Page 1

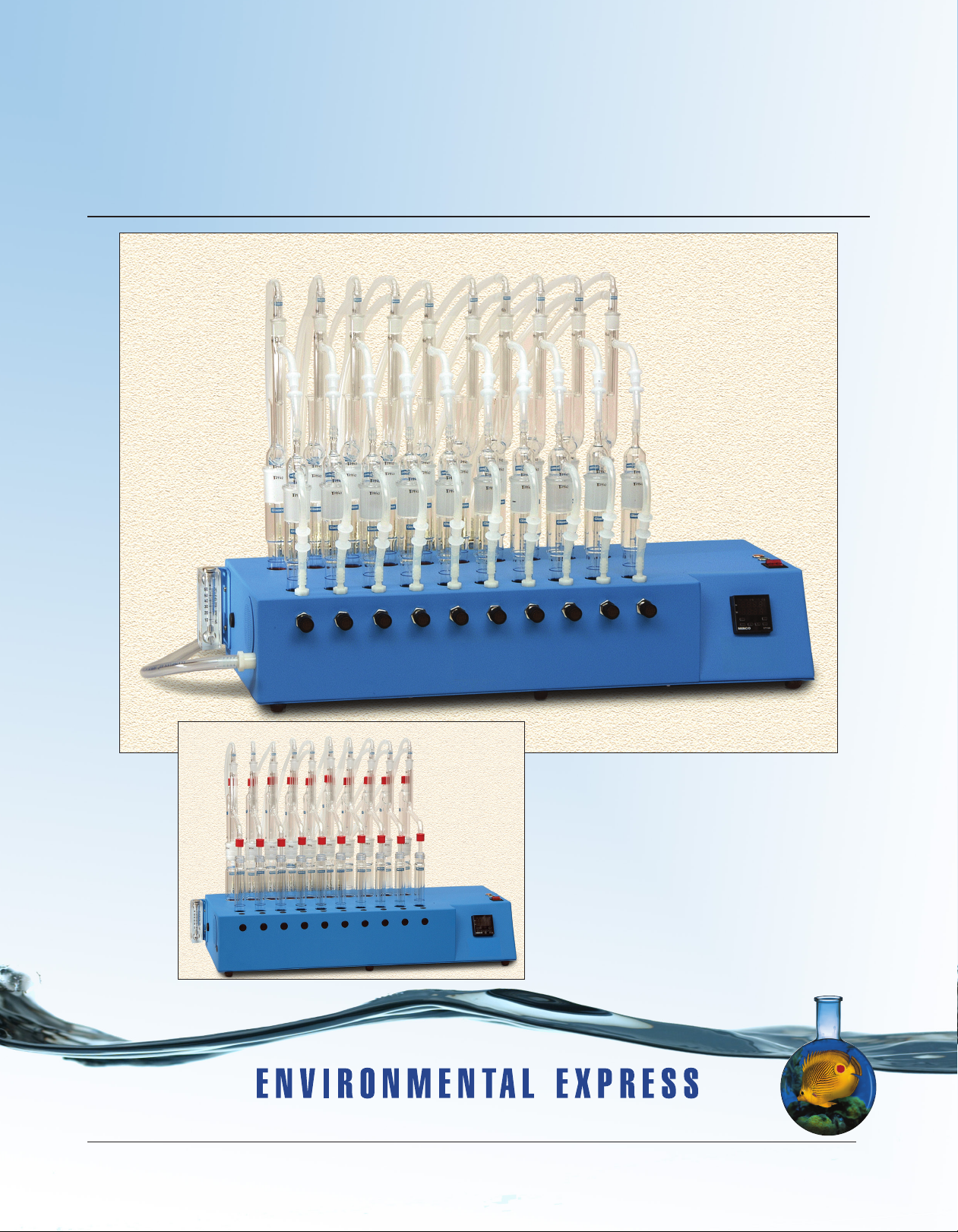

MicroBlock™ Distillation System

Operation & Instruction Manual

MicroBlock-V

System with

Cyanide

Glassware

MicroBlock-R

System with

Ammonia

Glassware

Call 800.343.5319 or 843.881.6560 • www.environmentalexpress.com

Copyright Environmental Express, Inc, July 2013

Page 2

MicroBlockTM: Operation and Instruction Manual Contents

Dear Valued Customer,

Thank you for purchasing a

MicroBlock from Environmental

Express. We pride

ourselves on providing

innovative products

designed to improve

accuracy, efciency,

and safety in your

laboratory. Please take

some time to read your product

manual before using your MicroBlock.

As always, our Technical Sales

and Technical Support Teams are

available to assist with any questions

you have regarding our products.

Best Regards,

Contents:

General Information

Warranty 1

Safety Information 2

Getting Started

Parts Included 3

MICROBLOCK

TM

Glassware, Parts and Systems 4

Unpacking and Setup 5

Instrument Controls and Description 6

Wiring Diagram 7

Simplied Temperature Controller Instructions 8

Manual and Automatic Operation 9

MicroBlock™ Distillations:

Total Cyanide Method 10-12

Al Jurgela

Chief Executive Ofcer

Environmental Express, Inc.

Cyanide Glassware Illustration 10

Total Ammonia Method 13-14

Ammonia Glassware Illustration 13

Total Recoverable Phenolics 15-17

Phenolics Glassware Illustration 15

Troubleshooting 18

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express

Page 3

MicroBlock™: Operation and Instruction Manual General Information

Limited Warranty

The MicroBlock from Environmental Express, Inc. is guaranteed to heat, hold temperature, and adequately perform

specied laboratory distillations for a period of one year from the date of shipment. This warranty extends to parts, labor, and

any approved transportation charges. This warranty applies only to damage or failure caused by normal laboratory use.

Environmental Express, Inc. makes no other warranty, expressed or implied for this product with respect to merchantability,

tness for a particular use or any other matter. Environmental Express, Inc. is not liable for any consequential or compensatory

damages arising from use of, or in conjunction with this product. The maximum liability shall be the invoice price of this

product.

