Page 1

Heavy Duty LE Rotator Operation Manual

E N V I R O N M E N T A L E X P R E S S

843.881.6560nFax 843.881. 3964nwww.environmentalexpress.com

PRODUCT INFORMATION:

Item # LE1002/LE1003

Date of Purchase

LE Rotator Serial #

(Please record the serial # of your LE Rotator here for easy reference. Your serial

# is located on the back of your rotator.)

Copyright Environmental Express, Inc., January 2011

Page 2

Introduction

Heavy Duty LE Rotator Manual

ongratulations on the purchase of

your Heavy Duty LE series rotator

C

from Environmental Express. Each

unit is constructed from the finest

materials and quality components to

ensure many years of dependable

service.

The large 6.25" x 6.25" x 12.75"

stainless steel compartments on the LE

rotator accommodate most zero space

extractors and many styles of glass and

plastic bottles. The box-style design

offers a greater degree of safety than

other rotator designs.

The 12-position sample box is

constructed of 14-gauge stainless steel

welded and reinforced at all joints. The

drive shaft is a full 1" in diameter to

prevent any breakage, even with offcenter loads. Glass bottles containing

extraction fluid are shielded within the

stainless steel box, not rotating exposed

in your laboratory.

Rotators use Brother

120VAC (also available in 240VAC)

high-efficiency gear motors with selflubricating drive chains. Brother gear

motors are designed in accordance with

today’s most stringent industrial

standards to ensure longer service life

and increased reliability. These allhelical gears are among the quietest

available and have the very high surface

hardness required to ensure extended

wear resistance commonly associated

with EPA Method 1311.

®

1/6hp, 60Hz,

A self-lubricating chain prevents

slippage and requires no maintenance.

Precise, constant speed control

(30rpm) is maintained during long

hours of continuous operation.

The advantage that stands out with

the LE Heavy Duty Rotator is the quiet,

consistent and dependable service this

well designed power system delivers.

Accessories available for use with

the Heavy Duty LE Rotator include:

-

Compartment spacers/cushions

-

A variety of bottles and extraction

devices

Heavy Duty LE1002/LE1003

Rotator Product Warranty:

The Environmental Express Heavy Duty LE

Rotators are warranted against defects in

materials and workmanship, when used in

accordance with applicable instructions for the

period of one year from the date of shipment.

This warranty extends to parts and labor, applies

only to damage or failure caused by normal

laboratory use and is limited to product repair.

If Environmental Express is unable to repair the

Rotator, the customer may, at his or her option,

receive a replacement or a full refund.

Environmental Express makes no other warranty,

expressed or implied, for this product with

respect to fitness for a particular use or any

other matter. Environmental Express is not liable

for any consequential or compensatory damages

arising from the use of, or in conjunction with

this product. The maximum liability shall be the

invoice price of the product.

Safety Precautions:

Please read this manual carefully. It contains valuable information that will

prevent damage to the machine and/or serious bodily injury to personnel.

CAUTION

-

Always stay clear of rotating parts!

-

Failure to read and practice these safety

precautions could result in serious damage to

equipment and/or cause serious bodily injury to

operating personnel.

-

Do not attempt to use this equipment if you are

not familiar with the dangerous characteristics it offers.

-

This unit can develop significant torque. IT CAN HURT

YOU. Do not allow clothing or long hair near an

operating unit.

-

Never remove protective guards. Failure to comply

could cause serious damage to equipment and/or

serious bodily injury — including electrocution.

-

All repairs should be performed by a qualified

technician.

1 • Environmental Express

www.environmentalexpress.com

Page 3

Basic Operating Procedures

Heavy Duty LE Rotator Manual

Please read this manual before plugging in your unit.

Placement of Your LE Rotator:

t is important that your rotator is

situated in a safe, cool and dry

I

environment. The rotator weighs in

excess of 172 pounds. With this in

consideration, a solid structure such as

a counter top is an ideal location. If a

sturdy counter top is not available

place the unit directly on the floor.

The unit should be placed far enough

away from the front edge of the

counter to avoid possible contact with

passersby.

Caution: Never allow the power cord

to come into contact with rotating

components.

The use of extension cords should

be avoided if at all possible. The unit

should be placed close enough to a

grounded electrical outlet to enable use

of the factory power cord. If it is

impossible to avoid use of an extension

cord, make sure that you use a threeprong 14 AWG cord (or larger, i.e. 12

AWG) only. Using too small of an

extension cord will cause the cord to

become very hot thus becoming a fire

risk. Failure to comply could also cause

serious damage to the electrical

components of your rotator and would

void your warranty.

