POWER-170 & 250

Installation and Wiring

Instructions

Installation and Wiring

Instructions

POWER-170 & 250 CENTRIFUGAL EXTRACTOR FANS

Suitable for kitchen applications

Thank you for placing your confidence in EnviroVent by buying this product. It

has been manufactured in accordance with current technical safety regulations,

production and quality standards as laid down by the international Quality

Standard ISO 9001. Please read this instruction booklet carefully before installing

or operating the product. It contains important information on personal and user

safety measures to be followed whilst installing, using and carrying out

maintenance work on the equipment. Once the product has been installed, please

pass this booklet to the end user.

Check that the product is in perfect condition while unpacking. Any fault or

damage caused in origin is covered by the EnviroVent guarantee. Please make

sure that the product corresponds to the one you have ordered and that the

details on the instruction label fulfil your requirements.

IMPORTANT:

BE SURE TO HAVE READ AND UNDERSTOOD THESE INSTRUCTIONS BEFORE

BEGINNING THE INSTALLATION PROCESS

SAFETY AND RECOMMENDATIONS:

SITING A POWER 170 OR 250

All wiring must comply with Building Regulations and the current I.E.E. Wiring

Regulations (BS7671) or the equivalent standards for your country. The final

installation should be examined and tested by a competent person.

Do not install near sources of heat in excess of 40°C.

Do not site fan near obstacles which can obstruct airflow.

Position away from any source of water spray. Do not site in a shower enclosure.

Ducted Applications. In circumstances where an excessive amount of moisture is

present in the air, then a condensation trap will need to be installed in the exhaust

duct. Horizontal ducts should fall away from the fan unit. Ducts passing

through an unheated roof void should be insulated.

POWER-250 HP & POWER-170 HP. These fans are fitted with automatic

electronic humidity sensors. They should ideally be mounted on an inside wall

between the major moisture source and the door to the other rooms of the building.

Do not site closer than 100mm to cupboards, etc. Do not site above a radiator or

other heat source. We recommend the HP models are mounted as shown in Fig.

2.1.

INSTALLATION: POWER

–

170 & 250

Fig. 1

Fig. 3

Fig. 3

Fig. 2

Fig. 4

Fig. 5

Fig. 6

Fig. 7

FAN

Fig. 8

Fig. 9

FAN

FAN

Fig. 10

%RH

%RH

ref.9019012300

ref.9019012300

POWER-170 & 250 CENTRIFUGAL EXTRACTOR FANS

Suitable for kitchen applications

DESCRIPTION

Suitable for both ceiling and wall installation, the POWER fans may be adapted to an

individual duct or to a communal ventilation system (Fig. 1).

The discharge port, situated at the side on the back of the extractor housing, enables it

to be installed anywhere on the wall or ceiling, even in inaccessible corners (Figs.2 & 3).

NOTE: Pullcord models DP and HP should be mounted as shown in Fig.2.1 If NOT

mounted as Fig.2.1, a support (not supplied ) must guide the pullcord so that it does not

rub the fan body. The pullcord (if used) MUST be easy to operate.

INSTALLATION

IMPORTANT: ENSURE THAT THE MAINS SUPPLY IS SWITCHED OFF BEFORE

MAKING ELECTRICAL CONNECTIONS.

- Making use of the template enclosed, make a 100mm diameter round hole in the wall or

ceiling.

NOTE: A 115mm dia. hole is required if a wall sleeve is utilised.

- Drill the holes for the screws and insert the respective plugs in them. Take the extractor fan

and withdraw the grille by pressing on the shoulders at the bottom (Fig.4).

- Remove retaining screw and lift off the terminal box cover (Fig.5).

-The installation may be made with the cable flush fitted by piercing either of the two notches

provided for this (Fig.6.1), or else with surface wiring, using the side cable inlet (Fig.6.2).

- Insert some 150mm of cable into the extractor housing and pass it through the cable

clamp.

- Fix the extractor to the wall. Arrange the foam rubber provided, around the discharge port

so that it fits closely to the duct. Secure the extractor housing to the wall by inserting and

tightening its screws.

