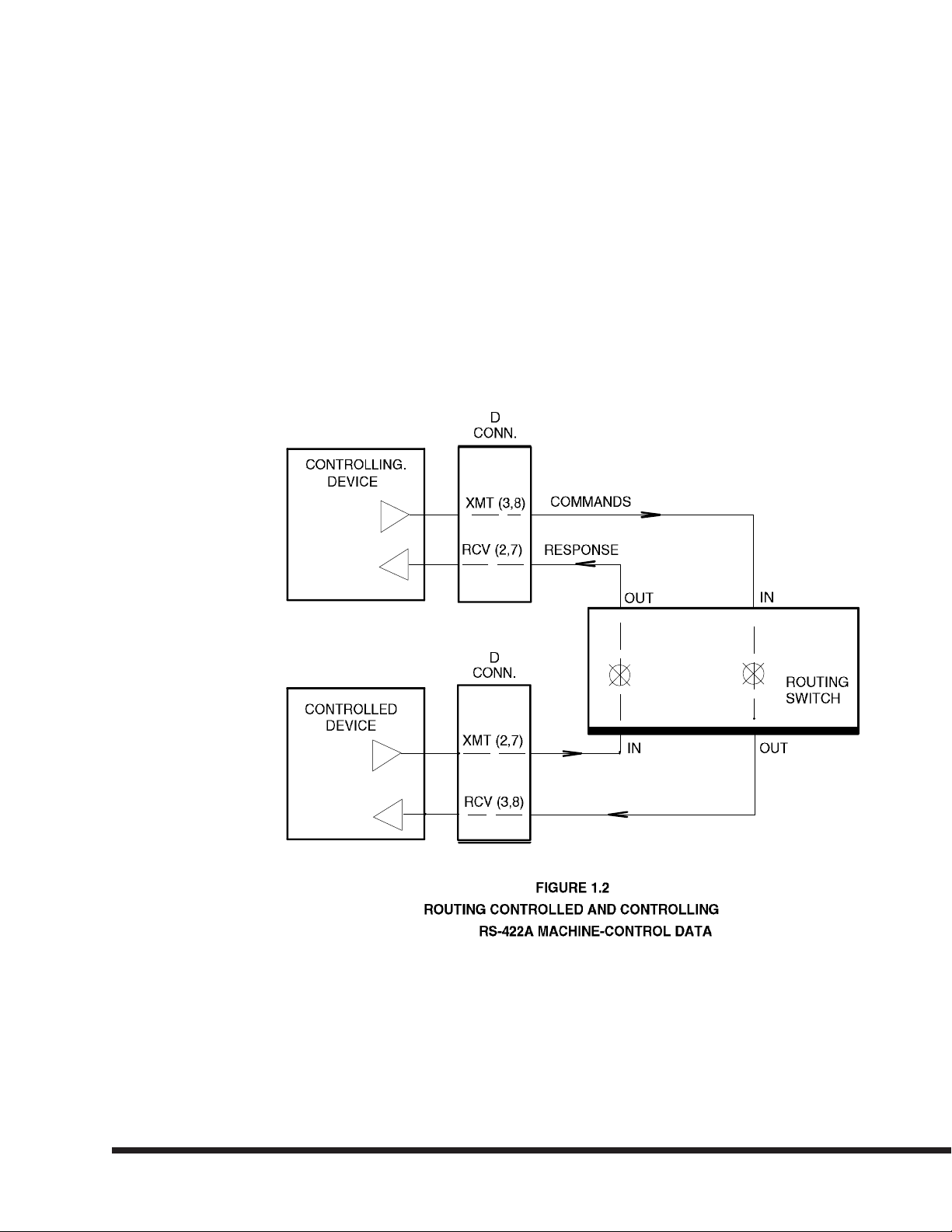

Because commands are broadcast on one balanced pair and responses

received on another, the systems crosspoint count, wiring density and complexity

are inherently double that of a video or audio router. Fig. 1.2 shows the twolevel connection required to implement a route through a conventional data

switch. To pass through the switch, the connection must be separated into two

components: the command, which travels from source to destination, and the

response, which returns through the switch from destination to source. Cables

are split such that transmitting pins from both machines are hooked to switch

input blocks, and receivers to output blocks. Additionally, the router-control

system must be highly specialized, for it now must address two connections

with every connect command it issues.

NV3128 RS-422A Machine-Control Data Switch 1-6

Page 17

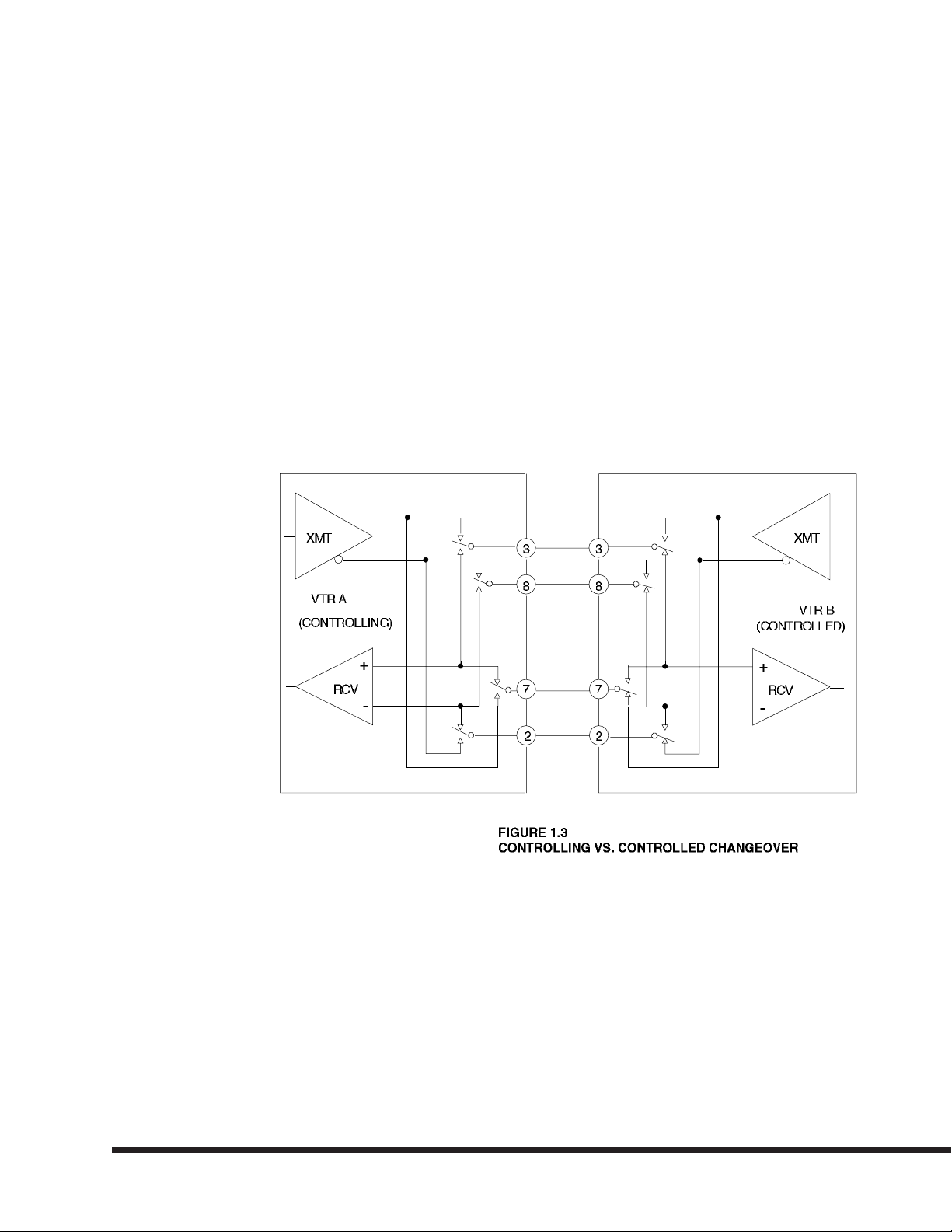

To further complicate matters, the sense of transmit and receive connections

in many modern machines is switchable. That is, internal circuitry within the

machine reassigns the interface pin assignments to allow it to operate in either

controlled or controlling mode. Fig. 1.3 illustrates the physical pin swapping

within each of two directly connected devices. On most units the changeover

is a physical switch, but on some, such as the Sony D1 VTR, the pin flip is

under software control. In either case, the traditional routing switch cannot

adapt to a reversal of data direction, and thus severely compromises a systems

flexibility. Referring again to Fig. 2, note that the physical connection fixes the

operating mode - controlled or controlling - of the device. If pin pair 3/8 from

a machine is connected to a router input, then that machine is a controlling

device from now until someone gets out a crimping tool and rewires the

connection.