Repair Policy

Under Warranty Repair

If the MicroBlock should fail to operate within the warranty period (one year from date of shipment) Environmental

Express, Inc. will repair and ship it back to the customer at our expense. The remainder of the warranty period will be honored

from the original ship date. Environmental Express, Inc. will bear the cost of ground transportation both to and from the

customer’s location, and bear the cost of any parts, labor and cleanup required.

However, if it is determined that the damage to the MicroBlock was caused by negligence or improper use, this warranty

will not apply. The warranty is also void if the system is used beyond its intended purpose or in the event of any unauthorized

repair. In such cases, reasonable and customary repair charges will apply. Repair charges will be quoted prior to work being

done.

Note: This warranty does not apply to any glassware associated with the MicroBlock.

Out of Warranty Repair

If the MicroBlock fails after the warranty period has lapsed, the repair procedure is as follows:

First, notify an Environmental Express, Inc. customer service representative of product’s failure and place an order for

repair. Whenever possible, our customer service technician will walk you through possible troubleshooting scenarios which may

enable you to repair your block on site.

If on-site repair is not possible, the customer may return the non-working unit to Environmental Express, Inc. using

appropriate shipping containers and insurance. Repair charges will be assessed and estimated prior to work being done.

Repair charges will include all freight costs as well as reasonable and customary charges for parts and labor. A loaner MicroBlock

MAY be available during the repair period. There are only a limited number of these units. A reasonable charge for “cleanup”

will be charged if a loaner is issued. The customer will be responsible for all shipping charges associated with a loaner unit.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 1

Page 4

MicroBlockTM: Operation and Instruction Manual General Information

MicroBlockTM Safety Information

1. The Environmental Express MicroBlock should be set up and operated in a chemical fume hood with a face

velocity of not less than 100 CFM.

2. Wear appropriate Personal Protective Equipment (PPE) suitable for use with caustic and corrosive materials.

3. Do not operate the MicroBlock in the vicinity of combustible material.

4. Be certain the MicroBlock power cord is properly grounded by consulting your in-house electrician.

5. During operation the surfaces around the heater assembly will get HOT. Do not touch the outer surface.

6. Do not move the MicroBlock system while hot.

7. Do not attempt to operate the MicroBlock system over 190°C.

8. Allow the MicroBlock to cool for 20 minutes before removing glassware. Separation of the “hot” glassware

components could result in bumping, boil over, and/or spraying of hot corrosive/caustic materials.

9. Review Material Safety Data Sheets for all materials used or generated during the operation of the MicroBlock.

Avoid breathing any vapors that may come off of the MicroBlock system, they may be harmful or fatal.

10. Water and vacuum (if used) should be continued until the MicroBlock has cooled down to prevent boil over. The

electric cord should be kept plugged into its outlet until the unit has cooled down.

11. If boil over does occur during operation of the MicroBlock operation, immediately wipe the system down with

neutralizing solution, such as a mild solution of sodium bicarbonate.

12. Unplug the MicroBlock from the outlet prior to cleaning exterior surfaces. Wipe with damp sponge or towel after

each use, rst with mild sodium bicarbonate or similar solution followed by Dl or distilled water. Avoid solutions

on or near the controls.

13. If a MicroBlock system with a vacuum is used, install an excess gas trap in the vacuum line to remove excess

vapors.

14. Use micro-porous boiling chips in each distillation ask to prevent bumping.

15. It is recommended that a tray or petri dishes be used under the drain outlets to catch any spills from boil over

and/or breakage.

Note: The above list contains some basic recommendations and safety precautions. By no measure

should this list be considered complete. More rigorous enhanced precautions may be necessary

while operating this equipment.

Please consult your Safety Manager and Material Safety Data Sheets prior to operating

this equipment.

Contact Environmental Express Inc. if there are any questions. User assumes all liability for

damages arising from the operation of this equipment.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 2

Page 5

MicroBlockTM: Operation and Instruction Manual Getting Started

Parts Included

MICROBLOCK HEATING UNIT

Includes:

Heater Block, Temperature Controller with Timer, Fuse Holder with 15 amp Fuse, Flowmeter, Power Relay,

Fan with Thermostat, Water Manifold with Quick Disconnect Fittings, High Temperature Switch and

Glass Breakage Drain Outlets.

VACUUM FRONT SECTION

Includes:

(if purchased for cyanide operation) Vacuum Valves, Vacuum Barbs and Vacuum Manifold.

If purchased for ammonia/phenol/uoride operation only, vacuum components are not included.

MANUAL

Includes:

Operating Instructions with Wiring Diagram and Temperature Controller Operating Instructions.

COMPLETE TUBING SET

Includes:

20 Water Manifold-to-Cold Finger Tubes with Quick Disconnect ttings, 10 Reaction Flask-to-Absorption Impinger

Tubes (if cyanide glassware purchased), 10 Absorption Flask-to-Vacuum Tubes (if cyanide glassware purchased), 1

Manifold Water Inlet Tube, 1 Manifold Water Drain Tube and 1 Vacuum Tube (if cyanide glassware purchased).

GLASSWARE

Includes:

(if cyanide glassware purchased), 20 Reaction/Absorption Flasks, 10 Distillation Heads, 10 Cold Fingers and 10

Absorption Impingers. Includes (if Ammonia/Phenol/Fluoride glassware purchased), 10 Reaction Tubes, 10 Distillation

Heads, 10 Cold Fingers, 10 Receiver Tubes, 10 Ammonia Outlet Tubes and 10 Phenol/Fluoride Outlet Tubes.

BOILING CHIPS:

Includes:

A small sample of boiling chips, Environmental Express # C5249.

