Envision NDS026 Series, NDS064 Series, NDS072 Series, NDS038 Series, NDS049 Series Installation Manual

Page 1

Geothermal/Water Source Outdoor Split Heat Pump

2 to 6 Tons Dual Capacity

Installation Information

Water Piping Connections

Electrical Data

Startup Procedures

Troubleshooting

Preventive Maintenance

NDS Installation Manual

IM1004SN 03/11

Page 2

Page 3

Table of Contents

Model Nomenclature........................................................... 4

General Installation Information ................................................5-8

Water Quality ................................................................. 8

Water Piping.................................................................. 9

Electrical Data ................................................................10

Thermostat Wiring ............................................................10

Dimensional Data..............................................................11

Physical Data .................................................................11

Model Nomenclature - Air Handler ...............................................12

Coil Data - Air Handler .........................................................12

Physical Data - Air Handler .....................................................13

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Model Nomenclature - Coil .....................................................13

Refrigerant Coil Compatibility...................................................13

Wiring Schematics..........................................................14-17

Microprocessor Control .....................................................18-21

Operation Logic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DIP Switch Settings........................................................... 22

Refrigeration ............................................................. 23-24

Line Set Sizes ................................................................ 24

Pressure/Temperature Conversion Chart for R-410A............................... 25

Operating Parameters......................................................... 26

Pressure Drop................................................................ 27

Compressor and Thermistor Resistance ......................................... 27

Refrigerant Circuit Guideline ................................................... 28

Heat of Extraction/Rejection Data .............................................. 28

Reference Calculations........................................................ 29

Legend ..................................................................... 29

Operating Limits .............................................................29

Startup and Troubleshooting................................................ 30-32

Preventative Maintenance ..................................................... 33

Replacement Procedures ......................................................33

Service Parts List ............................................................. 34

Page 4

NDS OUTDOOR SPLIT INSTALLATION MANUAL

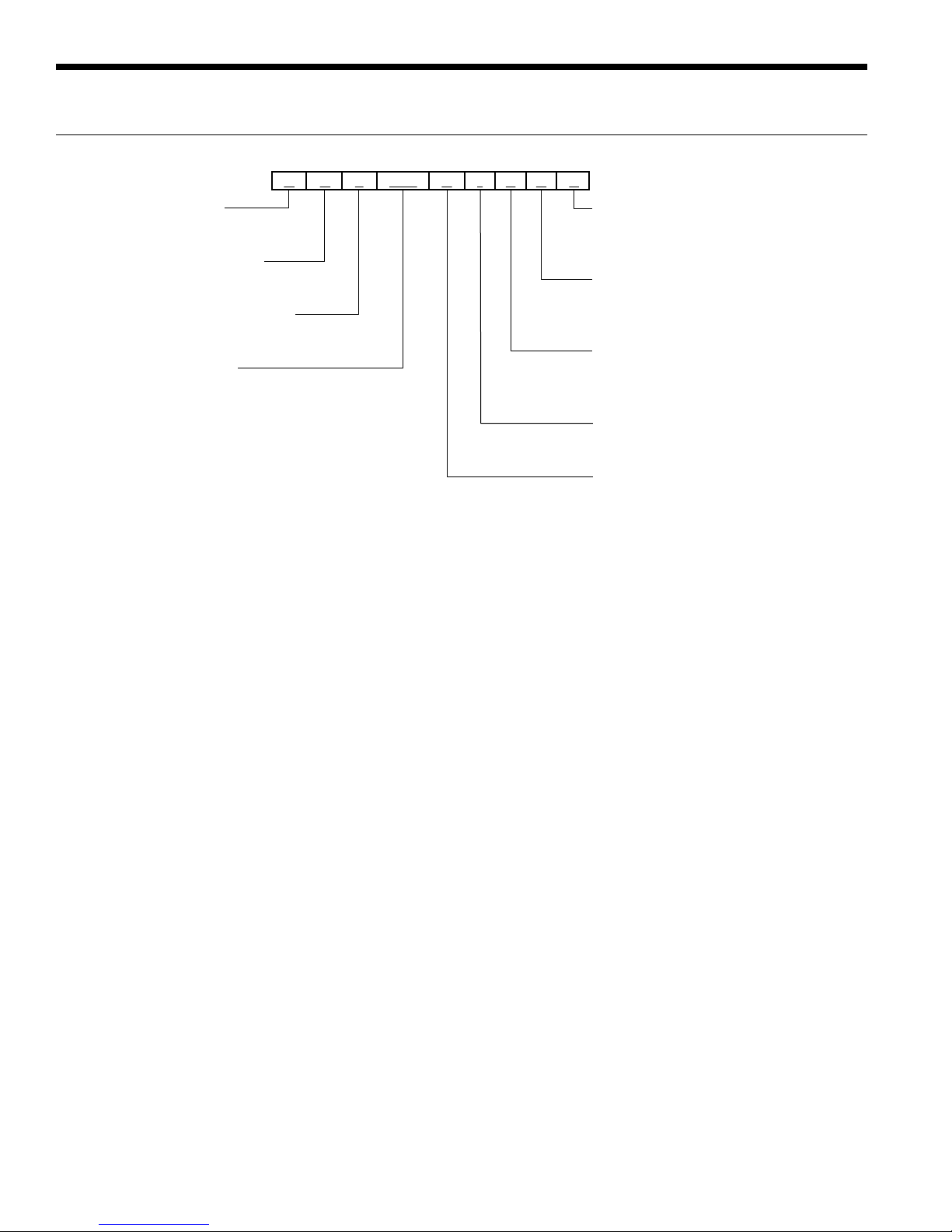

Model Nomenclature

1 2 3

D S

N

Model Type

N = Envision

Compressor Type

D = Dual Capacity

Cabinet Configuration

S = Outdoor Split

Unit Capacity

026

038

049

064

072

NOTE: *026-049 uses the FC1-GL and 060-072 uses

the FC2-GL, the flow center is factory installed. If these

flow centers do not meet the flow requirements, select

A = None for digit 10.

4-6

0497A819010A11C

Coax Options

C = Copper

N = Cupronickel

Flow Center

A = None

B = Flow Center*

IntelliStart Options

0 = No IntelliStart

3 = IntelliStart

Voltage

1 = 208-230/60/1

Vintage

A = Current

4

Page 5

General Installation Information

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Safety Considerations

WARNING: Before performing service or

maintenance operations on a system, turn off main

power switches to both units. Turn off accessory

heater power switch if applicable. Electrical

shock could cause personal injury. Installing and

servicing heating and air conditioning equipment

can be hazardous due to system pressure and

electrical components. Only trained and qualified

service personnel should install, repair or service

heating and air conditioning equipment.

Installing and servicing heating and air conditioning

equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service

personnel should install, repair or service heating and air

conditioning equipment. Untrained personnel can perform

the basic maintenance functions of cleaning coils and

cleaning and replacing filters. All other operations should

be performed by trained service personnel. When working

on heating and air conditioning equipment, observe

precautions in the literature, tags and labels attached to the

unit and other safety precautions that may apply, such as

the following safety measures:

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use a quenching cloth for brazing operations.

• Have a fire extinguisher available for all brazing

operations.

Moving and Storage

Move units in the normal “up” orientation. Units may be

moved and stored per the information on the packaging.

Do not stack more than three units in total height. Do not

attempt to move units while stacked. When the equipment

is received, all items should be carefully checked against

the bill of lading to be sure all crates and cartons have been

received. Examine units for shipping damage, removing

the units from the packaging if necessary. Units in question

should also be internally inspected. If any damage is noted,

the carrier should make the proper notation on the delivery

receipt, acknowledging the damage.

Condensate Drain

Follow the blower coil manufacturer’s instructions.

Duct System

All blower coil units/air coils must be installed as specified

by the manufacturer’s installation instructions; however, the

following recommendations should considered to minimize

noise and service problems.

An air filter must always be installed upstream of the air coil

on the return air side of the air handler or furnace. If there

is limited access to the filter rack for normal maintenance, it

is suggested that a return air filter grill be installed. Be sure

that the return duct is properly installed and free of leaks

to prevent dirt and debris from bypassing the filter and

plugging the air coil.

In applications using galvanized metal ductwork, a flexible

duct connector is recommended on both the supply and

return air plenums to minimize vibration from the blower. To

maximize sound attenuation of the unit blower, the supply

and return plenums should include an internal duct liner

of 1-inch thick glass fiber or be constructed of ductboard.

Insulation is usually not installed in the supply branch

ducts. Ducts in unconditioned areas should be wrapped

with a minimum of 1-inch duct insulation. Application of

the unit to uninsulated ductwork in an unconditioned

space is not recommended as the unit’s performance will

be adversely affected. If the air handler is connected to

existing ductwork, a previous check should have been

made to assure that the duct system has the capacity to

handle the air required for the unit application. If ducting

is too small, as in replacement of heating only systems,

larger ductwork should be installed. All existing ductwork

should be checked for leaks and repairs made accordingly.

The duct systems and diffusers should be sized to handle

the design airflow quietly. If air noise or excessive airflow

is a problem, the blower speed can be changed to a lower

speed to reduce airflow. This will reduce the performance

of the unit slightly in heating; however, it will increase the

temperature rise across the air coil. Airflow must still meet

minimum requirements.

Split Unit Location

Locate the split compressor section away from areas that

may disturb the customer and in a way that allows easy

removal of the access panels and the top of the cabinet.

Provide sufficient room to make water, electrical and

refrigerant line connections and allow space for service

personnel to perform maintenance. The NDS split is

approved for outdoor installation when properly installed.

Air Coil Location

Refer to the air handler manufacturer’s instructions for the

blower coil unit for details on installing the air handling

portion of the system.

Equipment Selection

The following guidelines should be used when mating an

Envision Split to an air handler/coil.

• Select R-410A components only.

• Match the air handler to the air handler coil data table.

• Indoor matching adjustable TXV is factory installed on

every NAH air handler/coil. Fixed orifice or cap tube

systems should not be used.

• Minimum of two (2) blower speeds

Utilizing Existing Coil or Air Handler

It is recommended that a new R-410A air handler be

installed with an Envision Split considering the long term

5

Page 6

NDS OUTDOOR SPLIT INSTALLATION MANUAL

General Installation Information cont.

benefits of reliability, warranty, etc. versus the short term

installation cost savings. However, the existing air handler

may be retained provided the following:

• Coil currently is R-410A rated

• Coil uses a TXV. No capillary or fixed orifice systems

should be used

• A life expectancy of more than 7 years remaining for the

air handler and components

• Flush air coil and line set

When utilizing the existing air coil or line set, only flushing

compounds that vaporize should be used; which means

they are packaged in a pressurized disposable cylinder. It is

preferable to use a flushing agent that removes oil, water,

and acid, plus, is biodegradeable and non-toxic. The flushing

agent should be safe to use with both HCFC and HFC

refrigerants. Once a flushing agent has been selected, follow

the instructions provided with the product.

The first step should be purging the lines or air coil with

nitrogen. Purging with nitrogen first will remove some of

the particulate and residual oil which will allow the flushing

agent to work better. Never blow the flushing agent

through a compressor, filter drier, or txv as it will cause the

components to fail.

When flushing is complete and the final system is assembled,

an acid check should be preformed on the system. Acid test

kits are available from most HVACR distributors.

An air filter must always be installed upstream of the air coil

on the return air side of the air handler or furnace. If there

is limited access to the filter rack for normal maintenance,

it is suggested that a return air filter grille be installed. Be

sure that the return duct is properly installed and free of

leaks to prevent dirt and debris from bypassing the filter

and plugging the air coil.

Ensure that the line set size is appropriate to the capacity

of the unit (refer to Line Set Sizes table). Line sets should

be routed as directly as possible, avoiding unnecessary

bends or turns. All wall penetrations should be sealed

properly. Line set should not come into direct contact

with water pipes, floor joists, wall studs, duct work, floors,

walls and brick. Line set should not be suspended from

joists or studs with a rigid wire or strap which comes into

direct contact with the tubing. Wide hanger strips which

conform to the shape of the tubing are recommended.