Yet another frustration in implementing a switched machine-control system:

one-to-many connections have historically been problematic. Sending a

command down a daisy chain of slaved devices is not difficult, and many

machines provide a second D connector to accommodate the cable loop

through. But it is difficult for the controlling device to discern which of the

slaved machines is responding, and - worse- there is a strong probability of

bus contention. Again, the user must get out of his chair, find his trusty crimping

tool, and disable the responding transmit connection on all but one of the

controlled machines. While keeping plant technicians gainfully employed, this

activity defeats the purpose of a routing switch.

NV3128 RS-422A Machine-Control Data Switch 1-7

Page 18

Video equipment offers a sufficient diversity of control options to add another

layer of complexity to routing.

The Sony BVU machines have a single D connector for both controlling and

controlled traffic. The direction of data traffic is controlled by the remote

switch.

The Sony BETA machines hard wire two D connectors together, again for both

controlled and controlling traffic. Although the second connector facilitates

daisy-chained control, it does nothing to diminish the probability of bus

contention this feature invites.

D1 and D2 VTRs use two D connectors, configurable with software as

controlled or controlling. Additionally, these machines can resolve their

involvement in bus contention in a daisy-chained control configuration.

Traditionally, installations have resorted to relay routers or analog audio

routers to switch machine control data, and have just had to tolerate the

limitations and expense caused by the logistical complexity. Analog audio

routers and relay routers share three further disadvantages: They take up a lot

of space, they use a lot of electricity and they cost a lot money.

A SOLUTION:

The NV3128 fully addresses the idiosyncrasies of routing RS-422A machine

control data. Its compact, eight rack-unit frame is small enough to be installed

in the suite. Its 65 watt off-the-line power requirement is less than most light

bulbs. And its cost is a fraction of alternative solutions. Capable of NRZI data

rates up to 5 Mbits/Sec., it offers 128 I/O ports in a non-blocking X-Y matrix.

It is also available in a 64-port configuration that can be field upgraded to 128

ports by simply adding an additional I/O module.

NV3128 RS-422A Machine-Control Data Switch 1-8

Page 19

DYNAMIC PORTS

The power of the NV3128 as a data router begins with its singular ability to

dynamically configure each of its 128 I/O ports to one of three states:

controlling, controlled or high impedance. Executed automatically with each

take command, this transparent changeover action in the router emulates the

mode-swapping capability of the external machines. It simultaneously simplifies

a system and expands its overall capability.

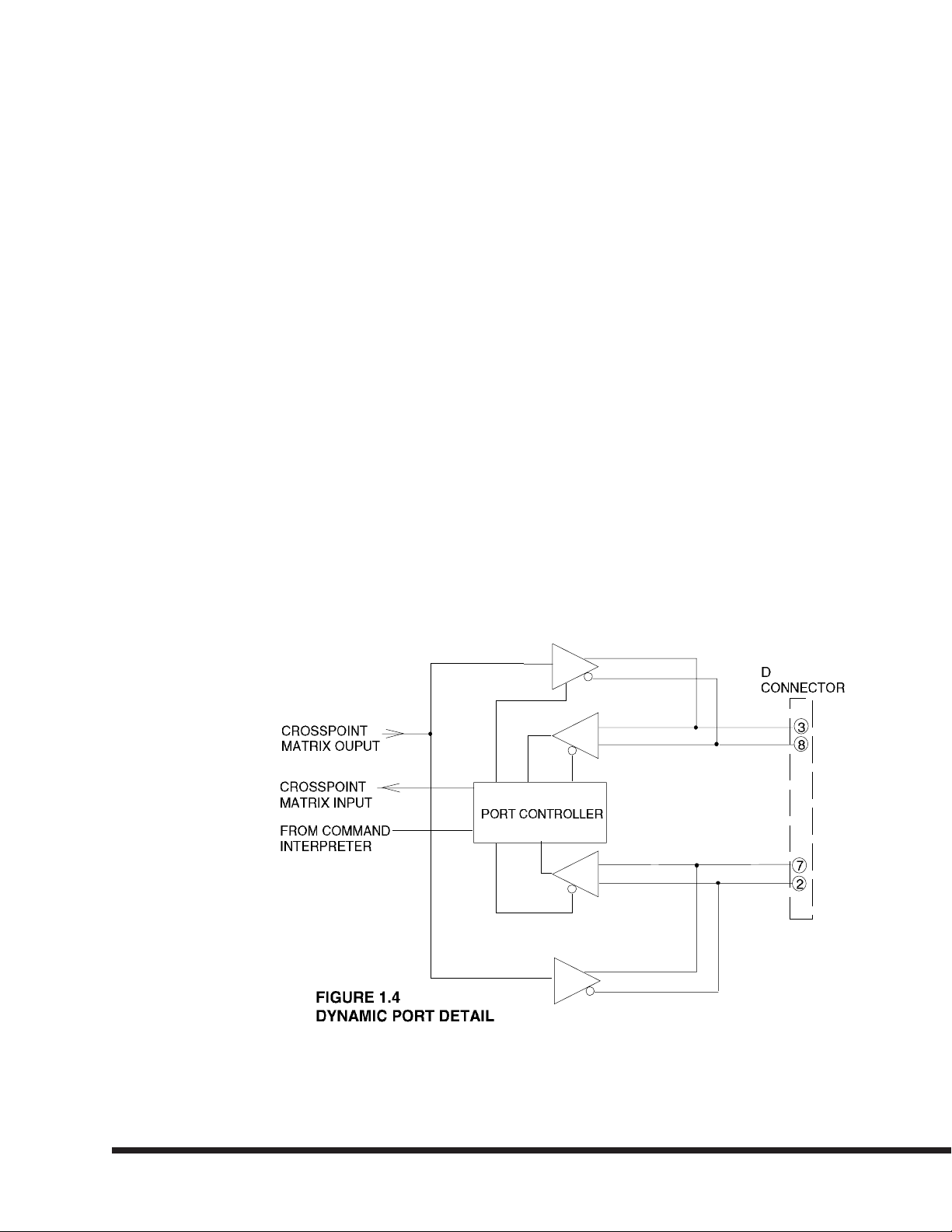

Fig. 1.4 illustrates this essential circuit function. Each I/O port presents a

physical implementation of the standard RS-422A interface, to which a

machine is connected without regard to data direction. Between the physical

interface and the X-Y crosspoint matrix is a gated pair of RS-422A transceivers.

Upon receipt of a Take command, the routers Control Card/Command

Interpreter parses the incoming connection information and designates the

port to which the source device is connected as controlled and the port to

which the target is connected as controlling. It then sends this state of the

port information to port controllers on the I/O modules. These port

controllers, in turn, send gating signals to the transceiver pairs, turning the

receivers and transmitters on or off appropriate to the direction of data flow.

The valid port states are controlling , controlled, and controlling no response

routed.