Parts Not Included

TRAY OR PETRI DISHES:

It is recommended that a tray or two petri dishes or equal be used under the drain outlets.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 3

Page 6

StirBase: Operation and Instruction Manual Getting Started

MICROBLOCKTM Glassware and Parts

Item No. Description:

C5012 MicroBlcok-V Cyanide Reaction/Absorption Flask

C5012 MicroBlock-V Cyanide Reaction/Absorption Flask

C5210 Cold Finger for Distillation Glassware

C5212 Cyanide Glassware for MicroBlock, 1 Unit w/out tubing

C5213 Ammonia/Phenol Pierced Cap, 10pk

C5214 Ammonia/Phenol Glassware for MicroBlock

C5214B Ammonia/Phenol Reaction Tube

C5216 Cyanide Distillation Head, Style 2

C5217 Absorption Impinger for Cyanide

C5218 PTFE-Faced Septas for Distillation Cap, 20pk

C5219 Ammonia/Phenol Distillation Head

C5221 Tubing & Quick Connect Fittings for 10 Sets Cn Glass

C5222 Tubing & Quick Connect Fittings for 10 Sets Glassware

C5225 Silicon Sealing Ring, 10pk

C5226 Outlet Tube for Ammonia Distillation

C5227 Outlet Tube for Phenol

C5228 Receiver Tube for Ammonia/Phenol Distillation

C5229 Absorption Impinger

C5249 MicroBlock Carbon Boiling Chips, 8oz

C5253 Upgrade Heater Mat Replacement Kit for MicroBlock

C5257 Replacement Fan for Microblock

C5260 Female Quick Disconnect Body for Water Manifold, 2pk

C5261 MicroBlock-V Needle Valve

MICROBLOCKTM Ammonia/Phenol Systems

Item No. Description:

C5203 MicroBlcok-V System with 10 sets Penol/Ammonia Glassware

C5230 MicroBlock R w/ 10 sets Phenol/Ammonia Glassware

C5231 MicroBlock R, Block only

MICROBLOCKTM Cyanide Systems

Item No. Description:

C5200 MicroBlcok-V System with 10 sets Cyanide Glassware

C5200-240 MicroBlock R w/ 10 sets Cyanide Glassware, 240V

C5201 MicroBlock V, Block only

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 4

Page 7

StirBase: Operation and Instruction Manual Getting Started

Unpacking and Setup

I. Unpack the heating unit and place it in a chemical fume hood with the temperature controller facing outward.

2. Unpack 10 glassware sets. The glassware is packed 5 sets per box. The glassware should be cleaned according to the

protocol and assembled in the MicroBlock unit. If the chemistry being done requires the use of a frit, refer to page

12, paragraph 7.17 for frit cleaning.

3. Unpack the bags of tubing which were packed with the heating unit.

4. Review the diagrams. Familiarize yourself with parts, names, and locations of the parts for the chemistry you are doing.

5. Save original packaging material in a dry area to be used if item needs to be returned for service. Refer to warranty

policy on page 1.

6. Connect tubing to the MicroBlock unit as follows:

A. Connect a 5-foot reinforced tube to the hose barb on the outlet water manifold (right side, away from owmeter). Place

the other end into a suitable drain.

B. Connect the other 5-foot reinforced tube to the lower owmeter hose barb and the other end to a suitable needle valve

cold water source. This needle valve is used to control the ow of water and is not supplied with the MicroBlock.

C. If the chemistry is for Cyanide, connect the 5-foot vacuum tube to the white hose barb located on the left side of the

unit (behind the vacuum knobs). Connect the other end to an excess gas trap (scrubber ask lled with NaOH solution).

Connect gas trap to your vacuum source.

Note: The excess gas trap and vacuum source are not supplied with the MicroBlock.

7. Assemble the glassware into the MicroBlock in the following manner (reference Figures 2 - 5)

Note: Names used here are for the Cyanide design of glassware.

A. Place a Reaction/Absorption Flask into the left-most heat block position. This is the Reaction Flask.

B. Place the Distillation Head into the Reaction Flask.

C. Place the Cold Finger into the joint at the top of the Distillation Head.

D. Place a Reaction/ Absorption Flask into the left-most front position. This is the Absorption Flask.

E. Place the Absorption Impinger into the Absorption Flask.

F. Repeat steps A through E for the remaining glassware, working from left to right.

G. To remove the glassware, reverse the above procedure.

8. Connect tubing to the glassware and MicroBlock as follows:

Note: 20 Manifold-to-Cold Finger tubes are supplied at the same lengths. These tubes are long enough to remove the

Cold Finger from the Distillation Head without disconnecting the Quick Disconnect Fitting. You may nd them long

if you are going to use the Quick Disconnect Fitting to remove the Cold Finger, if so the tubing can be easily cut.

A. The Cold Finger tubing lines are the lines having a quick disconnect tting attached. Connect one end of a line to

the upper barb on the Cold Finger. Insert the Quick Disconnect Fitting into the forward adapter on the water manifold

(water inlet), squeezing the metal tab rst. Push in until the tab clicks out. Repeat the process for the other nine Lower

Cold Finger Condensers.

B. Repeat step A using the other 10 tubing lines going to the lower Cold Finger barb and the back adapter on the water

manifold (water drain).

C. The Distillation Head-to-Absorption Impinger tubing bag contains ten lengths with a slip connector in the middle.

Connect one open end to the barb at the top of the Distillation Head, and the other end to the barb on the Absorption

Impinger .

D. The Absorption Impinger-to-Vacuum tubing bag contains ten lengths, each with a slip connector near one end. Connect

the longer tube to the side barb on the Absorption Impinger, and the shorter tube to the vacuum barb on the MicroBlock

unit.

9. Plug the power cord into an outlet rated for 115 volts, 15 amps. If the Red Rocker Switch glows, turn it off.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 5

Page 8

HotBlock: Operation and Instruction Manual Getting Started

Instrument Controls and Description

Control Location Description

Red Lighted Rocker

Switch

Black Rocker Switch

Green Pilot Light

Amber Pilot Light

Top Right on Unit

Right Side of

Temperature Controller

Top Right on Unit

Top Right on Unit

A DPST switch that turns power on

and off.