Isolate hanger straps from line set insulation by using metal

sleeves bent to conform to the shape of insulation. Line

set insulation should be pliable, and should completely

surround the refrigerant line.

NOTE: Improper installation of equipment may result in

undesirable noise levels in the living areas.

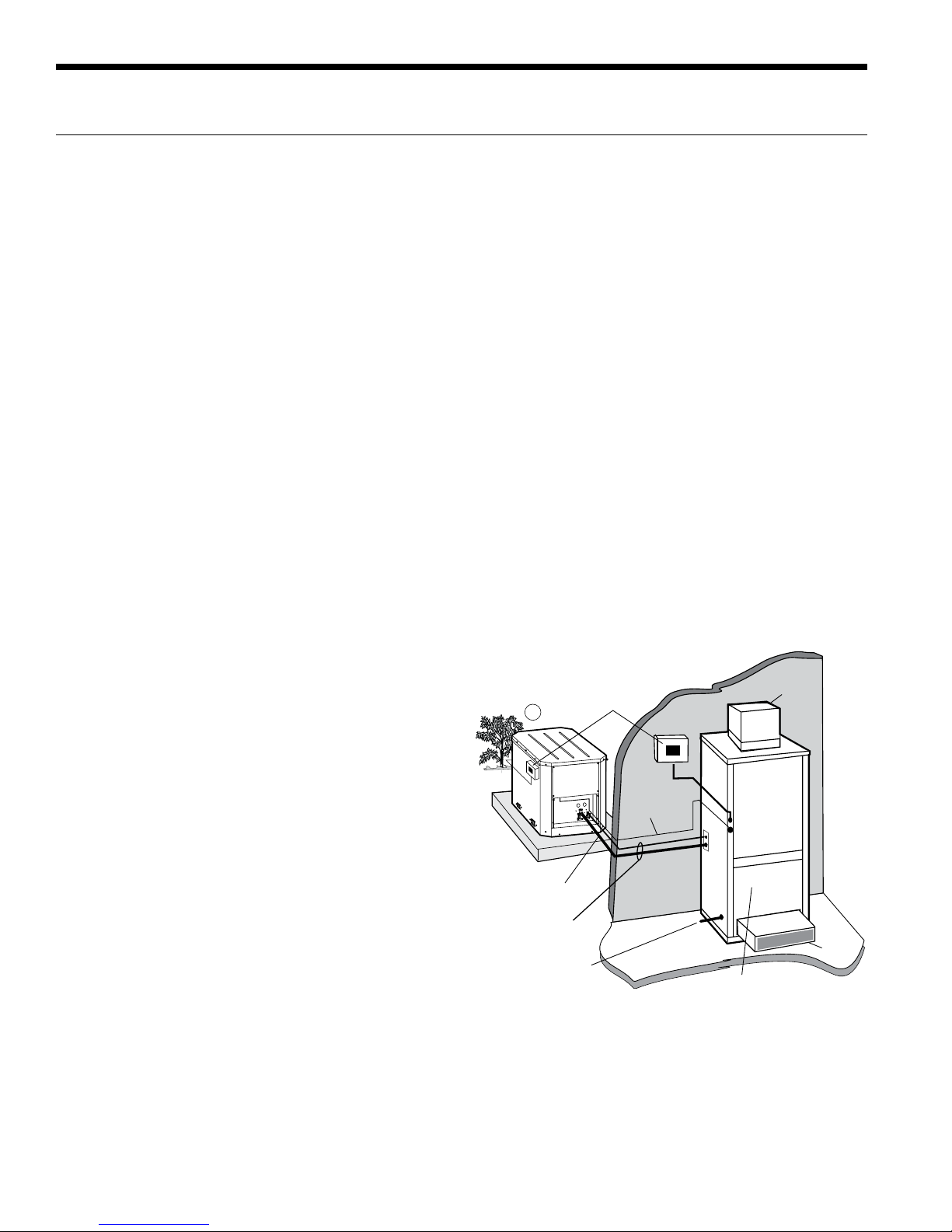

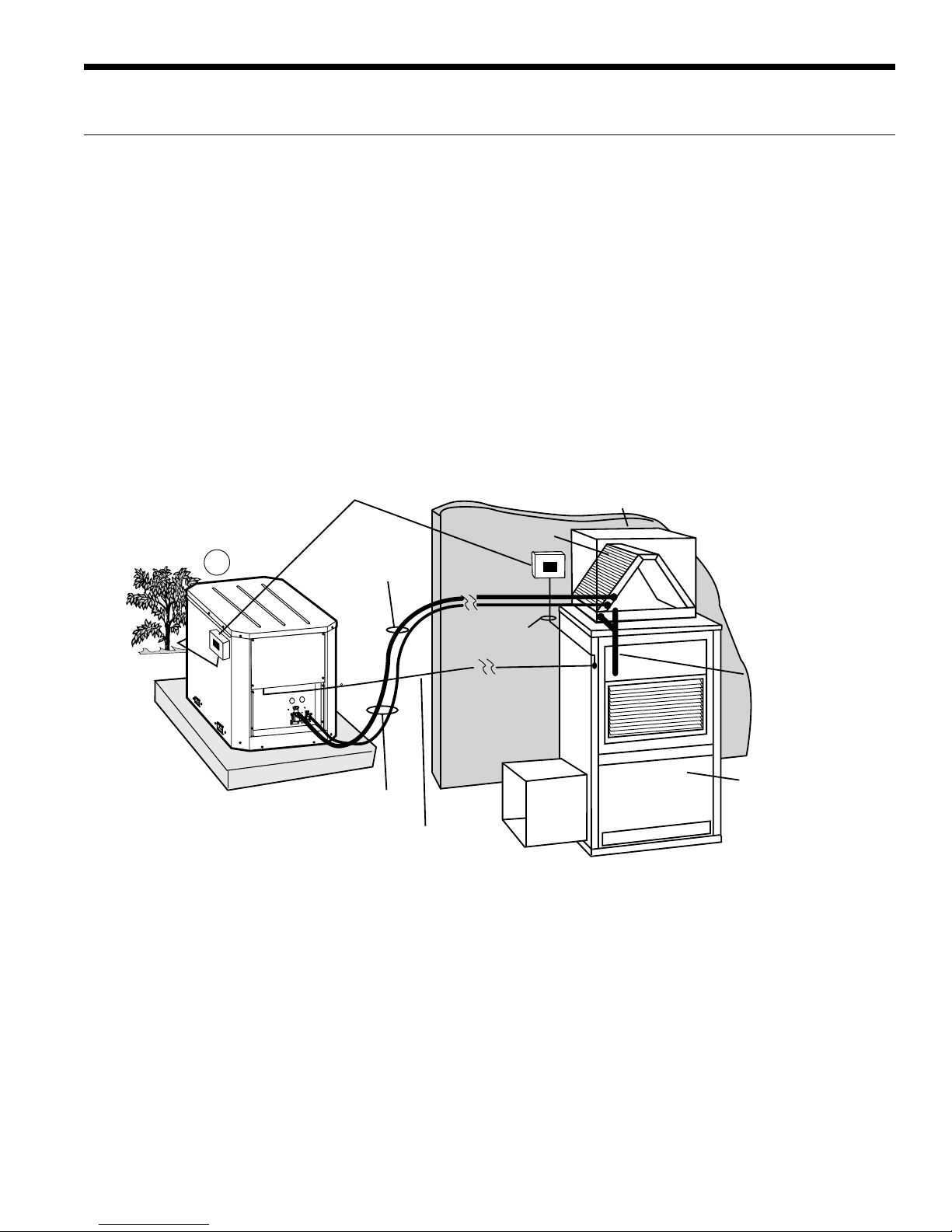

Typical Split System Application Remote Blower Coil

Connection to Air Coil

Typical Split System Application - Remote Blower Coil

and Typical Split System Heat Pump Coil Add-on Fossil

Fuel Furnace illustrations show typical Envision Split

installations. The Line Set Sizes table shows typical line

set diameters and maximum length. Line sets over 60 feet

are not recommended. If the line set is kinked or deformed

and cannot be reformed, the bad section of pipe should be

replaced. A restricted line set will affect unit performance.

As in all R-410A equipment, a reversible liquid line filter

drier is required to ensure all moisture is removed from the

system. This drier should be replaced whenever “breaking

into” the system for service. All line sets should be insulated

with a minimum of 1/2” closed cell insulation. All exterior

insulation should be painted with UV resistant paint or

covering to ensure long insulation life.

Air Handler Installation

Air handlers used with dual capacity units must be capable

of operating with a minimum of 2 blower speeds. Refer to

the manufacturer’s instructions for the blower coil unit for

details on installing the air handling portion of the system.

All blower coil units/air coils must be installed as specified

by the manufacturer’s installations instructions. However,

the following recommendations should be considered to

minimize noise and service problems.

Insulated

Suction Line

Lineset

To Air Handler

Condensate Drain

(must be trapped)

Disconnect

Low

Voltage Wire

Remote Air Handler

(Maximum Recommended Distance is

60' Between Units)

Supply

Duct

Air

Handler

Return

Duct

6

Page 7

General Installation Information cont.

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Dual Fuel Systems

Envision units can be connected to fossil fuel furnaces that

include an A-coil or slab coil. Dual fuel installations utilize

the Envision heat pump for heating until the point that

auxiliary heat is called for on the thermostat. At that point,

the furnace will be enabled and the heat pump will be

disabled. The Envision heat pump provides air conditioning

through the furnace’s refrigerant coils.

Refer to the furnace manufacturer’s installation manual

for the furnace installation, wiring and coil insertion. A

WaterFurnace Dual Fuel thermostat or a field-installed

DPST relay is required. See the Typical Split System Heat

Pump Coil Add-on Fossil Fuel Furnace illustration for

typical Dual Fuel application.

Typical Split System Heat Pump Coil

Add-on Fossil Fuel Furnace

Disconnect

Insulated

Suction Line

In add-on Envision Split applications, the coil should

be located in the supply side of the furnace to avoid

condensation damage to the furnace heat exchanger. A

high temperature limit should be installed upstream of the

coil to de-energize the compressor whenever the furnace

is operating. Without this switch, the Envision Split will trip

out on high pressure. A dual fuel thermostat can remove

the Y1 and Y2 calls when a W call is energized to allow gas

furnace backup on an Envision Split application. Refer to

the Thermostat Wiring section for details.