+

-

+

-

NV3128 RS-422A Machine-Control Data Switch 1-9

Page 20

CROSSPOINT ARCHITECTURE

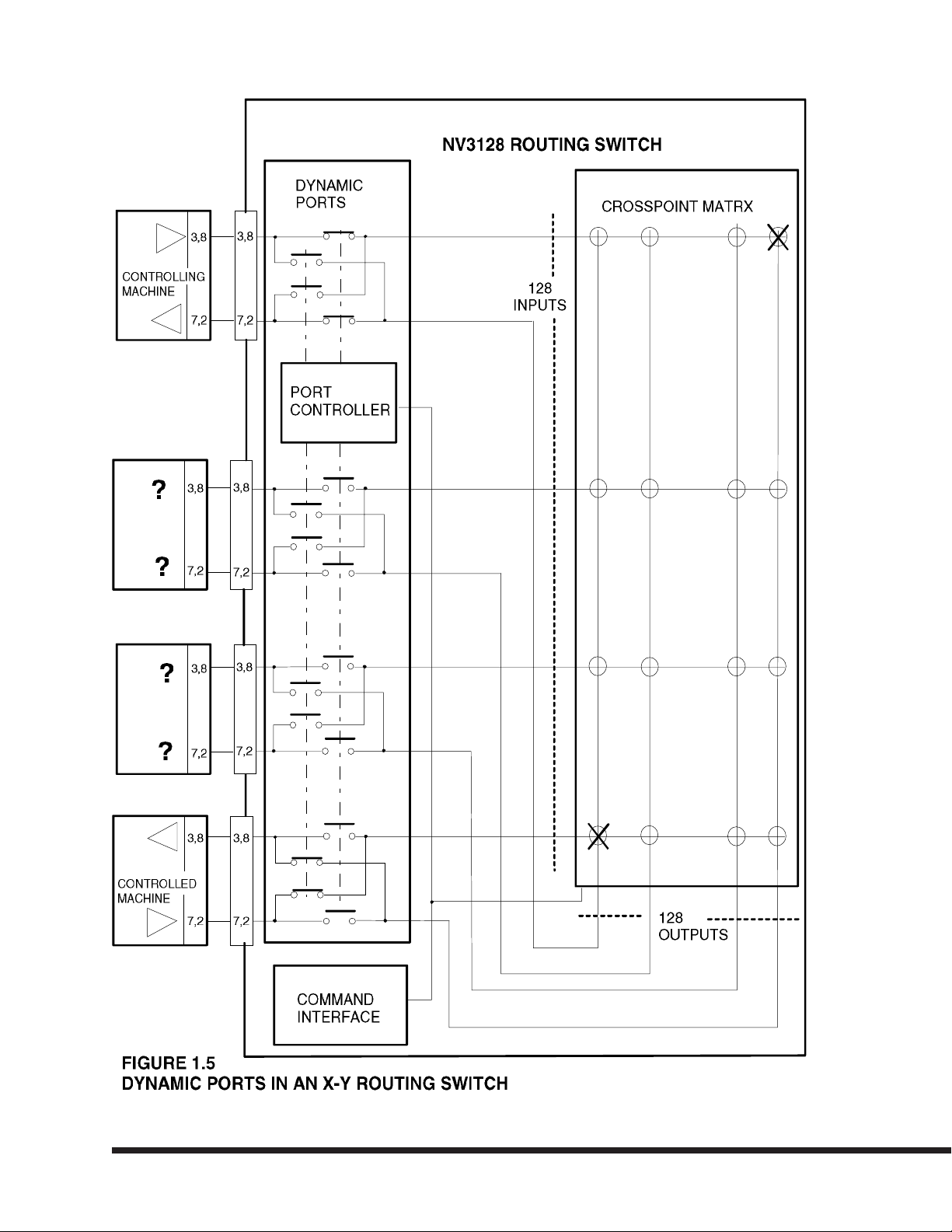

Figure 1.5 is a simplified representation of the interface between the I/O

connectors, the dynamic ports, and the crosspoint matrix. The crosspoint

matrix itself consists of four LSI 64x64 crosspoint chips connected in a

unidirectional 128x128 m by n architecture. In this non-blocking scheme,

any of the 128 inputs can be switched to any of the 128 outputs. Each output

is controlled by a double-buffered register with a load and an active segment.

Upon receipt of an XY take command, the command interpreter fills the load

segment with the address of the input port to which the output will be

connected. The take is consummated when the crosspoint strobe dumps the

contents of the load registers into the active registers. The entire process of

mapping the switch in this fashion occurs within one video vertical retrace

time.

At the crosspoint level, the NV3128 is an X-Y matrix switch. But from the

vantage point of the user, the semantics of routing architecture break down: the

straightforward concepts of input and output, sufficient to describe program

route matrices, no longer have meaning. Despite the complexity, inherent in the

dynamic ports is an expanded capability. Unlike a program router, which has

a fixed I/O dimension, each of the 128 ports can be connected to any other

port. Each of the ports can be either source or destination.

For each requested machine connection, the router uses the input command

information to ensure that the controlling machine automatically sees a controlled

router port, and that the controlled machine looks back into a controlling port.

In practice, this means that the NV3128 can dynamically implement the

connections of Fig. 1 and Fig 3 in successive sessions. In Fig. 1.1, the editor

controls VTR A, which is a controlled device. In a further session, VTR A

dubs down to VTR B, with VTR A now a controlling device, as shown in Fig.

1.3. In a conventional routing switch, this arrangement would require physical

re-connecting of the machines involved. Although there are routing systems

with high-impedance outputs that can be forced into such a mapping, the cost

is a doubling of the number of connections, a 4-times expansion of the number

of crosspoints, and associated increments in operating costs.

NV3128 RS-422A Machine-Control Data Switch 1-10

Page 21

NV3128 RS-422A Machine-Control Data Switch 1-11

Page 22

MULTIDROP COMMAND CHAINS

Gating off the response transmitter in a controlled port is an effective and

transparent technique to resolve bus contention in a multi-drop command

chain. In such a mapping, the controlling device sends commands to multiple

destinations, but only one destination is allowed to respond. All other

controlled-port transmitters are gated off. By design, the NV3128 controller

allocates the response transmission path to the first target connected to the

source, therefore the user designates the responding machine by the ordering

of his take salvo.

1.3 I/O

A passive connector-interface backplane couples the active I/O modules and

their external connections. Active modules can thus be removed without

disturbing external cabling.

Data port connectors are RS-232 9-pin D. Video reference input ports are

BNC. A female, 9-pin D connector recieves the serial router control system

cable, and a 37-pin female D connector implements a parallel router-control

interface (older frames only). Both control interfaces and both reference

inputs provide unbuffered loop-through connectors.

1.4 PHYSICAL

Physically, the NV3128 frame installs in a 19" EIA equipment rack. Its

aluminum frame requires no additional cooling, and will operate in ambient

temperatures in the range from 0-50 degrees celcius. The 8 rack-unit high

frame houses two backplanes, one for inter-module signal traffic, the other

mounting I/O connectors. The active modules are inserted from the front of

the frame. The modules consist of:

· Crosspoint Assembly (1) EM0041-XX

· I/O Assembly (2 - NV3128, 1 - NV3064-D) EM0040-XX

· Universal Control (1, redundant 2nd optional) EM0134-XX

· Power Supply (1, redundant 2nd optional) PS2001-01

NV3128 RS-422A Machine-Control Data Switch 1-12

Page 23

1.5 ANCILLARY EQUIPMENT

The NV3128 operates in a sophisticated audio/video environment, typically

supporting a mix of modern digital equipment and older analog gear. To

facilitate the integration of this diverse machinery, NVision has developed a

wide and growing family of ancillary products including the NV1000 series

processing equipment and the NV4000 series. These product lines include

analog, AES/EBU, SDI, and HD-SDI distribution amplifiers, reference

generators, delay modules, codecs, DACs, ADCs, digital audio embedders/

disembedders, and fiber optic transceivers and converters.

1.6 SYSTEM SPECIFICATIONS

Specifications for the NV3128 Data Router are listed in Table 1-1 on the

following page.

NV3128 RS-422A Machine-Control Data Switch 1-13

Page 24

TABLE 1-1 NV3128 SPECIFICATIONS

INPUTS/OUTPUTS

Number

NV3128-128 128

NV3128-64 64

Protocol RS-422A, Balanced ,9-PinD Connector,

Dynamically configured as controlled or controlling

Input Impedance 100 ohms

Input Range 200mV to 10V p-p

Output 7V p-p, Low Impedance

PERFORMANCE

Control Update 100% remap of switch < 16 mSec.

RS-422A Data Rate 5MBits/sec. NRZI maximum

MECHANICAL

Frame 8 EIA rack units, aluminum

Dimensions 356mm W x 483mm H x 381mm D

(14" x 19" x 15")

Weight 20.5 Kgs. (45 Lbs.)

ELECTRICAL

Input Voltage 90-135VAC, 180-270VAC selectable, 50/60 Hz

Pwr. Consumption 65 Watts nominal

NV3128 RS-422A Machine-Control Data Switch 1-14

Page 25

CHAPTER 2: INSTALLATION

NV3128 RS-422A Machine-Control Routing Switch 2-1

Page 26

NV3128 RS-422A Machine-Control Routing Switch 2-2

Page 27

CHAPTER TWO - INSTALLATION

CAUTION: THE FOLLOWING INSTALLATION PROCEDURES ARE

INTENDED FOR QUALIFIED SERVICE PERSONNEL ONLY. TO

REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT PERFORM

ANY SERVICING OTHER THAN THAT CONTAINED IN THE OPERATING INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO SO.

REFER ALL INSTALLATION AND SERVICE TO QUALIFIED PERSONNEL.

2.1 HARDWARE INSTALLATION

The following discussion makes frequent reference to Fig 2.1

The NV3128 installs in a 19-inch EIA equipment rack. No fans or

cooling are required, but adequate free air space should be maintained

around the equipment.

1. Using the 2MM allen key supplied, remove the doors and vanity ear

covers from the front of the frames.