Note: This switch does not control the

cooling fan.

Enables the heater block circuit.

When turned on, the Green Pilot Light

is illuminated and heating is enabled.

When turned off, the Green Pilot Light

is off and the heater is disabled. The

Temperature Controller will remain on,

temperature to be monitored during idle

or cooldown periods.

Operates when the power is turned on

by the Red Lighted Rocker Switch and

heating is enabled by the Black Rocker

Switch. If the Green Pilot Light does not

illuminate when RedLighted Rocker

Switch is illuminated and the Black

Rocker Switch is turned on, the High

Temperature Switch is not closed and

must be re-set.

Operates during the heating cycle. Light

turns on and off indicating heating

element is getting power.

Temperature

Controller/Timer

Main Fuse Holder

High Temp Switch

Power Relay

Front Right on Unit

Right Rear of Unit

Left End of Heater

Block Inside Unit

Right Rear Inside

Controls the operation of the heater

block up to its maximum temperature

of 190°C. Turns the power on and off

to the heating elements and can be

programmed to heat at slower rate

than maximum and programmed to

automatically shut the power off at

the selected time. See Temperature

Controller Operating Instruction Manual.

A 15 amp fuse must be in place for unit

to operate.

Note: The Temperature Controller and

Fan are fused separately.

Protects unit from burnout caused by

failure of the Temperature Controller

and/or Power Relay. May be re-set by

removing rubber body plug on side of

unit and pushing the re-set button inside

of unit. Always use a non-metallic device

to make this adjustment.

Controls power between the temperature

controller and the heating elements.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 6

Page 9

HotBlock: Operation and Instruction Manual Getting Started

Figure 1 - Wiring Diagram

Black

Power Cord

Main Fuse

Amber Pilot Light

Green Pilot Light

Red Lighted

Rocker Switch

Rocker Switch

Temperature

Controller

Black

Rocker Switch

Water Oulet (Drain)

Water Manifold with

QuickDisconnect Fittings

Water Inlet

on Bottom

Flowmeter

Rubber Body Plug

Vacuum Valves

Vacuum

Connection

Vacuum Barbs

Vacuum Valves

Drain Oulets

(petri Dish or Tray is

Recommended Under Outlets)

(High Temp Switch Inside)

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 7

Page 10

HotBlock: Operation and Instruction Manual General Information

Simplied Temperature Controller Instructions

Front Panel Key Functions

Alarm Lamp

Set Point 1 Lamp

Set Point 2 Lamp

Process Display

Set Point Display

Manual Indicator

The decimal point ashes when Self Tune is operating

Keys are illuminated when pressed. Key functions are as follows:

INDEX: Menu Navigation. Pressing the INDEX key advances the display

to the next menu item. May also be used in conjunction with other keys

as noted below.

UP ARROW: Increments a value, changes a menu item, or selects

the item to ON. The maximum value obtainable is 9999 regardless of

decimal point placement.

DOWN ARROW: Decrements a value, changes a menu item, or selects

the item to OFF. The minimum value obtainable is -1999 regardless of

decimal point placement.

ENTER: Pressing ENTER stores the value or the item changed. If not

pressed, the previously stored value or item will be retained. The

display will ash once when ENTER is pressed.

AUTO/MANUAL (CT16A3): This key toggles the control output between

Automatic mode and Manual mode. Press and hold key for three

seconds to activate. See section on AUTO/MANUAL operation on Page 9.

RUN/HOLD (CT16A3): This key toggles the Ramp/Soak program

functions between Run mode (program runs as set up) , and Hold

mode (program functions are suspended). Press and hold key for three

seconds to activate. See section on Ramp/Soak (Page 9) for further

details.

Remote Set Lamp

Heater Fail Lamp

°F Indicator

°C Indicator

Percent Lamp

Hold Lamp

UP ARROW & ENTER: Menu Access. Pressing these keys

simultaneously brings up the secondary menu starting at

the alarm, tune, or cycle item (depending on programming).

Pressing these keys for 5 seconds will bring up the secure

menu.

INDEX & DOWN ARROW: Menu navigation. Pressing these

keys simultaneously will allow back-up of one menu item,

or if at the rst menu item, will cause the display to return

to the primary menu.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 8

Page 11

HotBlock: Operation and Instruction Manual Getting Started

Manual Operation

1. Press the INDEX key to change to set-point display, the SV display will have SPI displayed.

2. Change the process set point (PV display) by pressing the UP ARROW or DOWN ARROW key to change the value, and

press the ENTER key to retain it.

3. Press the INDEX key to return to the process / set point display. The unit will heat to this temperature and hold.

Automatic Operation

Note: These instructions are for a ramp, hold and shut off, you can have up to 16 ramps and hold settings. The example is

for a 20 minute ramp to 125°C hold at 125°C for 60 minutes and turn off.

1. Press the UP ARROW & ENTER keys simultaneously for one second only to get into the Secondary Menu.

2. Press the INDEX key 10 times until the SV display shows PROg. If the PV display is ON it must be turned OFF by pressing

the UP ARROW or DOWN ARROW key and press ENTER to retain it.

3. Press the INDEX key once until PSET is displayed.

4. Press the UP ARROW key to turn the Program Function ON if it is not on and press ENTER to retain it.

5. Press the INDEX key once, the SV display should now be STAT. Press the UP ARROW to turn on the Primary Menu if it is

not ON and press ENTER to retain it.

6. Press the INDEX key once, the SV display should now be TBAS. Press the UP ARROW to change the Ramp/Soak Time Base

to minutes. The PV display should now be 60 S, press ENTER to retain the setting.

7. Press the INDEX key once, the SV display should now be IT. Press the UP ARROW or DOWN ARROW to set 20minutes for

the rst segment and press ENTER to retain the setting.

8. Press the INDEX key once, the SV display should now be ISP. Press the UP ARROW or DOWN ARROW to set 125 value for

the temperature and press ENTER to retain the setting.