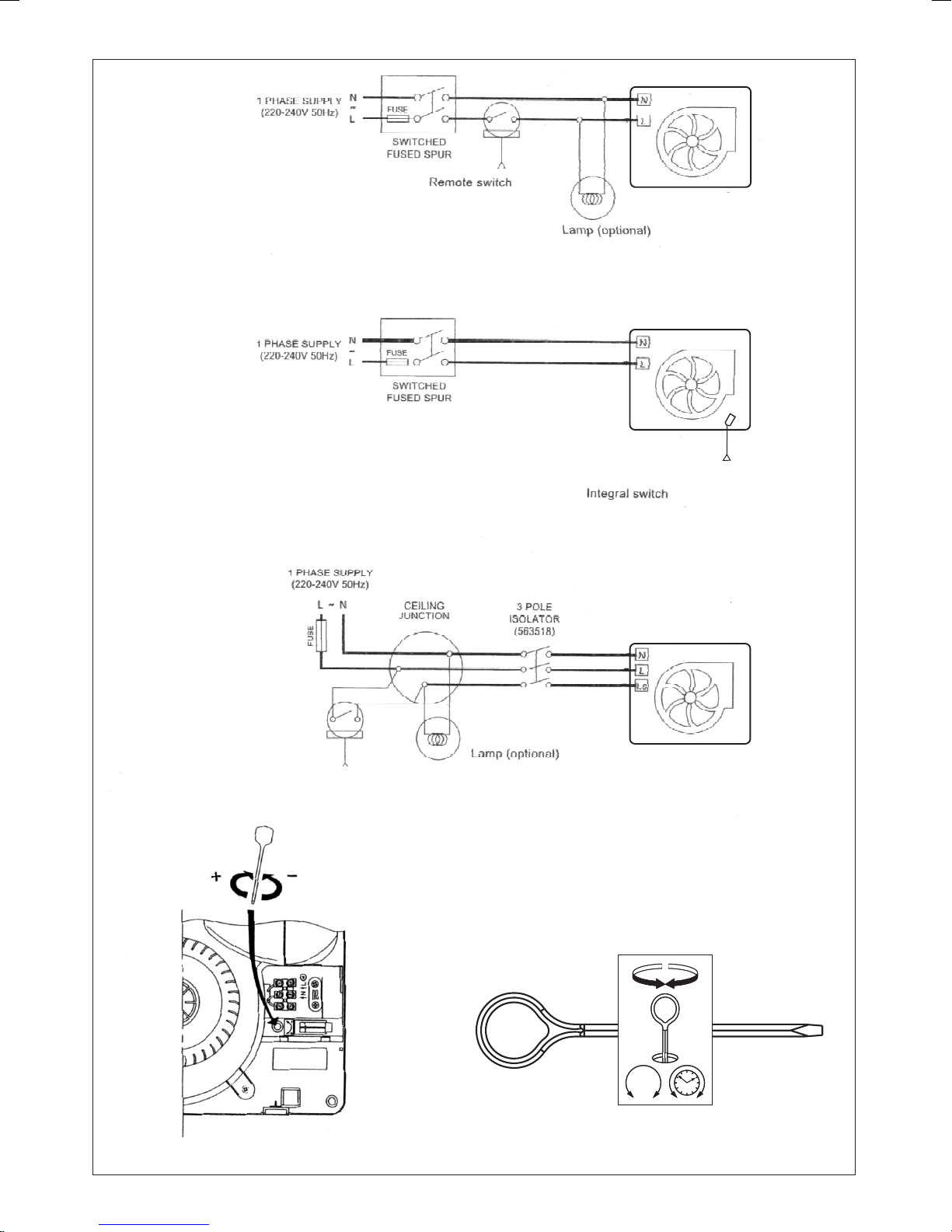

WIRING

WARNING: This fan MUST NOT be earthed. It is double insulated. This fan MUST be

connected to a 220-240V 50Hz AC single phase mains supply.

There must be a double pole isolator in the installation with a contact separation of at least

3mm.

Connections depend upon the model of POWER fan being installed and the required mode

of operation.

Ensure that the mains supply is SWITCHED OFF before starting any wiring.

POWER 170 S AND 250 S

Single speed fan. Controlled by remote switch (e.g. light switch or Auto -Sensor), Fig.7.

The neon indicator is lit when the fan is running.

POWER 170 P2S AND 250 P2S

Dual speed and OFF. Low speed running for permanent “trickle” ventilation / High speed

override / OFF, controlled by integral pullcord switch, Fig.8. Pullcord switch sequence –

OFF, LOW, HIGH. The neon indicator is lit when the fan is running.

The POWER 250 P2S only, may alternatively be connected for remote switching. The

remote switch (e.g. light switch) will switch between permanent LOW speed “trickle”

ventilation an HIGH speed override. There is no OFF position with remote switching. Use

Fig.9 for wiring to a remote switch, when the integral pullcord switch must be set for LOW

speed and the pullcord cut off close to the fan.