2. For installation in a telco style rack, reverse the front mounting

flanges on the frame prior to bolting the frame into the rack.

3. Lift the frame into the rack, and secure the frame to the rack by the

front mounting flanges using rack screws (not supplied).

4. Replace the doors on the front of each frame.

5. Operate the ejector/injector tabs on each of the active circuit

modules to disconnect them from the backplanes. Leave the modules

partially inserted in the card guides, but electrically disconnected.

CAUTION: THE SETTING OF JUMPER J1 ON EACH POWER SUPPLY ASSEMBLY

MUST MATCH THE VALUE OF THE APPLIED AC INPUT VOLTAGE OR DAMAGE

TO THE EQUIPMENT MAY RESULT.

6. Unscrew its captive latch and remove the PS2001-01 Power Supply

Assembly from the frame by pulling straight back on its cover/handle.

Determine the value of the AC line voltage supplying the rack. Ensure

that the setting of Jumper J1 on the supply matches the value of the

applied line voltage. Repeat for the redundant supply, if present.

7. Re-insert power supply(ies) in the frame. Ensure its connectors

mate with the backplane before seating the power supply assembly into

the frame.

NV3128 RS-422A Machine-Control Routing Switch 2-3

Page 28

8. Connect the AC line cord at the rear of the frame and to the input

AC, which powers up the NV3128. Ensure the system powers up

correctly.

a. LEDs on the Power Supply front panel should glow.

b. Measure the voltages at the DC tespoints on the Power

Supply. The value should be within +/- 1VDC of the value

silkscreened at the test point. (If no boards are plugged in, the

voltages will be very high, around ±9 and ±20 volts.)

9. Disconnect the AC line cord(s) from the PS2001 power supply(ies).

Secure the Power Supplies with the front panel captive latch screws.

10. Cable the system as explained later in this chapter.

11. Set jumpers on the Command Interpreter (older systems only) as

discussed later in this chapter.

12. Engage all active circuit modules. Ensure they are plugged into

their correct slots as silkscreened on the frame and front panels.

13. Re-connect the AC line cords.

a. LEDs on the active modules should glow, indicating power is

on.

b. As an extra precaution, measure the voltages at the DC test

points on each active module in the frame. The value should be

within +/-5% of the value silkscreened at the test point.

NV3128 RS-422A Machine-Control Routing Switch 2-4

Page 29

FIGURE 2.1 FRAME INSTALLATION

NV3128 RS-422A Machine-Control Routing Switch 2-5

Page 30

2.2 CONFIGURATION

2.2.1 THE UNIVERSAL CONTROL OR COMMAND INTERPRETER

The Universal Control Card (EM0134-XX) constitutes the current

control module for the NV3128 Router. It includes a Test/Normal

jumper near the front of the card that should always be set to Normal

mode. In addition there are two AES Ref jumpers that are not used in

the NV3128.

Partitioning, port configuration, and diagnostic interface settings are

done using the UniDiag PC software program. See the UniDiag Manual

for instructions.

The Command Interpreter and the Matrix Control II are obsolete

control cards for the NV3128 Router. Some instructions in this section

apply only to older systems having these cards. These instructions have

been retained for the benefit of customers who own older systems, but

they are labeled "(OBSOLETE)" so that they are clearly identifiable.

2.2.2 PARTITIONING (OBSOLETE)

In systems using the newer Universal Control Card, partitioning is done

with UniDiag. Older systems with the Command Interpreter are

partitioned using the steps that follow.

The NV3128 consists of a single physical partition whose I/O

dimension is the dimension of the routing switch, either 128x128 or

64x64. A shadow partition can be created to allow multidrop command

hookups. By enabling the second ghost partition, I/O ports are

addressed on either of two controller levels. A port addressed on the

first level is configured for point-to-point routes. The same port

addressed on the second controller level is configured for multidrop

routes. Section 3.1 discusses the distinctions between the two types

of Take.

NV3128 RS-422A Machine-Control Routing Switch 2-6

Page 31

PARTITION DIP SWITCHES (OBSOLETE)

1. Two banks of dip switches on the Control Interface Module

configure the partition information for the NV3128. Bank 1 defines the

physical partition, Bank 2 enables the ghost partition and defines its

controller level.

BANK 1 SECT A S293

BANK 1 SECT B S290

BANK 2 SECT A S285

BANK 2 SECT B S247

The bit settings are discussed on the following pages. X denotes "don't

care" setting.

PARTITION BIT SWITCH - SECTION A

PARTITION 8 7 6 5 4 3 2 1

0 ENABLE

1 ENABLE X X

RE-INITIALIZE

(BANK I)

X

LEVEL ID

(msb)

LEVEL ID

(msb)

---- ---- ----

---- ---- ----

LEVEL ID

(lsb)

LEVEL ID

(lsb)

PARTITION BIT SWITCH - SECTION B

PARTITION 8 7 6 5 4 3 2 1

O

1 X X X X X X X X

Input Length

(msb)

------ ------

Input Length

(lsb)

Output Length

(msb)

------ ------

Output Length

(lsb)

NV3128 RS-422A Machine-Control Routing Switch 2-7

Page 32

SETTINGS:

ENABLE (s8):

ON: Partition defined in switchbank is enabled.

OFF: Partition is disabled.

RE-INITIALIZE BIT/MULTIDROP ENABLE (s7):

OFF: On power-up following a shutdown of less than twenty minutes,

the system restores the crosspoint address map stored in batterypowered RAM. In Bank 2, when bit 7 is OFF, multidrop is disabled

and point to point routing is enabled in the second partition.

ON: On power-up, the system remaps the entire switch with all

outputs connected to the NULL input defined in software. In Bank 2,

when bit 7 is ON multidrop is enabled in a shadow partition.

MONITOR LEVEL BIT (s6):

* Implemented for AES/EBU digital audio versions only. Not used on

NV3128

LEVEL ID (s5 - s1):

Bit 5 (MSB) through bit 1 (LSB) of the A switch section create a 5bit binary number that is the logical level of the phsyical partition. This

is the level the controller will use to address the partition.

EXAMPLES:

00001 = level 1

where 0 denotes an OFF bit and 1 denotes an ON bit.

10001 = level 17.

The range is from 0-31. Some control protocols define levels

alphabetically, in which case 0=A and 25=Z.

NV3128 RS-422A Machine-Control Routing Switch 2-8

Page 33

INPUT LENGTH (s8-s5):

Bit 8 (MSB) through bit 5 (LSB) of the B switch section create a fourbit binary, modulo 32 number that matches the input dimension of the

switch. The length of the partition is the number in the switch times 32.

For the NV3128, the number is 0100 (128). For a 64 port version of

the switch, the number is 0010. No other configuration is valid for a

data switch.

EXAMPLE:

0100 (decimal 128) = an input address range of 128 consecutive

physical addresses.

Note that the settings of this switch are meaningless for the ghost

partition, whose input range shadows the range of the physical partition.

OUTPUT LENGTH (s4-s1):

Bit 4 through Bit 1 of the B switch section create a 4-bit binary, modulo

32 number that configures the output dimension of the partition. As for

the input length setting, the valid values for a data switch are 0100

(decimal 128, NV3128 default) and 0010 (decimal 64, small data

switch).

2.2.3 MATRIX CONTROL II JUMPERS (OBSOLETE)

The obsolete Matrix Control II module includes two jumpers that must be set

in order to define the router type. For older systems having these modules, set

the jumpers as follows:

JUMPER SETTINGS MEANING

J701 X-Y Audio type router

PORT Port type router

J702 3256 3256 Matrix

3128 3128 Matrix

NV3128 RS-422A Machine-Control Routing Switch 2-9

Page 34

2.2.4 CONFIGURING THE SERIAL INTERFACE (OBSOLETE)

2.2.4.1 JUMPER SETTINGS (OBSOLETE)

The serial data interface between the control system and the NV3128

can be either RS-422A or RS-232. For the newer Universal Control

module, the serial interface ports are set up using UniDiag. For the

older Command Interpreter, jumpers on the Command Interface

Module select parameters appropriate to the chosen protocol.

To select the protocol for data interchange with the obsolete Command

Interpreter, set jumpers on the module as shown in the following table.

RS-422A/RS232 SELECT - J203

RS-422A RS-232

1-9 9-17

2-10 10-18

3-11 11-19

4-12 12-20

5-13 13-21

6-14 14-22

7-15 15-23

8-16 16-24

DCE/DTE SELECT J284

DCE DTE

1-5 5-9

2-6 6-10

With all other jumpers in the RS232 position, J295 and J296 select

DCE or DTE operation.