9. Press the INDEX key once, the SV display should now be ZT. Press the UP ARROW or DOWN ARROW to set 60 minutes for

the (hold) second segment and press ENTER to retain the setting.

10. Press the INDEX key once, the SV display should now be ZSP. Press the UP ARROW or DOWN ARROW to set 125 value for

the hold temperature and press ENTER to retain the setting.

11. Press the INDEX key 29 times until the SV display has PEND on it. Press the UP ARROW or DOWN ARROW key until the

display shows 0OFF (Program End Action) and press ENTER to retain the setting.

12. Return to the HOME position by waiting for the Secondary Menu display to time out or by pressing the UP ARROW &

ENTER keys and then the DOWN ARROW & INDEX keys.

13. Press the UP ARROW & ENTER keys to get into the Secondary Menu.

14. Press the INDEX key 10 times until the SV display is PRO9. Press the UP ARROW or DOWN ARROW key to turn ON Ramp/

Soak Feature and press ENTER to retain the setting.

15. Return to the HOME position by waiting for the Secondary Menu display to time out or pressing the UP ARROW &

ENTER keys and then the DOWN ARROW & INDEX keys

16. The unit when turned on will be in the hold mode. To run the program press the HOLD key for 3 seconds. The unit will

now heat to 125°C in 20 minutes, hold at 125°C for 60 minutes and turn the heat off.

17. To re-start the program, turn the main switch off and on, press the k key for 3 seconds.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 9

Page 12

HotBlock: Operation and Instruction Manual MicroBlockTM Distillations

Total Cyanide Distillation with the MICROBLOCK

1.0 SCOPE AND APPLICATION

1.1 This method replicates US EPA

method number 335.4 titled

“Determination of Total

Cyanide by Semi-Automated

Colorimetry”. It is applicable

for the determination of total

cyanide in drinking, ground,

surface, and saline waters,

as well as, domestic and

industrial wastes, and soils.

1.2 The standard range is typically

5 to 500μg/L. Lower detection

limits can be achieved by

using a longer path length

ow cell in the analysis step

when using an automated

continuous ow analyzer.

2.0 SUMMARY OF METHOD

2.1 The cyanide as HCN is

released from metal-cyanide

complexes by means of

an acidic manual reuxdistillation whereby the

HCN gas that is formed is

separated from the sample

matrix and absorbed in a

dilute solution of sodium

hydroxide. The distillate can

be analyzed for cyanide by

semi-automated colorimetry,

manual colorimetry,

titrimetric, or ion-selective

electrode.

2.2 Reduced volume versions of this method that use the same reagents and molar ratios as in the original method are

acceptable provided they meet the quality control and performance requirements stated in the method.

3.0 INTERFERENCES

There are several known interferences with this method.

A few of these are: Aldehydes Thiocyanates Nitrate-nitrite

Thiosulfates Chlorine Suldes

Some of these interferences are reduced or eliminated by the distillation process. For example, the nitrate-nitrite

interference is eliminated by addition of sulfamic acid during the distillation step. Further, the addition of

magnesium chloride, which acts as a catalyst, will promote the breakdown of refractory iron-cyanide complexes. The

reagent preparations for these two interferences will be summarized in the REAGENT PREPARATION SECTION. For all

other pretreatment procedures refer to the US EPA method number 335.4.

4.0 CHEMICALS REQUIRED – DISTILLATION ONLY

4.1 Sodium Hydroxide

4.2 Sulfuric Acid, 18N

4.3 Magnesium Chloride, if refractory iron-cyanide complexes are present

Figure 2 - Cyanide Glassware

Drain

Water

Inlet

TM

Distillation

Head

C5216

Reaction

Absorption

Flask

C5012

Cold Finger

C5210

Slip Connector

Absorption

Impinger

C5217

Vacuum Inlet

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 10

Page 13

HotBlock: Operation and Instruction Manual MicroBlockTM Distillations

Total Cyanide Distillation with the MICROBLOCK

4.4 Sulfamic Acid – if Nitrates and Nitrites are present

4.5 Potassium Cyanide

4.6 Potassium Hydroxide

4.7 Reagent Water ASTM Type II or Equivalent

4.8 Boiling Chips – Environmental Express # C5249

Note: The toxicities for each of the reagents used in this procedure are not fully documented. Treat each chemical as a

potential health hazard and limit exposure. Exercise good laboratory technique with an emphasis on safety.

5.0 EQUIPMENT AND SUPPLIES

5.1 The MicroBlock distillation glassware setup and tubing connections are shown in Figure 2 (Cyanide Style #1).

Part Number Description

C5012 Reaction/Absorption Flask

C7110 Snip & Pour, 1.25N NaOH, 50 x 10mL

C5210 Cold Finger

C5217 Absorption Impinger

C5216 Distillation Head

5.2 Helpful Accessories (Part# BT844004)

5mL delivery Repipette for 18N H2SO4 addition

5mL delivery Repipette for Mg2Cl addition

TM

Continued

6.0 REAGENT PREPARATION – DISTILLATION ONLY

6.1 Sodium Hydroxide Solution, Stock, 1.25N

Dissolve 50g of NaOH in reagent water and dilute to 1L.

6.2 Sodium Hydroxide Solution, Working, 0.25N

Dilute 200mL of 1.25N stock solution to 1L with reagent water.

6.3 Sulfuric Acid, 18N

Place a 1L glass container in an ice bath with a magnetic or mechanical stirrer. Add 500mL of reagent water. Slowly add

500mL of concentrated Sulfuric Acid drop-wise while stirring. Replenish ice in the ice-bath if required. Exercise caution

when preparing this reagent because of the exothermic nature of the reaction. After all the sulfuric acid has been

added, dilute to 1L with reagent water and mix thoroughly. Cool to room temperature before use.

6.4 Magnesium Chloride Reagent

Dissolve 510g of MgCl2:6 H2O in reagent water and dilute to 1L.

Note: This reagent is required if it is known that refractory iron-cyanide complexes are present.