Basic Operating Procedures:

nce you have read this manual

thoroughly, ensure that the power

O

switch is in the OFF position and

that all obstacles and personnel are

clear of the unit. Plug the power cord

into a 120VAC (LE1002) or 240VAC

(LE1003) outlet, as described in the

previous section. Turn the unit on to

confirm operation. The switch should

always glow amber during operation.

Refer to the troubleshooting section of

this manual if the unit does not operate.

To load the compartments, turn the

latch counterclockwise to release

tension. Open the lid and load the

compartments to suit your needs.

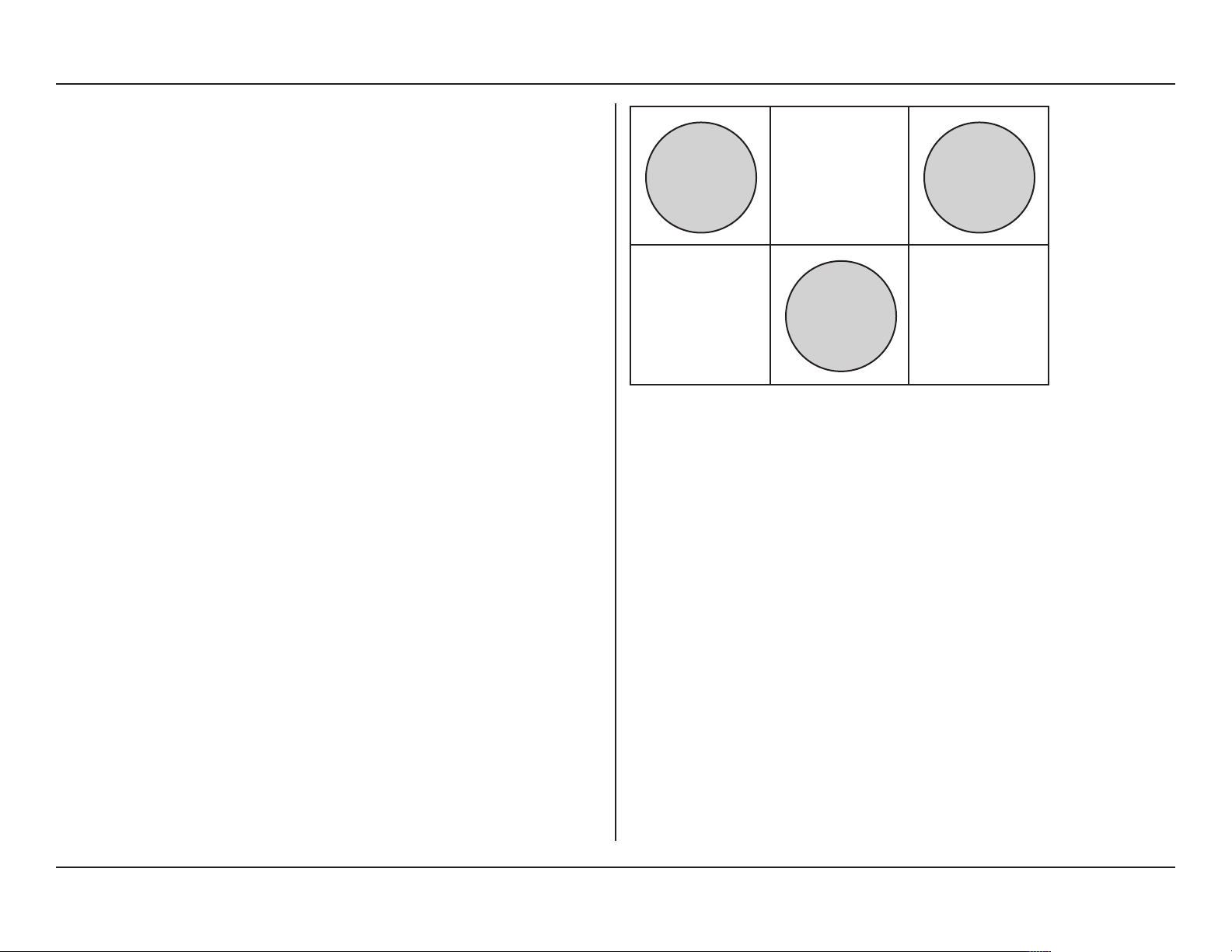

Caution:

It is important to offset your load

(Refer to figure 1). For example, when

you are loading a 12-place unit, and

you have 6 bottles to load, avoid

putting all six bottles on the front or

back side of the box. Put the first bottle

in the back left compartment, the

second bottle in the second front

compartment, the third bottle in the

third back compartment and so on.

By doing this, you will reduce the

stress on the geared components thus

allowing your rotator to last much

longer.