Supply Duct

"A" or

Slab Coil

Lineset To Air Handler

Wire From Furnace

Thermostat

Wire To

Thermostat

Return

Duct

Condensate

Drain

(must be trapped)

Up-Flow

Fossil Fuel

Furnace

7

Page 8

NDS OUTDOOR SPLIT INSTALLATION MANUAL

mpp 02 naht sseLmpp 2 naht sseLmpp 2 naht sseLainommA

mpp 5. naht sseLmpp 5. naht sseLmpp 5. naht sseLetafluS ainommA

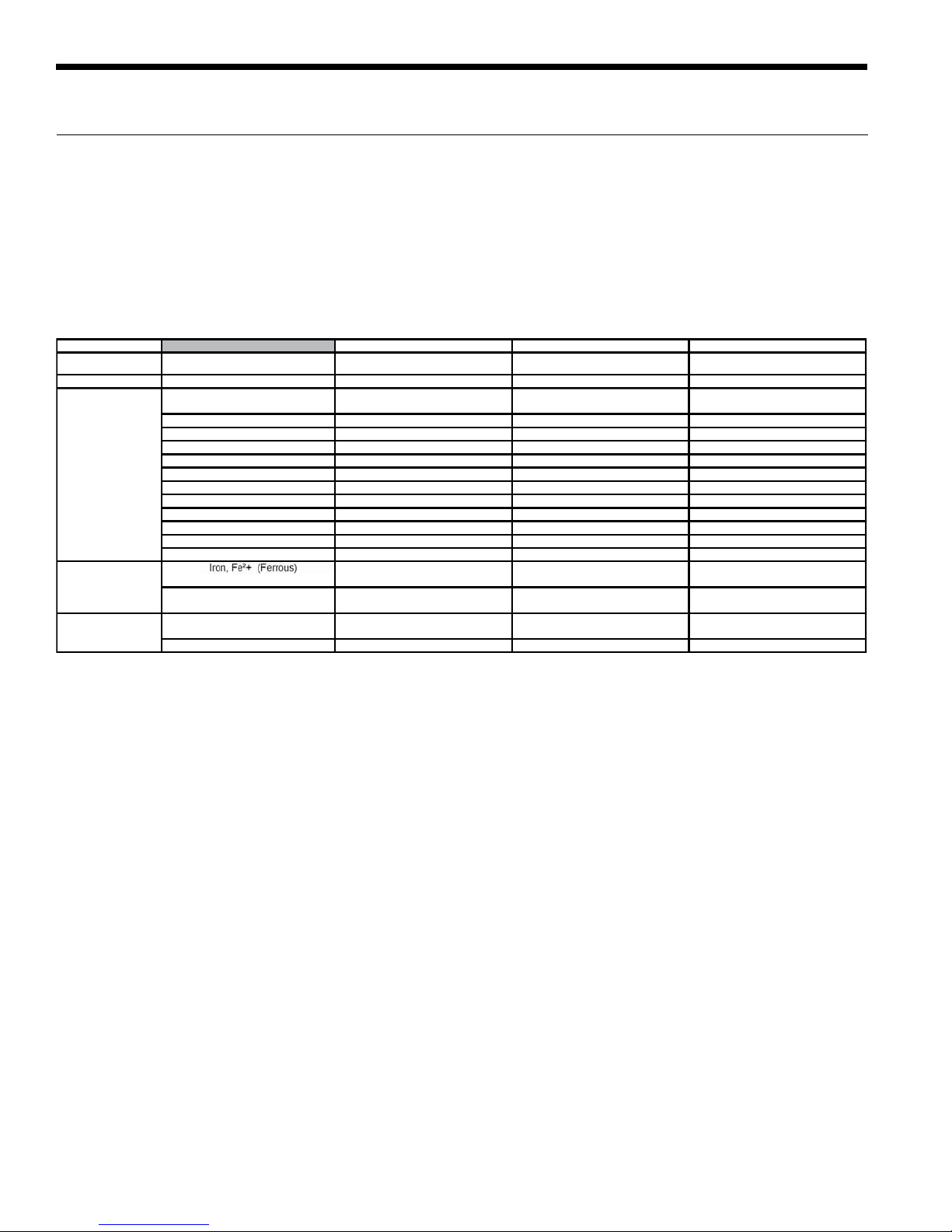

Water Quality

In ground water situations where scaling could be heavy

or where biological growth such as iron bacteria will be

present, a closed loop system is recommended. The heat

exchanger coils in ground water systems may, over a period

with extremely hard water, the owner should be informed

that the heat exchanger may require occasional flushing.

Failure to adhere to the guidelines in the water quality table

could result in loss of warranty.

of time, lose heat exchange capabilities due to a buildup

of mineral deposits inside. These can be cleaned, but only

by a qualified service mechanic, as special solutions and

pumping equipment are required. Hot water generator coils

can likewise become scaled and possibly plugged. In areas

pH Acidity/Alkalinity 9 - 7 9 - 7 9 -7

Scaling Calcium and Magnesium Carbonate (Total Hardness) less than 350 ppm (Total Hardness) less than 350 ppm (Total Hardness) less than 350 ppm

Hydrogen Sulfide

Corrosion mpp 5. naht sseLmpp 5. naht sseLmpp 5. naht sseLedirolhC ainommA

LSI Index

Iron Fouling

(Biological Growth) Iron Oxide

Erosion Suspended Solids

Note:

Grains = PPM divided by 17

mg/l is equivalent to PPM

Bacterial Iron Potential

Less than .5 ppm (rotten egg smell

appears at 0.5 PPM)

+

0.5 to -.05

Less than 1 ppm. Above this level

deposition will occur.

Less than 10 ppm and filtered for max of

600 micron size

Units with cupronickel heat exchangers are recommended

for open loop applications due to the increased resistance

to build-up and corrosion, along with reduced wear caused

by acid cleaning.

+

0.5 to -.05

Less than 1 ppm. Above this level

deposition will occur.

Less than 10 ppm and filtered for max of

600 micron size

Less than 1 ppm. Above this level

Less than 10 ppm and filtered for max of

+

0.5 to -.05

deposition will occur.

600 micron size

leetS sselniatS 613lekciN-orpuC 01/09reppoClairetaM

mpp 1 naht sseLmpp 05 - 01

mpp 002 naht sseLmpp 521 naht sseLmpp 521 naht sseLsetafluS

mpp 5. naht sseLmpp 5. naht sseLmpp 5. naht sseLenirolhC

mpp 003 naht sseLmpp 521naht sseLmpp 02 naht sseLsedirolhC

mpp 05 -01mpp 05 - 01mpp 05 naht sseLedixoiD nobraC

mpp 5. naht sseLmpp 5. naht sseLmpp 5. naht sseLetartiN ainommA

mpp 5. naht sseLmpp 5. naht sseLmpp 5. naht sseLedixordyH ainommA

mpp 0051-0001mpp 0051-0001mpp 0001 naht sseL)SDT( sdiloS devlossiD latoT

mpp 2. < mpp 2. < mpp2. <

ces/tf 6<ces/tf 6 <ces/tf 6 < )retaW hserF( yticoleV dlohserhT

8

Page 9

Water Piping

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Residential NDS split units are supplied standard with

GeoLink swivel connections with P.T. ports.

CAUTION: Water piping exposed to outside

temperatures may be subject to freezing.

Water Piping

The proper water flow must be provided to each unit

whenever the unit operates. To assure proper flow, use

pressure/temperature ports to determine the flow rate.

These ports should be located at the supply and return

water connections on the unit. The proper flow rate cannot

be accurately set without measuring the water pressure

drop through the refrigerant-to-water heat exchanger.

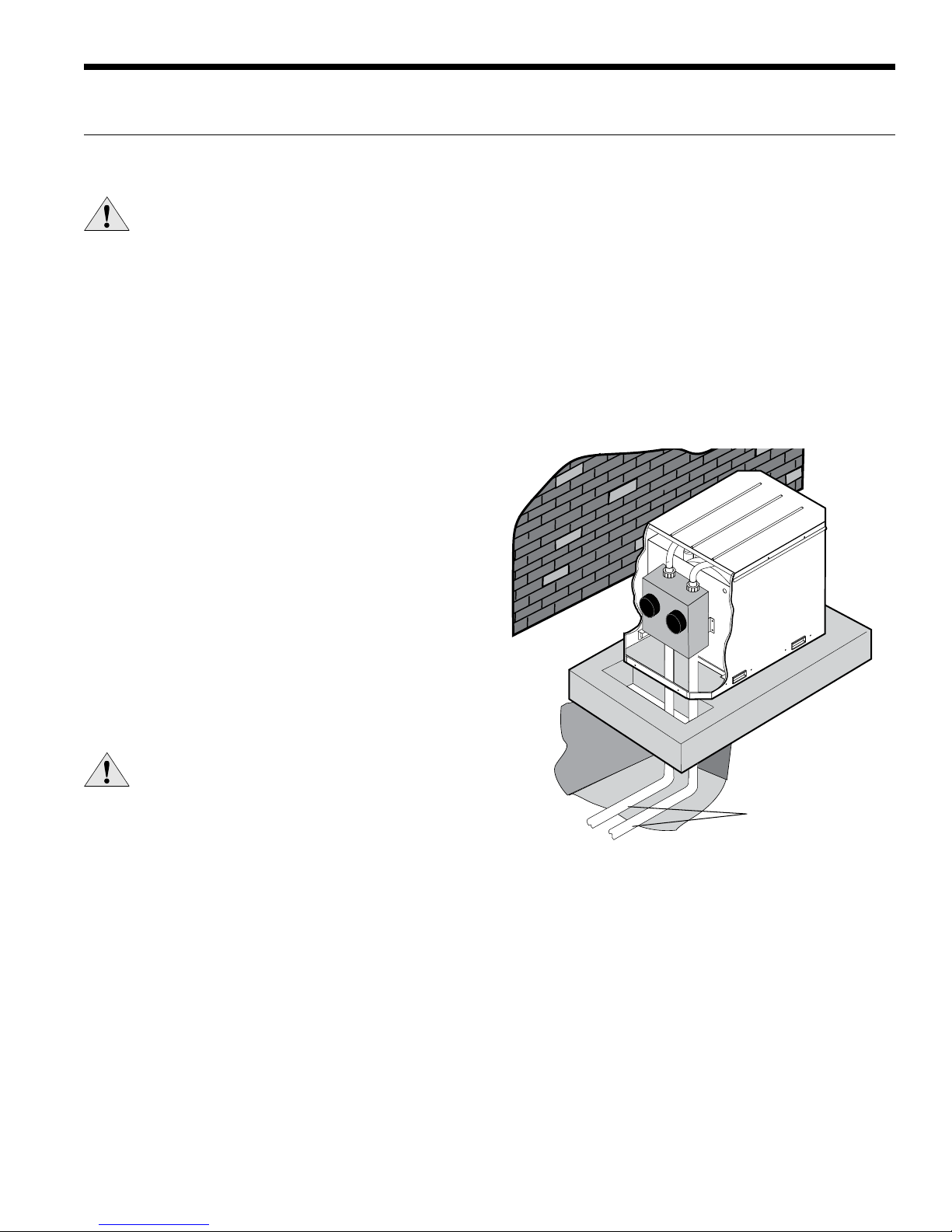

Closed Loop - Earth coupled Systems

(Outdoor Installations)

Locate unit on an air pad with access hole as shown below.

When mounting on an existing concrete pad, holes must

be bored through to accommodate 1 1/4-inch P.E. pipe with

1/2-inch insulation.

Connecting To Earth Loop

The earth loop trench should be continued directly under

the unit as shown in the Typical Split System Outdoor

Installation Using Closed Loop. Make the connections to

optional fittings from the loop circulator pump(s) and

ensure proper backfill to support the loop pipe during

trench settling. All 1 1/4-inch piping should be insulated

with a minimum of 1/2-inch closed cell insulation from

below the ground surface to the loop circulator.

Flow Center Installation

Flow centers FC1-GL or FC2-GL, as needed, may be

internally mounted on the NDS splits, Two stub tubes with

barbs are pre connected to the coax. Two tubes with brass

fittings, to adapt to the flow center, 2 hoses to connect

between the two sets of tubes, and four hose clamps are

included with each NDS unit. The brass adapter fittings

have plastic swivel connectors that also accept 1 in. O.D.

copper pipe (sweat).

NOTE: For ease of installation, attach provided hoses to

coax first and then trim to fit to elbows on flow center.

Typical Split System Outdoor Installation

Using Closed Loop

IMPORTANT: A freeze detection thermostat is

installed in the unit to automatically start loop

circulator pump if loop temperature drops

below 20°F. Loop freeze detection should also

be maintained to the lowest temperature the

insulated loop may encounter in the case of

power failure.

Open Loop (Indoor Installations)

NDS Splits can be installed on an open loop system, but

only indoors. All NDS Splits are supplied with GeoLink

swivel connectors. The swivel connectors will also accept a

1 in. O.D. copper pipe (sweat) which can be connected in an

open loop system.