6.5 Sulfamic Acid

Dissolve 20g of reagent grade sulfamic acid in reagent water and dilute to 1L.

Note: This reagent is required if it is known that nitrates-nitrites are present.

6.6 Potassium Cyanide, Stock Standard

Dissolve 2.51g of KCN in reagent water containing 2.0g of KOH. Dilute to 1L. Concentration of 1 mL = 1mg CN.

Standardize with 0.0192 N AgNO3 on a monthly basis. Refer to US EPA method number 335.4 paragraph 7.9 for the

AgNO3 preparation.

6.7 Potassium Cyanide, Intermediate Standard

Dilute 10mL of Stock Cyanide Standard to 100mL with reagent water. Concentration of 1mL = 100.0µg CN.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 11

Page 14

HotBlock: Operation and Instruction Manual MicroBlockTM Distillations

Total Cyanide Distillation with the MICROBLOCK

6.8 Potassium Cyanide, Working Standard

Prepare a series of standards covering the working range. Dilute 10mL of the Intermediate Standard to 100µL with

reagent water. Concentration of 1mL = 10µg CN. Prepare fresh daily or before each use.

7.0 PROCEDURE

7.1 Pipette 50mL of sample or an aliquot diluted to 50mL with reagent water into the MicroBlock Reaction Flask.

Add a pinch of boiling chips. For solid samples weigh 1g or less to the nearest 0.01g, dilute to 50mL and

add boiling chips.

7.2 Pipette 50mL of 0.25N NaOH into the Absorption Flask. If using the Snip & Pour concentrate pour the entire 10mL of

the 1.25N NaOH into the absorption ask. Dilute to 50mL using DI Water. Refer to the schematic for the appropriate

placement positions and exible tubing connections to cool the Cold Finger with running tap water. All air/vacuum

valves are in the OFF position.

7.3 Repeat 7.1 and 7.2 for all samples to be distilled up to a maximum of 10.

7.4 Position the Cold Finger and Absorber Impingers.

7.5 Turn tap water ON after assuring all tubing connections are rmly placed. A water ow rate of 50 to 60 gallons per

hour is required.

7.6 Turn ON the vacuum and slowly adjust each valve to provide an air ow bubble rate of several bubbles per second

for each position as viewed in the absorption vessel.

7.7 If nitrate-nitrite is known to be present add 5mL of sulfamic acid reagent through the reagent inlet. Allow the air

ow to mix for several minutes.

7.8 Slowly add 5.0mL of 18N sulfuric acid though the reagent inlet.

7.9 If iron cyanide complexes are known to be present add 2.0mL of magnesium chloride reagent. If excess foaming

occurs, add an additional 2mL. Allow a few minutes to mix.

7.10 Turn the heat ON and set the temperature of the heating block to 150°C.

7.11 Set the timer for 1 hour.

7.12 Timer will automatically turn OFF power to the heater block at the pre-selected time.

7.13 Disconnect the Distillation Head and Absorption Impinger by separating the Slip Connector. Turn air/vacuum valves

to the OFF position. Repeat for each sample position.

7.14 Allow the tap water to continue circulating through the Cold Fingers which will cool the heater block more rapidly in

preparation for the next run.

7.15 The distilled cyanide in the 0.25N NaOH solution is now ready for analysis.

7.16 Immediately after the run is nished, place the Absorption Impinger in distilled water. Do not let the impinger dry

out since the NaOH may clog the frit.

7.17 If the frit becomes clogged, clean with concentrated HCl using an ultrasonic bath. If this procedure is not successful

use aqua regia.

7.18 After use clean exterior surfaces with a damp sponge. For acid spills sponge with a diluted solution of sodium

carbonate followed by distilled water.

TM

Continued

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 12

Page 15

HotBlock: Operation and Instruction Manual MicroBlockTM Distillations

Ammonia Distillation with the MICROBLOCK

1.0 SCOPE AND APPLICATION

1.1 This method covers the

determination of ammonia

in drinking, ground, surface,

and saline waters and

domestic and industrial

wastes.

1.2 The applicable range is 0.01

to 2.0mg/L ammonia as N.

Higher concentrations can be

determined by dilution.

2.0 SUMMARY OF METHOD

2.1 The sample is buffered at pH

9.5 with borate buffer for

aqueous samples to decrease

hydrolysis of cyanates and

other organic nitrogen

compounds. Under acidic

conditions these compounds

can form ammonia. The

sample is distilled into 0.04N

sulfuric acid or 2% boric

acid depending upon the

analytical technique used to

quantitate for ammonia.

2.2 Reduced volume versions of

this method that use the

same reagents and molar

ratios are acceptable provided they meet the quality control and performance requirements stated in the method.

Figure 3 - Ammonia Glassware

Drain

Water Inlet

TM

Cold Finger

C5210

Cap C5213, and

PTFE-Faced Septa

C5218

Distillation

Head

C5219

Reaction

Tube

C5214-B

Cap C5213,

and Silicone

Sealing Ring

C5225

Long Stem

Outlet Tube

for Ammonia

C5226

Receiver Tube

C5228

3.0 INTERFERENCES

3.1 Cyanate in certain industrial wastes will hydrolyze to some extent even at pH 9.5, which is recommended for

distillation.

3.2 Residual chlorine must be removed prior to distillation by treatment with sodium thiosulfate or sodium sulte.

4.0 CHEMICALS REQUIRED – DISTILLATION ONLY

Note: The toxicities for each of the reagents used in this method are not fully documented. Treat each chemical as a potential

health hazard and limit exposure. Exercise good laboratory technique with emphasis on safety.

4.1 Sodium Hydroxide

4.2 Sodium Tetraborate

4.3 Sulfuric Acid

4.4 Sodium Thiosulfate

4.5 Sodium Sulte

4.6 Ammonium Chloride

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 13

Page 16

HotBlock: Operation and Instruction Manual MicroBlockTM Distillations

Ammonia Distillation with the MICROBLOCK

4.7 Reagent Water ASTM Type II or Equivalent, especially ammonia-free

Note: Such water is best prepared by passage through an ion-exchange column containing a strongly acidic cation exchange

resin mixed with a strongly basic anion exchange resin.