NV3128 RS-422A Machine-Control Routing Switch 2-10

Page 35

2.2.5 PARALLEL INTERFACE (OBSOLETE)

Newer NV3128 frames do not include a parallel interface. The older NV3128

frames with the Command Interpreter card included a parallel connector which

could be used with the Pesa parallel interface. Because the Universal Control

card does not support the parallel interface, older frames that have the Universal

Control card cannot make use of the parallel interface connector.

2.2.6 CONFIGURING THE DIAGNOSTIC INTERFACE (OBSOLETE)

NVision furnishes a configuration and diagnostic computer utility with

the routing switch. For newer systems having the Universal Control

Card, the program is called UniDiag. For older systems having the

Command Interpreter, the collection of programs is called NVUtils.

The program(s) run on a PC compatible computer. An RS-232

connection is made to the computer from a nine-pin D connector at the

front of the Control/Command Interface Module, or from the RS-232

Diag connector at the back of the frame.

For the older Command Interpreter, jumpers on the Control Interface

Module select between DTE and DCE modes of operation. For the

newer Universal Control Module, this selection is made using UniDiag.

DIAGNOSTIC PORT DTE/DCE SELECTION (OBSOLETE)

JUMPER DCE DTE

J53 1-2 2-3

J54 1-2 2-3

NV3128 RS-422A Machine-Control Routing Switch 2-11

Page 36

Additionally, two jumpers float or ground pins 5 and 9 of interface

connector J40 for further configuration flexibility.

JUMPER FLOAT GND SIGNAL

J29 1-2 2-3* Signal GND

J30 1-2* 2-3 RI (pin 9)

* = DEFAULT CONFIGURATION

Two final jumpers,J500 and J700 , enable or disable the diagnostic

output:

DIAGNOSTICS ENABLE/DISABLE (OBSOLETE)

JUMPER ENABLED DISABLED

J500 1-2* 2-3

J700 1-2* 2-3

* = DEFAULT CONFIGURATION

NV3128 RS-422A Machine-Control Routing Switch 2-12

Page 37

2.2.7 CONFIGURING THE REFERENCE INPUT

The NV3128 can derive its timing from a Video Reference input, or it

can free run. The reference input is normally a video black burst signal,

but optionally can be an AES/EBU digital audio bitstream.

Both video and audio reference inputs require that their connection

end-points be terminated in the cables characteristic impedance to

avoid line reflections. When the NV3128 is the end of the line for

either reference signal, the connection should be terminated in 75

ohms (video) or 110 ohms (digital audio). When the reference input

connection is daisy chained or looped through the NV3128 and endterminated at some other piece of equipment, the NV3128 termination

should be set to a high impedance.

For the newer Universal Control Card, the reference should be

terminated at the looping connector on the back of the frame. For the

older Command Interpreter, jumper J72 selects the reference video

impedance, and jumper J190 selects the AES/EBU reference input

impedance.

IMPEDANCE SELECT (OBSOLETE)

JUMPER FUNCTION 1-2 2-3

J275 Video Ref In 75 ohms High Impedance

J190 AES/EBU Ref In 110 ohms High Impedance

REFERENCE INPUT GROUND (OBSOLETE)

Jumper J298 on the connector interface module selects the AES/EBU

reference input shield termination.

TERMINATED FLOATING

1-2 2-3

NV3128 RS-422A Machine-Control Routing Switch 2-13

Page 38

2.3 CABLING THE NV3128

Figures 2-2 and 2-3 at the end of this section show the rear panel

connections on the NV3128. Notice that there are old and new frames

corresponding to the old Command Interpreter and the new Universal

Control Card.

2.3.1 DATA I/O

Machine control I/O connections to the rear panel are straightforward.

D connectors terminated according to the following pin-out are plugged

into any of the 128 terminals provided.

2.3.2 CABLING THE SERIAL COMMAND INTERFACE

The control-system interface cable connects to the jack marked RS422 PRIMARY CNTRL" on the new frames or "RS-422/RS232 Controlled In" on the old frames. To implement a loop-through

connection for a multidrop, networked command environment, connect

the next piece of equipment to the looping connector next to the

primary control connector. It should be noted that the maximum

number of chained connections is six without undue signal degradation.

RS-422A:

An RS-422A cable connecting the Controller to the primary control

data connector should be a nine-wire cable meeting the EIA RS-422

specification. The connector at the NV3128 end must be a nine-pin D

connector with male pins. The connector at the controller side is

typically a nine-pin D connector with male pins. The connection list

follows:

NV3128 RS-422A Machine-Control Routing Switch 2-14

Page 39

RS-422 Cable Pin-Out

PIN Controlling Device Controlled Device

1 Frame Ground Frame Ground

2 Receive A Transmit A

3 Transmit B Receive B

4 Transmit Common Receive Common

5 Spare Spare

6 Receive Common Transmit Common

7 Receive B Transmit B

8 Transmit A Receive A

9 Frame Ground Frame Ground

NV3128 RS-422A Machine-Control Routing Switch 2-15

Page 40

RS232 (OBSOLETE):

The NV3128 Control/Command Interpreter interface is always a DCE

device when operating in RS-422A mode. As shown above, the system

can be configured as either DTE or DCE equipment in RS-232 mode.

It should be noted, however, that the selection of DTE or DCE involves

only the exchange of pins 2 and 3 at one end of the interconnecting

cable. The exchange can be made in the cable, or on the controller

board. The exchange may or may not need to be made depending on

the pin configuration, 9 or 25, of the driving DTE. The exchange may

need to be reversed if a standard 25-pin/9-pin adaptor has been added

to the driving devices serial port. Pin-out for that arrangement is

shown below:

The rules of thumb presented on the following page may help you make

the DTE/DCE connection.

RS-232 DCE VS. DTE DECISION (OBSOLETE)

OPTION I: If the controlling RS232 device communicates over a 25pin serial port:

1. Configure the Control Interface Module as a DTE.

2. Use a 9-pin to 9-pin cable with no connection exchange.

3. Connect the cable to the driving, 25-pin port using a common 25pin/9-pin adaptor such as that used to connect a mouse to a computers

serial port. The adaptor swaps the connections.

NV3128 RS-422A Machine-Control Routing Switch 2-16

Page 41

OPTION II: If the controlling RS232 device communicates over a 25pin serial port:

1. Configure the Control Interface Module as a DTE

2. Create (or buy) a 9-pin (male) to 25-pin (female) cable using the

9-pin to 25-pin RS-232 wire list below.

9-PIN CONNECTOR 25-PIN CONNECTOR

18

23

32

4 20

57

66

74

85

922

OPTION III: If the controlling RS232 device communicates over

a 9-pin serial port:

1. Configure the Control Interface Module as a DCE.

2. Connect the Control Interface Module and the controlling device

using a 9-pin to 9-pin (male to female) cable, connected straight

through ( no exchange of pins).

NV3128 RS-422A Machine-Control Routing Switch 2-17

Page 42

2.4 ADDING A REDUNDANT CONTROLLER

A second Universal Control/Command Interpreter can be specially

ordered and installed for increased system reliability. If you have the

Universal Control card, you must also have the Universal Control

frame in order to install a redundant control card. Contact Technical

Support to verify that your frame can accept a redundant controller.

To install:

1. Remove the existing Universal Control/Command Interpreter from

the frame.

2. Replace the firmware PROMS on the existing module. In some

cases, new firmware supplied on floppy disks or sent to you by email

can be downloaded into the PROMs using UniDiag instead of replacing

the PROMs.

3. Plug both existing and new redundant control cards into the frame.

Note that Universal Control and Command Interpreter modules cannot

be interchanged under all applications.

2.5 IMPLEMENTING HOT CHANGEOVER (OBSOLETE)

Relay terminals on the rear panel of the NV3128 provide control of the

NV3128 should a hot changeover system be required. Call NVision

Technical Support as listed in Chapter 5 of this manual for instructions

in implementing this feature. This feature is available only for obsolete

systems and not for newer systems using the Universal Control card.

NV3128 RS-422A Machine-Control Routing Switch 2-18

Page 43

2.6 PC DIAGNOSTIC INTERFACE (UNIDIAG/NVUTILS)

NVision furnishes a configuration and diagnostic computer utility with

the routing switch. For newer systems having the Universal Control

Card, the program is called UniDiag. For older systems having the

Command Interpreter, the collection of programs is called NVUtils or

RouterDiag. The program(s) run on a PC compatible computer.

Connect the PC RS-232 serial port to the nine-pin D connector at the

front of the Control/Command Interface Module (preferred), or to the

RS-422/RS-232 Diag connector at the back of the frame. For newer

systems, detailed information about this interconnection and the

diagnostic program can be found in the UniDiag manual.