Loop Supply

and Return

Piping

9

Page 10

NDS OUTDOOR SPLIT INSTALLATION MANUAL

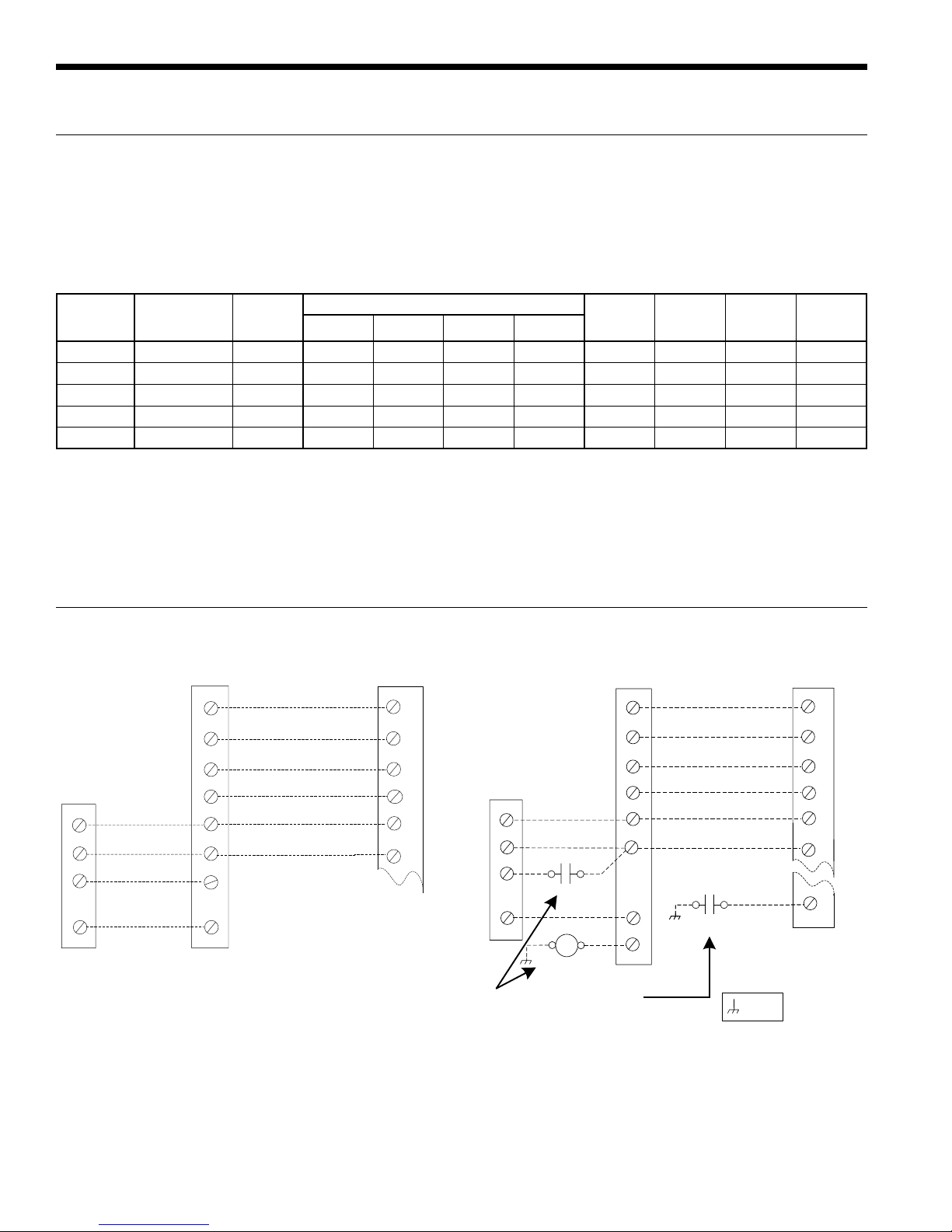

Typical EZ Wiring Diagram

Electrical Data

General

Be sure the available power is the same voltage and phase

as that shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the

National Electric Code, whichever is applicable. See unit

electrical data for fuse or cicuit breaker sizing information.

Model

026

038

049

064

072

Rated

Voltage

208-230/60/1 197/253 16.0 10.2 52.0 18.0 5.4 15.6 17.0 25

208-230/60/1 197/253 26.0 16.6 82.0 29.0 5.4 22.0 23.4 40

208-230/60/1 197/253 33.0 21.1 96.0 34.0 5.4 26.5 2 7. 9 50

208-230/60/1 197/253 40.0 25.6 118.0 41.0 5.4 31.0 32.4 60

208-230/60/1 197/253 42.5 2 7.2 150.0 53.0 5.4 32.6 34.0 60

Rated voltage of 208-230/60/1.

HACR circuit breaker in USA only.

Min/Max voltage of 197/253.

All fuses Class RK-5

* With optional IntelliStart

Thermostat Wiring

Thermostat Wiring

Air Handler

C

R

W

G

Common Common

24 VAC

Fan

Thermostat

Y1

Y2

O

L

C

R

W

G

Voltage

Min/Max

1st Stage Compressor

2nd Stage Compressor

Reversing Valve

Fault Signal

24 VAC

Compressor Ext

MCC RLA LRA LRA*

Thermostat Wiring for Dual Fuel Applications

Envision Split

Y1

Y2

O

P1

Lo

C

R

Fossil Fuel

Furnace

C

R

W

G

Auxiliary Heat Relay

Loop

FLA

Thermostat

Y1

Y2

O

L

Common Common

24 VAC

Fan

C

R

G

W

Unit

FLA

1st Stage Compressor

2nd Stage Compressor

Reversing Valve

Fault Signal

24 VAC

Total

Auxiliary

Heat Relay

Min

Circ

Amp

Max

Fuse/

HACR

Envision Split

Y1

Y2

O

LO

C

R

Shut

Down

1/17/11

P1

P2

Air Handler transformer must be at least 75 VA.

Note: Field installed DPST dual fuel relay

(Required for dual fuel installation)

or use TP32U03 or TP32U04

10

Auxiliary Heat Relay

= chassis

Page 11

NDS OUTDOOR SPLIT INSTALLATION MANUAL

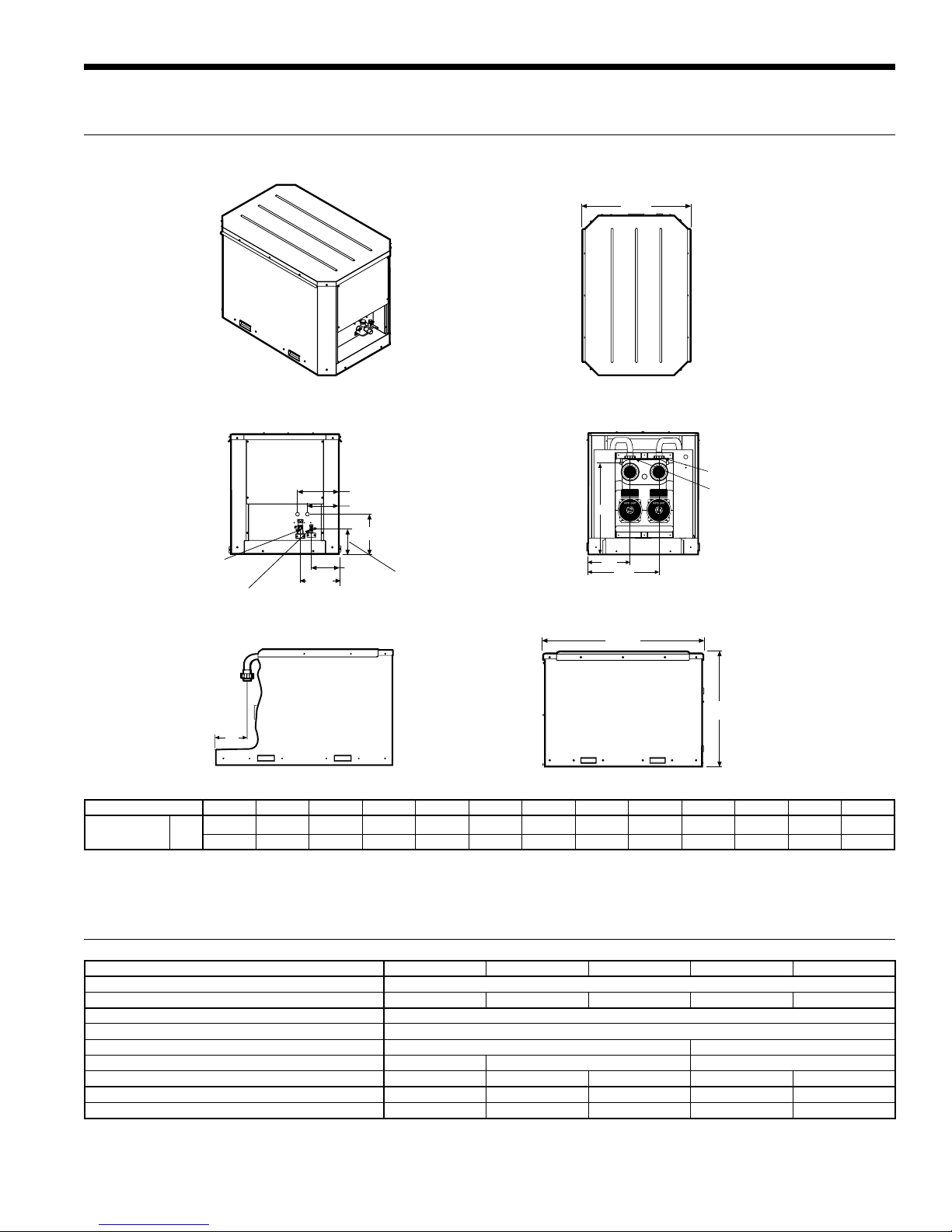

Dimensional Data

Cabinet Dimensions and Refrigerant Piping Connections

Top View

B

Rear View

J

K

L

WATER OUT

WATER IN

Suction Line

Connection

Liquid Line

Connection

Front View

D

E

F

H

I

G

Lineset connections are braze type

internally mounted

Side View

Side View

M

Model A B C D E F G H I J K L M

in

026 thru 072

Refer to Physical Dimensions and Piping Connections drawings

36.0 23.9 26.7 9.3 7.1 9.0 5.6 8.2 10.7 18.9 8.7 14.8 7.0

[cm] [91.4] [60.7] [67.8] [23.7] [18.0] [22.8] [14.2] [20.9] [27.2] [48.0] [22.1] [37.6] [17.8]

A

C

Physical Data

Model 026 038 049 064 072

Compressor (1 each) Dual Capacity Scroll

Factory Charge R-410A, oz [kg] 52 [1.47] 56 [1.59] 90 [2.55] 92 [2.61] 104 [2.95]

Coax and Water Piping

Water Connections Size - Swivel- in [mm] GeoLink Swivel Connectors

Brass Service Valve - Liquid Line - in [mm] 3/8 [9.525] 1/2 [12.7]

Brass Service Valve - Suction Line - in [mm] 5/8 [15.875] 3/4 [19.05] 7/8 [22.2 25]

Coax and Piping Water Volume - gal [l] 0.7 [2.6] 1.3 [4.9] 1.6 [6.1] 1 .6 [6.1] 1.6 [6.1]

Weight - Operating, lb [kg] 189 [86] 236 [107] 250 [ 113] 271 [123] 290 [132]

Weight - Packaged, lb [kg] 209 [95] 256 [116] 270 [122] 291 [132] 3 10 [141]

All units have TXV expansion devices, and 1/2 in. [12.2 mm] and 3/4 in. [19.1 mm] electrical knockouts.

Brass service valves are sweat type valves.