4.8 Boiling Chips, Environmental Express # C5219

5.0 EQUIPMENT AND SUPPLIES

5.1 The MicroBlock distillation glassware setup and tubing connections are shown in Figure 3 with long outlet tube.

Part Number Description

C5214-B Reaction Tube, Skirted

C5219 Distillation Head

C5210 Cold Finger

C5228 Receiver Tube

C5226 Long Stem

C7010 Snip & Pour, 0.2N H2SO4, 50 x 10mL

C7120 Snip & Pour, 20g/L Boric Acid, 50 x 10mL

6.0 REAGENT PREPARATION – DISTILLATION ONLY

6.1 Sodium Hydroxide, 0.1N

Dissolve 4g of NaOH in reagent water and dilute to 1L.

6.2 Sodium Tetraborate Solution, 0.025 M

Dissolve 5.0g of Na2B4O7 [anhydrous] or 9.5g of Na2B4O7 :10H2O and dilute to 1L with reagent water.

6.3 Borate Buffer Solution

Add 88mL of 0.1N Sodium Hydroxide solution to 500mL of 0.025 M sodium tetraborate and dilute to 1L with reagent

water.

6.4 Sodium Thiosulfate Solution

Dissolve 3.5g Na2S2O3 : 5H2O to 1L of reagent.

Note: One mL of this solution will remove 1mg/L of residual chloride in 500mL of sample.

6.5 Sodium Sulte Solution

Dissolve 0.9g Na2SO3 :5H2O to 1L of reagent water.

Note: One mL of this solution will remove 1mg/L of residual chlorine in 500mL of sample.

6.6 Stock Ammonium Chloride

Dissolve 3.819g of anhydrous ammonium chloride, previously dried at 105°C, and dilute to 1L with reagent water.

1.0mL = 1.0mg NH3-N.

6.7 Standard Ammonium Chloride, Solution A

Dilute 10.0mL of Stock Solution to 1L with reagent water.

1.0mL = 0.01mg NH3-N.

6.8 Standard Ammonium Chloride, Solution B

Dilute 10.0mL of Stock Solution A to 100mL with reagent water.

1.0mL = 0.001mg NH3-N.

TM

Continued

7.0 PROCEDURE

7.1 Preparation of distillation glassware. Steam out the distillation glassware using 50mL reagent water with a

pinch of boiling chips until no trace of ammonia can be detected.

7.2 If residual chlorine is present add sodium thiosulfate or sodium sulte equivalent to the chlorine level.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 14

Page 17

HotBlock: Operation and Instruction Manual MicroBlockTM Distillations

7.3 To a 50mL sample add 1N NaOH drop-wise with mixing and adjust to pH 9.5.

7.4 Transfer sample to the Reaction Tube, skirted, and add 2.5mL of borate buffer followed by a pinch of boiling chips.

7.5 To the Receiver Tube add 5-10mL of 20g/L Boric Acid or 0.2N H2SO4. If using the Snip & Pour concentrate pour the

entire contents of the tube in the Reaction Tube. The tip of the long stem must be below the level of boric acid or

sulfuric acid.

7.6 Repeat for all samples to be distilled up to a maximum of 10.

7.7 Assemble the distillation glassware setup as shown in Figure 3.

7.8 Turn on the tap water to cool the Cold Finger after ensuring all tubing connections are tight. Check for any leaks.

7.9 Turn the power ON and set heater block temperature to 190°C and the timer to 60 minutes.

7.10 Collect a minimum of 30mL of distillate.

7.11 Turn power OFF.

7.12 Unscrew the cap holding the Long Stem in the receiver tube and remove from all distillation positions to prevent

any suck back of the distilled sample. When the Long Stem is disconnected, gently let it rest at the bottom of the

Receiver Tube.

7.13 Dilute the distillate collected in the Receiver Tube to the 50mL graduation mark with ammonia-free water.

7.14 Place a collection tray or individual beakers located directly below where the Receiver Tubes were removed to catch

any further distillate. Distillation will continue because the heater block is still hot.

7.15 After each use clean exterior with a damp sponge.

7.16 When the heater temperature falls below 100°C, the next run can be started.

TOTAL Recoverable phenolics With the MicroBlock™

1.0 SCOPE AND APPLICATION

1.1 This method is for the

determination of phenolic

compounds in drinking,

ground, surface, and saline

waters, and domestic and

industrial wastes.

1.2 The applicable range is

2-500µg/L. The working

ranges are 2-200µg/L or 10500µg/L.

2.0 SUMMARY OF METHOD

2.1 This method is based on

the distillation of phenol

followed by the reaction

with alkaline ferricyanide

and4-aminoantipyrine. The

color complex is measured

at 505 or 520nm. Whether

the analysis is performed

by manual or automated

continuous ow analyzers, a

50mm path length measuring

optical cell is required to

achieve a detection limit of

2µg/L.

Figure 4 — Phenol glassware

Drain

Water Inlet

Cold Finger

C5210

Cap C5213, and

PTFE-Faced Septa

C5218

Distillation

Head

C5219

Reaction

Tube

C5214-B

Cap C5213, and

Silicone Sealing Ring

C5225

Short Stem

Outlet Tube

C5227

Receiver Tube

C5228

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 15

Page 18

HotBlock: Operation and Instruction Manual MicroBlockTM Distillations

TOTAL Recoverable phenolics With the MicroBlock™ Continued

2.2 Phenol is used as the standard even though the various forms of phenol react differently with the colorimetric

reaction. The result obtained represents the minimum concentration present in the sample.

2.3 Reduced volume versions of this method that use the same reagents and molar ratios are acceptable provided they

meet the quality control and performance requirements stated in the method.