CABLING COMPLETE

You are now finished making cable connections to the NV3128

Router. The remainder of this section explains how to install NVUtils

for use in configuring routers that have the old Command Interpreter

module. Newer routers with the Universal Control Card can skip the

remainder of this section and go to the UniDiag manual for configuration

information.

NV3128 RS-422A Machine-Control Routing Switch 2-19

Page 44

FIG 2-2. REAR CONNECTIONS (NEW FRAME)

VIDEO

REF 1

REF 2

ALARMS

ETHER

NET

NODE

BUS

RS-232

DIAG

CTL1

CTL2

RS-232

MEZ DIAG

RS-422

PRIMARY CtL

VIDEO

CTL1

CTL2

RS-422

SECONDARY CTL

LOOP THRU

LOOP THRU

VIDEO REF

INPUTS 1 & 2

UNIDIAG REAR

CONNECTOR

CONTROL

SYSTEM

CONNECTORS

MACHINE CONTROL CONNECTORS 1 - 128

NV3128 RS-422A Machine-Control Routing Switch 2-20

Page 45

FIG 2-2. REAR CONNECTIONS (OLD FRAME)

FIG 2-3. REAR CONNECTIONS (OLD FRAME)

NV3128 RS-422A Machine-Control Routing Switch 2-21

Page 46

2.4 PC-BASED SOFTWARE INSTALLATION (OBSOLETE)

IMPORTANT NOTE: The remainder of this section applies only to

older systems using the Command Interpreter module. For newer

systems using the Universal Control Card, skip the remainder of this

section and go to the UniDiag manual.

GENERAL

NVUtils is a collection of PC compatible computer programs that

provide diagnostics and control of the NVision family of digital

routing switches. The utilities currently consist of two programs,

NVTake and NVMap. Both programs communicate with the router

Control Interface Module using RS-232 data-exchange protocol,

requiring either the configuration of the module for that protocol or

the intervention of an RS232/RS-422A converter.

NVTAKE

NVTake is a simple, minimally featured router control system. The

program sends takes and take salvos to the routing switch Control

Interface Module using controller commands from a long and growing

list of protocols. Take salvos can be saved to disk and reloaded. For

some protocols, the program affords crosspoint address queries and

listings.

NVMAP

NVMap is a multi-purpose configuration and diagnostic tool. It

allows the user to:

1. Query the routers crosspoints connections

2. Query the routers output monitor connections

3. Query and edit the configuration of the router/control interface.

4. Remap the correlation between the controller addresses and the

physical switch addresses (the scramble map).

NVMap also provides diagnostic messages showing the results of

controller commands sent to the router.

INSTALLATION:

NVUtils requires a PC compatible computer and at least one RS232 cable. A second cable is required for simultaneous operation of

both programs in a multi-tasking environment.

NV3128 RS-422A Machine-Control Routing Switch 2-22

Page 47

SOFTWARE INSTALLATION

FIXED DISK

A. Create an NVUtil subdirectory for the program and its map data.

B. Change Directory to the NVUtil subdirectory.

C. Copy the program files from the supplied diskette.

D. Create a batch file to invoke each program. The batch files should

exist in a directory within the computers command search environment.

Each batch file shall first position the computer in the NVUtil

subdirectory, then invoke the desired program. This approach

guarantees that configuration and salvo files are saved to and loaded

from a consistent disk location.

E. SAMPLE INSTALL SESSION:

C:> MD NVUtils

C:> CD NVUtils

C:> COPY A:*.*

C:> CD \COMMANDS

C:> EDIT NVTAKE.BAT

:=========================

:SAMPLE NVTake.BAT |

:=========================

C:

CD \NVUtils

NVTAKE V 1 38400

C:> EDIT NVMap.BAT

:=========================

:SAMPLE NVMap.BAT |

:=========================

C:

CD \NVUtils

NVTAKE V

NV3128 RS-422A Machine-Control Routing Switch 2-23

Page 48

OPERATION FROM A FLOPPY DISK

A. Copy the program files supplied to a blank floppy.

B. Invoke either program from the floppy. Edited map, config and

salvo files will be saved to the floppy in the course of the program

session.

C. Remove the floppy and store it safely.

HARDWARE CONFIGURATION

A. Refer to "Configuring the Diagnostic Interface" earlier in this

section to configure the diagnostic interface for RS-232 operation.

Additionally, configure the serial controller data port for RS-232

operation if the use of NVTake is anticipated.

B. Connect the RS-232 cable to the computer serial port, COM1 or

COM2, and to the appropriate connector on the router Control

Interface.

· NVMap communicates with the diagnostic data port J400, located

on the front of the Command Interface Module.

· NVTake communicates with the RS422/RS232 Command Data

Port at the rear of the frame.

NV3128 RS-422A Machine-Control Routing Switch 2-24

Page 49

CHAPTER 3: OPERATION

NV3128 RS-422A Machine Control Data Routing Switch 3-1

Page 50

NV3128 RS-422A Machine Control Data Routing Switch 3-2

Page 51

CHAPTER 3 - OPERATIONS

The NV3128 requires no operator intervention. The router may be

controlled completely via the selected control system. Section 3.1

discusses the connection algorithms for point-to-point (Level I) and

multidrop (Level II) Takes issued by the control system to control the

router. Section 3.2 covers the computer-based management unilities.

3.1 CONNECTION NOTES

The Universal Control/Command Interpreter intercepts XY connection

commands from the router control system and converts them to

connection instructions for the physical crosspoint matrix. The same

commands also determine the configuration of the involved I/O ports,

controlling or controlled. In their simplest form, the received commands

use the following syntax:

New Source -> New Destination

If, for example, the received input specifies "connect I/O port 2 to

I/O port 3," the router does the following two tasks:

1. Configures port 2 as a controlled (the source machine is controlling)

and port 3 as a controlling device ( the destination machine is controlled).

2. Sends a control message to the crosspoint matrix selecting the

appropriate crosspoint connections to open the forward and reverse

data channels. (Note that the forward and reverse data channels can

also be set up using the REV SRC/DEST function in UniDiag. See the

UniDiag manual for details about this function.)

From the perspective of the control system, an I/O port is a tiered

address in the following hierarchy :

MATRIX: ( ignored - or 0 - for all but very large systems)

LEVEL: (0-31)

PORT ADDRESS (0-2048 or larger)

Some NVISION routing switches can be divided into physical partitions,

each partition consisting of a contiguous range of physical addresses,

and each defined as a unique level. However, the NV3128 does not

support true partitioning. Rather, a second, "phantom" partition shadows

the single physical partition and allows it to be addressed on two

logical levels. On the first level, the rules for point-to-point connections

apply. A command at the second level will address the same physical

ports, but will enact the rules for connections with multiple destinations.

NV3128 RS-422A Machine Control Data Routing Switch 3-3

Page 52

On older systems, DIP switches on the Command Interpreter establish

the logical ID for each of the two levels and also configure the partition

parameters. On newer systems with the Universal Control module,

levels and partitions are set up using UniDiag.

3.1.1 POINT-TO-POINT CONNECTION RULES:

1. If Requested Destination is in use as a source:

Find all destinations, break connections and tristate (turn off) the ports.

2. If Requested Destination is already tied to Source

Find all the Destination ports to which that Source port is tied. Break

all connections between that Source and its Destinations. Tristate

Source Port and all its Destinations.

3. If requested Source is in use as a Destination

Find all Sources tied to that port . Break those connections and tristate

the Source ports.

4. Configure Source and Destination ports and make the forward and reverse

crosspoint connections.

3.1.2 MULTIDROP CONNECTION RULES

A connection in which a single source connects multiple destinations is always

addressed on Level II. The first destination connected is the controlled device

with answer-back capability. The received signals at all subsequent port

connections are not routed.

1. If requested Source is currently driving other Destinations:

tristate the response line of the requested Destination port.

2. If Requested Destination is in use as a source:

Find all destinations, break connections and tristate (turn off) the ports.

3. If requested Source is in use as a Destination

Find all Sources tied to that port . Break those connections and tristate

the Source ports.

NV3128 RS-422A Machine Control Data Routing Switch 3-4

Page 53

3.2 COMPUTER UTILITIES (OBSOLETE)

The following information applies only to older systems with the

Command Interpreter module. Newer systems with the Universal

Control module use UniDiag instead of the NVUtils described below.

See the UniDiag manual for details.

NVUtils is a collection of PC compatible computer programs that provide

diagnostics and control of the NVision family of digital routing switches. The

utilities currently consist of two programs, NVTake and NVMap. Both

programs communicate with the router Control Interface Module using RS232 data-exchange protocol, requiring either the configuration of the module

for that protocol or the intervention of an RS232/RS-422A converter.