10/29/08

11

Page 12

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Model Nomenclature - Air Handler

1-3 4-6 7 8-9 10 11 12

NAH 036 A 00 0 1 R

Model Type Air Coil

NAH = Envision Series Air Handler R = Refrigerant

Unit Capacity

Refrigerant Models Nom. CFM Motor

022 MBTUH 800 1 = ECM 208-230/60/1

026 MBTUH 925

030 MBTUH 980

036 MBTUH 1225

042 MBTUH 1425

048 MBTUH 1625

060 MBTUH 1760

Hydronic Models

026 MBTUH 925

036 MBTUH 1225 Electric Heat

048 MBTUH 1625 00 = No electric heat

060 MBTUH 1760 05 = 5 kW (available on 022-036 only)

Vintage 15 = 15 kW (available on 042-060 only)

A = Current 20 = 20 kW (available on 060 only)

H = Hydronic

Disconnect

0 = No breaker installed

(only on 5kW & 10kW heaters)

1 = Breaker installed

(only on 15kW & 20kW heaters)

10 = 10 kW (available on 030-060 only)

NOTE: Kit NAHBC must be ordered to field convert the NAH042-060 to bottomflow air discharge.

Coil Data - Air Handler

Envision Split Model Matching Air Handler Coil Surface Area (ft2) FPI Rows Tube Diameter

022 - 038

042 - 072

NAH036 5.83 12 2 3/8 in.

NAH060 5.83 12 3 3/8 in.

Compatibilty Table - Air Handler

Air Handler

NAH022A***1R

NAH026A***1R

NAH030A***1R

NAH036A***1R

NAH036A***1R

NAH042A***1R

NAH048A***1R

NAH048A***1R

NAH060A***1R

NAH060A***1R

NAH060A***1R

NAH060A***1R

Indoor Split Model

(Single)

NSZ022 - 800 5

- NDZ026 NDS026 925 5

NSZ030 - - 980 5, 10

NSZ036 - - 1225 5, 10

- NDZ038 NDS038 1225 5, 10

NSZ042 - - 1425 10, 15

NSZ048 - - 1625 10, 15

- NDZ049 NDS049 1625 10, 15

NSZ060 - - 1760 10, 15, 20

- NDZ064 NDS064 1760 10, 15, 20

NSZ070 - - 1760 10, 15, 20

- NDZ072 NDS072 1760 10, 15, 20

Indoor Split Model

(Dual Capacity)

Outdoor Split Model

(Dual Capacity)

Airflow(CFM) Electric Heat (kW)

6/9/08

12

Page 13

Physical Data - Air Handler

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Air Handler Model Number (Refrigerant)

Air Coil Total Face Area, ft2 [m2]

Tube outside diameter - in. [mm]

Evaporator

Coil

Refrigerant R-410a

Nominal cooling capacity - tons [kW] 1.8 [6.44] 2.1 [7.59] 2.5 [8.79] 3 [10.55] 3.5 [12.30] 4 [14.06] 5 [17.58]

Condensate drain connection - (FPT) in. [mm]

Blower Wheel Size (Dia x W), in. [mm]

Blower motor type/speeds

Blower motor output - hp [W]

Filter Standard - 1" [51mm] MERV3 disposable, in. [mm]

Electrical characteristics (60hz)

Shipping weight - lbs. [kg]

Operating weight - lbs. [kg]

Number of rows

Fins per inch

Suction line connection - in. [mm] sweat

Liquid line connection - in. [mm] sweat

NAH022 NAH026 NAH030 NAH036 NAH042 NAH048 NAH060

5.83 [0.54]

3/8 [9.52]

2 3

12

5/8 [15.87] 7/8 [22.22]

3/8 [9.52]

3/4 [19.05]

11 x 10 [279 x 254]

ECM variable speed

1/2 [373] 1 [746]

20 x 24 [508 x 635]

208/230 - 1ph

215 [97.52] 220 [99.79]

195 [88.45] 200 [90.71]

Model Nomenclature - Coil

1-2 3

NR

A

Model Type

NR = Envision Refrigerant Coil

NH = Envision Hydronic Coil

Configuration Refrigerant Models

A = "A" Coil 026 MBTUH

Coil

4

C

5-7

026

8

C

Cabinet

C = Encased

U = Uncased

Capacity

036 MBTUH

048 MBTUH

060 MBTUH

Hydronic Models

060 MBTUH

1/11/08

NOTE: All Refrigerant Coils include TXV.

Refrigerant Coil Compatibility

Encased/Uncased Coil

NRAC026* NSZ022 - 800

NRAC026* - NDZ026 NDS026 925

NRAC026* NSZ030 - - 980

NRAC036* NSZ036 - - 1225

NRAC036* - NDZ038 NDS038 1225

NRAC048* NSZ042 - - 1425

NRAC048* NSZ048 - - 1625

NRAC048* - NDZ049 NDS049 1625

NRAC060* NSZ060 - - 1760

NRAC060* - NDZ064 NDS064 1760

NRAC060* NSZ070 - - 1760

NRAC060* - NDZ072 NDS072 1760

Indoor Split Model

(Single)

Indoor Split Model

(Dual Capacity)

13

Outdoor Split Model

(Dual Capacity)

Recommended Airflow

(CFM)

7/14/08

Page 14

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Thermistor

Light Emitting Diode - Green

Relay Coil

Capacitor w/ Bleed Resistor

Switch-High Pressure

Switch-Low Pressure

Polarized Connector

Factory Low voltage wiring

Factory Line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

DC Voltage PCB traces

Internal junction

Quick connect terminal

Wire nut

Field wire lug

Ground

Fuse

CC -

CR1 -

CR2-

CR3 -

CR4 -

F1 and F2 -

FD -

HP -

LP -

RV -

SW1 -

SW2 -

SW3 -

Compressor Contactor

Loop Pump Relay1

Fuses

Freeze Detection sensor

High Pressure Switch

Low Pressure Switch

Reversing Valve Coil

Not Used

DIP Package 8 Position

DIP Package 5 Position

Relay Contacts -

N.O., N.C.

G

T

132

P

L1

Loop Pump Relay2

Not Used

CS -

Compressor Solenoid

Not Used

Legend

1 - Connection of remote unit that does not have a loop pump

for slave operation.

2 - 24V Accessory relay (see SW2 -3 for description of operation)

3 - Field installed DPDT dual fuel relay. (Required for dual fuel

installation)

4 - DHW pump only in models with hot water generation option.

5 - Comfort Alert fault output to Premier Control Board

6 - This Switch allows the unit to down stage with the t-stat

when OFF and finish on second stage when ON. Finish

second stage reduces stage changing in recip dual capacity

compressors and should be ON for unzoned Dual Cap

E-Series or Premier 2 speed units.

Notes

Crankcase Heater

CA -

Comfort Alert

LED Flash Code Desc ription

Green S olid Module Has Power

Red Solid Y1 Present But Compressor Not Running

Code 1 Long Run Time

Code 2 Sy stem Pressure Trip

Code 3 Short Cyc ling

Code 4 Locked Rotor

Code 5 Open Circuit

Code 6 Open Start Circuit

Code 7 Open Run Circuit

Code 8 W elded Contactor

Code 9 Low Voltage

Yellow

Comfort Alert Status

Wiring Schematics

Dual Capacity Split - 208-230/60/1

Loop Pump(s)

Comfort

Alert

R

C

Y2

Y

1/2 HP 208-230/60/1

Pump

Recovery

Violet (3)

CC

Heat

Unit

Pump

G

NOTE 1

C

SL1 In

SL1 Out

Optional

Remote Unit

Without

Loop Pump

L2

L1

Yellow (6)

Black (5)

White (4)

Violet (2)

Black (1)

CR1

CCHI

CC-GND

P1

R

C

Y1

Y2

W

O

G

LO

P2

Shut

Down

C

SL1 In

SL1 Out

Not

Used

NOTE 2

P3

Acc Com

Acc NC

Acc NO

1 2 3

Gray(9)

Yellow(8)

NO

COM

CR2

CC

1

2

3

4

5

6

7

8

1

1

1

2

2

2

3

3

3C

4

5

6

7

1

2

3

ECM2

Air Flow

Settings

SW1

P4

S

C

R

Blue

Unit Power

208-230/60/1

G

FP

Red (11)

Crankcase Heater

Black Black

Fused L2

NO

COM

Fused L2

NO NC

COM

CR3

NO NC

CR4

Black (7)

Comfort Alert

Run

Capacitor

Red (12)

Green/Yellow

F1-10A 240V

COM

Fused L1

Microprocessor

Logic Control

(DC Voltage)

SW2

On

On

1

2

3

4

5

6

7

8

9

10

NOT USED

11

12

1

Test / Norm

2

Loop / Well

3

Fan / Comp

4

Not Used

5

Not Used

6

Inputs / Norm

7

Outputs / Norm

8 Pulse L / Constant L

SW3

On

Dual/ Single Capacity

1

2

3

4

5

nd

Normal/Finish on 2

No RPM / RPM

Must be On

Envision / E Series or Premier

NOTE 6

Tan (16)

240V L2

Orange (14)

Red Black

CC

L2 L1

Brown (15)

240V L1

P6

8

13

7

4

5

14

12

6

15

10

9

2

1

3

11

16

P5

11

4

9

2

10

3

8

1

12

5

13

6

7

14

DC SOL

CS

+

-

Comfort A lert

RV

T

LP

HP

FD

F1-10A 240V

R

C

Tan

Orange

Orange

Not Used

Not Used

Not Used

Not Used

Yellow

Yellow

Blue

Blue

Black

Black

NOTE 5

L

NOT USED

R

R

R

R

R

G

Status LED PCB

Y

R

SW4

LED Normal Display Mode

Field Selection Dips - #1 On, #6 On, #7 On

Not Used

Drain

FD thermistor (loop<15°F,well<30°F) Lockout

Water Flow

High Pressure

High Press

Low Pressure / Comfort Alert

Low Press/CA

Not Used

Air Flow

Microprocessor malfunction*

Status

Not Used

DHW Limit

Not Used

DHW off

*Green LED not flashing

14

Current Fault Status

#1 Off, #6 On, #7 On

Not Used

FD thermistor (loop<15°F, well<30°F)

High Pressure

Low Pressure / Comfort Alert

Not Used

Not Used

Not Used

Not Used

Diagnostic Modes

Inputs

#6 Off, #7 On

Y1

Y2

O

Not Used

Not Used

SL1

SL2

Outputs

#6 On, #7 Off

Lo Capacity Compressor

Hi Capacity Compressor

RV

FAN

Not Used

Loop Pump 1

Loop Pump 2

Outpu ts2

#6 Off, #7 Off

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not UsedNot UsedNot Used

Page 15

Wiring Schematics cont.

Dual Capacity Split - 208-230/60/1 cont.

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Notes

1 - Connection of remote unit that does not have a loop pump

for slave operation.

2 - 24V Accessory relay (see SW2 -3 for description of operation)

3 - Field installed DPDT dual fuel relay. (Required for dual fuel

installation)

4 - DHW pump only in models with hot water generation option.

5 - Comfort Alert fault output to Premier Control Board

6 - This Switch allows the unit to down stage with the t-stat

when OFF and finish on second stage when ON. Finish

second stage reduces stage changing in recip dual capacity

compressors and should be ON for unzoned Dual Cap

E-Series or Premier 2 speed units.

Legend

Factory Low voltage wiring

Factory Line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

DC Voltage PCB traces

Internal junction

Quick connect terminal

Wire nut

Field wire lug

L1

Ground

Relay Contacts N.O., N.C.

Fuse

CA CS CC CR1 CR2CR3 CR4 F1 and F2 FD HP LP RV SW1 SW2 SW3 -

P

Comfort Alert

Compressor Solenoid

Compressor Contactor

Not Used

Loop Pump Relay1

Loop Pump Relay2

Not Used

Fuses

Freeze Detection sensor

High Pressure Switch

Low Pressure Switch

Reversing Valve Coil

Not Used

DIP Package 8 Position

DIP Package 5 Position

Crankcase Heater

Thermistor

T

Light Emitting Diode - Green

G

Relay Coil

Capacitor w/ Bleed Resistor

Switch-High Pressure

Switch-Low Pressure

132

Polarized Connector

240V - L1

CR1- DHW

Pump

CC-GND

CC

CCLO

CCHI

P4

1 2 3 4 5 6 7 8

1 2 3

R C Y1 Y2 GOW L

Logic Board - Physical Layout

240V - L1

N.O.