3.0 INTERFERENCES

3.1 Interferences from sulfur compounds are eliminated by acidifying the sample to a pH 4.0 and aerating briey by

stirring.

3.2 Oxidizing agents such as chlorine detected by the liberation of iodine upon acidication in the presence of

potassium iodide are removed immediately after sampling by the addition of ferrous ammonium sulfate. If chlorine

is not removed, the phenolic may be partially oxidized and the results may be low.

3.3 Background contamination from plastic tubing and sample containers must be avoided. Use glass tubes

wheneverpossible.

3.4 Method interferences may be caused by contaminants in the reagent water, reagents, glassware , and other

processing apparatus that bias the analyte response.

4.0 CHEMICALS REQUIRED – DISTILLATION ONLY

4.1 Sodium Hydroxide

4.2 Sulfuric Acid

4.3 Ferrous Ammonium Sulfate – if chlorine is present at the time of sampling.

4.4 Phenol

4.5 Reagent Water ASTM Type II or Equivalent

4.6 Boiling Chips, Environmental Express # C5219

Note: The toxicities for each of the reagents used in this method are not fully documented. Treat each chemical

as a potential health hazard and limit exposure. Exercise good laboratory technique with an emphasis on safety.

5.0 EQUIPMENT AND SUPPLIES

5.1 The MicroBlock distillation glassware setup and tubing connections are shown in Figure 4 with short outlet tube.

Part Number Description

C5214-B Reaction Tube, Skirted

C5219 Distillation Head

C5210 Cold Finger

C5228 Receiver Tube

C5226 Short Stem Outlet Tube

6.0 REAGENT PREPARATION – DISTILLATION ONLY

6.1 Stock Phenol

Dissolve 0.50g phenol in 500mL reagent water. Add 0.25mL of concentrated sulfuric acid as a preservative.

1.0mL = 1.0mg phenol.

6.2 Standard Phenol, Solution A

Dilute 1.0mL of the Stock Phenol Solution to 100mL with reagent water.

1.0mL = 0.01mg phenol.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 16

Page 19

HotBlock: Operation and Instruction Manual MicroBlockTM Distillations

TOTAL Recoverable phenolics With the MicroBlock™ Continued

6.3 Standard Phenol, Solution B

Dilute 10.0mL of Standard Phenol Solution A to 100mL with reagent water.

1.0mL = 0.001mg phenol.

6.4 Standard Phenol, Solution C

Dilute 10.0mL of Standard Phenol Solution B to 100mL with reagent water.

1.0mL = 0.0001mg phenol.

6.5 Sodium Hydroxide, 0.1 N [1+9]

Dissolve 4.0g of NaOH in 1L of reagent water.

6.6 Sulfuric Acid, 10% [1+9]

Slowly add 10mL of concentrated sulfuric acid to 70mL of reagent water. Cool and dilute to 100mL.

6.7 Ferrous Ammonium Sulfate

Dissolve 0.55g of ferrous ammonium sulfate in 250mL reagent water containing 0.5mL sulfuric acid and dilute to

500mL.

7.0 PROCEDURE

7.1 Pipette 50mL of sample into a beaker. Adjust pH to 4 with NaOH [1+9] or with Sulfuric Acid [1+9]. Transfer to the

skirted Reaction Tube. For soil samples, weigh 1g or less into beaker and 50mL reagent water. Adjust pH to 4 with

NaOH [1+9] or sulfuric acid [1+9] while stirring and transfer to the skirted Reaction Tube. Add a pinch of boiling

chips.

7.2 Repeat 7.1 for all samples to be distilled up to a maximum of 10.

7.3 Assemble the distillation glassware setup as shown in Figure 4h and position in the heater block.

7.4 Turn on the tap water to cool the Cold Finger after ensuring all tubing connections are tight. Check for leaks.

7.5 Turn power ON and set heater block temperature to 190°C and timer to 60 minutes.

7.6 When approximately 45mL of sample is distilled add 5mL of reagent water using a syringe by piercing the rubber

septum located on the top of the Distillation Head.

7.7 When 50mL of sample is collected in the Receiver Tube remove by unscrewing the cap containing the Short Stem.

7.8 When all samples have distilled turn the power OFF.

7.9 Add 5mL increments of reagent water to the Reaction Tube by piercing the septum using a syringe. Since the heater

block is still hot the distillation process will continue. Place a collection tray or beakers to catch any further distillate.

7.10 After each use clean exterior with a damp sponge.

7.11 When the heater temperature falls below 100°C, the next run can be started.

Note: If boil over occurs, add 2-3 drops of Antifoam B agent to the sample prior to distillation.

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 17

Page 20

HotBlock: Operation and Instruction Manual Troubleshooting

Troubleshooting

Problem Possible Cause Solution

Temperature Controller Display Blank

Red Lighted Rocker Switch not lit Unit turned off Turn on Red Lighted Rocker Switch

Unit unplugged or no power to unit Plug unit into 120 VAC/20A outlet

Main fuse blown Replace 15A/250V fuse

Internal failure Call for service

Red Lighted Rocker Switch lit Units with S/N 2056 and below

High Temp Switch tripped Reset High Temp Switch

Green Pilot Light not lit High Temp Switch tripped Reset High Temp Switch

Units with S/N 2057 and above

heater turned off Turn on Black Rocker Switch

Internal failure Call for service

Unit does not heat to operating

temperature Green Pilot Light lit See above

Process Temperature not set Set correct operating temperature

High Temp Switch tripped Reset High Temp Switch

Units with s/n 2057 and above

heater turned off Turn on Black Rocker Switch

High Temp Switch failure Call for service

High Temp Switch trips Block temperature above Set operating temperature to

repeatedly safe range 190°C or below

High Temp Switch failure Call for service

Block temperature exceeds set

value by more than 1°C Internal failure Call for service

Temperature Controller

displays error message Refer to Controller Manual

800.745.8218 / 843.576.1147 / www.environmentalexpress.com Environmental Express • 18

Loading...

Loading...