POWER 170 HP AND 170HP

The fan contains an integral humidity sensor. In automatic mode the control switches the

fan on at LOW speed when the room Relative Humidity (RH) reaches the set-point. The

fan will continue to run until the room RH falls below the set-point. To prevent night time

tripping the humidity sensing is inactive below 10ºC.

The integral pullcord or a remote switch (e.g. light switch) will switch between automatic

humidity control and manual override at HIGH speed. The Light Emitting Diode (LED)

indicator will be lit for manual override. The LED will NOT light under automatic humidity

control, even if the fan is running. There is no permanent OFF position.

Use Fig.8 for wiring the manual override by the integral pullcord. Use Fig.9 for wiring the

manual override to a remote switch, when the pullcord must be switched to the automatic

position (LED off) and the cord cut off close to the fan.

The humidity control is factory set to switch on at about 72% RH.

To LOWER the set-point use a small screwdriver to turn the adjuster ANTI-CLOCKWISE,

Fig.10. This makes the controller MORE sensitive to RH, i.e. it will come on at a lower

RH.

To RAISE the set -point use a small screwdriver to turn the adjuster CLOCKWISE, Fig 10.

This makes the controller LESS sensitive to RH, i.e. it will come on at a higher RH.

NOTES: 1. Upon installation it is possible that the humidity control will make the fan run

continuously until it has acclimatized to the environment.

2. The fan uses a „soft start feature i.e. the motor will take several seconds to

reach speed.

POWER 170 T AND 250 T

Single speed with overrun timer. The fan must be wired to a remote switch (e.g. light

switch),Fig.9. When switched “ON”, the fan will operate at full speed, and will continue to

run for a pre-set time after the switch is turned “OFF”. The timer is factory set at 20

minutes. To reduce the operating time, turn the adjuster in an anti -clockwise direction,

Fig.10. The neon indicator is lit when the fan is running.

After wiring is completed, replace terminal block cover and grille. Turn on mains

supply and check operation.

N.B. If used in a lighting circuit, for reliable operation, we recommend a

tungsten filament lamp. The manufacturers of some fluorescent and low energy

lighting systems indicate that these can interfere with electronic timer circuits.

CLEANING AND MAINTENANCE

IMPORTANT: DISCONNECT FROM THE MAINS SUPPLY BEFORE CARRYING

OUT CLEANING OR MAINTENANCE

The POWER fans have a safety switch which automatically isolates the fan motor

when the outer grille is removed. In this way, the fan may be cleaned without any risk

of electric shocks.

For cleaning purposes, remove the outer grille (Fig.4) and, if your model is a POWER

250, take out the filter at the back of it as well. The filter and the grille may be cleaned

by hand in hot soapy water and the extractor housing wiped with a damp cloth.

We recommend you do not try to remove any more parts than those mentioned as any

tampering would automatically cancel the guarantee.

All regulations and requirements MUST be strictly followed to prevent hazards to life and property

both during and after installation, and during any subsequent servicing and maintenance.

AFTER SALES SERVICE

We recommend you not to dismantle or remove any other parts than those mentioned,

as any tampering would automatically cancel the guarantee. If you detect any fault,

contact EnviroVent on 01423 810810.

Thank you for choosing EnviroVent - the fastest growing ventilation company in the

UK.

And remember, if you have any problems please call our dedicated Technical Team on

the Hotline 0845 27 27 810.

All EnviroVent products are designed to be recycled when they reach the end of their

working life. To save the environment and to reduce landfill, please call EnviroVent on

0845 27 27 810 to arrange for the fan to be returned to the factory.

EnviroVent Ltd

EnviroVent House

Hornbeam Business Park

Harrogate

HG2 8PA

GUARANTEE

The POWER range products are covered by a two year guarantee,

subject to the specified maintenance stated within this booklet. In the

event of any failure of the fan within two years of supply- excluding

only wilful or careless damage – we will exchange the fan free of

charge.

EnviroVent Ltd

EnviroVent House

Hornbeam Business Park

Harrogate

HG2 8PA

Name and address of purchaser ………………………………………………...

Model ……………………………………………………………………………….

Date of purchase ………………………………………………………………….

Dealer stamp

EnviroVent Ltd

Harrogate

Hg2 8PA

01423 810 810

info@envirovent.com

Ref. 9023007701

Loading...

Loading...