Fused L1

F1

N.O.

CR2- Loop

Pump

Fused L2

CR3-

N.C.

N.O.

Microprocessor

SW1

SW2

OnOff

C

C

R

R

P1

LED Flash Code Desc ription

Green S olid Module Has Power

Red Solid Y1 Present But Compressor Not Running

Yellow

OnOff

1

2

3

4

5

6

7

8

9

10

11

12

Code 1 Long Run Time

Code 2 Sy stem Pressure Trip

Code 3 Short Cyc ling

Code 4 Locked Rotor

Code 5 Open Circuit

Code 6 Open Start Circuit

Code 7 Open Run Circuit

Code 8 W elded Contactor

Code 9 Low Voltage

1

2

3

4

5

6

7

8

2

3 4 5P26 71

Shut

C C

Down

Comfort Alert

Physical Layout

POWER

Y2

Y

Data

Port

L

R

C

DC

Sol

ALERT

TRIP

Comfort Alert Status

Fused L2

Com

SL1INSL1

SW3

Fused L2

Fused L2

240V - L2

240V - L2

F1

N.O.

Com

CR4-

9

1

10

2

11

3

12

4

P6

13

5

14

6

15

7

16

Out

8

9

10

11

12

13

14

P3

1 2 3

ACCNOACCNCACC

8

1

2

3

P5

4

5

6

7

COM

OnOff

1

2

3

4

5

SL2INSL2

Out

97P788-01 4/19/10

15

Page 16

NDS OUTDOOR SPLIT INSTALLATION MANUAL

1 2 3

P4

Thermistor

Light Emitting Diode-Green

Relay Coil

Capacitor w/ Bleed Resistor

Switch - High Pressure

Switch - Low Pressure

Polarized Connector

Factory Low voltage wiring

Factory Line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

DC Voltage PCB traces

Internal junction

Quick connect terminal

Wire nut

Field wire lug

Ground

Fuse

CC -

CR1 -

CR2-

CR3 -

CR4 -

F1 and F2 -

FP -

HP -

LP -

RV -

SW1 -

SW2 -

SW3 -

Compressor Contactor

Loop Pump Relay 1

Fuses

Freeze Detection sensor

High Pressure Switch

Low Pressure Switch

Reversing Valve Coil

Not Used

DIP Package 8 Position

DIP Package 5 Position

Relay Contacts -

N.O., N.C.

G

T

132

P

L1

Loop Pump Relay 2

Not Used

CS -

Compressor Solenoid

Not Used

Legend

Crankcase Heater

CA - Comfort Alert

1 - Connection of remote unit that does not have a loop pump

for slave operation.

2 - 24V Accessory relay (see SW2 -3 for description of operation)

3 - Field installed DPDT dual fuel relay. (Required for dual fuel

installation)

4 - DHW pump only in models with hot water generation option.

5 - Comfort Alert fault output to Premier Control Board

6 - This Switch allows the unit to down stage with the t-stat

when OFF and finish on second stage when ON. Finish

second stage reduces stage changing in recip dual capacity

compressors and should be ON for unzoned Dual Cap E

Series or Premier 2 speed units.

Notes

Run Winding

Active

Start

Common

IntelliStart

2

1

PB2

Red

Blue

Pink

Black

LED Flash Code Desc ription

Green Solid Module Has Power

Red Solid Y1 Present But Compressor Not Running

Code 1 Long Run Time

Code 2 Sys tem Pressure Trip

Code 3 Short Cyc ling

Code 4 Locked Rotor

Code 5 Open Circuit

Code 6 Open Start Circuit

Code 7 Open Run Circuit

Code 8 Welded Contactor

Code 9 Low Voltage

Yellow

Comfort Alert Status

Wiring Schematics cont.

Dual Capacity Split with IntelliStart - 208-230/60/1

Loop Pump(s)

Comfort

Alert

R

C

Y2

Y

Violet (3)

CC

1/2 HP 208-230/60/1

Pump

G

Heat

Recovery

Unit

Yellow (6)

NOTE

1

C

SL1 In

SL1 Out

Optional

Remote Unit

Without

Loop Pump

Pump

L2

L1

Black (5)

White (4)

Violet (2)

Black (1)

CR1

CCHI

CC-GND

P1

R

C

Y1

Y2

W

O

G

LO

P2

Shut

Down

C

SL1 In

SL1 Out

Not

Used

NOTE 2

P3

Acc Com

Acc NC

Acc NO

1 2 3

Gray(9)

Yellow(8)

SW1

CR2

ECM 2

Air Flow

Settings

NO

COM

SW2

On

1

2

3

4

5

6

7

8

9

10

NOT USED

11

12

NO

COM

CC

1

2

3

4

5

6

7

8

1

1

1

2

2

2

3

3

3C

4

5

6

7

1

2

3

P4

Fused L2

NO NC

CR3

On

1

Red (11)

Fused L2

COM

Microprocessor

Logic Control

(DC Voltage)

Test / Norm

2

Loop / Well

3

Fan / Comp

4

Not Used

5

Not Used

6

Inputs / Norm

7

Outputs / Norm

8 Pulse L / Constant L

Unit Power

208-230/60/1

G

FP

Crankcase Heater

Black B lack

NO NC

CR4

Black (7)

SW3

On

Dual/ Single Capacity

1

Normal/Finish on 2

2

No RPM / RPM

3

Must be On

4

Envision / E Series or Premier

5

Blue

Comfort Alert

Run

Capacitor

Red (12)

Green/Yellow

F1-10A 240V

COM

nd

NOTE 6

240V L2

Fused L1

Tan (16)

Orange (14)

S

R

CC

T2

L2 L1

C

Brown (15)

240V L1

P6

8

13

7

4

5

14

12

6

15

10

9

2

1

3

11

16

P5

11

4

9

2

10

3

8

1

12

5

13

6

7

14

Black

DC SOL

CS

+

-

Red

T1

F1-10A 240V

R

C

NOT USED

NOTE 5

Tan

Orange

Orange

Not Used

Not Used

Not Used

Not Used

Yellow

Yellow

Blue

Blue

Black

Black

Comfort A lert

L

RV

T

LP

HP

FD

Status LED PCB

SW4

R

R

R

R

R

G

Y

R

LED Normal Display Mode

Field Selection Dips -#1 On, #6 On, #7 On

Drain

Not Used

Water Flow

FD thermistor (loop<15°F,well<30°F) Lockout

High Press

High Pressure

Low Press/CA

Low Pressure / Comfort Alert

Air Flow

Not Used

Status

Microprocessor malfunction*

DHW Limit

Not Used

DHW off

Not Used

*Green LED not flashing

Current Fault Status

#1 Off, #6 On, #7 On

Not Used

FD thermistor (loop<15°F, well<30°F)

High Pressure

Low Pressure / Comfort Alert

Not Used

Not Used

Not Used

Not Used

16

Diagnostic Modes

Inpu ts

#6 Off, #7 On

Y1

Y2

O

Not Used

Not Used

SL1

SL2

Outpu ts

#6 On, #7 Off

Lo Capacity Compressor

Hi Capacity Compressor

RV

FAN

Not Used

Loop Pump 1

Loop Pump 2

Outpu ts2

#6 Off, #7 Off

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not UsedNot UsedNot Used

Page 17

Wiring Schematics cont.

Dual Capacity Split with IntelliStart - 208-230/60/1 cont.

NDS OUTDOOR SPLIT INSTALLATION MANUAL

PB2

2

1

Pink

Blue

Black

Red

Run Winding

Active

Start

Common

Legend

Factory Low voltage wiring

Factory Line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

DC Voltage PCB traces

Internal junction

Quick connect terminal

Wire nut

L1

Field wire lug

Ground

Relay Contacts N.O., N.C.

Fuse

CA - Comfort Alert

CS CC CR1 CR2CR3 CR4 F1 and F2 FP -

HP LP RV SW1 SW2 SW3 -

P

Compressor Solenoid

Compressor Contactor

Not Used

Loop Pump Relay 1

Loop Pump Relay 2

Not Used

Fuses

Freeze Detection sensor

High Pressure Switch

Low Pressure Switch

Reversing Valve Coil

Not Used

DIP Package 8 Position

DIP Package 5 Position

Crankcase Heater

Thermistor

T

Light Emitting Diode-Green

G

Relay Coil

Capacitor w/ Bleed Resistor

Switch - High Pressure

Switch - Low Pressure

132

Polarized Connector

IntelliStart

240V - L1

CR1- DHW

Pump

CC-GND

CC

CCLO

CCHI

P4

1 2 3 4 5 6 7 8

1 2 3

R C Y1 Y2 GOW L

Logic Board - Physical Layout

240V - L1

N.O.

Fused L1

F1

N.O.

CR2- Loop

Pump

Fused L2

CR3-

N.C.

N.O.

Microprocessor

SW1

SW2

OnOff

C

C

R

R

P1

LED Flash Code Desc ription

Green Solid Module Has Power

Red Solid Y1 Present But Compressor Not Running

Yellow

OnOff

1

2

3

4

5

6

7

8

9

10

11

12

Code 1 Long Run Time

Code 2 Sys tem Pressure Trip

Code 3 Short Cyc ling

Code 4 Locked Rotor

Code 5 Open Circuit

Code 6 Open Start Circuit

Code 7 Open Run Circuit

Code 8 Welded Contactor

Code 9 Low Voltage

1

2

3

4

5

6

7

8

2

3 4 5P26 71

Shut

SL1INSL1

C C

Down

Comfort Alert

Physical Layout

POWER

Y2

Y

Data

Port

L

R

C

DC

Sol

ALERT

TRIP

Comfort Alert Status

240V - L2

Fused L2

Fused L2

Fused L2

240V - L2

F1

N.O.

Com

Com

CR4-

9

1

10

2

11

3

12

4

P6

13

5

14

6

15

Out

16

8

9

10

11

12

13

14

P3

1 2 3

ACCNOACCNCACC

7

8

1

2

3

P5

4

5

6

7

COM

SW3

OnOff

1

2

3

4

5

SL2INSL2

Out

Notes

1 - Connection of remote unit that does not have a loop pump

for slave operation.

2 - 24V Accessory relay (see SW2 -3 for description of operation)

3 - Field installed DPDT dual fuel relay. (Required for dual fuel

installation)

4 - DHW pump only in models with hot water generation option.

5 - Comfort Alert fault output to Premier Control Board

6 - This Switch allows the unit to down stage with the t-stat

when OFF and finish on second stage when ON. Finish

second stage reduces stage changing in recip dual capacity

compressors and should be ON for unzoned Dual Cap E

Series or Premier 2 speed units.

97P788-02 4/19/10

17

Page 18

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Microprocessor Control

Startup

The unit will not operate until all the inputs and safety

controls are checked for normal conditions. At first powerup, a four-minute delay is employed before the compressor

is energized.

Component Sequencing Delays

Components are sequenced and delayed for optimum

space conditioning performance.

Accessory Relay

An accessory relay on the control board allows for field

connection of solenoid valves, electronic air cleaners, etc.

The accessory relay has a normally open output and a

normally closed output.

Short Cycle Protection

The control employs a minimum “off” time of four minutes

to provide for short cycle protection of the compressor.

Shutdown Mode

A 24VAC common signal to the “shutdown” input on

the control board puts the unit into shutdown mode.

Compressor and blower operation are suspended.