Software installation and hardware configuration are detailed in Chapter 2 of

this manual.

NVTAKE

NVtake is a simple, minimally featured router control system. The

program sends takes and take salvos to the routing switch Control

Interface Module using controller commands from a long and growing

list of protocols. Take salvos can be saved to disk and reloaded. For

some protocols, the program enables crosspoint address queries and

listings.

NVMAP

NVMap is a multi-purpose configuration and diagnostic tool. It allows

the user to:

1. Query the routers crosspoints connections

2. Query the routers output monitor connections (for routing

switches that support output monitors).

3. Query and edit the configuration of the router/control

interface.

4. Remap the correlation between received controller addresses

and the physical switch addresses (the scramble map). This

ability greatly enhances the NV3128's ability to mesh with

existing router control systems.

NVMap also provides diagnostic messages showing the results of

controller commands sent to the router.

NV3128 RS-422A Machine Control Data Routing Switch 3-5

Page 54

3.2.1 OPERATING INSTRUCTIONS - NVTAKE (OBSOLETE)

INVOCATION:

NVTAKE [H | U | V | E | R] [1|2] [9600|38400]

Where argument 1 is the router control protocol from the following list:

H = Horiz on control protocol

U = Utah Scientific

V = Vistek

E = ESBus

R = BTS

and argument 2 is the communications port, default = COM1. Argument 3

is the serial portss baud rate. Default = 9600 Invoking NVTAKE with no

arguments displays the programs syntax summary.

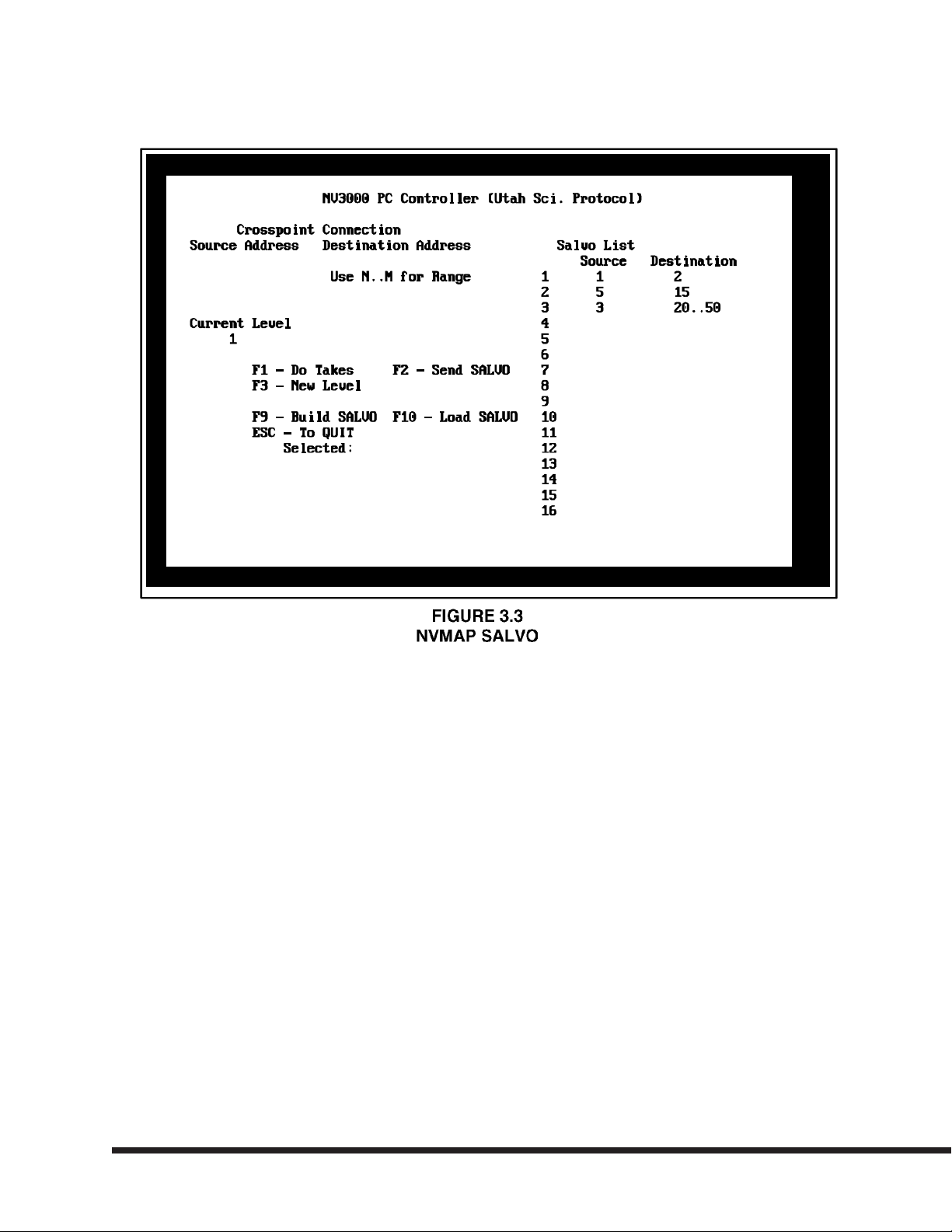

Figure 3.1 illustrates the basic NVTake screen.

OPERATIONS

The various functions of the program are invoked with function keys from

the following list:

F1 Send a single take

F2 Send a salvo of takes

F3 Change to level to which the controller sends commands

F4 Query a single crosspoint (Vistek protocol only)

F5 List 10 sequential crosspoint connections. (Vistek protocol only)

F6 List all destinations connected to a single source. (Vistek protocol only)

F3 CHANGE ROUTER LEVEL

The F3 function key allows changing the level to which the controllers

commands are issued. The level IDs of most routing protocols are

numeric. Vistek uses the alpha characters A-Z. Again, point-to-point

connections are addressed on level one. Connections involving multiple

destinations are addressed on level two.

NV3128 RS-422A Machine Control Data Routing Switch 3-6

Page 55

F1 SENDING A SINGLE TAKE

The F1 function key enters the single-take mode of operation. The

cursor moves to the source address prompt in the upper left hand

corner of the screen. When source and destination addresses have

been entered, the take is sent to the routers Control Interface. A

results message is displayed on the lower right-hand portion of the

screen, either COMMAND COMPLETED or TIME OUT, NO

RESPONSE.

The single-take command mode supports one-to-many addressing,

allowing a single source to connect to a range of destinations. The

syntax for the destination address entry is [START RANGE

ADDRESS]..[END RANGE ADDRESS].

EXAMPLE:

SOURCE ADDRESS 2

DESTINATION ADDRESS 3

NV3128 RS-422A Machine Control Data Routing Switch 3-7

Page 56

F9 - BUILD A SALVO TABLE

The F9 function key initiates building or editing a take salvo. The

cursor position prompts source and destination address fields.

Keyboard arrows move around the list.

A single source may be connected to multiple destinations in the salvo,

but when multiple sources are connected to a single destination, the last

entry over-rides any predecessor.

ESC ends the table-editing session. The program asks whether or not

to save the table to disk. If the answer is yes, The program requests

a filename. The program assigns the file extension .SVO to the entered

file name. The file name must be eight characters or less, so no path

prefixes are permissable. If the answer is no, the salvo remains in

memory, and can be sent (F2) or re-edited.

NV3128 RS-422A Machine Control Data Routing Switch 3-8

Page 57

F10 - LOAD A SALVO FROM DISK

The F10 function key loads a file from the current directory from which

NVTAKER was launched. The program asks for the name of the file

defining the salvo. Enter the name with no extension.

F2 - SEND A SALVO

The F2 function key sends the salvo information currently in the

computers memory to the control interface. A results message is

displayed on the lower right-hand portion of the screen, either

COMMAND COMPLETED or FAILED.

NV3128 RS-422A Machine Control Data Routing Switch 3-9

Page 58

QUERYING SYSTEM CONNECTIONS (VISTEK PROTOCOL ONLY)

F4 - QUERY A SINGLE CROSSPOINT

The F4 function key enters the single-crosspoint query mode. The

cursor is positioned on the destination address field. Upon entry of the

destination field, the source address connected to that destination will

be returned in the Source Address field.

F5 - QUERY MULTIPLE CONNECTIONS

The F5 function key enters the multiple-crosspoint query mode. The

cursor is positioned on the Destination Address field. Upon entry of

the destination field, the crosspoint connections to that and to the next

higher nine address are displayed in the lower left-hand corner of the

display.