Figure 1, proper

loading sequence

Rotator Specifications—

Dimensional Information: LE1002/LE1003 (12-place) 24.5"W x 43.6"L

Weight: 172lb.

Shipping Weight: 262lb. Delivery by truck only.

Electrical: Gearmotor LE1002 — Brother 1/6 HP/120VAC/60Hz/1.7AMP (FL)

Gearmotor LE1003 — Brother 1/6 HP/240VAC/50Hz/.8 AMP (FL)

Switch/Circuit Breaker — 15AMP Integral Unit

Capacitor LE 1002 — 120 VAC/24µF (+10 to -5%)

Capacitor LE1003 — 240 VAC/6µF (+10 to -5%)

Bearings: NTN

Drive Components: Synchronous Self Lubricating Chain

Rotating Box and Guard: Custom Fabricated from type 304 Stainless Steel.

Frame: Custom Fabricated from Mild Steel Components.

®

Sealed Ball, Maintenance Free, Heavy Duty Flanged.

Synchronous Timing Sprockets

Paint and Prime Coat, Chemical Resistant Two-Part Industrial Enamel.

2 • Environmental Express

Call 1.843.881.6560

Page 4

Troubleshooting Guide

The unit is plugged into the wall outlet, the

switch is on but nothing happens:

1. Is wall outlet “hot”? Check the breaker box and

try plugging another electrical device into the

outlet to see if it works.

2. Does the switch on the unit light up? If not, the

internal circuit breaker may have tripped. Try

turning the switch off and back on to reset the

circuit breaker. If the switch illuminates, but the

unit still does not operate, unplug the unit

immediately and call 1.843.881.6560 or

1.800.343.5319 for technical support. Only a

competent electrician should attempt to work on

the electronics of this unit. Failure to comply

may void your warranty.

The motor runs but the box does not rotate:

1. There could be several possibilities for this;

stripped gears in the gearbox, a broken chain or

loose set screws on pulleys are a few things to

suspect. If this problem has occurred, please

contact technical support at 1.843.881.6560 or

1.800.343.5319. Please do not attempt to retrofit

any components. (If your unit is still under

warranty, you may be entitled to parts at no

expense to you.)

Rotator Assembly Drawing

Heavy Duty LE Rotator

Detail A

5

Detail B

Rotator

Side View

See Detail A and Detail B, page 4.

The unit makes noise while rotating:

1. After continued use over several years, it may be

necessary to grease the two bearings. This is a

very simple process. Unplug the unit, insert the

grease gun fitting over the zerk nipple located on

the bottom of each flanged bearing. Pump the

grease gun until you notice a slight trace of

grease discharge out of the bearing insert. This

should correct the problem.

3 • Environmental Express www.environmentalexpress.com

Page 5

Rotator Assembly Drawings Heavy Duty LE Rotator Manual

Detail A

Detail B

Parts List:

Item # Description

1 Extractor Box

2 Belt Guard

3 Rotator Frame

4 Motor

5 Drive Chain

6 Circuit Breaker Switch

7 Leveling Feet

8 Power Cord

9 N/A

10 15 Tooth Sprocket

11 3/4" Flange Bearing

12 3/8" - 16 Socket Cap Screw

13 12 - 10 3/4" Taper Lock Bushing

14 5/16" - 18 Socket Cap Screw

15/16 5/16" - Flange Nut

4 • Environmental Express Call 1.843.881.6560

Page 6

Drive Chain Adjustment and Maintenance

Maintaining proper chain tension:

The chain needs to be inspected routinely to

maintain proper chain tension. If the chain

develops 1/4" or more of slack it should be

tightened using the procedure below.

Steps to loosen chain:

1. Loosen the jam nuts using a 7/16" wrench.

2. Loosen the adjusting bolts, which are the bolts

that hold tension against the motor, with a 3/16"

allen wrench.

3. Loosen the four bolts on the motor using a 1/4"

allen wrench so that the motor can be slid over.

Steps to tighten chain:

1. Tighten the adjusting bolts with a 3/16" allen

wrench which actually pushes the motor back

into position. The chain should have no slack.

Rotator Assembly Drawing with Drive Chain

Heavy Duty LE Rotator

Drive Chain

2. Tighten the jam nuts using the 7/16" wrench

so that the motor will not slide out of position.

3. Tighten the bolts on the motor using the 1/4"

allen wrench.

Rotator

Side View

with Drive Chain

5 • Environmental Express www.environmentalexpress.com

Page 7

Wiring Schematic (shown for single phase 120VAC) Heavy Duty LE Rotator Manual

6 • Environmental Express Call 1.843.881.6560

Loading...

Loading...