Heating Operation

Heat, 1st Stage (Y1)

The blower motor is started on low speed immediately

(PSC ON), the loop pump is energized 5 seconds after the

“Y1” input is received, and the compressor is energized on

low capacity 10 seconds after the “Y1” input. The blower

is switched to medium speed 15 seconds after “Y1” input

(ECM only).

Heat, 2nd Stage (Y1,Y2) Dual Capacity Units

The second stage compressor will be activated 5 seconds

after receiving a “Y2” input as long as the minimum first

stage compressor run time of 1 minute has expired. The

ECM blower changes from medium to high speed 15

seconds after the “Y2” input.

The Comfort Alert will delay the second stage compressor

until 5 seconds after it receives a “Y2” from the board.

Heat, 3rd Stage (Y1,Y2,W) Dual Capacity Units

The 1st stage of resistance heat is energized 10 seconds

after “W” input, and with continuous 3rd stage demand,

the additional stages of resistance heat engage 90 seconds

after the first stage.

Safety Controls

The Envision control receives separate signals for a high

pressure switch for safety, a low pressure switch to prevent

loss of charge damage, and a low suction temperature

thermistor for freeze detection. Upon a continuous

30-second measurement of the fault (immediate for

high pressure), compressor operation is suspended, the

appropriate lockout LED begins flashing. (Refer to the

“Fault Retry” section below.)

Testing

The Envision control allows service personnel to shorten

most timing delays for faster diagnostics. (Refer to the

Field Selection DIP switch table.)

Fault Retry

All faults are retried twice before finally locking the unit

out. An output signal is made available for a fault LED at

the thermostat. The “fault retry” feature is designed to

prevent nuisance service calls.

Diagnostics

The Envision control board allows all inputs and outputs to

be displayed on the LEDs for fast and simple control board

diagnosis. (Refer to the Field Selection DIP Switch SW2-1

table.)

Emergency Heat (W only)

The blower is started on high speed, and the first stage of

resistance heat is energized 10 seconds after the “W” input.

Continuing demand will engage the additional stages of

resistance heat 90 seconds after the first stage.

Cooling Operation

In all cooling operations, the reversing valve directly

tracks the “O” input. Thus, anytime the “O” input is

present, the reversing valve will be energized.

Cool, 1st Stage (Y1,O)

The blower motor is started immediately, the loop pump(s)

is energized 5 seconds after the “Y1” input is received.

The compressor will be energized (on low capacity for

Dual Capacity units) 10 seconds after the “Y1” input.

The ECM blower will shift from low to medium speed 15

seconds after the “Y1” input (85% of medium speed if in

dehumidification mode).

Cool, 2nd Stage (Y1, Y2, O) Single Speed Units

The blower changes to high speed (85% of high speed if

in dehumidification mode) 15 seconds after the “Y2” input

(ECM only).

18

Page 19

Microprocessor Control cont.

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Cool, 2nd Stage (Y1, Y2, O) Dual Capacity Units

The second stage compressor will be activated 5 seconds

after receiving a “Y2” input as long as the minimum first

stage compressor run time of 1 minute has expired. The

ECM blower changes to high speed 15 seconds after the

“Y2” input (85% of high speed if in dehumidification mode).

The Comfort Alert will delay the second stage compressor

until 5 seconds after it receives a “Y2” from the board.

Blower (G only)

The blower starts on low speed (PSC ON). Regardless of

blower input “G” from thermostat, the blower will remain

on low speed for 30 seconds at the end of each heating,

cooling or emergency heat cycle.

Lockout Conditions

During lockout mode, the appropriate unit and thermostat

lockout LEDs will illuminate. The compressor, loop pump,

and accessory outputs are de-energized. The blower will

continue to run on low speed. If the thermostat calls for

heating, emergency heat operation will occur.

Comfort Alert lockouts cannot be reset at the thermostat.

All other lockout modes can be reset at the thermostat

after turning the unit off, then on, which restores normal

operation but keeps the unit lockout LED illuminated.

Interruption of power to the unit will reset a lockout

without a waiting period and clear all lockout LEDs.

High Pressure

This lockout mode occurs when the normally closed safety

switch is opened momentarily (set at 600 PSI).

Low Pressure

This lockout mode occurs when the normally closed low

pressure switch is opened for 30 continuous seconds (set

at 40 PSI). A low pressure fault may also be indicated when

a Comfort Alert lockout has occurred.

Freeze Detection (Water Flow)

This lockout mode occurs when the freeze detection

thermistor temperature is at or below the selected point

(well 30°F or loop 15°F) for 30 continuous seconds.

19

Page 20

NDS OUTDOOR SPLIT INSTALLATION MANUAL

* Reset ALERT flash code by removing 24 VAC power from module.

Microprocessor Control cont.

Compressor Monitoring/Comfort Alert

The Comfort Alert displays abnormal compressor

conditions through a unique flash code and communicates

the conditions to the heat pump microprocessor control.

The heat pump microprocessor will determine which fault

to act on and ignore. Fault codes 2 (system pressure),

4 (locked rotor), 6 (open start circuit), and 7 (open run

circuit) will result in a lockout. All other fault codes are

passive. All compressor alerts are displayed on the module

by flashing the yellow Alert LED a specific number of times

consecutively followed by a pause, and then repeated. The

number of consecutive flashes or “Flash Code” correlates

to a specific abnormal condition. The red “TRIP” LED

means there is a thermostat demand signal “Y” present but

the compressor is not running. The green “POWER” LED

means the module has power.

Green "POWER" LED - module has power

Red "TRIP" LED - Thermostat "Y" demand signal is present, but the compressor is not running.

Comfort Alert Flash Codes

Yellow "ALERT" LED LED Description Cause

Flash Code 1 Long Run Time Not applicable

Flash Code 2 System Pressure Trip Not applicable

Flash Code 3 Short Cycling Compressor run time of less than 3 minutes on 4 consecutive cycles

Flash Code 4 Locked Rotor Four consecutive compressor protector trips indicating compressor won't start

Flash Code 5 Open Circuit "Y" thermostat demand signal with no compressor current

Flash Code 6 Open Start Circuit "Y" thermostat demand signal with no current in the start circuit

Flash Code 7 Open Run Circuit "Y" thermostat demand signal with no current in the run circuit

Flash Code 8 Welded Contactor Current detected with no "Y" thermostat demand signal present

Flash Code 9 Low Voltage Less than 17 VAC detected in control circuit

* Flash code number corresponds to a number of LED flashes, followed by a pause and then repeated.

* TRIP and ALERT LEDs flashing at the same time indicates control circuit voltage is too low for operation.

* Reset ALERT flash code by removing 24 VAC power from module.

* Last ALERT flash code is displayed for 1 minute after module is powered on.

Resetting Comfort Alert Codes

Alert codes can be reset manually by cycling power off and on to the Comfort Alert module. Alert codes will reset automatically if

conditions return to normal.

Flash Code Number LED Description Automatic Reset of Alert Codes

Flash Code 1 Long Run Time Not applicable

Flash Code 2 System Pressure Trip Not applicable

Flash Code 3 Short Cycling Four "alert free" on and off cycles to reset automatically

Flash Code 4 Locked Rotor Four "alert free" on and off cycles to reset automatically

Flash Code 5 Open Circuit One "alert free" on and off cycles to reset automatically

Flash Code 6 Open Start Circuit One "alert free" on and off cycles to reset automatically

Flash Code 7 Open Run Circuit One "alert free" on and off cycles to reset automatically

Flash Code 8 Welded Contactor One "alert free" on and off cycles to reset automatically

Flash Code 9 Low Voltage Resets when voltage rises above 19 VAC

20

Page 21

Microprocessor Control cont.

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Thermostat Displays

Fault Flash

When using a TA32W02 or TP32W03 thermostat and

SW2-8 is in the pulsing “L” position, FaultFlash will enable

a user to view the thermostat and count the fault indicator

flashes to determine the lockout condition the unit is

experiencing.

user to view the thermostat and determine the fault. The

thermostat can be configured to show either lockout text

or lockout codes.

The LED board on the front of the unit will display all

lockouts. The Low Pressure LED will flash for a low pressure

condition or a Comfort Alert fault. If the low pressure

lockout was caused by Comfort Alert codes 4, 6 or 7, then

the Comfort Alert will be flashing. If no Comfort Alert code

ComforTalk

is visible, then it is a low pressure lockout.

When using a TP32U03, 04 or 05 thermostat and SW2-8

is in the pulsing “L” position, ComforTalk will enable the

The following tables show the codes that will be displayed on the different ComforTalk and FaultFlash thermostats.

FaultFlash Thermostats ComforTalk Thermostats

TA32W02 and TP32W03 Thermostats TP32U03, TP32U04 and TP32U05 Thermostats

Thermostat Display

Lockout Code

Lockout Description Lockout Description

2 Flashes High Pressure Fault "High Pressure" or "E2" High Pressure Fault

3 Flashes Low Pressure Fault "Low Pressure" or "E3" Low Pressure Fault

4 Flashes Not Applicable "E4" Not Applicable

5 Flashes Water Flow Fault "Water Flow" or "E5" Water Flow Fault

6 Flashes Not Applicable "E6" Not Applicable

7 Flashes Condensate Fault "Condensate" or "E7" Condensate Fault

8 Flashes Voltage out of Range "Voltage Range" or "E8" Voltage out of Range

9 Flashes RPM Fault "RPM" or "E9" RPM Fault

10 Flashes

Lockout code 10 - see Comfort Alert module to determine the specific flash code for

compressor abnormalities.

Comfort Alert Compressor

Module Fault

Thermostat Display

Lockout Code

"Comfort Alert" or "E10"

These thermostats can be configured to display the lockout condition "text" or error number.

* A slow flash of 1 second on and off means the heat pump microprocessor SW2-1 is configured

for "Test Mode" or thermostat is miswired.

Lockout code 10 - see Comfort Alert module to determine the specific flash code for

compressor abnormalities.

Comfort Alert Compressor

Module Fault

21

Page 22

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Operation Logic Data

OPER ATION LOGIC

Compressor-Lo

Compressor-Hi

Rev Valve

Loop Pu mps

Secondary 1 - Out

Secondary 2- Out

Emerg LED

T-Stat Signal

STG1 STG2 STG3 EMERG STG1 STG2

On Off Off Off On Off -

Off On On Off Off On -

Off Off Off Off On On -

On On On Off On On On

On On On Off On On -

Off On On Off Off On -

Off Off Off On Off Off -

Y1 Y 1, Y2 Y1, Y2, W W Y1, O Y1 , Y2, O -

HE ATIN G COOLING

DUAL CAPACIT Y UNITS

DIP Switch Settings

DIP SWITCH

NUMBER

SW1 N /A NOT USE D N/A N/A

Service/Test Mode - Allows control of “NORM” or “TEST” operational

modes. Test mode accelerates most timing functions 16 times to allow

1

faster troubleshooting. Test mode also allows viewing the “CURRENT”

status of the fault inputs on the LED display.

Freeze Detection Setting

2

This DIP allows field selection of freeze detection fault sensing for well

water (30°F) or anti-freeze protected earth loops (15°F).

Accessory Relay

3

Allows field selection of the accessory relay to operate with the compressor

SW2

SW3

or blower.

4 NOT USED N/A N /A

5 NOT USED N /A N /A

Input Diagnostics - Allows viewing the inputs from the thermostat to the

6

control board such as Y1, Y2, O, G, W, SL1-In on the LED display.

Output Diagnostics - Allows viewing the outputs from the control board

7

such as the compressor, reversing valve, blower, and loop pump on the LED

display.

Thermostat Selection

Configures the control for a pulsed lockout signal (ComforTalk and

8

FaultFlash thermostats) or continuous 5 VAC lockout signal.

1 Single or Dual Capacity Operation Dual Cap 1 Speed

Zoned/Finish on Second Stage

This switch allows the unit to down stage with the thermostat when off and

2

finish with second stage when on. Finish on second stage reduces stage

changing in reciprocating dual capacity compressors.