F6 - LIST DESTINATIONS CONNECTED TO A SOURCE

The F6 function key initiates a listing of all the destinations currently

connected to the specified source address. Enter the source address

in the Source Address field. Enter in the Destination Address field the

destination from which the search for connections should begin.

ESC quits the program.

NV3128 RS-422A Machine Control Data Routing Switch 3-10

Page 59

3.2.2 OPERATING INSTRUCTIONS - NVMAP (OBSOLETE)

INVOCATION:

NVMAP [H | U | V | E | R] [1|2]

Where argument 1 is the router control protocol from the following list:

H = Horiz on control protocol

U = Utah Scientific

V = Vistek

E = ESBus

R = BTS

and argument 2 is the communications port, default = COM1. Invoking

NVMap with no arguments displays the programs syntax summary.

OPERATION:

NVMap operates from two screens. Screen I provides diagnostic

messages, allows inquiries into current router crosspoint connections,

and permits editing of scramble map parameters. Screen II selects the

active router level and permits editing the scramble map.

Function key F10 toggles from Screen I to screen II.

Function key F1 invokes HELP from either screen.

ESC exits from HELP and any of the various edit modes.

NV3128 RS-422A Machine Control Data Routing Switch 3-11

Page 60

NV3128 RS-422A Machine Control Data Routing Switch 3-12

Page 61

Screen I

Query crosspoint connections:

1. Enter the number of the lowest output port you want to query

2. The screen will display the connections made to the first 16 output ports

starting with the address entered.

Query output monitor connections:

1. Depress function key F3

2. The state of the output monitor connections is displayed in

the upper right-hand corner of the screen.

Diagnostic messages:

Diagnostic messages are sent to screen I continuously. Messages

include take results , synch presence reports and errors.

Configuration management.

The program allows the user to view and edit the controller/router

interface configuration. Operation is managed through function

keys:

F2 = upload current interface configuration from the router

F8 = Edit configuration

F4 = Download edited configuration

1. Uploading current configuration (F2) displays information for the

levels selected in the routers Control Interface Modules dip switches.

2. The F8 function key invokes the configuration editor. The editor will

automatically sequence the cursor through the available edit fields.

The user can alter

· The start point for the range of controller input addresses to be

processed by the scramble map.

· The input port specified as the default crosspoint connection.

· The start point for the range of controller output addresses to be

processed by the scramble map.

The ESC key ends the edit session and prompts whether or not to

download the edited configuration to the router.

NV3128 RS-422A Machine Control Data Routing Switch 3-13

Page 62

Screen II

Editing the scramble map:

1. Function Key F7 allows setting the router level on which the scramble

map is to operate. ESC exits this edit mode.

2. Function key F 2 loads the scramble map currently active in the router

controller RAM.

3. Function Key F3 loads a scramble map previously saved to disk.

4. Function key F8 invokes the scramble map editor.

5. Function key F4 downloads the edited scramble map, along with the

configurationinformation entered in screen I, to the router.

6. Function key F5 loads the edited scramble map, along with the

configuration information from Screen I, to disk. Prompt is for a file name.

The default file-name extension is .CFG.

· The scramble map operates on up to 256 addresses. The ranges of

addresses available to a given map begin at the points defined in Screen

I.

· Initially, undefined map fields within the configured partition range will

consist of --- entries. Out of range fields are blank.

· Keyboard arrow keys guide the editor through the fields. The enter key

accepts the keyed in data.

· Two physical inputs can be a mapped to a single input controller

address, and two physical outputs can be mapped to a single output

controller address. This allows pairs of connections to be made with

a single take. However:

Physical input ports may be assigned to multiple controller addresses.

Physical output ports may only assigned to a single controller address.

Because of this restriction, output port entries must be nulled or reassigned before they can be re-used. To empty a field, enter a

SpaceBar followed by Enter.

· Some control systems begin their addressing with 0. The NVision

routers begin their physical addressing at 1.

· The ESC key ends the edit session.

NV3128 RS-422A Machine Control Data Routing Switch 3-14

Page 63

CHAPTER 4: THEORY OF OPERATION

NV3128 RS-422A Machine-Control Data Routing Switch 4-1

Page 64

NV3128 RS-422A Machine-Control Data Routing Switch 4-2

Page 65

CHAPTER FOUR - THEORY OF OPERATION

4.1 SYSTEM

Fig 1.5 is repeated here to demonstrate the bidirectional flow of data through

the routing switch. The illustration shows a controlling machine sending and

receiving data through a controlled port on the router. Two crosspoints enable

the forward and reverse data paths through the switch. A controlled machine

receives and answers this command traffic through a controlling port.

4.1.1 CONTROL STRUCTURE

The Universal Control/Command Interpreter module receives commands

from an external control system and uses that information to pre-set an address

map of the entire crosspoint matrix. The address map is stored in doublebuffered RAM to prevent command updates from interfering with any take

activity in process. A programmable gate array transforms the address map into

the addresses and control commands that govern the operation of the crosspoint

modules. The mapping activity is continuous, with the Universal Control/

Command Interpreter module constantly pre-loading the crosspoints doublebuffered registers. At the take interval, a strobe pulse derived from the

reference input on the Universal Control/Command Interpreter module updates

the crosspoint registers with the pre-set information.

The Universal Control/Command Interpreter module additionally sends

information based on incoming commands to the I/O modules' on-board port

controllers. This data effectively causes one port to be configured as controlled,

and the other port in the route to be configured as controlling. The controlling

port will be associated with the source or destination parameter, depending on

the configuration of Reverse Src/Dest. See the explanation of Reverse Src/Dest

in the UniDiag manual for details.

NV3128 RS-422A Machine-Control Data Routing Switch 4-3

Page 66

NV3128 RS-422A Machine-Control Data Routing Switch 4-4

Page 67

4.2 CIRCUIT OPERATION

The following discussion provides an overview of circuit operation for

each of the circuit boards in the NV3128 Router frame. Because repair

is done by replacing modules rather than repairing them, schematics

and bills of material are not provided but may be requested from

NVISION Technical Support.

4.2.1 I/O CONNECTOR INTERFACE

ASSY: EM0038-XX

RS-422A Machine Control data enters the NV3128 through PCmounted D connectors on this passive connector interface assembly.

On each D connector, an RC circuit AC couples the input shield

terminal to ground. High density Metral connectors route the signals

back to the active I/O and Command Interpreter Modules.

A bayonet style BNC connector receives the reference video input and

loops it through to a second to facilitate daisy chain connections.

Alarms and changeover connections arrive via Phoenix terminal blocks.

Two spare BNCs are provided to accomodate possible future

customization.

D connector sets carry command information from the external router

control system, the diagnostic interface, and (on older frames) the

parallel interface. The RS-232 and RS-422 interfaces are 9-pin D

connectors, and the parallel interface is a 37-pin D. The primary

control and parallel connectors have neighboring connectors that can

be used for loop through. Note that the primary ports and their loopthru connectors are not equivalent; you must connect the control

system directly to the primary port.

4.2.2 SIGNAL BACKPLANE:

ASSY: 0039-XX

This captive, passive assembly mounts the high-density Metral

connectors that carry the intra-frame signal traffic.

NV3128 RS-422A Machine-Control Data Routing Switch 4-5

Page 68

4.2.3 CROSSPOINT MODULE: ASSY EM0041-XX

INPUT DATA

Input signal data flows into the crosspoint module from the signal

backplane. The data is resistor coupled into buffer/driver integrated

circuits, then passed onto the data bus for application to the crosspoint

ICs.

Control data from the Command Interpreter arrives through the

backplane and into a similar circuit. The control data contains two

buses: a register bus that addresses specific crosspoint outputs and a

data bus that holds the address of the input to which an output will

connect.

CROSSPOINTS

The crosspoint module uses four 64x64 crossbar ICs to crossconnect any of 128 outputs with any of the 128 inputs in the crosspoint

matrix. The chips address registers are double buffered. Control

information is stored in a load register, then transferred to the active

register on arrival of a strobe pulse, the signal "BNKLDI".

OUTPUT DATA

MISC:

Outputs from the crosspoint chips are driven over the signal backplane

to the I/O modules by 16 octal buffer/line-driver integrated circuits.

A submodule and associated circuitry process raw DC from the power

supply to produce a carefully regulated and current limited +5VDC for

distribution across the module.

NV3128 RS-422A Machine-Control Data Routing Switch 4-6

Page 69

4.2.4 I/O ASSEMBLY: EM0040-XX

The I/O module is a bidirectional interface between the router's