3 ECM Blower Monitoring - Set for No PRM on split systems No RPM RPM

4 NOT USED N/A N/A

On dual capacity units this switch allows stage change: on the fly when off,

5

and 1 minute delay when on. A delay is required on all reciprocating dual

capacity units.

DESCRIPTION OFF POSITION ON POSITION

Te s t Norm

Loop

(Sensing 15° F)

Blower Comp

Diagnostic Inputs

viewed at LEDs

Diagnostic

Outputs viewed at

LEDs

Pulsed “L”

signal

Normal -

All other systems

Envision E-Series or Premier

Normal Display

viewed at LEDs

Display viewed

SL1 - IN ON

Well

(Sensing 30° F)

Normal

at LEDs

Continuous “L”

signal

Finish on 2nd

Unzoned Dual

Capacity

E-Series or

Premier 2 speed

22

Page 23

Refrigeration

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Leak Testing

The refrigeration line set must be pressurized and

checked for leaks before purging and charging the unit.

To pressurize the line set, attach refrigerant gauges to the

service ports and add an inert gas (nitrogen or dry carbon

dioxide) until pressure reaches 60 to 90 PSIG. Never use

oxygen or acetylene to pressure test. Use an electronic leak

detector or a good quality bubble solution to detect leaks

on all connections made in the field. Check the service

valve ports and stem for leaks and all connections made in

the field. If a leak is found, repair it and repeat the above

steps. For safety reasons do not pressurize the system

above 150 psi. Purge pressure from line set. The system is

now ready for evacuating and charging.

System Evacuation

Ensure that the line set and air coil are evacuated before

opening service valves to the split unit. The line set must be

evacuated to at least 200 microns to remove the moisture

and air that may still be in the line set and coil. Evacuate

the system through both service ports to prevent false

readings on the gauge because of pressure drop through

service ports.

Charge Amount When Using NAH Air Handler

The Envision Split is shipped with a facotry pre-charge. This

volume of refrigerant is not sufficient to run the system and

additional refrigerant must be added. If using an NAH Air

Handler please refer to the table in this section for charge

amounts to be added. The “Factory Charge” column is the

charge amount the compressor section/split is shipped

with from the factory. The “Charge Amount with NAH Air

Handler” column is the total amount of charge for the NAH

Air Handler + Compressor section/split. This column does

not factor in additional refrigerant needed for the line set.

The installer of the system must add charge appropriately

for the specific length of the line set. A 3/8 in. liquid line is

calculated at 0.50 oz. of charge per linear foot, and a 1/2

in. liquid line is calculated at 1.0 oz. of charge per linear

foot using R-410A refrigerant. The suction line will not hold

“liquid” and should be ignored for the charge calculation.

Example: NDS036/NAH036 with 20 ft. of 3/8 in. liquid

line. Remember that when using the NAH

Air Handler, the column “Charge Amount

with NAH Air Handler” will be used. Now

calculate for the additional 20 ft. ineset.

Additional refrigerant to be added = (20 ft. x 0.5 oz.)

= 10 oz.

Solution: 10 oz. should be added to the recommended

charge of 86 oz. found in the “Charge Amount

with NAH Air Handler” column for a total charge

of 96 oz.

After initial charge, the system should be operated and

the system subcooling and superheat verified to the Unit

Operating Parameters table.

If an air handler manufactured by others is used then

refrigerant should be added to the Envision Split factory

pre-charge. Refrigerant should be added for liquid line

length. This should result in a slightly under-charged

system exhibiting low subcooling and high superheat.

As charge is added, the subcooling should rise and the

superheat should fall.

Charging the System

Charge Method – After purging and evacuating the line set,

fully open the service valves counterclockwise. Add R-410A

(liquid) into the liquid line service port until the pressure

in the system reaches approximately 200 PSIG. Never add

liquid refrigerant into the suction side of a compressor.

Start the unit and measure superheat and subcooling. Keep

adding refrigerant until the unit meets the superheat and

subcooling values in the Operating Parameters tables.

Checking Superheat and Subcooling

Determining Superheat

1. Measure the temperature of the suction line at the

point where the expansion valve bulb is clamped.

2. Determine the suction pressure in the suction line

by attaching refrigeration gauges to the schrader

connection on the suction side of the compressor.

3. Convert the pressure obtained in Step 2 to the

saturation temperature by using the Pressure

Temperature Conversion Chart for R-410A.

4. Subtract the temperature obtained in Step 3 from

Step 1. The difference is the amount of superheat for

the unit. Refer to the Operating Parameters tables for

superheat ranges at specific entering water conditions.

Superheat Adjustment

TXVs are factory set to a specific superheat; however, the

superheat should be adjusted for the application. To adjust

the TXV to other superheat settings:

1. Remove the seal cap from the bottom of the valve.

2. Turn the adjustment screw clockwise to increase

superheat and counterclockwise to decrease

superheat. One complete 360° turn changes the

superheat approximately 3-4°F, regardless of

refrigerant type. You may need to allow as much as 30

minutes after the adjustment is made for the system to

stabilize.

3. Once the proper superheat setting has been achieved,

replace and tighten the seal cap.

WARNING: There are 8 total (360°) turns on the superheat

adjustment stem from wide open to fully closed. When

23

Page 24

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Refrigeration cont.

adjusting the superheat stem clockwise (superheat

increase) and the stop is reached, any further clockwise

turning adjustment will damage the valve.

Determining Subcooling

1. Measure the temperature of the liquid line on the

small refrigerant line (liquid line) just outside the

split cabinet. This location will be adequate for

measurement in both modes unless a significant

temperature drop in the liquid line is anticipated.

2. Measure the liquid line pressure by attaching

refrigerant gauges to the schrader connection on the

liquid line service valve.

3. Convert the pressure obtained in Step 2 to the

saturation temperature by using the Pressure

Temperature Conversion Chart for R-410A.

4. Subtract the temperature in Step 1 from the

temperature in Step 3. The difference will be the

subcooling value for that unit. Refer to the Operating

Parameters tables for subcooling ranges at specific

enter water conditions.

Line Set Sizes

20 feet 40 feet 60 feet

Unit

Size

026 NAH026 5/8” OD 3/8” OD 3/4” OD 3/8” OD 3/4” OD 1/2” OD 52 74

038 NAH036 3/4” OD 3/8” OD 3/4” OD 3/8” OD 3/4” OD 1/2” OD 56 86

049 NAH048 3/4” OD 3/8” OD 7/8” OD 3/8” OD 7/8” OD 1/2” OD 90 115

064 NAH060 7/8” OD 1/2” OD 7/8” OD 1/2” OD 1-1/8” OD 1/2” OD 92 112

072 NAH060 7/8” OD 1/2” OD 7/8” OD 1/2” OD 1-1/8” OD 1/2” OD 104 132

NOTES: * The “Charge Amount with NAH Air Handler” column is based on the charge amount for an NAH Air Handler +

Compressor Section Split.

Additional charge will have to be added accordingly for line set length.

After charge is added, adjustments can be made to get appropriate subcooling and superheat.

Additional charge for R-410A is 0.50 oz. per ft. for 3/8 in. and 1.0 oz. per ft. for 1/2 in. tube.

Air

Handler

Suction Liquid Suction Liquid Suction Liquid

Factory

Charge (oz.)

*Charge

Amount

with NAH

Air Handler

(oz.)

4/16/10

24

Page 25

NDS OUTDOOR SPLIT INSTALLATION MANUAL

Pressure/Temperature Coversion Chart for R-410A

PRESSURE

(PSIG)

60 8.5 180 63.5 300 96.3 420 120.6 540 140.0

62 9.9 182 64.2 302 96.8 422 120.9 542 140.3

64 11.2 184 64.8 304 97. 2 424 121.3 544 140.6

66 12.5 186 65.5 306 97. 7 426 121.6 546 140.9

68 13.8 188 66.1 308 98.1 428 122.0 548 141.2

70 15.1 190 66.8 310 98.6 430 122.3 550 141.4

72 16.3 192 6 7. 4 312 99.0 432 122.7 552 141.7

74 17.5 194 68.0 314 99.5 434 123.0 554 142.0

76 18.7 196 68.7 316 99.9 436 123.4 556 142.3

78 19.8 198 69.3 318 100.4 438 123.7 558 142.6

80 21.0 200 69.9 320 100.8 440 124.1 560 142.9

82 22.1 202 70.5 322 101.2 442 124.4 562 143.2

84 23.2 204 71.1 324 101.7 444 124.8 564 143.5

86 24.3 206 71.7 326 102.1 446 125.1 566 143.7

88 25.4 208 72.3 328 102.5 448 125.4 568 144.0

90 26.5 210 72.9 330 103.0 450 125.8 570 144.3

92 2 7.5 212 73.5 332 103.4 452 126.1 572 144.6

94 28.6 214 74. 1 334 103.8 454 126.5 574 144.9

96 29.6 216 74 .7 336 104.2 456 126.8 576 145.1

98 30.6 218 75.3 338 104.7 458 127.1 578 145.4

100 31.6 220 75.8 340 105.1 460 127.5 580 145.7

102 32.6 222 76.4 342 105.5 462 127.8 582 146.0

104 33.5 224 77. 0 344 105.9 464 128.1 584 146.2

106 34.5 226 77.5 346 106.3 466 128.5 586 146.5

108 35.4 228 78 .1 348 106.7 468 128.8 588 146.8

110 36.4 230 78.7 350 107.2 470 129.1 590 1 47.1

112 37. 3 232 79.2 352 107.6 472 129.4 592 147.3

114 38.2 234 79.8 354 108.0 474 129.8 594 147.6

116 39 .1 236 80.3 356 108.4 476 130.1 596 147.9

118 40.0 238 80.9 358 108.8 478 130.4 598 148.2

120 40.9 240 81.4 360 109.2 480 130.7 600 148.4

122 41.7 242 81.9 362 109.6 482 131.1 602 148.7

124 42.6 244 82.5 364 110.0 484 131.4 604 149.0

126 43.4 246 83.0 366 110.4 486 131.7 606 149.2

128 44.3 248 83.5 368 110.8 488 132.0

130 45.1 250 84.1 370 111.2 490 132.3

132 45.9 252 84.6 372 111.6 492 132.7

134 46.7 254 85.1

136 4 7.5 256 85.6 376 112.3 496 133.3

138 48.3 258 86.1 378 112.7 498 133.6

140 49.1 260 86.6 380 113.1 500 133.9

142 49.9 262 8 7.1 382 113.5 502 134.2

144 50.7 264 87.7 384 113.9 504 134.5

146 51.5 266 88.2 386 114.3 506 134.9

148 52.2 268 88.7 388 114.7 508 135.2

150 53.0 270 89.2 390 115.0 510 135.5

152 53.7 272 89.6 392 115.4 512 135.8

154 54.5 274 90.1 394 115.8 514 136.1

156 55.2 276 90.6 396 116.2 516 136.4

158 55.9 278 91.1 398 116.5 518 136.7

160 56.6 280 91.6 400 116.9 520 13 7.0

162 5 7. 4 282 9 2.1 402 117.3 522 137.3

164 58.1 284 92.6 404 117.6 524 137.6

166 58.8 286 93.0 406 118.0 526 137.9

168 59.5 288 93.5 408 118.4 528 138.2

170 60.2 290 94.0 410 118.7 530 138.5

172 60.8 292 94.5 412 119.1 532 138.8

174 61.5 294 94.9 414 119.5 534 139.1

176 62.2 296 95.4 416 119.8 536 139.4

178 62.9 298 95.8 418 120.2 538 139.7

TEMP

°F

PRESSURE

(PSIG)

TEMP

°F

PRESSURE

(PSIG)

374 112.0 494 133.0

TEMP

°F

PRESSURE

(PSIG)